Nuclear reactor core capable of improving neutron flux rate

A neutron fluence rate, nuclear reactor technology, applied in the direction of reactor, moderator/core structure, nuclear engineering, etc., can solve problems such as insufficient, thermal neutron fluence rate increase, etc., to achieve fission neutron fluence rate Effect of high and fast neutron fluence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

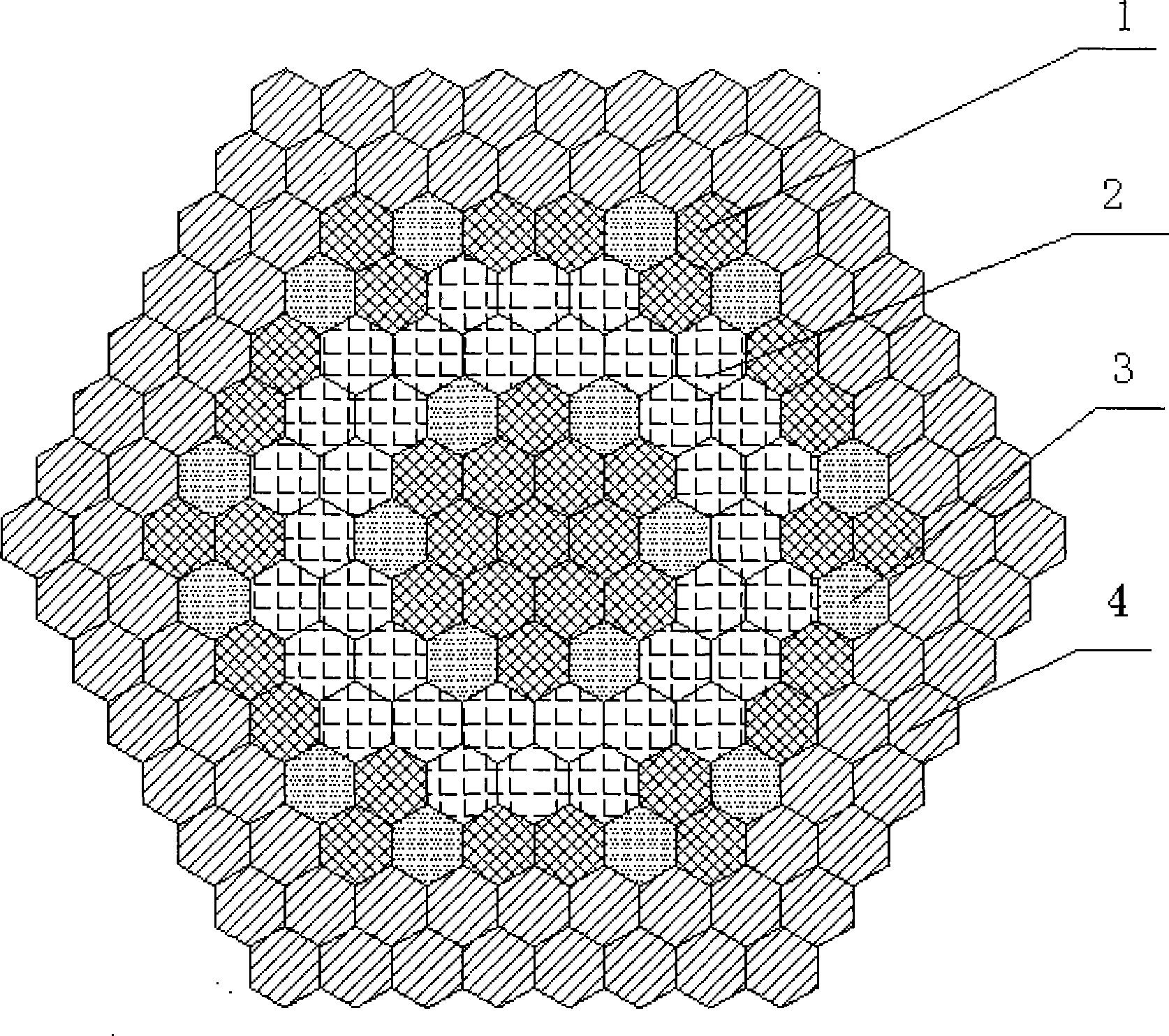

[0031] In this embodiment, the High Flux Engineering Test Reactor (HFETR) is taken as an example, the core is hexagonal, the reactor power is 90 MW, 36 boxes of fuel assemblies, and thermal neutron moderation scheme. The core layout is as figure 1 .

[0032] The core is arranged in a hexagonal ring from the center to the outside, with a total of seven circles.

[0033] The beryllium thermal neutron well area is followed by 1 box of beryllium blocks 1 in the center, 6 boxes of beryllium blocks 1 arranged in a quincunx shape on the periphery (first circle), 6 boxes of beryllium blocks 1 arranged in a quincunx shape in the second circle, and 6 boxes of control rods Body 3 composition. Among them, six boxes of control rod followers 3 are arranged on six corners.

[0034] The fuel assembly area is arranged in two outer circles (3rd and 4th circles) of the beryllium thermal neutron trap, and consists of 36 boxes of fuel assemblies 2 in total. Among them, six boxes of beryllium b...

Embodiment 2

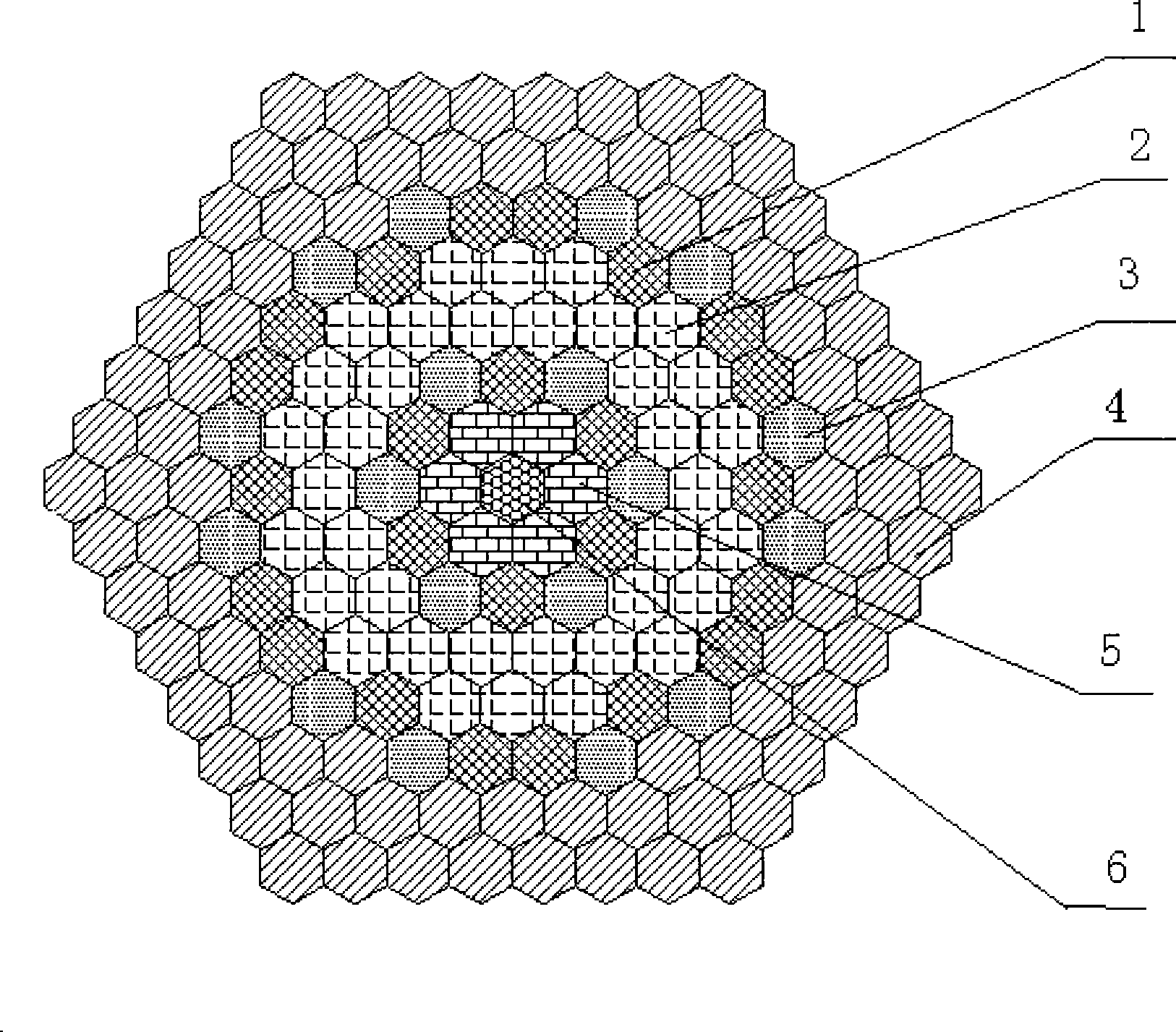

[0045] In this embodiment, the High Flux Engineering Test Reactor (HFETR) is taken as an example. The core is hexagonal and the reactor power is 110MW. For the purpose of fast neutron breeding, fuel assemblies with high uranium content (core thickness 0.7mm, cladding thickness 0.4mm) are placed in 7 of the 19 boxes of beryllium to form a fast neutron breeding area, and pressurization or increase the flow rate method for deriving the heat of fission. Core layout as attached figure 2 shown.

[0046] The core is arranged in a hexagonal ring from the center to the outside, with a total of 7 circles.

[0047] The beryllium thermal neutron trap area consists of a center box of high-uranium fuel assemblies 6 with fast neutron test channels, 6 boxes of high-uranium fuel assemblies arranged in a quincunx shape on the periphery (the first circle) 5, and a quincunx-shaped 1-2 circle. 1-1 (1 box of beryllium block—1 box of control rod follower—1 box of beryllium block) consists of 6 b...

Embodiment 3

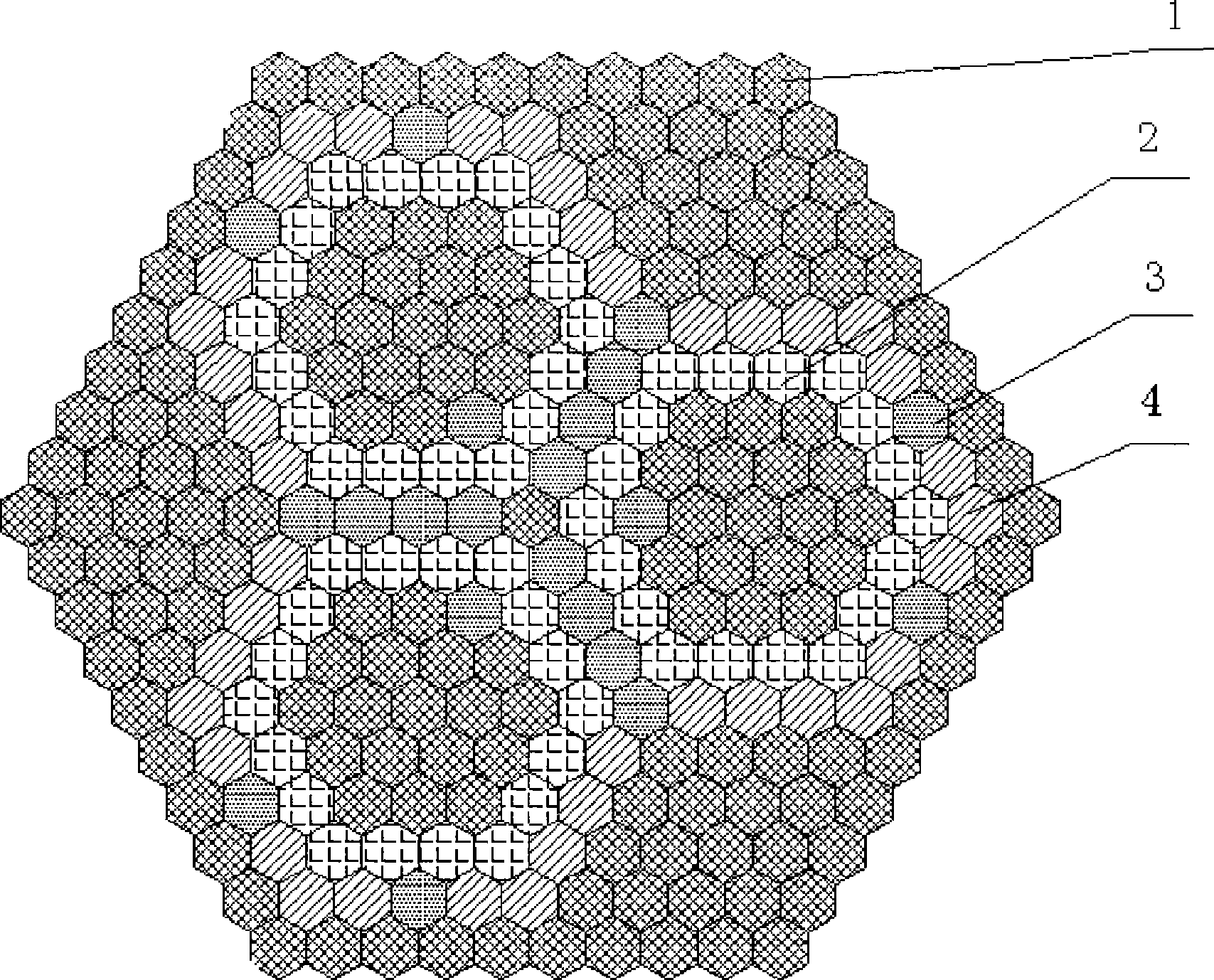

[0057] In this embodiment, the High Flux Engineering Test Reactor (HFETR) is taken as an example, the reactor power is 135MW, and the core is loaded with 54 boxes of fuel assemblies, which are divided into three sub-cores, and each sub-core contains 18 boxes of fuel assemblies. The core layout is as image 3 .

[0058] The entire core is arranged in a hexagonal ring from the center to the outside, with a total of 9 circles, which is called the large core. The three sub-cores inside the large core are distributed in a 120° rotational symmetry in the core. The center of the sub-core is in the fourth circle of the large core, and the center of each sub-core is arranged outwardly in a hexagonal ring, with a total of 4 circles.

[0059] Each sub-core is arranged as follows:

[0060] The beryllium thermal neutron trap area is composed of 1 box of beryllium block 1 in the center, 18 boxes of beryllium block 1 and 1 box of control rod beryllium follower 3 arranged in a quincunx sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com