Patents

Literature

34results about How to "Meet reinforcement needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

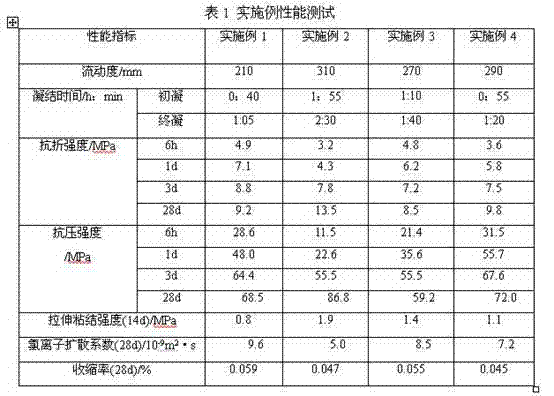

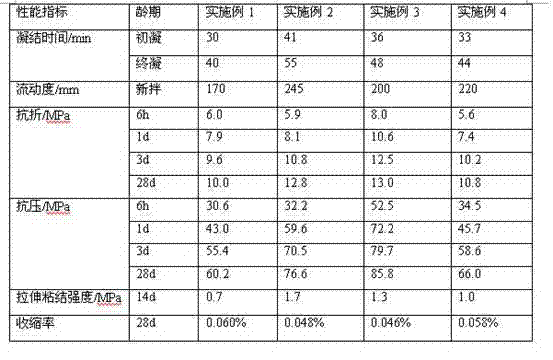

Rapid-hardening and early-strength structural reinforcement materials based on aluminate cement and steel slag

InactiveCN102295447AIncrease productivityImprove construction efficiencySolid waste managementFiberSlag

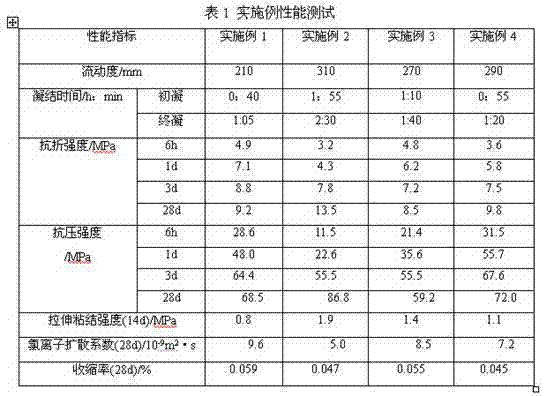

The invention belongs to the technical field of building materials, in particular relates to a quick-hardening early-strength structure reinforcement material based on aluminate cement and steel slag. The structure reinforcement material consists of aluminate cement, steel slag, ore slag powder, fly ash, silicon ash, a retarder, a water reducing agent, a latex powder, cellulose ether, a defoamer and poval fiber. By using the material provided by the invention, the problems of the common cement-based reinforcement material, such as high construction difficulty, long wet operation time and low early strength, can be solved. According to the invention, a composite gel material supplemented by steel aggregate, a composite additive and fiber is subjected to dry mixing and then packaged for supply; in scene, the structure reinforcement material provided by the invention can be used after adding water and stirring; and the structure reinforcement material has the characteristics of high early strength, good cracking resistance, good permeability resistance, small shrinkage, excellent durability and the like, is easy to construct and is suitable for reinforcing works of buildings, wharfs, bridges, dams, railways, tunnels and the like.

Owner:TONGJI UNIV

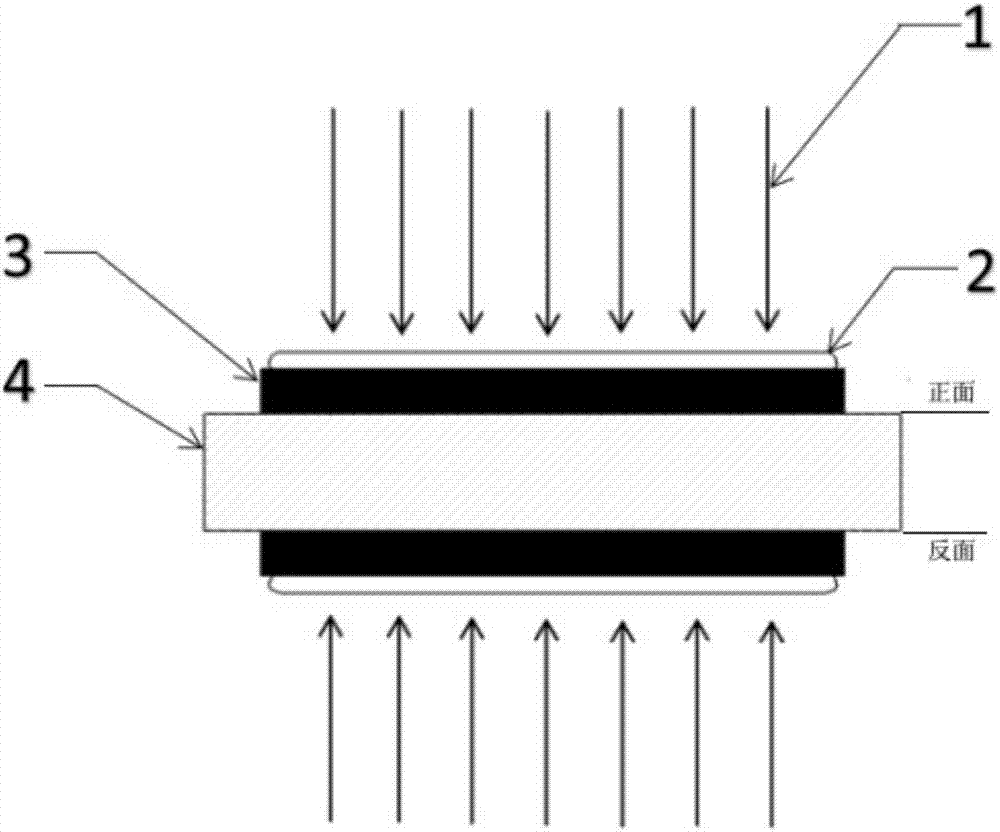

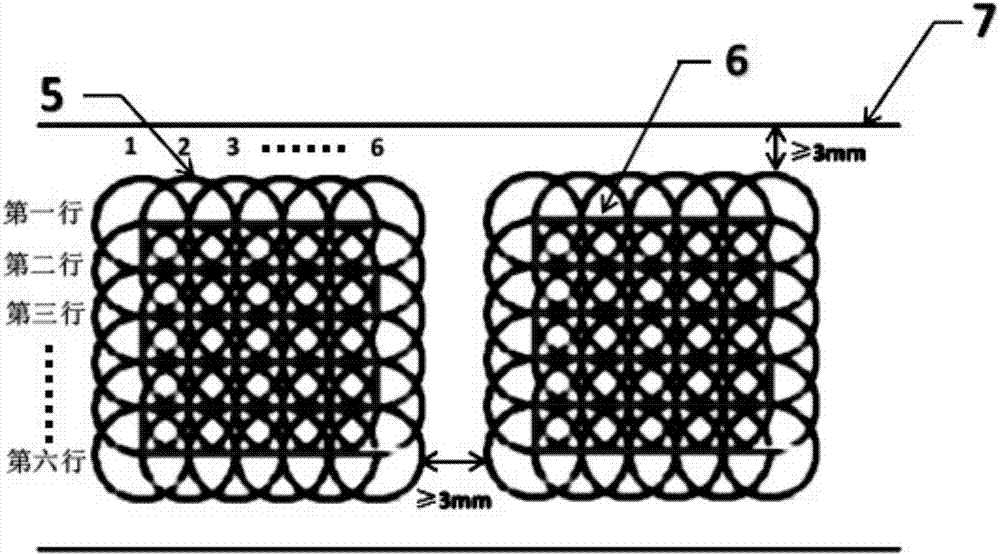

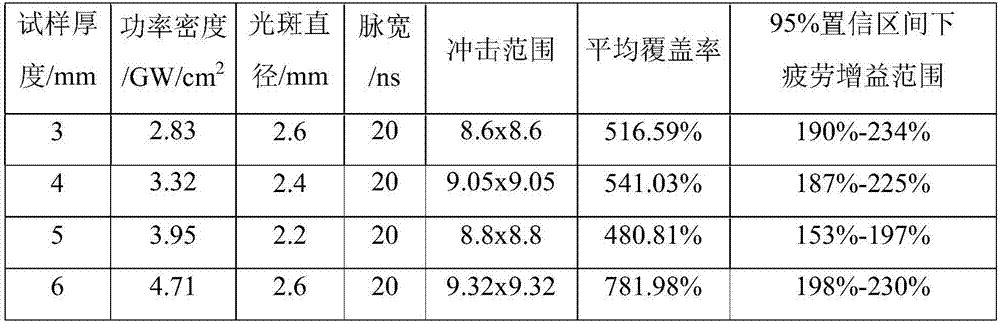

Laser impacting strengthening method for small-hole components different in thickness

ActiveCN107267742AImprove scienceControl deformationWelding/soldering/cutting articlesLaser beam welding apparatusStatistical analysisQuality control

The invention provides a laser impacting strengthening method for small-hole components different in thickness. In the method, different technology parameters are adopted for laser impacting strengthening of the small-hole components different in thickness, the statistics analysis is conducted after a large number of tests, the empirical formula is obtained, the empirical formula is the relation of the power intensity and small-hole component thickness and is shown in the specification, the power density of laser impacting strengthening of the small-hole components different in thickness can be determined according to the relation, and a related technology parameter selecting and determining method is provided. According to the method, after the small-hole components different in thickness are subjected to laser impacting strengthening through the proper technology, reasonable residual compressive stress distribution can be obtained, a good strengthening effect is achieved, and effective impact quality control can be conducted on the components; and on the premise that the fatigue life of the small-hole components is guaranteed, workpiece deformation is controlled.

Owner:JIANGSU UNIV

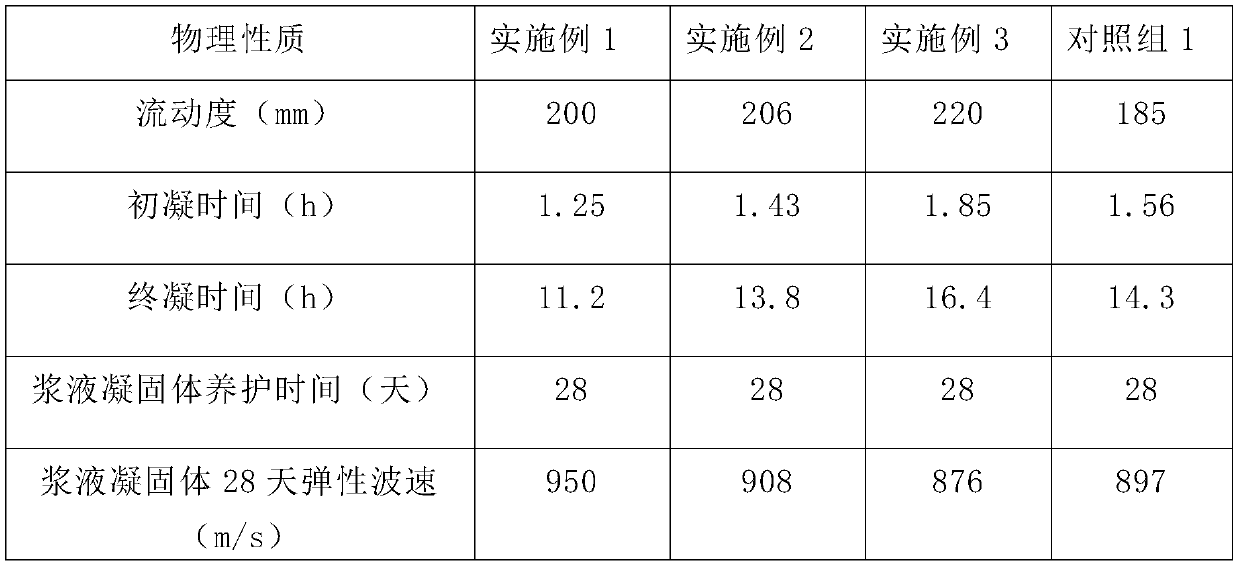

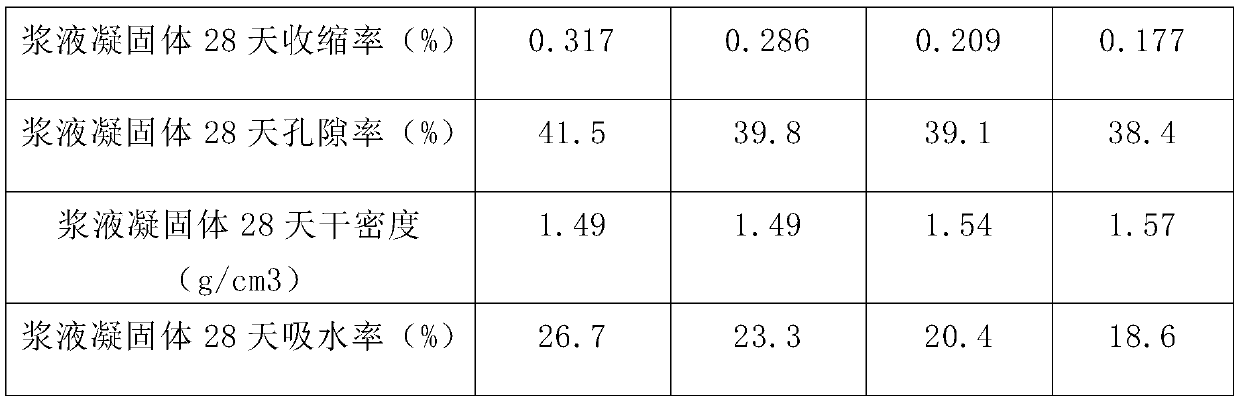

Rapid structural strengthening material taking steel slag as aggregate

InactiveCN102211918AImprove workabilityGood construction performanceSolid waste managementSlagHigh energy

The invention belongs to the technical field of construction materials, and particularly relates to a rapid structural strengthening material taking steel slag as aggregate. The rapid structural strengthening material consists of sulphate aluminium cement, steel slag, slag powder, pulverized fuel ash, calcined kaolin, emulsion powder, cellulose ether, an anti-forming agent and a water reducing agent, wherein the steel slag is thermally-stewed or aged steel slag of which the basicity coefficient is not less than 1.6. Due to the adoption of the rapid structural strengthening material, the problems of high energy consumption, long wet construction time and poor durability of the ordinary cement-based strengthening material can be solved, and the material cost and the construction cost can be saved. The rapid structural strengthening material can be used by adding water into a compound gelled material, steel slag aggregate and a compound additive and stirring on site, has the characteristics of high workability, fast developed strength, high mechanical property, high durability, small contraction rate and the like, and is suitable for strengthening projects of various buildings, bridges and large dams.

Owner:TONGJI UNIV

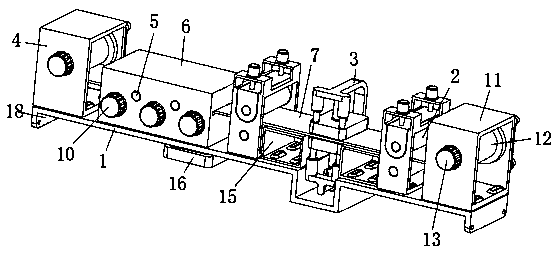

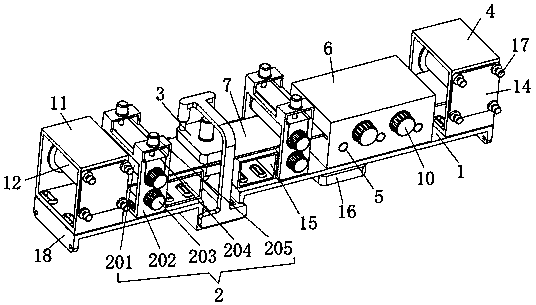

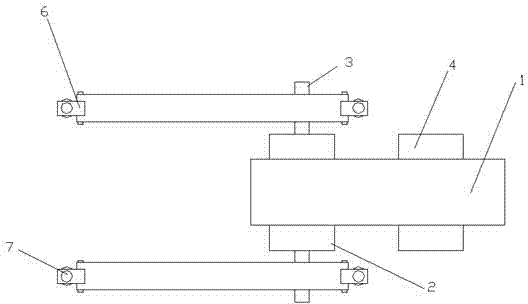

Positioning cutting mechanism and high-precision chip mounter

InactiveCN111246673AHigh degree of automationImprove usabilityPrinted circuit manufactureElectric machineryDrive motor

The invention relates to the technical field of chip mounters, and in particular relates to a positioning cutting mechanism and a high-precision chip mounter. The positioning cutting mechanism comprises a connecting plate; connecting protrusions are integrally formed at the left end and the right end of the connecting plate; the connecting protrusions and the chip mounter body are fixedly mountedthrough bolts; the left end and the right end of the connecting plate are fixedly provided with an unwinding device and a winding device through bolts correspondingly; the unwinding device and the winding device are fixedly provided with winding drum driving motors through bolts correspondingly; and the output ends of the winding drum driving motors drive winding drums facilitating installation ofreinforcing sheet strips. The beneficial effects are that: the positioning cutting mechanism of the chip mounter can use a straightener to straighten a reinforcing sheet strip, and then use a conveying device and a cutting device to automatically position and cut the reinforcing sheet; and in addition, the device can cut reinforcing sheets of different shapes by replacing different cutting templates, so that the reinforcing requirements of different chip mounting operations are met, and the automation degree and usability of the chip mounter are greatly improved.

Owner:孟娜妮

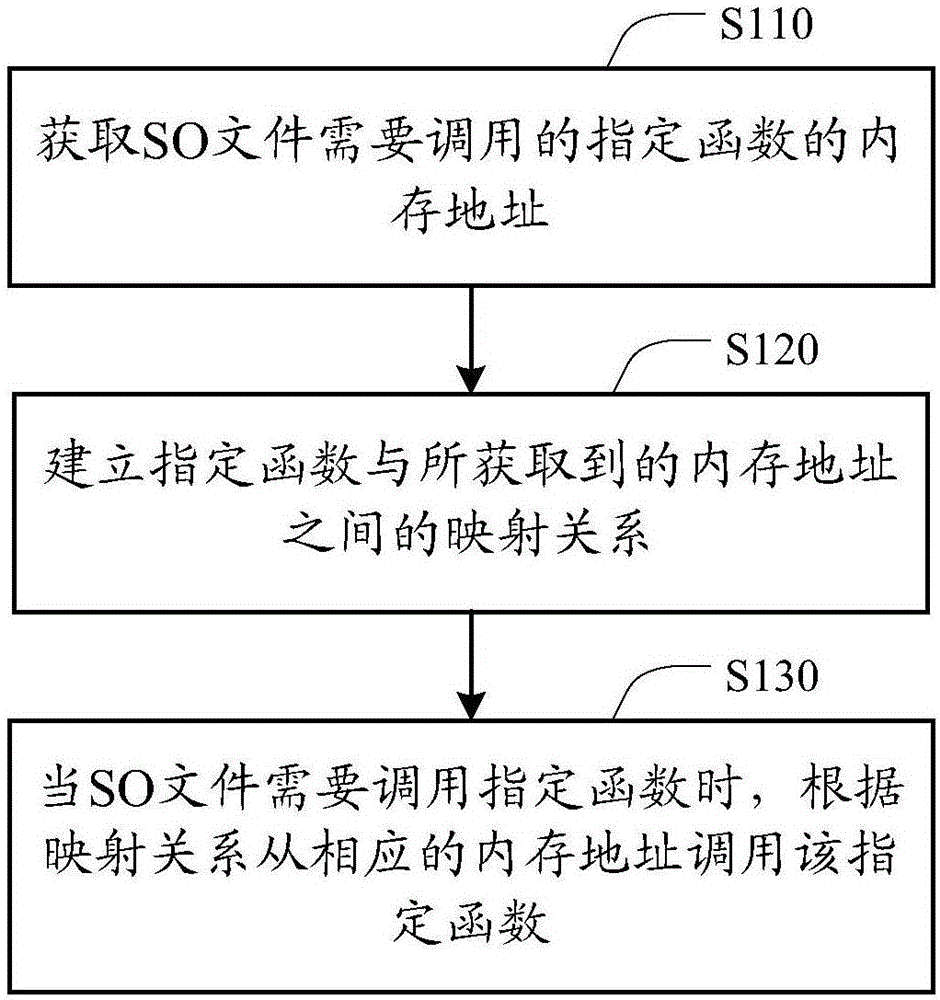

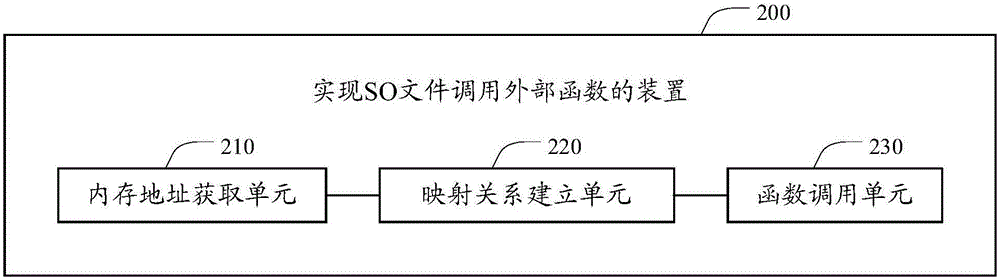

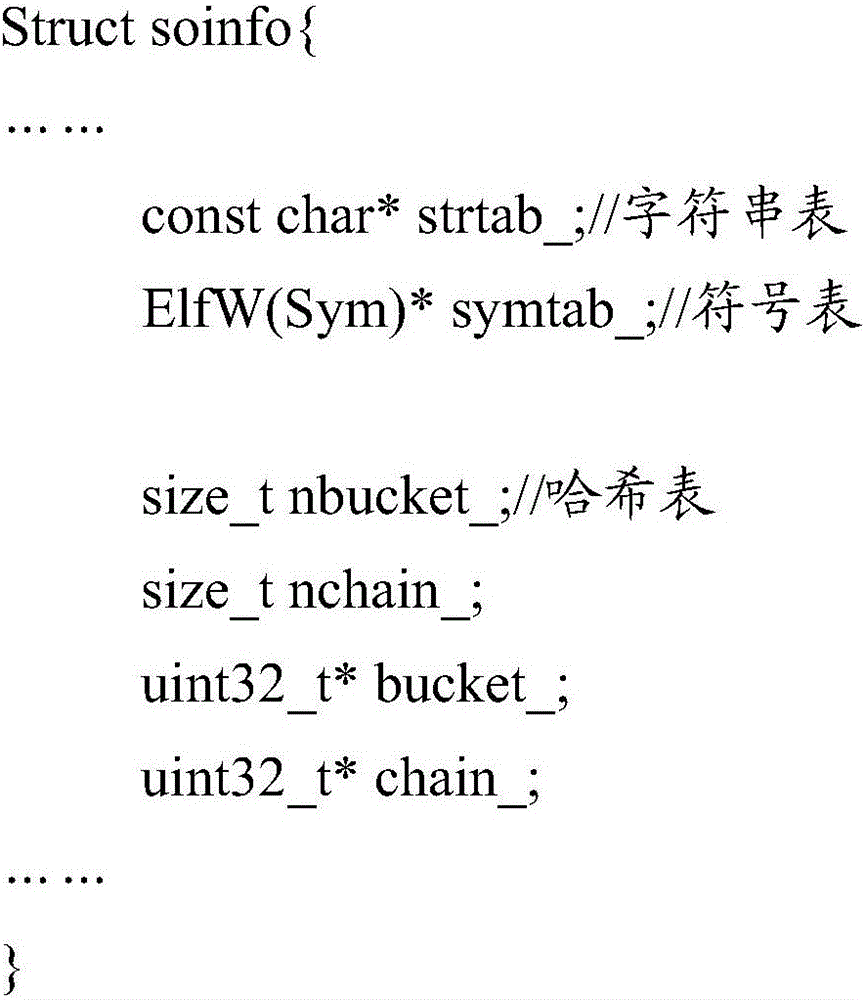

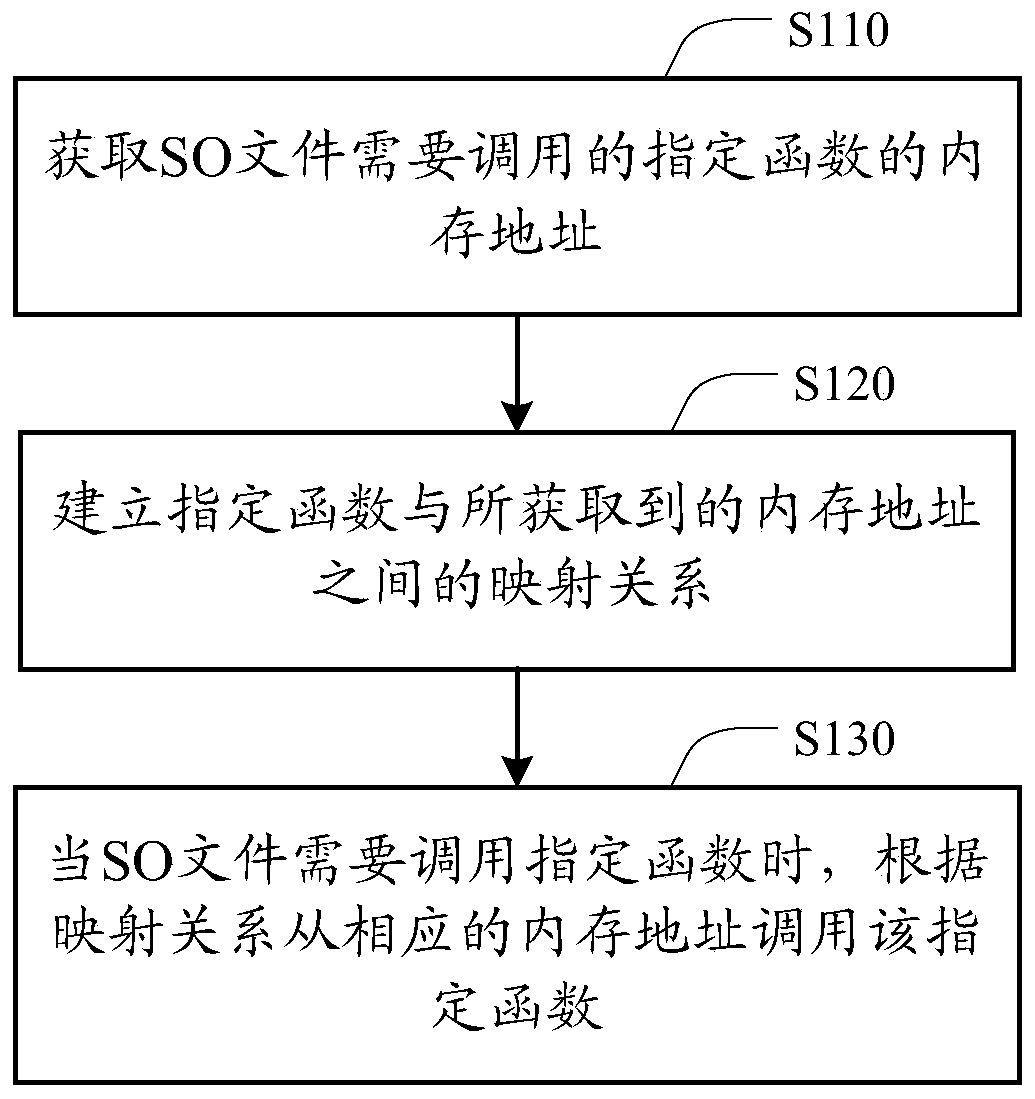

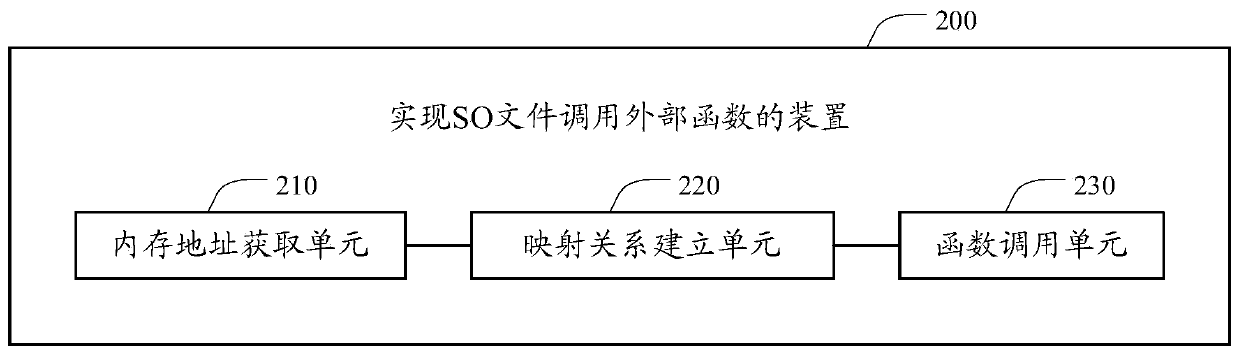

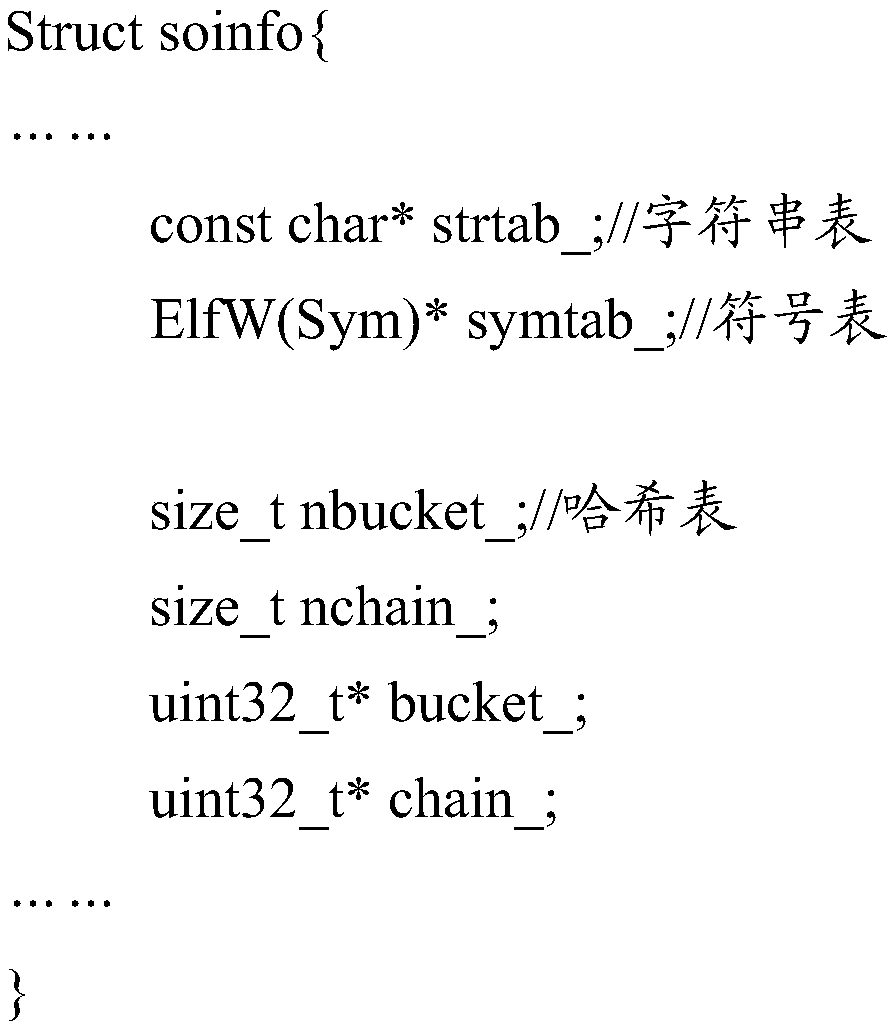

Method and device for SO files to call external functions

ActiveCN106708516AMeet reinforcement needsProgram documentationSpecific program execution arrangementsMemory addressSoftware engineering

The invention discloses a method and a device for SO files to call external functions. The method comprises the steps of getting memory addresses of the external functions which are needed to be called by the SO files, establishing mapping relations between specified functions and the obtained memory addresses, calling the specified functions from the corresponding memory addresses according to the mapping relations when the SO files need to call the specified functions. According to the technical scheme, when the SO files call the specified external functions, the calling process no longer depends on the memory addresses of the specified external functions provided by a system. The method and device are suitable for the SO files wrapped in a shell and meet the requirement of reinforcing the SO files.

Owner:三六零数字安全科技集团有限公司

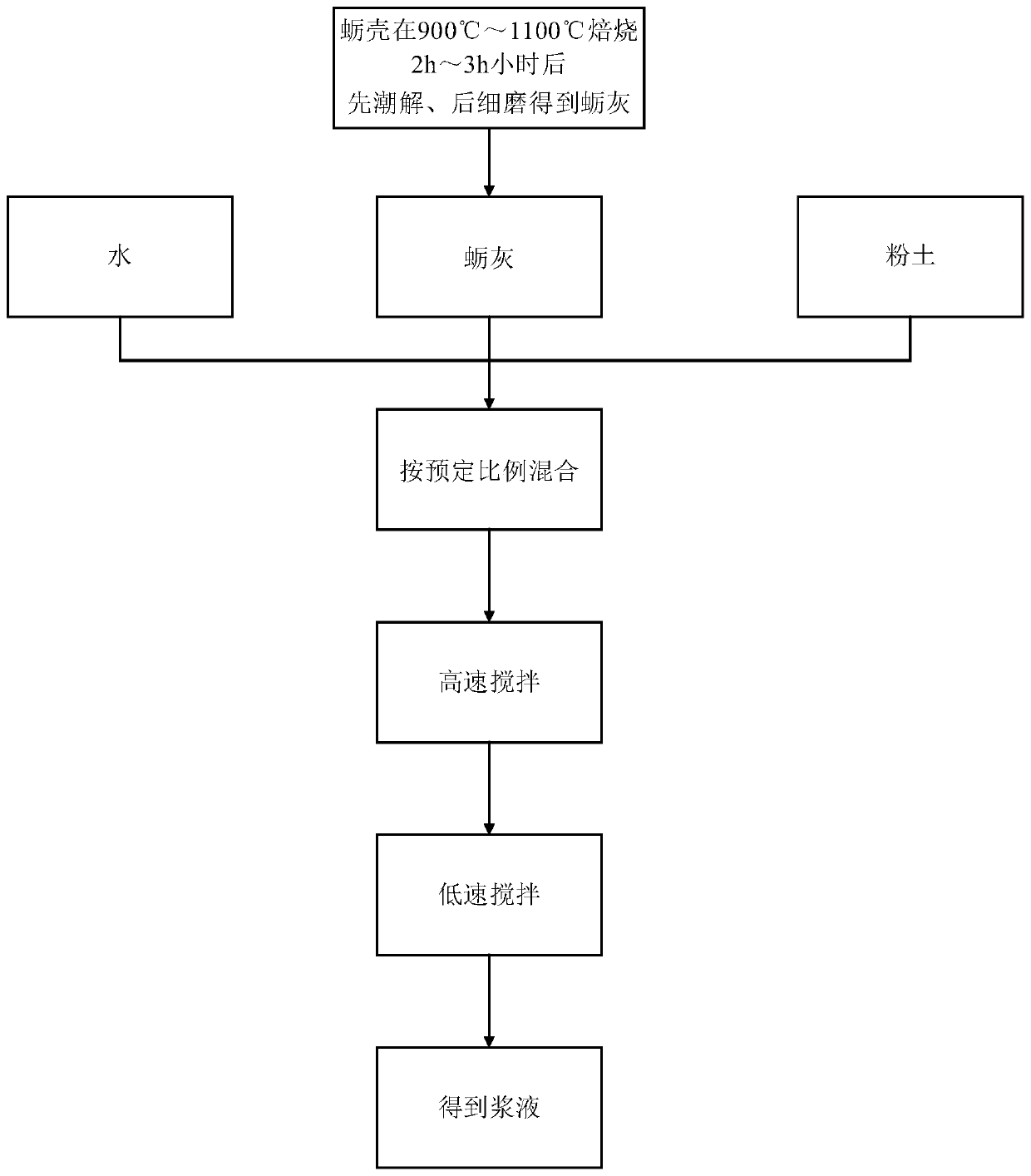

Oyster ash silt slurry for repairing hollow drums and cracks and anchoring of mural and preparation method thereof

Owner:中国文化遗产研究院

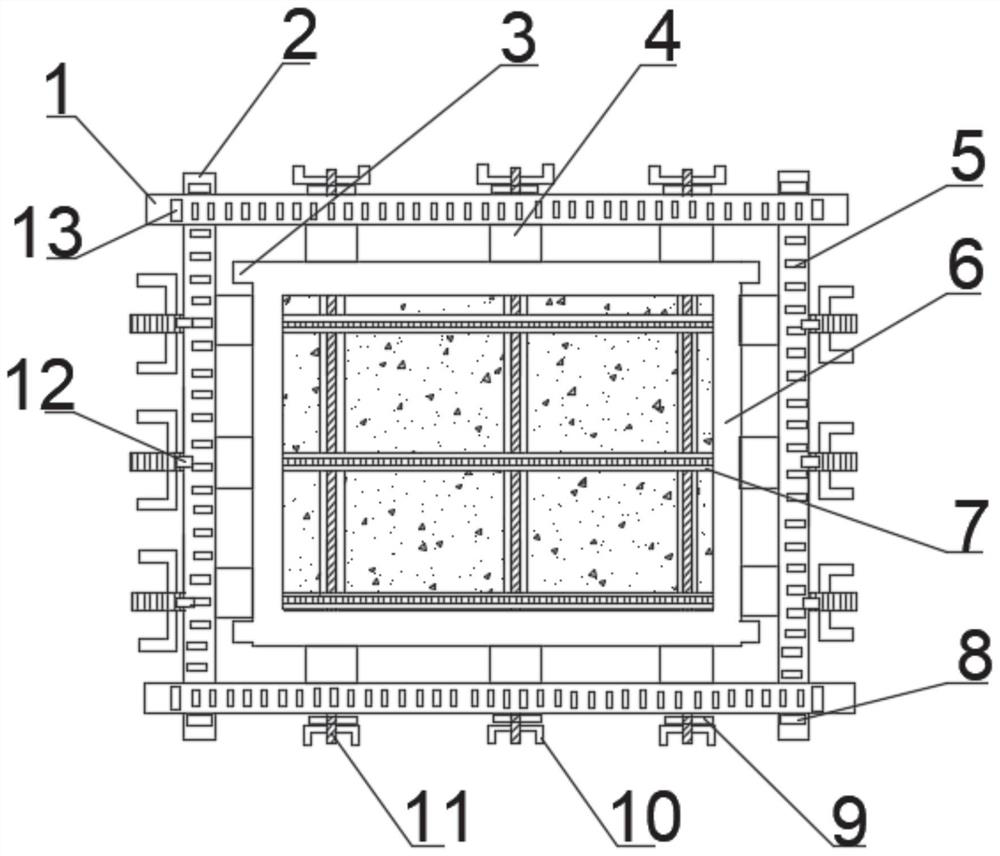

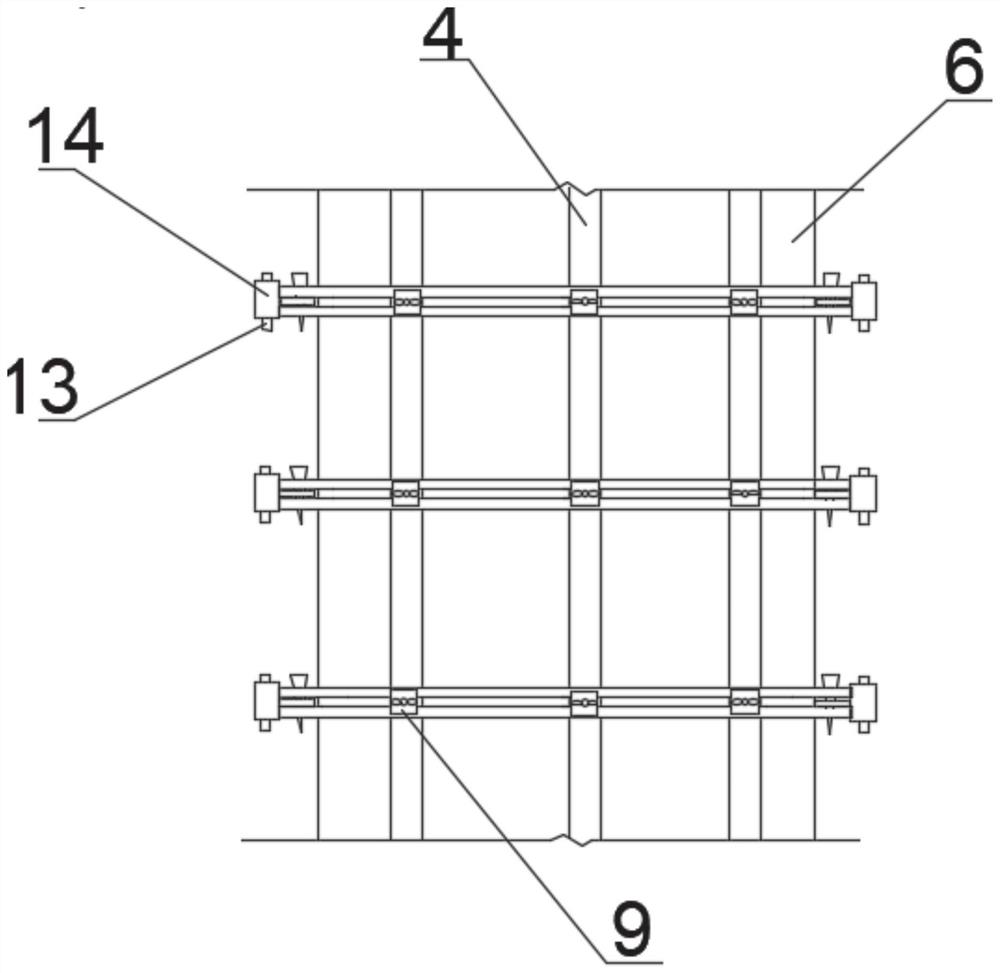

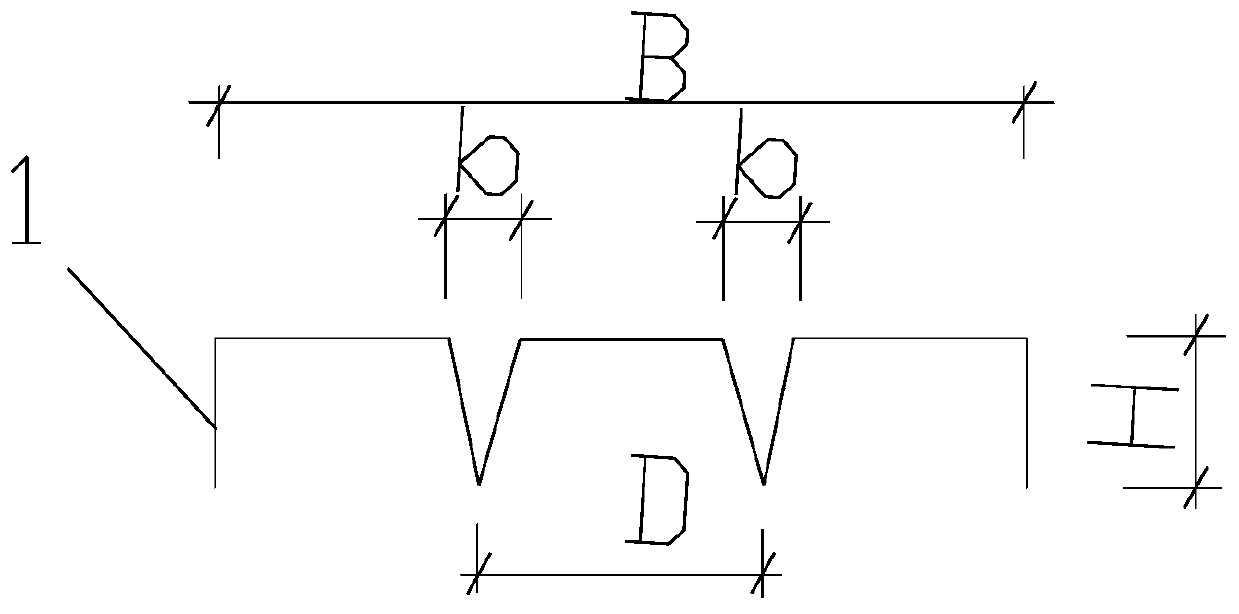

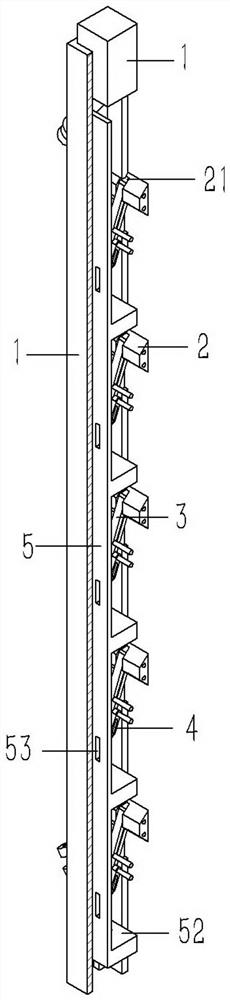

High and large concrete formwork reinforcing system

InactiveCN111779270AAvoid cold seamsAvoid wrong stationAuxillary members of forms/shuttering/falseworksWood plankSteel casting

The invention discloses a high and large concrete formwork reinforcing system. The high and large concrete formwork reinforcing system comprises two first channel steels, second channel steels, woodenboards, a steel formwork and split bolts. The edge portion of the steel formwork is provided with reinforced edges. The wooden boards are vertically arranged on the periphery of the steel formwork atintervals. The two opposite sides of the periphery of the wooden boards are transversely provided with the two first channel steels. The two ends of the two first channel steels are wrapped through fixed blocks. The two first channel steels are fixed through first fixed plates. The second channel steels are transversely arranged on the other two sides of the periphery of the wooden boards. The second channel steels are inserted in the gap between the two first channel steels. The second channel steels are fixed through second fixed plates. The corresponding positions of the wooden boards arefurther reinforced through split bolts. Each split bolt comprises gaskets, a cast steel nut and a screw rod, wherein the gaskets include the first gasket and the second gasket; the first gasket is square, and the second gasket is arc-shaped. The first gaskets are arranged on the corresponding sides of the first channel steels, and the second gaskets are arranged on the corresponding sides of the second channel steels. The high and large concrete formwork reinforcing system effectively improves the appearance quality and has high practicality.

Owner:SHANDONG WATER CONSERVANCY CONSTR ENG CO LTD

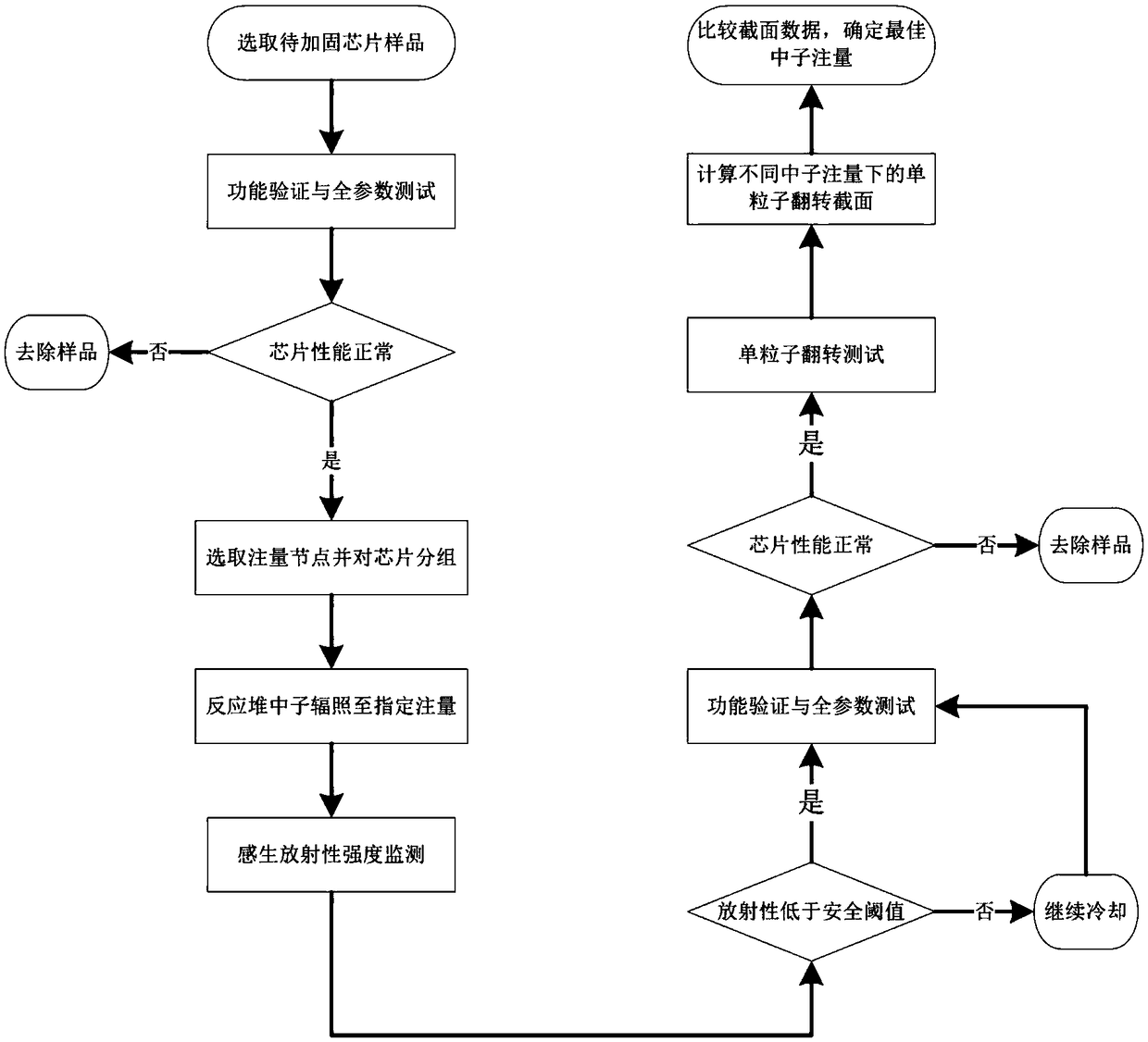

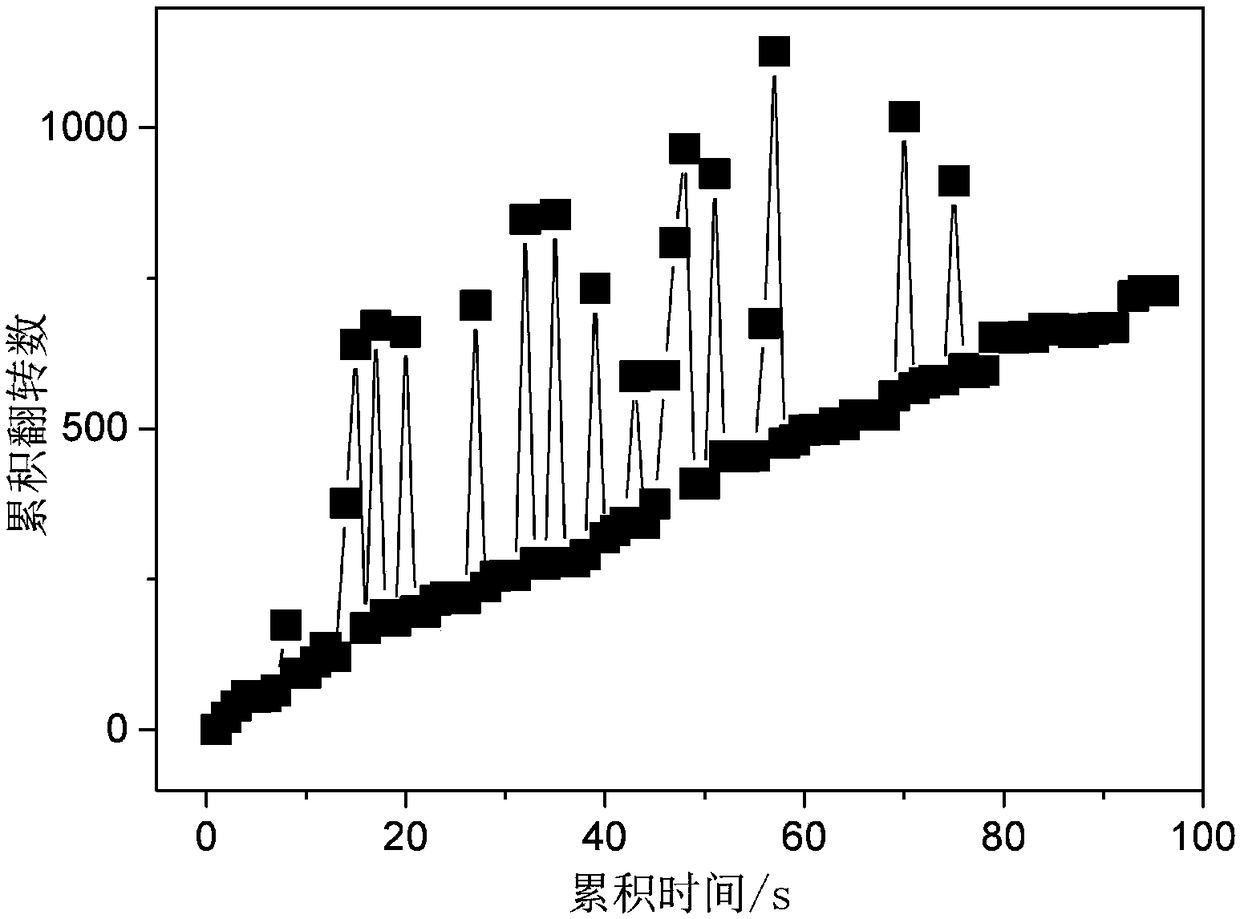

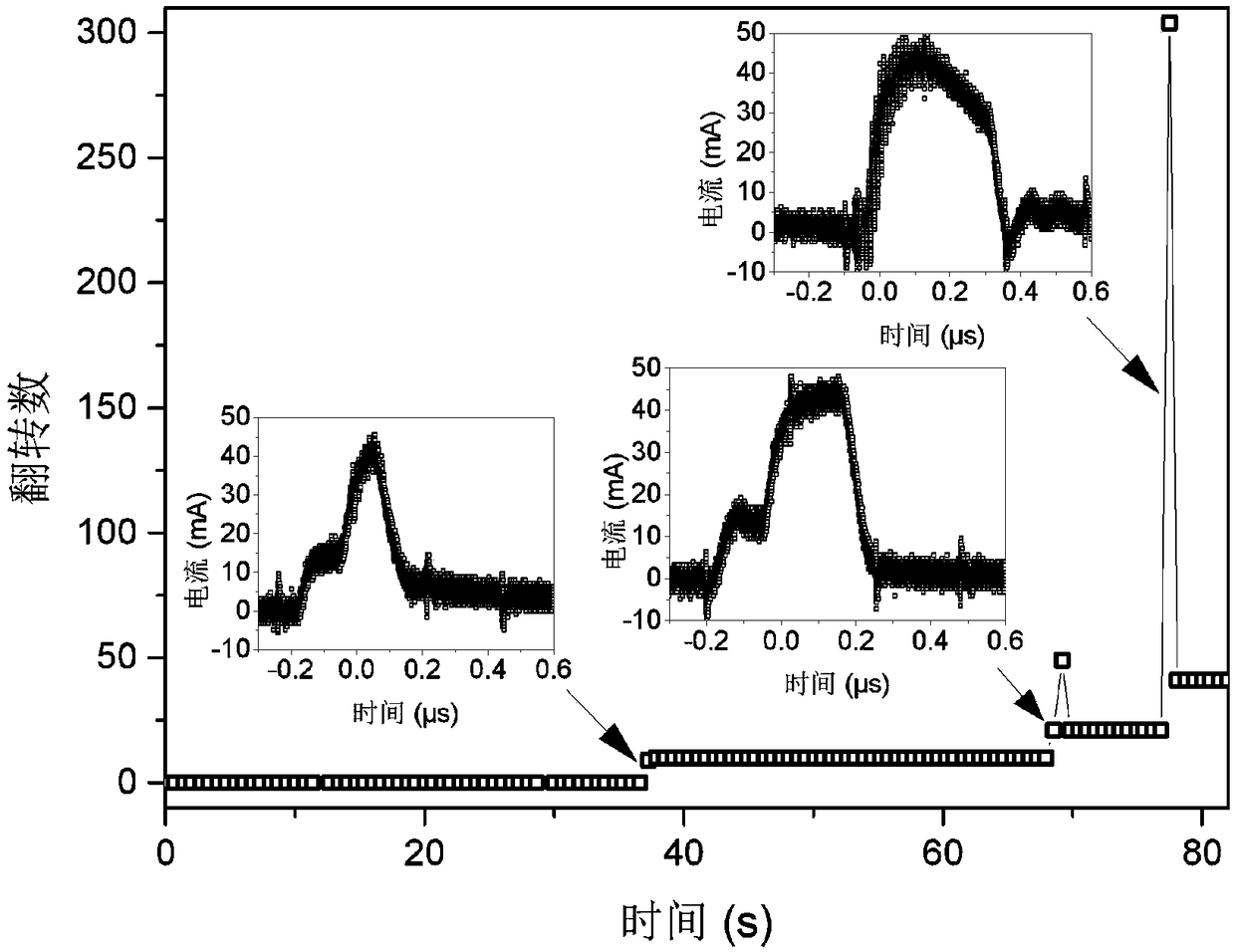

A ferroelectric memory anti-single event upset reinforcement method and system

InactiveCN108962307AMeet reinforcement needsReduce development costsDigital storageInduced radioactivityNeutron irradiation

The invention discloses a ferroelectric memory anti-single event upset reinforcement method and system. The method includes the steps of carrying out a functional verification and full-parameter teston several ferroelectric memories to be strengthened, and obtaining the functional verification results and full-parameter test results; carrying out reactor neutron irradiation on the ferroelectric memory to be strengthened to obtain a pre-irradiated ferroelectric memory; monitoring induced radioactivity of the pre-irradiated ferroelectric memory to obtain a reinforced ferroelectric memory; carrying out a functional verification and full-parameter test on the reinforced ferroelectric memory, and comparing the functional verification result, the full-parameter test result with the functional verification result of the reinforced ferroelectric memory and the full-parameter test result of the reinforced ferroelectric memory; carrying out a single event upset test on the normally reinforced ferroelectric memory. Reinforced ferroelectric memories can be directly used to replace unreinforced ferroelectric memories without changing the top design and production process conditions of ferroelectric memories, which saves the development cost.

Owner:XIANGTAN UNIV

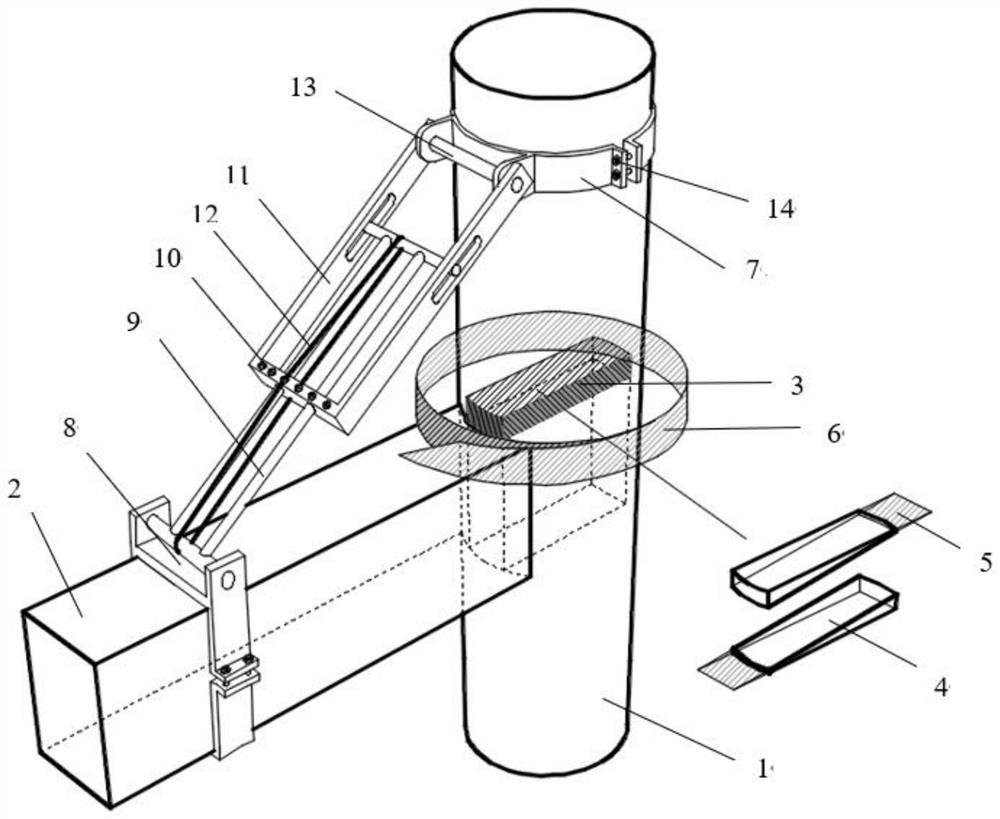

Reinforcing device and method for loose tenon-and-mortise joint of ancient building wood structure

ActiveCN114658257AGood self-resetting performancePlay a shock absorbing effectBuilding repairsProtective buildings/sheltersFiberCarbon fibers

The reinforcing device comprises a gap located between mortises and tenons, the gap is located between a tenon and the upper plane and the lower plane of a mortise opening, the gap is filled with two wedge-shaped wood blocks, and the portion, on the outer side of the gap, of a column body is wrapped with carbon fiber cloth. The upper side of the column is connected with the second component through the column connecting piece, the beam and the first component are connected together through the beam connecting piece, the beam and the column are perpendicularly arranged, the rod-shaped portion of the first component is inserted into the hole opening portion of the second component, and the shape memory alloy wire bypasses the upper rod-shaped portion and the lower rod-shaped portion of the first component and is anchored to the upper plane and the lower plane of one end of the second component. Anchoring is achieved through fastening of screws. According to the method, the anti-seismic performance of the damaged node can be effectively enhanced, and the reinforced node has the self-resetting capability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A method and device for implementing so files to call external functions

ActiveCN106708516BMeet reinforcement needsProgram documentationCode compilationMemory addressDatabase

The invention discloses a method and a device for SO files to call external functions. The method comprises the steps of getting memory addresses of the external functions which are needed to be called by the SO files, establishing mapping relations between specified functions and the obtained memory addresses, calling the specified functions from the corresponding memory addresses according to the mapping relations when the SO files need to call the specified functions. According to the technical scheme, when the SO files call the specified external functions, the calling process no longer depends on the memory addresses of the specified external functions provided by a system. The method and device are suitable for the SO files wrapped in a shell and meet the requirement of reinforcing the SO files.

Owner:三六零数字安全科技集团有限公司

Reinforced PVC (polyvinyl chloride) tube

InactiveCN102954290AMeet reinforcement needsSimple structureRigid pipesPolyvinyl chlorideEngineering

The invention discloses a reinforced PVC (polyvinyl chloride) tube, which comprises a PVC tube and a metal grid layer, wherein the outer layer of the metal grid layer is a plastic layer and is laid and sleeved at the periphery of the PVC tube. The reinforced PVC tube disclosed by the invention has the beneficial effects that the need of reinforcing is met, the structure of the reinforced PVC tube is simple, and the reinforced PVC tube is durable.

Owner:QINGDAO XINWANTONG PLASTIC IND

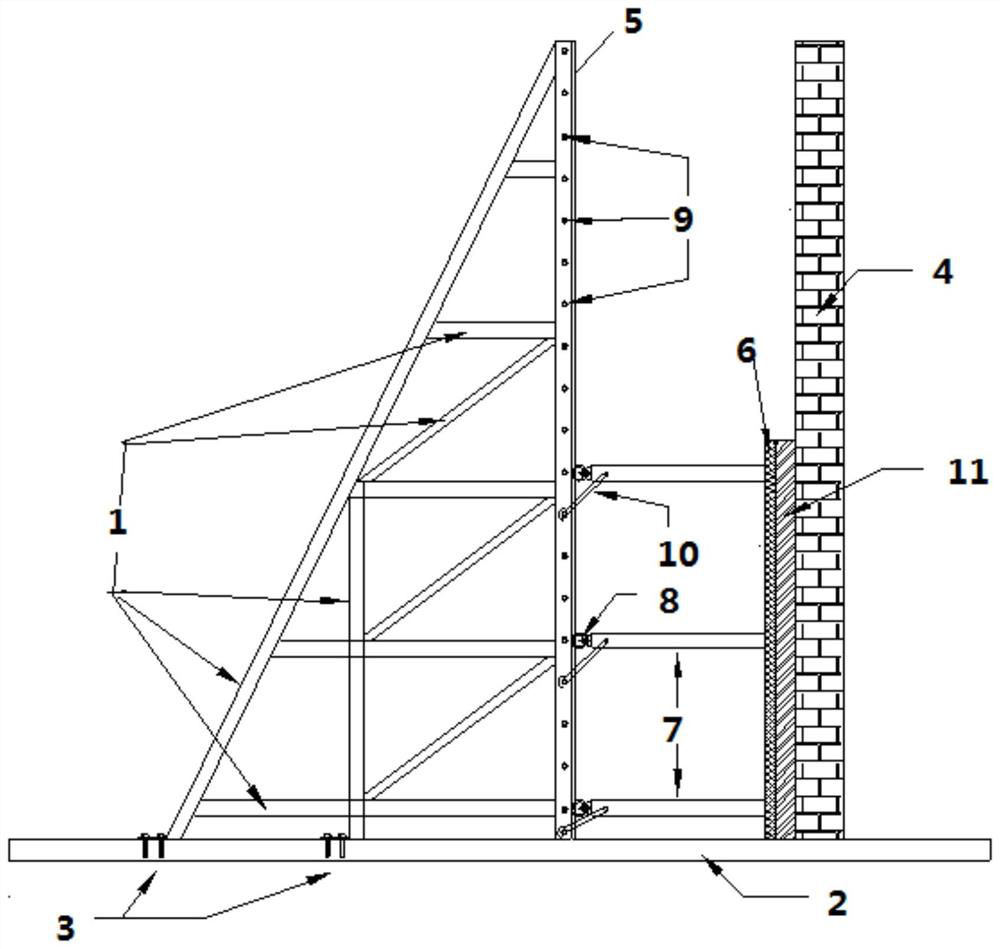

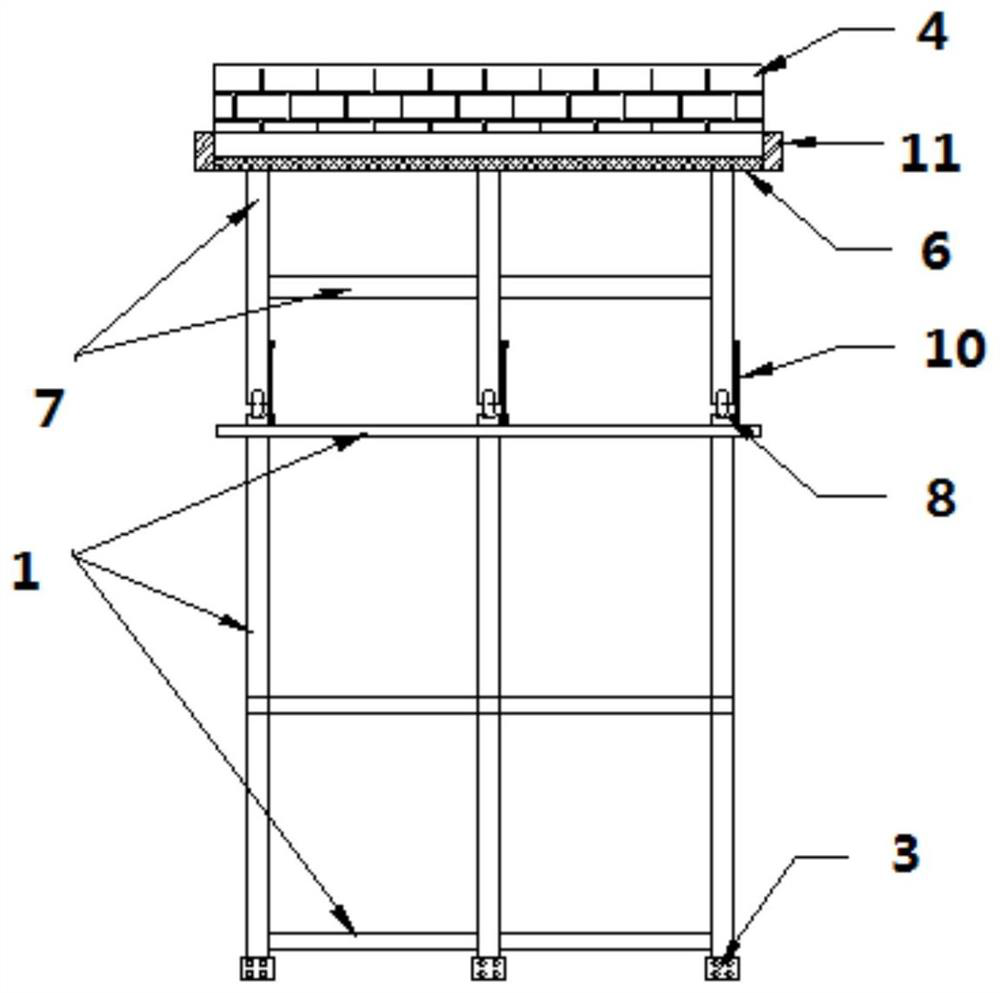

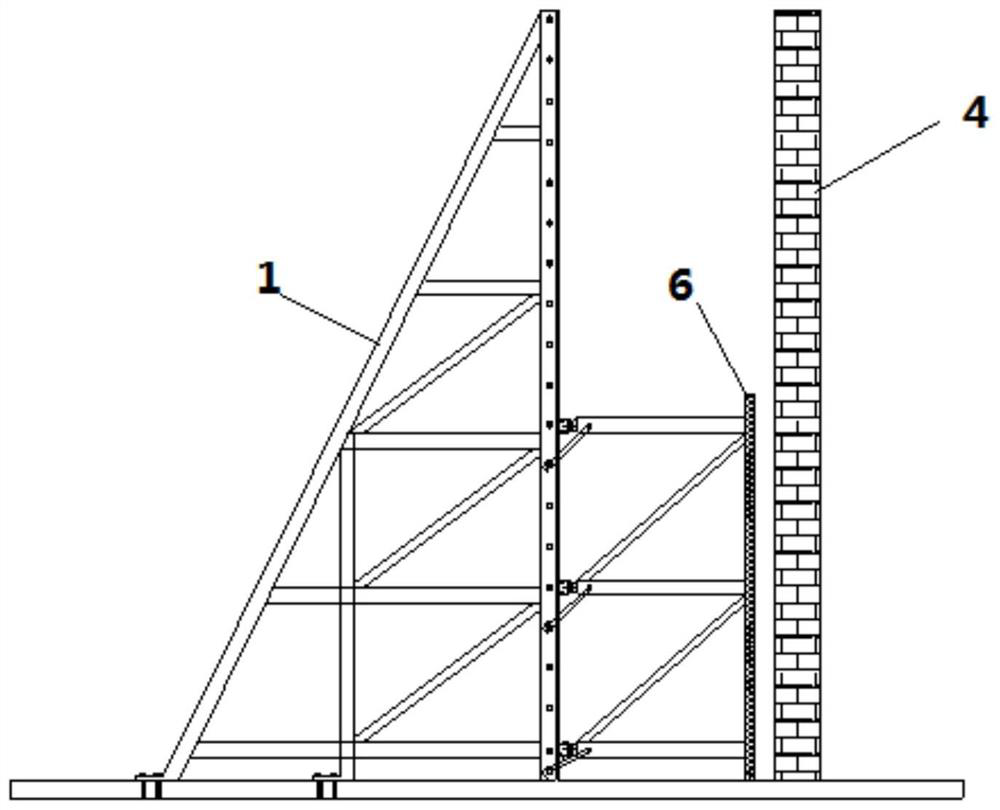

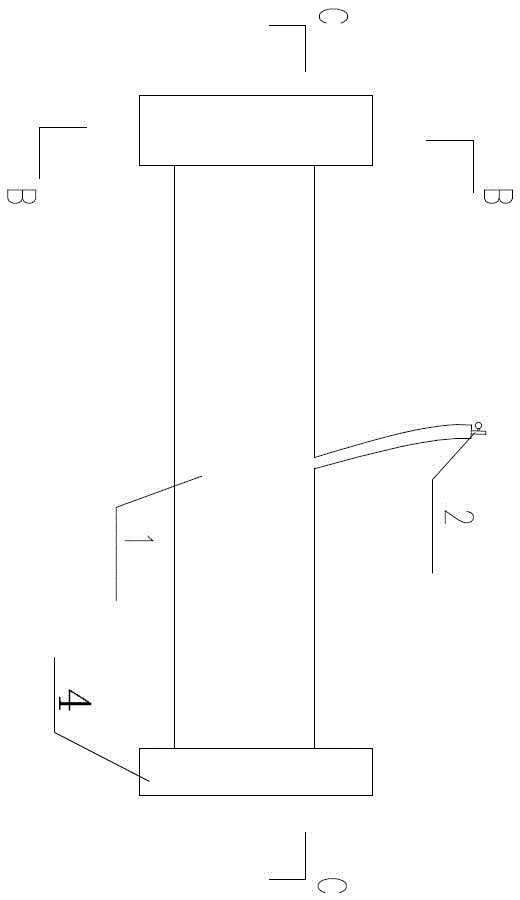

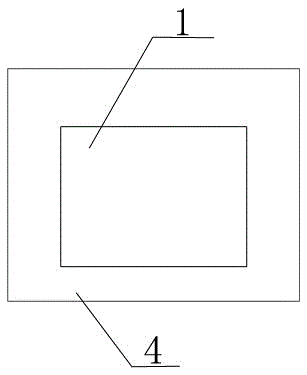

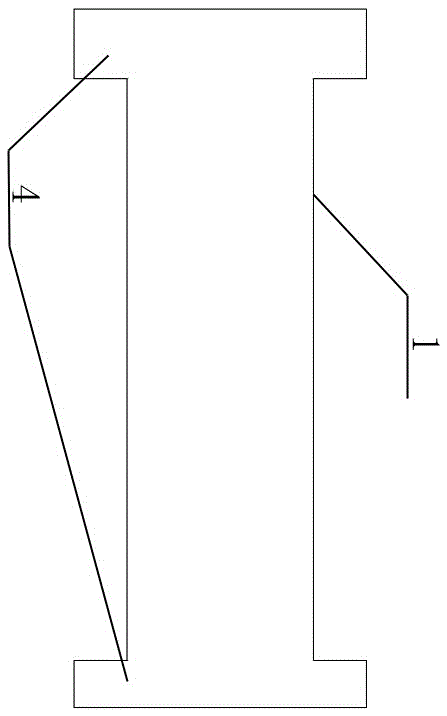

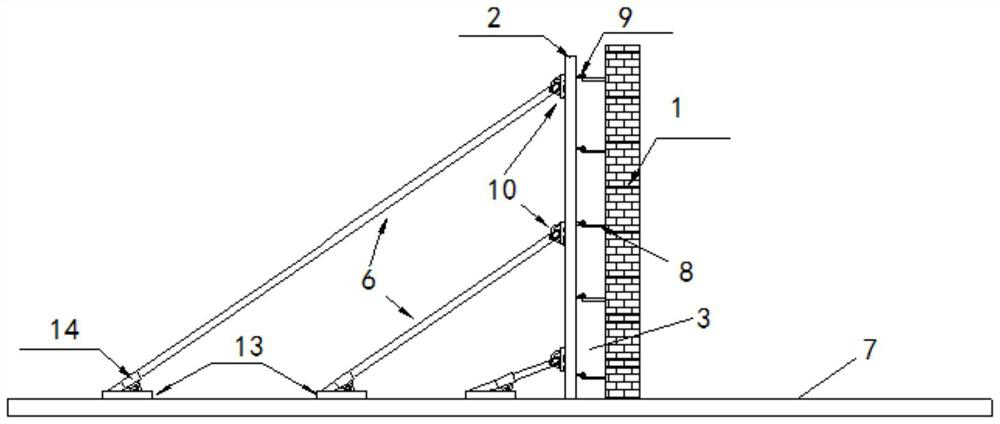

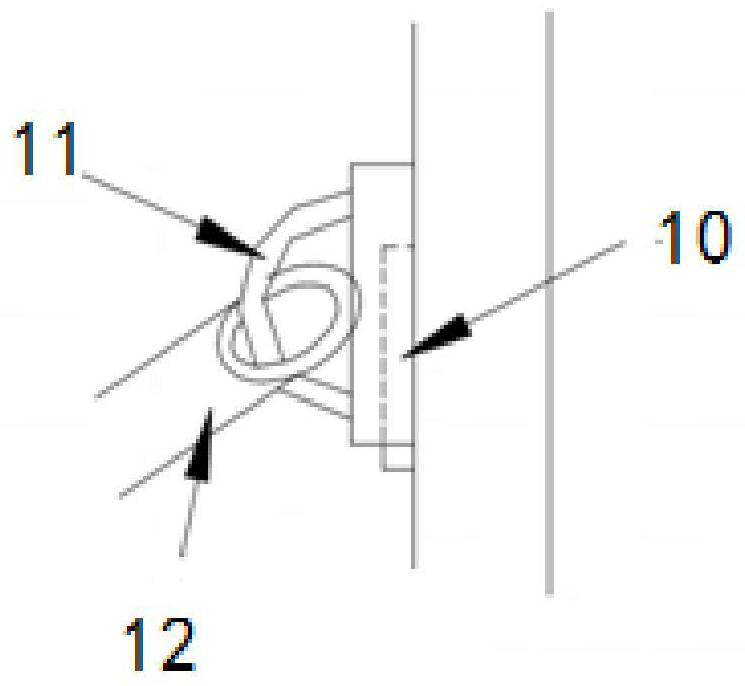

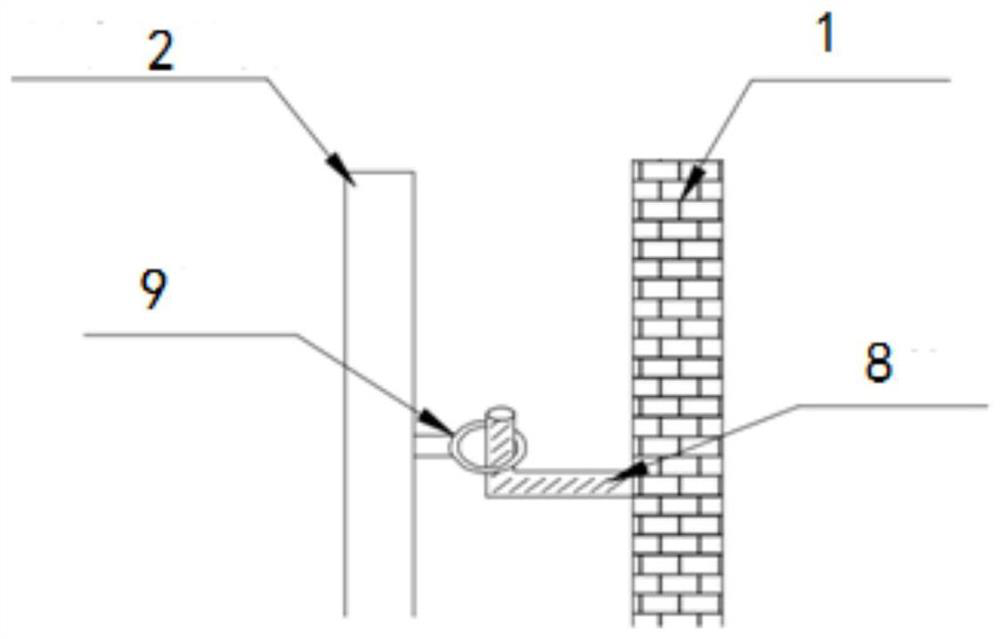

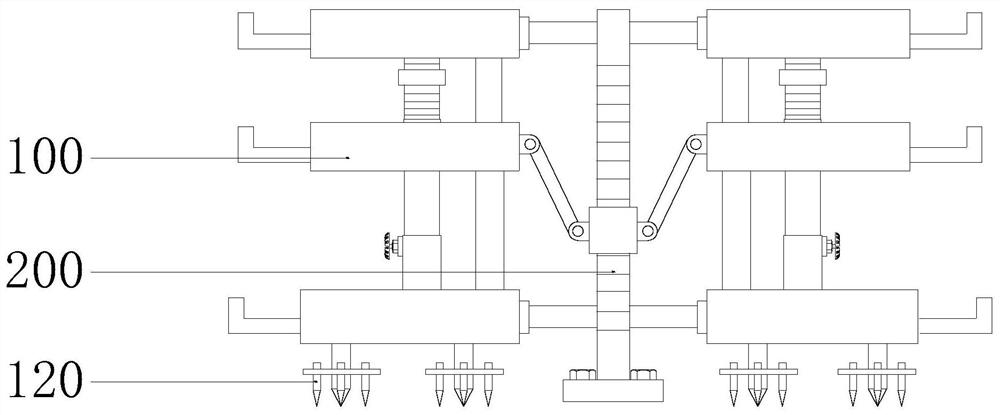

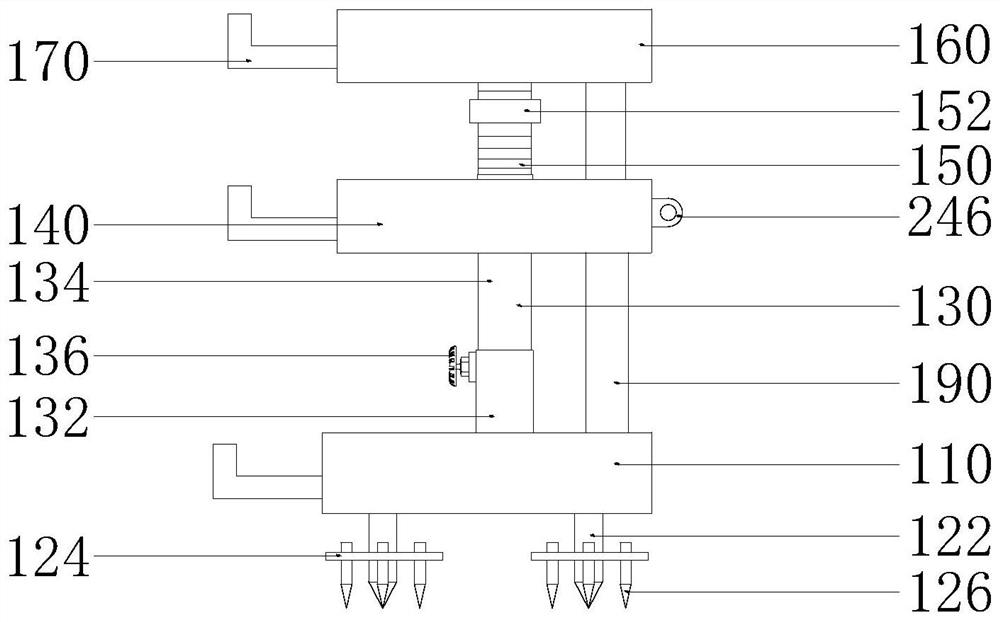

Sliding formwork supporting device for brick wall reinforcement and construction method

PendingCN113719148AMeet reinforcement needsNo damageBuilding repairsForms/shuttering/falseworksBrickArchitectural engineering

The invention provides a sliding formwork supporting device for brick wall reinforcement and a construction method. A supporting steel frame is connected with a floor on one side of a brick wall; a sliding rail is arranged on the side, close to the brick wall, of the supporting steel frame; the sliding rail is parallel to the brick wall; a formwork is arranged at the to-be-reinforced position on one side of the brick wall; one end of a supporting steel rod is connected with a pulley; the pulley is arranged on the sliding rail; the other end of the supporting steel rod is connected to the formwork; the formwork slides up and down along the sliding rail by utilizing the characteristics of the sliding formwork supporting device; the ground clearance of the formwork is controlled; and then the brick wall is subjected to layered formwork supporting reinforcement. The brick wall reinforcement requirement can be met; construction is convenient and fast; the brick wall is not damaged, and the historical building protection requirement is met; steel pipes, square timbers, fasteners and other reinforcement materials are not needed, the formwork supporting cost is low, and economic benefits are high; and the construction site environment limitation is small. Compared with a traditional formwork supporting mode, the sliding formwork supporting device is easy and convenient to use, the brick wall is not damaged, and the reinforcement efficiency and the reinforcement quality are improved.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

A kind of reinforcement method of engineering hollow member

ActiveCN103993750BEasy constructionGood reinforcement effectBuilding repairsBridge erection/assemblyShotcreteMaterials science

The invention relates to a reinforcement method of a hollow component for engineering. The method comprises the following steps that (1) an air-bag inner mold is manufactured according to the section shape of the hollow component; (2) a hole is formed in the top of the hollow component, and the air-bag inner mold is placed in the hollow component; (3) the air-bag inner mold is inflated until the air pressure in the air-bag inner mold is 3 MPa-6 MPa; (4) a concrete interfacial agent is ejected to the inner wall of the hollow component to wet the inner wall of the hollow component, self-leveling concrete is poured in the space formed between the hollow component and the air-bag inner mold from the hole formed in the top of the hollow component, and concrete curing is performed; (5) the hole is repaired to complete reinforcement. According to the reinforcement method, only an original structure top plate needs to be holed, placed in the component and then used after being inflated, so that construction is convenient; compared with a traditional reinforcement method, the reinforcement effect is better, and meanwhile reinforcement cost is reduced; the concrete is poured in a layered mode, and therefore the situation that the air-bag inner mold deforms and enlarges due to pressure can be prevented; Besides, the section and size of an end mold can be adjusted to meet the reinforcement requirements of structures with different types.

Owner:巩义市相济装配构件有限公司

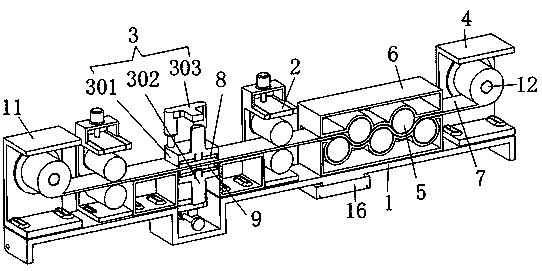

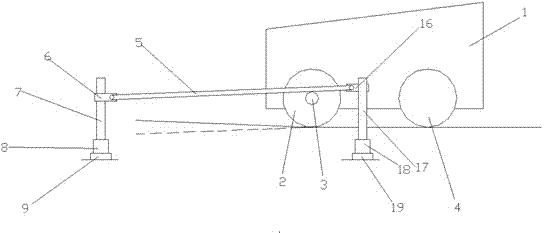

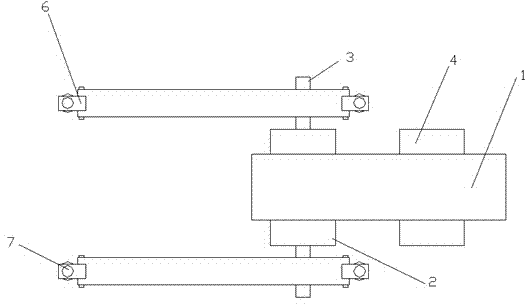

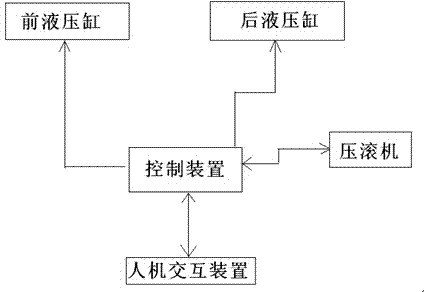

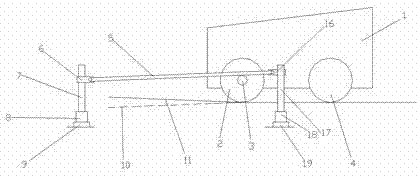

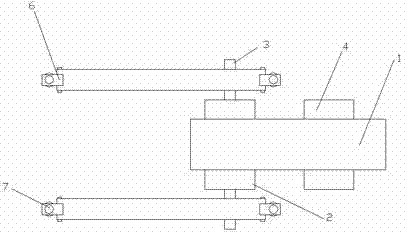

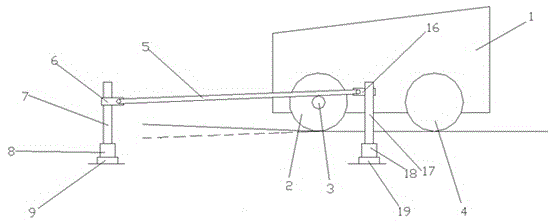

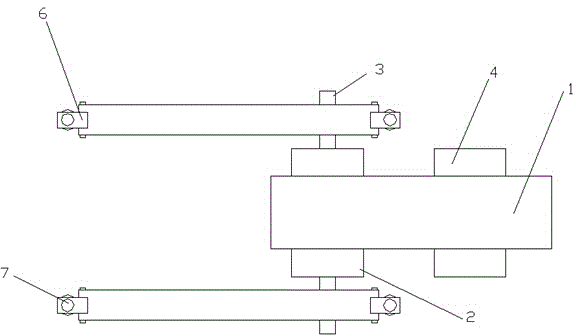

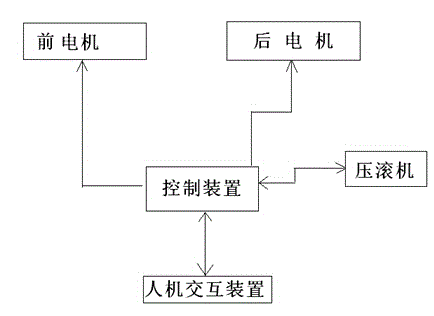

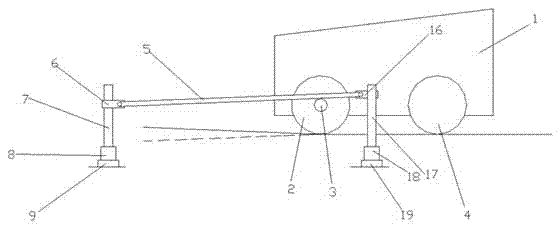

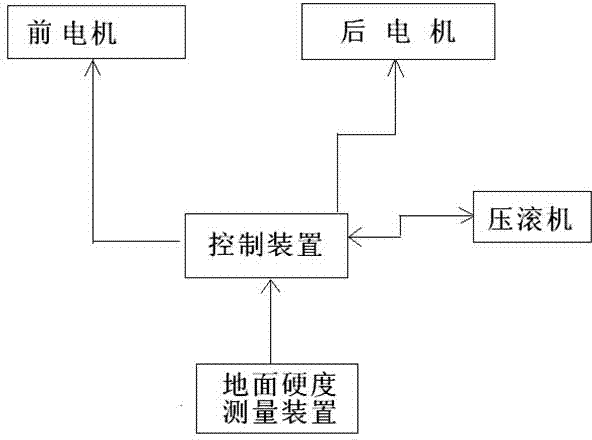

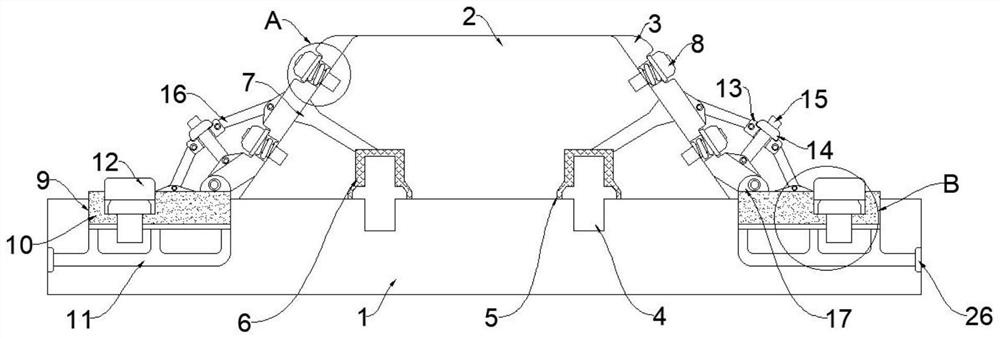

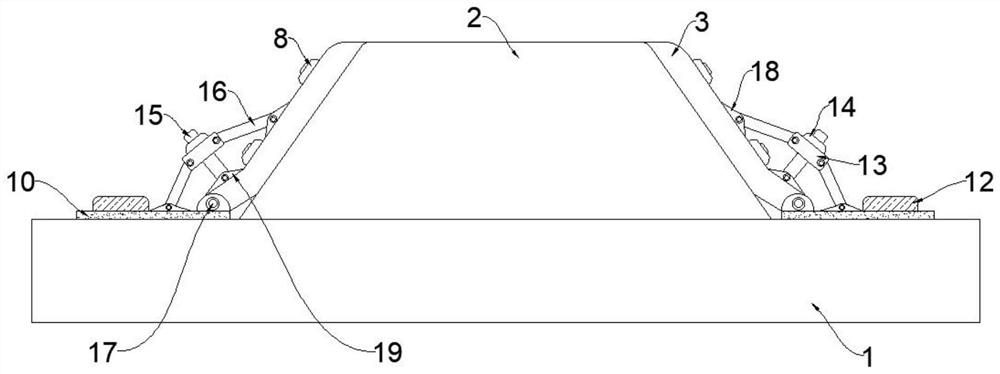

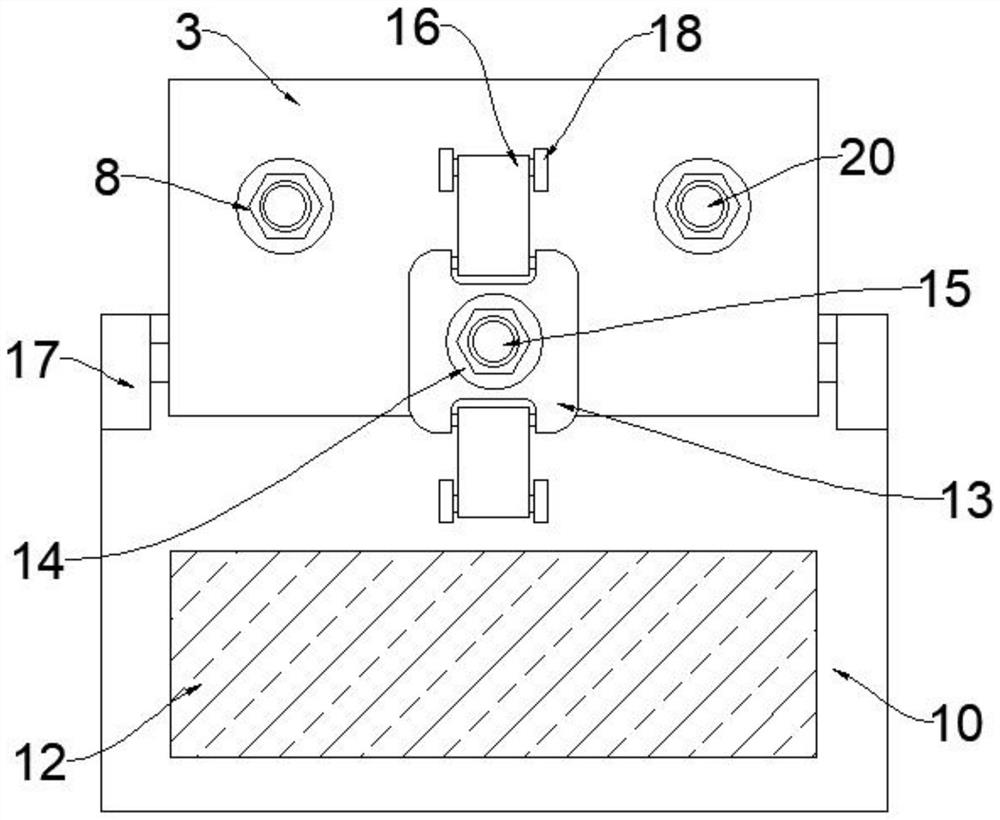

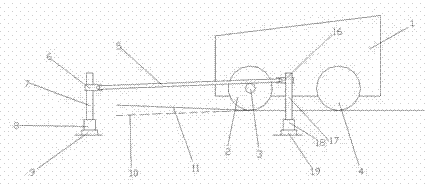

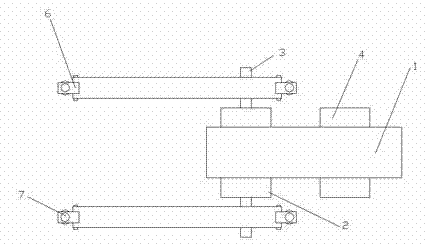

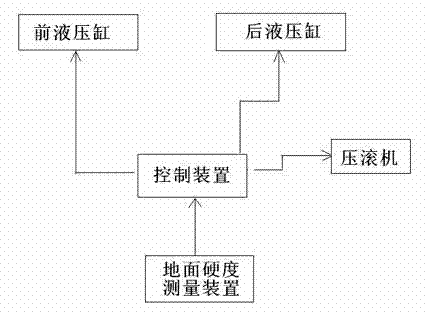

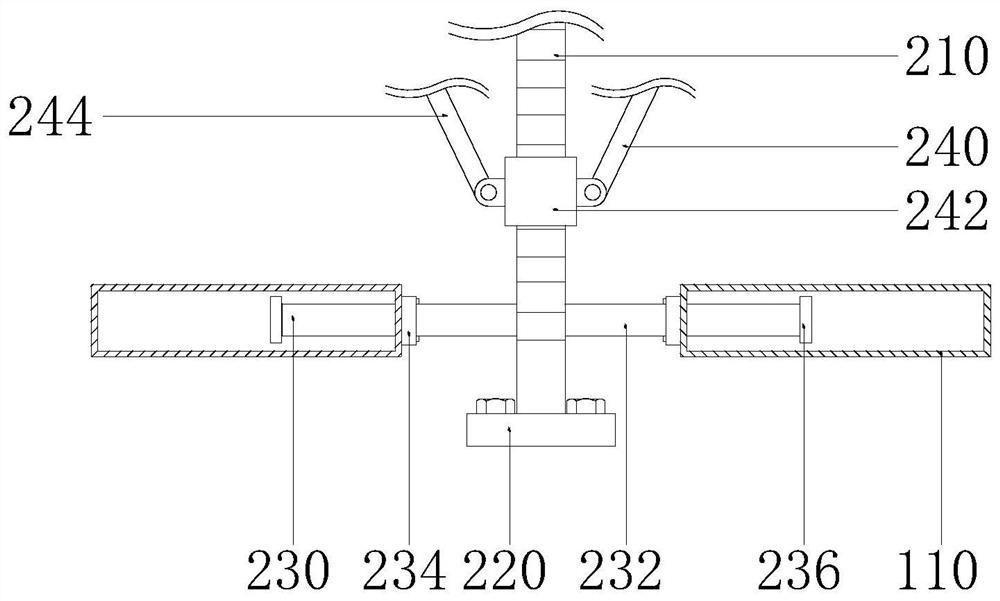

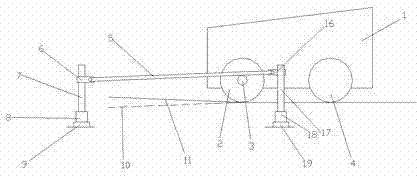

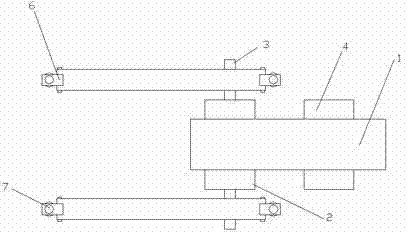

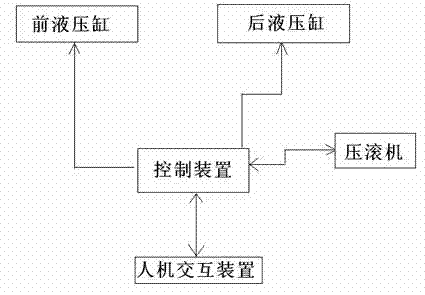

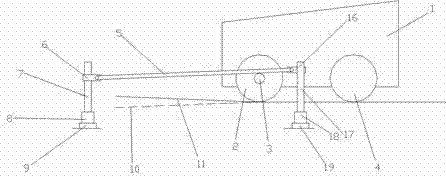

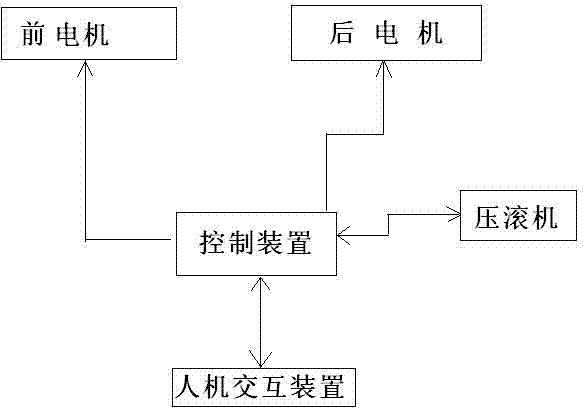

Pavement reinforcement system

ActiveCN103498395BMeet reinforcement needsFully automatedRoads maintainenceHydraulic cylinderRail pressure

A pavement reinforcement system comprises a rolling machine, two rail pressure sets and a control system. The rolling machine comprises a body, a compacting roll and a driving roll. Each rail pressure set comprises a front telescoping system, a rear telescoping system and a rail pressure bar. The control system comprises a control device and a man-machine interaction device. The man-machine interaction device is capable of receiving rolling reduction information entered by a user and transmitting the information to the control device. The control device is capable of controlling a hydraulic cylinder of the front telescoping system and a hydraulic cylinder of the rear telescoping system to operate correspondingly. The rolling machine can operate under control of the control device.

Owner:启东市天汾电动工具技术创新中心

Reinforced pressure-proof PVC pipe

The invention discloses a reinforced pressure-proof PVC pipe. The reinforced pressure-proof PVC pipe is characterized by being prepared from, by weight, 55-60 parts of PE, 45-50 parts of PS, 15-23 parts of polyvinyl butyral, 10-16 parts of alcohol-soluble resin, 13-19 parts of sodium salicylate, 12-17 parts of sodium acetate, 15-20 parts of acrylic acid stearate, 20-26 parts of isodecyl acrylate and 12-23 parts of isopropyl acrylate. The reinforced pressure-proof PVC pipe has the advantages of meeting the reinforcing requirement and being simple in structure and durable.

Owner:宁贻伟

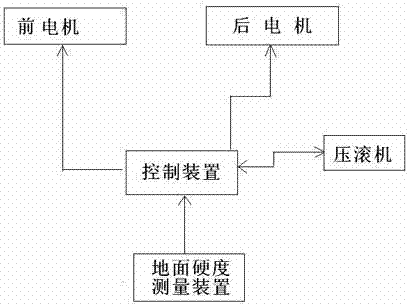

Rolling equipment

ActiveCN103498463AMeet reinforcement needsFully automatedSoil preservationElectric machineryRail pressure

The invention discloses rolling equipment which comprises a rolling machine, two rail pressure devices and a control system. The rolling machine comprises a machine body, a compaction roller and a drive roller. Each rail pressure device comprises a front stretchable system, a rear stretchable system and a rail pressure rod. The control system comprises a control device and a ground hardness measuring device. The ground hardness measuring device transmits ground hardness information to the control device. According to the ground hardness information, the control device can control a motor of the front stretchable system and a motor of the rear stretchable system to conduct corresponding actions so as to adjust the rail pressure rods. The rolling machine can move under the control of the control device.

Owner:启东市天汾电动工具技术创新中心

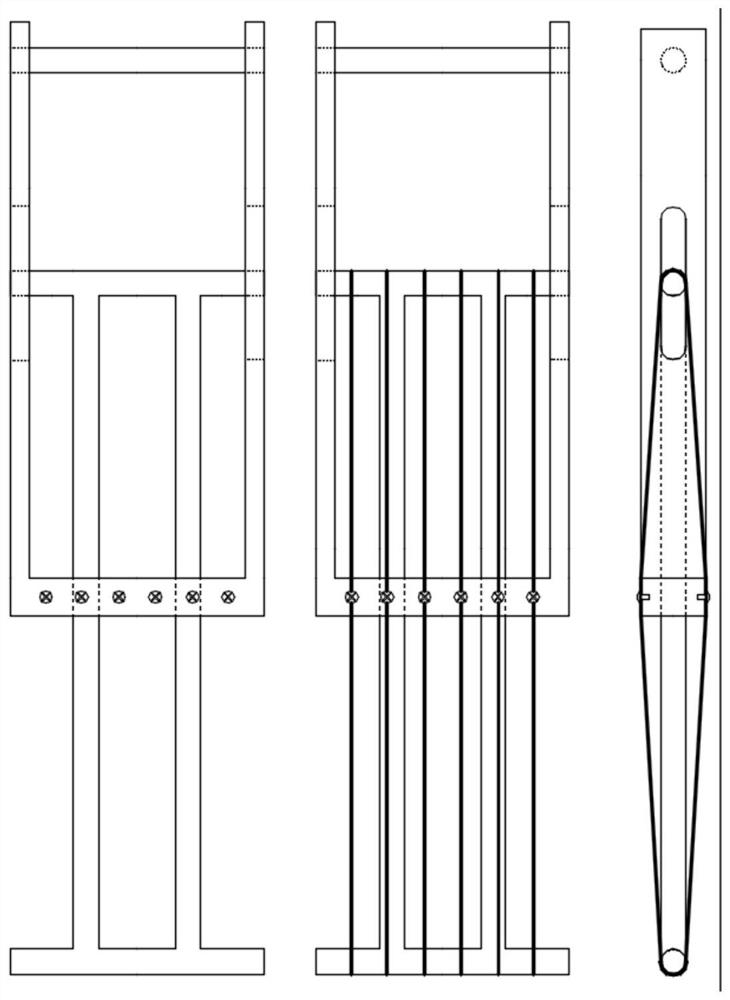

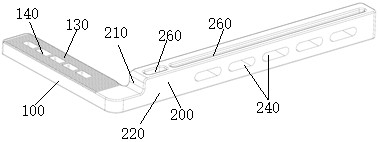

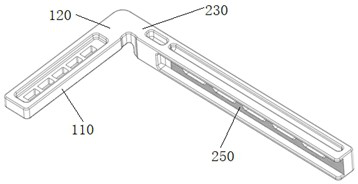

Head dragon component used for reinforcement of building formwork head structure

ActiveCN113585751BReasonable use of mechanical propertiesQuality improvementAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

The invention provides a head dragon component used for strengthening the head structure of building formwork, and relates to the technical field of building formwork. The head dragon component includes: an end plate and a head dragon body, and the end plate and the head dragon body are integrally formed and form a right angle to each other The end plate is provided with end plate teeth and end plate connection holes, and the end plate is provided with a plurality of equidistant rectangular connection holes, which can be connected with the end plate connection holes of the same model of the same type of dragon that are opposite to each other; the body of the head dragon is provided with The connecting holes of the template and the teeth of the end plate are provided with equidistant meshing teeth, and the convex and concave teeth have the same shape, and are arranged in dislocation and reverse connection. The two head dragon components can be equipped with reinforcement systems of different head thicknesses at the head formwork, so that the bending moments generated in all directions of the formwork head structure are offset by the head dragon's own structure and assembly system, and the strength of the three sides of the formwork head structure is enhanced. The mechanical synergy of the reinforcement components solves the technical defect of weak reinforcement mechanics at the corners of the formwork head structure existing in the prior art, and significantly improves the forming effect of the concrete components.

Owner:天津仝元材料科技有限公司

Rolling system

InactiveCN103498464BMeet reinforcement needsFully automatedSoil preservationRail pressureControl system

The invention discloses a rolling system which comprises a rolling machine, two rail pressure devices and a control system. The rolling machine comprises a machine body, a compaction roller and a drive roller. Each rail pressure device comprises a front stretchable system, a rear stretchable system and a rail pressure rod. The control system comprises a control device and a human-computer interaction device. The human-computer interaction device can receive rolling reduction information input by a user and transmit the rolling reduction information to the control device. The control device can control the front stretchable system and the rear stretchable system to conduct corresponding actions so as to adjust the rail pressure rods. The rolling machine can move under the control of the control device.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Rolling equipment

ActiveCN103498463BMeet reinforcement needsFully automatedSoil preservationRail pressureControl system

The invention discloses rolling equipment which comprises a rolling machine, two rail pressure devices and a control system. The rolling machine comprises a machine body, a compaction roller and a drive roller. Each rail pressure device comprises a front stretchable system, a rear stretchable system and a rail pressure rod. The control system comprises a control device and a ground hardness measuring device. The ground hardness measuring device transmits ground hardness information to the control device. According to the ground hardness information, the control device can control a motor of the front stretchable system and a motor of the rear stretchable system to conduct corresponding actions so as to adjust the rail pressure rods. The rolling machine can move under the control of the control device.

Owner:启东市天汾电动工具技术创新中心

Existing building wall single-face reinforcing system and construction method

PendingCN114293802AEasy constructionFormwork is simple and fastBuilding repairsBuilding material handlingSteel tubePipe support

According to the existing building wall single-face reinforcing system and the construction method, the prefabricated concrete reinforcing outer skin is fixed to one side of the brick wall through the wall planting ribs and the tie rings, and the back face of the prefabricated concrete reinforcing outer skin is reinforced through three steel pipe supports; the supporting angle of the steel pipe support can be adjusted through the hinge support and the adjustable lantern ring, after concrete pouring of the reinforcing surface layer is completed, only the steel pipe support and the hinge support need to be dismantled, and the prefabricated concrete reinforcing outer skin is reserved as a reinforcing structure. The brick wall reinforcing requirement can be met; construction is convenient and fast, formwork erecting is simple and fast, and formwork dismounting is not needed; reinforcing materials such as steel pipes, square timbers and fasteners are not needed, the formwork erecting cost is low, economic benefits are high, the prefabricated concrete reinforcing skin is reserved as a reinforcing structure, the reinforcing strength is remarkably improved, and the environmental limitation of a construction site is small.

Owner:NO 2 CONSTR GRP CO LTD OF SHANGHAI CONSTR GRP

Strengthening Structure and Construction Method of Highway Subgrade

ActiveCN112501968BAdjust the tilt angleTilt angle limitRoadwaysExcavationsArchitectural engineeringBase course

The invention discloses a road subgrade reinforcement structure and a construction method, comprising a soil base, a road subgrade body is arranged above the soil base; a storage slot, the storage slot is arranged on the upper end of the soil base; a reinforcement seat, the reinforcement seat is arranged at The inside of the storage slot; the roadbed protective plate, the roadbed protective plate is arranged on both sides of the road subgrade body, the first hinge seat is arranged between the two roadbed protective plates and the reinforcing seat, and the first hinge seat and the reinforcing seat are Through screw connection, the first hinge seat is rotatably connected with the roadbed protection plate. The realization can play a role in reinforcing the side end of the roadbed, thereby inhibiting the expansion of the side end of the roadbed under force to the outside, effectively avoiding the landslide of the roadbed, improving the reinforcement effect, making the use more stable and improving the safety of use.

Owner:荀敬川

Quick-hardening early-strength structure reinforcement material based on aluminate cement and steel slag

InactiveCN102295447BIncrease productivityImprove construction efficiencySolid waste managementFiberPolyvinyl alcohol

The invention belongs to the technical field of building materials, in particular relates to a quick-hardening early-strength structure reinforcement material based on aluminate cement and steel slag. The structure reinforcement material consists of aluminate cement, steel slag, ore slag powder, fly ash, silicon ash, a retarder, a water reducing agent, a latex powder, cellulose ether, a defoamer and poval fiber. By using the material provided by the invention, the problems of the common cement-based reinforcement material, such as high construction difficulty, long wet operation time and low early strength, can be solved. According to the invention, a composite gel material supplemented by steel aggregate, a composite additive and fiber is subjected to dry mixing and then packaged for supply; in scene, the structure reinforcement material provided by the invention can be used after adding water and stirring; and the structure reinforcement material has the characteristics of high early strength, good cracking resistance, good permeability resistance, small shrinkage, excellent durability and the like, is easy to construct and is suitable for reinforcing works of buildings, wharfs, bridges, dams, railways, tunnels and the like.

Owner:TONGJI UNIV

Structure reinforcing material taking steel slag as aggregate

InactiveCN102199025BImprove mobilityLittle loss of fluiditySolid waste managementSteelmakingMechanical property

The invention belongs to the technical field of building materials, and in particular relates to a structure reinforcing material taking steel slag as aggregate. The material consists of cement, the steel slag, mineral slag powder, fly ash, zeolite powder, latex powder, cellulose ether, an antifoaming agent and a polycarboxylic acid water reducing agent. The steel slag is subjected to hot closed treatment; the problem that the common steel slag easily cause low stability of the material can be solved, and the solid waste in the steelmaking industry, namely the steel slag is recycled and efficiently utilized; the cost of the conventional cement-based reinforcing material can be reduced, and the material has higher construction property, mechanical property and durability; and the material has high compression strength, breaking strength and durability and low shrinkage, and is suitable for the reinforcing engineering of various buildings and bridges.

Owner:TONGJI UNIV

Pavement reinforcing equipment

ActiveCN103485261AMeet reinforcement needsFully automatedRoads maintainenceControl systemControl engineering

The invention discloses pavement reinforcing equipment comprising a roller press, two sets of rail pressing devices and a control system, wherein the roller press comprises a machine body, a compacting roller and a driving roller; each set of the rail pressing device comprises a front telescopic system, a back telescopic system and a rail pressing rod; the control system comprises a control device and a ground hardness measuring device, the ground hardness measuring device transmits ground hardness information to the control device, the control device can control hydraulic cylinders of the front telescopic system and the back telescopic system to perform corresponding actions, and the roller press can move under the control of the control device.

Owner:启东市天汾电动工具技术创新中心

Road bridge crack reinforcing structure and reinforcing method thereof

InactiveCN112359734AMeet reinforcement needsReinforcement needs benefitBridge erection/assemblyRoads maintainenceArchitectural engineeringBridge maintenance

The invention provides a road and bridge crack reinforcing structure, and belongs to the technical field of road and bridge maintenance. The road and bridge crack reinforcing structure comprises a fixing assembly and a connecting assembly. The inserting piece is connected to the lower portion of the bottom plate, the adjusting rod is connected to the upper portion of the bottom plate, the threadedrod is connected to the upper surface of the fixing plate in a threaded mode, the connecting pipe is communicated with the pouring hole, and the connecting pipe penetrates through the fixing plate and the bottom plate. The base is connected to the bottom end of the lead screw, the connecting piece penetrates through the lead screw, the connecting piece is connected with the bottom plate and the top plate, one end of the reinforcing piece is hinged to the lead screw, and the other end of the reinforcing piece is connected with the fixing plate. The gap repairing effect can be improved, the size of the steel structure can be adjusted, the reinforcing requirements of cracks with different widths and depths can be met, and the practicability of the steel structure is improved.

Owner:SUQIAN FENGCHI SECURITY & PROTECTION

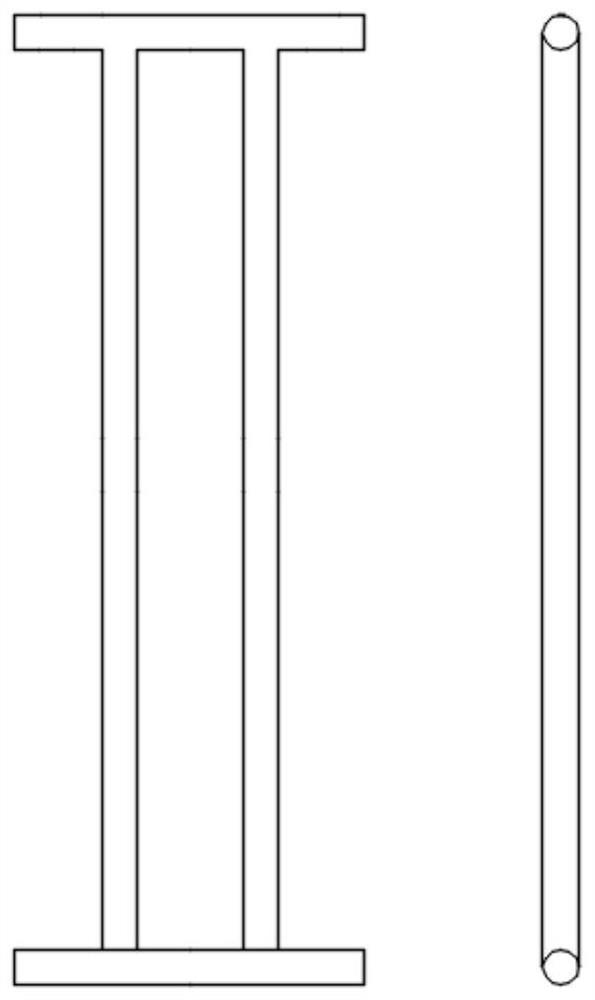

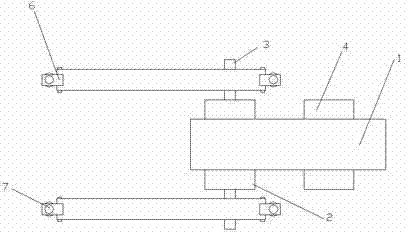

Metal truss for wall assembly board

InactiveCN111530922AReasonable structureFit closelyBuilding reinforcementsMetal rolling arrangementsAutomatic controlStructural engineering

The invention relates to a metal truss for a wall assembly board. The cross section of the metal truss is an M or n shaped structure; and the metal truss is formed by adopting a rolling mill to carryout cold rolling on a steel net. The metal truss is formed in the following way: at first, round steel is welded into a net, and then the net is rolled by the rolling mill to form the structure, and the cross section of the structure is M or n shaped. The metal truss has the following advantages: the structure is reasonable, the rolling equipment and anticorrosion spraying equipment are compact incooperation, the operation is simple, production is carried out through rolling of the rolling mill, automatic control is applicable, and the personnel allocation of the existing production line is reduced.

Owner:ANGANG CONSTR CONSORTIUM

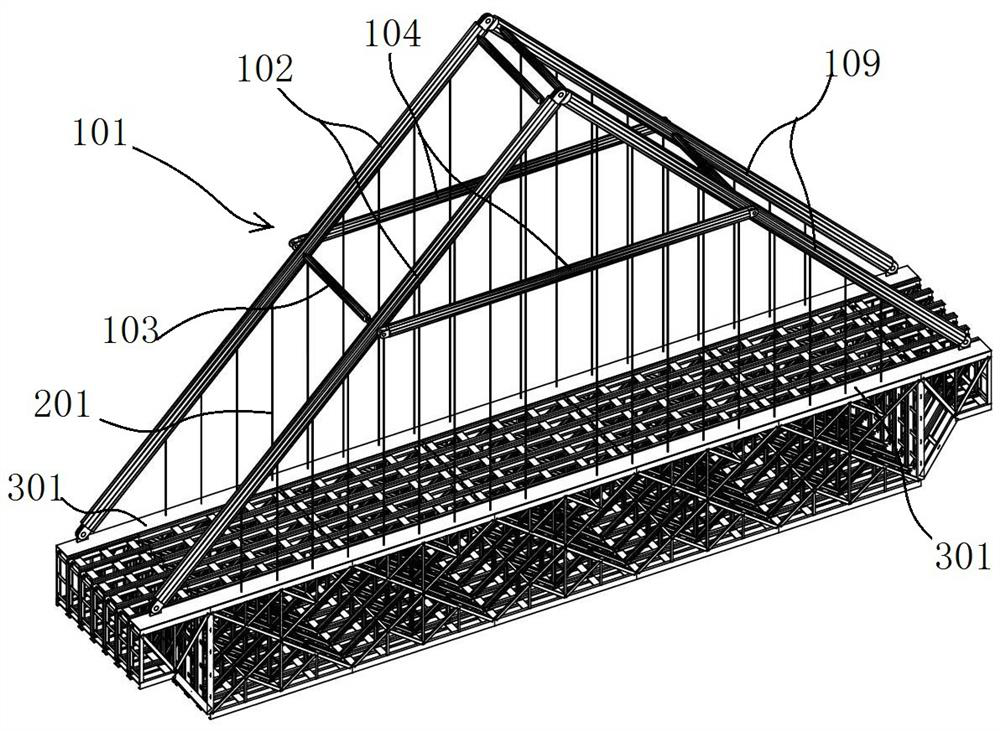

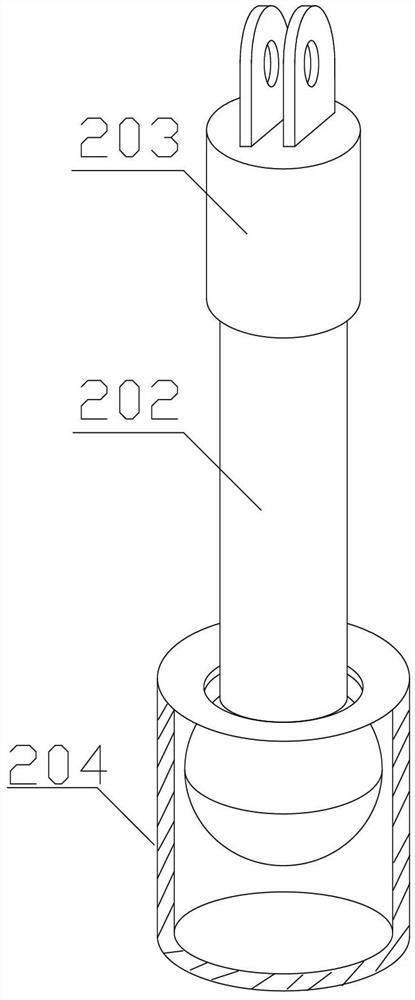

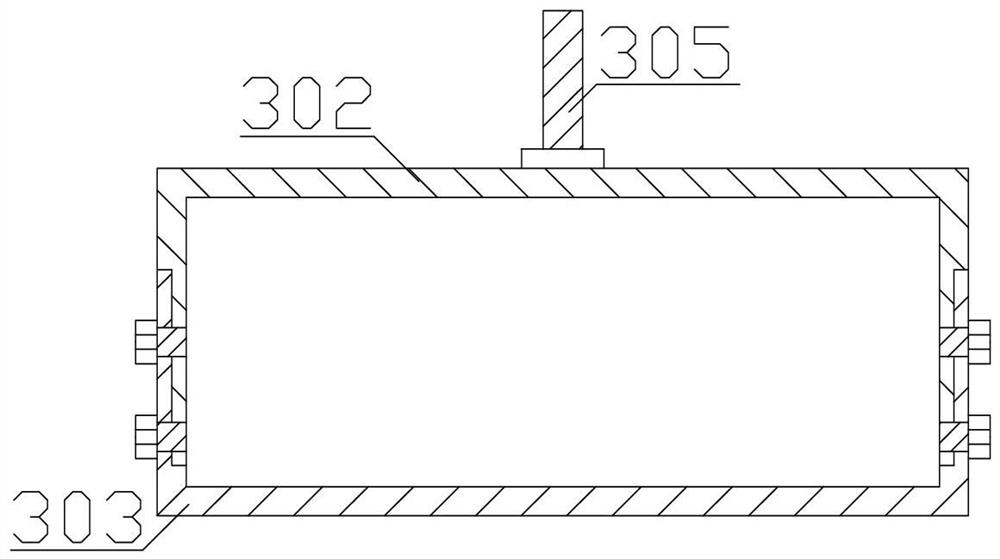

An External Prestressed Reinforcement Device of Type 64 Railway Military Beam

ActiveCN109629398BAdjustable lengthMeet reinforcement needsBridge structural detailsBridge erection/assemblyClassical mechanicsEngineering

The invention relates to an external prestressed reinforcing device for a six-four type railway military beam, which includes a triangular bracket, a connecting body and a prestressed cable; Rod connection; prestressed cables include double-ear anchor ends, tension ends and steel strands; connectors include top plates and bottom plates; tension bolts and single ears A are fixedly installed on the top surface of the top plate; tension ends and tension ends The bolts are fixedly connected, and the anchor ends of the double ears are connected with the corresponding upper and lower triangular brackets; the present invention installs the connecting body and the triangular bracket on the upper chord of the six-four beam, and installs the prestressed cable between the connecting body and the triangular bracket, so that Each node of the upper chord is prestressed vertically upward to offset the vertical unfavorable load caused by the self-weight of the six-four beam and the passing of the train, thereby reducing the deflection of the six-four beam and improving the force condition of the vertical bar and other members .

Owner:SHIJIAZHUANG TIEDAO UNIV

Pavement reinforcement system

A pavement reinforcement system comprises a rolling machine, two rail pressure sets and a control system. The rolling machine comprises a body, a compacting roll and a driving roll. Each rail pressure set comprises a front telescoping system, a rear telescoping system and a rail pressure bar. The control system comprises a control device and a man-machine interaction device. The man-machine interaction device is capable of receiving rolling reduction information entered by a user and transmitting the information to the control device. The control device is capable of controlling a hydraulic cylinder of the front telescoping system and a hydraulic cylinder of the rear telescoping system to operate correspondingly. The rolling machine can operate under control of the control device.

Owner:启东市天汾电动工具技术创新中心

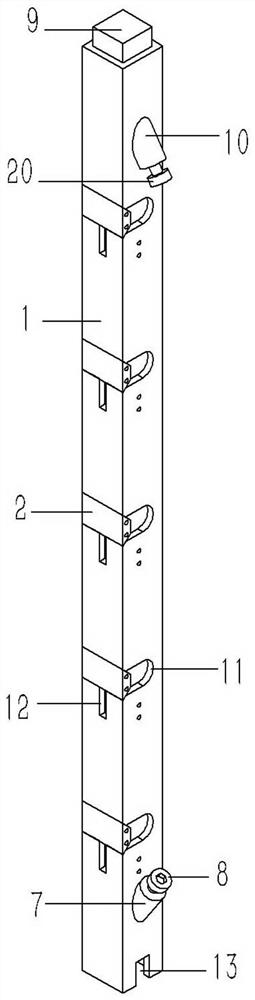

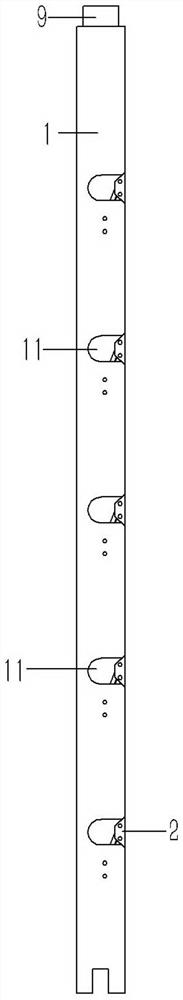

Protective window reinforcing handrail convenient to assemble and connect

ActiveCN114439358AMeet reinforcement needsEasy to install and disassembleFixed grillesIsosceles trapezoidBaluster

A protective window reinforcing handrail convenient to assemble and connect comprises a vertical square tube, a plurality of inserting grooves penetrating through the two side walls of the square tube are formed in the front end face of the square tube, the inserting grooves are linearly, vertically and evenly distributed in the square tube, check blocks in the shape of an isosceles trapezoid are inserted into the inserting grooves of the square tube, and a vertical groove is formed in the middle of the rear end face of each check block. Two inclined connecting rods are inserted into the grooves, transverse upper supporting shafts are fixed to the two side walls of the upper ends of the inclined connecting rods, the upper supporting shafts are inserted into the check blocks, transverse lower supporting shafts are fixed to the two side walls of the lower ends of the inclined connecting rods, and the lower supporting shafts are inserted into the two side walls of the square pipe; inclined driving rods are fixed to the portions, on the two sides of the inclined connecting rod, of the lower supporting shaft in an inserted and sleeved mode, the driving rods are inserted into the square pipes, and guide grooves are formed in the driving rods. The designed protective window reinforcing railing can meet the reinforcing requirement of the transverse railing on the protective window railing, meanwhile, the transverse railing is convenient to mount and dismount, and the protective window railing is greatly convenient to assemble.

Owner:ZHONGSHA CONSTR GROUP

Rolling system

InactiveCN103498464AMeet reinforcement needsFully automatedSoil preservationInteraction deviceRail pressure

The invention discloses a rolling system which comprises a rolling machine, two rail pressure devices and a control system. The rolling machine comprises a machine body, a compaction roller and a drive roller. Each rail pressure device comprises a front stretchable system, a rear stretchable system and a rail pressure rod. The control system comprises a control device and a human-computer interaction device. The human-computer interaction device can receive rolling reduction information input by a user and transmit the rolling reduction information to the control device. The control device can control the front stretchable system and the rear stretchable system to conduct corresponding actions so as to adjust the rail pressure rods. The rolling machine can move under the control of the control device.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com