Laser impacting strengthening method for small-hole components different in thickness

A technology of laser shock strengthening and laser shock, which is applied in the direction of laser welding equipment, manufacturing tools, welding/welding/cutting items, etc., can solve the problems of small hole damage, affecting the surface quality of hole precision and hole wall, and achieve good deformation and improvement Scientific and effective in ensuring the quality of the hole wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

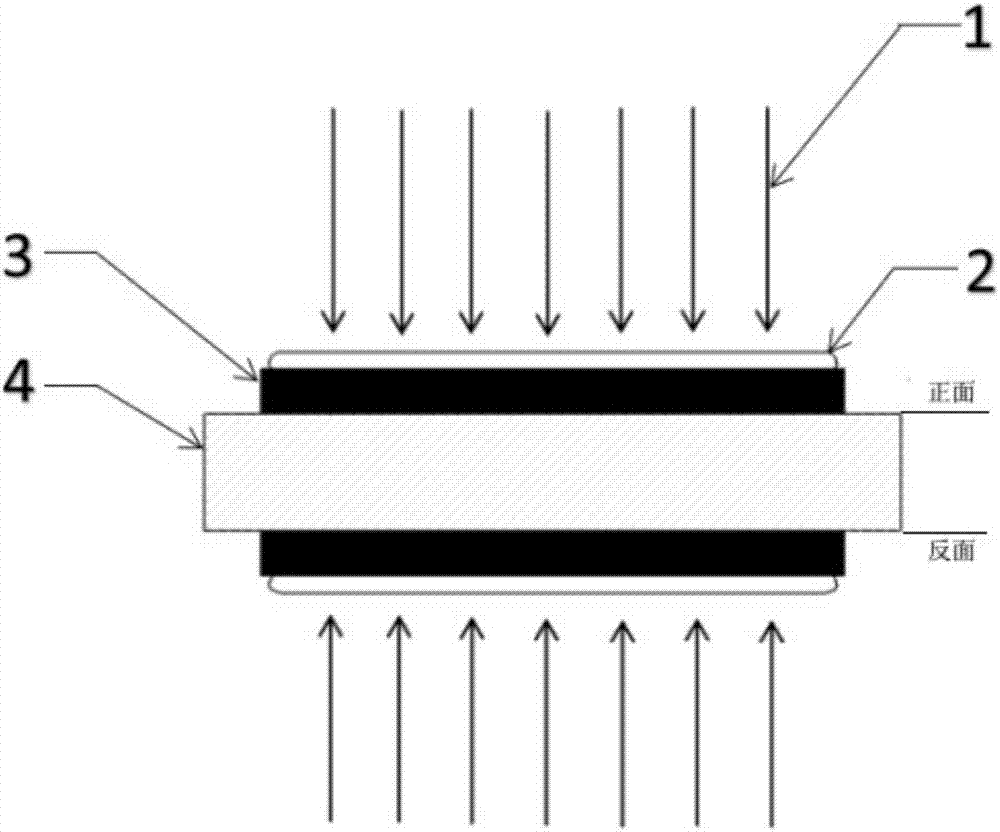

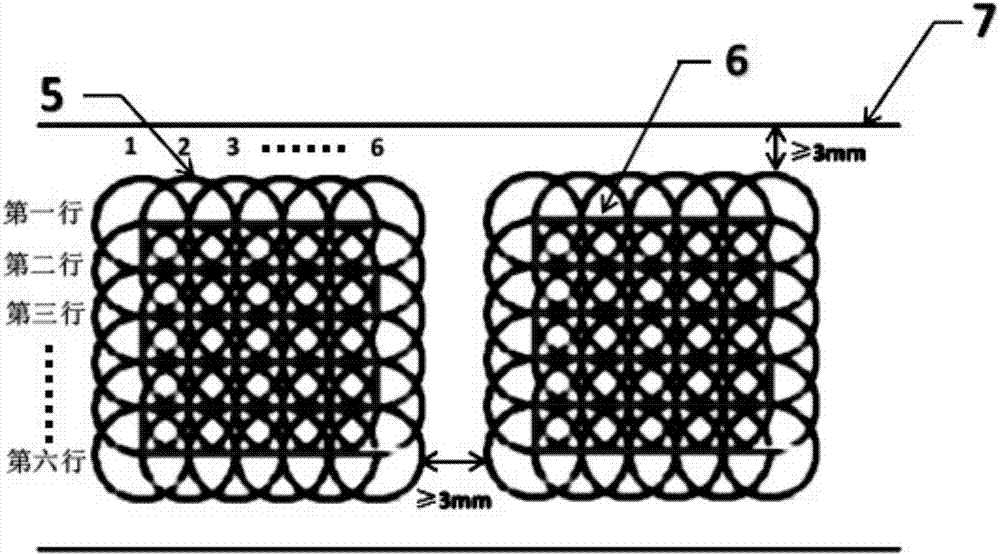

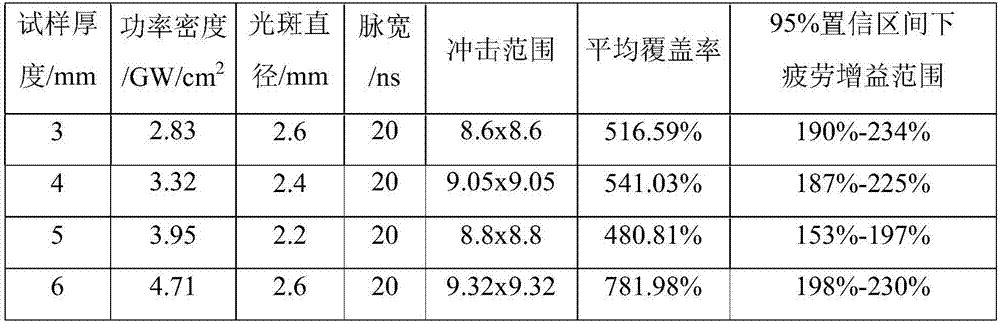

[0034] In this example, the material used is 7050-T7451 aluminum alloy sheet material, the thickness is 3mm, 4mm, 5mm, 6mm, and the hole diameter to be opened is 2.6mm. Such as figure 1As shown, the surface of the small hole component 4 is first pretreated, and then aluminum foil is pasted on the surface of the component to be opened as the energy absorbing layer 3, and water is used as the constraining layer 2 to make the water flow through the surface of the aluminum foil at a constant speed. The small-hole component 4 is fixed on the numerical control workbench with a fixture, and the running path of the numerical control workbench is programmed so that the laser can just strengthen the part of the component to be drilled. According to the selected constrained layer 2 is water, the absorption layer 3 is aluminum foil, according to P>2σ s , It can be seen that k=1, σ s =441Mpa, I 0 Should be greater than the lower limit of 0.78GW / cm 2 .

[0035] empirical formula B=...

example 2

[0040] The difference between this example and Example 1 is that the material used in this example is TC4-DT titanium alloy sheet material with a thickness of 3mm, 4mm, and 6mm, and the hole size to be opened is 2.6mm. The surface of the small-hole component 4 is first pretreated, and then the aluminum foil 3 is pasted on the surface of the component with openings as an energy absorption layer, and water 2 is used as a constraining layer to make the water flow through the surface of the aluminum foil at a uniform speed. Fix the component on the CNC workbench with a fixture, and program the running path of the CNC workbench so that the laser can just strengthen the part to be drilled. According to the selected constrained layer and absorbing layer, according to P>2σ s , It can be seen that k=1, σ s =811Mpa, I 0 Should be greater than the lower limit of 2.63GW / cm 2 .

[0041] empirical formula B=2.6, considering the stiffness and surface hardness of titanium alloy compre...

example 3

[0045] The difference between this example and Example 1 is that the material used in this example is 2024-T62 aluminum alloy sheet, the thickness is 2.5mm and 5mm, and the size of the holes to be opened is 2mm. Such as figure 1 As shown, the surface of the small hole member 4 is pretreated first, and then aluminum foil is pasted on the surface of the member with openings as the energy absorbing layer 3, and 4.5 mm thick K9 glass is used as the constraining layer 2. The component 4 is fixed on the CNC workbench with a fixture, and the running path of the CNC workbench is programmed so that the laser can just strengthen the part of the material to be drilled. According to the selected constrained layer and absorbing layer, according to P>2σ s , It can be seen that k=1.62, σ s =340Mpa, I 0 Should be greater than 0.18GW / cm 2 .

[0046] empirical formula B=6, A is about 4.8, and the laser power density of the small hole component 4 with a thickness of 2.5mm can be 1.57GW / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser pulse width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com