Road bridge crack reinforcing structure and reinforcing method thereof

A technology for strengthening structures and cracks, which is applied in the direction of bridge reinforcement, roads, bridges, etc., can solve the problems of steel structure adjustment, poor gap repair effect, and inability to adapt to cracks, etc., to improve reliability, strengthen reliability, and increase contact range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

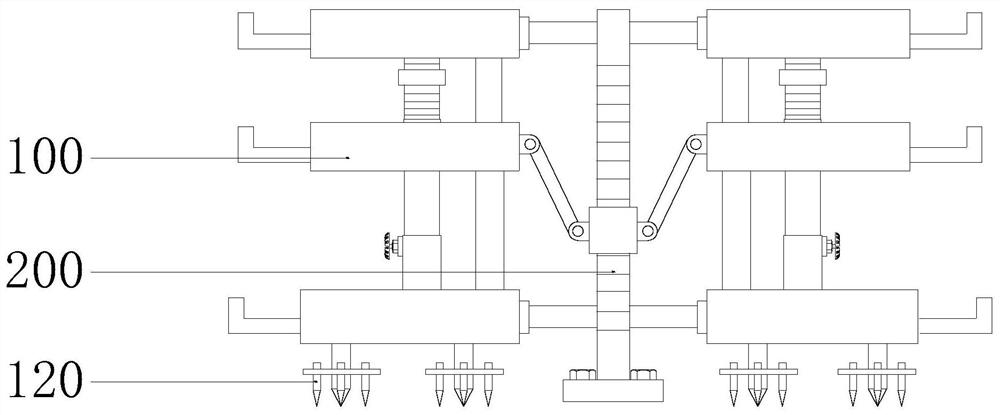

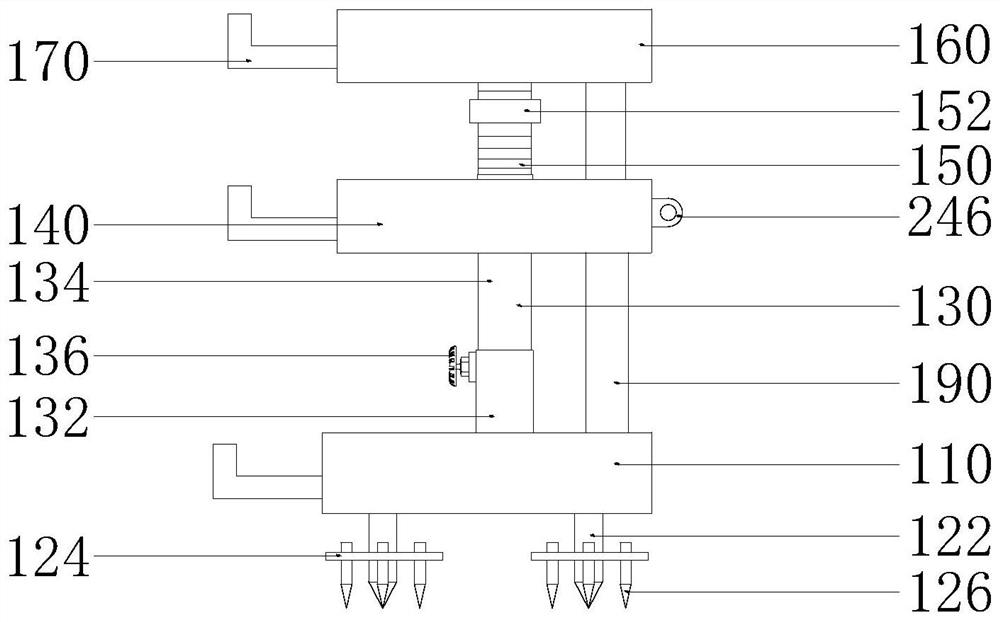

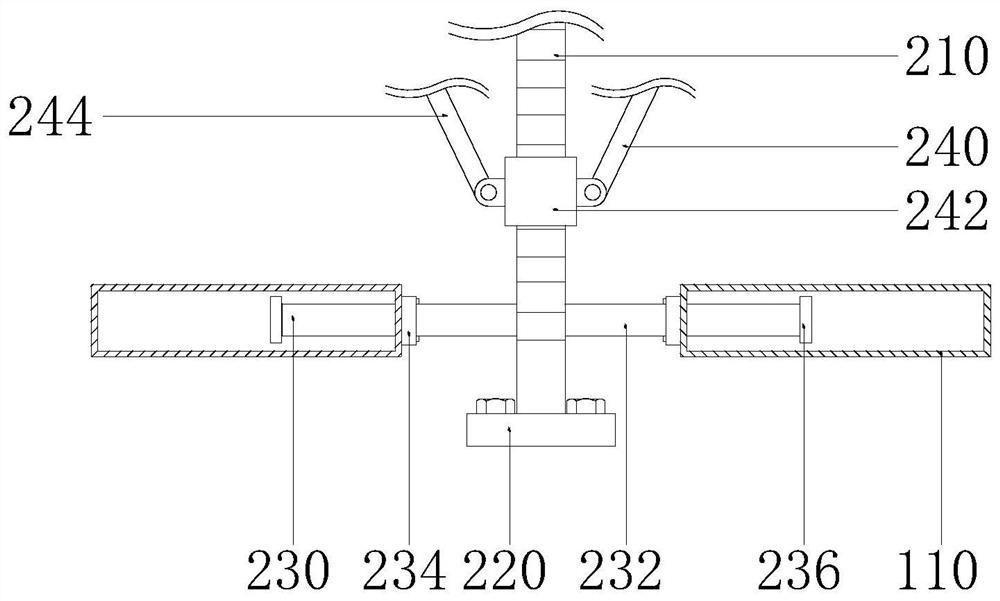

[0037] see Figure 1-5 , the present invention provides a technical solution: a road bridge crack reinforcement structure includes a fixing assembly 100 and a connecting assembly 200 .

[0038] see Figure 1-5 , the fixing assembly 100 includes a bottom plate 110, a tightening member 120, an adjusting rod 130, a fixing plate 140, a threaded rod 150, a top plate 160, a fixing block 170 and a connecting pipe 190, the tightening member 120 is connected to the bottom of the base plate 110, and the adjusting rod 130 Connected above the bottom plate 110 , the fixed plate 140 is connected above the adjusting rod 130 , the fixed plate 140 is provided with a threaded hole 142 , and the threaded rod 150 is threadedly connected with the fixed plate 140 through the threaded hole 142 . The threaded rod 150 is threaded on the upper surface of the fixing plate 140 , and the threaded rod 150 is fixed with an adjusting block 152 , and the adjusting block 152 is fixedly sleeved on the outer su...

Embodiment 2

[0041] see Figure 1-5 , the present invention provides a technical solution: a road bridge crack reinforcement structure includes a fixing assembly 100 and a connecting assembly 200 .

[0042] see Figure 1-5 , the fixing assembly 100 includes a bottom plate 110, a tightening member 120, an adjusting rod 130, a fixing plate 140, a threaded rod 150, a top plate 160, a fixing block 170 and a connecting pipe 190, the tightening member 120 is connected to the bottom of the base plate 110, and the tightening member 120 includes an insertion rod 122 and a connection plate 124 , the insertion rod 122 is fixedly connected under the bottom plate 110 , and the connection plate 124 is fixed on the insertion rod 122 . The provision of the inserting rod 122 is conducive to a more reliable connection between the bottom plate 110 and the foundation. Connecting plate 124 is connected with post 126, and there are multiple posts 126. Setting post 126 helps to increase the contact range betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com