Metal truss for wall assembly board

A technology for assembling plates and metals, applied in metal rolling, structural elements, building components, etc., which can solve problems such as cumbersome control procedures for automatic rolling of steel bars, small equipment and personal safety guarantees, and large production workshop space and site occupation , to achieve the effect of being suitable for automatic control, reducing equipment capital and site investment, and being simple and easy to use and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

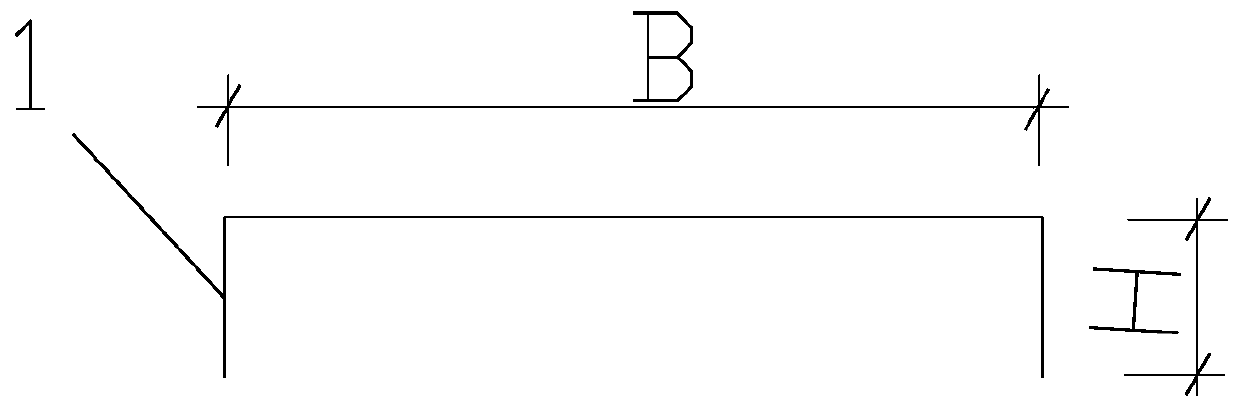

[0033] See figure 1 , Select cold-rolled 16Mn steel plate to make expanded metal mesh, plate thickness: h=3mm, square mesh: k=50×50mm. Roll the truss with a large cross-section by using a rolling mill with large rolls. The size of the truss is: length L×width B×height H=2960mm×560mm×60mm.

Embodiment 2

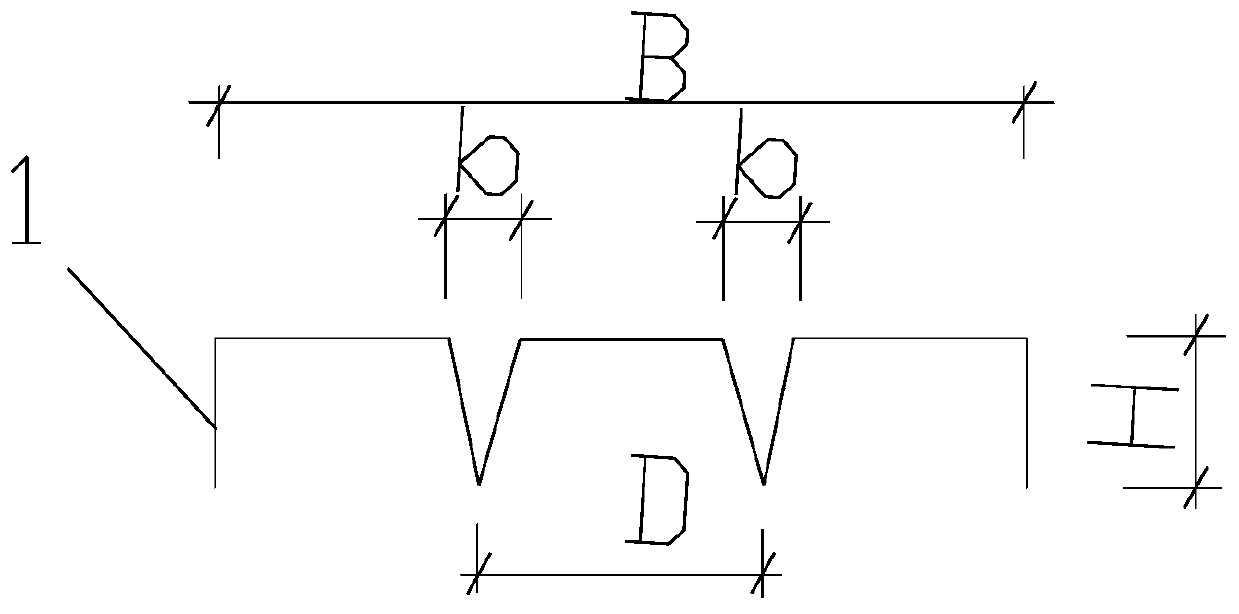

[0035] See figure 2 , choose cold-rolled carbon steel plate to make expanded mesh, plate thickness: h=5mm, square mesh: k=100×100mm. M-shaped cross-section trusses are rolled by rolling mills with M-shaped rolls, and the dimensions of the trusses are: length L×width B×height H=3560mm×1160mm×80mm.

Embodiment 3

[0037] See figure 1 , choose hot-rolled Q235 round bar, round bar diameter Straightening, sizing, and automatic welding to form a mesh with a mesh size of 60×60mm, and then use a rolling mill to roll into a truss with a large cross-section; truss size: length L×width B×height H=2960mm×560mm×60mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com