Patents

Literature

119 results about "Square mesh" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

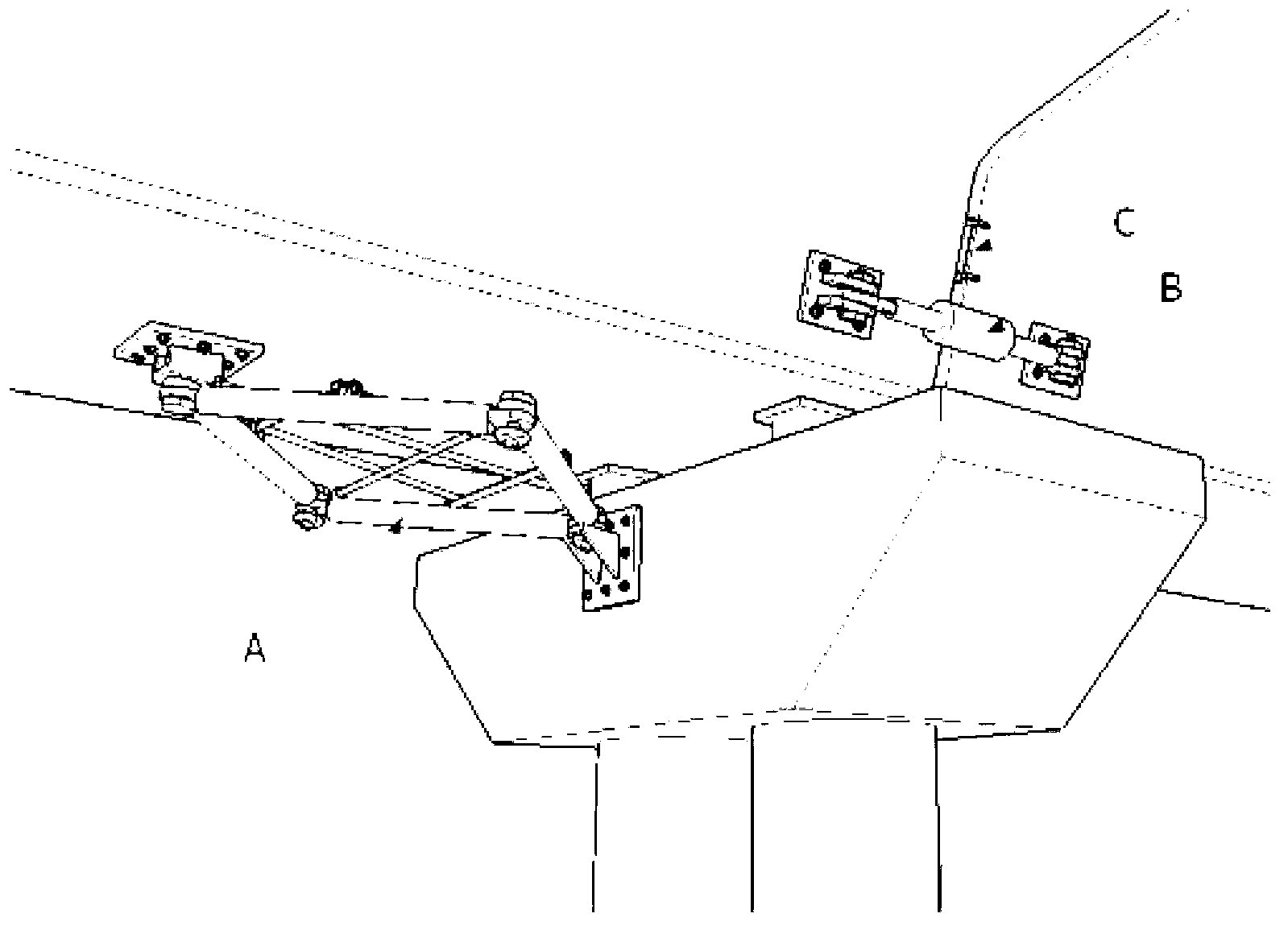

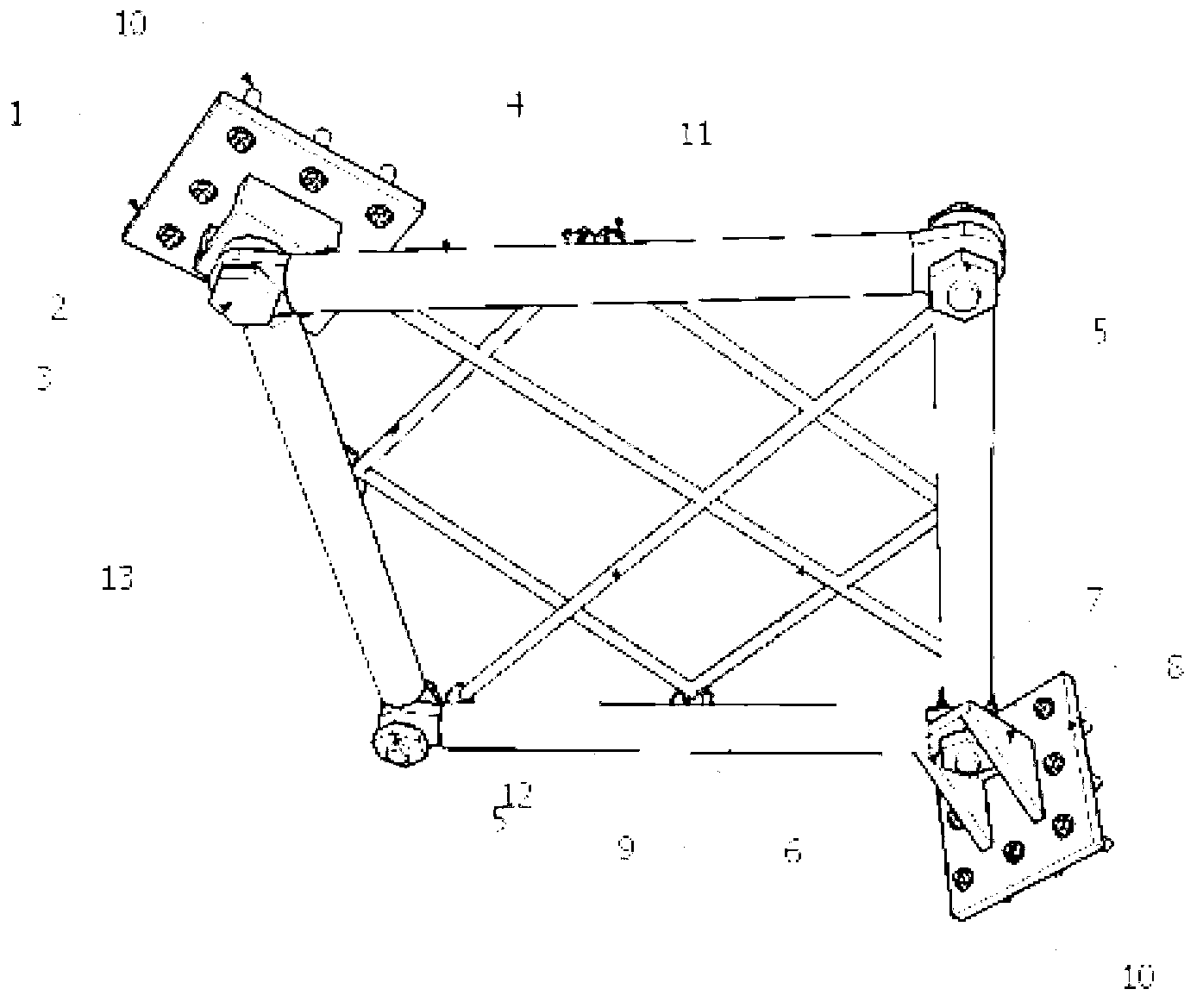

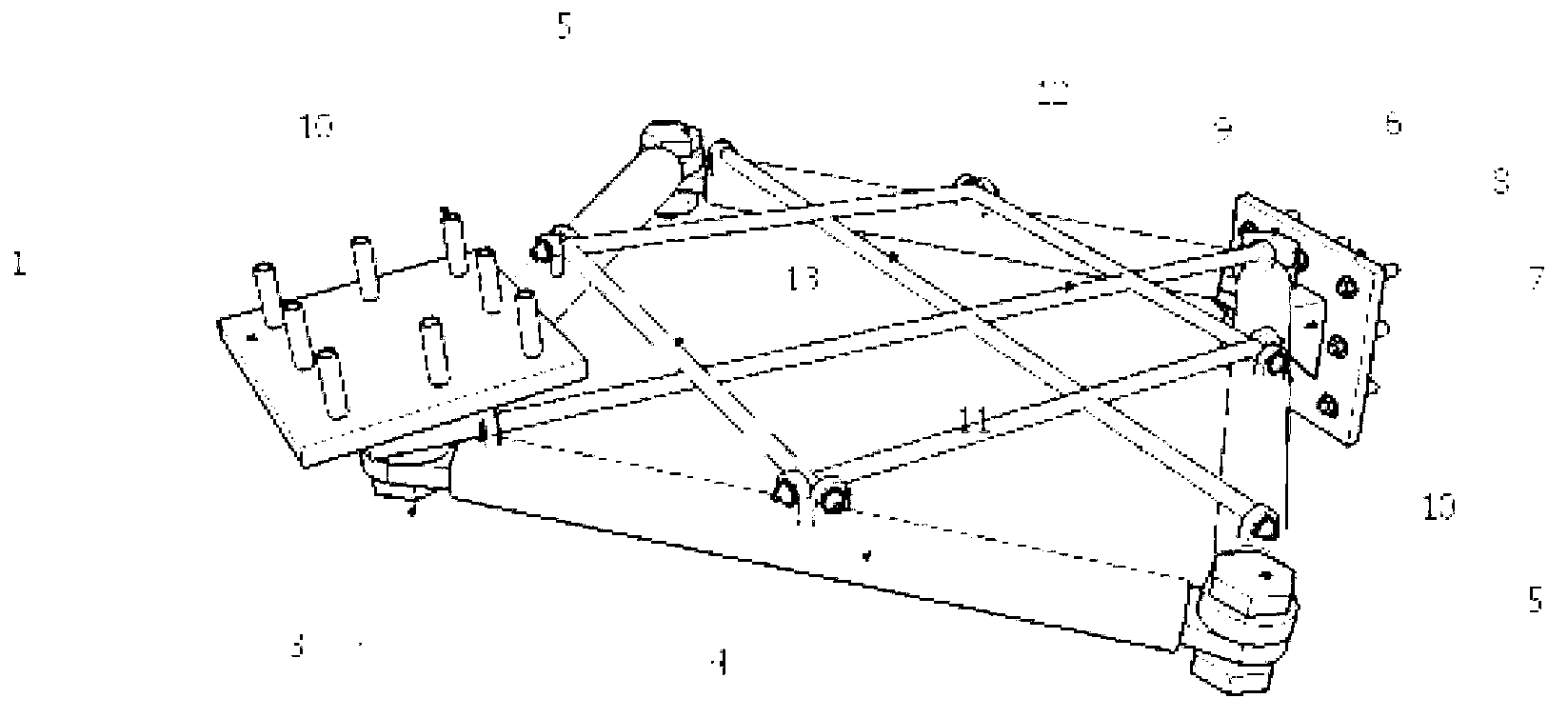

Vertical beam falling-off prevention system

InactiveCN103306193AImprove work performanceAvoid destructionBridge structural detailsShape-memory alloyAbutment

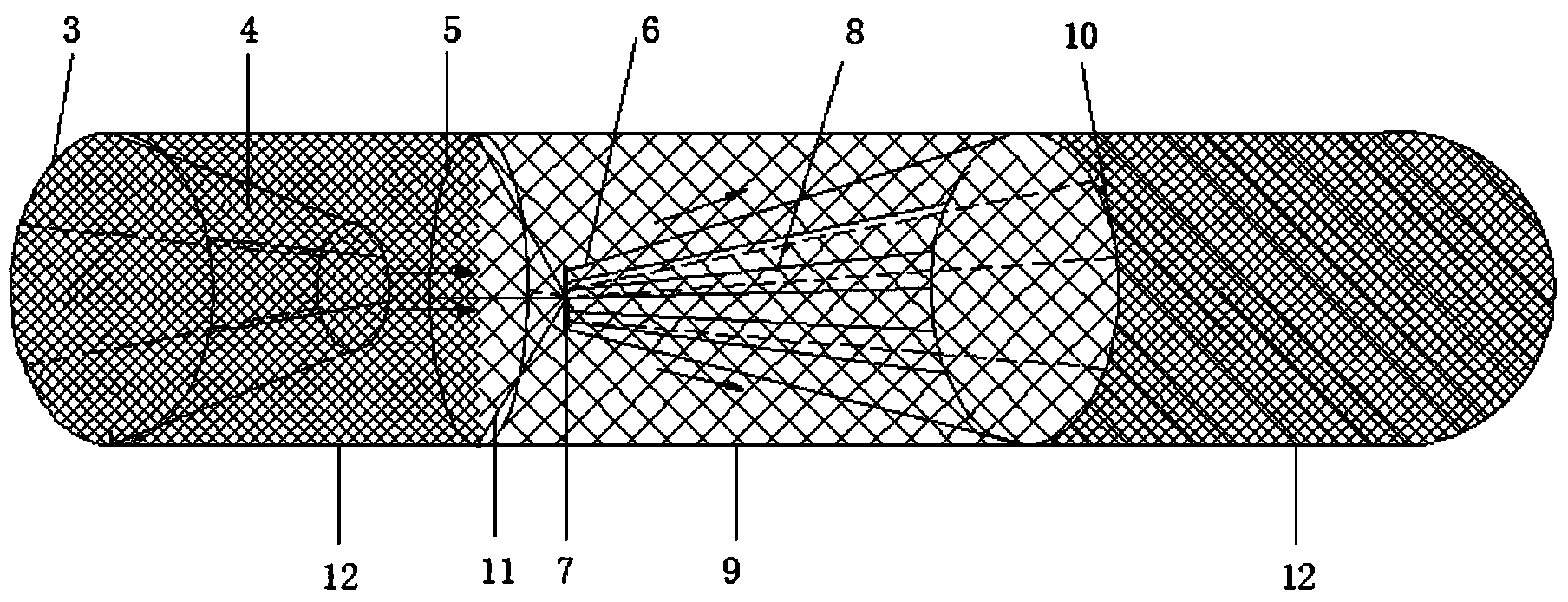

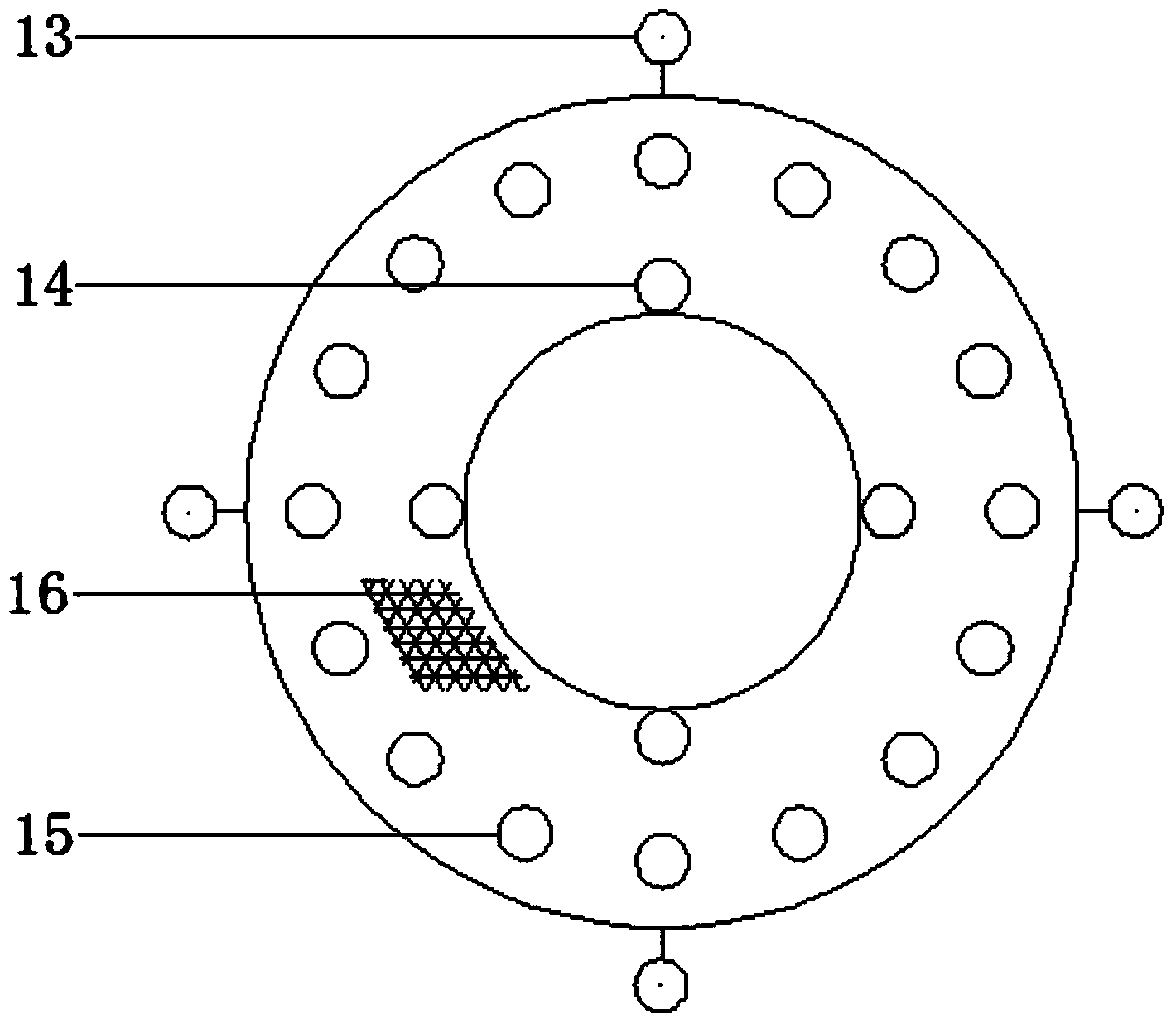

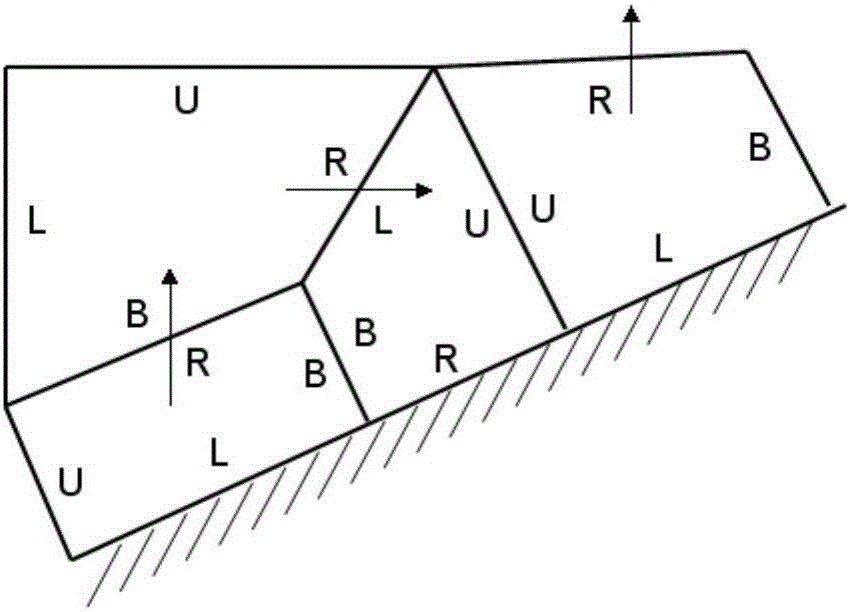

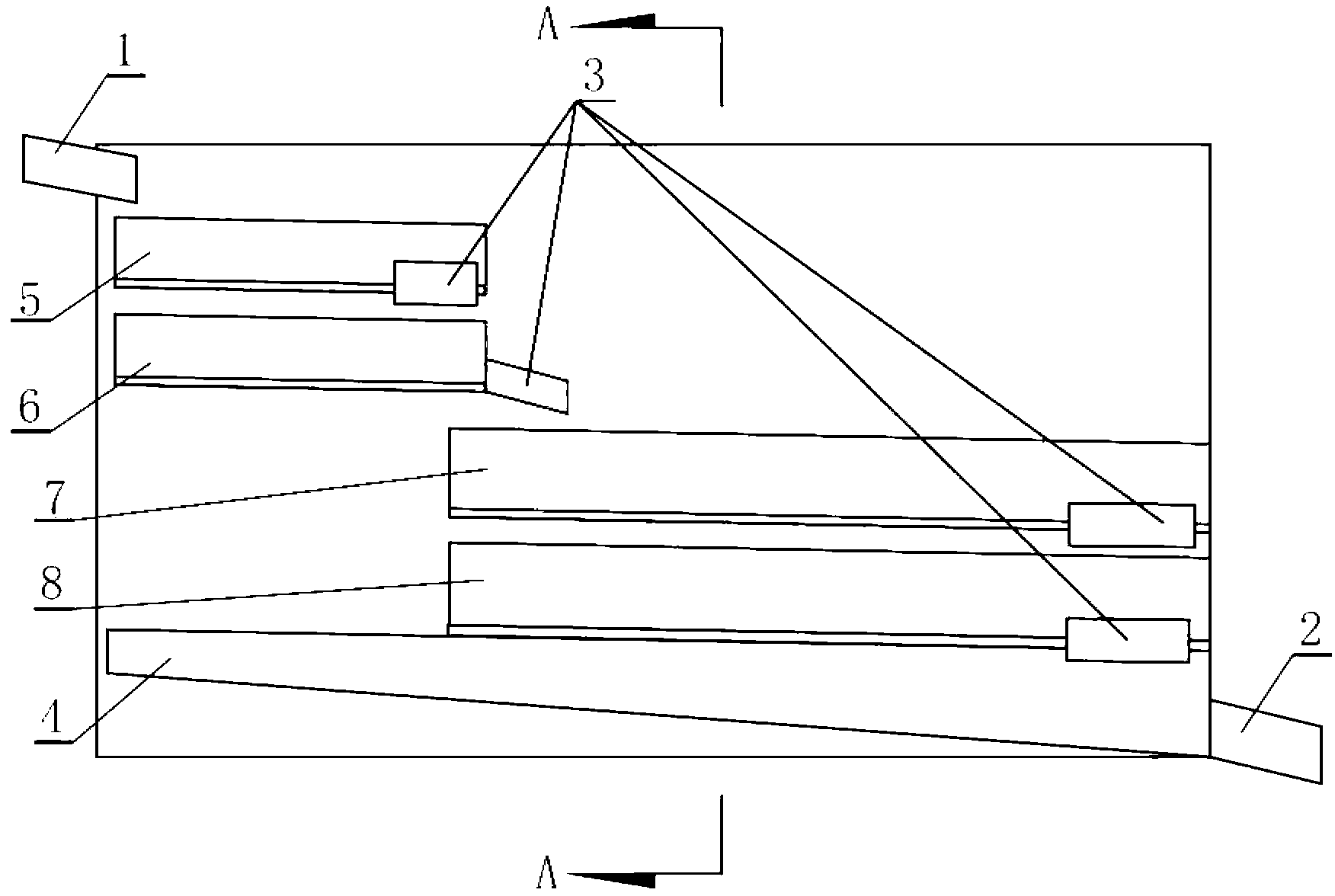

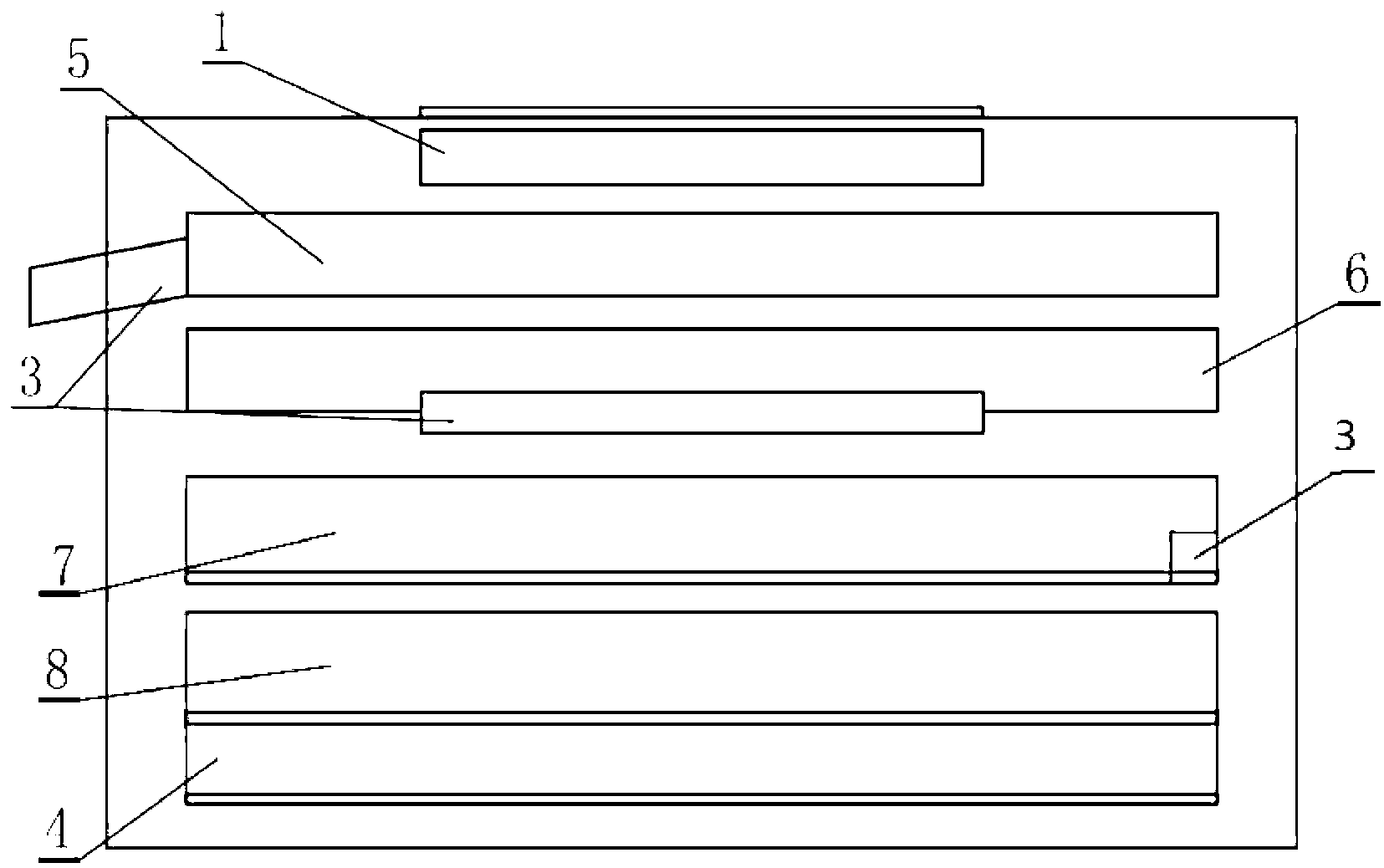

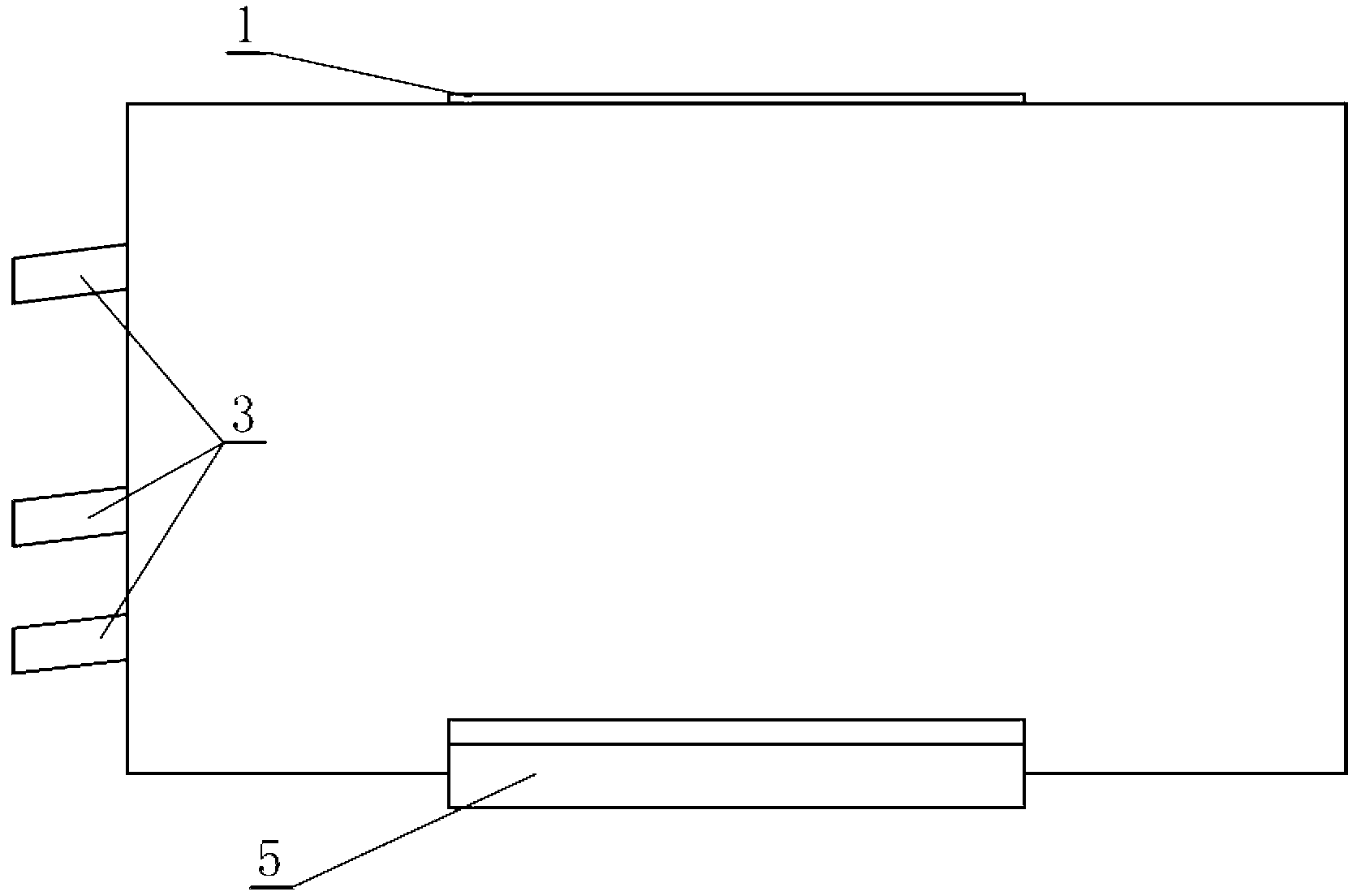

The invention discloses a vertical beam falling-off prevention system. The system comprises three parts: the first part are square mesh energy consumption falling-off prevention beams placed and connected between a beam bottom and a capping beam, the second part are sliding cylinder connecting rod devices connected with two side surfaces of a bridge end above a pier and abutment, and a third part are anti-collision pieces placed at connection parts of bridge web boards. The invention relates to a vertical limit energy consumption beam falling-off prevention protective device for a bridge under earthquake. The protective device is simple in manufacturing, convenient to assemble and light in self weight. During normal operation, the device can be freely stretched out and drawn back along with the structure, under the action of the earthquake, the square mesh energy consumption falling-off prevention beams and sliding connecting rods drive shape memory alloy wires to be stretched for bearing force and wasting energy so as to effectively absorb earthquake destroy energy, and can limit the bridge to generate large displacement, so that under the action of strong shock, the damage due to the falling off of beams is effectively prevented, and the anti-collision pieces at the beam end can prevent the beam from collision. The system provided by the invention can effectively solve the problem that vertical displacement safety, continuous energy consumption capacity and falling off beam capacities of railway bridges under earthquake can not be ensured.

Owner:CHINA RAILWAYS CORPORATION +2

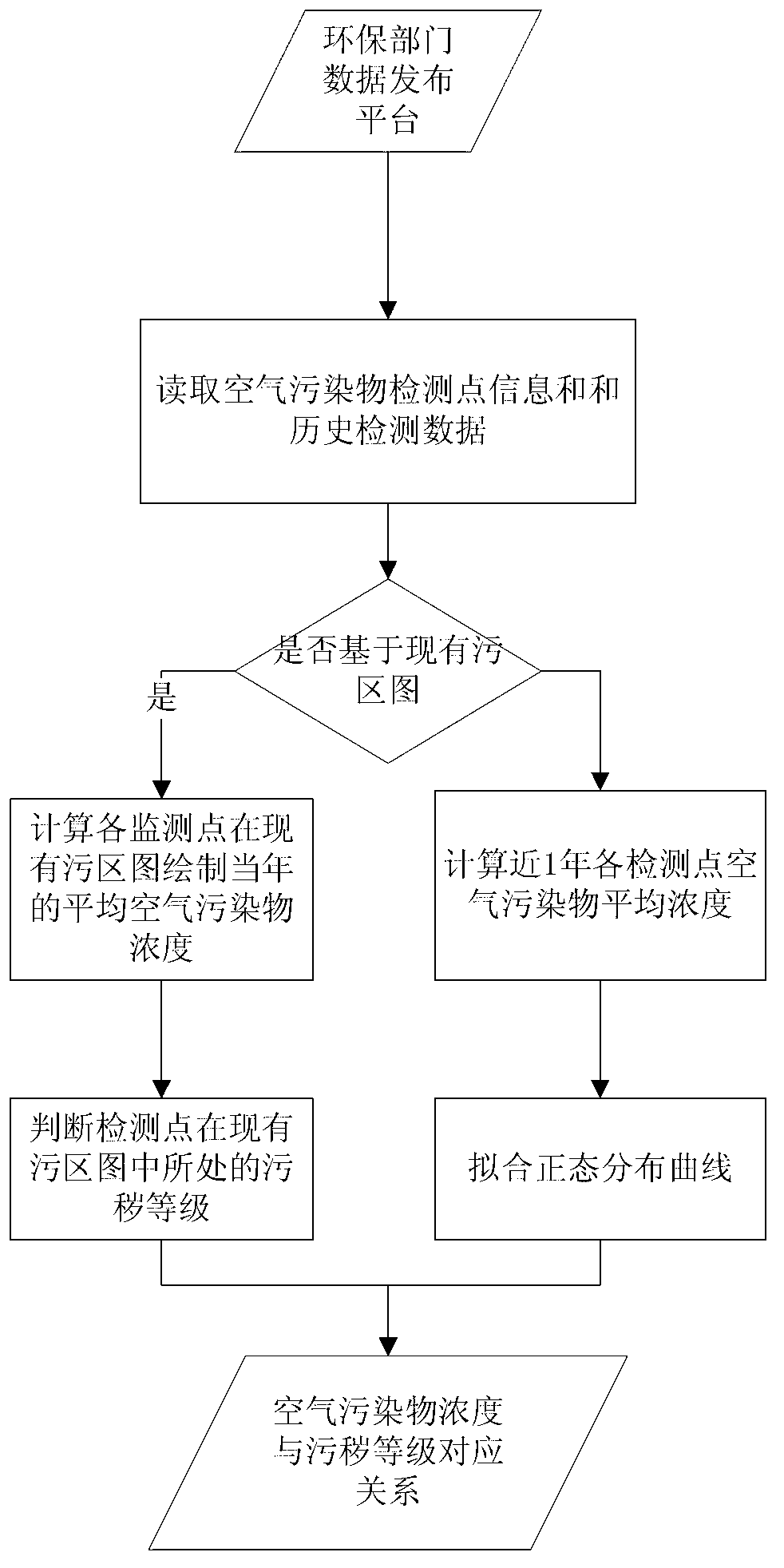

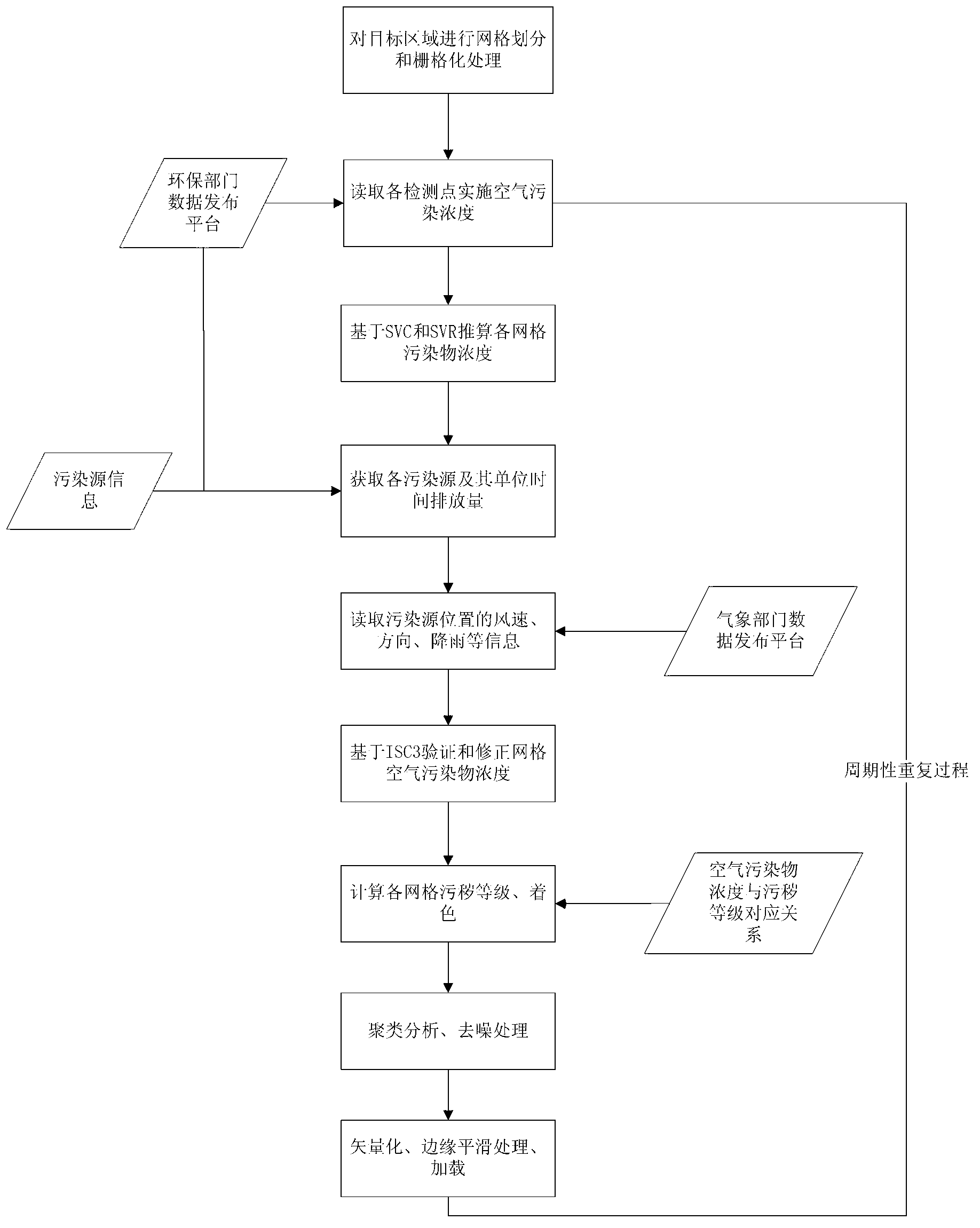

Method for drawing real-time dynamic three-dimensional power grid contamination area distribution diagram

ActiveCN103325068AReduce incidenceIntuitive reflectionData processing applicationsPower gridSquare mesh

A method for drawing a real-time dynamic three-dimensional power grid contamination area distribution diagram includes the steps of S1, establishing a corresponding relation between air pollutant concentration and the gradation for surface pollution, and S2, drawing the contamination area distribution diagram. The S2 further includes the steps of S2-1, conducting square mesh generation and rasterization processing on an object region, S2-2, reading real-time air pollutant concentration, S2-3, calculating the air pollutant concentration, S2-4, reading the position, the discharging type and the discharging amount of pollution sources, S2-5, reading the data of wind directions, wind speeds and rainfalls, S2-6, checking and amending the air pollutant concentration by the aid of the data obtained in the steps (4) and (5), S2-7, dividing the gradation for surface pollution and coloring according to the corresponding relation in the S1, S2-8, making a clustering analysis and denoising, S2-9, conducting vectorization and smoothing, and loading DOM, DEMs, power grid device information and the pollution sources to a three-dimensional GIS platform, S2-10, repeating the steps from (2) to (9) for 5-60 minutes to form the dynamic contamination area distribution diagram.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

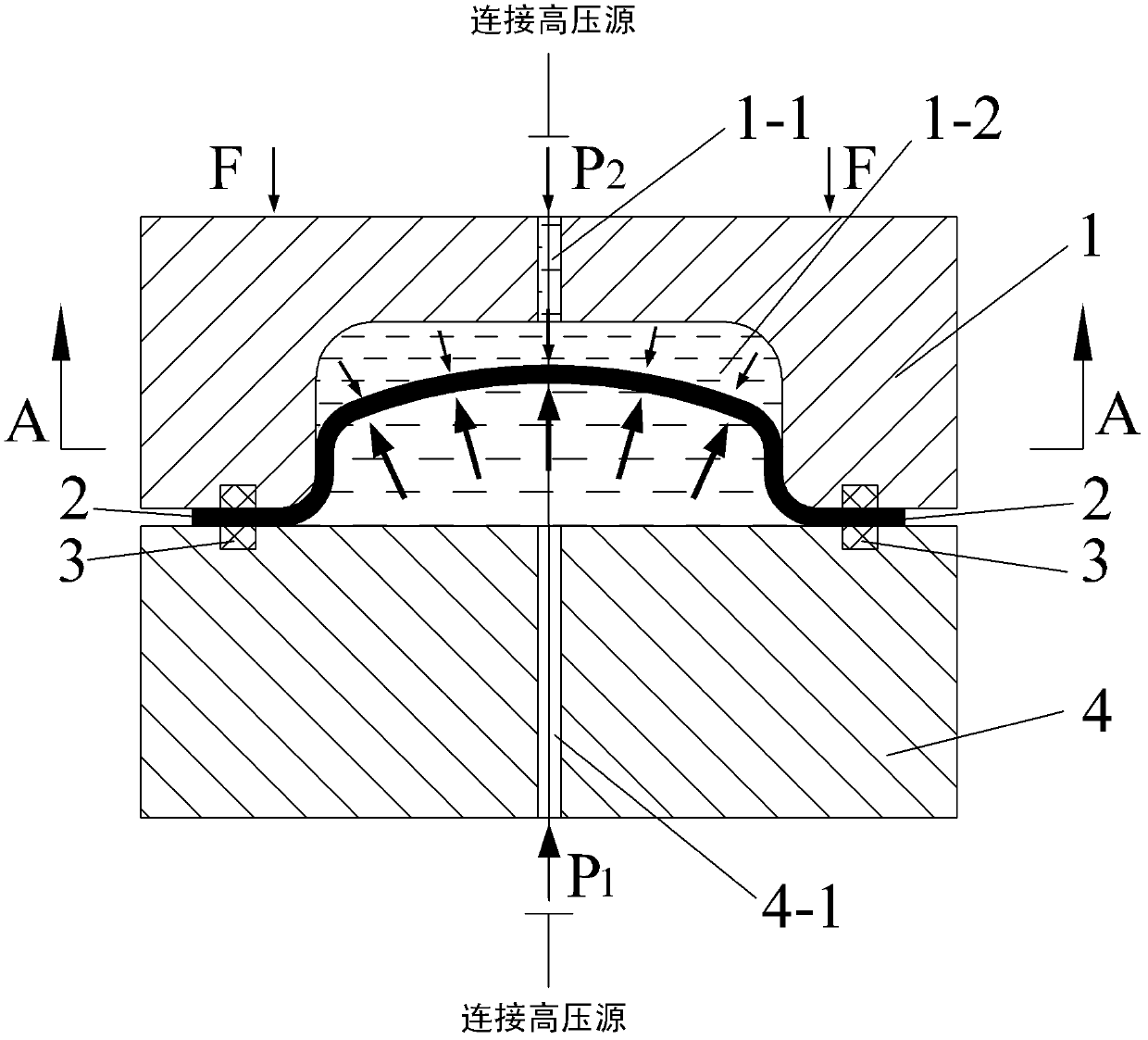

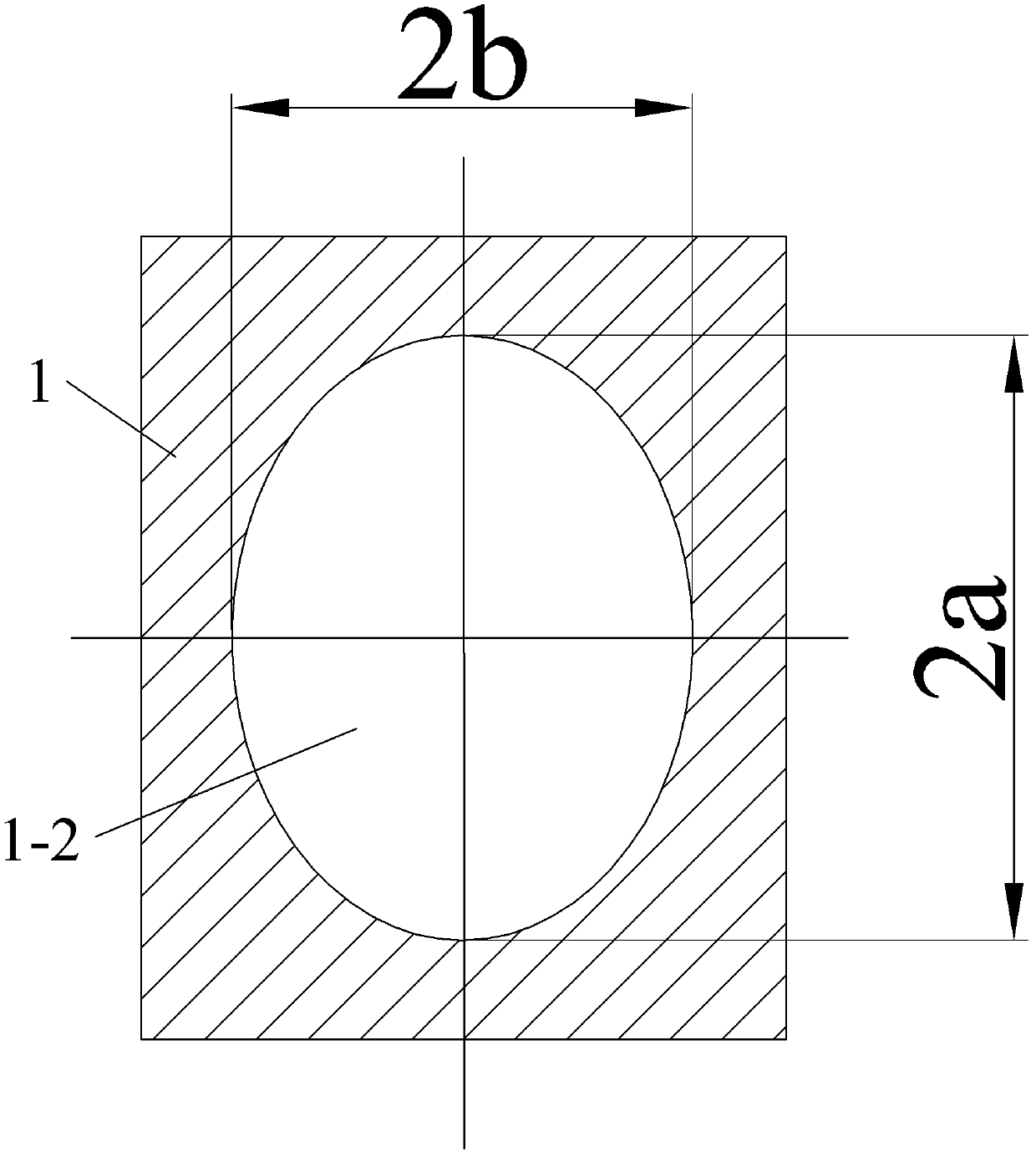

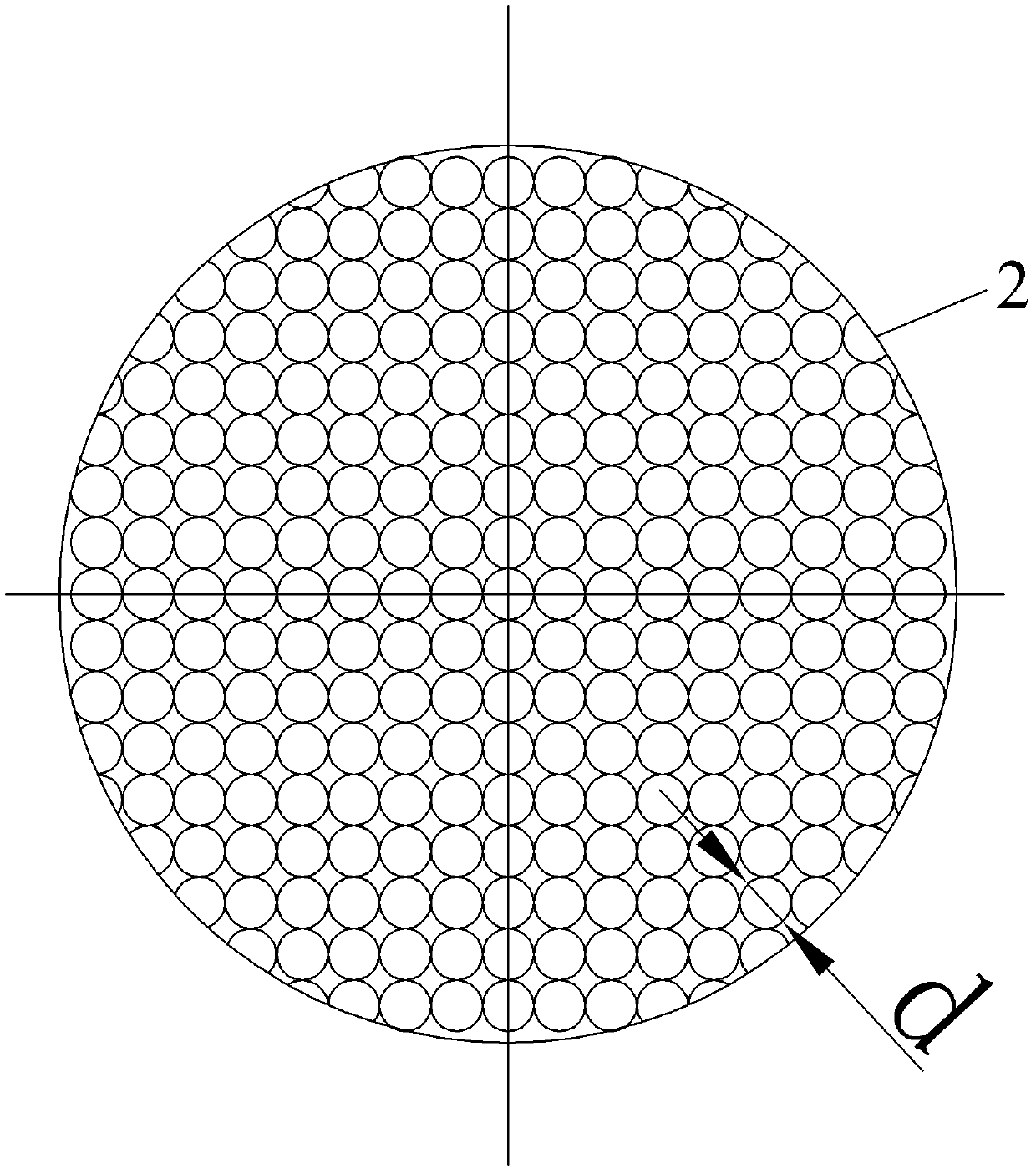

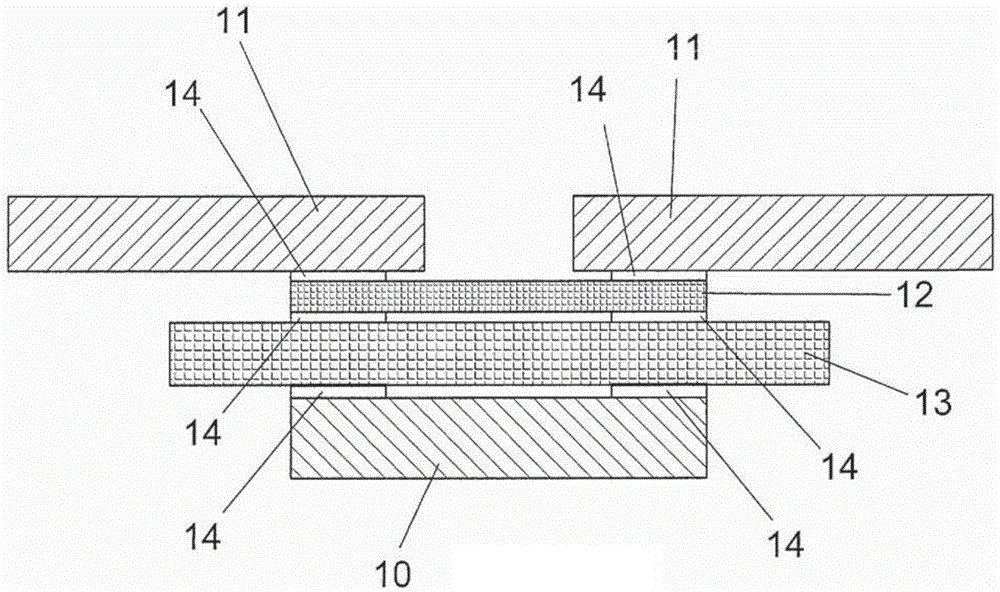

Device and method for testing forming limit of sheet material in three-dimensional stress state

InactiveCN102607969ASimple methodEasy to implementInvestigating material ductilityTest sampleLimit strain

The invention provides a device and a method for testing a forming limit of a sheet material in a three-dimensional stress state, relating to the device and the method which are used for testing the forming limit of the sheet material. Aiming to the problems that the forming limit of the sheet material in the three-dimensional stress state is difficult to test and an influence of normal pressure to the forming limit is difficult to estimate, the device comprises an upper die and a lower die. In a test, a fluid medium is injected into the lower die, a test sample of the sheet material is placed, mold clamping force is applied, the fluid medium is injected into the upper die, and pressurized deformation is carried out by controlling pressure in the upper die and the lower die in sequence. Braking strains of the test sample of the metal sheet material can be calculated according to measured data before and after circular or square mesh deformation, namely epsilon 1=Ln[d1-d / d] and epsilon 2=Ln[d-d2 / d]; a plurality of groups of different limit strain data points can be obtained by changing a ratio of a long shaft to a short shaft of an oval cross section of a cavity; and the obtained data points can be connected or fitted by respectively using the epsilon 1 and the epsilon 2 as a transverse coordinate and a vertical coordinate, so as to obtain the sheet material forming limit curve at the three-dimensional stress state at a certain normal pressure condition to estimate the influence of the normal strain to the forming limit in the three-dimensional stress state.

Owner:HARBIN INST OF TECH

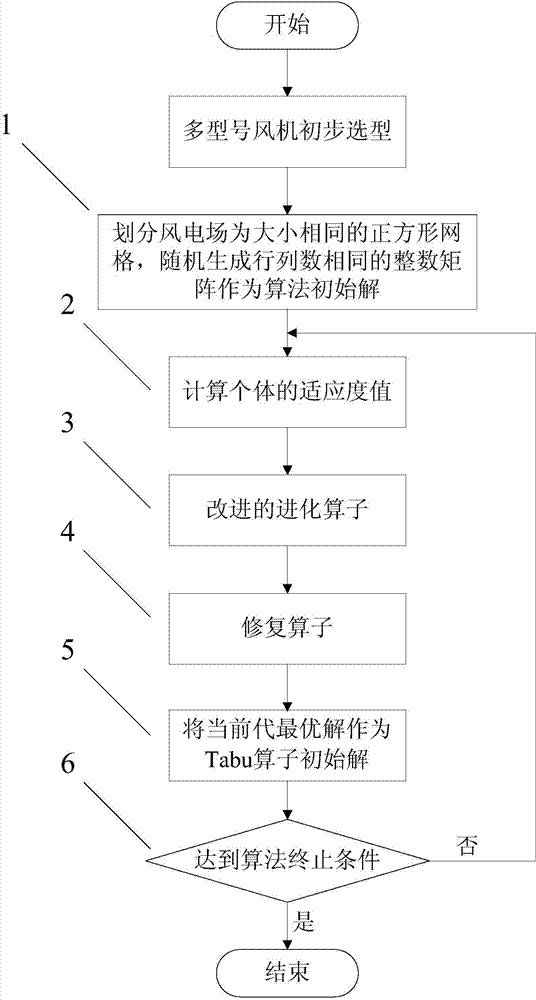

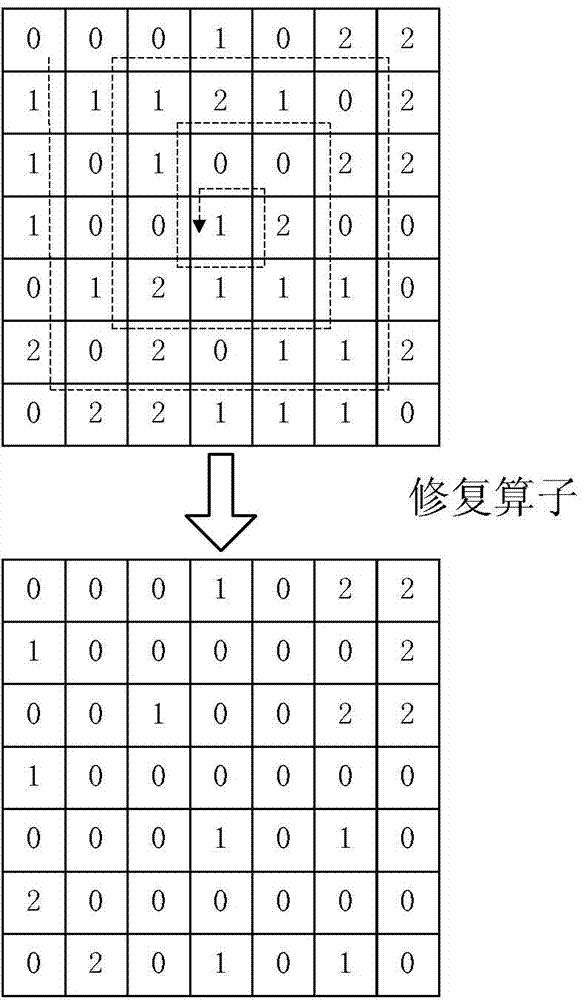

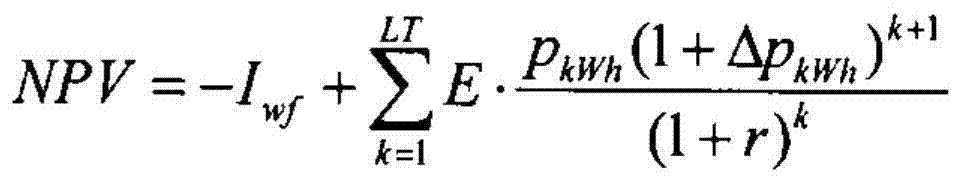

Wind farm multi-model draught fan optimized arrangement method based on genetic algorithm

InactiveCN103793566ACoding is intuitiveIntuitive and accurate position relationshipSpecial data processing applicationsAlgorithmSquare mesh

Owner:TONGJI UNIV

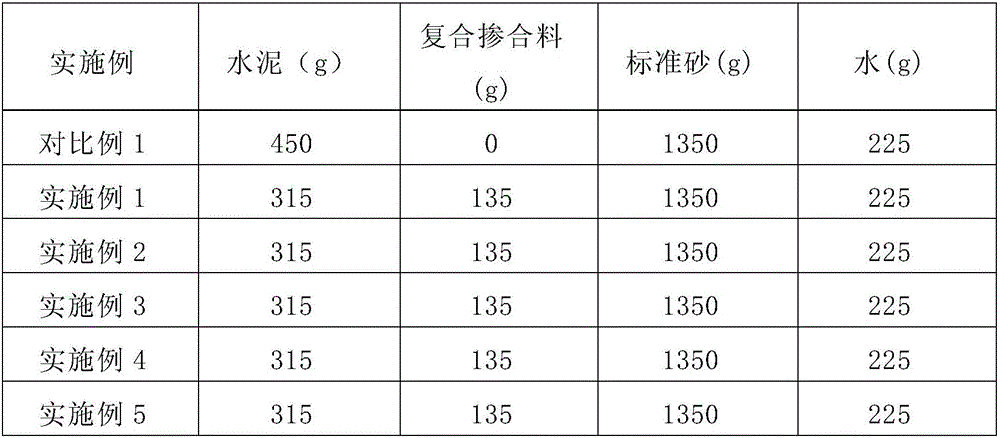

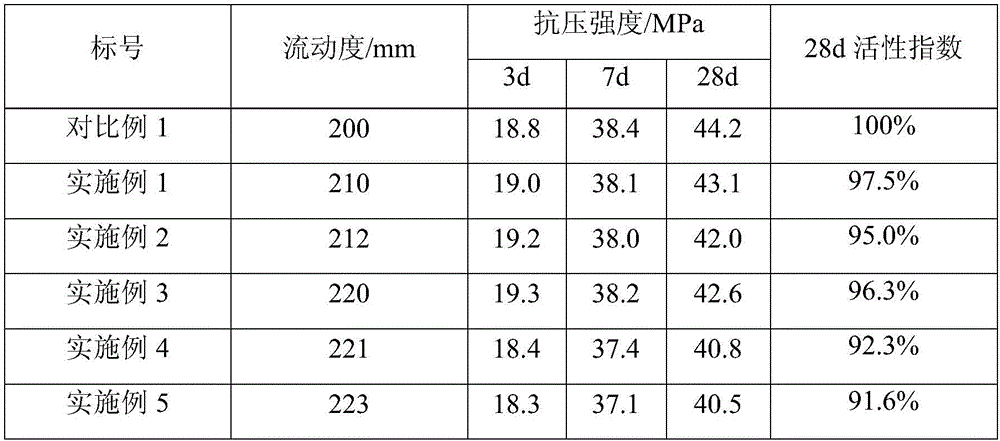

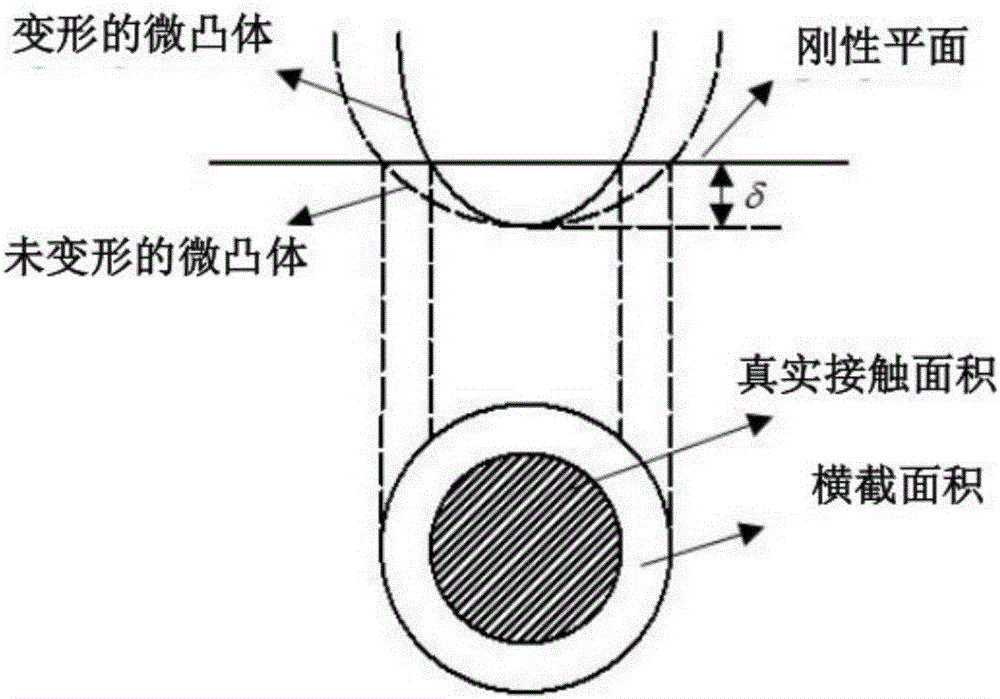

Granite powder composite mineral admixture and preparation method therefor

The invention relates to a granite powder composite mineral admixture and a preparation method therefor. The admixture contains raw materials, i.e., modified granite powder, modified pulverized coal ash, slag and a reinforced activator, wherein the mass content of the former three kinds of raw materials is as follows: the mass content of the modified granite powder is 40 to 70 parts, the mass content of the modified pulverized coal ash is 10 to 25 parts, the mass content of the slag is 15 to 35 parts, the sum of mass contents of the three kinds of raw materials is 100 parts, and the mass of the reinforced activator accounts for 0.1% to 0.3% the total mass of the former three kinds of raw materials. The preparation method comprises the steps: proportionally weighing the raw materials, i.e., the modified granite powder, the modified pulverized coal ash, the slag and the reinforced activator, mixing the raw materials, then, putting the mixture into a ball mill, carrying out milling until the screening volume of a square-mesh screen with the pore size of 45 microns is lower than 10%, baking the obtained screen underflow, and carrying out cooling, thereby obtaining the granite powder composite mineral admixture. According to the scheme of the invention, the activity of the granite powder is enhanced, the utilization ratio of the granite powder is increased, and thus the economic and social benefits are very good.

Owner:WUHAN UNIV OF TECH

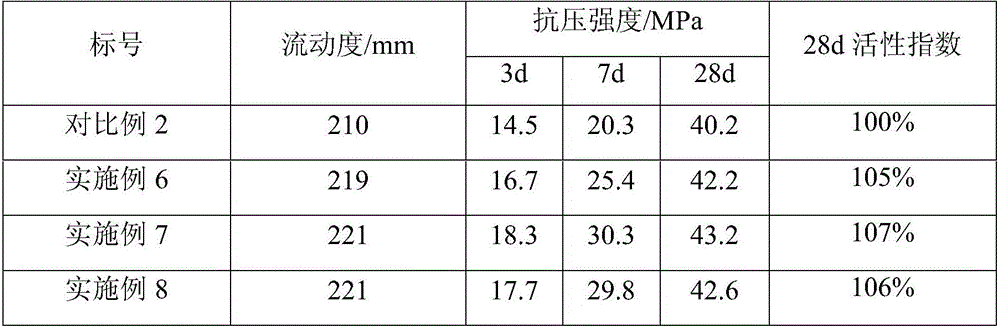

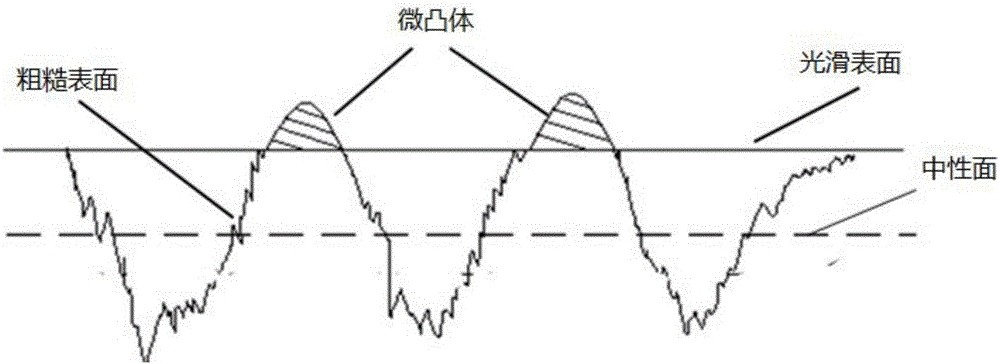

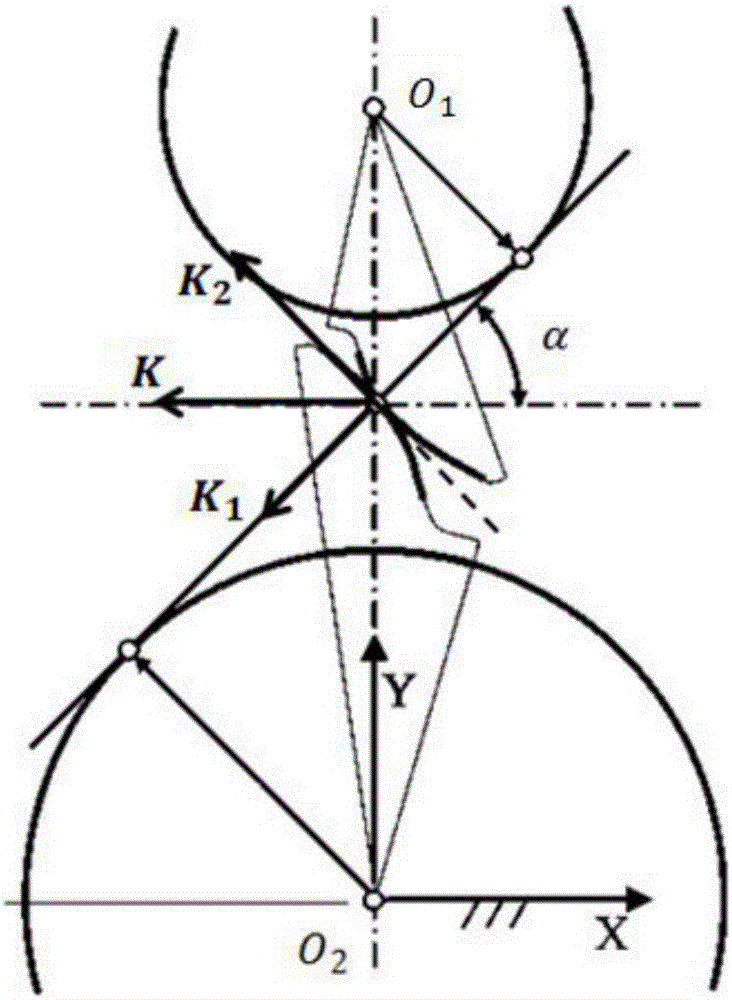

Rough surface-based three-dimensional contact stiffness calculation method for spur gear

ActiveCN106844818APrecise contact stiffnessSolve the disadvantages of smooth contactGeometric CADDesign optimisation/simulationContact pressureEngineering

The invention discloses a rough surface-based three-dimensional contact stiffness calculation method for a spur gear. The method comprises the steps of firstly by adopting hexahedral mesh generation, requiring all square meshes on a tooth surface to be equal in area; calculating contact pressure distribution of the smooth tooth surface based on a finite element method, and extracting node pressure intensity of a contact region; calculating normal contact stiffness and tangential contact stiffness of a single square mesh based on a fractal theory; and calculating the contact stiffness of the tooth surface. According to the method, the precision of a gear contact stiffness calculation model is further improved; the defect of smooth contact according to a Hertz theory in an original calculation process is overcome; an influence law of a roughness parameter on a gear stiffness characteristic in a rough tooth surface contact process and a calculation method are disclosed; and meanwhile, a finite element-based three-dimensional contact stiffness calculation model is more accurate than an original two-dimensional calculation model or calculation formula, and the influence of errors in actual assembling and manufacturing processes of the gear is considered, so that the gear contact stiffness is more accurate and a foundation is laid for gear dynamics analysis.

Owner:BEIJING UNIV OF TECH

Manufacturing method for flowered nickel screen die roll

InactiveCN101559663AEasy to prepareReduce processScreen printersForme preparationCopper platingLaser engraving

The invention relates to a manufacturing method for a flowered nickel screen die roll. The technical process comprises the following steps: machining, copper plating, grinding, glue coating, pattern fabrication, laser engraving, corrosion, rubber filling and nickel plating. The preparation method is characterized in that: the pattern fabrication process comprises the following steps: applying a 70 mesh screen to a needed pattern grey scale file to obtain square mesh points with various sizes and directly form a pattern; eliminating screen pattern information loss caused by screen wires of a common nickel screen; synthetically sorting a grey chart file, the laser engraving expansion, the corrosion expansion and the die roll nickel plated screen expansion to form a laser engraved file which is represented by grey scale values from 0 to 100; and adopting a file with the grey scale value above 98 to fabricate a minimal screen wall, and adopting a file with the grey scale value below 3 to fabricate a maximal screen wall. The method adopts the grey chart and the screen with the same meshes and different mesh sizes to form the pattern, and directly fabricates the pattern on the die roll of a nickel plated circular screen. The electroplated nickel circular screen is directly used for printing without pattern information loss, and has rich gradual change gradations.

Owner:上海希尔彩印制版有限公司

Waste stone dust-containing high performance superfine sand concrete gel material and use method thereof

ActiveCN101353245AStable and improved performanceImprove distributionSolid waste managementSlagStone dust

A high-performance superfine sand concrete cementitious material with waste stone powder and an application method thereof pertain to the field of construction materials. The method comprises the following steps: firstly, the waste stone powder is dried and sieved by a 200-mesh sieve, the sieved part and original particles of the water quenched blast furnace slag are mixed and ground to not more than 5% screen residue of 0.045mm square mesh sieve, wherein, the weight percentage of the waste stone powder is 30-40% and the weight percentage of the water quenched blast furnace slag is 70-60%; the water quenched blast furnace slag, mixed fine powder of the waste stone powder, original particles of cement clinker, a water reducing agent or a pumping agent are mixed and ground to not more than 5% screen residue of 0.045mm square mesh sieve according to a certain proportion, the powder obtained is the high-performance superfine sand concrete cementitious material. The cementitious material obtained, superfine sand and coarse aggregate are mixed to obtain the high-performance superfine sand concrete with good working performance, low dry shrinkage, no crack, high strength and good lasting quality. The material has the three beneficial effects of consuming waste stone powder, solving the problem of sand rareness in normal construction in part areas and promoting popularization and application of the high performance concrete.

Owner:UNIV OF SCI & TECH BEIJING

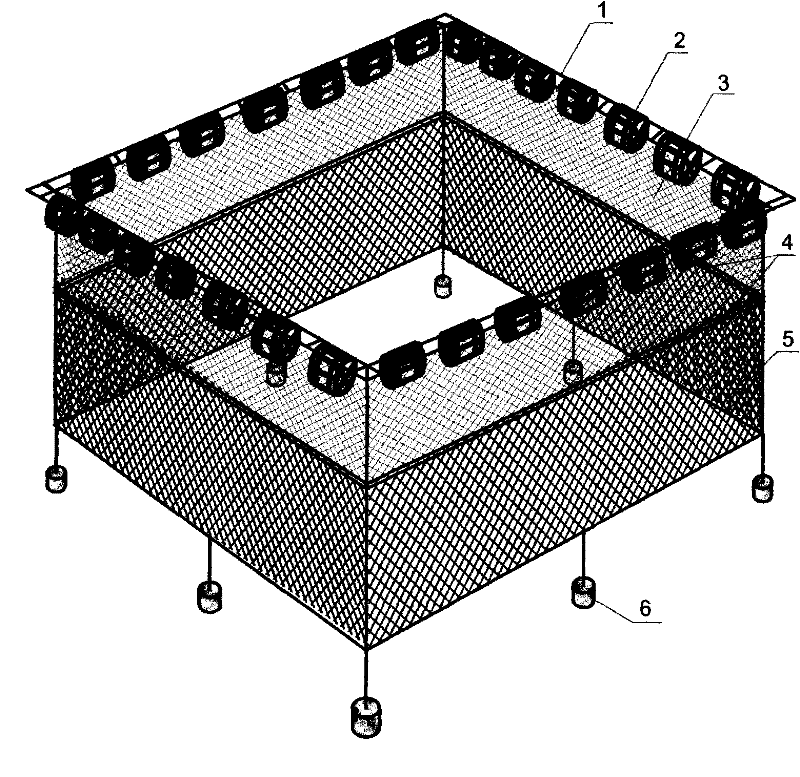

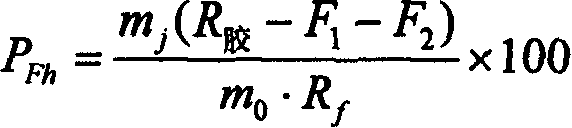

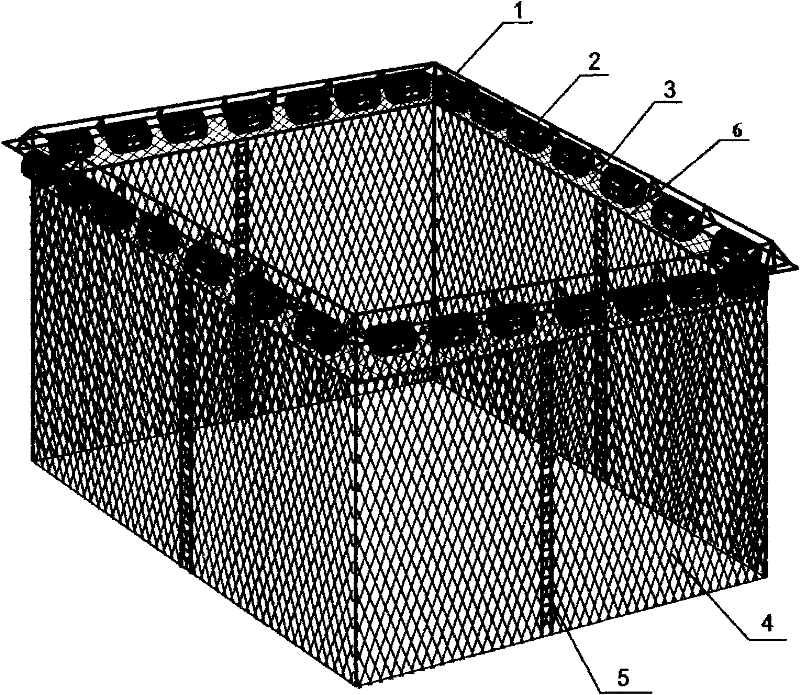

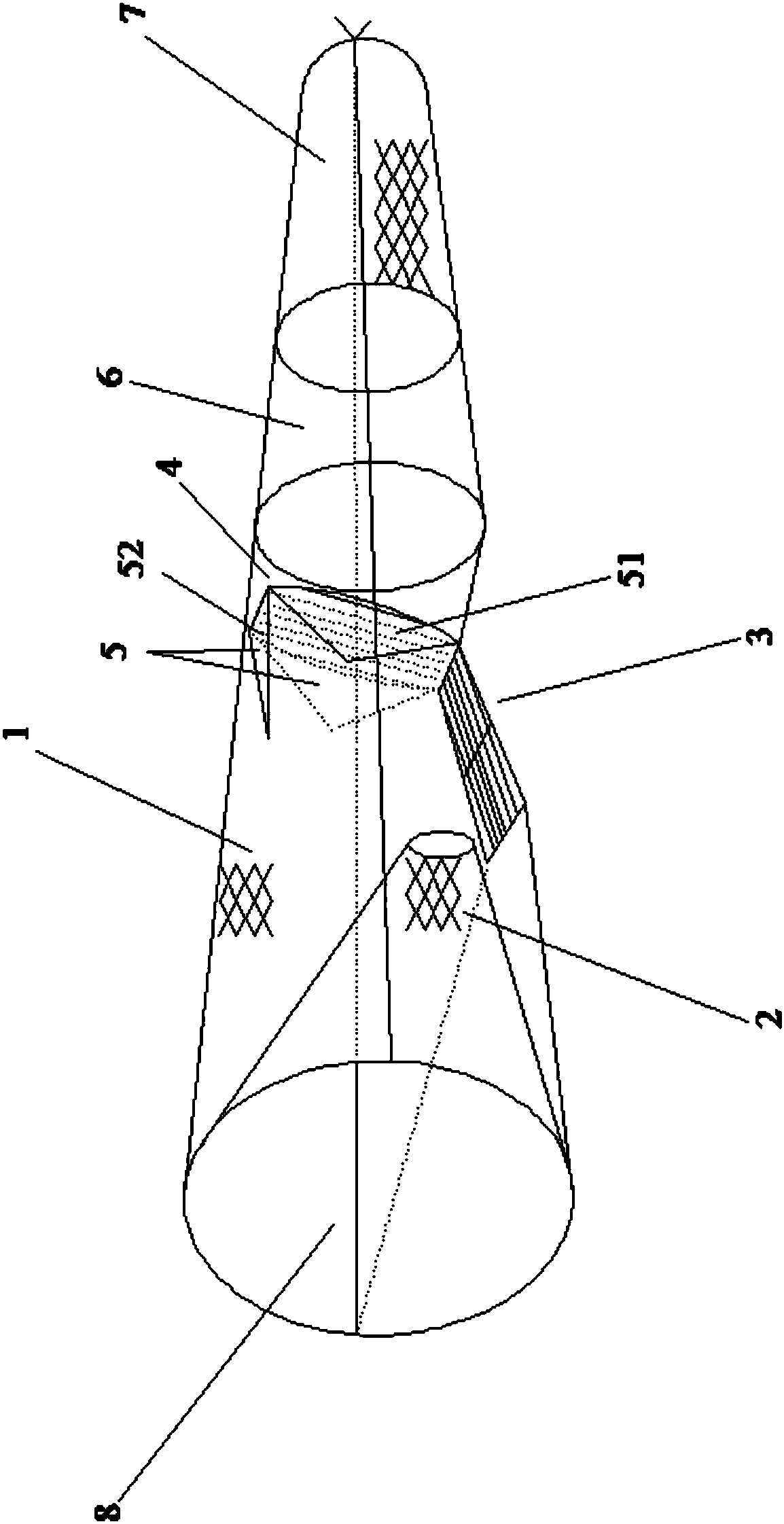

Method for processing net-combined-type neritic square net cage

InactiveCN102239815ASolve the problem of energy saving and consumption reductionReduce energy saving and consumption reductionClimate change adaptationPisciculture and aquariaComputer scienceBuoyancy

The invention discloses a method for processing net-combined-type neritic sea square net cages, relates to an aquaculture net cage, and provides a method for processing neritic square net cages. In the invention, a high-strength rope, a high-strength nylon warp knitting net and a copper alloy inclined square net are adopted. The method provided by the invention is characterized in that a double floating tube square frame structure is adopted in a buoyancy system of the net cage; 28 cylindrical foam floaters with the same specification are arranged under the two rows of floating tube frames; the net system of the net cage combines a first high-strength nylon warp knitting net, a second copper alloy inclined square net and a high-strength nylon warp knitting net used for the bottom of the net cage; after being equipped with ropes, the net at the bottom of the net cage is assembled on a high-density polyethylene frame; a vertical force net is longitudinally arranged along the net from the upper horizontal rope of the first high-strength nylon ware knitting net to the bottom of the net cage; 8 sinking blocks are hung on the high-density polyethylene frame used for the bottom of the net bottom evenly, and the weight of each sinking block is 5kg. The method provided by the invention is suitable to be applied to neritic square net cages.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

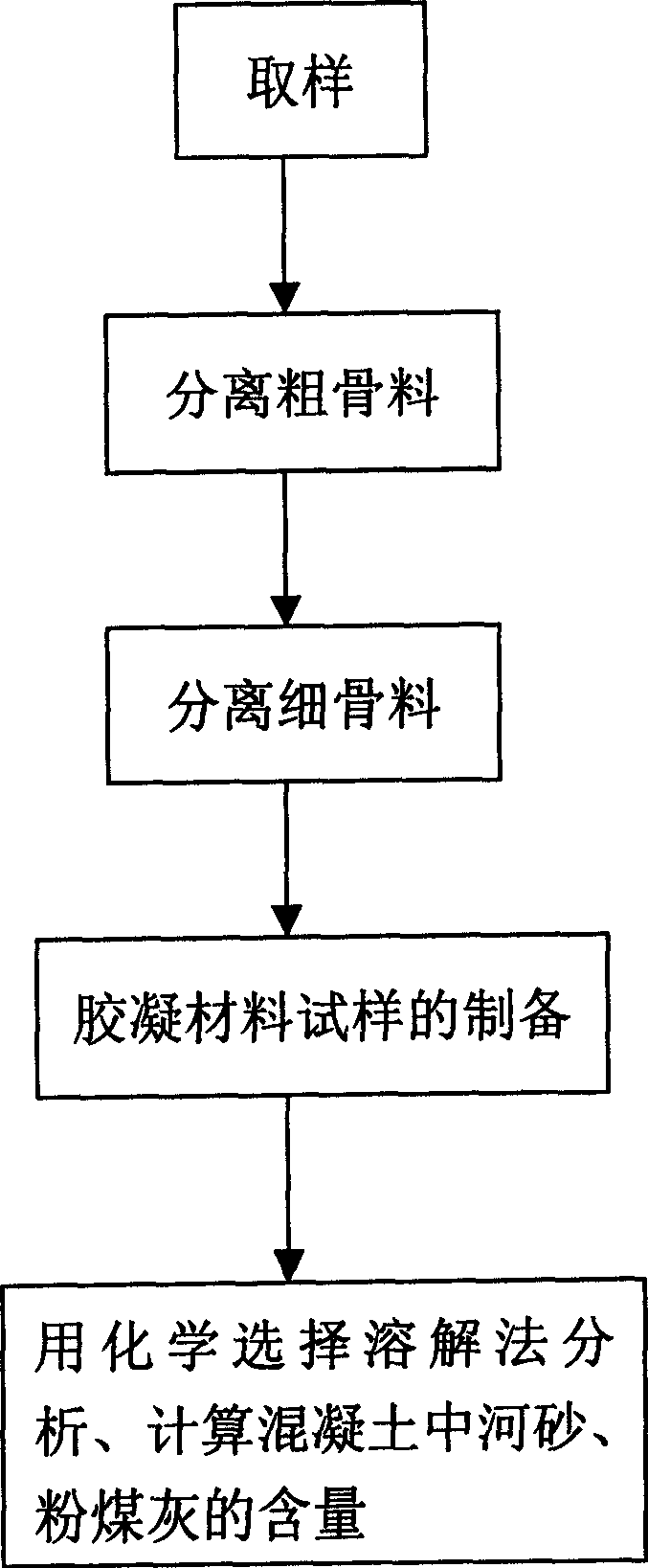

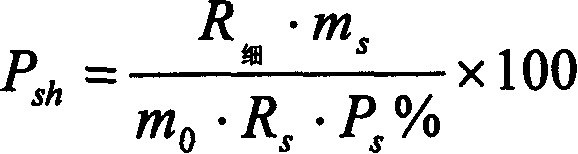

Method for detecting content of river sand and fly ash in concrete mixture

InactiveCN1789965AThe detection method is simpleFast detection methodWeighing by removing componentMaterial analysis by observing effect on chemical indicatorScreening methodSquare mesh

The invention discloses a content testing method of river sand and coal ash in the concrete mixture, which comprises the following steps: sampling; segregating rough aggregate; segregating fine aggregate; preparing the gelatinization material sample; analyzing through chemical selection solution method; calculating the content of river sand and coal ash in the concrete, wherein the rough aggregate segregation adapts wash screening method of 4.75mm standard square mesh sieve; the fine aggregate segregation adapts wash screening method of 0.15mm standard square mesh sieve; the preparation of gelatinization material sample adapts the ceramic funnel to extract and filter the gelatinization material and water mixing paste and dry the filtered cement paste in the baking oven at 105-110 deg.c to constant weight.

Owner:重庆市节能技术服务中心

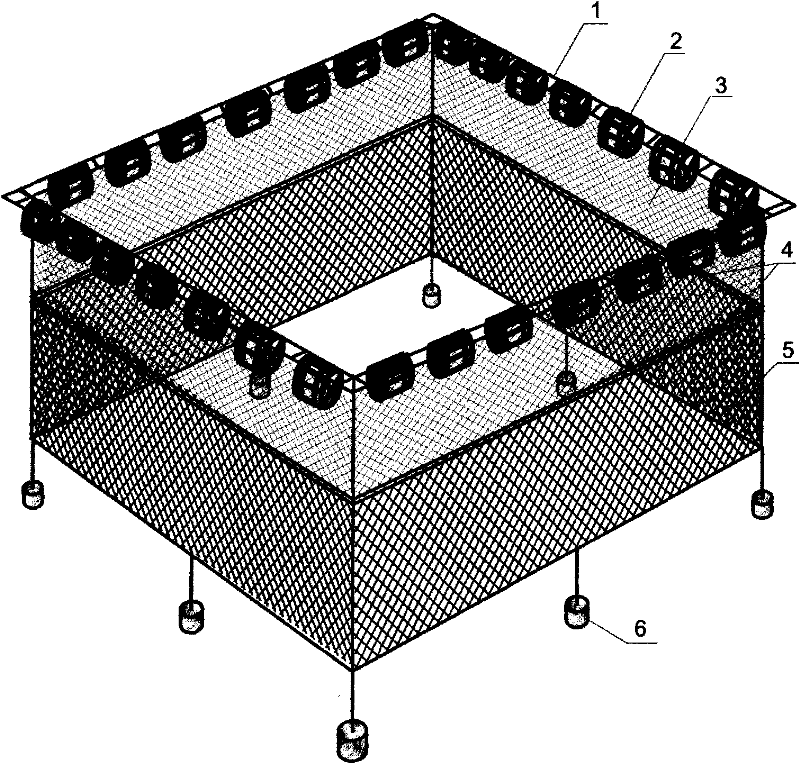

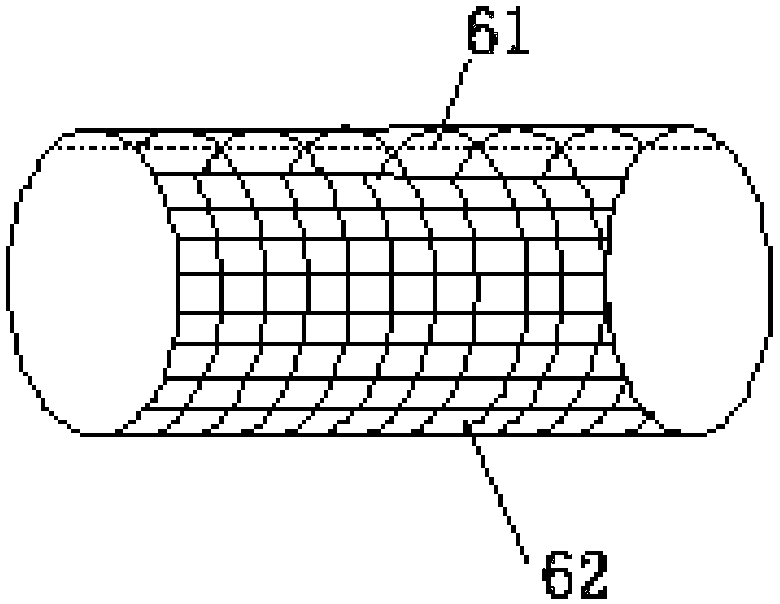

Combined box body system used for floating net cage and mated frame system thereof

ActiveCN102239814AImprove the box volume retention rateImprove antifouling functionClimate change adaptationPisciculture and aquariaPolyamideEngineering

The invention provides a combined box body system used for a floating net cage and a mated frame system thereof, relating to a seawater cultivation floating net cage. A copper alloy inclined square mesh, a copper alloy weaving mesh, high-strength polyamide warp knitting fishnet, ropes, a galvanized iron pipe and foam buoys. The combined box body system is characterized in that a floating net cageframe system comprises two rows of square galvanized iron pipe frames; the foam buoys are distributed below the two rows of galvanized iron pipe frames; the fishnet system of a net cage body combinesa first high-strength polyamide warp knitting fishnet, a second copper alloy inclined square mesh and the copper alloy weaving mesh used for the bottom of the net cage'; the edge installing wire ropeof the fishnet at the bottom of the net cage is assembled on a square high-strength polyamide pipe frame; the high-strength polyamide pipe frame and a horizontal wire rope at the lower edge of the second copper alloy inclined square mesh are connected by an ultrahigh-strength rope; and a vertical force net is installed in the vertical direction of the fishnet and extends to the edge wire rope of the copper alloy weaving mesh used for the bottom of the net cage.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

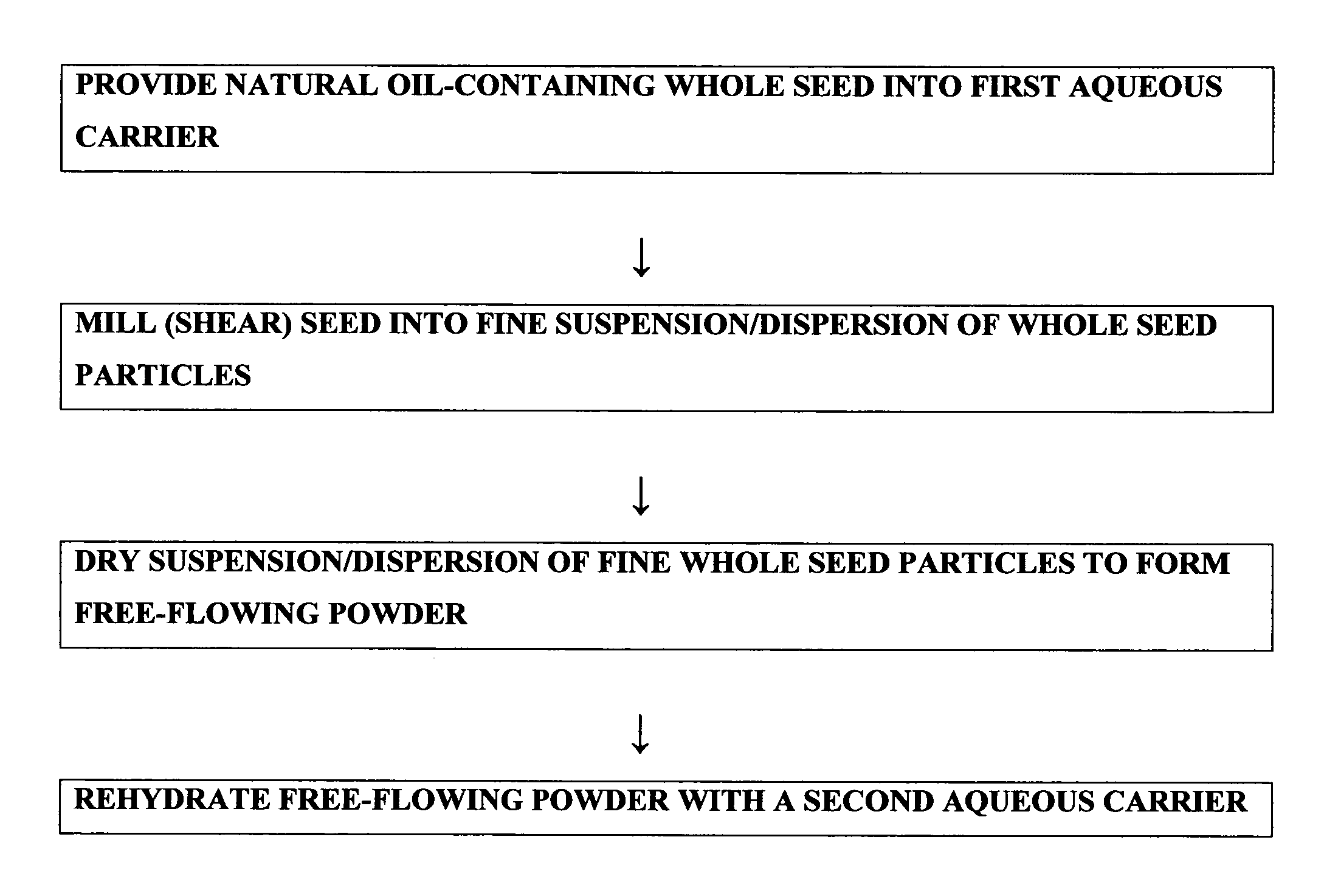

Whole seed processing and controlled viscosity products

A method provides a milled whole seed product from a whole seed having at least 0.01% by total weight of oil therein. The whole seed is added to an aqueous carrier which is physically milled at a shear rate of at least 3,000 r.p.m. The shearing is continued until at least 50% by weight of seed solids will pass through a square mesh screen having 1.2 mm screen hole dimensions. The solids in aqueous carrier is collected as a suspension or dispersion in the aqueous carrier. The collected seed solids in aqueous carrier are dried to form a free-flowing powder. The free-flowing powder is rehydrated with a second aqueous medium to form a non-mucilaginous suspension or dispersion.

Owner:MAS MARKETING HLDG

Device and method for actively stimulating juvenile fishes to escape

The invention relates to a device and a method for actively stimulating juvenile fishes to escape. The device can be applied to sac-type fishing gears such as a trawl and a trap net, and comprises a cylindrical cod-end consisting of a front rope loop, a funnel net, a rope loop, a square mesh section, a rear rope loop and meshes, wherein the cylindrical cod-end is connected onto a net body to form the whole trawl. The device is characterized by further comprising a luminous circular ring arranged in the middle of the cod-end, four fixing holes are formed in the inner periphery of the luminous circular ring and connected with the rope loop through four cords, and the horizontal distance between the rope loop and the luminous circular ring ranges from 20cm to 30cm. In order to further drive the juvenile fishes, a conical rope array comprising at least three hollow small bells and a plurality of ropes is arranged on the periphery of the luminous circular ring. Obviously, the juvenile fishes can be actively stimulated to escape the trawl, juvenile fish resources can be protected, and the device is simple in structure, easy to manufacture and low in material cost.

Owner:OCEAN UNIV OF CHINA

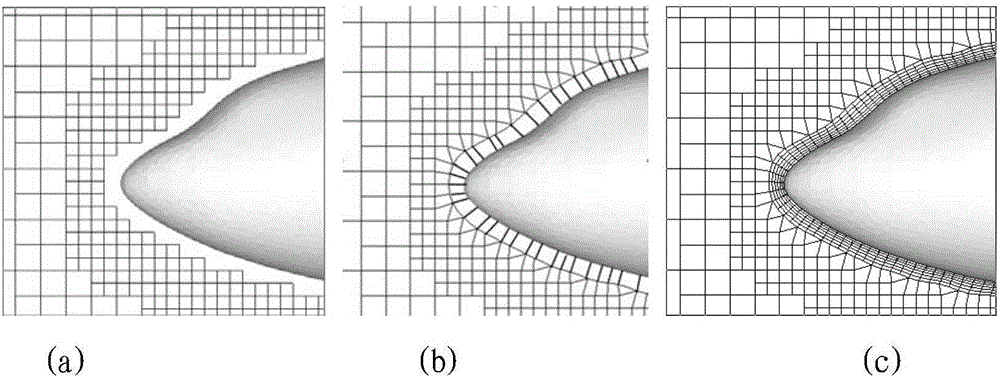

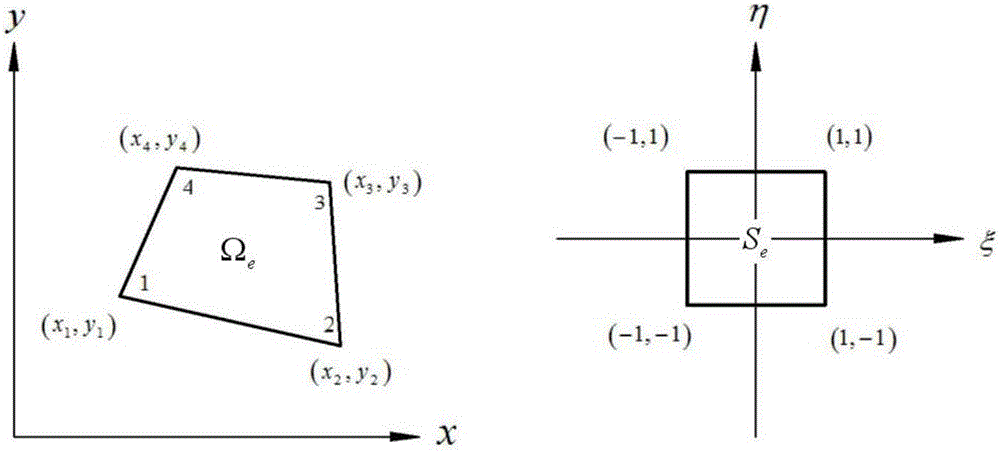

Numerical simulation method for obtaining aircraft flow fields

ActiveCN106682262AHigh precisionSolving Complex Flow PhenomenaGeometric CADSustainable transportationRegular gridFlight vehicle

The invention relates to a numerical simulation method for obtaining aircraft flow fields, wherein an interrupted Galerkin method based on non-structural right angle meshes is used to solve the flow field, and right angle meshes with a quadtree structure are used to disperse a to-be-solved flow field area into a set of meshes; each quadrilateral mesh is processed by dual-linear coordinate conversion, so each mesh under a current physical coordinate system can be mapped onto the next regular mesh in a computational coordinate system, so standard square meshes can be obtained; conservation variables in units under the computational coordinate system are obtained through numerical computation; a front face, a lower face, a left face and a right face of each mesh under the physical coordinate system are determined; according to differences between the left and right vibrations of unit interfaces, an interrupted detector is established; and the conservation variables in each mesh are processed by flow field display on the disperse meshes, so flow field distribution can be obtained. According to the invention, the interrupted Galerkin method based on the non-structural right angle meshes is introduced into flow field computation, so accuracy of the flow field computation is increased, and complicated flow phenomena can be solved.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Multi-level thinning screen separation device for caboes

InactiveCN103302023AImprove screening efficiencyUnified specificationsSievingScreeningEngineeringSquare mesh

The invention discloses a multi-level thinning screen separation device for caboes, which comprises a screen separation driving device, a feed opening, a crushed cabo outlet and sieves, wherein the screen separation driving device drives the sieves; the sieves include a bar grate-shaped sieve, a square-mesh sieve, an elliptical slot hole sieve and a round hole sieve from high to low sequentially; each sieve comprises a baffle, a screen mesh and an oversize outlet; the feed opening corresponds to the screen mesh of the bar grate-shaped sieve; and the screen mesh of the bar grate-shaped sieve also corresponds to the that of the square-mesh sieve; the screen mesh of the square-mesh sieve corresponds to a crushed cabo collecting tank; the oversize outlet of the square-mesh sieve corresponds to the screen mesh of the elliptical slot hole sieve; the screen mesh of the elliptical slot hole sieve corresponds to that of the round hole sieve; and the screen mesh of the round hole sieve also corresponds to the crushed cabo collecting tank. According to the invention, the different sieves at different layers are used for effectively separating cabo heads, overlong stems, long stems, short stems, crushed stems and smashed pieces of the stemmed caboes subjected to threshing and redrying, and accordingly, the cabo specification is uniform, which can more meet the requirements of tobacco primary process procedures, and facilitate classification packaging, storage and transportation of the caboes.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

A method for detecting water absorption of coke

InactiveCN102288511ASatisfy breathabilityFulfil requirementsWeighing by absorbing componentCombustionRoom temperature

The invention discloses a method for detecting water absorption of coke, comprising the following steps: (1) pulverizing the coke to 10-20 mm, sieving it horizontally with a 10 mm square-hole sieve, and taking the coke on the sieve as a sample; Put the sample into a drying box to dry, take out and cool down to room temperature to get dry coke; (3) add water to the dry coke to submerge the dry coke, and soak it; (4) filter the water out of the soaked coke, and use a cotton cloth to remove the water on the surface of the coke. Absorb it, and weigh the wet coke mass; (5) Calculate coke water absorption: coke water absorption = (wet coke mass - sample mass) ÷ sample mass × 100%. The method and the required equipment of the invention are simple and low in cost, and the gas permeability and combustion performance of the coke are evaluated by detecting the water absorption of the coke to guide the production.

Owner:XINXING DUCTILE IRON PIPES CO LTD

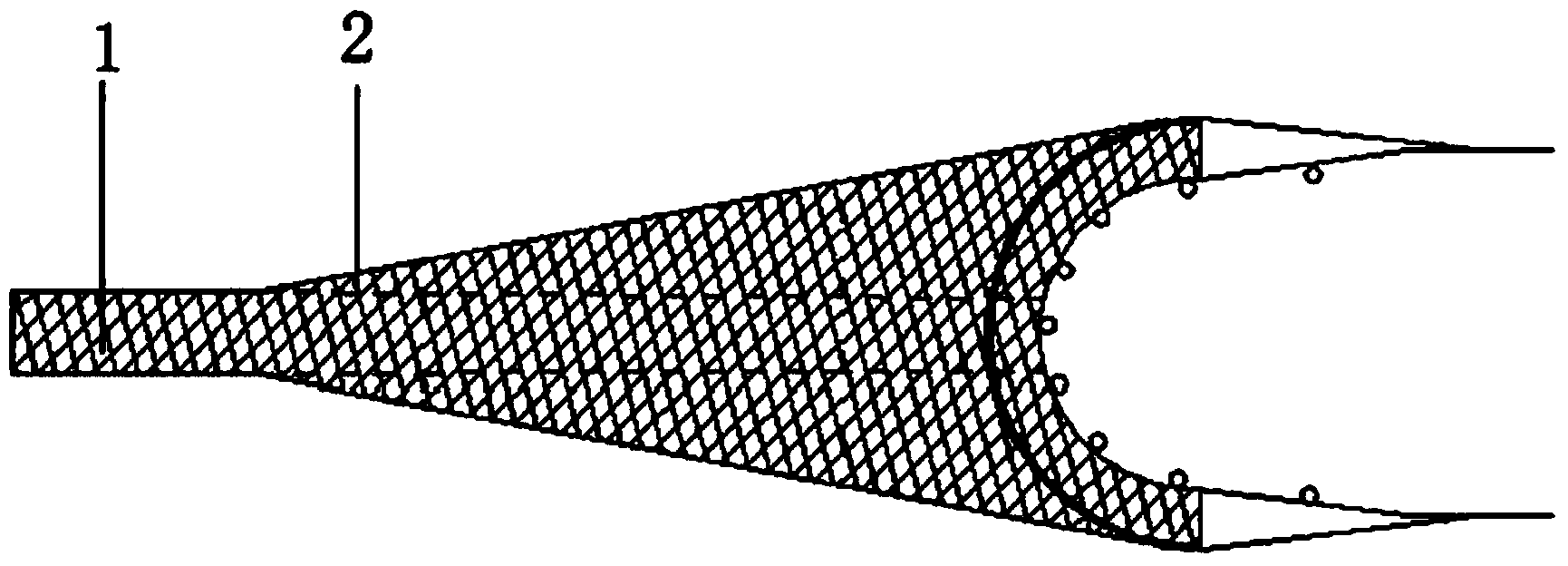

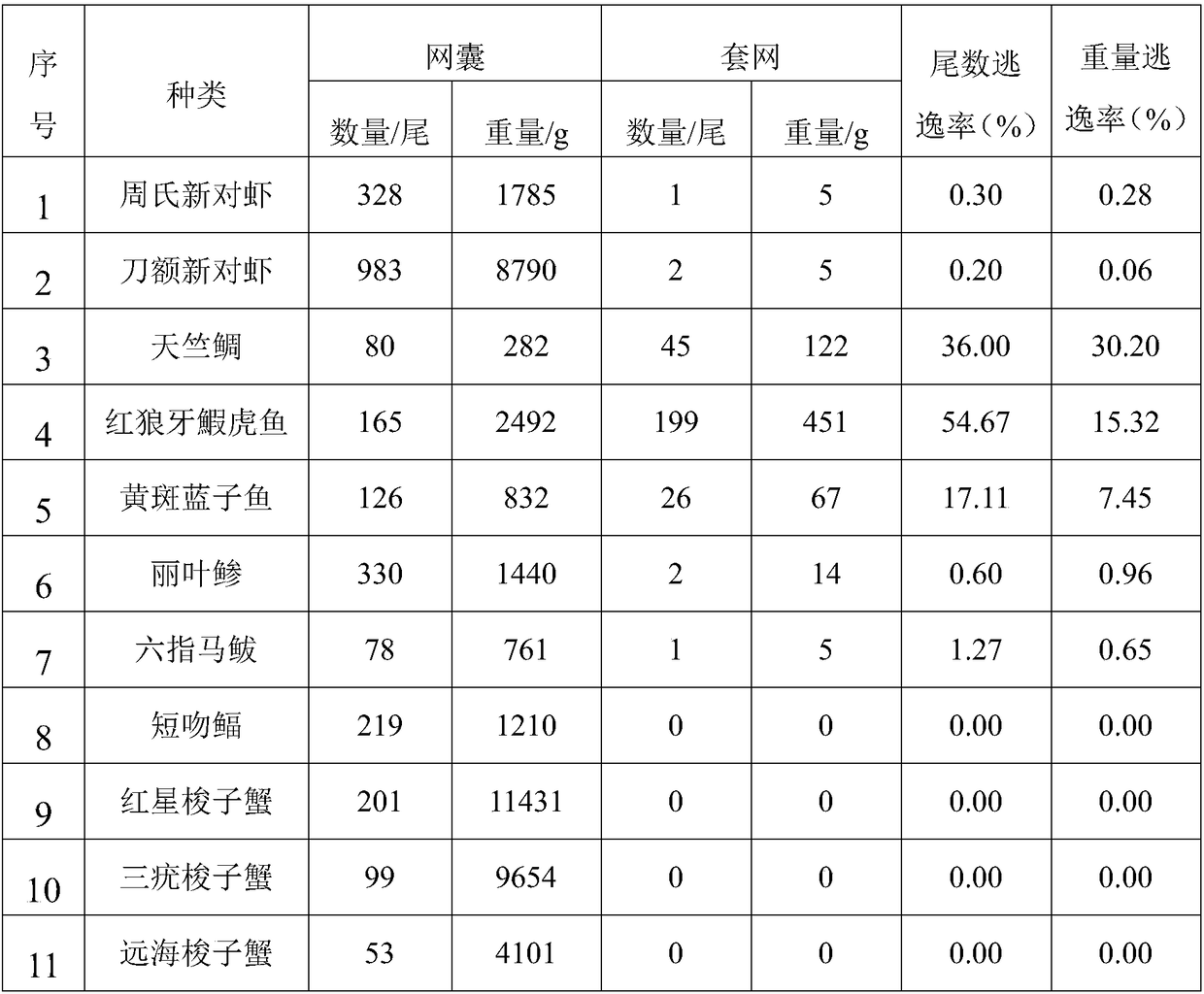

Shrimp trawl selective device

InactiveCN108575924AIncreased selectivity between speciesIncrease intraspecific selectivityFishing netsFiberShrimp

The invention provides a shrimp trawl selective device which comprises a drum net cover, a guide net, a transverse separation grid, a longitudinal separation grid, an escape opening, a square mesh netbody, a net bag and a longitudinal force line. The tail end of the drum net cover is connected with the net bag, and the square mesh net body is further connected between the drum net coat and the net bag, and the square mesh net body is a node-free square mesh net cover, a square-mesh escape window is formed in the back of the net body; the drum net coat, the square-mesh net body, the longitudinal force line is arranged on the two sides of the net bag, and the longitudinal force line is an ethylene fiber rope. The guide net is located inside the drum net coat and is in a funnel shape with alarge end and a small end, and the large end of the guide net is sewed with the inlet end of the drum net coat, and a transverse separation grid is arranged at the abdomen of the drum net coat corresponding to the small end of the guide net, a longitudinal separation grid is arranged at the outlet end of the drum net coat, and an escape opening is formed in the drum net coat. According to the method and the device disclosed by the invention, the intra-species and inter-species separation of the byproduct can be realized.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

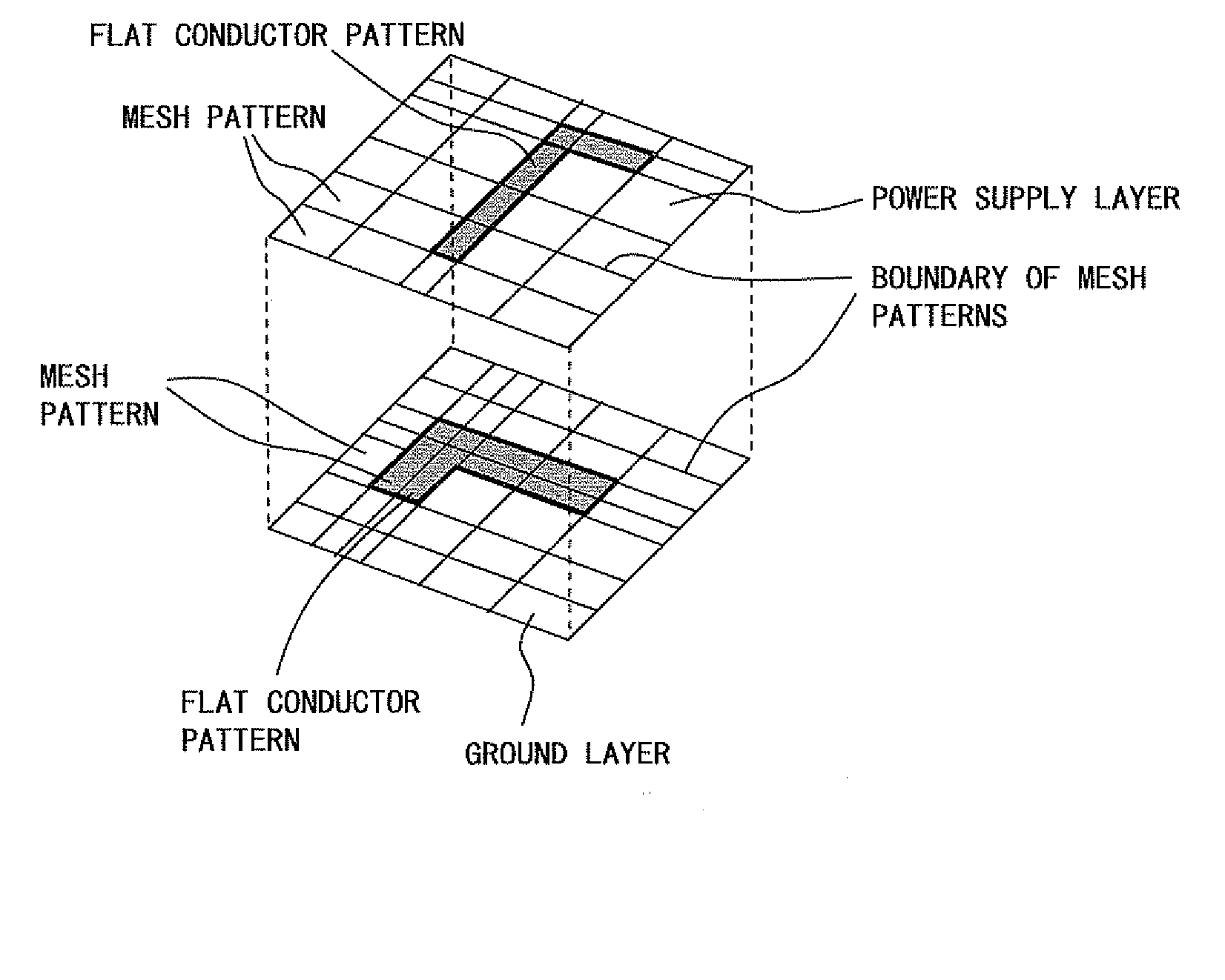

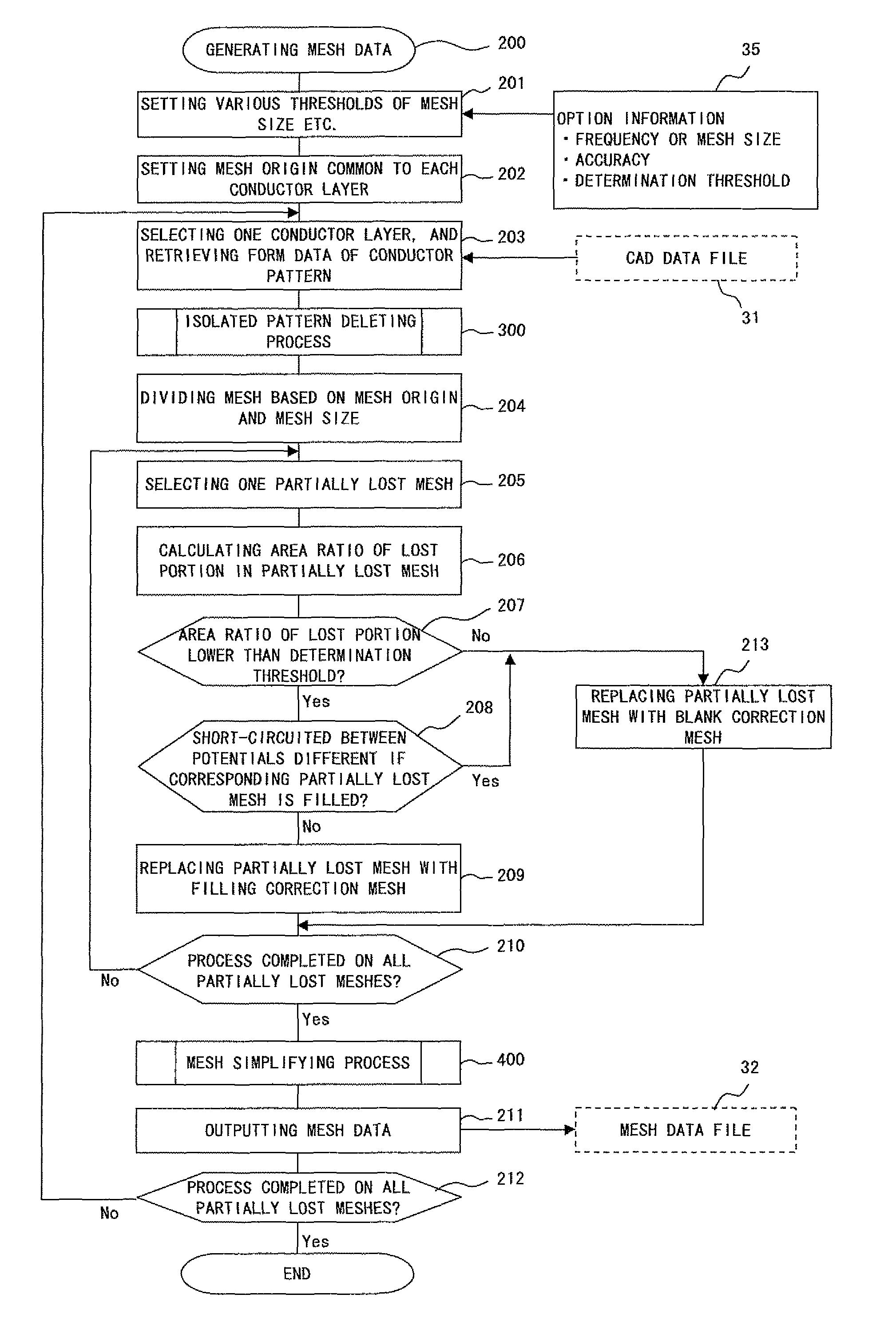

Electromagnetic field intensity calculating method and apparatus

InactiveUS20080079443A1Correctly and efficiently generatingGenerate efficientlyResistance/reactance/impedenceAnalogue computers for electric apparatusElectrical conductorEngineering

There is provided an electromagnetic field intensity calculator for calculating the intensity of electromagnetic field radiated from an electric circuit device based on a moment method. A conductor pattern obtained from CAD data is divided into a square mesh pattern. In the mesh pattern of the outline part, the entire region in the mesh pattern is filled with the conductor pattern according to the ratio of area between the conductor pattern region and the blank region, or subjected to correction for blanking, so that a mesh data model is automatically configured by mesh pattern group consisting of only squares conforming to the moment method and reflecting the outline of the conductor pattern.

Owner:FUJITSU LTD

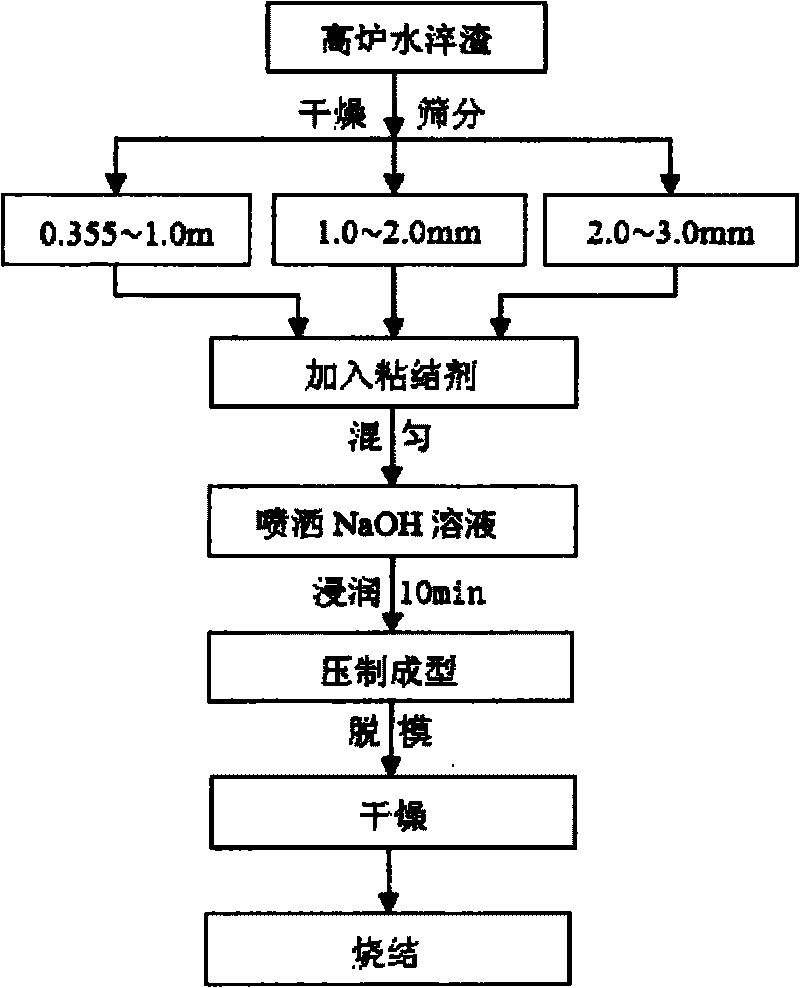

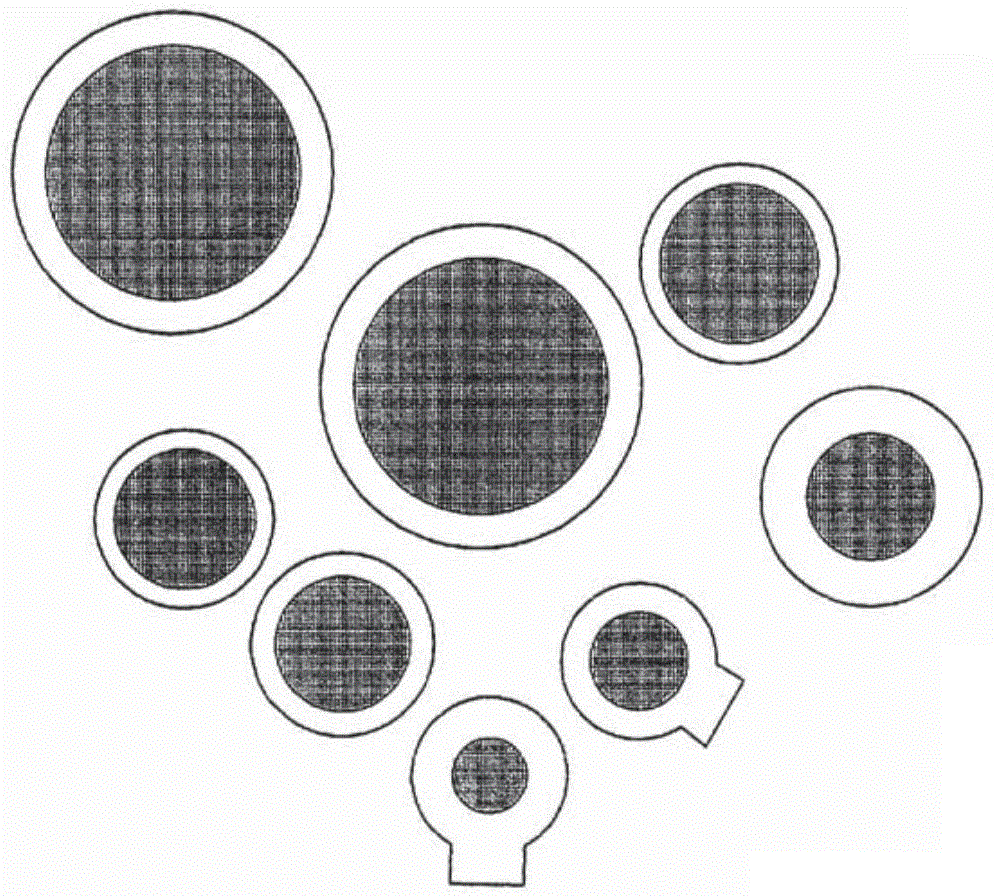

Method for manufacturing porous sound absorption material by using blast furnace water quenching slag

InactiveCN101696092ASimple preparation processLess investmentSolid waste managementSound proofingResonanceSlag

The invention discloses a process for manufacturing a porous sound absorption material by using blast furnace water quenching slag. In the method, the porous sound absorption material having a certain strength and excellent sound absorbing performance is manufactured by screening granular blast furnace water quenching slag processed by a water quenching process with a square-mesh sieve according to a certain grain size degree, making a bonding agent from silica powder added with solution of NaOH, performing compression forming at a pressure of 1.5 to 4.0MPa and sintering the formed product at a high temperature of about 1,100 DEG C for 1 to 6 hours. For the sound absorption material manufactured by the process, the sound absorption coefficient is more than 0.70, the first resonance frequency is less than 350Hz, and the strength is more than 4.0MPa. The method provides a new application for the blast furnace water quenching slag and has the advantages of simple manufacturing process, small required investment and low production cost. And the application of the method is expected to create excellent economic and environmental benefits.

Owner:UNIV OF SCI & TECH BEIJING

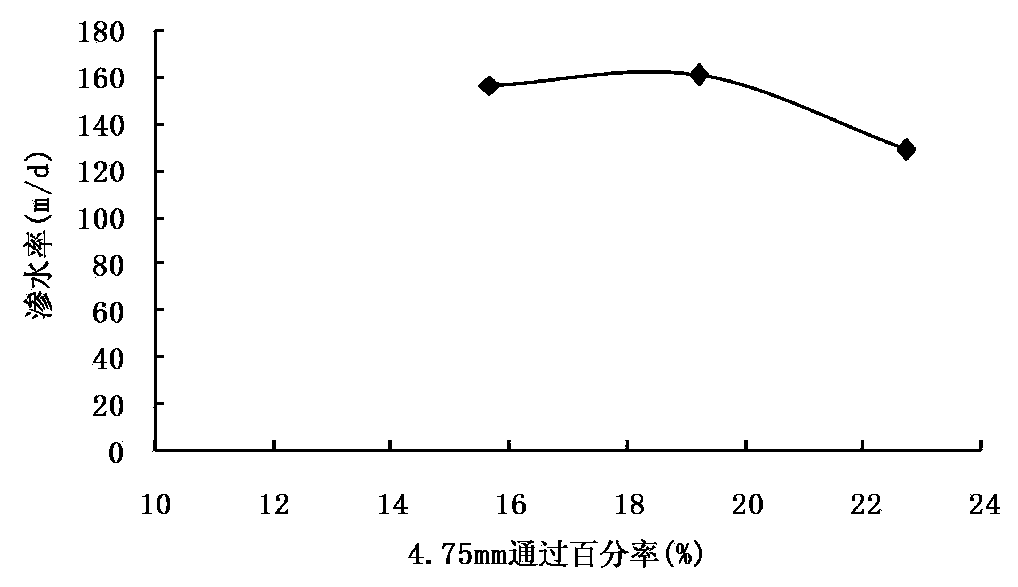

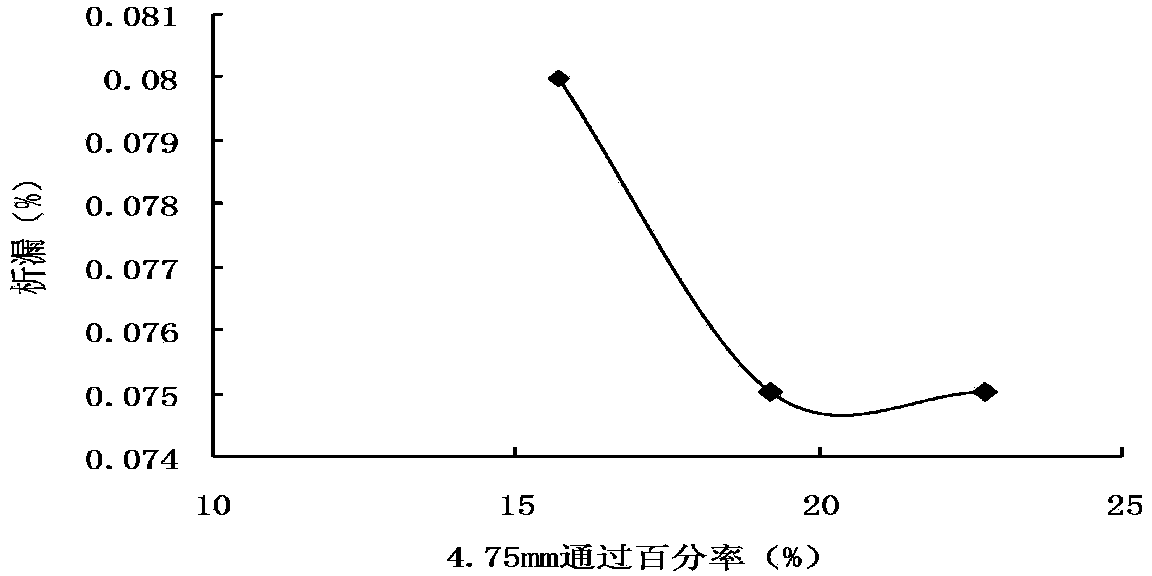

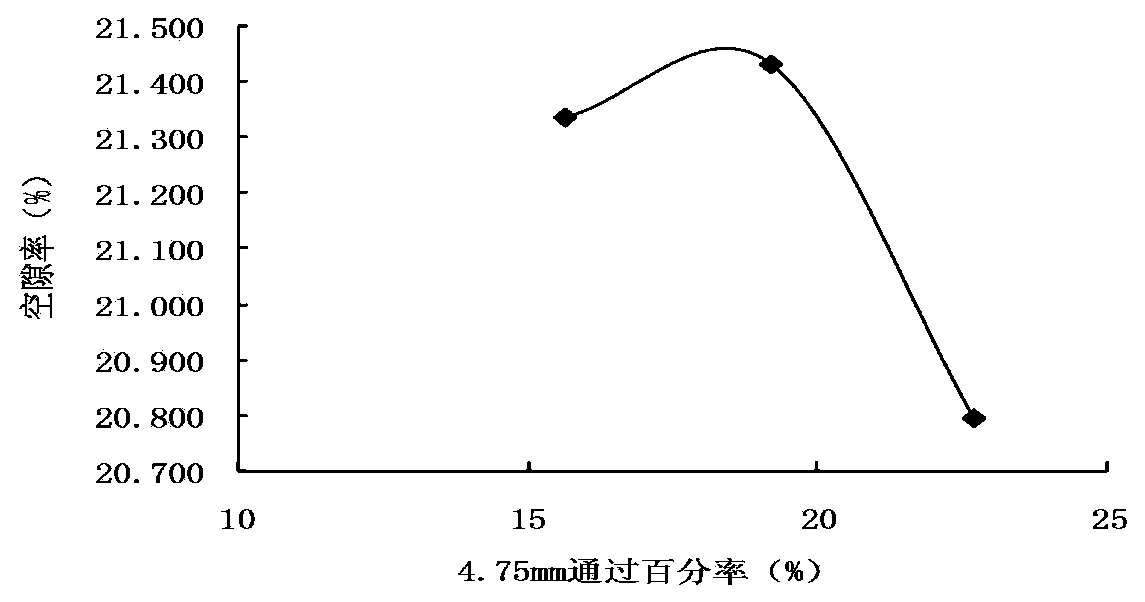

Low-noise asphalt pavement mixture and pavement construction quality control method

The invention discloses a low-noise asphalt pavement mixture which is composed of the following components in percentage by mass: 40-50% of basalt 10-15, 40-50% of basalt 5-10, 2-10% of stone dust, 2-6% of lime rock machine-made sand, less than 5% of ore powder, 0.2-0.6% of fiber and 6.0-7.0% of asphalt, totaling 100%. The size distribution of the ores is as follows: the percent of ores passing through a 16mm square mesh sieve is 100%, the percent of ores passing through a 13.2mm square mesh sieve is 86-100%, the percent of ores passing through a 9.5mm square mesh sieve is 56-74%, the percent of ores passing through a 4.75mm square mesh sieve is 11-25%, the percent of ores passing through a 2.36mm square mesh sieve is 6-10%, the percent of ores passing through a 0.075mm square mesh sieve is 2-4%, and the void volume of the mixture is 18-20%. The pavement prepared by the asphalt mixture has the advantage of low noise.

Owner:SHANDONG JIANZHU UNIV

Method for improving quality of fly ash concrete blending material

The invention provides a method for improving the quality of a fly ash concrete admixture. 50 to 97 percent of undisturbed fly ash, 1 to 30 percent of blast furnace slag, 1 to 30 percent of tailings of magnet quartzite type iron ore or quartzite tailings or marble tailings or granite tailings or stone powder scrapped during stone processing, 0.1 to 1 percent of melamine formaldehyde resin sodium sulfonate, in weight percentage, are mixed and ground together until the triage of a 0.045mm square-mesh sieve is less than or equal to 12 percent. The off-standard fly ash and III-grade fly ash with a gross amount over 80 percent can be improved into the I-grade fly ash or II-grade fly ash according to the method, the utilization value of inferior fly ash can be raised substantially, and the method has advantages of good economic benefit, enlarging the amount of admixture, saving cement and improving the performance of concrete.

Owner:UNIV OF SCI & TECH BEIJING

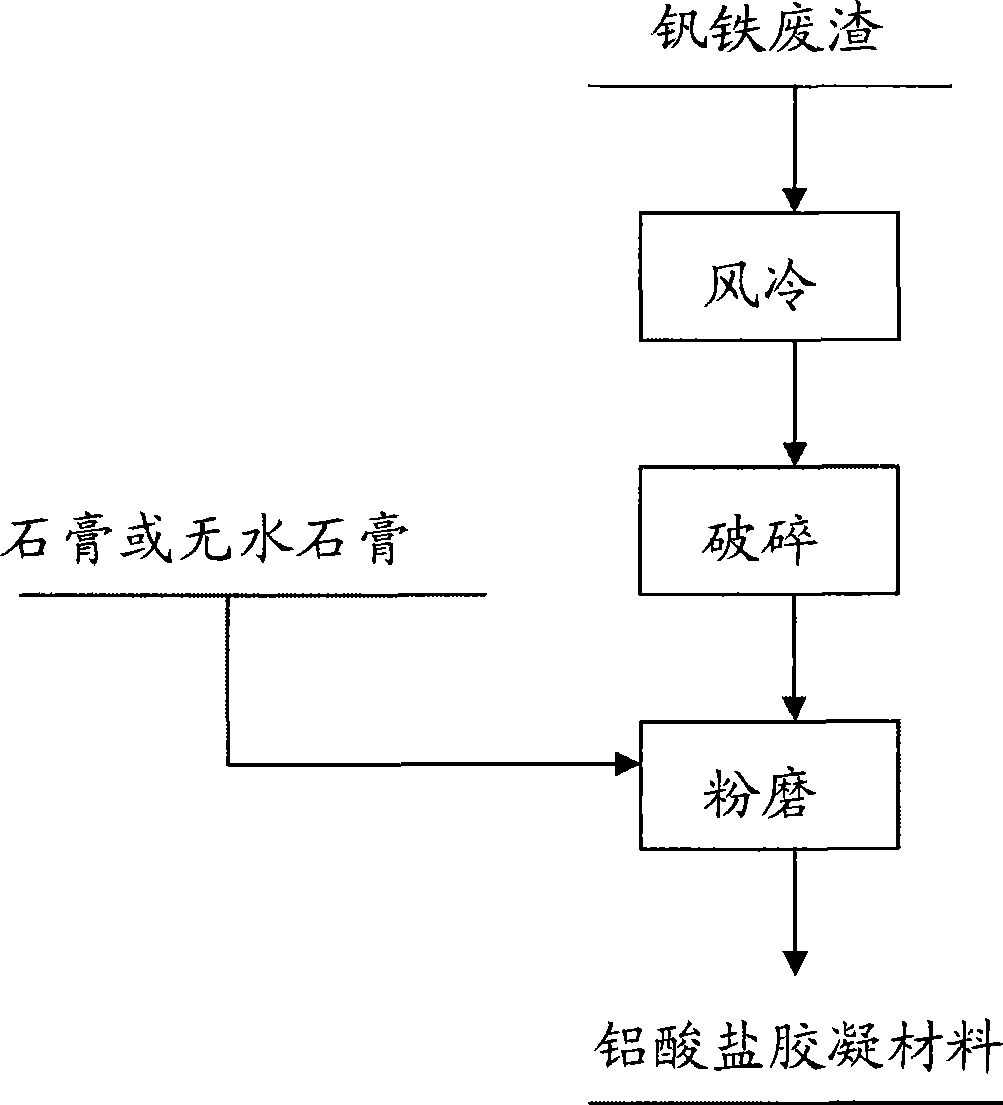

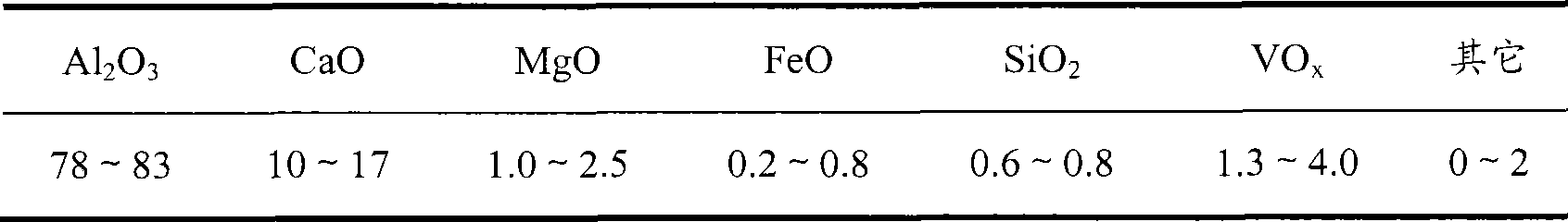

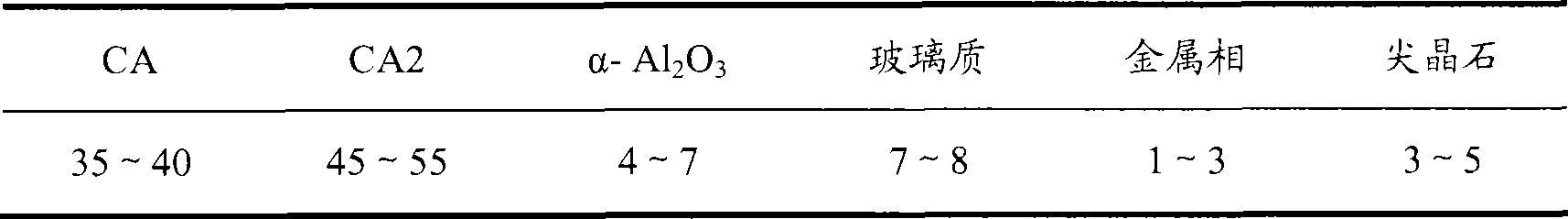

A preparation method for producing aluminate gelled material by ferro vanadium waste

InactiveCN101531476AReduce manufacturing costHigh refractorinessCement productionRefractorySquare mesh

The invention provides a preparation method for producing aluminate gelled material by ferro vanadium waste, which is characterized in that, after the discharged hot ferro vanadium waste is cooled by wind, the ferro vanadium waste is smashed and milled into powder, wherein the fineness is required to meet the requirement that not more than 20 percent of screen residue is left after going through a 0.045mm square mesh sieve; and then the aluminate gelled material is obtained. The aluminate gelled material is characterized by high fire resistance degree, high compressive strength and rupture strength, good corrosion resistance, etc., which can be widely applied to amorphous refractory products.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Magnetic field protecting and screening multi-layer textile construction

ActiveCN105493650AEasy to assembleReduce use costShielding materialsLoudspeaker screensMetal filamentSquare mesh

A laminated double-layer textile product comprises a square mesh ferro-magnetic alloy metal filament or thread technical fabric layer coupled to a square mesh synthetic monofilament technical fabric layer by laminating to provide a diffused joining of said two layers, said laminating comprising a hot-melt laminating.

Owner:SAATI

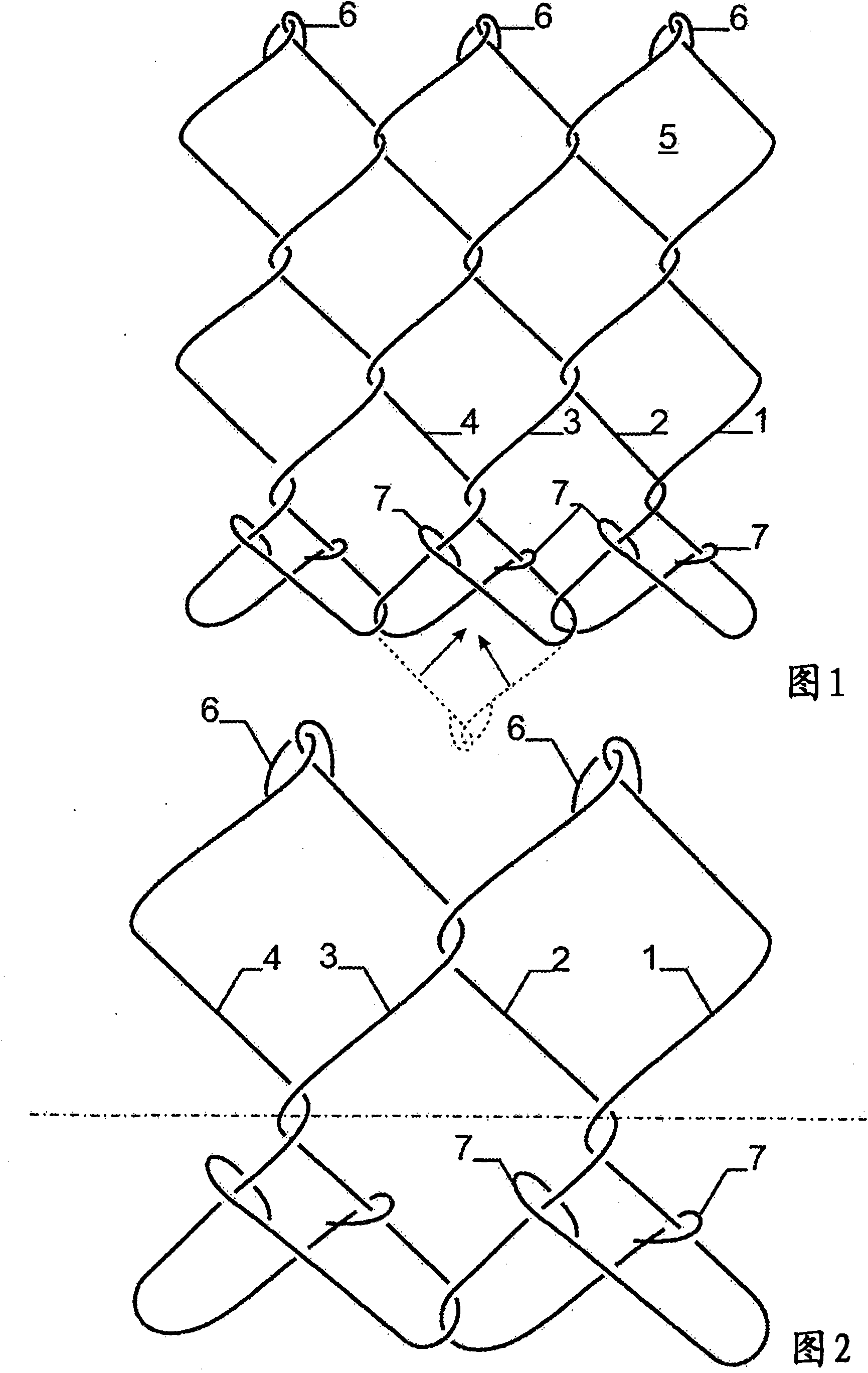

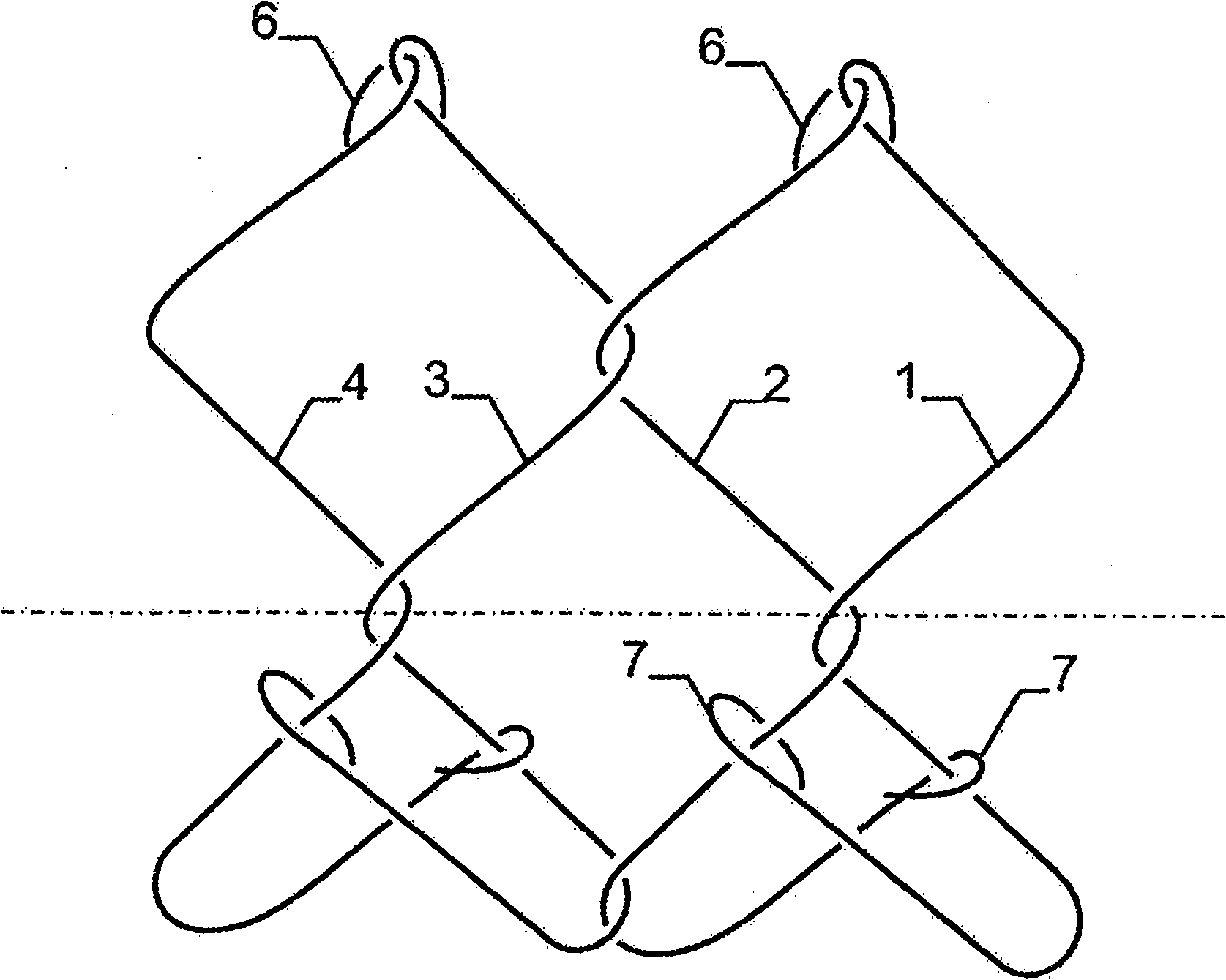

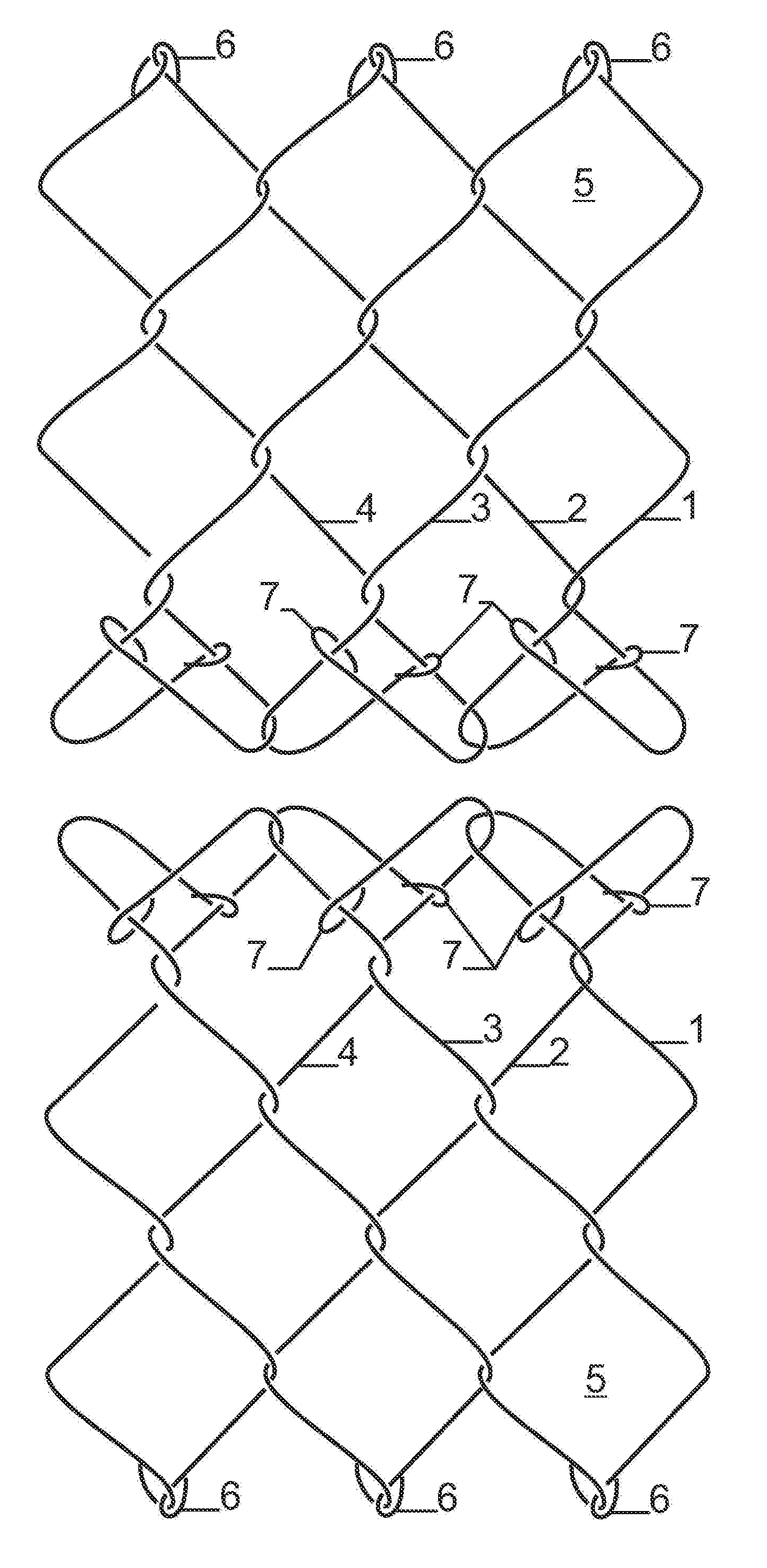

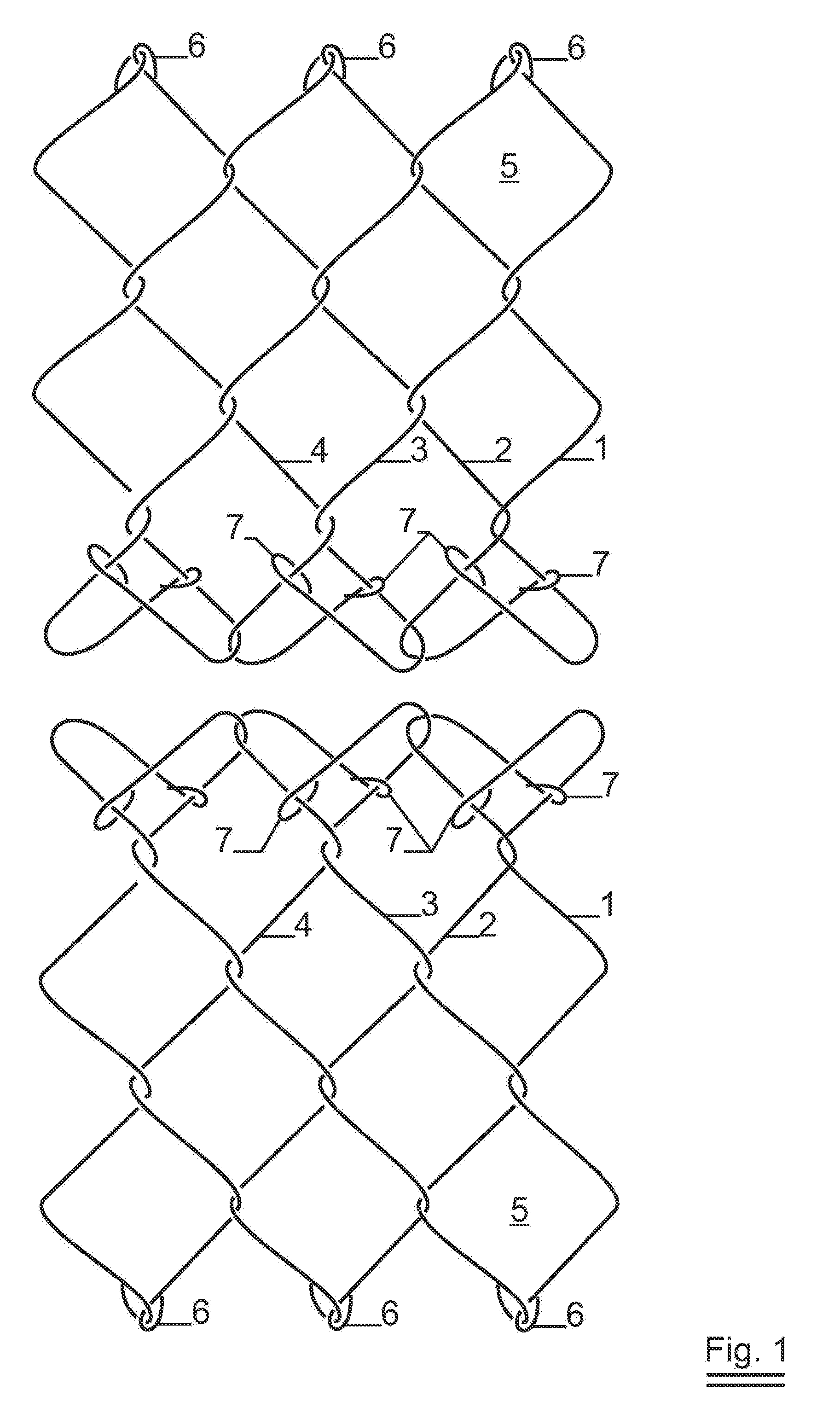

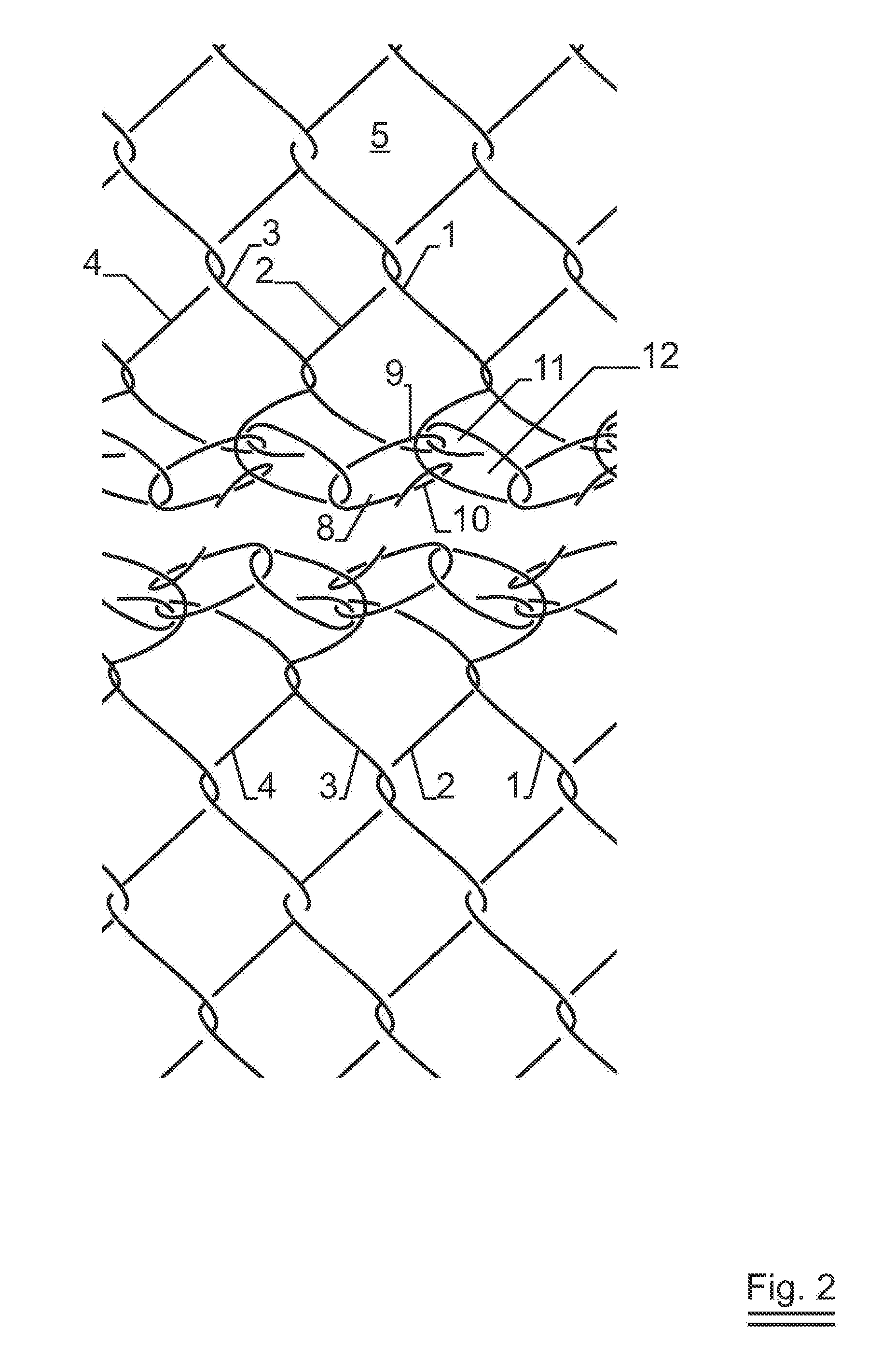

Chain link woven mesh with double knot

A chain link woven mesh comprises successive undulated transverse links (1,2,3,4), which are interconnected together at the bent portions of the links, whereby each pair of successive undulated links (1,2), (3,4) forms a row of adjacent rectangular or square meshes (5) with four sides. At least at one border of the mesh, for each pair of successive links, the last side of the first link (1) is bent upwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the second link (2). The last side of the second link (2) is bent downwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the first link (1). The advantage is that a very strong border is obtained.

Owner:NV BEKAERT SA

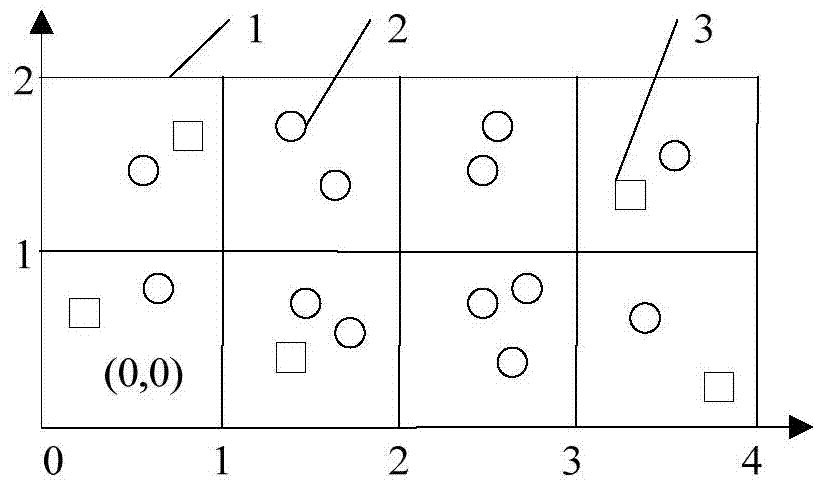

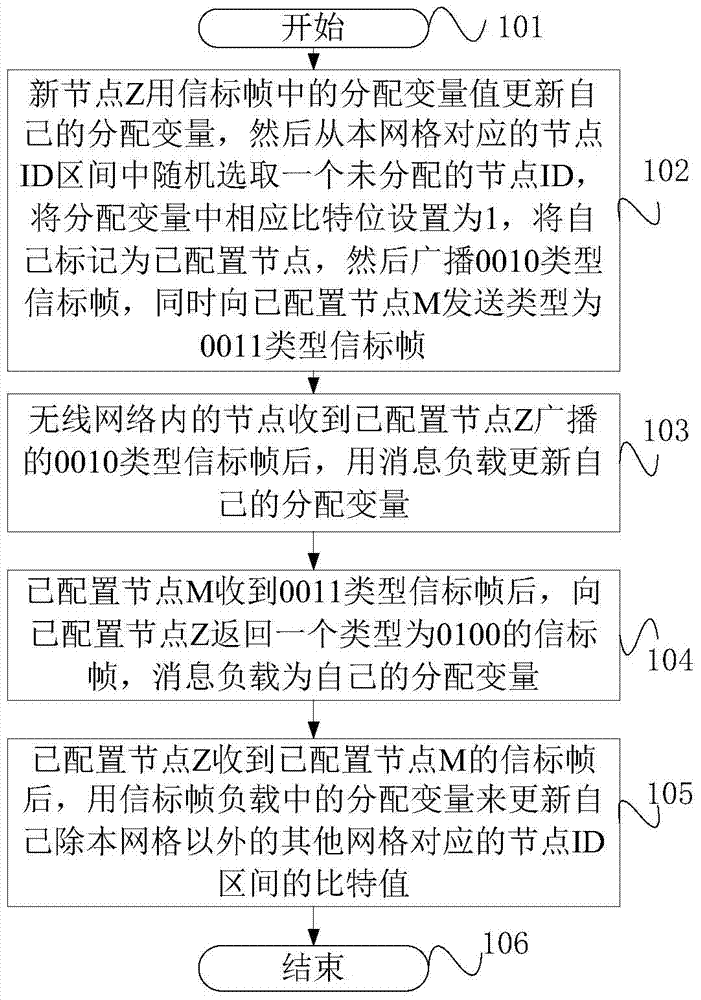

Communication implementation method for wireless network

ActiveCN103945415AThe configuration cost is reasonableLower latencyTransmissionWireless communicationWireless mesh networkSquare mesh

The invention discloses a communication implementation method for a wireless network. The movement area of the wireless network is composed of 2n1*2n2 two-dimensional square meshes, wherein n1 and n2 are positive integers, the side length is the transmission radius r of a mobile node, the coordinates of each mesh are (x, y), and x and y are nonnegative integers; the mobile node obtains the geographic coordinates (Gx, Gy) thereof through GPS technology, and the coordinates of the mesh where the mobile node is located are obtained according to a formula. The communication implementation method for the wireless network is used for such fields as vehicle monitoring, medical treatment and health, and national defense and military, for example, in the vehicle monitoring field, the communication implementation method technology for the wireless network is used for monitoring the road congestion, each vehicle can be provided with a plurality of nodes, after each node is configured with an address, the nodes can communicate information to transmit the road traffic situation to effectively avoid road congestion and keep traffic smooth, and therefore, the technology has high popularization value.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

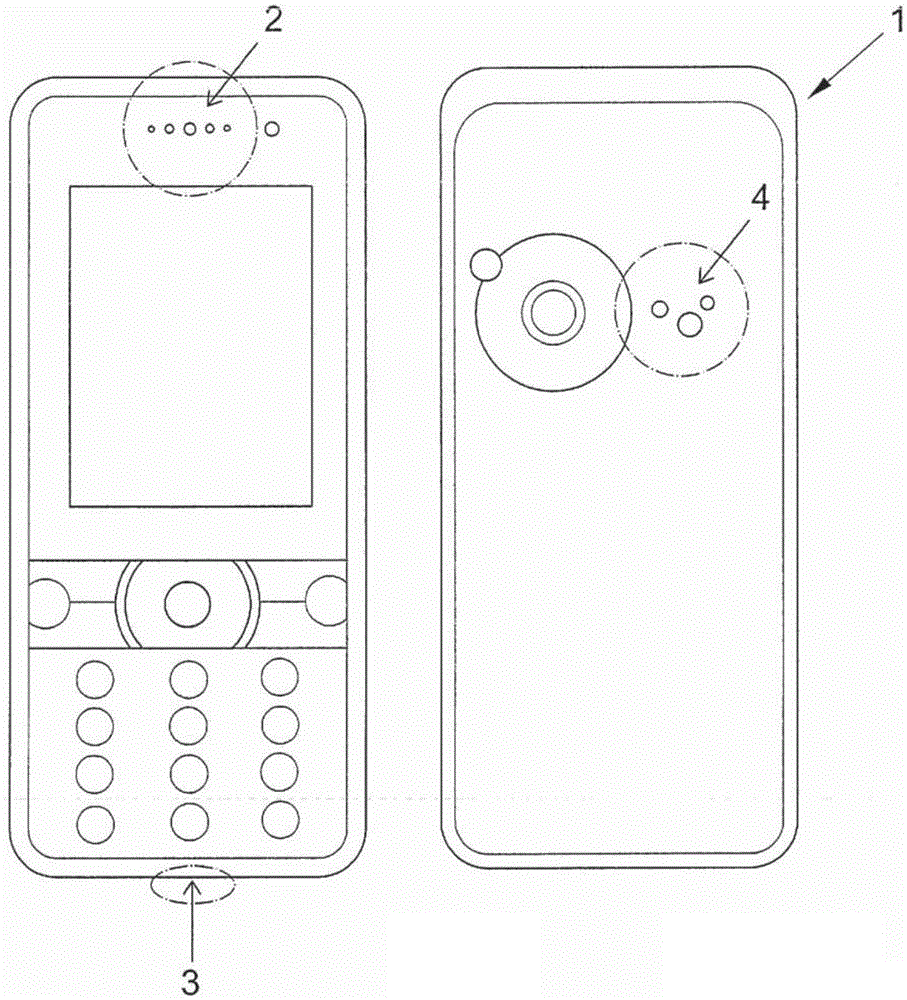

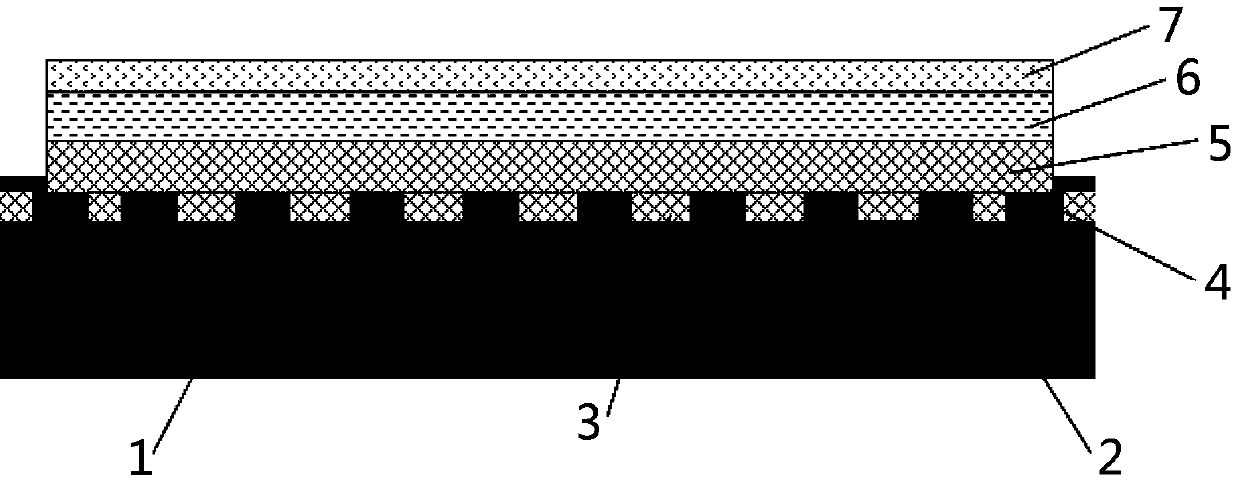

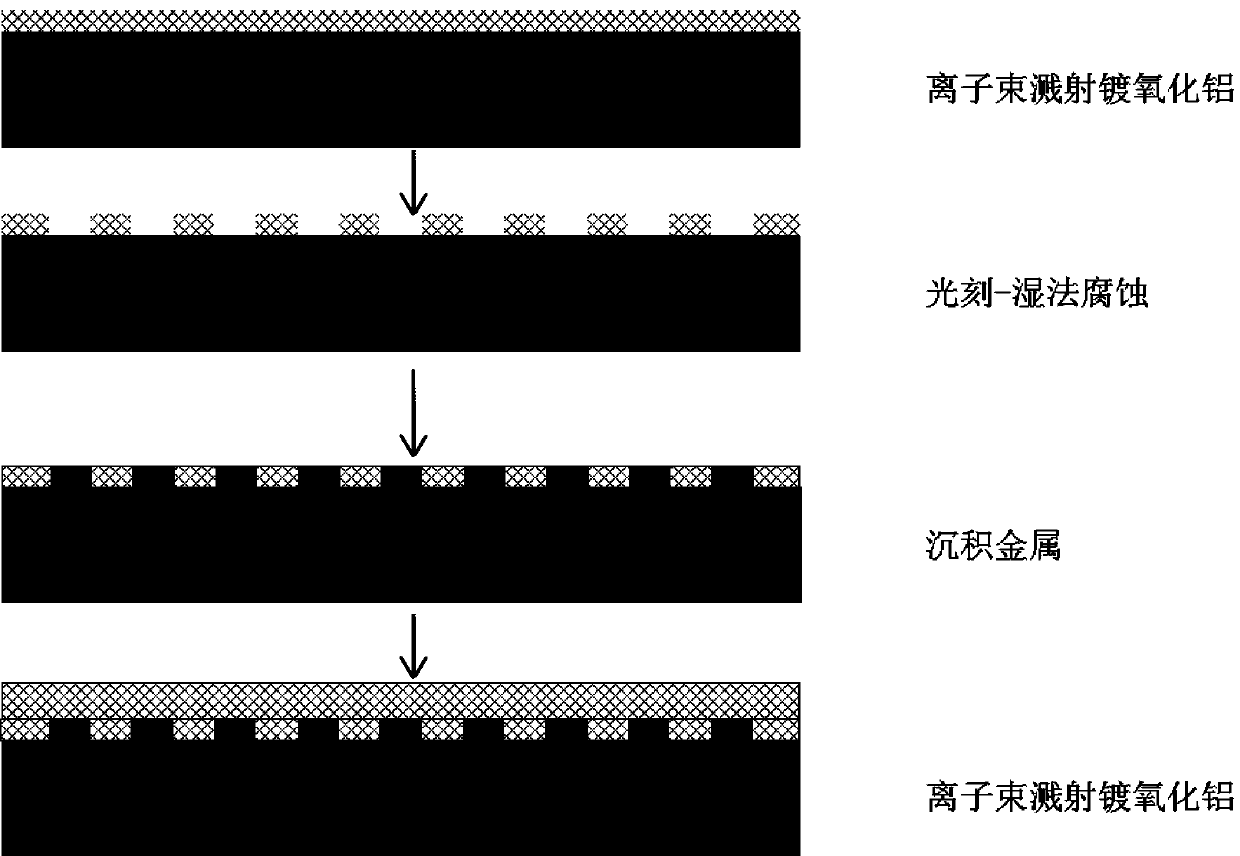

Sapphire optical window with electromagnetic shielding function and preparation method

ActiveCN110519976AWith 4MPa water pressure resistanceWith anti-salt sprayScreening rooms/chambersVacuum evaporation coatingElectromagnetic shieldingSquare mesh

The invention discloses a sapphire optical window with an electromagnetic shielding function. The sapphire optical window comprises a sapphire substrate; an electromagnetic shielding functional film layer, a hard multiband antireflection film and a hydrophobic film which are sequentially evaporated on the sapphire substrate. The electromagnetic shielding functional film layer is composed of a first aluminum oxide film layer, a metal mesh film layer embedded into the first aluminum oxide film layer and a second aluminum oxide film layer plated on the metal mesh film layer. The metal mesh film layer is formed by the periodic arrangement of square mesh units in a first aluminum oxide film layer, and the edge of the second electromagnetic shielding functional film layer is plated with an edgeelectrode film layer forming ohmic contact with the metal mesh. The invention also discloses a preparation method thereof. According to the invention, the sapphire optical window is mainly used in a marine environment and an underwater pressure-bearing environment, and the window has the functions of 4MPa water pressure resistance, salt mist resistance, seawater soaking resistance and mould resistance, and has high transmittance in visible light and medium-wave infrared bands, wherein the average electromagnetic shielding effectiveness at 30MHz-1.5 GHz bands reaches 30dB or above.

Owner:HUBEI JIUZHIYANG INFRARED SYST CO LTD

Mining mesh with double knot

A mining mesh comprises successive undulated transverse links (1,2,3,4), which are interconnected together at the bent portions of the links, whereby each pair of successive undulated links (1,2), (3,4), . . . forms a row of adjacent rectangular or square meshes (5) having four sides. The mesh is characterised in that at least at one border of the mesh, for each pair of successive links, the last side of the first link (1) is bent upwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the second link (2) and that the last side of the second link (2) is bent downwardly and backwardly over a sharp angle, whereby the end of this last side is hooked around the penultimate (last but one) side of the first link (1). The advantage is a stronger mining mesh where the overlap between two adjacent rolls can be limited.

Owner:NV BEKAERT SA

Electromagnetic field intensity calculating method and apparatus

InactiveUS8065101B2Generate efficientlyShorten the timeResistance/reactance/impedenceAnalogue computers for electric apparatusElectrical conductorSquare mesh

Owner:FUJITSU LTD

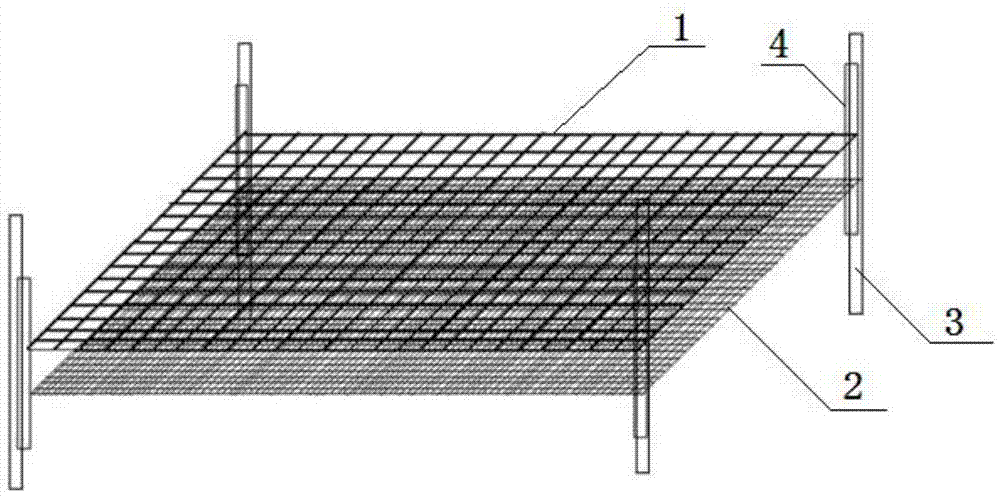

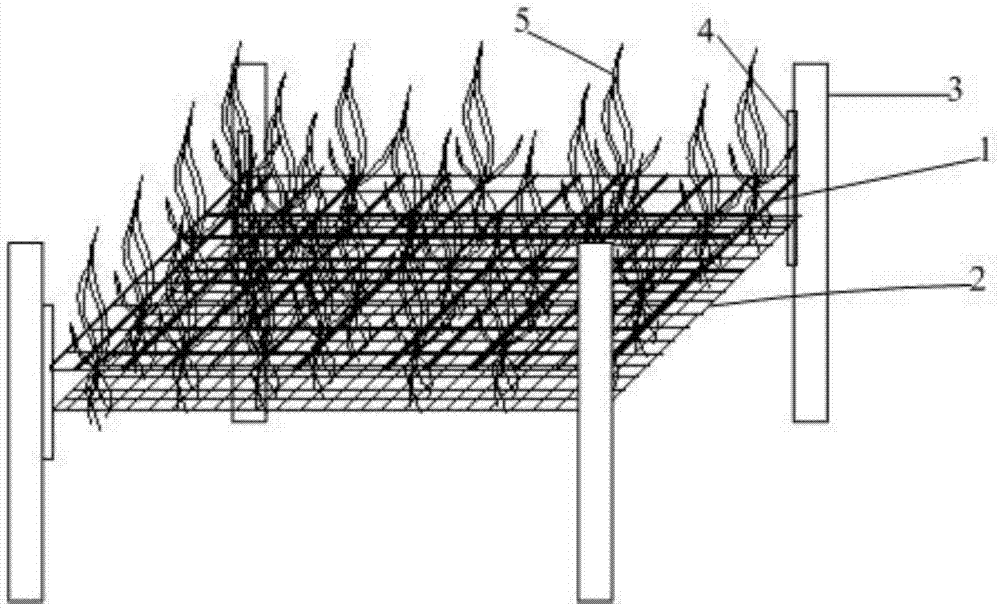

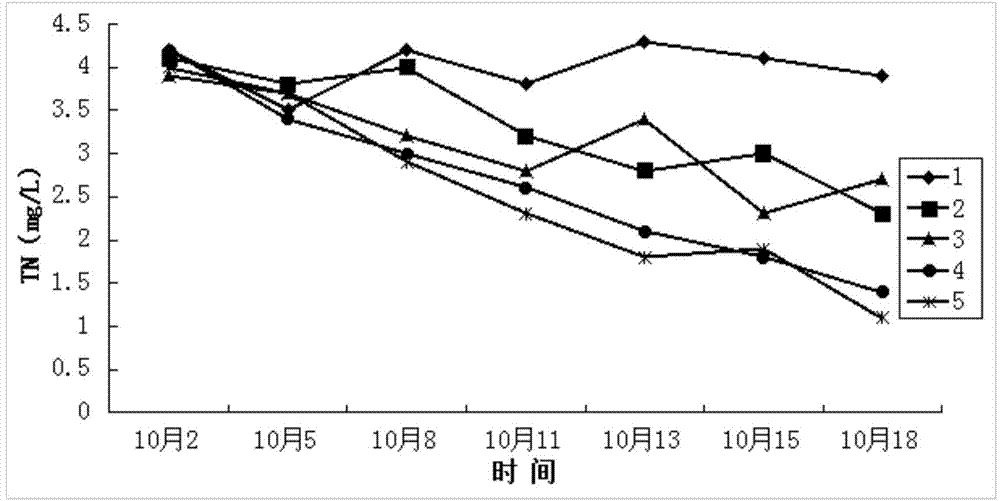

Double-layer net bed for repairing water by planting submerged plants and water repairing method

InactiveCN103663714AOvercome expensiveSimple structureBiological water/sewage treatmentVegetationVallisneria

The invention discloses a double-layer net bed for repairing water by planting submerged plants. The double-layer net bed comprises an upper net sheet and a lower net sheet, wherein the upper net sheet is a quadrilateral net sheet with square meshes, and the side length of the square is 1 -5cm; the lower net sheet is a quadrilateral fishing net with square meshes, and the side length of the square is 2-10mm; four corners of the upper net sheet and the lower net sheet are fixed on four piles in quadrilateral arrangement respectively; and the upper net sheet is 3-5cm away from the lower net sheet. According to the size of the upper mesh, a bundle of vallisneria can be exactly inserted into the mesh, and the roots of the vallisneria can be ensured to contact the lower net sheet; and according to changes of the water level and the transparency of water to be repaired, ecological niche is continuously changed so as to overcome the limitation on submerged vegetation restoration by the transparency and improve the repairing effect.

Owner:SHANGHAI OCEAN UNIV

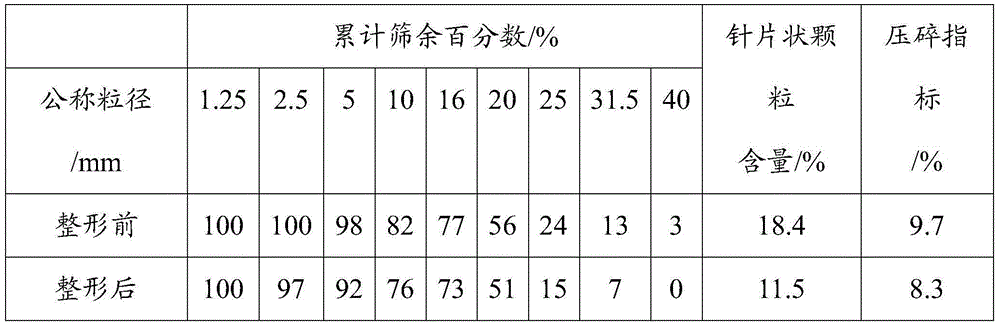

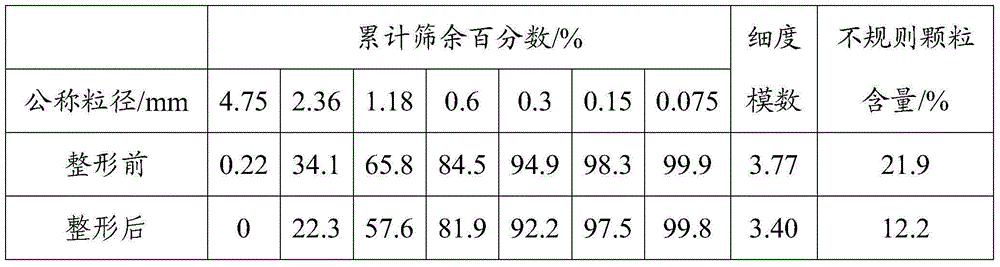

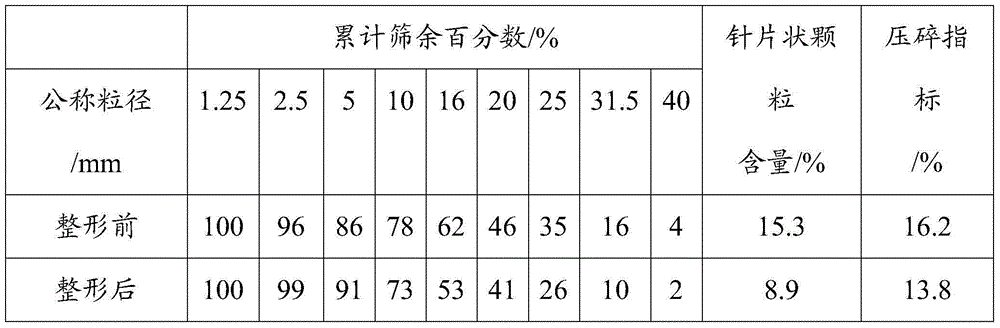

Particle shaping method for machine-made aggregate

InactiveCN105060753AHigh strengthReduce crush indexSolid waste managementSquare meshUltimate tensile strength

The invention discloses a particle shaping method for machine-made aggregate. The method comprises the steps that the broken machine-made aggregate is firstly sieved through a square mesh sieve to obtain the thick aggregate with the nominal particle diameter of 5-40 mm and the thin aggregate with the nominal particle diameter smaller than 5 mm, and then rolling shaping treatment is performed on the thick aggregate and the thin aggregate through a rolling machine to obtain the shaped thick aggregate and thin aggregate. According to the shaping method, the content of elongated and flaky particles can be decreased, the strength of the recycled aggregate is improved, and the improvement of the workability of a freshly mixed concrete mixture is facilitated.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com