Patents

Literature

71results about How to "Reduce energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

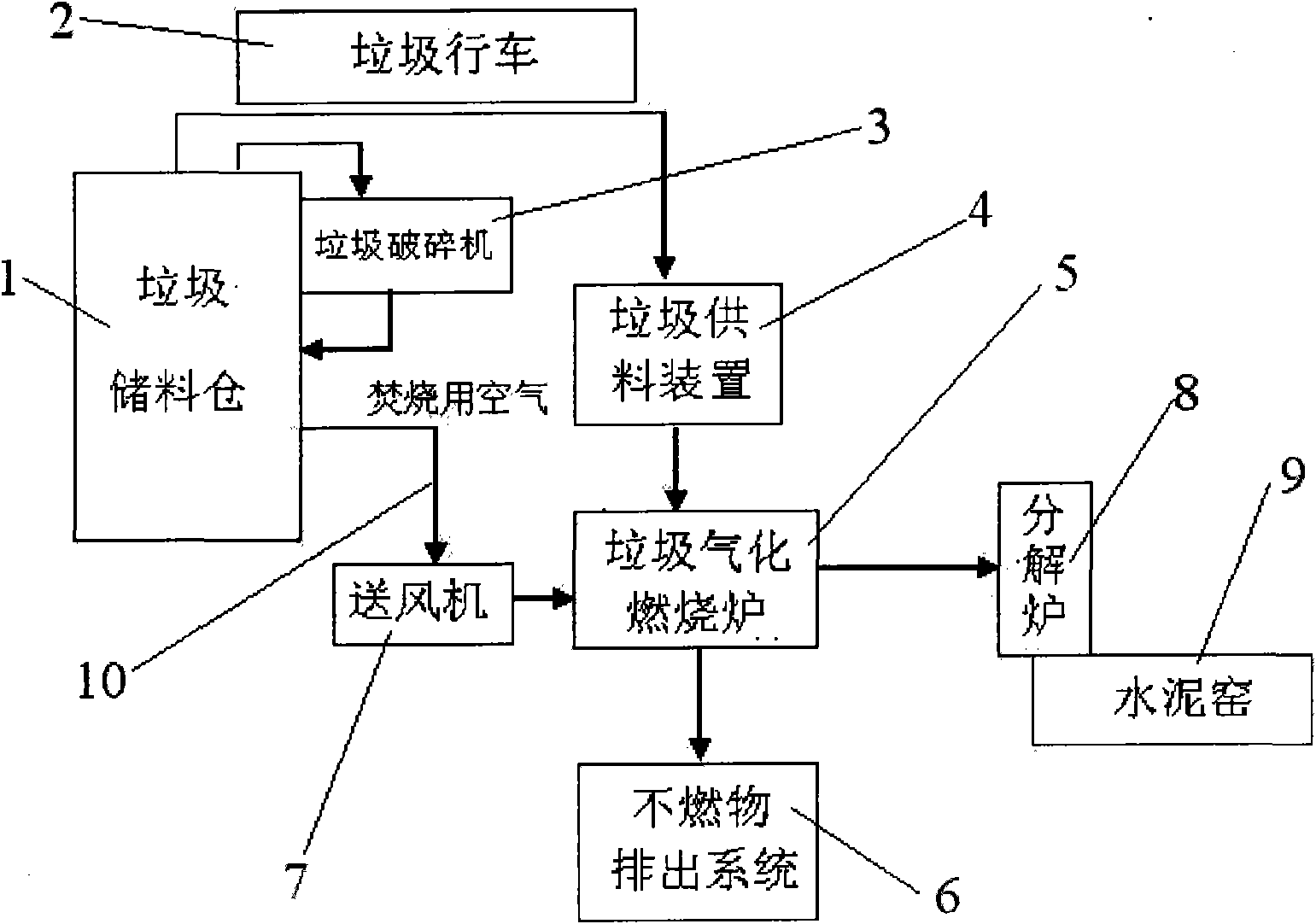

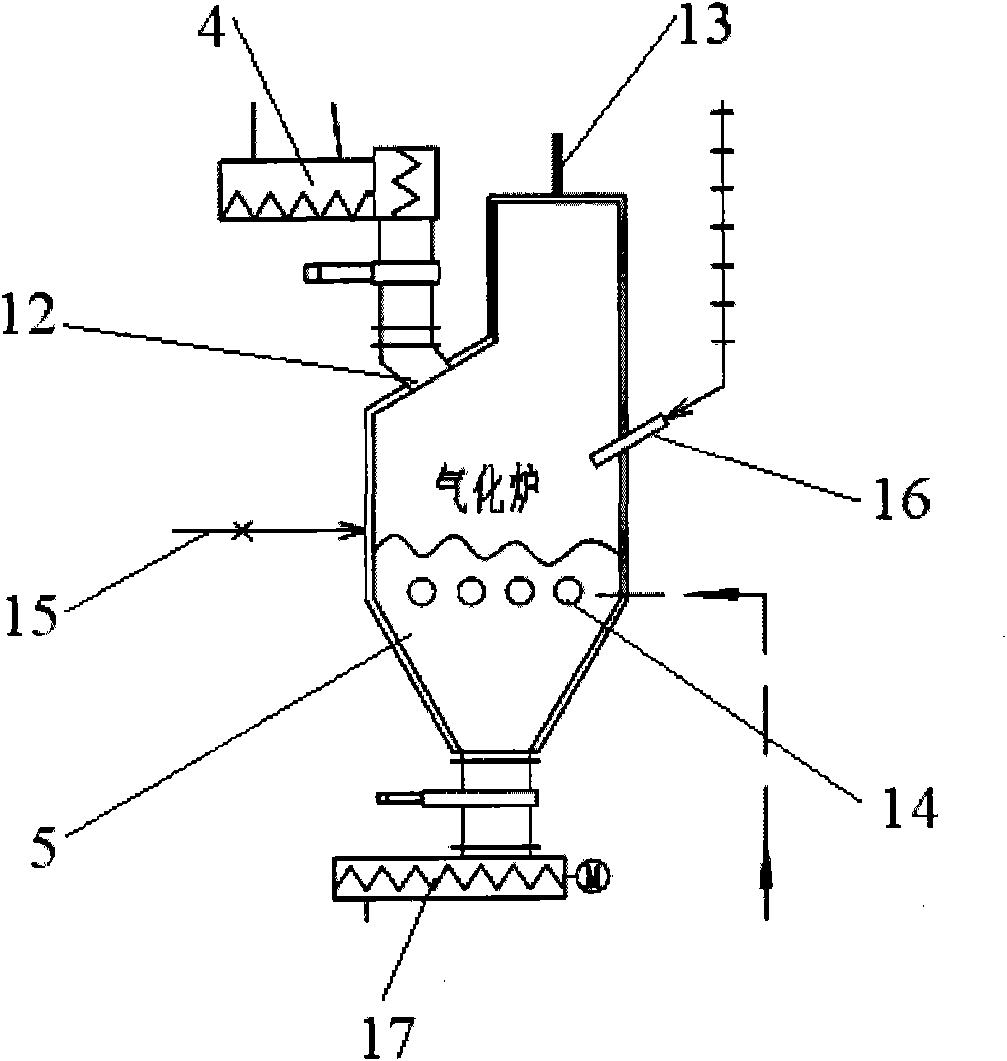

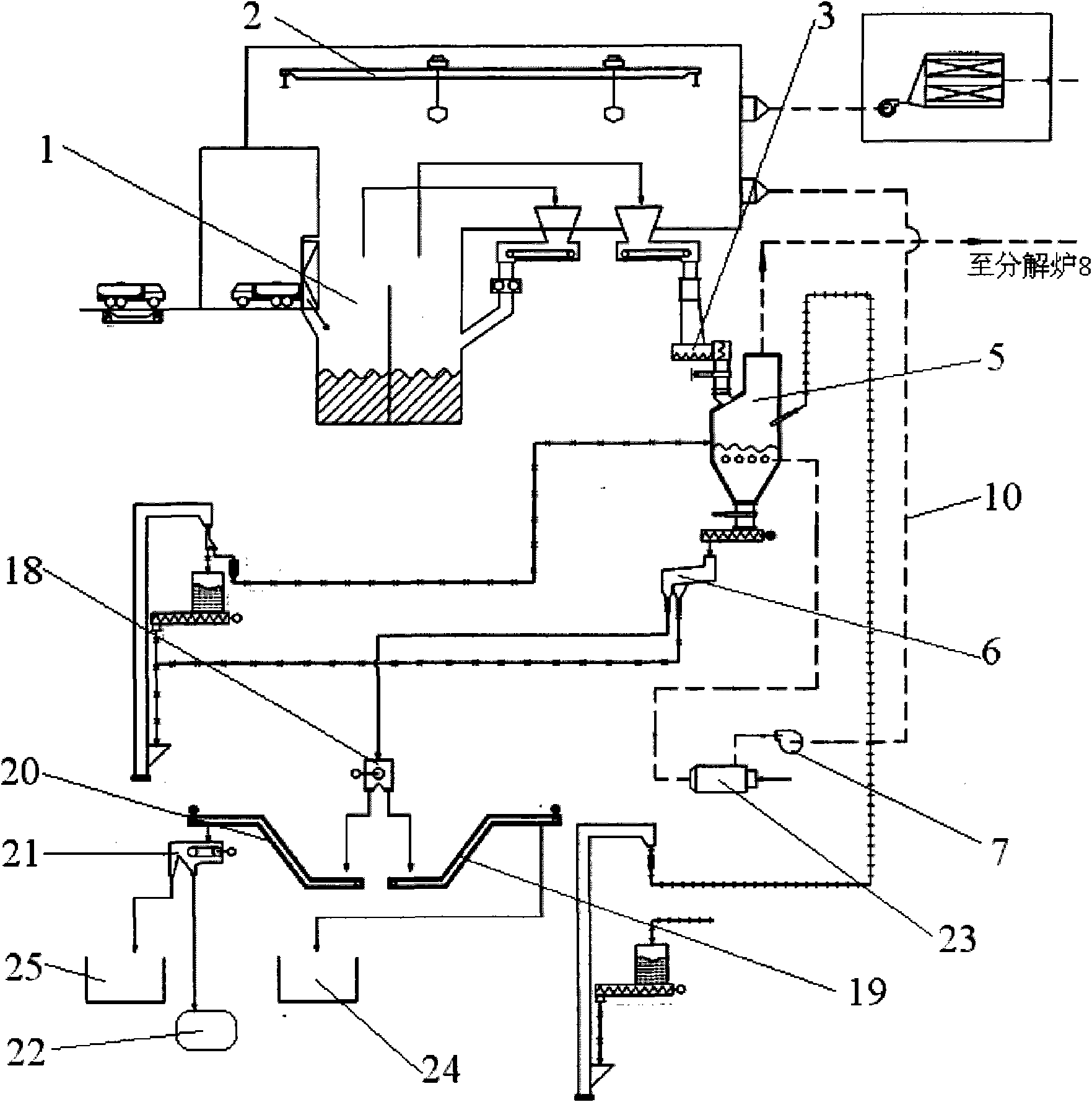

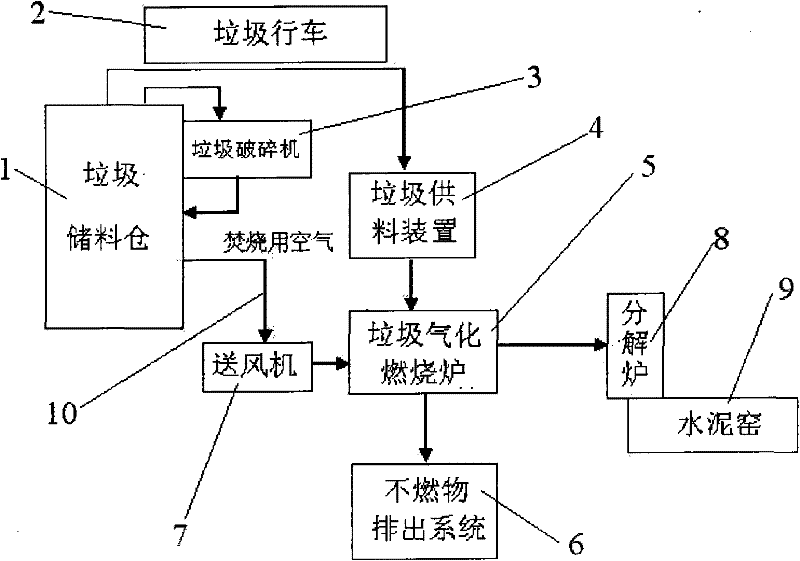

Garbage disposal system used in cement dry kiln production and disposal method thereof

ActiveCN101786809AExtended stayFull combustion processClinker productionCement kilnCombustion process

Owner:ANHUI CONCH GRP +2

Method for making microwave vaccum frozen and dried lemon piece

InactiveCN1849921AExtended production periodSolve the problem of excessive pesticide residuesFood preservationMicrowaveFreeze-drying

The present invention relates to a production method of microwave vacuum freeze-dried lemon slices. Said method includes the following steps: (1), sorting lemon fruit; (2), storing lemon fruit under the condition of constant temperature; (3), utilizing ozone to degrade pesticide residue on the lemon fruit and make sterilization; (4), cutting head and tail of lemon fruit, cleaning the lemon fruit by using ozone water and sterilizing; (5), slicing; (6), freezing sliced lemon; (7), prefreeze-drying; (8), microwave vacuum-drying; and (9), sealing and packaging so as to obtain the invented product.

Owner:SICHUAN HUATONG LEMON

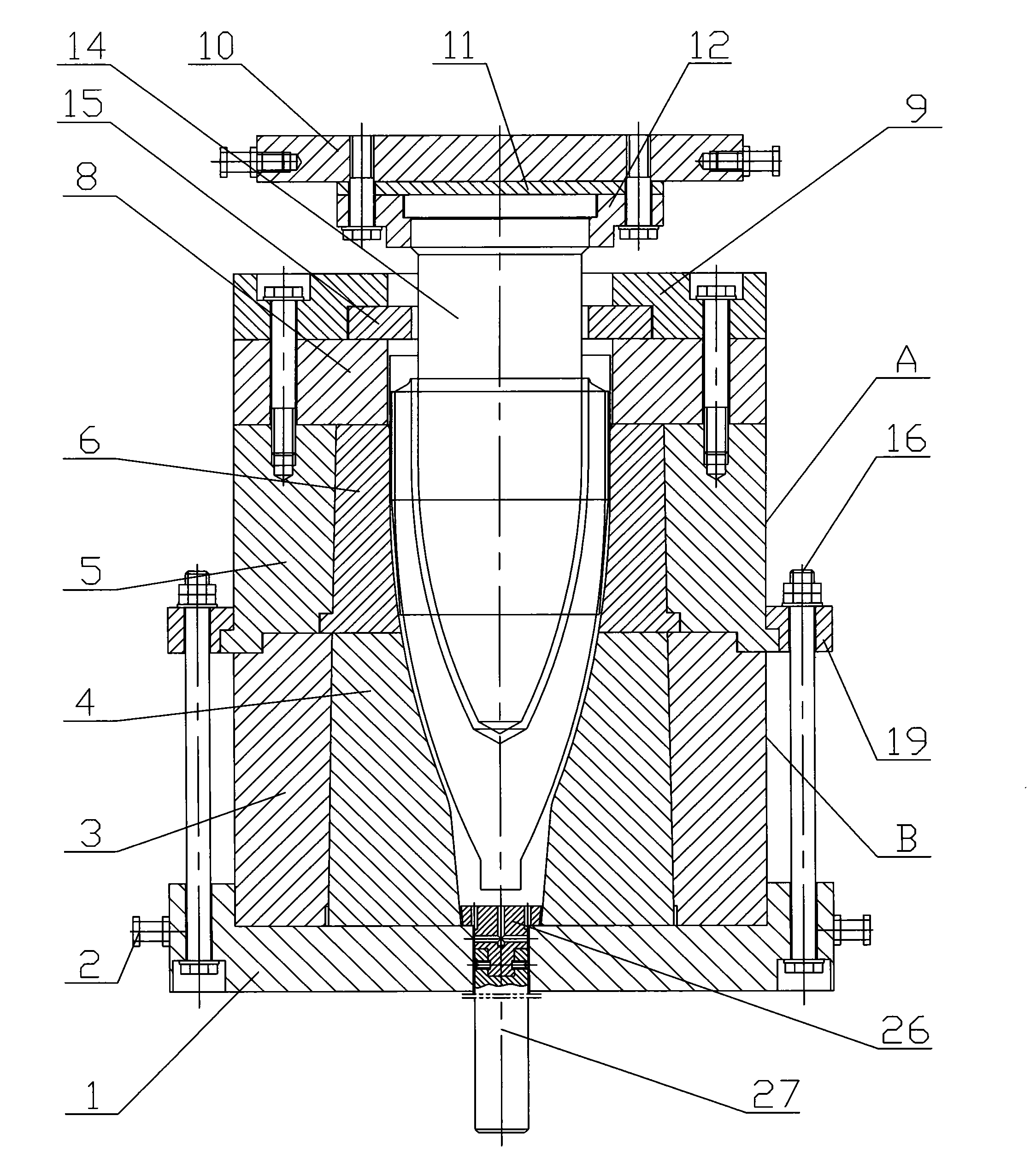

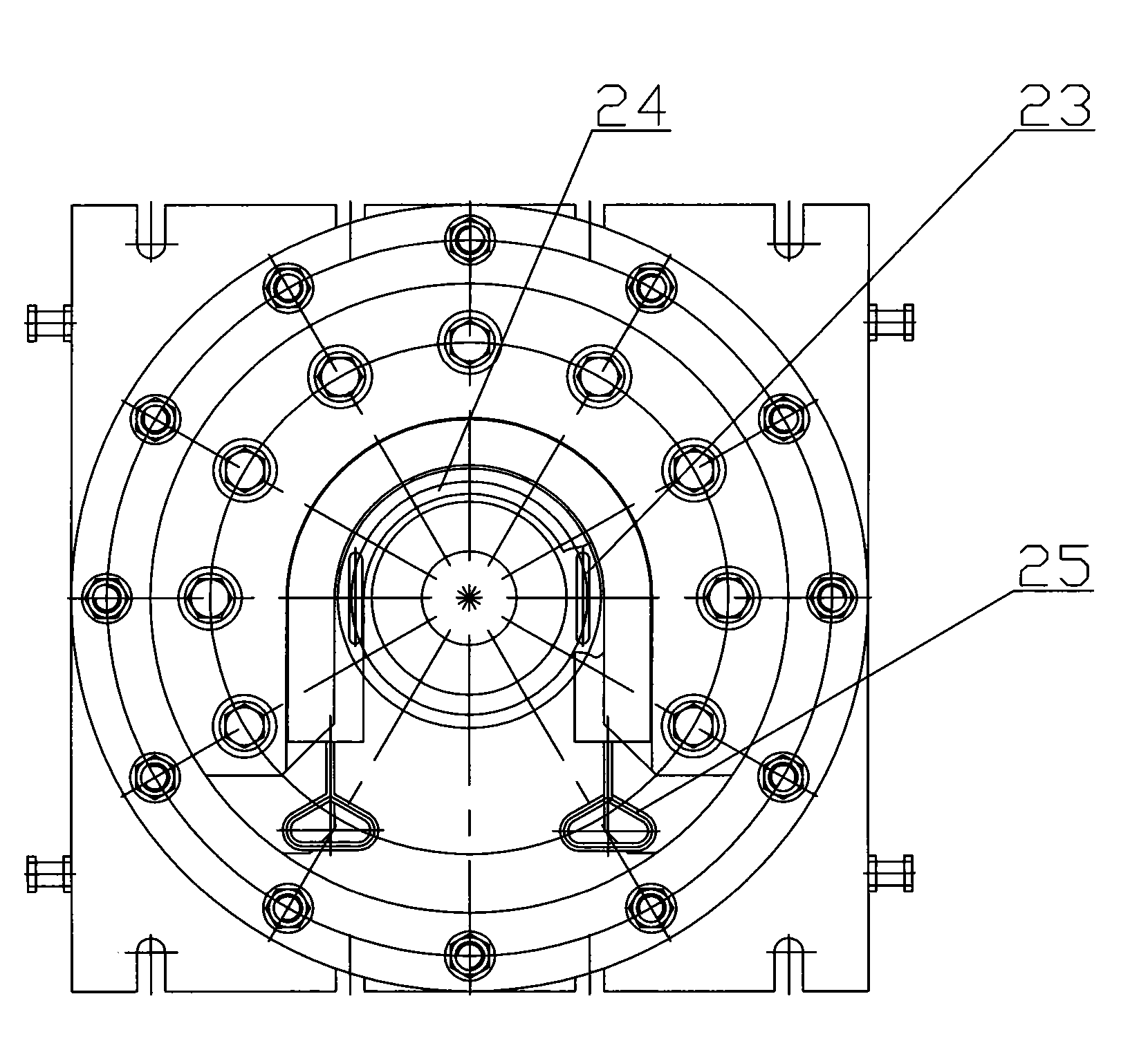

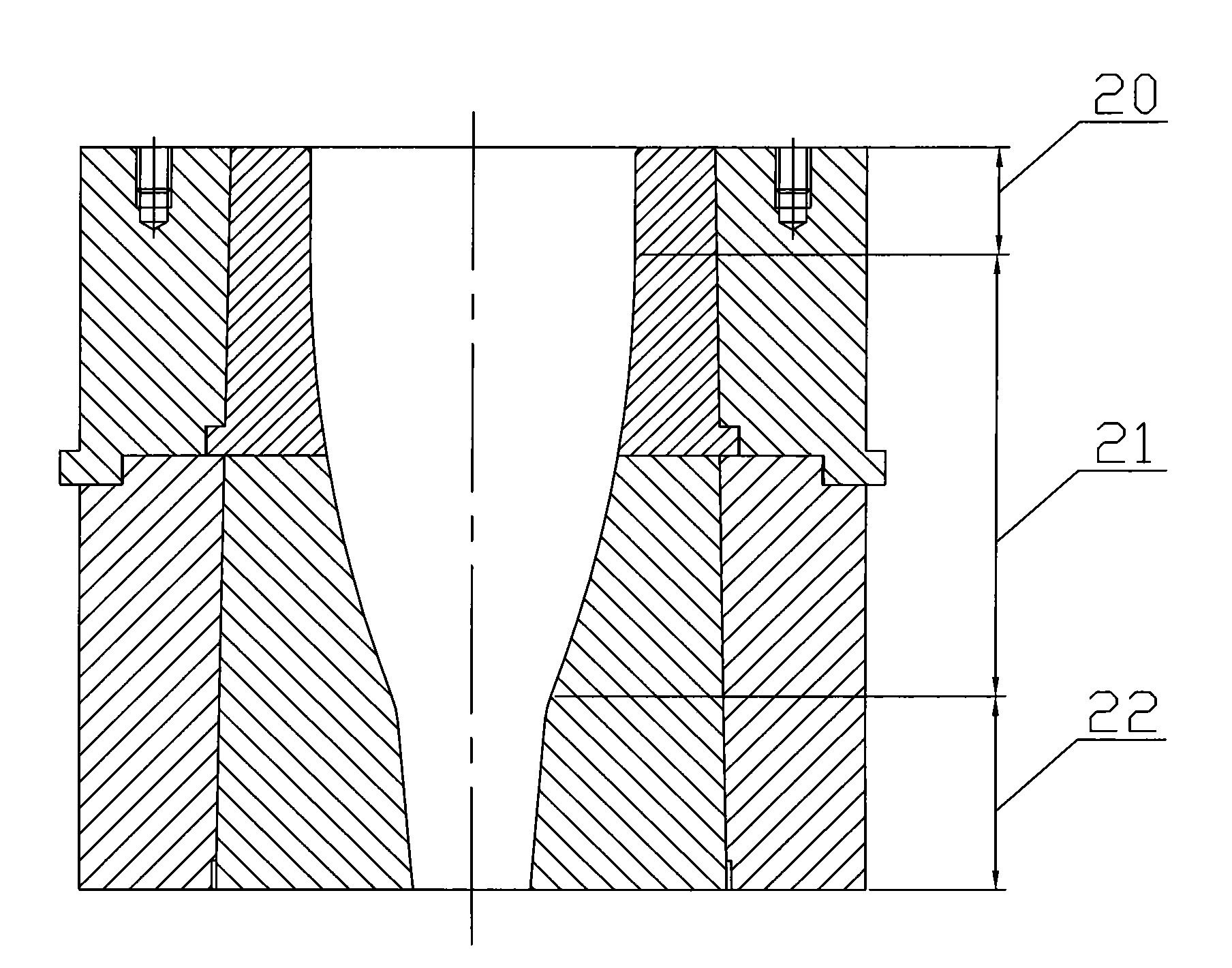

Extrusion die and method for extrusion molding inside and outside reduction blank by same

The invention provides an extrusion die and a method for extrusion molding inside and outside reduction blank by the same, which relate to a die and a method for extrusion molding blanks by the die, and are aimed to solve the problems that the adoption of the common blank extrusion molding die and method cannot mold a workpiece with an external shape of one end of a larger diameter and the other end of a smaller diameter, and the workpiece with an internal hole end of a larger diameter, a bottom part of a smaller internal diameter and a long axial length. The die is characterized in that a second assembly is arranged on a lower die seat; a first assembly is arranged on a second assembly; the die holes of a first lower die and a second lower die are combined to form into a lower die cavity; a cushion block and a discharging plate are detachably connected with a first pre-stressed ring; a convex die is arranged in the lower die cavity; the connection part of the convex die is arranged in a stepped through hole of a fixing plate of the convex die; and the fixing plate of the convex die is detachably connected with the cushion block and an upper die seat. The method comprises the following steps of blanking, turning, heating, extruding and annealing treatments, wherein the heating temperature is between 1100 DEG C and 1150 DEG C. With the adoption of the extrusion die and the method provided by the invention, the extrusion molding of inside and outside reduction blanks can be realized.

Owner:HARBIN JIANCHENG GRP

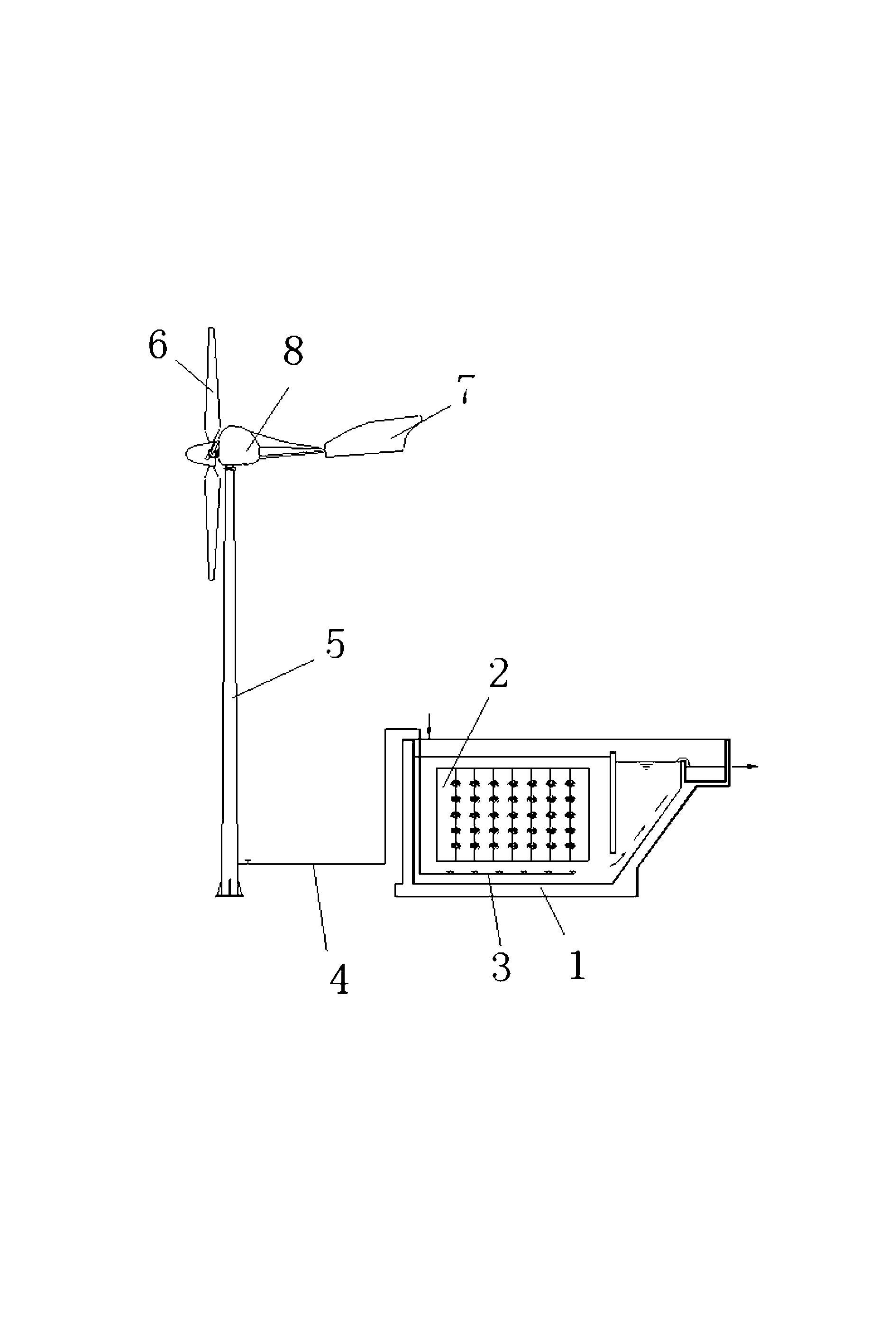

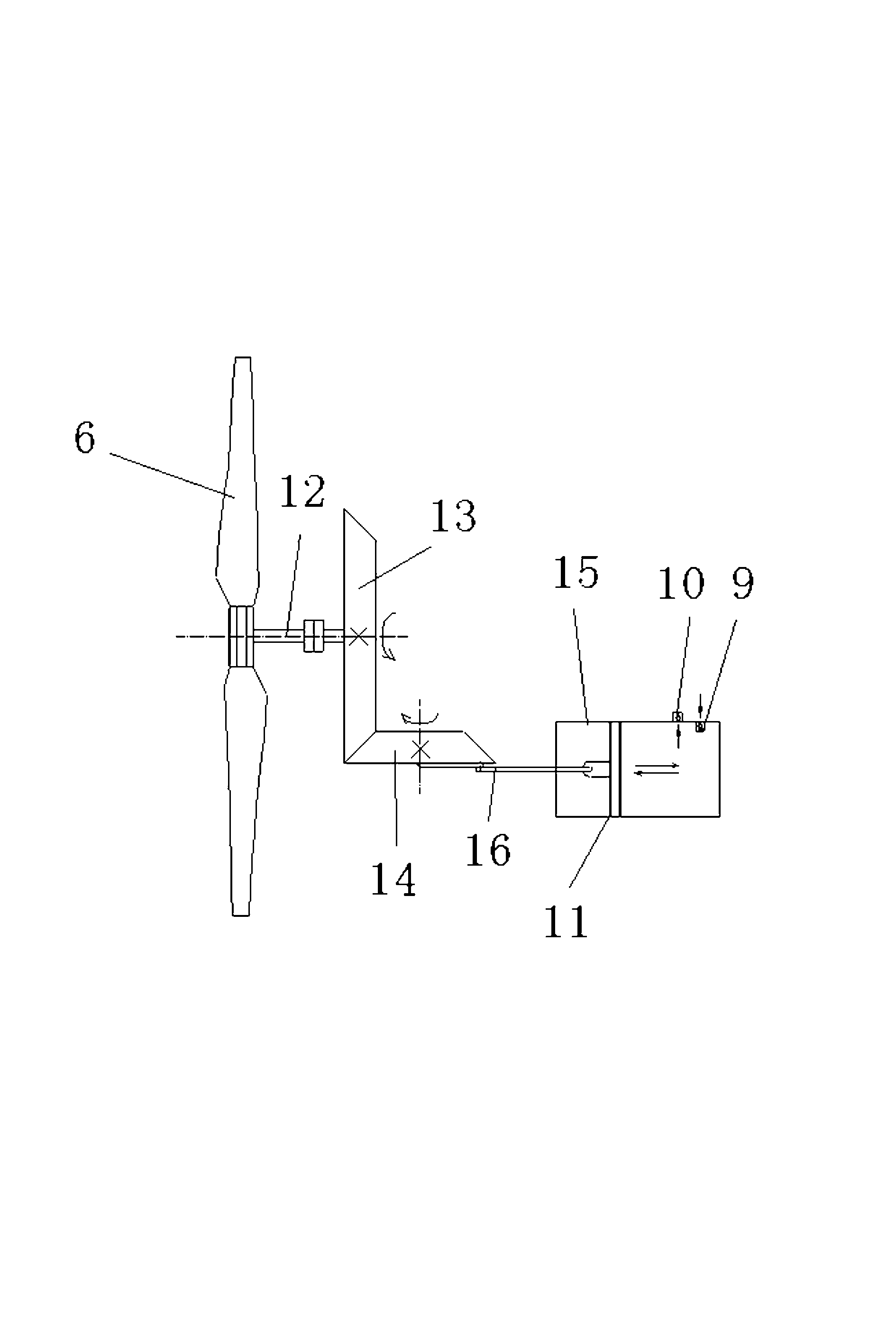

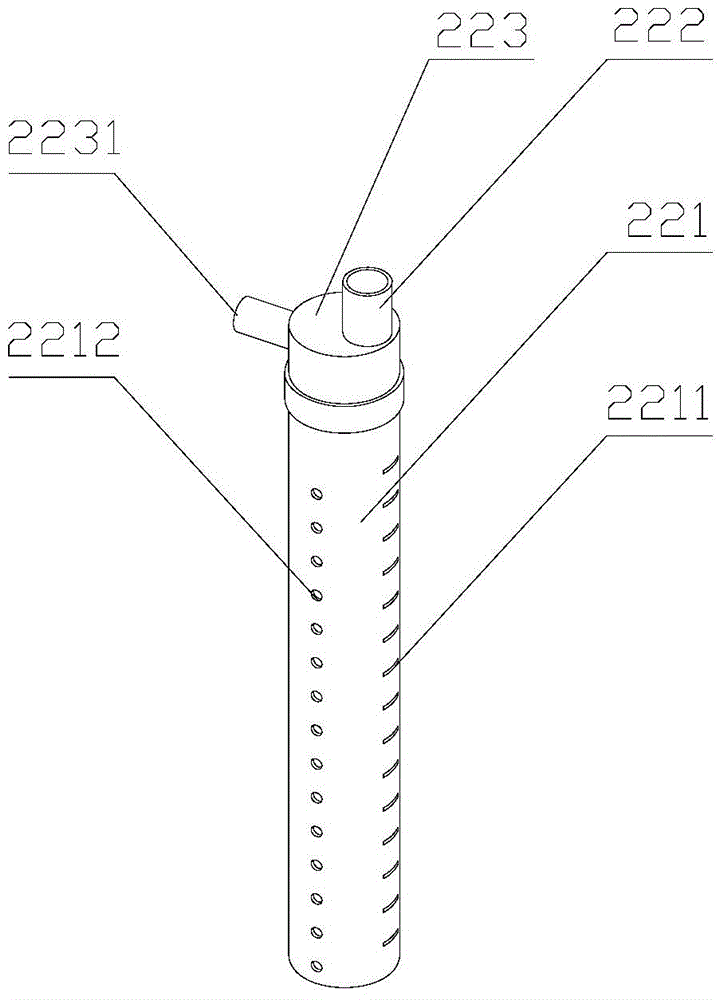

Wind-energy oxygen supply type countryside life sewage processing device and method

ActiveCN103130320AReduce lossesLarge air supplyTreatment using aerobic processesEnergy based wastewater treatmentMembrane methodSmall footprint

The invention provides a wind-energy oxygen supply type countryside life sewage processing device. The device is characterized in that a contacting oxidation pond comprises a pond body, a padding layer is arranged in the pond body, and a micro-hole aerator is arranged below the padding layer and is connected with a wind-energy oxygen supply machine through an air pipeline. According to the device, wind-energy oxygen supply technology and sewage biology membrane method processing technology are utilized, wind-energy oxygen supply type countryside sewage processing technology is developed, a corresponding device is constructed and is used for countryside life sewage processing, and therefore the improvement of the countryside ecology environment is provided with economic and effective technology support. The device gives full play to no energy consumption characteristic of the wind-energy oxygen supply technology and easy management of the biology membrane method processing technology, realizes organic integration of the energy saving and consumption reducing technology and pollution emission reduction technology, has the advantages of being free of power consumption, high in processing efficiency, convenient to manage, simple in operation, small in occupied area, and the like, and meeting requirements of countryside life for processing sewage.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Low-cost self-leveling mortar

The invention discloses a low-cost self-leveling mortar. The low-cost self-leveling mortar comprises the following components in proportions: 22-35% of quartz sand, 20-40% of modified fluorine gypsum, 18-25% of silicate cement, 4-18% of aluminate cement, 3-8% of zeolite powder, 4-8% of wollastonite powder, 8-18% of rapid hardening cement, 0.05-1.5% of de-foaming agent, 0.05-1% of water reducing agent, 0.05-0.3% of retarder, 0.01-2% of leveling agent, 0.1-2% of lignocelluloses, 0.1-2% of hydroxyethylcellulose, 0.1-2% of methylcellulose, 1-6% of casein and 0.02-0.06% of lithium carbonate. The low-cost self-leveling mortar has the advantages of high leveling property, wear resistance, stability, breaking strength and the like, good quality, high efficiency, low cost and helpfulness for energy saving, consumption reduction and environment improvement.

Owner:徐敏

Preparation method of polyacrylonitrile-based high-strength high-modulus carbon fibers

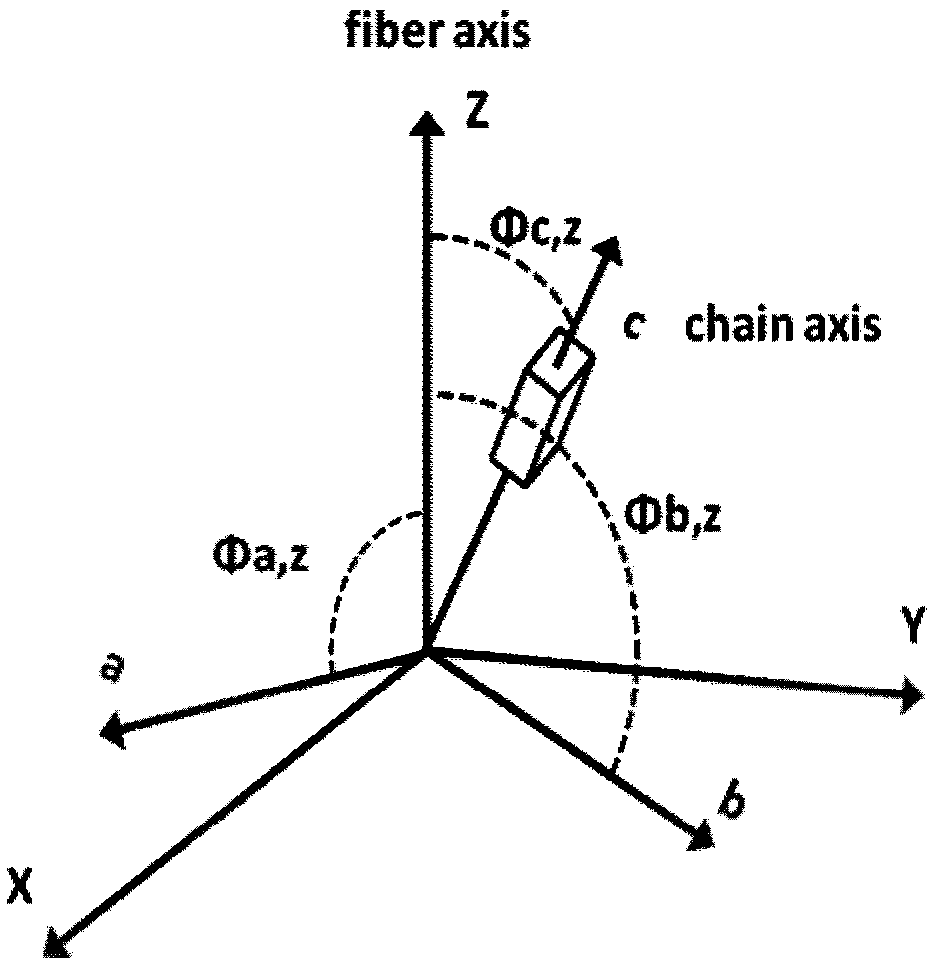

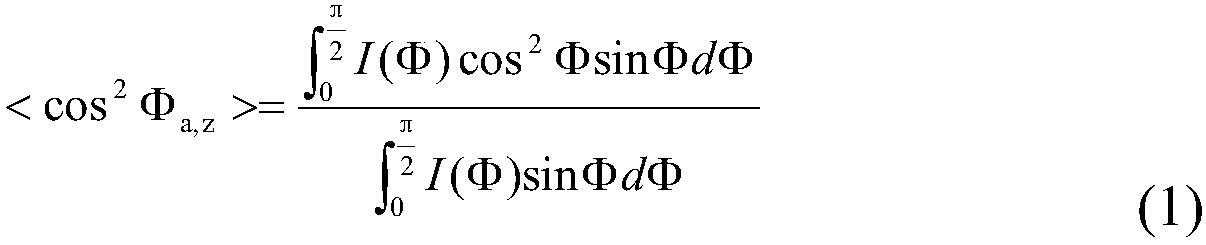

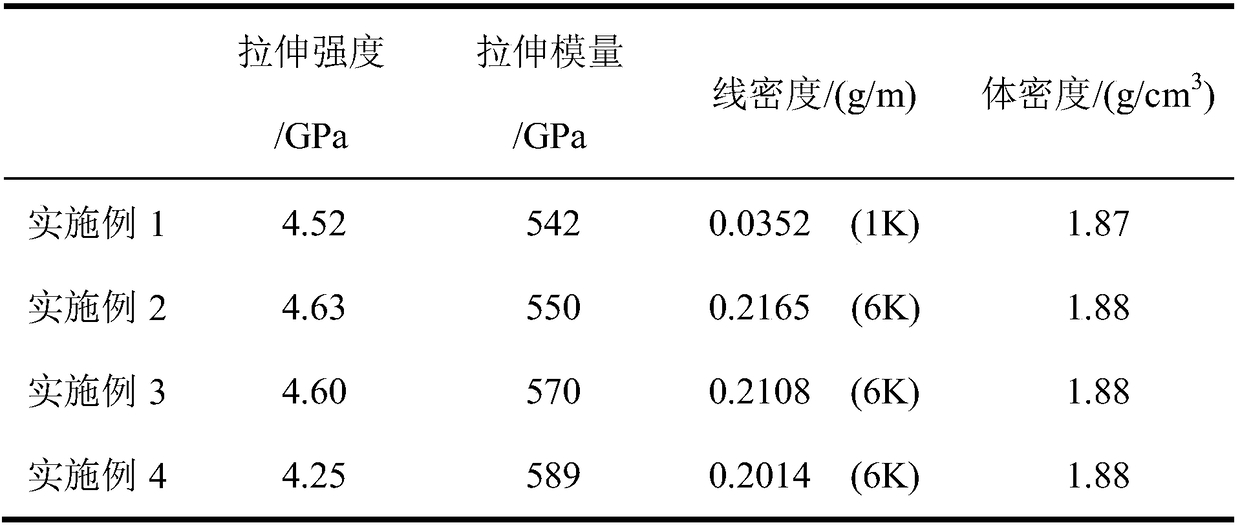

ActiveCN108286090AImprove stretching efficiencyLow processing temperatureFibre chemical featuresCarbonizationPolyacrylonitrile

The invention relates to a preparation method of polyacrylonitrile-based high-strength high-modulus carbon fibers. After polyacrylonitrile (PAN) precursors are subjected to conventional pre-oxidationand low-temperature carbonization, the carbon crystalline orientation can be effectively controlled by increasing the high-temperature carbonization temperature and matching a certain stretching, or increasing the high-temperature carbonization stretching ratio to obtain high-temperature carbonized fibers with an orientation angle of being not greater than 17.5 degrees, and high-temperature graphitization hot drawing treatment is conducted at a relatively low temperature to obtain the high-strength high-modulus carbon fibers with tensile strength of 3.8-5.0 GPa and tensile modulus of 500-600 GPa. The preparation method reduces the requirements on equipment for high-temperature graphitization, which is beneficial to energy saving and cost reduction, and the operation is simple and easy.

Owner:BEIJING UNIV OF CHEM TECH

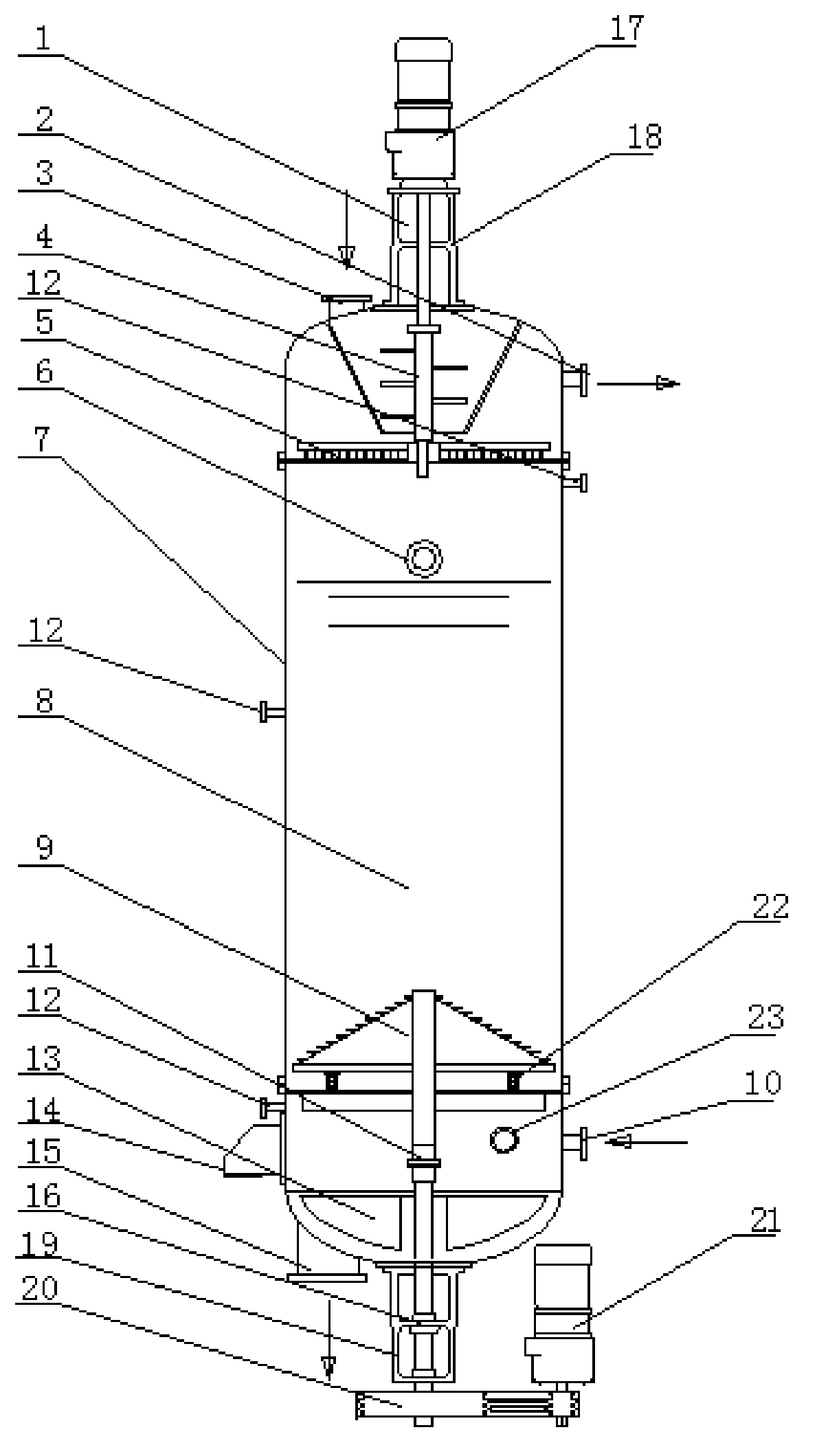

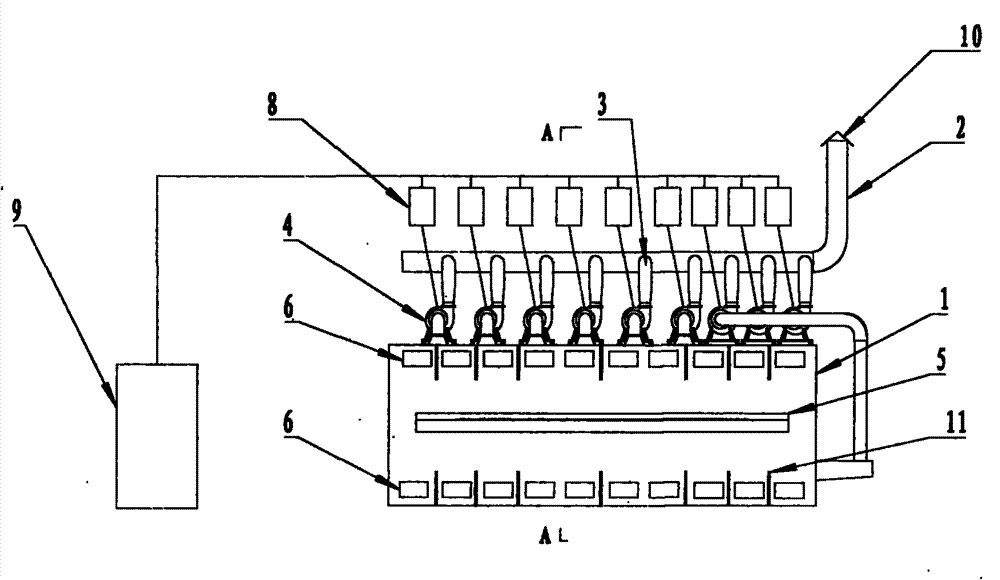

Device of producing wine by continuously distilling solid fermented grains

InactiveCN103131616AEfficient recyclingThe distillation process is stable and continuousAlcoholic beverage preparationChemistryProcess engineering

The invention relates to a device of producing wine by continuously distilling solid fermented grains. The device comprises an upper rotary device, a distillation tower shell body and a lower rotary device, wherein the upper rotary device, the distillation tower shell body and the lower rotary device are connected in sequence. The distillation tower shell body is in a cylinder shape or is a circular-truncated-cone-shaped tower. A solid fermented grain material inlet is formed in the top of the distillation tower shell body. A wine-steam outlet is formed at the upper side portion of the distillation tower shell body. A water steam inlet, a pressure measurement opening and a wine fermented grain distillation residue outlet are formed at the lower portion of the distillation tower shell body. A plurality of temperature measurement openings are formed at different positions of the distillation tower shell body. A support is arranged at the lower portion of the distillation tower shell body. A material loosening device, a material distributing device, an unloader, a coupler and a material collecting plate are arranged inside the distillation tower shell body from top to bottom in sequence. A distillation bed of steam-liquid-solid three-phrase heat and mass transfer is formed in the space between the material distributing device and the unloader. The device can achieve high-efficiency, high-yield and continuous distillation solid fermented grains to produce the wine and has the advantages of reducing pollution, saving energy and reducing consumption at the same time.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

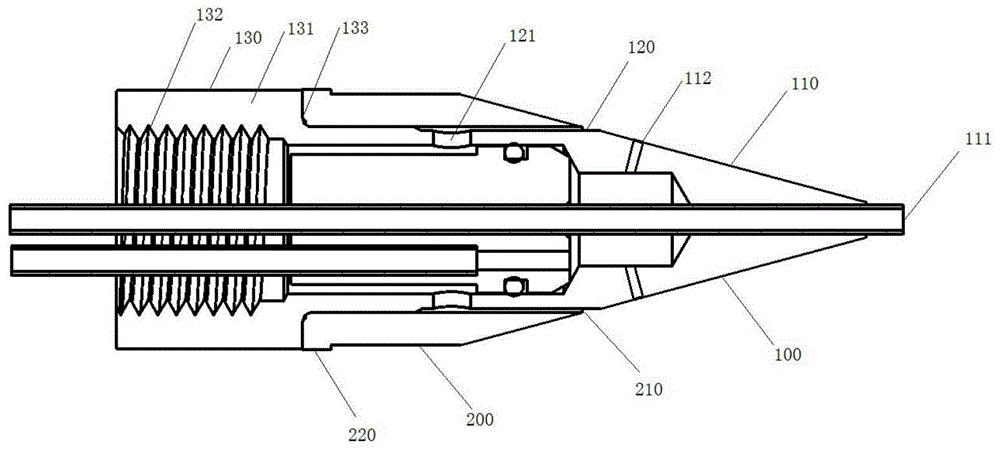

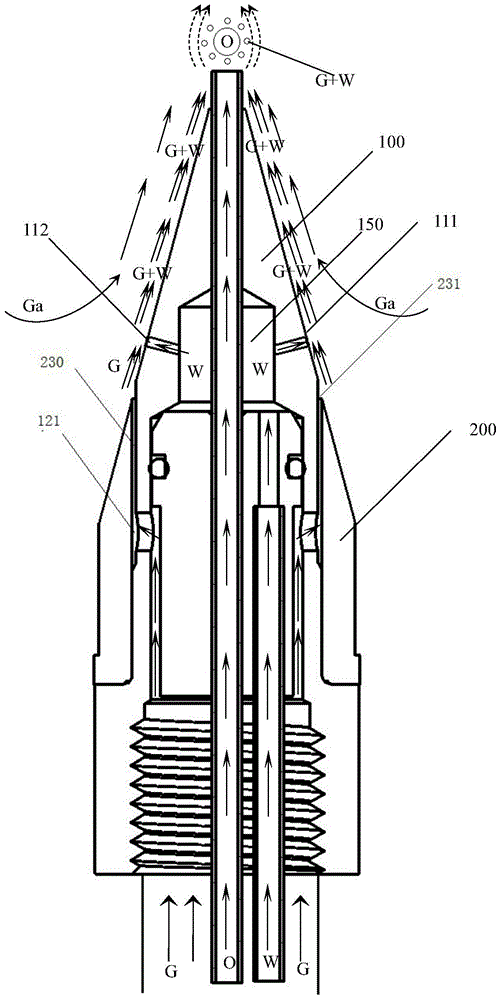

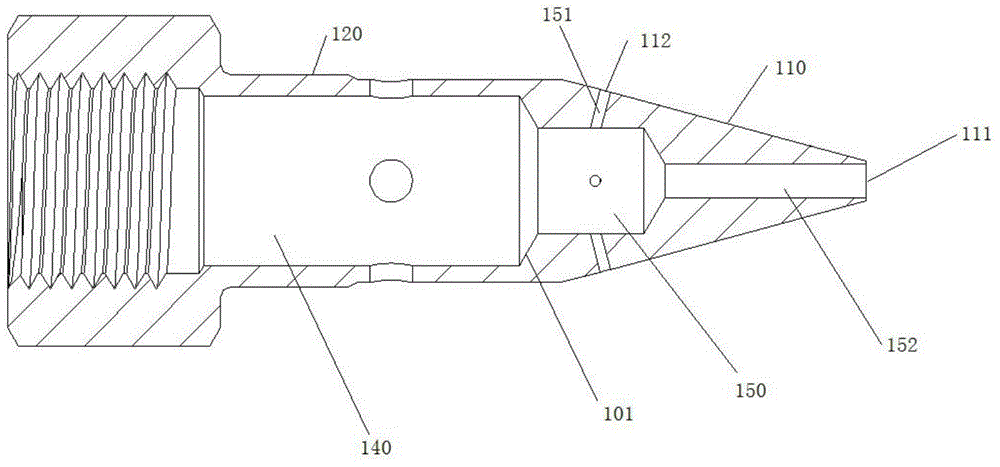

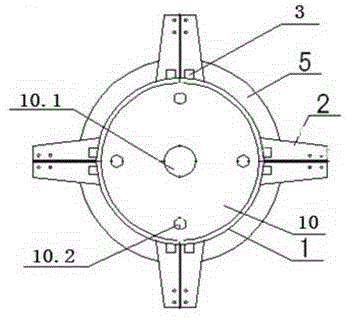

Oil-water-gas three-phase mixing nozzle and nozzle system comprising same

ActiveCN104985477AReduce precisionHigh surface finishSpray nozzlesLiquid spraying apparatusSpray nozzleOil water

The invention provides an oil-water-gas three-phase mixing nozzle which is characterized by comprising a nozzle body and a nesting ring, wherein the nozzle body comprises a head part, a middle part and a bottom part; the head part of the nozzle body is a cone, a jet hole is formed in the top end of the cone, and at least two water spray holes are uniformly distributed in the cone; the middle part of the nozzle body is a cylinder, and at least two gas holes are uniformly formed in the cylinder; the bottom part of the nozzle body is of a thread structure; the nesting ring and the middle part of the nozzle body form a clearance structure in a matching manner. The oil-water-gas three-phase mixing nozzle is simple in design and is suitable for a variety of oils and used in trace lubrication devices for metal processing.

Owner:苏州金兆环保节能设备有限公司

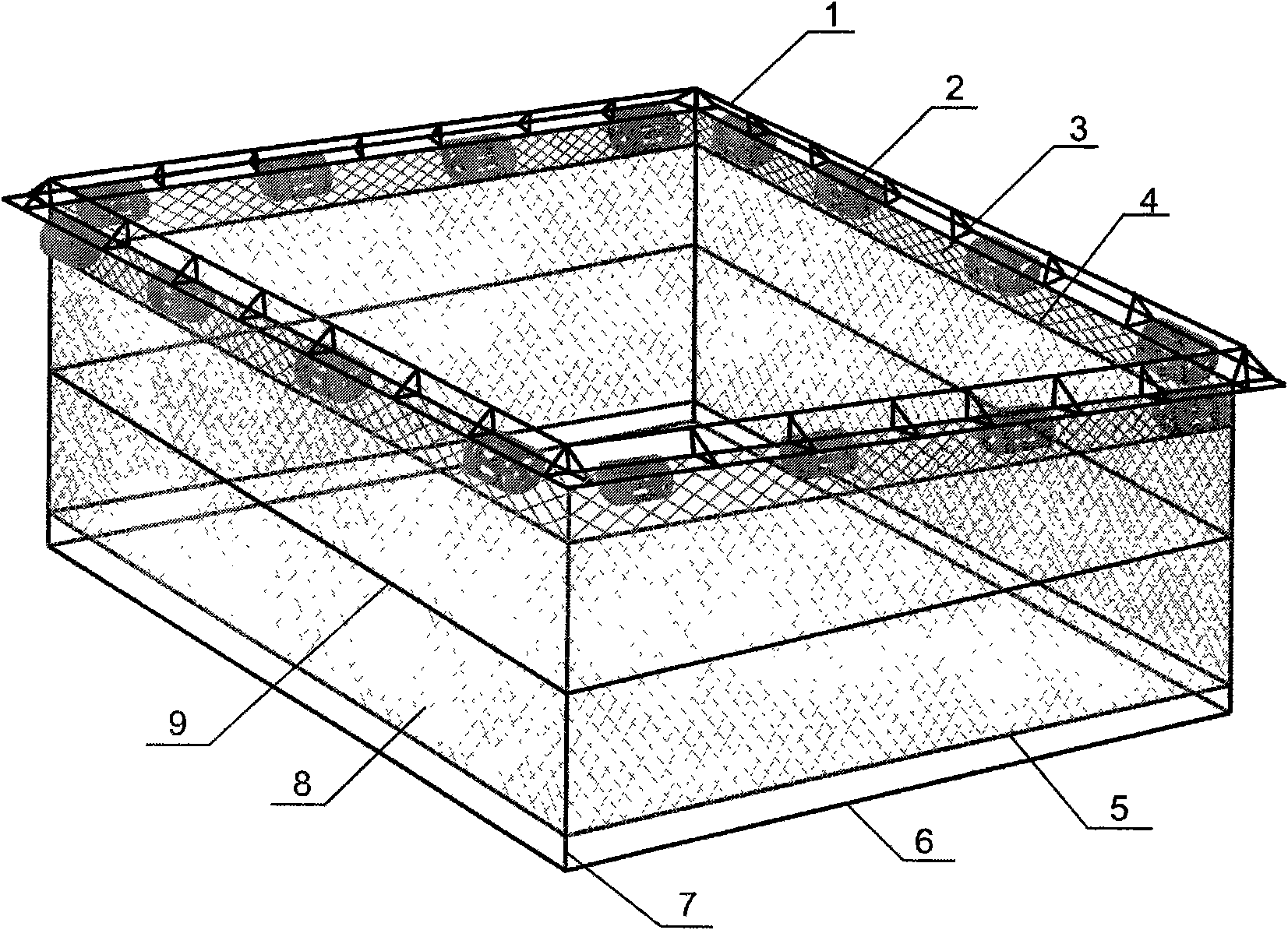

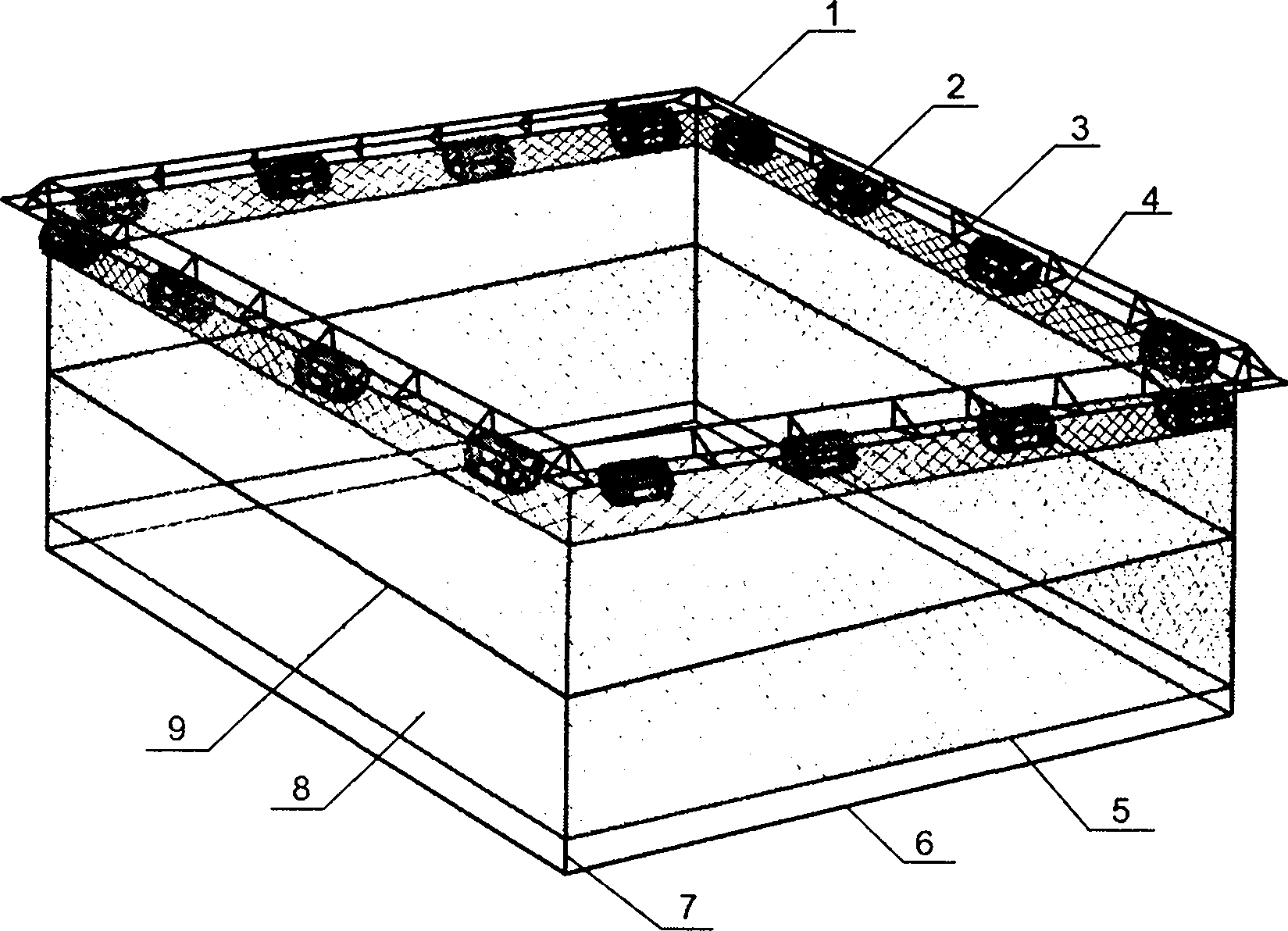

Method for manufacturing antifouling and antibiosis type yellow croaker net cage

InactiveCN102763610AReduce harmImprove survival rateClimate change adaptationPisciculture and aquariaAntibiosisEngineering

The invention discloses a method for manufacturing an antifouling and antibiosis type yellow croaker net cage, which relates to a method for manufacturing a mariculture net cage. According to the invention, the method for manufacturing the antifouling and antibiosis type yellow croaker net cage adopts a buoyancy force system and a netting system, and is characterized in that the buoyancy force system adopts a combination buoyancy force form of 'an anti-aging high-density polyethylene double-floating-pipe cylindrical frame structure + 18 cube cystosepiments with each edge length of 60cm; the netting system adopts a combination structure netting form of 'a first box longitudinal netting + a second box longitudinal netting + a net cage bottom netting; the net cage bottom netting is assembledon a circular high-density polyethylene pipe support which is wrapped with a layer of polyamide multifilament wrap knitting net; and three cross lacing lines are installed at the bottom of the net cage, a polypropylene rope is tied at the cross point of the cross lacing lines, and two foam float bowls which are externally wrapped by double-layer seawater corrosion protection canva and nylon nets are tied at the other end of the polypropylene rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

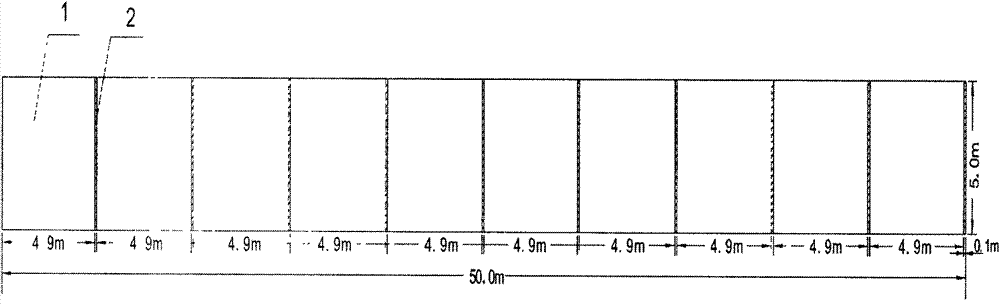

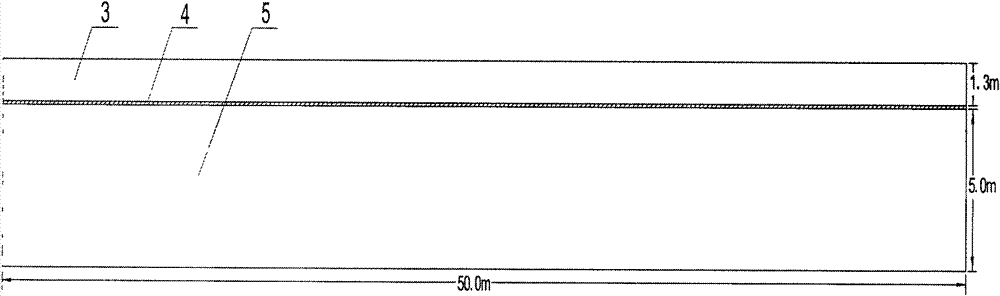

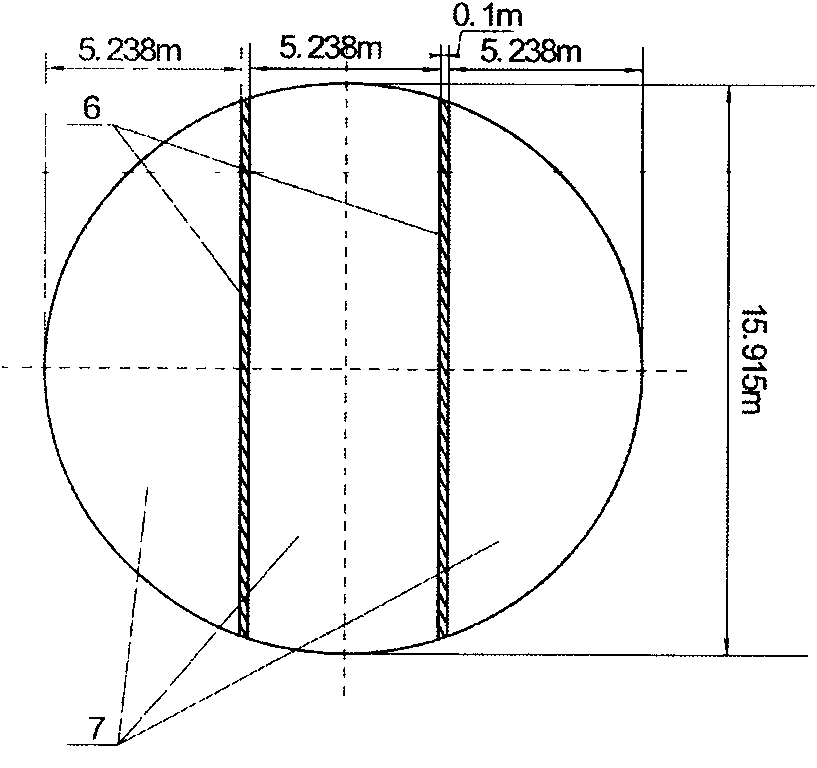

Method for making turbot cultivation net cage

InactiveCN102308764ASolve the problem of energy saving and consumption reductionReduce energy saving and consumption reductionClimate change adaptationWire networkPolyamideSynthetic fiber

The invention discloses a method for making a turbot cultivation net cage, and relates to making of turbot cultivation equipment. In the method, a galvanized iron pipe, a high-strength single fast knot polyethylene net, a high-strength polyamide wrap knitting net, a high-strength fishing polyethylene rope, a cylindrical plastic foam floater, high-strength fishing lines and a copper alloy (LC68700) stretching net are used. The method is characterized in that: a net cage floating support is made of a hot-dip galvanized iron pipe; the cylinder plastic foam floater is coated with waterproof clothand a layer of waste netting; a netting system for the net cage consists of a double-layer synthetic fiber netting serving as a first netting and the combined copper alloy (LC68700) stretching net serving a second netting; the first netting and the second netting are connected in a vertical half-soft mode; the net bottom of the net cage is provided with a square synthetic fiber netting; a square galvanized iron pipe framework is hung under the net bottom of the net cage; horizontal outlines and vertical force outlines are arranged on a side-surface netting of a cage body of the net cage; and the net cage floating support is connected with a floating rope frame matched with the net cage system through by a cable.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

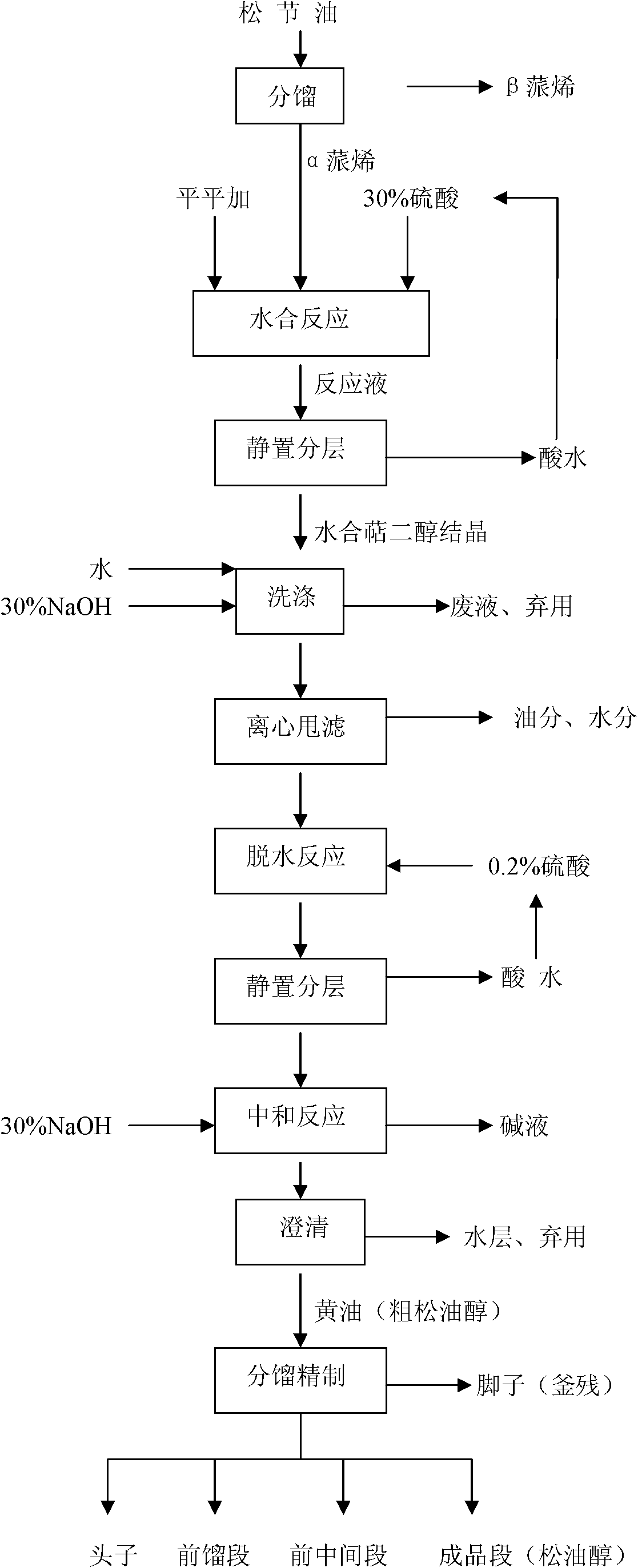

Method for synthesis of terpineol by supersonic wave assistance

ActiveCN102627528AReduce generationEmission reductionPreparation by OH group eliminationUltrasonic assistedCavitation

The invention discloses a method for synthesis of terpineol by supersonic wave assistance. The method is characterized in that through a two-step technology, hydration, dehydration and neutralization are carried out under supersonic wave assistance. Through preferable selection of appropriate supersonic wave parameters and utilization of cavitation of supersonic waves, reinforcement emulsification effects are improved; reaction rates and selectivity of hydration and dehydration are improved; efficiency of neutralization washing is reinforced; and the consumption of washing water is reduced.

Owner:云南森美达生物科技股份有限公司

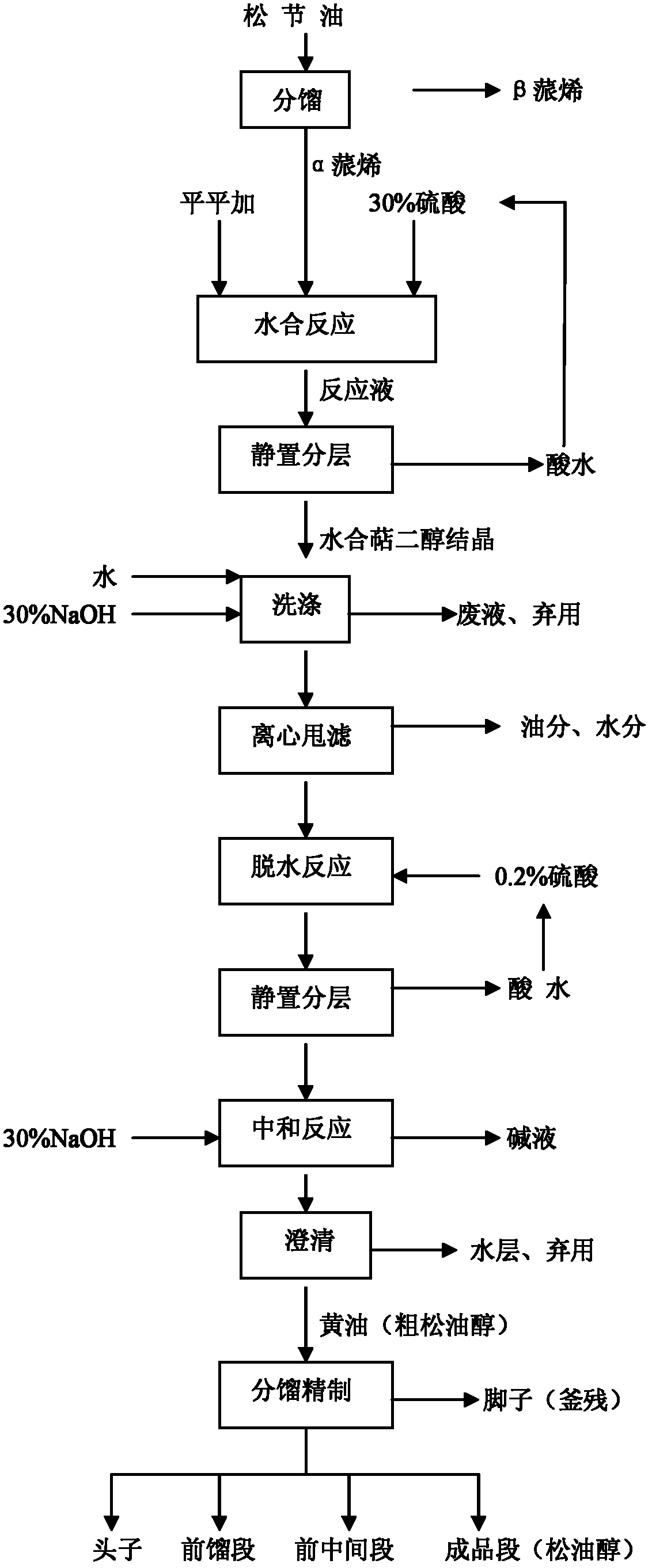

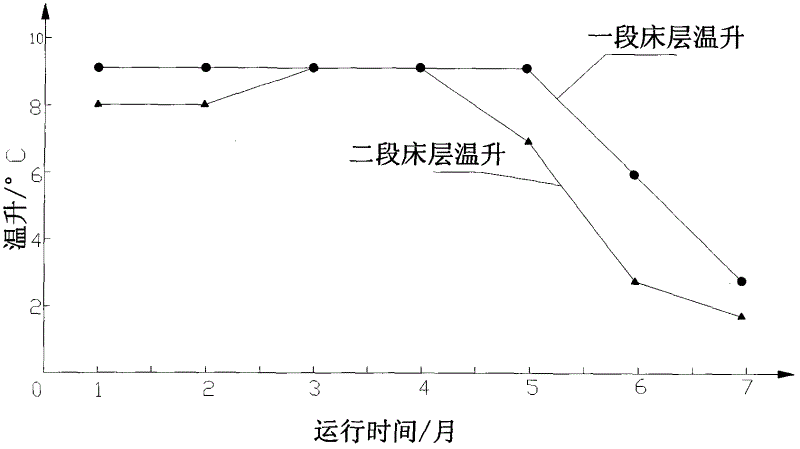

On-line agent changing method of methyl tert-butyl ether (MTBE) expanded bed reactor

InactiveCN102617296AIncrease production capacityThe agent changing process is simpleEther preparation by compound additionMethyl tert-butyl etherChemistry

The invention discloses an on-line agent changing method of a methyl tert-butyl ether (MTBE) expanded bed reactor. A first-stage reactor and a second-stage reactor are selectively cut out from a reaction unit at proper time according to the inactivation degree of catalysts in the two reactors, catalysts in the corresponding reactors are replaced, the second-stage reactor and the first-stage reactor still realize independent production and operation, the work of the device does not stop, and the goal of isolation cyclic agent changing is realized. The agent changing method provided by the invention has the characteristics that the operation is simple, and the operation is easy.

Owner:XI'AN PETROLEUM UNIVERSITY

Energy-saving system of cooling air hose of glass annealing kiln and cooling method of glass tape

The invention relate to an energy-saving system of a cooling air hose of a glass annealing kiln and a cooling method of a glass tape. Each pipeline is equipped with a draught fan which is provided with a frequency converter, and the frequency converters are freely controlled by an industrial personal computer to reaching the purpose of adjusting the rotating speed of the draught fans, so that each branch air hose is more convenient to control. The size of the cooling air amount of each branch air hose can be conveniently adjusted according to the temperature adjusting demands of glass plates in different regions, so that the temperatures in each region in the annealing kiln is reasonable and the best glass annealing effect is achieved. The equipment investment is reduced, the pipeline system is simplified, the energy utilization rate of the manufacturer is greatly improved and the electric energy consumption of the ventilating system of the annealing kiln is reduced, so that the effect of saving energy and protecting the environment is realized.

Owner:洛阳建材机械厂

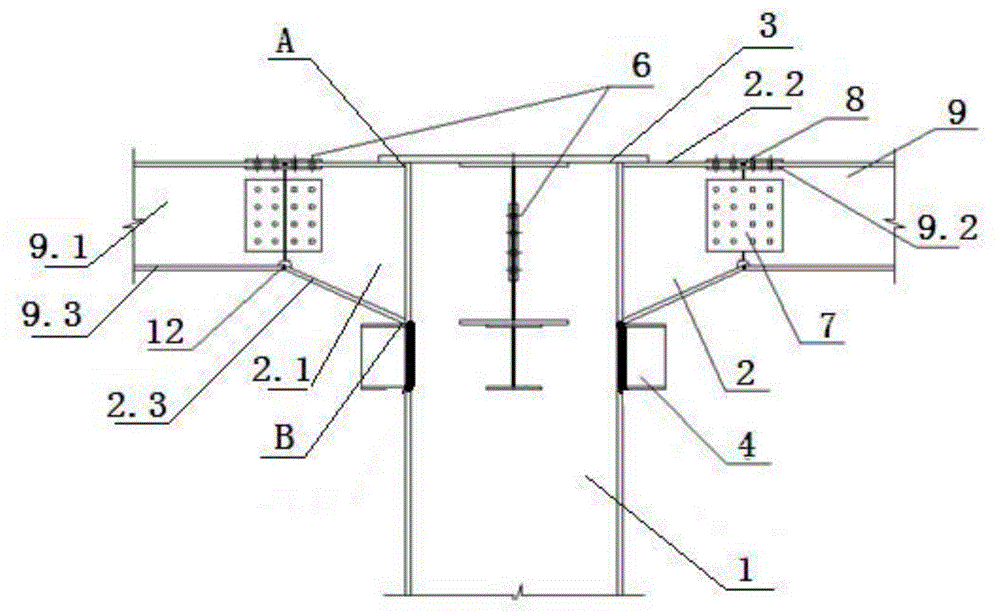

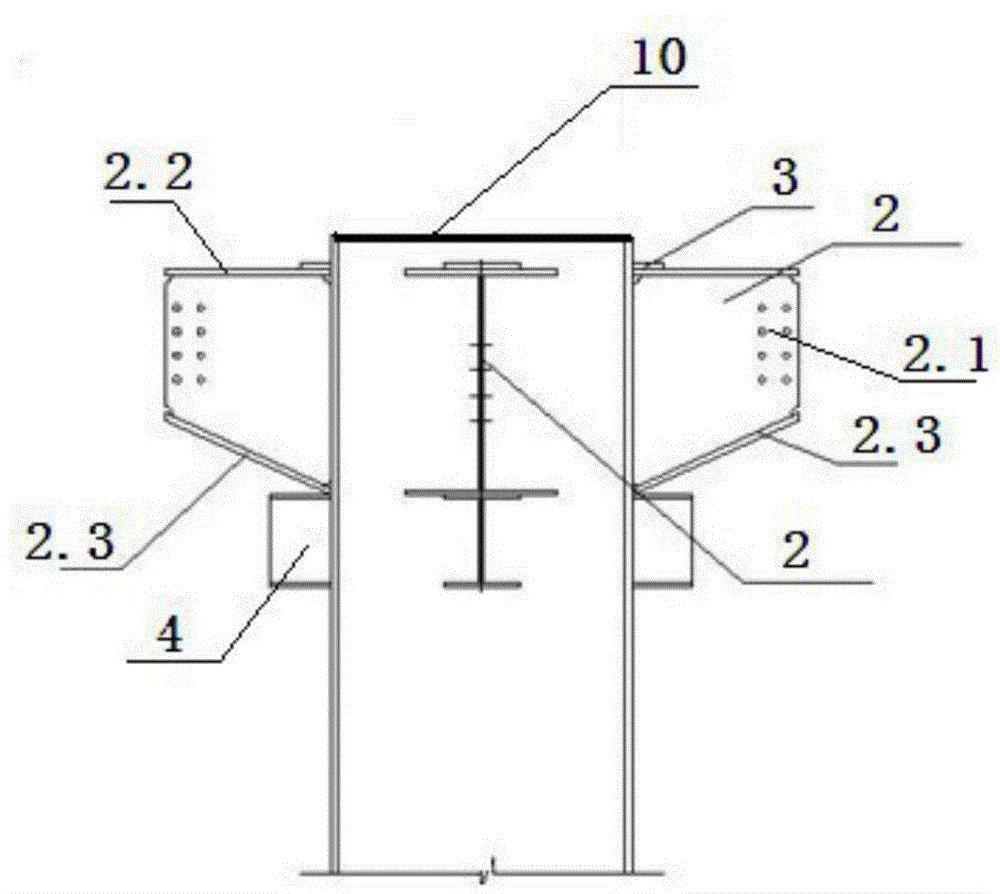

Steel stand column beam

InactiveCN104405042AIncrease profitGuaranteed appearanceBuilding constructionsEngineeringEnergy conservation

The invention discloses a steel stand column beam. The steel stand column beam comprises a steel stand column and a plurality of column beam connecting node components, wherein the plurality of column beam connecting node components are in central symmetry and are uniformly distributed along the outer wall of the steel stand column; each column beam connecting node component comprises a web, an upper flange plate and a lower flange plate; an upper connecting node A is provided with a fixed limiting plate, and a lower connecting node B is provided with a limiting bracket; and the steel stand column beam also comprises a plurality of first clamping plates and a plurality of second clamping plates, and each clamping plate is provided with a high-strength bolt connection pair; the web is connected with a main plate of an H-shaped steel beam through the first clamping plates; the upper flange plate is connected with an upper plate of the H-shaped steel beam through the second clamping plates; a cover plate is arranged on the top end surface of the steel stand column, and a grouting hole and a plurality of vent holes are formed on the cover plate; two flange ring stiffened plates are arranged on the middle part in the steel stand column. By adopting the steel stand column beam, the steel stand column beam technology is more advanced, the process is more complete, safe and applicable, the quality is better guaranteed, the utilization rate of the plate is increased, the energy conservation and consumption reduction can be realized, the environment-friendly requirement can be met, and the component quality and construction quality can be improved.

Owner:湖北源盛钢构有限公司

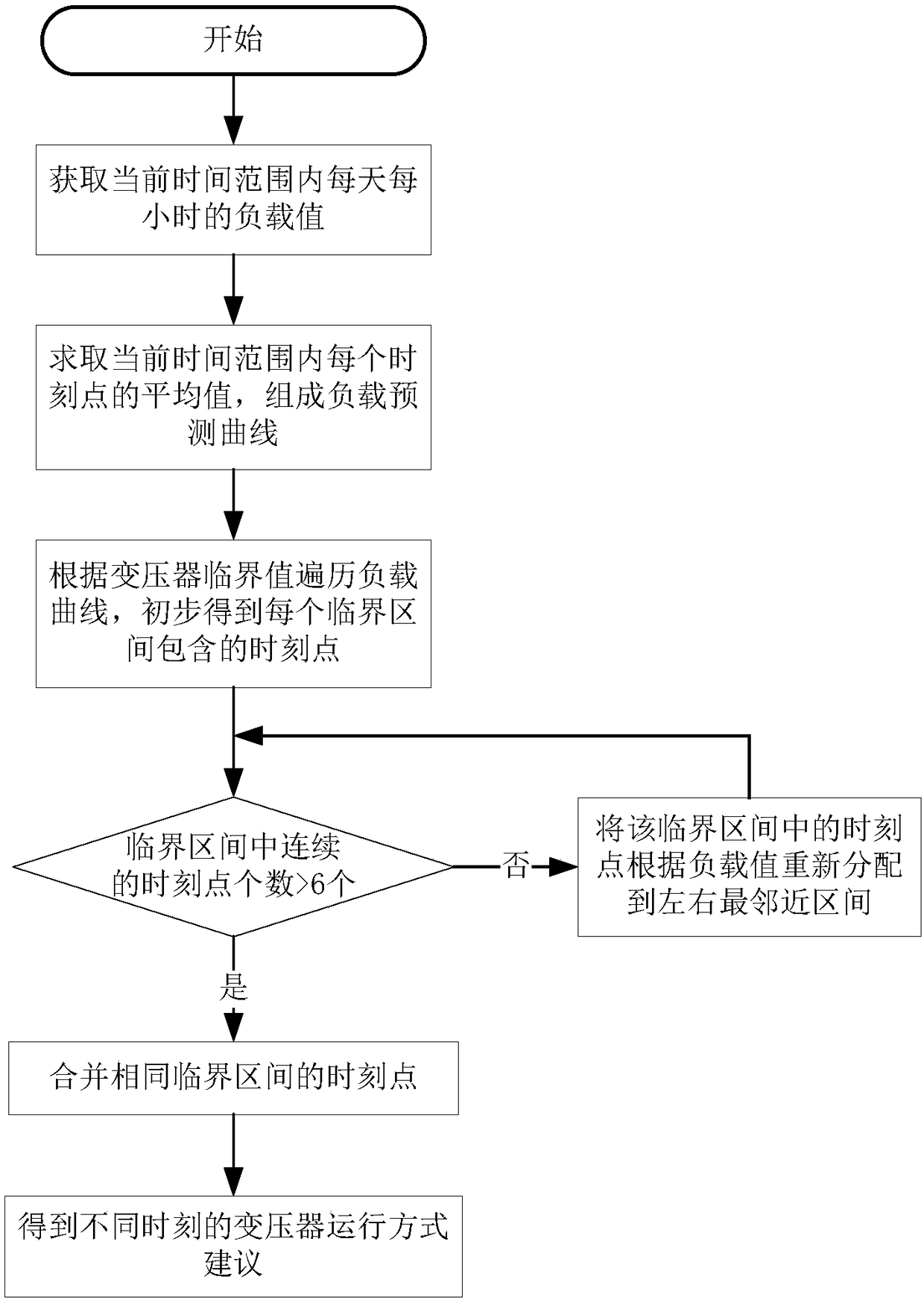

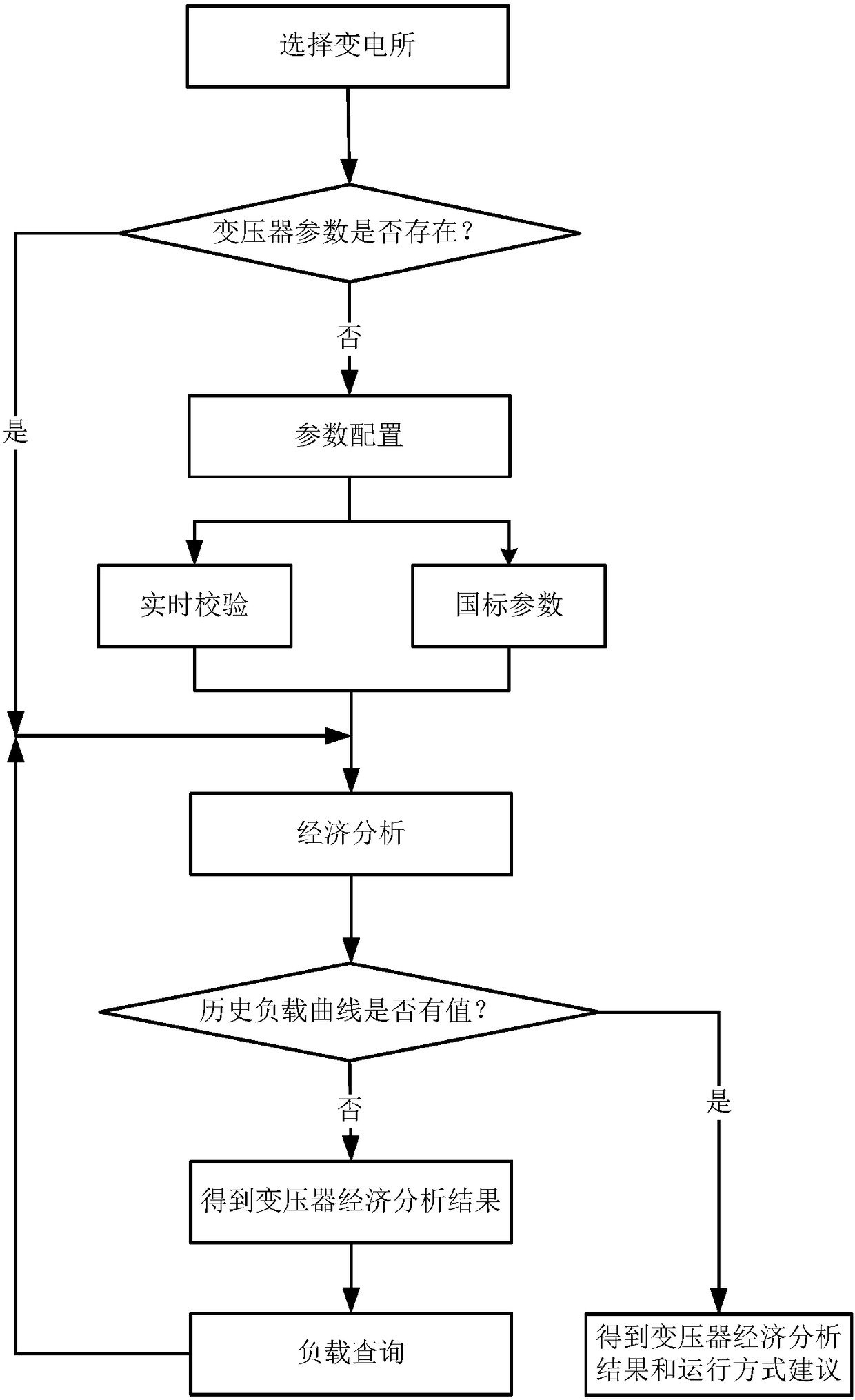

Intelligent on-line analysis system for transformer operation

InactiveCN108805310AReduce lossReduce energy saving and consumption reductionForecastingResourcesTransformerSimulation

The invention relates to economical operation mode research and operation suggestion prediction of a transformer, in particular to an intelligent on-line analysis system for transformer operation. Thesystem comprises an equipment tree, a transformer parameter configuration module, a load inquiry module and an analysis display module. The load data of the actual operation of the transform is utilized to intelligently forecast the load condition of the transformer in the future, and finally, the economic operation report of the transformer and the operation mode suggestions of the transformer in different time periods are given, a convenient intelligent means for mastering the economic operation situation and trend of the transformer is given, and the economy of the transformer operation inthe distribution network can be effectively improved and the overall electric energy loss of the distribution network system is reduced.

Owner:SUWEN ELECTRIC ENERGY TECH

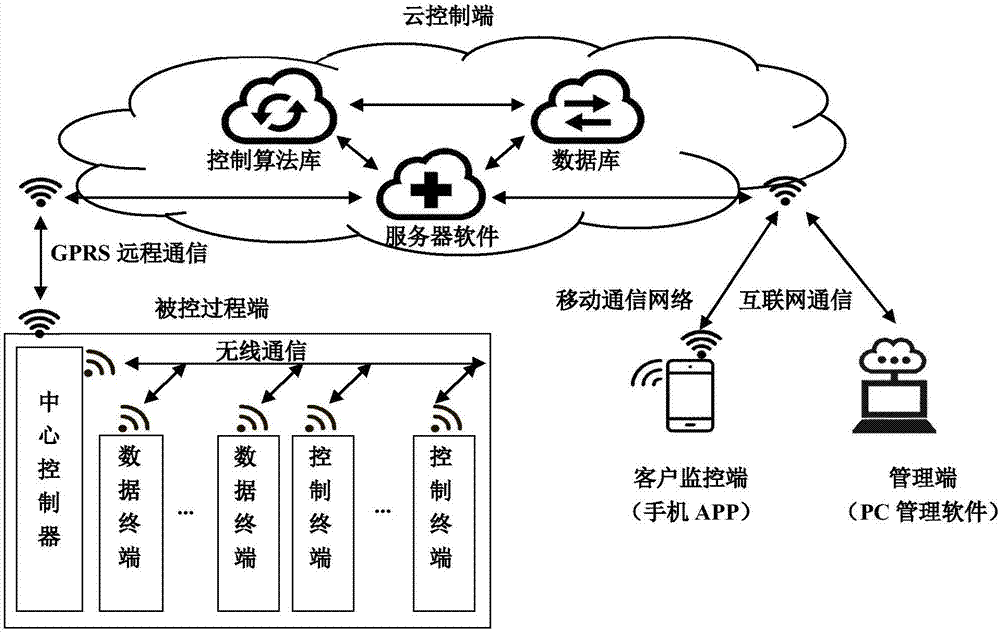

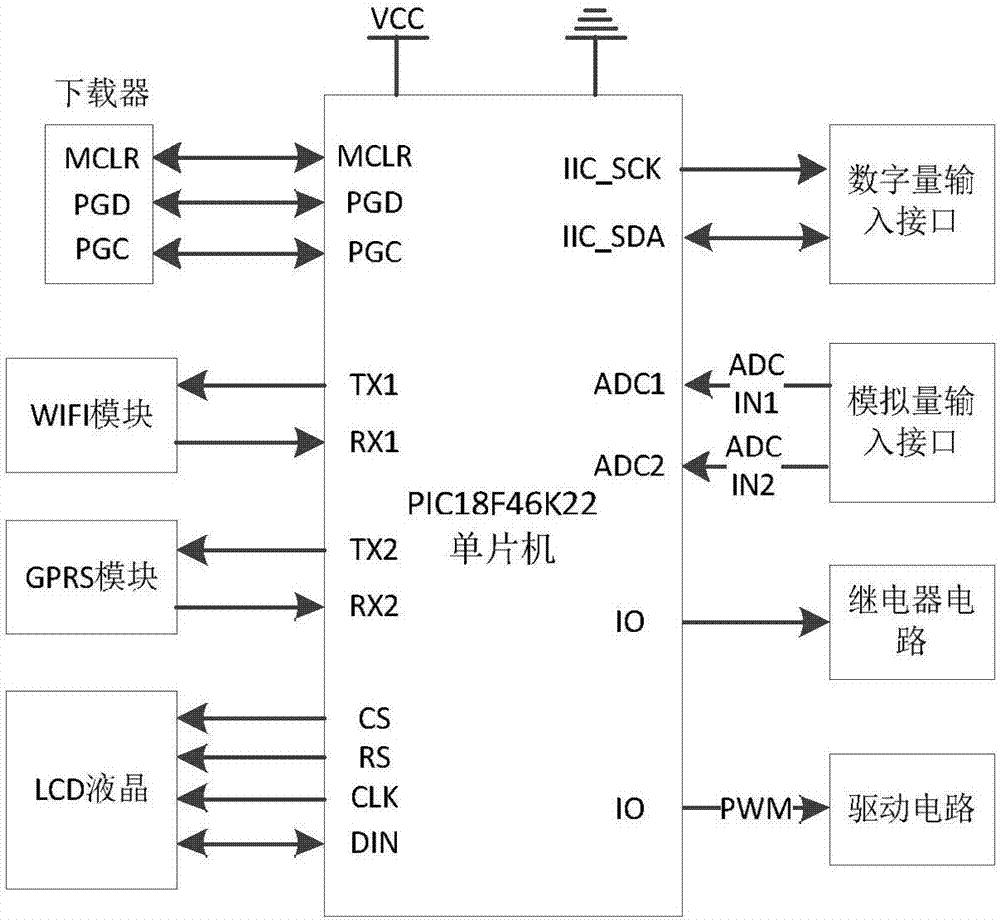

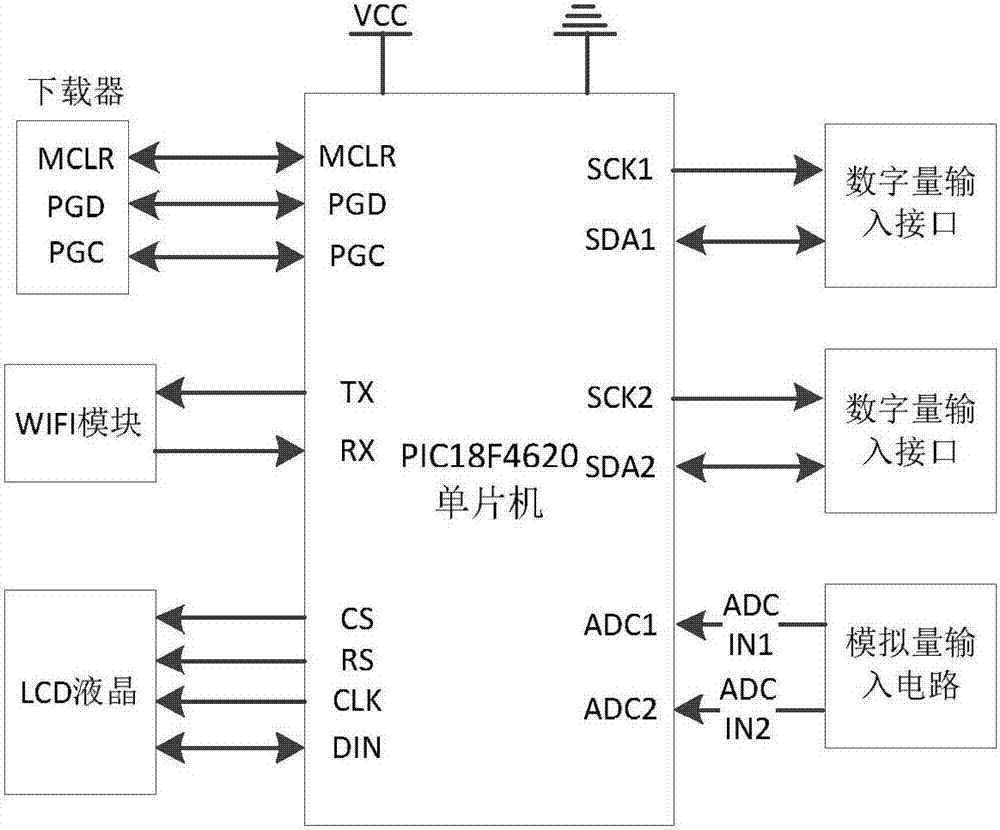

Greenhouse environment cloud control system and control method thereof

PendingCN107018207AEasy to calculate in real timeReduce software and hardware configuration requirementsTransmission systemsTemperature control using electric meansData informationData acquisition

The invention relates to a greenhouse environment cloud control system and a control method thereof. According to the system, a cloud control end operates a control algorithm and stores data information; a controlled process end carries out remote communication with the cloud control end and performs data collection and control functions of the whole control system; a client monitoring end installs a mobile terminal with APP monitoring software and accesses a remote cloud control end through the mobile Internet; a management end accesses the remote cloud control end through the Internet and realizes cloud management of the whole system; and the control method is an interval control algorithm of a non-square control system. According to the system and the method, a control algorithm library and a database are arranged in remote cloud to form a cloud controller; rapid computing, non-disturbance rapid switching and the like of a complex control algorithm are finished through utilization of the strong computing capability of the cloud; large-scale data storage is realized; the controlled process end only needs to send filed collection data and receive a remote control signal through a high-speed remote communication channel; system costs of the system are clearly reduced; and the flexibility of the control system is improved.

Owner:NORTHEASTERN UNIV +1

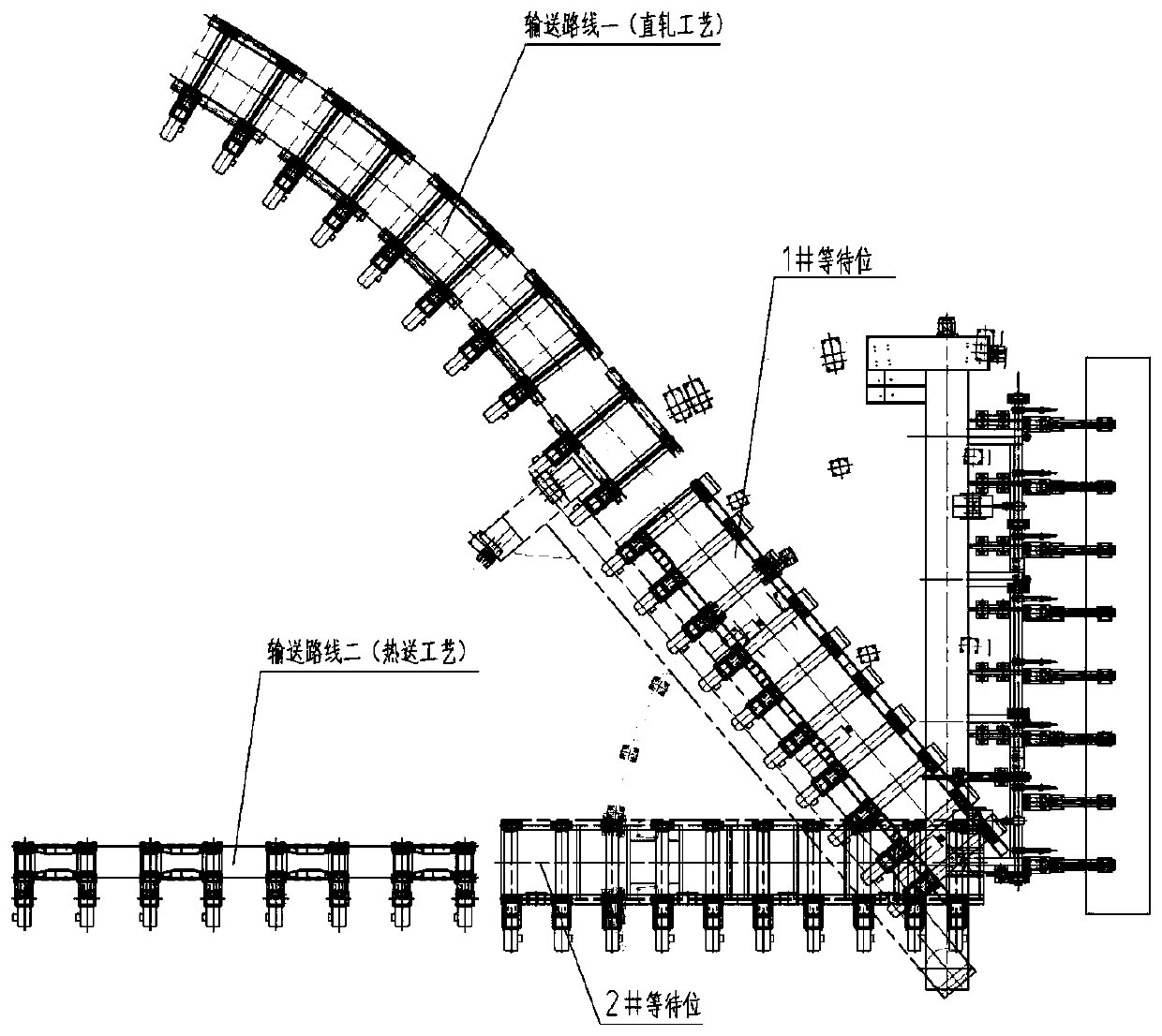

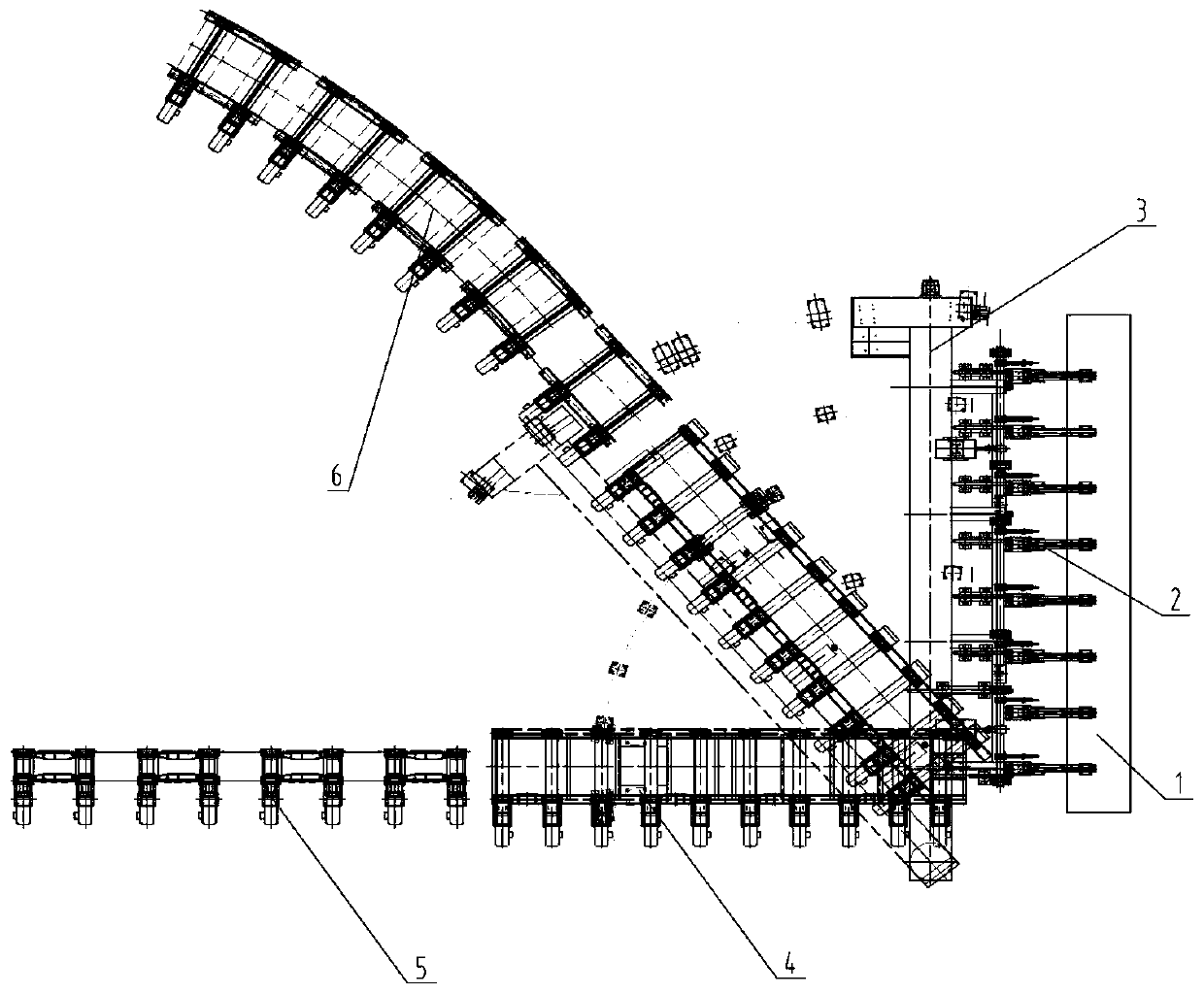

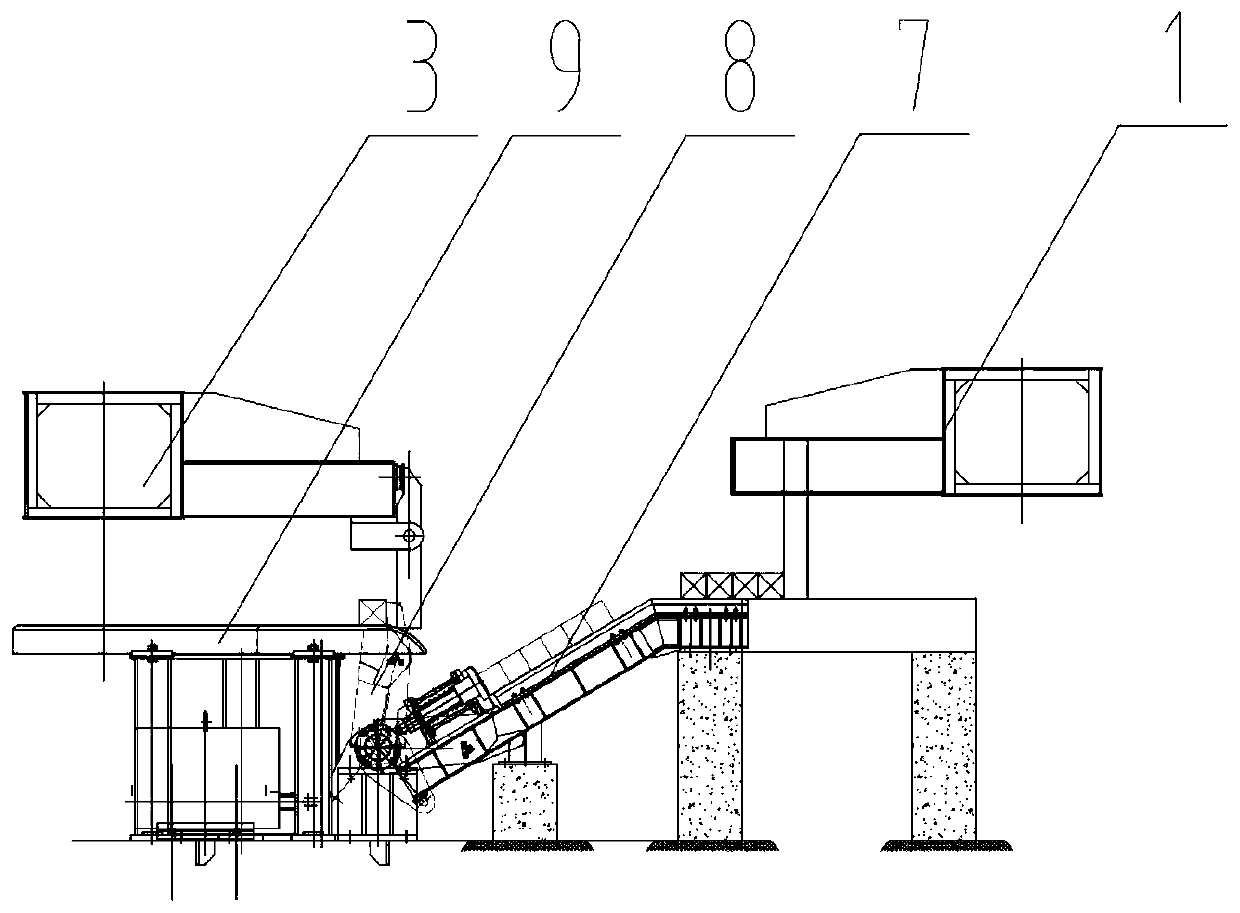

Steel billet conveying system

PendingCN110386449AFast deliveryReduce temperature dropConveyor partsRoller-waysMetallurgySmall footprint

The invention provides a steel billet conveying system and belongs to the technical field of conveying of steel billets. The steel billet conveying system comprises a steel pushing machine (1), a steel splitting machine (2), a rotating steel-shifting machine (3), a rotating roller channel (4), a straight-roller conveying roller channel (5) and an arc-shaped conveying roller channel (6), wherein the steel splitting machine (2) comprises a steel splitting tank (7), a steel-splitting shifting claw (8) and a steel storage platform frame (9). Devices of the system can form various process routes through different combination manners; the steel billet conveying process requirements under different operation conditions can be met; the system has the advantages of simple device structures, variousprocess combination manners, flexible process routes, high automation degree, stable operation, rapid conveying speed and small occupied area; meanwhile, the steel billets can be rapidly conveyed inthe process of thermal conveying or direct rolling production process of the steel billets; the temperature reduction of the steel billets can be effectively reduced; energy conservation and consumption reduction can be achieved; the production operation efficiency of workshops can be improved; and the production cost can be reduced.

Owner:BEIJING SHOUGANG INT ENG TECH

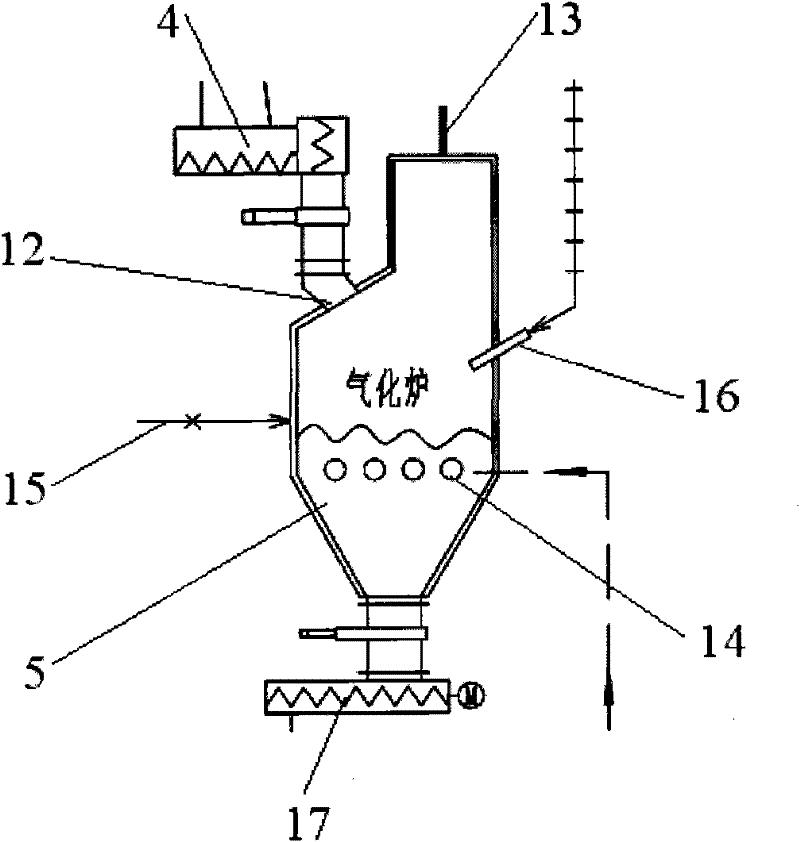

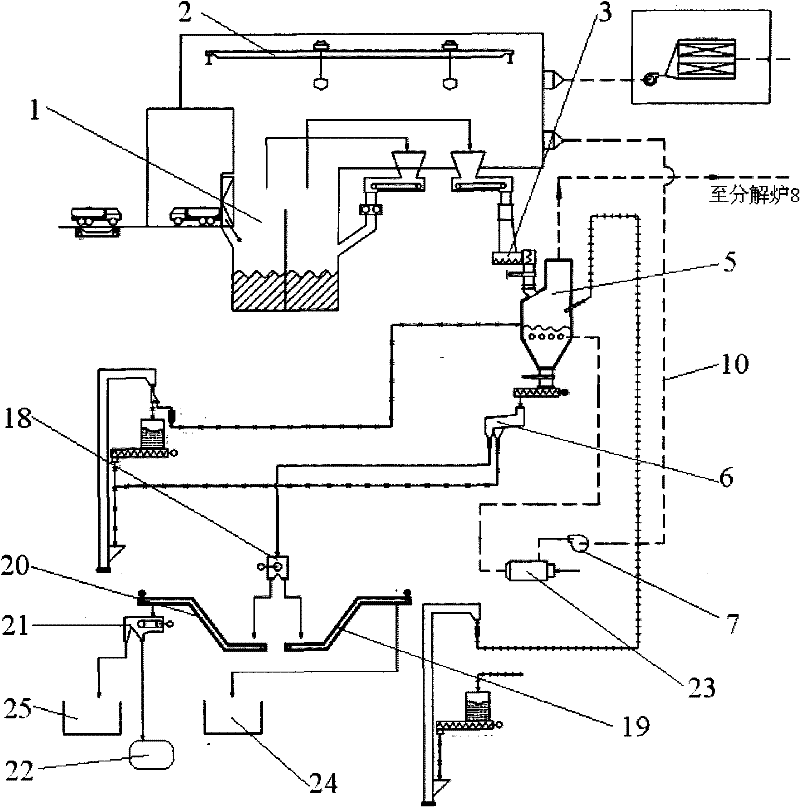

Garbage disposal system used in cement dry kiln production and disposal method thereof

The invention discloses a garbage disposal system used in cement dry kiln production, comprising a garbage storage silo, a garbage crusher, a garbage supplying device and a decomposing furnace in dry cement production, and a rotary cement kiln for cement dry production, wherein the garbage disposal system is provided with a garbage gasification burner, the garbage supplying device is communicatedwith the garbage inlet of the garbage gasification burner, an air exhaust port of the garbage gasification burner is communicated with the decomposing furnace through a pipeline, and the material outlet of the decomposing furnace is communicated with the material inlet of the cement kiln. Through the technical proposal, the invention realizes long detention time of the gas generated by garbage burning in the kiln, completes combustion process, high disposal temperature and completes burning under the high temperature; the invention completely avoids the odor generation during the garbage burning process and especially the dioxin generation, reducing the pollution to the environment, and fully utilizes the energy generated by the garbage burning; compared with prior art, the invention has the advantages of less investment, and good economic benefit and social benefit.

Owner:ANHUI CONCH GRP +2

Antifouling and anti-biting cultivation net cage of huangsha (Chinese character) turtle

InactiveCN102763622AEnsure safetyWith anti-fouling functionAnimal husbandryIsosceles trapezoidChinese characters

The invention discloses an antifouling and anti-biting cultivation cage of a huangsha (Chinese character) turtle. The antifouling and anti-biting cultivation net cage comprises a cage body top part, cage sides and a cage bottom. The antifouling and anti-biting cultivation cage is characterized in that the top part of the cage body adopts an anti-biting small-screen ultra-high molecular weight polyethylene net to be sutured into an annular net; the cage side adopts a combined net formed by a copper alloy woven mesh, a netting half-soft state connection, the copper alloy woven mesh, the nettinghalf-soft state connection, the copper alloy woven mesh, the netting half-soft state connection, the copper alloy woven mesh, the netting half-soft state connection and a nylon mesh; a foam floater is arranged on an upper middle line of the copper alloy woven mesh as a buoyancy system; the cage bottom adopts the combined netting of a nylon woven mesh and the copper alloy woven mesh; a cylindricalheavy block is respectively suspended at four corners of the box body for the cage; a back sunning table is arranged inside the cage; the cross section of the back sunning table is an isosceles trapezoid; the distance from an upper bottom to a lower bottom of the isosceles trapezoid is 30cm; and the part of the back sunning table, in the water, is 16-20cm in vertical height, and the cage is fastened on a fixed parking system of an aquaculture area by a connection rope.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

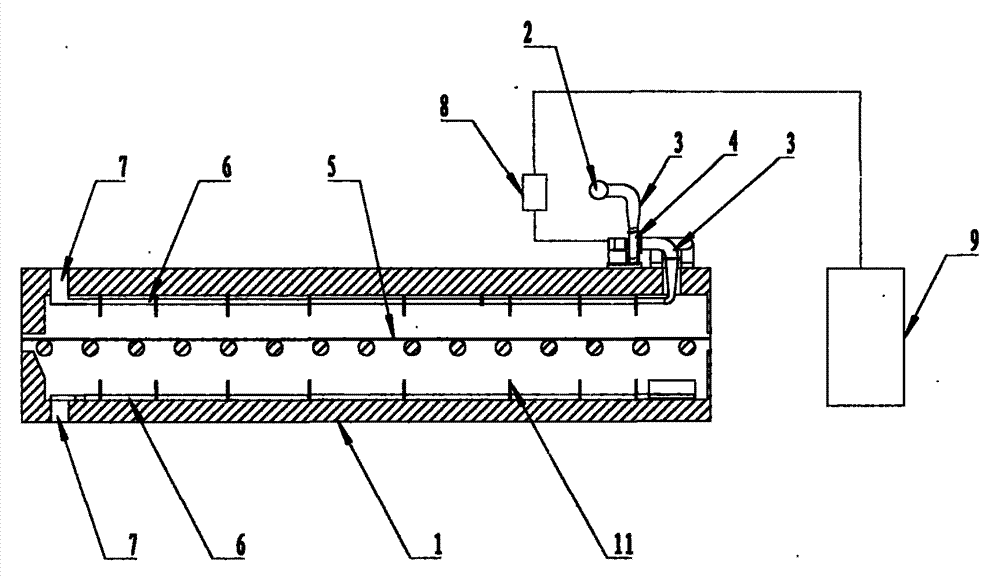

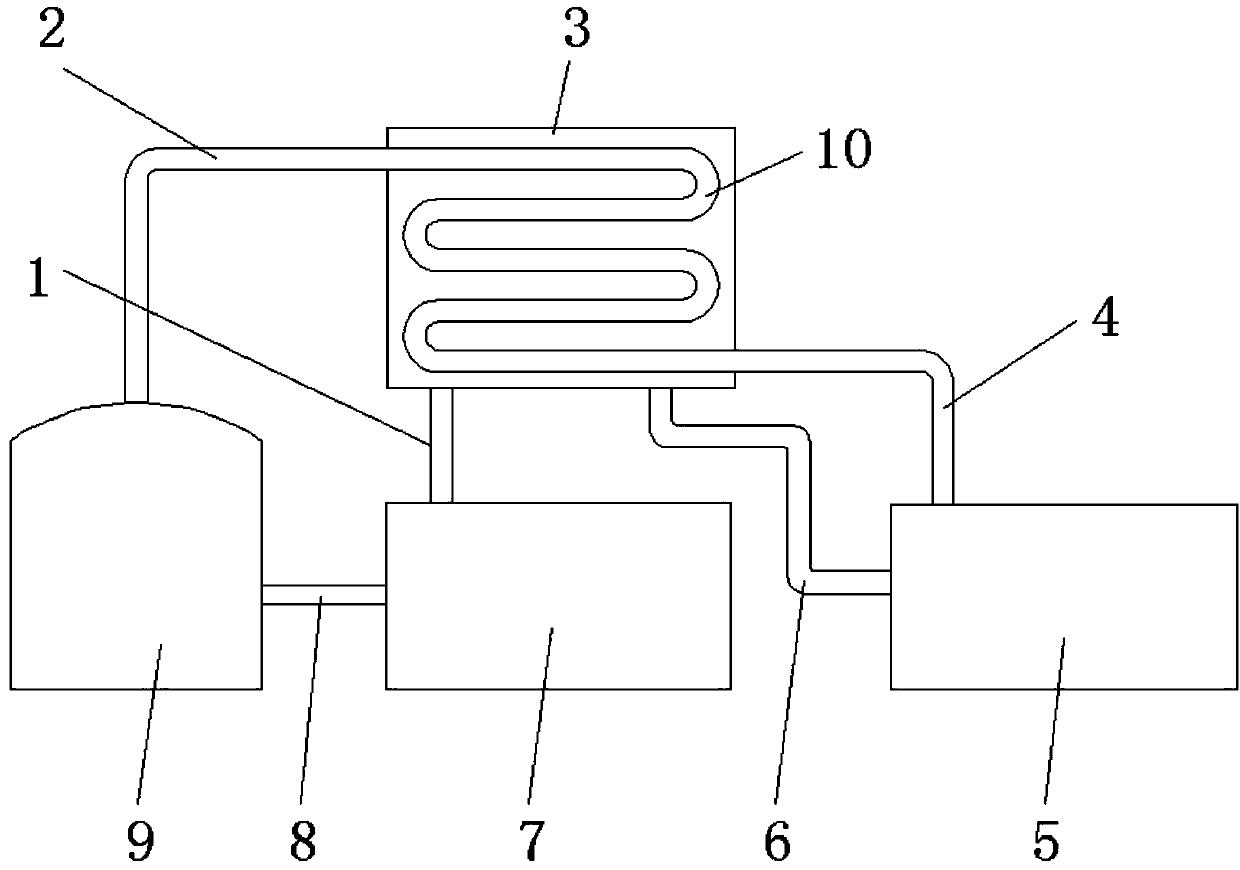

Rubber belt vulcanization steam recycling system

ActiveCN103742897AOutstanding and Beneficial Technical EffectsShorten heating timeFeed water supplyEnergy industryElectricityVulcanization

The invention belongs to the technical field of steam recycling, and in particular refers to a rubber belt vulcanization steam recycling system. A boiler is communicated with a vulcanizing boiler through a pipe I and conveys steam to the vulcanizing boiler, the upper part of the vulcanizing boiler is provided with a pipe II through which the saturated steam can escape, the other end of the pipe II is connected with one side of a poll on the boiler, the other side of the pool on the boiler is provided with a pipe IV, a pipe III for communicating the pipe II and the pipe IV and condensing the steam is arranged in the pool on the boiler, the other end of the pipe IV is communicated with a reservoir, a pipe V for supplying water to the pool on the boiler is arranged between the reservoir and the pool on the boiler, and a pipe VI for supplying water to the boiler is arranged between the pool on the boiler and the boiler. According to the rubber belt vulcanization steam recycling system, the steam can be recycled continuously, the efficiency of whole thermodynamic system is obviously improved, expenses on electricity, coal, water and pollution treatment are saved, and obvious effect is provided for reducing energy consumption of plants and improving economic performance.

Owner:ZHEJIANG SANXING RUBBER BELT

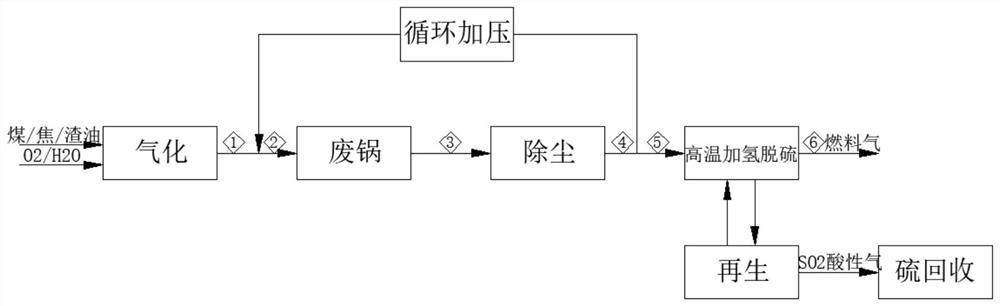

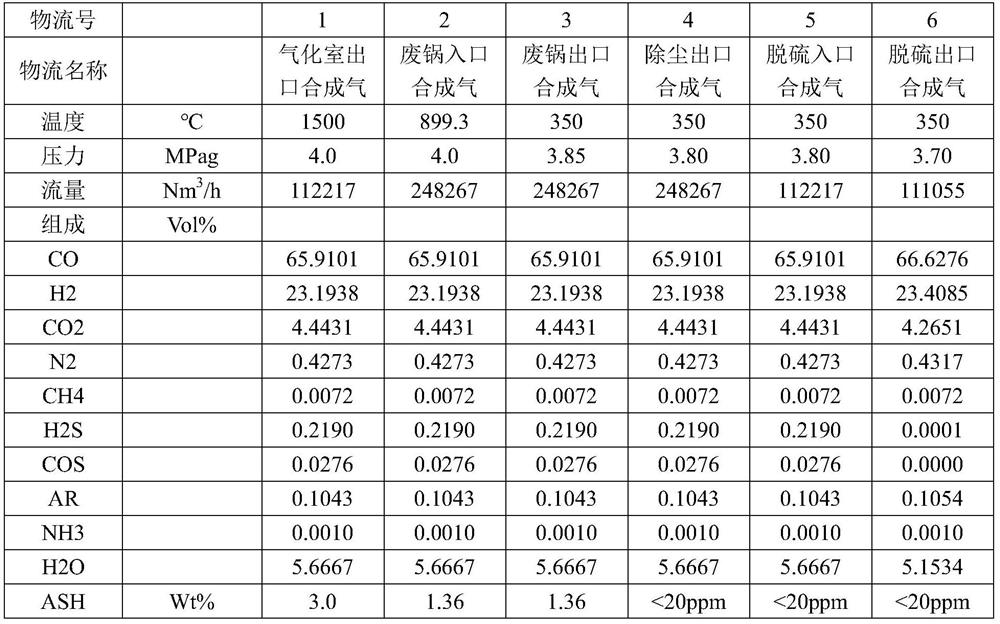

Process for preparing fuel gas from gasified synthesis gas through high-temperature hydrodesulfurization

InactiveCN112480972AReduce sensible heat lossImprove thermal efficiencyGaseous fuelsEnergy inputHydrodesulfurizationSorbent

The invention relates to a process for preparing fuel gas from gasified synthesis gas through high-temperature hydrodesulfurization. The process is free of a synthesis gas washing process, a COS hydrolysis unit and a synthesis gas cooling unit, the process flow is shortened, and the investment is reduced. The high-temperature synthesis gas does not need to be washed and cooled, the sensible heat loss of the synthesis gas is small, the heat efficiency is relatively high, and energy conservation and consumption reduction are facilitated. The COS hydrogenation reduction removal process is considered in desulfurization, the removal rate of sulfides is increased, and the purification effect is guaranteed. Compared with the process that gasified high-temperature synthesis gas directly enters a waste boiler cooler, the process adopts a post-dust-removal gas circulating chilling process, so that the risk of slagging and ash deposition of a waste boiler is reduced. Compared with a gas circulation chilling process after water washing, the gas circulation chilling process after dust removal has the advantages that water carried by the synthesis gas can be reduced to the maximum extent, the influence of water components on the performance of a desulfurization adsorbent is reduced, and the heat value of the fuel gas can be increased.

Owner:SINOPEC NINGBO ENG +2

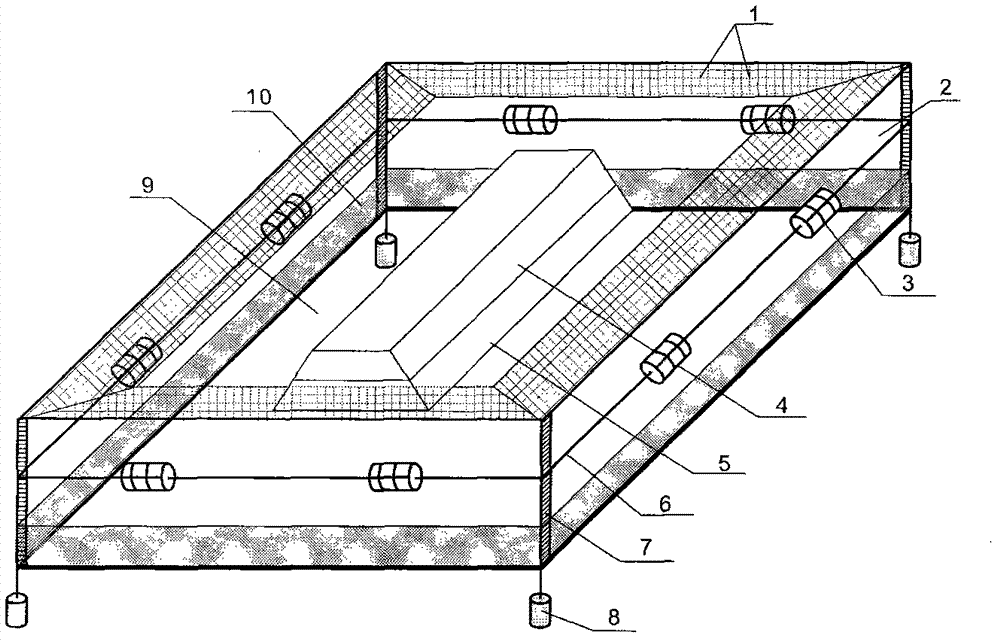

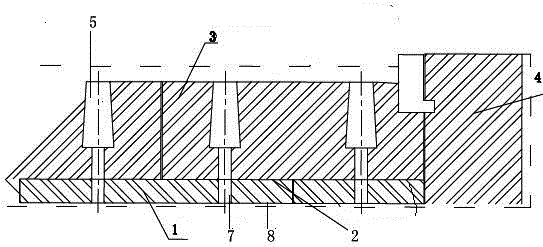

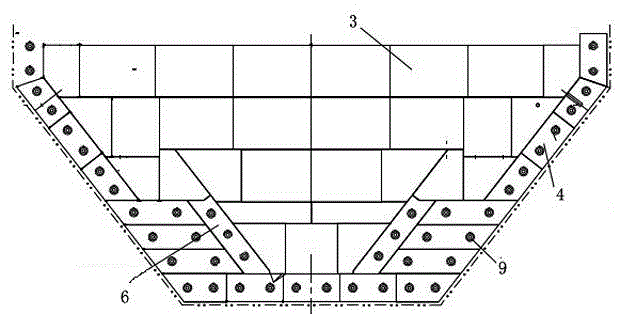

Molten tin bath bottom-brick structure

The invention discloses a molten tin bath bottom-brick structure. The molten tin bath bottom-brick structure comprises molten tin bath underlay bricks arranged on a tank bottom steel plate at the bottom of the molten tin bath, wherein the molten tin bath bottom bricks are arranged on the molten tin bath bottom underlay bricks; a first seepage-proof layer is arranged between the molten tin bath underlay bricks and the tank bottom steel plate; a second seepage-proof layer is arranged between the molten tin bath underlay bricks and the molten tin bath bottom bricks; tank sealing holes are formed in the upper sides of the molten tin bath underlay bricks; through holes are formed in the molten tin bath bottom bricks, the second seepage-proof layer and the molten tin bath underlay bricks, which are located below the tank sealing holes, and the molten tin bath bottom bricks, the second seepage-proof layer and the molten tin bath underlay bricks are mounted on the tank bottom steel plate at the bottom of the molten tin bath through fixing bolts; fixed side-locating bricks are fixedly connected with the both sides of the molten tin bath bottom bricks, and comprise side wall bricks and inverted-Y-shaped bricks located on the inner sides of the side wall bricks; graphite linings are arranged between the side wall bricks and the molten tin bath bottom bricks. The molten tin bath bottom-brick structure provided by the invention can overcome the defect in the prior art, realize molten tin bath insulation, save energy, reduce consumption, and meanwhile completely solve the adverse effect caused by displacement bias of the side-locating bricks and the graphite linings.

Owner:YICHANG CSG PHOTOELECTRIC GLASS

Green recycling method of spent platinum catalyst

ActiveCN108342577AHigh recovery rateAdaptableProcess efficiency improvementElectric furnaceElectric arc furnacePtru catalyst

The invention relates to the field of secondary resource comprehensive utilization of spent platinum catalysts, in particular to a green recycling method of a spent platinum catalyst. The green recycling method of the spent platinum catalyst is sequentially carried out according to the following steps of A, pretreating materials; B, compounding and mixing the materials; C, melting through an electric-arc furnace; and D, preparing powder through an iron alloy. According to the green recycling method of the spent platinum catalyst provided by the invention, an applicable material range is wide,a carrier dissolving effect is good, the platinum group metal enriching times is high, the platinum group metal content in enriching residues is high, the platinum group metal recovery is high, and the equipment corrosion is low. The precious metal recovery rate is high, the material applicability is high, the usage of auxiliary materials is reduced, the energy is saved, the consumption is reduced, and the production cost is low.

Owner:GUIYAN RESOURCE YIMEN

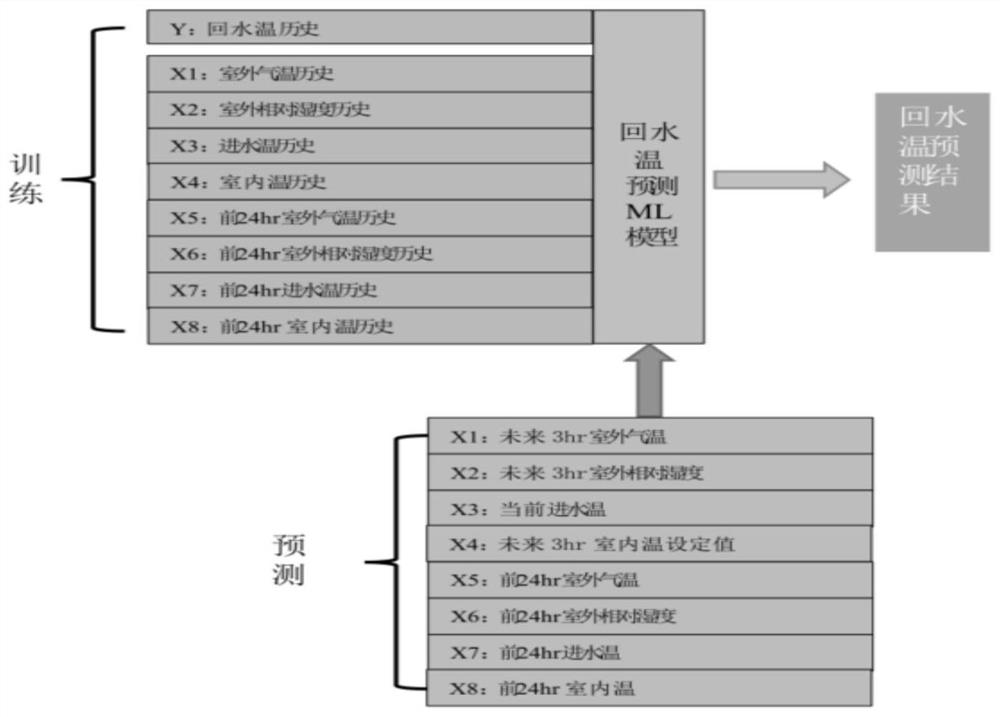

Intelligent heat supply room temperature regulation and control system based on machine learning algorithm

ActiveCN113606650ASave hardware investmentLow costLighting and heating apparatusCharacter and pattern recognitionMachine learningData input

The invention provides an intelligent heat supply room temperature regulation and control system based on a machine learning algorithm and relates to the related field of heat supply room temperature regulation and control. According to the intelligent heat supply room temperature regulation and control system based on the machine learning algorithm, the heat supply types of the terminal users are divided into five types according to coefficients at least including building energy consumption characteristics and building maintenance structures, furthermore, enterprise customer service charging data are hooked, and the heat supply user types are dynamically refreshed in real time; the regulation and control data are input into trained user room temperature regulation and control prediction models established in a classified mode, the predicted average water supply and return temperature of the user room temperature at the preset moment and the predicted load heat of the user side are obtained, and regulation and control of the user room temperature are achieved in combination with station control circulating pump regulation, building unit valve control and user side regulating valve control; and the user room temperature regulation and control prediction models are established in a classified manner by utilizing a lifting tree machine learning algorithm, and precise regulation and control of the user room temperature are realized in combination with the station control circulating pump regulation or the building unit valve and user side regulating valve control.

Owner:ZIBO DISTRICT HEATING LTD CO

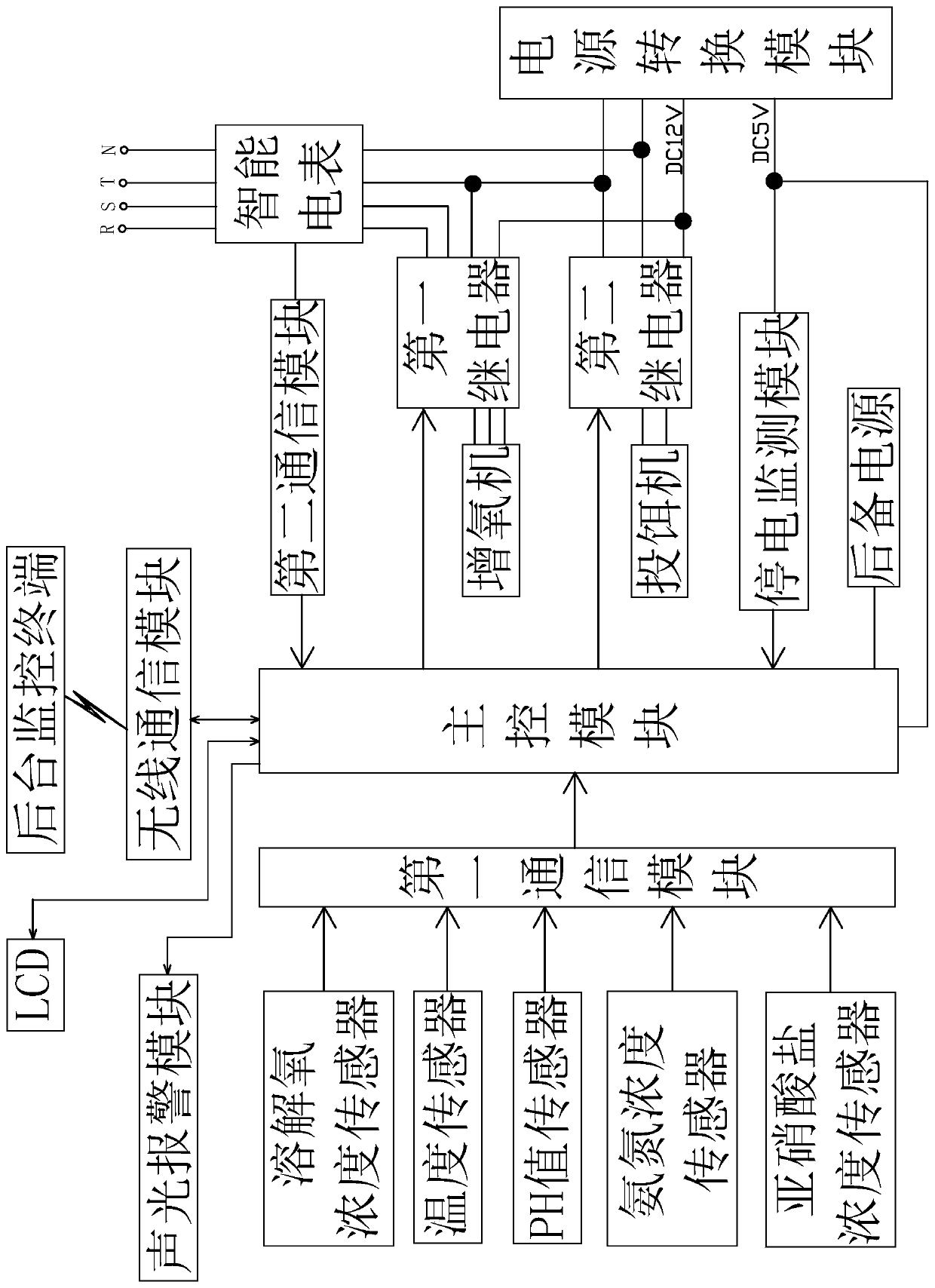

Culture water area water quality monitoring and electric equipment power loss alarm system

PendingCN111047804AHigh accuracy of water quality monitoringHigh precisionMeasurement devicesTransmission systemsAquaculture industryWater quality

The invention provides an aquaculture water area water quality monitoring and electric equipment power loss alarm system. The system comprises a sensor group for detecting water quality; an intelligent electric meter used for monitoring the three-phase power supply state of the power grid; a main control module used for system main control; a first communication module and a second communication module used for realizing information interaction between the sensor group and the intelligent electric meter and the main control module; a background monitoring terminal used for remote monitoring; awireless communication module used for realizing wireless information interaction between the main control module and the background monitoring terminal; an LCD used for field display and control; asound-light alarm module used for emitting sound-light alarm on site; a power failure monitoring module used for monitoring whether a power grid is powered off or not; a backup power supply used for providing a temporary working power supply during power failure; and an aerator and a bait casting machine which are used for working under the control of the main control module. A set of automatic monitoring system which is low in cost and convenient to use and operate is provided for the aquaculture industry, and energy conservation, consumption reduction, production increase and income increaseof the aquaculture industry are facilitated.

Owner:JIANGSU ELECTRIC POWER CO +1

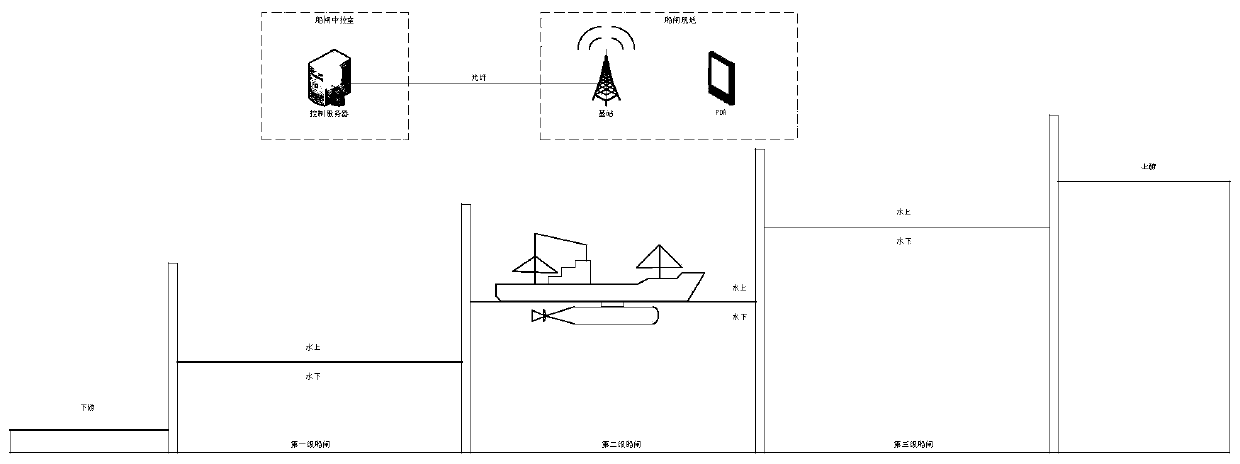

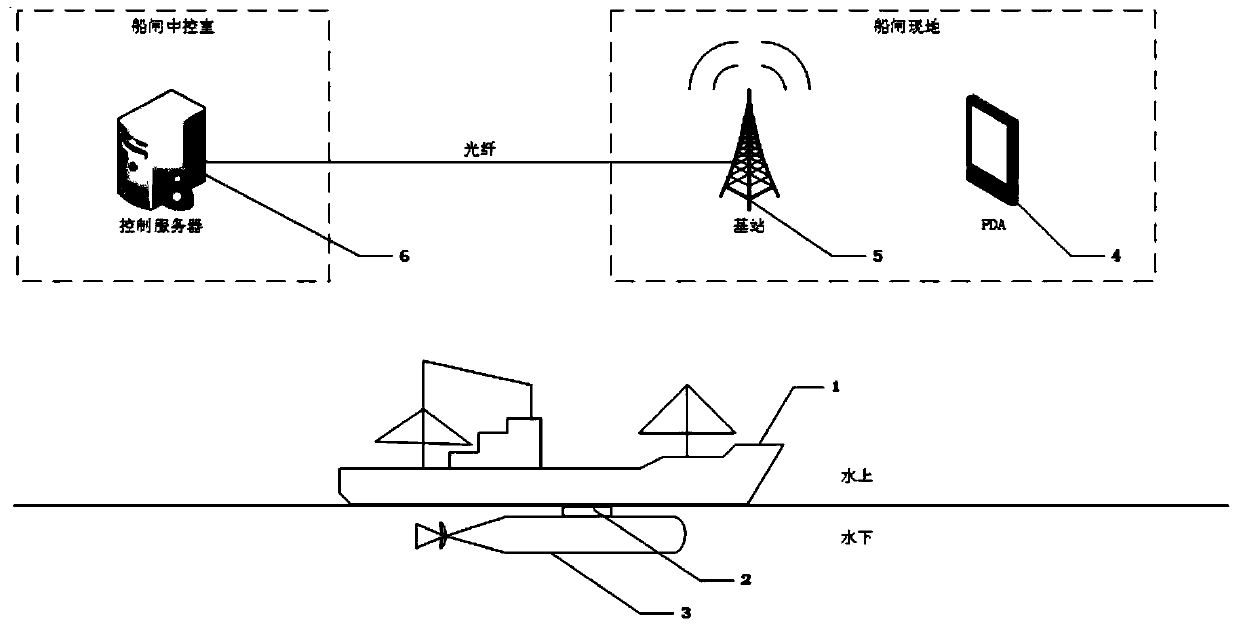

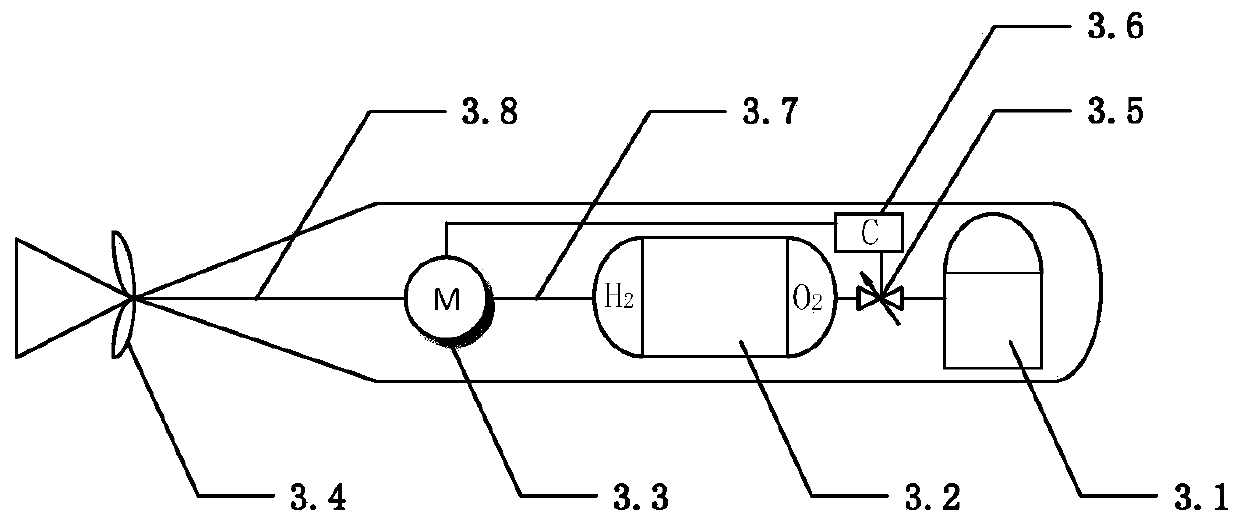

Hydropower station ship lock navigation ship towing system based on hydrogen fuel cell

PendingCN110562390ANavigation realizationReduce pollutionTowing/pushing equipmentHydrogen fuel cellHydrogen fuel

The technical scheme adopted by the invention discloses a hydropower station ship lock navigation ship towing system based on a hydrogen fuel cell. The system is characterized by comprising a navigation ship, an underwater electromagnetic chuck and a hydrogen fuel cell submarine type towing ship, wherein the hydrogen fuel cell submarine type towing ship is located below water, the underwater electromagnetic chuck is fixedly arranged on the upper surface of the hydrogen fuel cell submarine type towing ship, the underwater electromagnetic chuck is attracted to the bottom surface of a navigationship after being electrified, and the hydrogen fuel cell submarine type towing ship drives the navigation ship to move in the water. The system has the important significances to noise pollution of adiesel engine of a ship lock of a hydropower station, the energy conservation and consumption reduction of equipment, reservoir area environment pollution reduction, the navigation efficiency improving, and the zero emission of ship lock navigation of the hydropower station.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

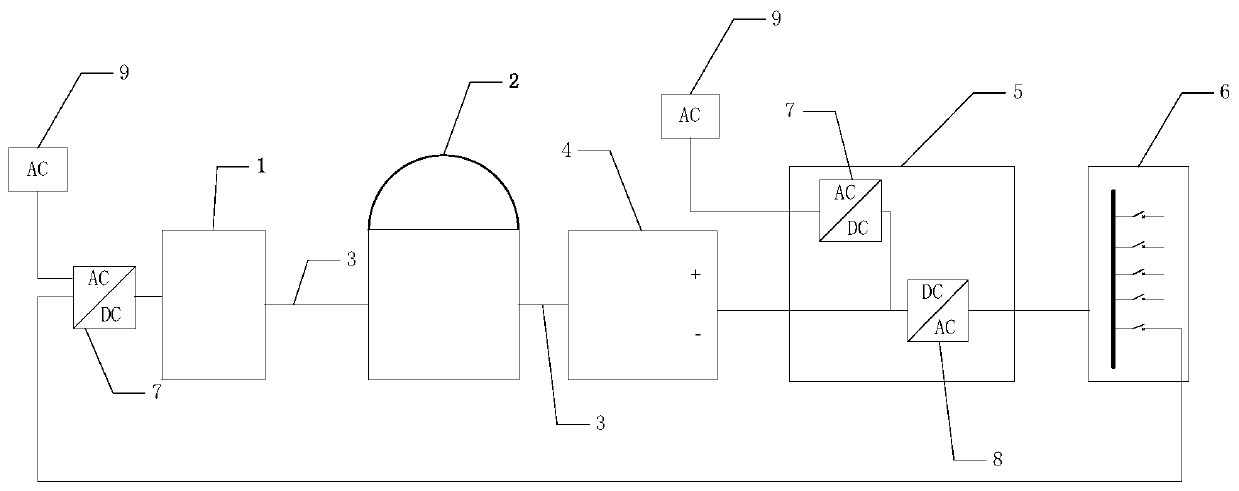

Hydropower station hydrogen energy uninterrupted alternating current power supply system

PendingCN110518691AZero emissionHave memory effectFuel cellsEmergency power supply arrangementsPower stationAc power system

The invention provides a hydropower station hydrogen energy uninterrupted alternating current power supply system, which comprises a hydropower station hydrogen production system, a hydropower stationhydrogen storage system, a hydrogen conveying pipeline, a hydrogen fuel cell stack, a UPS main cabinet, a UPS power distribution cabinet and a power station service alternating current, wherein the output end of the power station service alternating current is electrically connected with the input end of a rectification module and the input end of the UPS main cabinet; the output end of the rectification module is electrically connected with the input end of the hydropower station hydrogen production system; the output end of the hydropower station hydrogen production system is communicated with the input end of the hydropower station hydrogen storage system through the hydrogen conveying pipeline; the output end of the hydropower station hydrogen storage system is communicated with the input end of the hydrogen fuel cell stack through the hydrogen conveying pipeline; the output end of the hydrogen fuel cell stack is electrically connected with the input end of the UPS main cabinet; the output end of the UPS main cabinet is electrically connected with the input end of the UPS power distribution cabinet; the output end of the UPS power distribution cabinet is electrically connectedwith the input end of the rectification module. According to the invention, the requirements of zero emission and zero pollution can be realized in the long-term operation and maintenance process.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

One-step production method of thermoplastic polyurethane waterproof coiled material

The invention discloses an one-step production method of a thermoplastic polyurethane waterproof coiled material. The method comprises the following steps: (1) heating solid raw material to be liquid, weighing liquid raw material according to the mixing ratio, and uniformly mixing; (2) conveying the liquid raw material to a screw extruder to chemically react and melt; (3) preparing through a film forming machine to obtain a Tpu film. Compared with the prior art, the method has the advantages that the fixed processing mode and process of the Tpu film are completely changed, the energy consumption is small, the resource and energy are saved, the carbon discharge is reduced, and the effects on energy saving and consumption reduction are obvious; the method has outstanding characteristics and obvious improvement on either improvement or active effect of energy saving and emission reduction.

Owner:茹家佑

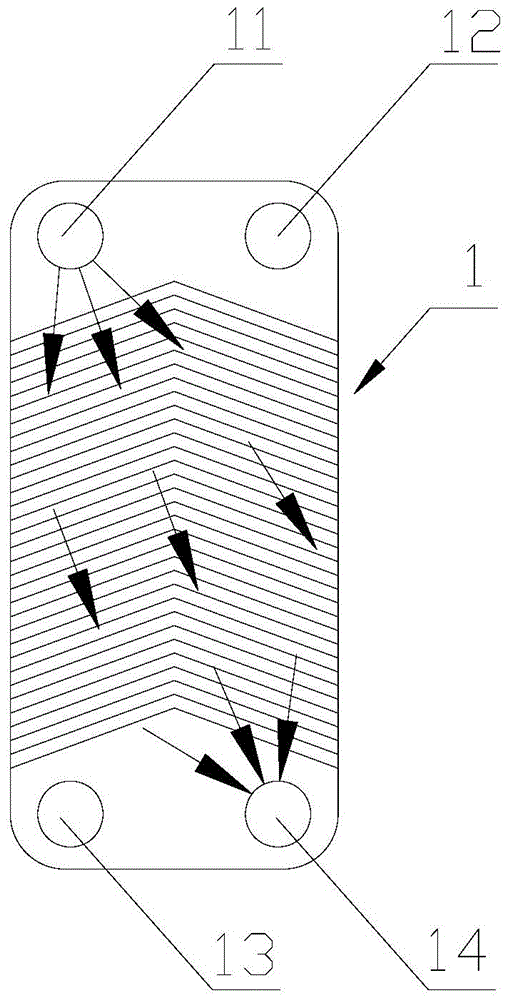

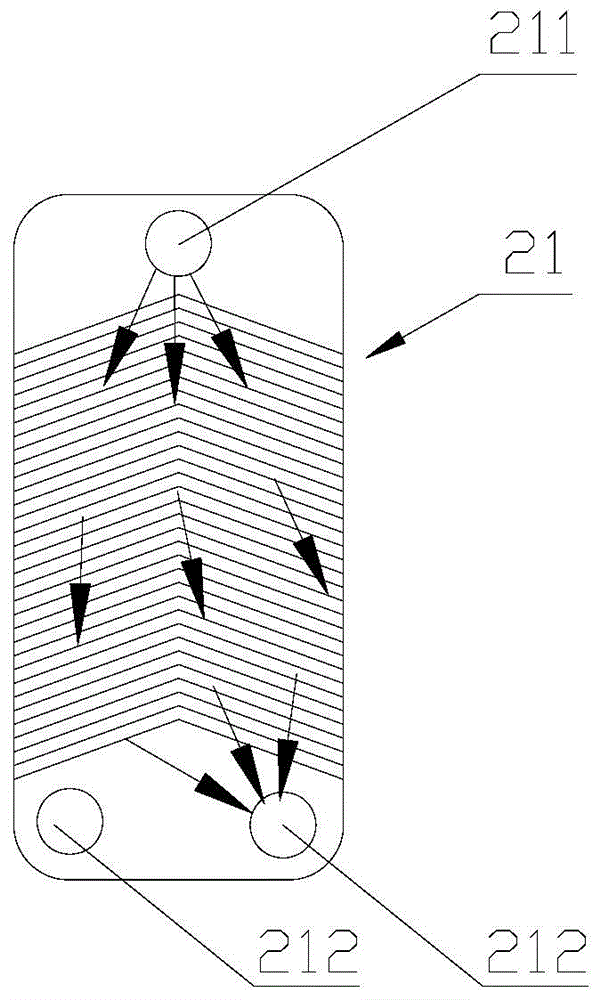

Plate heat exchanger

ActiveCN103090707BEvenly distributedChange the size of the pressure dropHeat exchanger casingsLaminated elementsPlate heat exchangerEngineering

The invention discloses a plate heat exchanger. The plate heat exchanger comprises plate sheets (21) which are stacked; interplate flow channels are formed among the plate sheets (21); the plate heat exchanger also comprises a flow distributor (22) which is communicated with the interplate flow channels and comprises at least two pipelines which are arranged in parallel; all the interplate flow channels are communicated with an independent pipeline; and adjacent interplate flow channels are communicated with different pipelines of the flow distributor respectively. The flow distributor of the plate heat exchanger at least comprises two pipelines, so that the number of single flowing holes on the plate sheets can be reduced; therefore, the heat exchange efficiency of fluid and the utilization rate of the plate sheets can be improved; an area where the fluid can flow is enlarged, and the fluid can be distributed more uniformly among the plates; and moreover, according to the plate heat exchanger with the structure, pressure drop is easy to adjust, and the fluid distribution condition under the working condition of phase change can be changed.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS CO LTD

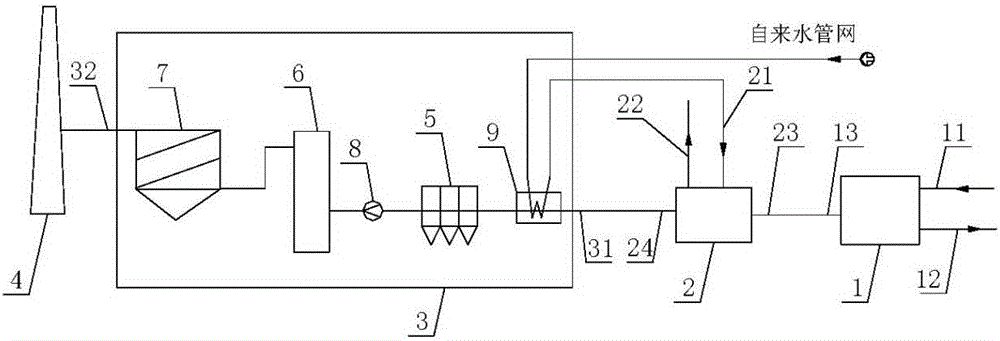

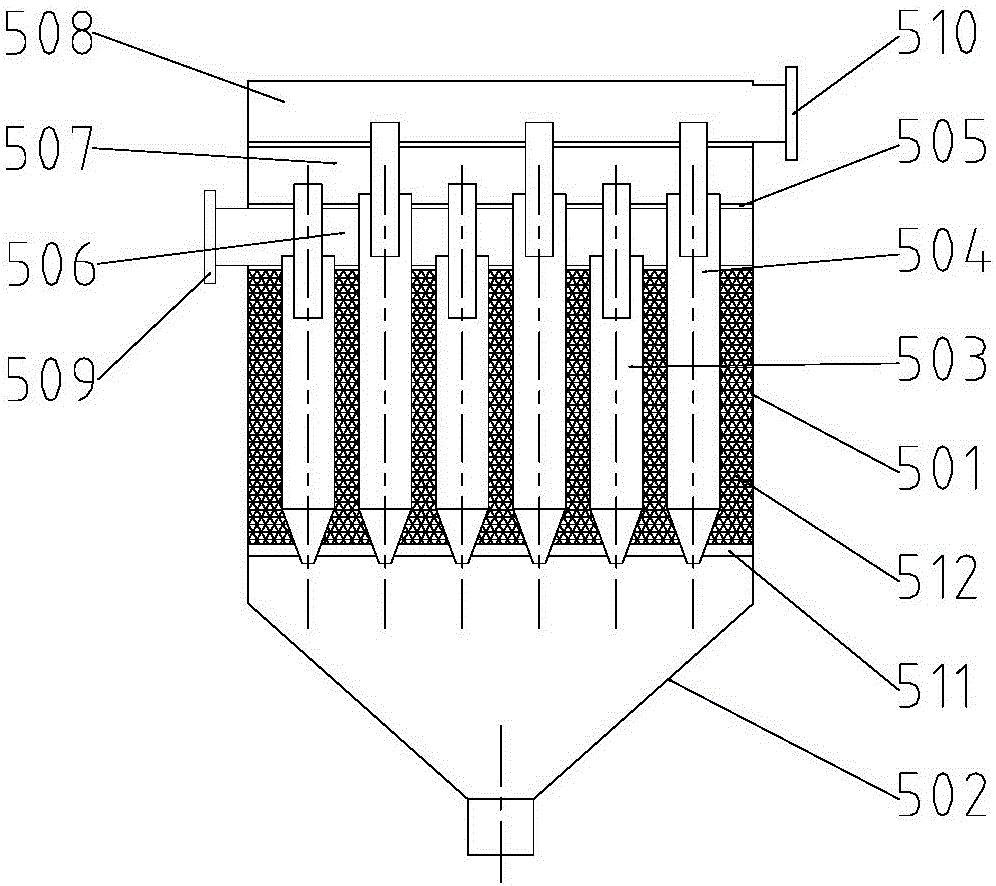

Multi-stage dust removal polyaluminium chloride production boiler system

InactiveCN106345207AReduce consumptionReduce emission concentrationCombination devicesEnergy inputFlue gasEngineering

The invention discloses a multi-stage dust removal polyaluminium chloride production boiler system which comprises a heat conduction oil boiler, a waste heat boiler, a sulfur and dust removal device and a high-rise chimney, wherein the heat conduction oil boiler is provided with a heat conduction oil inlet pipeline, a heat conduction oil outlet pipeline and a coal-fired flue gas pipeline; the waste heat boiler is provided with a water supply pipeline, a steam pipeline, a flue gas inlet pipeline and a flue gas outlet pipeline; the sulfur and dust removal device is provided with a flue gas inlet pipeline and a flue gas outlet pipeline; the coal-fired flue gas pipeline of the heat conduction oil boiler is communicated with the flue gas inlet pipeline of the waste heat boiler; the flue gas outlet pipeline of the waste heat boiler is communicated with the flue gas inlet pipeline of the sulfur and dust removal device; the flue gas outlet pipeline of the sulfur and dust removal device is communicated with the high-rise chimney; the water supply pipeline of the waste heat boiler is communicated with a running water pipe network; the sulfur and dust removal device comprises a dry type dust remover, a sulfur removal tower and a wet type electric dust remover; the dry type dust remover is a ceramic multi-pipe dust remover.

Owner:CHONGQING LANJIE GUANGSHUN WATER PURIFICATION MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com