Device of producing wine by continuously distilling solid fermented grains

A technology of solid fermentation and fermented grains, applied in the field of wine making, can solve the problems of reducing the quantity of finished wine, affecting the distribution of fractions, and low yield, and achieves the effects of stable and continuous distillation process, stable product quality and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

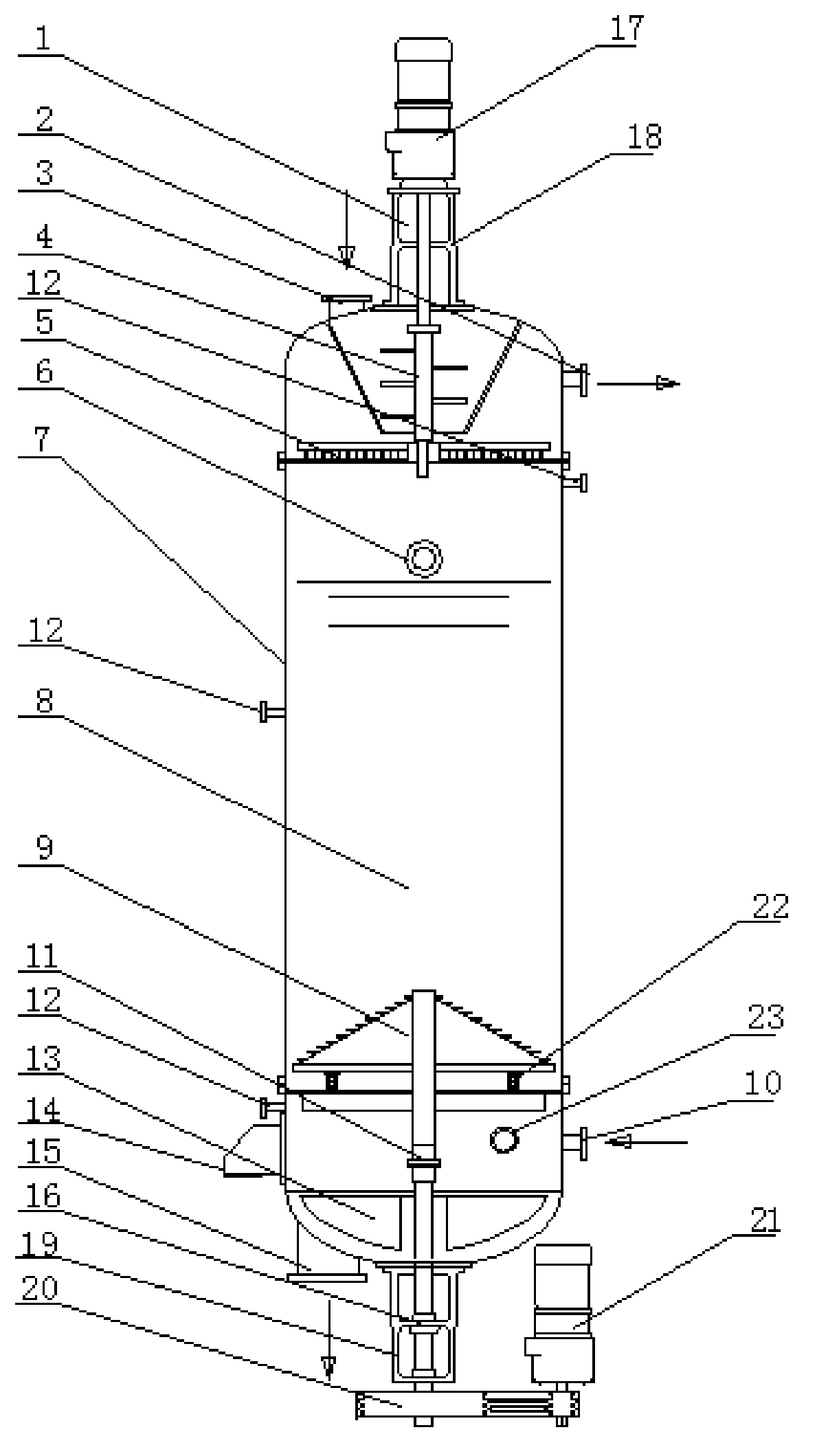

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0019] see figure 1 .

[0020] The present invention is a device for continuously distilling solid fermented wine grains to produce liquor, which comprises an upper rotating device 1, a distillation tower shell 7 and a lower rotating device 16 connected in sequence; the distillation tower shell 7 is a cylindrical or conical tower , the top of the distillation tower housing 7 is provided with a solid wine grains material inlet 3, the upper side of the distillation tower housing 7 is provided with a wine vapor outlet 2, and the lower part is provided with a water vapor inlet 10, a pressure measuring port 23 and a wine Distillation residue discharge port 15; multiple temperature measuring ports 12 are provided at different positions of the distillation tower shell; the temperature measuring ports 12 are used to test the temperature of the distillation bed; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com