Molten tin bath bottom-brick structure

A tin bath bottom brick and tin bath technology, applied in the field of trough bottom brick structure, can solve the problems of high power usage of electric heating, displacement of movable fixed edge bricks, and inability to achieve predetermined functions, etc., so as to reduce temperature and reduce The amount used, the effect of reducing the amount of tin penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

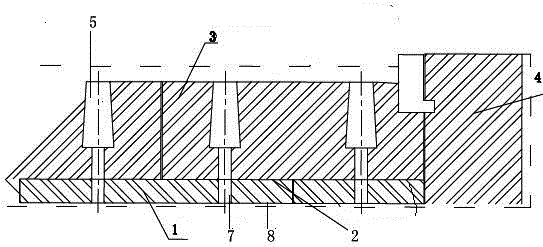

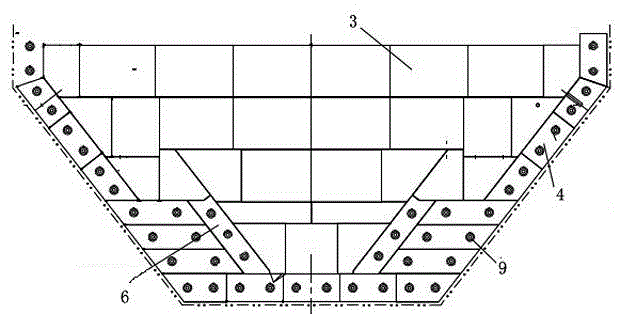

[0021] Such as figure 1 with figure 2 As shown, a tin bath bottom brick structure includes a tin bath bottom lining brick 1 arranged on the bottom steel plate of the tin bath,

[0022] The tin bath bottom brick 1 is provided with the tin bath bottom brick 3, the first anti-seepage layer 8 is arranged between the tin bath bottom brick 1 and the tank bottom steel plate, and the tin bath bottom brick 1 and the tin bath bottom brick 3 The second anti-seepage layer 2 is provided, the upper side of the tin bath bottom lining brick 1 is provided with a sealing hole 5, the tin bath bottom brick 3, the second anti-seepage layer 2, the tin bath bottom lining brick 1 and the bottom of the sealing hole 5 The first anti-seepage layer 8 is provided with a through hole 7, which is installed on the steel plate at the bottom of the tin tank through fixing bolts;

[0023] Both sides of the tin bath bottom brick 3 are fixedly connected with fixed side bricks, and the fixed side bricks are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com