On-line agent changing method of methyl tert-butyl ether (MTBE) expanded bed reactor

A technology of reactor and expanded bed, which is applied in the field of catalyst on-line replacement, can solve the problems of shutdown catalyst regeneration, etc., and achieve the effects of increased production capacity, low energy consumption, and significant benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

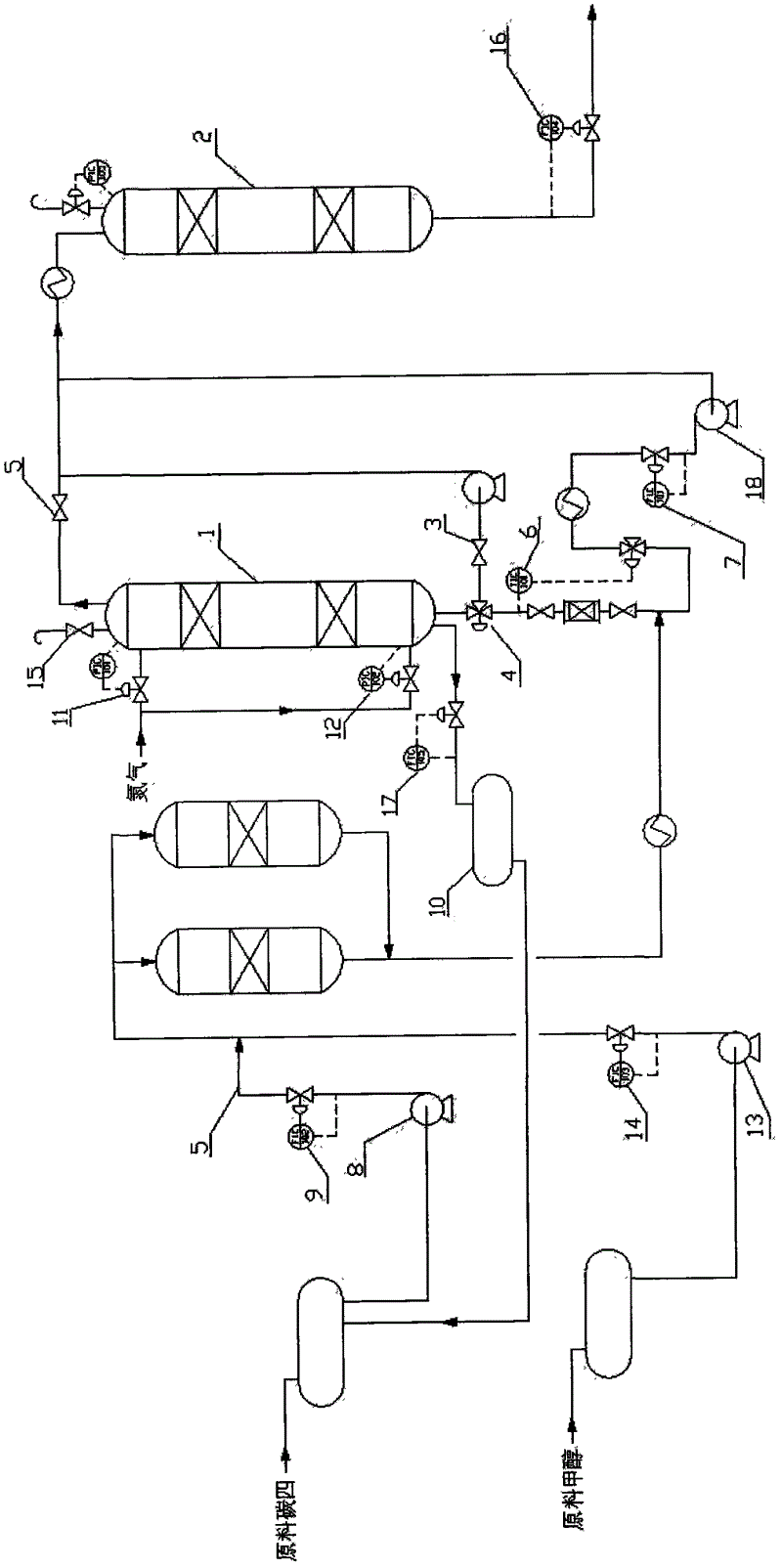

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

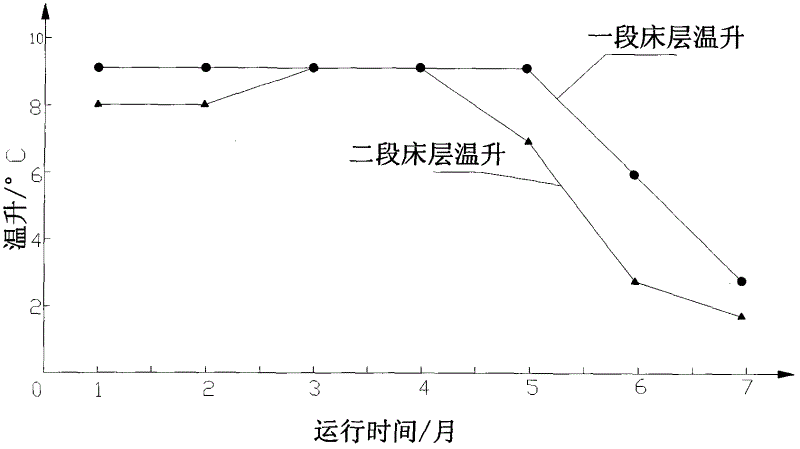

[0038] refer to figure 2 , the problems faced by the secondary reactor running alone:

[0039] (1) Temperature control

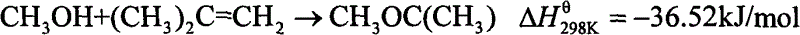

[0040] The two-stage fixed-bed reactor, which originally assumed a conversion rate of about 10%, had to undertake a conversion rate of about 80% to 90% when operating alone. The secondary reactor is not designed with a circulation heat extraction system, and corresponding measures should be taken to prevent the phenomenon of "flying temperature" when it is running independently.

[0041] (2) Pressure control

[0042] After the primary reactor is cut out, the resistance of the reaction material decreases, the system pressure increases, the heat of vaporization of the material decreases, and the side reaction products will be produced in large quantities due to the increase of the system temperature. It is necessa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com