Patents

Literature

468 results about "Catalytic distillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic distillation is a branch of reactive distillation which combines the processes of distillation and catalysis to selectively separate mixtures within solutions. Its main function is to maximize the yield of catalytic organic reactions, such as the refining of gasoline. The earliest case of catalytic distillation was thought to have dated back to 1966; however, the idea was officially patented in 1980 by Lawrence A. Smith, Jr. The process is currently used to purify gasoline, extract rubber, and form plastics.

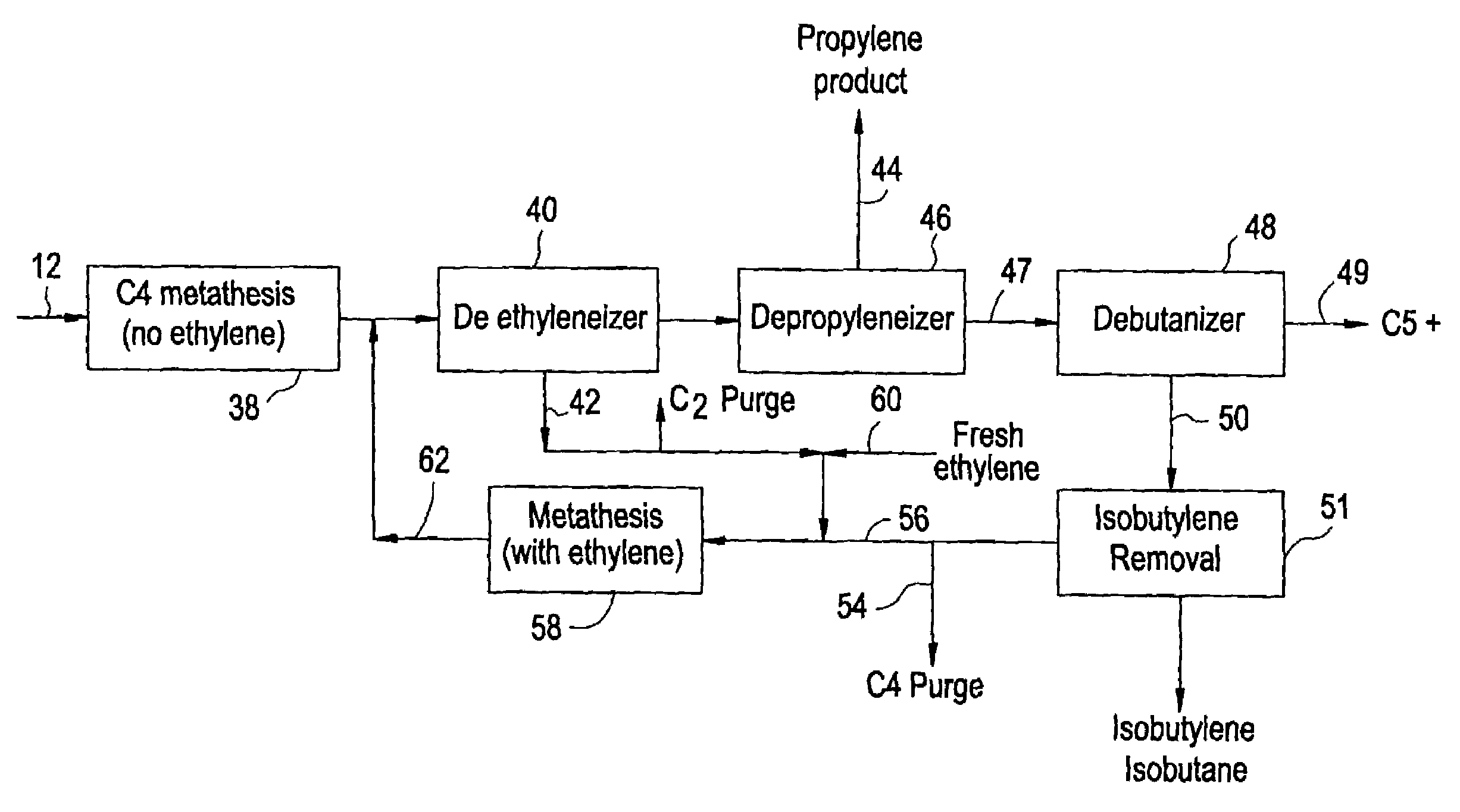

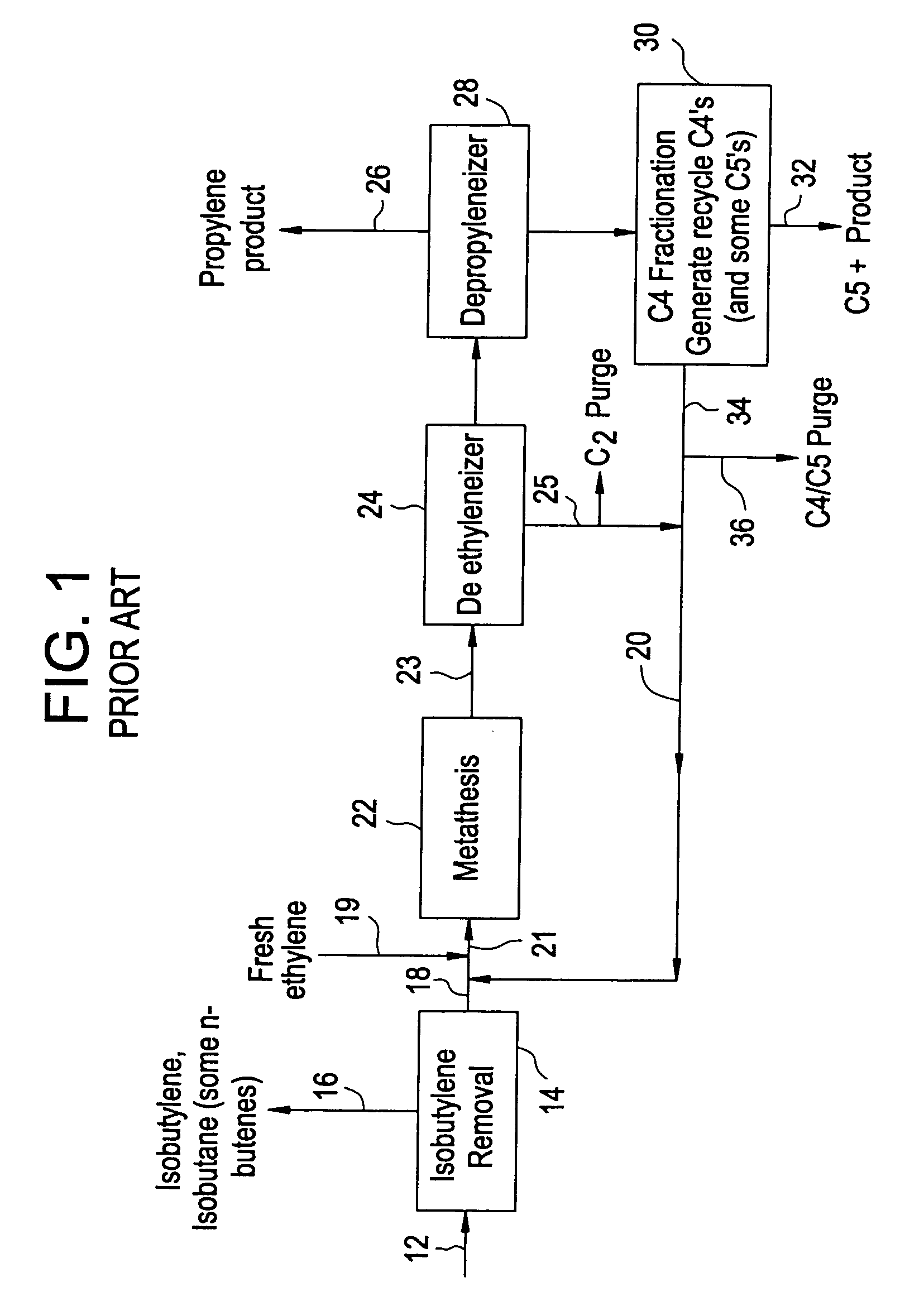

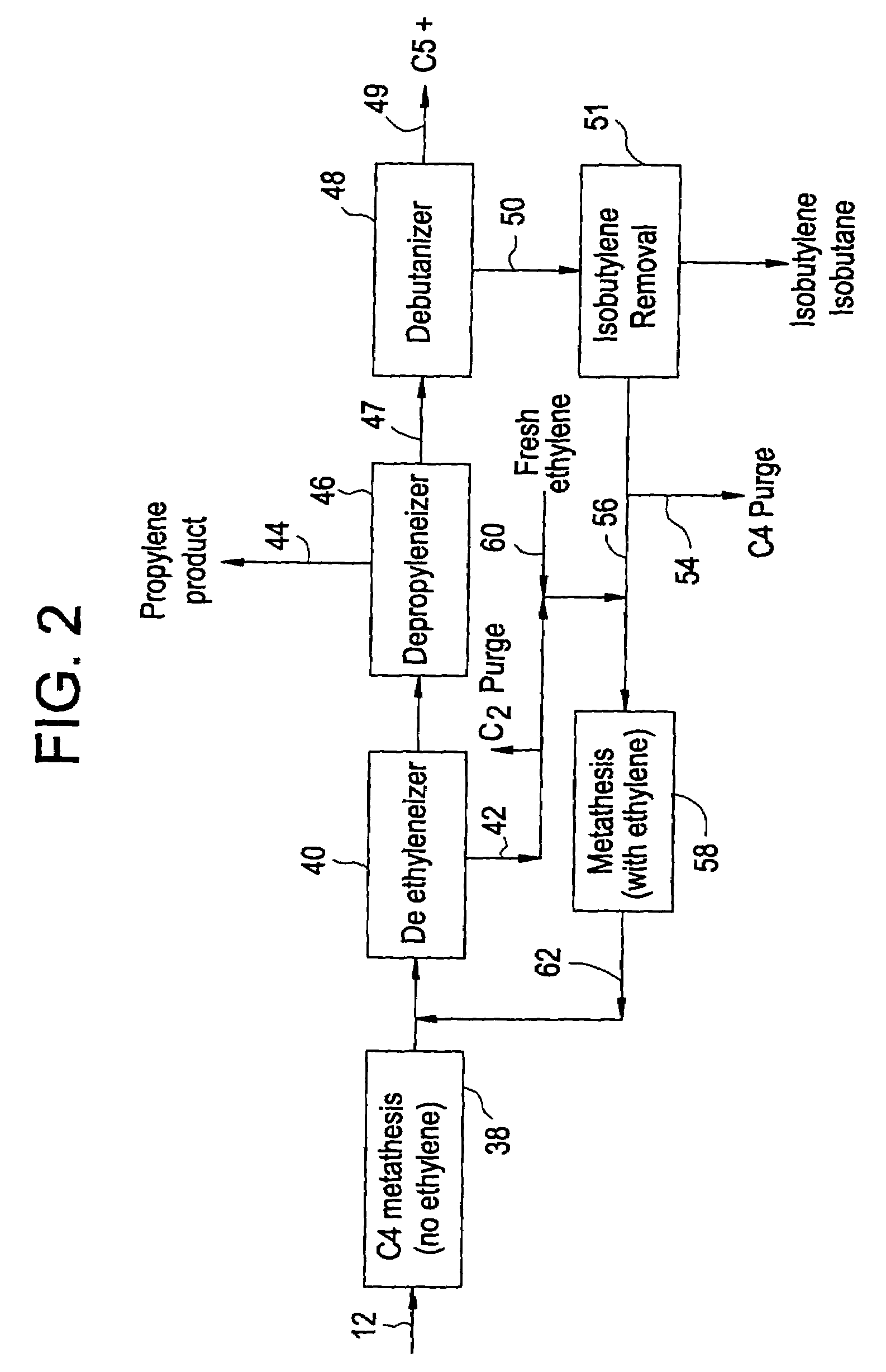

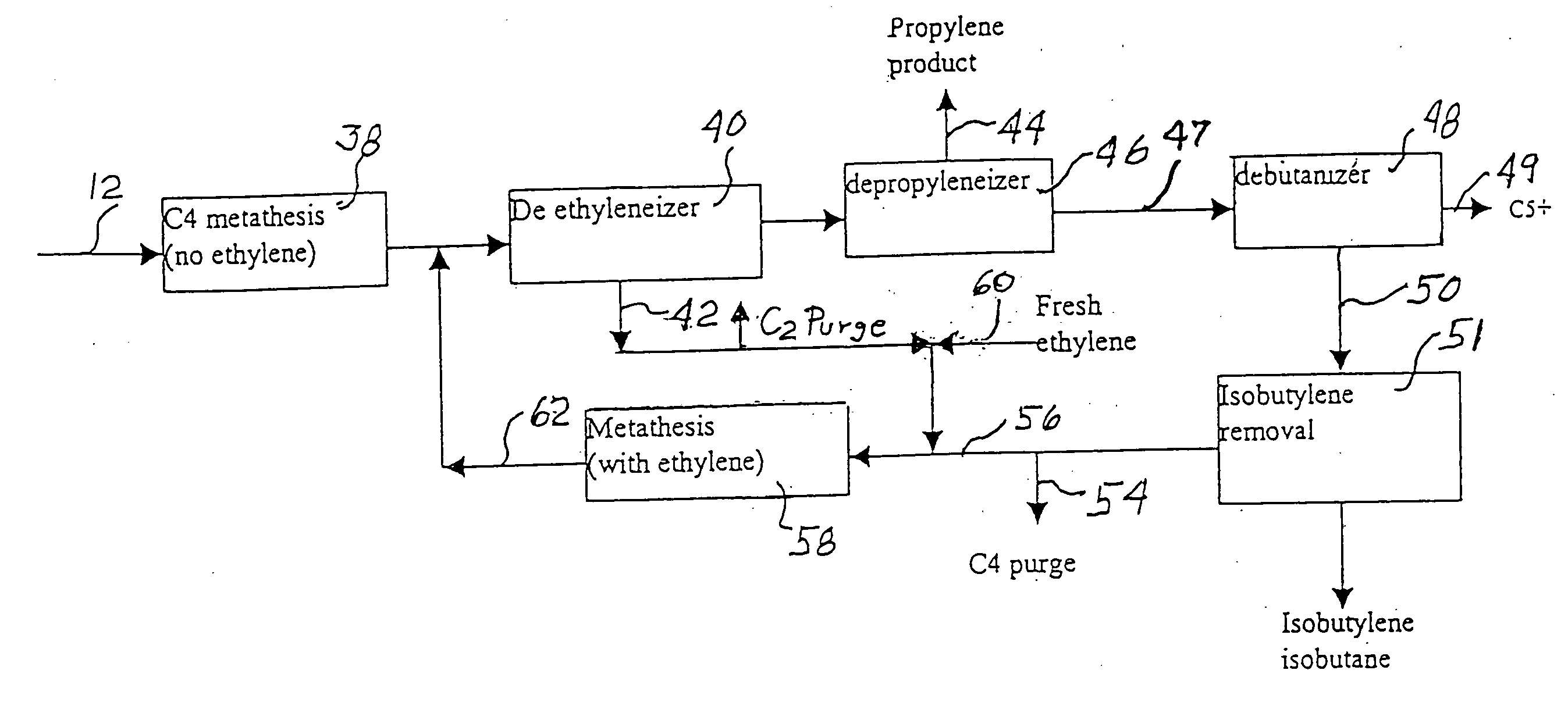

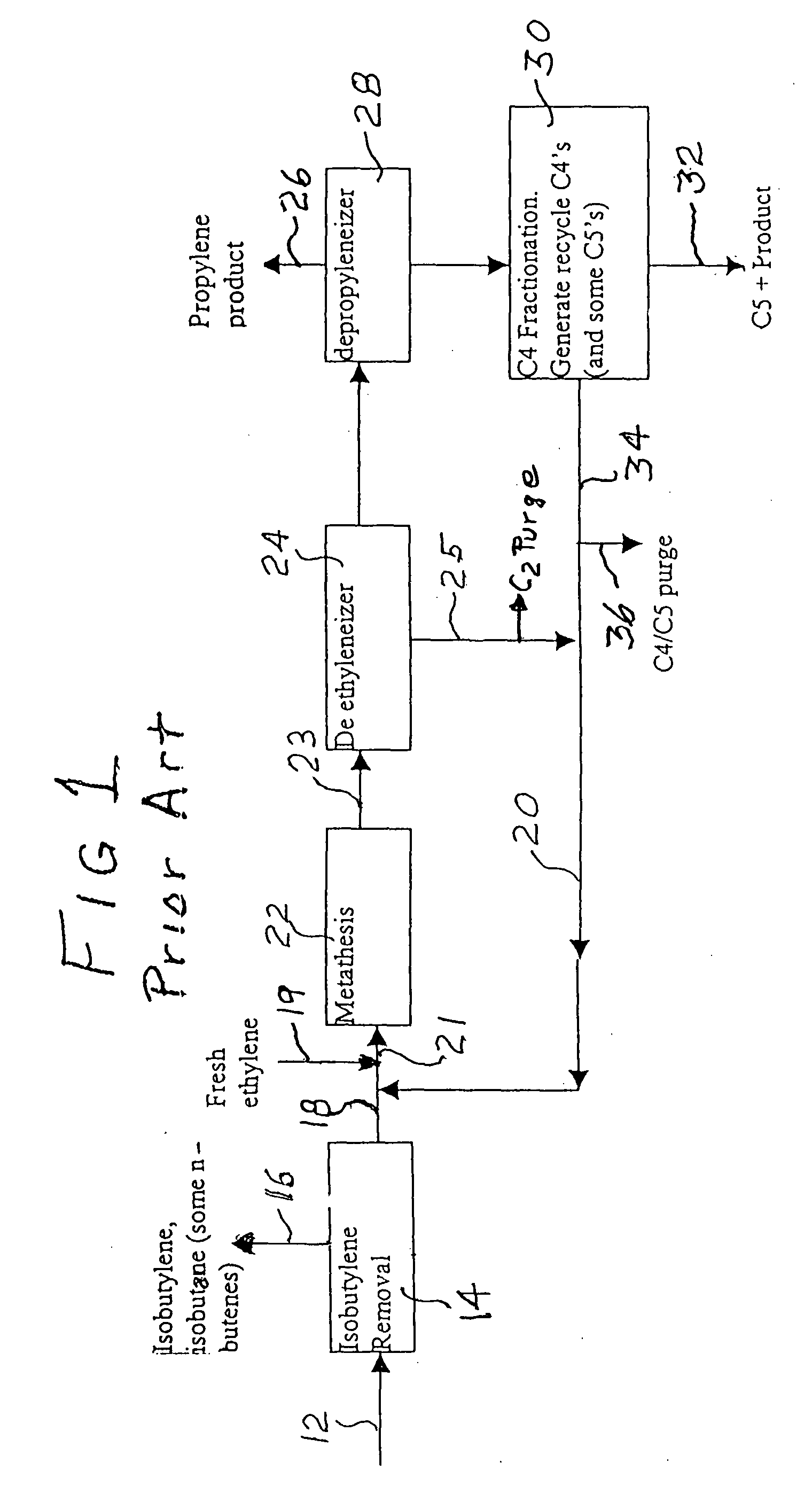

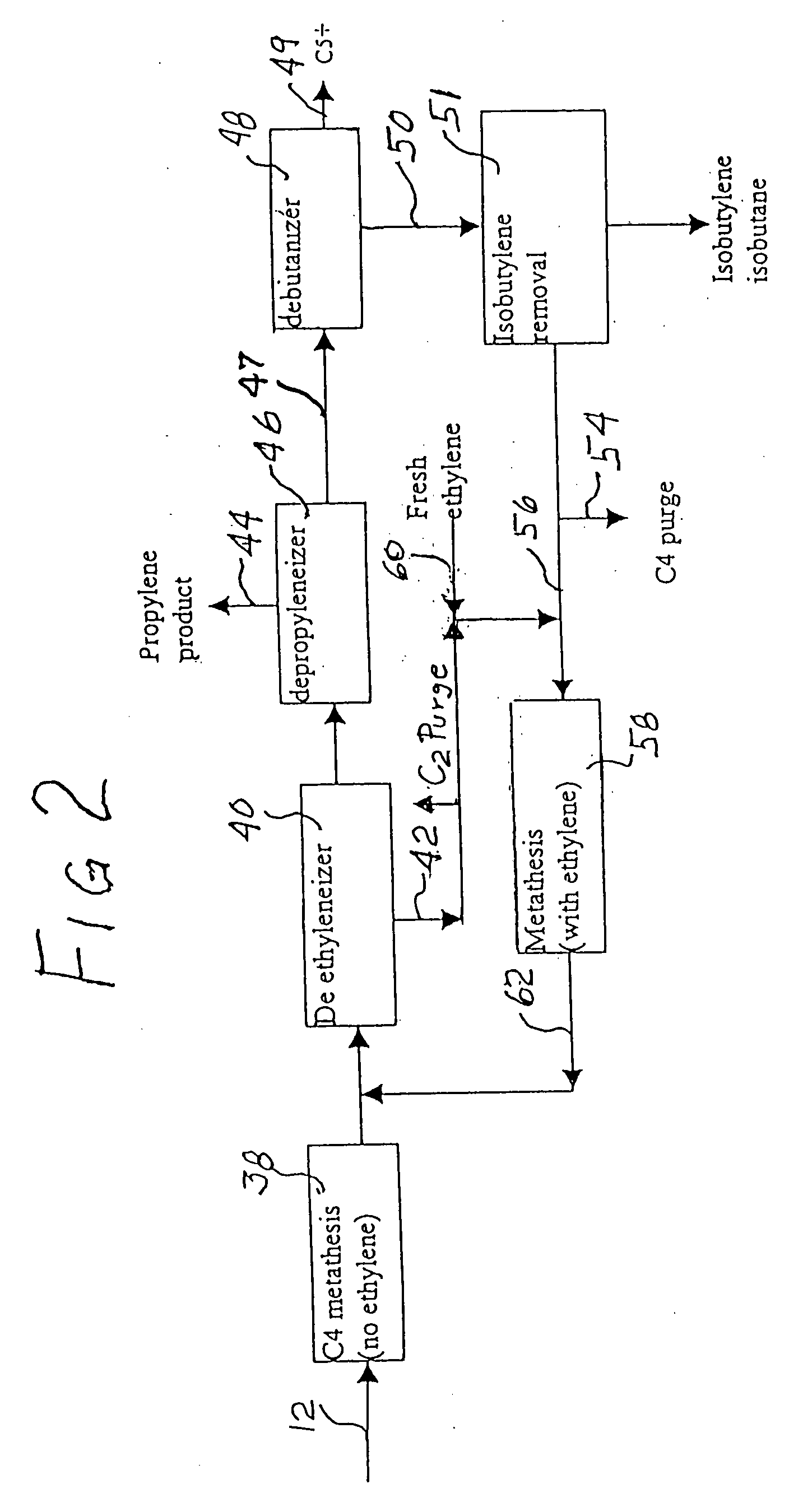

Processing C4 olefin streams for the maximum production of propylene

ActiveUS7214841B2Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

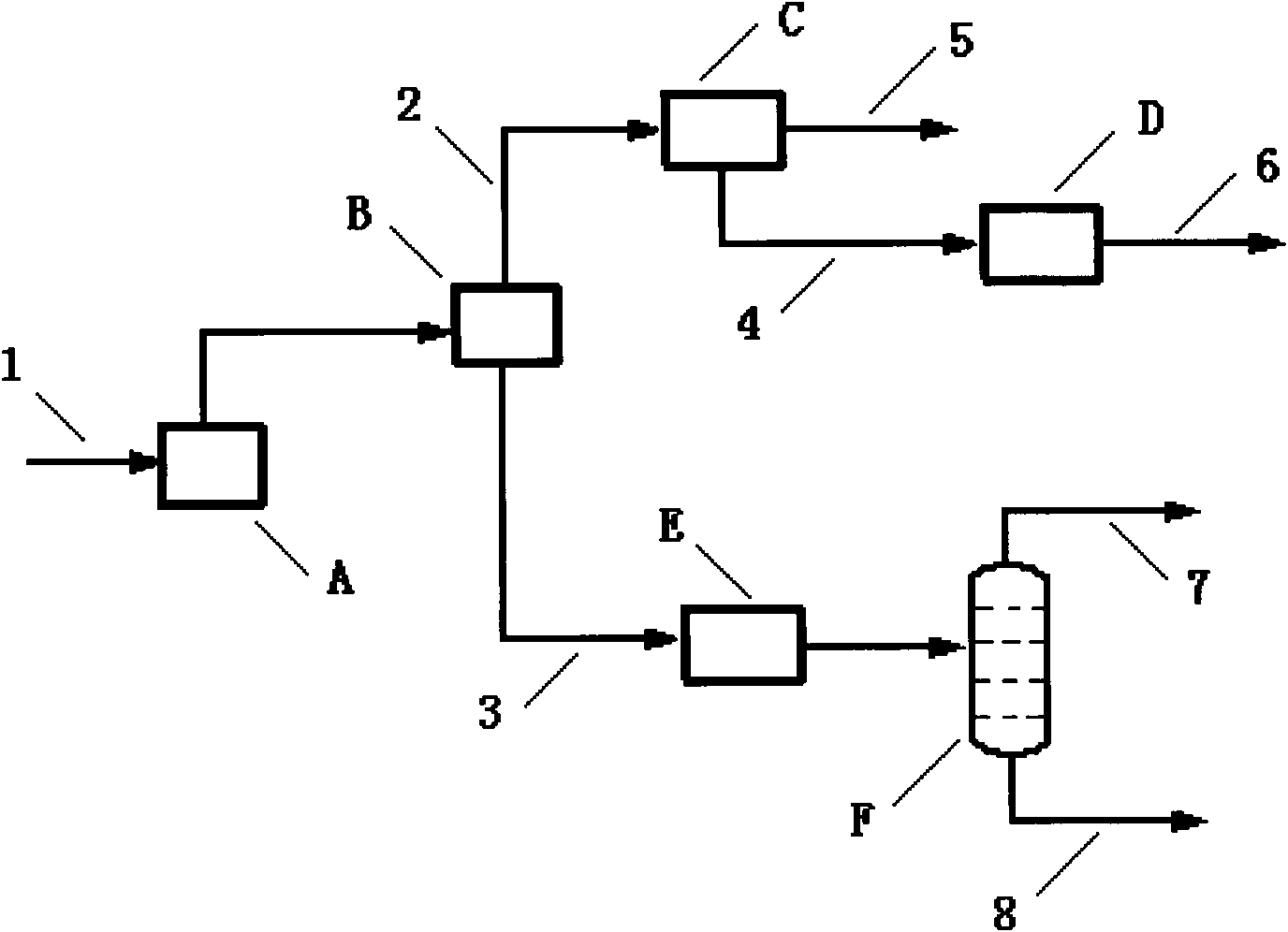

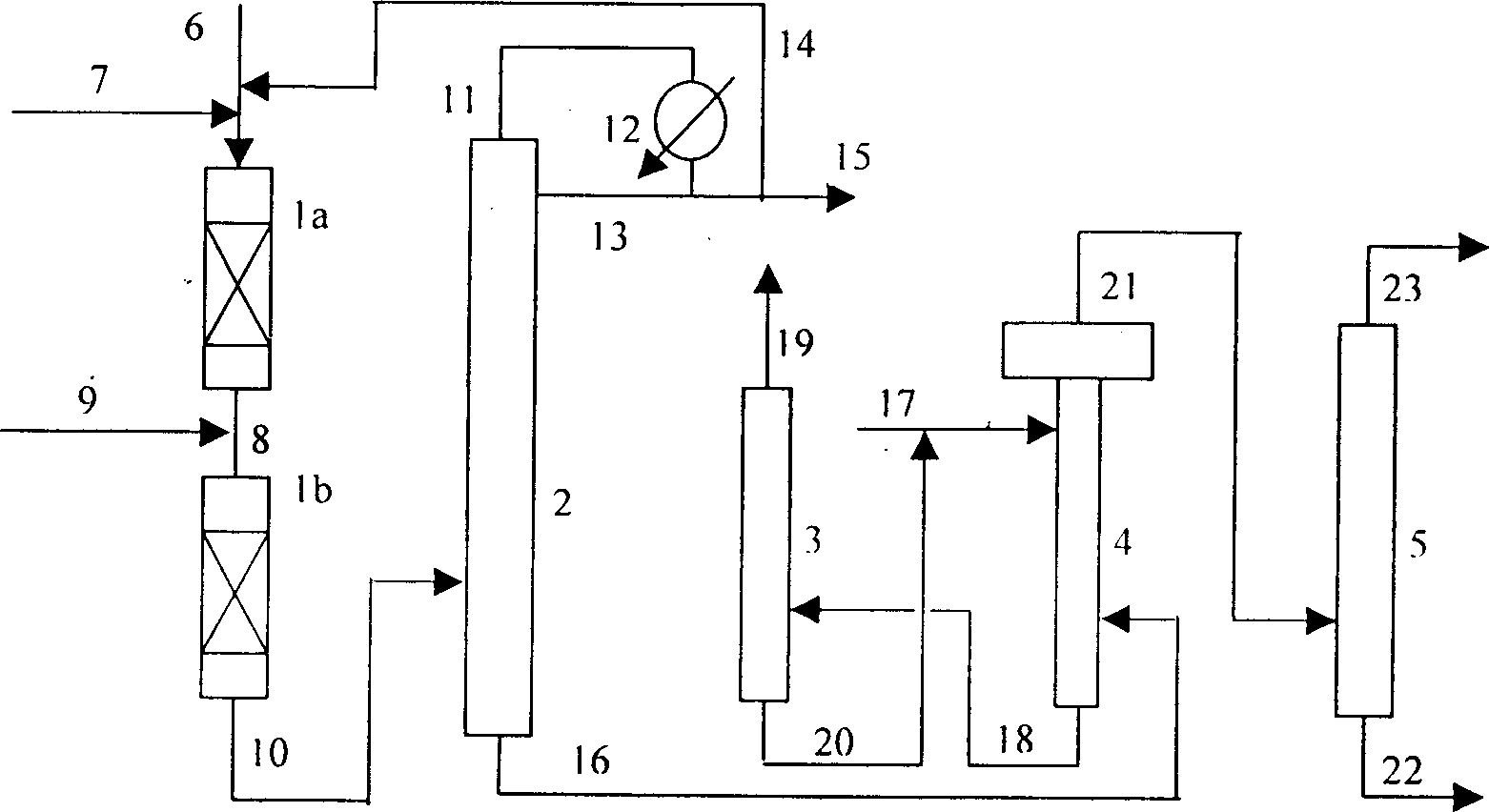

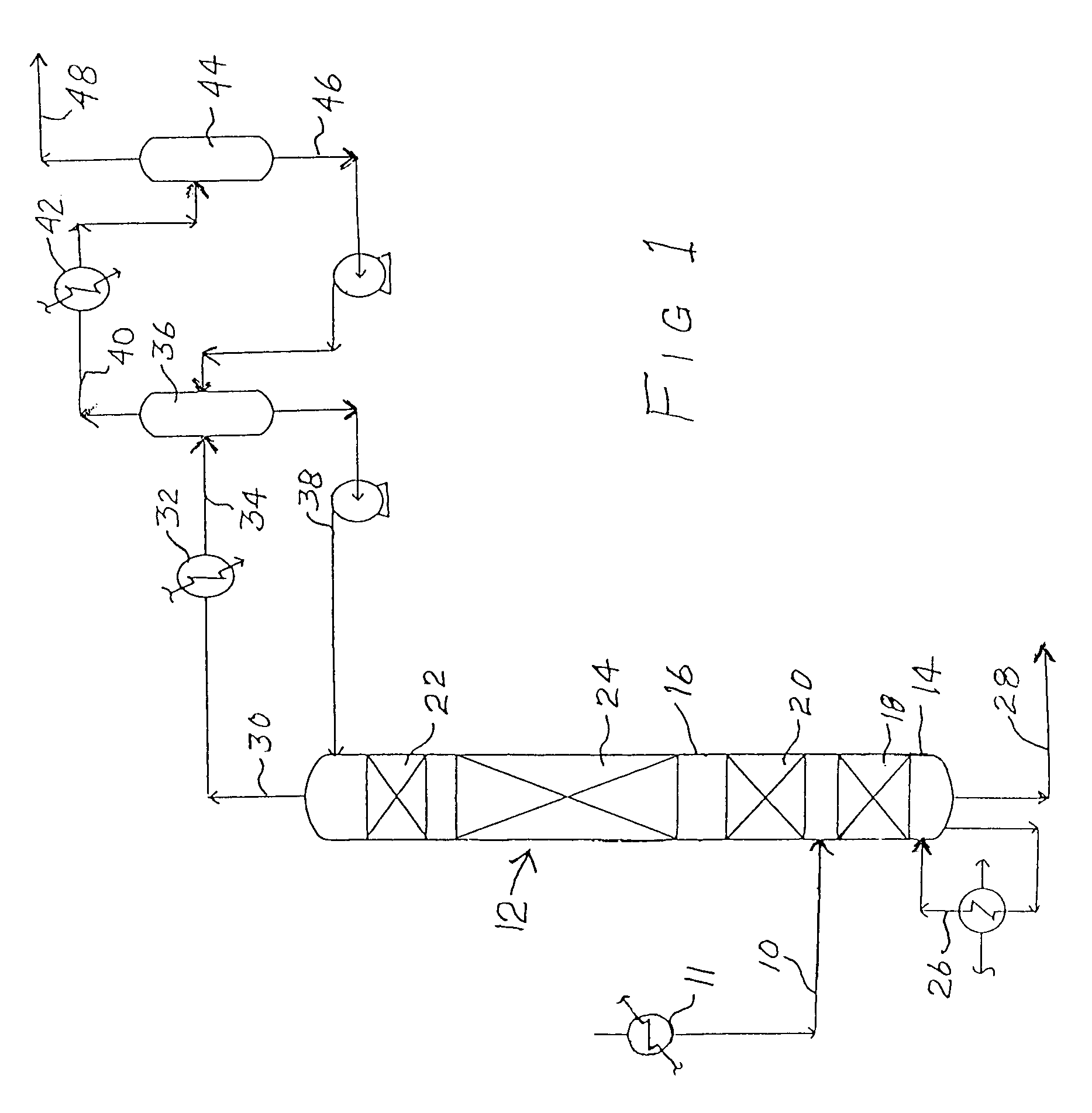

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

Processing C4 olefin streams for the maximum production of propylene

ActiveUS20050014981A1Maximize productionImprove the level ofChemical industryCatalystsCatalytic distillation2-Butene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso- and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

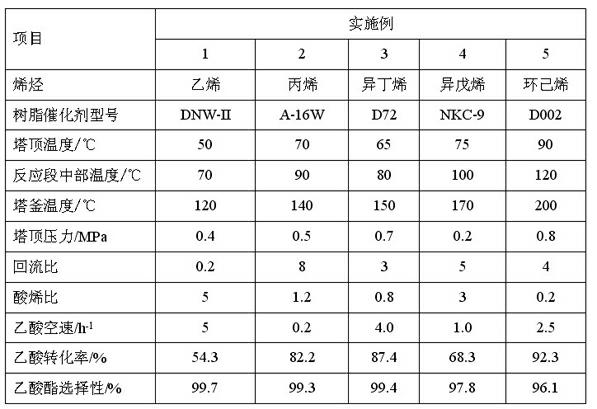

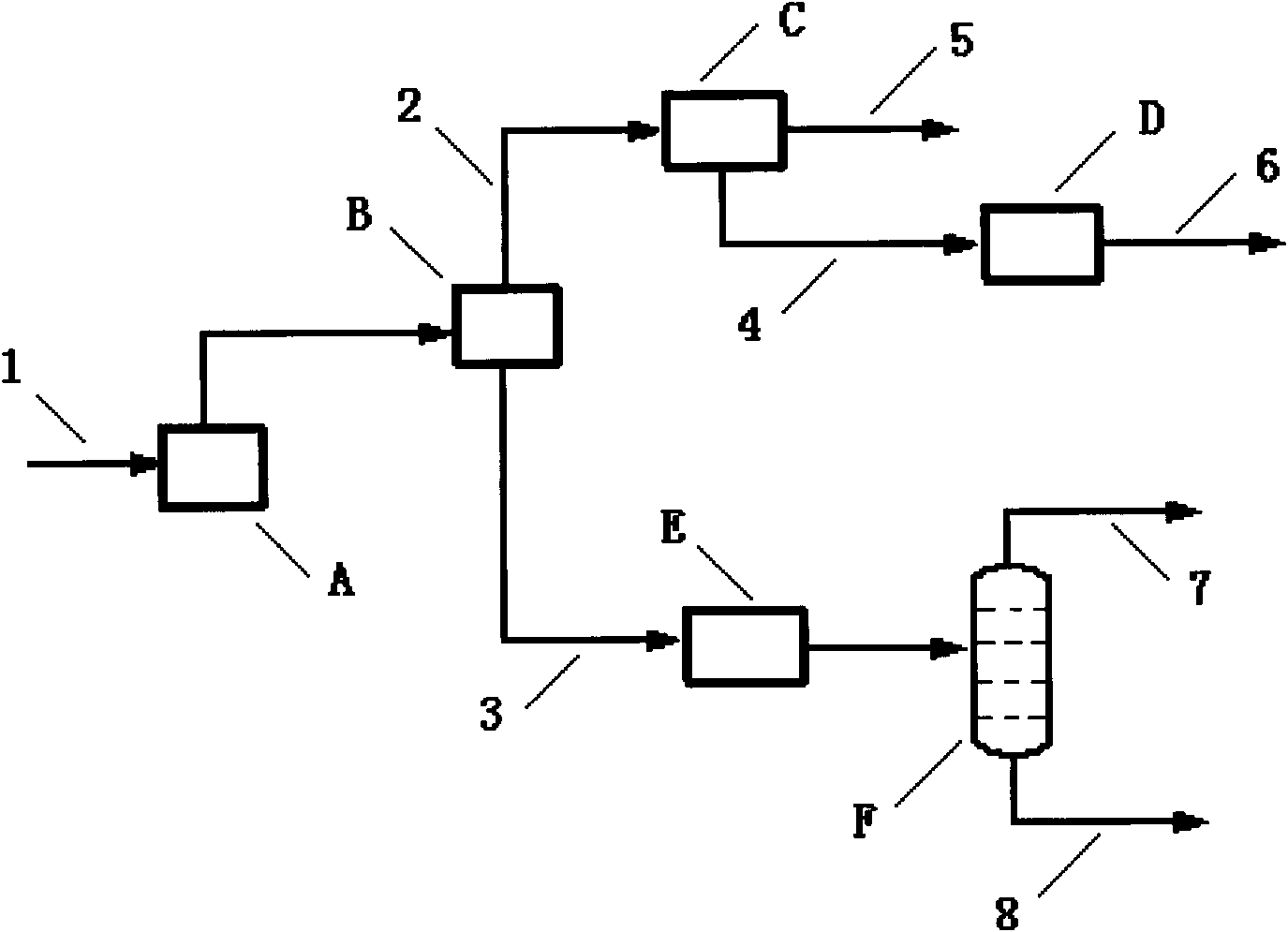

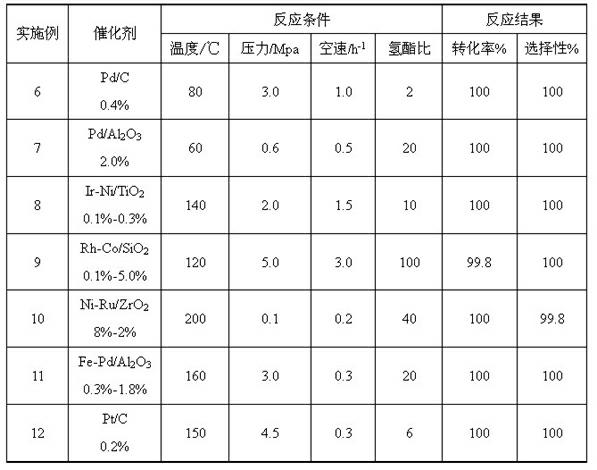

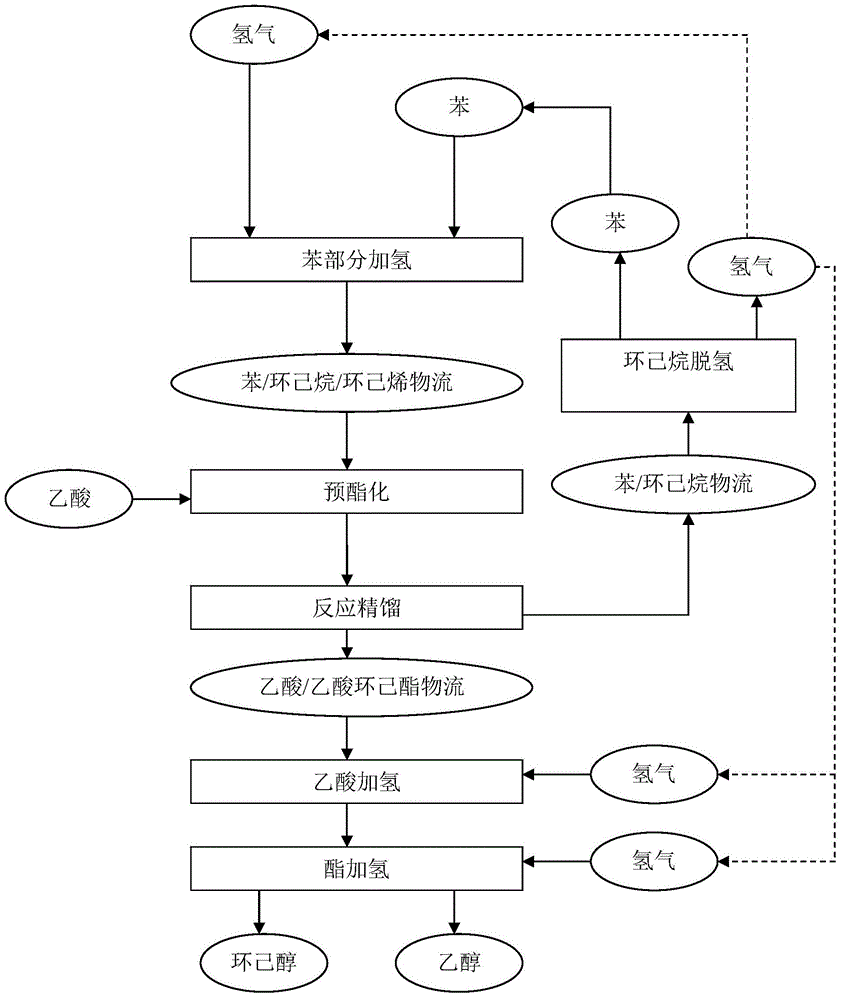

Method for preparing alcohols from olefin

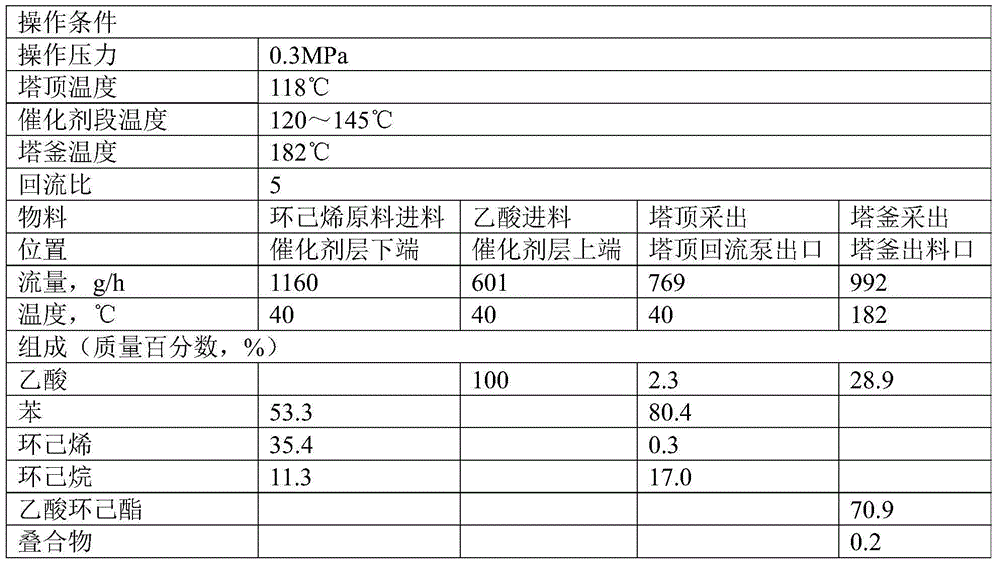

ActiveCN102146019AImprove conversion rateSimple processOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidAlcohol

The invention discloses a method for preparing alcohols from olefin. The method comprises an esterification process and a hydrogenation process. The method comprises the following steps of: performing countercurrent contact on olefin and acetic acid in a catalytic distillation tower on the surface of a solid acid catalyst, and synthesizing corresponding acetic ester by catalytic esterification; and then catalytically converting the acetic ester and hydrogen into corresponding alcohols in a fixed bed reactor by using the synthesized acetic ester as a raw material under a copper-containing hydrogenation catalyst and reaction conditions. The method has the characteristics of simple process flow, mild reaction conditions, low energy consumption, high raw material conversion rate and good production selectivity. Moreover, the method for preparing the corresponding alcohols from the olefin can be also used for preparing acetic ester and ethanol products which are wide in application.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

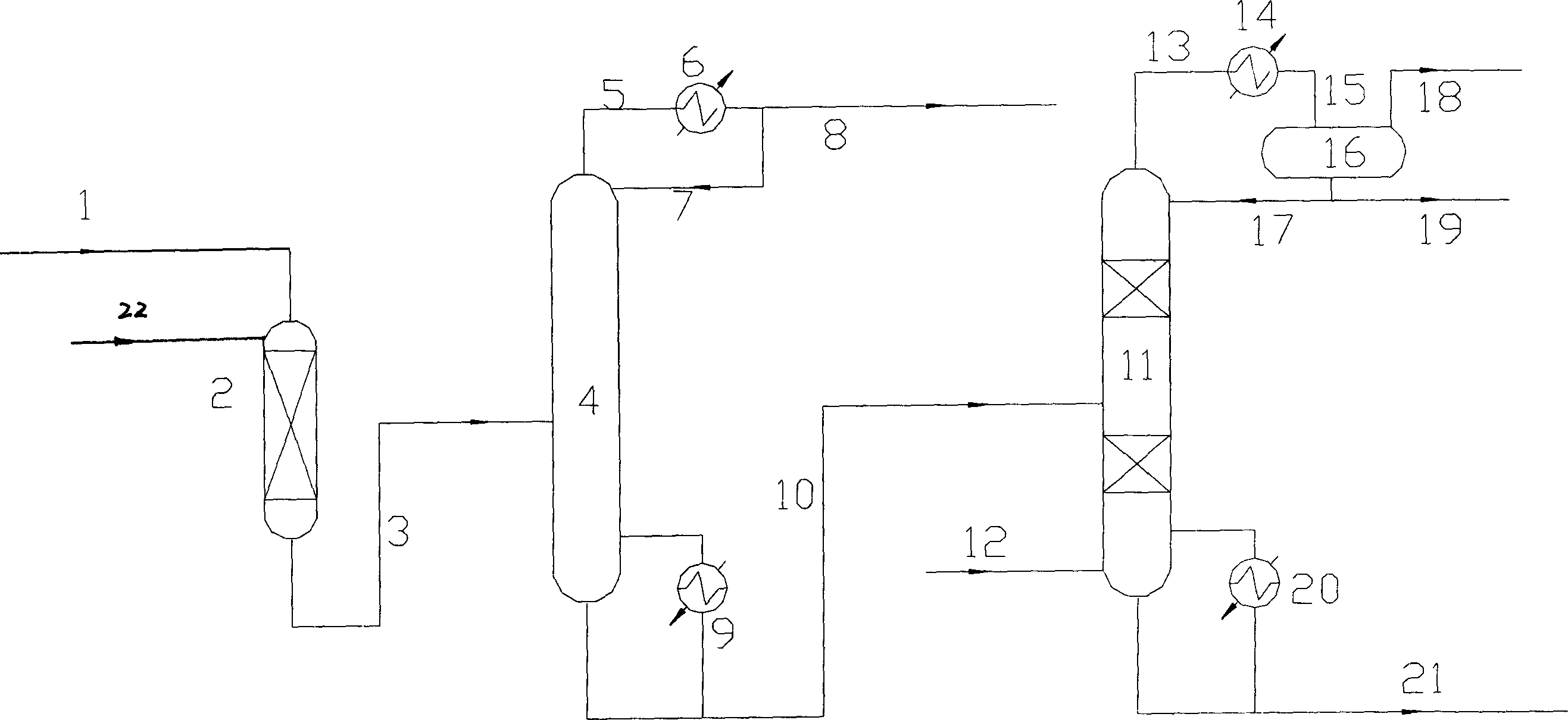

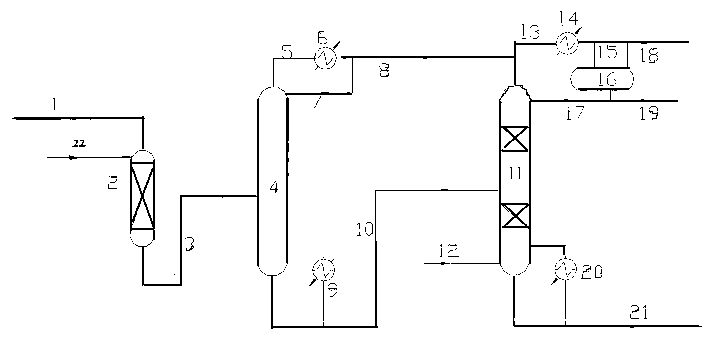

Method for preparing isobutylene by comprehensively using mixed C4

InactiveCN102070391AHigh purityIncrease added valueHydrocarbon by isomerisationChemical industryButeneHigh concentration

The invention provides a method for preparing isobutylene by comprehensively using mixed C4 and mainly solves the problems of low overall utilization efficiency and low additional value of the mixed C4 byproduct of a refinery or a steam cracking device. An aim is fulfilled by adopting a technical scheme which comprises the following steps of: (1) selectively hydrogenating to remove butadiene in the mixed C4; (2) isomerizing butylenes-1 in the mixed C4 obtained in the first step into butylenes-2 by using catalytic distillation technology, and simultaneously dividing the mixed C4 into two strands of materials, namely the first material comprising isobutylene and iso-butane, and the second material comprising n-butane and butylenes-2; (3) separating the first material through an etherifying device to obtain high-purity isobutylene and high-concentration iso-butane; (4) dehydrogenating the iso-butane to obtain the high-purity isobutylene; and (5) isomerizing the butylenes-2 of the second material into the isobutylene by using isomerizing technology, and simultaneously separating to obtain higher-purity n-butane. The method can be applied to the industrial field of producing the high-purity isobutylene.

Owner:王伟跃

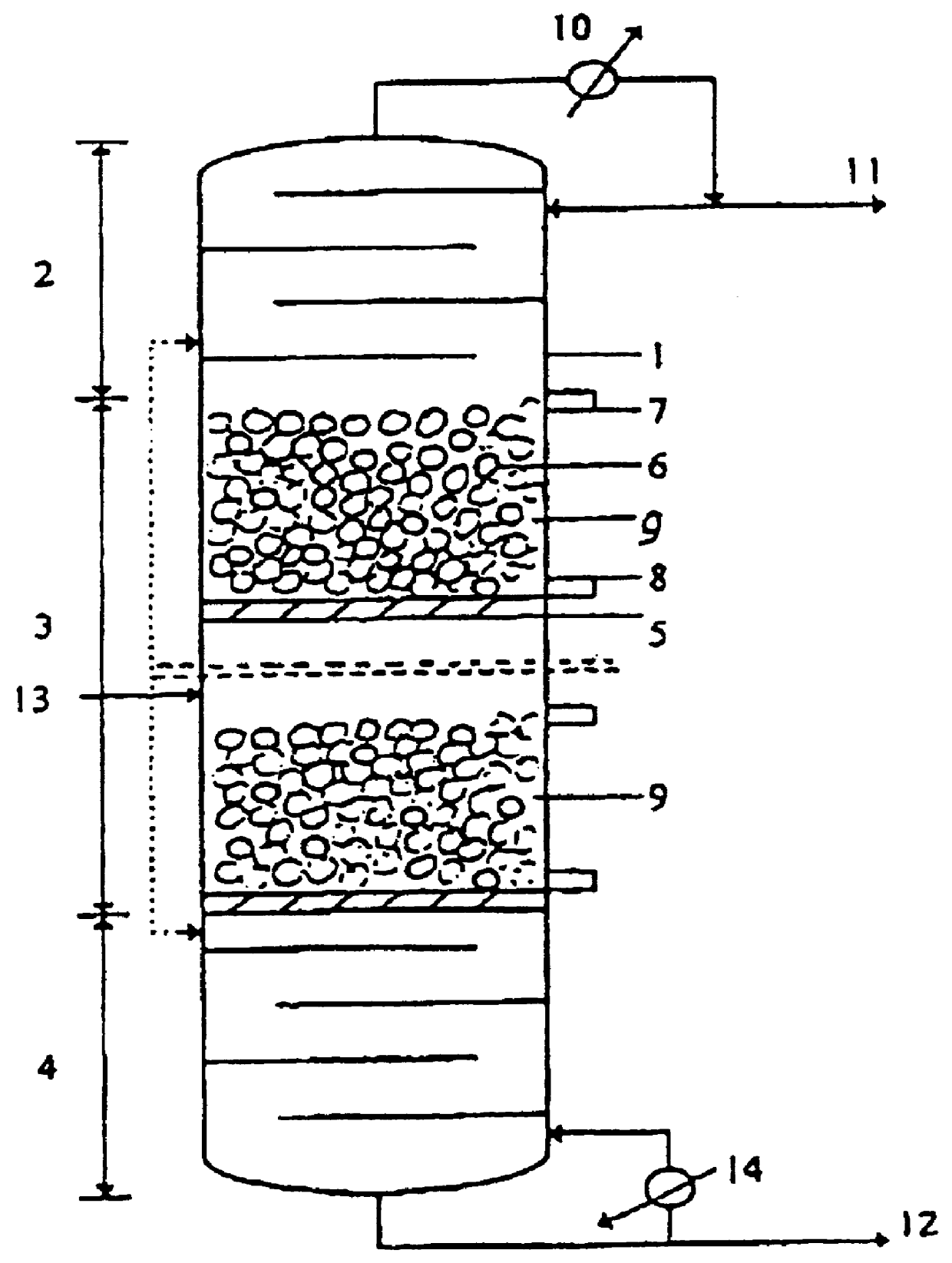

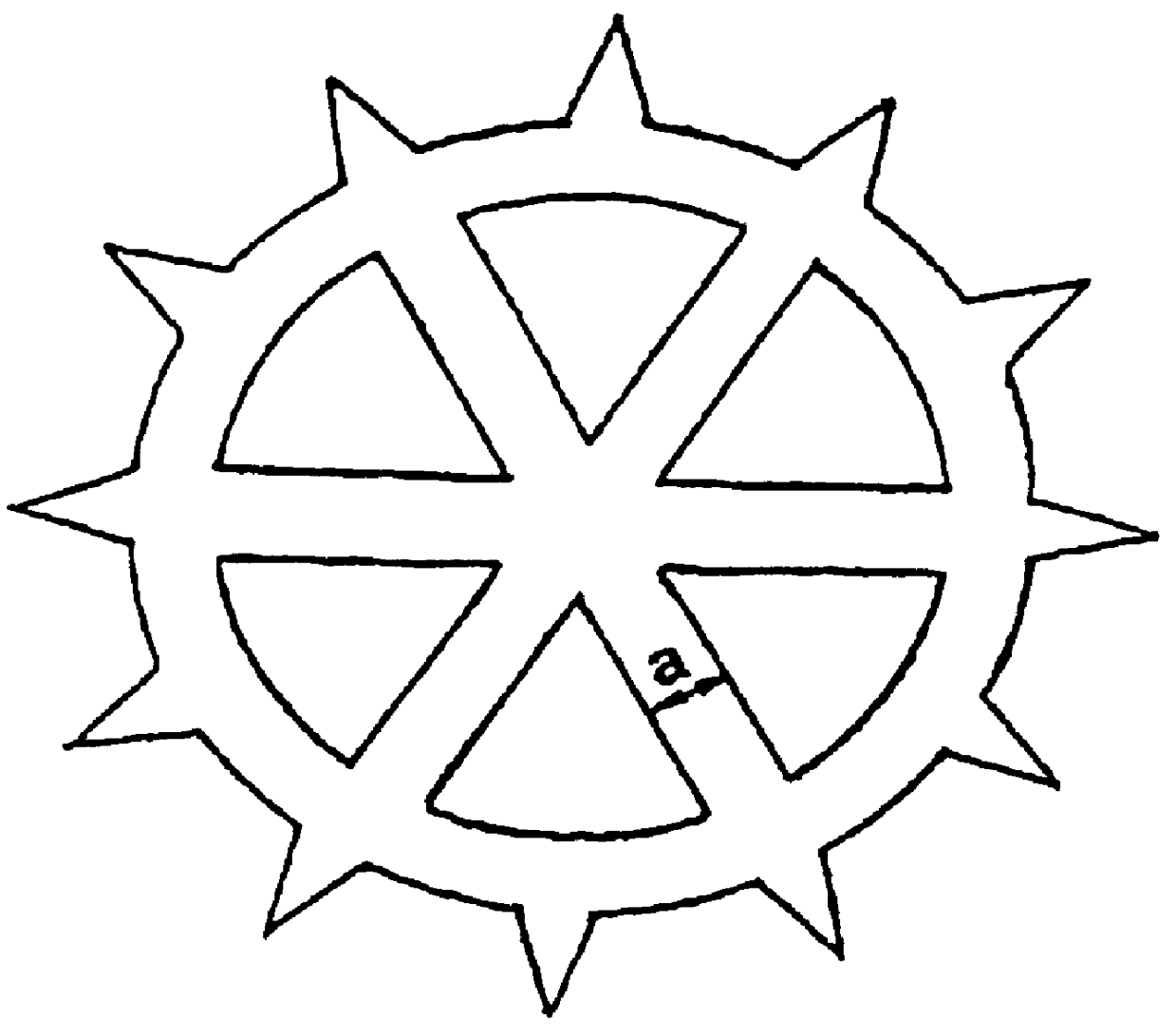

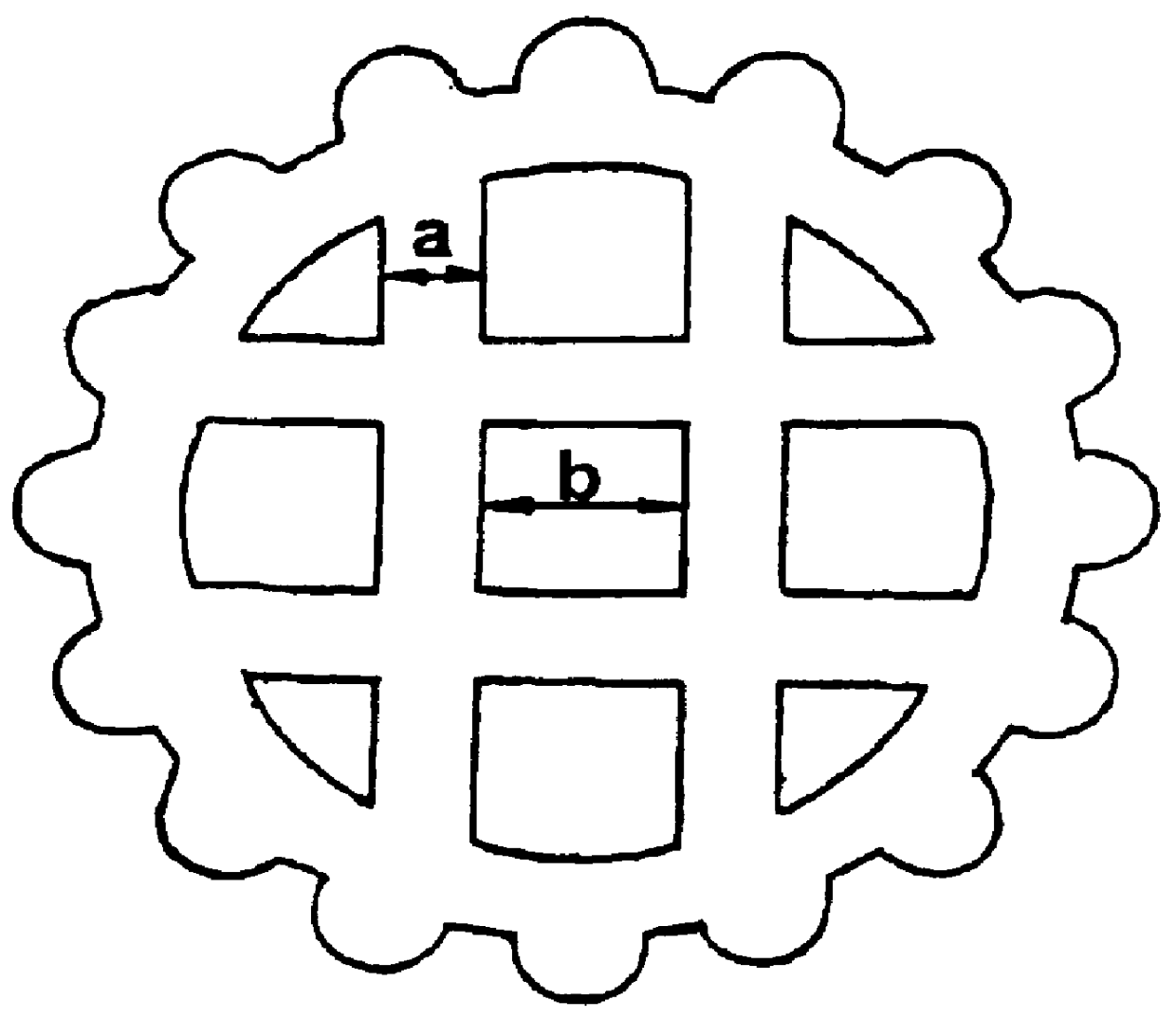

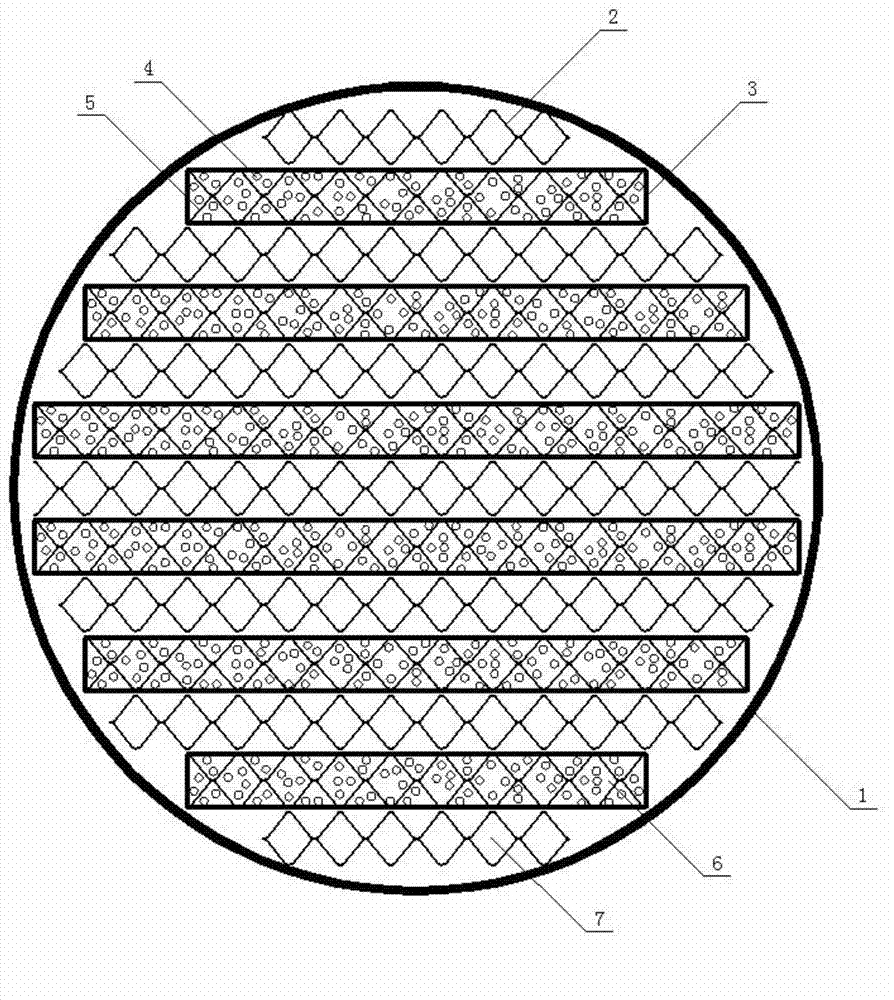

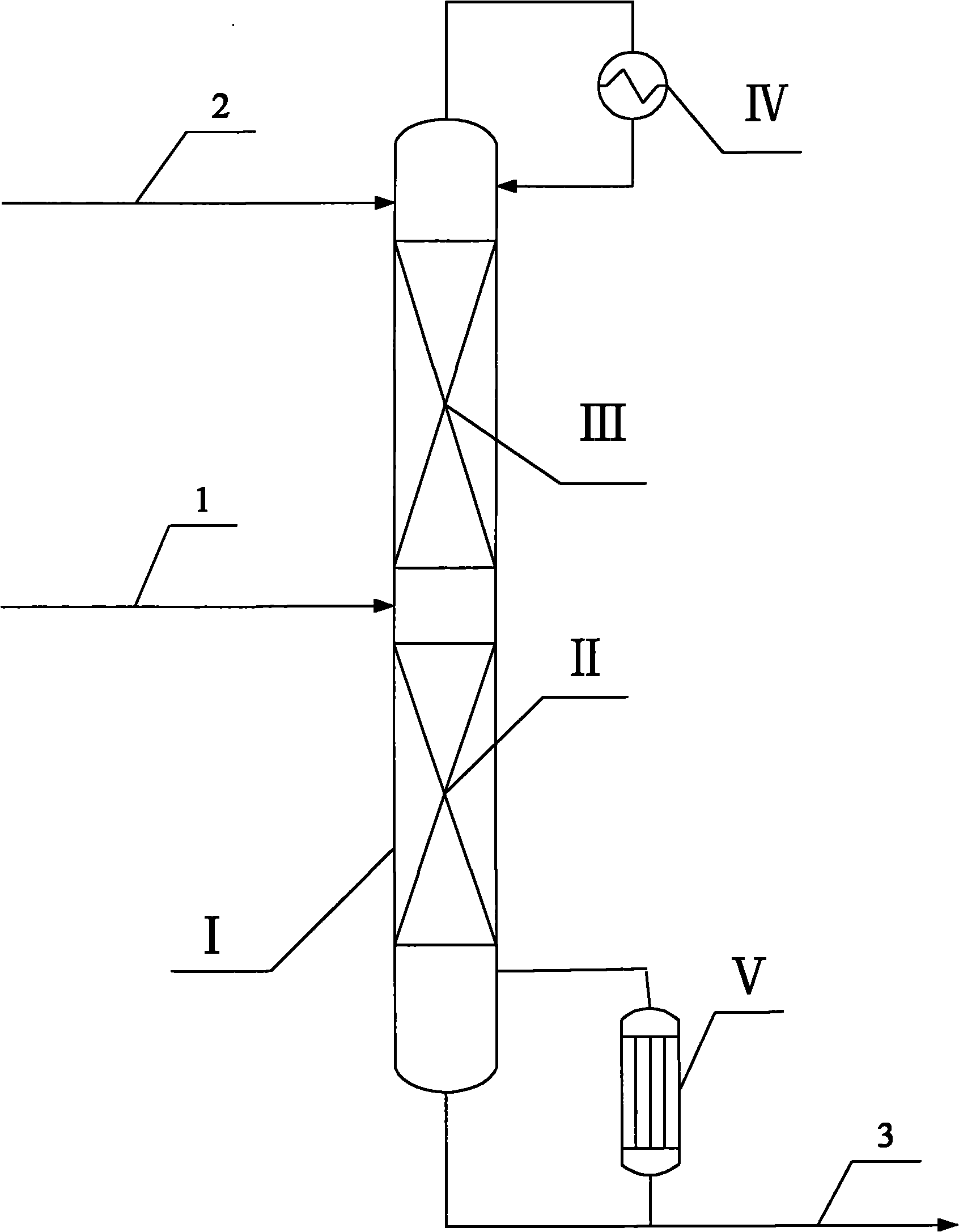

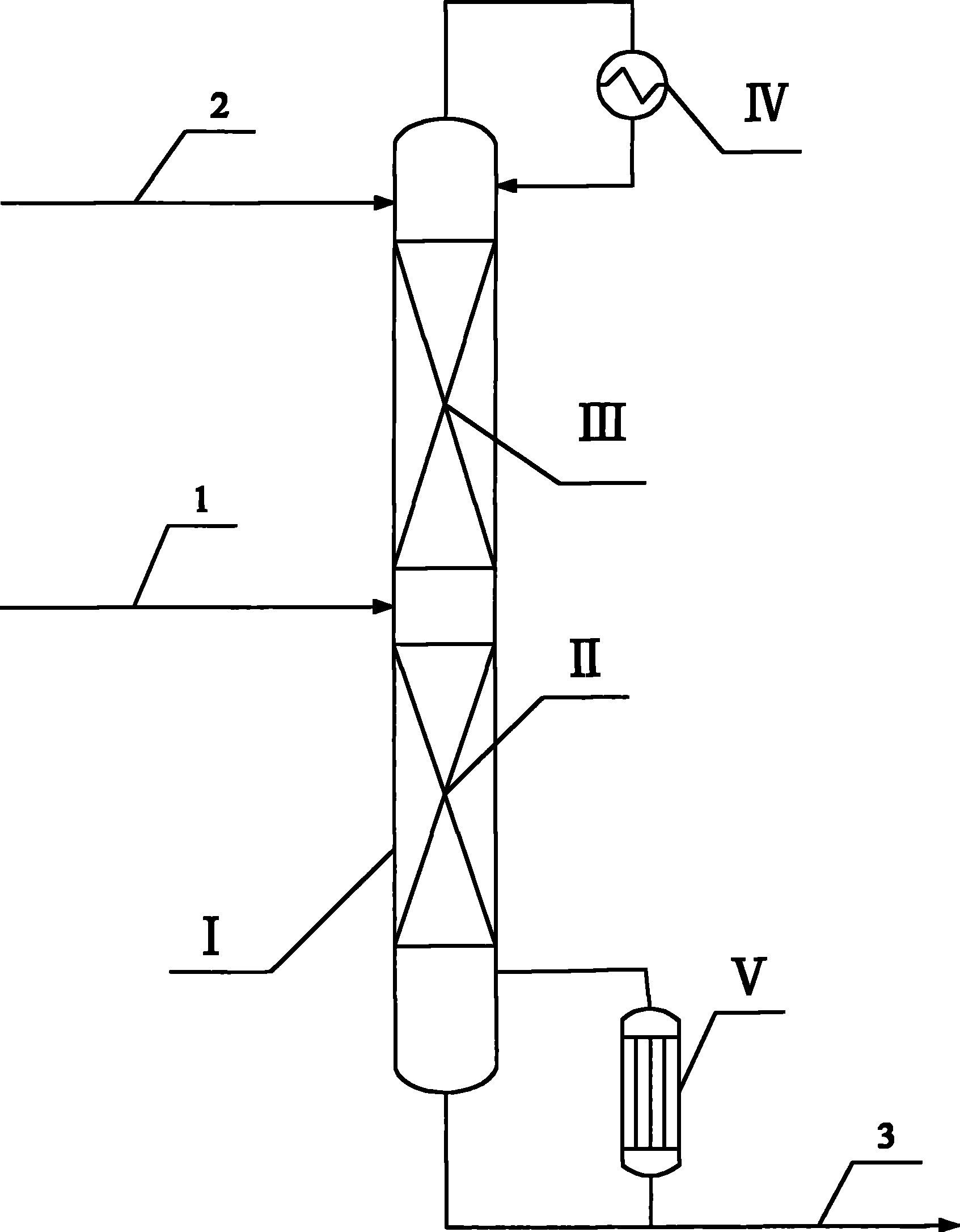

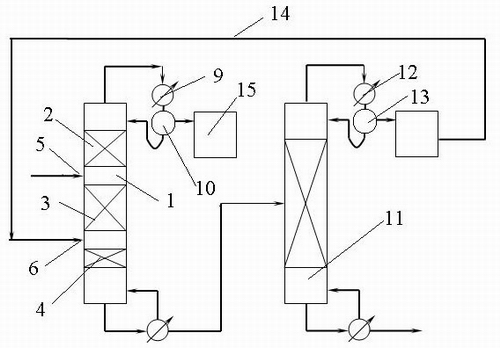

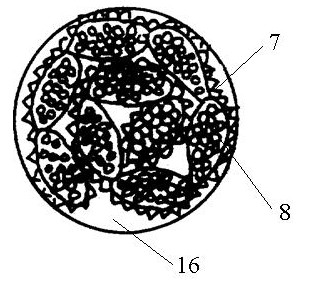

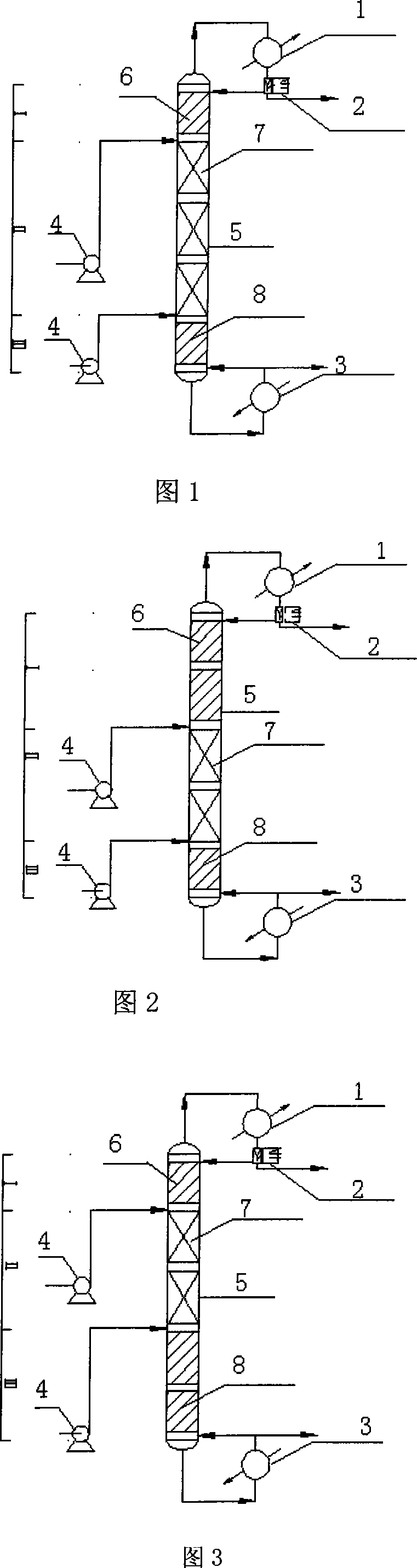

Dual functional catalyst of packing type and the catalytic distillation equipment

InactiveUS6117812AIncrease counter current flow fluxLarge external surface areaMolecular sieve catalystsOther chemical processesFractionationCatalytic distillation

The present invention relates to a dual functional catalyst having both the catalytic reaction function and fractionation function and a catalytic distillation equipment for packing the catalyst therein. Said catalyst has a special shape and can be packed at random into the reaction section of said equipment. So, there exist adequate free spaces inside pellet and between pellets, enabling the vapor and liquid streams to pass through the catalyst beds directly and countercurrently, and contact with the dual functional catalyst directly. The reaction between the reactants and fractionation of products can be carried out simultaneously. Thus a high reaction efficiency is achieved. No special inner part is needed in the reaction section to pack the catalysts, so the structure of the equipment is simple and easy to operate, and the investment and cost of operation are low.

Owner:CHINA PETROCHEMICAL CORP +1

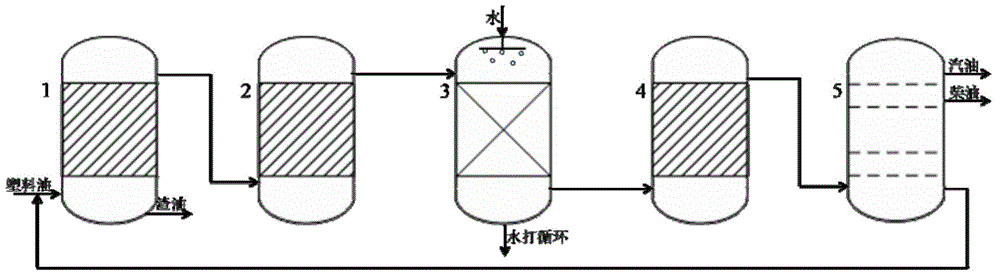

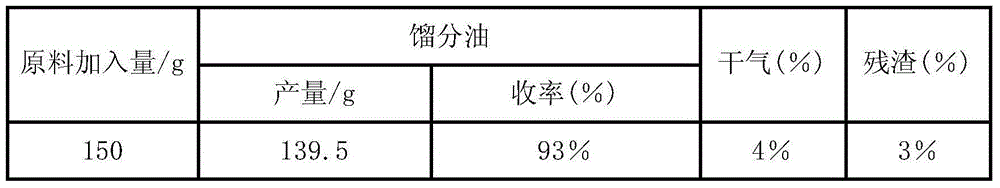

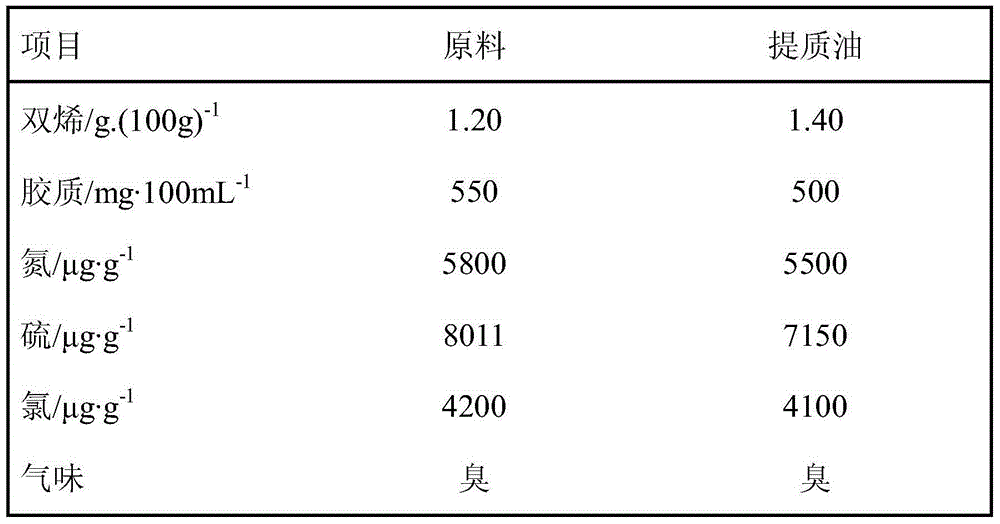

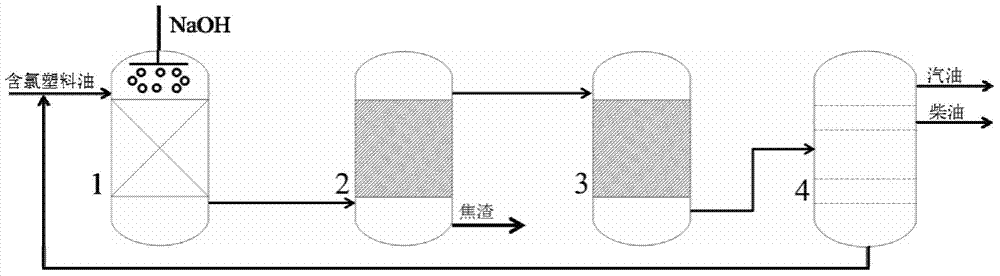

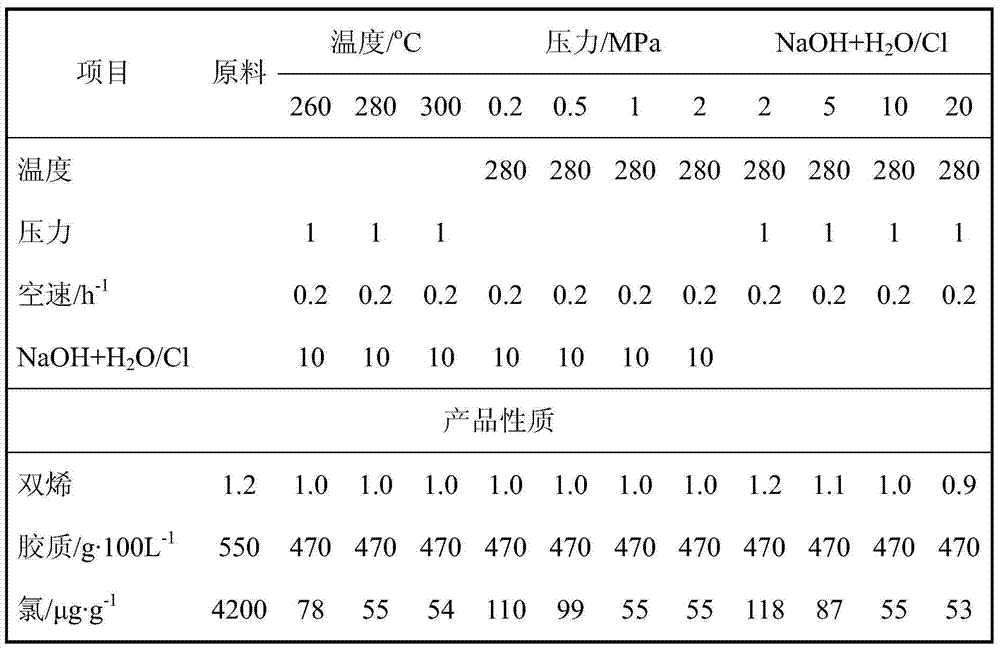

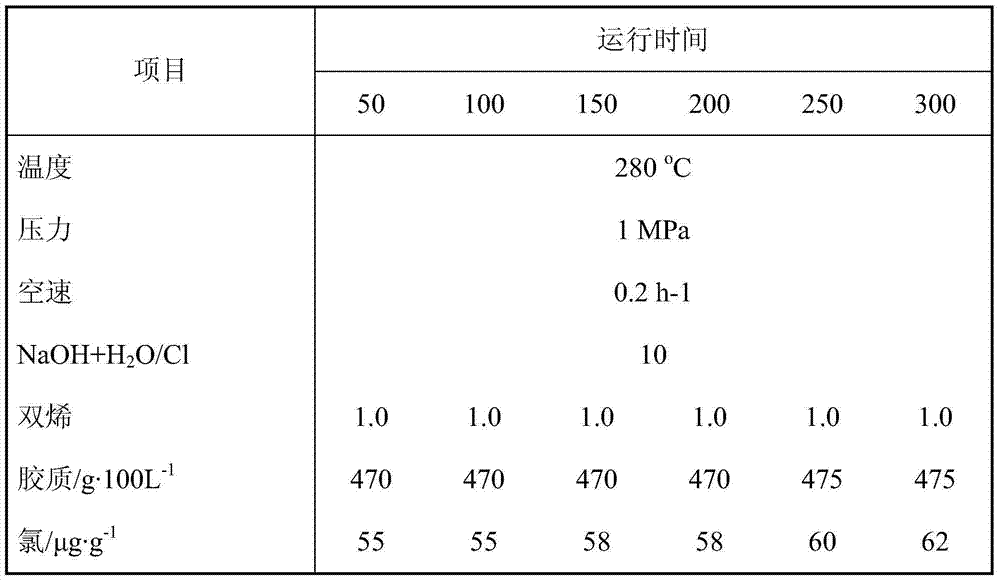

Method for producing clean fuel by adopting chlorine-containing plastic oil

InactiveCN103980938AImprove acid resistanceExtend your lifeLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesCatalytic distillationPetroleum engineering

The invention discloses a method for producing a clean fuel by adopting chlorine-containing plastic oil, and belongs to the fields of environmental protection and energy technologies. The method is characterized by comprising the steps of injecting the chlorine-containing plastic oil into a catalytic distillation tower filled with a molecular sieve / alumina catalyst for reaction and rectification; performing heat exchange on the chlorine-containing plastic oil after catalytic cracking, feeding the chlorine-containing plastic oil after heat exchange into a low-pressure liquid phase hydrogenation tower, and performing hydrogenation and dechlorination, wherein the used catalyst is a supported metal catalyst; feeding the distillate oil after the liquid phase hydrogenation into a washing tower, circulating the aqueous phase of the lower layer at the tower bottom, compressing the washed distillate oil of the upper layer, feeding the distillate oil into a hydrofining tower, hydrofining with a sulfide catalyst, removing monoene compounds through monoene hydrogenation saturation reaction, removing sulfur, nitrogen and colloids to obtain mixed gasoline and diesel oil without peculiar smell and with high quality, distilling to obtain distillate oil of gasoline and diesel oil, and mixing the heavy oil at the tower bottom and the chlorine-containing plastic oil serving as a raw material for reacting again. The method has the advantages that the process is simple and the activity and selectivity of the catalysts are high, and has good economic benefits and industrial application prospect.

Owner:DALIAN UNIV OF TECH +1

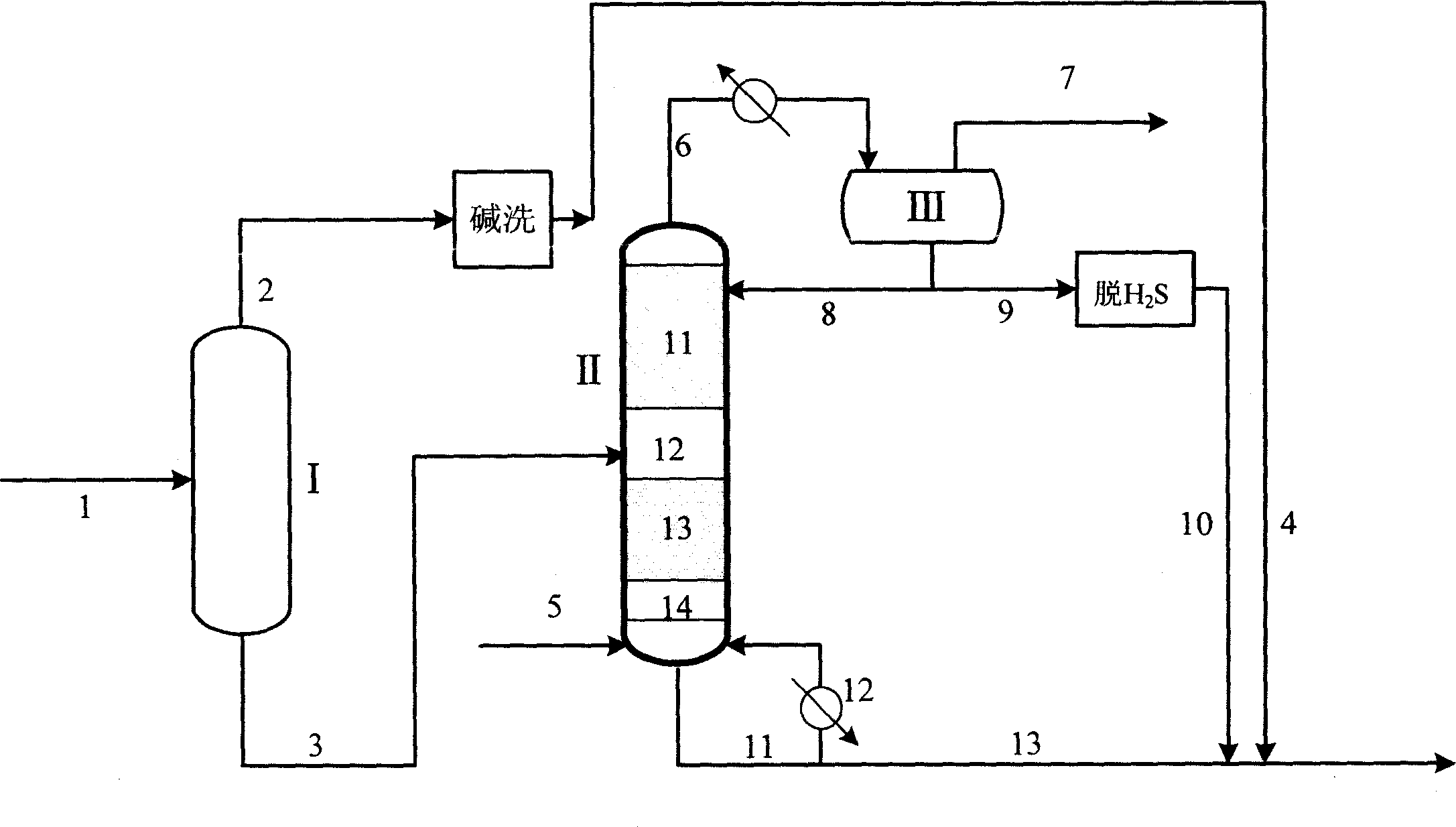

Desulfurization process of gasoline

A process for desulfurizing gasoline includes such steps as reaction between thiol and diolefin in gasoline in fixed-bed reactor to generate S-contained compound with higher boiling point, separatingout low-sulfure light fraction from the gasoline in distilling tower, hydrodesulfurizing or selective hydrodesulfurizing in catalytic distilling tower to convert said S-contained compound and other sulfide to hydrogen sulfide, discharging the hydrogen sulfide, residual hydrogen and part of gasoline fraction from the tower top, and discharging the heavy components of gasoline from tower still. Itsadvantages are less consumption of hydrogen and high output rate of liquid.

Owner:CHINA PETROLEUM & CHEM CORP

Process for making a lube base stock from a lower molecular weight feedstock in a catalytic distillation unit

InactiveUS6841711B2Sufficient reaction rateImprove oil yieldHydrocarbon by hydrogenationLiquid hydrocarbon mixtures productionCatalytic distillationHydrocarbon

A process for making a lube base stock wherein an olefinic feedstock is contacted with an oligomerization catalyst in a catalytic distillation unit to produce a product having a higher number average molecular weight than the olefinic feedstock. That product is separated zone in the catalytic distillation unit into a light byproduct fraction and a heavy product fraction that includes hydrocarbons in a lube base stock range.

Owner:CHEVROU USA INC

Processing C4 olefin streams for the maximum production of propylene

In order to maximize the production of propylene when the external supply of ethylene is limited, the C4 cut from a hydrocarbon cracking process is first subjected to autometathesis prior to any isobutylene removal and without any ethylene addition. This favors the reactions which produce propylene and pentenes. The ethylene and propylene produced are then removed leaving a stream of the C4's and heavier components. The C5 and heavier components are then removed leaving a mixture of 1-butene, 2-butene, isobutylene, and iso-and normal butanes. The isobutylene is next removed preferably by a catalytic distillation hydroisomerization de-isobutyleneizer. The isobutylene-free C4 stream is then mixed with the product ethylene removed from the autometathesis product together with any fresh external ethylene needed and subjected to conventional metathesis producing additional propylene.

Owner:ABB LUMMUS GLOBAL INC

Method for preparing dimethyl succinate

ActiveCN102070448ASimple separation processImprove responseOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystSolid acid

The invention discloses a method for preparing dimethyl succinate. The method comprises two reaction processes of esterification and hydrogenation and the reaction processes are as follows: (1) after pre-esterification reaction, maleic anhydride-methanol solution enters a catalytic distillation tower from the upper rectifying section of the tower, methanol enters the tower from the lower stripping section of the catalytic distillation tower, the reaction section is filled with solid acid catalyst, the two material flows perform countercurrent contact on the surface of the catalyst to perform esterification reaction and synthetize dimethyl maleate; and (2) dimethyl maleate and hydrogen are placed in a fixed bed reactor to perform hydrogenation reaction and generate the dimethyl succinate product in the presence of hydrogenation catalyst under a certain reaction condition. The method of the invention has the advantages of high raw material conversion rate and good product selectivity; and the process flow is simple, the energy consumption is low, no pollution can be caused and the scale production of dimethyl succinate can be realized.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

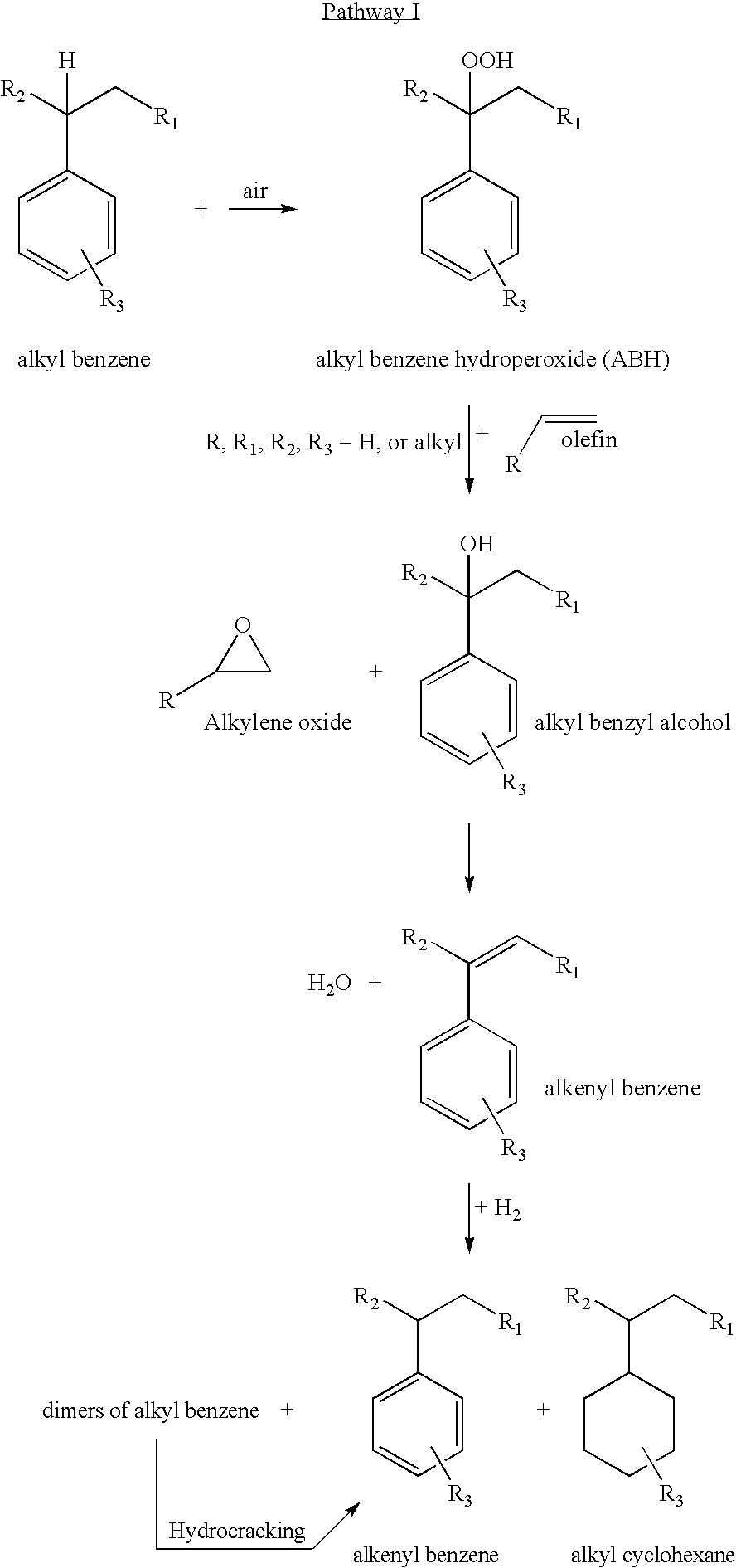

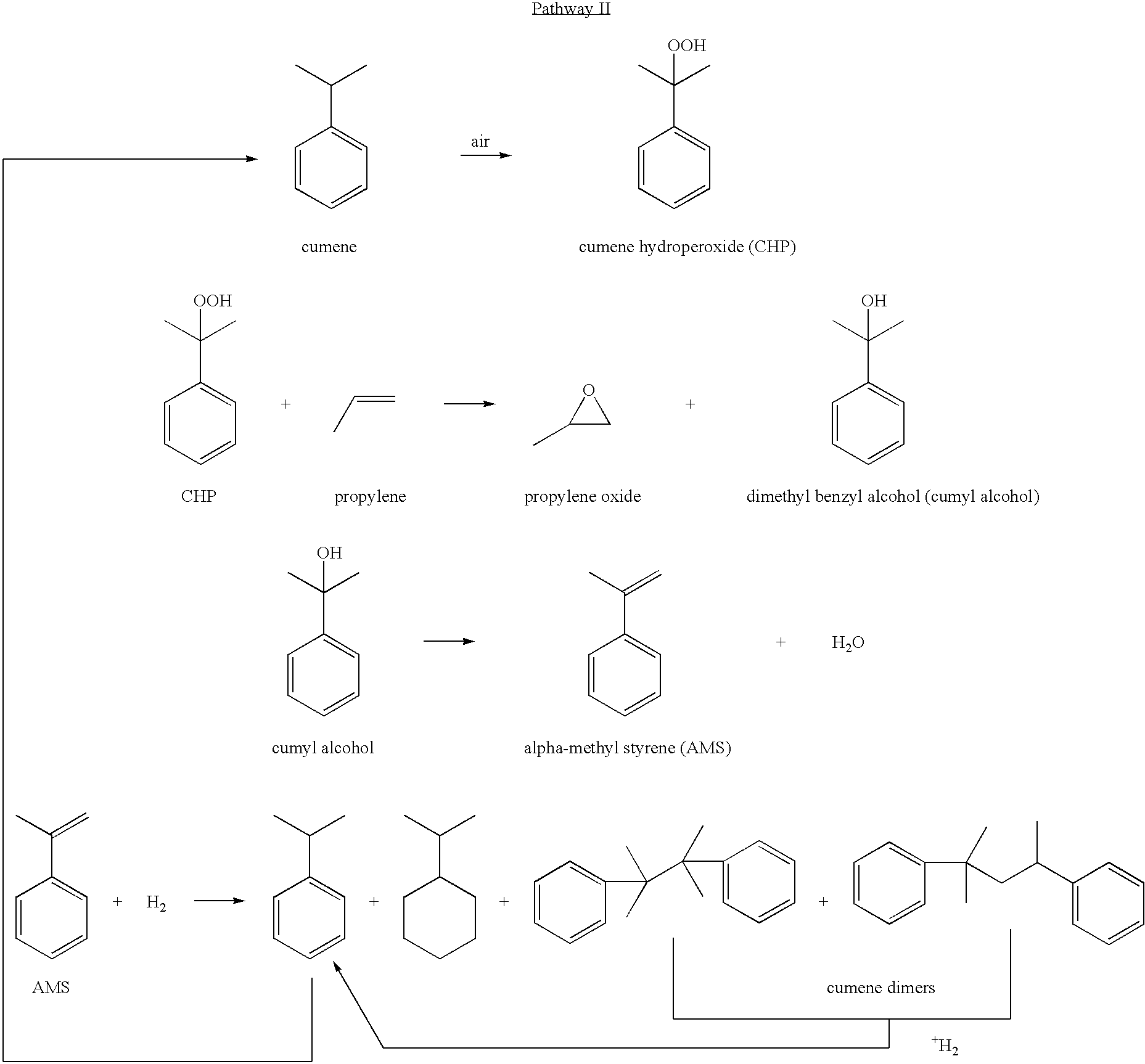

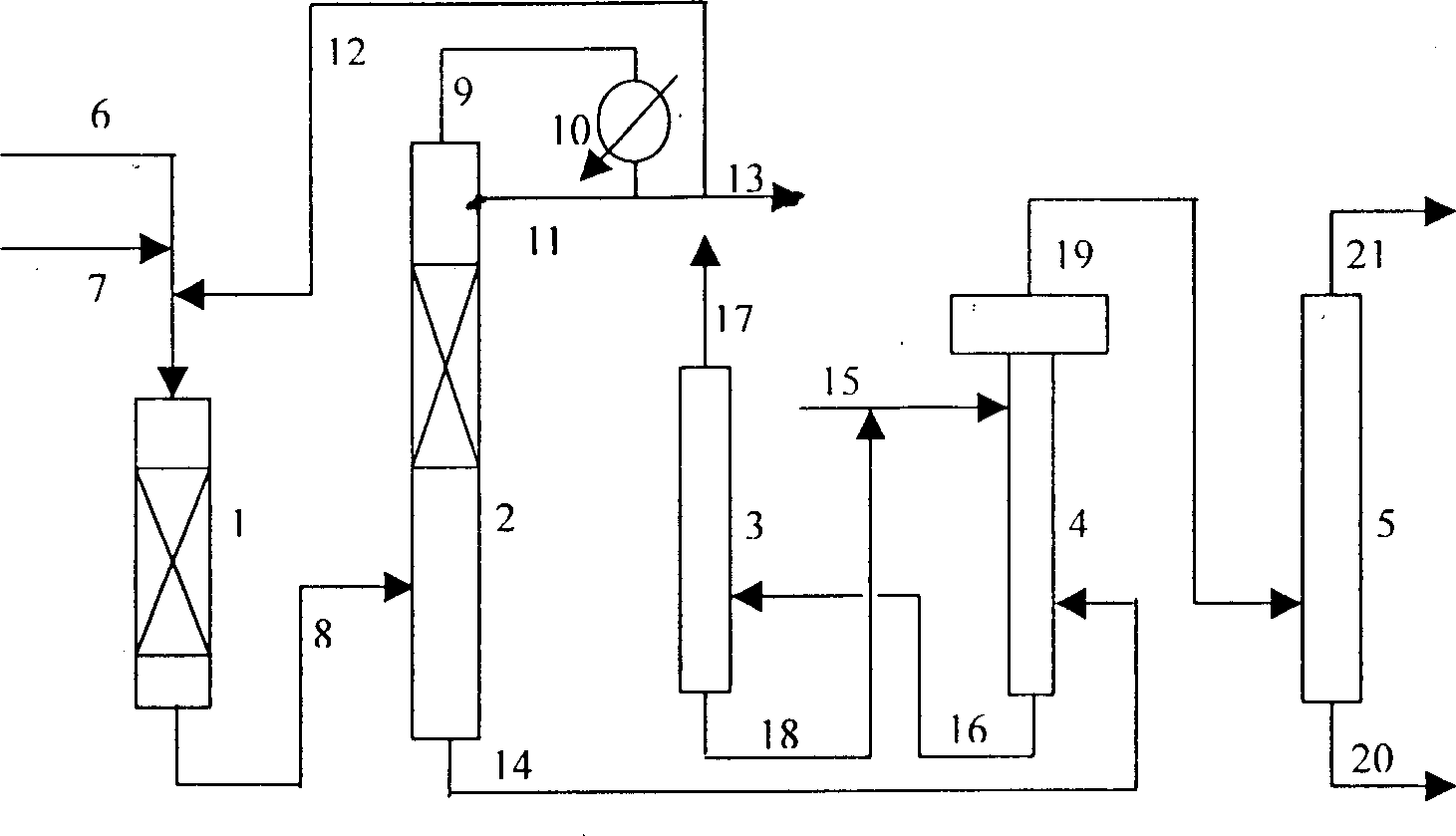

Process for producing alkylene oxide

A process for preparing an alkylene oxide, which process comprises:(i) oxidizing an alkylbenzene to obtain a stream comprising alkylbenzene hydroperoxide,(ii) contacting at least part of the alkylbenzene hydroperoxide obtained in step (i) with an olefin to obtain a product stream comprising an alkylene oxide(iii) separating alkylene oxide compound from the product stream of step (ii) to obtain (a) a residual product stream comprising alkylphenyl alcohol, and (b) alkylene oxide,(iv) feeding at least a part of the residual product stream comprising alkylphenyl alcohol to a reactor having a catalytic distillation zone, and concurrently in the reactor,(a) contacting the residual product stream comprising alkylphenyl alcohol with hydrogen in the catalytic distillation zone to convert the alkylphenyl alcohol in the residual product stream to alkylbenzene and form a reaction mixture, and(b) separating alkylbenzene from the reaction mixture by fractional distillation,(v) withdrawing a stream comprising alkylbenzene and having a reduced concentration of alkylphenyl alcohol than the feed stream from the reactor at a position upper from the catalytic reaction zone;(vi) withdrawing from the reactor at a position lower than the catalytic distillation zone a bottom stream comprising dimer(s) of alkylbenzene;(vii) converting the dimer(s) of alkylbenzene in the bottom stream from (vi) to alkylbenzene; and(viii) recycle at least a part of the alkylbenzene produced from (iv)(b) and / or (vi) to step (i).

Owner:SHELL OIL CO

Method of producing diisobutylene using mixed C4

InactiveCN1410403AImprove conversion rateHighly selective dimerizationHydrocarbons from unsaturated hydrocarbon additionHydrocarbonsFixed bedCatalytic distillation

A process for preparing diisobutylene from C4 mixture includes such steps as polymerizing reaction of C4 mixture under the existance of catalyst and depressant with two or more stages of fixed-bed reactor, and then separating out diisobutylene. Its advantages are high transform rate (more than 90%), high purity (more than 98%), and high total content of C8 (more than 92%).

Owner:CHINA PETROLEUM & CHEM CORP

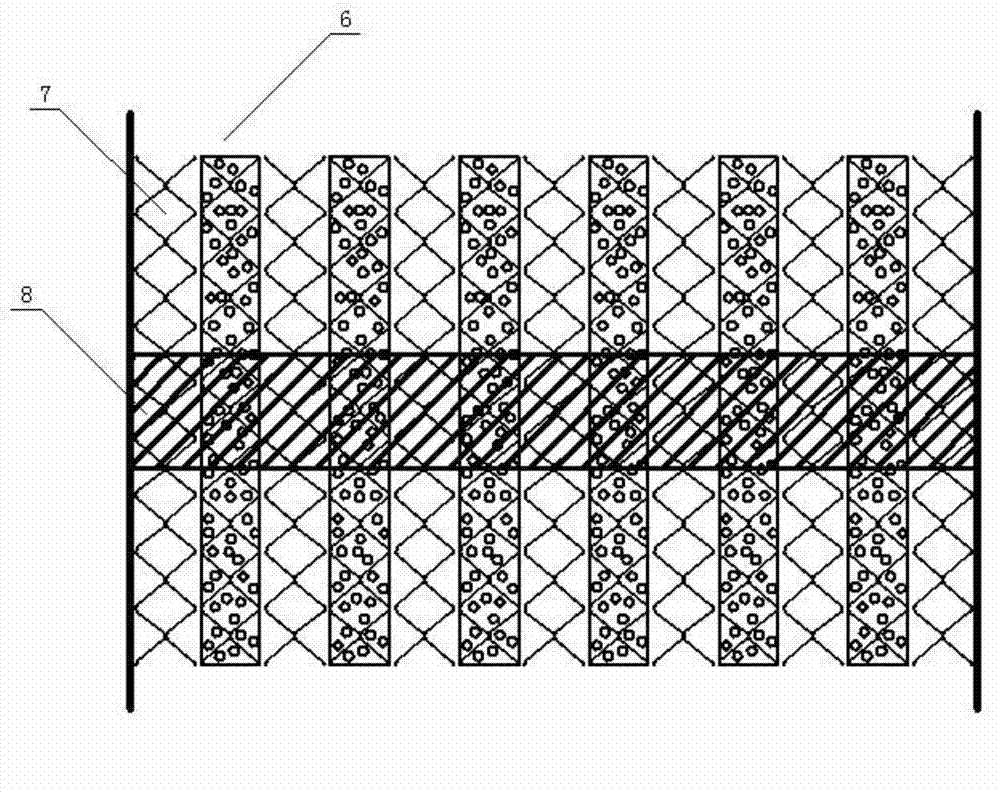

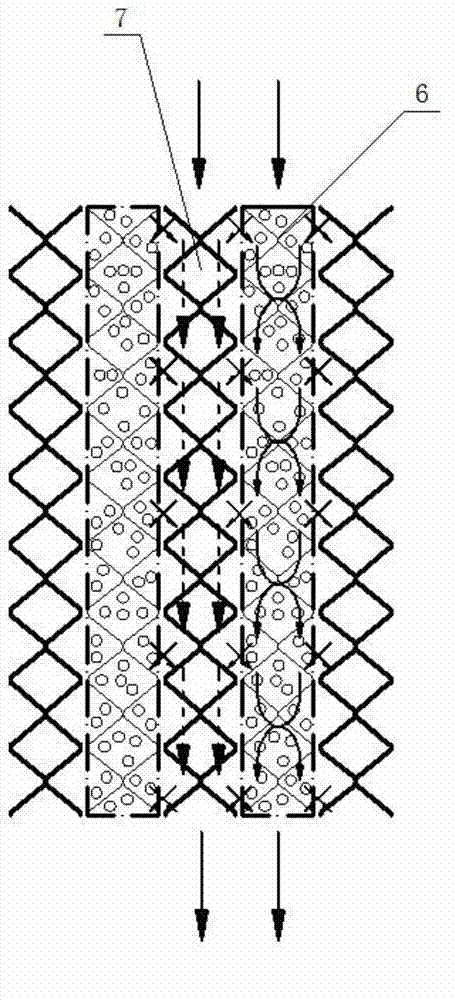

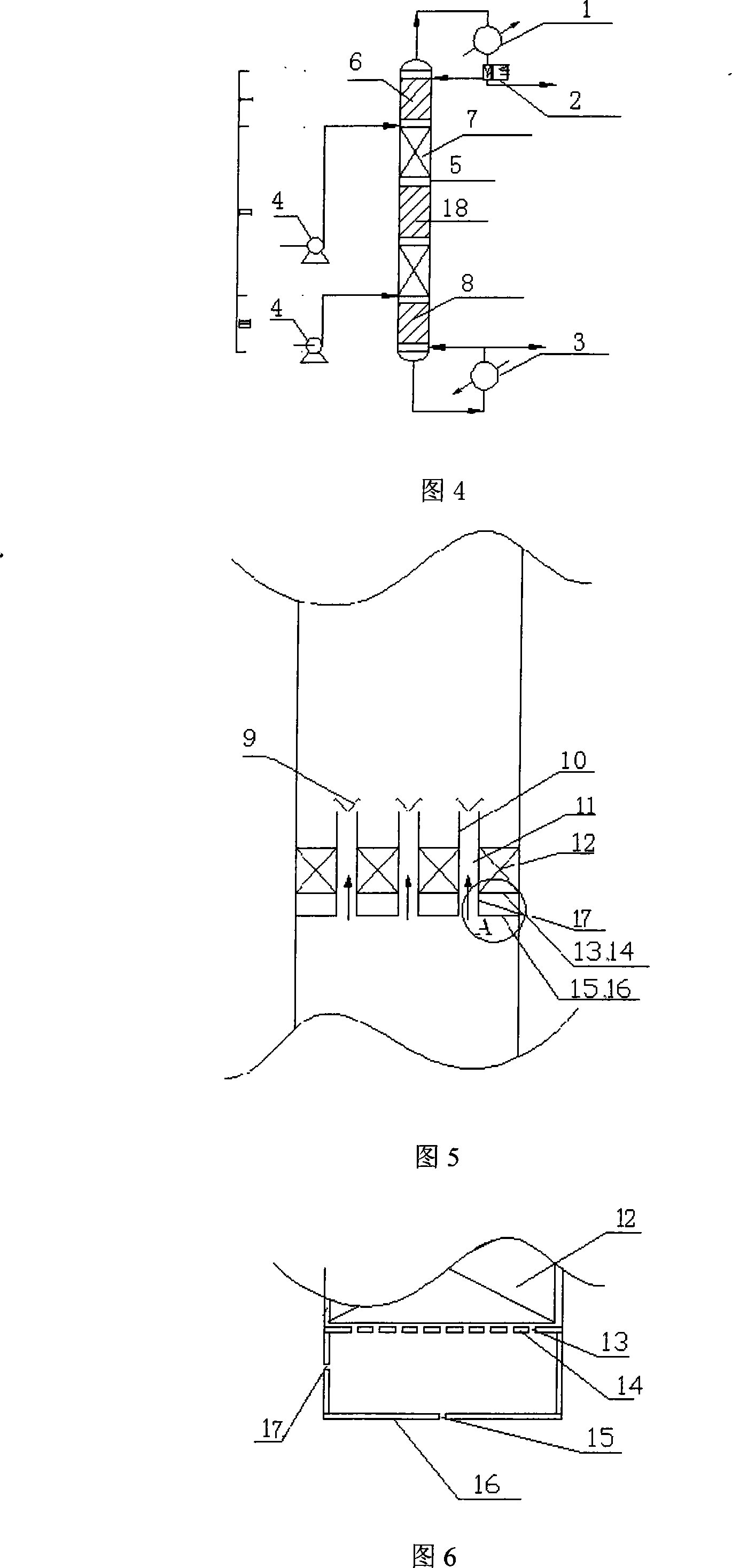

Catalytic distillation filler with alternative flow structure

The invention relates to catalytic distillation filler with an alternative flow structure. Two assemblies A and B are arranged inside a filler layer. The assembly A is formed by assembling filler sheets of windowing stream guidance type fillers, externally coating a layer of a wire mesh, internally fixing a catalyst and sewing the wire mesh. The assembly B is regular filler, such as the windowing stream guidance type filler, corrugated filler, wire mesh corrugated filler, orifice corrugated filler, rolled pore plate corrugated filler, honeycomb filler and the like. The assembly B and the assembly A are alternatively and vertically placed to obtain the efficient catalytic distillation filler provided by the invention. A window for the windowing stream guidance type filler can improve an atmosphere liquid mass transfer process; gas liquid repeatedly and alternatively flows between the window and the filler sheets, so that the use amount of the catalyst is reduced, and the contact time of a reactant and the catalyst can be controlled by adjusting the amount of the catalyst. The assembly A and the assembly B are alternatively placed, so that the reactant and products can be continuously separated to a tower top and a tower bottom, and a reaction is pushed to be carried out.

Owner:TIANJIN UNIV

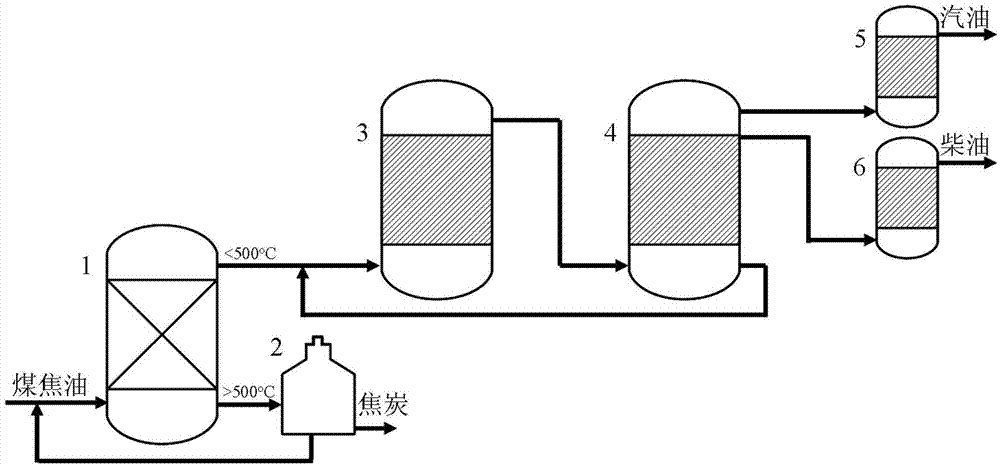

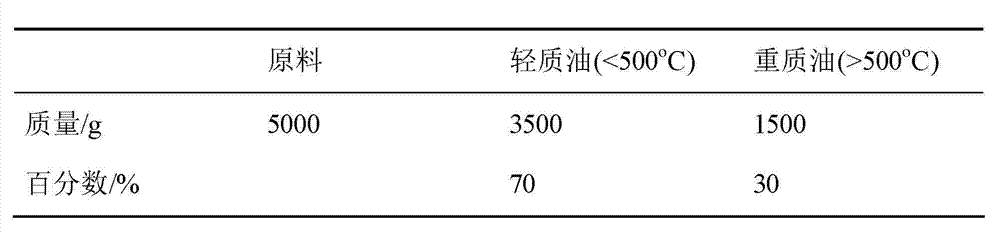

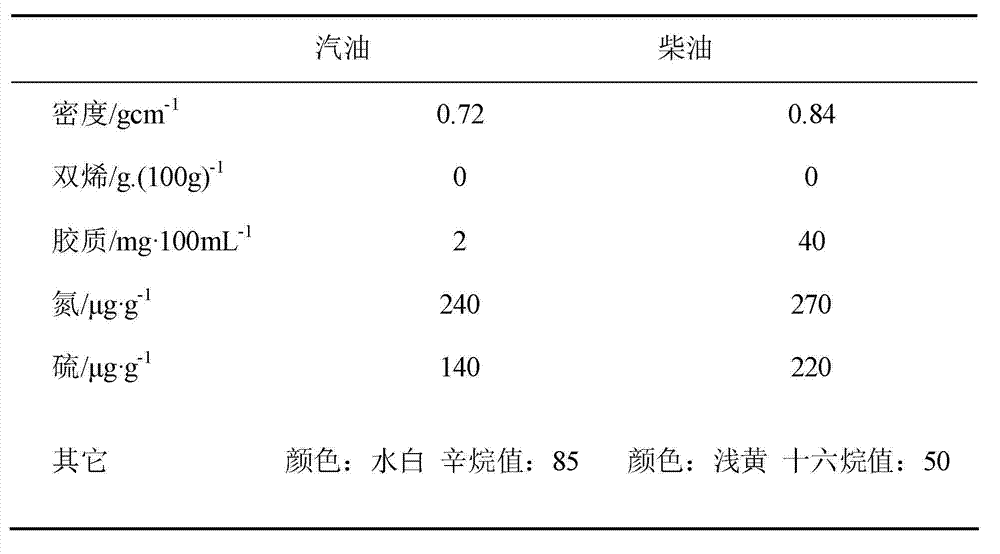

Method for preparing clean fuel oil from coal tar

ActiveCN103289740AHigh yieldImprove conversion rateChemical industryTreatment with hydrotreatment processesCatalytic distillationFuel oil

Belonging to the technical field of coal chemical industry and energy sources, the invention discloses a method for preparing clean fuel oil from coal tar. The method is characterized by: distilling coal tar to split into light oil and tower bottom heavy oil, subjecting the tower bottom heavy oil to delayed coking, then mixing it with coal tar and conducting distillation again, subjecting the light oil to high-pressure hydrogenation and catalytic distillation cracking to split it into distillate oil less than 180DEG C, distillate oil greater than 180DEG C and less than 360DEG C, and distillate oil greater than 360DEG C, letting the distillate oil less than 180DEG C directly enter a low-pressure gasoline hydrogenation reactor to undergo hydrofining so as to obtain high-quality gasoline, letting the distillate oil greater than 180DEG C and less than 360DEG C directly enter a low-pressure diesel oil hydrogenation reactor to undergo hydrofining to obtain high-quality diesel oil, mixing the distillate oil greater than 360DEG C with light oil and letting the mixture directly enter a high-pressure hydrogenation reactor to undergo reaction again. The catalytic distillation catalyst and the sulfide catalyst used in the invention select appropriate carriers and active components according to the composition and properties of coal tar. The method provided in the invention has a simple process, lowers equipment investment cost, employs catalysts with high activity and selectivity, has high yields of gasoline and diesel oil, provides a new approach for utilization of coal tar, and has good economic benefits and industrial application prospects.

Owner:DALIAN UNIV OF TECH

Regeneration process for waste lubrication oil

ActiveCN101307272AImprove protectionKeep Lubricant ComponentsVacuum distillationLubricant compositionEvaporationEnvironmental engineering

The invention discloses a regeneration process for waste lubricating oil, which belongs to the waste oil regeneration and recovery field. The waste lubricating oil is settled and precipitated, and is firstly subject to the reduced pressure topping distillation at a temperature of 260 DEG C and a vacuum degree of 20mmHg; then the topped waste lubricating oil is increased to between 380 and 400 DEG C, enters an evaporation tower for secondary reduced pressure distillation under the condition of a vacuum degree between 1 and 5mmHg, and enters a continuous catalytic distillation device, and a distillate is cooled to generate lubricant regenerated base oil with the yield more than 80 percent. Compared with the prior art, the process avoids using backward processes with heavier pollution such as acid cleaning, alkali neutralization and so on, and has high yield and better application prospect.

Owner:LUOYANG HAOHAI IND & TRADE

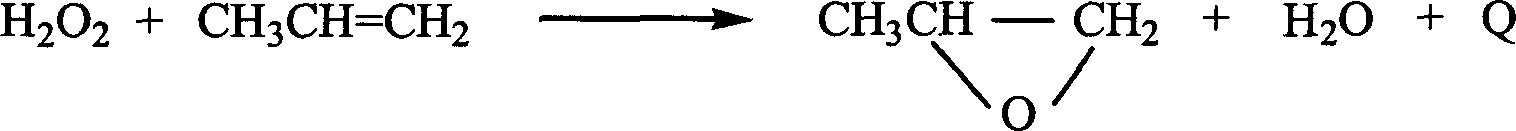

Catalytic distillation method of olefine direct epoxidation

InactiveCN1534031AHigh utilization rate of reaction heatSimple structureOrganic chemistryChemical industryMolecular sieveDesorption

A catalytic distiling process for directly epoxidating olefine features that a tower which is vertically and sequentially divided into distilling segment, reaction segment and desorption segment is only used, and includes reacting between olefine, hydrogen peroxide, solvent and Ti-Si molecular sieve catalyst, condensing the excessive solvent and olefine and returning them back to reaction segment, and separating product from the substance discharged from tower bottom. Its advantages are high thermal efficiency and less energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing high-quality gasoline/diesel from chlorine-containing plastic oil

ActiveCN104726134AEfficient removalRealize resource utilizationTreatment with hydrotreatment processesMolecular sieveEconomic benefits

The invention discloses a method for producing high-quality gasoline / diesel from chlorine-containing plastic oil, belonging to the technical fields of environmental protection and energy. The method is characterized by comprising the following steps: injecting chlorine-containing plastic oil into a high-temperature dechlorination tower filled with active alumina to perform high-temperature dechlorination, spraying a small amount of NaOH water solution on the top of the high-temperature dechlorination tower, and sending the dechlorinated plastic oil into a catalytic distillation tower filled with a molecular sieve / alumina catalyst to perform reaction and rectification; and pressurizing the plastic oil subjected to catalytic distillation into a hydrofining tower, distilling the hydrofined distillate oil under normal pressure, cutting into gasoline and diesel according to the recovered temperature, and mixing the tower bottom heavy oil and the raw material chlorine-containing plastic oil to react. The dechlorination catalyst and sulfide catalyst used by the method can be prepared by proper methods according to the composition and performance of the plastic oil. The method has the advantages of simple technique, high catalyst activity and high selectivity, and has favorable economic benefits and industrial application prospects.

Owner:DALIAN UNIV OF TECH

Method for preparing polyoxymethylene dimethyl ether

ActiveCN102372611AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationReboilerCatalytic distillation

The invention relates to a method for preparing polyoxymethylene dimethyl ether, which mainly solves the problems of low conversion rate of trioxymethylene and low selectivity of DMM 3-8 in current polyoxymethylene dimethyl ether production. According to the invention, under the effective reaction condition, methylal and trioxymethylene are reacted in a catalytic distillation tower, a components separation is performed simultaneously, steam at the top of the tower is condensed and then reflowed, a first part of the materials at the bottom of the tower is vaporized by a reboiler and returned back to the catalytic distillation tower, a second part of the materials is taken as produced liquid, the mass ratio of the first part to the second part is 1-10:1, wherein the trioxymethylene enters from the top of the tower, methylal can enter from any position from a stripping section to the tower top. The technical scheme of catalyst capable of being a heterogeneous phase acidic catalyst can effectively solve the problem, and the catalyst can be used for industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

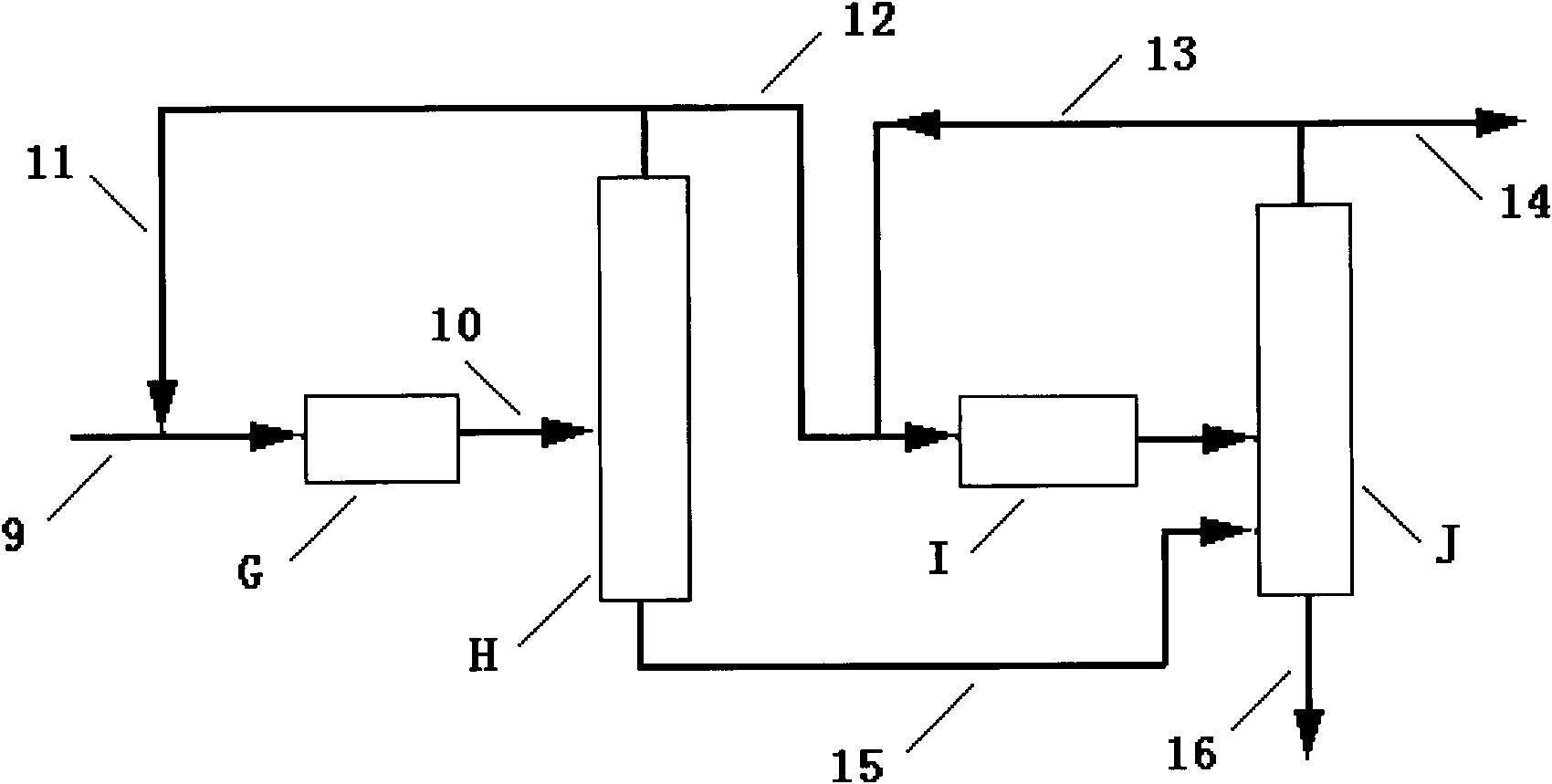

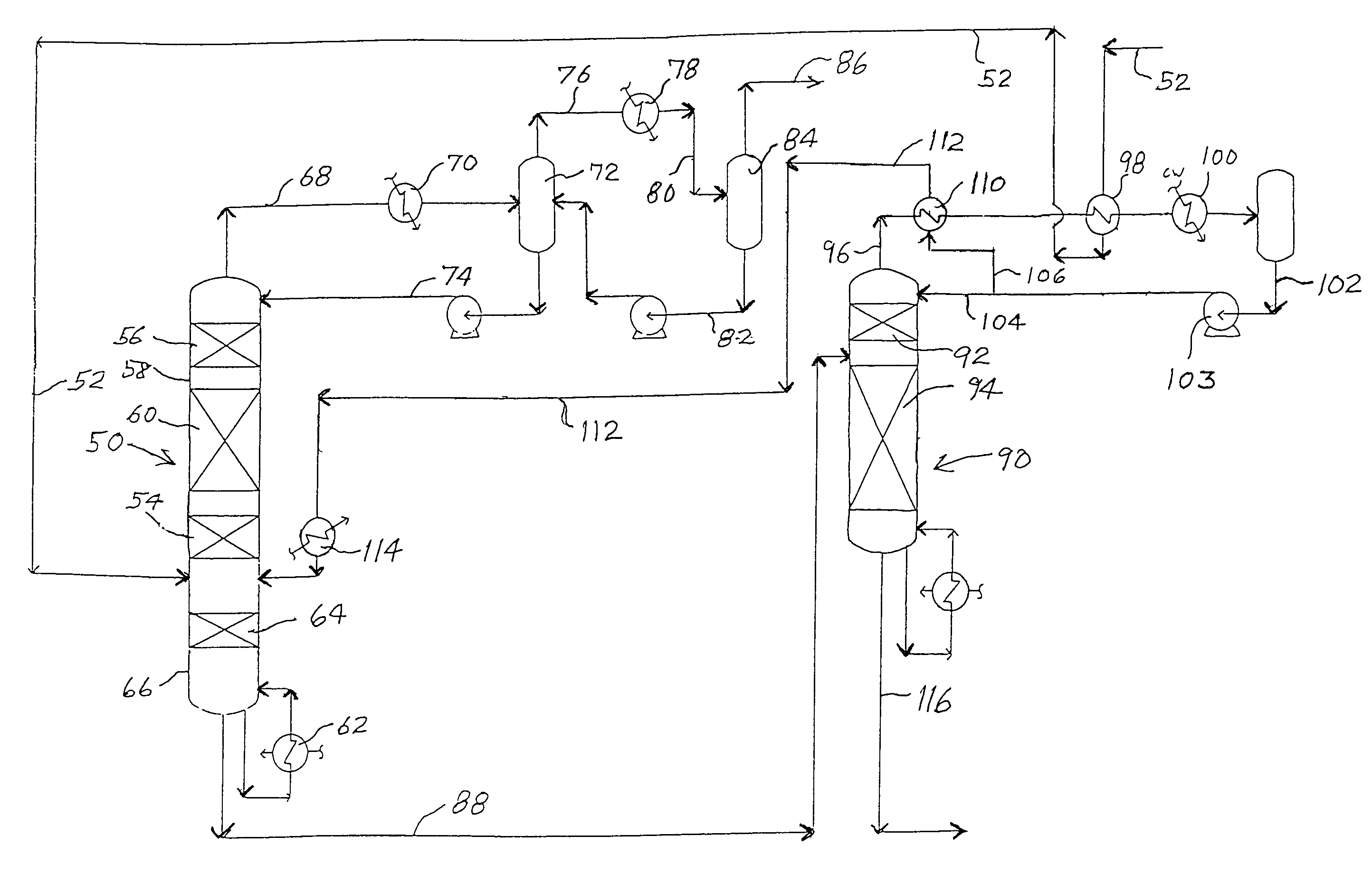

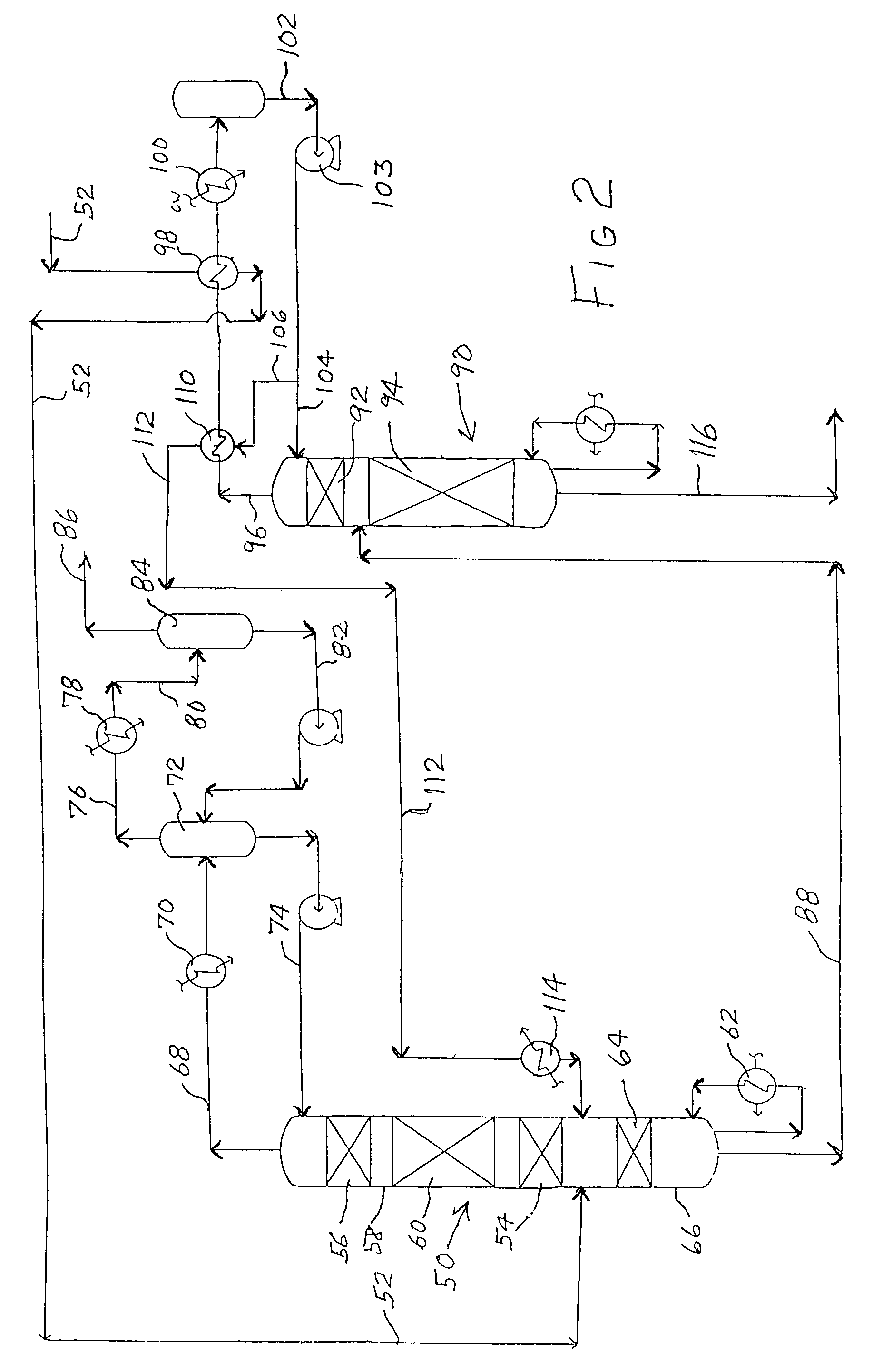

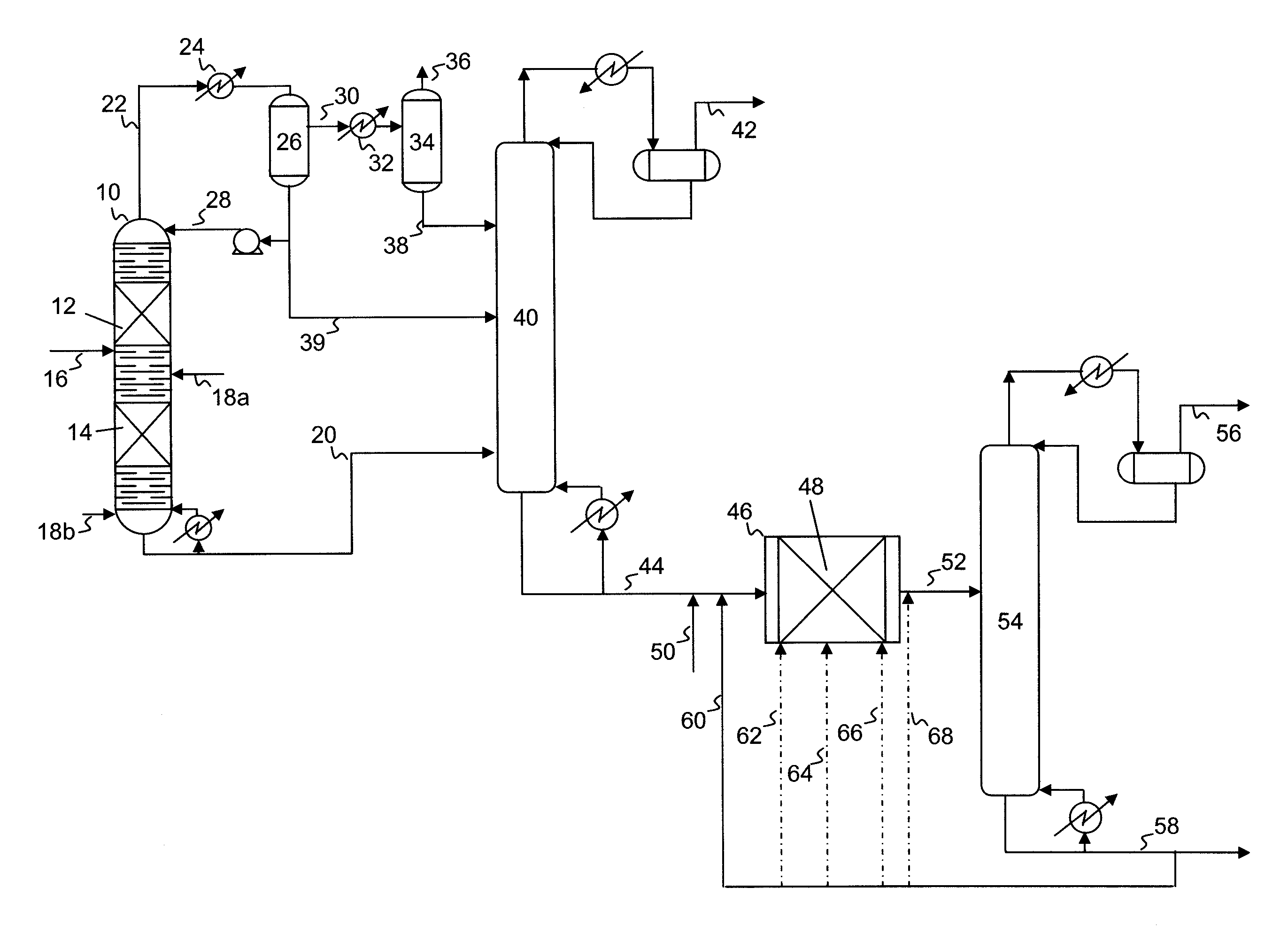

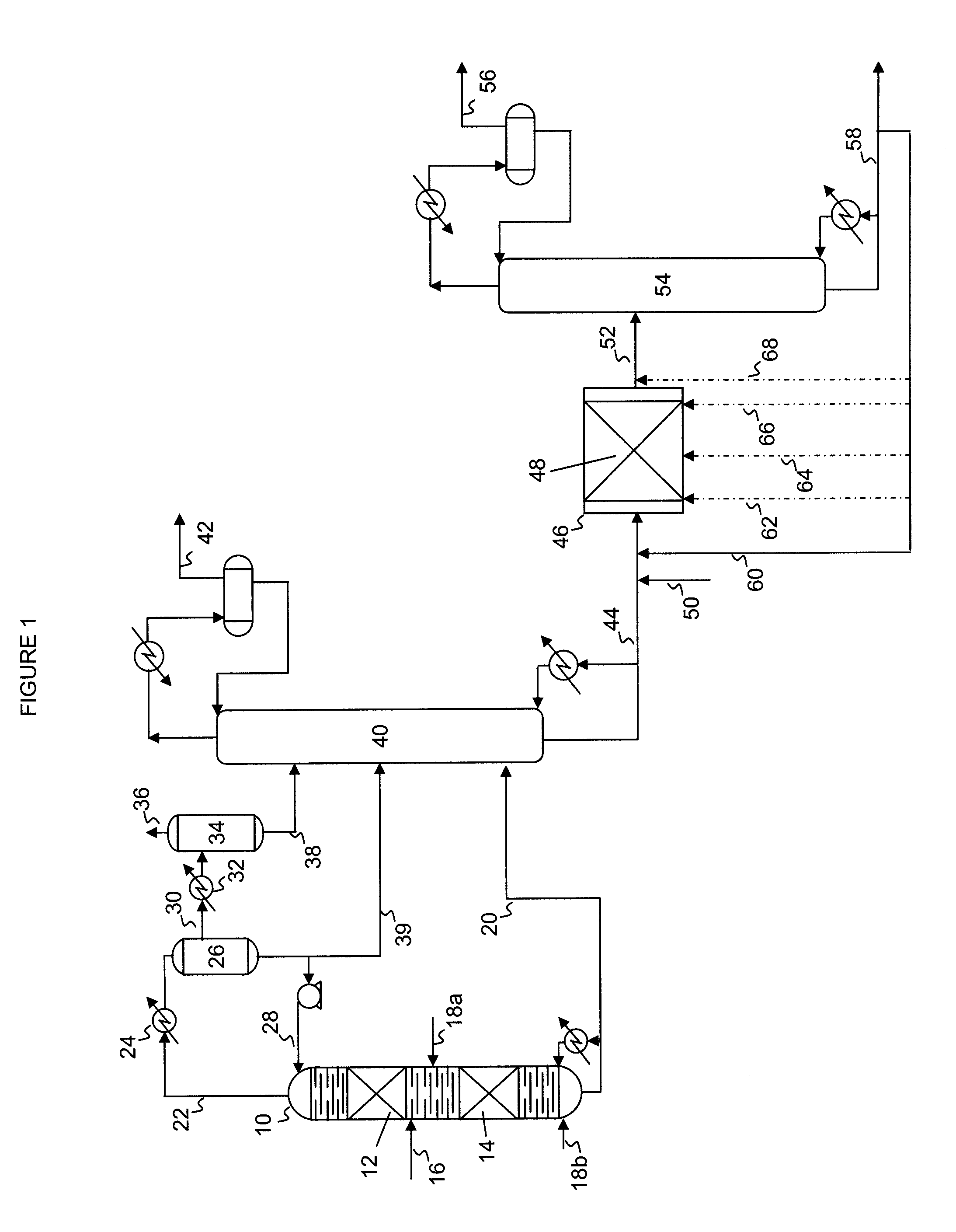

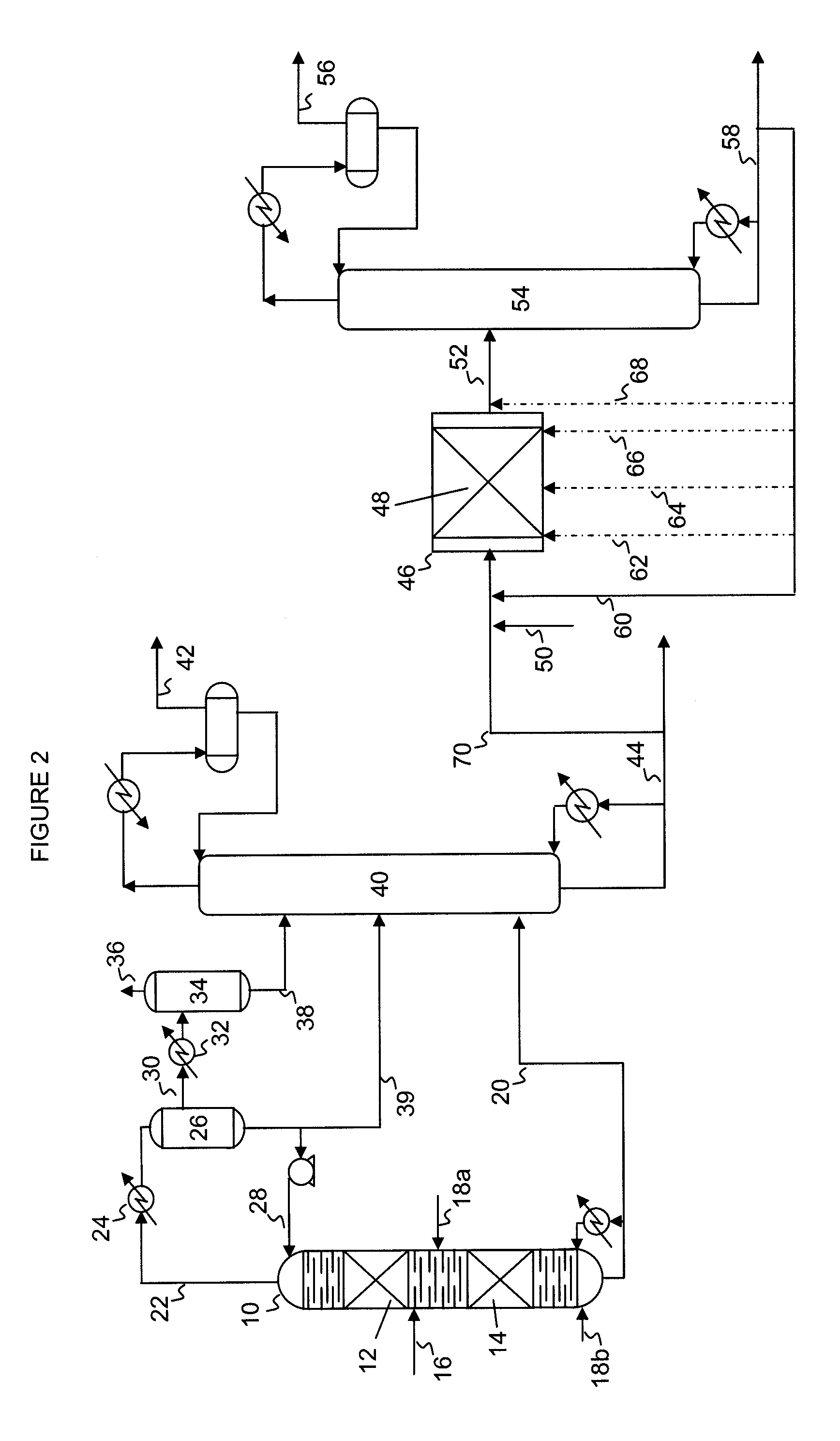

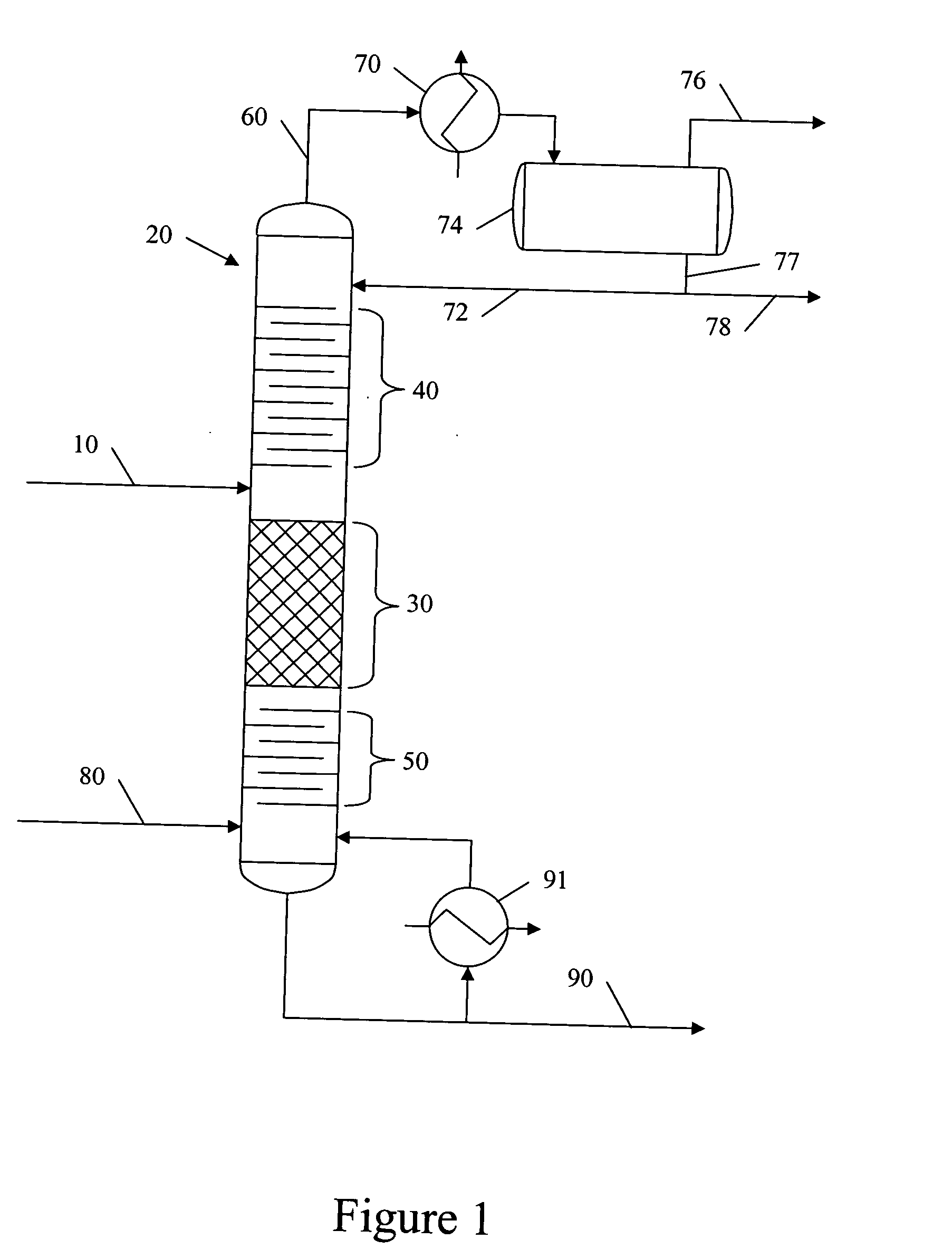

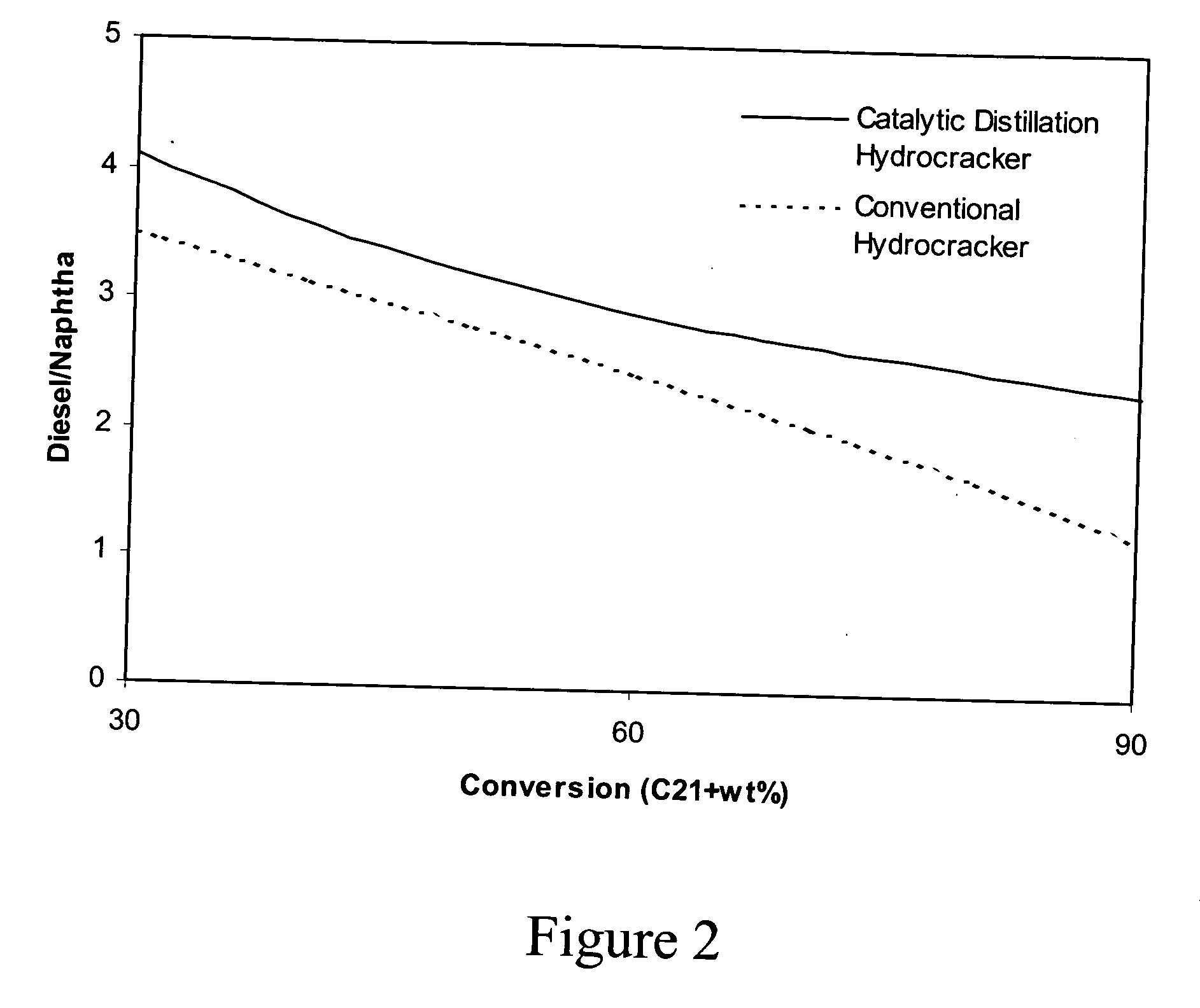

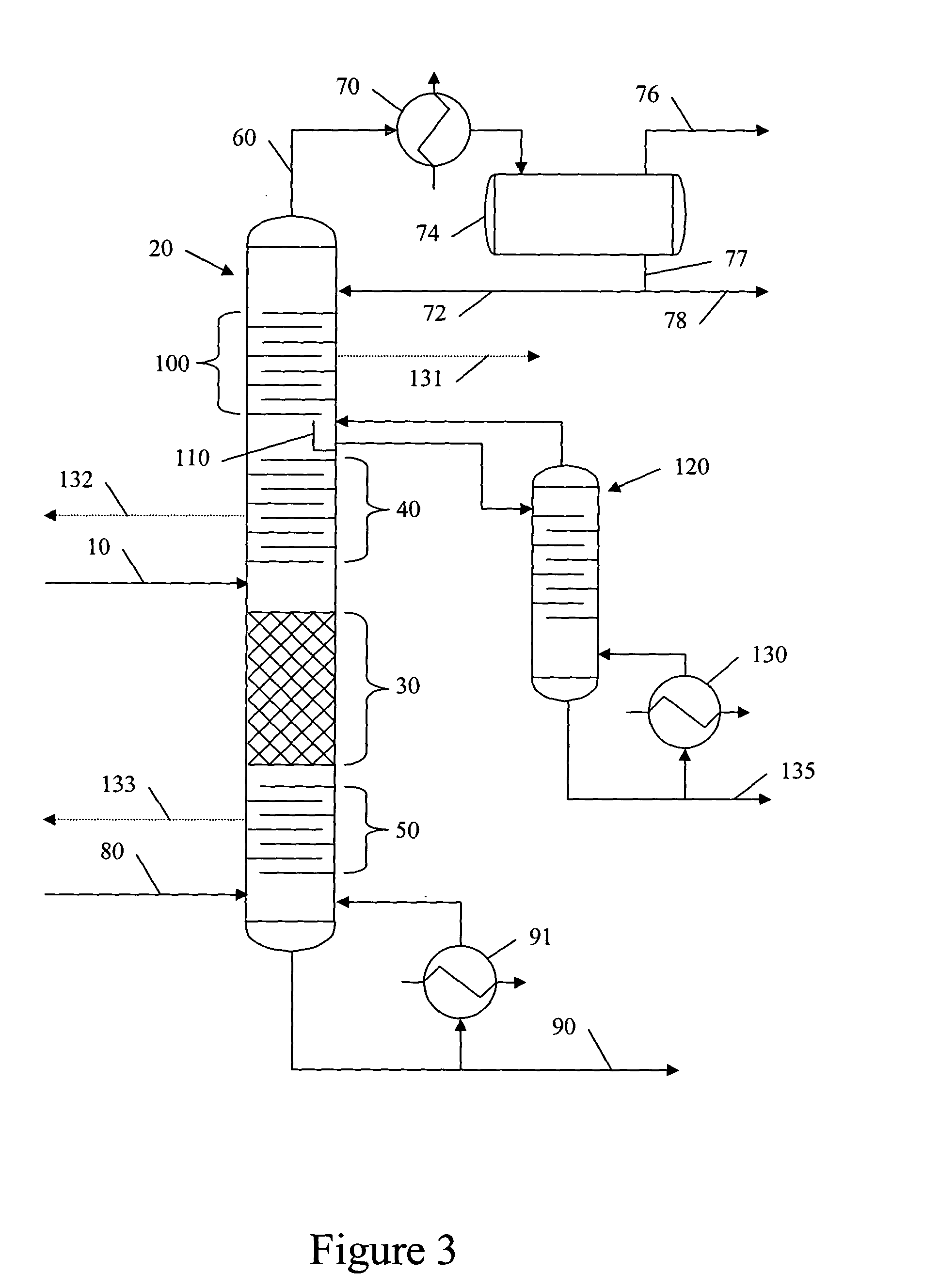

Dual pressure catalytic distillation hydrogenation column system for the front end of an ethylene plant

ActiveUS7045669B2Maximize catalyst bed temperatureReduce fouling rateTreatment with plural serial cracking stages onlyHydrocarbon by hydrogenationFractionationCatalytic distillation

The charge gas from the thermal cracking of a hydrocarbon feedstock is processed in a front-end catalytic distillation hydrogenation system of an olefins plant to more effectively recover ethylene and propylene product and to process the by-products. The rate of fouling in the system is reduced by employing two columns in the system with the first column operating at a higher pressure and the second column operating at a lower pressure. The hydrogenation as well as fractionation takes place in the first column while the second column is only a fractionator. The temperature of the bottoms from each column is maintained at a temperature less than 200° C. to avoid fouling.

Owner:CHEM RES & LICENSING CO

Dimethoxym ethane catalytic distillation production process and production equipment thereof

InactiveCN102070417AContinuous operationReduce production energy consumptionOrganic chemistryOrganic compound preparationCatalytic distillationReaction zone

The invention relates to a dimethoxym ethane catalytic distillation production process and production equipment thereof. The process comprises the following steps that: raw materials of methanol and formaldehyde respectively enter a reaction zone from the lower part and the upper part of the reaction zone, the two raw materials carry out aldolization and steam-liquid mass transfer in the reaction zone under the effect of catalysts, and the continuous catalytic distillation process is realized. The production equipment is characterized in that a catalytic distillation device adopts a tower device, cation exchange resin is used as the catalysts, the catalysts of the cation exchange resin are filled in a bundling bag mode to form catalyst structural units, and the structural units form the reaction zone in a rectifying tower, wherein the catalyst structural units are formed through vertical and staggered arrangement. The invention adopts the catalytic distillation tower filled with catalyst bundling bags to produce dimethoxym ethane and has the advantages of high yield, small circulation quantity, low energy consumption and the like.

Owner:FUZHOU UNIV

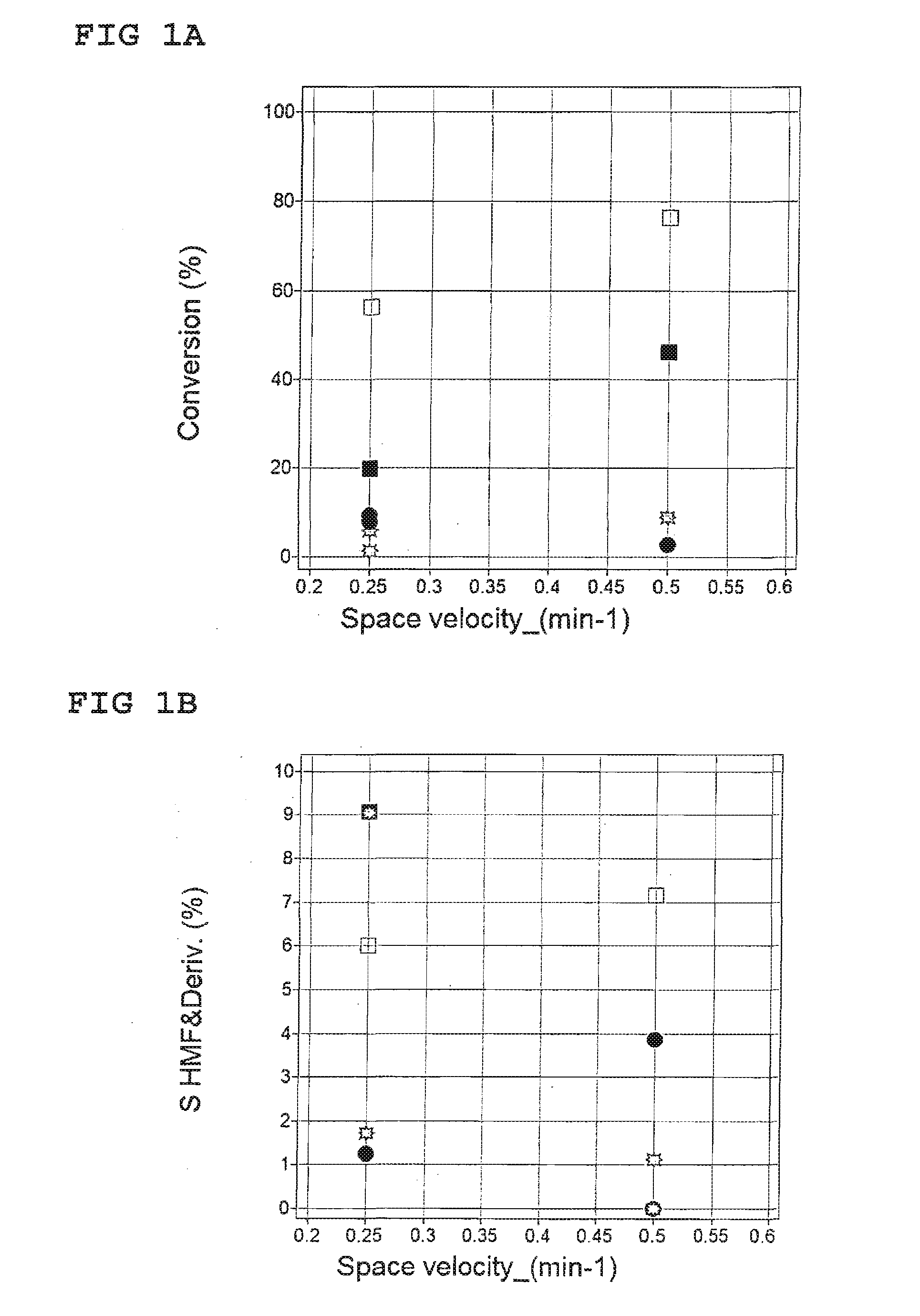

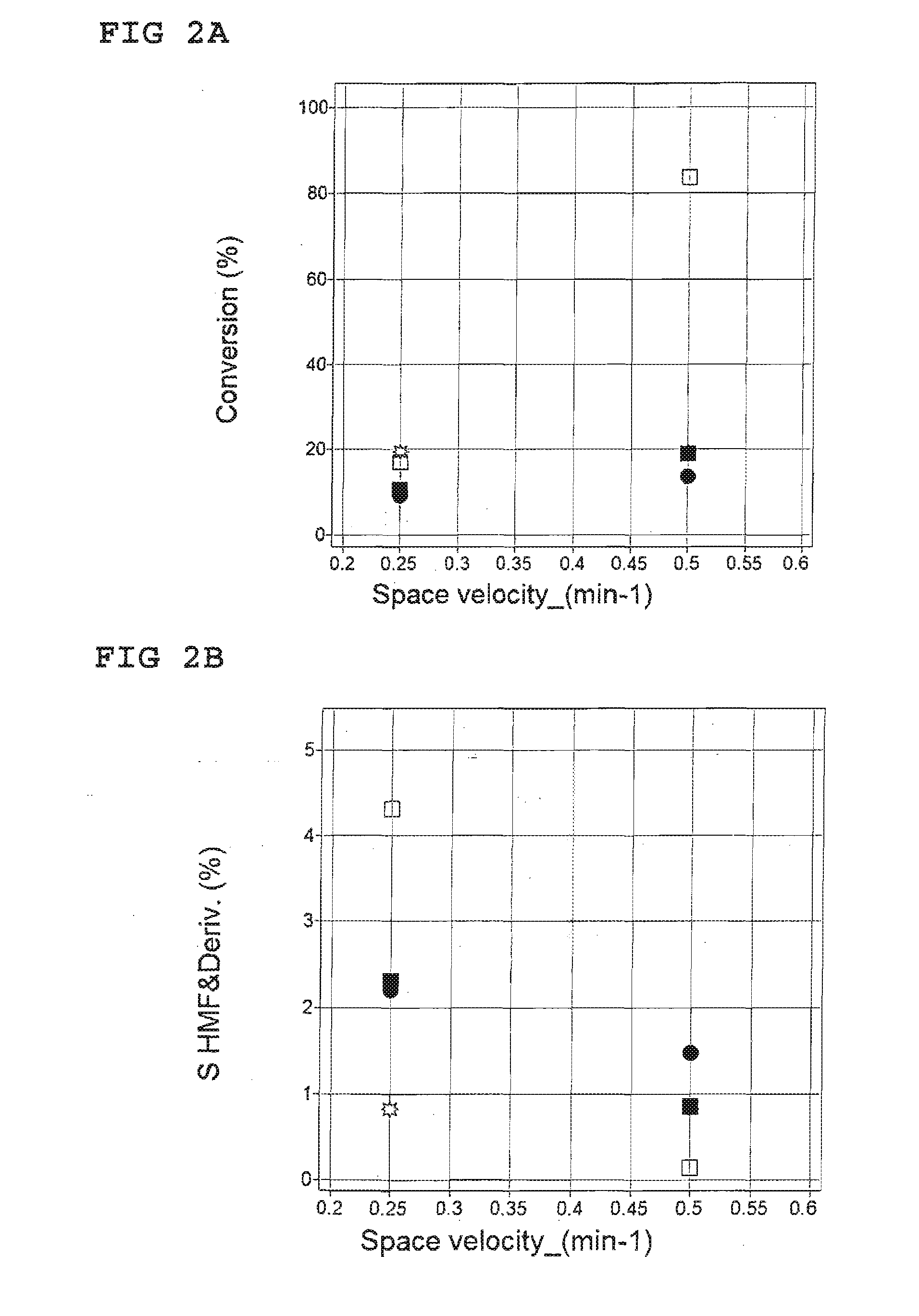

Method for the synthesis of 5-hydroxymethylfurfural ethers and their use

Owner:FURANIX TECH BV

Catalyst for production of ethyl benzene using ethylene and benzene and its preparation method and application

InactiveCN1589967AMolecular sieve catalystsCatalyst activation/preparationAlkyl transferMolecular sieve

A catalyst for preparing the high-purity (99.9%) ethylbenzene from ethene and benzene by liquid-phase alkylation and use of fixed-bed reactor, slurry-bed reactor or catalytic distilling reactor is prepared from molecular sieve MCM-22, halogen and inertial component.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

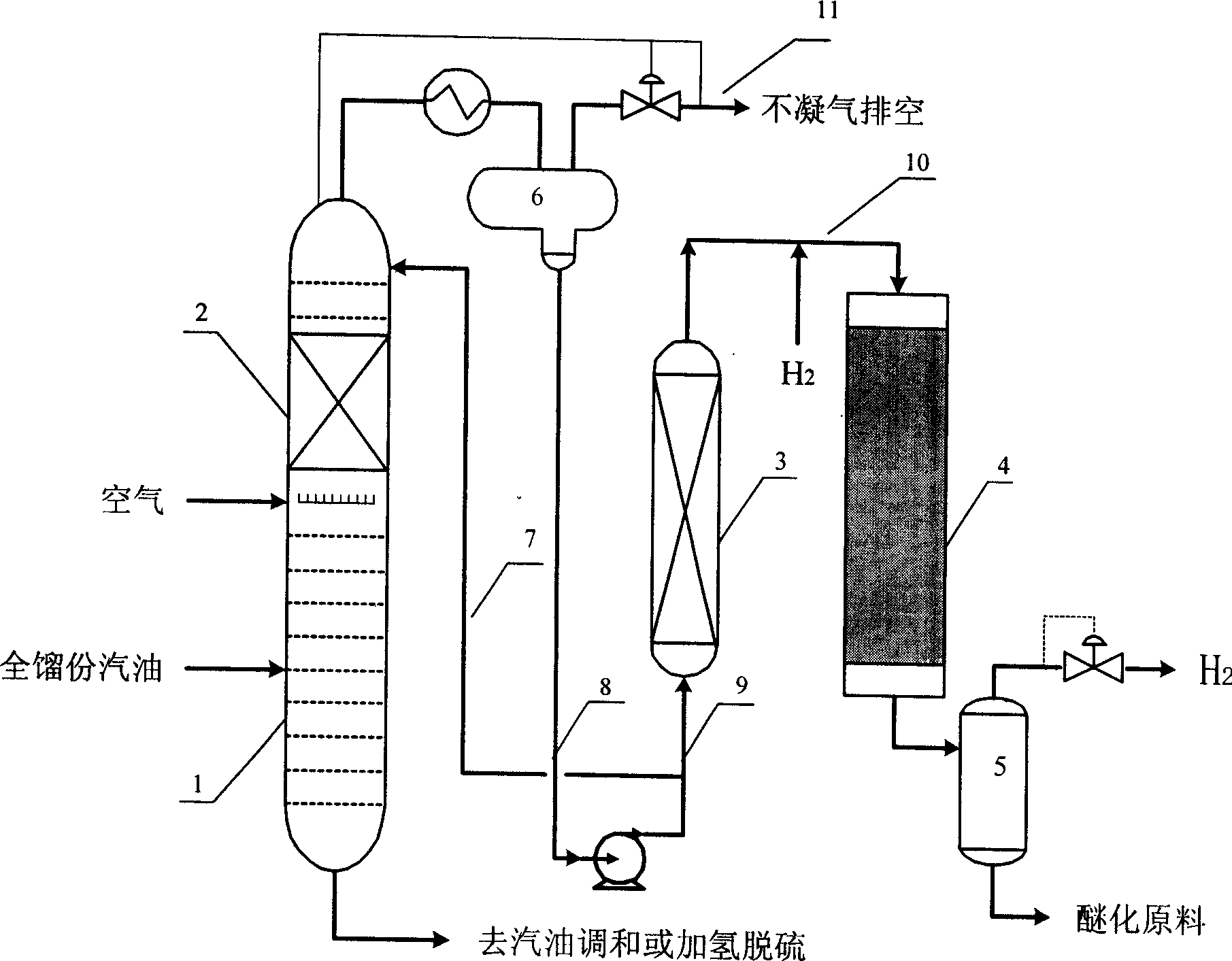

Method for separating and refining etherification material from catalytic cracking gasoline

A process for separating the raw esterifying material from catalytically cracked gasoline and refining it includes such steps as introducing said gasoline to catalytic distilling tower, contacting with thiol-removing catalyst while fractionating to convert thiol to bisulfide, discharging the bisulfide and heavy component from tower bottom and the light gasoline rich in C5-C6 isomerized olefine from tower top, removing N-contained compound from said light gasoline by denitrifying absorption bed, and selective hydrogenating for removing biolefine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite catalyst for the selective oligomerization of lower alkenes and the production of high octane products

InactiveUS20070123743A1Increase pressureSelectivity is compromisedCatalytic crackingHydrocarbon by hydrogenationCatalytic distillationAlkene

The present invention relates to a) a catalytic composite comprising a support structure and a catalytic species that is deposited on the support structure, b) a process for the selective oligomerization of lower alkenes and mixtures of alkenes, which process comprises contacting the lower alkenes with the catalytic composite in a catalytic distillation apparatus and under catalytic distillation conditions, and c) a process for producing high octane products, which process comprises hydrogenating one or more catalytic distillation apparatus and under catalytic distillation conditions.

Owner:WATERLOO UNIV OF

Hydrodesulfurization process with selected liquid recycle to reduce formation of recombinant mercaptans

ActiveUS20120048776A1Easy to produceCatalytic naphtha reformingTreatment with hydrotreatment processesThiolNaphtha

Processes for the desulfurization of a cracked naphtha by the reaction of hydrogen with the organic sulfur compounds present in the feed are disclosed. In particular, processes disclosed herein may use one or more catalytic distillation steps followed by further hydrodesulfurization of the naphtha in a fixed bed reactor. It has been found that the formation of recombinant mercaptans in the fixed bed reactor effluent may be reduced or eliminated by reducing the concentration of hydrogen sulfide and / or olefins at the exit of the fixed bed reactor. The reduction or elimination in the formation of recombinant mercaptans may be accomplished by recycling a select portion of the fixed bed reactor effluent to the fixed bed reactor, where the select portion has a relatively low or nil concentration of olefins. Processes disclosed herein may thus facilitate the production of hydrodesulfurized cracked naphthas having a total sulfur content of less than 10 ppm, by weight.

Owner:CHEM RES & LICENSING CO

Process for preparing tertiary butanol

InactiveCN1511815AImprove conversion rateHigh selectivityChemical industryPreparation by hydroxy group additionHydration reactionCatalytic distillation

The present invention relates to preparation process of tertiary butanol with C4 mixture containing isobutylene as material and through hydration reaction. The present invention features that isobutylene in C4 mixture fraction and water produce hydration to produce tertiary butanol inside catalytic distillation tower in the presence of catalyst and non-ionic surfactant. The said preparation process has high isobutylene converting rate, high tertiary butanol selectivity and low tertiary butanol producing cost.

Owner:QILU PETRO CHEM - SINOPEC

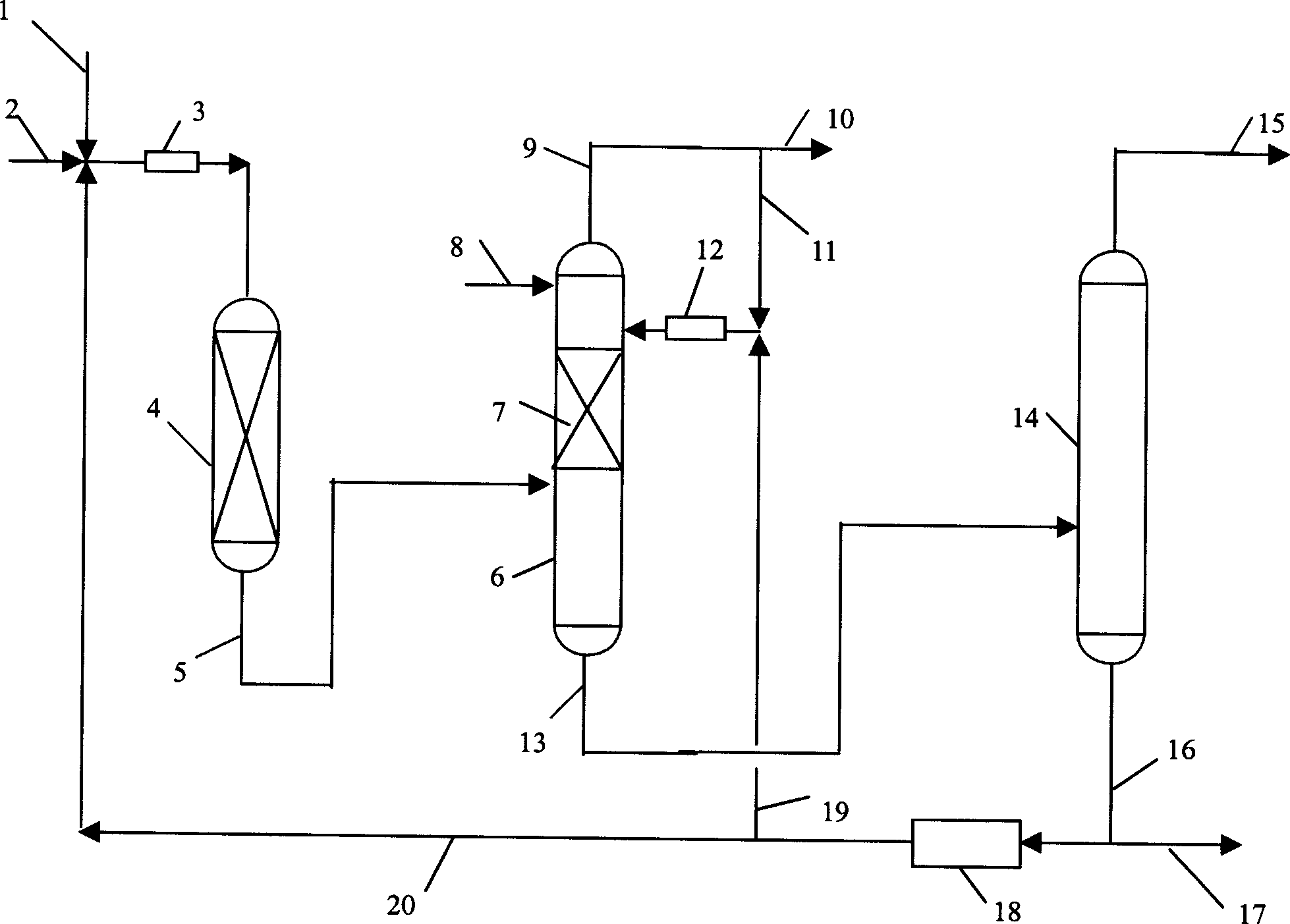

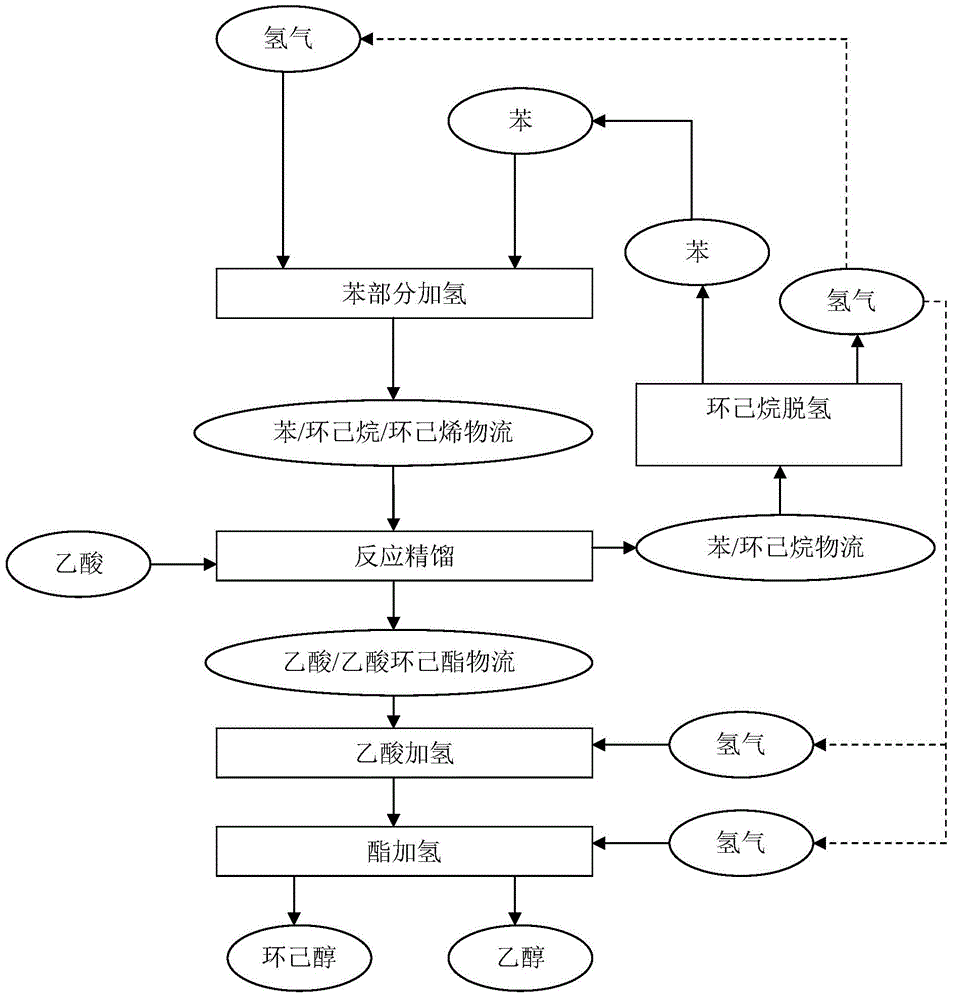

Method for coproducing cyclohexanol and alkanol

InactiveCN104557465AImprove efficiencyLow costOrganic compound preparationCarboxylic acid esters preparationBenzeneAcetic acid

The invention provides a method for coproducing cyclohexanol and alkanol. The method comprises the following steps: preparing benzene and / or cyclohexane into cyclohexene, carrying out addition-esterification on the cyclohexene in a catalytic distillation tower, obtaining carboxylic acid / cyclohexyl carboxylate material flow at the bottom of the tower, hydrogenating the material flow to obtain the cyclohexanol and the alkanol. The esterification and hydrogenation reactions in the method have high conversion rate and selectivity, and high atom economy; the process is environment-friendly; the alkanol is coproduced when the cyclohexanol is produced, in particular, when acetic acid is used, the cheap acetic acid is converted into ethanol with high cost and large market capacity in an indirect manner, so as to increase the economical efficiency of the process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic distillation hydroprocessing

InactiveUS20050035026A1Improve efficiencyHigh outputRefining to change hydrocarbon structural skeletonHydrocarbon distillationCatalytic distillationHydrocarbon

A method for hydroprocessing a hydrocarbon synthesis product feed to form upgraded fuels and lubricating oils. In a preferred embodiment, the method includes the steps of: (a) contacting a Fischer-Tropsch product with a hydroprocessing catalyst to produce a desired distillate; and (b) counter-currently stripping the desired distillate as it is produced. The method may include distilling the desired distillate or distilling the treated Fischer-Tropsch product.

Owner:CONOCOPHILLIPS CO

System and method for producing n-butyl acetate by using methyl acetate and n-butyl alcohol ester exchange reaction

InactiveCN101219950ASimple processEasy to operatePreparation by ester-hydroxy reactionChemical industryReboilerTransesterification

The invention discloses a method and a system for utilizing transesterification of methyl acetate and n-butanol to prepare n-butyl acetate. The reaction system substantially consists of a reboiler, a catalytic distillation column, a condenser, a feeding pump and a reflux ratio controller; among which, the catalytic distillation column is provided with a liquid collecting plate, a gas exit tube, a catalyst packet, a supporting plate and a catalytic reaction segment consisting of bottom plates. An overflow outlet is arranged on a tube wall of the gas exit tube at the lower end of the liquid collecting place and is higher than the catalyst packet. A lacrimal foramen is arranged on the bottom plate; the catalyst packet and a sieve hole is arranged on the supporting plate; a liquid leaking hole is arranged on the tube wall of the gas exit tube between the supporting plate and the bottom plate. The preparation method is to add the methyl acetate and n-butanol into the column respectively from the top and bottom of the catalytic reaction area. A molar ratio of the methyl acetate to the n-butanol is 0.5:5, a reaction temperature is 50 DEG C to 90 DEG C, and a reflux ratio is 0.5 to 30 under a normal pressure operation. The technical proposal of the invention enhances the conversion rate of the methyl acetate, simplifies the operation procedure and overcomes the problem of equipment corrosion.

Owner:TIANJIN UNIV

Gasoline hydrodesulfurization method

ActiveCN101108983AHigh desulfurization rateFlexible handlingRefining to eliminate hetero atomsHydrogenHydrodesulfurization

A method using the gasoline hydrogenation to desulfurize is provided, which is carried out in a catalytic distillation column. The catalytic distillation column is divided into a rectification process section, a fractionation section, a stripping reaction section and a stripping section from top from bottom. The preheated raw materials are led into the fractionation section and the hydrogen is led into the bottom of the stripping section; the lighter components fractionated from the fractionation section enter into the section and conduct hydrodesulfurization reaction with the hydrogen under the contact with hydrodesulfurization catalyst A; the discharge on the tower top gains the liquid after cooling and separating; one part of the discharge returns to the rectification process section as the overhead reflux and the other part works as the desulfurized products 1; the heavier components fractionated enter the stripping reaction section and conduct hydrodesulfurization reaction with the hydrogen under the contact with hydrodesulfurization catalyst B and is discharged from the reboiler on the tower bottom after the a stripping section further separates the H2S to work as the desulfurized products 2. The method provided by the invention can obviously improve the rate of the desulfurization of gasoline and have low loss of the octane number of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com