Method for preparing alcohols from olefin

A technology of olefins and acetates, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of high reaction pressure, low single-pass conversion rate, low reaction conversion rate, etc., and achieve mild reaction conditions , High raw material conversion rate, good product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

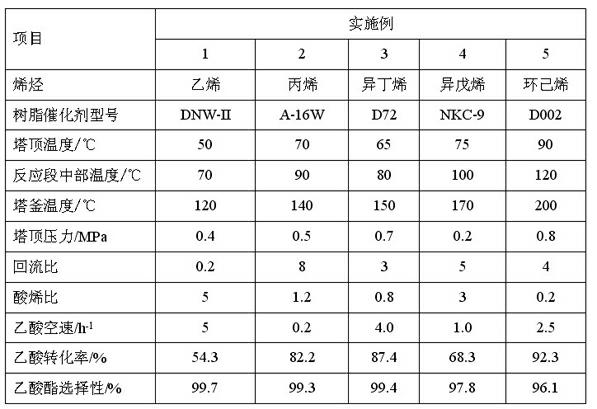

[0016] In the catalytic distillation tower, a certain proportion of olefins and acetic acid are countercurrently contacted on the surface of different solid acid catalysts, and the corresponding acetates are synthesized by catalytic esterification. The specific data are shown in Table 1.

[0017] Table 1 Synthesis of acetate from acetic acid and olefins by catalytic distillation

[0018]

Embodiment 6

[0020] The catalyst is CuO-ZnO-Al 2 o 3 (CuO content is 20% (wt), ZnO content is 70% (wt), Al 2 o 3 The content is 10% (wt)), the raw material for hydrogenation is sec-butyl acetate, the process conditions are: the reaction temperature is 170°C, the reaction pressure is 7.0Mpa, and the ester liquid space velocity is 0.1h -1 , The hydrogen ester molar ratio is 40. The reaction results are: ester conversion rate 93.5%, ethanol selectivity 100%, sec-butanol selectivity 100%.

Embodiment 7

[0022] The catalyst is CuO-MnO 2 -BaO-ZrO 2 (CuO content is 60% (wt), MnO 2 content of 20% (wt), BaO content of 5% (wt), ZrO 2 The content is 15% (wt)), the hydrogenation raw material is ethyl acetate, the process conditions are: the reaction temperature is 190°C, the reaction pressure is 3.0Mpa, and the ester liquid space velocity is 0.3h -1 , The hydrogen ester molar ratio is 160. The reaction result is: ester conversion rate 94.2%, ethanol selectivity 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com