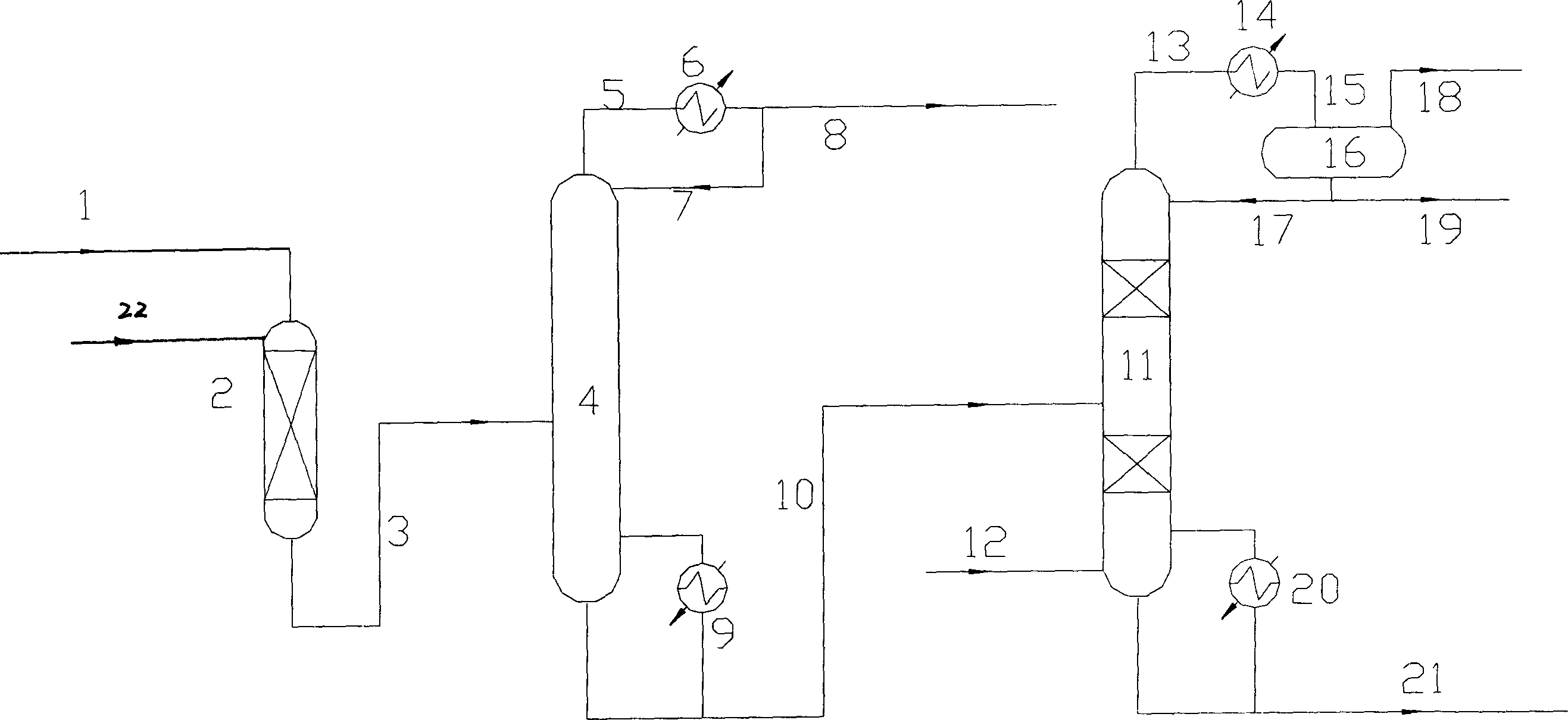

Desulfurization process of gasoline

A process, hydrodesulfurization technology, applied in the petroleum industry, refining hydrocarbon oil, through selective hydrofining, etc., can solve the problems of cumbersome loading, small operating flexibility, and increased chance of hydrogenation saturation of olefins, etc., to achieve liquid recovery The effect of high efficiency, large operation flexibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] The sulfur content in the raw material FCC gasoline is 1534 μg / g, the sulfur content of the gasoline treated by the process of the present invention is reduced to 106 μg / g, the desulfurization rate reaches 93%, and the antiknock index loss is 1.2. Embodiment 2: used raw material, processing capacity, reaction condition are identical with embodiment 1, and difference is that the tower top discharging capacity of common distillation tower is adjusted to 310Kg / h, and catalytic distillation tower tower kettle discharging capacity is 365Kg / h . The distribution of the obtained sulfur-containing compounds in each cut is shown in Table 4, and the streams obtained by pipelines (8), (19) and (21) are blended, and the properties of the obtained desulfurized gasoline are shown in Table 5:

[0032] raw material

[0033] Alkanes content, %(V / V)

Embodiment 3

[0034] The sulfur content in the raw material FCC gasoline is 1534 μg / g, and after being treated by the process of the present invention, the sulfur content is reduced to 66 μg / g, the desulfurization rate reaches 95.7%, and the antiknock index is 1.4. Embodiment 3: The raw materials used, the processing capacity, and the reaction conditions are the same as in Example 2, except that what is packed in the catalytic distillation tower is a selective hydrodesulfurization catalyst, and the carrier of the catalyst consists of 70 parts of magnesium aluminum spinel, 15 It is made of aluminum hydroxide dry rubber powder and 15 parts of calcium aluminate cement, and the active components Mo and Co loaded on the catalyst are finally made of MoO 3 , CoO accounted for 8.3% and 1.6% by weight of the entire catalyst, respectively. The distribution of the obtained sulfur-containing compounds in each cut is shown in Table 6, and the streams obtained by pipelines (8), (19) and (21) are reconcil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com