Patents

Literature

232 results about "Peroxy acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

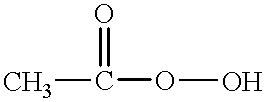

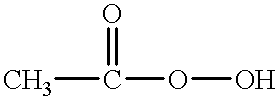

A peroxy acid (often spelled as one word, peroxyacid, and sometimes called peracid) is an acid which contains an acidic –OOH group. The two main classes are those derived from conventional mineral acids, especially sulfuric acid, and the peroxy derivatives of organic carboxylic acids. They are generally strong oxidizers.

Modification of nanotubes oxidation with peroxygen compounds

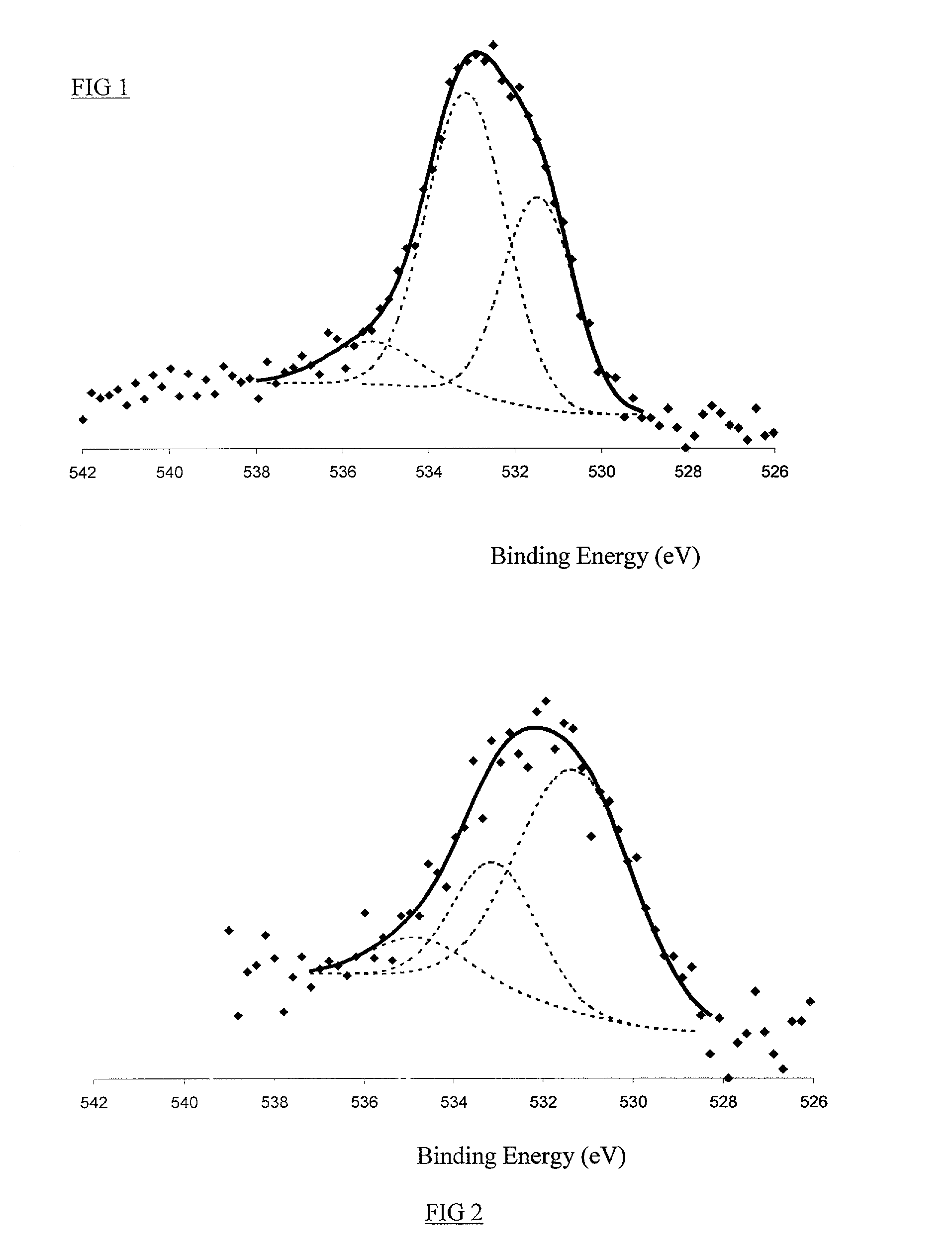

InactiveUS20030039604A1Easy to shapeEasy to measureMaterial nanotechnologyNanostructure manufactureCompound aNanotube

A method of chemically modifying carbon nanotubes having a diameter less than one micron comprising: contacting the nanotubes with a peroxygen compound selected from the group consisting of organic peroxyacids, inorganic peroxoacids and organic hydroperoxides, or a salt thereof, under oxidation conditions and thereby producing modified carbon nanotubes. Oxidation of the nanotubes increases the degree of dispersion of aggregates of nanotubes and aids in the disassembling of such aggregates. The dispersed nanotubes are used to prepare rigid structures and can be used in electrodes and capacitors.

Owner:HYPERION CATALYSIS INT

Tooth whitening compositions

InactiveUS7189385B2Efficient and great capabilityImprove abilitiesCosmetic preparationsTeeth fillingWhitening AgentsPeroxy acid

Novel compositions and methods are disclosed for cosmetically treating teeth in a manner to increase brightness or shade of the teeth. The compositions include a low molecular weight compound having a high acetyl group functionality useful in the production of a peroxy acid which then acts as a whitening agent.

Owner:DISCUS DENTAL LLC

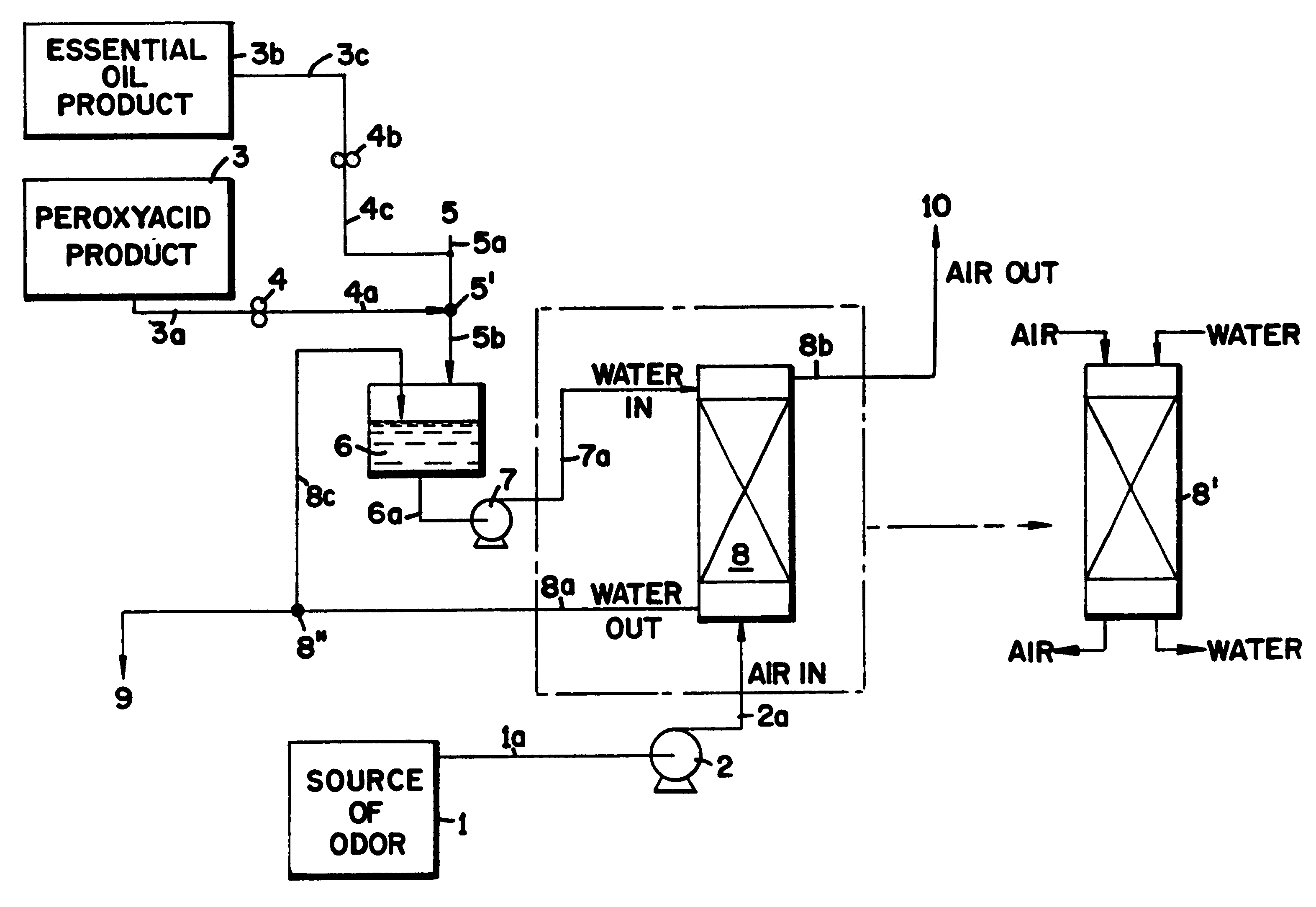

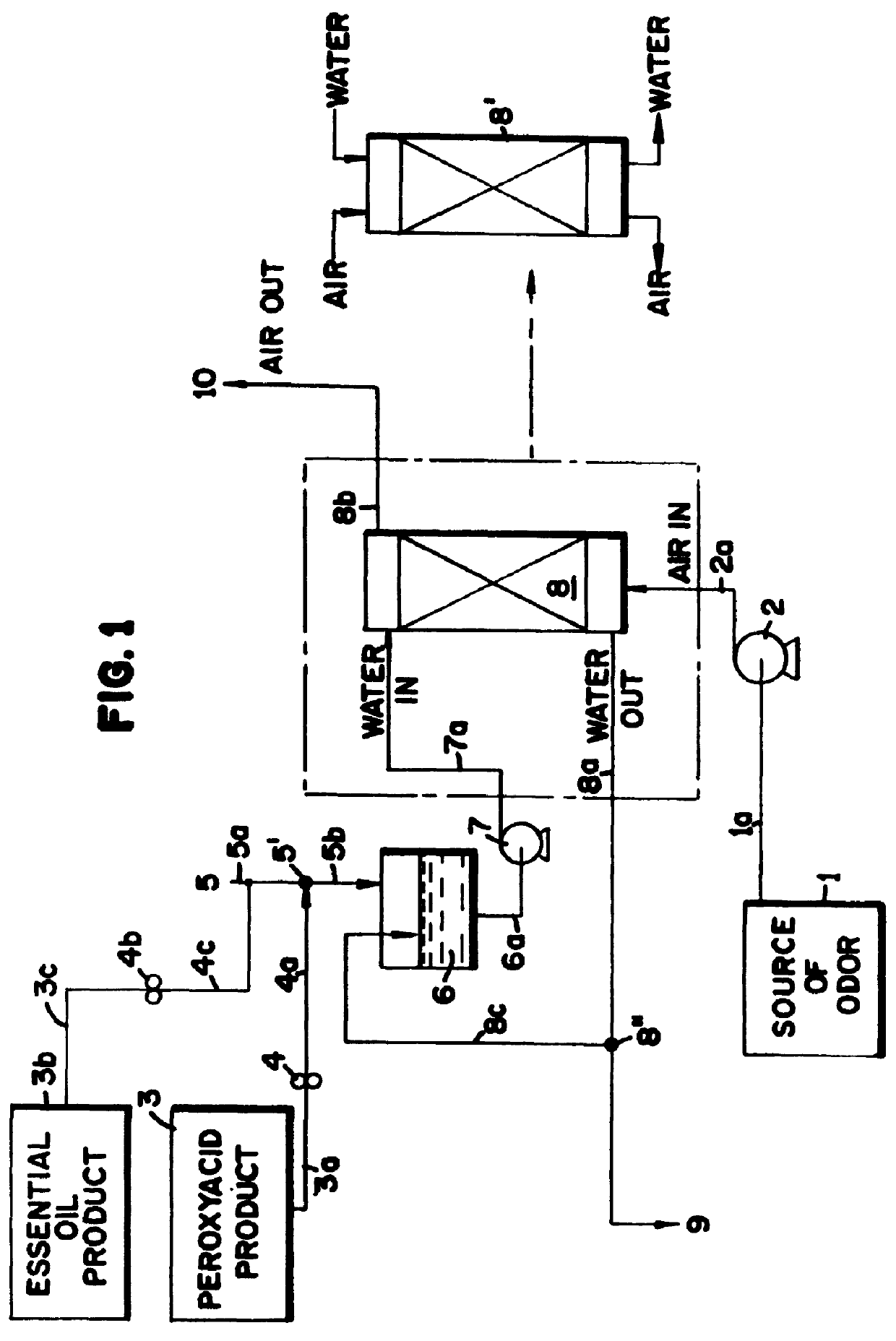

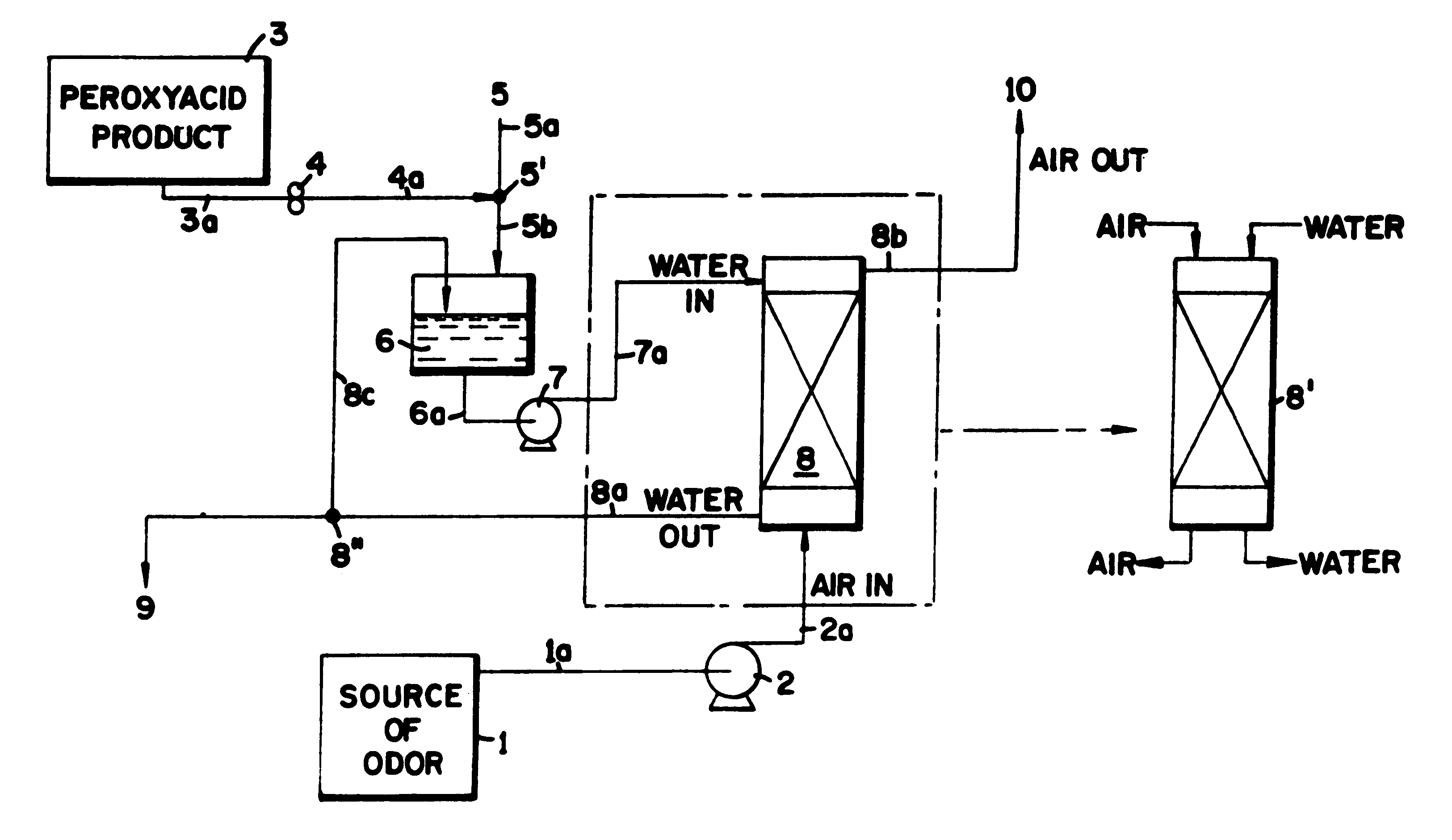

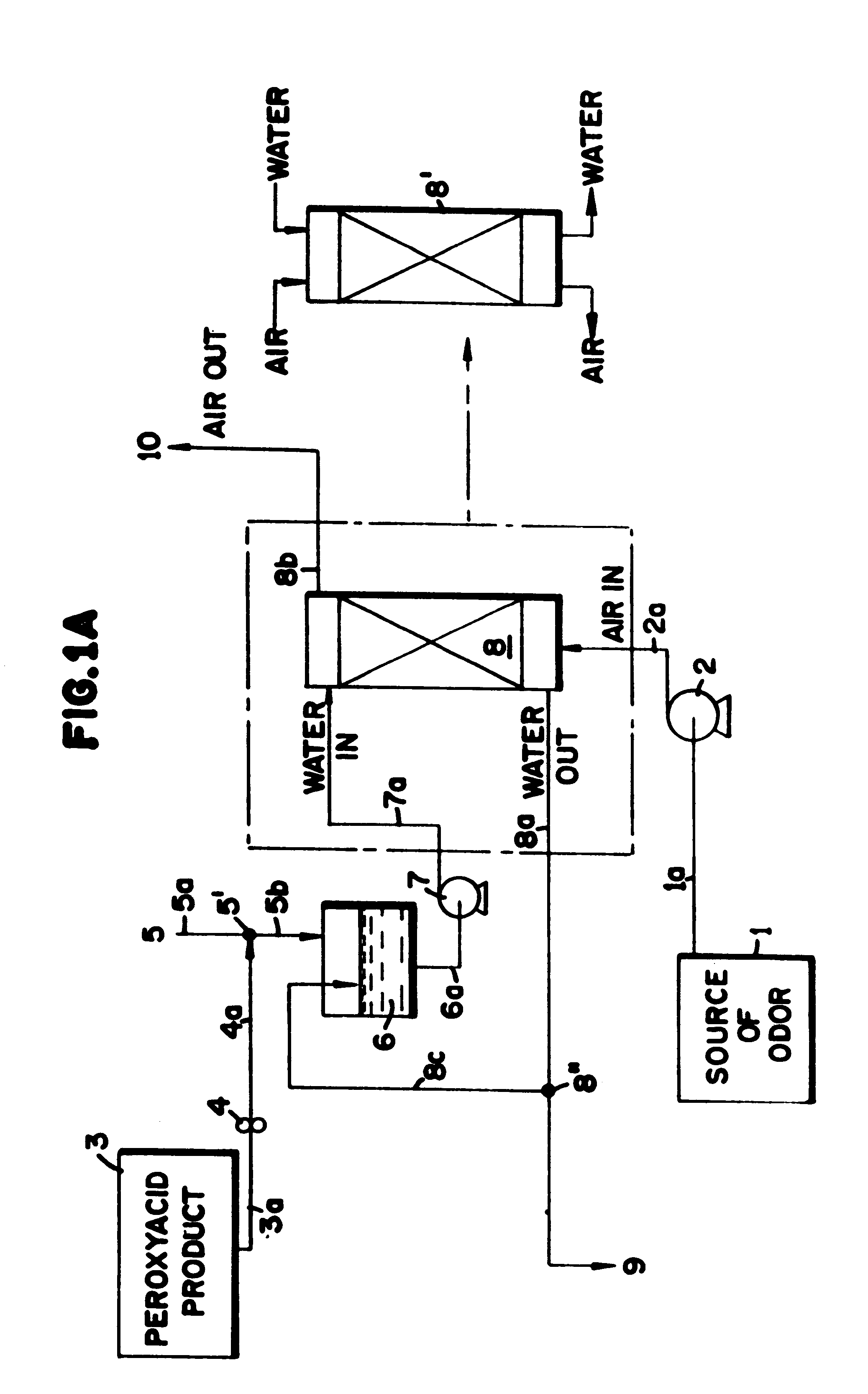

Simultaneous use of peroxygen and olefin compound in odor reduction

InactiveUS6277344B1Improved malodor removalEnhanced mass transferCyanogen compoundsOrganic chemistryGas phasePeroxy acid

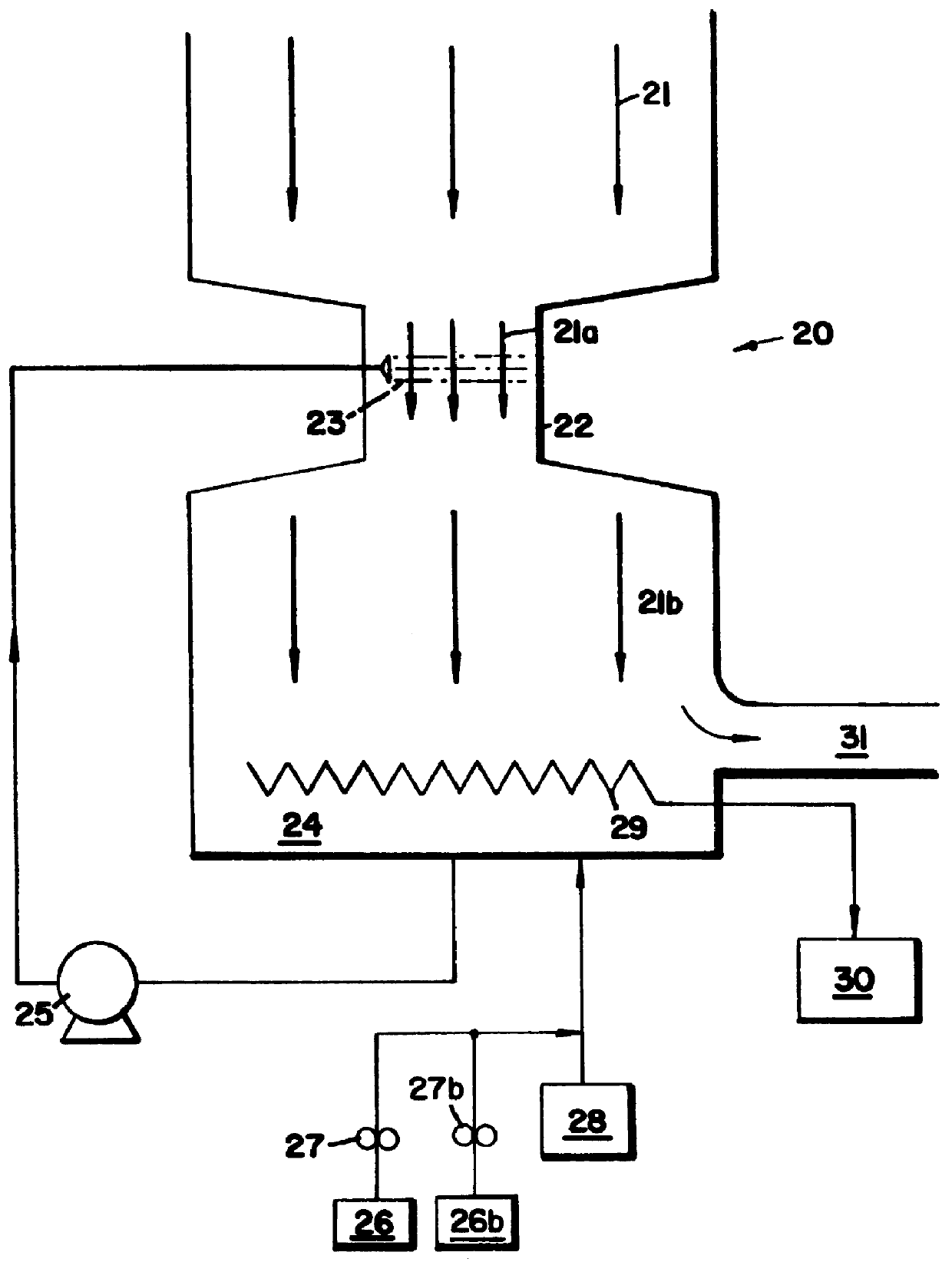

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peroxyacid compound and one or more essential oils. When contacted with the peroxyacid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

Peroxyacid compound use in odor reduction

InactiveUS6015536AReduce concentrationLess objectionable odor levelUsing liquid separation agentChemical/physical processesGas phasePeroxy acid

Disclosed is a process for the treatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent in either a counterflow or cocurrent flow process. In the process, the effluent is contacted with an aqueous solution comprising a peracid compound. When contacted with the peracid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. In this way, odor removal from the gas is preferred and odor compounds are efficiently transferred into the aqueous treatment solution. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

Modification of nanotubes oxidation with peroxygen compounds

InactiveUS20030086858A1Easy to measureGood dispersionMaterial nanotechnologyNanostructure manufactureCompound aNanotube

Owner:HYPERION CATALYSIS INT

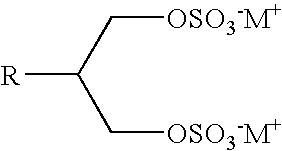

Detergent compositions having a specific hydrophobic peroxyacid bleaching system and anionic surfactant

InactiveUS6689732B1Anionic surface-active compoundsNon-surface-active detergent compositionsOrganic chemistrySURFACTANT BLEND

Granular detergent compositions, particularly phosphate-containing detergent compositions, contain a specific hydrophobic peroxyacid bleaching system and a specific anionic surfactant system. The compositions are suitable for use in laundry washing methods.

Owner:THE PROCTER & GAMBLE COMPANY

Bleaching compositions

InactiveUS6444634B1Non-surface-active detergent compositionsOrganic/inorganic per-compounds compounding agentsPhosphateBacterial activity

Granular detergent compositions and in particular low density, phosphate containing detergent compositions comprise a specific bleaching system containing hydrophobic peracid bleach and hydrophilic peracid bleach and a peroxide source. These detergent compositions have specific low levels of available oxygen from hydrophobic aid hydrophilic peroxyacid bleach, specific ratios of available oxygen from the hydrophobic peracid bleach to the hydrophilic peracid bleach and specific ratios of available oxygen of the peroxide source to the available oxygen of the peracids. These specific mixed bleach systems are useful for sanitization or reduction of bacterial activity.

Owner:THE PROCTER & GAMBNE CO

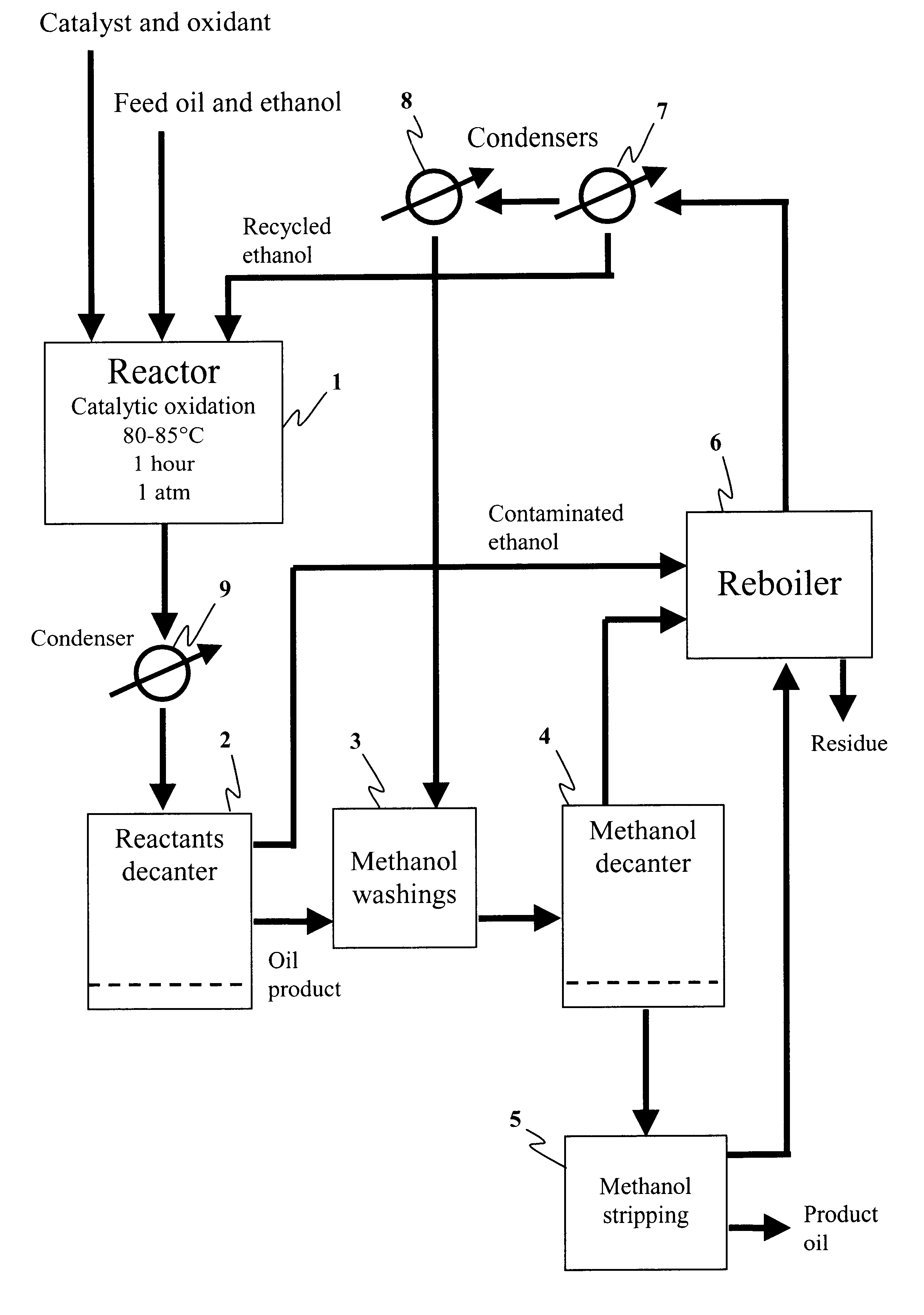

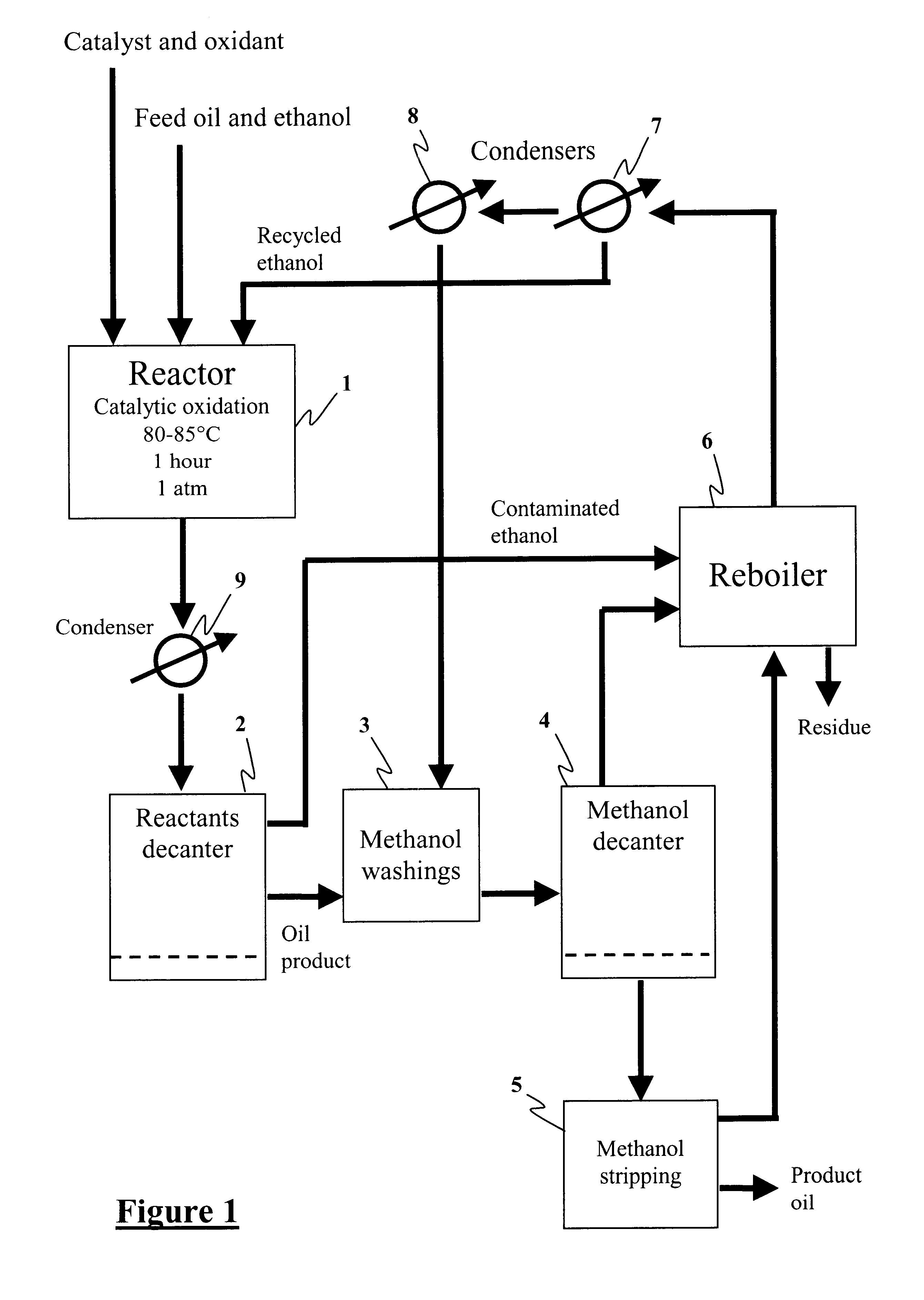

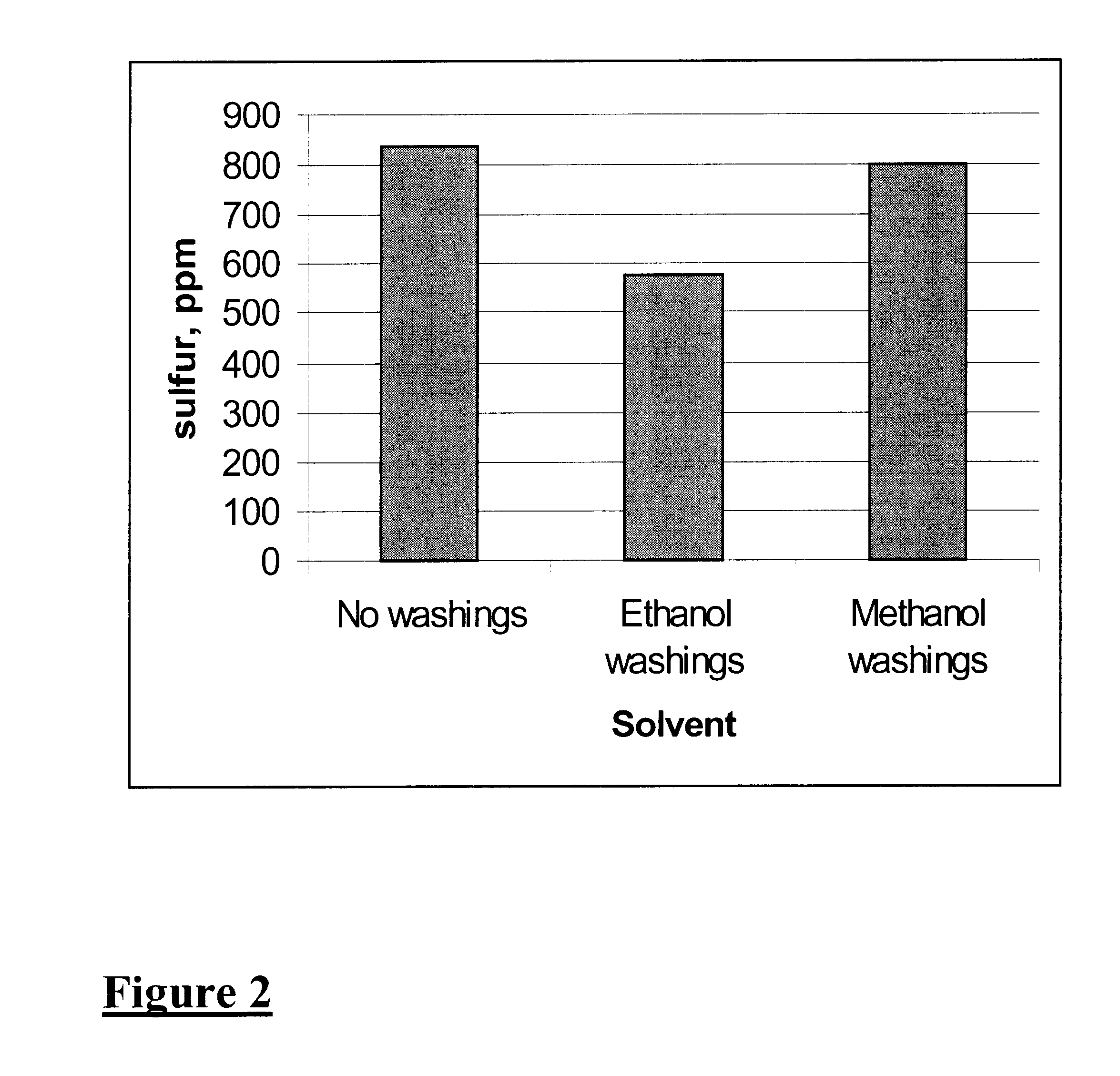

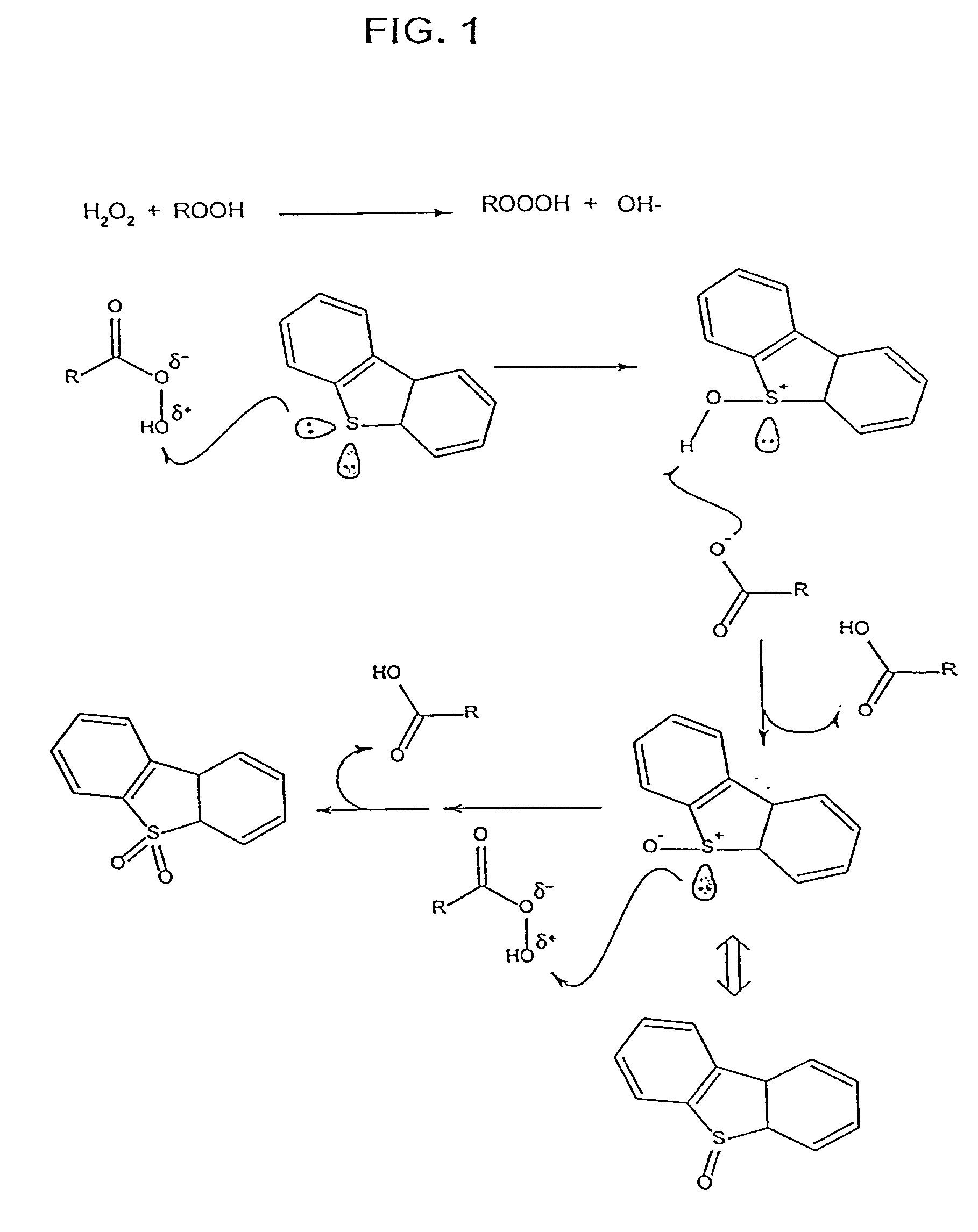

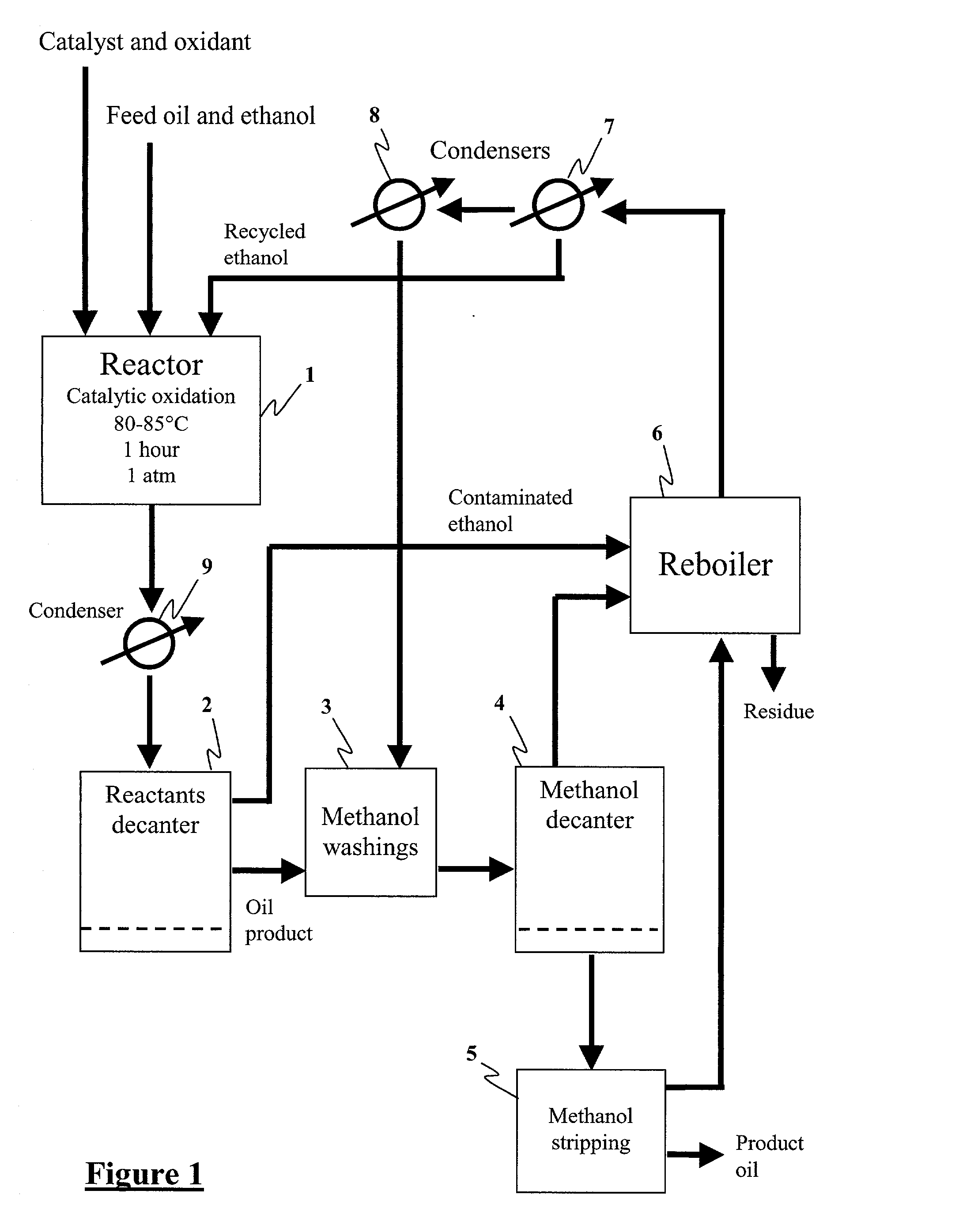

Method for the production of hydrocarbon fuels with ultra-low sulfur content

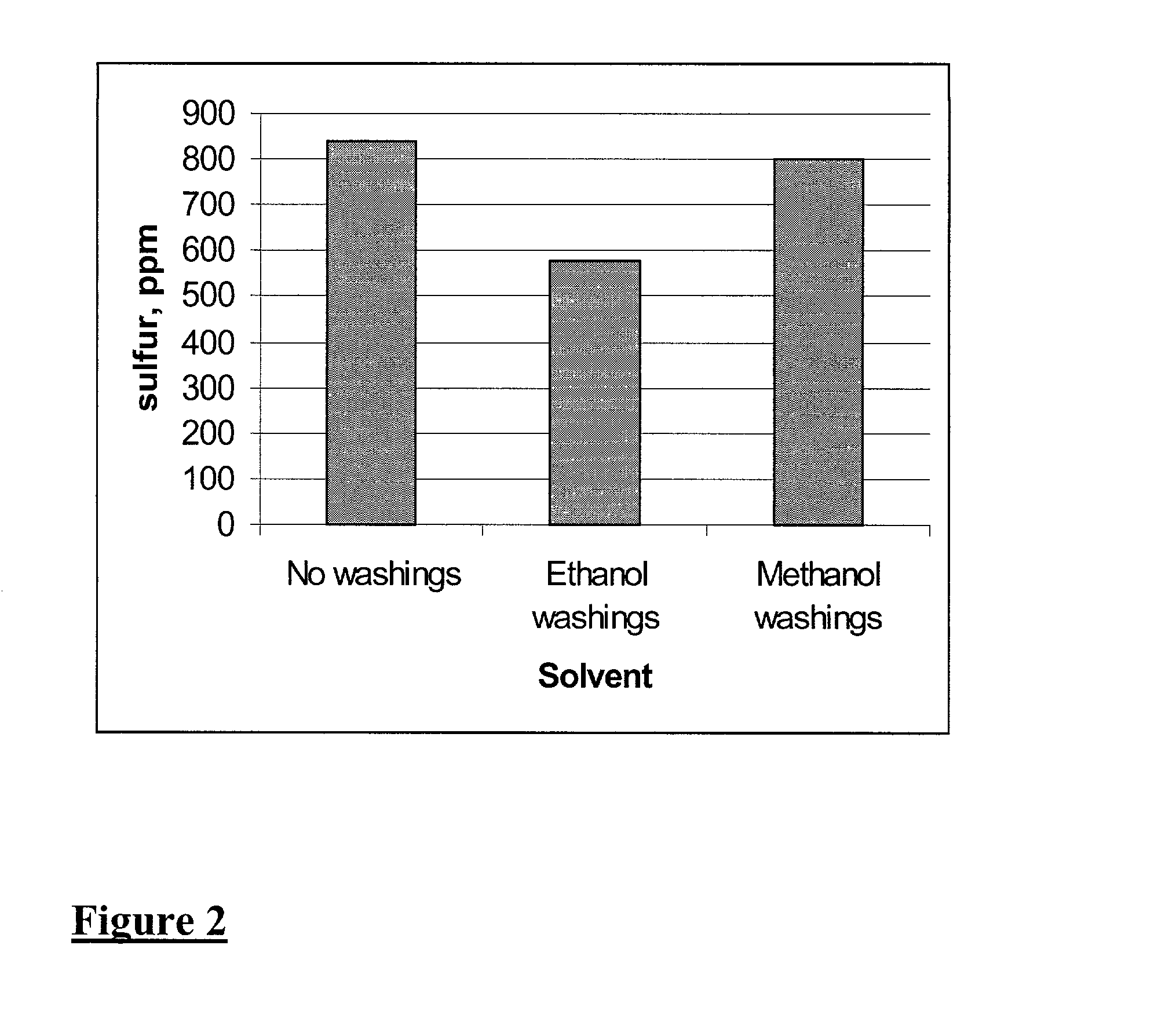

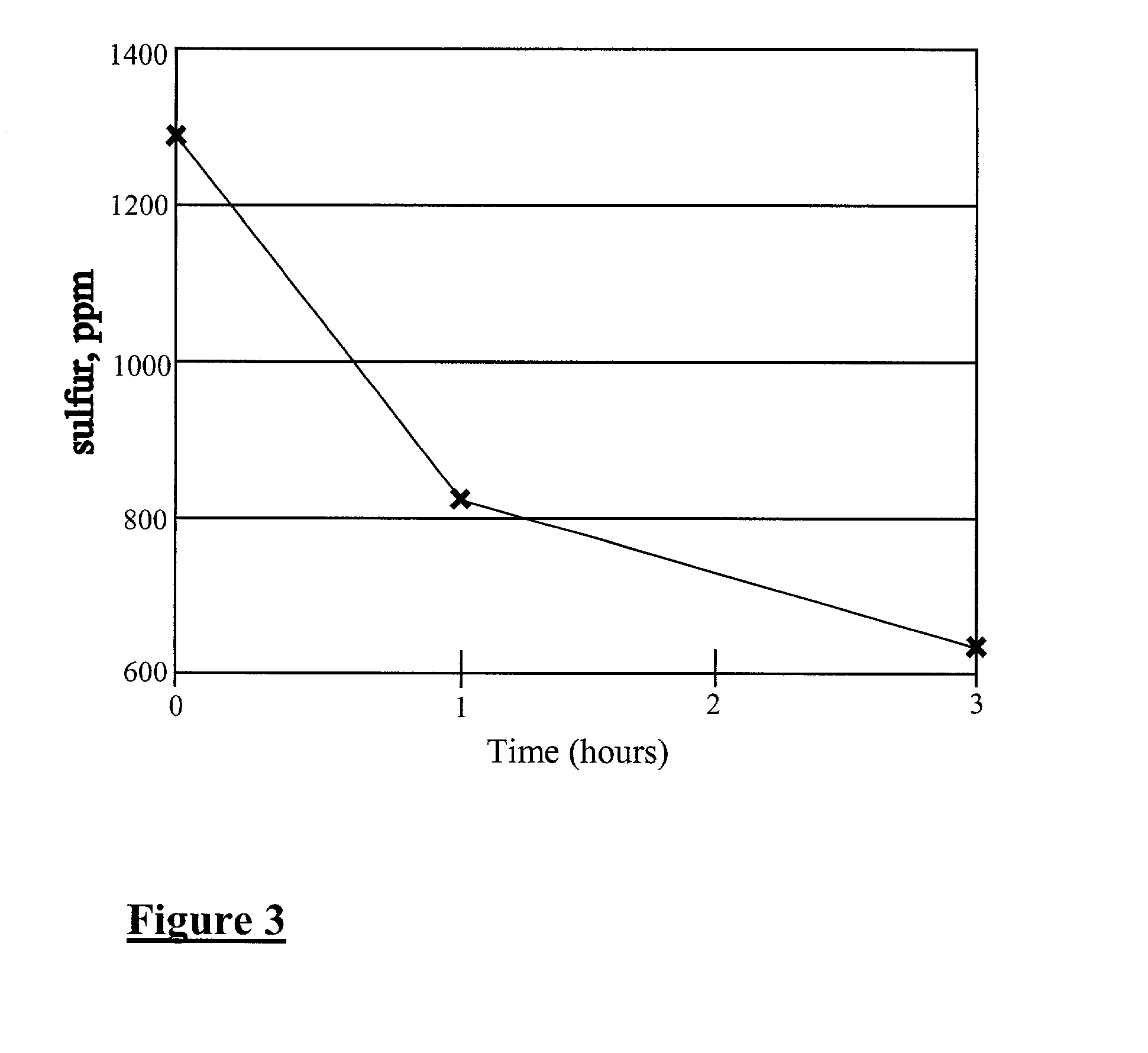

InactiveUS6673236B2Efficient oxidationReduce sulfur contentRefining with oxygen compoundsCatalytic naphtha reformingAlcoholCatalytic oxidation

The present invention provides a method for producing hydrocarbon fuels with ultra-low levels of sulfur. The method involves catalytic oxidation of the sulfurous compounds within the hydrocarbon fuel, followed by extraction of the oxidized (and polarized) sulfurous compounds using a polar solvent. The present invention teaches the involvement of ethanol during catalytic oxidation. In this way, the oxidation catalyst has a dual-role in the oxidation process: firstly the catalyst directly oxidizes the sulfurous compounds, and secondly the oxidation catalyst converts of a small portion of the alcohol to the corresponding peroxy acid, which also helps to drive the oxidation process.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

Enhanced method of using peroxyacid compounds in odor reduction

Disclosed is a process for the pretreatment of a plant fluid effluent containing odor compounds including an alkyl mercaptan or an alkyl thiol, an amine compound, ammonia, hydrogen sulfide and mixtures thereof by contacting the plant effluent with an atomized aqueous solution comprising a peroxy acid compound. When contacted with the peroxy acid, odor compounds in the effluent are oxidized and converted from the gaseous phase into a chemically modified highly aqueous soluble phase in the aqueous treatment. The use of such a process produces a significant improvement in odor quality index as measured by a conventional process using an expert panel when compared to conventional treatment methods.

Owner:ECOLAB USA INC

Process for the preparation of peroxy acids

ActiveUS20090221704A1Easy to controlIncrease powerBiocideOrganic compound preparationPeroxy acidCarboxylic acid

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

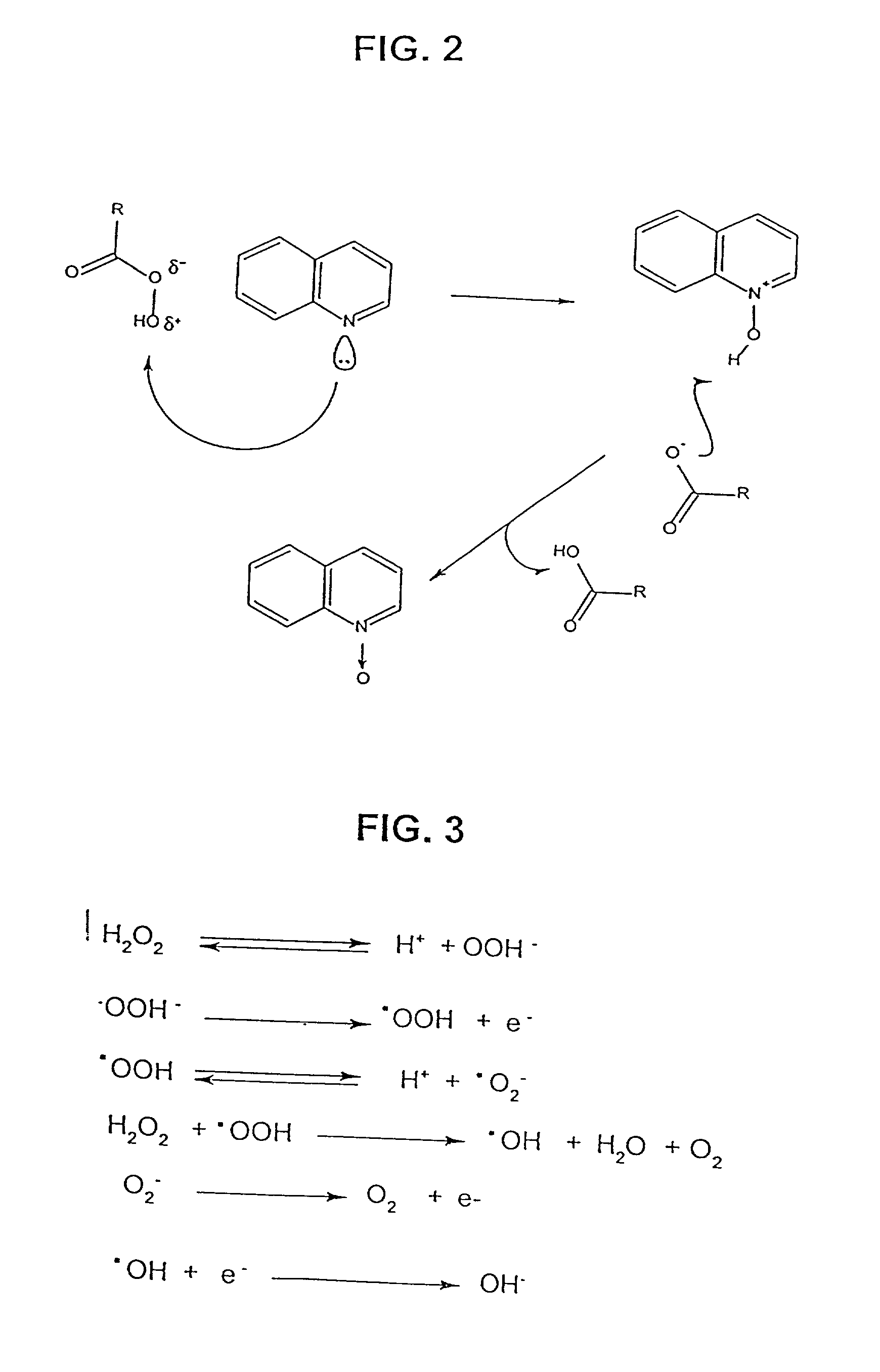

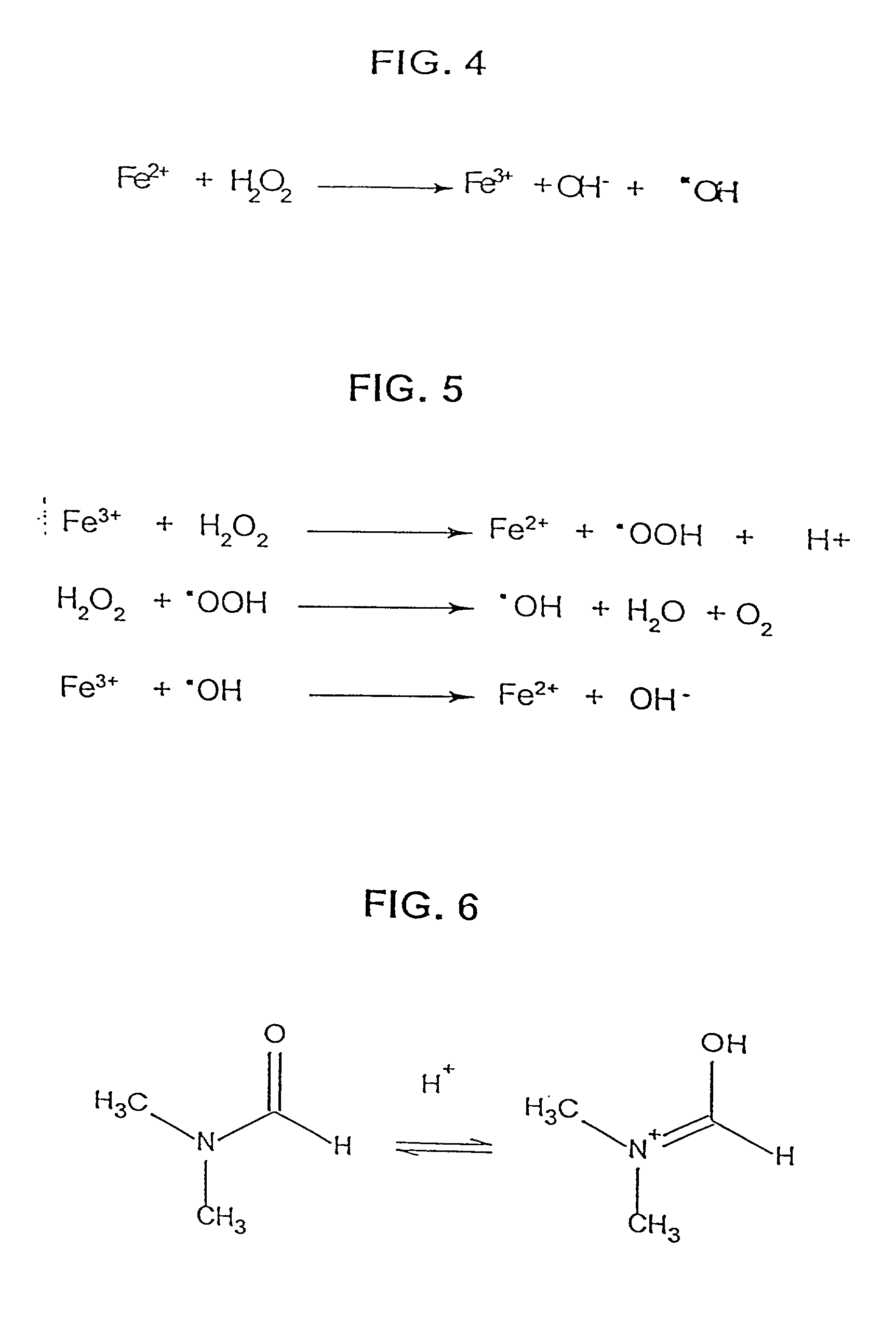

Process for the catalytic oxidation of sulfur, nitrogen and unsaturated compounds from hydrocarbon streams

InactiveUS20020189975A1Refining with metalsRefining with oxygen compoundsCatalytic oxidationPeroxy acid

A process for the catalytic oxidation of sulfur and nitrogen contaminants as well as unsaturated compounds present in a hydrocarbon fossil oil medium is described, the process comprising effecting the oxidation in the presence of at least one peroxide, at least one acid and a pulverized raw iron oxide. The process shows an improved oxidation power towards the contaminants typically present in a fossil oil medium, this deriving from the combination of the peroxy-acid and the hydroxyl radical generated in the reaction medium due to the presence of an iron oxyhydroxide such as a limonite clay, which bears a particular affinity for the oil medium. The process finds use in various applications, from a feedstock for refining until the preparation of deeply desulfurized and deeply denitrified products.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

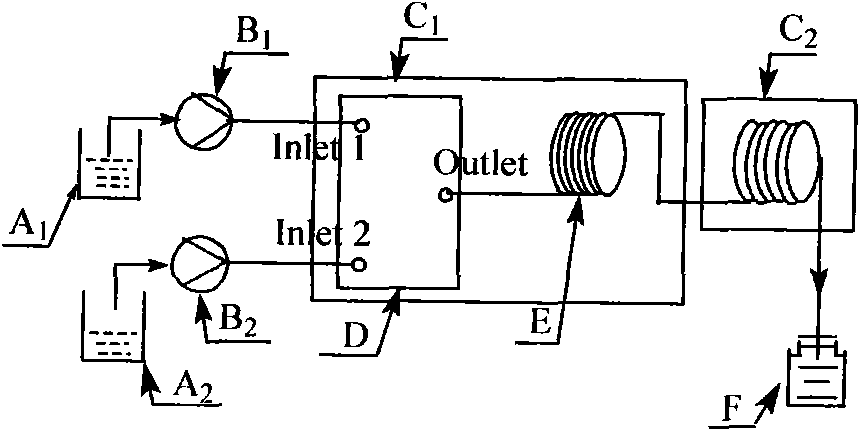

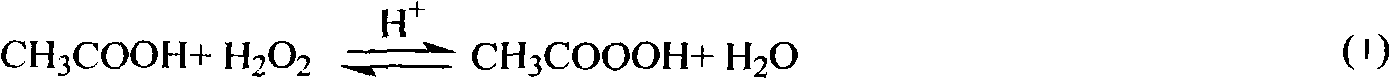

Method for preparing epoxy fatty acid methyl ester

The invention relates to a method for preparing epoxy fatty acid methyl ester. The method comprises the following specific steps of: mixing hydrogen peroxide and formic acid or acetic acid; adding a catalyst and a stabilizer into mixed liquor; pumping fatty acid methyl ester into a microstructure reactor; separating the epoxy fatty acid methyl ester from a reacted material; introducing a reaction product into a separator; standing to delaminate lower layer water solution; washing an upper layer organic phase with water; and drying the washed upper layer organic phase to obtain the epoxy fatty acid methyl ester. In the entire process of the method, a strong exothermic reaction is performed, and a peroxy acid synthesis reaction is performed together with an epoxidation reaction, so that the epoxy fatty acid methyl ester is synthesized in situ at one time. The production process has the advantages of high safety, low energy consumption, continuity and high product quality by adopting micro-reaction production technology of the invention.

Owner:NANJING UNIV OF TECH

Process for the preparation of peroxy acids

ActiveUS8828910B2Easy to controlIncrease powerBiocideOrganic compound preparationCarboxylic acidPeroxy acid

The present invention relates to a process for the preparation of a solution comprising a first peroxy acid comprising performic acid and a second peroxy acid, said process comprising forming a carboxylic acid solution comprising a first carboxylic acid comprising formic acid, a second carboxylic acid and hydrogen peroxide, wherein the amount of formic acid is from 0.5 to 20% by weight of the amount of the second carboxylic acid, and allowing the components to react to form a solution comprising performic acid and said second peroxy acid, the amount of peroxy acids being at least 5% by weight. The invention also relates to a storable solution comprising performic acid and said second peroxy acid. The solution can be used as a disinfecting agent for controlling micro-organisms.

Owner:KEMIRA OY

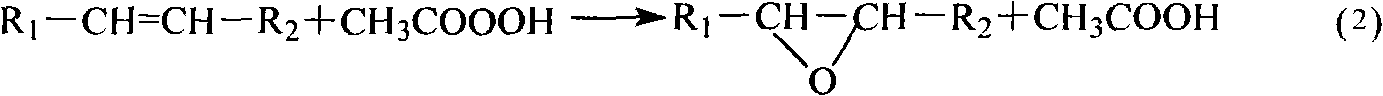

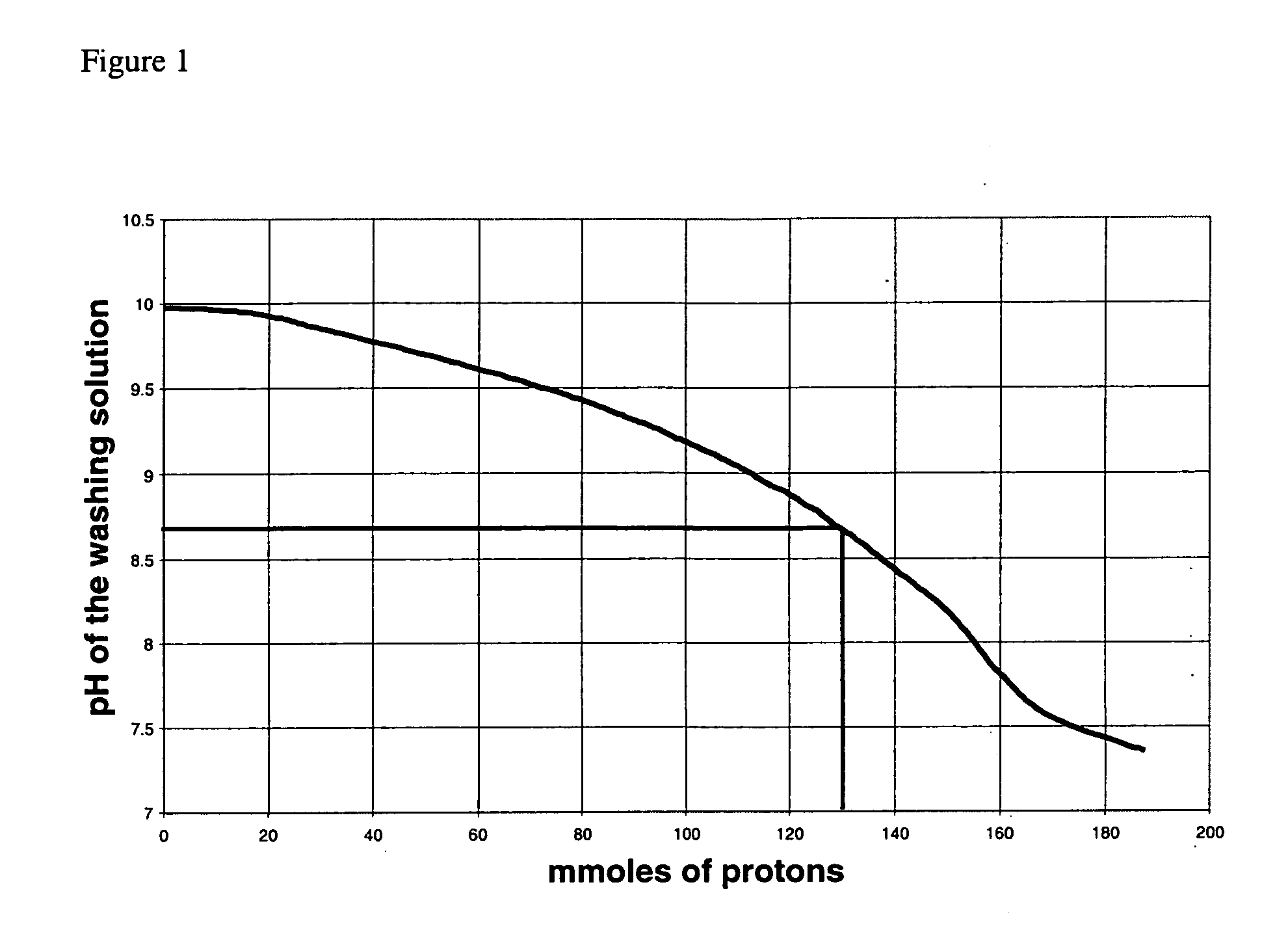

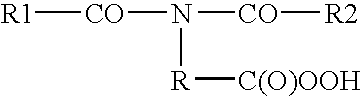

Liquid bleaching compositions

InactiveUS20050222003A1Improves bleaching performanceImprove performanceInorganic/elemental detergent compounding agentsOrganic/inorganic per-compounds compounding agentsBleachProton

The present invention relates to liquid bleach additive compositions comprising an imido-type peroxy acid and a source of protons.

Owner:THE PROCTER & GAMBLE COMPANY

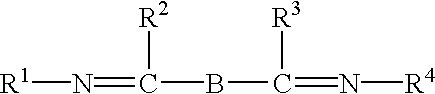

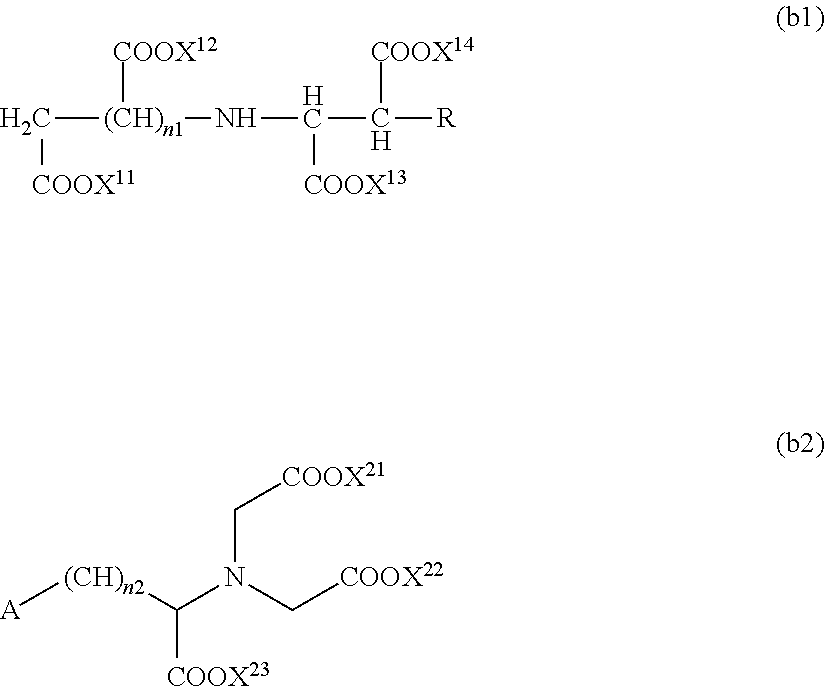

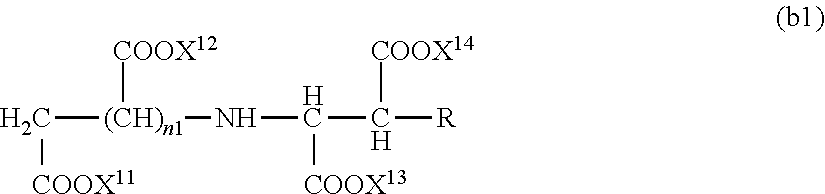

Disinfectant composition and disinfecting method

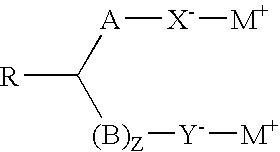

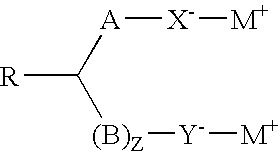

InactiveUS20120164236A1Effectively eliminating gram negative bacteriaImprove disinfection effectInorganic/elemental detergent compounding agentsBiocideZinc compoundsPeroxy acid

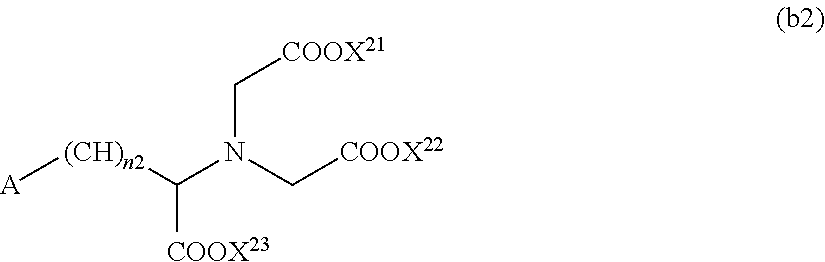

The present invention relates to a disinfectant composition containing the following components (A) to (D): component (A): a zinc compound, component (B): a chelate compound represented by the following general formula (b1) or (b2), component (C): hydrogen peroxide or a peroxide that releases hydrogen peroxide in water, and component (D): an organic peroxy acid precursor that generates an organic peroxy acid by reacting with the component (C). According to the present invention, a disinfectant composition and a disinfecting method can be provided that enable the effective elimination of gram negative bacteria adhered to textile products, and particularly cotton products.

Owner:LION CORP

Method for preparing polylol with soybean oil

InactiveCN101195577AOrganic compound preparationCarboxylic acid esters preparationPolyesterPeroxy acid

The invention relates to a method for preparing polyol which is epoxidised by soybean oil and further preparing polyurethane foam plastic, wherein the preparation technical of polyol comprises the procedures as follows: first, preparing epoxy soybean oil by peroxy acid home position generation method of soybean oil, the epoxy value is between 2.0 and 7.0, and then preparing soybean oil polyol by catalyzing epoxy soybean oil under acid or alkaline. The hydroxyl value of polyol is between 100 and 700 mgKOH / g and the viscosity can be controlled by changing distilling temperature. The polyol replaces polyether or polyester polyol to synthesize polyurethane foam plastic which can be applied in the insulation material and the like. The invention is characterized in adopting acid or alkaline as catalyst to catalyze ring-opening reaction and obtaining polyol of different viscosities through different distilling temperature.

Owner:TIANJIN POLYTECHNIC UNIV

Cleaning compositions

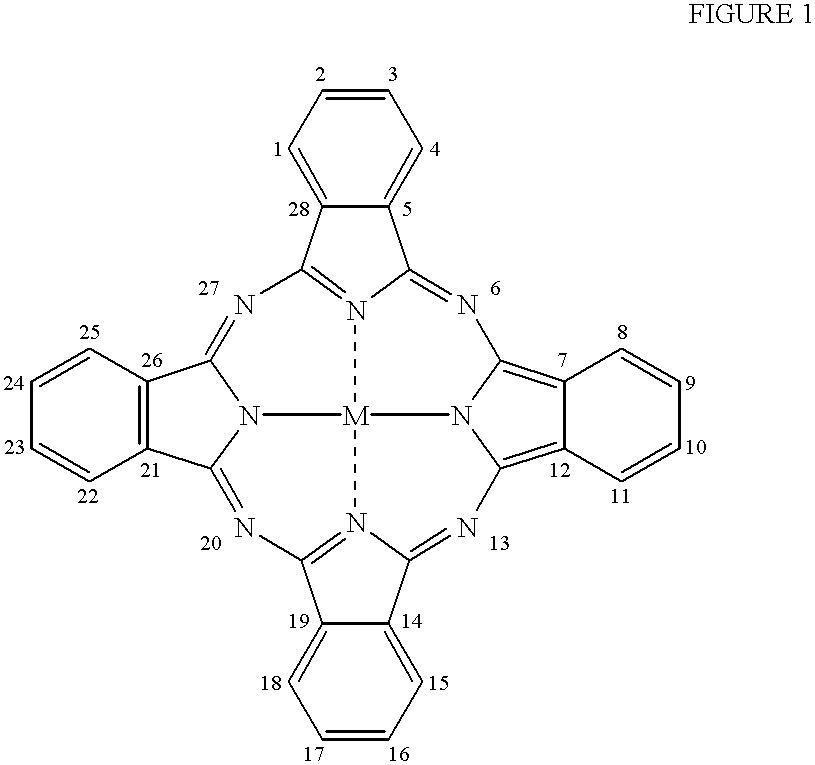

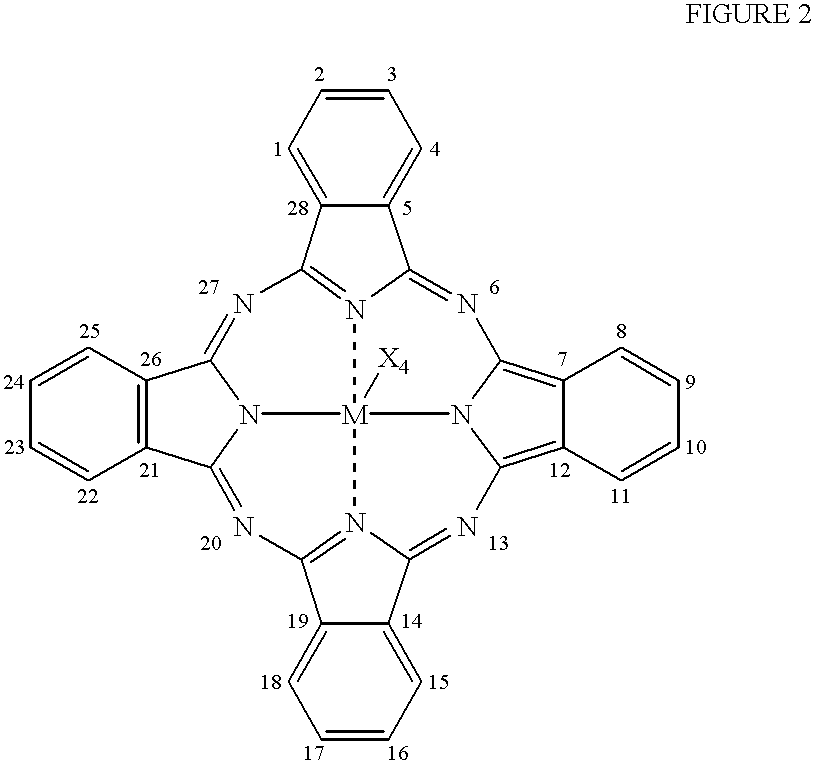

InactiveUS6339055B1Organic detergent compounding agentsAnionic surface-active compoundsMethacrylatePorphyrin

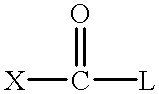

The present invention relates to a photo bleaching compositions comprising:A) from 0.5 ppm by weight, of a photo bleaching agent, said agent comprising:a) a polymeric component, said polymeric component comprising one or more polymeric compounds having an average molecular weight of from 500 to 1,000,000 wherein at least 50% of the monomers which comprise said polymeric compounds comprise one or more di-polar, aprotic groups and have a polymerizable vinyl moiety, the balance comprising monomers selected from the group consisting of acrylic acid, acrylic acid esters, acrylic acid amides, methacrylic acid, methacrylic acid esters, methacrylic acid amides, and mixtures thereof; andb) a photo bleaching component, said photobleaching component comprising a porphyrin or a phthalocyanine ring wherein said phthalocyanine ring can optionally be substituted at one or more ring positions, and said ring comprising a transition metal or cation having an oxidation state of two or greater;wherein said photo bleaching component is integrated with said polymeric component to form said photo bleaching agent and the weight ratio of polymeric component (a) to photobleaching component (b) is from 1:1 to 1000:1;B) from 0.1% by weight, of a peroxy acid bleaching compound precursor; andC) the balance carriers and adjunct ingredients.

Owner:THE PROCTER & GAMBLE COMPANY

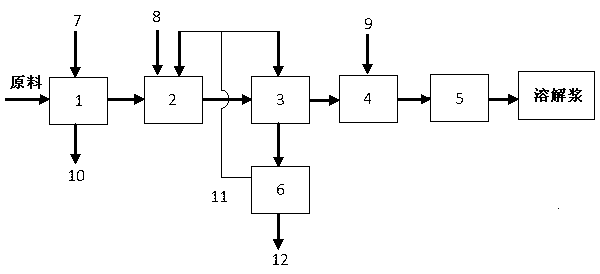

Production method of dissolving pulp

The invention relates to a production method of dissolving pulp. The method comprises the steps of pre-hydrolyzing plant fibrous raw materials by water, steam or diluted acid, then digesting the materials by peroxy acid, and processing the materials by hemicellulase, thus obtaining the dissolving pulp. The dissolving pulp produced by the method has the whiteness more than 90% ISO (International Standards Organization), and the content of Alpha-cellulose is more than 92%, and the content of pentosan is less than 2.0%. The method is applicable to wood and non-wood fibrous raw materials.

Owner:济南绿泉新材料科技有限公司

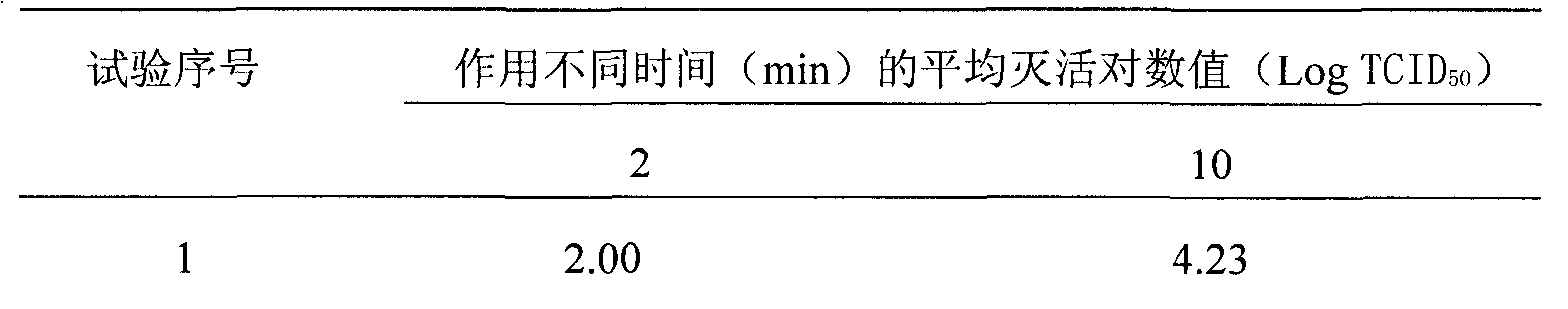

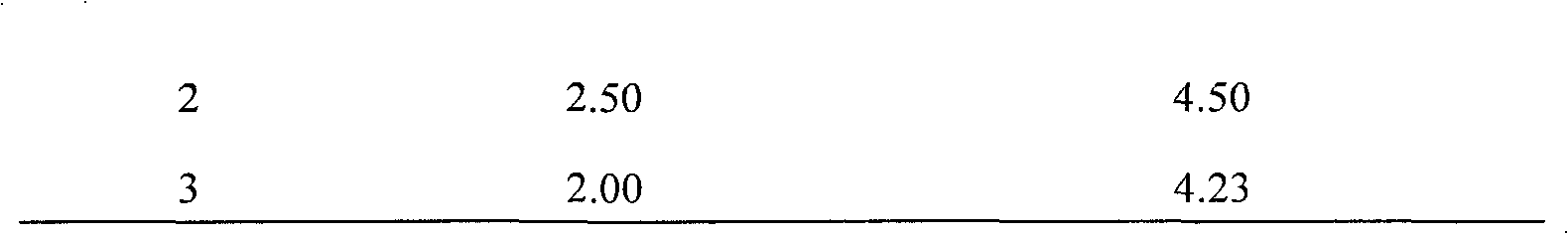

Solid binary peroxy acid disinfectant

The invention discloses a compound high-efficiency biochemical disinfectant with low corrosivity, which comprises the following materials in percentage by weight: 10-80% of main oxidant A and 20-90% of synergistic assistant B, wherein the main oxidant A is a solid peroxide; the synergistic assistant B comprises an activator containing an amide group or ester group; and the main oxidant A and the synergistic assistant B in the disinfectant adopt binary package. Before use, the main oxidant and the synergistic assistant are prepared in proportion into a water solution with the mass concentration of 0.1-10% for disinfection. The disinfectant can efficiently disinfect pathogens of various viruses, bacteria, spores and the like, has good disinfecting effects on toxic and harmful materials of organic phosphorus, sulfur and the like, chemical reagents and the like, and simultaneously has good storage stability, low corrosivity on the surface of disinfection equipment, personnel security and no pollution to the environment.

Owner:中国人民解放军防化指挥工程学院

Granular cleaning and disinfecting composition

InactiveUS20100075883A1Decreased gas formationReadily solubleInorganic/elemental detergent compounding agentsBiocideDissolutionPeroxy acid

The present invention relates to a granular cleaning and disinfecting composition generating a peroxy acid upon dissolution in water comprising: (1) 15-60 wt % of a percarbonate, (2) 8-35 wt % of an acylating agent, (3) 0.5-5 wt % a nonionic surfactant, (4) 0.1-3 wt % of a phosphonate as a foam inhibitor, having a bulk density between 0.5 and 1.4 kg / L as well as a method for cleaning or disinfecting with a low-foaming peroxy acid containing use solution obtained upon dissolution of the granular composition in water.

Owner:ECOLAB USA INC

Method for the production of hydrocarbon fuels with ultra-low sulfur content

InactiveUS20030075483A1Efficient oxidationReduce sulfur contentRefining with oxygen compoundsCatalytic naphtha reformingAlcoholCatalytic oxidation

The present invention provides a method for producing hydrocarbon fuels with ultra-low levels of sulfur. The method involves catalytic oxidation of the sulfurous compounds within the hydrocarbon fuel, followed by extraction of the oxidized (and polarized) sulfurous compounds using a polar solvent. The present invention teaches the involvement of ethanol during catalytic oxidation. In this way, the oxidation catalyst has a dual-role in the oxidation process: firstly the catalyst directly oxidizes the sulfurous compounds, and secondly the oxidation catalyst converts of a small portion of the alcohol to the corresponding peroxy acid, which also helps to drive the oxidation process.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

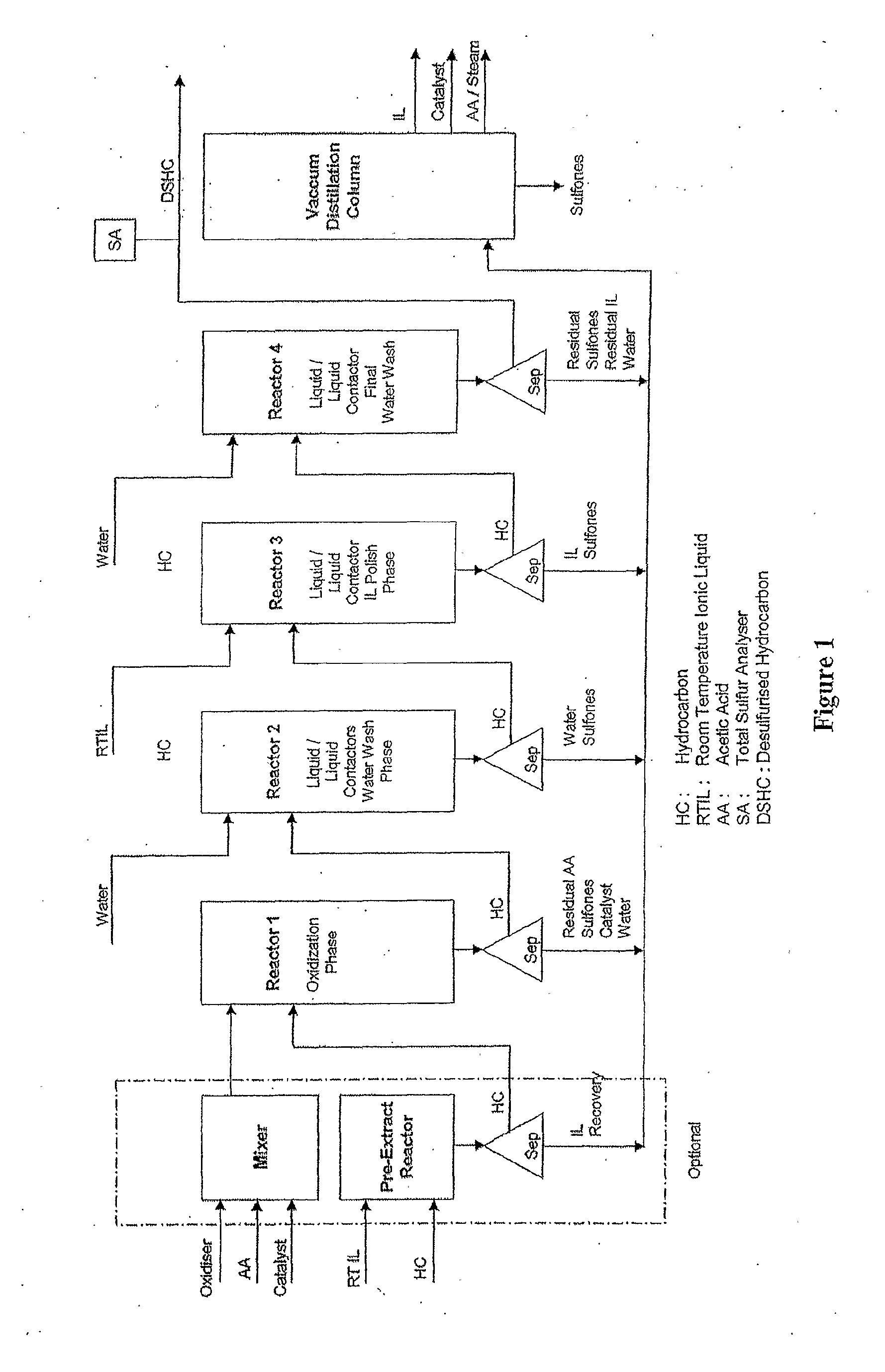

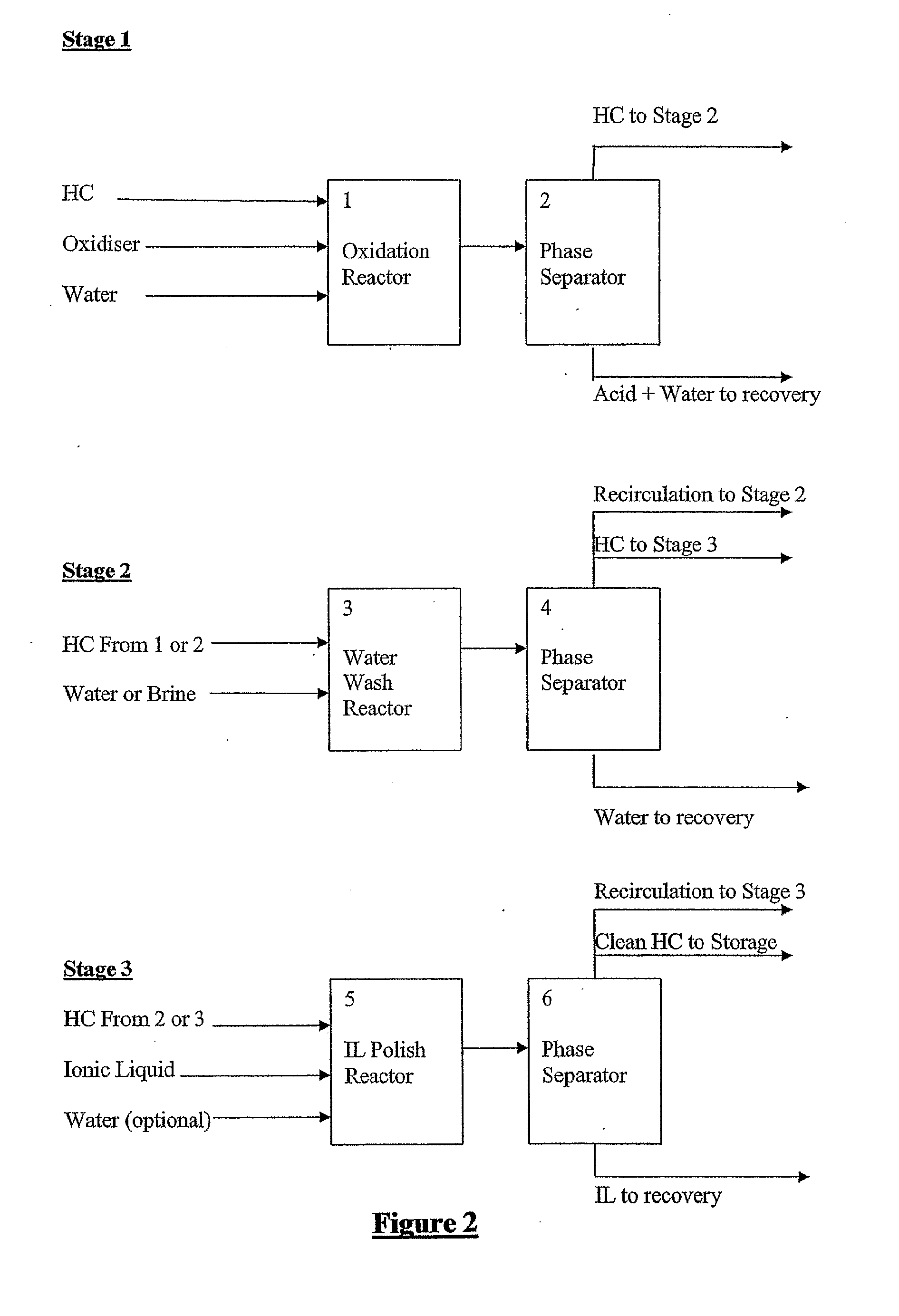

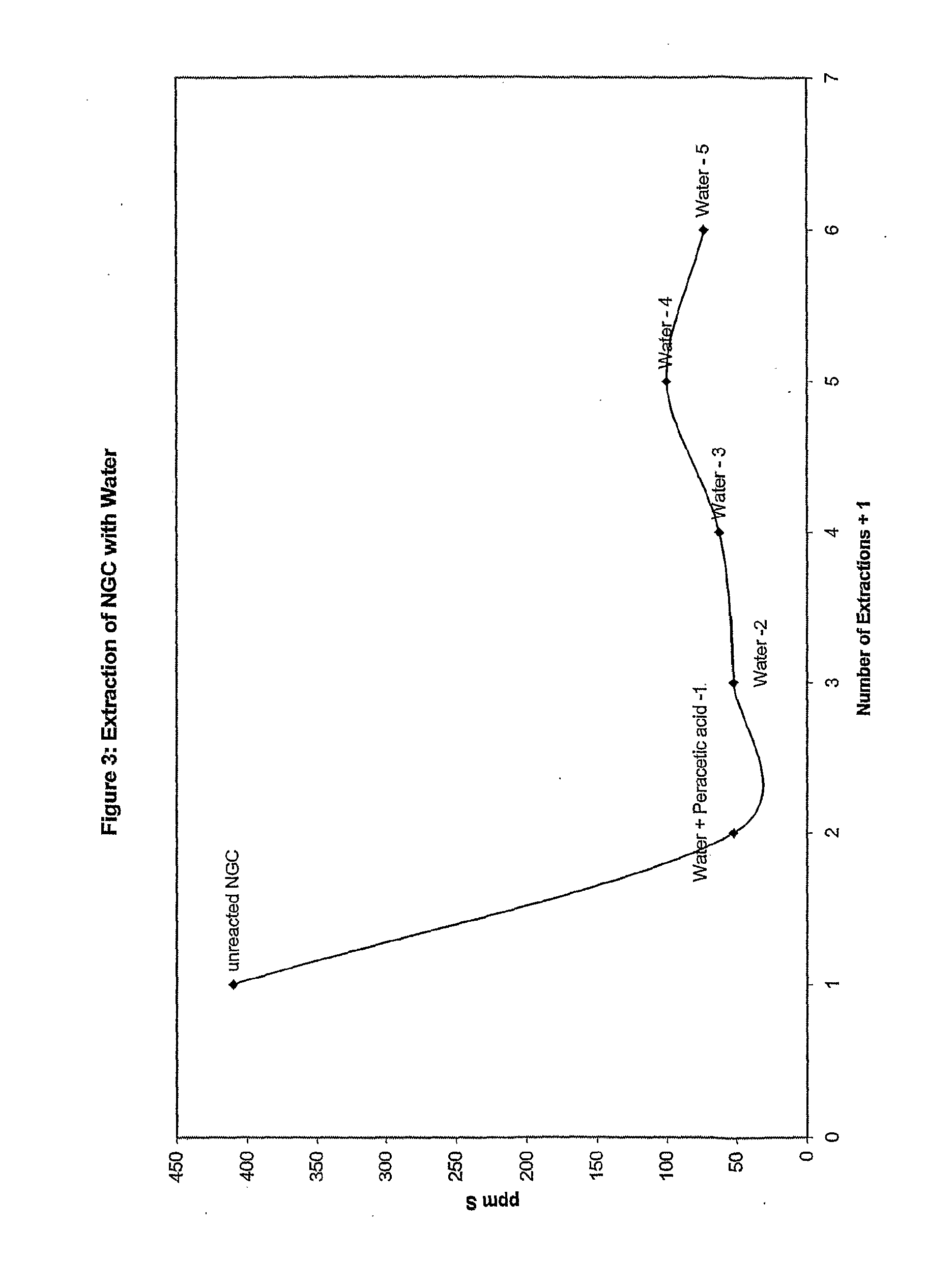

Process for Removing Sulphur From Liquid Hydrocarbons

ActiveUS20110203972A1Low and easy to handle waste streamSimple and economically viableRefining with oxygen compoundsTreatment with plural serial refining stagesPartial oxidationDistillation

A process for the deep desulfurisation of hydrocarbons (HC), in particular Natural Gas Condensate (NGC), and HC comprising diesel, pre-extracted diesel and naphtha, is described which is capable of reducing the sulfur content of these HC from 500 to 30 ppm. The process comprises contacting the hydrocarbon material with an oxidant selected from organic peroxy acids, organic peroxides, inorganic peroxides and mixtures thereof, in at least a stochiometric amount sufficient to oxidise a sulfur compound to a sulfone compound; contacting the hydrocarbon material with an aqueous extractant to allow at least a portion of the oxidised sulfur compounds to be extracted into the aqueous extractant, and separating the hydrocarbon material from the aqueous extractant to give a hydrocarbon material of reduced sulfur content. Optionally, the process may include a second and subsequent extractions with the aqueous extractant to further reduce sulfur content. A final extraction with an IL may be conducted. The invention also provides for substitution of the aqueous extractant with an IL in one or more of the other extraction steps. The extractants and by products generated during f01 oxidation can be recovered by simple distillation techniques.

Owner:ULTRACLEAN FUEL LTD

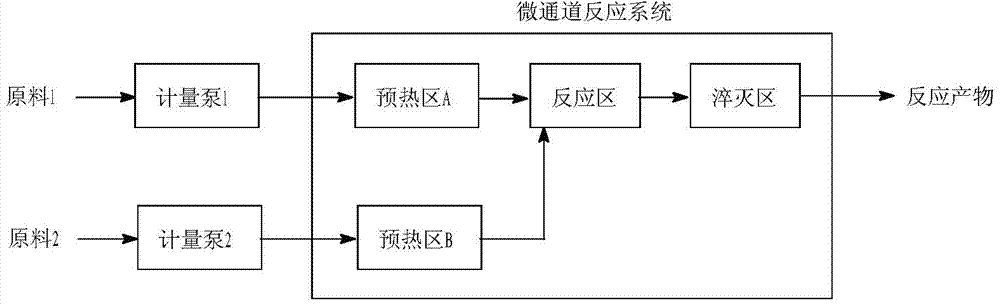

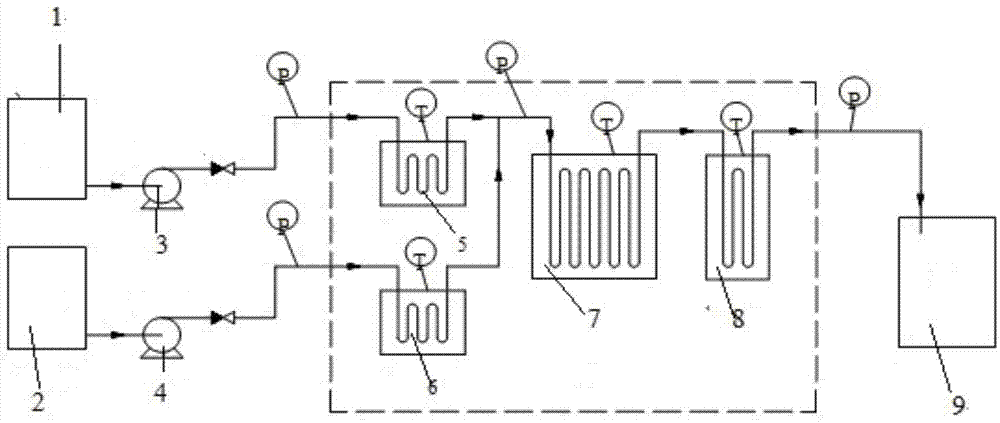

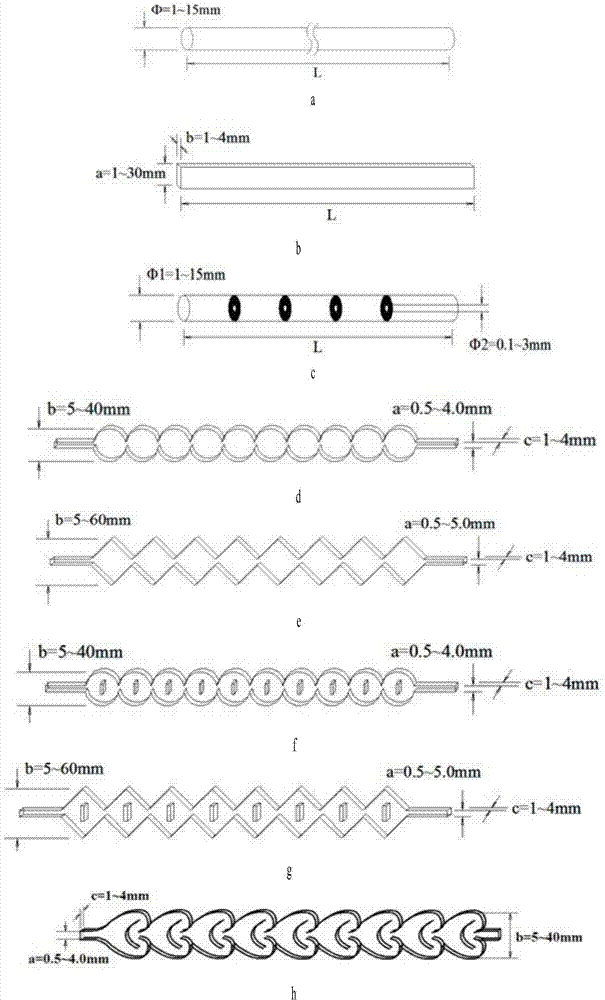

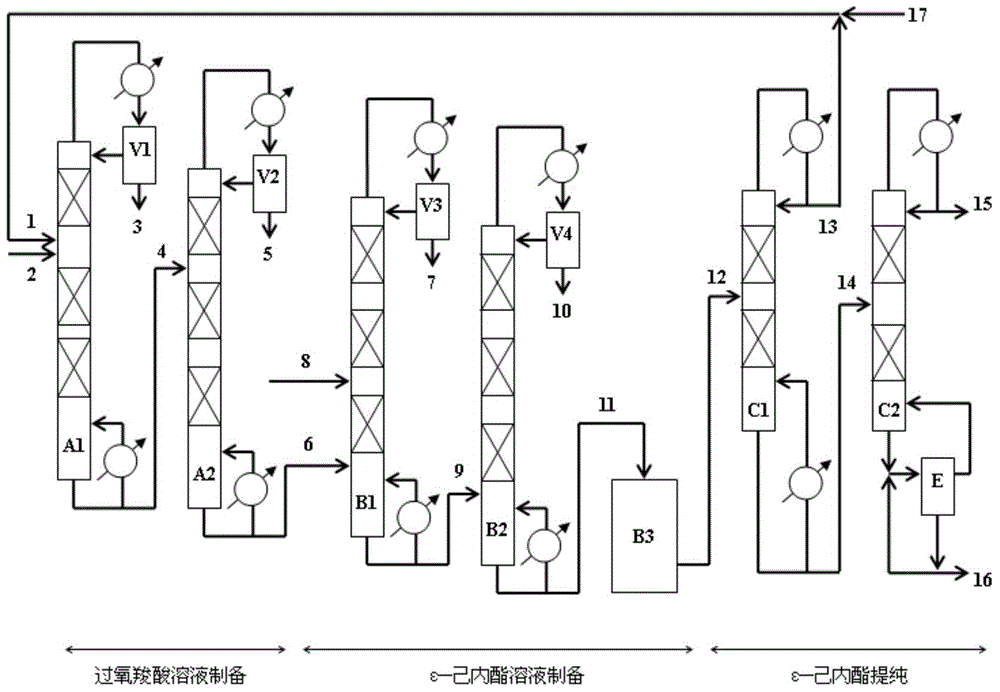

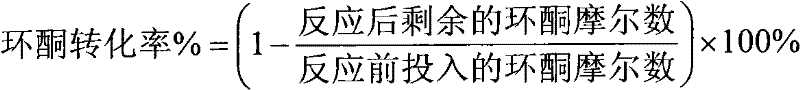

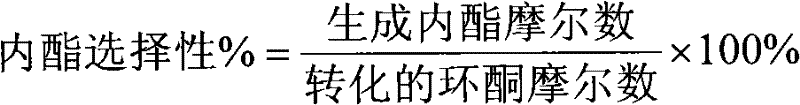

Continuous reaction technological method for preparing epsilon-caprolactone, and microchannel reaction equipment

InactiveCN103539770AShort reaction timeImprove reaction efficiencyOrganic chemistryChemical/physical/physico-chemical microreactorsCyclohexanoneAcetic anhydride

The invention relates to a continuous reaction technological method for preparing epsilon-caprolactone, and microchannel reaction equipment, belonging to the technical field of organic synthesis. The method takes cyclohexanone as initial reaction raw material and peracetic acid generated in the reaction of hydrogen peroxide and acetic anhydride as an oxidizing agent, and the processes such as peroxy acid preparation, cyclohexanone oxidation and the like are continuously completed in a microchannel reactor system. The continuous reaction technological method effectively controls the temperature in the reaction process, is high in safety, does not need an additional solvent, catalyst and stabilizing agent, is beneficial to separation and purification of caprolactone, and enables the high-yield continuous production of the epsilon-caprolactone to be possible; the microchannel reaction equipment provided by the invention highly meets the requirements of the reaction technology. The conversion rate of the cyclohexanone reaches 50-95%, and the selectivity of the epsilon-caprolactone is 80-100%.

Owner:CHANGZHOU UNIV

Process for continuous preparation of high purity epsilon-caprolactone

InactiveCN105646433ARealize continuous productionHigh catalytic efficiencyOrganic chemistryOrganic acidCyclohexanone

The present invention discloses a process for continuous preparation of high purity epsilon-caprolactone, according to the process, a reaction and separation integrated apparatus is used for continuous preparation and separation of an organic peroxy acid and epsilon-caprolactone, wherein the reaction and separation integrated apparatus comprises a catalytic reaction rectifying column, a reaction rectifying column, a stirring reactor and a rectifying column which are in turn connected, and the process is as follows: an organic acid and hydrogen peroxide are introduced into the catalytic reaction rectifying column for oxidation reaction to separate water under catalysis of strong acid cation exchange resin, the organic peroxy acid produced by the reaction enters the reaction rectifying column, and a crude epsilon-caprolactone solution is obtained by oxidizing reaction of the organic peroxy acid and cyclohexanone entering form the middle part of the reaction rectifying column; and a high yield of the high purity epsilon-caprolactone can be continuously obtained by rectification separation of the crude epsilon-caprolactone solution. The process is simple in operation and mild in reaction conditions, and the product is stable in quality and can meet the industrial production.

Owner:CHINA PETROLEUM & CHEM CORP

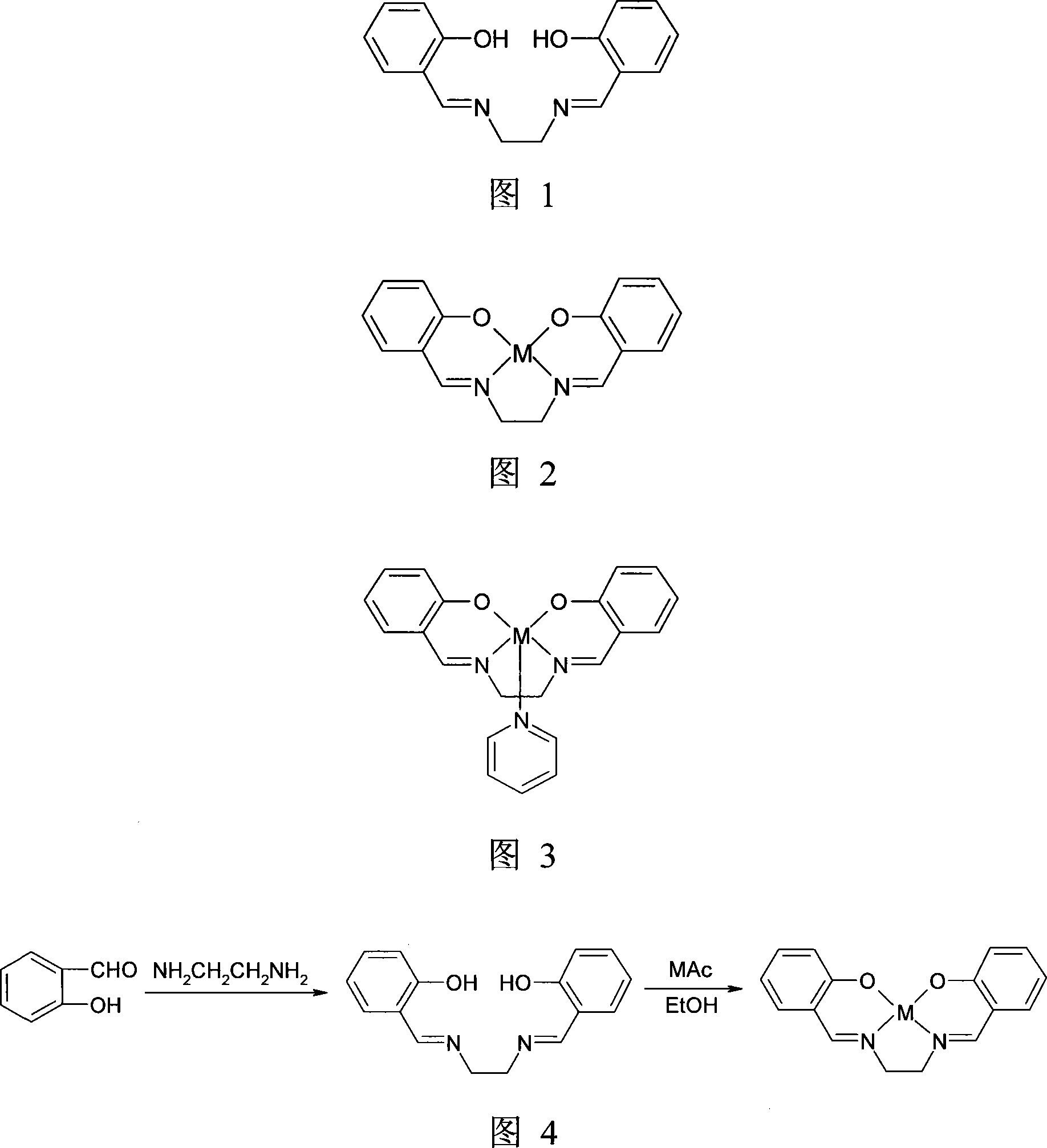

Novel non-chlorine bleaching technique for bamboo pulp

A novel totally chlorine-free bamboo-pulp bleaching process is provided. The invention relates to a novel totally chlorine free (TCF) bamboo-pulp bleaching process, is a new bionic bleaching technology for paper pulp. The invention essentially comprises the following procedures: (1) Synthesizing enzyme-imitated metal salen, using Schiff base salen to react with metallic organic acid salt to synthesize metal salen; (2) Pre-treatment bleaching bamboo pulp, carrying out bleaching pre-treatment on the oxygen delignification sulfate bamboo pulp with metal salen, NaOH, H2O2 and O2 existing; (3) Subsequent TCF bleaching, carrying out three bleaching treatments, namely, alkaline treating enhanced by hydrogen peroxide, bleaching by peroxy acid and bleaching by hydrogen peroxide the bamboo pulp pre-treated by enzyme-imitated metal salen. For the invention, the source is wide, the metal salen is easy to synthesize, the yield rate is high, the cost is low, the consumption is very low; the metal salen is easy to store, has no demanding requirement on the environment, can obviously improve the whiteness of paper pulp, reduce the load of waste water pollution in bleaching, and saves the use of bleaching chemicals.

Owner:KUNMING UNIV OF SCI & TECH

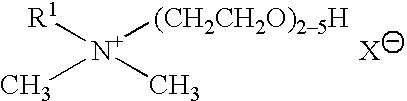

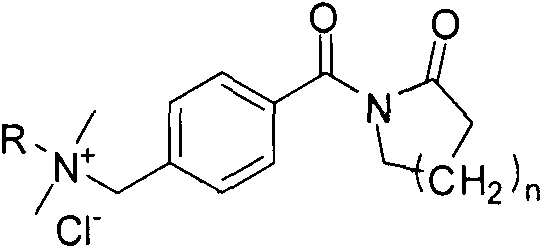

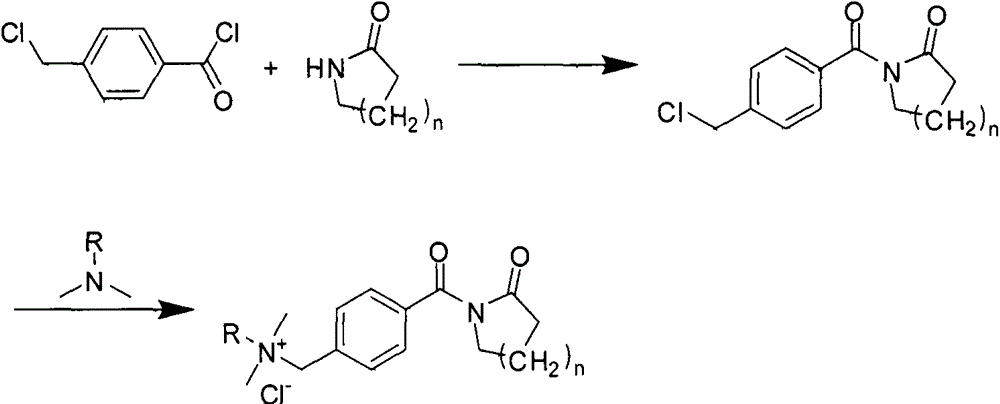

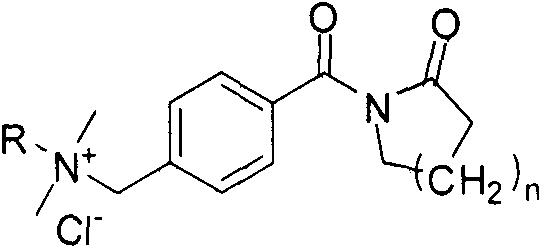

Synthesis method for cationic bleaching activating agents with surface activity

InactiveCN103554024AOrganic detergent compounding agentsOrganic chemistryQuaternary ammonium cationSynthesis methods

The invention relates to a synthesis method for cationic bleaching activating agents with surface activity, belonging to the field of fine chemical engineering. According to the method, a series of cationic bleaching activating agents with different carbon chain-length quaternary ammonium salt groups are synthesized by adopting alkyl dimethyl tertiary amine, 4-(chloromethyl)benzoyl chloride and lactam as intermediates. The leaching activating agent has stronger affinity on the surface of a material with surface electronegativity in an aqueous solution, can react with hydrogen peroxide on the surface of the material to produce extremely active peroxy acid, can bleach the material at a low temperature so as to effectively remove the pigment impurities on the surface of the material. The cationic bleaching activating agent can be used for industrial bleaching and household washing of textiles.

Owner:JIANGNAN UNIV

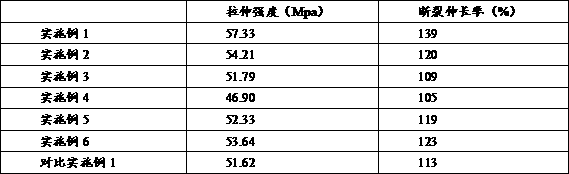

Modified starch-based biodegradable plastic and preparation method thereof

InactiveCN110734633ADoes not affect usable mechanical propertiesIncreased degradation ratePlant protective coveringsPolymer sciencePolyvinyl alcohol

The invention discloses a modified starch-based degradable plastic and a preparation method thereof. The degradable plastic comprises the following preparation raw materials in parts by mass: 60-80 parts of polylactic acid, 20-30 parts of polyvinyl alcohol, 40-70 parts of modified starch, 3-15 parts of a cross-linking agent, 0-5 parts of a plasticizer and 0-3 parts of a dispersing agent, wherein the modified starch is alkenyl succinic acid esterified starch and / or peroxy acid esterified starch. According to the preparation method, double bonds are introduced into the polymer to increase the breaking probability of macromolecular chain, and a dioxygen bond is introduced into the polymer to provide a better living environment for aerobic microorganisms, so that the aerobic decomposition rateof the degradable plastic is fundamentally increased.

Owner:SHANDONG SI DA KE BIODEGRADABLE TECH CO LTD

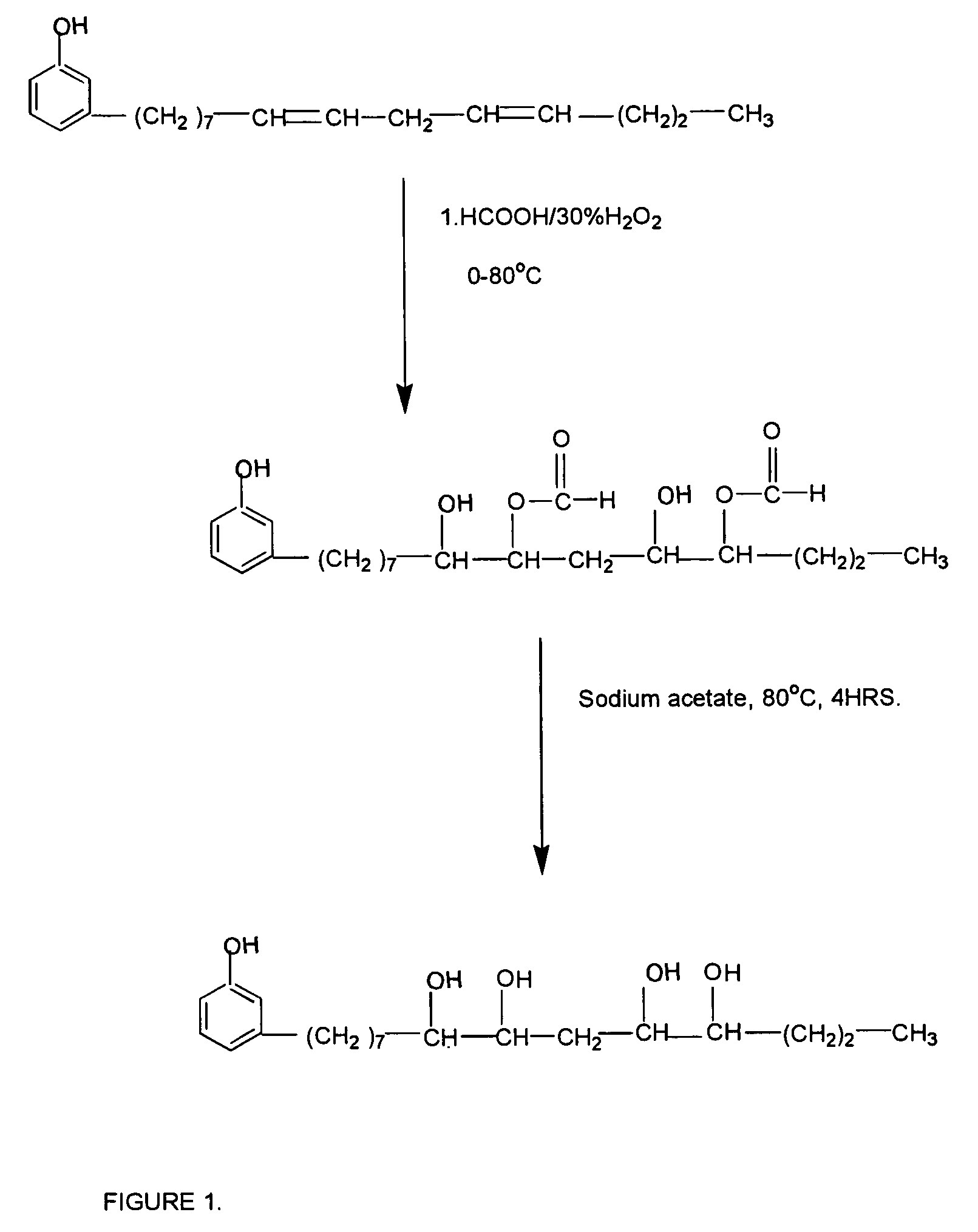

Process for preparing polyurethane polyol and rigid foams therefrom

InactiveUS7244772B2Increase contentImprove distributionOrganic compound preparationHydroxy compound separation/purificationPolymer sciencePeroxy acid

We describe a process for the preparation of polyurethane polyol from CARDANOL 3-(8pentadecenyl)phenol, derived from cashew nut shell liquid (CNSL), a renewable resource material. The polyol is made by oxidation with peroxy acid generated in situ to give epoxidised CARDANOL 3-(8-pentadecenyl)phenol and the epoxy derivative is converted to the polyol in the presence of the organic acid. The cardanol-based polyol may be reacted with isocyanate to form polyurethane. Alternatively blowing agents are included with the cardanol-based polyol before it is reacted with the isocyanate. These polyols are especially suitable for making rigid foams of very low density and high compressive strength.

Owner:COUNCIL OF SCI & IND RES

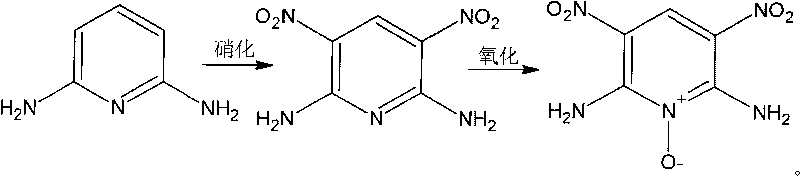

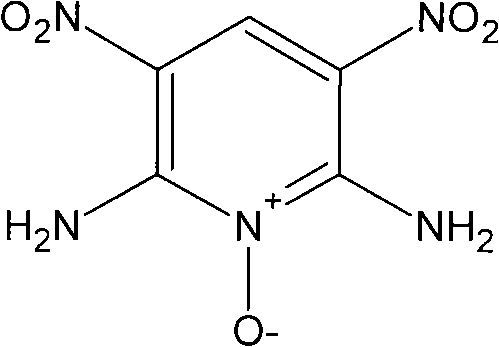

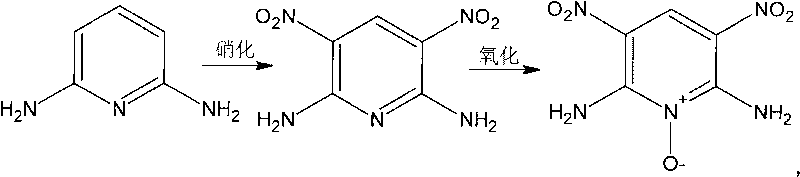

Composite method of high-energy insensitive explosive 2,6-diamino-3,5-dinitro pyridine-1-oxide

InactiveCN101735146ASimple post-processingHarm reductionOrganic chemistryNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsHigh energyPeroxy acid

The invention relates to a composite method of high-energy insensitive explosive 2,6-diamino-3,5-dinitro pyridine-1-oxide. In the method, 2,6-diamino pyridine is nitrified in a mixed acid or super acid nitrifying system; mixture is poured into trash ice to separate out yellow sediment; solid obtained by filtering is boiled by distilled water, and yellowish-brown solid is obtained by filtering; in acetic acid, or trifluoroacetic acid or organic acid solution, the nitrogen oxidation reaction of the 2,6-diamino-3,5-dinitro pyridine is realized at the temperature of 75-250 DEG C in the presence of peroxy acid and catalyst; and luminous yellow solid is obtained by filtering after reaction ends. The invention has moderate reaction condition, does not need special devices, has abundant raw material resources, low cost, simple technology, safe and reliable production, simple product aftertreatment and small harm on environment and satisfies the basic requirements of industrial scale-up production; in addition, the invention has high total yield of target products, obviously lowers cost and has stronger market competitiveness.

Owner:NANJING UNIV OF SCI & TECH

Lactone production method

ActiveCN102453017AImprove conversion rateGood choiceOrganic chemistryMolecular sieve catalystsHysteresisDesorption

A lactone production method is characterized in that a reaction is performed in the presence of a catalyst with a molar ratio of cyclic ketone, a solvent, and hydrogen peroxide of 1:(0-80):(0.2-20) and a mass ratio of the catalyst and the cyclic ketone of 1:1-100 at a temperature of 5-75 DEG C and a pressure of 0.1-6.0 MPa, and lactone is obtained through recovery; the catalyst comprises a molecular sieve which is a titanium silicon molecular sieve with a MFI crystal structure; the crystal grain has a hollow structure, and the cavity part of the hollow crystal grain has a radial length of 5-300 nanometers; the molecular sieve sample has a benzene adsorption quantity of at least 70 mg / g under a condition with a temperature of 25 DEG C, P / P0 of 0.10, and adsorption time of 1 hour, and as for the low temperature nitrogen adsorption of the molecular sieve, a hysteresis loop exists between an adsorption isotherm and a desorption isotherm. Compared with the prior art, the invention overcomes the disadvantages of complex production process, equipment corrosion, potential safety hazard existence, and severe environment pollution for traditional peroxy acid oxidation methods.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com