Modified starch-based biodegradable plastic and preparation method thereof

A starch-based technology for degrading plastics, applied in botany equipment and methods, plant protection, plant protection covers, etc., can solve the problem of insignificant degradation rate of degradable plastics, achieve fast degradation rate, improve vitality, and optimize the ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

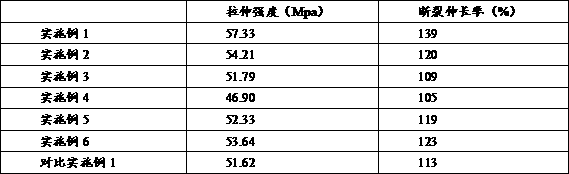

Examples

preparation example 1

[0036] Preparation Example 1 Preparation of octenyl succinic esterified starch

[0037] S1: Dissolve hyaluronic acid with a molecular weight of 8,000-10,000 in water, vortex fully to dissolve, and prepare an aqueous hyaluronic acid solution with a mass concentration of 10% for later use;

[0038] S2: Take 100 parts of cornstarch, add water three times the volume of the starch, gelatinize at 100°C for 20 minutes, cool to room temperature, dry at 40-45°C, grind, pass through a 100-mesh sieve to obtain pregelatinized corn starch;

[0039] S3: Dissolve the pregelatinized starch prepared in step S2 in water to form an aqueous solution with a mass concentration of 30%, adjust the pH value of the solution at room temperature to 8.5-9.0, slowly add 10 parts of octenyl succinic anhydride diluted with ethanol dropwise, and add as you go Stir, react overnight, centrifuge at 2000g, discard the supernatant, wash 5 times with 95% ethanol, dry at 40-45°C, pulverize, and pass through a 100-m...

preparation example 2 10

[0040] Preparation Example 2 Preparation of dodecenyl succinic esterified starch

[0041] The preparation method is the same as Preparation Example 1, the difference is that in step S3, the pH value of the solution is adjusted to 8.5-9.0 at room temperature, and then 10 parts of dodecenyl succinic anhydride diluted with ethanol are slowly added dropwise to prepare dodecenyl succinic anhydride starch.

preparation example 3

[0042] Preparation Example 3 Preparation of Peroxodisulfated Starch

[0043] S1: Dissolve hyaluronic acid with a molecular weight of 8,000-10,000 in water, vortex fully to dissolve, and prepare an aqueous hyaluronic acid solution with a mass concentration of 10% for later use;

[0044] S2: Take 100 parts of potato starch, add water of 3.5 times the volume of starch, gelatinize at 100°C for 20 minutes, cool to room temperature, dry at 40-45°C, grind, pass through a 100-mesh sieve to obtain pregelatinized potatoes starch;

[0045] S3: Dissolve the pregelatinized starch prepared in step S2 in water to form an aqueous solution with a mass concentration of 30%, adjust the pH value of the solution at room temperature to 8.5-9.0, slowly add 6 parts of peroxodisulfuric acid solution with a concentration of 0.1 g / mL dropwise, Stir while adding, react overnight, centrifuge at 2000g, discard the supernatant, wash 5 times with pure water, dry at 40-45°C, pulverize, pass through a 100-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com