Patents

Literature

217results about How to "Fast degradation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

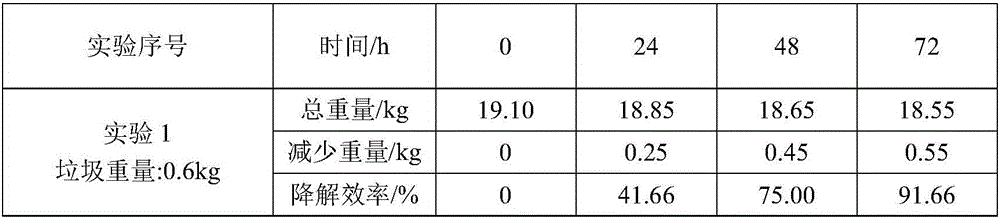

Kitchen garbage degrading composite microbial inoculum and preparation method and application thereof

ActiveCN106591178AEfficient degradationFast degradation rateBacteriaSolid waste disposalStaphylococcus cohniiStaphylococcus xylosus

The invention relates to a kitchen garbage degrading composite microbial inoculum and a preparation method and application thereof. The kitchen garbage degrading composite microbial inoculum is prepared by mixing a mixed inoculum of bacillus amyloliquefaciens, radiation-resistant methylobacterium, dispersed pantoea, pseudomonas oryzihabitans, citrobacter freundii and staphylococcus cohnii and a carrier, wherein the mass of the mixed inoculum accounts for 15-25% of the total mass of the kitchen garbage-degrading composite microbial inoculum; the mass ratio of the bacillus amyloliquefaciens, the radiation-resistant methylobacterium, the dispersed pantoea, the pseudomonas oryzihabitans, the citrobacter freundii and the staphylococcus cohnii is (1.5-3):(1-1.5):(1-1.5): (1-1.5):(1-1.5):(1-1.5); the kitchen garbage-degrading composite microbial inoculum is used for degrading kitchen garbage. Compared with the prior art, the kitchen garbage degrading composite microbial inoculum has the advantages as follows: the kitchen garbage degrading composite microbial inoculum can effectively degrade common vegetables, grains, fish, poultry meat and other kitchen garbage, has the degradation rate being above 80%, is high in degradation speed rate and small in odor, does not produce pollutants or poisonous substances, and is low in cost and stable in performance.

Owner:SHANGHAI NORMAL UNIVERSITY +1

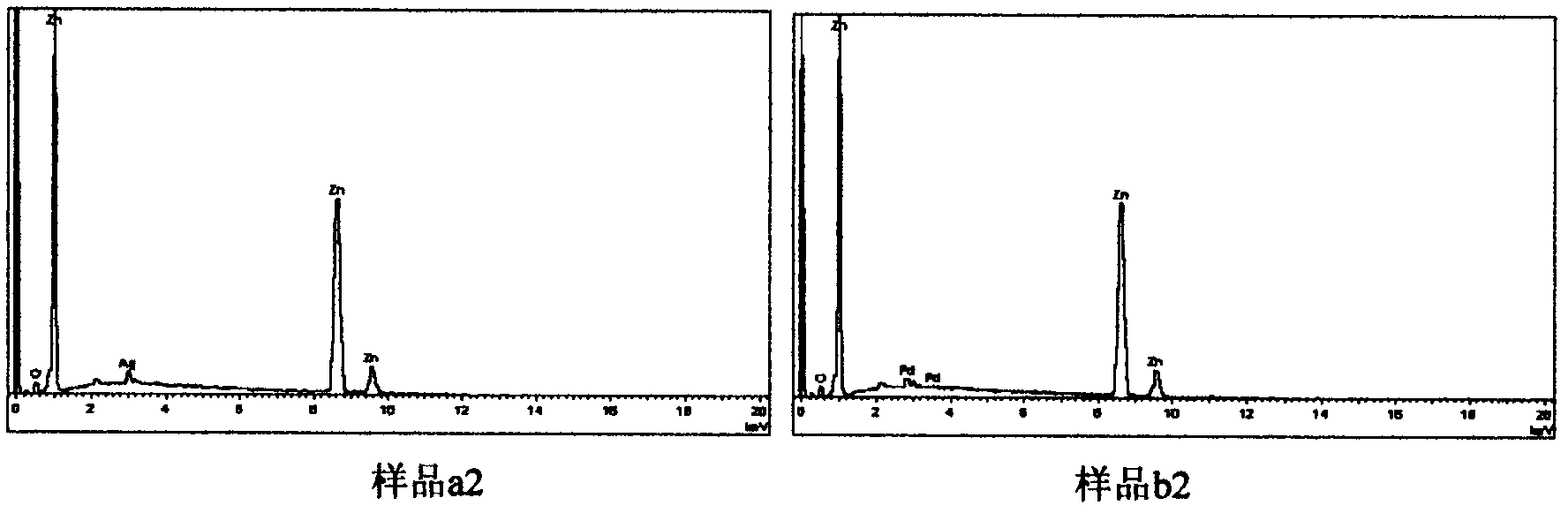

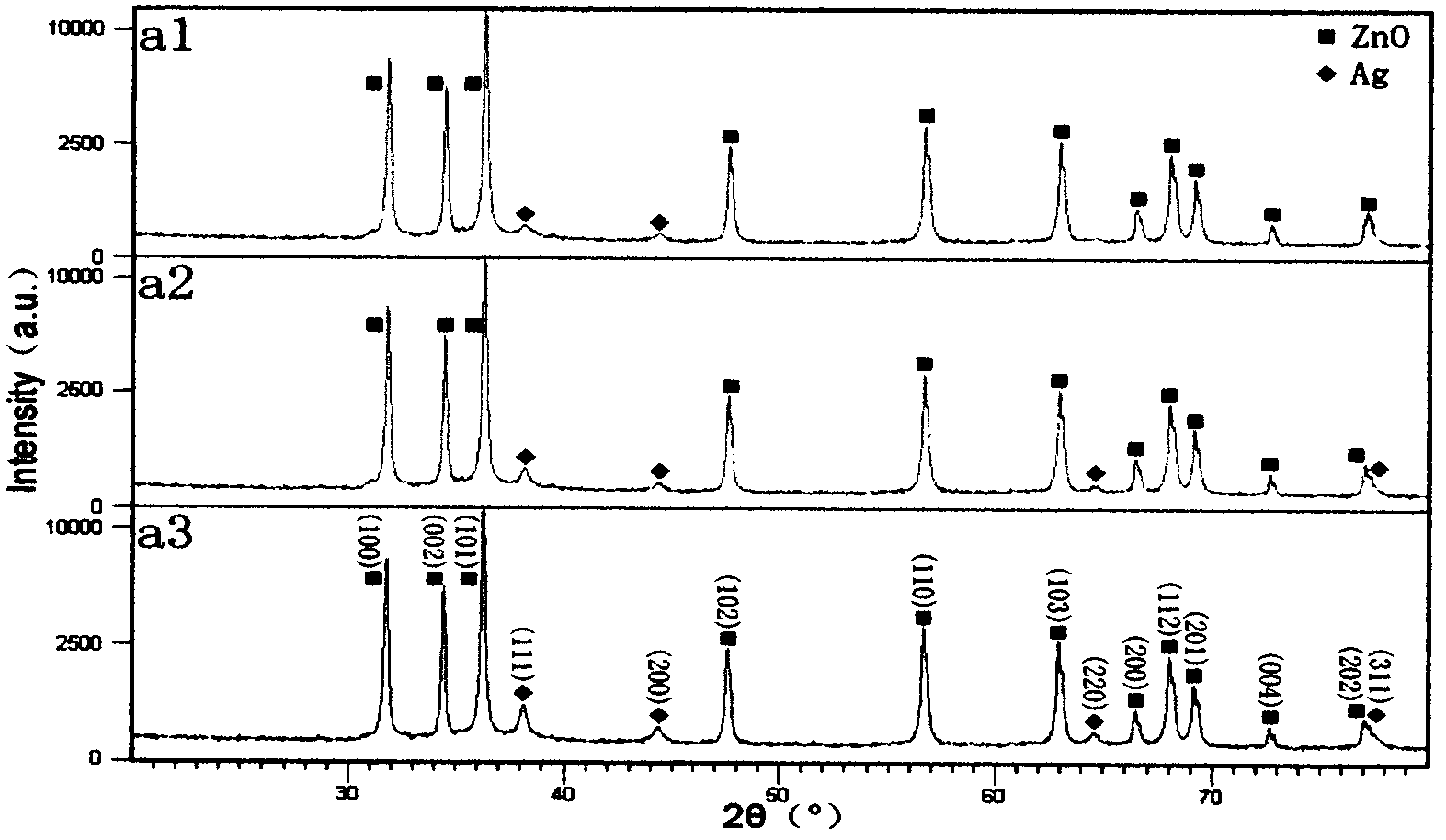

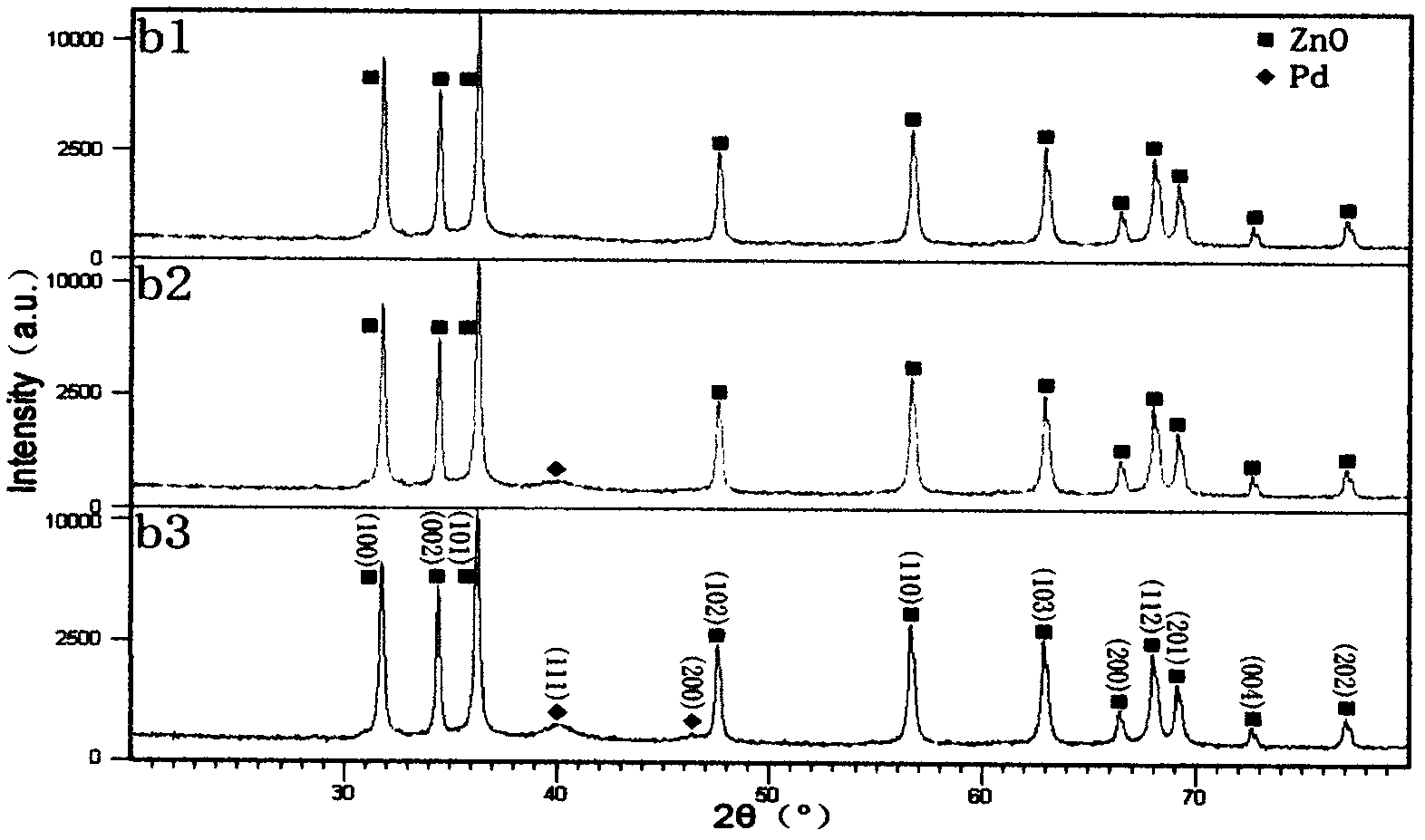

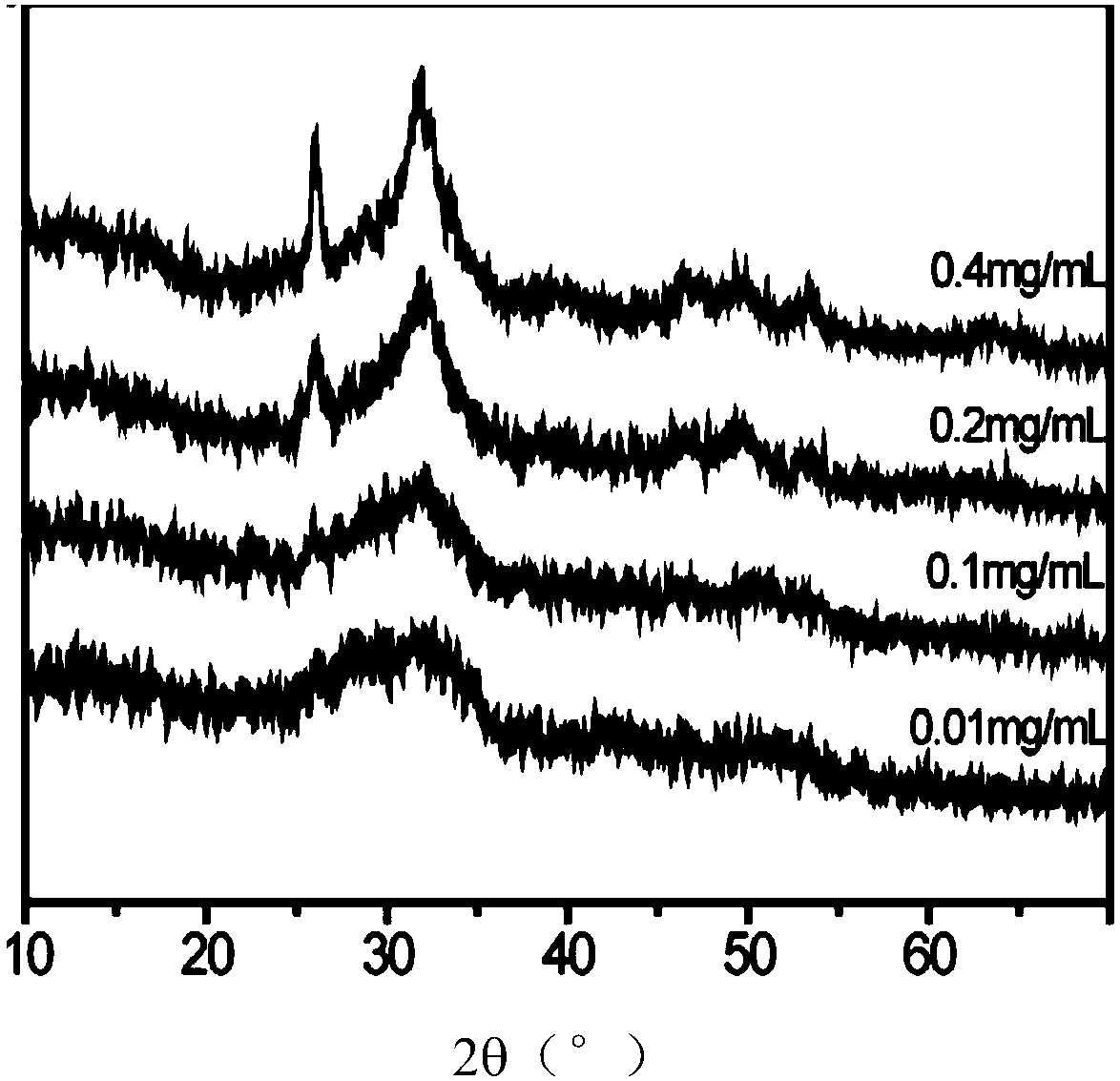

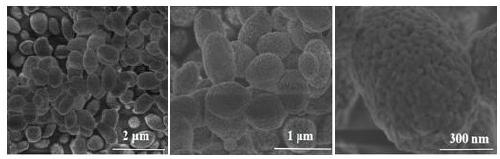

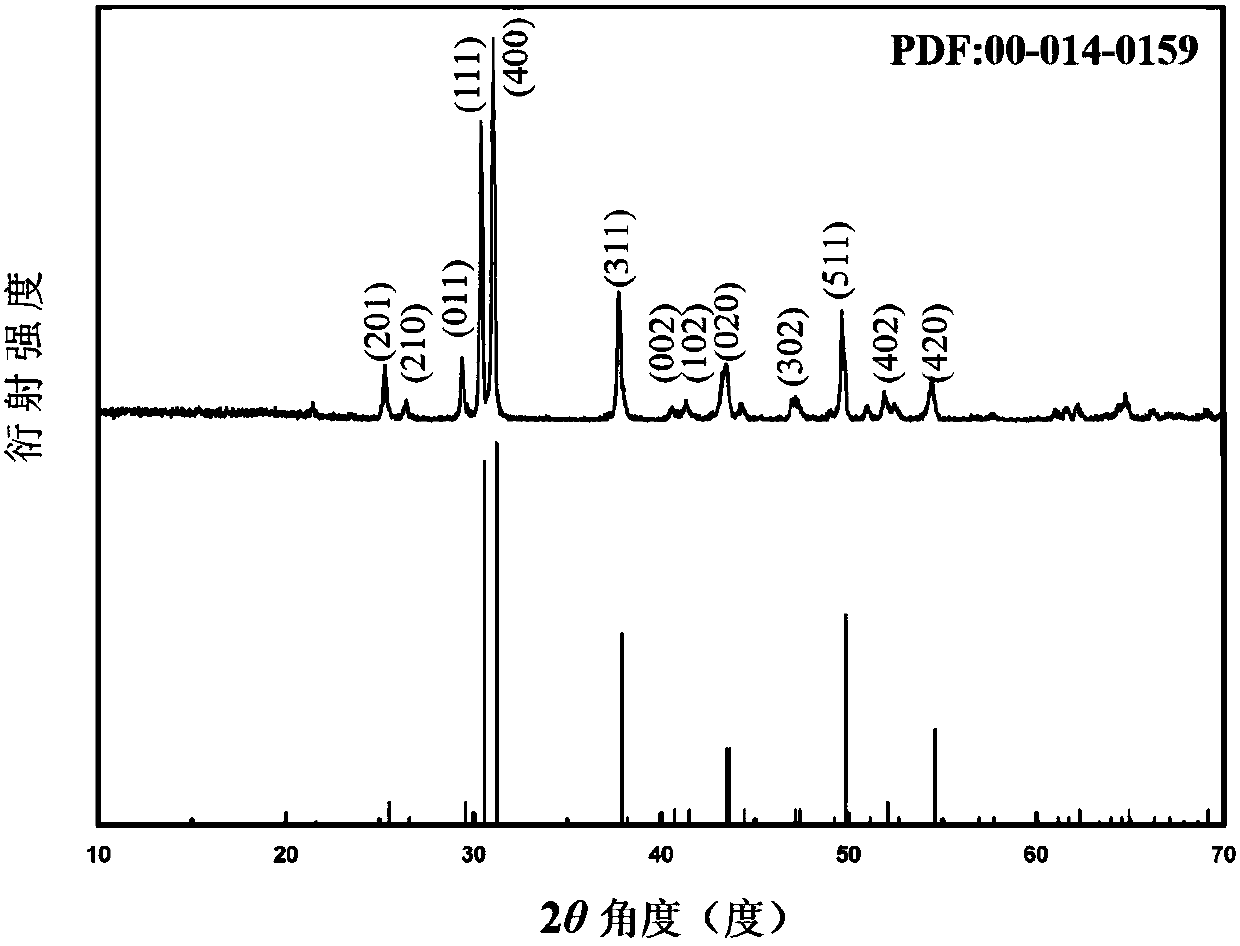

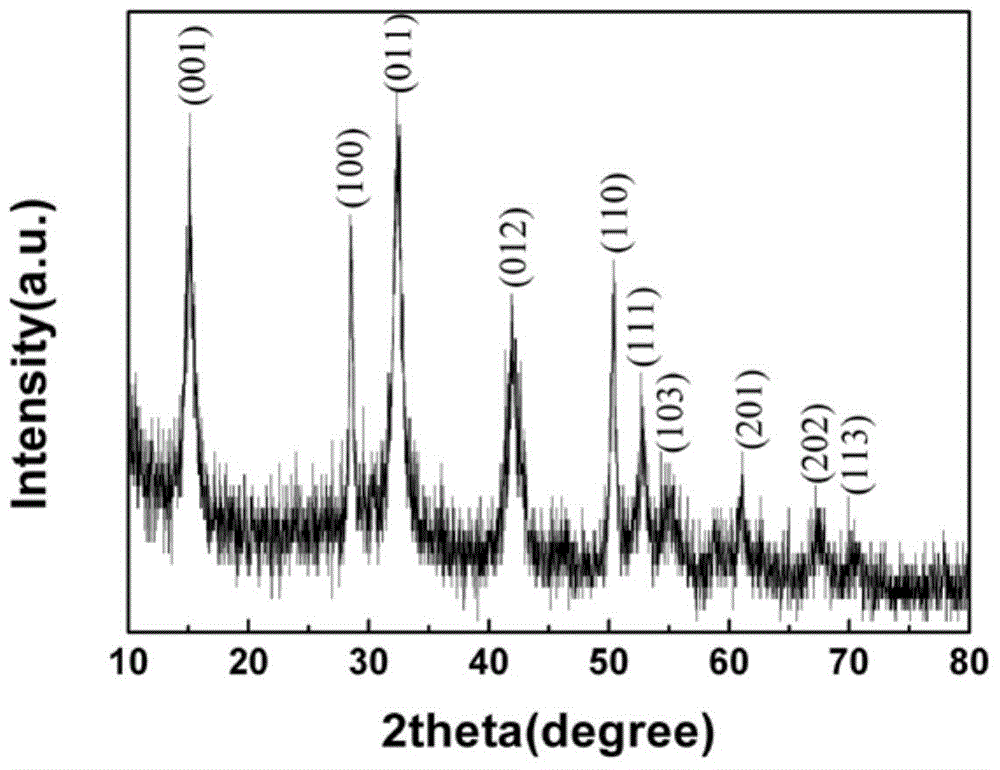

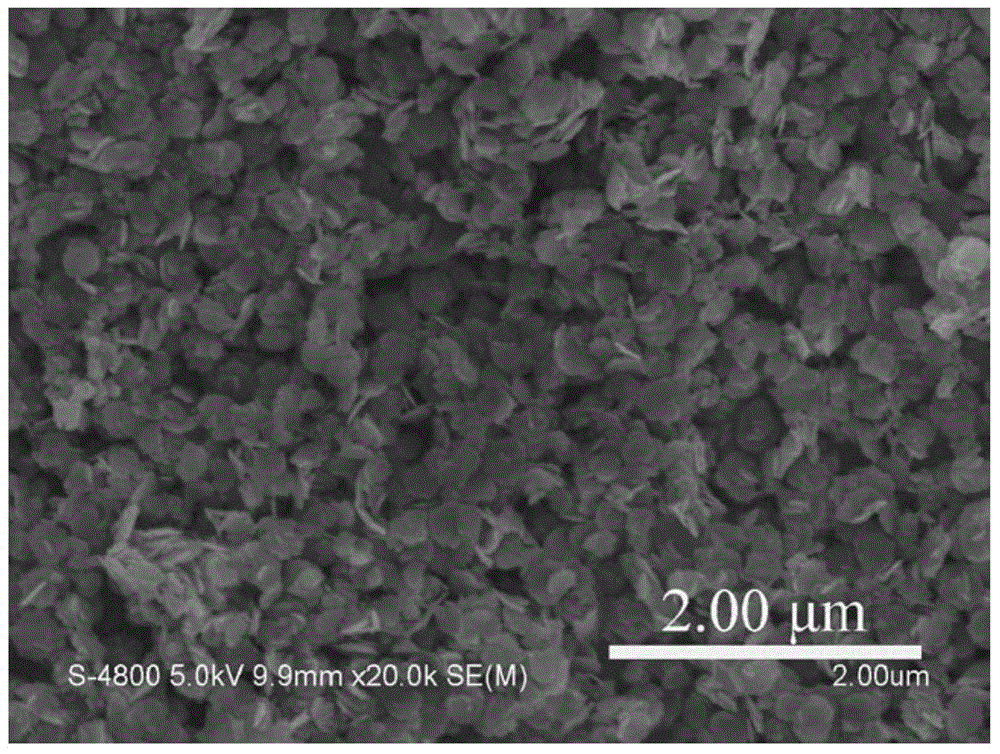

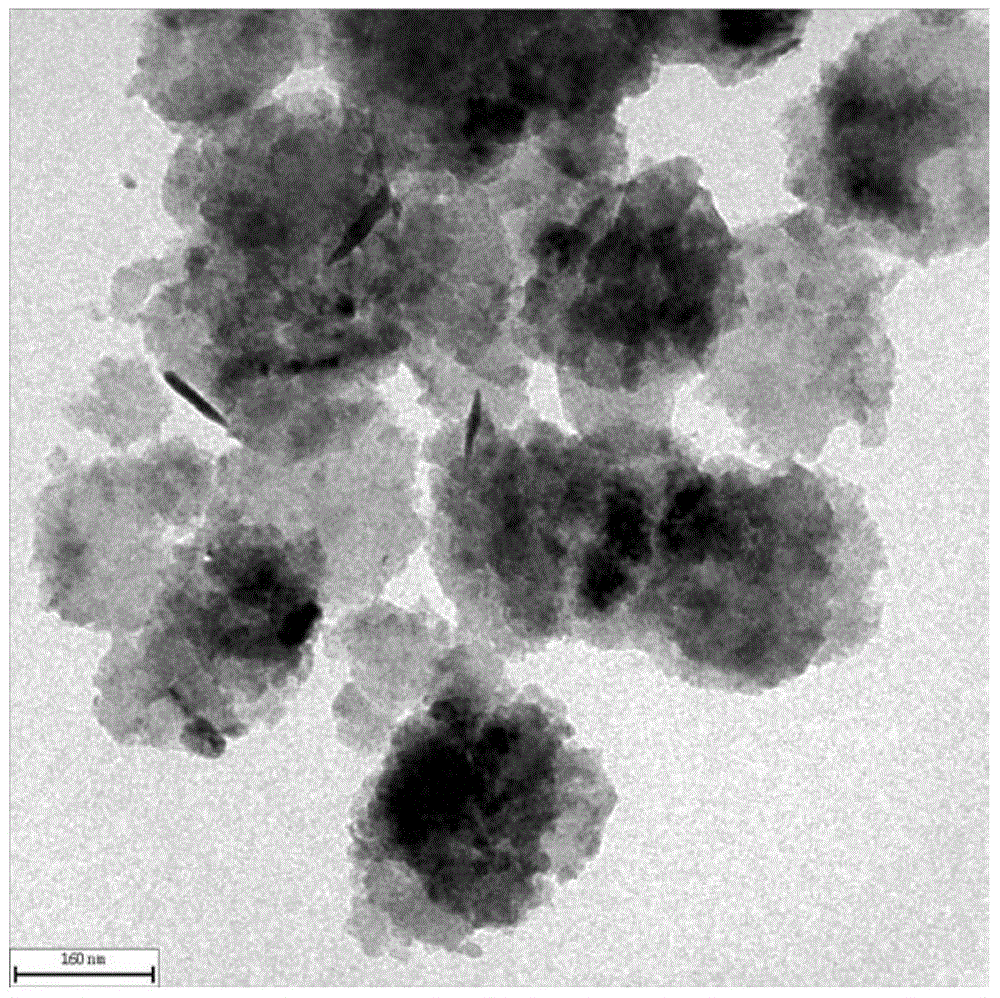

Precious metal-doped ZnO nanoscale particles and use of the precious metal-doped ZnO nanoscale particles as photocatalyst for unsymmetrical dimethylhydrazine wastewater degradation

ActiveCN102626625AGood lookingHigh crystallinityWater/sewage treatment by irradiationGeneral water supply conservationCrystallinityUnsymmetrical dimethylhydrazine

The invention relates to precious metal-doped ZnO nanoscale particles and a use thereof. The precious metal-doped ZnO nanoscale particles are ZnO / Ag and ZnO / Pd nanoscale particles which are prepared from zinc acetate, sodium hydroxide, silver nitrate and palladium chloride by an ethanol auxiliary hydrothermal method, wherein the diffraction peak of ZnO belongs to a hexagonal wurtzite structure; a space crystal group of ZnO belongs to P63mc(186); a point lattice constant a of ZnO is equal to a point lattice constant b of ZnO and is equal to 0.3249nm; a point lattice constant c of ZnO is equal to 0.5205nm; the diffraction peak of Ag is in accordance with a standard map JCPDF:87-0717; a space crystal group of Ag belongs to Fm-3m(225); a point lattice constant a of Ag is equal to a point lattice constant b of Ag, is equal to a point lattice constant c of Ag and is equal to 4.086nm; the diffraction peak of Pd is in accordance with a standard map JCPDF:88-2335; a space crystal group of Pd belongs to Fm-3m(225); and a point lattice constant a of Pd is equal to a point lattice constant b of Pd, is equal to a point lattice constant c of Pd and is equal to 3.900nm. The use of the precious metal-doped ZnO nanoscale particles comprises that the precious metal-doped ZnO nanoscale particles are utilized as a photocatalyst for unsymmetrical dimethylhydrazine wastewater degradation. Compared with the prior art, the precious metal-doped ZnO nanoscale particles have good morphology and a high degree of crystallization; a preparation method of the precious metal-doped ZnO nanoscale particles is simple and has good repeatability; a result of a test shows that the precious metal-doped ZnO nanoscale particles can be degraded faster and more thoroughly under sunlight; and the precious metal-doped ZnO nanoscale particles have a lower production cost, better energy-saving effects and a certain referential meaning for industrial application.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

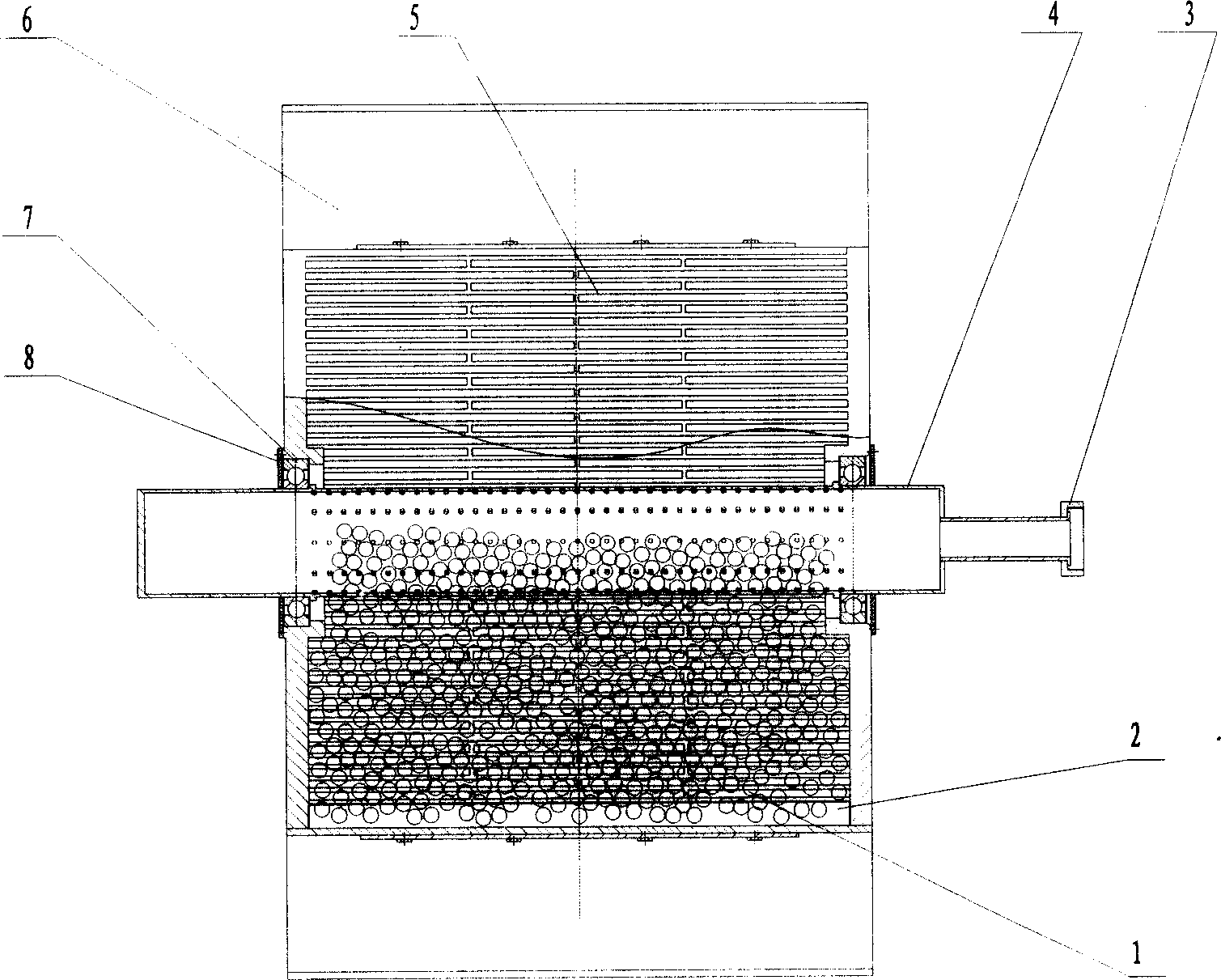

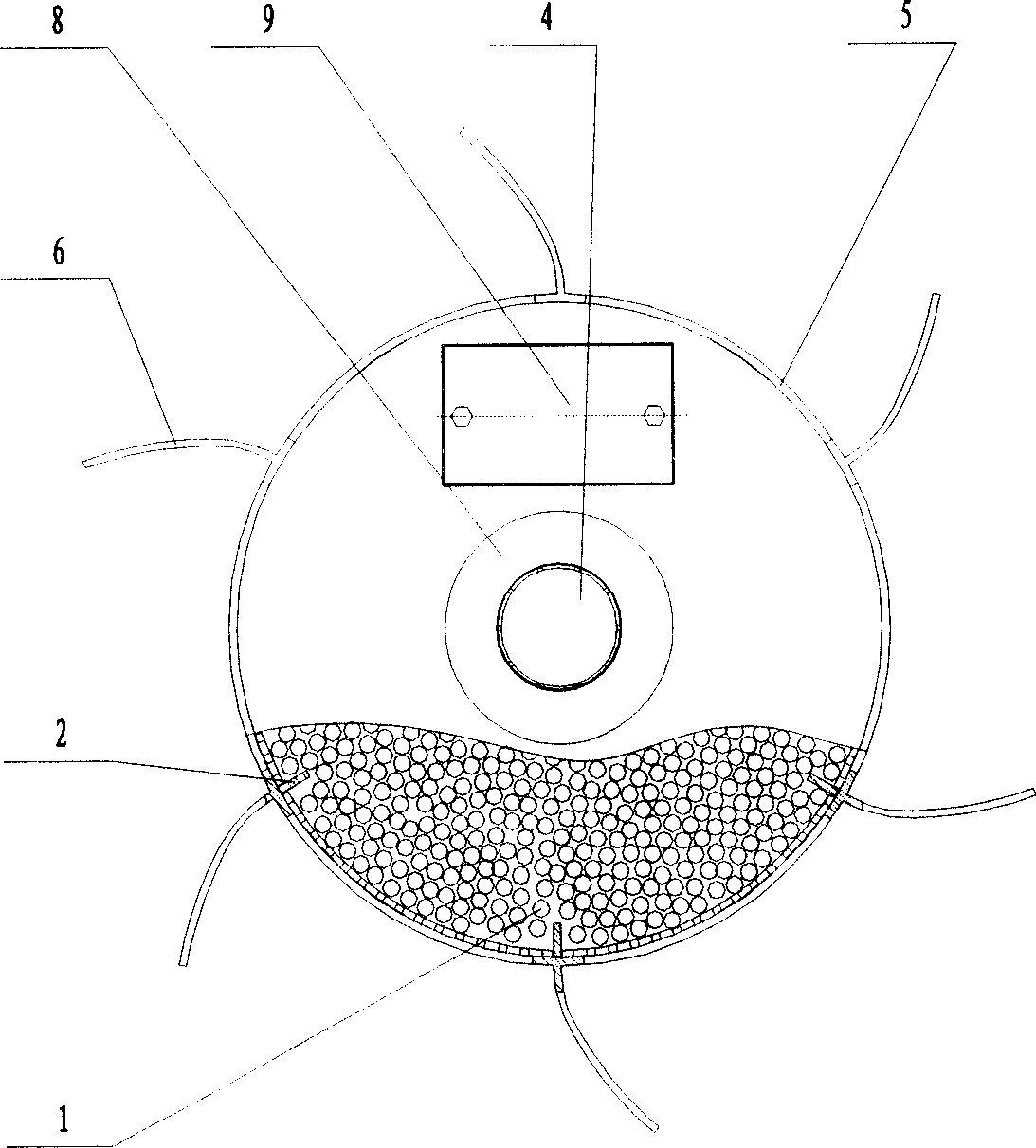

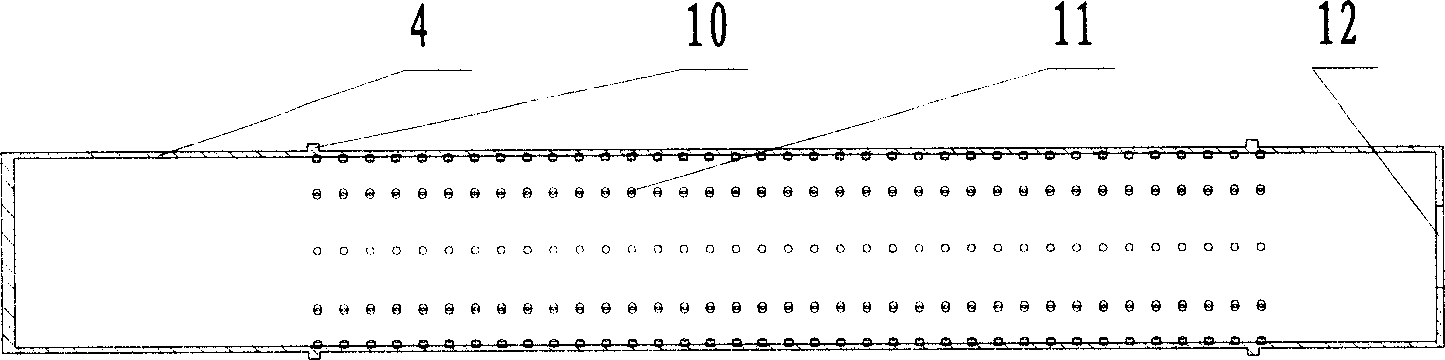

Rotating cage type floating stuffing biological sewage treatment method and equipment thereof

InactiveCN1654359APromote sheddingEasy to handleSustainable biological treatmentBiological water/sewage treatmentDecompositionPollutant

The present invention relates to water treating technology, and is especially one kind of rotary cage type biological suspended stuffing sewage treating method and apparatus. The apparatus includes central shaft, rotary cage, inner and outer vanes, suspended stuffing, bearing and bearing cover plate. The central shaft is connected to the rotary cage to form rotating pair, the bearing is located with the bearing cover plate and screws, the suspended stuffing is filled into the rotary cage, and the inner and outer vanes are screwed to peripheral wall of the rotary cage. The inflowing sewage drives the outer vanes to rotate the rotary cage and mixes with the suspended stuffing and central aerating airflow, the inner vanes of the rotary cage form homogeneous gas, liquid and solid fluid to make sewage well contact with biological membrane on the stuffing and aerating airflow for biodegradation and airflow oxidation decomposition of organic pollutant and purification of sewage.

Owner:SOUTH CHINA UNIV OF TECH

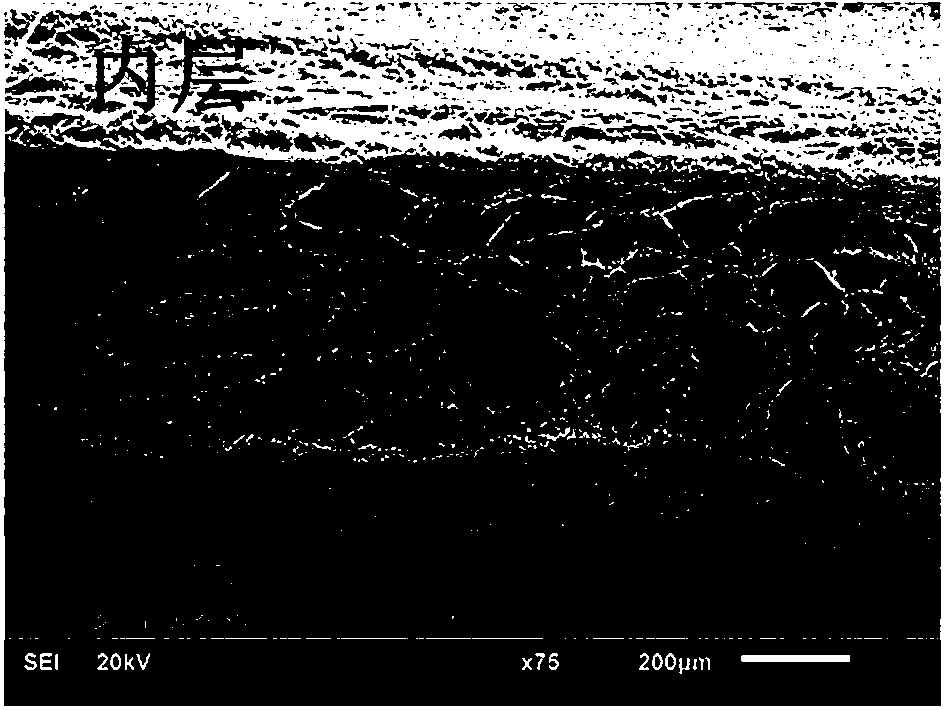

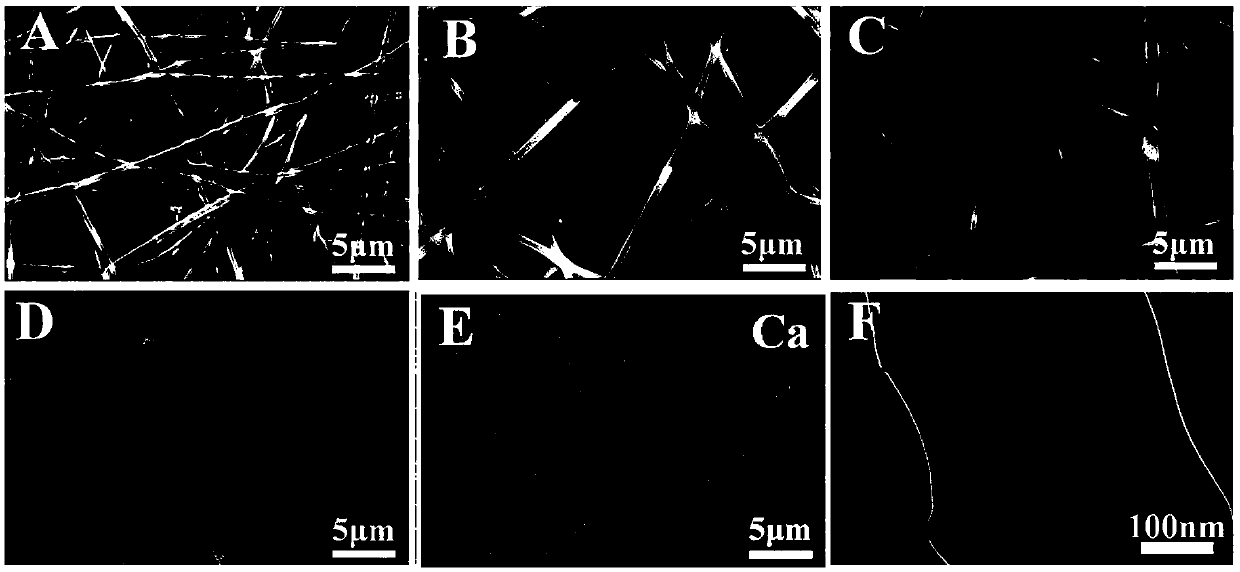

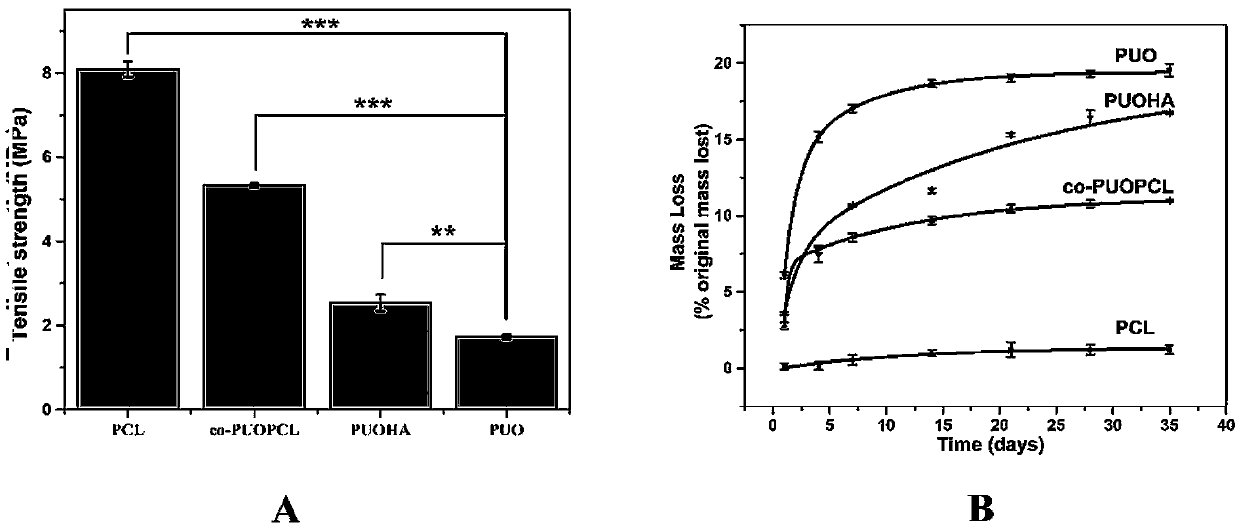

Biological membrane stent material with gradient degradation effect and preparation method thereof

The invention relates to a biological membrane stent material with gradient degradation effect and a preparation method thereof. The biological membrane stent material is provided with an inner layer,a middle layer and an outer layer which are mutually combined, wherein the inner layer is an electrospinning fiber membrane and is prepared by mixing composite polyurethane of polyoxyethylene and nanometer hydroxyapatite into medical polyurethane material, the mass of the composite polyurethane is equal to 2.5 to 10wt% of the mass of the medical polyurethane material, and the mass of the nanometer hydroxyapatite is equal to 0 to 60wt% of the mass of the stent material; the middle layer is coated to the surface of the inner surface, and is a mixed electrospinning fiber membrane, and the mixedelectrospinning fiber membrane is formed by weaving the electrospinning fiber of polycaprolactone containing 0.2 to 0.5wt% of calcium salt component and the electrospinning fiber of composite polyurethane; the outer layer is coated to the surface of the middle layer, and is an electrospinning fiber membrane which is formed by the polycaprolactone containing 0.2 to 0.5wt% of calcium salt component.The biological membrane stent material has the advantages that the functions of the natural biological membrane can be simulated to promote the tissue regeneration, and the biological membrane stentmaterial can be widely applied to the fields and industries of biology and medicines.

Owner:SICHUAN UNIV

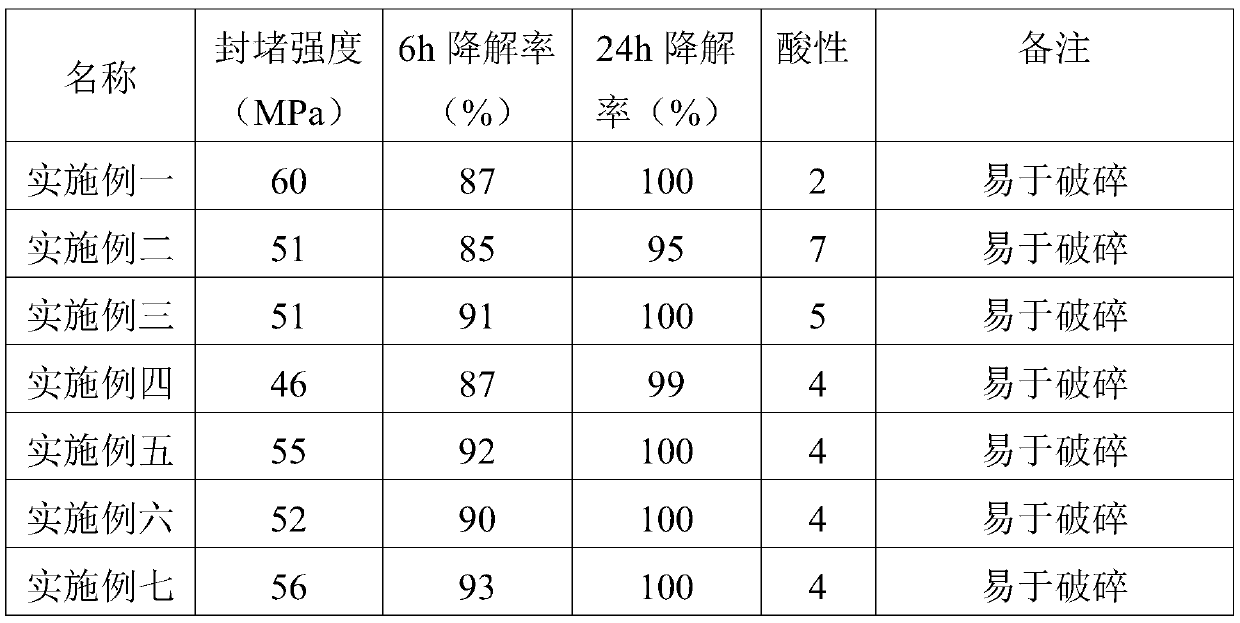

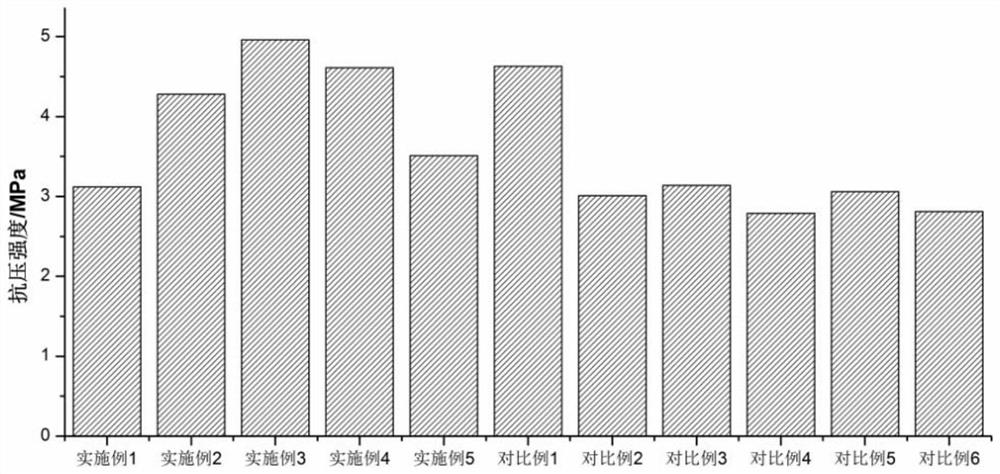

Acid controllable rigid temporary plugging agent and preparation method thereof

ActiveCN110669482ASmall molecular weightEasily brokenDrilling compositionPolymer scienceGlycolic acid

The invention provides an acid controllable rigid temporary plugging agent and a preparation method thereof. The raw materials of the acid controllable rigid temporary plugging agent comprise a resinmatrix, wherein the resin matrix comprises polylactic acid and polyglycolic acid with a mass ratio of (1-9): 1. The preparation method of the acid controllable rigid temporary plugging agent comprisesthe following steps: mixing the raw materials of the rigid temporary plugging agent, then melting, blending and granulating at 160-270 DEG C to obtain the acid controllable rigid temporary plugging agent. The acidic controllable rigid temporary plugging agent has high plugging strength, easy crushing, controllable dissolution speed and controllable acid release amount.

Owner:FIVE STAR DOWNHOLE SERVICE INC

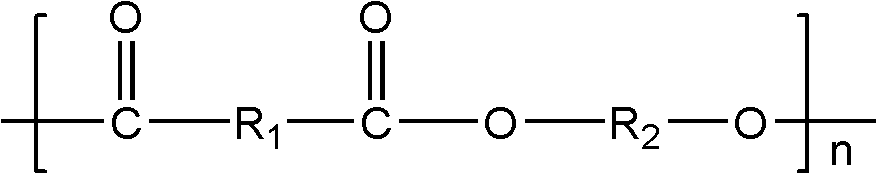

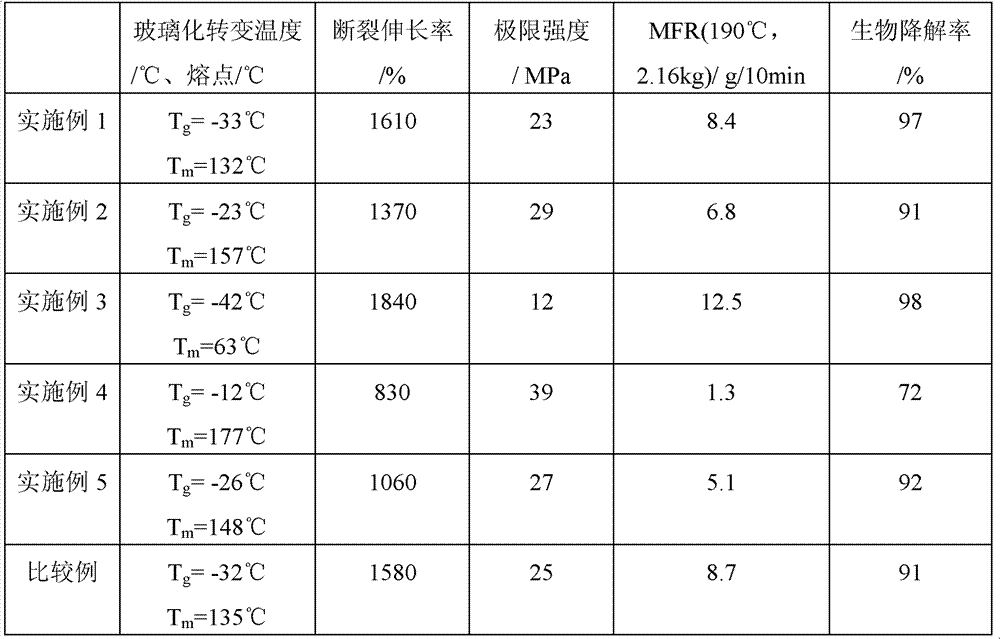

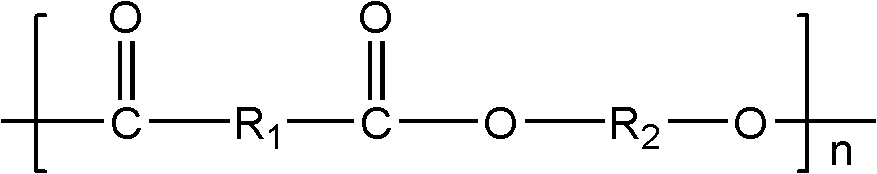

Biodegradable aromatic-aliphatic copolyester and preparation method thereof

ActiveCN103087305AExcellent thermodynamic propertiesPromote degradationMaterial synthesisCopolyester

The invention belongs to the technical field of polymer material synthesis and preparation, and discloses biodegradable aromatic-aliphatic copolyester and a preparation method thereof. The biodegradable aromatic-aliphatic copolyester disclosed in the invention has the a constitutional repeating unit as shown in the specification, wherein R1 is selected from groups as shown in the specification; R3 is selected from Li, Na, K, Rb, Cs, Fr, Be, Mg, Ca, Sr, Ba or Ra; R4 is selected from Li, Na, K, Rb, Cs, Fr, Be, Mg, Ca, Sr, Ba or Ra; R2 is selected from groups as shown in the specification; n=1-1000; p=0-11; q=2-13. According to the invention, binary acid or ester containing a sulfonate group is added, which effectively improves the hydrophilic performance of the copolyester, makes polyester plastics be easier to be adsorbed, decomposed, and absorbed by microbe such as bacteria and the like, and provides plastics with better biodegradability.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

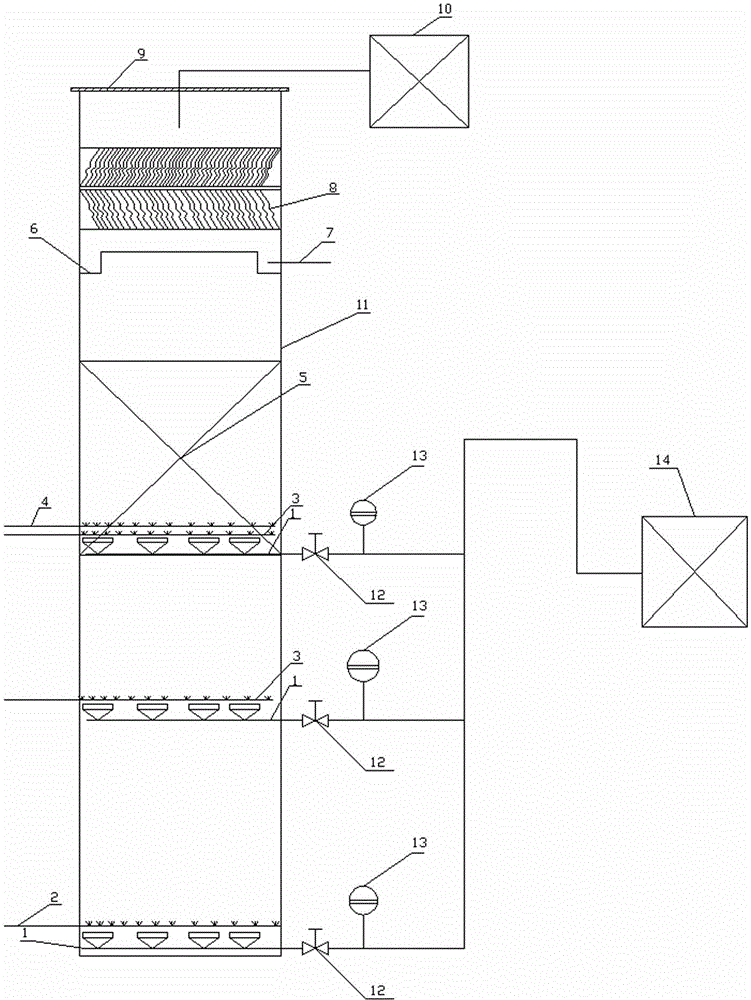

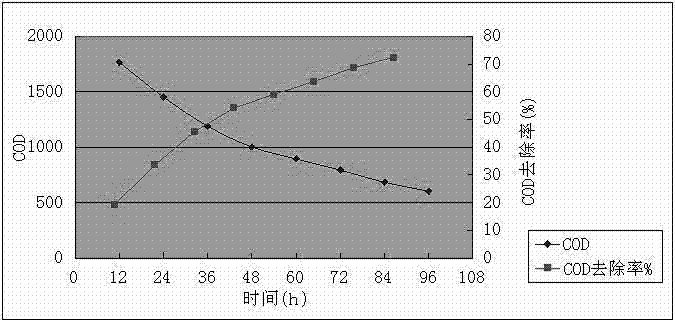

Catalytic ozonation water treatment device

InactiveCN104150578ANot ruled outReduce processing costsWater/sewage treatment by oxidationIndustrial waste waterLiquid state

The invention belongs to the field of industrial waste water deep treatment equipment, and particularly relates to a multi-stage advanced catalytic ozonation water treatment device. The device mainly comprises a titanium microporous aerator, H2O2 feeding systems, liquid-state specific catalyst feeding systems, solid-state specific catalysts, a corrugated plate demister and a tail gas collection and destruction system. Waste water flows in the treatment device through a water inlet pipe, the bottom, the middle part and the upper part of the treatment device are respectively provided with a different amount of ozone feeding systems, H2O2 feeding systems, liquid-state specific catalyst feeding systems, and solid-state specific catalysts, and meanwhile, tail gas is demisted through a corrugated plate and then is collected and delivered to the destruction system for destruction, so as to avoid the pollution to an environment. According to the catalytic ozonation water treatment device, the color and COD in industrial waste water can be effectively removed, the treatment method is simple, and the cost is low and the treatment efficiency is high.

Owner:TAIZHOU INST OF SCI &TECH NUST

Plant fiber material composite and preparation method of plant fiber product

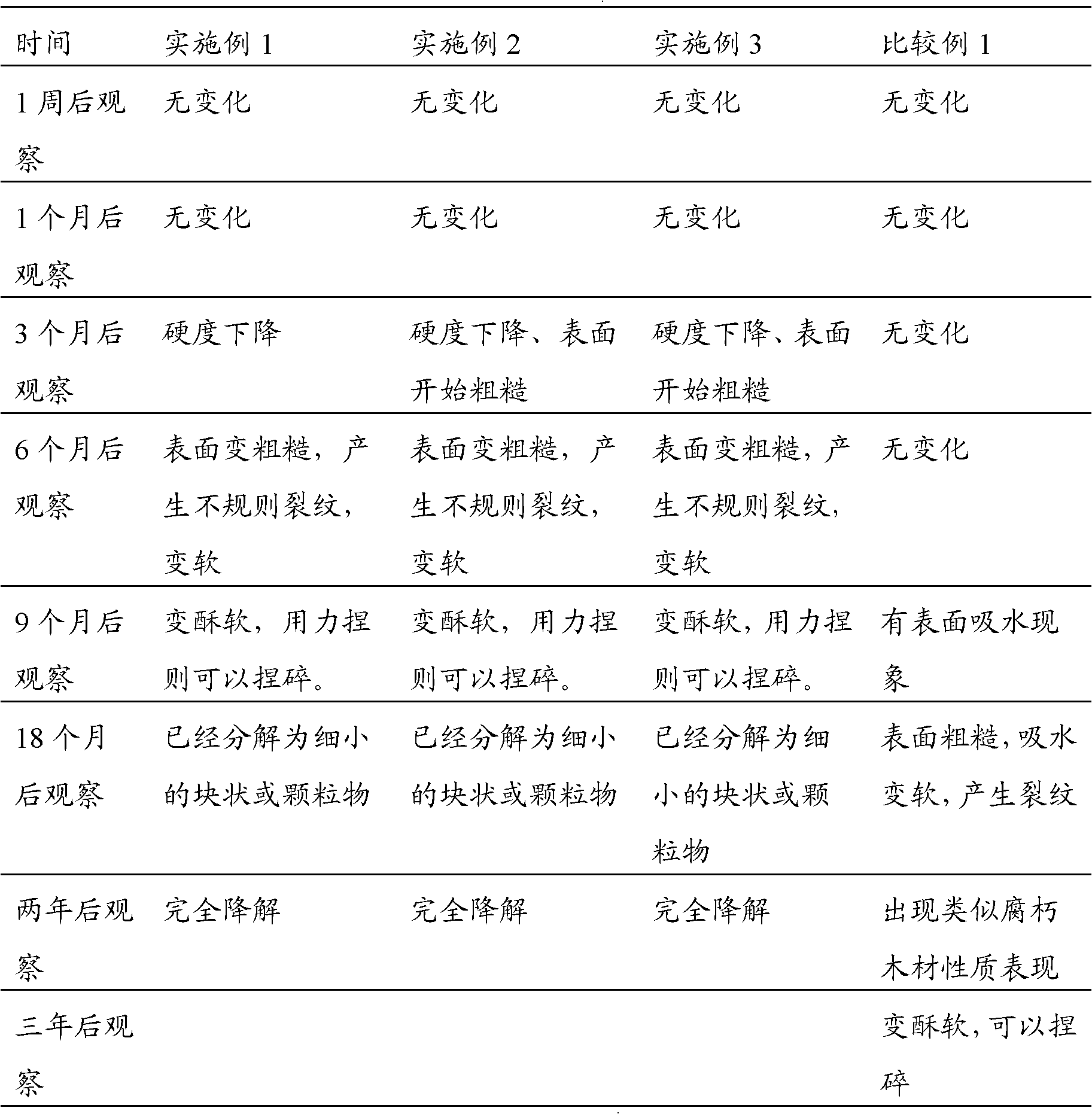

The embodiment of the invention discloses a plant fiber material composite and a preparation method of a plant fiber product. The method comprises: 40wt% to 50wt% of plane fiber powder, 30wt% to 40wt% of soy protein adhesive, 5wt% to 10wt% of corn starch, 5wt% to 10wt% of glycerol, 4wt% to 7wt% of cavings and 3wt% to 8wt% of water are mixed and molded through heating and mould pressing to prepare the plant fiber product. The soy protein adhesive has the action of adhesion, and the protein component in the soy protein adhesive can supply rich nutrition components for microorganisms, and accelerates the decomposition of the plant fiber product by utilizing the microorganisms and the degradation of the plant fiber product in the degradation course of the plant fiber product. The experiment result indicates that the prepared plant fiber product has quicker degradation rate, starts to be degraded in 2 to 6 months, can be completely degraded in two years and has the advantages of no pollution and environmental friendliness.

Owner:宁波木林森纤维科技有限公司

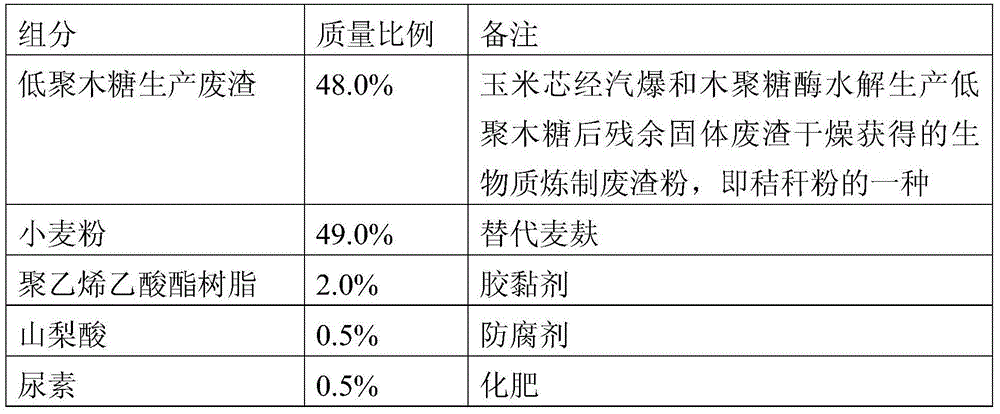

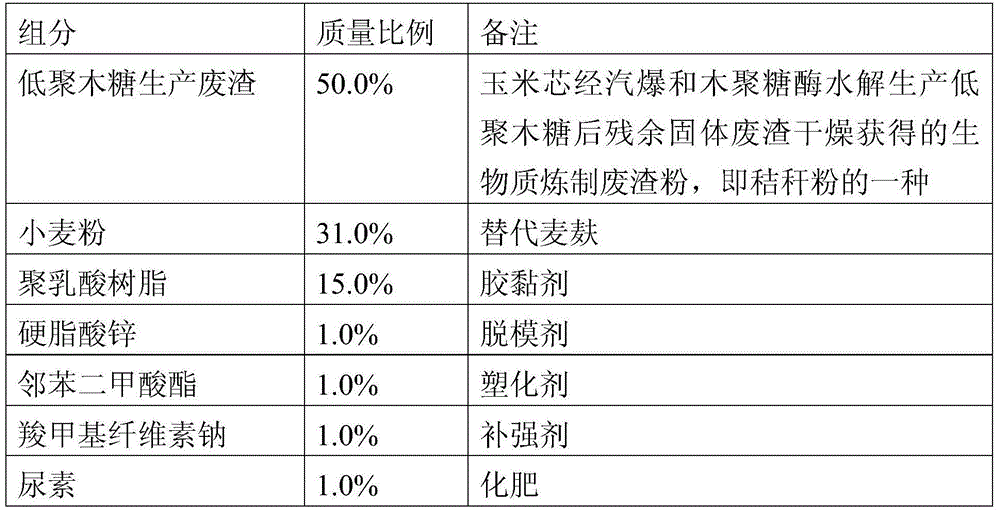

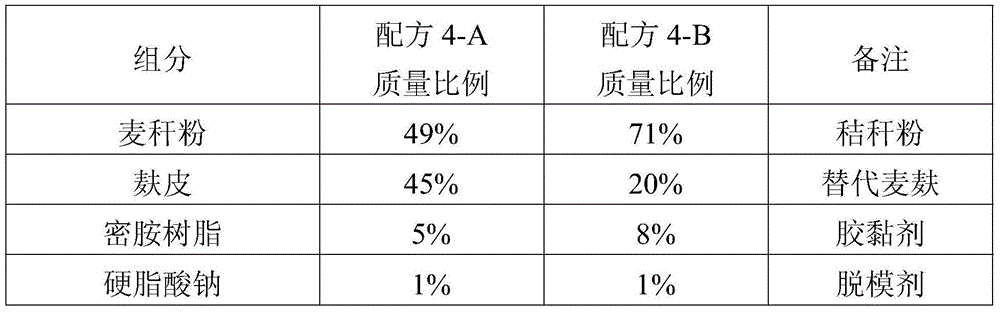

Degradable bio-based seedling raising pot, production method thereof, regulation method in degradation period and application of degradable bio-based seedling raising pot

InactiveCN105613100AImprove liquidityImprove gelatinizationCultivating equipmentsRoot systemAdhesive

The invention discloses a degradable bio-based seedling raising pot, a production method thereof, a regulation method in a degradation period and an application of the degradable bio-based seedling raising pot. The degradable bio-based seedling raising pot is produced from straw powder, wheat bran and an adhesive through dry-method hot pressing after mixing. The degradable bio-based seedling raising pot can keep certain strength in a seedling raising process and is relatively complete in appearance, after seedlings and the pot are transplanted to a field simultaneously, the pot can crack and disintegrate rapidly, and plant root extension is facilitated.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

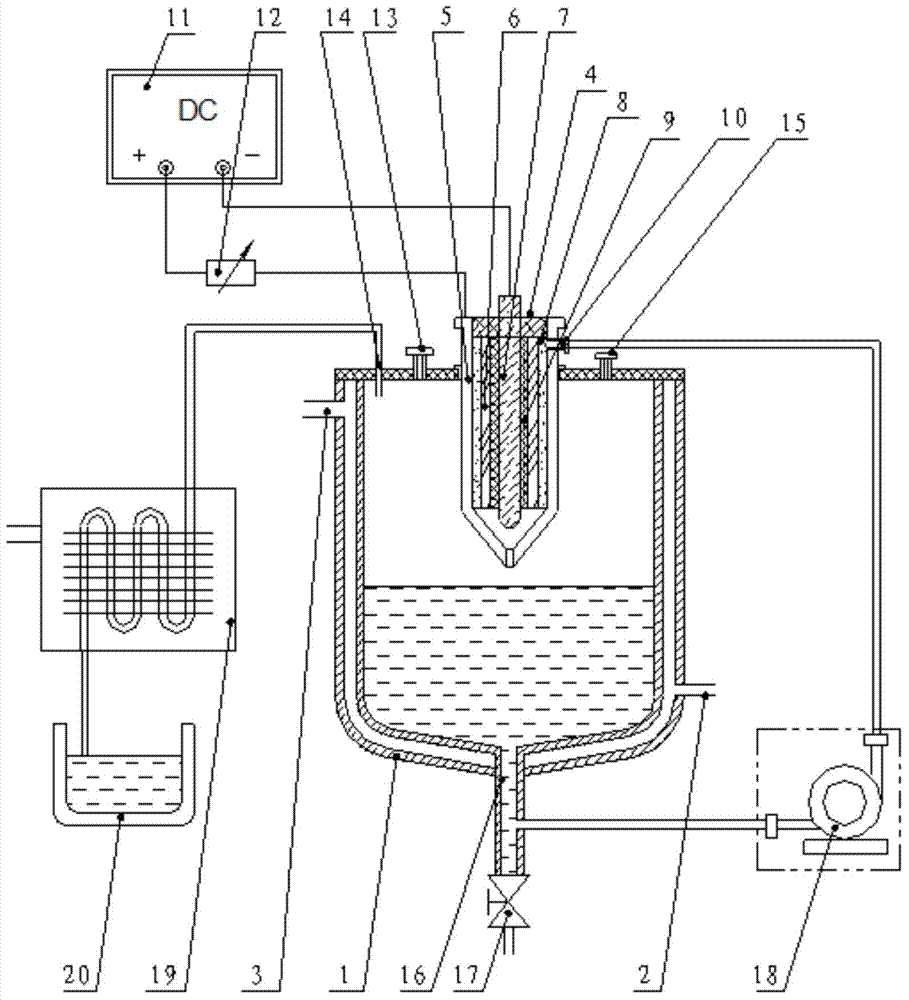

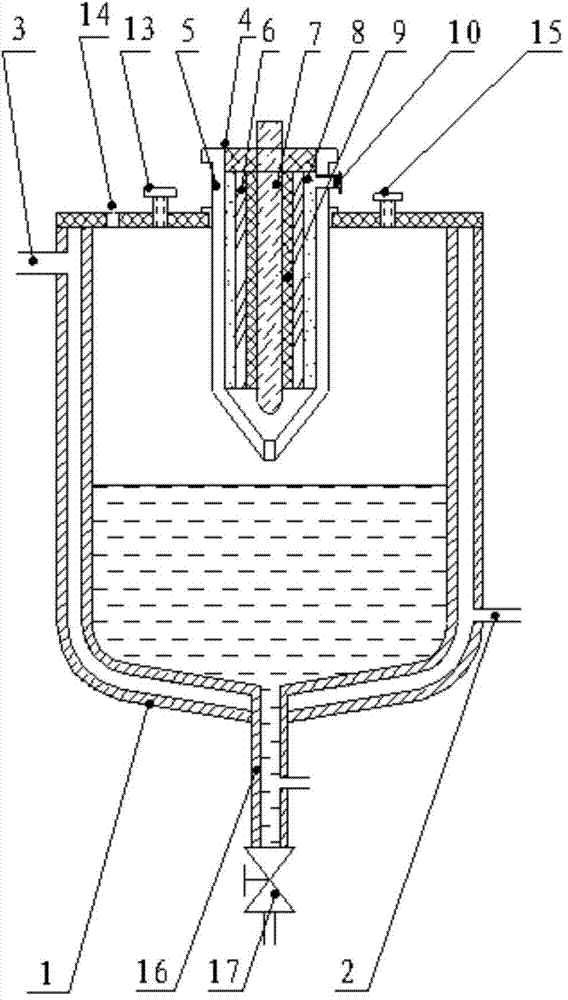

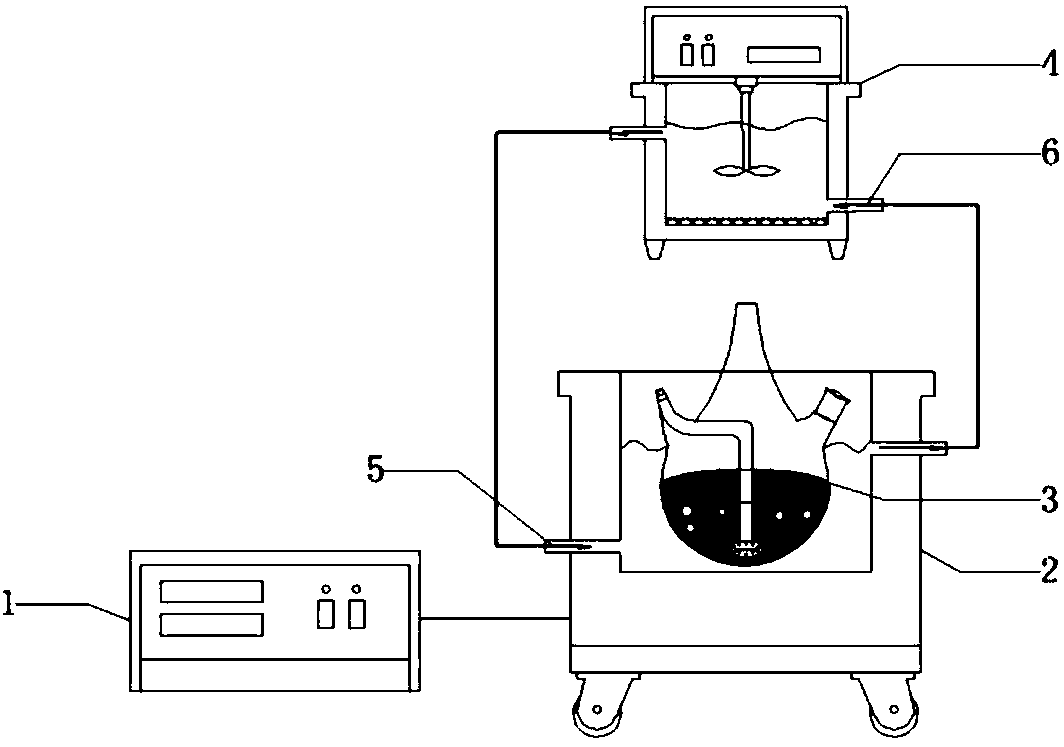

Device and method for treating organic waste water by water plasma torch

ActiveCN103896361AImprove energy efficiencyFast degradation rateHydrogenWater/sewage treatment by irradiationPlasma torchPollutant

The invention discloses a device and a method for treating organic waste water by a water plasma torch. The device comprises a water plasma torch waste water treatment reactor; the method comprises the steps of: directly using organic water to be treated as the working medium of the water plasma torch to generate a steam plasma jet, and introducing the steam plasma jet into the organic waste water to treat organic pollutants in the water; the device and method for treating the organic waste water by the water plasma torch have the advantages that the energy utilization efficiency is high, the organic waste water is rapid in degradation rate, and meanwhile the organic waste water can be converted into synthesis gas, thus achieving the resourcezation and energization of the organic waste water; the device and the method is particularly applicable to the treatment of the organic waste water which is high in concentration and difficult to degrade.

Owner:中科等离子体科技(合肥)有限公司

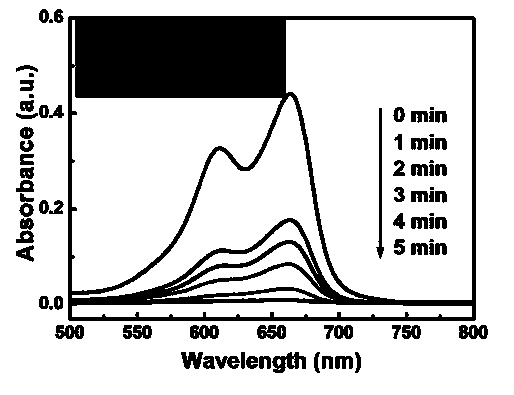

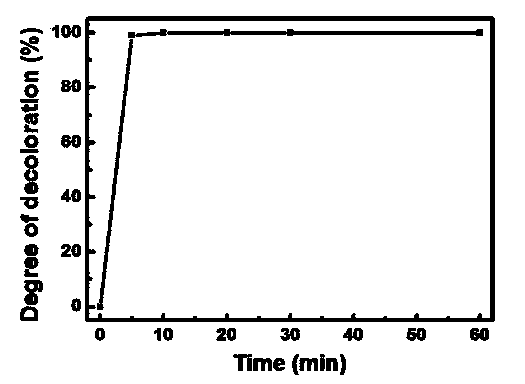

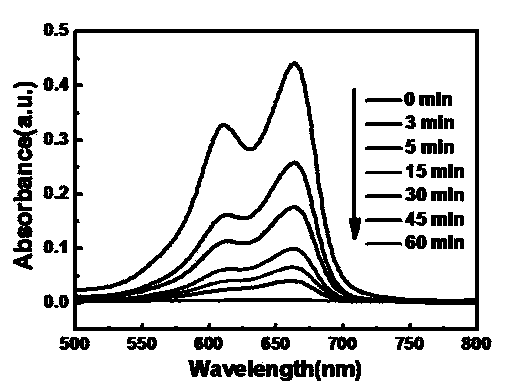

Method for degrading methylene blue with hydrogen peroxide under catalysis of graphene/MnO2 nano-composite

InactiveCN103508545APromote enrichmentReduce dosageWater/sewage treatment by oxidationCatalytic oxidationHydrogen peroxide degradation

The invention discloses a method for degrading methylene blue with hydrogen peroxide under the catalysis of a graphene / MnO2 nano-composite. The method has the advantages of high catalytic activity, fast degradation speed, high degradation rate, and energy saving. The method has the steps that: a methylene blue water solution with a concentration of 25-100mg / L is fetched; a graphene / MnO2 composite and hydrogen peroxide are added; and a catalytic oxidation reaction is carried out under a temperature of 25-50 DEG C. In the graphene / MnO2 composite, the mass percentage of MnO2 is 77-91%. A dose ratio of graphene / MnO2 composite to the methylene blue water solution is 0.2g / L. Mass concentration of hydrogen peroxide is 30%. Dose ratio of hydrogen peroxide to the methylene blue water solution is 200ml / L.

Owner:LIAONING NORMAL UNIVERSITY

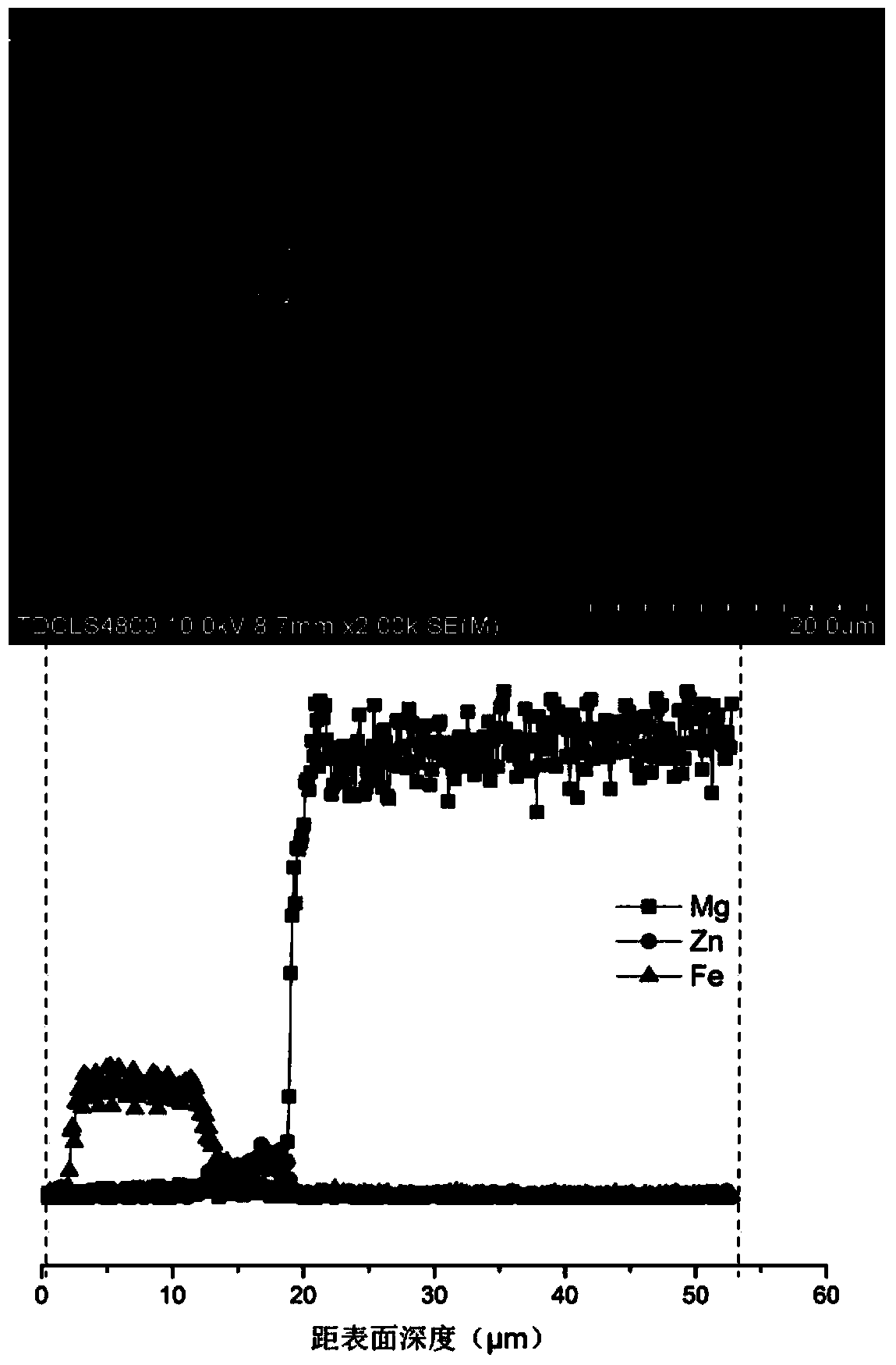

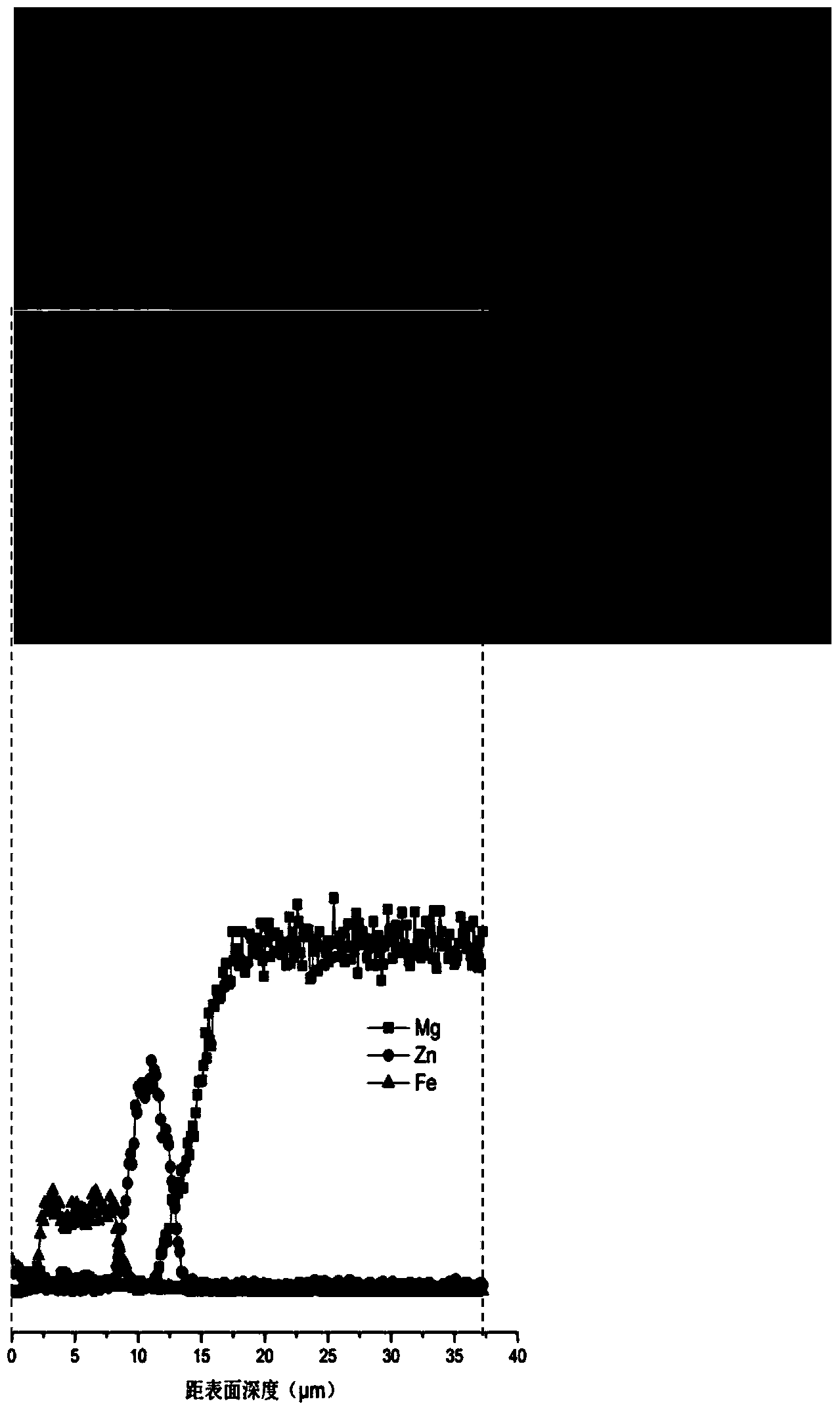

Degradable iron, zinc and magnesium-based gradient composite material based on biological bone healing and preparation thereof

InactiveCN103465542AAvoid secondary surgeryTight and reliableProsthesisMetal layered productsIntermediate stageBone cell

The invention discloses a degradable iron, zinc and magnesium-based gradient composite material based on biological bone healing. A zinc layer and an iron layer are sequentially arranged on the surface of a magnesium matrix, and the thickness or the diameter of the magnesium matrix is 30-90% of bone dimension in the repaired part. The thicknesses of the zinc and iron layers are respectively determined according to the corrosion rates of zinc and iron in an in vitro simulated body fluid. According to the composite material, rigid fixation in early stage is realized to promote bone healing, the composite material is gradually degraded, use of the material with lower rigidity is transited to dynamic fixation, and finally, the material is fully absorbed in vivo to prevent from being taken out in the second operation. Rapid degradation in the non-mechanical bearing later stage is realized, and growth by differentiation of bone cells and ingrowth of blood vessels on the surface of material are induced by hoping to combine the advantages that iron in higher rigidity in the early stage realizes rigid fixation and zinc in lower rigidity in the middle stage realizes dynamic fixation by means of quicker corrosion rate of magnesium. Finally, the composite material is fully absorbed, so as to realize the bone repairing purpose. The composite material disclosed by the invention is applicable to gradient structure designs of internal fixing materials after fracture with change demands on mechanical property with the passage of time.

Owner:TIANJIN UNIV

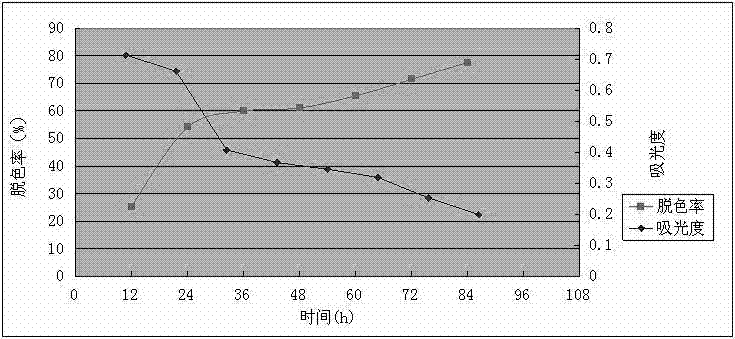

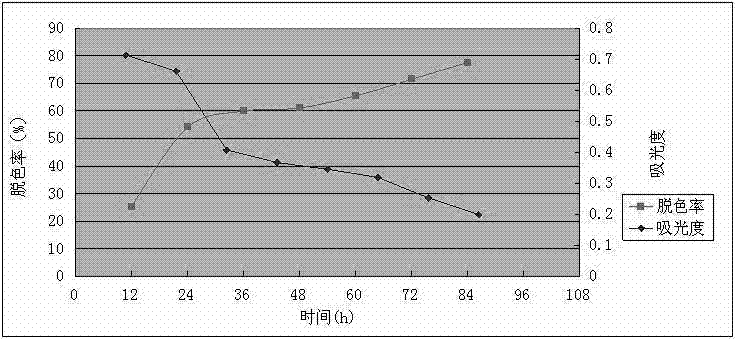

A method for rapidly reducing the chroma of printing and dyeing wastewater by using white rot fungi

InactiveCN102259986AConducive to survivalGood effectWaste water treatment from textile industryBiological water/sewage treatmentBiofilmColor printing

The invention discloses a method for rapidly reducing the chromaticity of printing and dyeing wastewater by utilizing white rot fungi. First, the film is hung, and after the biofilm is mature, the whole reactor officially enters the operation stage, and 1 L of printing and dyeing wastewater is added, so as to realize the color change of the printing and dyeing wastewater. degree reduction operation. The treatment method of the invention can completely degrade various synthetic dyes into CO2 and H2O, also has good effect on decolorization of dye wastewater, and is of great significance to environmental protection and sustainable development in my country.

Owner:SHAOXING UNIVERSITY

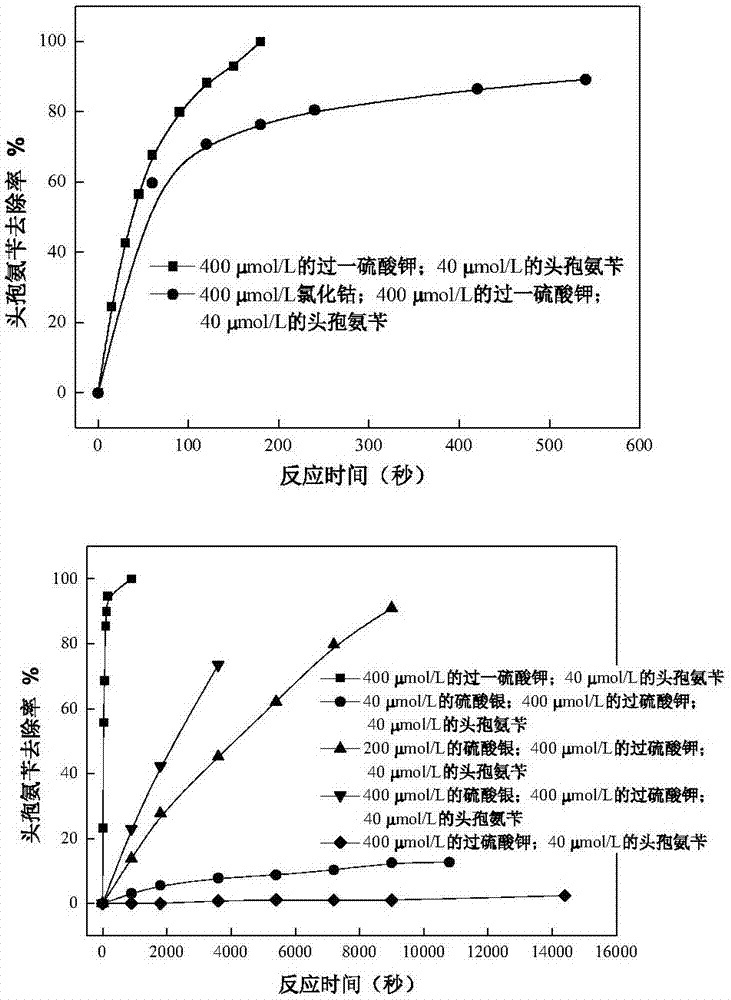

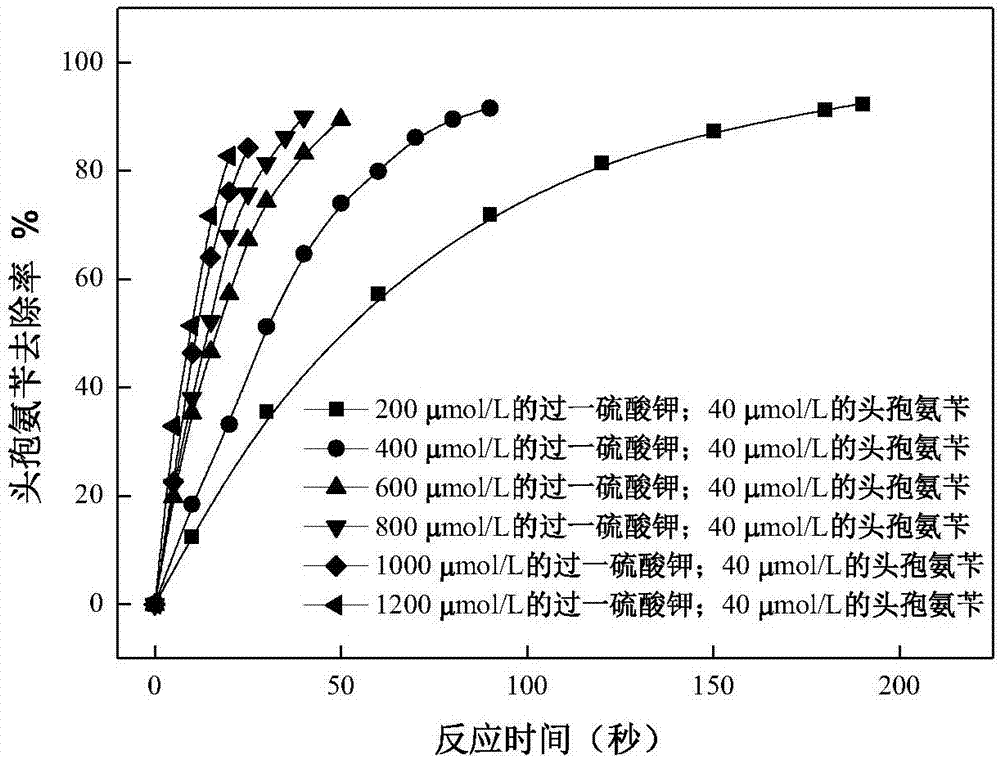

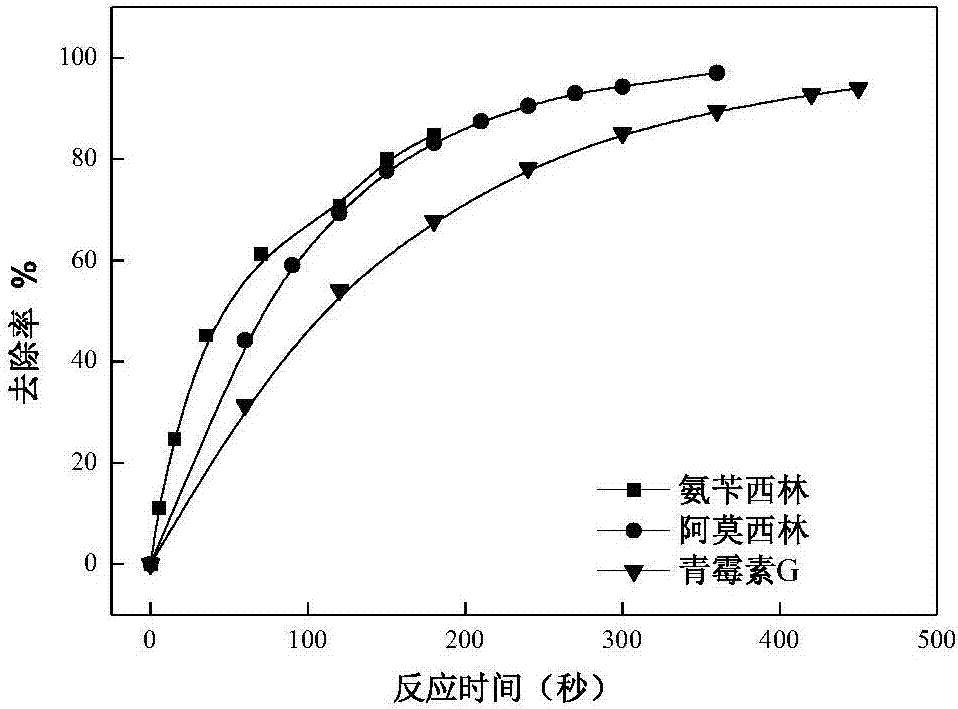

Method of rapidly degrading beta-lactam antibiotic in water

ActiveCN107298478AGood removal effectReduce energy consumptionWater contaminantsWater/sewage treatment by oxidationPersulfateBiological activation

The invention relates to a method of rapidly degrading a beta-lactam antibiotic in water. The method concretely comprises the following steps: adding a certain quantity of peroxymonosulfate (PMS) as an oxidant in waste water which contains a beta-lactam antibiotic (such as cephalexin, i.e. CFX) at normal temperature and normal pressure, uniformly stirring, carrying out reaction for a period of time under a neutral condition while keeping a pH value of a system, and removing a pollutant with oxidative degradation. According to the method provided by the invention, the peroxymonosulfate as the oxidant has very high selectivity to the beta-lactam antibiotic, directly oxidizes and removes the pollutant without an additional persulfate activation step, is rapid in degradation with very little influence caused by other organic matters in a water body, and is more beneficial to removing the beta-lactam antibiotic in a polluted water body.

Owner:SUZHOU UNIV OF SCI & TECH

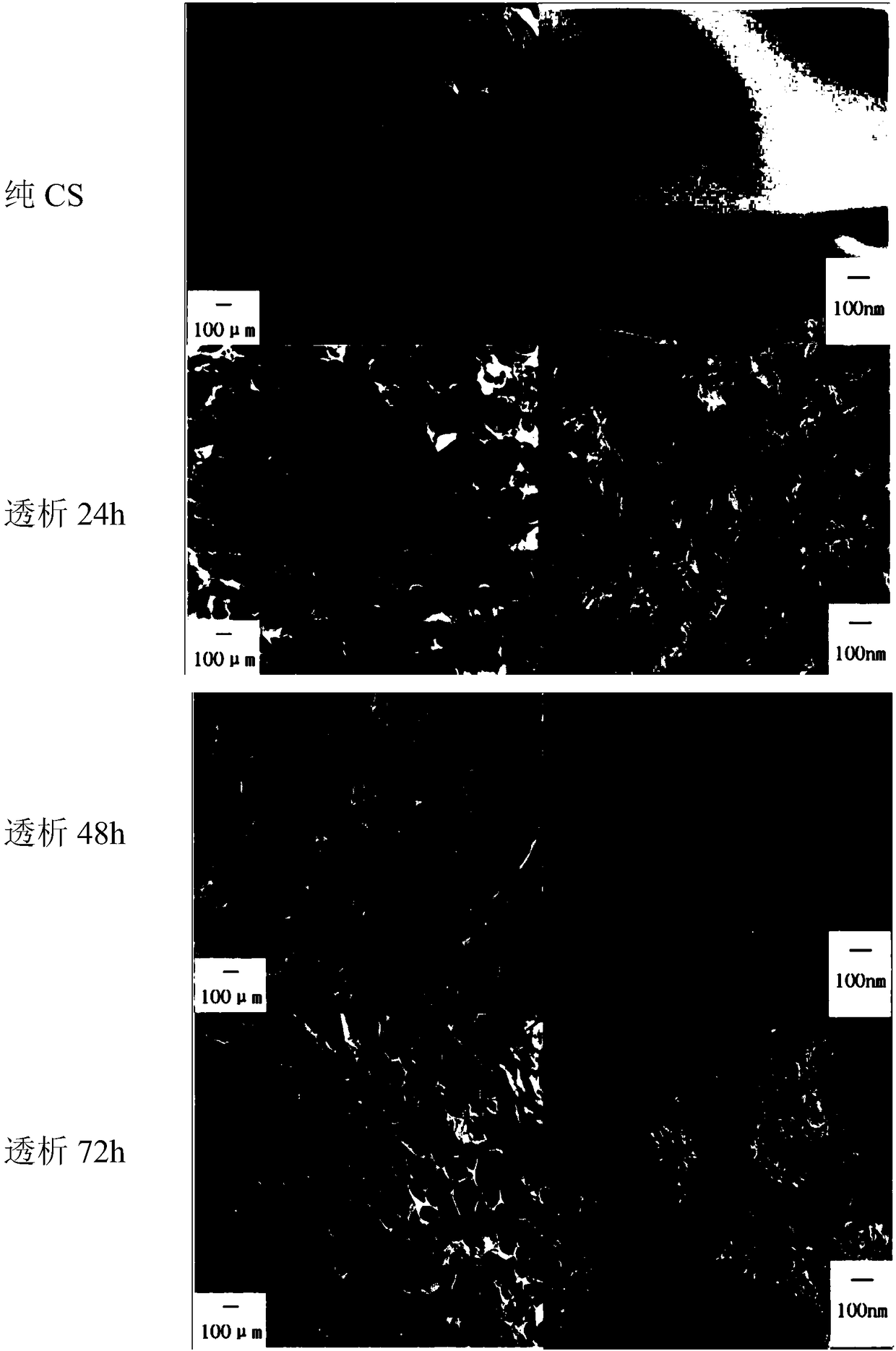

Nanometer hydroxyapatite/chitosan porous composite scaffold material as well as bionic dialysis mineralization preparation method and application thereof

InactiveCN108478880AGood biocompatibilityHigh biosecurityTissue regenerationProsthesisFreeze-dryingPorous composite

The invention belongs to the technical field of bone tissue engineering, and discloses a nanometer hydroxyapatite / chitosan porous composite scaffold material as well as a bionic dialysis mineralization preparation method and application thereof. The method comprises the following steps that (1) chitosan is dissolved in an acetic acid solution to obtain a chitosan solution; the chitosan solution isput into a container for freezing; freeze drying is performed to obtain an early-period chitosan porous scaffold; (2) the early-period chitosan porous scaffold is soaked in alkali liquid; water washing is performed until the pH is 7 to 8; freeze drying is performed to obtain a chitosan porous scaffold; (3) the chitosan porous scaffold is soaked in an alkaline phosphatase solution; then, the chitosan porous scaffold and the alkaline phosphatase solution are charged into a dialysis bag; the dialysis bag is put into a mixed solution of calcium glycerophosphate and CaCl2; constant-temperature constant-speed stirring is performed for mineralization; taking out, washing and freeze drying are performed to obtain the nanometer hydroxyapatite / chitosan porous composite scaffold material. The nanometer hydroxyapatite / chitosan porous composite scaffold material can be applied to the field of bone tissue engineering, particularly the bone defect repair.

Owner:JINAN UNIVERSITY

Antibiotic wastewater degradation process

InactiveCN105502775AEffective control of concentrationLow costWater treatment parameter controlWater/sewage treatment by irradiationPersulfateUltraviolet lights

The invention relates to an antibiotic wastewater degradation process. The antibiotic wastewater degradation process comprises the steps of firstly adding persulfate into pretreatment wastewater so as to obtain a mixed solution, regulating pH of the mixed solution with an acid liquid or an alkali liquid, carrying out first illumination on the mixed solution by virtue of 200nm-300nm ultraviolet light after the pH regulation, adding a thiosulfate solution into the mixed solution, and carrying out secondary illumination by virtue of 300nm-400nm ultraviolet light, so as to obtain water in which antibiotics are removed. According to the antibiotic wastewater degradation process, the antibiotics in the wastewater are degraded, the degradation speed is high, the degradation efficiency is high, the degradation effect is good, furthermore, the raw material cost is low, by-products are toxic-free, and the concentration of the antibiotics in water can be effectively controlled. Data show that the degradation rate of the degradation process to the antibiotics in the wastewater reaches up to 91%-96%.

Owner:中华人民共和国济南出入境检验检疫局

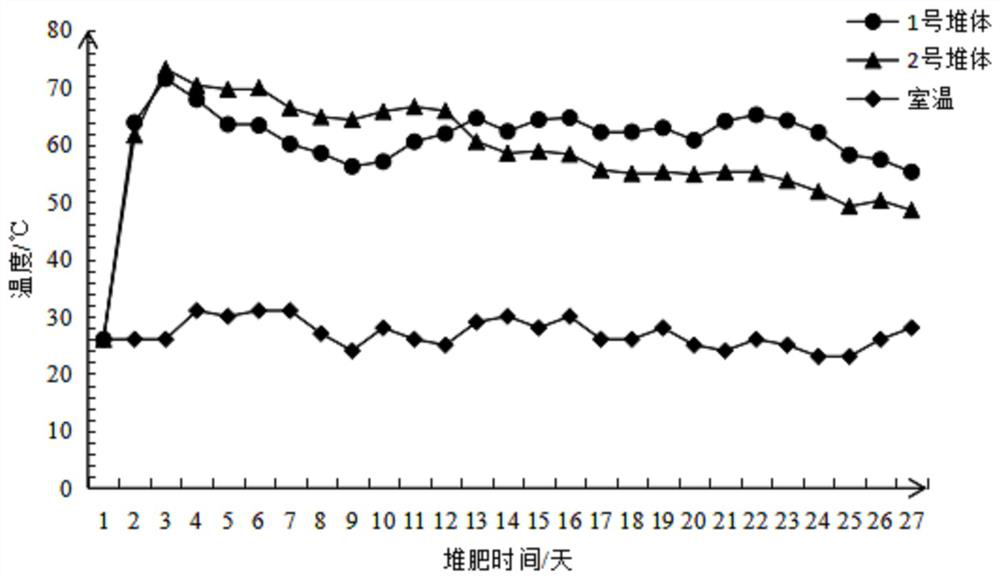

Decomposition agent for branch composting treatment and preparation method thereof

PendingCN112481176AEfficient lignin degradation functionPromote degradationBio-organic fraction processingBacteriaBiotechnologyMicrobial agent

The invention relates to a decomposition agent for branch composting treatment. The microbial agent is a solid biological microbial agent which is obtained by inoculating a composite bacterial liquidcontaining active ingredients of bacillus velezensis, bacillus arabinodoxae, bacillus megaterium, bacillus kaempferiae and bacillus megatherium on a solid fermentation substrate and fermenting, wherein the effective viable count of the microbial agent is not less than 1.0 * 10 < 10 > cfu / g. The cellulase activity, the laccase activity, the manganese peroxidase activity and the lignin peroxidase activity in the solid biological agent are not lower than 100.0 U / g, 1.0 U / g, 1.0 U / g and 1.5 U / g respectively, and when the solid biological agent is used for composting treatment, the degradation efficiency of lignin and cellulose can be improved, and the composting rate and quality can be improved.

Owner:INST OF AGRI ENVIRONMENT & RESOURCE SHANXI ACAD OF AGRI SCI

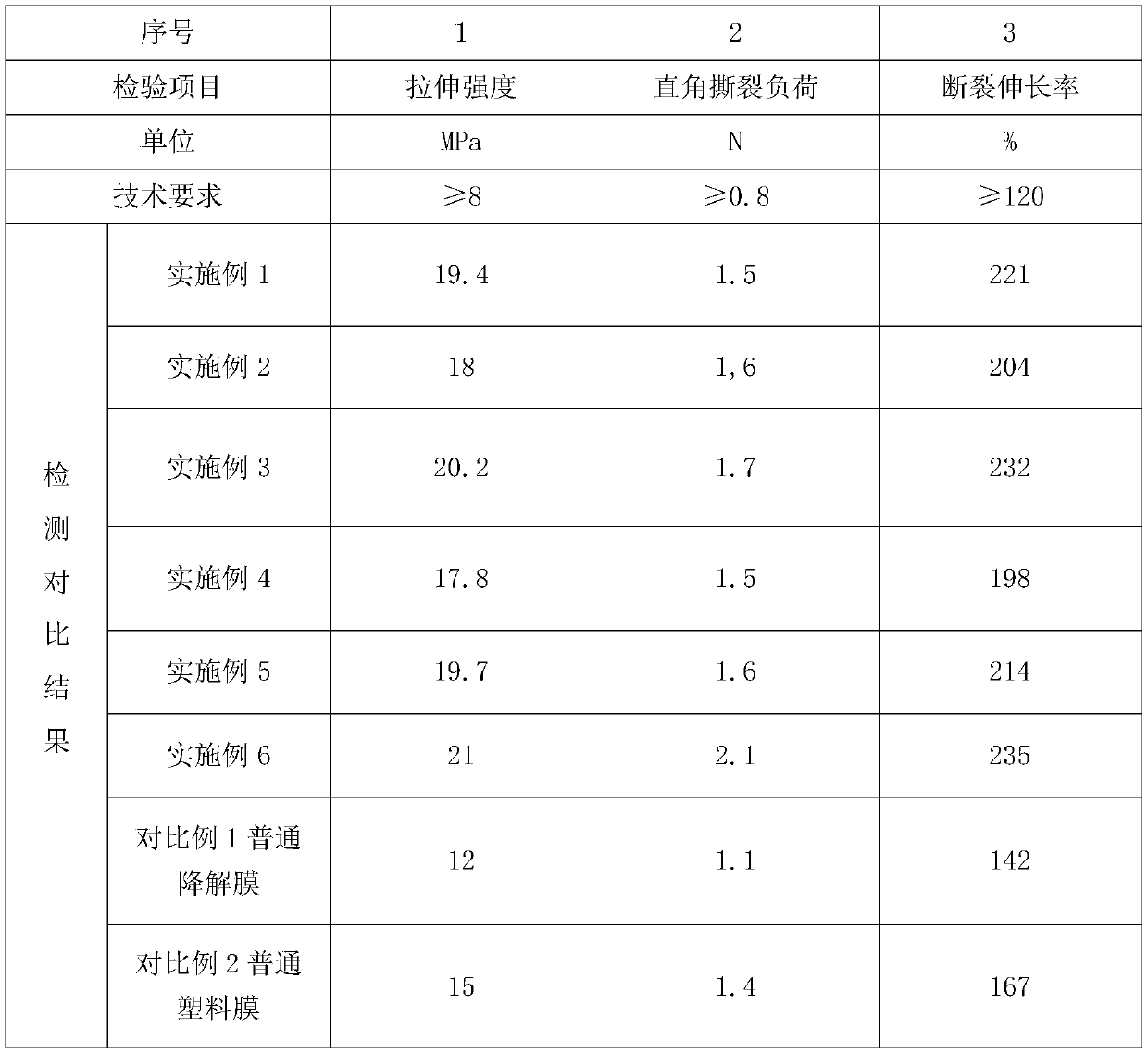

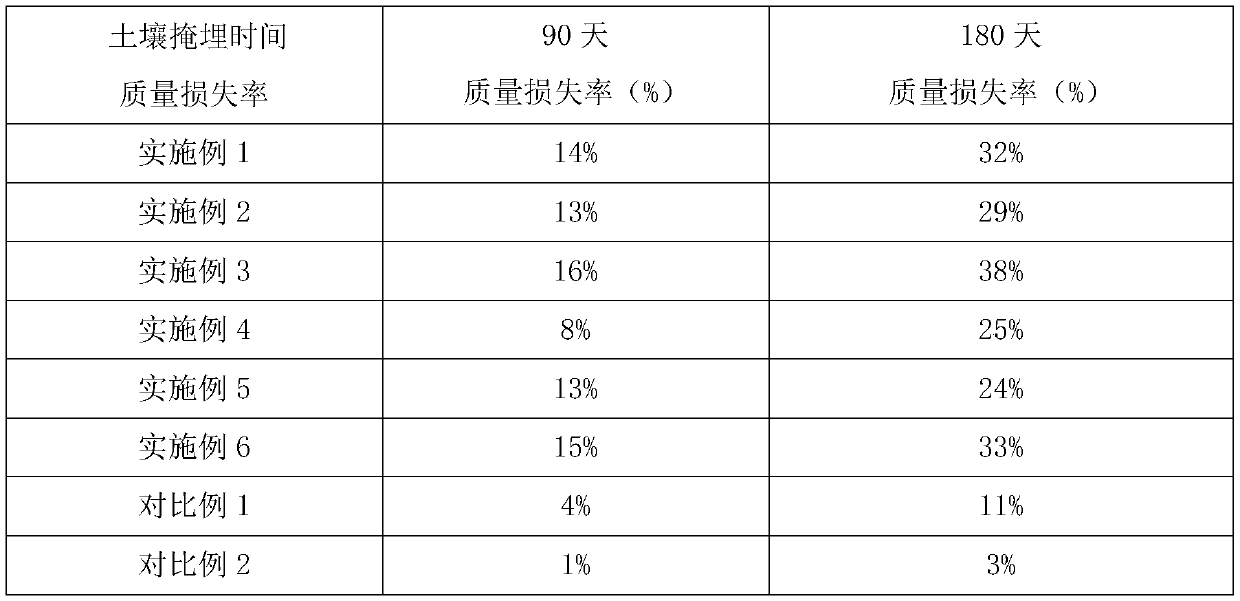

Biodegradable material containing bamboo powder, and preparation method thereof

The invention relates to the technical field of novel degradable materials, in particular to a biodegradable material containing bamboo powder, and a preparation method thereof. The biodegradable material comprises 15-30 parts of the bamboo powder, 2-6 parts of calcium carbonate and 40-65 parts of biodegradable resin, and coupling agents, biodegradable enzymes, phase solvents, photoinitiators, plasticizers, chain extenders, lubricants, active agents and the like are added to prepare the biodegradable material. The biodegradable material and the preparation method thereof have the advantages that the biodegradable material is made from the bamboo powder, the biodegradable resin, the coupling agents, the biodegradable enzymes, the plasticizers and the like, and the photoinitiators and auxiliary agents are added, so that the biodegradable material can have better mechanical properties and higher degradation rate than other existing plastic materials under the action of different factors in the natural environment; the biodegradable material is easy to prepare, wide in application range, sanitary and environmentally friendly.

Owner:汕头市雷氏塑化科技有限公司

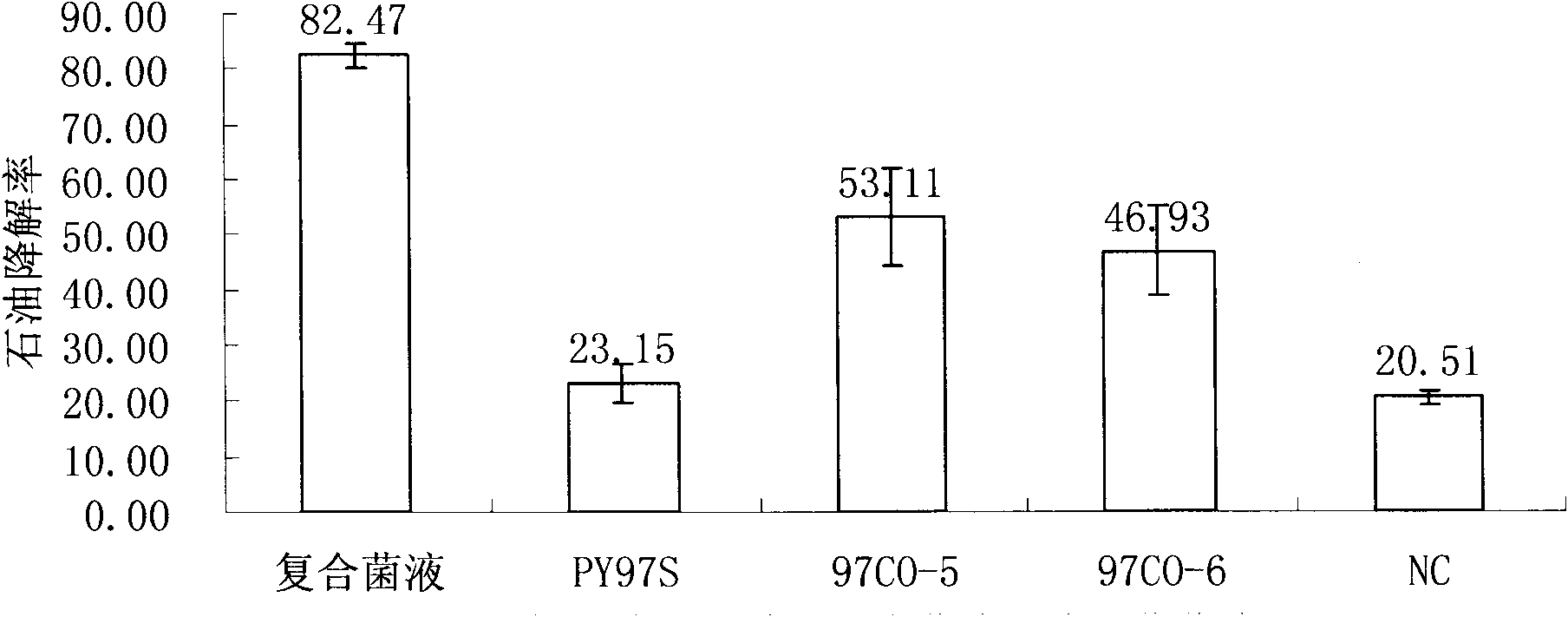

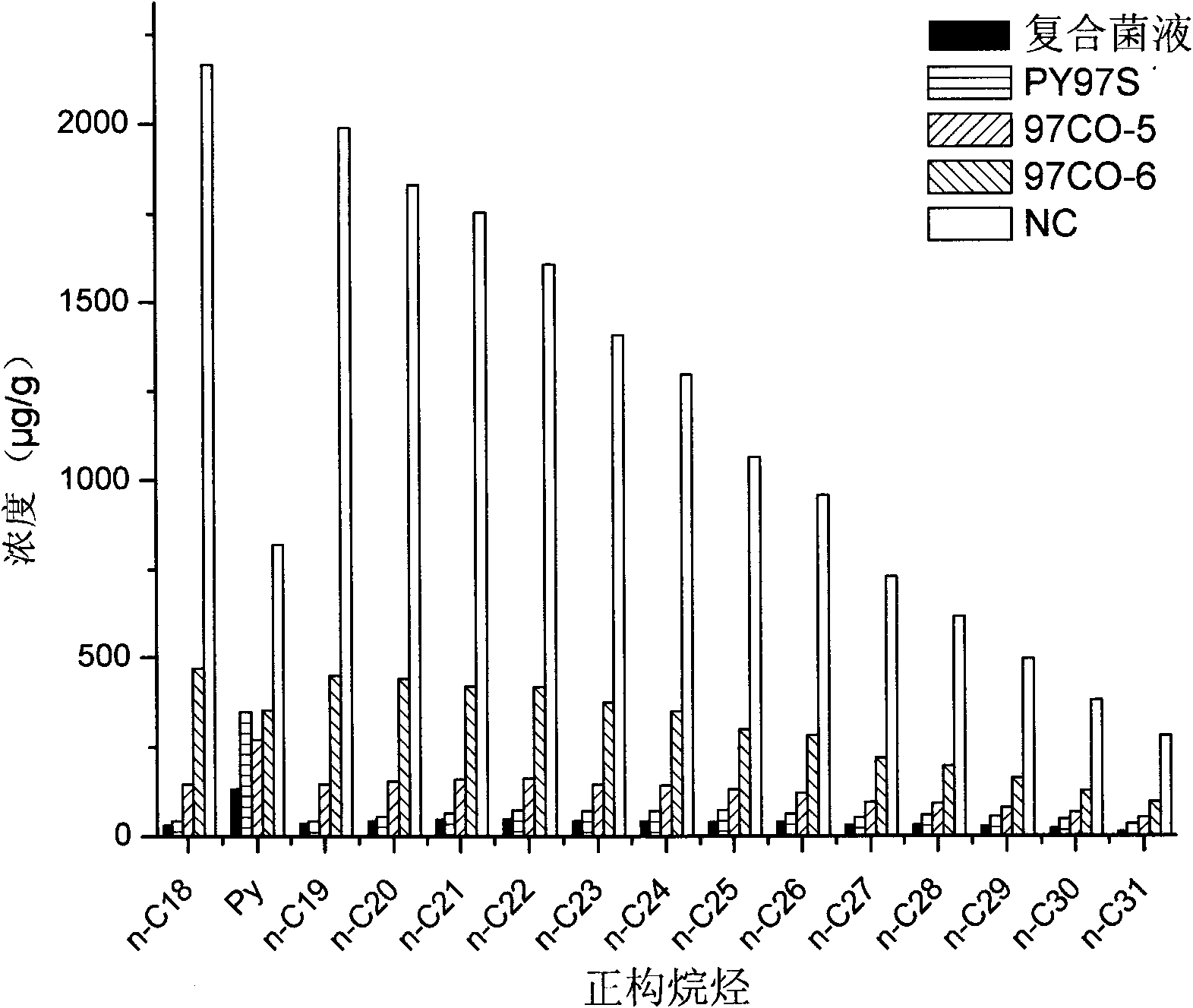

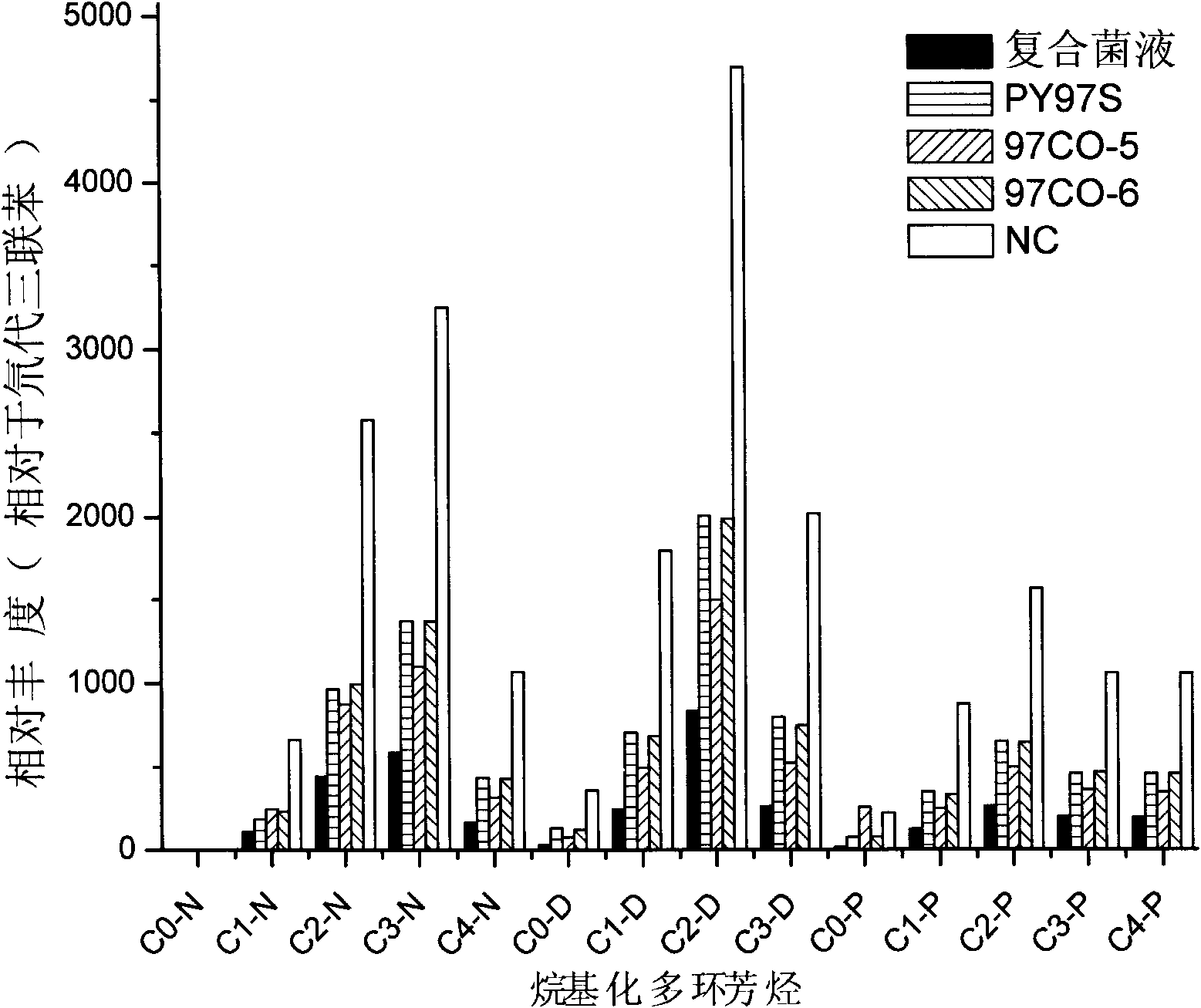

Composite bacteria liquid for cooperative degradation of petroleum and preparation method thereof

ActiveCN101914442AFast degradation rateIncreased degradation rateBacteriaMicroorganism based processesAlkaneSodium acetate

The invention relates to a composite bacteria liquid for cooperative degradation of petroleum and a preparation method thereof. The composite bacteria liquid is formed by mixing fermentation liquids of two strains of alcanivorax 97CO-5 and 97CO-6 and a strain of marinobacter PY97S wherein cell concentration is 107 to 109 CFU / mL. The preparation method comprises the steps of: inoculating seed liquids of the alcanivorax and the marinobacter respectively by 5% of inoculation quantity into an M8 culture medium or sodium acetate culture medium; fermenting and culturing under the conditions of 25 DEG C, the ventilation volume of 0.25m<3> / h, the stirring speed of 150rpm and defoaming by a fed defoamer; mixing all the fermentation liquids to prepare the composite bacteria liquid; centrifuging to prepare 5 times concentrate; and finally storing at 4 DEG C. The composite bacteria liquid is suitable for biodegradation of petroleum pollution at lower environmental temperature and thoroughly degrading alkane components and aromatic components in the petroleum, has higher petroleum degradation ratio than bacteria liquid with single degradation bacteria, has obvious cooperative degradation effect, and is applied to biological repair of coastlines or beaches polluted by ocean spilled petroleum.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA +1

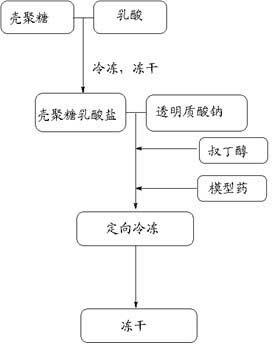

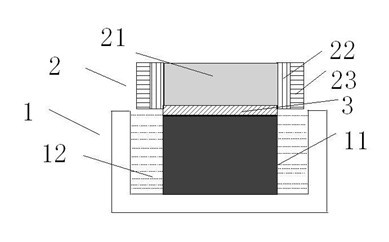

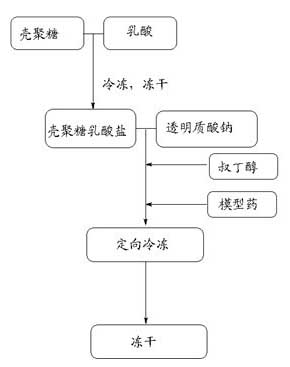

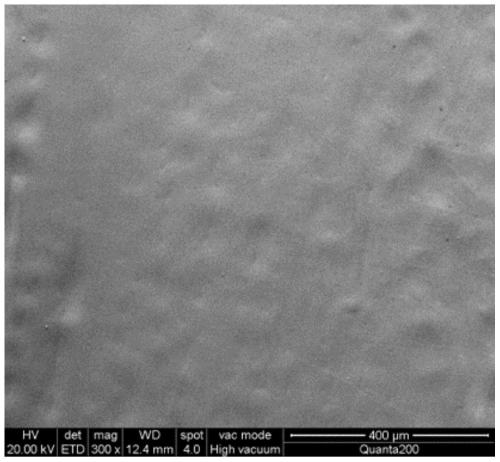

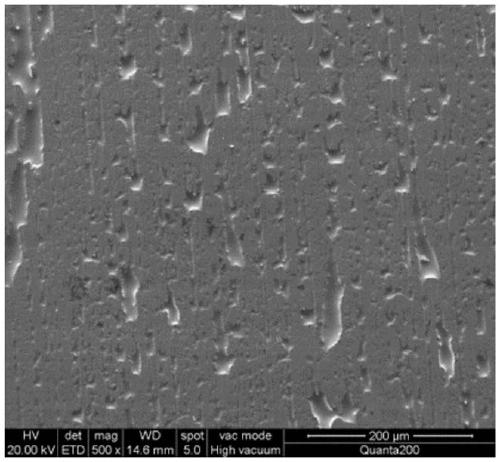

High-ventilated degradable medicine-carrying skin wound dressing as well as preparation method and device thereof

ActiveCN102210885AHigh air permeabilityImprove water absorptionDomestic cooling apparatusLighting and heating apparatusMoisture retentionSodium hyaluronate

The invention discloses a high-ventilated degradable medicine-carrying skin wound dressing as well as a preparation method and device thereof, and belongs to the technical field of medical new materials. The high-ventilated degradable medicine-carrying skin wound dressing comprises the following components in percentage by weight: 45-50% of chitosan lactate; 45-50% of sodium hyaluronate and 5-10%of antibiotic. In the porous bioactivity dressing provided by the invention, a composite material of the chitosan lactate and the sodium hyaluronate is utilized as a substrate, and the antibiotic is loaded on the substrate. The dressing based on a special refrigerating process has the advantages of vertical pore ducts, high ventilation property, high hydroscopicity and moisture retention, therebyincreasing the permeability of the wound surface; the redundant exudate can be immediately absorbed while the moisture on the surface of the wound cannot be excessively evaporated. The dressing has long-term and effective effect on treating the surface of the wound so as to avoid the pain of the patient caused by frequent dressing change.

Owner:PKU HKUST SHENZHEN HONGKONG INSTITUTION +1

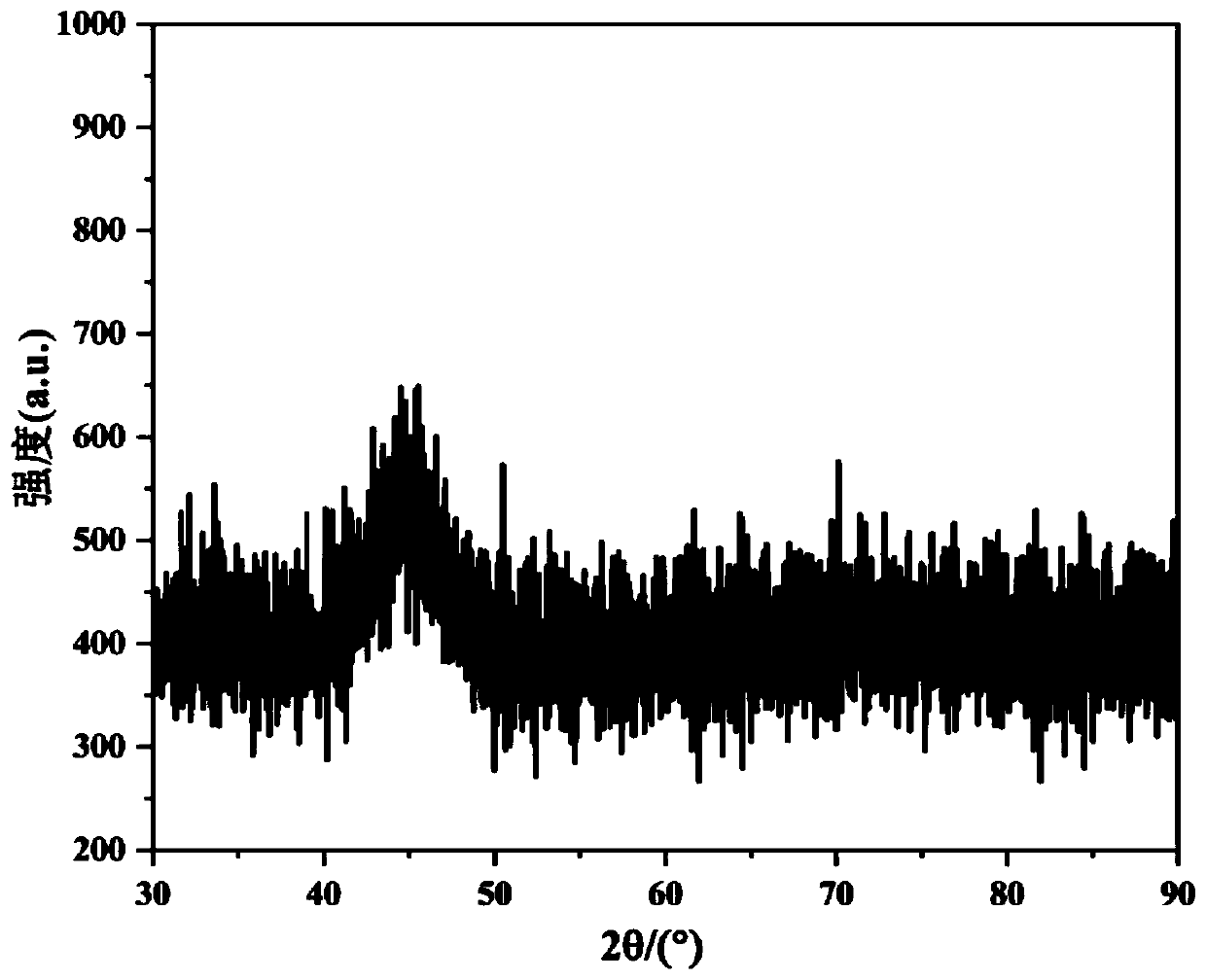

Fe-Si-B amorphous alloy strip, preparation method thereof and application of Fe-Si-B amorphous alloy strip in degradation of azo dye wastewater

InactiveCN109811278AFast degradation ratePromote degradationWater contaminantsWater/sewage treatment by oxidationAlloyDyeing wastewater

The invention belongs to the technical field of wastewater treatment, and discloses an Fe-Si-B amorphous alloy strip, a preparation method thereof and application of the Fe-Si-B amorphous alloy stripin degradation of azo dye wastewater. The composition of the Fe-Si-B amorphous alloy strip is FemSinBp, wherein m is larger than or equal to 75 and smaller than or equal to 83, n is larger than or equal to 7 and smaller than or equal to 15, p is larger than or equal to 7 and smaller than or equal to 15, and m+n+p is equal to 100; and preferably, the composition of the Fe-Si-B amorphous alloy stripis Fe78Si11B11. The invention further discloses a preparation method of the Fe-Si-B amorphous alloy strip and application of the Fe-Si-B amorphous alloy strip in degradation of the azo dye wastewater. The strip provided by the invention has relatively good corrosion resistance and relatively high catalytic activity, has very fast degradation rate to azo dyes and is low in cost.

Owner:SOUTH CHINA UNIV OF TECH

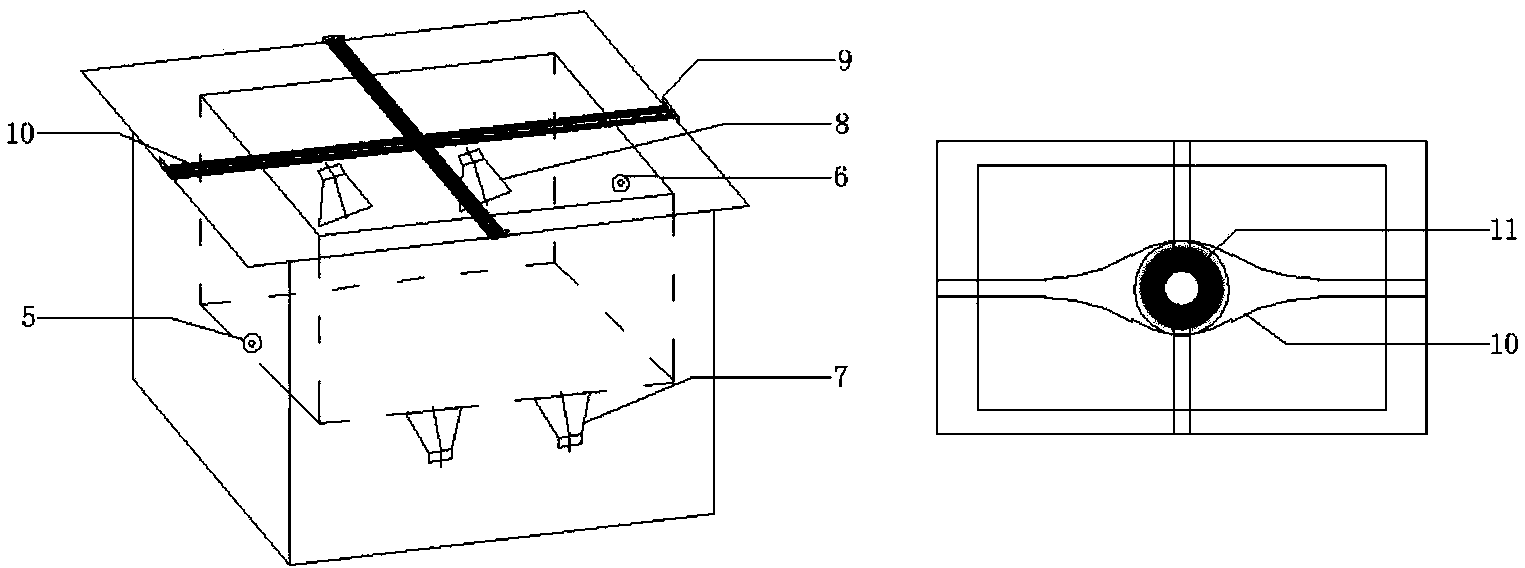

Low-power dual-frequency ultrasonic/Fenton oxidation reactor device

ActiveCN104326526AReduce energy consumptionReduces corrosion damageWater treatment compoundsWater/sewage treatment with mechanical oscillationsDual frequencyFenton reagent

The invention belongs to the technical field of degradation-resistant industrial wastewater treatment, and particularly relates to a method and a device for carrying out low-power dual-frequency ultrasonic irradiation / Fenton oxidation coupled treatment on industrial wastewater. The invention is designed for solving the technical problem that in an existing ultrasound / Fenton oxidation united technology, single-frequency ultrasonic irradiation of the same direction is non-uniform, and the yield of .H is low. The technical scheme of the invention is as follows: a low-power dual-frequency ultrasonic / Fenton oxidation reactor device comprises a dual-frequency ultrasonic generator, an ultrasonic cleaning tank and a Fenton oxidation reactor. The invention also provides a method for treating industrial wastewater by using the device. The device disclosed by the invention can be used for treating industrial wastewater, and has the advantages of low energy consumption, uniform ultrasonic irradiation, high utilization rate of Fenton reagents, high oxidative degradation rate of degradation-resistant organic pollutants, rapid degradation rate, and the like.

Owner:CHONGQING UNIV

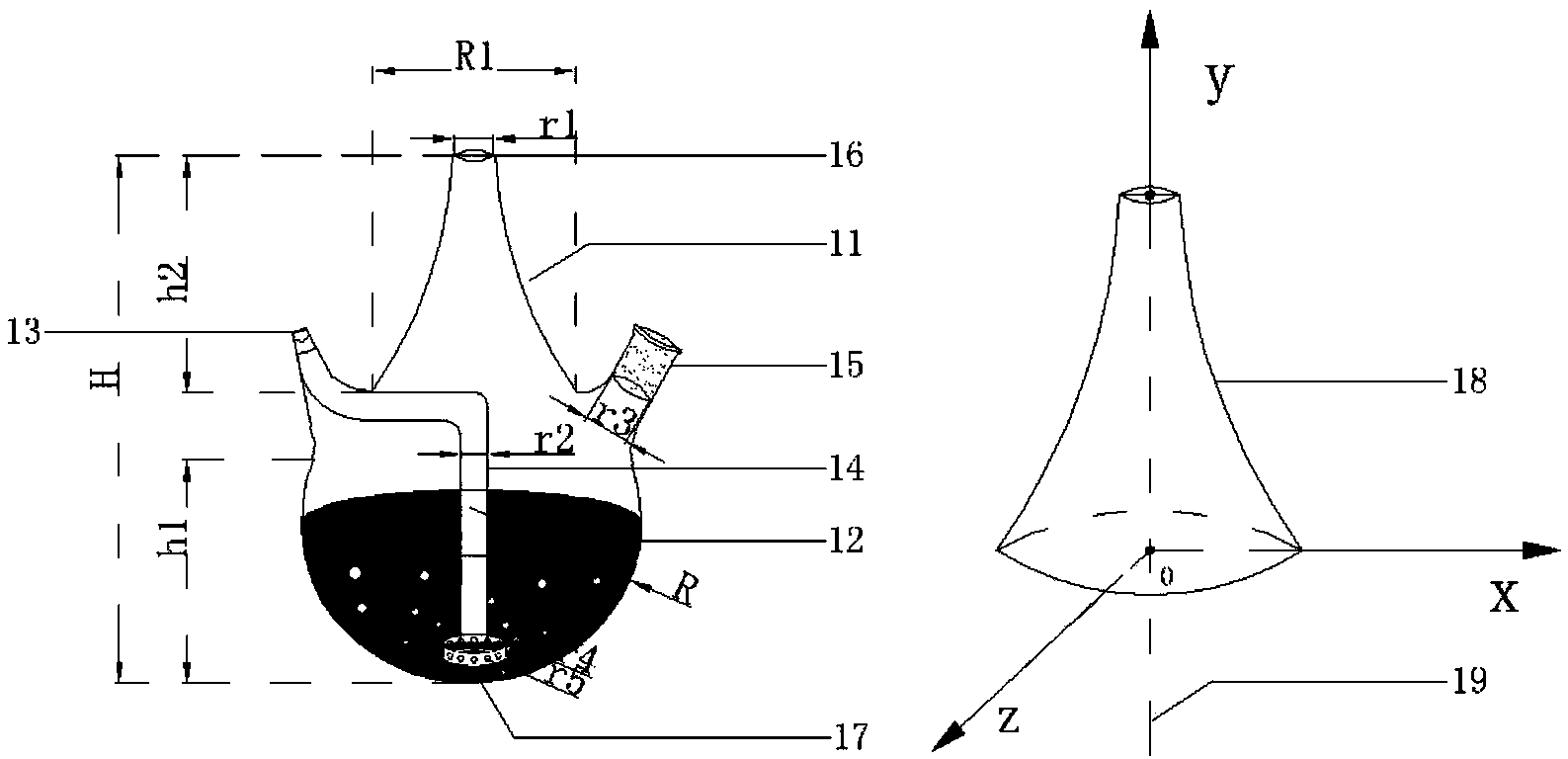

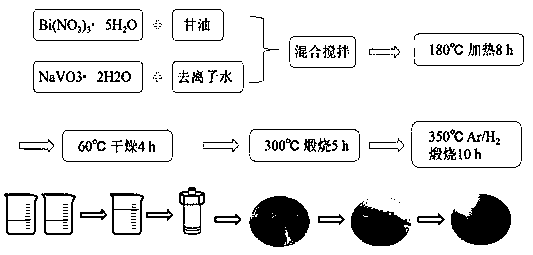

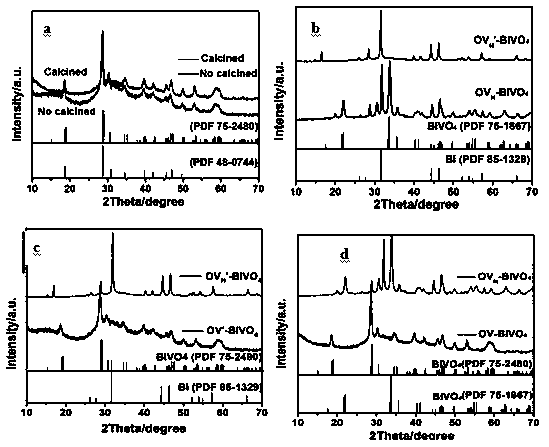

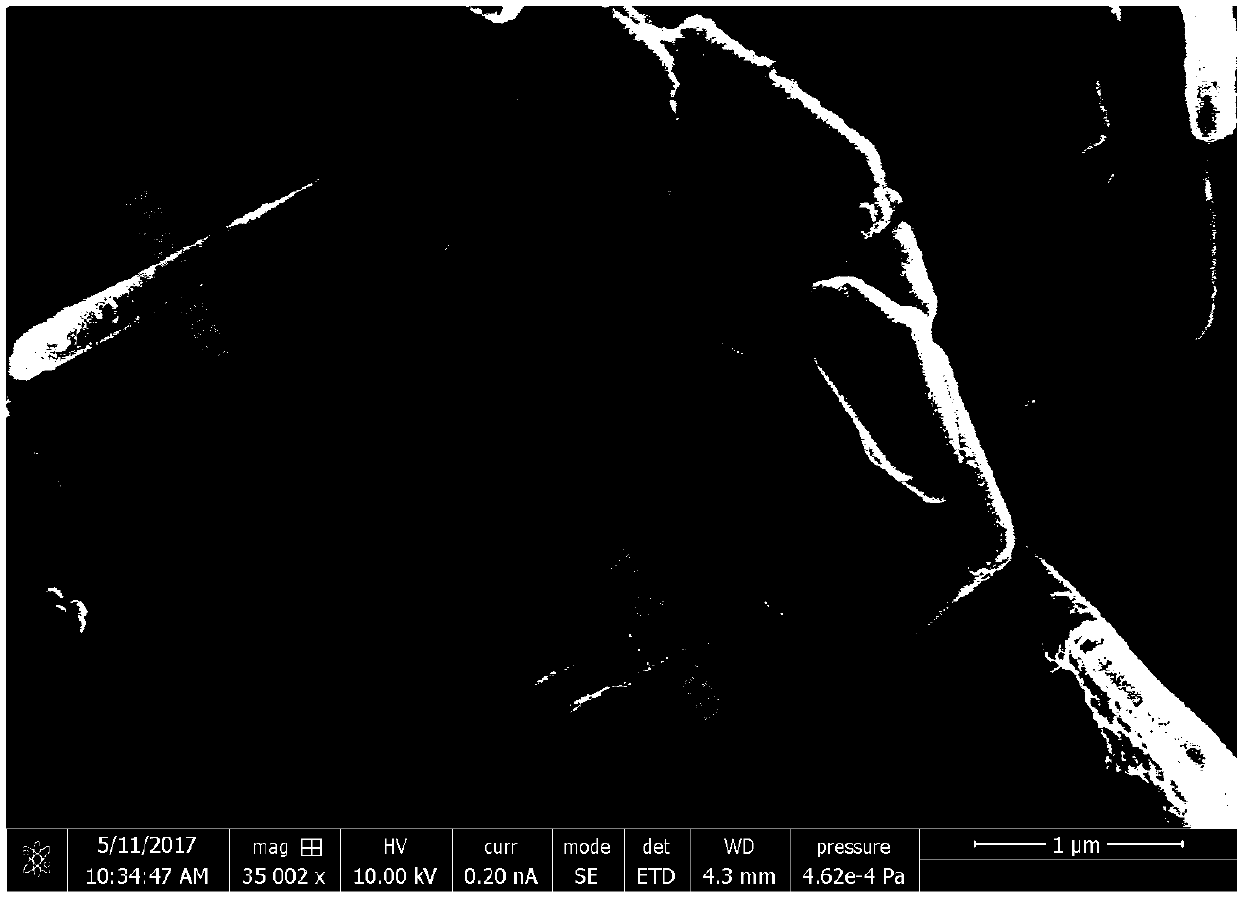

H-occupied BiVO4-OVs photocatalytic material and production method and application thereof

ActiveCN109985618ABroaden the range of light absorptionWide light absorption rangeWater/sewage treatment by irradiationWater treatment compoundsSolventHigh pressure

The invention discloses a method for producing an H-occupied BiVO4-OVs photocatalytic material and application of the H-occupied BiVO4-OVs photocatalytic material. The production method comprises thesteps of dissolving a certain molar weight of Bi(NO3)3.5 H2O in glycerin; dissolving a certain molar weight of NaVO3.2 H2O in deionized water; mixing solutions; transferring a mixed solution into a teflon-lined high-pressure kettle, and maintaining 180 DEG C for 8 h; conducting 10000-rpm centrifugal separation on a solvothermal synthesis product, washing the solvothermal synthesis product subjected to 10000-rpm centrifugal separation with deionized water and ethyl alcohol, and drying the washed solvothermal synthesis product subjected to 10000-rpm centrifugal separation at 60 DEG C for 4 h; calcining the solvothermal synthesis product, which is thoroughly washed, in a muffle furnace at 300 DEG C for 5 h; and conducting annealing on a calcined product in an Ar / H2 atmosphere at 350 DEG C for10 h to obtain the H-occupied BiVO4-OVs photocatalytic material. The H-occupied BiVO4-OVs photocatalytic material has the advantages that a photoresponse range is wide, the catalytic activity is high, the degradation rate is high, and the hydrolysis ability is high; and solar energy can be fully and effectively used.

Owner:SHAANXI UNIV OF SCI & TECH

Hydrothermal preparation method capable of controlling thickness of tin selenide with sheet structure

ActiveCN107934924AControl thicknessEasy to handleNanotechnologyMetal selenides/telluridesPhenanthrolinePollution

The invention provides a hydrothermal preparation method capable of controlling the thickness of tin selenide with a sheet structure. The hydrothermal preparation method comprises the following steps:dissolving tartaric acid in distilled water, then adding tin dichloride, and carrying out stirring until a solution is clear and transparent so as to obtain a solution A; then successively adding selenium dioxide, sodium hydroxide and sodium borohydride into distilled water so as to prepare a solution B; slowly adding the solution A into the solution B and carrying out stirring; then adding a morphological controlling agent 1,10-phenanthroline, 2,2-dipyridine or 4,4-dipyridyl, carrying out stirring, and then carrying out a reaction at 180 DEG C in a hydrothermal reaction vessel for 6-24 h; and successively carrying out centrifuging, washing and drying to obtain black tin selenide powder. According to the invention, the thickness of flaky SnSe is controlled by adding the morphological controlling agent in hydrothermal process; raw materials and the produced solutions in the whole process are easy to treat and have no pollution; and the hydrothermal preparation method is low in preparation cost, simple in operation process and high in repeatability, and can prepare high-purity flaky tin selenide.

Owner:SHAANXI UNIV OF SCI & TECH

SnS2 nanosheet as well as preparation method and application thereof

InactiveCN104096530APlay a coordination roleImprove adsorption capacityMaterial nanotechnologyPhysical/chemical process catalystsAdsorption equilibriumSynthesis methods

The invention provides an SnS2 nanosheet as well as a preparation method and an application thereof. The SnS2 nanosheet with both high adsorption and a high visible light catalysis degradation property is prepared with simple chemical liquid phase synthesis method. The preparation technology is simple and low in cost. The SnS2 nanosheet which can be applied to both adsorption and visible light degradation has the advantages of high adsorption, short adsorption equilibrium time, high visible light catalysis degradation efficiency, high degradation rate, environment-friendliness and the like.

Owner:ANHUI NORMAL UNIV

Preparing methods and applications of microbacterium paraoxidans and broad-spectrum polychlorinated biphenylase preparation thereof

ActiveCN109762751ABroad spectrum of degradationEase of operation at scaleBacteriaContaminated soil reclamationMicroorganismMicrobiology

The invention relates to preparing methods and applications of microbacterium paraoxidans and a broad-spectrum polychlorinated biphenylase preparation thereof. The microbacterium paraoxydans ECO-2 ispreserved in China General Microbiological Culture Collection Center on June 01, 2018 and has the bacterial species preservation number of CGMCC No.15836. An intracellular complex enzyme obtained by induction culture of the microbacterium paraoxidans ECO-2 with a single substrate of biphenyl can degrade PCB28, PCB101 and / or PCB114 and other low-chloro and high-chloro PCBs, and the enzyme preparation has wide degradation spectrum, has significant difference from a fact that a product obtained from conventional known single induction culture can only degrade one component, and has wide application prospects.

Owner:ECOLOGY INST SHANDONG ACAD OF SCI

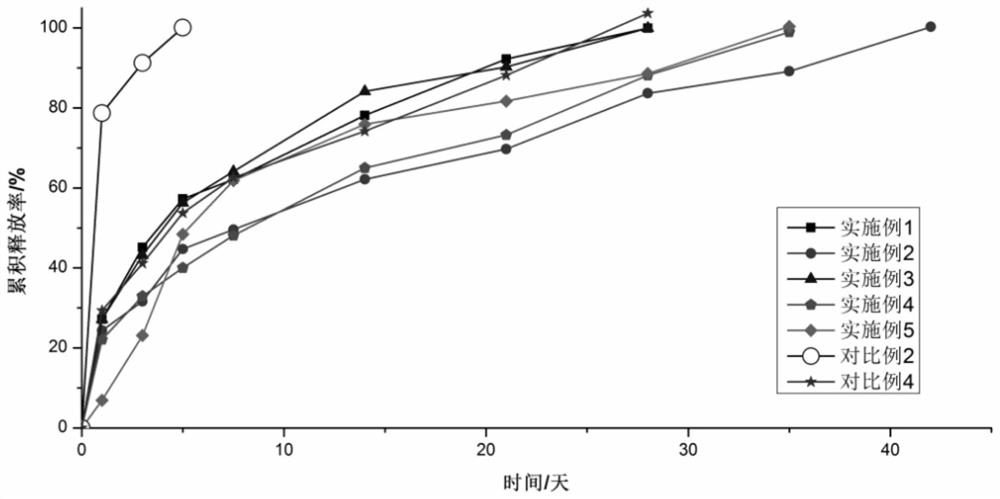

Composite stent as well as preparation method and application thereof

ActiveCN112587731AImprove mechanical propertiesGood osteoinductivityCoatingsMicrocapsulesCalcium silicatePolyester

The invention discloses a composite stent as well as a preparation method and application thereof. The composite stent comprises a stent matrix, drug-loaded microspheres and an alginate layer; the stent matrix is of a three-dimensional porous structure; the drug-loaded microspheres are fixed to the surface and pore channels of the stent matrix; the alginate layer covers the surfaces of the drug-loaded microspheres and the stent matrix; drug-loaded microspheres comprise carrier microspheres and drugs loaded on the carrier microspheres; the drugs consist of a bone repair medicine, and / or a growth factor; and the raw materials of the carrier microspheres are composed of degradable polyester and mesoporous calcium silicate. The composite stent is stable in structure, and has good drug slow releasing effect as well as osteogenic differentiation capacity; and moreover, the composite stent is capable of effectively promoting repair and reconstruction of bone tissue.

Owner:GUANGDONG PROV MEDICAL INSTR INST

Low-temperature thermoplastic sheet material and preparation method thereof

The invention relates to the field of medical apparatus and instruments, specifically to a low-temperature thermoplastic sheet material, and a preparation method and an application thereof. The low-temperature thermoplastic sheet material provided by the invention is prepared from 80 to 95 parts by weight of polycaprolactone, 5 to 20 parts by weight of polylactic acid and 2 to 4 parts by weight ofa coupling agent through a melting reaction, blend extrusion molding and irradiation crosslinking. According to the invention, a high-modulus polylactic acid material is introduced into a main body material of the low-temperature thermoplastic sheet material provided by the invention, so the low-temperature thermoplastic sheet material has higher strength, small degree of retraction and deformation, better fixing effect and stronger comfortable sensation; and after the low-temperature thermoplastic sheet material is discarded, the rate of degradation is rapider. Meanwhile, the low-temperaturethermoplastic sheet material adopts a manner of chemical coupling to further improve the compatibility between the polylactic acid and a polycaprolactone material, and the polylactic acid and the polycaprolactone material are uniformly distributed in the whole bulk structure, so uniform mechanical strength of all parts of the sheet material is guaranteed.

Owner:WEIGAO HLDG +2

Method for preparing ultravoilet catalytic degraded plastic using titanium dioxide as catalyst

The invention is a method for ultraviolet catalyzer degraded plastic which uses titanium dioxide as catalyzer, TiO2 nano powder and plastic are blended and dissolved in four hydrogen furan and produced into liquid, the liquid is dropped onto poly-lene fluorin ethylene board it is taken off after it is dried naturally, and then the ultraviolet catalyzer degraded plastic is obtained.

Owner:TSINGHUA UNIV

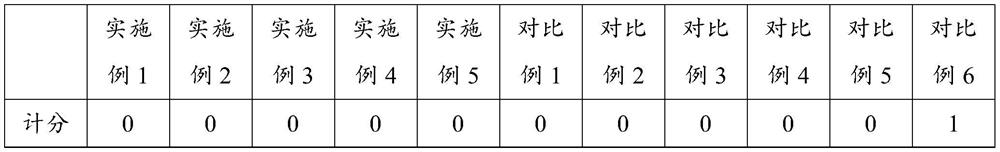

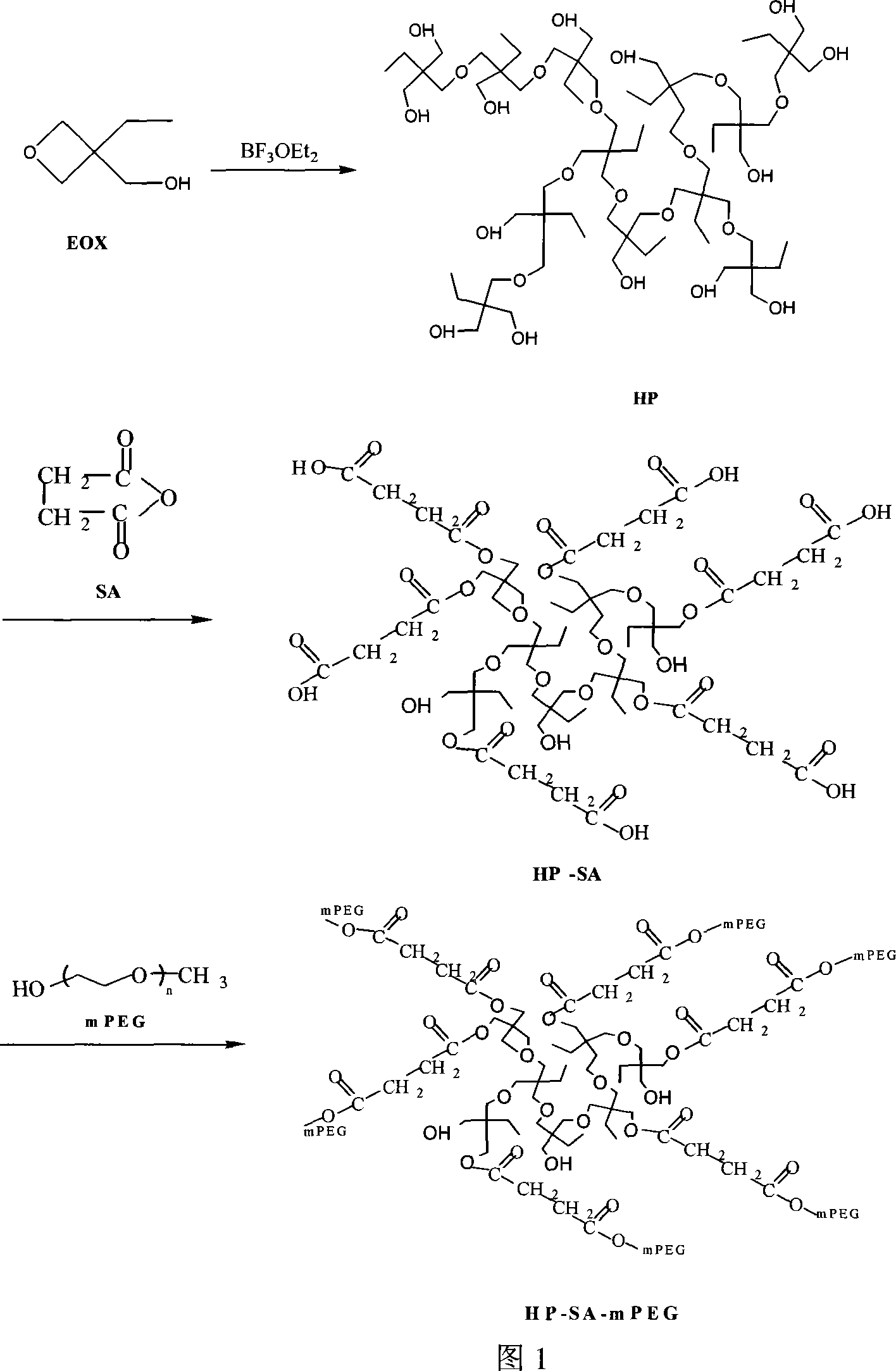

Degradable polyglycol modified ultra-branching polyether ester and preparation method thereof

InactiveCN101235134AIncrease the degree of branchingIncreased degradation ratePolyesterPolyethylene glycol

The invention discloses a degradable carbowax modified hyper branched polyester ether and a relative preparation method, belonging to medical material technical field. The preparation method comprises inducing monomer 3-ethyl-3-butoxy heterocyclic carbinol via inducer, processing cation open ring polymerization to obtain hydrophobic hyper branched polyether, adding succinic anhydride, reacting, adding methoxy polyethylene glyol, refluxing and dewatering, to obtain degradable carbowax modified hyper branched polyester ether which is represented as (CH3CH2C(CH2OH)2CH2O)m(CH3CH2C(CH2O)2CH2OH)n(CH3CH2C(CH2O)h(C4H2CH2CH2OCH3)p)I, wherein 0<=m<=20, 0<=n<=40, 0<=h<=40, 0<=i<=40, 6<=p<=85, m+n+h<=50. The invention can meet different biological medical applications, without any catalyst in synthesis and latent toxicity in product.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com