Hydrothermal preparation method capable of controlling thickness of tin selenide with sheet structure

A tin selenide, flake technology, applied in the direction of binary selenium/tellurium compound, metal selenide/telluride, nanotechnology, etc., can solve the problem of small thickness of flake pure phase SnSe, achieve small thickness and smooth operation process Simple, fast degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Weigh 1.2g of tartaric acid and dissolve it in 20mL of distilled water, stir until dissolved, then weigh 1mmol of tin dichloride and add it, stir until the solution is clear and transparent, and clear and transparent solution A is obtained. Weigh 1 mmol of selenium dioxide, 0.8 g of sodium hydroxide and 2 mmol of sodium borohydride into 15 mL of distilled water in sequence, and stir to obtain a transparent solution B.

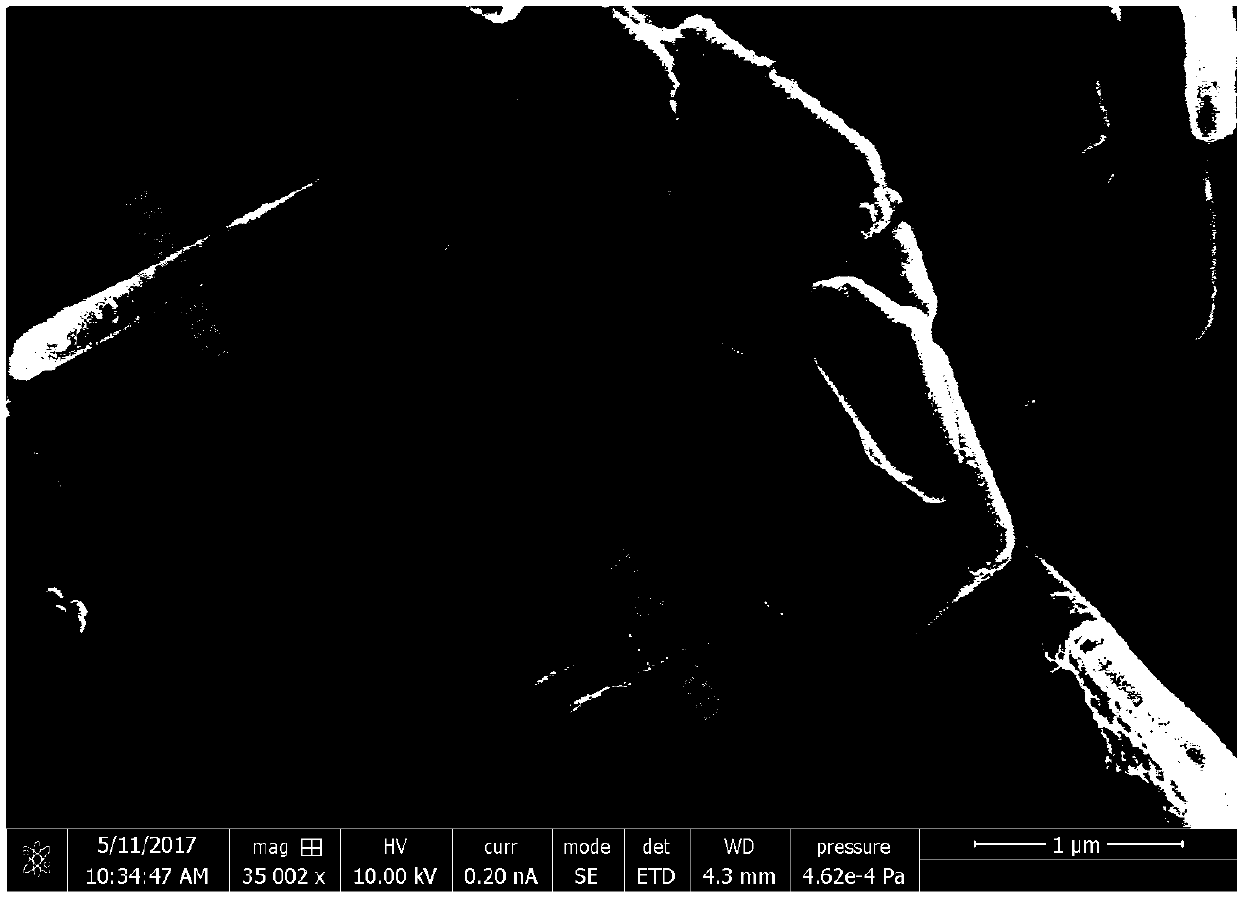

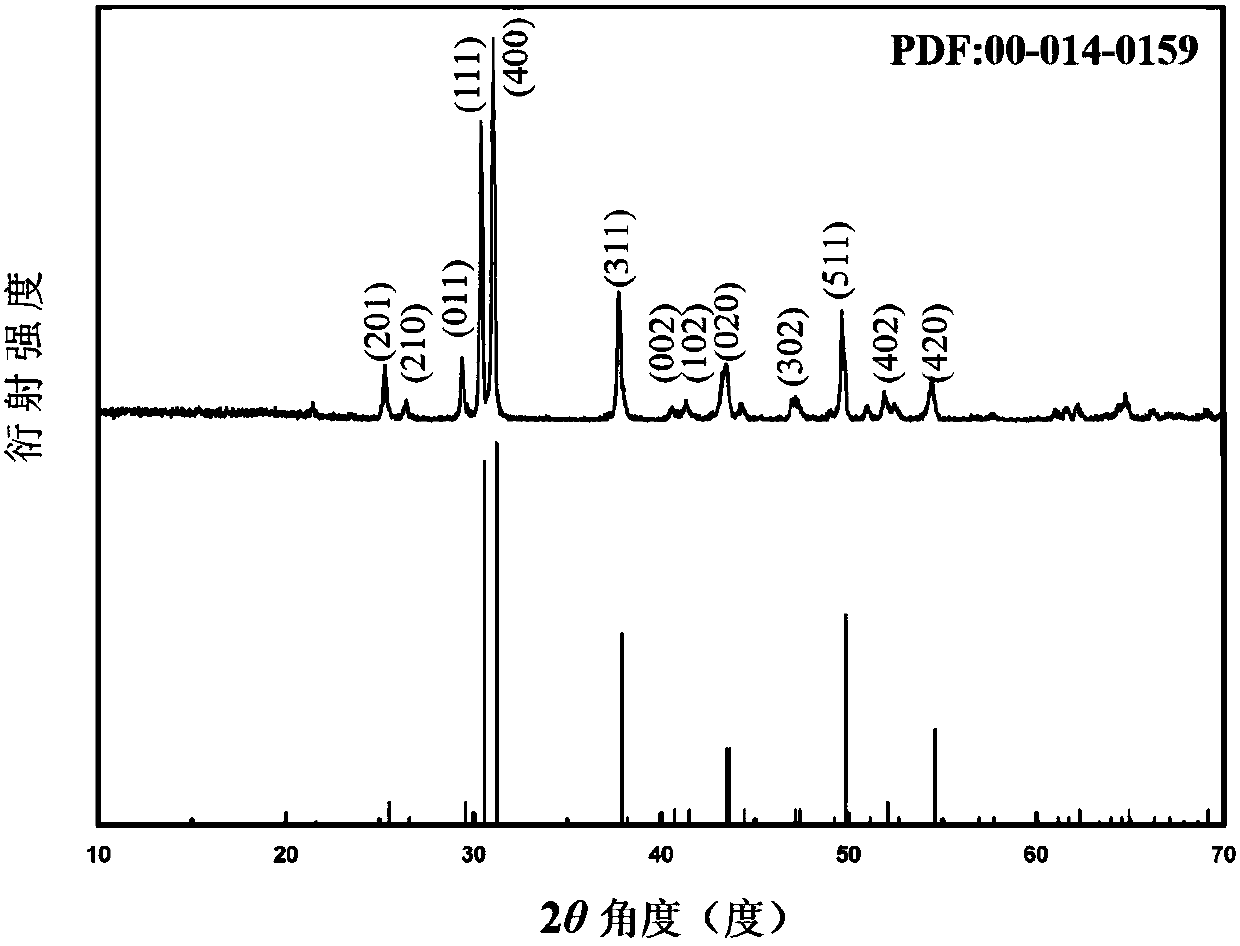

[0028] 2) Slowly add the clear and transparent solution A to the transparent solution B, stir at room temperature for 10 min, then add 1 mmol 1,10-phenanthroline and stir evenly, then transfer to a polytetrafluoroethylene-lined autoclave, and then Put it in an oven for reaction, start from room temperature, raise the temperature to 180°C at a rate of 5°C / min, keep it warm for 12 hours, then cool the reaction system to room temperature naturally, turn on the hydrothermal kettle, collect samples by centrifugation, and dry under vacuum at 60°C After 5 ho...

Embodiment 2

[0033] 1) Weigh 1.2g of tartaric acid and dissolve it in 20mL of distilled water, stir until dissolved, then weigh 1mmol of tin dichloride and add it, stir until the solution is clear and transparent, and clear and transparent solution A is obtained. Weigh 1 mmol of selenium dioxide, 0.8 g of sodium hydroxide and 2 mmol of sodium borohydride into 15 mL of distilled water in sequence, and stir to obtain a transparent solution B.

[0034] 2) Slowly add the clear and transparent solution A to the transparent solution B, stir at room temperature for 10 minutes, then add 1 mmol of 2,2-bipyridine and stir evenly, then transfer to a polytetrafluoroethylene-lined autoclave, and then put React in an oven, start from room temperature, raise the temperature to 180°C at a rate of 5°C / min, keep it warm for 12 hours, then cool the reaction system to room temperature naturally, turn on the hydrothermal kettle, collect samples by centrifugation, and dry at 90°C for 1 hour in vacuum Afterwards...

Embodiment 3

[0037] 1) Weigh 1.2g of tartaric acid and dissolve it in 20mL of distilled water, stir until dissolved, then weigh 1mmol of tin dichloride and add it, stir until the solution is clear and transparent, and clear and transparent solution A is obtained. Weigh 1 mmol of selenium dioxide, 0.8 g of sodium hydroxide and 2 mmol of sodium borohydride into 15 mL of distilled water in sequence, and stir to obtain a transparent solution B.

[0038] 2) Slowly add the clear and transparent solution A to the transparent solution B, stir at room temperature for 10 minutes, then add 1 mmol of 4,4-bipyridine and stir evenly, then transfer to a polytetrafluoroethylene-lined autoclave, and then put React in an oven, start from room temperature, raise the temperature to 180°C at a rate of 5°C / min, keep it warm for 12 hours, then cool the reaction system to room temperature naturally, turn on the hydrothermal kettle, collect samples by centrifugation, and dry under vacuum at 70°C for 2 hours Afterw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com