Acid controllable rigid temporary plugging agent and preparation method thereof

A temporary plugging agent and rigid technology, applied in the field of rigid temporary plugging agent and its preparation, can solve the problems of poor plugging strength, slow degradation speed, and difficult crushing, etc., and achieve the improvement of temporary plugging agent strength, degradation rate, and degradation fast speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

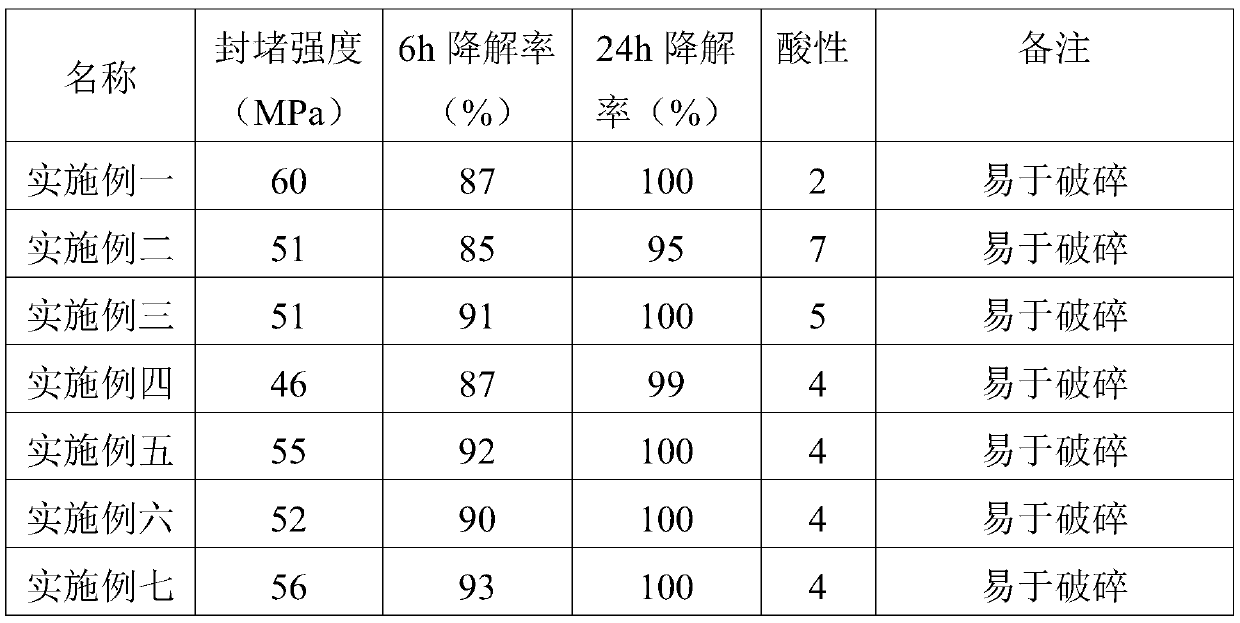

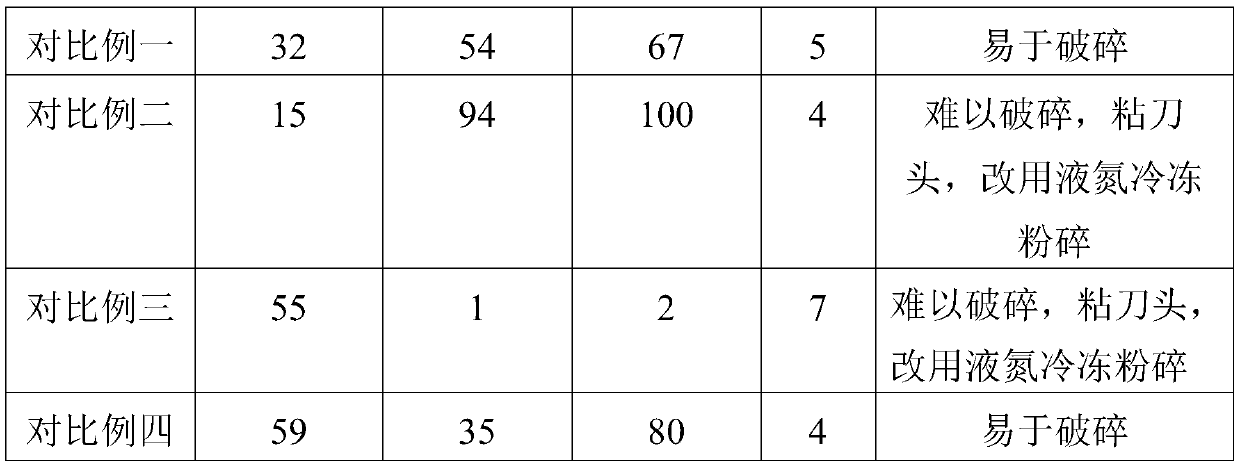

Examples

Embodiment 1

[0033]The rigid temporary plugging agent with controllable acidity described in this embodiment is composed of a resin matrix and an auxiliary agent as a raw material, and the resin matrix is composed of the following components in parts by mass: 50 parts of polylactic acid and 50 parts of polyglycolic acid; the auxiliary agent consists of the following Composition in parts by mass: 1 part of tetrabutyl titanate, 1 part of triphenyl phosphate, and 1 part of phenyl p-toluenesulfonate.

[0034] The method for preparing acidic controllable rigid temporary plugging agent described in this embodiment comprises the following steps:

[0035] S1. Weigh 50 parts of polylactic acid, 50 parts of polyglycolic acid and 1 part of tetrabutyl titanate, mix them in a high-speed mixer for 5 minutes, and then extrude and granulate them in a twin-screw extruder at 190-270°C to obtain the pre- mixed particles;

[0036] S2. Mix the pre-mixed granules obtained in step S1 with 1 part of triphenyl ...

Embodiment 2

[0038] The rigid temporary plugging agent with controllable acidity described in this embodiment, the raw material is composed of resin matrix and auxiliary agent, and the resin matrix is composed of the following components in parts by mass: 90 parts of polylactic acid, 10 parts of polyglycolic acid; the auxiliary agent consists of the following Composition in parts by mass: 4 parts of tetraisopropyl titanate, 100 parts of calcium carbonate, 5 parts of triphenyl phosphate, and 8 parts of diethyl p-oxalate.

[0039] The method for preparing acidic controllable rigid temporary plugging agent described in this embodiment comprises the following steps:

[0040] S1. Weigh 90 parts of polylactic acid, 10 parts of polyglycolic acid and 4 parts of tetraisopropyl titanate, mix them in a high-speed mixer for 5 minutes, and then extrude and granulate them in a twin-screw extruder at 190-270°C to obtain premixed granules;

[0041] S2. Mix the premixed granules obtained in step S1 with...

Embodiment 3

[0043] The rigid temporary plugging agent with controllable acidity described in this embodiment is made of a resin matrix and auxiliary agents as raw materials, and the resin matrix is composed of the following components in parts by mass: 70 parts of polylactic acid and 30 parts of polyglycolic acid; the auxiliary agent consists of the following The composition of parts by mass: 2 parts of tetraisopropyl titanate, 2 parts of tetrabutyl titanate, 50 parts of hydrotalcite, 5 parts of triphenyl phosphate, 8 parts of diethyl p-oxalate, 2 parts of dimethyl oxalate .

[0044] The method for preparing acidic controllable rigid temporary plugging agent described in this embodiment comprises the following steps:

[0045] S1. Weigh 70 parts of polylactic acid, 30 parts of polyglycolic acid, 2 parts of tetraisopropyl titanate, and 2 parts of tetrabutyl titanate, mix them in a high-speed mixer for 5 minutes, and then mix them in a twin-screw extruder at 190~ Extrude and granulate at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com