Patents

Literature

493 results about "Dimethyl oxalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl oxalate is the organic compound with the formula (CH₃O₂C)₂. It is the dimethyl ester of oxalic acid. Dimethyl oxalate is a colorless or white solid that is soluble in water.

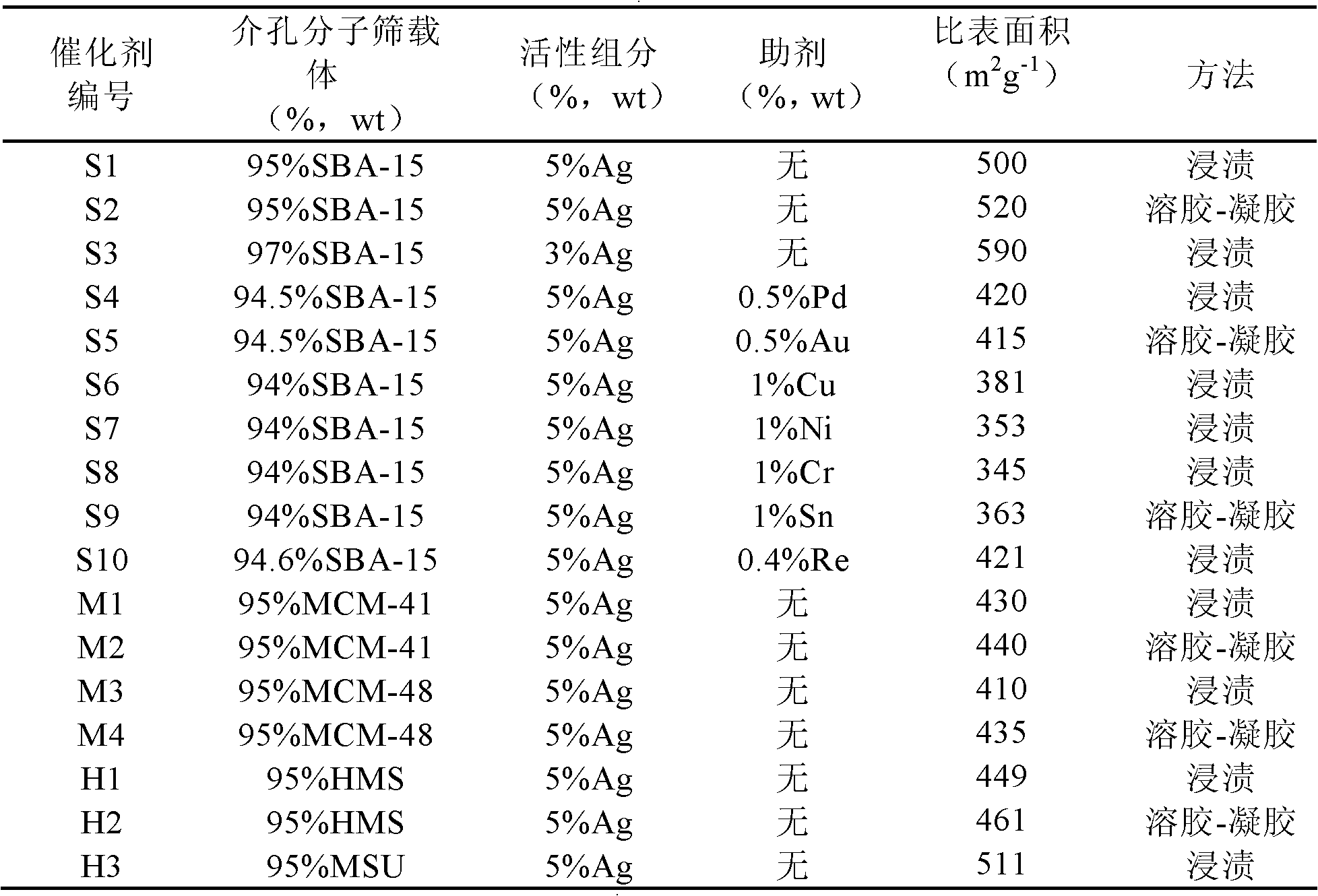

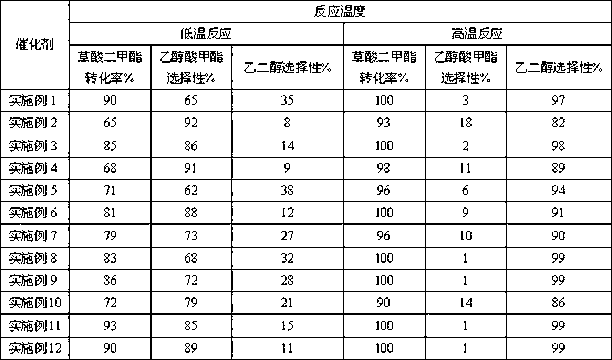

Effective catalyst used in hydrogenation of dimethyl oxalate to synthesizing ethylene glycol and production method thereof

InactiveCN101455976AGood dispersionHigh selectivityMolecular sieve catalystsOrganic compound preparationMolecular sieveNitrate

The invention provides an efficient catalyst used in glycol synthesis through dimethyl oxalate hydrogenation, and a preparation method thereof. A hexagonal mesoporous silicon molecular sieve is taken as a carrier which carries copper and additive metal, and the mass ratio of the copper to the additive metal to the hexagonal mesoporous silicon molecular sieve is 0.25-0.6:0.04-0.4:1. The preparation method comprises the following steps: soluble nitrates of the copper and the additive metal are compounded to be a metal ion solution with the total concentration between 0.5 and 2 M in water; the metal ion solution is slowly dripped into an aqueous solution containing the hexagonal mesoporous silicon molecular sieve; the adsorption temperature is between 20 and 90 DEG C; the solutions continue to be stirred at a constant temperature, so as to prepare a precursor; and the precursor is washed, dried, progressively heated to 250 to 950 DEG C and roasted, so as to obtain the powdered efficient catalyst. The catalyst has the advantages that the catalyst has a regular pore structure and high specific surface area, and can be better dispersed after an active copper species is stabilized by the additive metal and dispersed by the hexagonal mesoporous silicon molecular sieve, and the catalyst shows excellent hydrogenation activity and glycol selectivity in the reaction of synthesizing glycol through the catalytic hydrogenation of dimethyl oxalate.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

Method for preparing catalyst used in method for preparing ethanediol by dimethyl oxalate hydrogenation

InactiveCN101411990AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationCopper nitrateMesoporous silica

The invention relates to the field of chemical technology, in particular to a method for preparing a catalyst for hydrogenating dimethyl oxalate to prepare glycol. The method comprises the following steps: step one, copper nitrate is used to prepare a cuprammonium complex compound; step two, the cuprammonium complex compound is added with a mesoporous silica molecular sieve, is dripped with distilled water, and is filtered, washed, dried and roasted to prepare a catalyst precursor; and step three, the catalyst precursor is reduced in a hydrogen-nitrogen mixed atmosphere to prepare the catalyst. In the catalyst, according to mass percentage, the content of copper is between 5 and 40 percent; and the content of the mesoporous silica molecular sieve is between 60 and 95 percent. The method has the advantages that a silicon copper catalyst prepared through the new method has high catalytic activity and glycol selectivity in the reaction of hydrogenating the dimethyl oxalate to prepare the glycol, has long service life, smooth reaction performance and easy control.

Owner:FUDAN UNIV

Catalyst for synthesizing oxalic ester and preparation method thereof

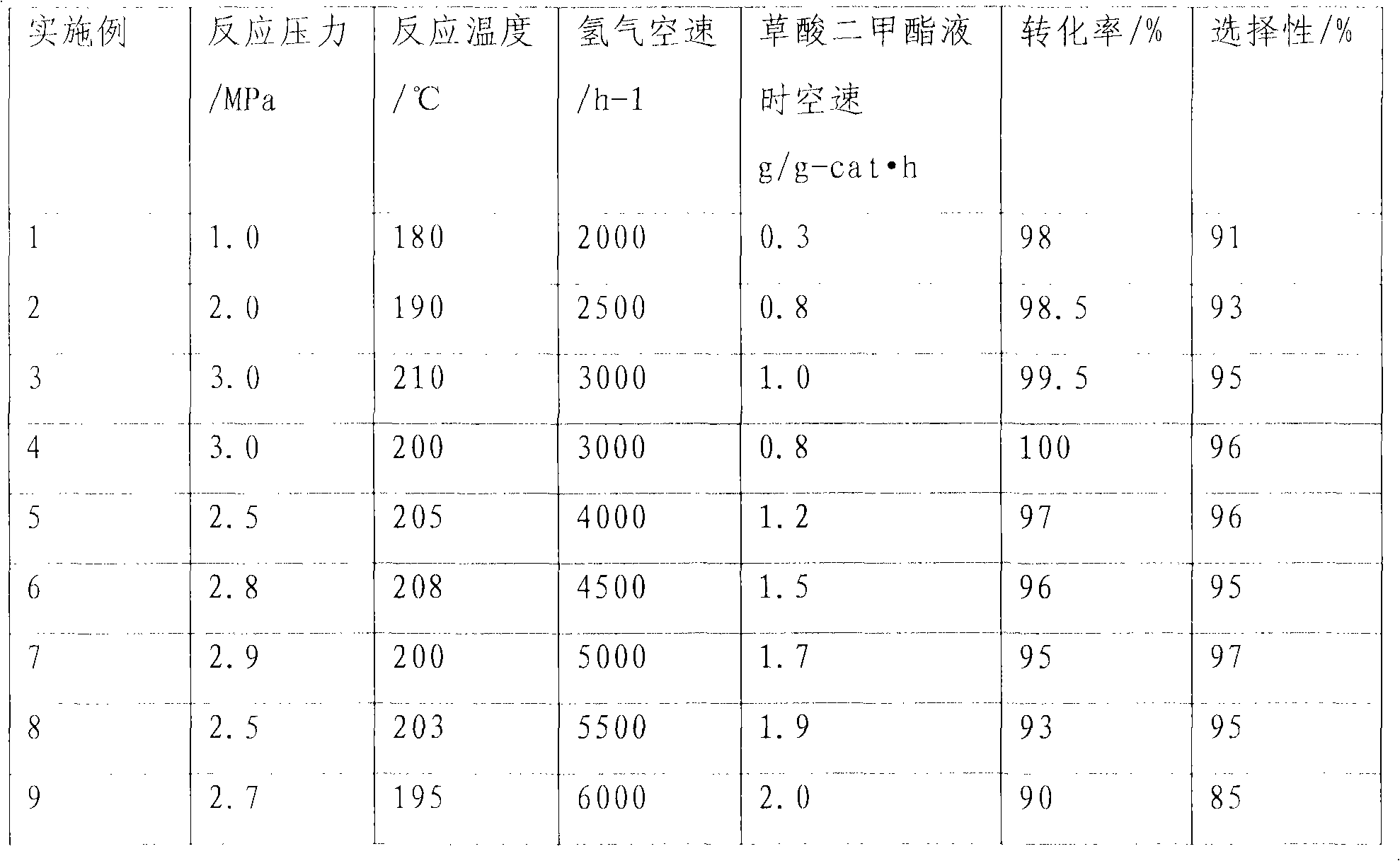

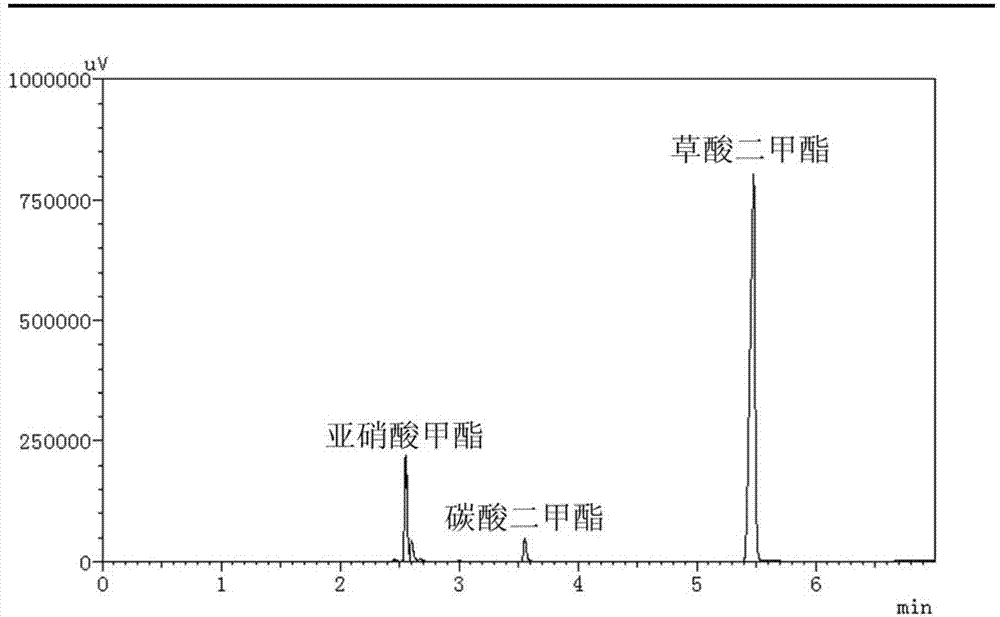

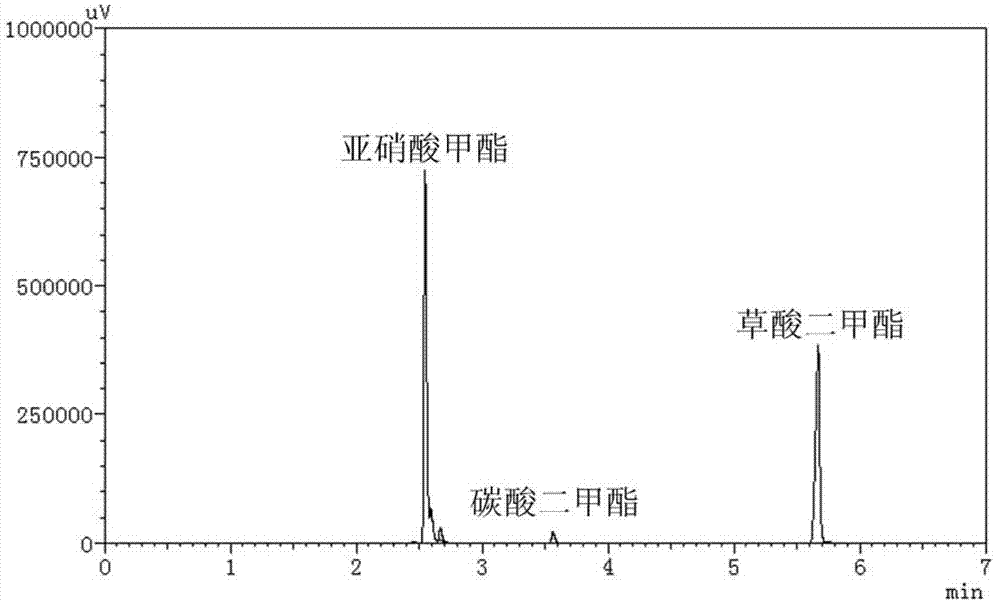

ActiveCN101596455ASmooth responseHigh reactivityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsActive componentDistilled water

The invention relates to a catalyst for synthesizing oxalic ester and a preparation method thereof. The catalyst contains active components of palladium and lanthanum which respectively account for 0.3-1.5 percent and 0.01-8 percent of the weight of a carrier, and the carrier is Alpha-Al2O3. The preparation method comprises the following steps: placing the Alpha-Al2O3 into alkaline solution, and processing the Alpha-Al2O3 in a high-pressure kettle under a temperature of 150-350 DEG C; washing the Alpha-Al2O3 with distilled water to neutral; drying the Alpha-Al2O3 under the temperature of 100-200 DEG C; dipping the Alpha-Al2O3 in solution with the concentration of lanthanum being 0.003-0.02 M, drying and baking; and dipping the Alpha-Al2O3 in solution with the concentration of palladium being 0.003-0.02 M, drying and baking under a temperature of 300-700 DEG C. The catalyst is applied to a reaction for synthesizing dimethyl oxalate by carbon monoxide and methyl nitrite and has the advantages of higher reacting activity and selectivity, long service life, stable reaction and easy control; and the space time yield of the dimethyl oxalate is 830g / L.h-1130g / L.h.

Owner:PETROCHINA CO LTD

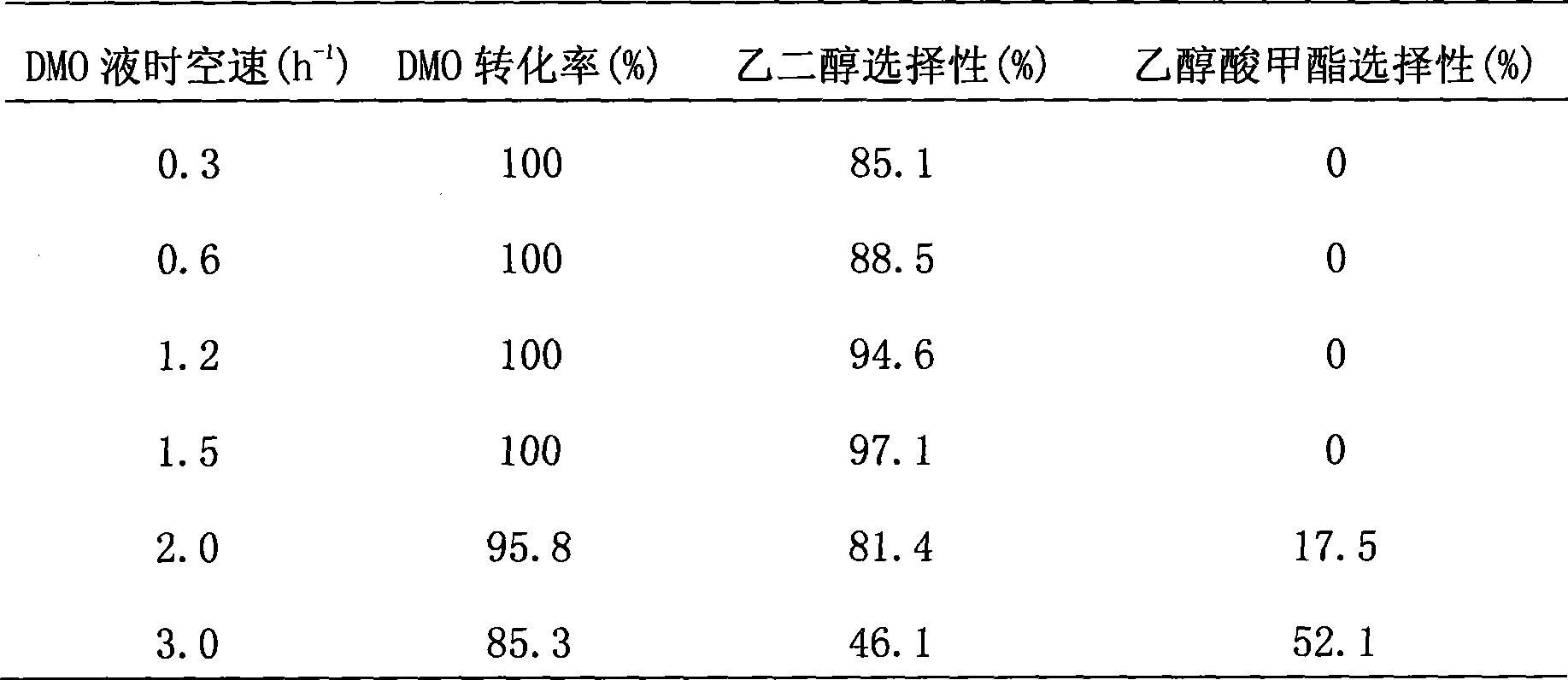

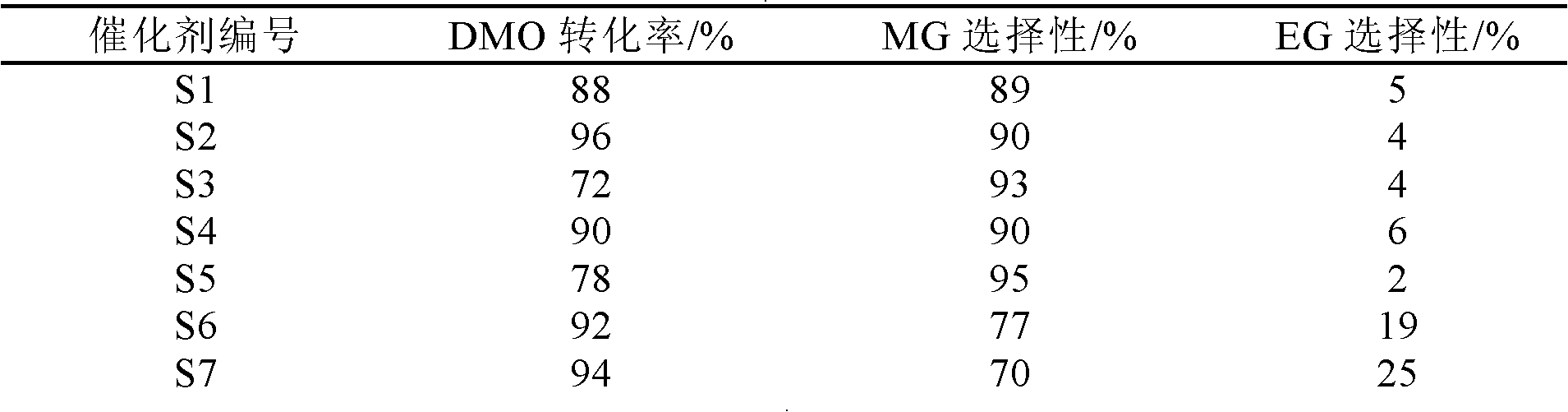

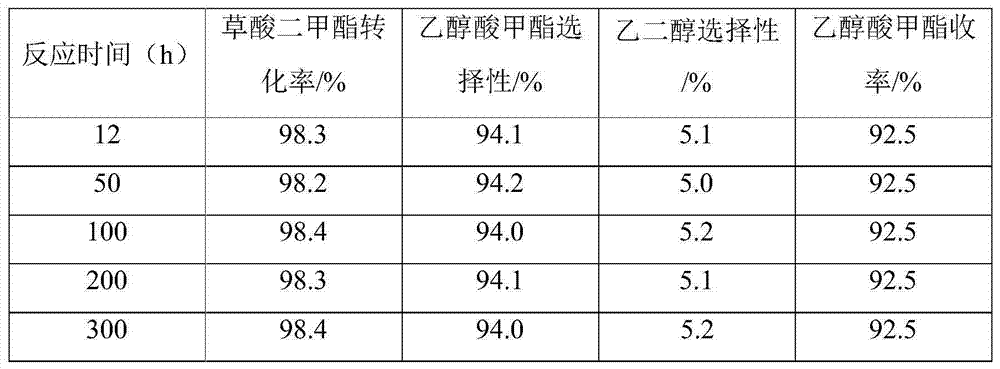

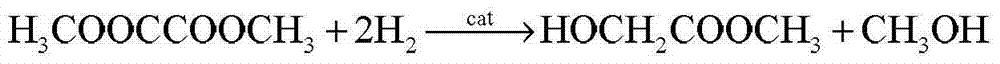

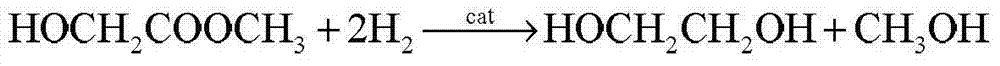

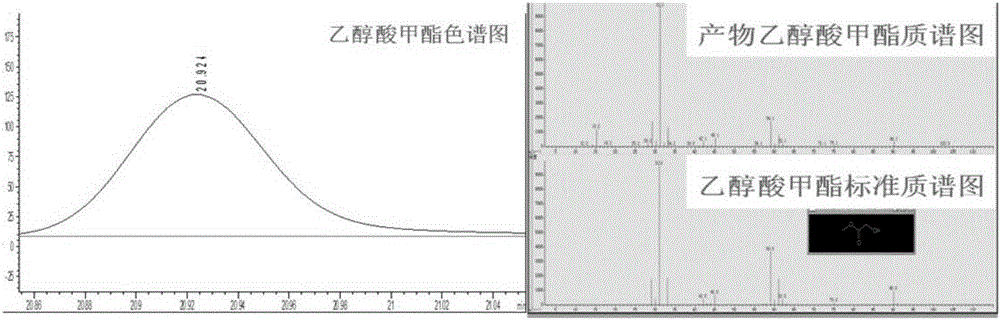

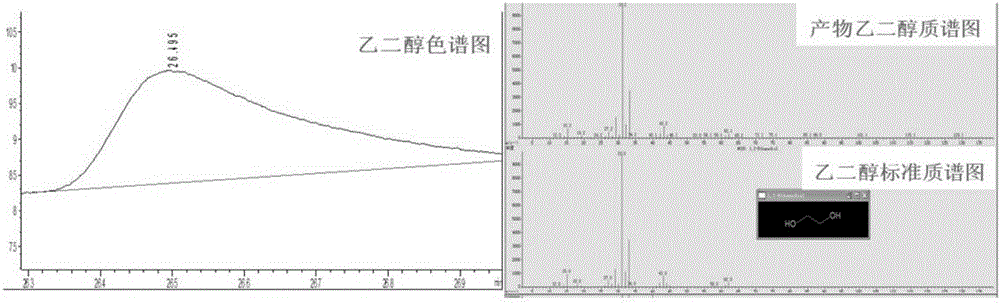

Method for synthesizing methyl glycollate and ethylene glycol by dimethyl oxalate hydrogenation

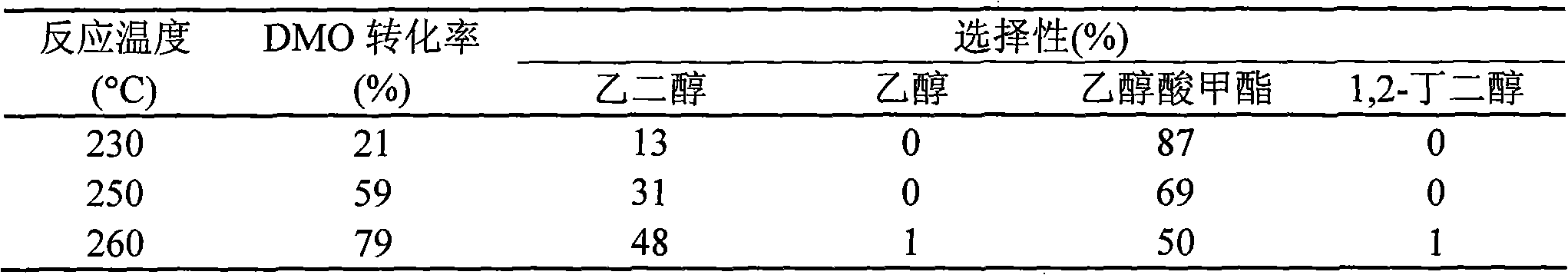

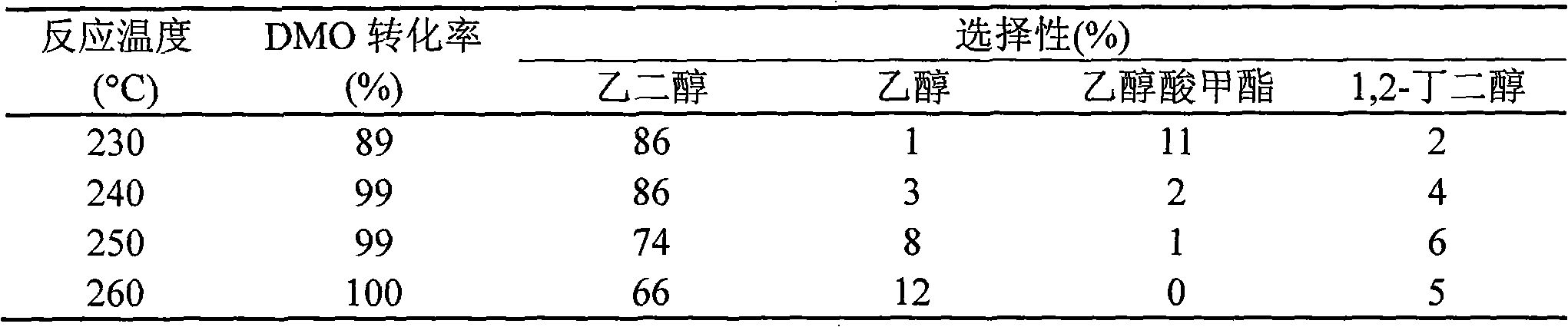

ActiveCN102336666AEasy to makeImprove performanceMolecular sieve catalystsOrganic compound preparationHydrogen pressureHydrogenation reaction

The invention discloses a method for synthesizing methyl glycollate and ethylene glycol by dimethyl oxalate hydrogenation. The method comprises the following steps of: performing hydrogenation reaction on dimethyl oxalate serving as a raw material under the action of a catalyst at the temperature of between 120 and 300 DEG C under the hydrogen pressure of 0.2 to 10.0MPa, performing fixed bed continuous reaction, and thus obtaining target products, namely the methyl glycollate and the ethylene glycol. The method is mild in reaction conditions and environmentally-friendly, the conversion rate of the dimethyl oxalate reaches over 99 percent, the total selectivity of the methyl glycollate and the ethylene glycol reaches over 98 percent, the selectivity of the methyl glycollate serving as a main product reaches 95 percent, and a new effective path is provided for preparing the methyl glycollate and the ethylene glycol by dimethyl oxalate hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

Catalyst for synthesizing methyl glycolate through hydrogenation by dimethyl oxalate and preparation method thereof

ActiveCN101700496AHigh reactivityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationDimethyl oxalateHigh selectivity

The invention discloses a catalyst for synthesizing methyl glycolate through hydrogenation by dimethyl oxalate and a preparation method thereof. The catalyst takes metal copper as a main active component, silver and manganese as auxiliary components and Al2O3 as a carrier, wherein the content of metal copper accounts for 25-50% of the mass of the catalyst, the content of metal silver accounts for 5-15% of the mass of the catalyst, the content of metal manganese accounts for 8-20%, and the content of Al2O3 accounts for 15-40% of the mass of the catalyst. In the reaction for synthesizing methyl glycolate through hydrogenation by dimethyl oxalate, the catalyst of the invention has the advantages of high reaction activity, simple preparation method, easily obtained raw material resource, low price, lower cost and longer service life, the methyl glycolate has high selectivity, stable reaction performance and easy controllability.

Owner:JIANGSU JINJU ALLOY MATERIAL

Method for preparing ethylene glycol by using dimethyl oxalate plus hydrogen

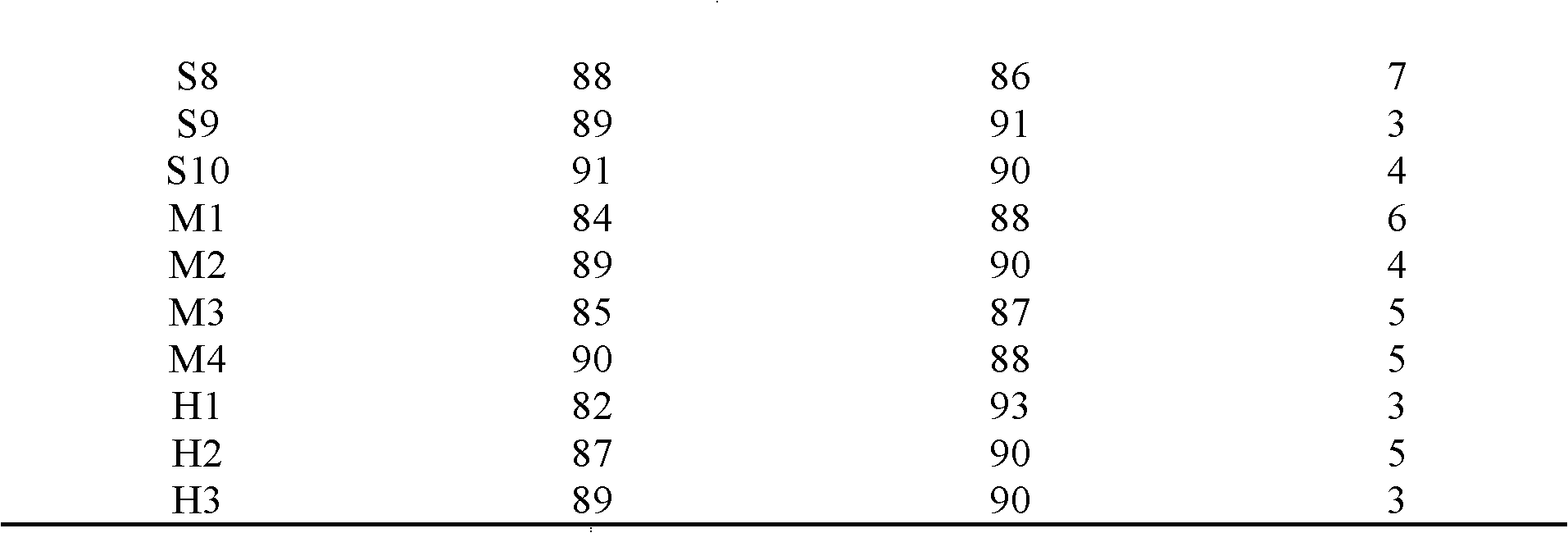

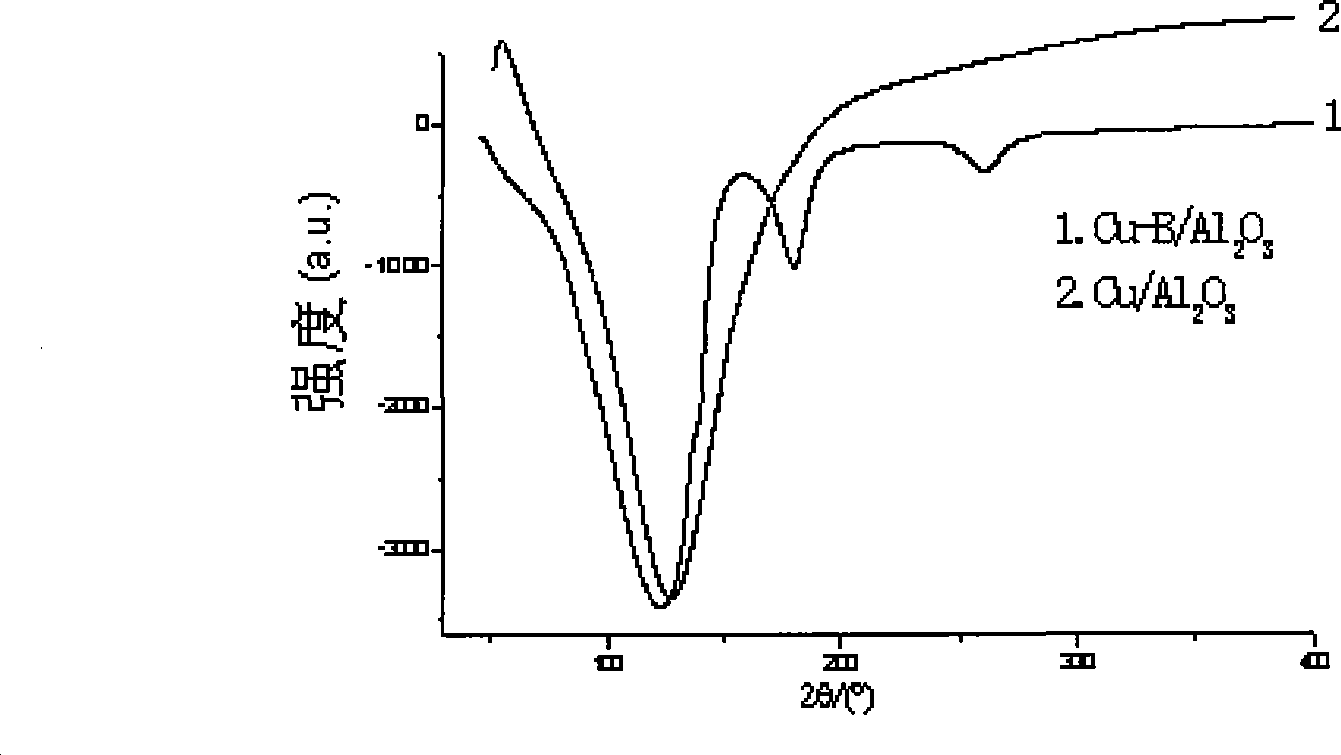

InactiveCN101445426ALow costSimple preparation processOrganic compound preparationHydroxy compound preparationHydrogenReaction temperature

The invention discloses a method for preparing ethylene glycol by using dimethyl oxalate plus hydrogen. The method comprises the following steps: in the presence of a catalyst, methanol solution containing dimethyl oxalate is contacted with hydrogen, and then ethylene glycol is acquired. The method is characterized in that according to weight percentage, the catalyst consists of the following components: 70 to 80 percent of carriers, 15 to 22 percent of copper, 5 to 8 percent of boron, and 0 to 4 percent of active metal additives. The method has the characteristics of low reaction temperature, high reaction activity, good selectivity, simple catalyst preparation process and low cost, and is easy for conducting industrial production.

Owner:SHANGHAI UNIV OF ENG SCI +1

Catalyzer for CO low-voltage gas-phase synthesizing of oxalic ester and method of preparing the same

InactiveCN101138722AOrganic compound preparationCarboxylic acid esters preparationTitanium metalGas phase

The present invention belongs to the oxalate preparation technical field and aims to provide a catalyst for synthesis of low pressure, high activity and high selectivity oxalate in a CO low-pressure gas phase, and a preparation method for the catalyst. The catalyst mainly uses the palladium metal as a main activated component, titanium and cerium as a promoter, and modified Alfa-Al2O3 as a carrier. The select content of palladium metal is 0.1 to 3.0 percent of the carrier weight, the content of the titanium metal is 0.02 to 1.5 percent of the carrier weight, and the content of the cerium metal is 0.01 to 0.75 percent of the carrier weight. The catalyst is manufactured with the method of immersion. The catalyst is manufactured with the method of immersion. Proven by experiments, the catalyst of the present invention is provided with the very high reaction activity and oxalate selectivity in the reaction to synthesize dimethyl oxalate or diethyl oxalate with carbon monoxide and nitrite. Moreover, the catalyst can resist affection by oxygen, hydrogen, water steam and other impurities. The catalyst is provided with the long usable life and the stable reaction performance, and can be easily controlled.

Owner:TIANJIN UNIV

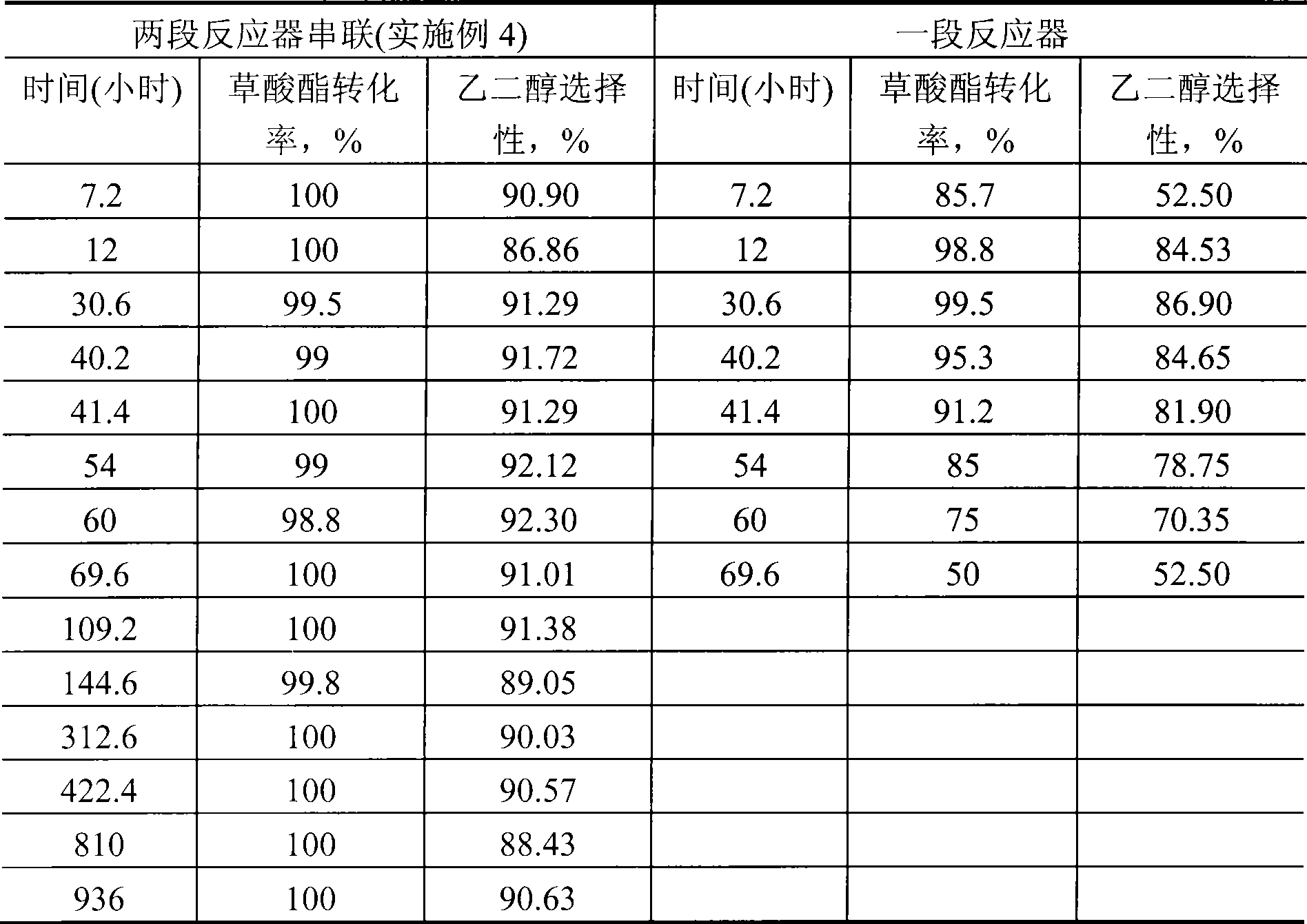

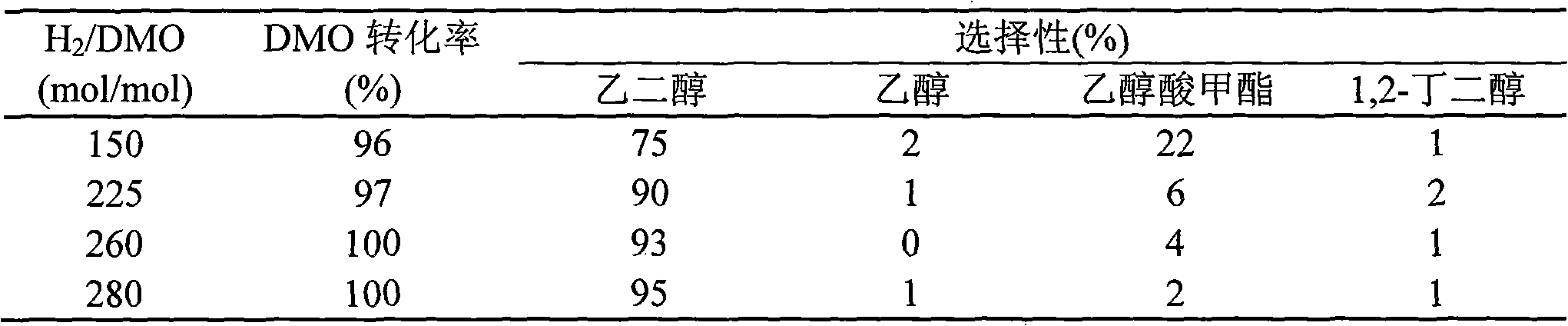

Method for preparing ethylene glycol from oxalic ester

ActiveCN101475441AImprove technical effectOrganic compound preparationHydroxy compound preparationOxalateHydrogen

The invention relates to a method for producing glycol from oxalate, which mainly solves the problem that the prior art is low in the selectivity of target products and short in the regeneration period of catalysts. The method adopts oxalate as raw material, and comprises the following steps that: (a) hydrogen and a first stream of raw material enter a first reaction zone to be in contact with a copper-bearing catalyst I so as to form a first stream of glycol-containing reaction effluent; and (b) the first stream of reaction effluent and a second stream of raw material enter at least one second reaction zone to be in contact with a copper-bearing catalyst II so as to form a second stream of glycol-containing reaction effluent, wherein the molar ratio of the first stream of raw material to the second stream of raw material is 0.1-10:1; the molar ratio of the hydrogen to the sum of the first and second streams of raw material is 20-300:1; the first stream of raw material is selected from dimethyl oxalate, diethyl oxalate or a mixture thereof; and the second stream of raw material is selected from dimethyl oxalate, diethyl oxalate or a mixture thereof. The technical proposal well solves the problem, and the method can be used in the industrial production for increasing the yield of glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for gas-phase synthesis of oxalate and its preparing process

InactiveCN1381310AHigh reactivityHigh selectivityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsNitriteGas phase

A catalyst for gas-phase synthesis of dimethyl (or diethyl) oxalate from CO and nitrite is prepared from alpha-Al2O3 as carrier and Ce and Pd as active components through the dipping method. Its advantages are high reaction activity and selectivity, long service life and easy control of reaction.

Owner:EAST CHINA UNIV OF SCI & TECH

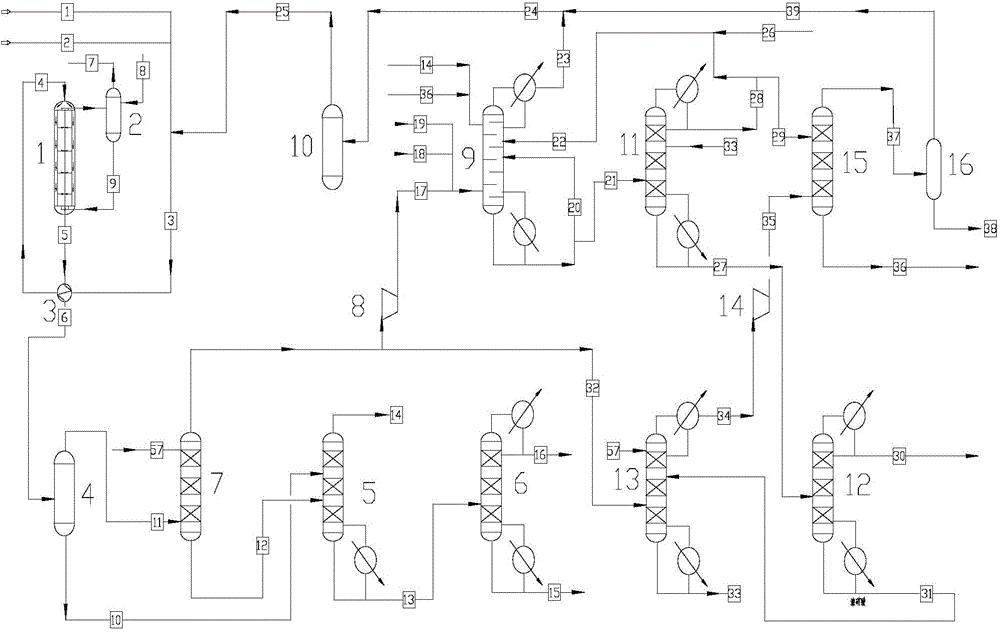

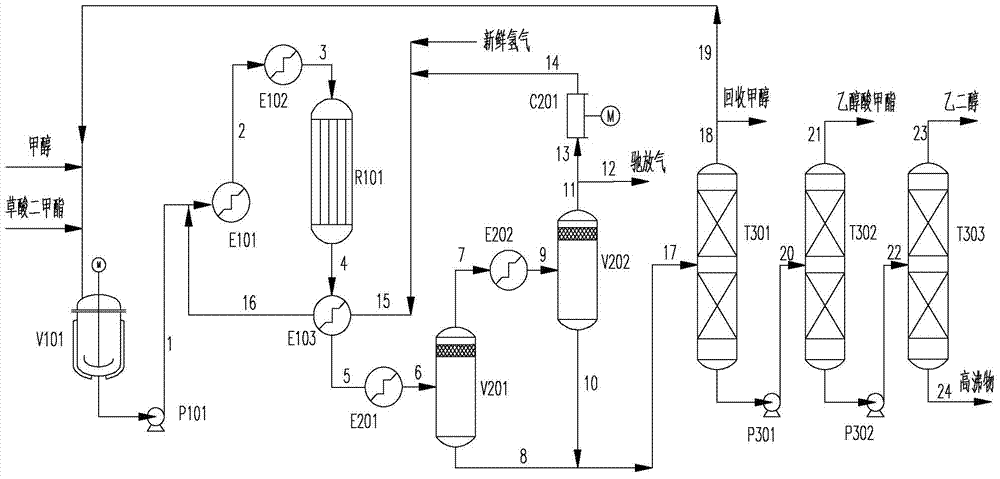

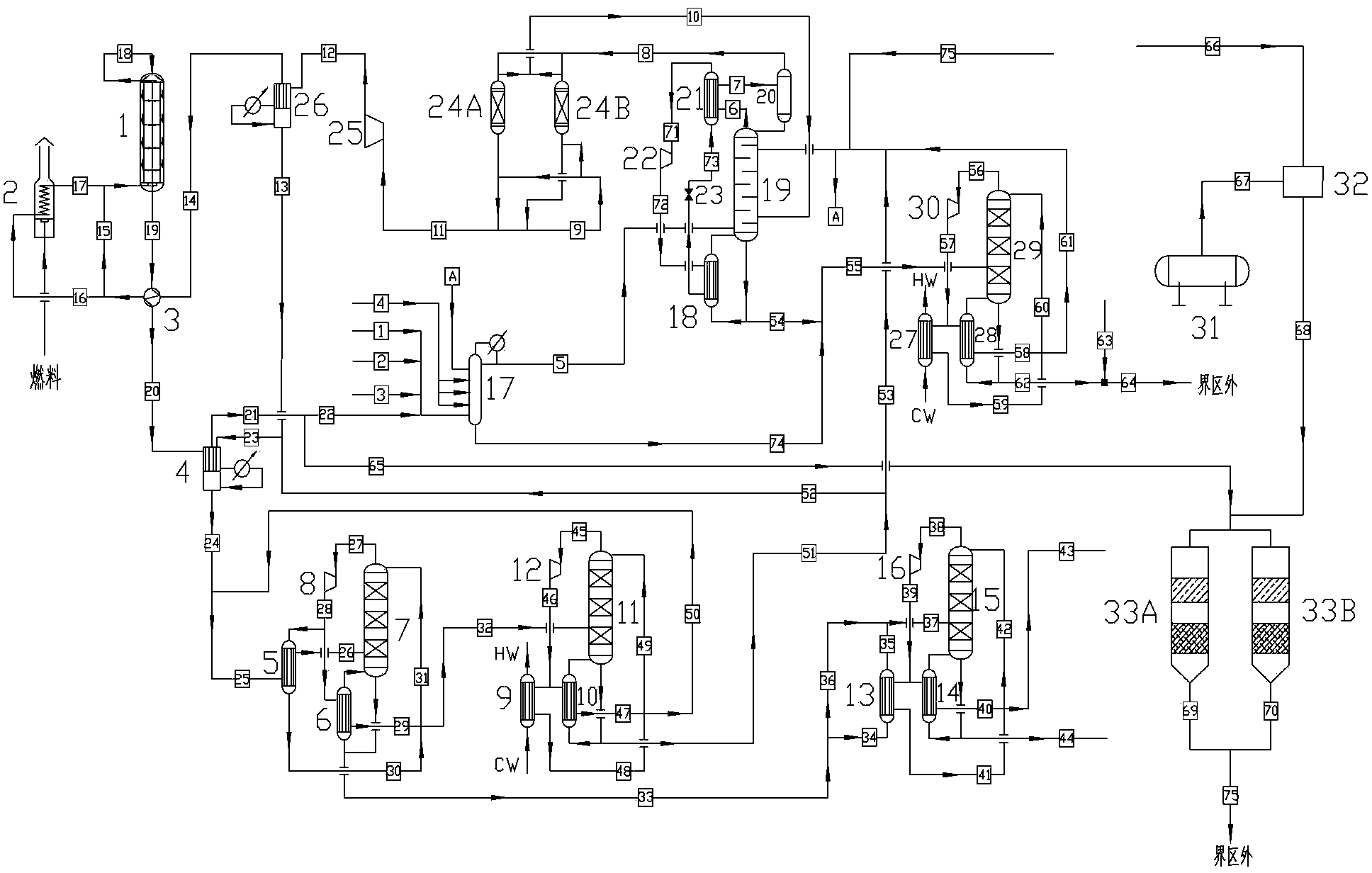

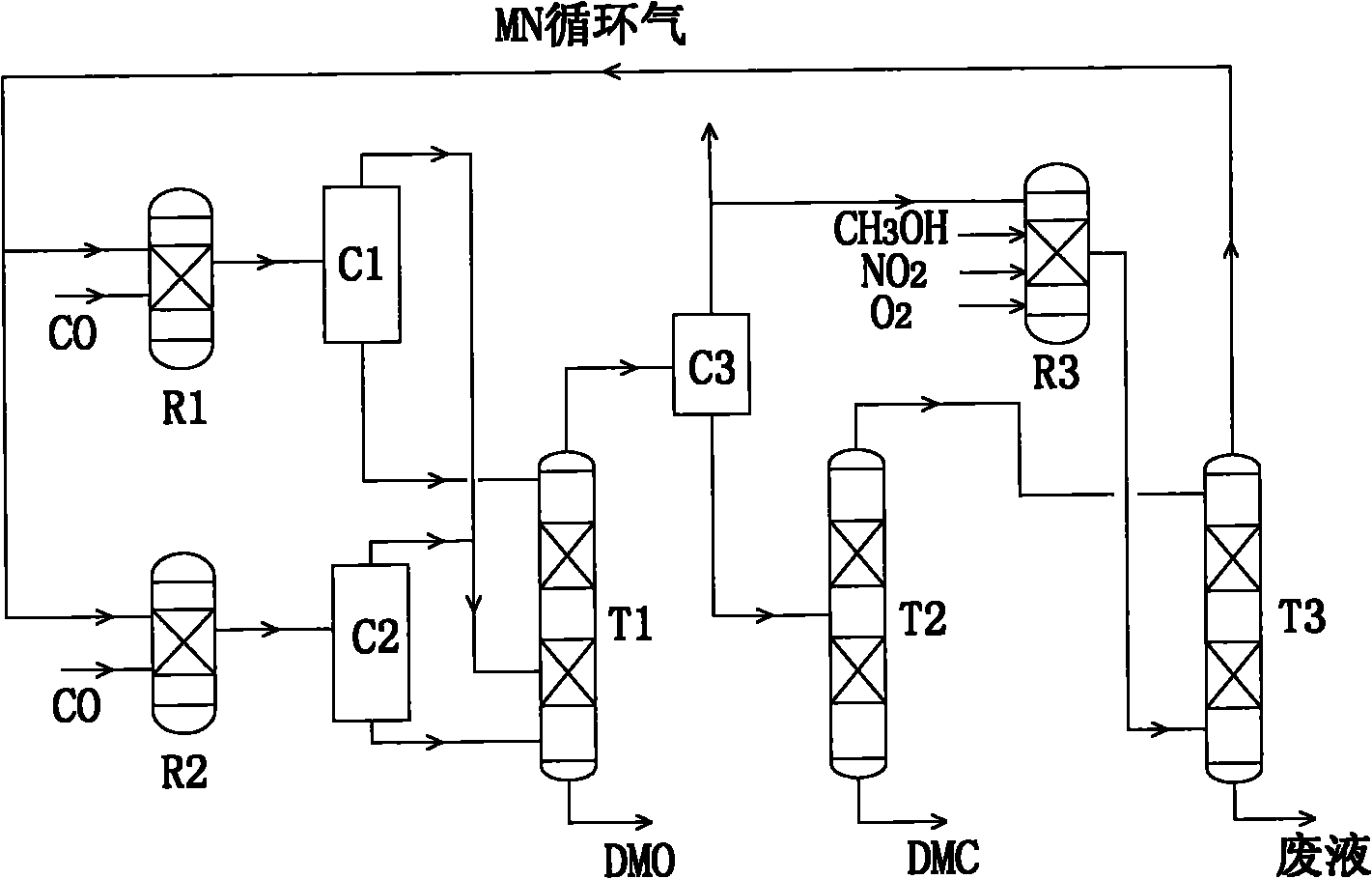

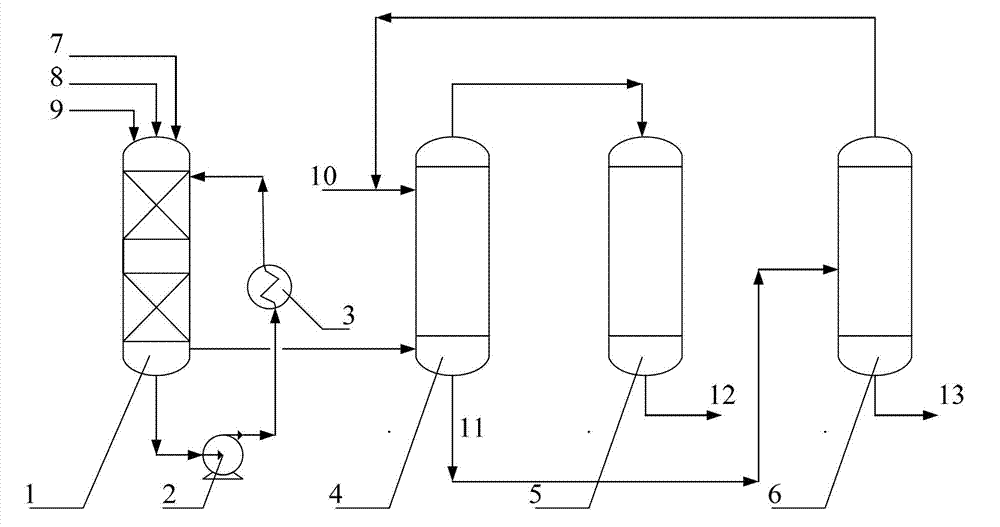

Technology and device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation

ActiveCN104098441AConducive to large-scale productionSmall volume requirementOrganic compound preparationEnergy inputSeparation technologyHigh pressure

The invention relates to a technology and a device system for producing dimethyl oxalate by high-pressure carbonylation of industrial synthesis gases and producing ethylene glycol through dimethyl oxalate hydrogenation. The technology comprises the following steps: adopting industrial NO, O2 and methanol as raw materials for an esterification reaction to produce methyl nitrite; adopting industrial CO and methyl nitrite for a carbonylation reaction in a plate reactor to produce carbonylation products, which mainly include dimethyl oxalate and dimethyl carbonate; separating the carbonylation products to obtain dimethyl carbonate products; subsequently adding hydrogen into dimethyl oxalate in the plate reactor to produce ethylene glycol products; conducting the coupling recovery treatment on waste acids in the esterification reaction and purge gases in the carbonylation reaction for recycling. The device system comprises an esterification reaction system, a carbonylation reaction system, a coupling recovery system for purge gases and waste acids and a hydrogenation reaction system. The technology has the characteristic that device consumption is remarkably reduced, and particularly the nitric acid waste liquid recycling and purge gas recycling technologies as well as the separation technologies thereof are highly coupled; recycling of the raw materials in reaction waste gases is realized, and the effect is remarkable.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

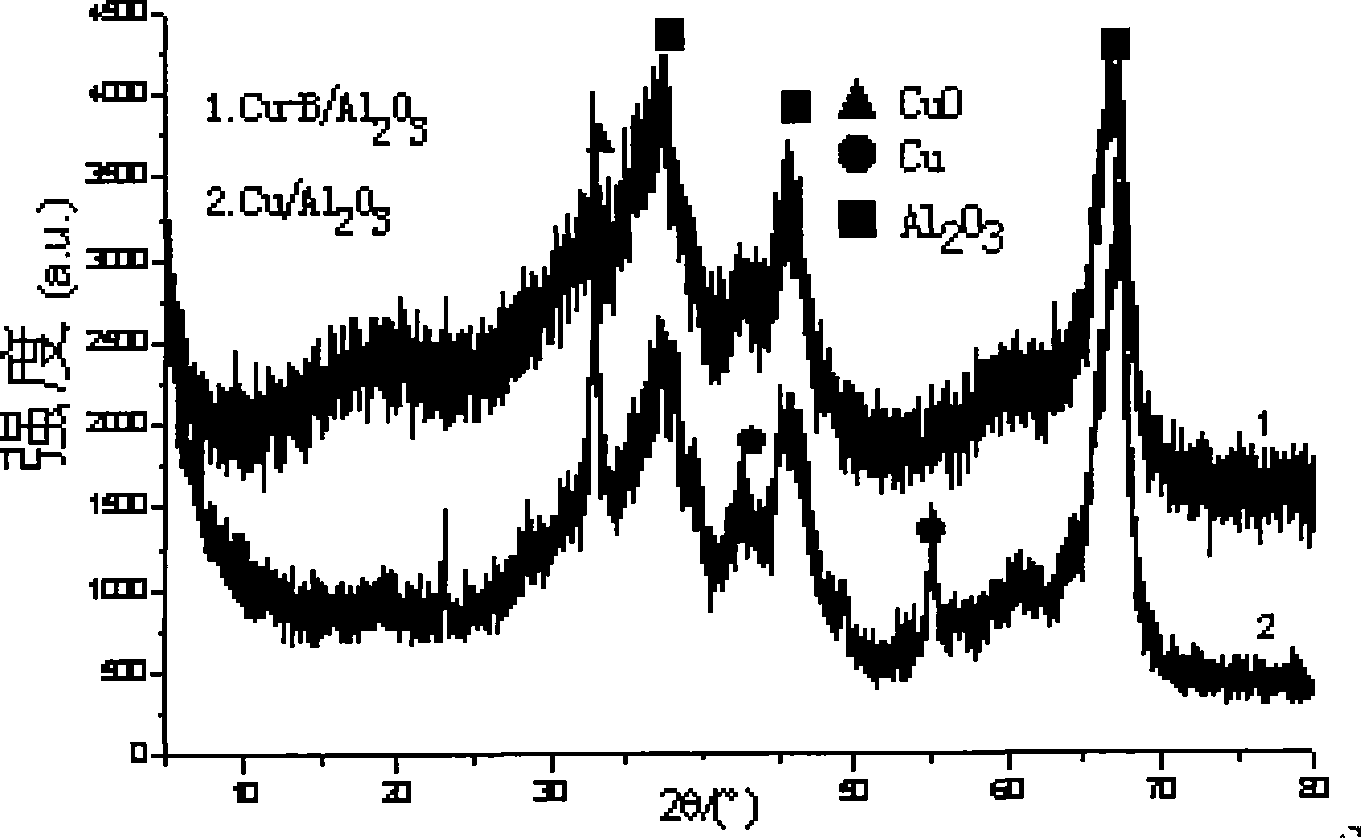

Catalyst for preparing ethylene glycol by dimethyl oxalate hydrogenation, and preparation and use thereof

ActiveCN102151568ALow investment costLow reaction temperatureOrganic compound preparationHydroxy compound preparationIridiumHigh activity

The invention discloses a catalyst for preparing ethylene glycol by dimethyl oxalate hydrogenation, which is characterized by containing the following components by weight percent: 30 to 60% of active metal, 5 to 30% of metal additive and 20 to 60% of carrier, wherein the active metal is one or any combination of more than two of the group consisting of zinc, magnesium, aluminum, silver, ruthenium and iridium, and the carrier is silicon dioxide. The invention further discloses a preparation method of the catalyst, comprising the steps of: 1) mixing and dissolving soluble salts of the copper and soluble salts of the metal additive to prepare aqueous solution, adding a silicon source of the carrier to the aqueous solution to form a mixed liquid A; 2) dissolving precipitating agent in water,dropwise adding the mixed solution A to aqueous solution B under stir, and put the resultant solution on standing; 3) filtering; 4) drying; 5) calcining; 6) forming; and 7) reducing. The catalyst of the invention has the advantages of moderate reaction conditions, high activity, good stability, high selectivity, environmental friendliness and simple preparation process.

Owner:山东华鲁恒升集团德化设计研究有限公司

Glycol catalyst prepared by dimethyl oxalate hydrogenation and preparation method thereof

ActiveCN101607205AAvoid structural damageHigh activityOrganic compound preparationHydroxy compound preparationHydrogenCopper nitrate

The invention discloses a glycol catalyst prepared by dimethyl oxalate hydrogenation and a preparation method thereof, which is characterized in that the catalyst takes copper nitrate or copper acetate as copper source, ludox as silicon source, ammonia, ammonium bicarbonate or urea as precipitant which are coprecipitated to prepare CuSi catalyst forerunner; one or two of Zn, Fe, Ag, and Pd is soaked in the catalyst forerunner and used as additive agent, and then mixture is baked in the temperature of 200 to 500 DEG C, and finally is beaten into pieces and formed to obtain the catalyst. The catalyst comprises 20-50% of Cuo, 0.005%-3% of additive agent and the rest of SiO2 according to mass percent of oxygen compound, wherein additive agent is oxidate of one or two of Zn, Fe, Ag, and Pd. Before using, the catalyst is reduced by hydrogen and nitrogen combination gas containing 1% to 90% of hydrogen; and the reduction temperature is 150 to 500 DEG C.

Owner:HAISO TECH

Catalyst for preparing methyl glycolate through dimethyl oxalate hydrogenation and synthetic method of catalyst

ActiveCN103785408AHigh selectivitySimple preparation processOrganic compound preparationCarboxylic acid esters preparationCopperBULK ACTIVE INGREDIENT

The invention discloses a catalyst for preparing methyl glycolate through dimethyl oxalate hydrogenation and a synthetic method of the catalyst, belonging to the technical field of preparation of methyl glycolate catalysts. The catalyst is prepared by taking NaOH as a precipitator, wherein Cu is a main active ingredient of the catalyst, alkaline silica sol serves as a carrier, one or more base metals in Mn, Zr and Zn serve as aids, the mass content of metal copper is 10-40 percent, the content of the other base metal aids is 5-10 percent, and the carrier content is 60-80 percent. According to the catalyst, the preparation method is simple, raw materials are readily available, preparation repeatability is high, high reaction activity is achieved in a methyl glycolate preparation reaction through the dimethyl oxalate hydrogenation, and the catalyst stability and the selectivity of the methyl glycolate are high.

Owner:CHANGZHOU UNIV

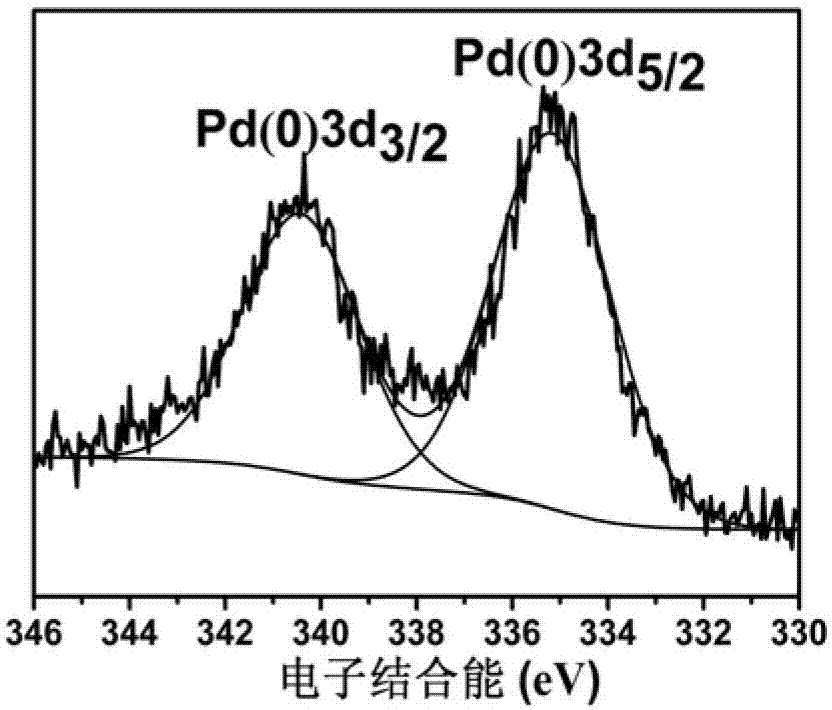

Bimetal nanometer catalyst as well as preparation and application method thereof

ActiveCN103041826AGood dispersionLarge specific surface areaPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsDispersityNano catalyst

The invention discloses a bimetal nanometer catalyst used for preparing dimethyl oxalate through CO gas-phase oxidative coupling as well as preparation and an application method of the bimetal nanometer catalyst, and belongs to the technical field of preparation of the dimethyl oxalate. The bimetal nanometer catalyst is characterized in that a catalyst carrier is Alpha-aluminium oxide, an active component is Pd-Cu nanometer grains, the average size of the grain is 2-3nm, the Pd content of the active component is 0.01-2% and Cu content is 0.01-0.04% according to the mass of the catalyst carrier. The catalyst is prepared through a room temperature normal position load method, the preparation method is simple, the energy dissipation is low, the catalyst is suitable for industrial production, the active component Pd-Cu nanometer grains in the catalyst has high dispersity, large specific surface area, small size and uniformity in distribution; the catalyst provided by the invention adopts the Pd-Cu bimetal nanometer grains as the active component, and a bimetal component synergistic effect and a nanometer effect are utilized to reduce the content of the noble metal PD to 0.1% under the premise of keeping the high activity and stability of the catalyst, therefore and the cost of the catalyst is greatly reduced, and the partial substitution of the noble metal is realized.

Owner:贵州鑫醇科技发展有限公司

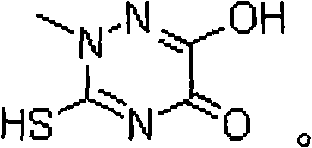

Method for synthesizing triazine ring

The invention discloses a method for synthesizing triazine ring, which is implemented by reacting aqueous methylhydrazine solution with ammonium sulfocyanate, and then preparing amino methyl sulfourea methanol solution by using methanol; performing cyclization reaction on amino methyl sulfourea methanol solution with dimethyl oxalate and sodium methylate, adjusting pH value with hydrochloric acid after finishing cyclization reaction, removing excessive sodium methylate, and filtering to prepare triazine ring sodium salt; aciding out the triazine ring sodium salt to obtain a crude triazine ring product; agitating the crude triazine ring product with hot water, washing, cooling, crystallizing, and drying to obtain a fine triazine ring product. The invention has high yield and low material cost, reduces labor intensity and pollution of waste gas, waste water and industrial residue.

Owner:NANTONG NABAIYUAN CHEM

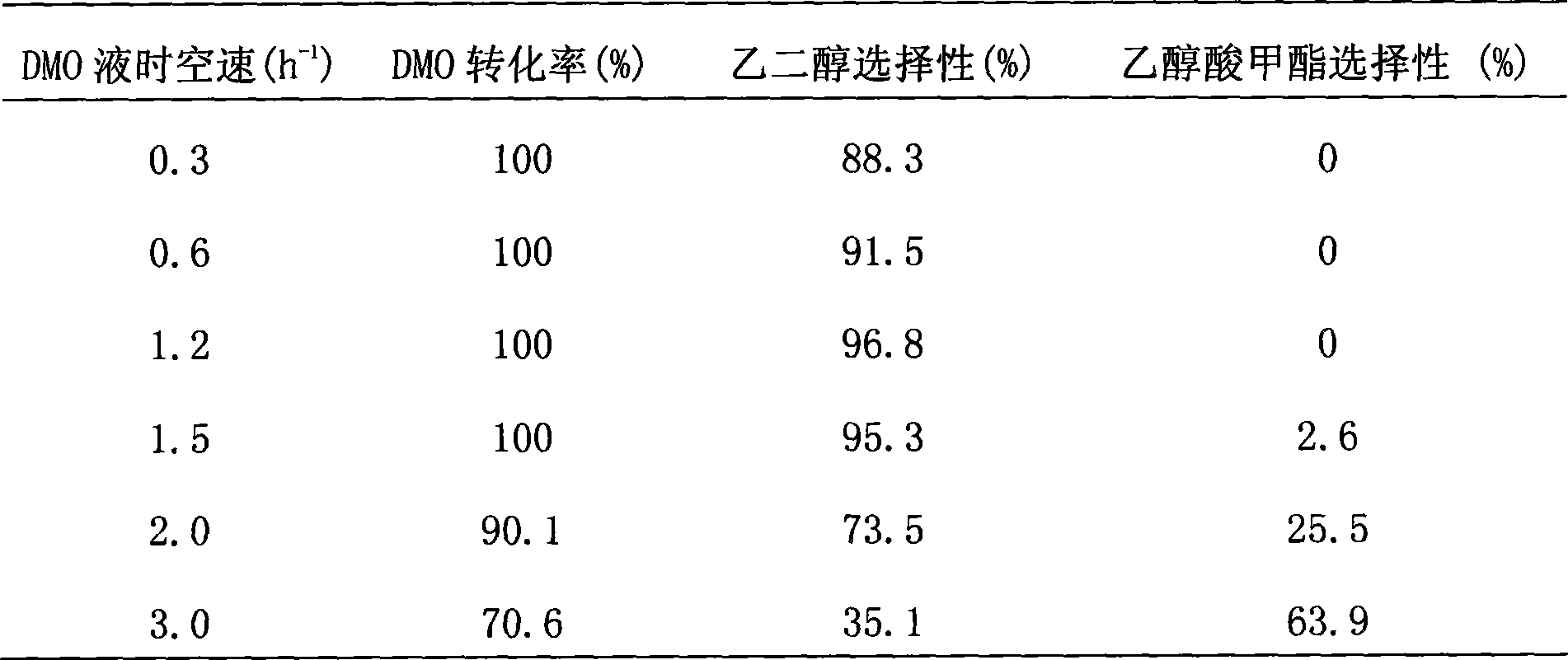

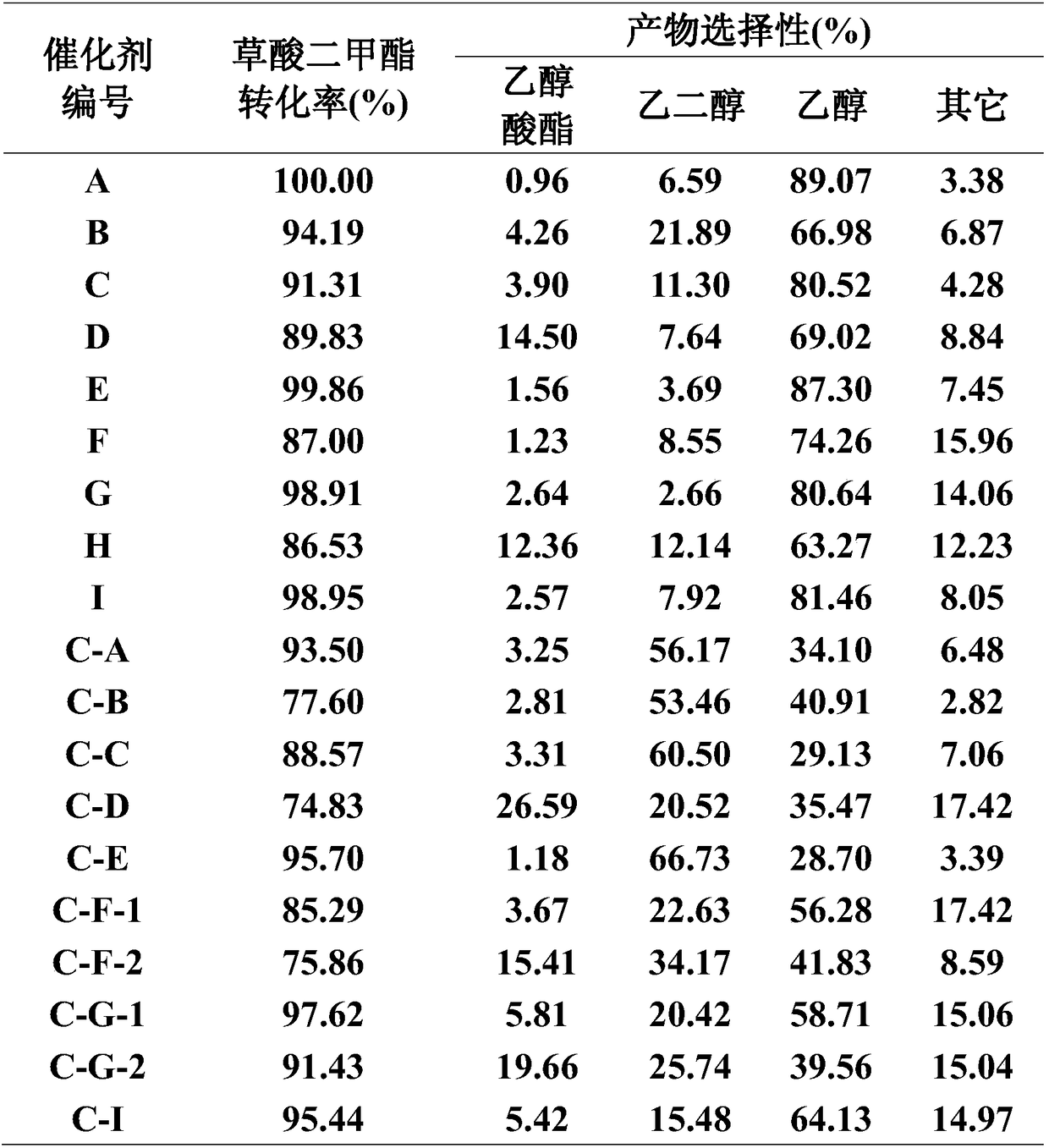

Catalyst and method for synthesizing methyl glycollate and ethylene glycol by virtue of dimethyl oxalate hydrogenation

InactiveCN104492429AImprove stabilityHigh activityOrganic compound preparationCarboxylic acid esters preparationActive componentDimethyl oxalate

The invention relates to a catalyst and a method for synthesizing methyl glycollate and ethylene glycol by virtue of dimethyl oxalate hydrogenation, and mainly aims to solve the problems that the catalyst in the prior art is low in activity and poor in stability. The invention adopts a technical scheme that the catalyst for synthesizing methyl glycollate and ethylene glycol by virtue of dimethyl oxalate hydrogenation comprises the following components in percentage by mass: 0.01-30% of an active component Ag, 0-10% of an auxiliary agent and the balance of a carrier, wherein the carrier is at least one of titanium dioxide and a carbon carrier, the active component is Ag, and the auxiliary agent is at least one of Cu, Ca, Ba, Mg, Au, Ru, Rh, Pd, Pt, Ni, Zn and Zr; and the method for synthesizing methyl glycollate and ethylene glycol by virtue of dimethyl oxalate hydrogenation is also adopted. Therefore, the problems are well solved by the technical scheme, and the technical scheme can be used in a process for synthesizing methyl glycollate and ethylene glycol by virtue of dimethyl oxalate hydrogenation.

Owner:SHANGHAI HUAYI GRP CO

Preparation method of catalyst used for synthesizing ethyl alcohol through hydrogenation on dimethyl oxalate, catalyst obtained by adopting preparation method and application thereof

ActiveCN108236955AHigh selectivityImprove conversion rateMolecular sieve catalystsOrganic compound preparationPtru catalystAlcohol

The invention relates to a method for preparing a catalyst used for synthesizing ethyl alcohol through hydrogenation on dimethyl oxalate. The catalyst contains a carrier, a catalytic active componentloaded on the carrier, and an optional catalytic promoter, concretely the catalyst contains: (A) based on element, 1-50wt% of elements which are selected from Cu, Fe, Ni, Co, Ag and Au and taken as the catalytic active component; (B) based on element, 0-10wt% of elements which are selected from third main group elements, transition elements and lanthanide elements and taken as the catalytic promoter; and (C) the carrier. The catalyst is prepared by adopting a urea-assisted hydrothermal synthesis method, and CO2 supercritical drying is adopted, so that high ethyl alcohol selectivity can be obtained, and high dimethyl oxalate conversion rate also can be obtained when the prepared catalyst is used for producing ethyl alcohol through hydrogenation on dimethyl oxalate. The invention also relates to the catalyst prepared by adopting the method provided by the invention and application of the catalyst in production of ethyl alcohol through hydrogenation on dimethyl oxalate.

Owner:HIGHCHEM

Copper and silicon catalyst for preparing ethanediol by hydrogenating dimethyl oxalate and preparation method thereof

ActiveCN101648134AHigh catalytic activityImprove catalytic selectivityOrganic compound preparationHydroxy compound preparationAlcoholAmmonium hydroxide

The invention discloses a copper and silicon catalyst for preparing ethanediol by hydrogenating dimethyl oxalate and a preparation method thereof. The copper and silicon catalyst is prepared by a one-pot method under conditions of taking ester orthosilicate as a silicon source and taking alcohol as a cosolvent and is concretely prepared in such a way that the ester orthosilicate is hydrolyzed andaged in a water-alcohol mixing solution of a copper ammonia complex, and then moisture, alcohol and ammonia are evaporated to enable copper components inside a copper ammonia solution to be uniformlysubsided, and finally washing, drying, roasting and reducing are carried out. The copper and silicon catalyst comprises copper and silicon dioxide, wherein the mol ratio of the copper to the silicon dioxide is 0.05-0.4 to 1. The copper and silicon catalyst shows very high reaction activity and selectivity in the reaction for preparing the ethanediol by hydrogenating the dimethyl oxalate and withina wider temperature range, is easy to operate and beneficial to industrial application.

Owner:ZHEJIANG UNIV

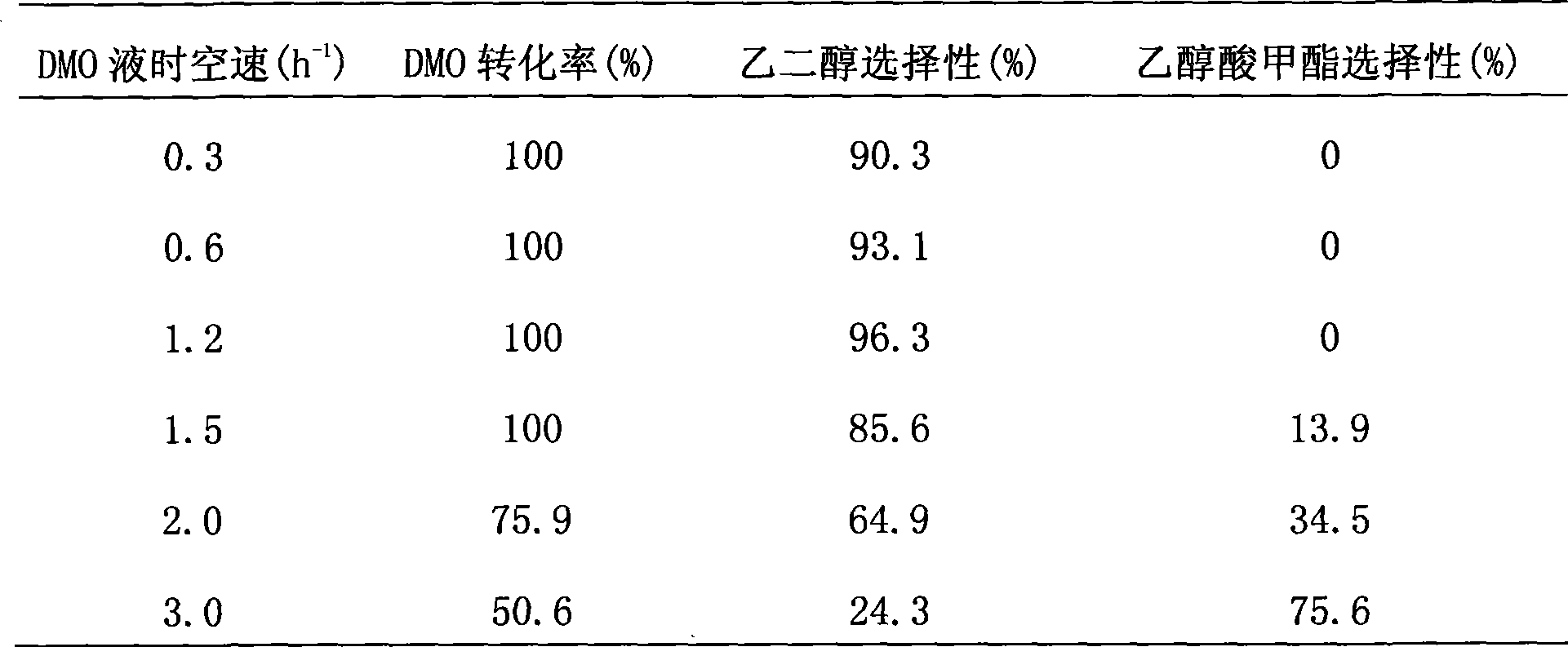

Production method of methyl glycolate

InactiveCN104262152AHigh selectivityReduce partial pressureOrganic compound preparationCarboxylic acid esters preparationDistillationMixed materials

The invention relates to a production method of methyl glycolate, aiming to mainly solve the problems of low conversion rate of dimethyl oxalate and low selectivity of methyl glycolate in the prior art. The production method of methyl glycolate comprises the following steps of (1) enabling a mixed material composed of a methanol solution of dimethyl oxalate and feed gas containing hydrogen to be in contact with a silver-containing catalyst in a reactor to react to obtain a mixture flow containing methyl glycolate, carrying out heat exchange, and then, enabling the mixture flow to enter a gas-liquid separation system; (2) sequentially carrying out condensation, primary gas-liquid separation, condensation and secondary low-temperature gas-liquid separation on the mixture flow subjected to heat exchange to obtain crude methyl glycolate; and (3) carrying out reduced-pressure distillation separation on crude methyl glycolate to obtain the methyl glycolate product. According to the technical scheme, the conversion rate of dimethyl oxalate can be higher than 99%, the selectivity of methyl glycolate can be higher than 80%, and the production method can be applied to industrial production of methyl glycolate.

Owner:SHANGHAI HUAYI GRP CO

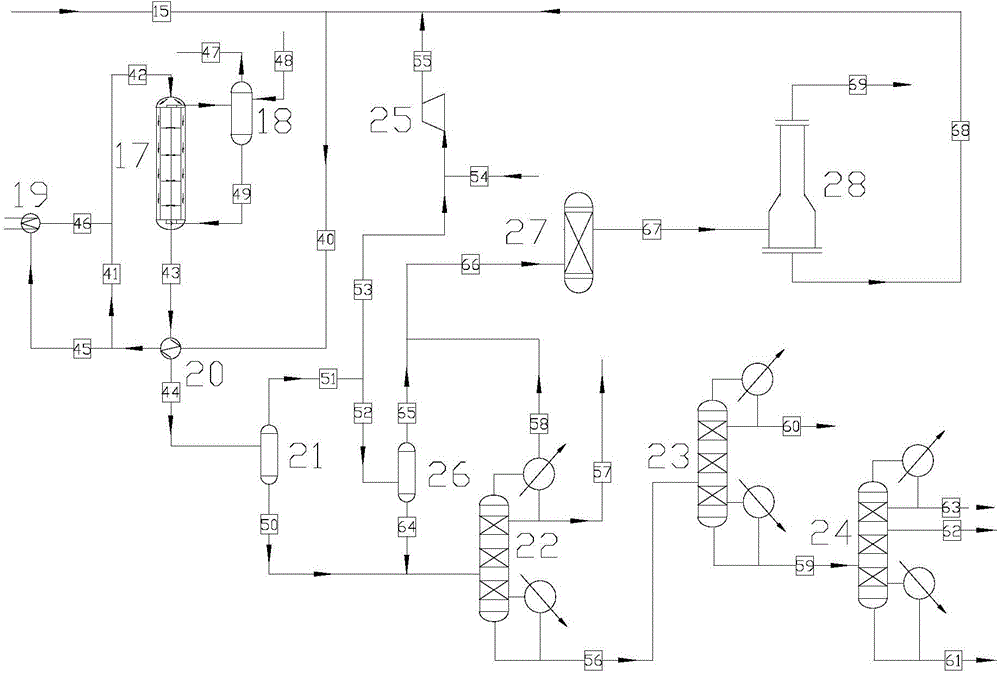

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

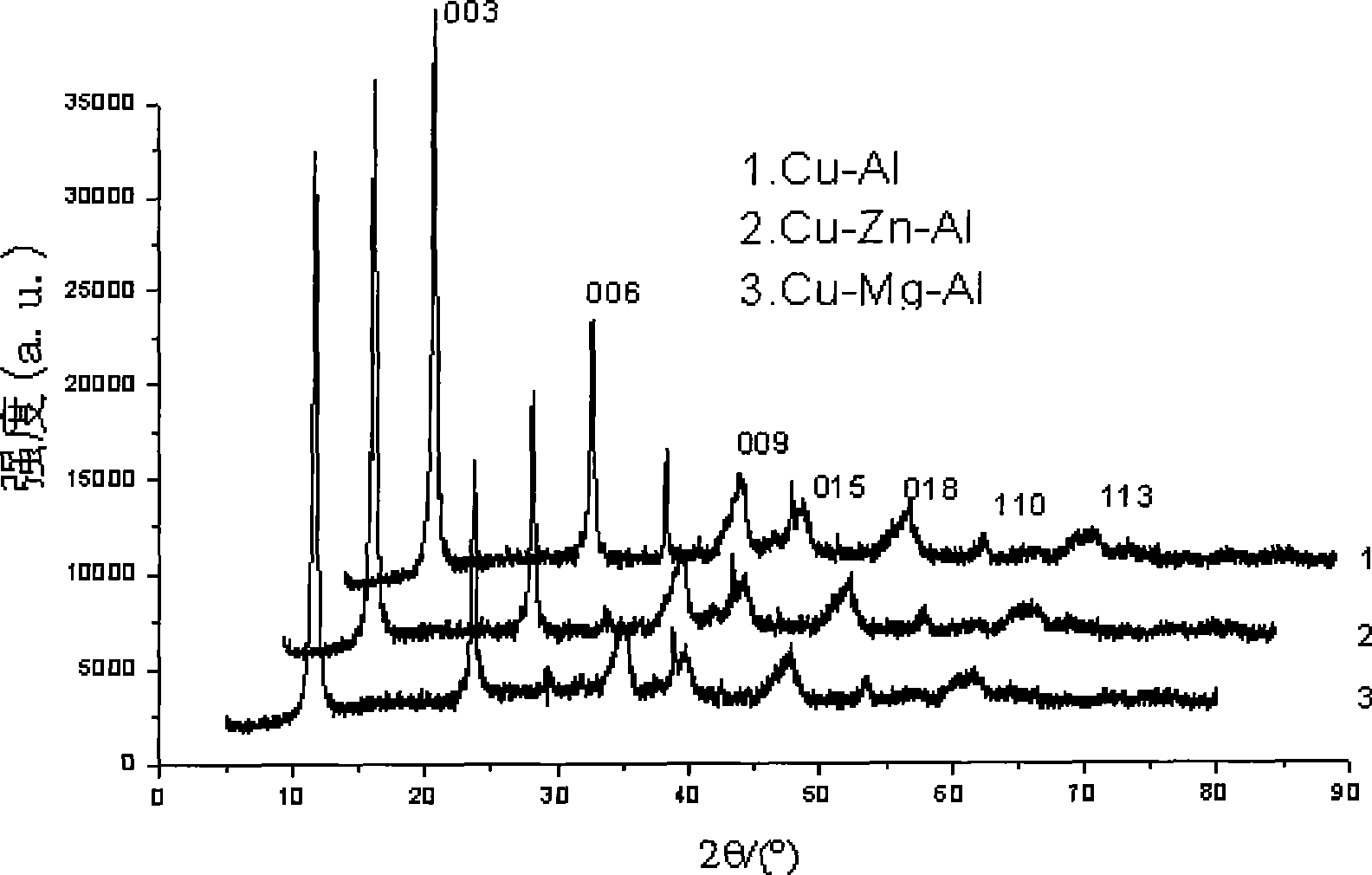

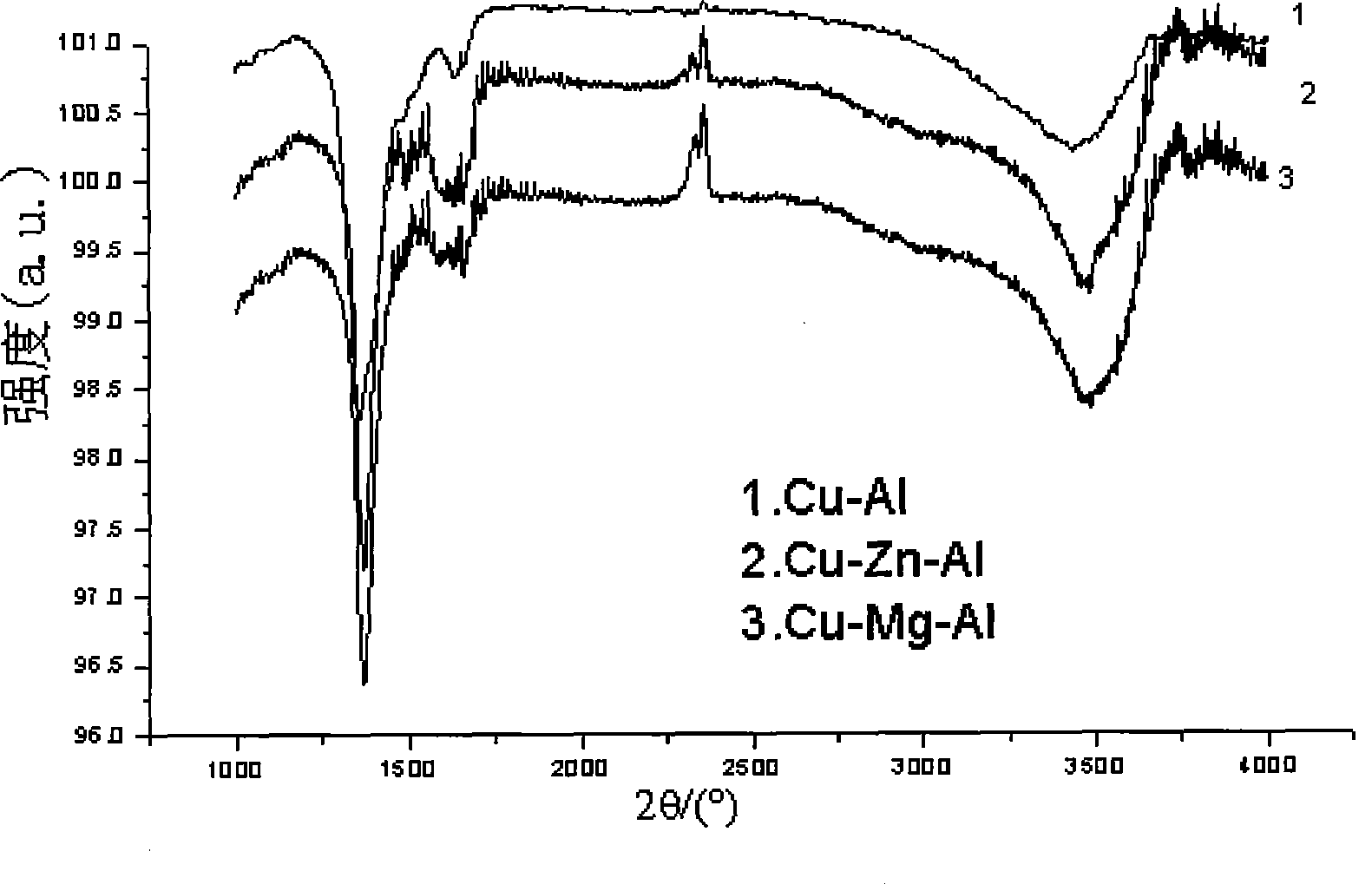

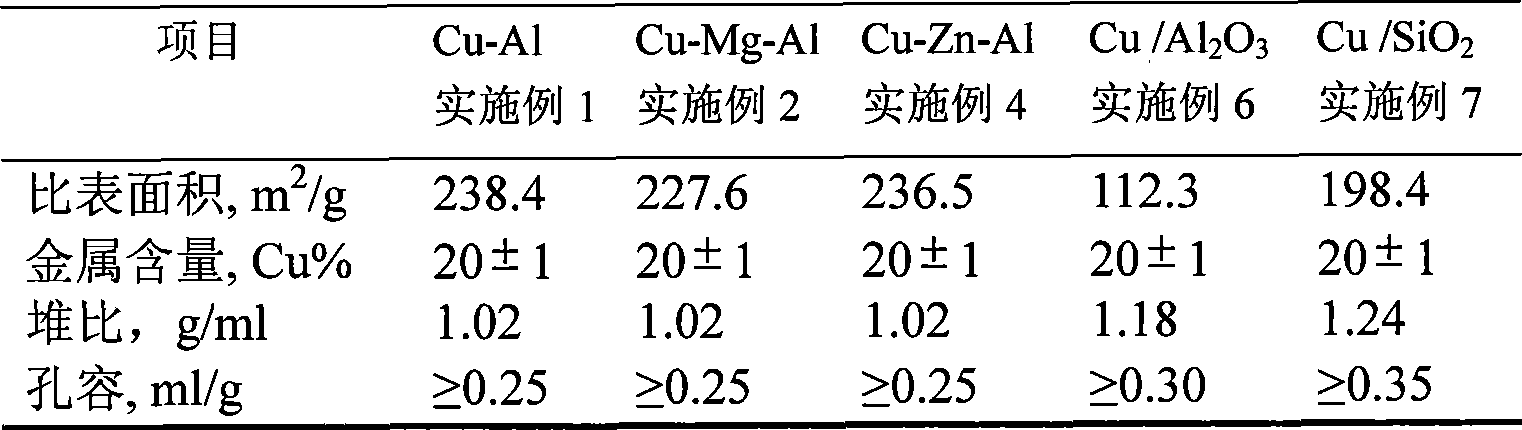

Ethylene glycol catalyst prepared by dimethyl oxalate plus hydrogen and preparation method and application thereof

InactiveCN101444735ALow reaction temperatureHigh activityOrganic compound preparationHydroxy compound preparationHydrogenReaction temperature

The invention discloses an ethylene glycol catalyst prepared by dimethyl oxalate plus hydrogen, a preparation method and application thereof. According to weight percentage, the catalyst comprises the following components: 70 to 84 percent of metal oxide, 1 to 5 percent of transitional metal additives, and 15 to 25 percent of copper. The catalyst belongs to an anion clay type hydrotalcite catalyst; and under the conditions that a reaction temperature is 160 to 230 DEG C, pressure is 1.0 to 5Mpa, a hydrogen ester molar ratio equals to 20-100:1, and a volume space velocity equals to 0.5 to 3h<-1>, the catalyst can be used in a reaction of preparing ethylene glycol by dimethyl oxalate plus hydrogen. The catalyst has the advantages of low reaction temperature, high activity, good selectivity, simple catalyst preparation process, easy operation and low cost, and is easy for conducting industrial production.

Owner:SHANGHAI UNIV OF ENG SCI +1

Method and device for co-producing dimethyl carbonate and dimethyl oxalate

ActiveCN101830806AReasonable deployment of productionLower energy requirementsOrganic compound preparationPreparation by carbon monoxide or formate reactionGas phaseTower

The invention discloses a method and a device for co-preparing di(C1-3) alkyl carbonate and di(C1-3) alkyl oxalate. The method comprises the following steps of: a) separating a product of a di(C1-3) alkyl carbonate synthesis reactor into a first liquid phase and a first gas phase; b) separating a product of a di(C1-3) alkyl oxalate synthesis reactor into a second liquid phase and a second gas phase; c) conveying the first liquid phase to a first rectifying tower from the tower top, conveying the combined first gas phase and second gas phase to the first rectifying tower from the middle lower part of the tower, conveying the second liquid phase to the first rectifying tower from the tower bottom, and generating basically pure di(C1-3) alkyl oxalate fraction from the bottom of the first rectifying tower during rectifying; d) separating the overhead fraction produced in the first rectifying tower into a third liquid phase and a third gas phase; and e) conveying the third liquid phase to a second rectifying tower from the middle part of the tower, and generating basically pure di(C1-3) alkyl carbonate from the bottom of the second rectifying tower. Only three rectifying towers are designed in the whole process through reasonable process design, so the energy requirement and operation expense are effectively reduced, and the equipment investment expense is saved.

Owner:PUJING CHEM IND SHA +1

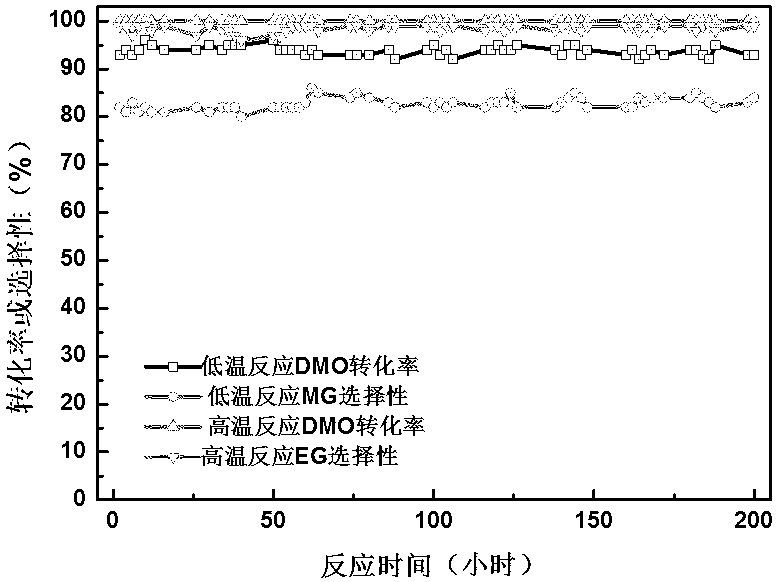

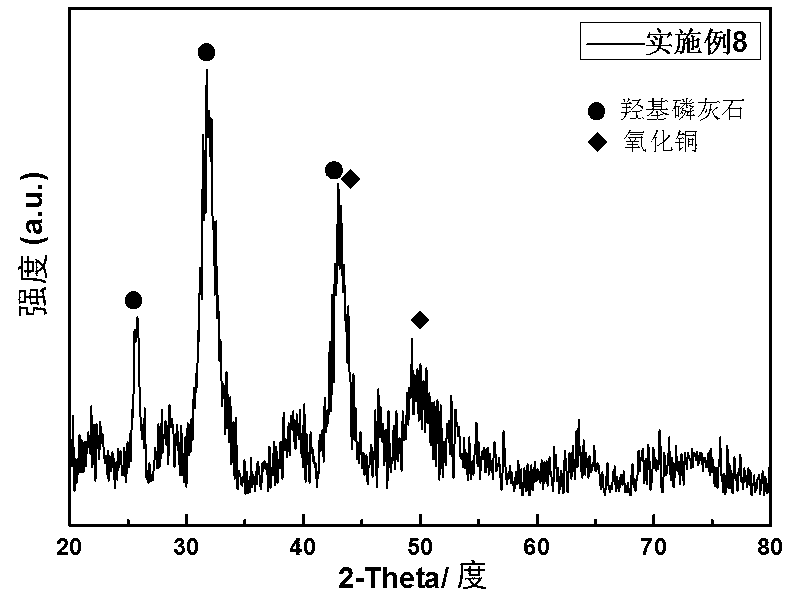

Copper-hydroxyapatite catalyst for synthesizing methyl glycolate and ethylene glycol and preparation method thereof

InactiveCN102989490AGood dispersionHigh activityPhysical/chemical process catalystsOrganic compound preparationChemical industryApatite

The invention belongs to the technical field of chemical industry, and particularly relates to an efficient catalyst for synthesizing methyl glycolate and ethylene glycol through gas-phase catalytic hydrogenation of dimethyl oxalate and a preparation method thereof. The catalyst is loaded with copper and other auxiliary metals by taking hydroxyapatite as a carrier. The preparation method of the catalyst comprises the following steps of: firstly preparing a hydroxyapatite suspension from calcium nitrate and diammonium hydrogen phosphate; adding soluble copper salt and soluble auxiliary metal slat, and performing metal loading by an ammonia distillation method; filtering; washing and drying the filter cake; and roasting to obtain a powdery catalyst for the gas-phase catalytic hydrogenation of dimethyl oxalate. Through the invention, controllable selectivity is realized on the hydrogenation products including methyl glycolate and ethylene glycol, the yield of methyl glycolate can reach 80% under low-temperature conditions, and the yield of ethylene glycol can reach 99% under high-temperature conditions; and the preparation method of the catalyst is simple and has good stability and relatively broad prospects in industrial application.

Owner:FUDAN UNIV

Catalyst for synthesis of diethyl oxalate employing carbon monoxide gas-phase catalytic coupling and preparation method thereof

InactiveCN101612580AHigh space-time yieldHigh reactivityPreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsGas phaseDiethyl oxalate

The invention discloses a catalyst for the synthesis of diethyl oxalate employing carbon monoxide gas-phase catalytic coupling and the catalyst adopts metal palladium as active component, alpha-Al2O3 as carrier and transition metal copper as promoter; wherein, the content of metal palladium is 0.1-5.0% of the carrier and the content of transition metal copper is 0.05-3.0%. The catalyst shows higher reactivity and higher time space yield of dimethyl oxalate in the reaction that carbon monoxide and ethyl nitrite are used to synthesize dimethyl oxalate. The invention also discloses a preparation method of the catalyst.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

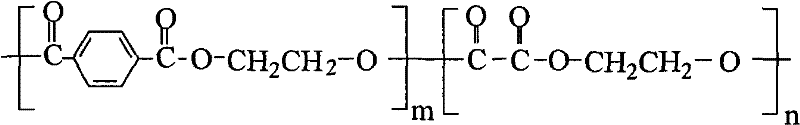

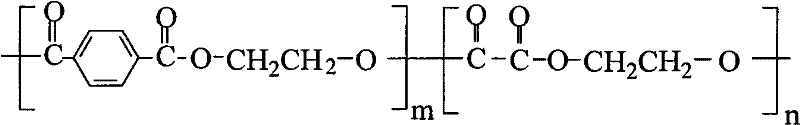

Preparation method of polyethylene terephthalate copolyester

InactiveCN102276808ABiodegradablePromote degradationMonocomponent copolyesters artificial filamentFiberPolyethylene terephthalate glycol

The invention discloses a preparation method of polyethylene terephthalate (ethylene glycol) terephthalate copolyester, which uses oxalate as a comonomer to prepare polyethylene terephthalate with terephthalic acid, its ester, and ethylene glycol. Ethylene glycol dicarboxylate copolyester. The melting point of the copolyester of the present invention is 210-250° C., the intrinsic viscosity is 0.3-1.5 dL / g, and has biodegradability. Compared with the biodegradable PET copolyester prepared by other methods, the preparation method is simple, the raw material cost is low, and the difference between the product performance and PET is small. Copolyesters can be used in the manufacture of fibers, films, sheets, bottles and other plastics.

Owner:CHINA PETROLEUM & CHEM CORP +1

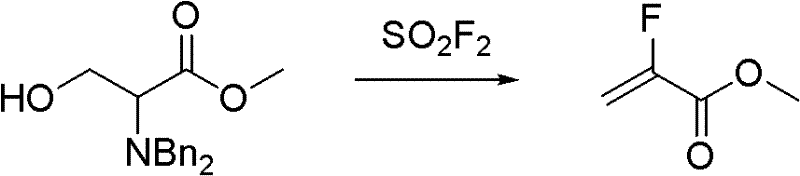

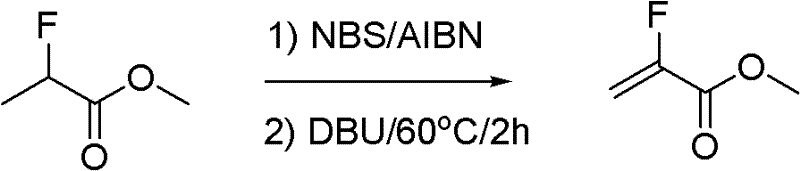

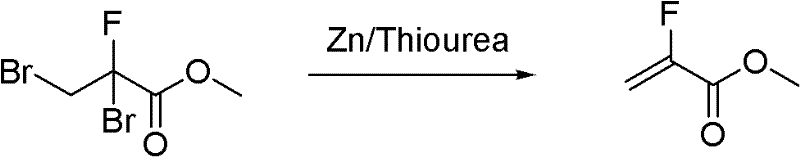

Synthesis method of methyl-alpha-fluoroacrylate and analogues thereof

InactiveCN102211998ALow costReduce manufacturing costOrganic compound preparationCarboxylic acid esters preparationSynthesis methodsSolvent

The invention relates to a synthesis method of methyl-alpha-fluoroacrylate and analogues thereof. The method comprises the following steps: step 1, based on methyl fluoroacrylate and dimethyl oxalate serving as raw materials, dissolving the raw materials in a solvent, and adding base for carrying out condensation reaction so as to generate sodium enolate or potassium enolate intermediate; and step 2, reacting sodium enolate or potassium enolate intermediate with paraformaldehyde or trioxane in the solvent so as to generate methyl-alpha-fluoroacrylate. According to the invention, cheap methyl fluoroacrylate and dimethyl oxalate are used as the raw materials, and the low-cost solvent and other reactants are selected, thus the method has the advantages of low preparation cost and high yield and can be suitable for large-scale industrial production.

Owner:RADIANT PHARMA & TECH

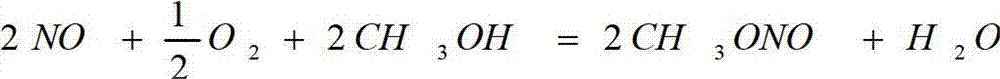

Method and equipment for continuously producing methyl nitrite

InactiveCN102898311AReduce generationInvestment minimizationNitrous acid preparation ester preparationMethyl nitrateOxygen

The invention relates to a method and equipment for continuously producing methyl nitrite in large scale. The method for producing methyl nitrite comprises the following steps of: carrying out the esterification of methanol, oxygen and a nitrogen oxide in an esterification reaction tower to obtain methyl nitrite; circulating and returning the liquid flow from the outlet at the bottom of the esterification reaction tower to the top of the tower, leading the gas flow from the outlet at the bottom of the esterification reaction tower to a purification tower and washing the gas from the bottom of the esterification tower by countercurrent contact with an organic purifier; drying the gas from the top of the purification tower in a dryer to obtain methyl-nitrite-containing dry gas; and leading liquid at the bottom of the purification tower to a recovery tower, and separating a recovery purifier. The methyl nitrite produced by the method can be directly used to prepare dimethyl oxalate through oxidization, carbonylation and coupling reaction with CO. Compared with the conventional production process, the method for producing methyl nitrite has the characteristics of economy, environment friendliness, less waste water and the like.

Owner:SHANGHAI HUAYI ENERGY CHEM

Loaded type transition metal phosphide catalyst as well as preparation method and application thereof

ActiveCN105251521AImprove hydrogenation activityImprove stabilityPhysical/chemical process catalystsOrganic compound preparationSilicon dioxideDimethyl oxalate

Owner:中科合成油内蒙古技术研究院有限公司

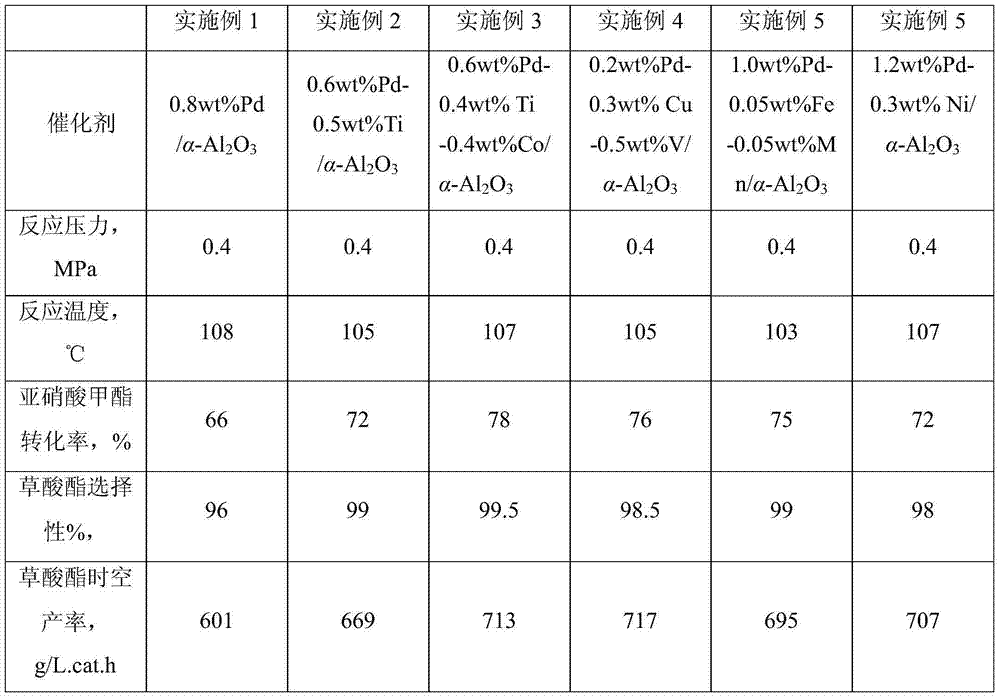

Catalyst for CO gas phase synthesis of dimethyl oxalate and preparation method of catalyst

InactiveCN104741116ASimple structureImprove active structurePreparation by carbon monoxide or formate reactionMetal/metal-oxides/metal-hydroxide catalystsGas phaseManganese

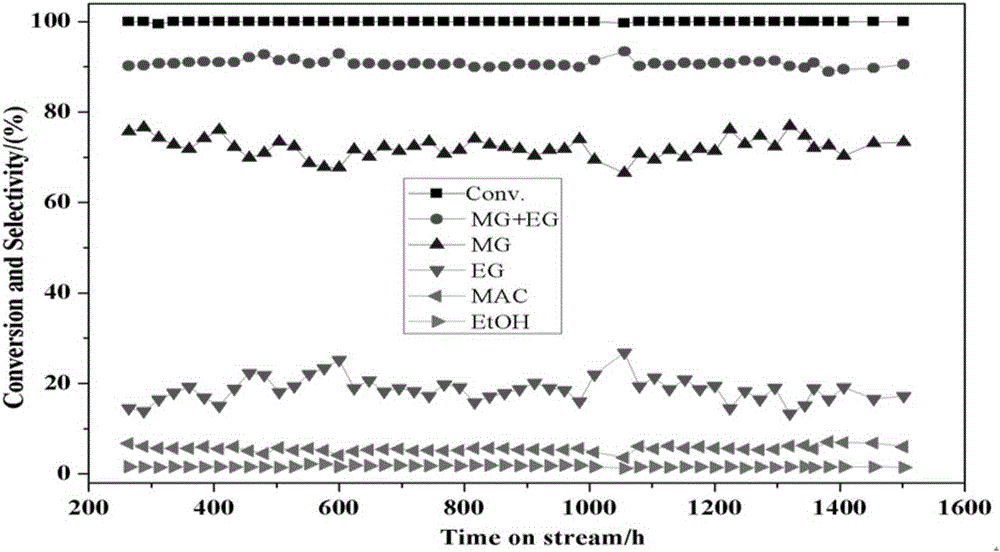

The invention relates to a catalyst for CO gas phase synthesis of dimethyl oxalate. The catalyst contains an active ingredient metal Pd, metal aids and a carrier, wherein the metal aids refer to one or two out of titanium, vanadium, manganese, iron, cobalt, nickel or copper; the carrier is selected from alpha-Al2O3 and has the specific surface area of 3-30m<2> / g, the pore volume of 0.01-0.5cm<3> / g and the mean pore size of 2-50nm; the content of the metal Pd accounts for 0.1-1.5 percent of the weight of the carrier; the content of the metal aids accounts for 0.05-0.8 percent of the weight of the carrier; and the catalyst is of an eggshell type structure. The catalyst has high activity and high space time yield under the low temperature condition of low than 110 DEG C, particularly the catalyst has high selectivity, the side reactions can be effectively reduced, and the catalyst can be used for realizing industrial synthesis of dimethyl oxalate.

Owner:SHANGHAI HUAYI ENERGY CHEM

Preparation method for synthesizing copper-based catalyst by sol-gel ammonia still process

InactiveCN102716744ALow activation temperatureImprove stabilityOrganic compound preparationHydroxy compound preparationSilicic acidReaction temperature

The invention relates to a method for synthesizing a copper-based catalyst by a sol-gel ammonia still process. Metallic copper is an active component of the catalyst, ortho-silicic acid ester serves as a silicon source, the copper-silicon catalyst prepared by the sol-gel process is treated after the ammonia still process by using alcohol as a cosolvent, and reactivity of dimethyl oxalate and selectivity of glycol are effectively improved. Compared with the sol-gel process, the method has the advantages that at a low reaction temperature (190-200 DEG C), the conversion rate of the dimethyl oxalate can be close to 100%, and the selectivity of the glycol is higher than 96%. The stability of the catalyst can be reduced by reducing the optimal active temperature of the catalyst, the preparation process of the catalyst is simple, and industrial amplification is facilitated.

Owner:河南能源化工集团研究总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com