Ethylene glycol catalyst prepared by dimethyl oxalate plus hydrogen and preparation method and application thereof

A technology of dimethyl oxalate and catalyst, which is applied in the field of copper-hydrotalcite catalyst and its preparation, can solve the problems of unsatisfactory batch preparation repeatability, insufficient research on ethylene glycol, and poor dispersion of active metals, etc., and achieve easy industrialization The effect of production, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

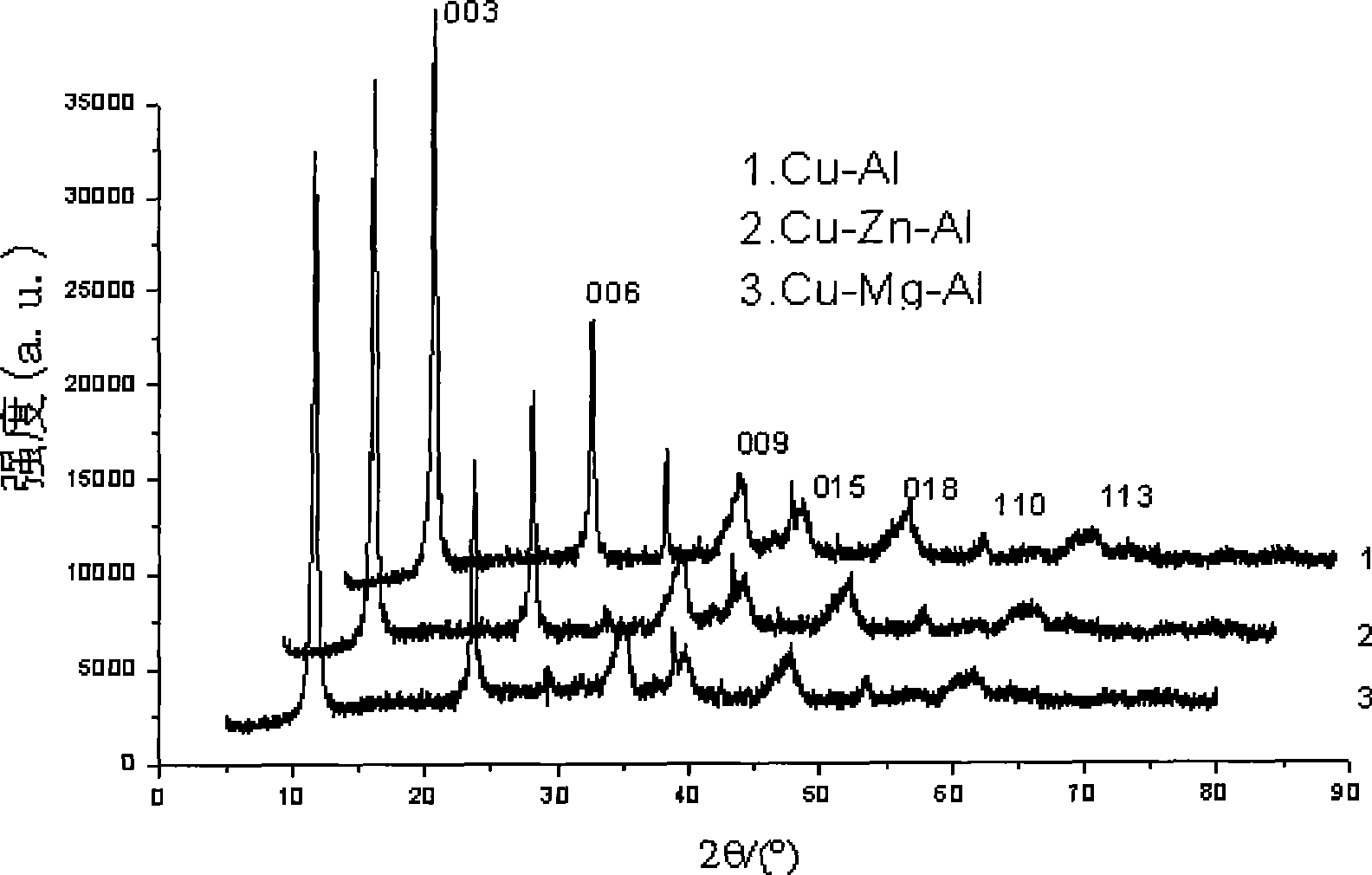

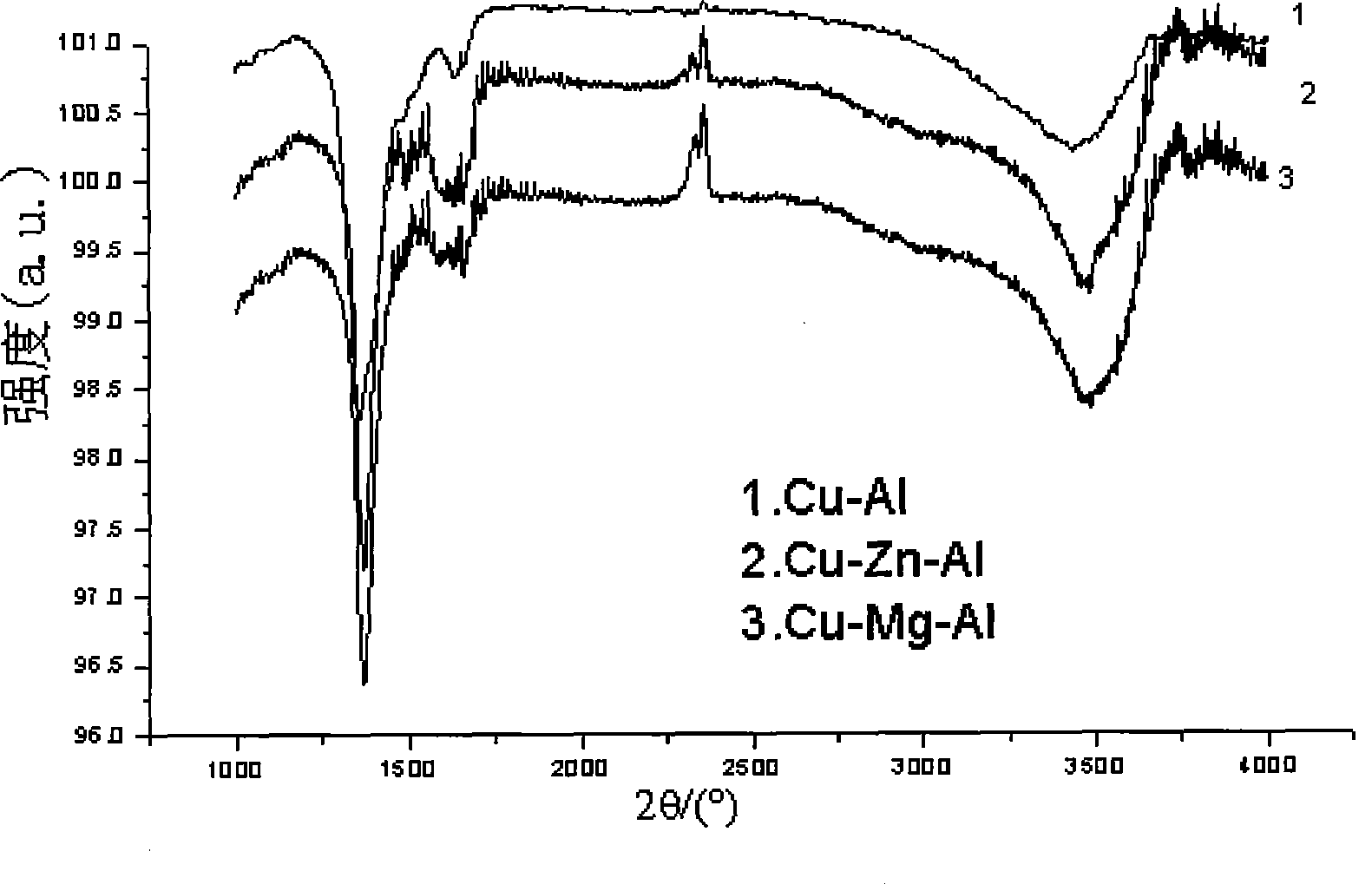

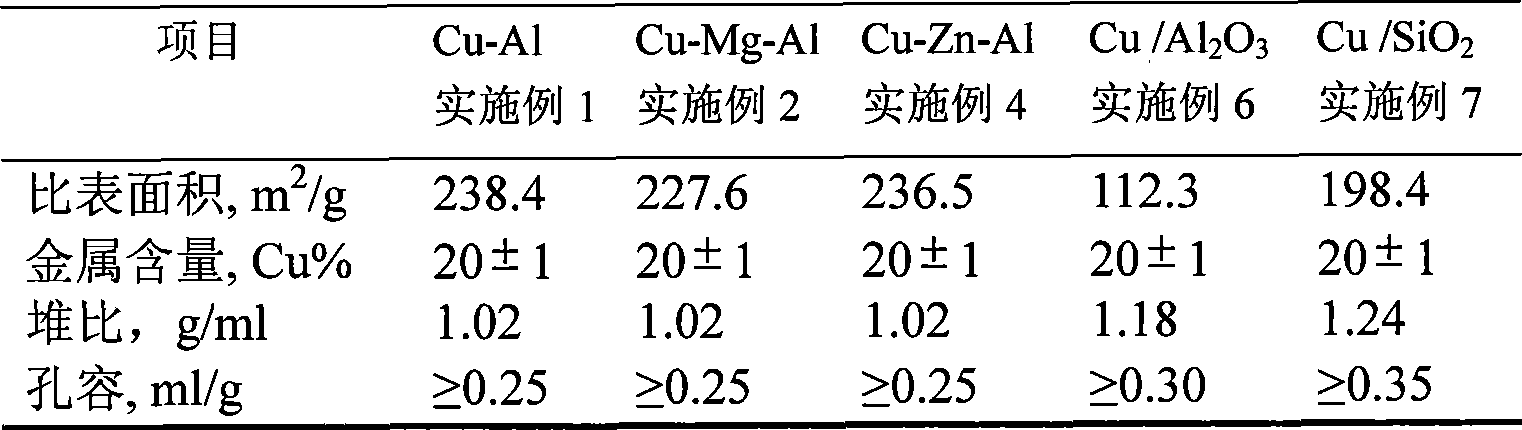

[0051] Synthesis of Cu-Al hydrotalcite (Cu 20w%):

[0052] Al(NO 3 ) 3 9H 2 O 7.5026g (0.02mol) and Cu(NO 3 ) 2 ·3H 2 O 1.9256g (0.00797mol) was dissolved in 100mL of distilled water to prepare 100ml of salt solution.

[0053] NaOH 0.8g (0.02mol) and NaCO 3 4. Put 2396g (0.04mol) in a 100ml beaker, add deionized water to make up to 100ml, and prepare 100ml lye.

[0054] Another NaOH 0.8g (0.02mol), NaOH 2 CO 3 4.24g (0.04mol)

[0055] Put the two solutions into two separating funnels respectively, add them dropwise into a beaker containing 300ml of distilled water under the vigorous stirring of a magnetic constant temperature heating stirrer, control the dropping rate at about 1 drop / s, and ensure the pH of the reaction system The value is 8.5. After the dropwise addition, stir and crystallize in a constant temperature water bath at 65±1°C for 12 hours. Filtrate, wash until neutral, dry the product at 80°C for 6 hours to obtain the Cu-Al binary hydrotalcite compo...

Embodiment 2

[0060] Synthesis of Cu-Mg-Al hydrotalcite (Cu 20w%):

[0061] 0.1molCu(Cu(NO 3 ) 2 ·3H 2 O 32.17g), 0.05molMg (Mg(NO 3 ) 2 ·6H 2 O 12.8g) and 0.1molAl (Al(NO 3 ) 3 9H 2 O 29.07g) was dissolved in 100mL of distilled water to prepare 100ml of salt solution.

[0062] NaOH 4g (0.1mol) and NaCO 3 16.96g (0.2mol) was placed in a 100ml beaker, and deionized water was added to make the volume to 100ml, and 100ml of lye was prepared.

[0063] Put the two solutions into two separating funnels respectively, add them dropwise into a beaker containing 300ml of distilled water under the vigorous stirring of a magnetic constant temperature heating stirrer, control the dropping rate at about 1 drop / s, and ensure the pH of the reaction system The value is 10. After the dropwise addition, stir and crystallize in a constant temperature water bath at 65±1°C for 12 hours. Filter, wash until neutral, dry the product at 80°C for 6 hours, then heat up to 450°C at a rate of 5°C / min and ro...

Embodiment 3

[0066] Synthesis of Cu-Co-Al hydrotalcite (Cu 15w%, Co 5w%):

[0067] Al(NO 3 ) 3 9H 2 O 7.5026g (0.02mol), Cu(NO 3 ) 2 ·3H 2 O 0.722g (0.00299mol) and Co (NO 3 ) 2 ·6H 2 O 0.314g (0.00108mol) was dissolved in some distilled water to prepare 100ml salt solution.

[0068] NaOH 0.8g (0.02mol) and NaCO 3 4.2396g (0.04mol) was dissolved in some distilled water to obtain 100mol alkali solution.

[0069] Put the two solutions into two separating funnels respectively, add them dropwise into a beaker containing 300ml of distilled water under the vigorous stirring of a magnetic constant temperature heating stirrer, control the dropping rate at about 1 drop / s, and ensure the pH of the reaction system The value is 8.5-10. After the dropwise addition, stir and crystallize in a constant temperature water bath at 40°C (tested, 80°C water bath will decompose the reaction product into brown-black powder particles, suspected to be CuO) for 12h. Filtrate, wash until neutral, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com