Patents

Literature

37results about How to "No overheating phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of double-hole-structure alumina supporter

ActiveCN102861617ALarge hole volumeNo overheating phenomenonCatalyst carriersMaterials scienceAmmonium bicarbonate

The invention discloses a preparation method of a double-hole-structure alumina supporter. The preparation method comprises the steps of weighing a certain quantity of pseudo-boehmite dry glue powders, evenly mixing the pseudo-boehmite dry glue powder with a certain quantity of peptizing agent and extrusion-auxiliary agent, then adding a certain quantity of ammonium bicarbonate aqueous solution in materials, mixing and nipping obtained materials into a plasticizer, squeezing into stripes and molding, placing molded materials in a sealing container, and roasting to prepare the alumina supporter after hydro-thermal treatment. The temperature of the hydro-thermal treatment is 70-120 DEG C, and the treatment time is 5-10 hours. Roasting is carried out at the temperature of 600-750 DEG C for 2-4 hours. The mass concentration of an ammonium bicarbonate solution is 40%-80%, the adding quantity of the ammonium bicarbonate solution is calculated according to NH<4+> and Al<3+>, and a molar ratio of the NH<4+> to Al<3+> is (0.5-1):1. According to the preparation method, the preparation procedure is simple, the prepared alumina supporter is in double-hole distribution and has good mechanical strength, and the preparation method is suitable to the field of preparation of heavy oil and residual oil hydrodemetallization catalysts and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

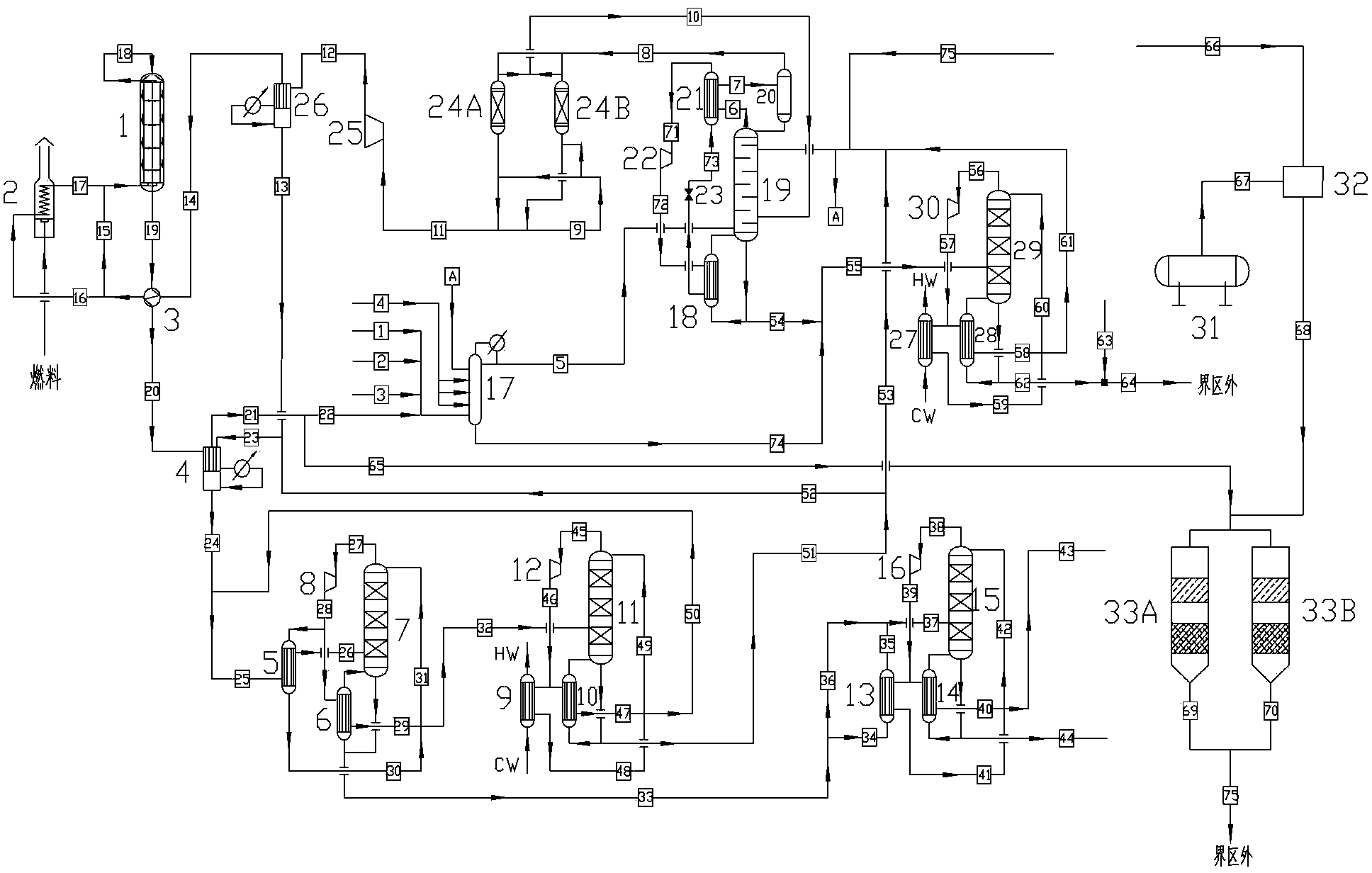

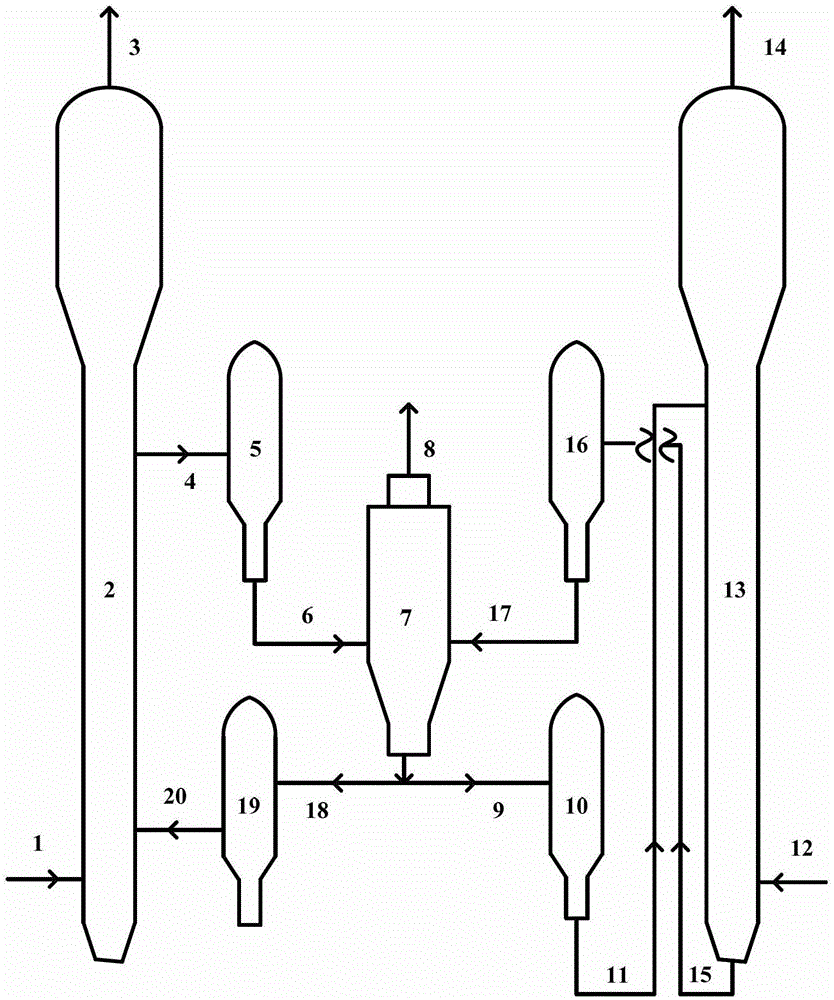

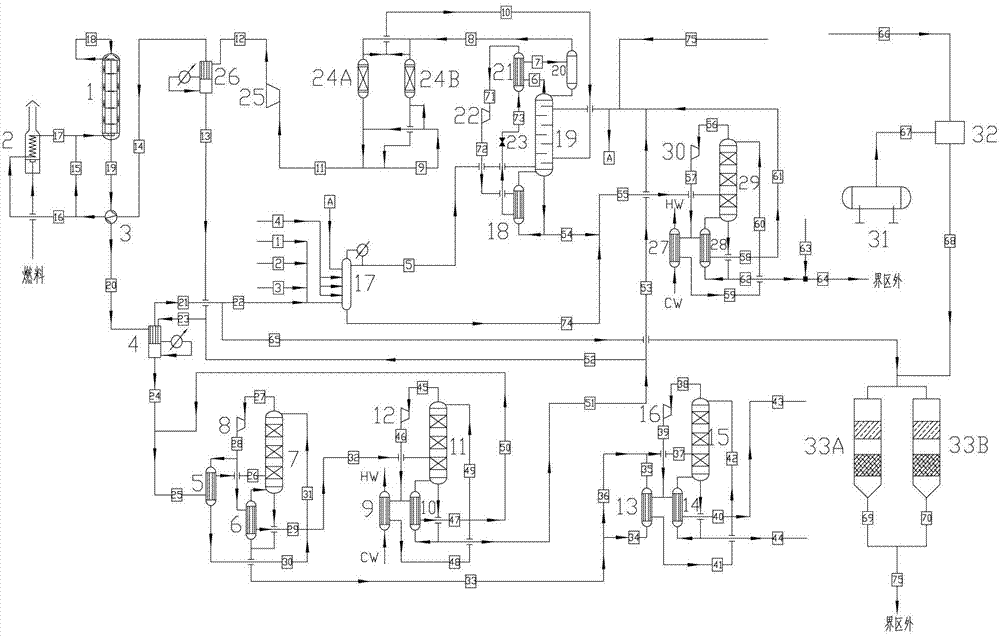

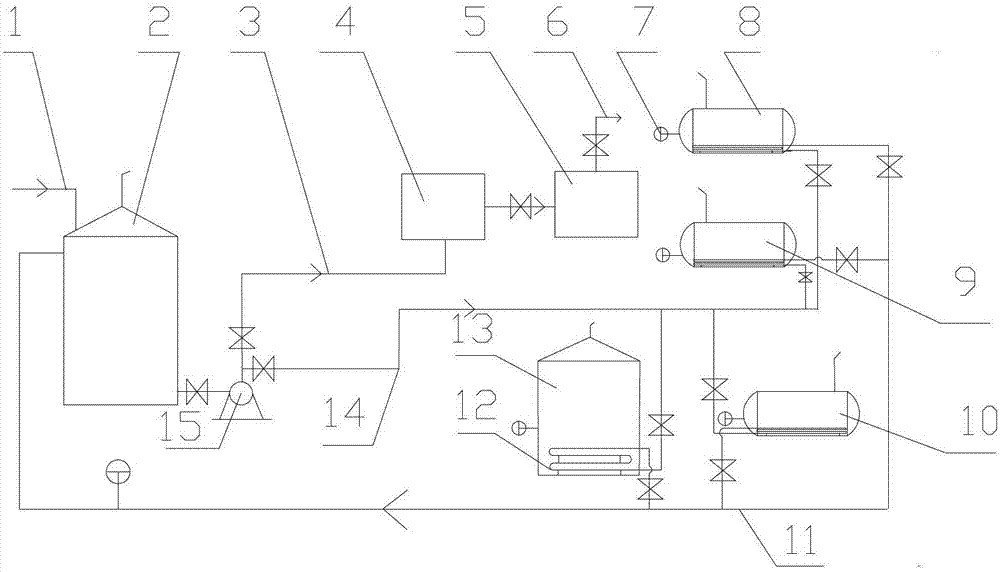

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428ANo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryMethyl carbonateGas phase

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

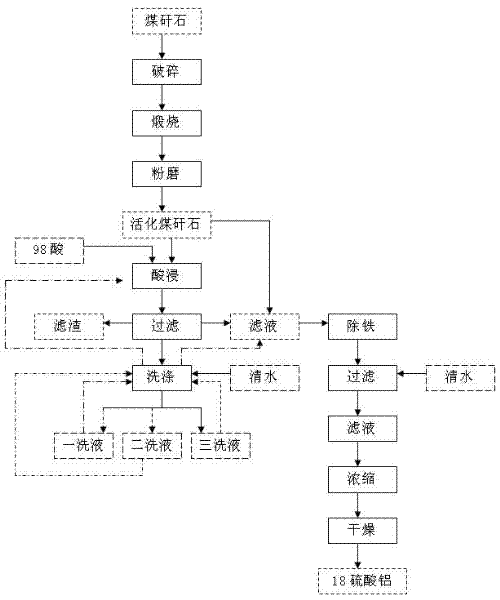

Method for producing low iron aluminum sulfate by utilization of coal gangue

InactiveCN102311136AGood slag activityUnderburn noneWaste processingSolid waste disposalSlagAluminum sulphate

The invention relates to a method for producing low iron aluminum sulfate by the utilization of coal gangue and belongs to the technical field of coal solid waste resource utilization. The method provided by the invention comprises the following steps of: carrying out calcination activation on coal gangue at the temperature of 785-850 DEG C, adjusting the pH of an aluminum sulfate solution by directly using the activated coal gangue, oxidizing divalent iron ions into trivalent ions, removing iron precipitate and a few gel in the aluminum sulfate solution by the utilization of the adsorption property of the coal gangue, producing low iron aluminum sulfate, recycling the removed iron slag, and terminating the recycling operation when the removed iron slag amount is greater than 120% of the acid-leach residue amount or the mass ratio of aluminium to iron in an iron-removing liquid is less than 160. The temperature of the calcinated coal gangue satisfies the operation condition for the boiling of a circulating fluidized bed. No addition of an auxiliary agent helps heat recovery. The activity of the coal gangue cinder is good, the grinding requirement is not high and the energy consumption is low. Hydrogen peroxide or ozone, air and variable valence element-containing hypervalent compounds KMnO4, MnO2 oxidizing agents are adopted to remove iron with less loss of aluminium. The ratio of Al2O3 to Fe in the product is greater than 160 and the quality of the product is high. The acid leaching reaction is carried out at normal pressure. And the production is easy to operate at low cost.

Owner:KUNMING UNIV OF SCI & TECH

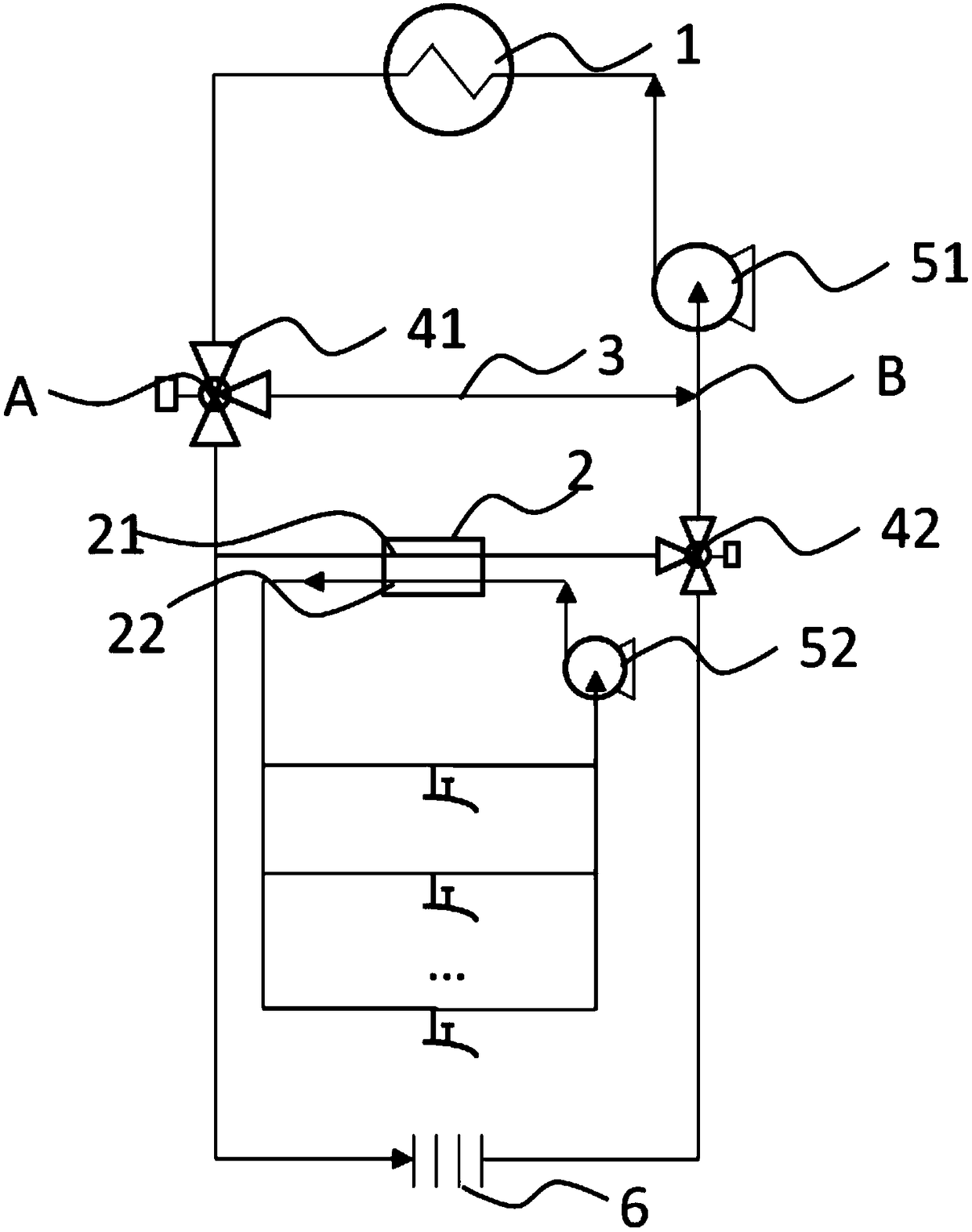

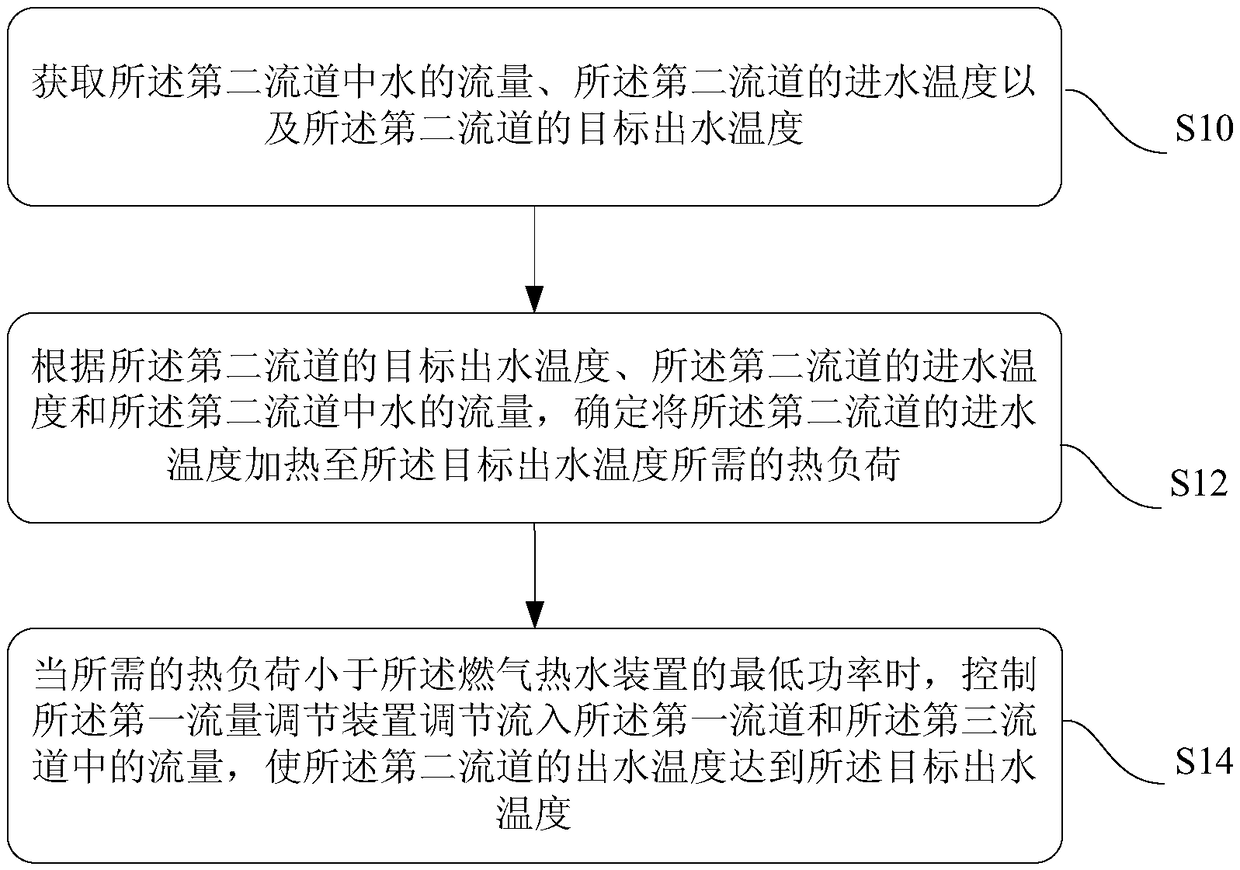

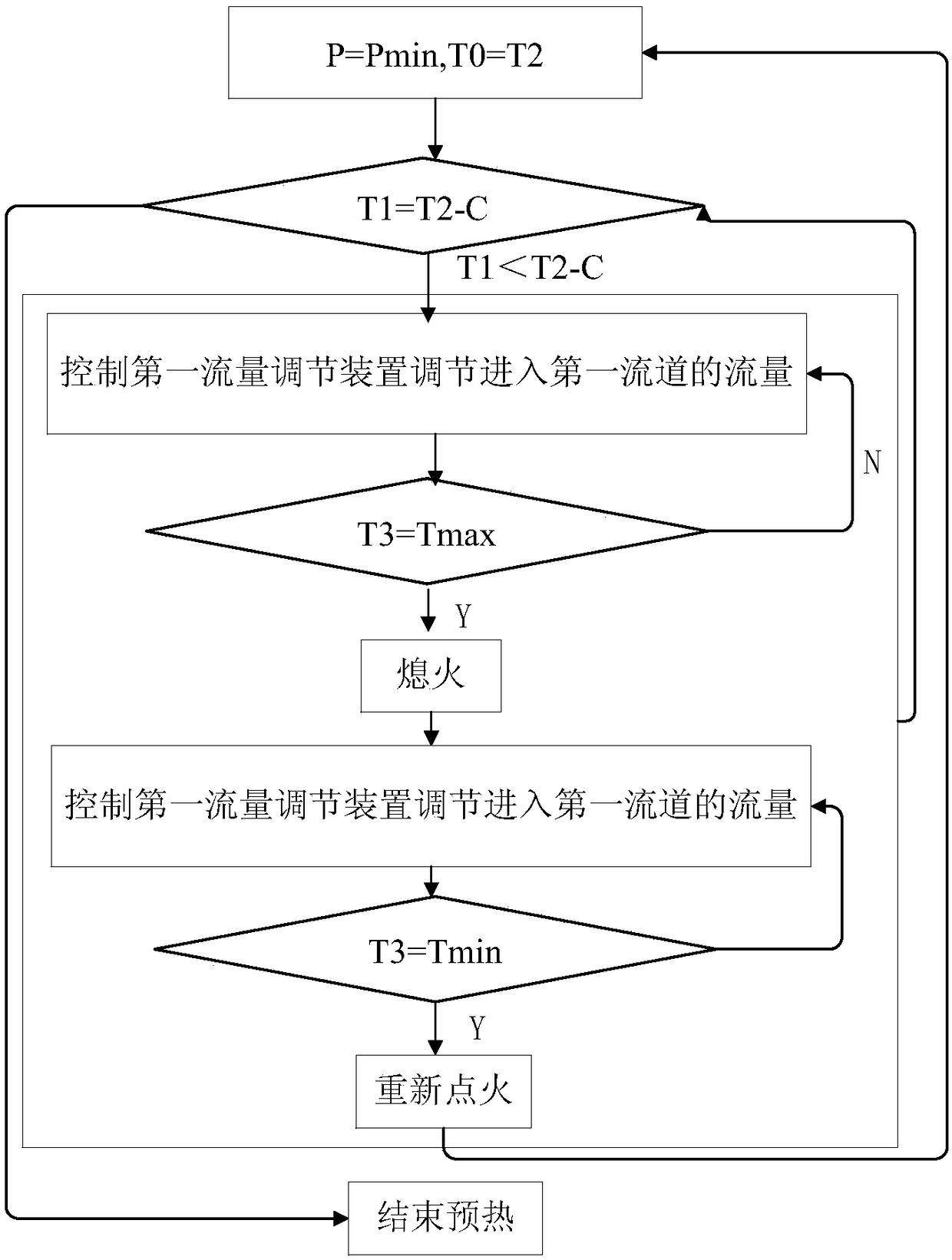

Gas-fired hot water device and control method thereof

The present invention discloses a gas-fired hot water device and a control method thereof. The gas-fired hot water device comprises: a first heat exchanger; a combustion device; a second heat exchanger with a first flow passage and a second flow passage, wherein the first flow passage is capable of communicating with the first heat exchanger; a third flow passage capable of communicating with thefirst heat exchanger; a first flow regulating device capable of distributing fluid flowing out of the first heat exchanger between the first flow passage and the third flow passage; a first water pumpcapable of driving fluid flowing through the first heat exchanger to flow into the first flow passage and / or the third flow passage; and a controller capable of controlling the first flow regulatingdevice and regulating the flow quantity of the first flow passage and the third flow passage when the thermal load required for the second flow passage is less than the minimum power of the combustiondevice. According to the device and the method of the present invention, hot water temperature can always be ensured to reach temperature set by a user by regulating the first flow regulating deviceand shunting the third flow passage when the required heat load is less than the minimum power of the gas-fired hot water device, thereby improving user experience.

Owner:A O SMITH CHINA WATER HEATER CO LTD

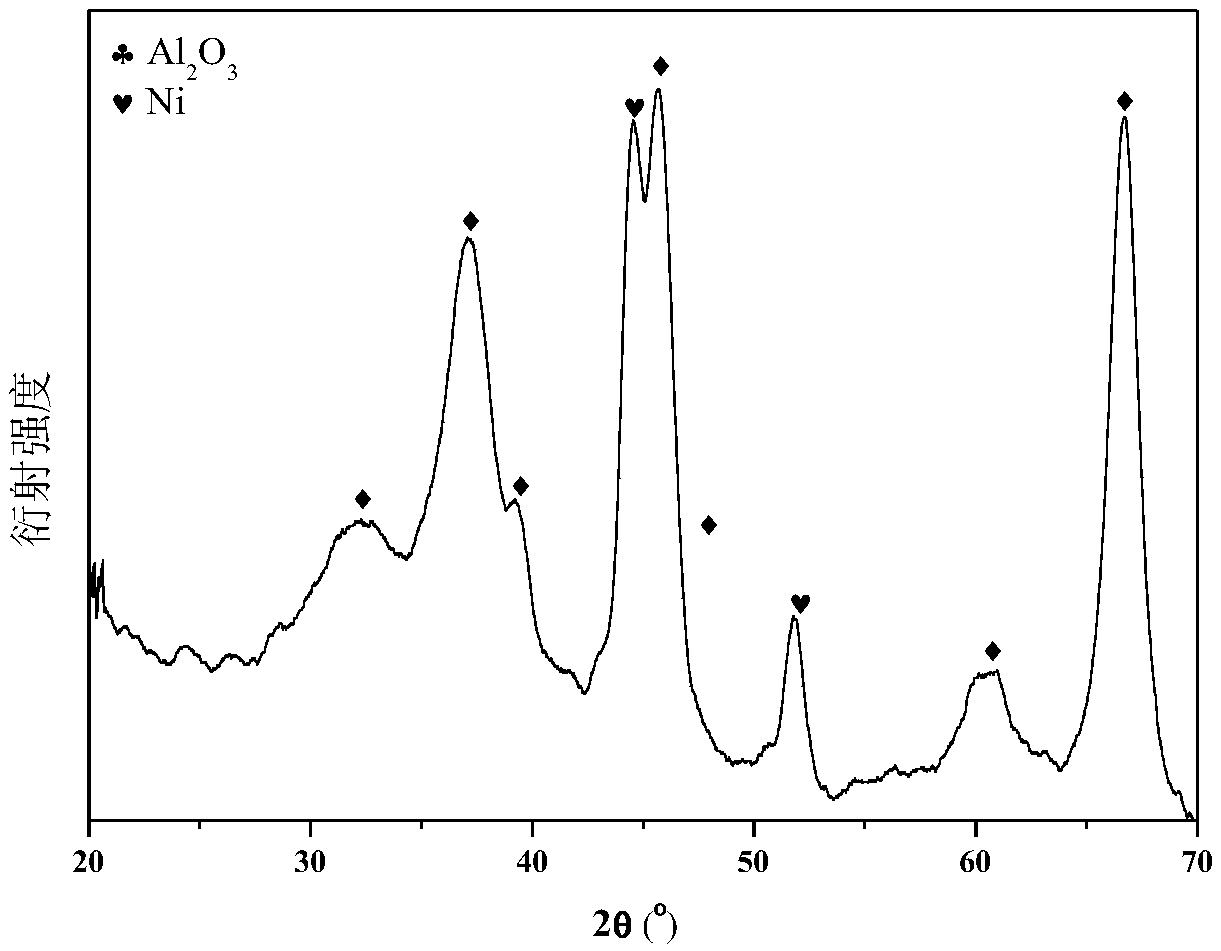

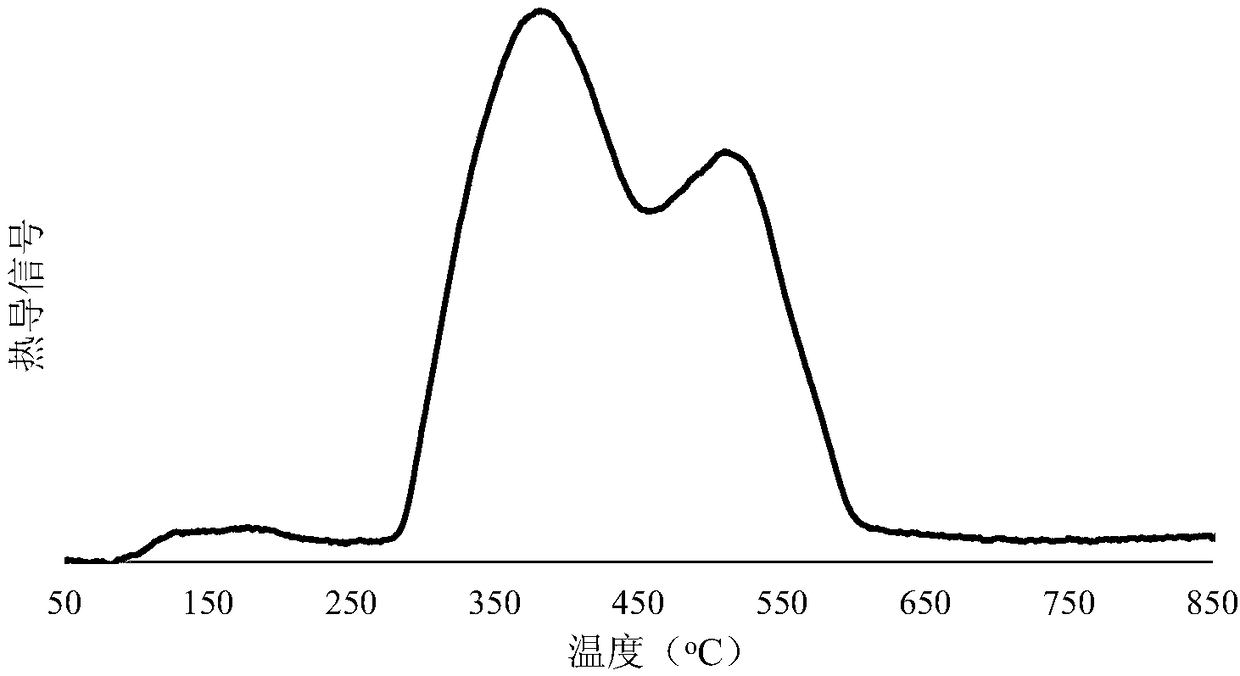

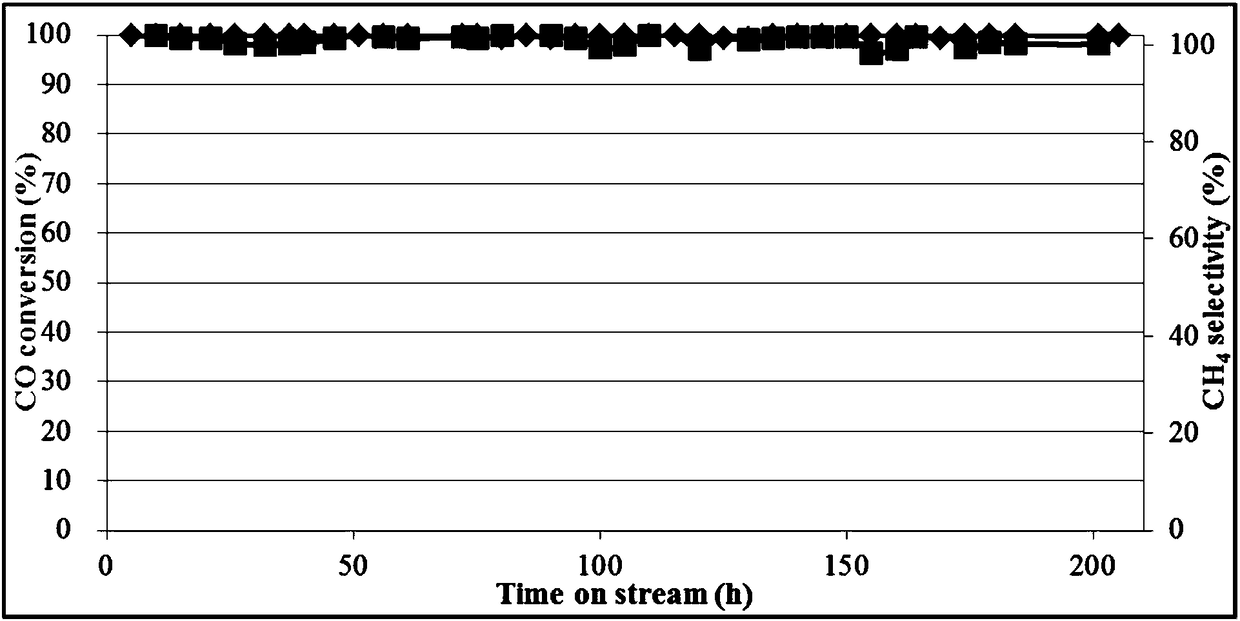

Methanation catalyst as well as preparation method and application thereof

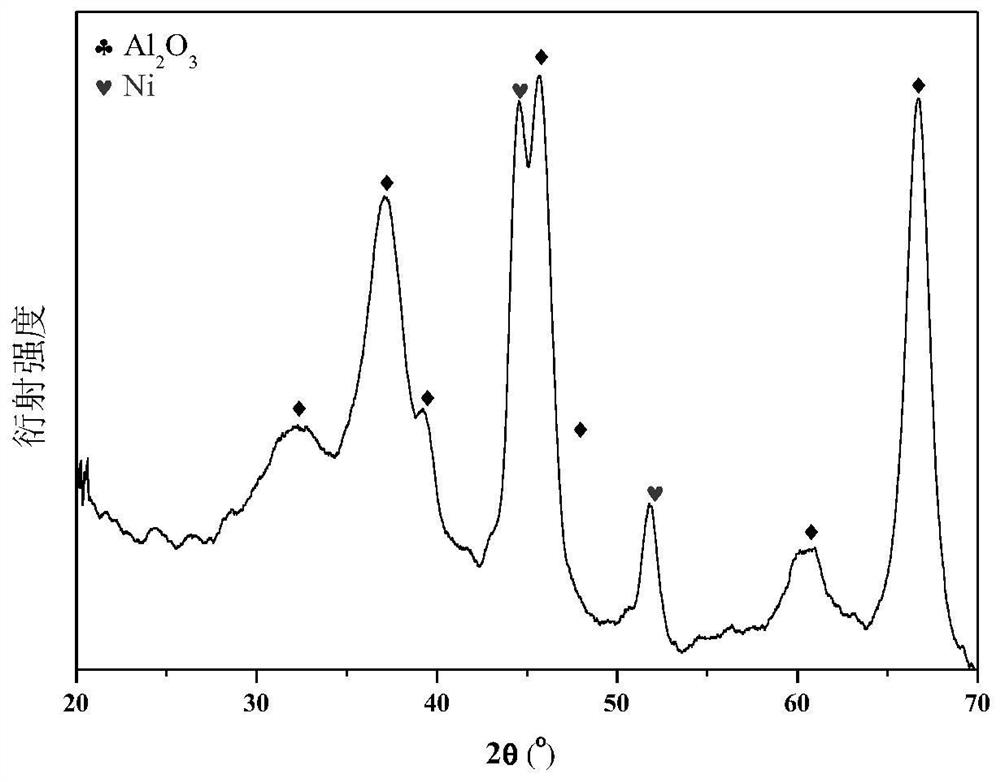

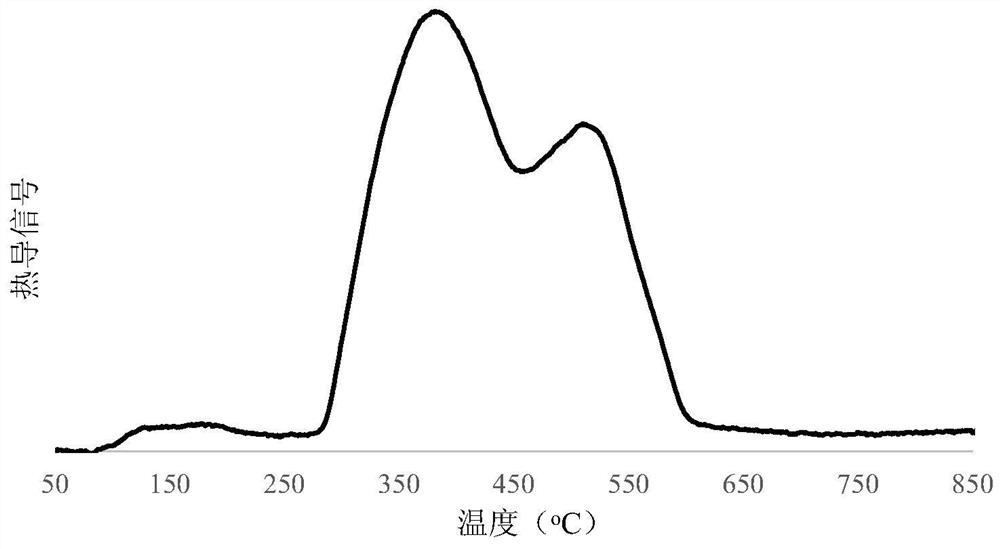

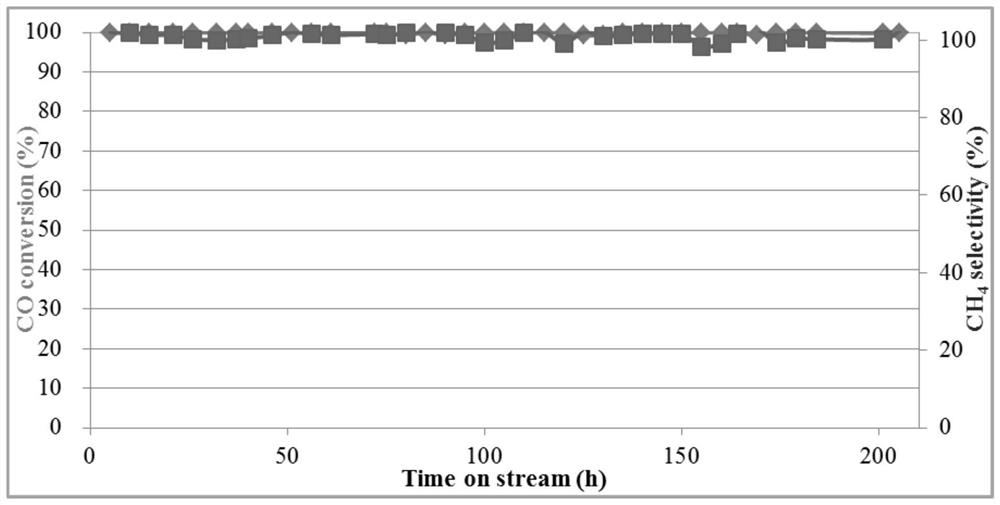

ActiveCN108355668AEvenly dispersedSmall grain sizeHeterogenous catalyst chemical elementsGaseous fuelsAlkaline earth metalPtru catalyst

The invention discloses a methanation catalyst as well as a preparation method and application thereof. The preparation method comprises the following steps: taking aluminum isopropoxide as a raw material to prepare aluminum sol through adopting a solvent-gel method; meanwhile, directly dissolving alkali metal auxiliary agent soluble salt and alkaline earth metal or rare earth metal modified auxiliary agent soluble salt into the aluminum sol; then concentrating, spraying and molding to obtain a micro-sphere carrier precursor; after drying and roasting, screening micro-sphere powder with a certain granularity range as a catalyst carrier; taking the micro-sphere powder as a carrier and loading active metal Ni and an auxiliary agent La2O3 by adopting a isovolumetric immersion method, so as toprepare the complete methanation catalyst applicable to a micro-channel reactor. The catalyst prepared by the method has relatively high activity, hydrothermal stability and carbon deposition resisting performance.

Owner:壹碳环投(北京)科技有限公司

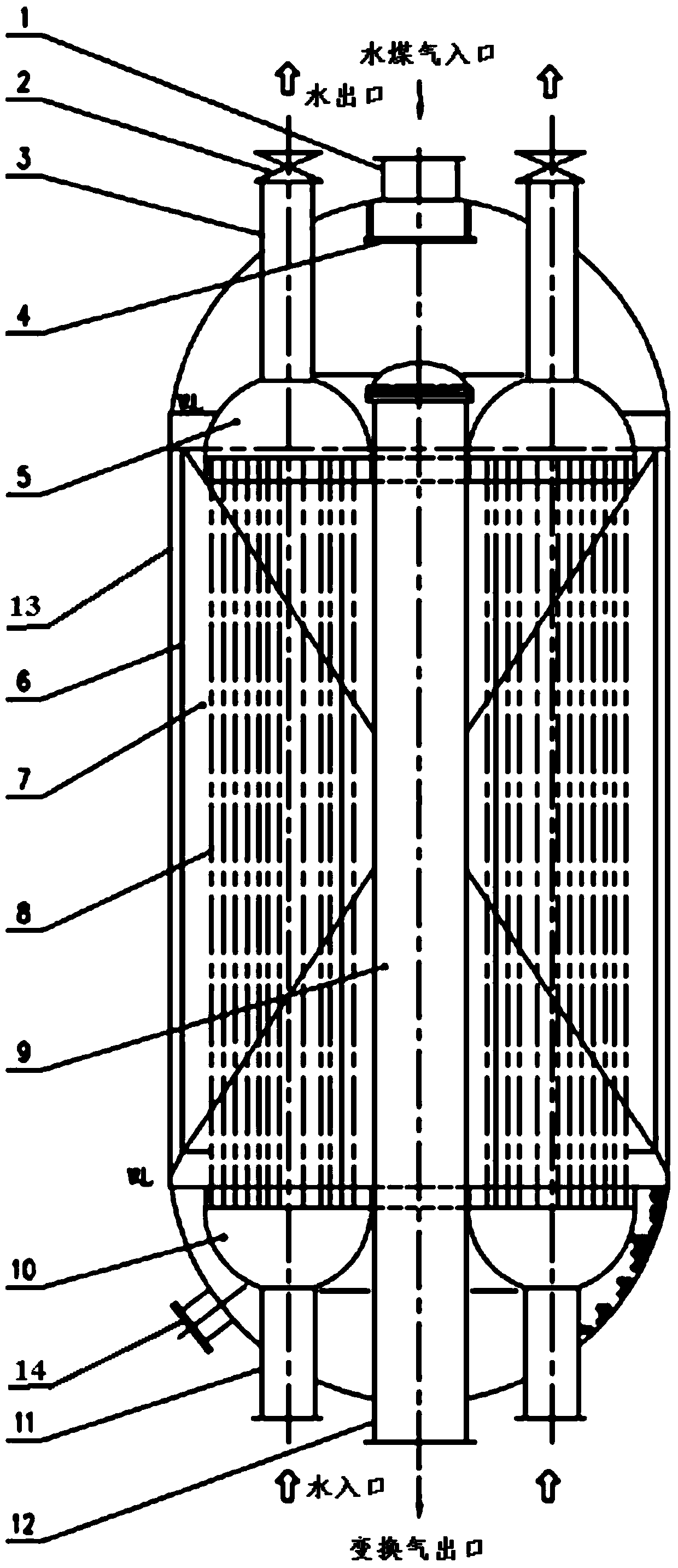

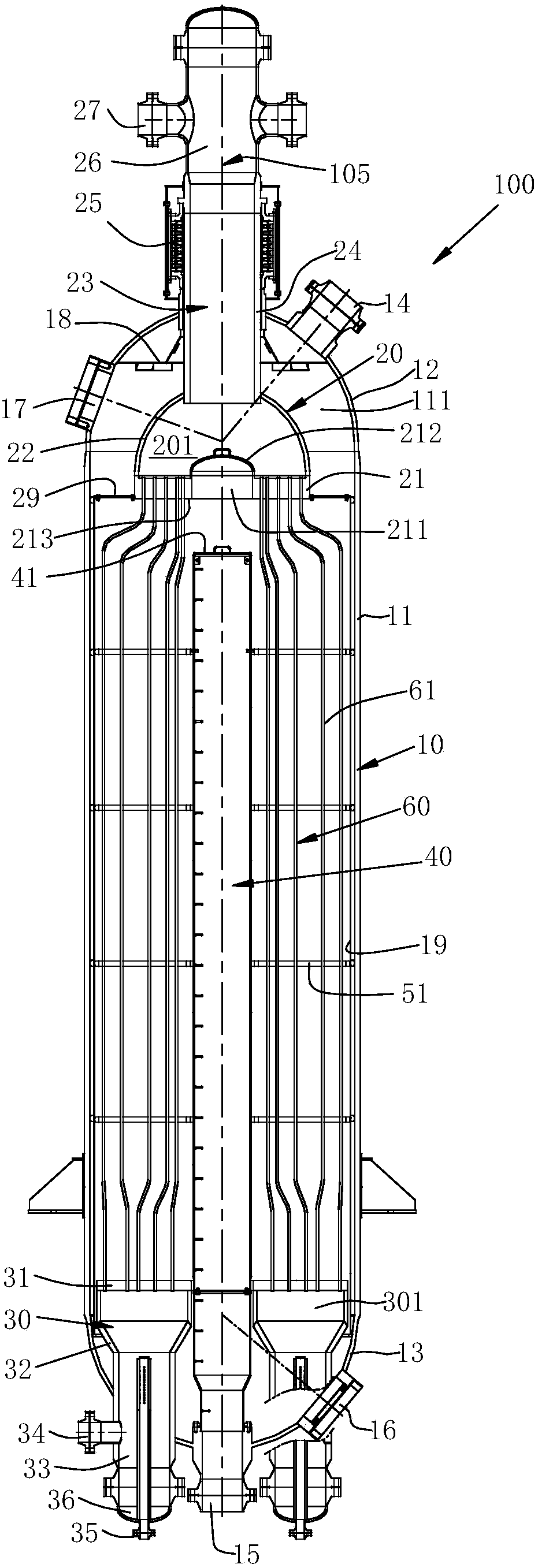

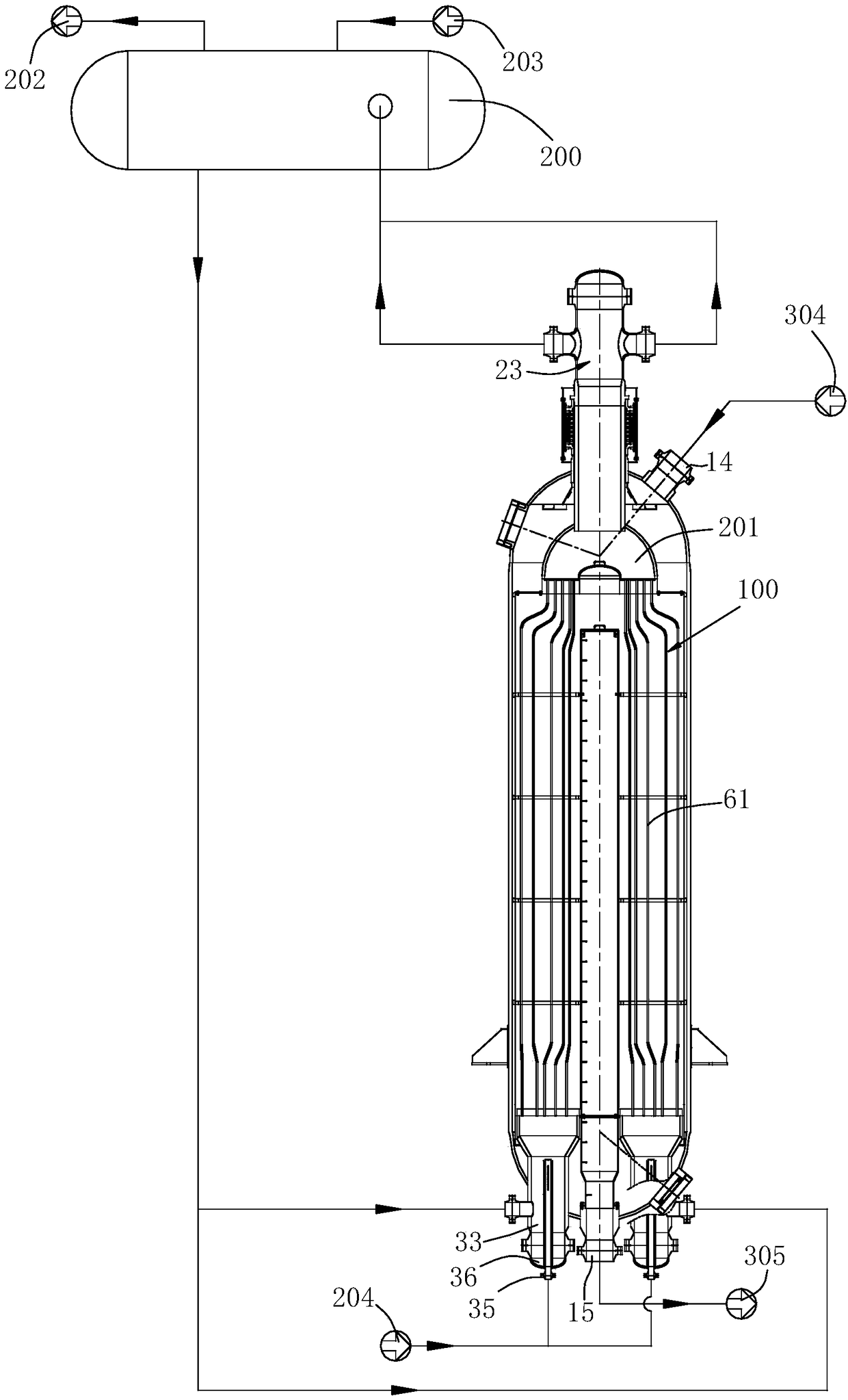

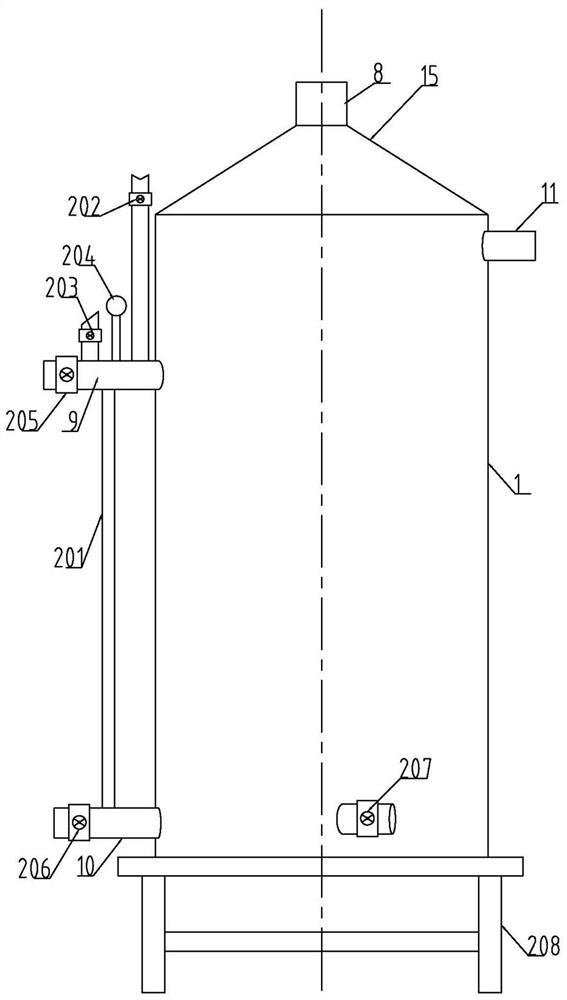

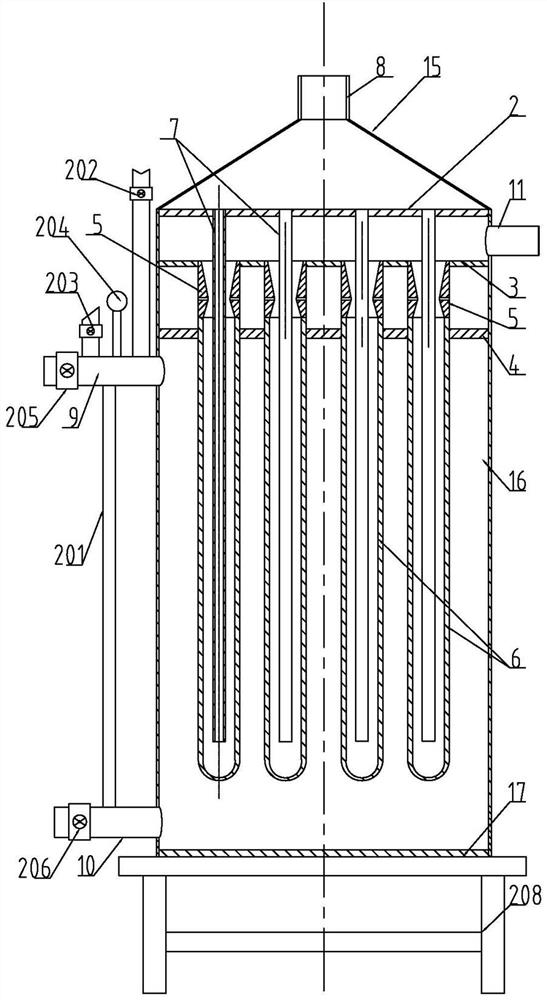

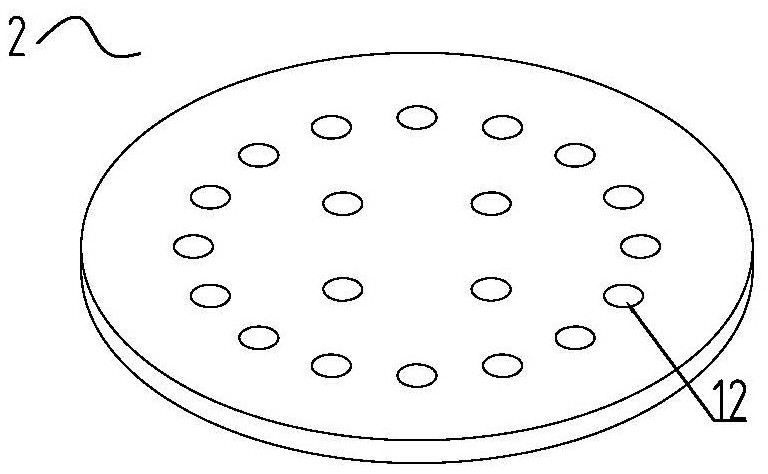

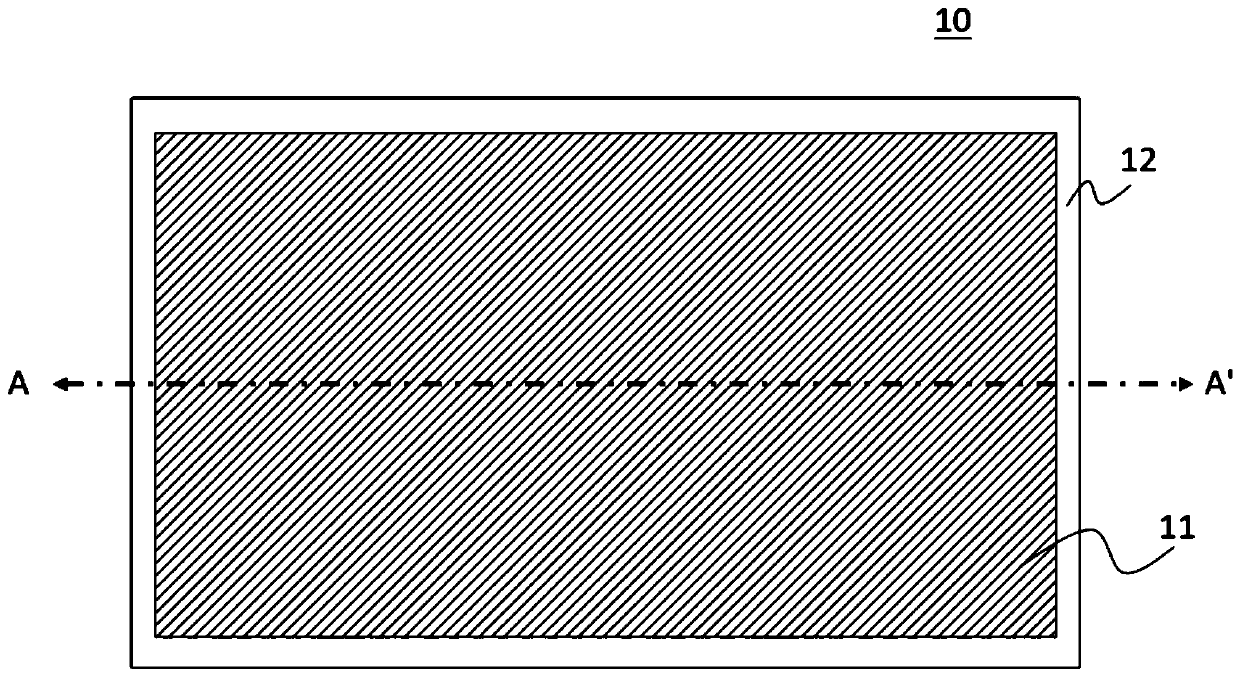

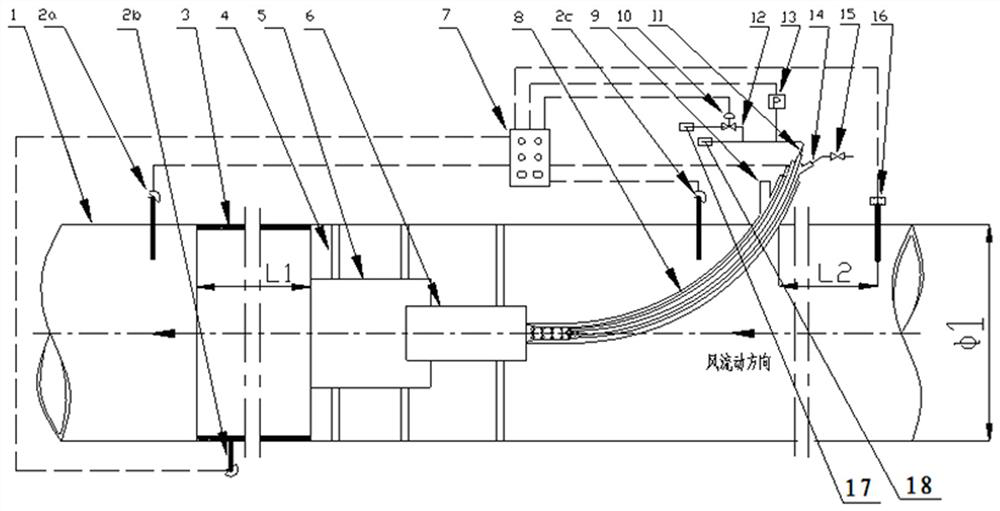

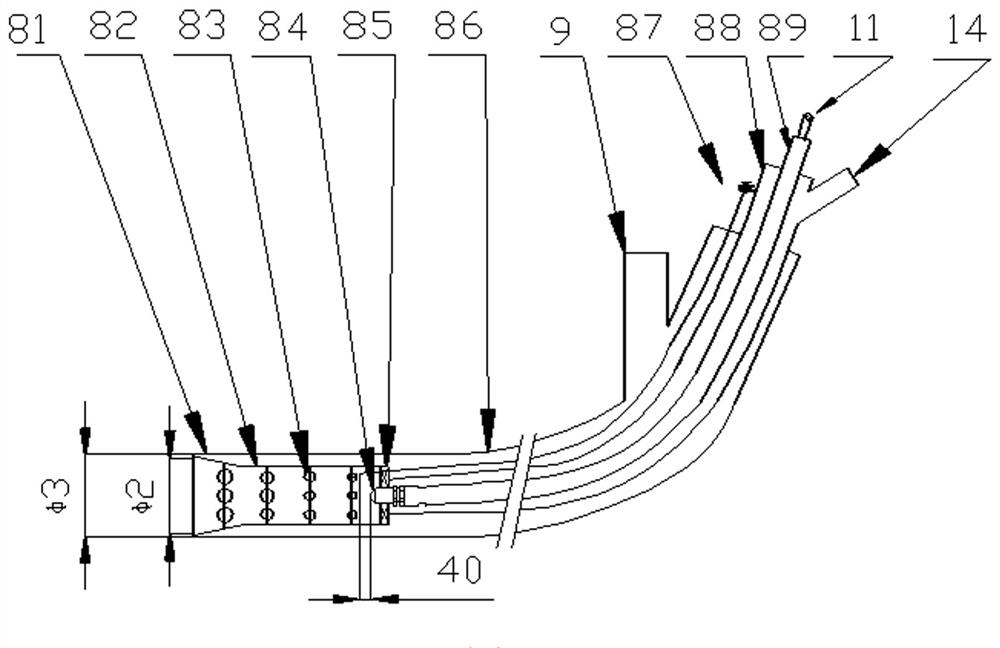

Radial flow by-product steam isothermal shift converter

InactiveCN105561889ANo overheating phenomenonUniform temperature distributionHydrogenChemical/physical processesEngineeringProcess engineering

The invention relates to the technical field of chemical engineering, in particular to a radial flow by-product steam isothermal shift converter. The radial by-product steam isothermal shift converter disclosed by the invention comprises a pressured furnace body, a catalyst bed, a gas distribution cylinder and a gas collector, and is characterized in that a raw material gas inlet and a water outlet are formed in the upper part of the pressured furnace body; a gas distributor is arranged in the pressured furnace body at the raw material gas inlet; a shift gas outlet and a water inlet are formed in the lower part of the pressured furnace body; the gas distribution cylinder is arranged between the inner wall of the pressured furnace body and the catalyst bed; the gas collector is arranged at the central axis of the pressured furnace body; a vertical heat extraction device is arranged in the catalyst bed, and comprises two ring-shaped tube boxes which are respectively arranged at the upper and lower positions of the catalyst red; a plurality of vertical column tubes are connected between the two ring-shaped tube boxes, and penetrate through the catalyst bed; the upper ring-shaped tube box is communicated with the water outlet; the lower ring-shaped tube box is communicated with the water inlet.

Owner:INNOVATIVE COAL CHEMICAL DESIGN INSTITUTE (SHANGHAI) CO LTD

Solid catalyst for synthesizing dimethyl ether by gas-phase method, its preparation and reactive process

InactiveCN1895779AEasy to prepareEasy to do reproducible preparationMolecular sieve catalystsEther preparation by compound dehydrationGas phaseMCM-41

A solid catalyst for the gas-phase synthesis of dimethylether is composed of ZSM-5 molecular sieve (50-90 Wt%) and zirconium oxide or MCM-41 molecular sieve (10-50 Wt%). Its preparing process and reaction technology are also disclosed.

Owner:NANKAI UNIV +1

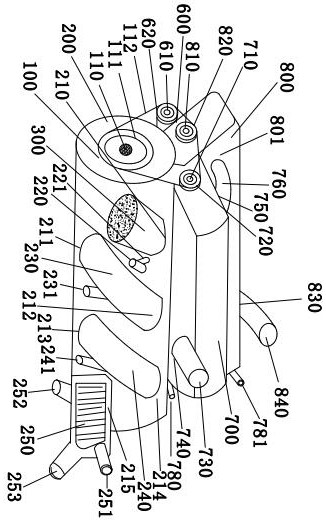

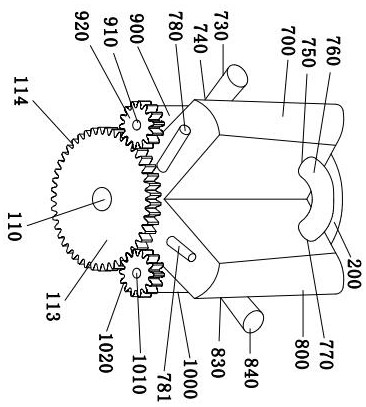

Auxiliary equipment of impeller cylinder combined engine

PendingCN113958408ALarge intake and exhaust volumeMeet gas supply requirementsRotary/oscillating piston combinations for elastic fluidsContinuous combustion chamberCombustion chamberHeat conservation

The invention discloses auxiliary equipment of an impeller cylinder combined engine. A cylinder is provided with a multi-stage air compressor for providing an air source for the engine and is provided with a high-pressure air storage tank; a first air injection hole outside the cylinder is provided with a heat preservation type combustion chamber and is connected with a group of air combustion switches for controlling; conditions are created for controlling the firepower and the air combustion ratio of the engine and doing work after air absorbs heat; one end of a first flow guide pipe and one end of a second flow guide pipe outside the cylinder are provided with a first flow guide branch pipe and a second flow guide branch pipe for heat preservation respectively; lubricating oil in the cylinder and the multi-stage air compressor is discharged into a first heat preservation type heat exchanger for heat exchange and then can be recycled; and a third exhaust hole outside the cylinder is provided with a second heat preservation type heat exchanger, and high-pressure air is subjected to heat absorption and pressurization by the two heat exchangers under the regulation and control of the air combustion switches and then returns into the cylinder through the two flow guide branch pipes for power assistance and work doing, so that the heat efficiency is higher. The heat engine belongs to an upgraded product of an internal combustion engine.

Owner:刘天锡

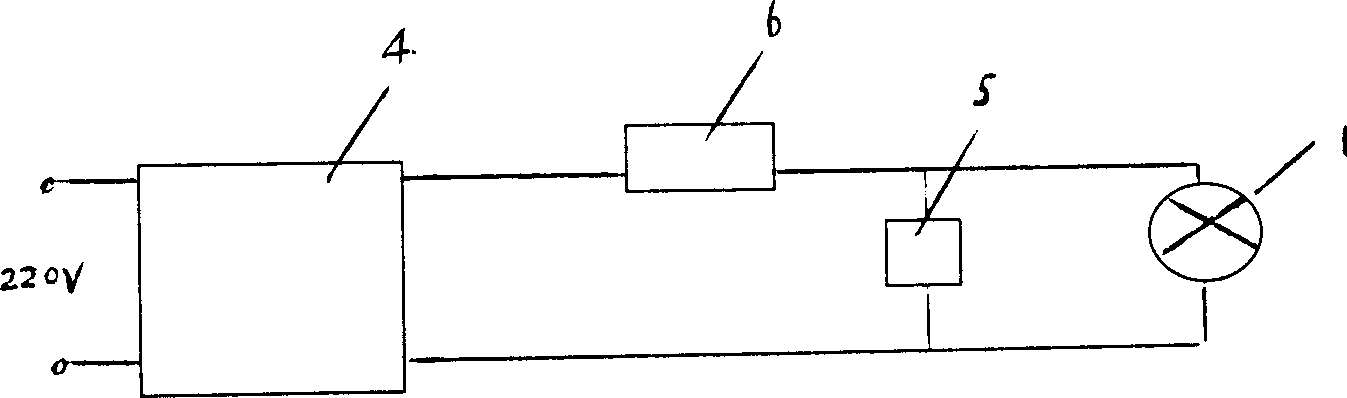

High-performance energy saving electric iron

The invention relates to an electric thermal welding device especially an energy-saving electric iron. The device comprises electrical source, small-sized tungsten halogen lamp as inner heater electric thermal barrel and brand iron head made by thin pipe of red copper, and takes compound heat-insulating material as heat-insulating layer with metal hull covering on it. The invention can adjust horsepower of electric iron and has the advantages of high heating efficiency, low hull temperature and long durability.

Owner:XIANGMING MIDDLE SCHOOL SHANGHAI

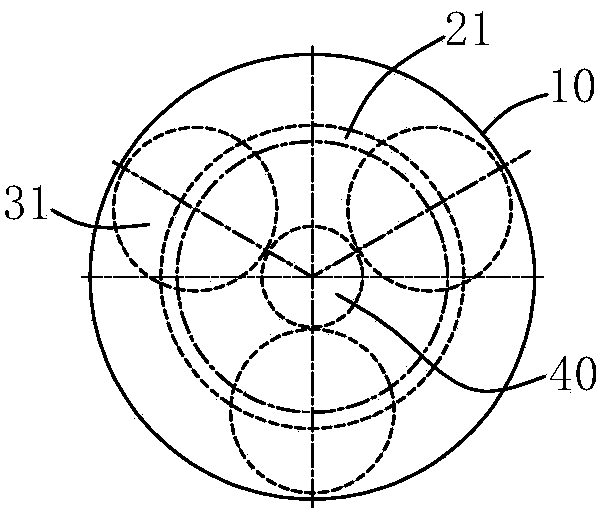

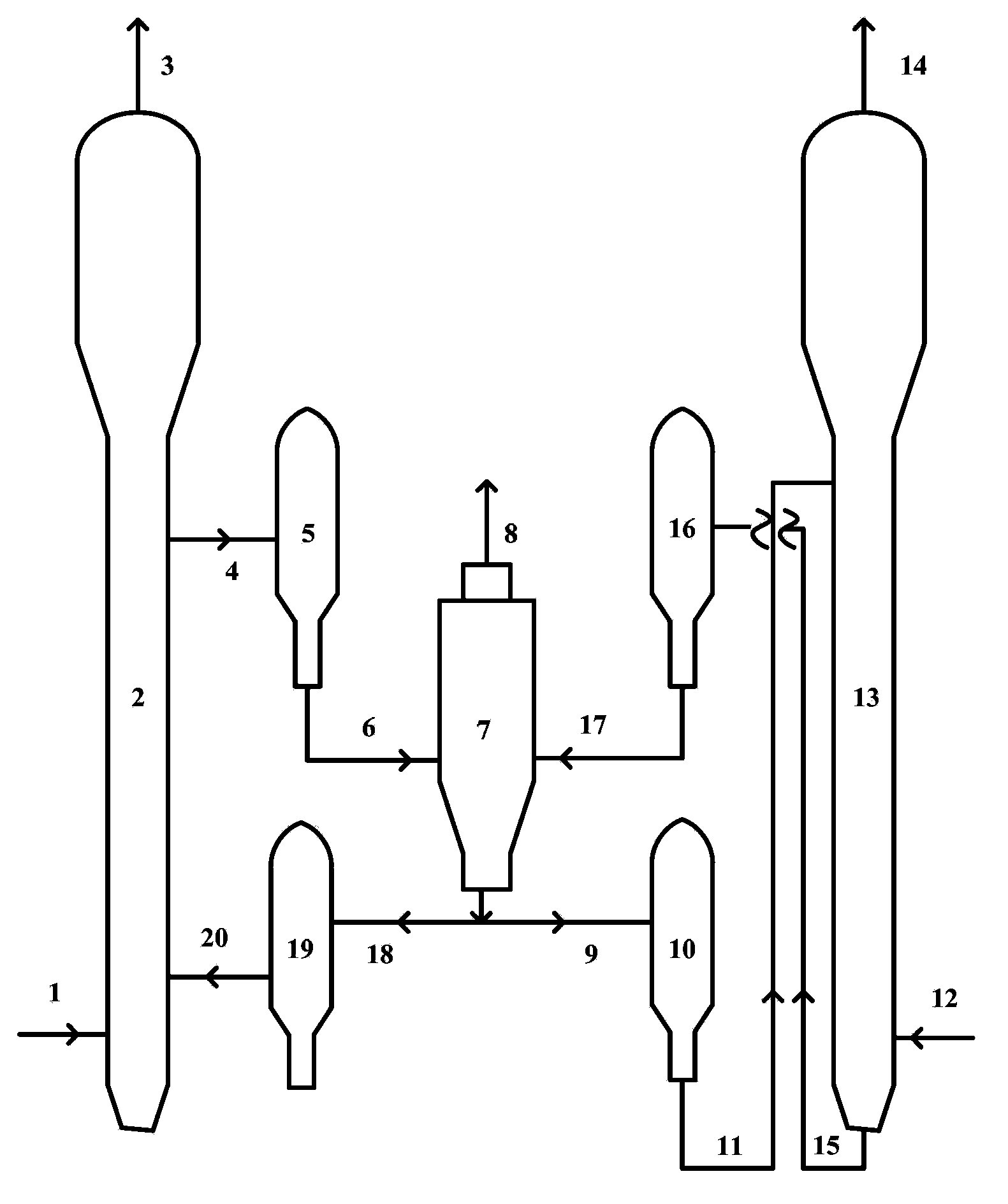

Asymmetric pipe-plate type bundle pipe reactor and methanol synthesis process

PendingCN108160008AEasy accessEasy maintenanceOrganic compound preparationHydroxy compound preparationBarrel ShapedProcess engineering

The invention discloses an asymmetric pipe-plate type bundle pipe reactor, which comprises a shell. Heat exchange pipes are arranged in the shell; the shell comprises a barrel-shaped barrel; only onefirst pipe-plate assembling unit is arranged on the upper end in the shell; three to six second pipe-plate assembling units are arranged on the lower end in the shell; the first pipe-plate assemblingunit is provided with only one first pipe plate; each second pipe-plate assembling unit comprises a second pipe plate; the upper end of each heat exchange pipe is connected with the first pipe plate;the heat exchange pipes are divided into multiple pipe groups; the lower end of the heat exchange pipe of each pipe group is arranged on one second pipe plate. The invention also discloses a methanolsynthesis process using the bundle pipe reactor. According to the reactor, the heat exchange pipes and the pipe plates are reasonably arranged in a limited space, so that an overhaul space of the reactor is enlarged within an allowable range, and the reactor can be processed and overhauled conveniently.

Owner:NANJING JUTUO CHEM TECH

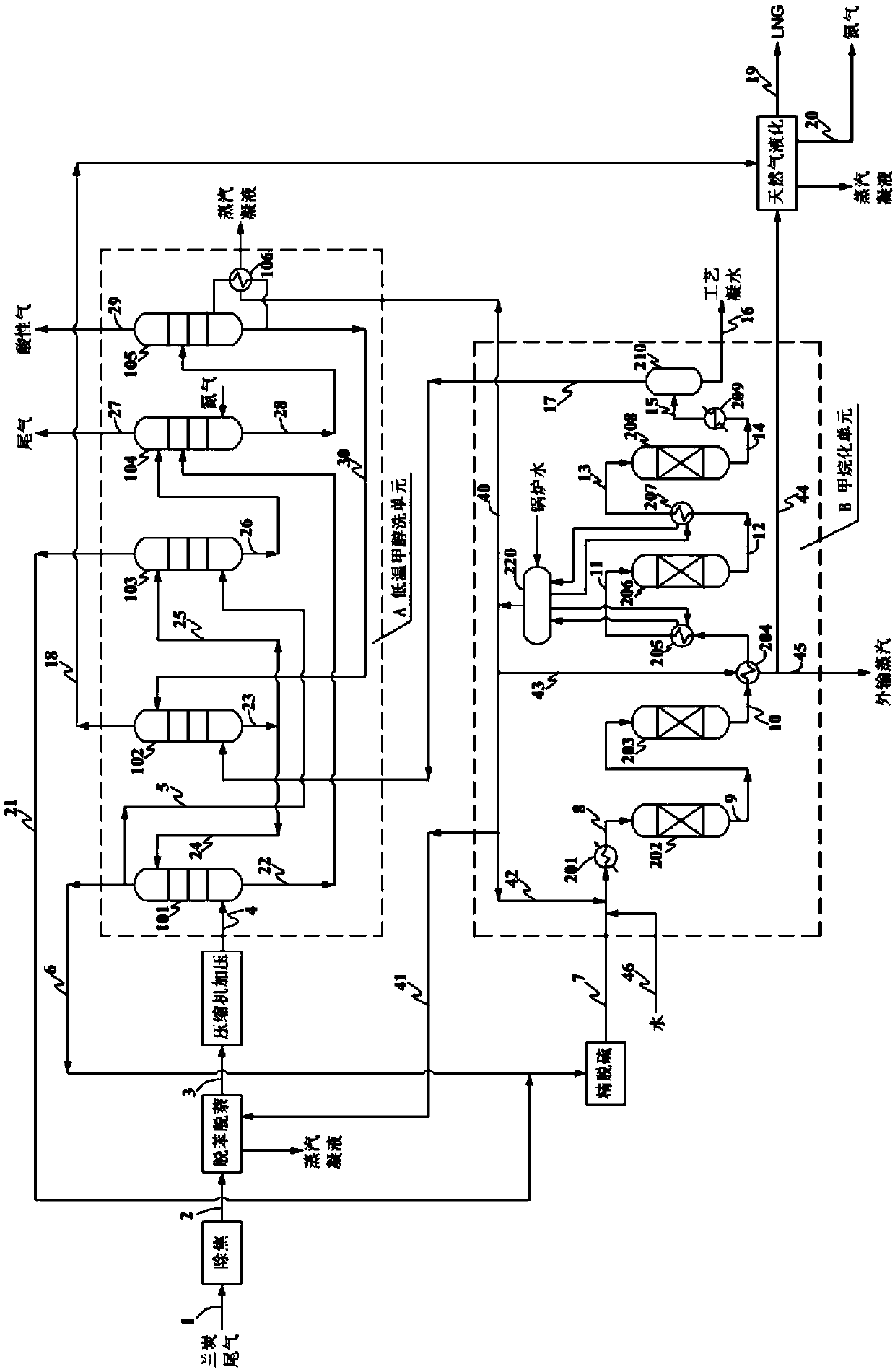

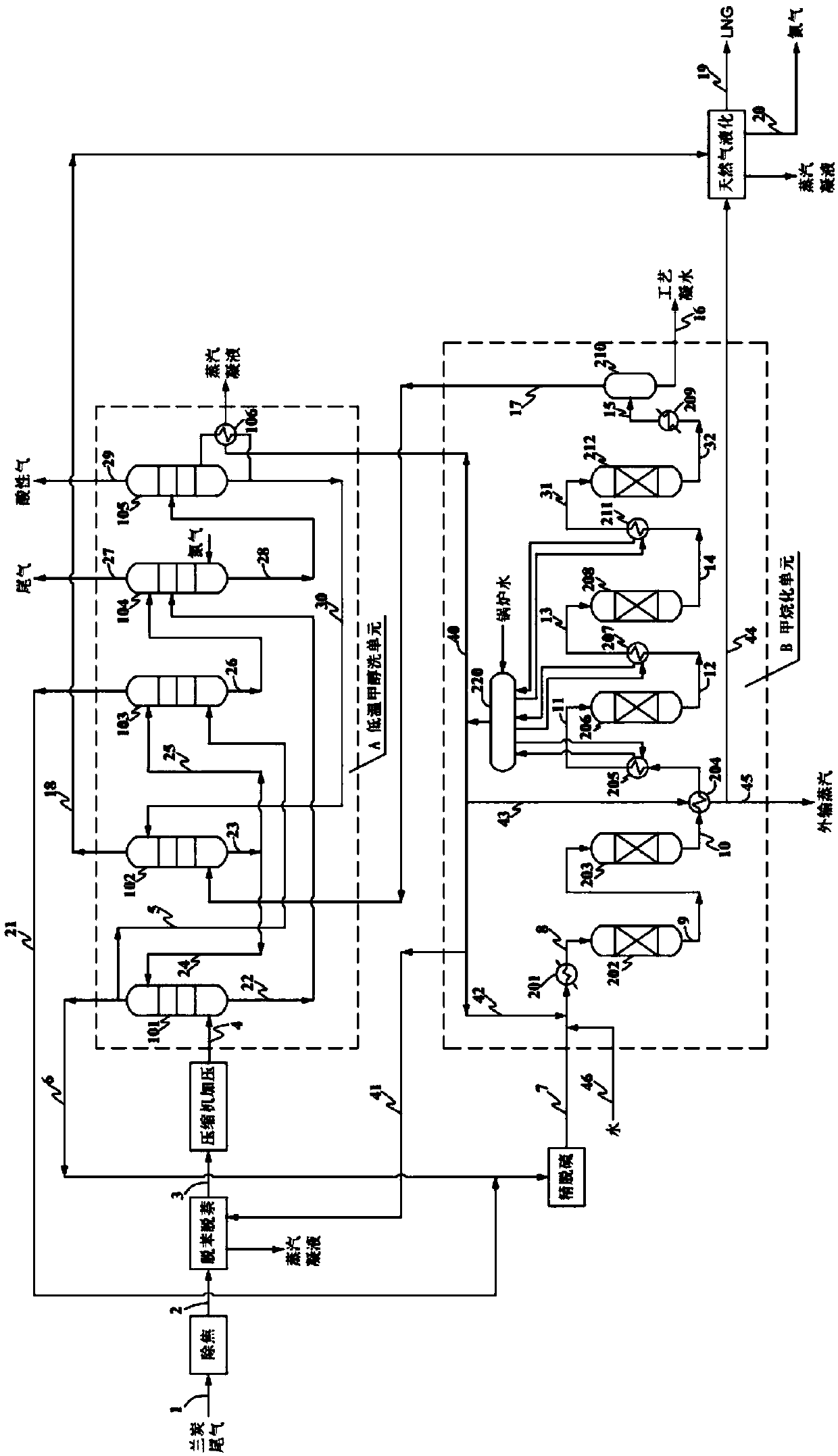

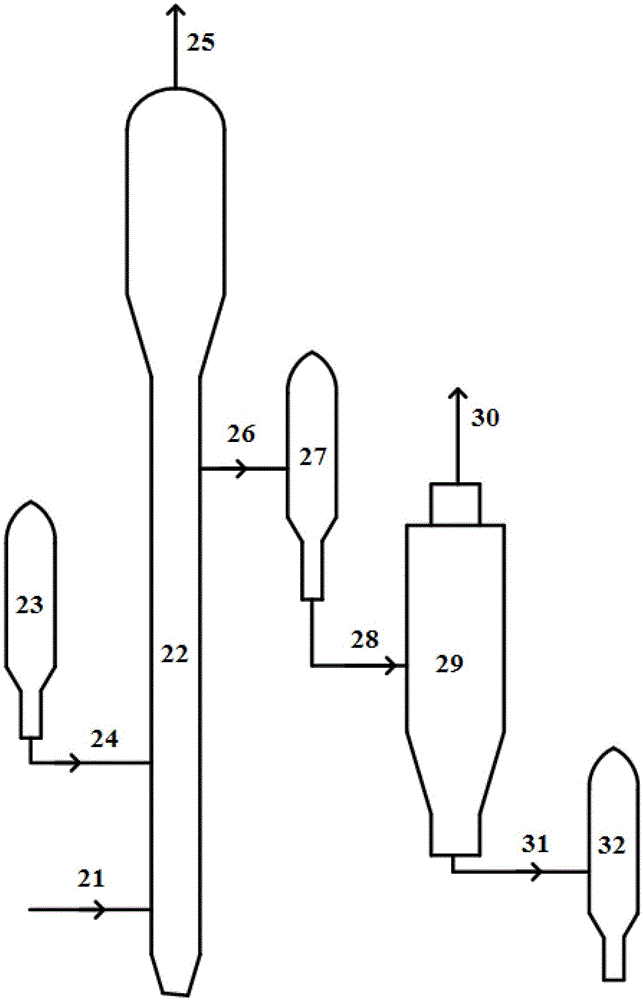

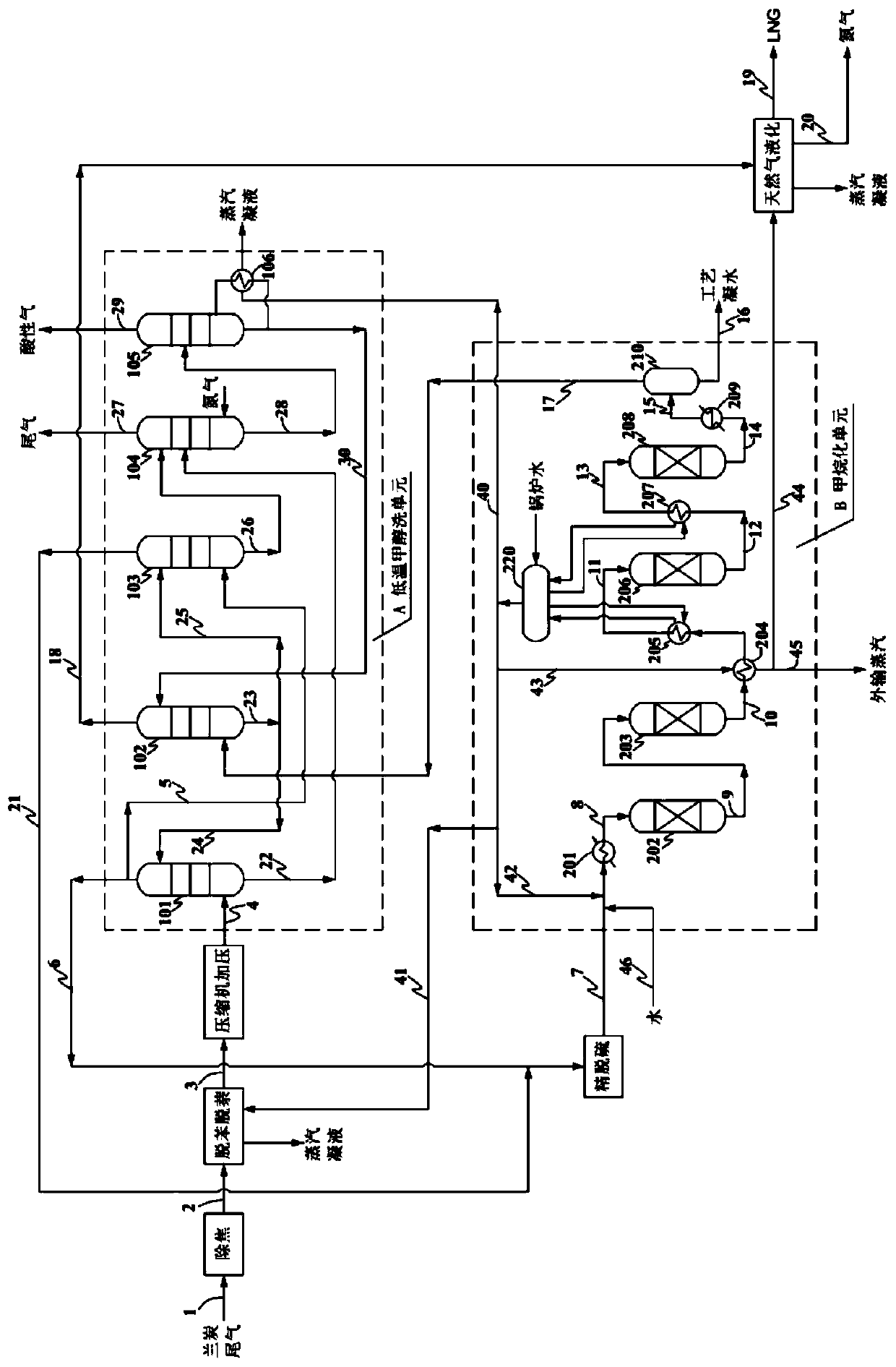

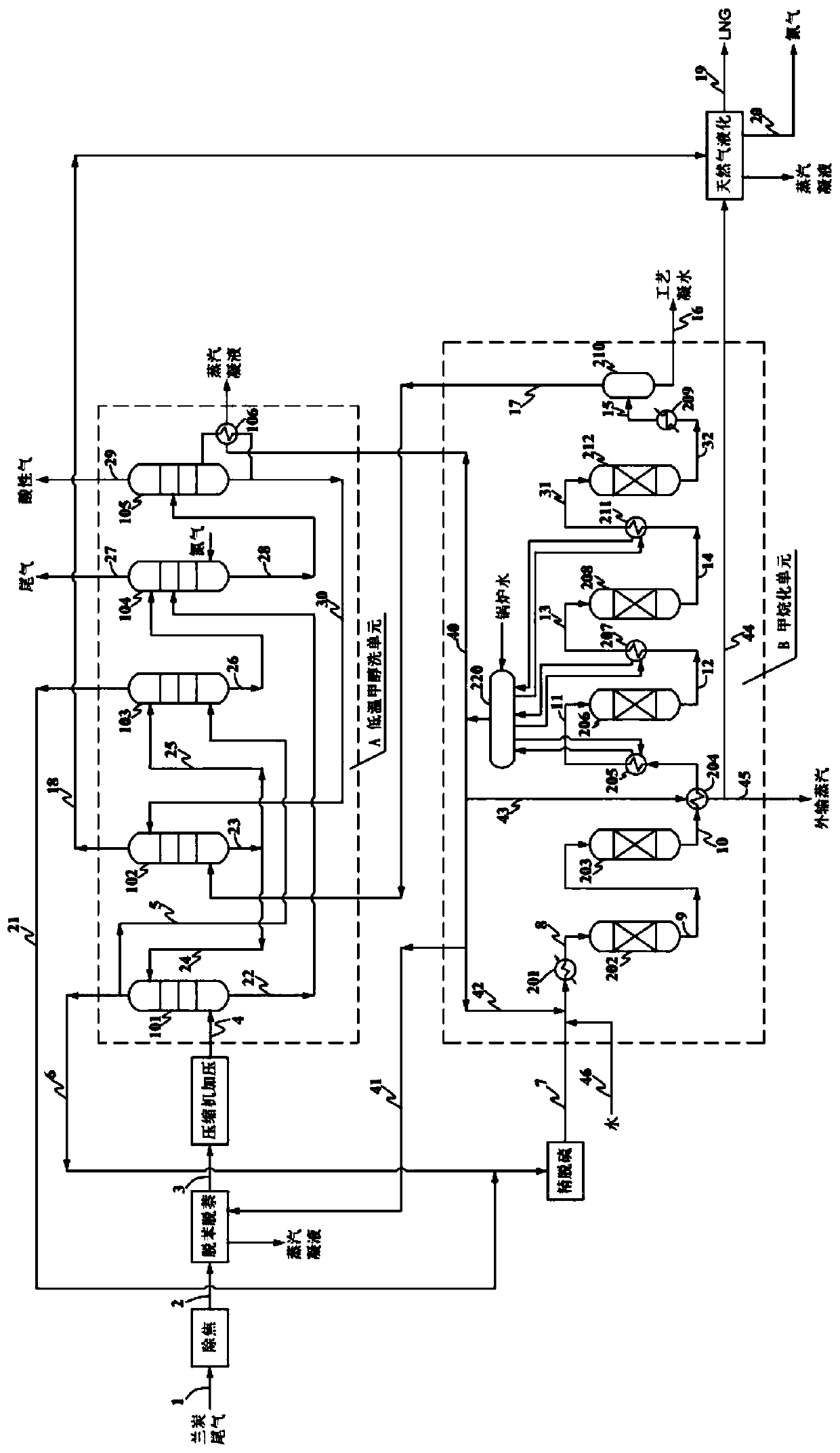

Method for preparing liquefied natural gas from semi-coke tail gas

The invention relates to a method for preparing liquefied natural gas from semi-coke tail gas. The method includes: firstly, after decoking and benzene and naphthalene removal of semi-coke tail gas, and sending to a rectisol unit for purification and desulfurization; then, mixing the desulfurized semi-coke tail gas with high-methane gas, jointly sending into a methanation unit for methanation to obtain a crude methane gas product, sending into the rectisol unit for purification and decarbonization; finally, performing cryogenic separation to remove nitrogen to obtain liquefied natural gas. Compared with the prior art, the method has advantages that by semi-coke tail gas treatment through the rectisol unit and the methanation unit, circulation absorbing agent consumption is sharply reduced,and energy consumption and system CH4 loss in a decarbonization process are reduced; in addition, by adoption of recovered CH4-rich gas and injection of water and / or system self-produced water vaporinto the methanation unit, methanation reaction temperature rise can be controlled so as to guarantee a methanation process against temperature runaway; moreover, heat balance of a whole system can beeffectively realized in the whole process, and economy in preparation of LNG (liquefied natural gas) from the semi-coke tail gas is improved.

Owner:WISON ENG

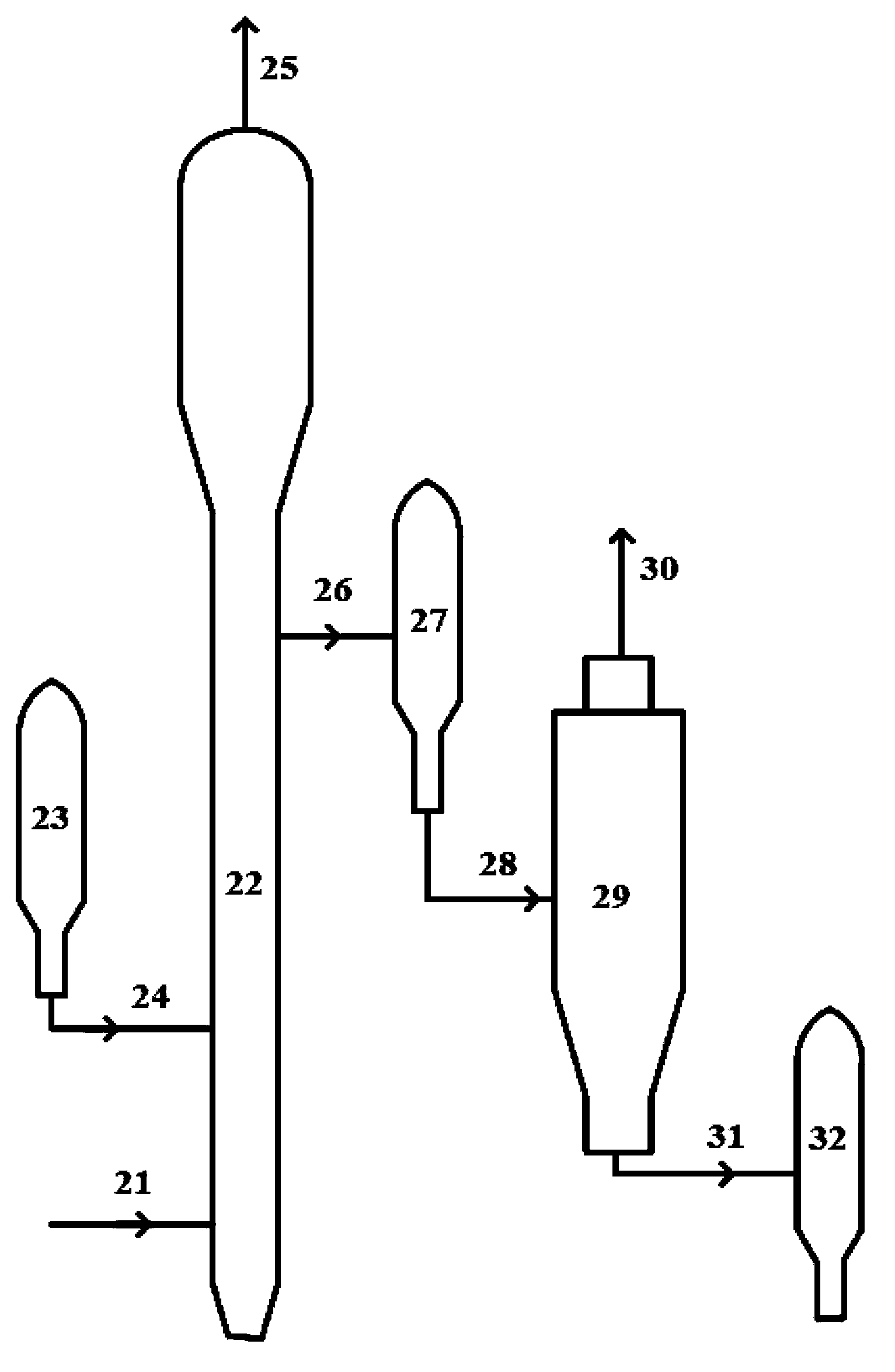

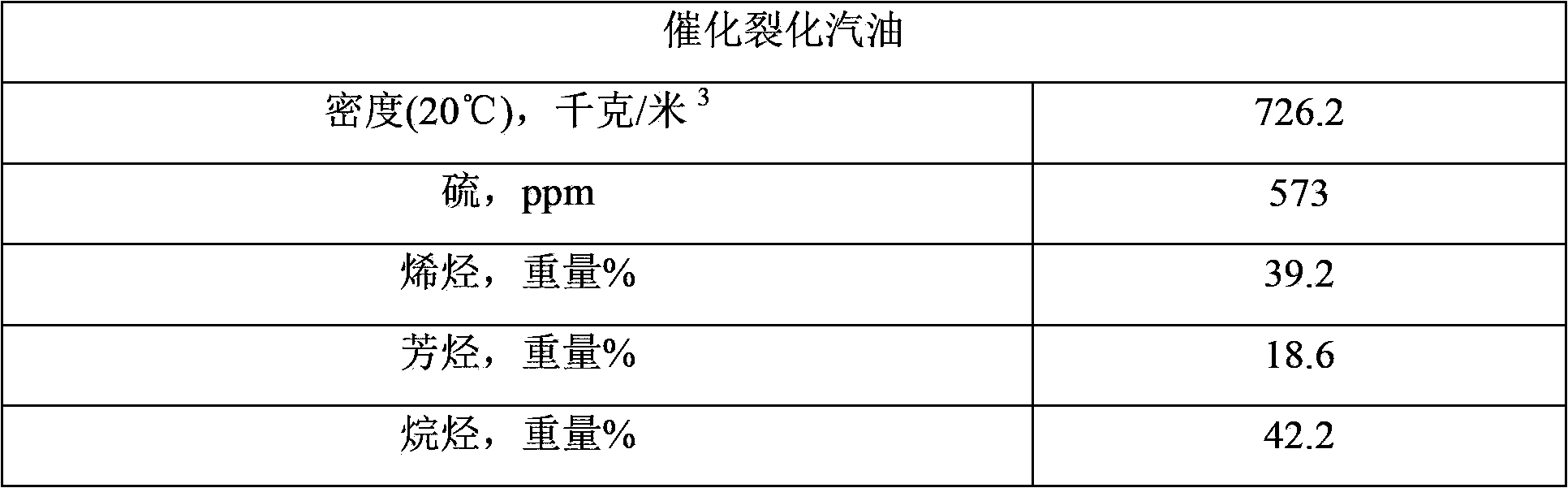

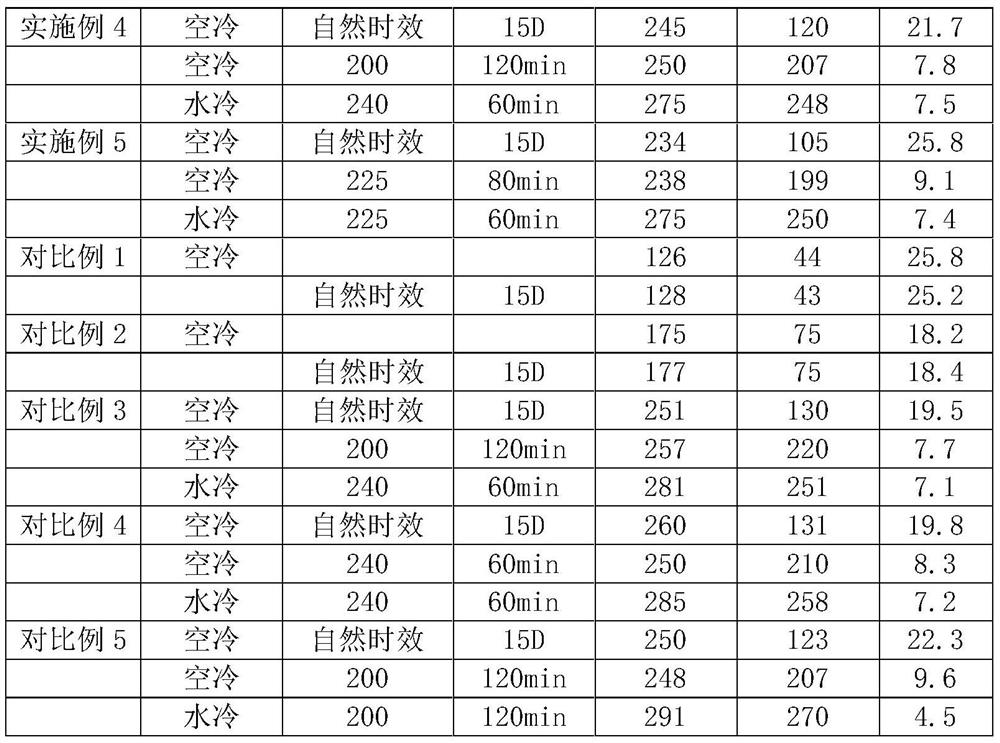

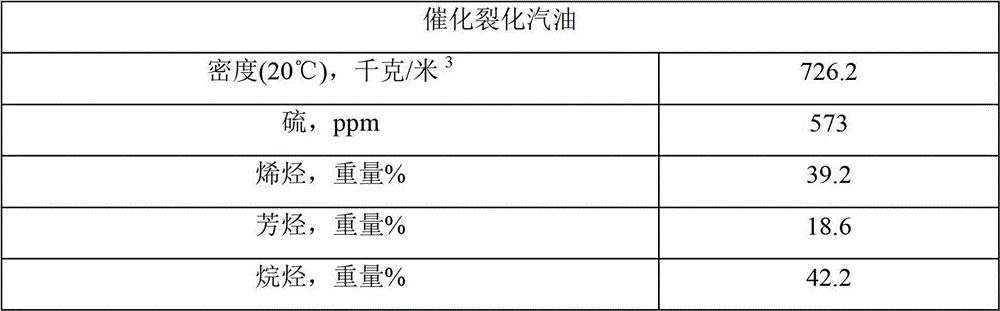

Pretreatment method for desulphurization adsorbents and desulphurization method for sulfur-containing hydrocarbon raw materials

ActiveCN103773440AReduced activityReduce saturation activityGaseous fuelsDispersed particle separationPretreatment methodHydrogen

The invention relates to a pretreatment method for desulphurization adsorbents. The pretreatment method comprises: desulphurization adsorbents and hydrocarbon raw materials containing alkenes are subjected to contact reaction under a non-hydrogen condition. The invention also relates to a desulphurization method for sulfur-containing hydrocarbon raw materials. The desulphurization method comprises: desulphurization adsorbents are pretreated according to the above method, and the pretreated desulphurization adsorbents are obtained; sulfur-containing hydrocarbon raw materials, hydrogen donors and the pretreated desulphurization adsorbents are subjected to contact reaction under an adsorption desulphurization reaction condition. The pretreatment method for desulphurization adsorbents takes an obviously short time, and when catalytic cracking gasoline with high content of alkenes is subjected to desulphurization, the pretreated desulphurization adsorbents obtained through the pretreatment method can prevent reactor temperature runaway phenomena caused by vast alkene saturation during the startup process effectively, and the startup difficulty is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

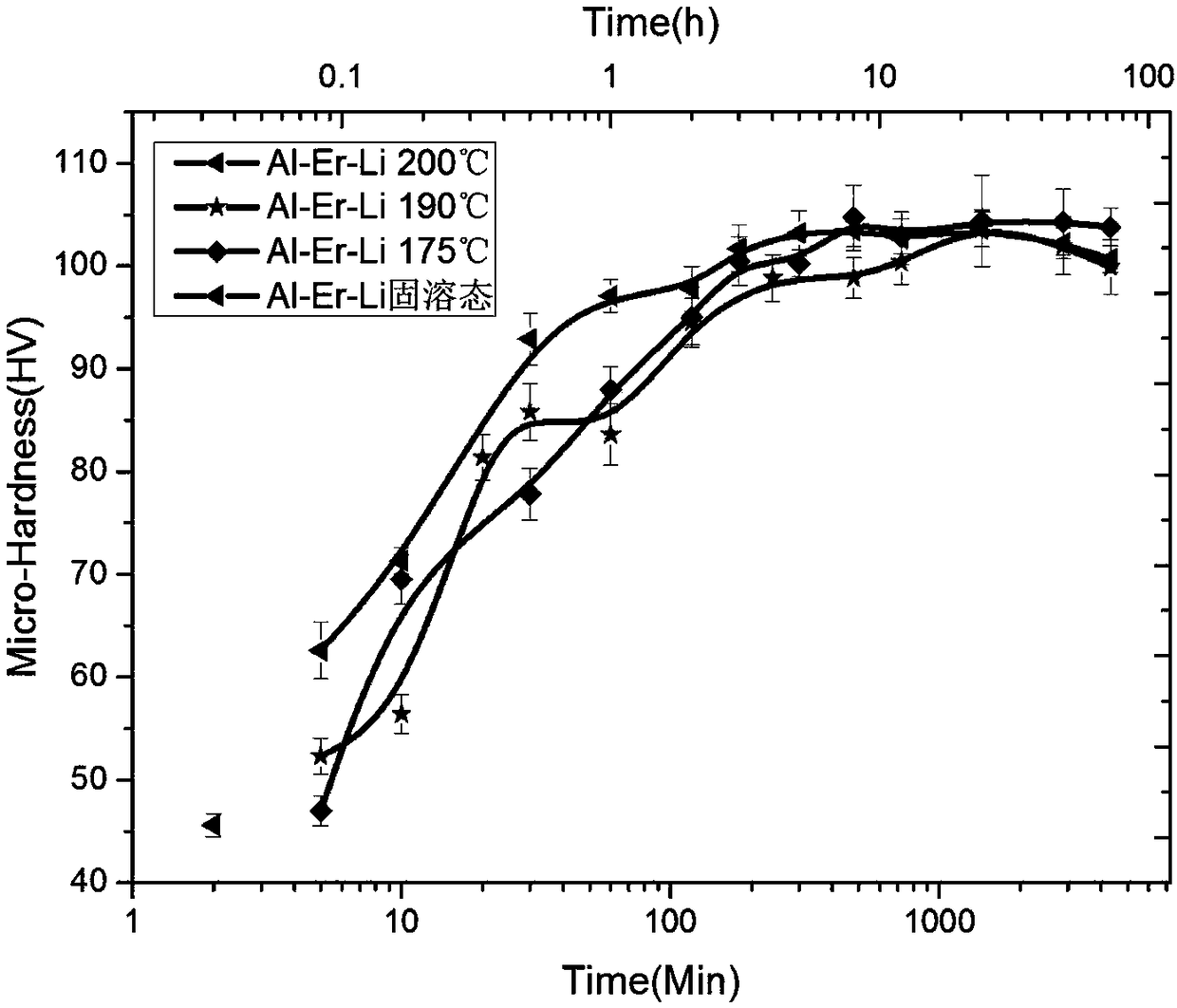

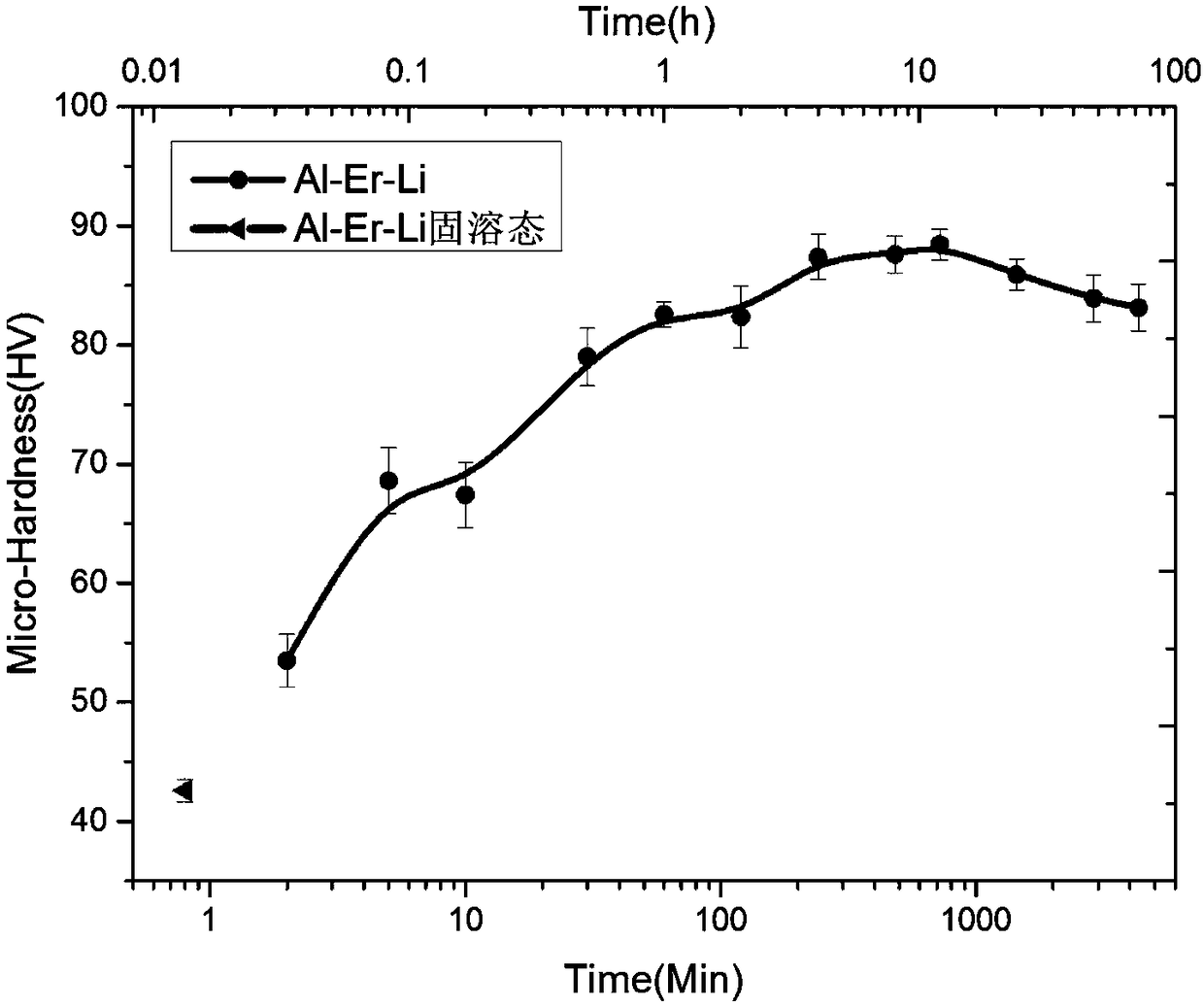

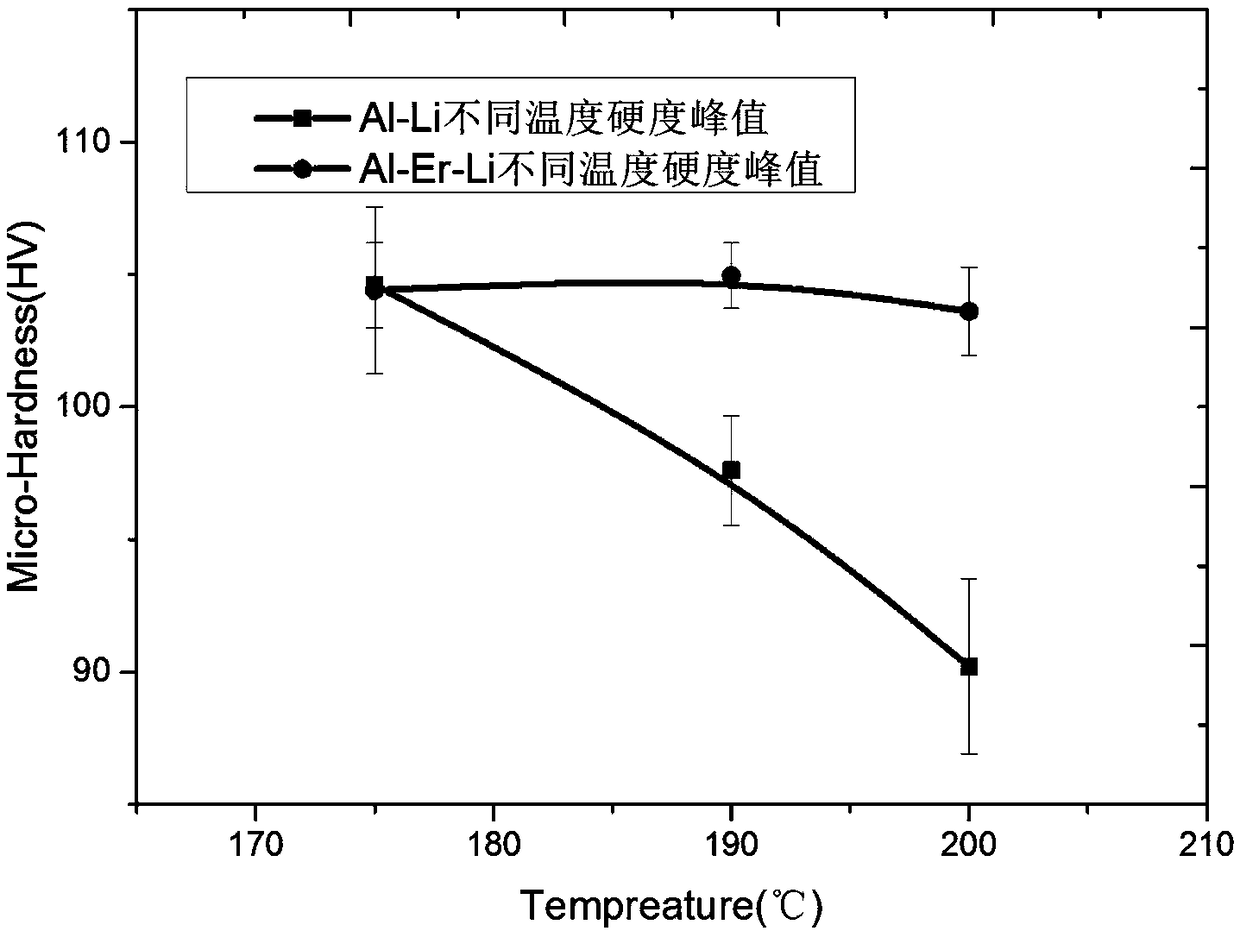

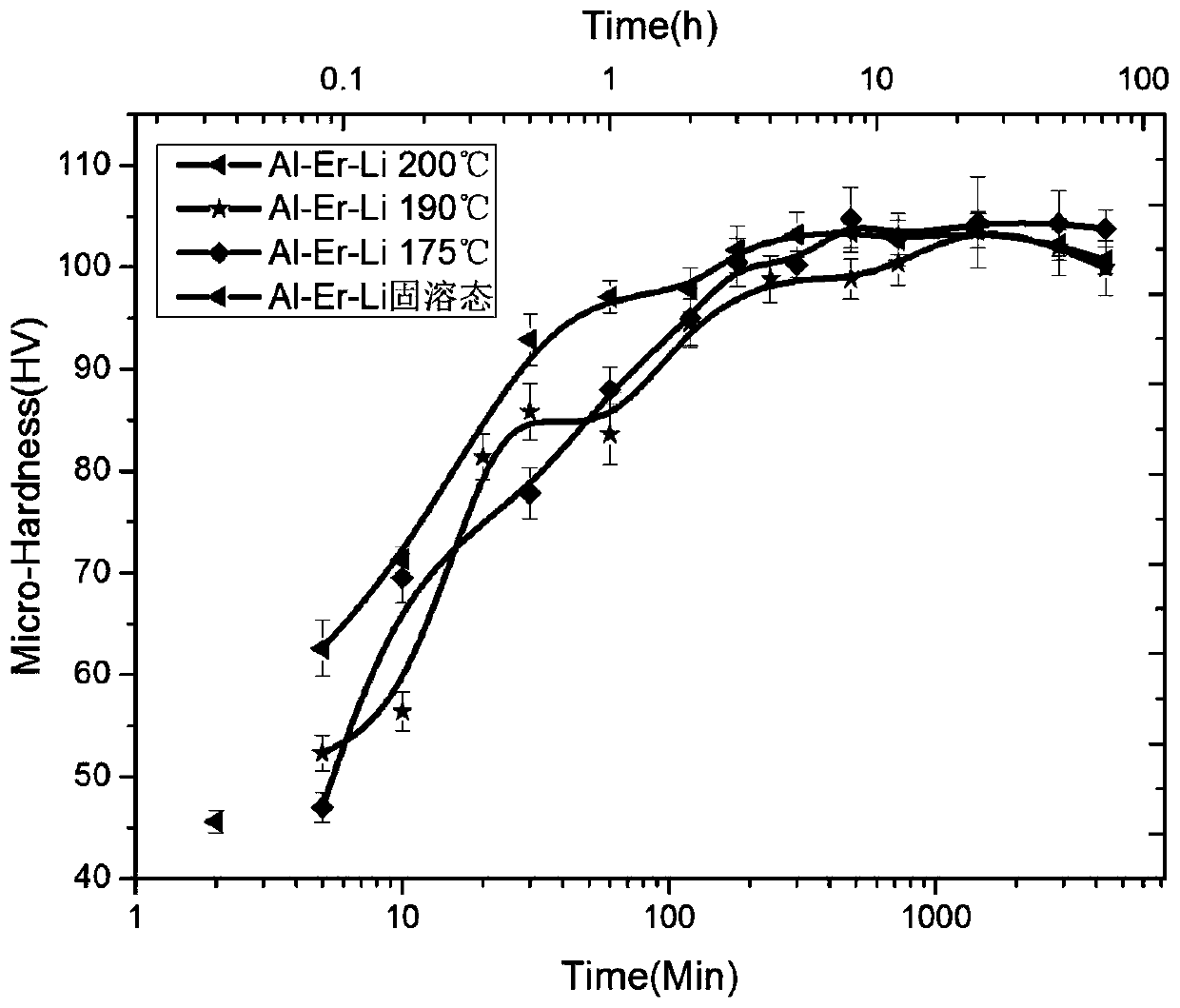

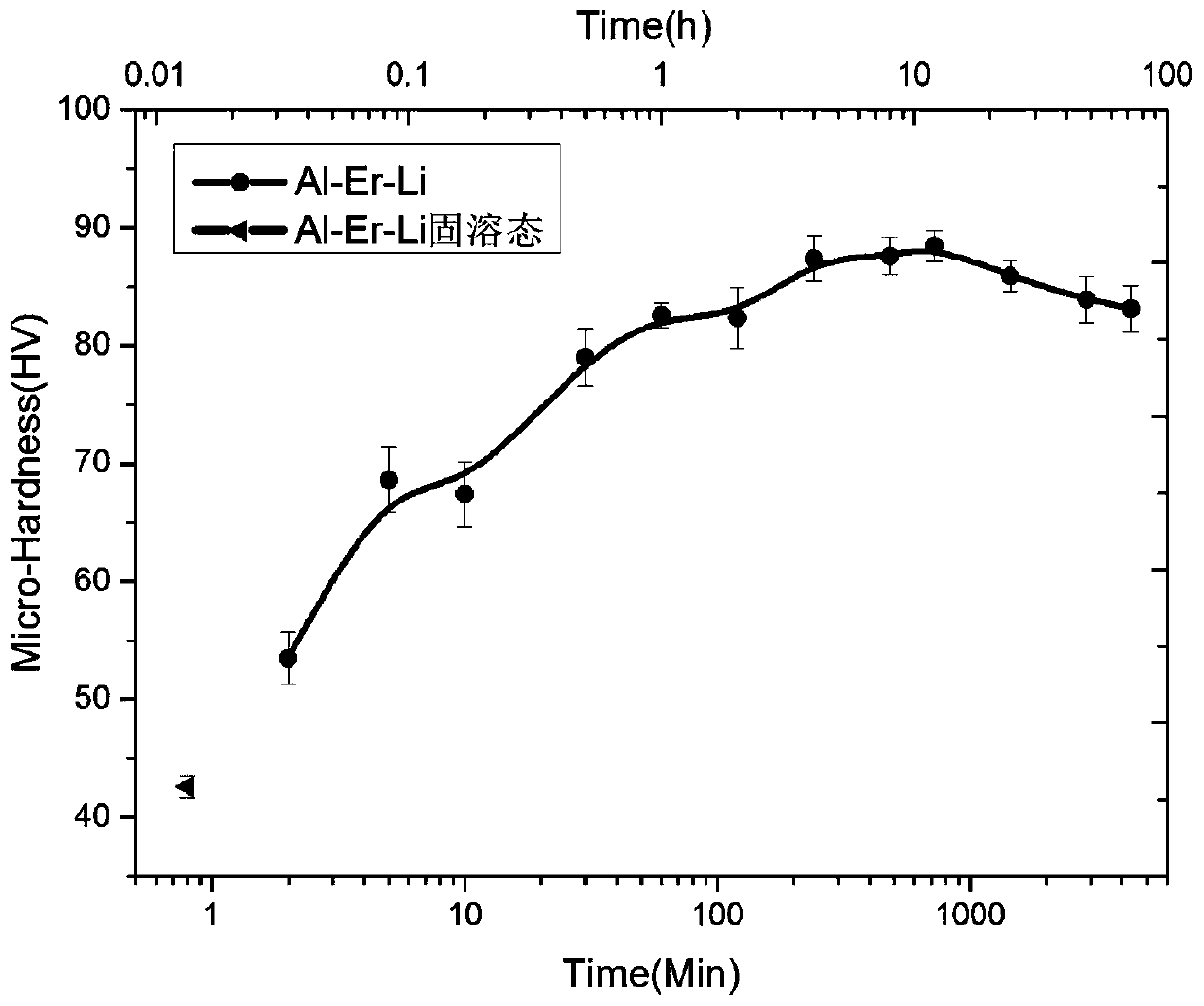

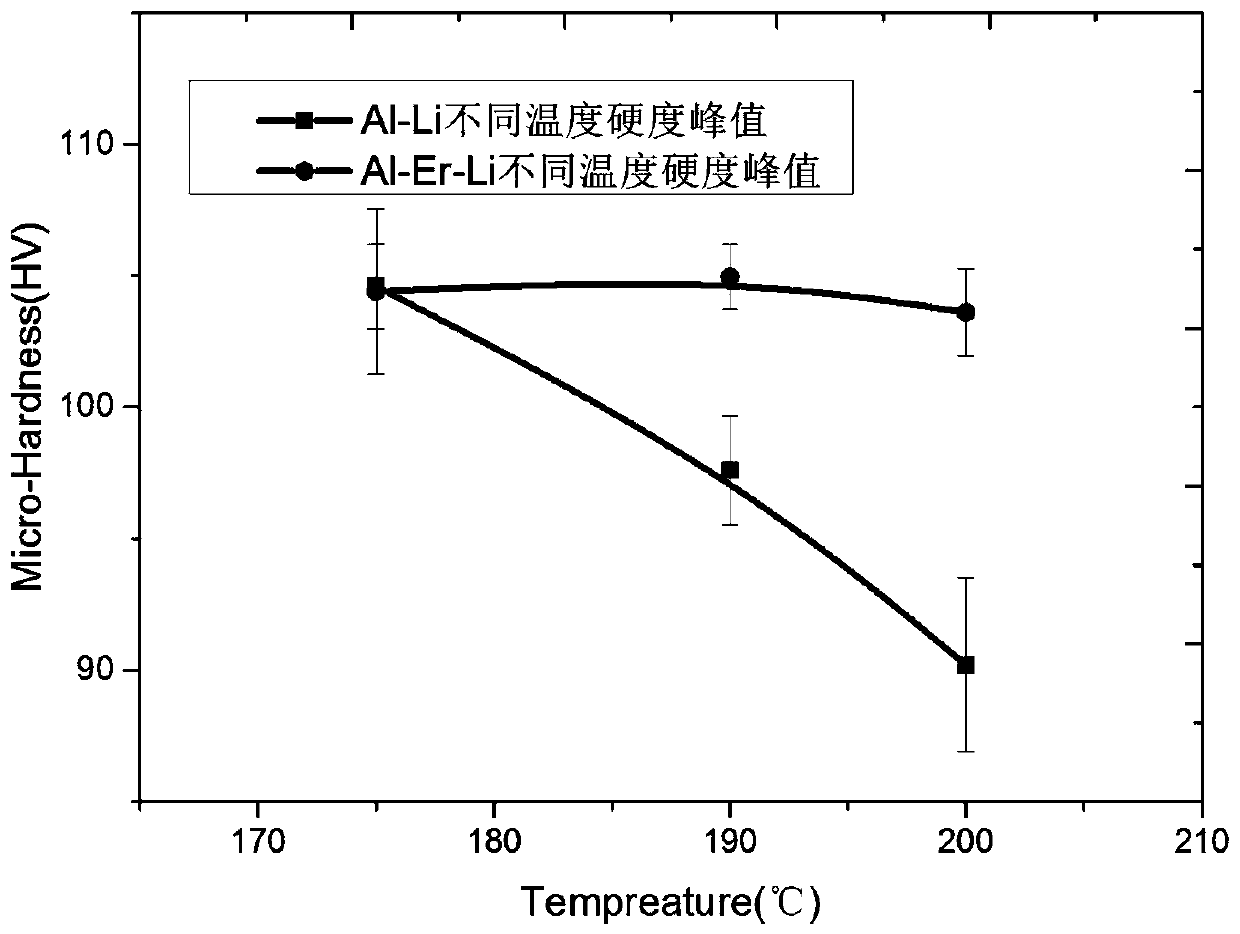

Ageing treatment process for Al-Er-Li alloy

The invention discloses an ageing treatment process for an Al-Er-Li alloy, and belongs to the technical field of non-ferrous metals. The alloy consists of the following components in percentage by mass: 0.1-0.19% of Er, 2.0-2.1% of Li, less than 0.1% of inevitable impurities and the balance Al. The ageing treatment process comprises the following steps of: casting the Al-Er-Li alloy, performing solid-solution treatment, and performing equal-temperature aging treatment for 24-48 hours at a temperature of 175-200 DEG C. After treated by the process, the Al-Er-Li alloy has peak ageing hardness which is kept to be higher than 100 HV.

Owner:BEIJING UNIV OF TECH

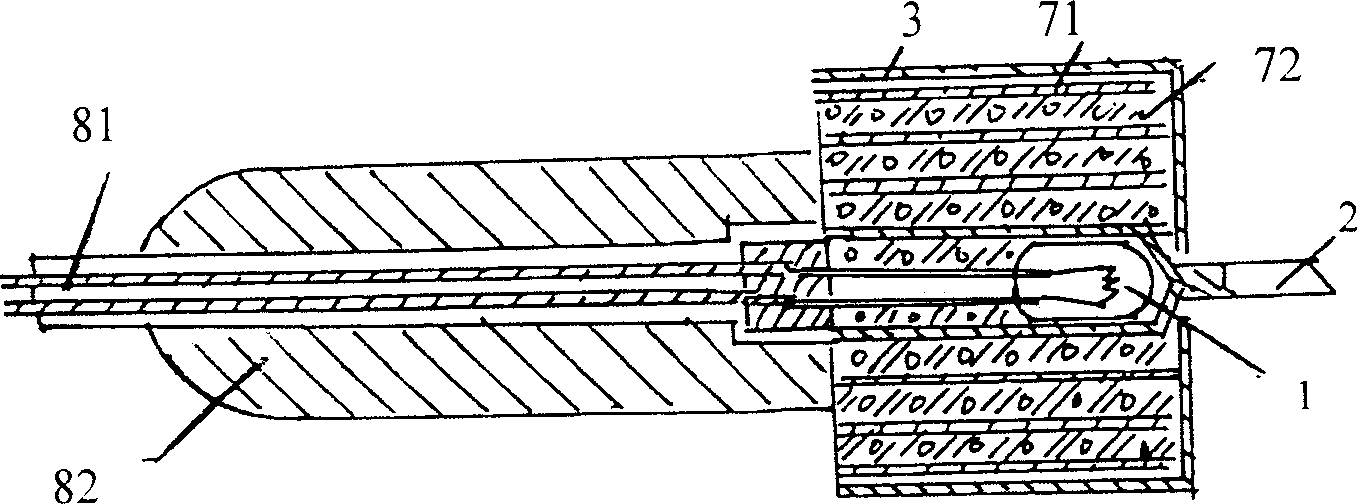

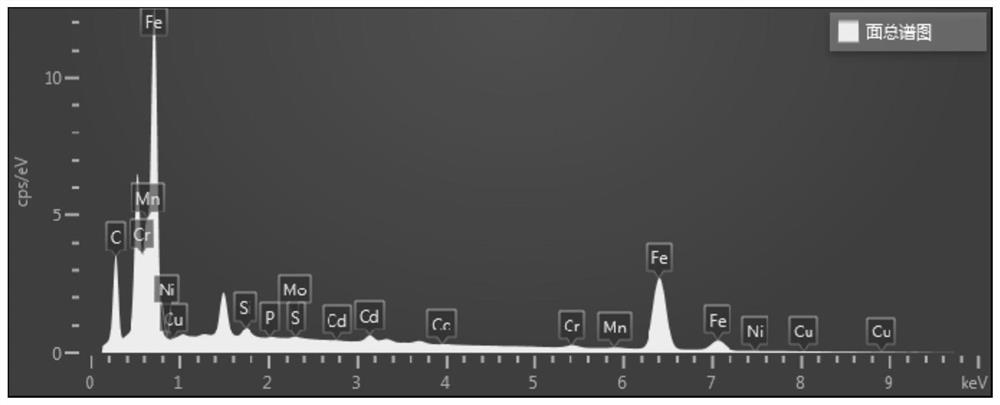

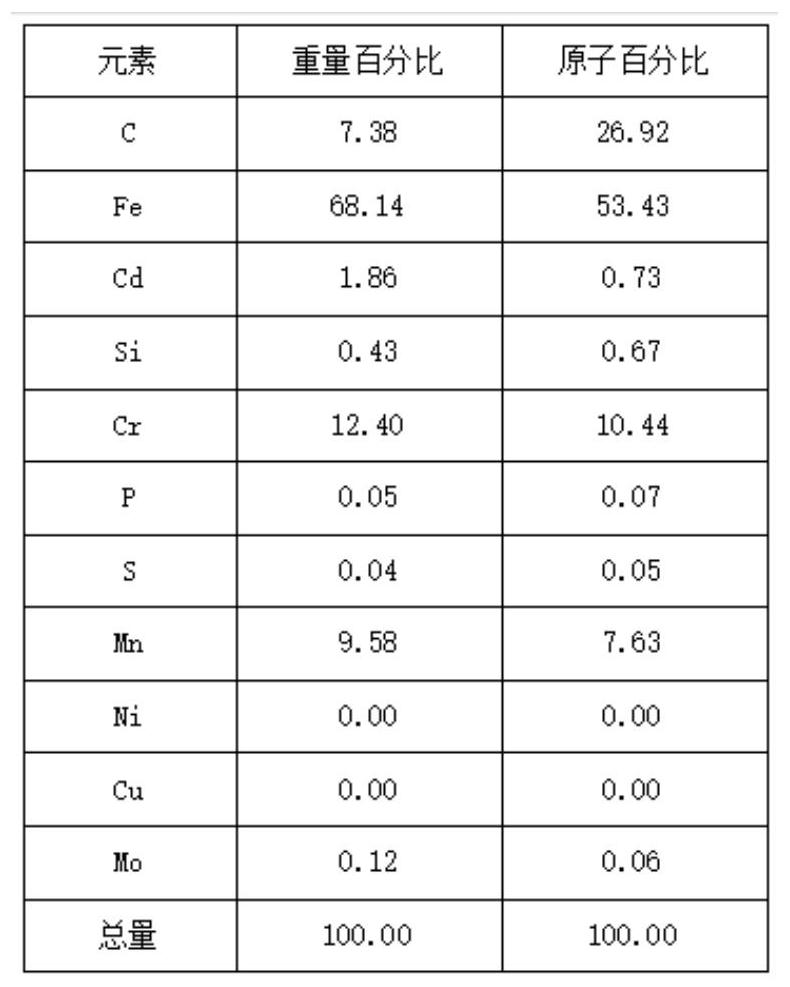

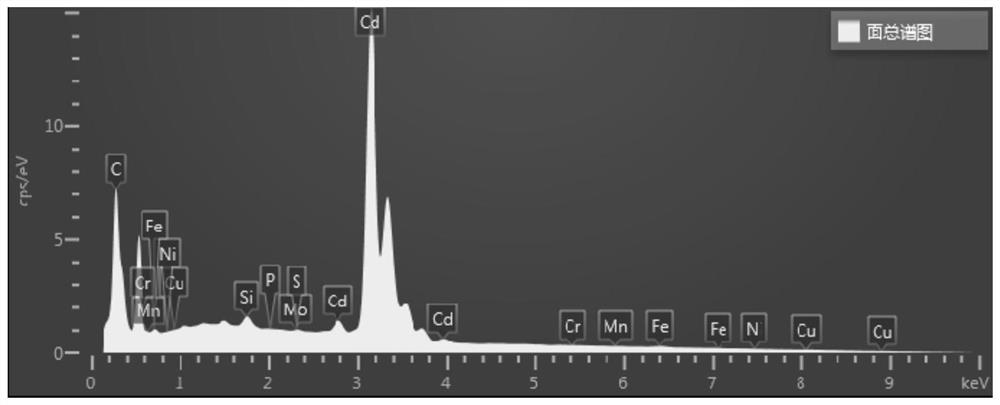

Method for cleaning cadmium coating on surface of workpiece through laser and laser cleaning device

InactiveCN113877893AEasy to cleanImprove cleaning efficiencyCleaning processes and apparatusPhysical chemistryPulse energy

The invention discloses a method for cleaning a cadmium coating on the surface of a workpiece through laser and a laser cleaning device. The cadmium coating on the surface of the workpiece is cleaned through the laser with the laser output power smaller than or equal to 100 W, the laser output repetition frequency ranging from 100 kHz to 1000 kHz, the laser pulse width ranging from 12 ns to 500 ns, the laser spot overlap rate smaller than or equal to 50% and the laser single pulse energy smaller than or equal to 0.5 mJ, and the number of laser cleaning times is larger than or equal to 8. The method can be used for fully cleaning the cadmium coating on the surface layer of the workpiece without causing an overburning phenomenon on the workpiece.

Owner:XIAN AIRCRAFT IND GROUP

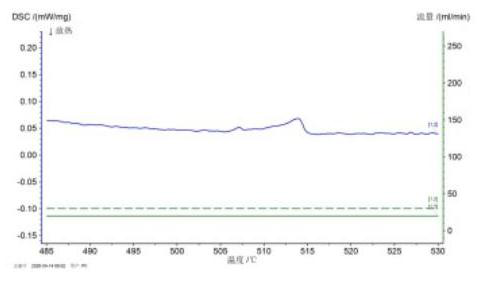

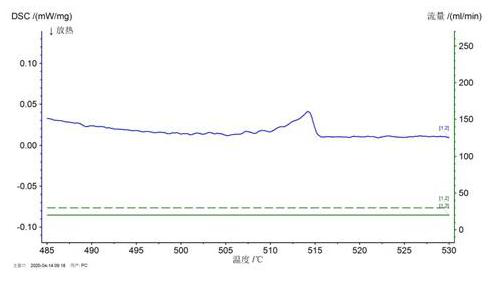

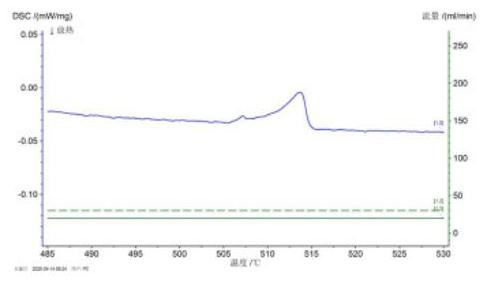

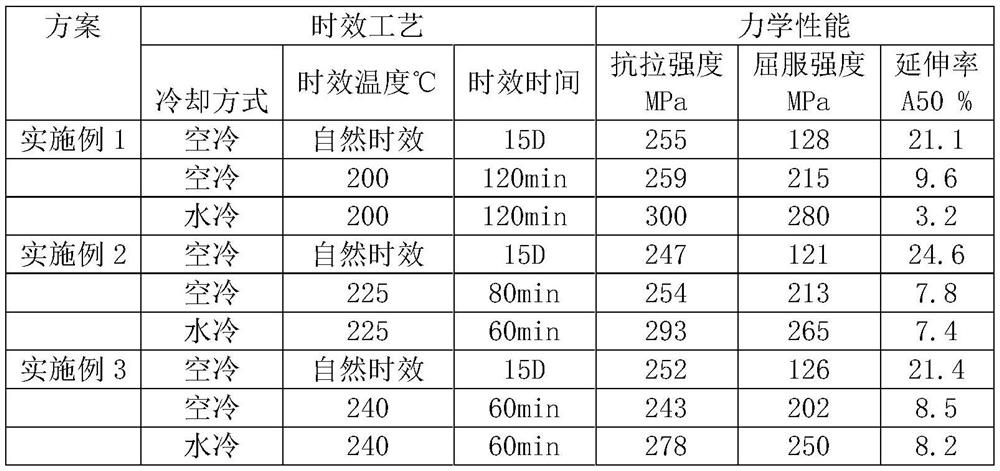

2324 aluminum alloy and homogenization heat treatment method thereof

ActiveCN114737144AHomogenization time shortenedSpeed up the dissolution rateProcess efficiency improvementIngotMelting temperature

The invention relates to a 2324 aluminum alloy and a homogenization heat treatment method thereof, and belongs to the technical field of aluminum alloy heat treatment, and the homogenization heat treatment method of the 2324 aluminum alloy comprises the steps that an aluminum alloy ingot is heated to 494-495 DEG C and then heated to 498-500 DEG C for 25-30 h, and finally the aluminum alloy ingot is air-cooled to 20-25 DEG C. According to the method, by means of slow heating at the melting temperature of the low-melting-point eutectic phase, the influence of the temperature on eutectic phase redissolution is fully exerted, redissolution of the low-melting-point eutectic phase is accelerated under the condition that it is guaranteed that the cast ingot is not overburnt, the redissolution time of theta (Al2Cu) and S (Al2CuMg) formed through non-equilibrium solidification is greatly shortened along with temperature rising, and therefore the casting quality of the cast ingot is improved. The time for homogenizing heat treatment of the aluminum alloy cast ingot is saved to a great extent, the heat treatment cost of the aluminum alloy is saved, and the machining efficiency of the aluminum alloy is improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Composite aluminum alloy plate for liquid cooling plate of new energy power battery and preparation method of composite aluminum alloy plate

The invention discloses a composite aluminum alloy plate for a liquid cooling plate of a new energy power battery and a preparation method of the composite aluminum alloy plate. The composite aluminum alloy plate comprises a core material layer and a protective layer, wherein the core material layer contains a Cr (chromium) element, precipitation of an Mg2Si phase at a grain boundary can be inhibited, the strength after artificial aging is improved, meanwhile, grains can be refined, the recrystallized grains are in a slender shape, and the corrosion resistance can be improved; the protective layer is made of Al-Mn alloy or 1-series alloy, in the brazing process, the protective layer can prevent the Mg element of the core material layer from diffusing to the surface, and the situation that the welding effect is affected by the poisoning effect of Mg is avoided.

Owner:YINBANG CLAD MATERIAL

Pretreatment method of desulfurization adsorbent and desulfurization method of sulfur-containing hydrocarbon feedstock

ActiveCN103773440BReduced activityReduce saturation activityGaseous fuelsDispersed particle separationPretreatment methodHydrogen

The invention relates to a pretreatment method for desulphurization adsorbents. The pretreatment method comprises: desulphurization adsorbents and hydrocarbon raw materials containing alkenes are subjected to contact reaction under a non-hydrogen condition. The invention also relates to a desulphurization method for sulfur-containing hydrocarbon raw materials. The desulphurization method comprises: desulphurization adsorbents are pretreated according to the above method, and the pretreated desulphurization adsorbents are obtained; sulfur-containing hydrocarbon raw materials, hydrogen donors and the pretreated desulphurization adsorbents are subjected to contact reaction under an adsorption desulphurization reaction condition. The pretreatment method for desulphurization adsorbents takes an obviously short time, and when catalytic cracking gasoline with high content of alkenes is subjected to desulphurization, the pretreated desulphurization adsorbents obtained through the pretreatment method can prevent reactor temperature runaway phenomena caused by vast alkene saturation during the startup process effectively, and the startup difficulty is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

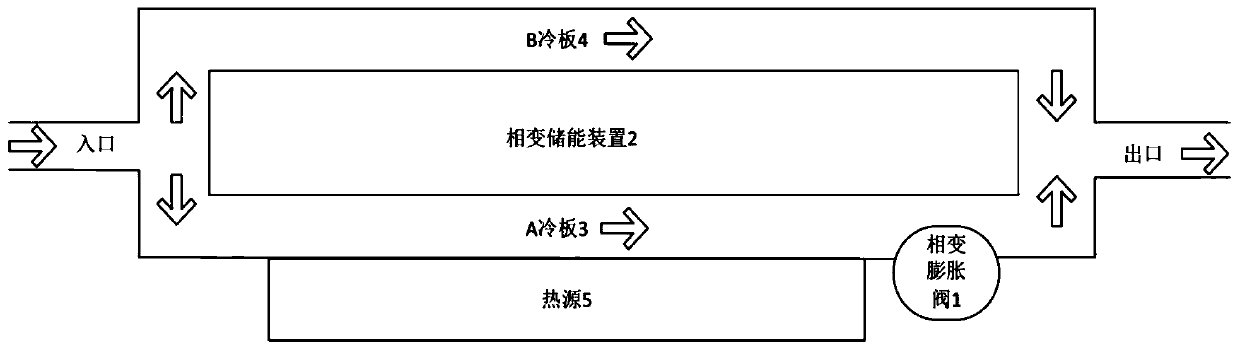

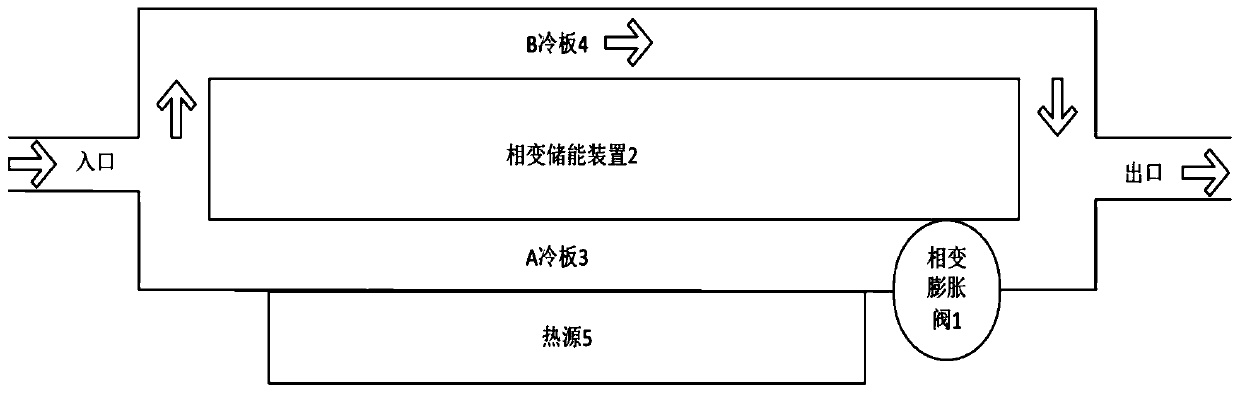

Method for controlling outlet temperature of cooling liquid of electronic equipment

ActiveCN110430715BReduce complexityAvoid High Complexity DefectsCooling/ventilation/heating modificationsControl electronicsLiquid cooling system

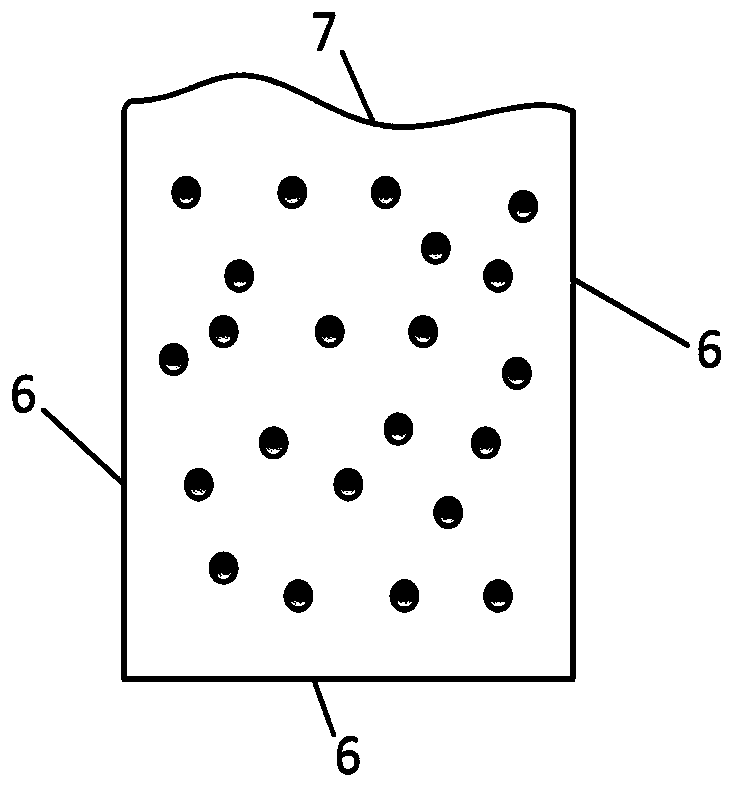

The invention discloses a method for controlling the temperature of the coolant outlet of an electronic device. The method can solve the problem that the temperature of the coolant outlet exceeds theupper limit when the electronic device is in transient operation. The method comprises the following steps of: selecting a phase change material having a phase change point between the highest workingambient temperature and the allowable temperature of a key component in the electronic device; packaging the selected phase change material in a phase change expansion valve having one side preparedfrom a flexible heat conduction material; packaging the selected phase change material in a metal plate to form a phase change energy storage device; constructing a liquid cooling system having an A cold plate, a B cold plate, the phase change energy storage device, the phase change expansion valve and diverting and converging pipelines; placing the phase change expansion valve downstream of an Acold plate flow channel; controlling the upper limit of the temperature of the coolant outlet when the electronic device is in transient operation by the synergistic effect of the valve effect and theenergy storage and discharge effect of the phase change device; if the heat sink A cold plate flow channel for heat transfer is cut off, the phase change energy storage device transfers the heat instead in order to supply the heat to the heat sink B cold plate.

Owner:10TH RES INST OF CETC

A kind of method for producing liquefied natural gas from blue carbon tail gas

The invention relates to a method for preparing liquefied natural gas from semi-coke tail gas. The method includes: firstly, after decoking and benzene and naphthalene removal of semi-coke tail gas, and sending to a rectisol unit for purification and desulfurization; then, mixing the desulfurized semi-coke tail gas with high-methane gas, jointly sending into a methanation unit for methanation to obtain a crude methane gas product, sending into the rectisol unit for purification and decarbonization; finally, performing cryogenic separation to remove nitrogen to obtain liquefied natural gas. Compared with the prior art, the method has advantages that by semi-coke tail gas treatment through the rectisol unit and the methanation unit, circulation absorbing agent consumption is sharply reduced,and energy consumption and system CH4 loss in a decarbonization process are reduced; in addition, by adoption of recovered CH4-rich gas and injection of water and / or system self-produced water vaporinto the methanation unit, methanation reaction temperature rise can be controlled so as to guarantee a methanation process against temperature runaway; moreover, heat balance of a whole system can beeffectively realized in the whole process, and economy in preparation of LNG (liquefied natural gas) from the semi-coke tail gas is improved.

Owner:WISON ENG

A kind of methanation catalyst and its preparation method and application

ActiveCN108355668BEvenly dispersedSmall grain sizeHeterogenous catalyst chemical elementsGaseous fuelsAlkaline earth metalPtru catalyst

The invention discloses a methanation catalyst, its preparation method and application. The present invention uses aluminum isopropoxide as a raw material, and adopts a solvent-gel method to prepare aluminum sol, and simultaneously dissolves the soluble salt of an alkali metal auxiliary agent and the soluble salt of an alkaline earth metal or rare earth metal modification auxiliary agent in the aluminum sol, and then After being concentrated and then spray-molded, the microsphere carrier precursor is obtained, and after drying and calcining, the microsphere powder in a certain particle size range is screened as the catalyst carrier. The microsphere powder was used as the carrier, and the active metal Ni and the additive La were loaded by the equal volume impregnation method. 2 o 3 , thus preparing a complete methanation catalyst suitable for microchannel reactors. The catalyst prepared by the method of the invention has higher activity, hydrothermal stability and carbon deposition resistance.

Owner:壹碳环投(北京)科技有限公司

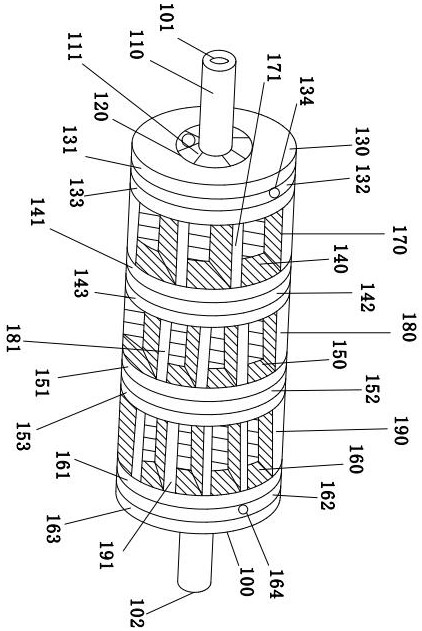

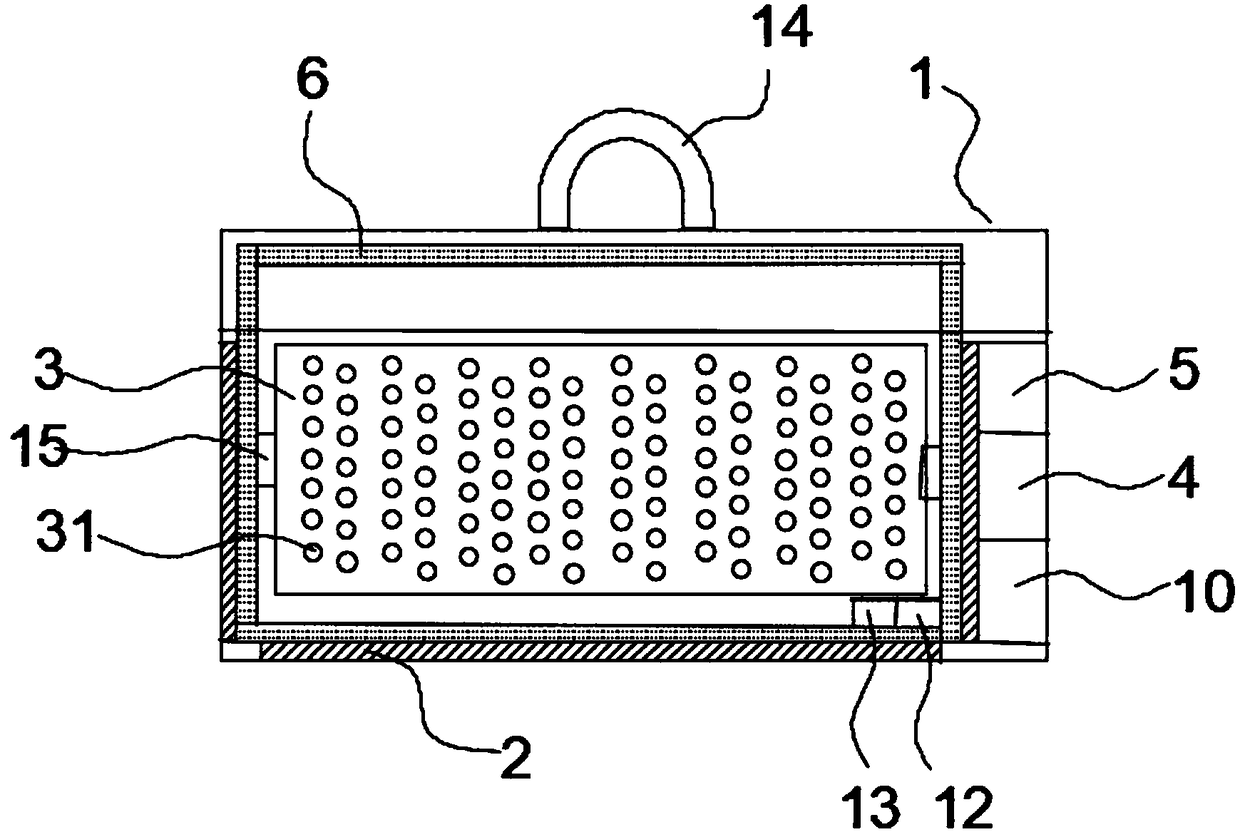

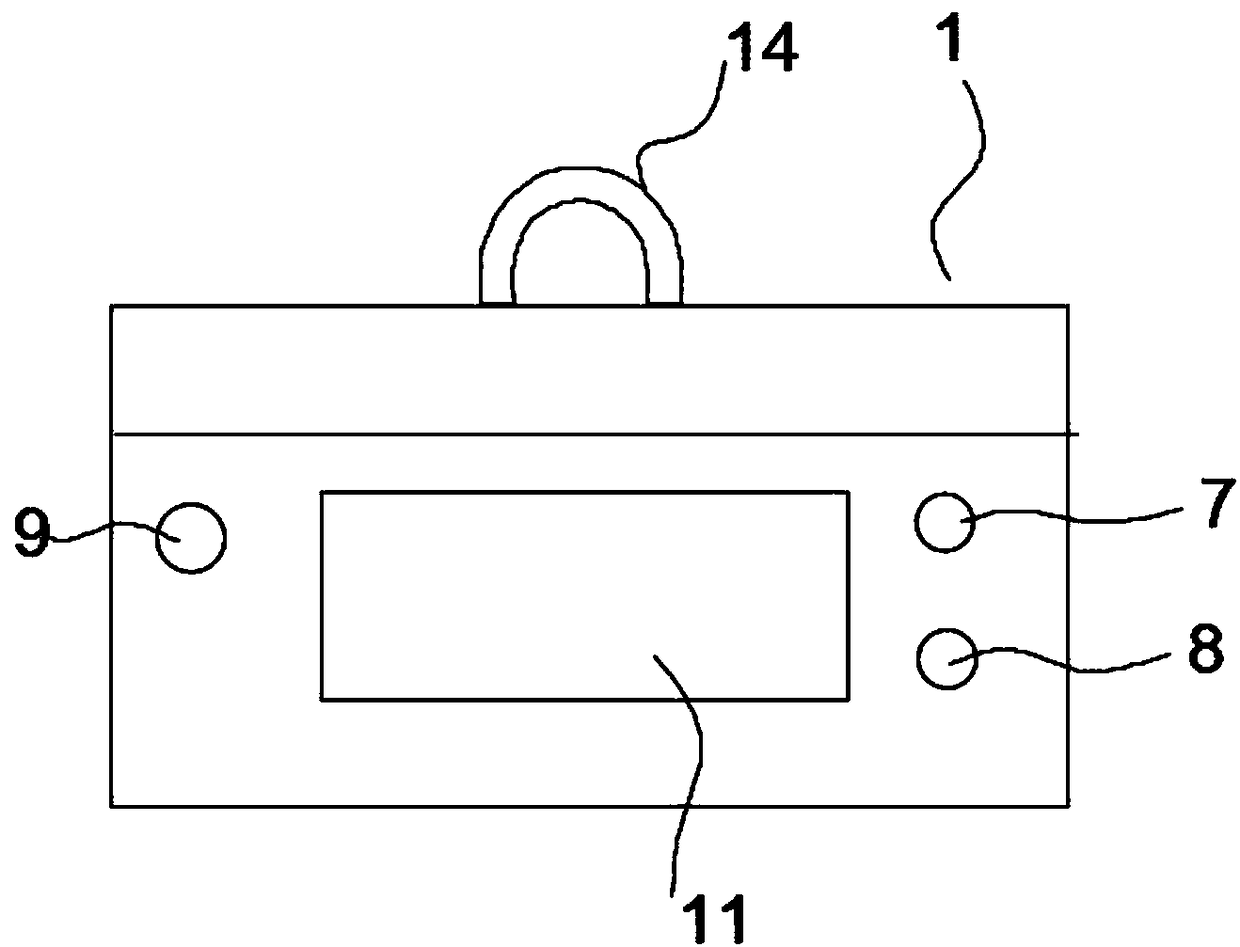

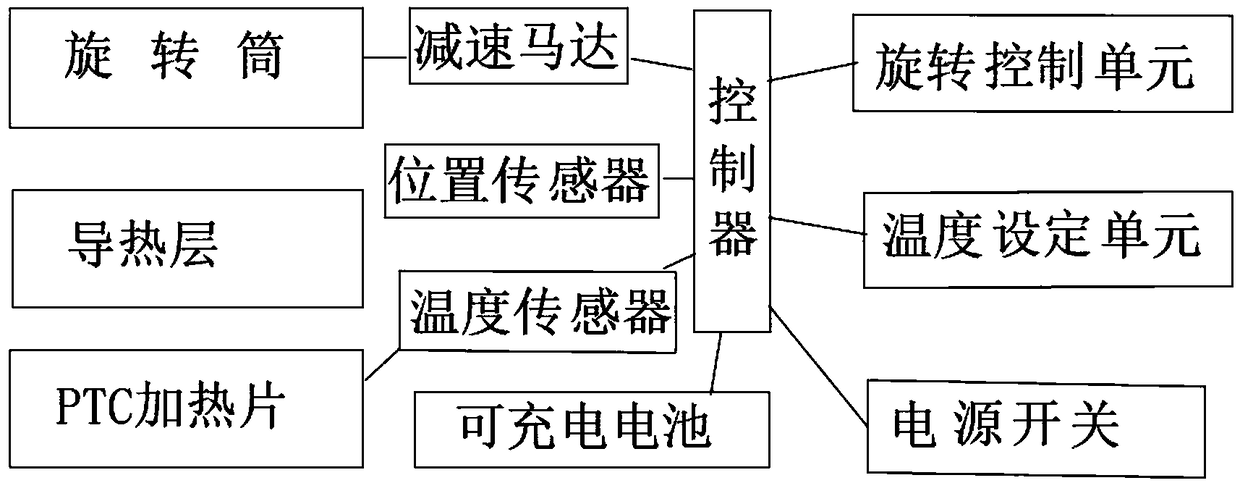

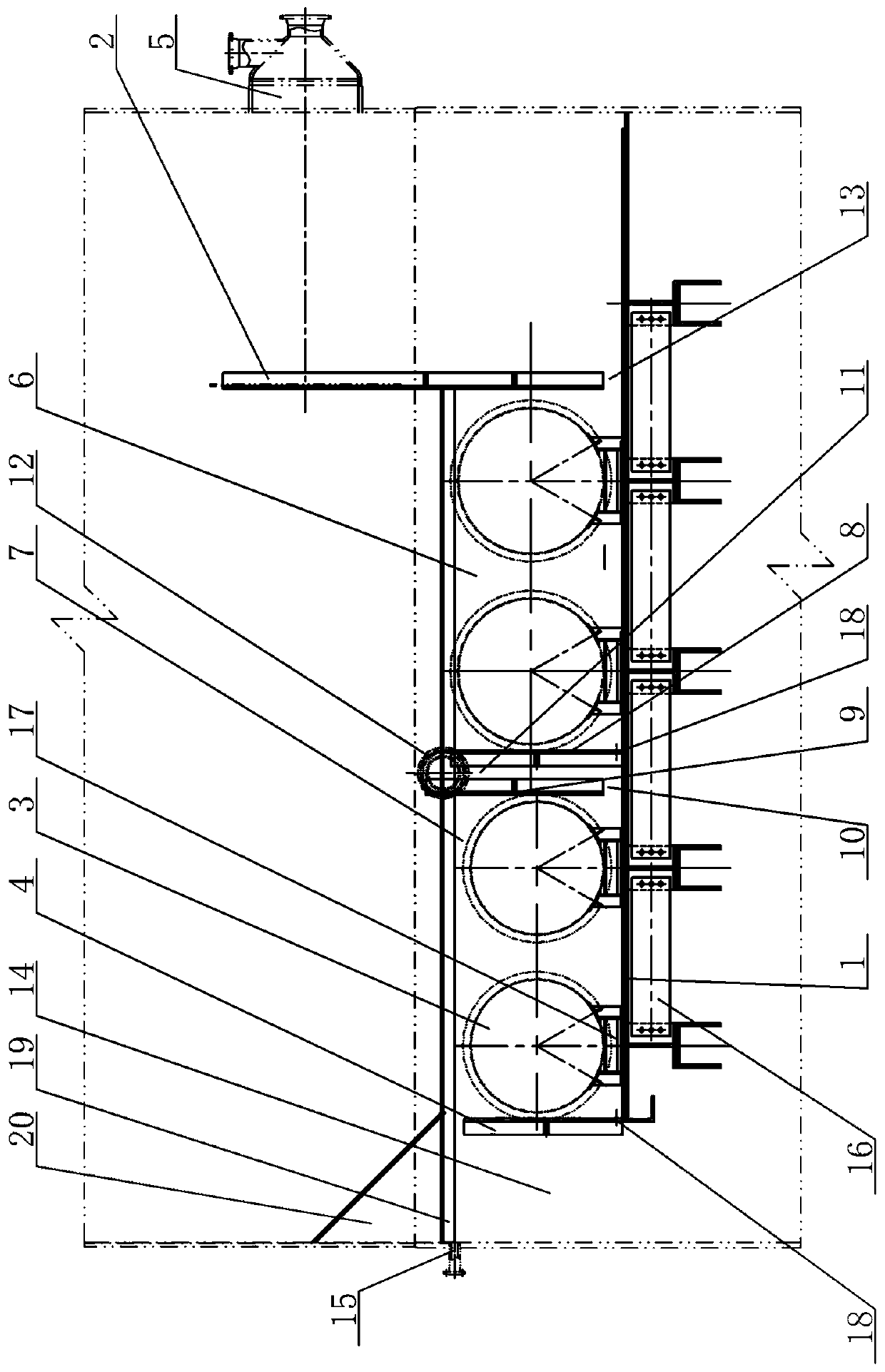

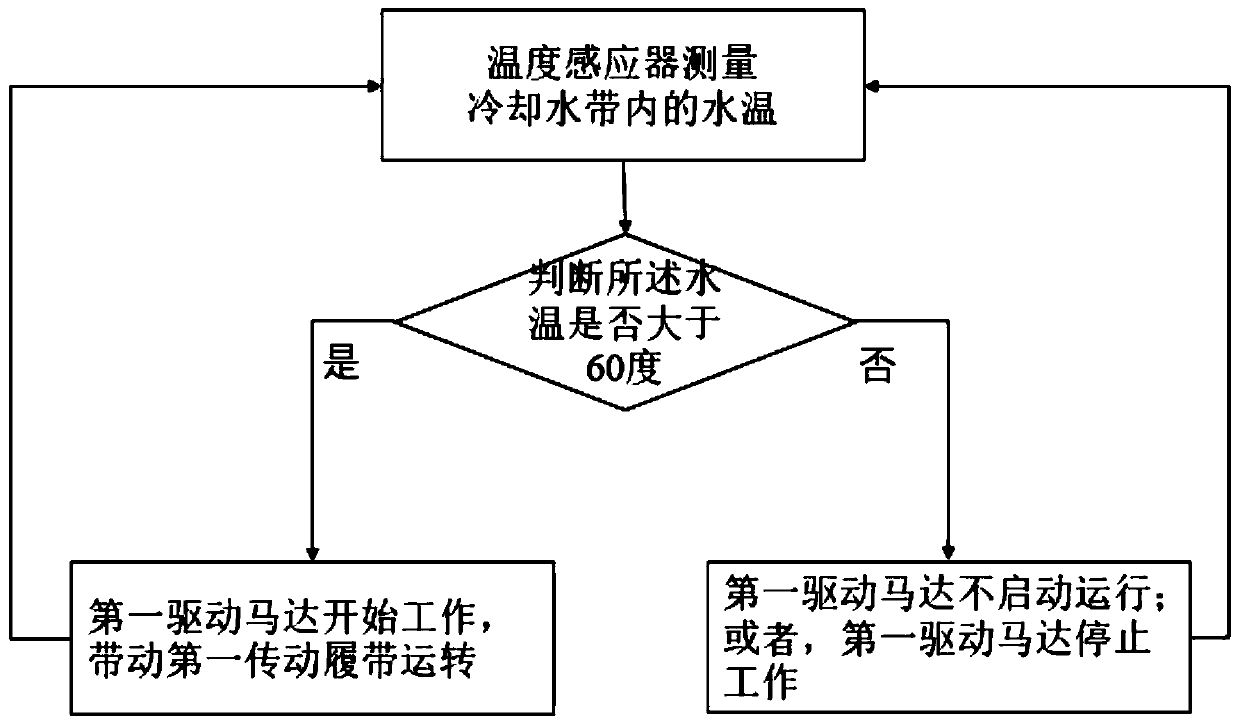

Portable device and method for banked blood rewarming

PendingCN108421101AAvoid uneven heating up and downEvenly heatedMedical devicesBlood transfusionEmbedded systemEngineering

The invention discloses a portable device and method for banked blood rewarming. The portable device for banked blood rewarming includes a portable casing, a heating piece, a rotating drum, a drivingmechanism and a controller. The heating piece, the rotating drum, the driving mechanism and the controller are located in the portable casing, the controller is connected with the driving mechanism, the driving mechanism is connected with the rotating drum and drives the rotating drum to rotate, the rotating drum is horizontally arranged, the rotating drum can rotate with the horizontal center line as the axis, the controller is connected with the heating piece, and the controller can control the heating of the heating piece and the rotation of the rotating drum. The portable device has the advantages that the portable device is simple to operate and simple in structure, the cost is reduced, banked blood is heated evenly, and the portable device is safe and reliable.

Owner:上海赋拓物联网技术有限公司

A kind of al-er-li alloy aging treatment process

The invention discloses an ageing treatment process for an Al-Er-Li alloy, and belongs to the technical field of non-ferrous metals. The alloy consists of the following components in percentage by mass: 0.1-0.19% of Er, 2.0-2.1% of Li, less than 0.1% of inevitable impurities and the balance Al. The ageing treatment process comprises the following steps of: casting the Al-Er-Li alloy, performing solid-solution treatment, and performing equal-temperature aging treatment for 24-48 hours at a temperature of 175-200 DEG C. After treated by the process, the Al-Er-Li alloy has peak ageing hardness which is kept to be higher than 100 HV.

Owner:BEIJING UNIV OF TECH

Heat exchanger arrangement structure of pre-concentration tower

PendingCN110793372ANo overheating phenomenonReliable arrangementIndirect heat exchangersEngineeringMechanical engineering

The invention provides a heat exchanger arrangement structure of a pre-concentration tower. By means of the heat exchanger arrangement structure, arrangement of heat exchangers is reliable and effective, and it is ensured that gas-liquid separation is efficient. The heat exchanger arrangement structure comprises a bottom transverse plate, a first longitudinal partition plate, the multiple heat exchangers, a second partition longitudinal plate assembly and a third longitudinal partition plate. One end of the bottom transverse plate extends to the corresponding position below a liquid inlet. Thefirst longitudinal partition plate blocks the corresponding height position of the liquid inlet. A third longitudinal partition plate protruding upwards is arranged at the other end of the bottom transverse plate. The multiple heat exchangers are arranged in the area, corresponding to the space between the first longitudinal partition plate and the third longitudinal partition plate, of the bottom transverse plate. The multiple heat exchangers are divided by the second partition longitudinal plate assembly to form two independent heat exchange cavities specifically including the first heat exchange cavity and the second heat exchange cavity. The second partition longitudinal plate assembly specifically comprises a first upper limiting partition plate and a second lower limiting partitionplate. The bottom of the first upper limiting partition plate is fixedly connected to the bottom transverse plate.

Owner:CSSC SHENGHUI EQUIP

Process for producing dimethyl carbonate from industrial synthetic gas

ActiveCN103408428BNo overheating phenomenonDoes not affect safe operationOrganic compound preparationChemical industryGas phaseWastewater

The invention relates to a process for producing dimethyl carbonate from industrial synthetic gas. According to the invention, O2, CO, N2, NO, and methanol are delivered into an esterification system for esterification; heavy component drawn from the esterification system is subjected to recovery treatment in a wastewater tower; light component drawn from the esterification system passes a compressor II and is subjected to a carbonylation reaction in a carbonylation reactor; the carbonylation reaction product is delivered into a second condensation separation tower, and is subjected to gas-liquid separation; separated liquid phase is refined in a pressurized rectification tower; part of non condensable gas is discharged from the separated gas phase, and the gas phase is continued to be subjected to a reaction in the esterification system; the discharged non-condensable gas is delivered into a denitration reactor; light component at a top of the pressurized rectification tower is subjected to further recovery treatment in a methanol recovery tower; heavy component from the pressurized rectification tower is delivered into a product tower; dimethyl carbonate is drawn from the top of the product tower, and dimethyl oxalate is drawn from the bottom of the product tower. The process has the economical and practical characteristics of low equipment investment, environment friendliness, energy saving, high catalyst efficiency, high raw material utilization rate, and the like.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

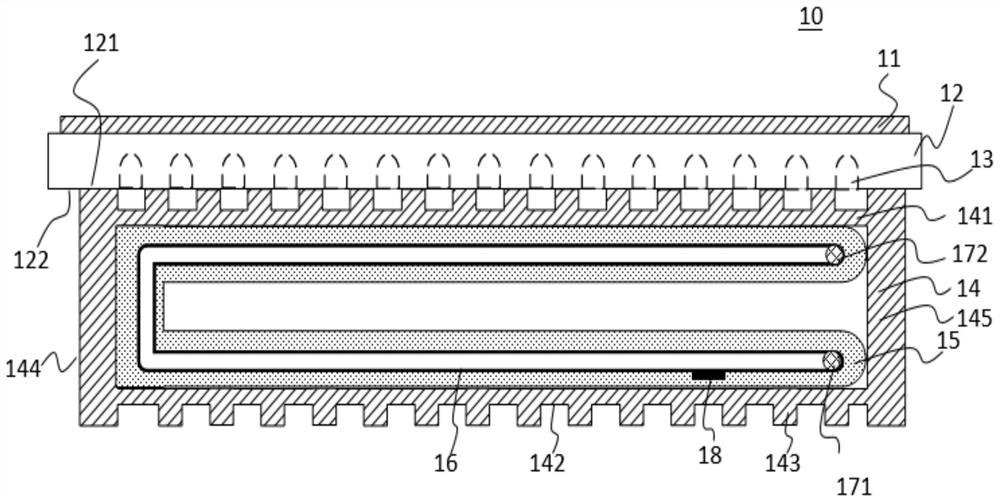

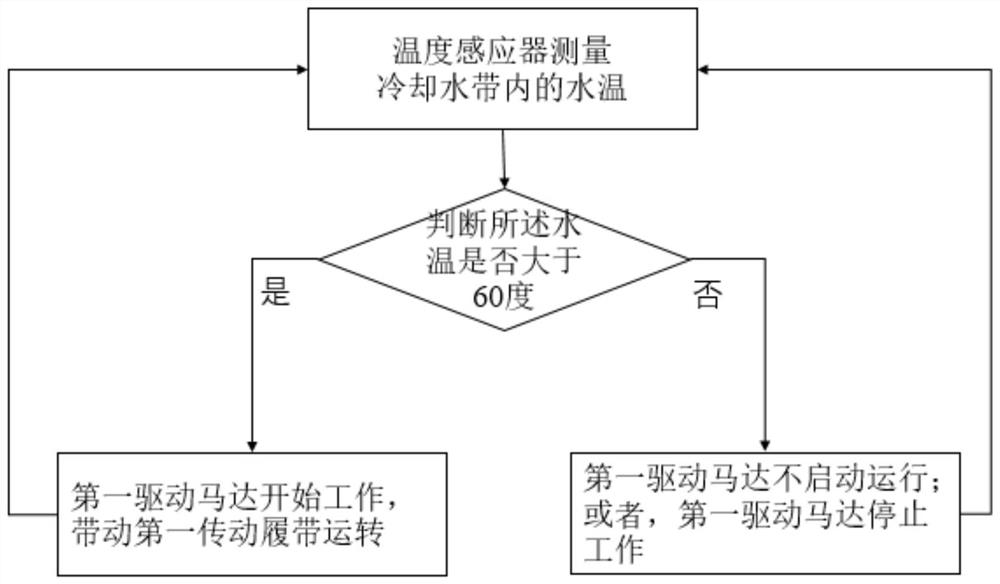

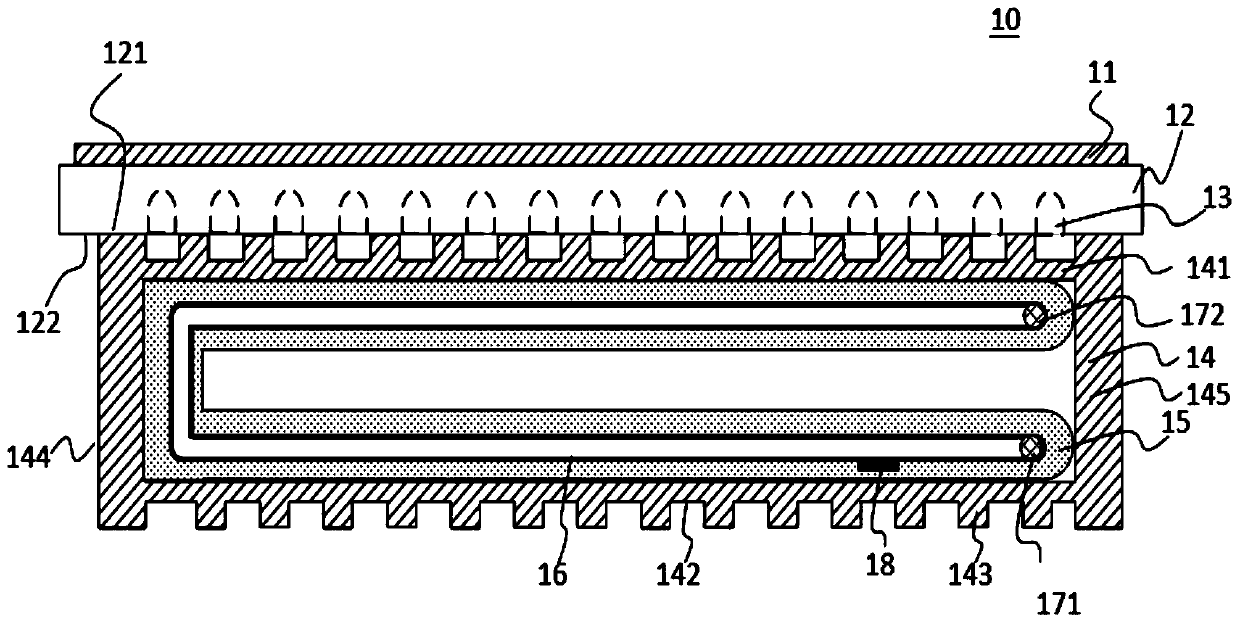

A water-cooled display module

ActiveCN110290679BWork lessNormal working temperaturePhotovoltaic supportsBatteries circuit arrangementsThermodynamicsEngineering

An embodiment of the present invention provides a water-cooled and heat-dissipating display module. The display module includes a display panel and a lamp board. A plurality of LED beads are arranged on the top surface of the lamp board near the display panel. A cooling cavity is provided at the bottom of the lamp board away from the display panel; a cooling water belt is arranged in the cooling cavity, and the cooling water belt is arranged along the inner surface of the cooling cavity. The display module provided by the present invention can increase the heat dissipation rate by arranging cooling water belts in the heat dissipation cavity, ensure that the working temperature of the lamp panel is normal, and will not cause excessive temperature, thereby ensuring the luminous efficiency and stable operation of the LED lamp bead The normality of sex and service life. In addition, because the heat generated by the light board is absorbed in time, it can also ensure the stable operation of the display panel.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Energy-saving method and system for heating coking crude benzene storage tank

ActiveCN102876394BNo overheating phenomenonReduce operating costsEnergy inputCombustible gas purificationHeat conservationStorage tank

Owner:NANJING IRON & STEEL CO LTD

High-temperature powder-containing gas cooling treatment and heat recovery device

InactiveCN113739600AAvoid cloggingEvenly distributedStationary tubular conduit assembliesThermodynamicsSteam condensation

The invention provides a high-temperature powder-containing gas cooling treatment and heat recovery device. The high-temperature powder-containing gas cooling treatment and heat recovery device comprises a barrel shell part, a gas outlet pipe fixing plate, a gas distribution pipe fixing plate, a gas-steam partition plate, a plurality of gas distribution guide pipes, a plurality of heat exchange branch pipes, a plurality of gas outlet guide pipes, a cooling gas outlet pipe, a steam outlet main pipe, a water supplementing pipe, a hot gas inlet pipe and a liquid level meter. According to the high-temperature powder-containing gas cooling treatment and heat recovery device, heat in gas is recovered in a steam form, the poor quality phenomenon (such as agglomeration and aerogel characteristic loss) that water vapor in the gas is condensed and consequently powder is damaged is avoided, and reliable conditions are provided for normal operation of equipment for collecting nanoscale powder in the gas through a dry method; hot gas flow is evenly distributed in each heat exchange branch pipe, the heat exchange efficiency is improved, the temperature of the gas in each heat exchange branch pipe is uniform, and the water vapor condensation phenomenon and the too high temperature phenomenon of the gas flow in each heat exchange branch pipe are avoided; and the high-temperature powder-containing gas cooling treatment and heat recovery device has the beneficial effects that blockage of a gas flow pipeline is avoided, the structure is compact, safety is high, and the service life is long.

Owner:郑州烯钰新材料科技有限公司

Water-cooling heat dissipation display module

ActiveCN110290679AWork lessNormal working temperaturePhotovoltaic supportsBatteries circuit arrangementsWorking temperatureEngineering

The embodiment of the invention provides a water-cooling heat dissipation display module, and the display module comprises a display panel and a lamp panel, wherein a plurality of LED lamp beads are arranged on the top face of the side, close to the display panel, of the lamp panel, and a heat dissipation cavity is formed at the bottom of the side, away from the display panel, of the lamp panel. A cooling water strip is arranged in the heat dissipation cavity and arranged along the inner surface of the heat dissipation cavity. According to the display module provided by the invention, the cooling water strip is arranged in the heat dissipation cavity, so that the heat dissipation rate can be increased, the normal working temperature of the lamp panel is ensured, the phenomenon of overhigh temperature is avoided, and the light emitting efficiency, the working stability and the service life of the LED lamp beads are ensured to be normal. In addition, due to the fact that the heat generated by the lamp panel is absorbed in time, the working stability of the display panel can be guaranteed.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

A kind of fuel type automatic air heater

Owner:山西京能吕临发电有限公司

Preparation method of double-hole-structure alumina supporter

ActiveCN102861617BLarge hole volumeNo overheating phenomenonCatalyst carriersMaterials scienceAmmonium bicarbonate

The invention discloses a preparation method of a double-hole-structure alumina supporter. The preparation method comprises the steps of weighing a certain quantity of pseudo-boehmite dry glue powders, evenly mixing the pseudo-boehmite dry glue powder with a certain quantity of peptizing agent and extrusion-auxiliary agent, then adding a certain quantity of ammonium bicarbonate aqueous solution in materials, mixing and nipping obtained materials into a plasticizer, squeezing into stripes and molding, placing molded materials in a sealing container, and roasting to prepare the alumina supporter after hydro-thermal treatment. The temperature of the hydro-thermal treatment is 70-120 DEG C, and the treatment time is 5-10 hours. Roasting is carried out at the temperature of 600-750 DEG C for 2-4 hours. The mass concentration of an ammonium bicarbonate solution is 40%-80%, the adding quantity of the ammonium bicarbonate solution is calculated according to NH<4+> and Al<3+>, and a molar ratio of the NH<4+> to Al<3+> is (0.5-1):1. According to the preparation method, the preparation procedure is simple, the prepared alumina supporter is in double-hole distribution and has good mechanical strength, and the preparation method is suitable to the field of preparation of heavy oil and residual oil hydrodemetallization catalysts and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com