Patents

Literature

172 results about "Mg element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

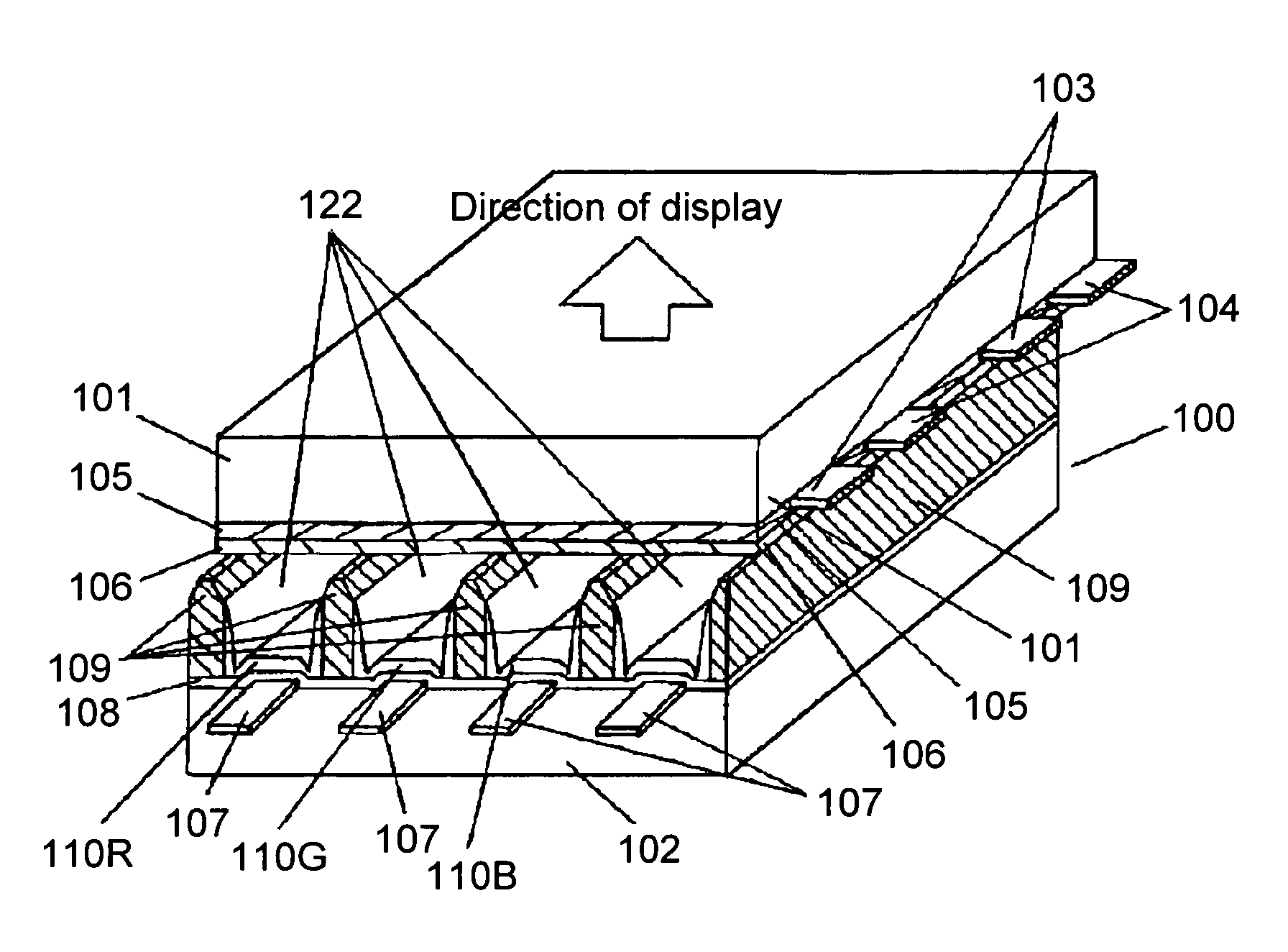

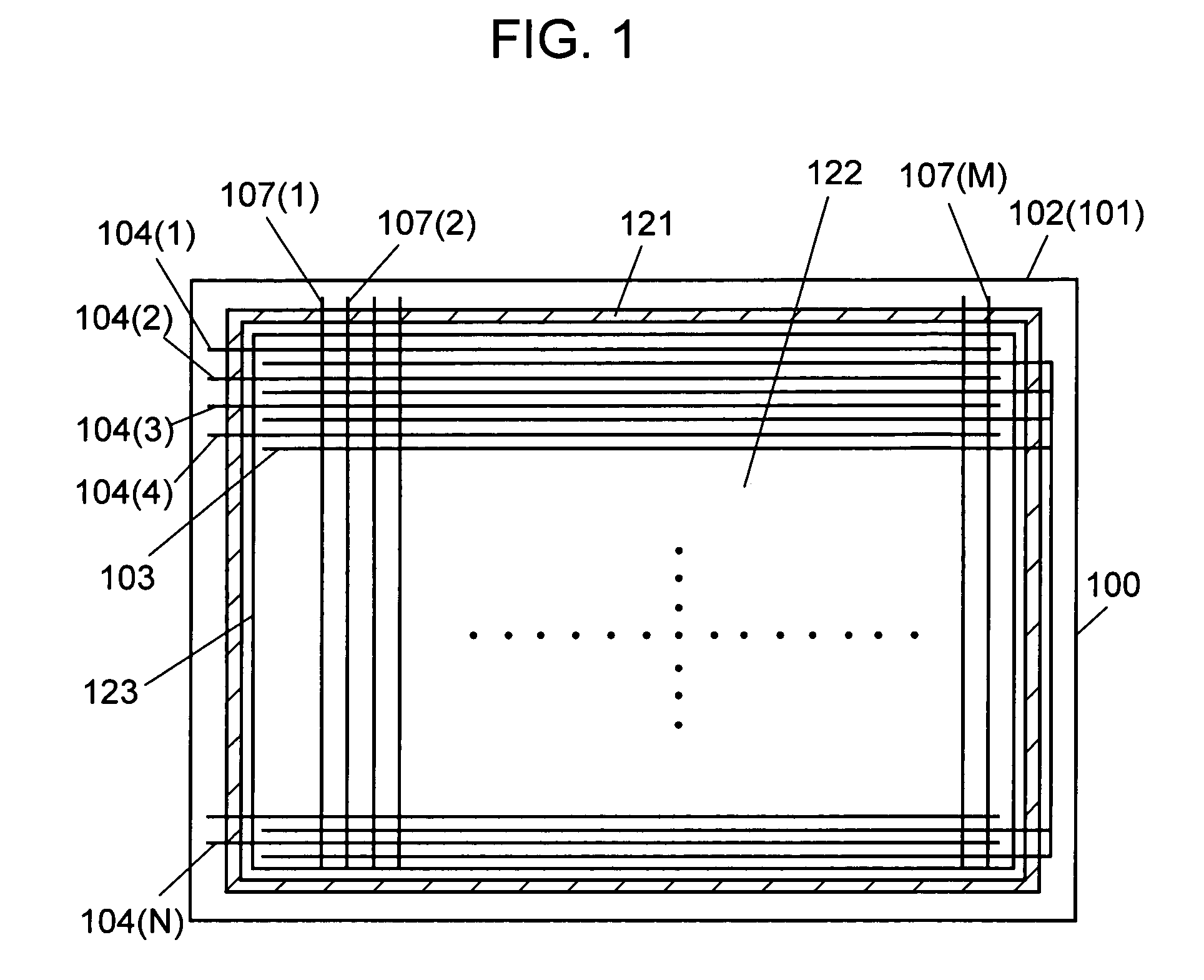

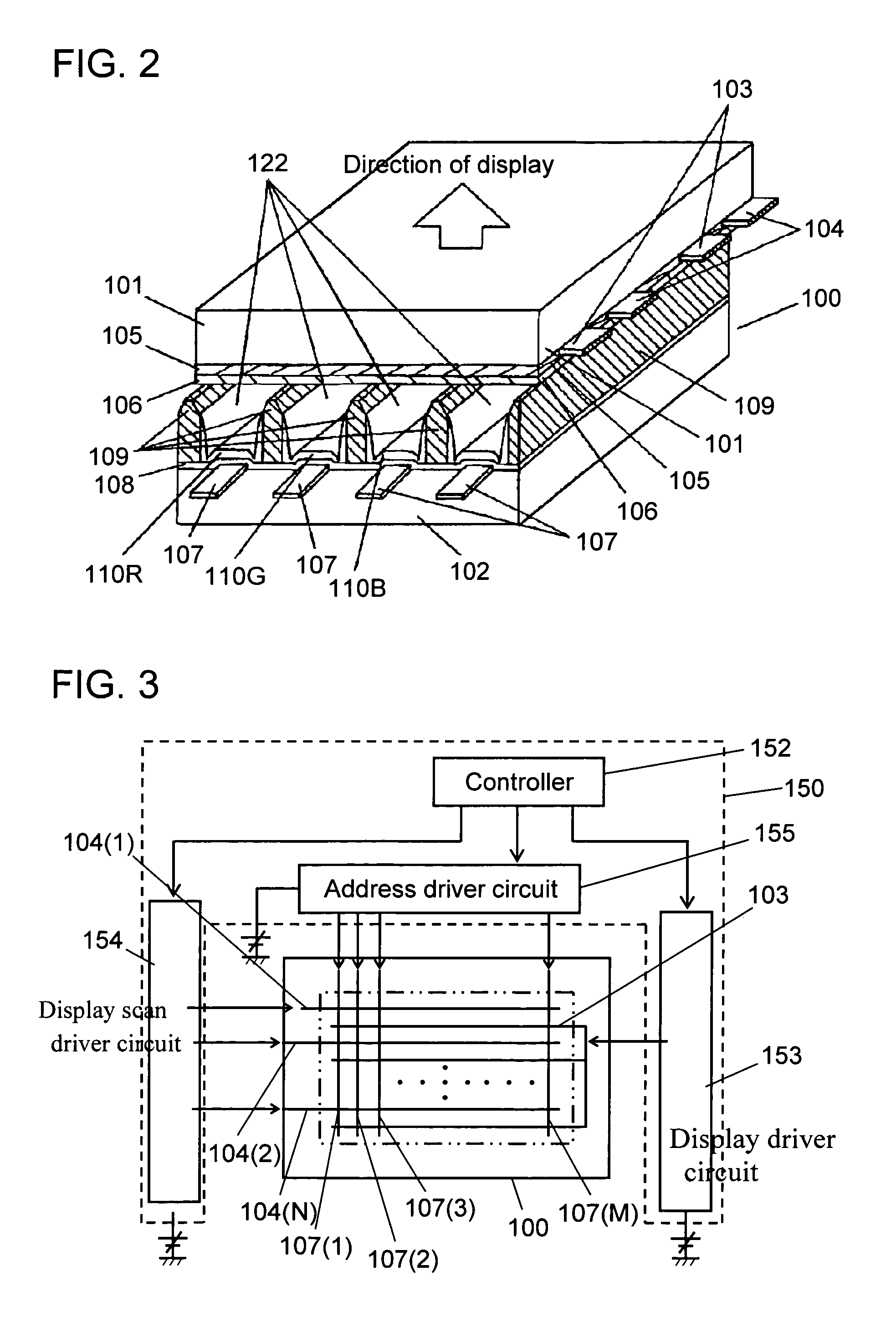

Plasma display unit, phosphor and process for producing phosphor

InactiveUS7208102B2Inhibition of adsorptionDecrease in luminanceAddress electrodesSustain/scan electrodesPhosphorFluorescence

A plasma display device exhibits suppressed luminance degradation of a phosphor, a suppressed change in chromaticity and improved discharge characteristics as a result of suppression of adsorption of water or hydrocarbon-containing gas on a surface of a blue phosphor. A blue phosphor layer used in the plasma display device is formed of a compound expressed by Ba1−XMgAl10O17:EuX or Ba1−x−ySryMgAl10O17:EuX and includes at least one element that is selected from Nb, Ta, Pr, P, As, Sb, Bi and Tm which substitutes for a part of its Al or Mg element.

Owner:PANASONIC CORP

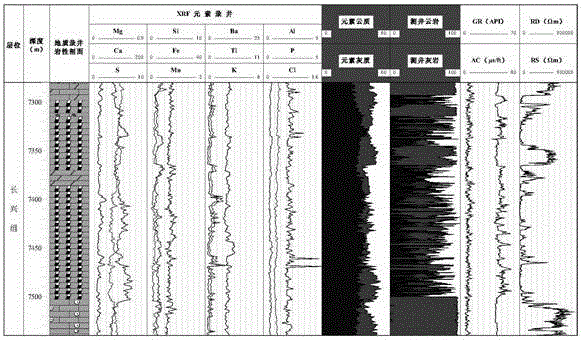

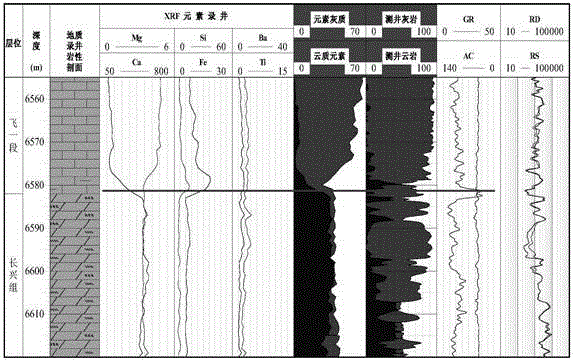

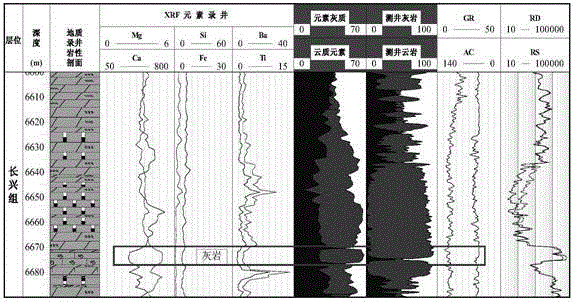

Method for quickly recognizing carbonate formation lithologies while drilling

ActiveCN104612675ASolve the problem of lithology identificationAccurate divisionBorehole/well accessoriesLithologyDolomite

The invention provides a method for quickly recognizing carbonate formation lithologies while drilling. The method includes the first step that the different lithologies are judged; the second step that rock debris of the different lithologies are sampled and are analyzed through the X-ray fluorescence element logging technology, and the Ca element pulse content and the Mg element pulse content are counted; the third step that rock debris of the different lithology centers are sampled, the Mg pulse content and the Ca pulse content of the different lithology centers are counted, and the average interval between the Mg pulse content and the Mg pulse content at the lithology center and the average interval between the Ca pulse content and the Ca pulse content at the lithology center are calculated; the fourth step that the Ca pulse content average value and the Mg pulse content average value of different lithologies are calculated respectively, then logging lithology recognition standards are obtained, and a lithology interpretation chart is established. The method achieves accurate recognition of the lithologies while drilling, judges that whether a horizontal well track passes through dolomite or not in time, and then provides a scientific basis for the necessity of adjustment of a track of an undrilled well segment and for predicament of the track of the undrilled well segment.

Owner:CHINA PETROCHEMICAL CORP +4

Alloy as magnesium element as matrix and its use as bone-fracture internal fixer

InactiveCN1743486AReduce intensityModerate starting strengthInternal osteosythesisProsthesisUltimate tensile strengthMg element

This invention discloses an alloy with Mg element as the matrix and the use as a fixer for fractures. Content of the composition and weight percentage is: Mg: 90-99.7%, other metals: 0.3~10%, which can be the fixer for fractures since it can provide suitable starting strength and degradation speed matched to knitting.

Owner:唐智荣

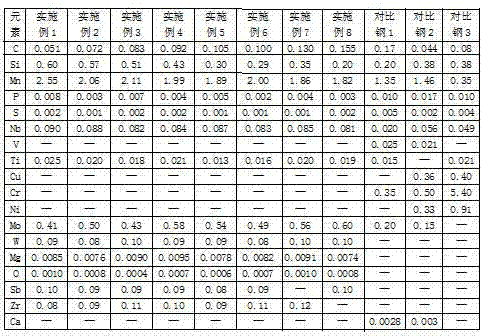

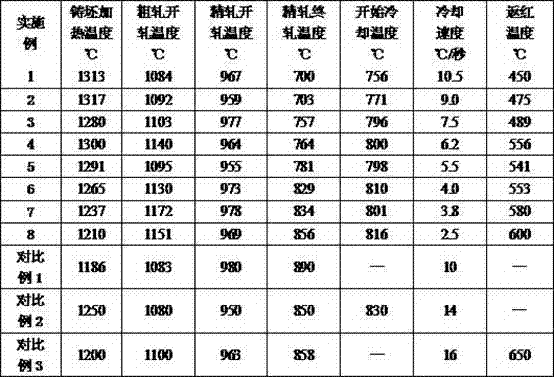

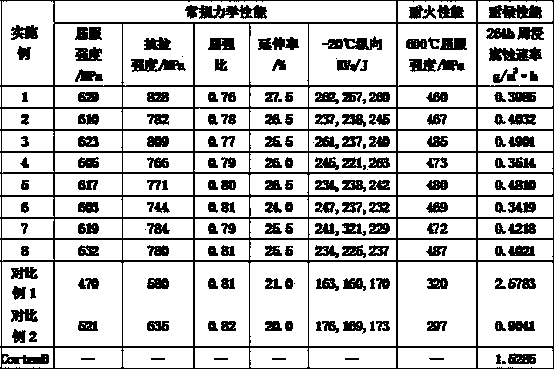

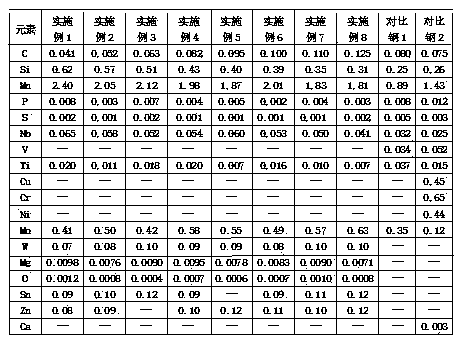

690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695773AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

The invention relates to a 690MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.051-0.155% of C, 0.20-0.60% of Si, 1.82-2.55% of Mn, at most 0.008% of P, at most 0.002% of S, 0.081-0.090% of Nb, 0.010-0.025% of Ti, 0.41-0.60% of Mo, 0.08-0.10% of W, 0.0071-0.0095% of Mg and at most 0.0010% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 690-850MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

Cultivation method of dendrobium officinale and special nutrient solution thereof

ActiveCN102668956APromote growth and developmentShorten the production cycleCultivating equipmentsSoilless cultivationMass ratioNutrient solution

The invention discloses a cultivation method of dendrobium officinale and a special nutrient solution thereof. The nutrient solution is composed of solutes and a solvent. The solvent is water, and the solutes include an N source, a P source, a K source, a Ca source, a Mg source, a Fe source, a B source, an Mn source, a Zn source, a Cu source and a Mo source, wherein the mass ratio of N element, P element, K element, Ca element and Mg element in the N source, the P source, the K source, the Ca source, the Mg source is (3-5): (1-4): (1-4): (1.5-2.5): 1. According to the cultivation method of the dendrobium officinale, solid culture can be performed under suitable artificial light or natural light, growth and development of the dendrobium officinale can be promoted, production cycle can be shortened, and yield and quality of the dendrobium officinale can be improved finally. Therefore, the cultivation method of the dendrobium officinale and the special nutrient solution thereof have broad application prospects.

Owner:CHINA AGRI UNIV

550MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel and production method thereof

ActiveCN103695772AImprove or reduce staffImprove or reduce property damageTemperature control deviceProof constructionRoom temperature

The invention relates to a 550MPa-yield-strength fire-resistant weather-resistant earthquake-proof construction steel which comprises the following components in percentage by weight: 0.041-0.125% of C, 0.31-0.62% of Si, 1.81-2.40% of Mn, at most 0.008% of P, at most 0.002% of S, 0.041-0.065% of Nb, 0.007-0.020% of Ti, 0.41-0.63% of Mo, 0.07-0.10% of W, 0.0071-0.0098% of Mg and at most 0.0012% of O. The production method comprises the following steps: desulfurizing molten iron; smelting in a converter; carrying out vacuum treatment, and adding the Mg element; carrying out conventional continuous casting, and heating the casting blank; carrying out sectional rolling; and carrying out finish rolling, and cooling for later use. The steel has the following advantages: the chemical components and technique are simple, the yield strength of the steel plate is 550-700MPa, the earthquake-proof property is good (the yield-tensile ratio is at most 0.83), the fire resistance is favorable (the yield strength at 600 DEG C is not lower than 2 / 3 of that at room temperature), and the corrosion resistance is better than CortenB. Besides, the steel grade has excellent impact toughness and weldability.

Owner:武汉钢铁有限公司

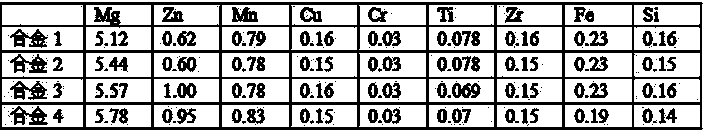

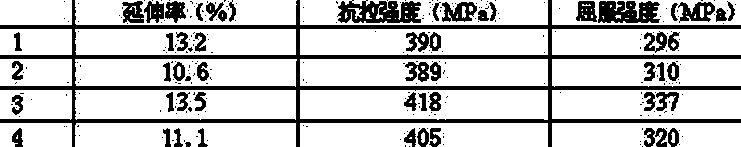

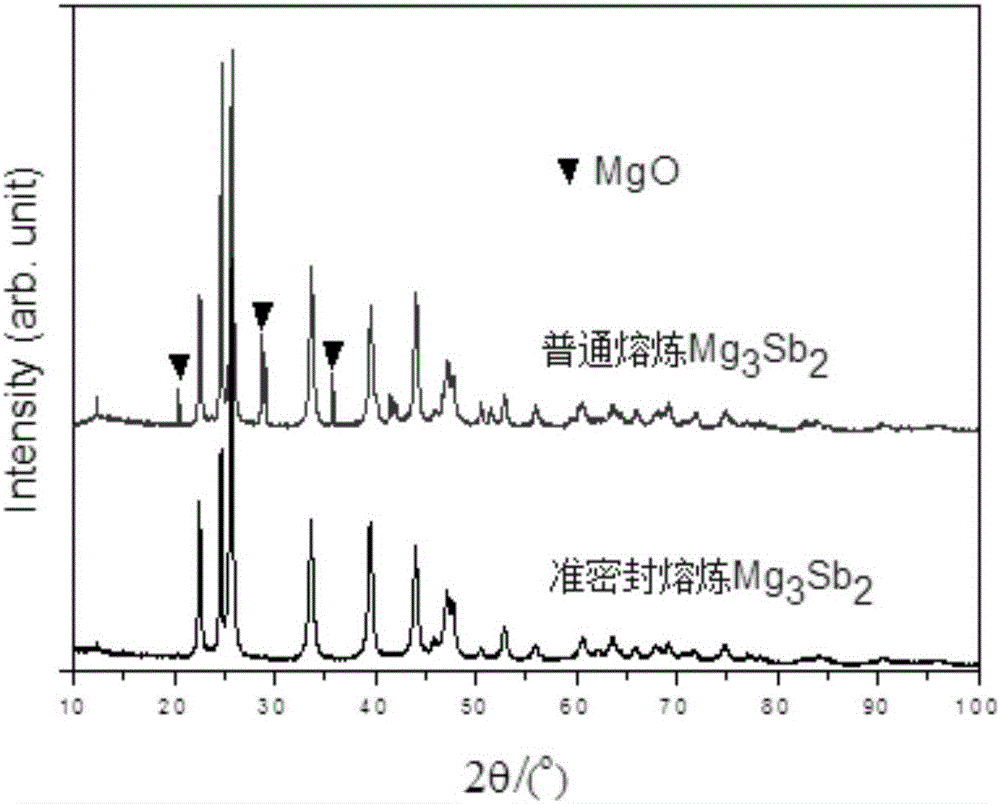

Aluminum alloy and alloy sheet thereof as well as preparation method of alloy sheet

The invention relates to an aluminum alloy and an alloy sheet thereof as well as a preparation method of the alloy sheet, belonging to the field of non-ferrous metal and preparation thereof. The aluminum alloy comprises the compositions in percentage by mass: 5.5-6.0% of Mg, 0.6-1.2% of Zn, 0.1-0.2% of Cu, 0.6-1.0% of Mn, 0-0.1% of Cr, 0-0.15% of Ti, 0.05-0.25% of Zr, 0-0.25% of Fe, 0-0.2% of Si, and the balance of Al. The stable-state or work hardening-state aluminum alloy sheet can be obtained by performing preheating or homogenization treatment to an alloy ingot prepared by the compositions, then carrying out corresponding hot rolling, cold rolling, annealing, prestretching and the like. Through the sheet, the continuous precipitation capability of Al3Mg2 in crystal boundary can be greatly reduced while the solid solution strengthening action of the Mg element can be ensured, and the sheet has excellent mechanical performance and anti-corrosion property compared with the traditional AA5059-H321 and AA5059-H131.

Owner:UNIV OF SCI & TECH BEIJING +1

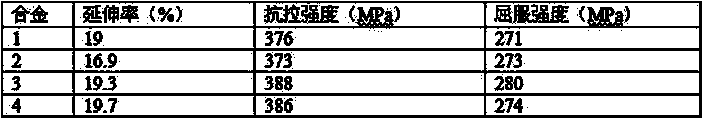

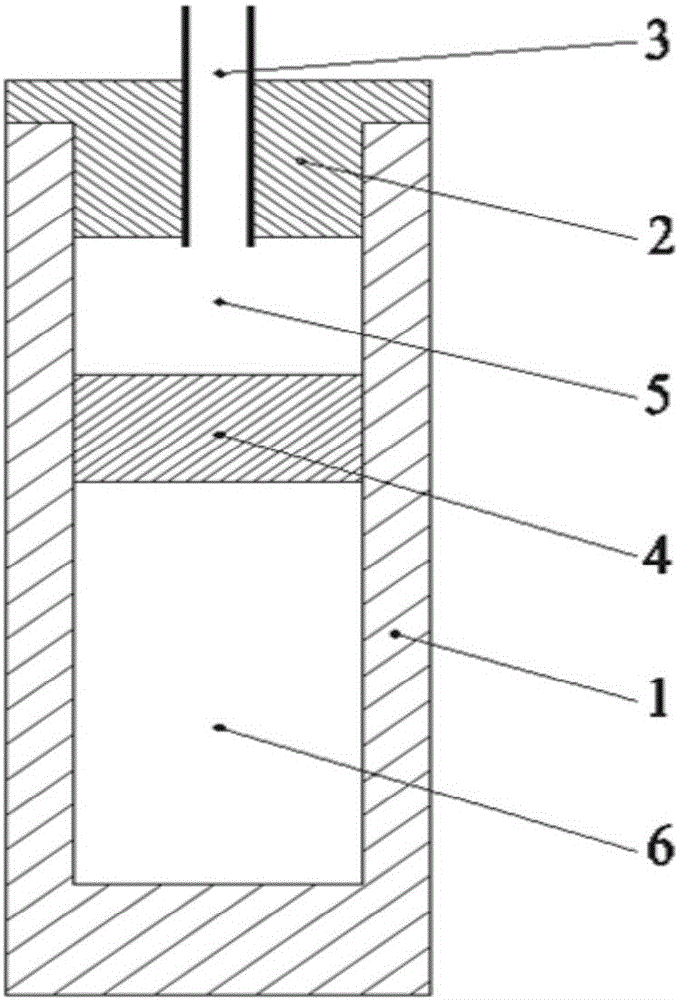

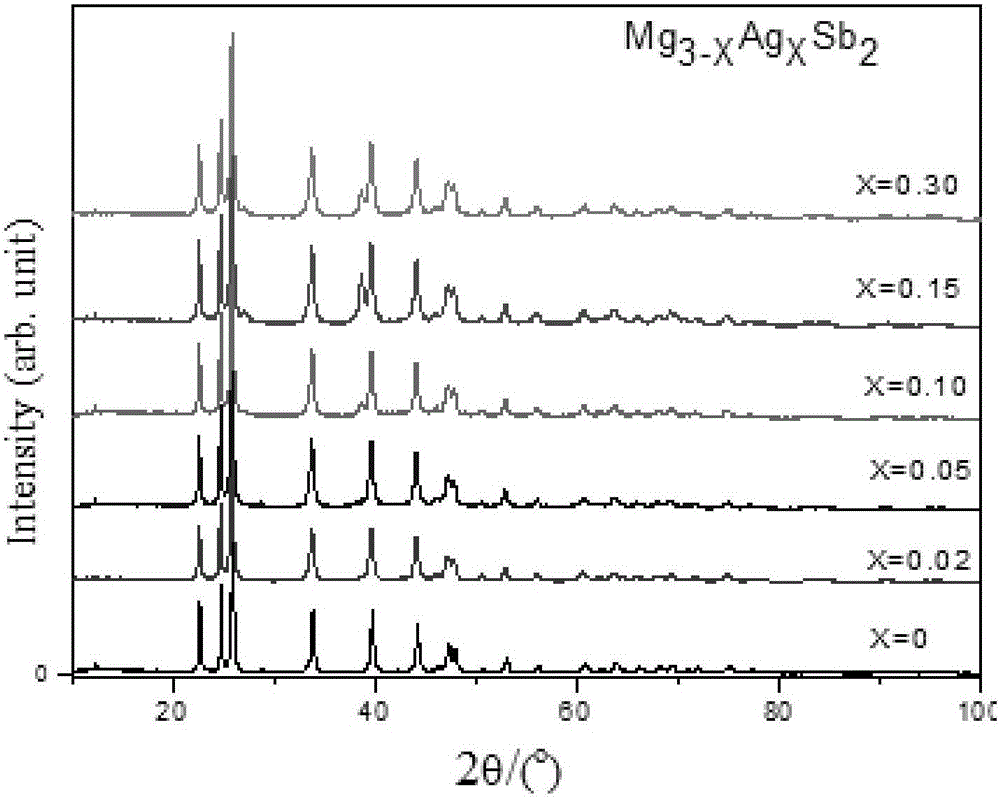

Preparation method for Mg3Sb2-based thermoelectric material

InactiveCN105695774ASuitable for a wide range of ingredientsLow costThermoelectric materialsArgon atmosphere

Provided is a preparation method for a Mg3Sb2-based thermoelectric material. A Mg3-xAxSb2-yBy block is prepared through the method combining induction smelting and the spark plasma sintering (SPS) technology; A is Ag, or Cu or the like, B is Si, or Ge, or Sn or the like, x is larger than or equal to 0 but smaller than or equal to 0.30, and y is larger than or equal to 0 but smaller than or equal to 0.20. The method includes the following steps that firstly, under the protection of high-purity argon gas which is deoxidized through an efficient deoxidizing agent, elementary raw materials are weighed according to stoichiometric ratios and placed into quasi-sealed smelting equipment to be smelted to ingots, and then the ingots are crushed; the crushed ingots are placed into a sintered carbide ball milling tank, and ball milling is carried out through mechanical ball milling equipment under the high-purity argon atmosphere; and then the ball-milled powder is loaded into a graphite die and then placed in an SPS cavity, and the high-compactness block is obtained after sintering under the vacuum atmosphere. According to the preparation method, cost is low, the ingredient application range is wide, operation is easy, reliability is high, and process parameters are easy to control; the problem that the Mg element is volatile and prone to oxidation can be solved, and the compactness and machinability of the material are improved.

Owner:BEIJING UNIV OF TECH

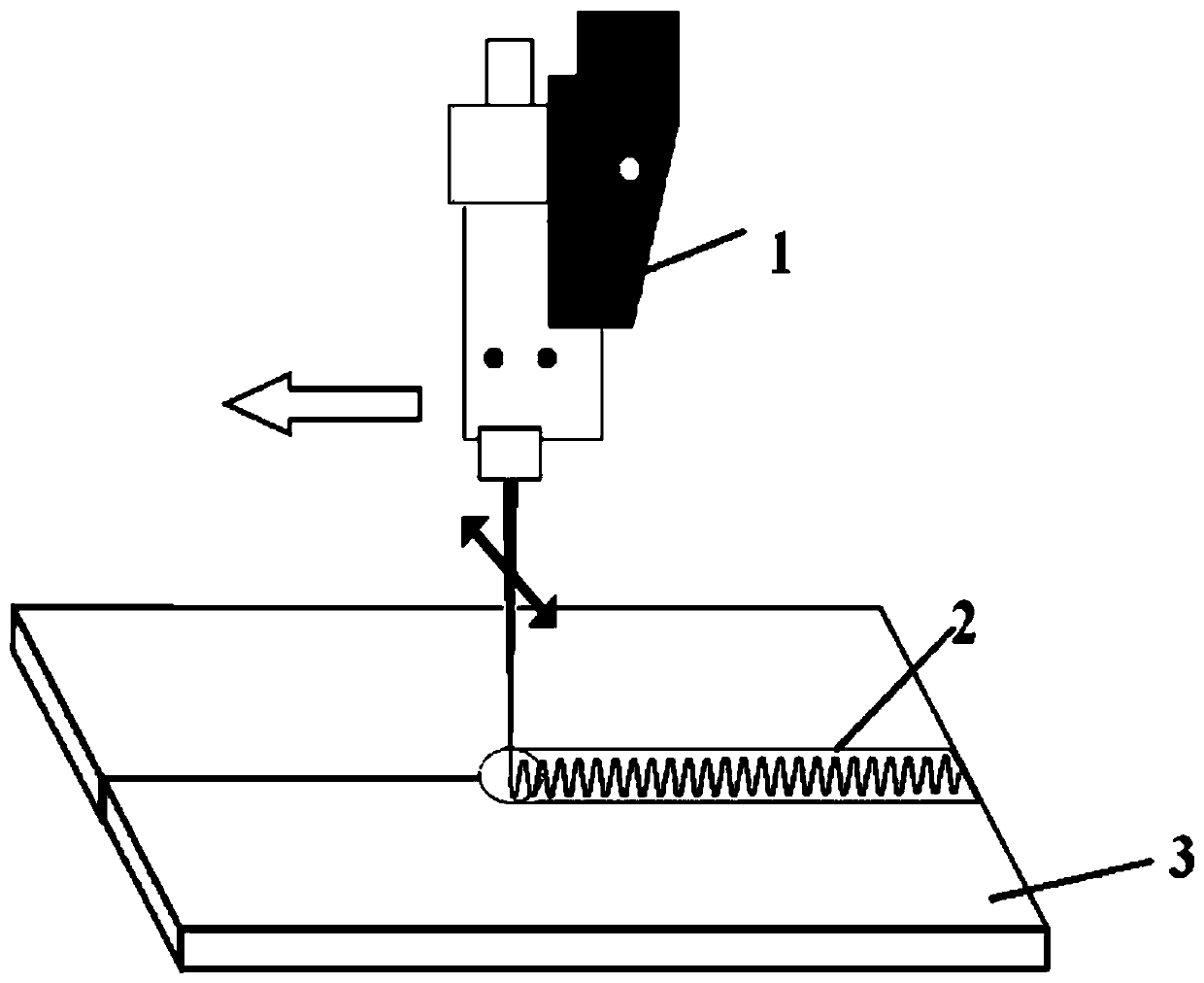

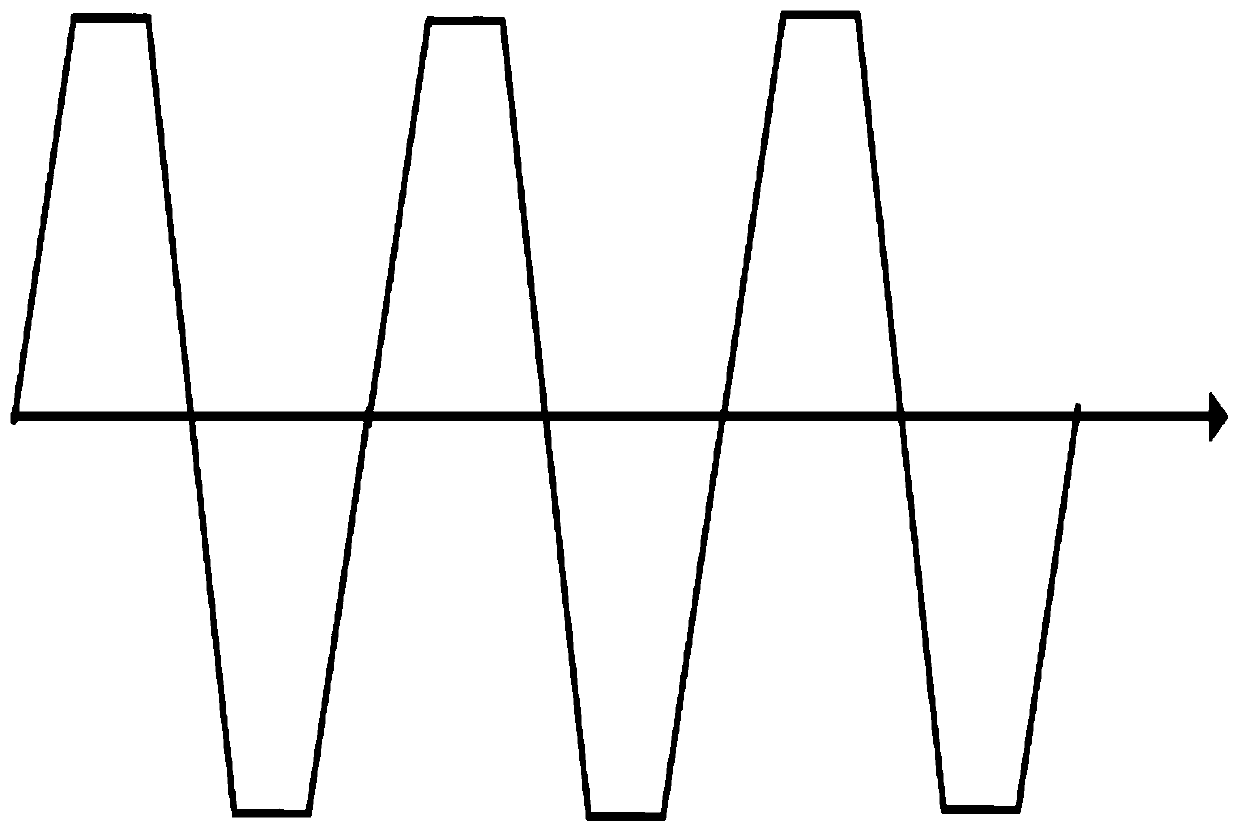

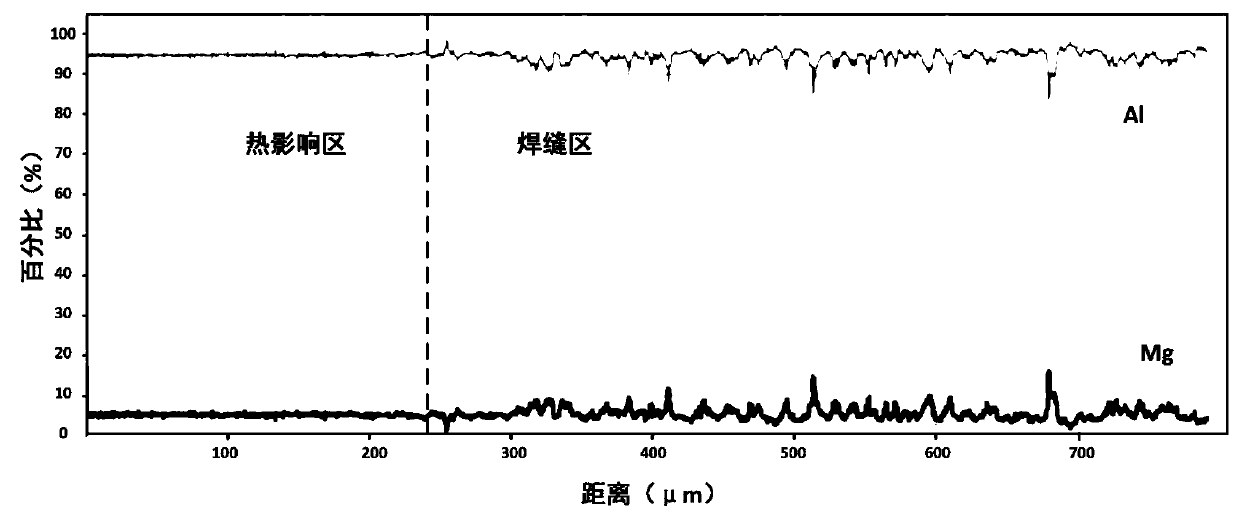

Homogenized Al-Mg series aluminum alloy weld microstructure laser welding method

InactiveCN110153557AAchieve homogenizationImprove efficiencyLaser beam welding apparatusBeta phaseShielding gas

The invention provides a homogenized Al-Mg series aluminum alloy weld microstructure laser welding method. The homogenized Al-Mg series aluminum alloy weld microstructure laser welding method comprises the following steps that (1), pre-welding polishing is carried out, wherein a weld center area is firstly mechanically ground, oxide skin on the weld surface is taken out, and acetone is used for wiping oil stains or other impurities; (2), pre-welding parameter adjustment is carried out, wherein a laser head of a laser device is aligned to the place, needing to be welded, of a workpiece, and theheight is adjusted; and (3), waveform welding is carried out, wherein the position needing to be welded is welded, protective gas is used for protection, laser beams advance in the weld direction inparallel, in the advancing process, a galvanometer is used for making the oscillating laser beams symmetrically move back and forth on the two sides in the welding direction, and the light spot motiontrajectory is a square wave path. In the welding process, oscillating of the laser beams can agitate a molten pool and delay solidification in the molten pool, Mg elements in the weld are uniformly distributed, the beta phase (Mg2Al3) is uniformly precipitated, the weld microstructure homogenization is achieved, and the weld mechanical properties are improved.

Owner:HUST WUXI RES INST

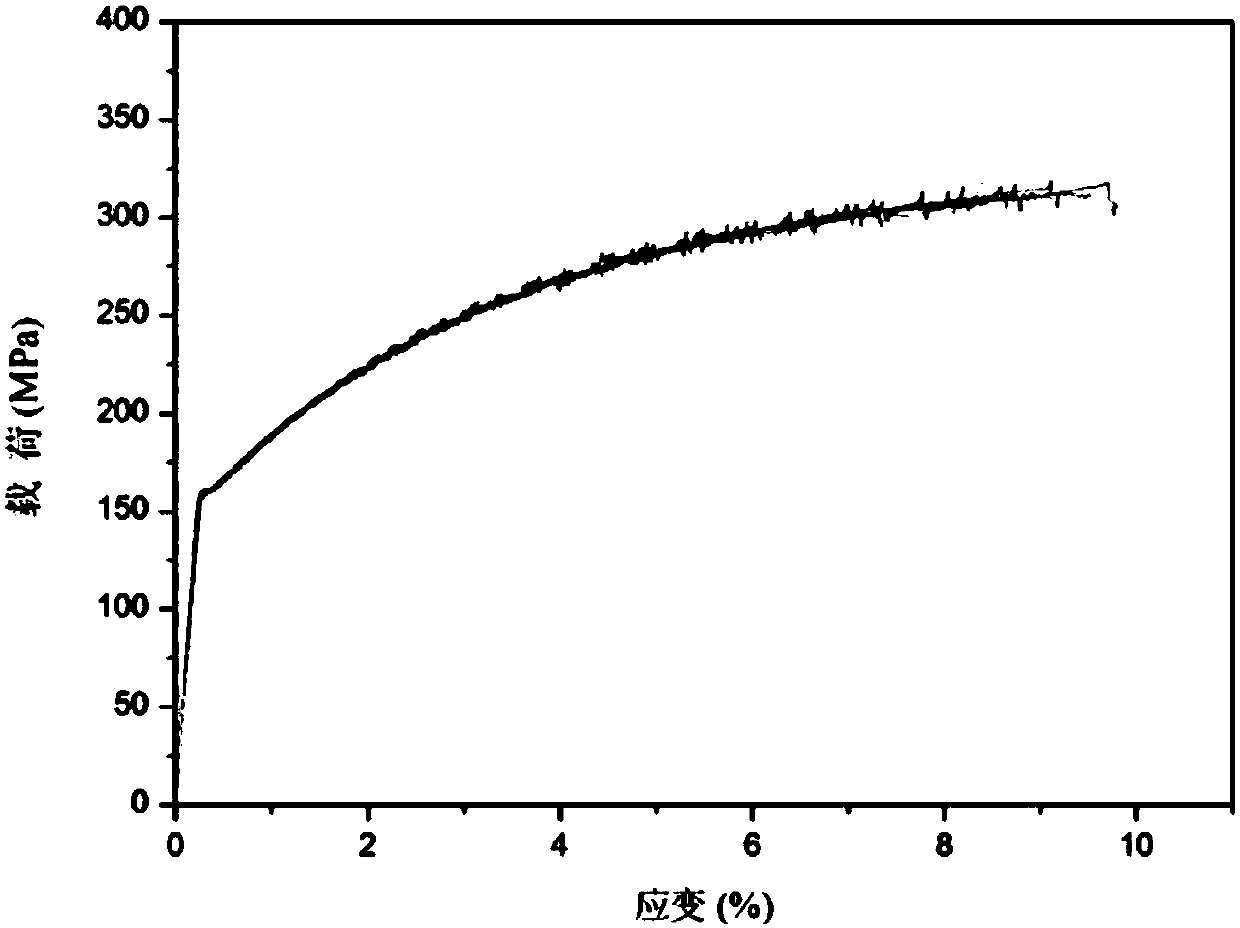

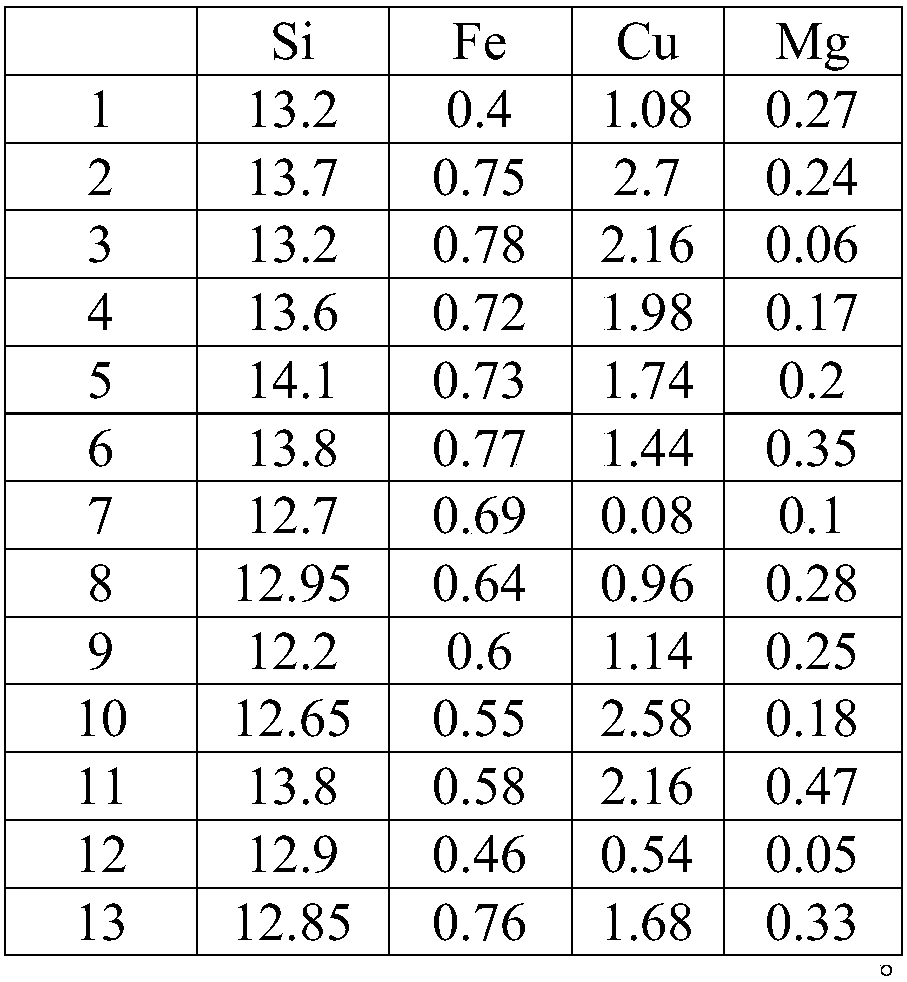

High-strength high heat conductivity thin-walled die casting aluminum alloy and preparation method thereof

The invention relates to a high-strength high heat conductivity thin-walled die casting aluminum alloy and a preparation method thereof. The alloy comprises the following elements in percentage by weight: 12-14wt% of Si, 0.05-3wt% of Cu, 0.40-0.80wt% of Fe, 0.00-0.05wt% of Mg, less than 0.05wt% of other impurities and the balance of Al. Compared with the prior art, by strictly controlling the total amount of Cu and Mg within 0.05-3wt% and then carrying out thermal treatment at 175 DEG C for 4h, Cu and Mg elements will not dissolved in a substrate, so that a micro dispersive CuAl2 second phaseand Mg17Al12 second phase are formed in the material. Fe element can prevent the material from being stuck to a die, so that a thin-walled product is casted more effectively. Meanwhile, the second phases can enhance the strength of the material effectively, so that the tensile strength of the material is greater than 300MPa, the yield strength is greater than 150MPa and the ductility is 8-10%.

Owner:苏州慧驰轻合金精密成型科技有限公司

Si-Ca-Al-Mg-RE (rare earth) composite deoxidizer and preparation method thereof

The invention belongs to the technical field of steel smelting deoxidization, and relates to an Si-Ca-Al-Mg-RE (rare earth) composite deoxidizer for molten steel deoxidization and a preparation method thereof. The composite deoxidizer is added to deoxidize molten steel in the converter or electric furnace tapping process or a refining process of an RH, LF (ladle furnace), VD (vacuum degasser) or the like. The alloy comprises the following components in percentage by weight: 40-50% of Si, 10-12% of Ca, 3-4% of Al, 1-1.5% of Mg, 10-20% of RE and the balance of iron. The preparation method comprises the following steps: 1) smelting in a vacuum furnace, vacuumizing the smelting furnace, and charging protective gas; 2) preheating the furnace, and adding preheated interalloy Si-Ca, Al, Si and Fe; 3) after the furnace material is molten, adding preheated RE-Mg interalloy, adding pure RE element, melting, evenly stirring, and standing; and 4) preheating the casting mold, and casting. The volatile elements Ca and Mg are added in the forms of interalloy Si-Ca and RE-Mg, thereby reducing the burnout rate of the Ca and Mg elements, and enhancing the deoxidizing effect and inclusion removal capacity of the alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Zirconia powder added with trace elements and preparation method thereof

The invention discloses zirconia powder added with trace elements, which comprises yttrium. The zirconia powder added with the trace elements is characterized in that trace La, Ce, Al, Ca, Ti and Mg elements are added into the zirconia powder, and the mass ratio of ZrO2 to (La, Ce, Al, Ca, Ti and Mg)Ox is 1:0.0001-0.008. The invention also discloses a preparation method for the zirconia powder. After the technical scheme is adopted, the trace La, Ce, Al, Ca, Ti and Mg elements are added when the yttrium-contained zirconia powder is prepared, and a reaction condition is controlled. After the produced zirconia powder is prepared into a ceramic body, the crystal structure of the ceramic body can be greatly reinforced by trace added ingredients, so that the produced ceramic body produced by the powder is unlikely to dissolve out yttrium and zirconium under the conditions of intermediate temperate (RT(range temperature)-200DEG C) and concentration below 15%, and the ceramic body has good structure stability, so the service life of the ceramic body is greatly prolonged.

Owner:FUJIAN JOHNSON MINING

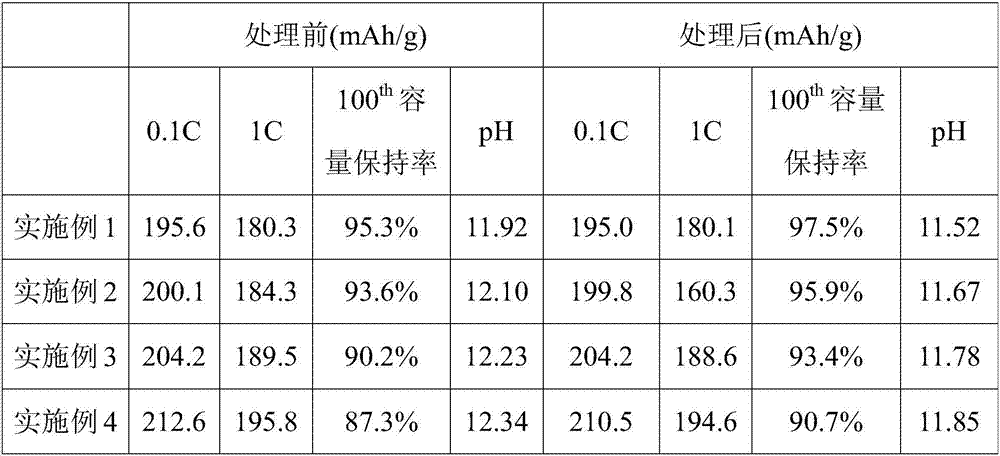

Layered positive electrode material for lithium-ion battery and preparation method of layered positive electrode material

ActiveCN107994212AStable crystal structureReduce surface residual alkali contentSecondary cellsPositive electrodesManganeseCobalt

The invention discloses a layered positive electrode material for a lithium-ion battery. The layered positive electrode material comprises a body and a B2O3 coating layer, wherein a chemical formula of the body is Li<x>(NiCoMn<c>)<1-y>M<y>O<2>, wherein x is smaller than or equal to 1.04 and greater than or equal to 0.96, y is smaller than or equal to 0.06 and greater than or equal to 0.01, ais smaller than or equal to 0.9 and greater than or equal to 0.8, a+b+c is equal to 1, and M is selected from at least one of an Al element, a Mg element, a Ti element and a Zr element. The inventionfurther discloses a preparation method of the layered positive electrode material for the lithium-ion battery. The method comprises the following steps of mixing a nickel-cobalt manganese hydroxide,a lithium source and a nano oxide additive evenly and carrying out first sintering to obtain unmodified powder; stirring the unmodified powder and water, carrying out centrifugal separation to obtaina solid material, drying and crushing to obtain washing powder; adding LIBOB to an organic solvent for dissolving, adding the washing powder for mixing, stirring, evaporating and carrying out second sintering to obtain the layered positive electrode material for the lithium-ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

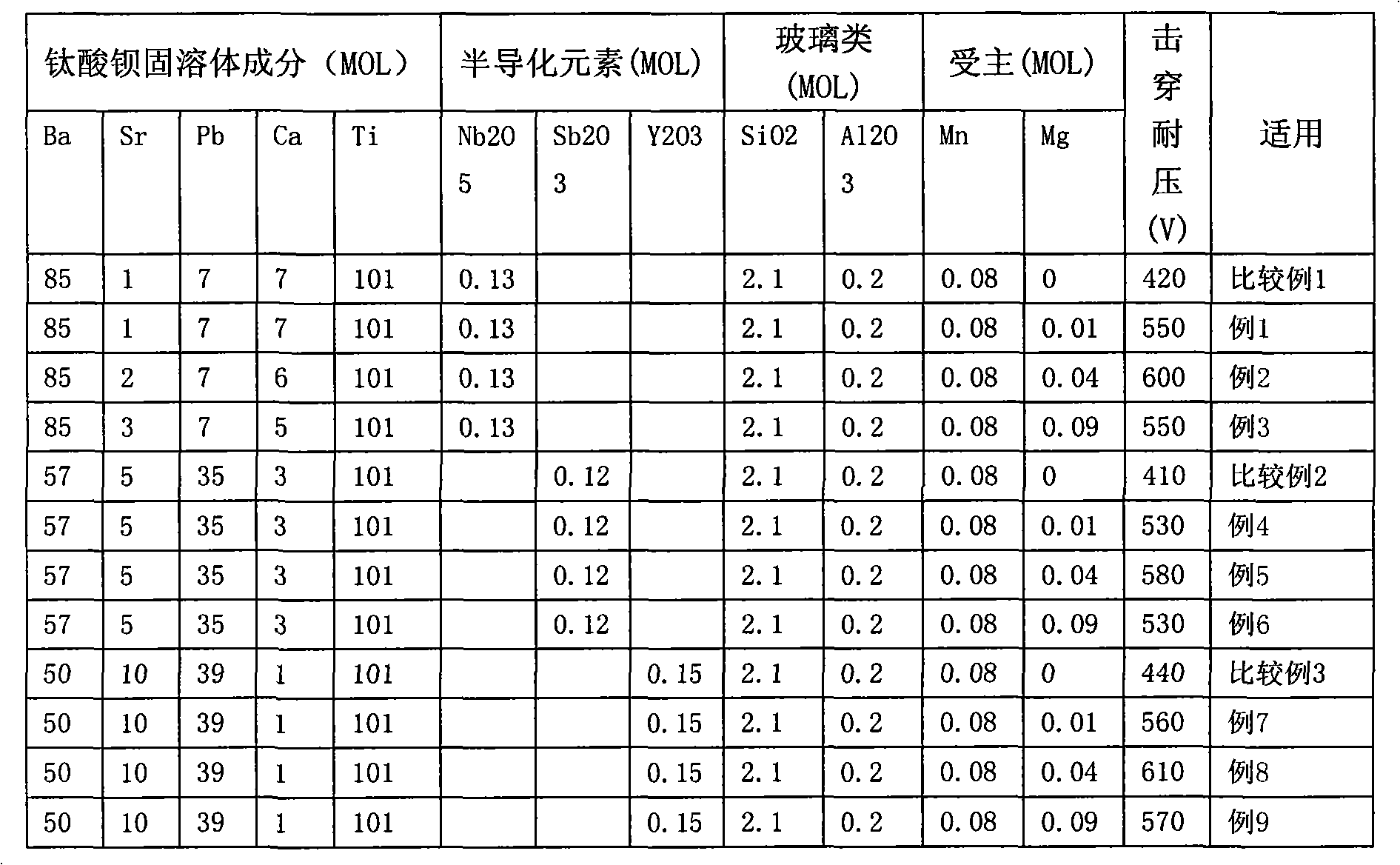

High temperature thermistor and manufacturing method thereof

The invention relates to a high temperature thermistor and a manufacturing method thereof. The high temperature thermistor is formed by barium titanate, lead titanate, calcium titanate, strontium titanate, semi-conducting elements, silicon oxide, titanium oxide, alumina, manganese dioxide and magnesium oxide, wherein the semi-conducting elements are one or more of niobium oxide, yttrium oxide andantimony oxide. The manufacturing method is characterized by adding water to barium titanate, lead titanate and the like in a ball mill and finely grinding the mixture, discharging and drying the ground mixture, presintering the ground mixture for 2h, grinding the ground mixture in the ball mill, adding PVA adhesive solution, pelleting the mixture, forming the mixture through pressing by a tabletpress, sintering the formed material to obtain semi-conducting ceramics, carrying out grinding and spraying the Al electrode, thus obtaining the product. The sintering potential barrier is increased in the sintering process by adding the Mg element, thus ensuring the grains to be fine and uniform and the voltage resistance to be high. The ceramic structure is denser by replacing Ba with Mg, thus being capable of blocking ionic migration in the abominable atmosphere and improving the stability in the strongly abominable atmosphere. The high temperature thermistor can withstand 500V voltage under extremely low oxygen partial pressure by being assembled in a sealed Al pipe.

Owner:DONGGUAN WOLI ELECTRONICS CO LTD

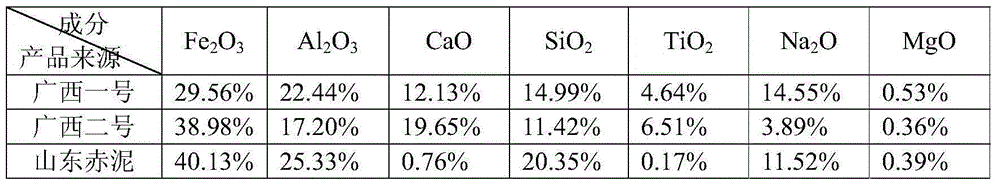

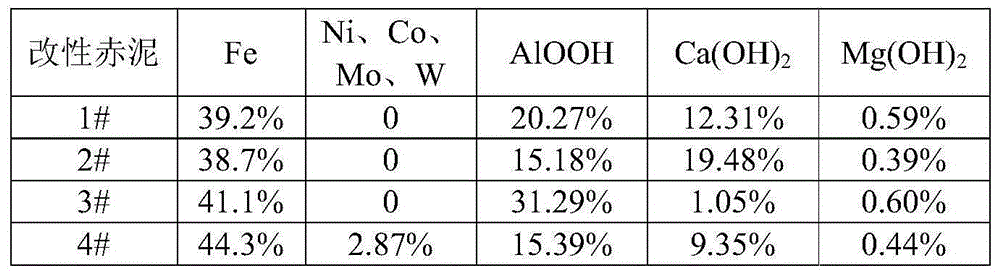

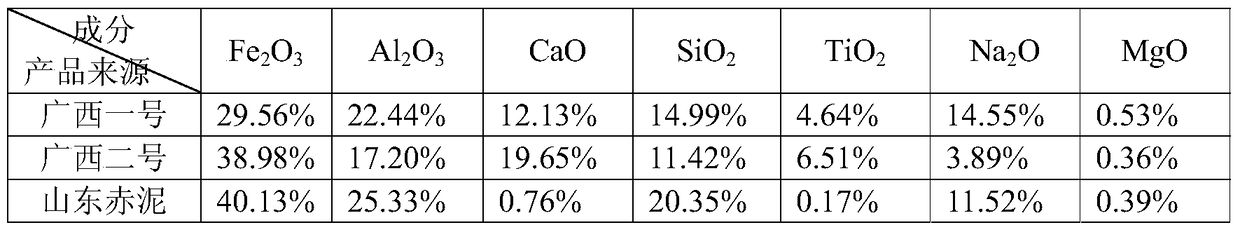

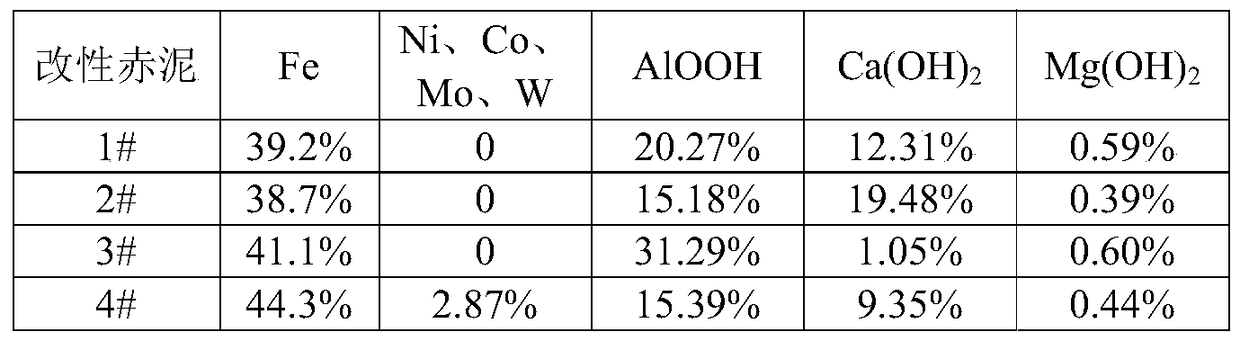

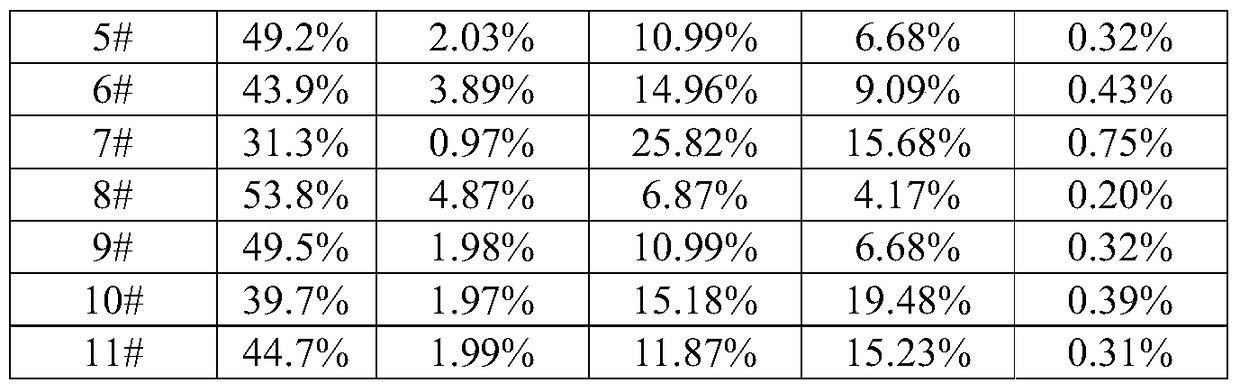

Modified red mud, modification method thereof and catalyst applicable to direct coal liquefaction

ActiveCN105170155ASolve the use problemPlay a role in separatingLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsRed mudMg element

The present invention provides a modified red mud, a modification method thereof and a catalyst applicable to direct coal liquefaction. The modified red mud comprises FeOOH, and a hydroxide mixture dispersed among FeOOH; wherein content of Fe in FeOOH in the modified red mud is 30wt%-55wt%; and the hydroxide mixture comprises hydroxides of Al, Ca and Mg. Iron in the red mud is converted into hydroxy ferric oxide, and the iron content is controlled within the range of 30wt%-55wt%; the Si and Ti elements in the red mud are removed, while the Al, Ca, and Mg elements are contained and convert into the hydroxides dispersed between FeOOH to play the roles of separation and dispersion, so that the FeOOH has small particle size, large specific surface area and good dispersion. Thereby, the modified red mud has high direct catalytic liquefaction activity on coal.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Modified red mud, its modification method and catalyst suitable for direct coal liquefaction

ActiveCN105170155BSolve the use problemSmall particle sizeLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsRed mudIron oxyhydroxide

The invention provides a modified red mud, its modification method and a catalyst suitable for direct coal liquefaction. The modified red mud includes FeOOH; and a hydroxide mixture dispersed between FeOOH, wherein the content of Fe element in FeOOH in the modified red mud is 30wt% to 55wt%, and the hydroxide mixture consists of Al element, Ca element and the hydroxide composition of Mg element respectively. By converting iron in red mud into iron oxyhydroxide, and controlling the content of iron in the range of 30wt% to 55wt%, while removing Si and Ti elements in red mud, while retaining elements such as Al, Ca and Mg and It is converted into hydroxide and dispersed between FeOOH to play the role of separation and dispersion, so that the particle size of FeOOH is smaller, the specific surface area is larger, and the dispersion is good, so that the modified red mud has a higher Catalytic activity for direct coal liquefaction.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Production technique of high-wear-resistance aluminum alloy section

The invention discloses a production technique of a high-wear-resistance aluminum alloy section. The alloy comprises the following elements in percentage by mass: 12-16% of Si, 4-6% of Mg, 2-3% of Zn, 0.6-1.2% of Mn, 0.4-0.8% of V, 0.3-0.5% of Cr, 0.2-0.3% of Ni, 0.18-0.22% of Ti, 0.1-0.15% of Co, 0.03-0.05% of As, 0.02-0.03% of In, 0.01-0.02% of P, 0.08-0.12% of RE and the balance of Al. By properly enhancing the Mg element content and optimizing the Si / Mg ratio, abundant Mg2Si phases can be generated in the alloy structure, and the hard granules can obviously enhance the wear resistance of the alloy; and small amounts of As, In and RE added into the alloy structure can improve the high-temperature stability of the alloy. The aluminum alloy section has the advantages of high strength, strong high-temperature stability and excellent wear resistance, and can be widely used in industrial wear-resistant parts.

Owner:ANHUI SHENGDA QIANLIANG ALUMINUM

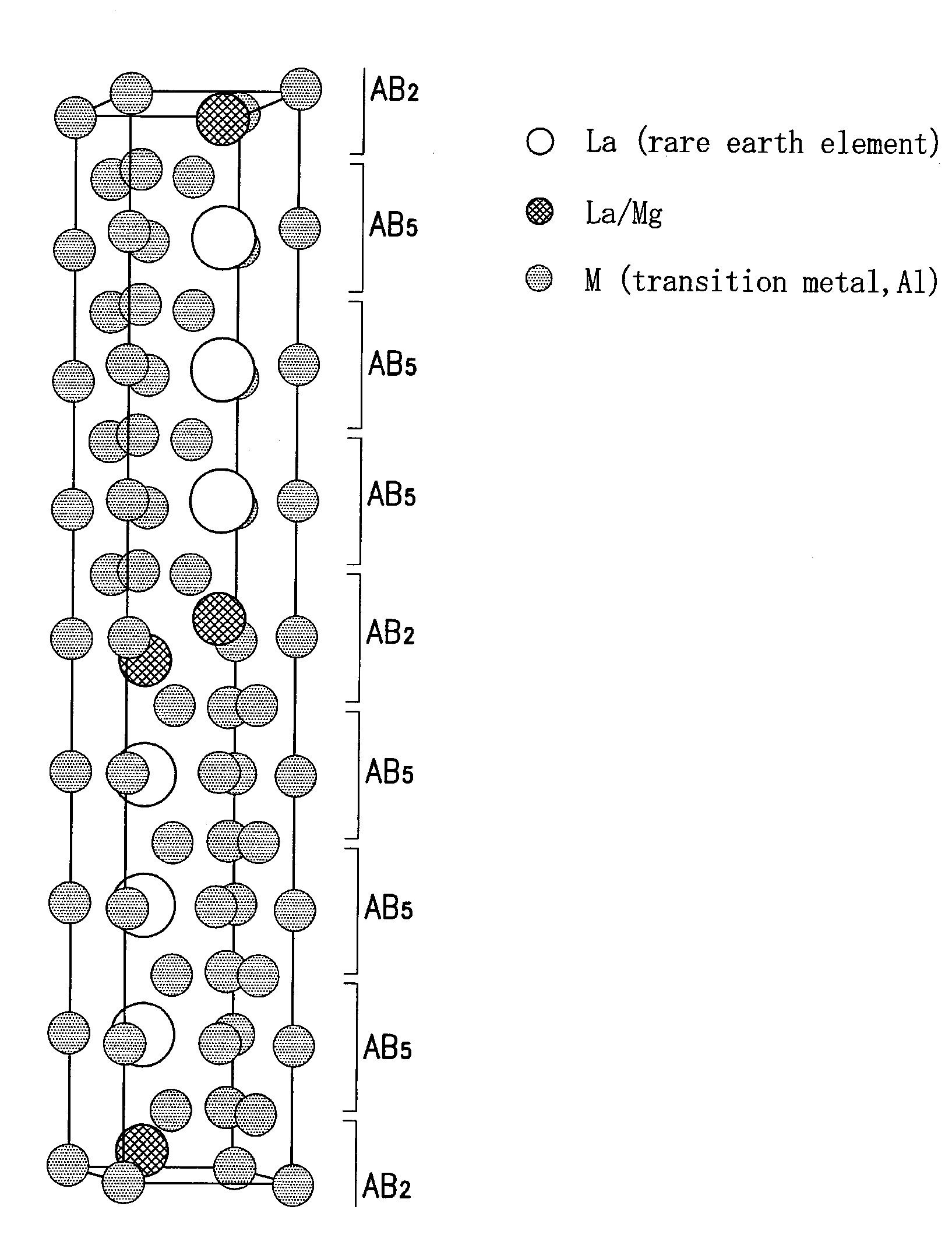

Hydrogen Absorbing Alloy, Hydrogen Absorbing Alloy Electrode, Secondary Battery and Production Method of Hydrogen Absorbing Alloy

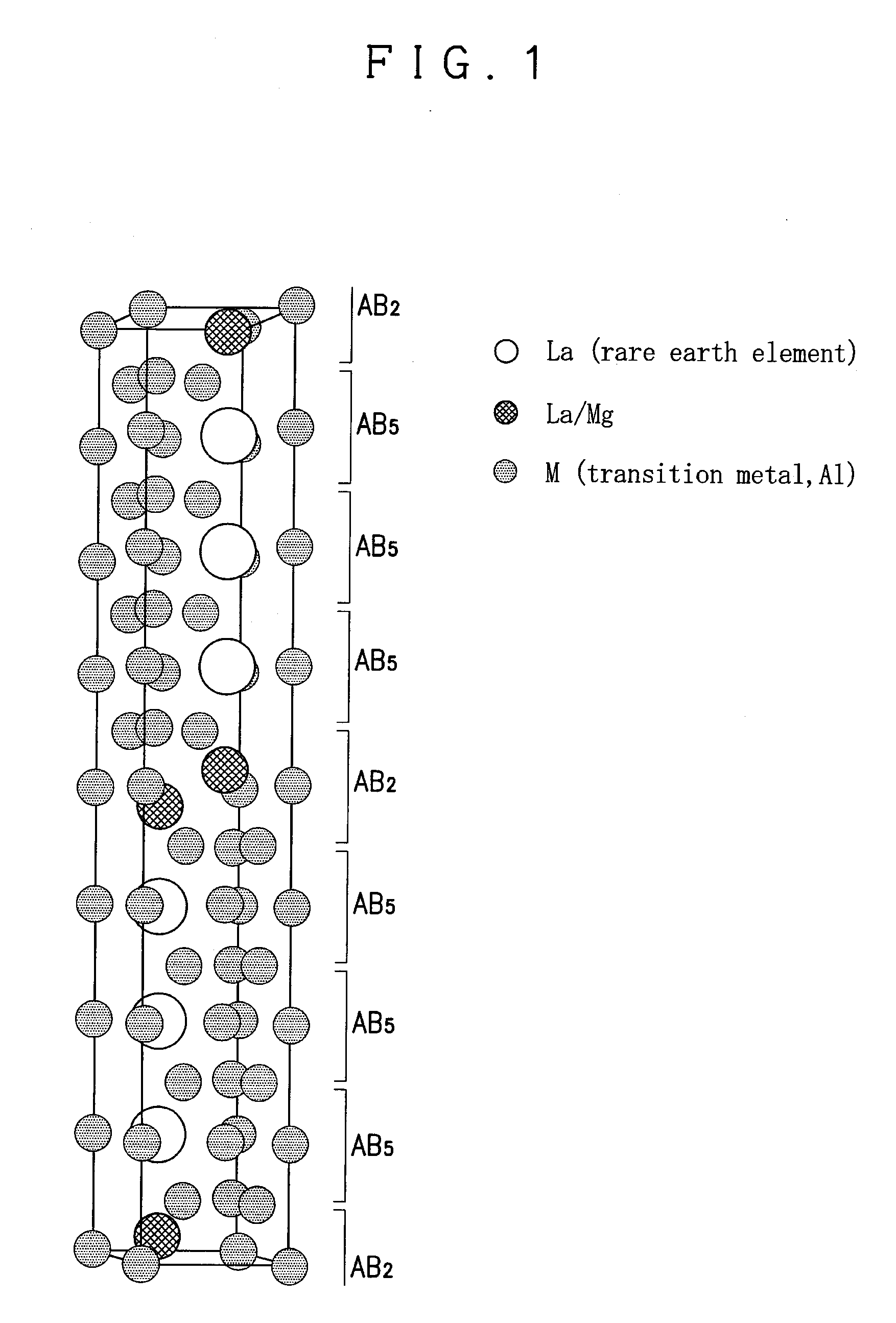

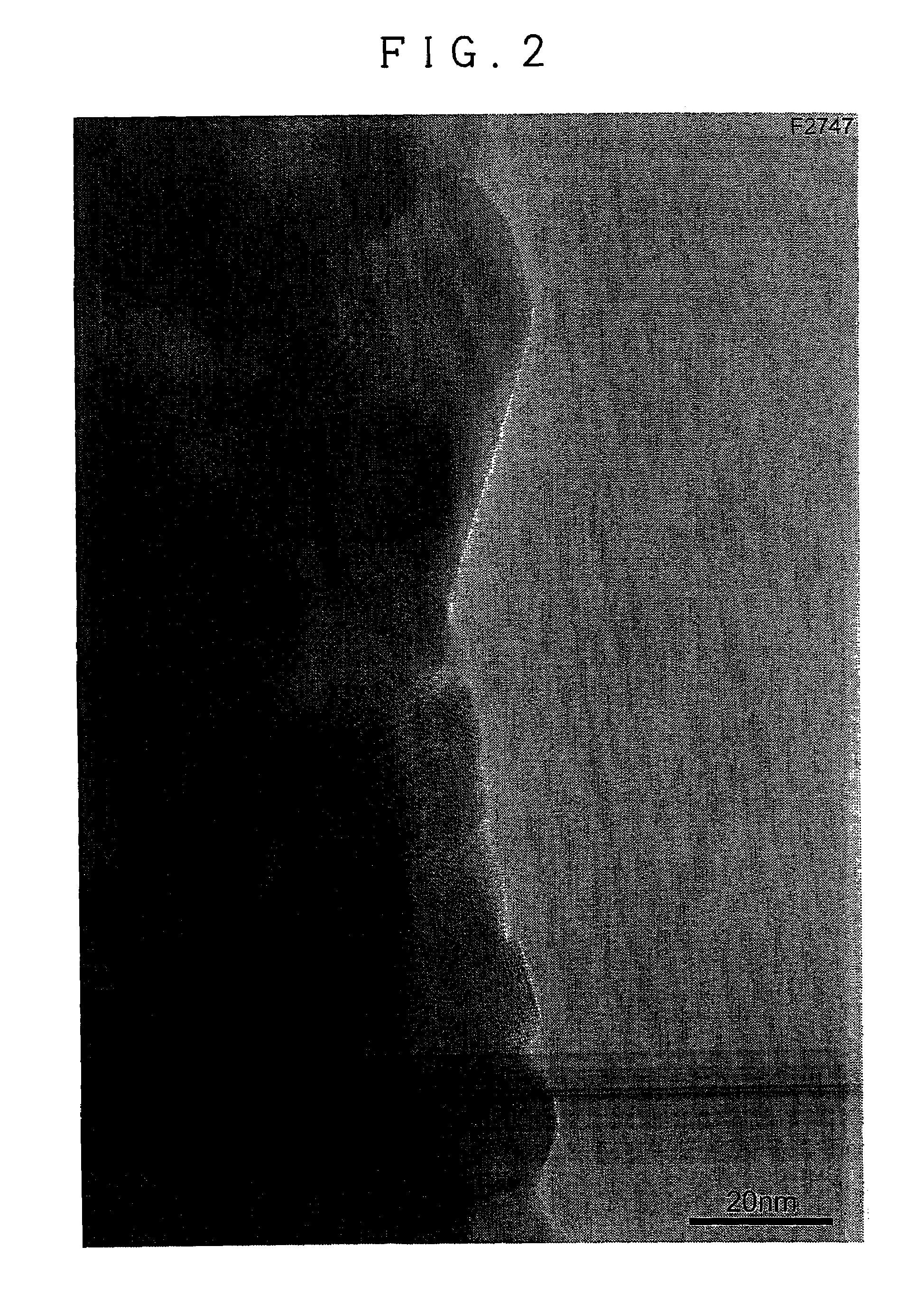

ActiveUS20090226342A1Improve hydrogen storage performanceIncreased durabilityReactant parameters controlCell electrodesRare-earth elementCrystal structure

The present invention provides a hydrogen absorbing alloy containing a phase of a Pr5Co19 type crystal structure having a composition defined by a general formula A(4−w)B(1+w)C19 (A denotes one or more element(s) selected from rare earth elements including Y (yttrium); B denotes an Mg element; C denotes one or more element(s) selected from a group consisting of Ni, Co, Mn, and Al; and w denotes a numeral in a range from −0.1 to 0.8) and having a composition as a whole defined by a general formula R1xR2yR3z (15.8≦x≦17.8, 3.4≦y≦5.0, 78.8≦z≦79.6, and x+y+z=100; R1 denotes one or more element(s) selected from rare earth elements including Y (yttrium); R2 denotes an Mg element, R3 denotes one or more element(s) selected from a group consisting of Ni, Co, Mn, and Al; the numeral of Mn+Al in the z is 0.5 or higher; and the numeral of Al in the z is 4.1 or lower).

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

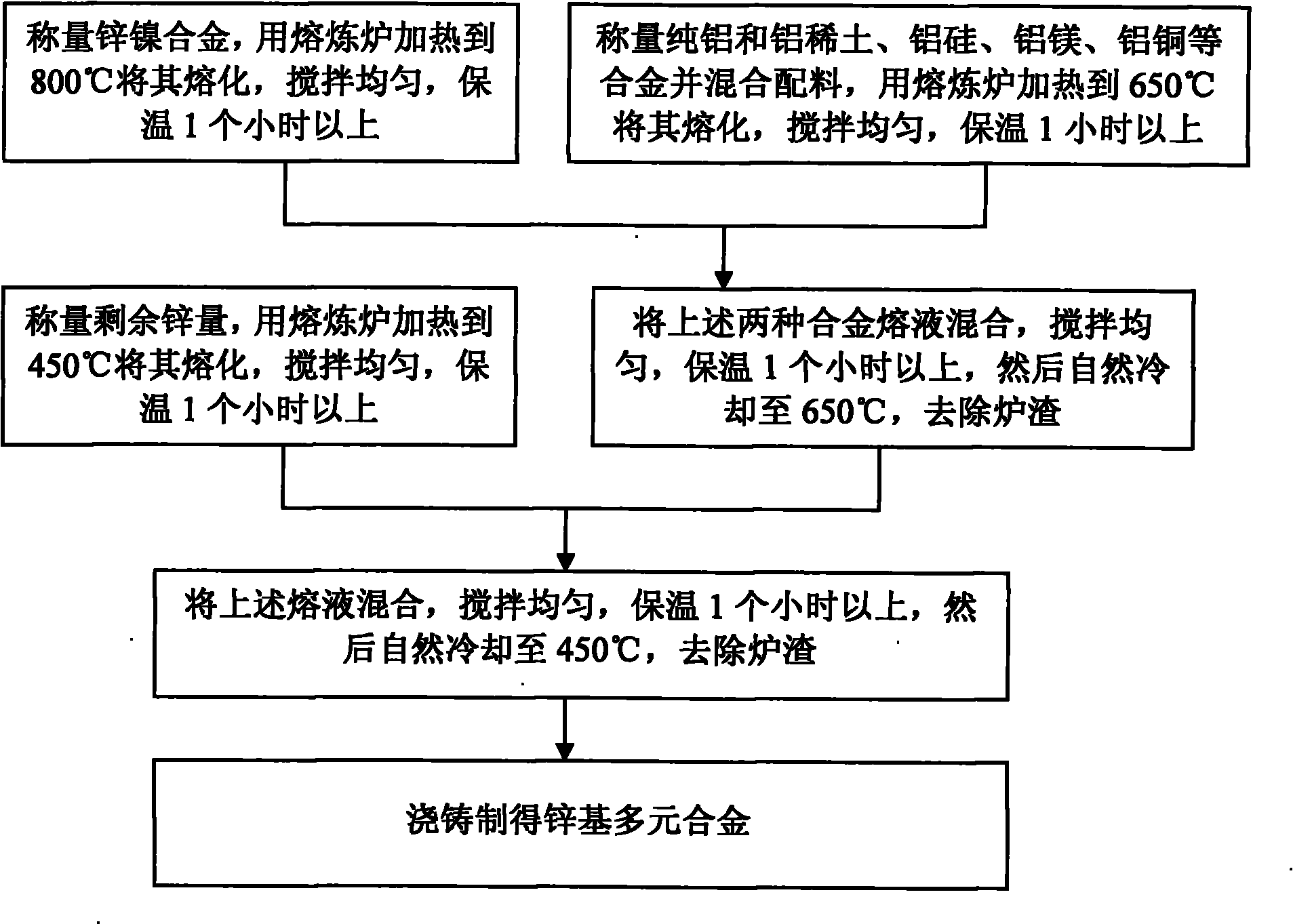

Zinc-based multi-element alloy for hot dipping and preparation method thereof

InactiveCN101818316AGood value for moneyReduce consumptionHot-dipping/immersion processesRare-earth elementDip-coating

The invention provides a zinc-based multi-element alloy for hot dipping and a preparation method thereof. The zinc-based multi-element alloy comprises the following components in percentage by mass: 2 to 3 percent of Al, 0.1 to 0.2 percent of RE(LA, Ce and PR mixed rare earth), 0.02 to 0.03 percent of Ni, 0.01 to 0.02 percent of Si, 0.01 to 0.02 percent of Mg, 0.005 to 0.01 percent of Cu and the balance of Zn. The zinc-based multi-element alloy has the advantages that: (1) in the alloy, the Al, Ni, Si, Cu and other elements are reasonably mixed, so the corrosion resistance of a hot-dip coating is obviously improved by over 20 percent than that of a pure zinc coating, meanwhile, the aluminium content is controlled within 3 percent so as to ensure that the alloy has good dip plating performance; and (2) in the alloy, La, Ce, Pr and other rare-earth elements and Mg element are reasonably mixed, so the fluidity and wetting performance of alloy plating solution are further improved, the surface quality of the coating is good, and the metal consumption is reduced by over 20 percent than that of the traditional galvanization. The zinc-based multi-element alloy and the preparation method thereof have obvious advantages in the aspects such as improving performance quality of hot-dip galvanized products, reducing metal consumption and reducing production cost.

Owner:KUNMING UNIV OF SCI & TECH

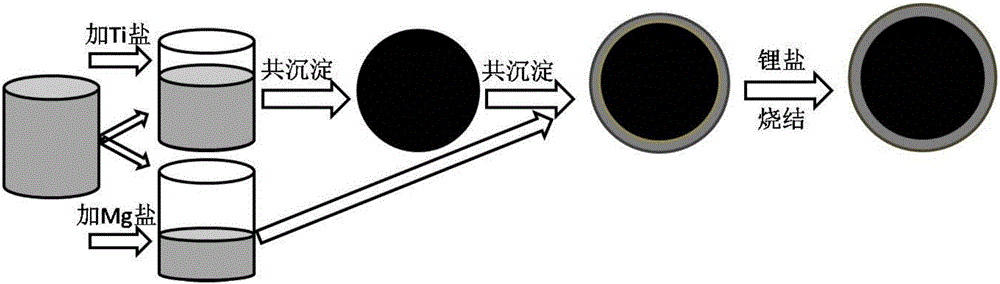

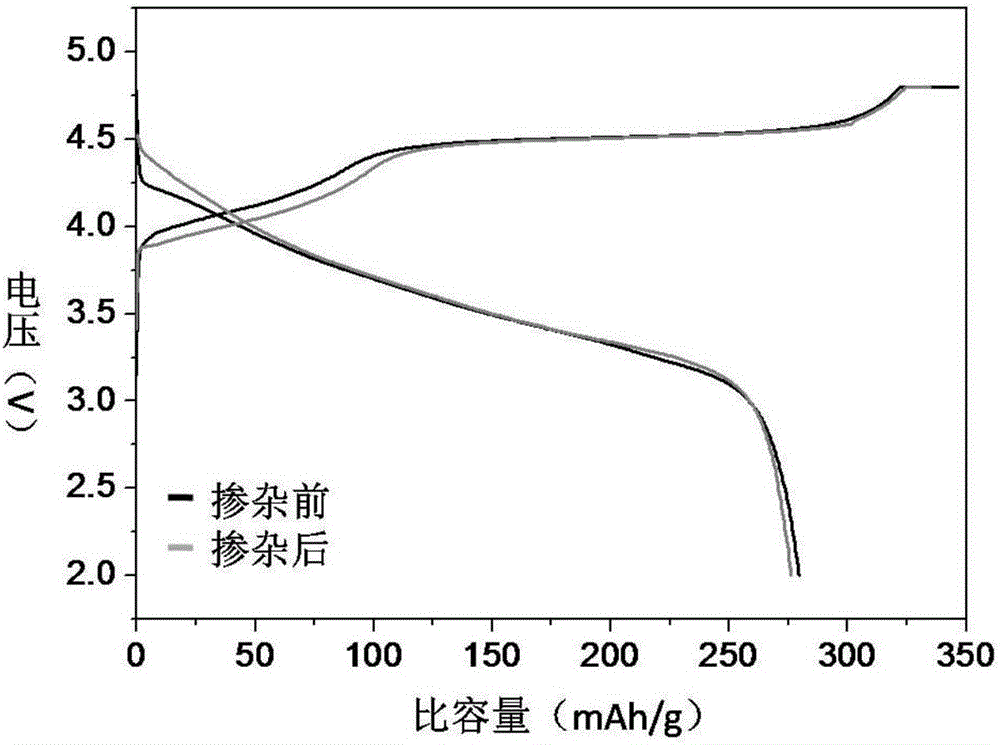

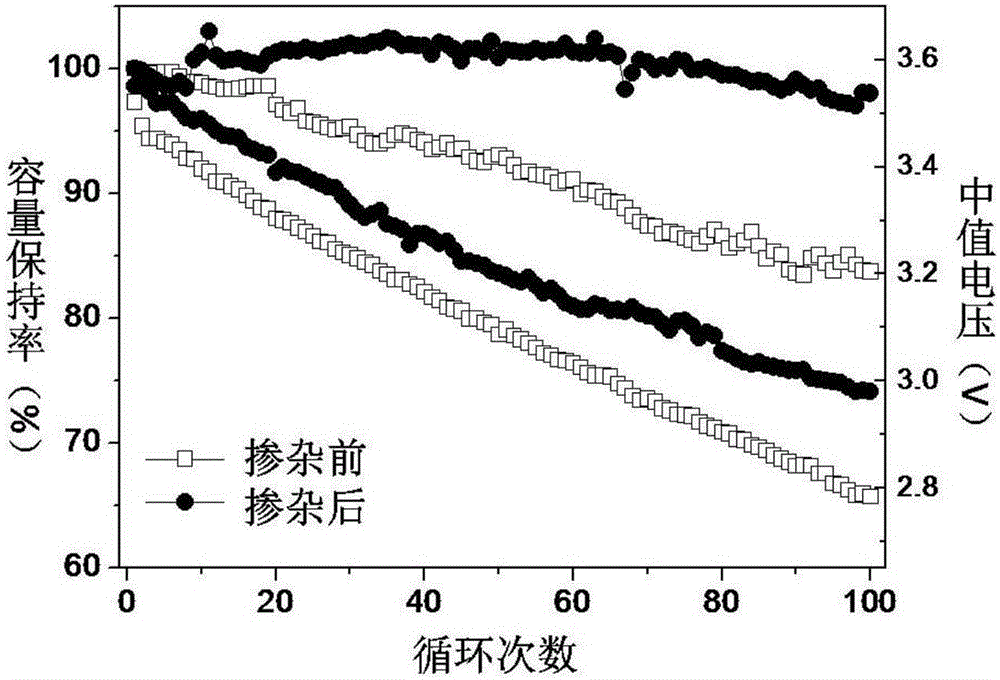

Preparation method of Mg and Ti composite doped lithium-rich manganese based positive electrode material

ActiveCN106711439AImprove cycle lifeMedian voltage dropCell electrodesSecondary cellsSurface layerManganese

The invention discloses a preparation method of an Mg and Ti composite doped lithium-rich manganese based positive electrode material, and belongs to the field of positive electrode materials of lithium ion batteries. A co-precipitation method is used for preparing a lithium-rich precursor, and Mg and Ti elements are added step by step for doping in the precursor co-precipitation preparing process. The preparation method comprises the following steps: adding the Ti element in the first half of a co-precipitation reaction, adding the Mg element in the latter half of the co-precipitation reaction, making the Ti element mainly distributed in a bulk phase, and making the Mg element mainly distributed in a surface layer of the precursor. The material properties are improved by controlling the distribution of the doping elements, so that on one hand, the doping amount of the doping elements can be reduced so as to improve the capacity per gram, and on the other hand, the functions of the two elements can be fully played, the effect superposition is achieved, and the interference between the elements during co-doping is reduced. At the same time, the preparation method is simple and is easy to industrialize.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

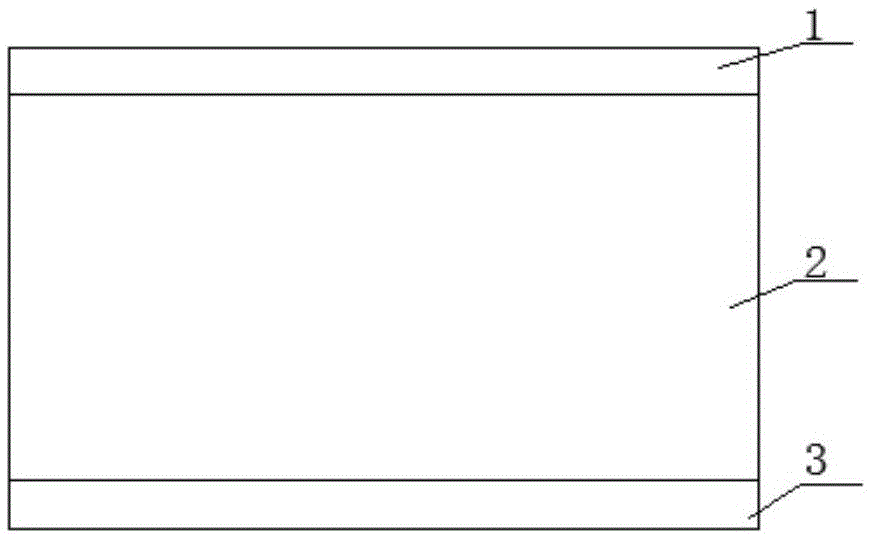

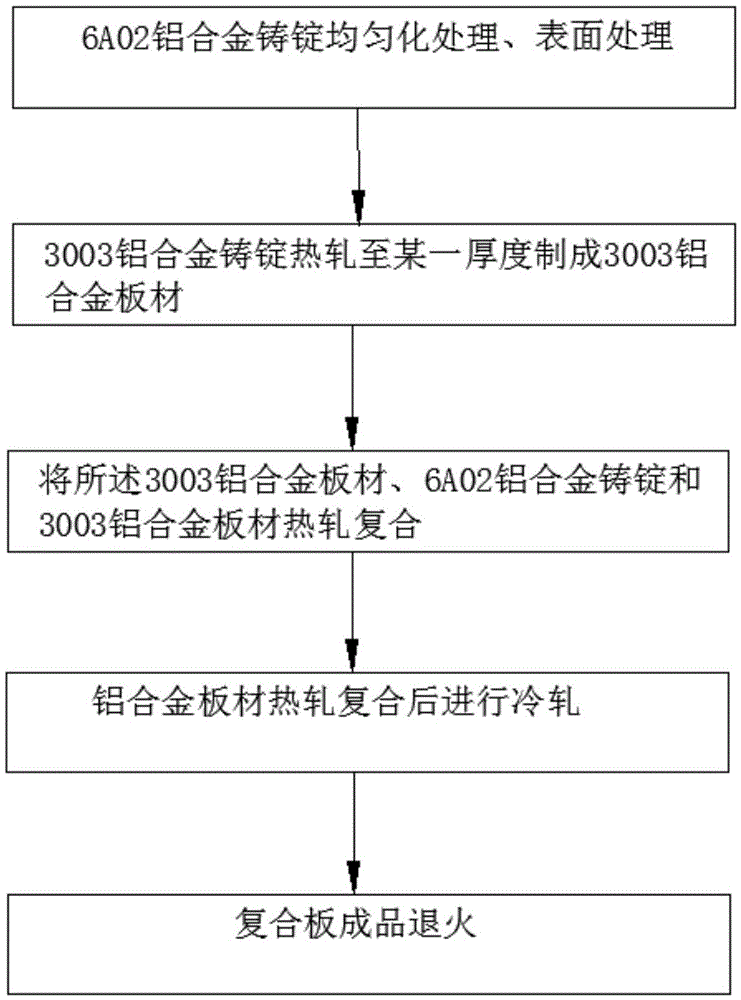

Method for compounding aluminum alloy composite board used for machining automobile oil cooler bottom board

InactiveCN105478474AIncrease productivityReduce manufacturing costMetal rolling arrangementsAlloy compositeIngot

The invention relates to a method for compounding an aluminum alloy composite board used for machining an automobile oil cooler bottom board. A 3003 aluminum alloy board, a 6A02 aluminum alloy cast ingot and a 3003 aluminum alloy board are hot-rolled and compounded according to the thickness proportion of 1:(8-15):1, so that the three-layer aluminum alloy composite board is obtained. By the adoption of the aluminum alloy composite board manufactured through the method, the situation that the welding quality of an oil cooler is affected due to the Mg element in a 6A02 core material of the aluminum alloy composite board in the protective atmosphere brazing process is avoided, protective atmosphere brazing of an oil cooler assembling piece can be smoothly finished, the production efficiency of the oil cooler is greatly improved, and the production cost is reduced.

Owner:YINBANG CLAD MATERIAL

Aluminium alloy strip used for housing of mobile phone lithium battery and method for preparing same

InactiveCN102747252AElimination of intragranular segregationUniform tissueElectrical batteryGranularity

An aluminium alloy strip used for a housing of a mobile phone lithium battery provided by the invention has tensile strength which can reach 170 to 190 MPa, an elongation rate after fracture being 3.0 to 5.0 % and an earing ration being 3 to 4 %, and can meet the requirements of the novel mobile phone battery housing for asymmetric-box-type large-proportion thin stretching and punching forming. A method for preparing the aluminium alloy strip used for the housing of the mobile phone lithium battery enables materials to be uniform in organization and no rough and nonuniform secondphase particles to exist through strictly controlling the mass percent of each alloy element, and treating by homogenizing annealing to eliminate intragranular segregation of Mn element before hot rolling. Due to the addition of a certain amount of Mg element, grain sizes of a finished product can be controlled to be below level one while improving the strength of the materials, so that the comprehensive properties such as material strength, toughness, deep-drawing and the like can be greatly improved.

Owner:招商局新材料科技重庆有限公司

Preparation method of high-strength copper alloy wire for automobile industry

InactiveCN104046816AGuaranteed electrical conductivityGuaranteed cutting effectWire rodTemperature resistance

The invention discloses a preparation method of a high-strength copper alloy wire for an automobile industry. The high-strength copper alloy wire is composed of the flowing elements in percentage by weight: 0.3-0.5% of Fe, 0.2-0.3% of Al, 0.4-0.6% of Sn, 0.2-0.4% of Cr, 0.1-0.2% of Ni, 0.15-0.25% of Be, 0.06-0.12% of Mo, 0.06-0.09% of Nd, 0.04-0.08% of Ta, 0.03-0.06% of Zr, 0.02-0.03% of P and the balance of copper and unavoidable impurities. According to the preparation method, on the basis of ensuring the electrical conductivity and machinability of the copper alloy wire, by increasing the content of a Mg element and adding a small amount of elements such as Nd, Ta and Zr and the like, the mechanical strength of a copper alloy is improved; and the high-strength copper alloy wire has the characteristics of good wear resistance, stress corrosion resistance and high temperature resistance, low cost, good processing performance, good welding performance, and the like.

Owner:RUIZHAN TONGLING TECH

Low-chlorine value biomass briquette fuel and production method thereof

The invention discloses a low-chlorine value biomass briquette fuel. According to the invention, the pretreated corn straws are taken as a raw material for anaerobic fermentation for 10-20 days, so that mechanical endurance of the briquette fuel is increased, magnesium carbonate is taken as an anti-slagging agent, during a combustion process, the Mg element and elements such as Si, K, and Na which are inherent in the corn straws and are capable of slagging are subjected to a reaction, a novel compound K2Mg(SO4)2 is generated and provides anti-slagging performance to the briquette fuel, and the produced briquette fuel has the advantages of low chlorine value and high combustion value, no harmful gas is discharged after combustion is carried out, and a boiler is not easily corroded.

Owner:蚌埠华东石膏有限公司

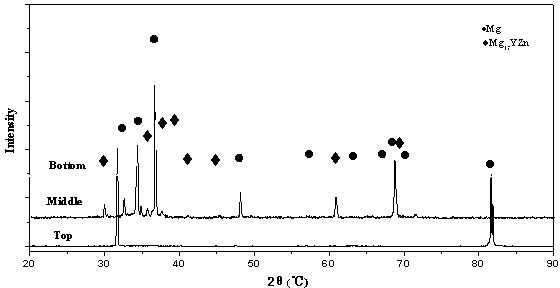

Method for preparing LPSO (Long Period stacking ordered) phase enhanced magnesium alloy gradient material

The invention relates to a method for preparing an LPSO (Long Period stacking ordered) phase enhanced magnesium alloy gradient material, belonging to the field of intermetallic compound preparation technology. The method comprises the steps of firstly, mixing pure magnesium and pure yttrium to prepare an Mg-Y alloy block, and then sequentially overlaying a pure magnesium block, a pure zinc block and the Mg-Y alloy block from bottom to top; simultaneously heating the overlaid metal blocks prepared in the above step and divided into the upper part and the lower part so as to remove vapor, and then introducing a protective gas for melting; after the melting process is completed, stopping the heating to the lower part, introducing cooling water so as to cool the lower part, regulating the heating temperature of the upper part to be below 300 DEG C for one-way cooling, then stopping heating, cooling to room temperature, thus preparing the LPSO phase-enhanced magnesium alloy gradient material. According to the method, the LPSO phase enhanced gradient material can be prepared through upward dispersion of Mg element with lower density and downward settlement of Zn and Y atoms with high density in the one-way cooling process.

Owner:KUNMING UNIV OF SCI & TECH

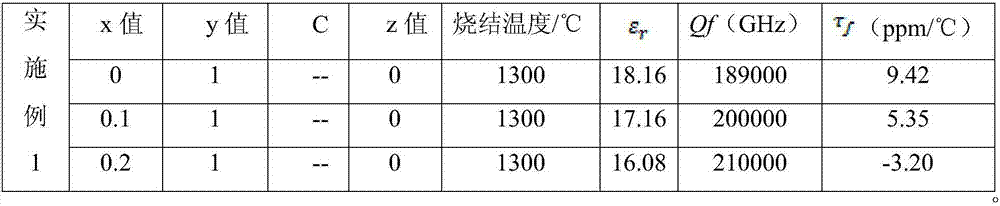

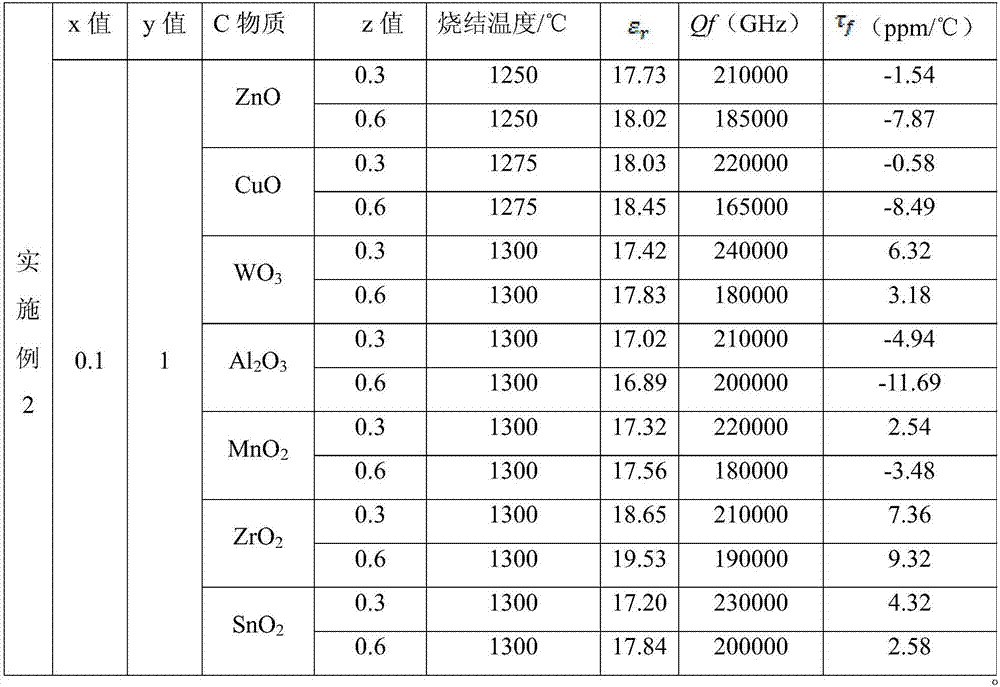

Microwave dielectric ceramic with extra-high quality factors, medium-low dielectric constants and near zero temperature coefficients, and preparation method of microwave dielectric ceramic

The invention relates to a microwave dielectric ceramic with extra-high quality factors, medium-low dielectric constants and near zero temperature coefficients, and a preparation method of the microwave dielectric ceramic. The chemical general formula of a magnesium ditantalum hexaoxide microwave dielectric ceramic is Mg<2.5+x>TaNbO<7.5+x>+y wt%B2O3+z wt% C, wherein x is greater than or equal to 0 and smaller than or equal to 0.2, the weight percentage content y wt% of B2O3 is that y is greater than or equal to 1 and smaller than or equal to 2 on the premise that the weight of the Mg<2.5+x>TaNbO<7.5+x> is 100%, the weight percentage content z wt% of C is that z is greater than or equal to 0 and smaller than or equal to 1 on the premise that the total weight of the Mg<2.5+x>TaNbO<7.5+x> and B2O3 is 100%, and C is at least one of ZnO, CuO, Al2O3, MnO2, WO3, ZrO2 and SnO2. The dielectric constants of the magnesium ditantalum hexaoxide microwave dielectric ceramic are adjusted through an Mg element and a Nb element, and the frequency temperature coefficient can also be correspondingly adjusted.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

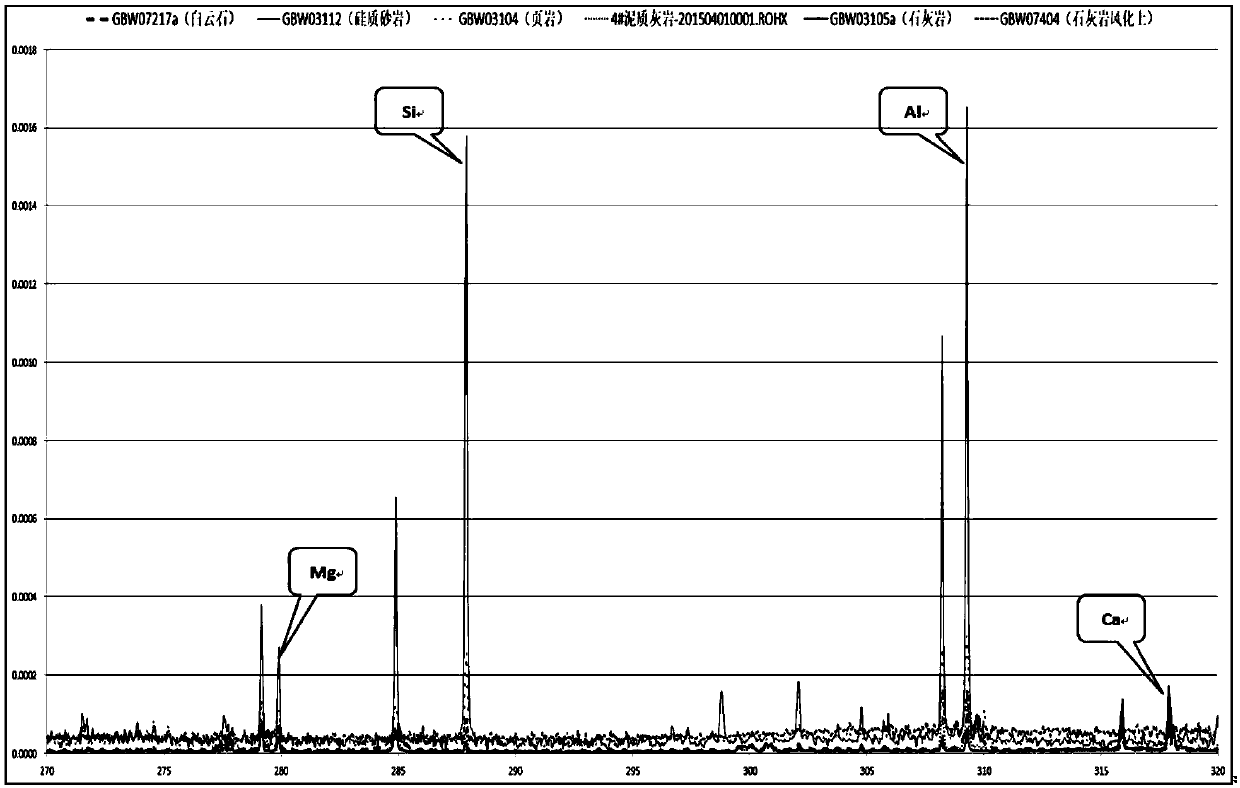

Recognition method of lithology of sand-shale-carbonatite

PendingCN109931053AImprove exploration and development benefitsQuick identificationBorehole/well accessoriesLithologyWell drilling

The invention provides a recognition method of lithology of sand-shale-carbonatite. The method is characterized by comprising the following steps: S1) detecting the content of Si, Al, Ca and Mg elements in a to-be-detected rock debris sample; and S2) calculating the total content XSS of SiO2 and Al2O3 and the total content XLD of CaO and Mgo in the to-be-detected rock debris sample; and judging the lithology of the to-be-detected rock debris sample according to the XSS and the XLD. Compared with the prior art, the method provided by the invention has the beneficial effects that firstly, the content of the Si, Al, Ca and Mg elements in the rock debris sample is detected, and the data of the content of the XSS and the XLD is calculated, so that quick, automatic and accurate recognition of the sand-shale-carbonatite is realized; the defects existing in the prior art are overcome; the method is convenient to operate; a recognition result of the lithology is accurate; and the method is beneficial to the recognition of oil and gas resource reservoirs, can improve the exploration and development benefits of oil and gas resources, and guides safe and efficient well drilling construction.

Owner:CHINA PETROCHEMICAL CORP +4

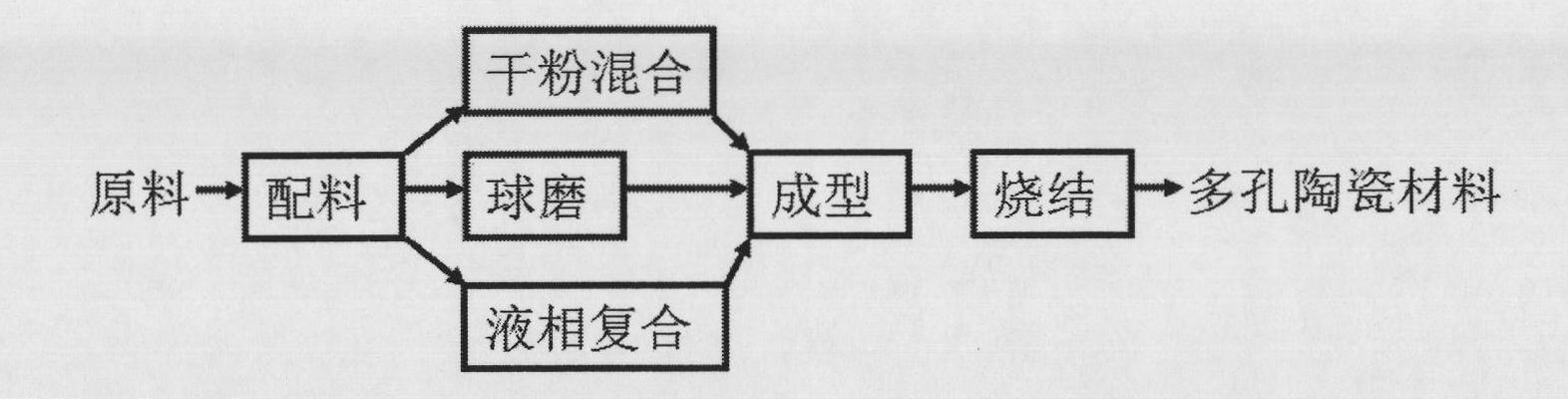

Inorganic porous ceramic material and preparation method thereof

The invention relates to an inorganic porous ceramic material and a preparation method thereof. The inorganic porous ceramic material is prepared from boron-containing compound, magnesium-containing compound and iron-containing compound, the molar ratio of the Mg element, the Fe element and the B element in the magnesium-containing compound, the iron-containing compound and the boron-containing compound is 1 : (0.10-1.65) : (0.33-1.95), and the inorganic porous ceramic material is obtained by mixing, compression moulding and sintering. The invention has the advantages that (1) the process is simple and the cost is low; (2) the inorganic porous ceramic material can be used as a catalyst carrier, and a gas-solid phase reaction filler and a boron source precursor and can also be used as an adsorbent; (3) when the heat of the inorganic porous ceramic material is preserved for 24 hours at the temperature of 800 DEG C, the maximum weight-loss ratio and the maximum weight gain ratio of the inorganic porous ceramic material are both smaller than 5wt.%, the compression strength is 1.02-2.50 MPa, and the volume density is 1.25-7.50g / cm3.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

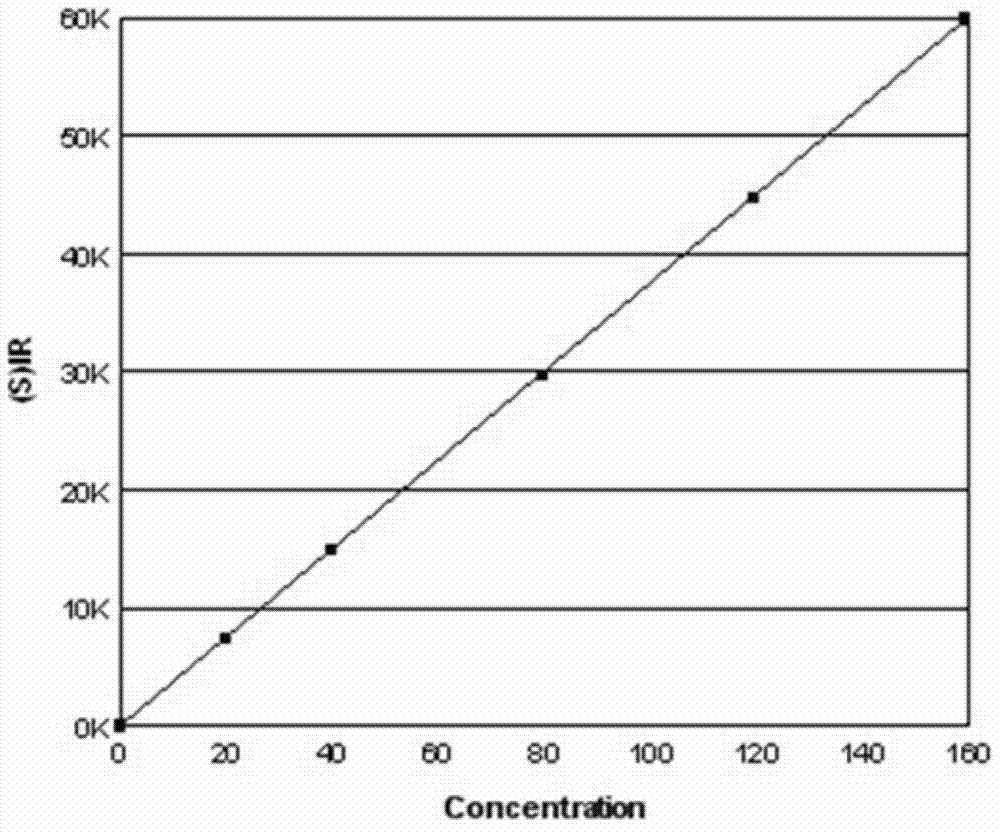

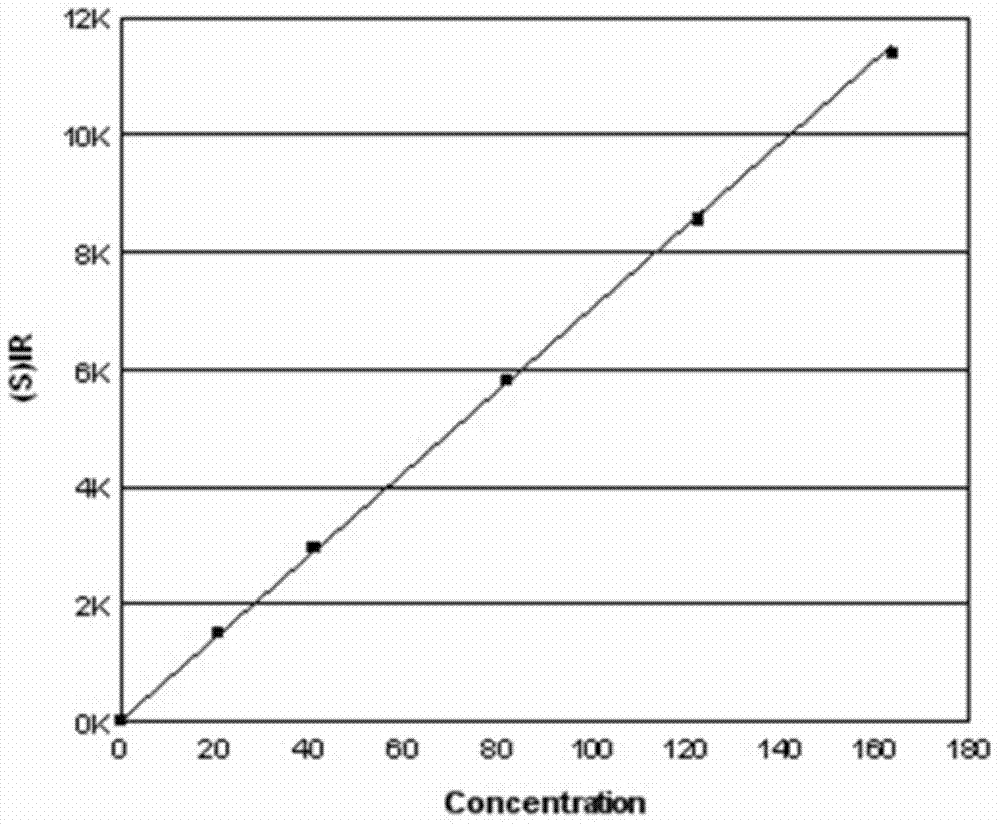

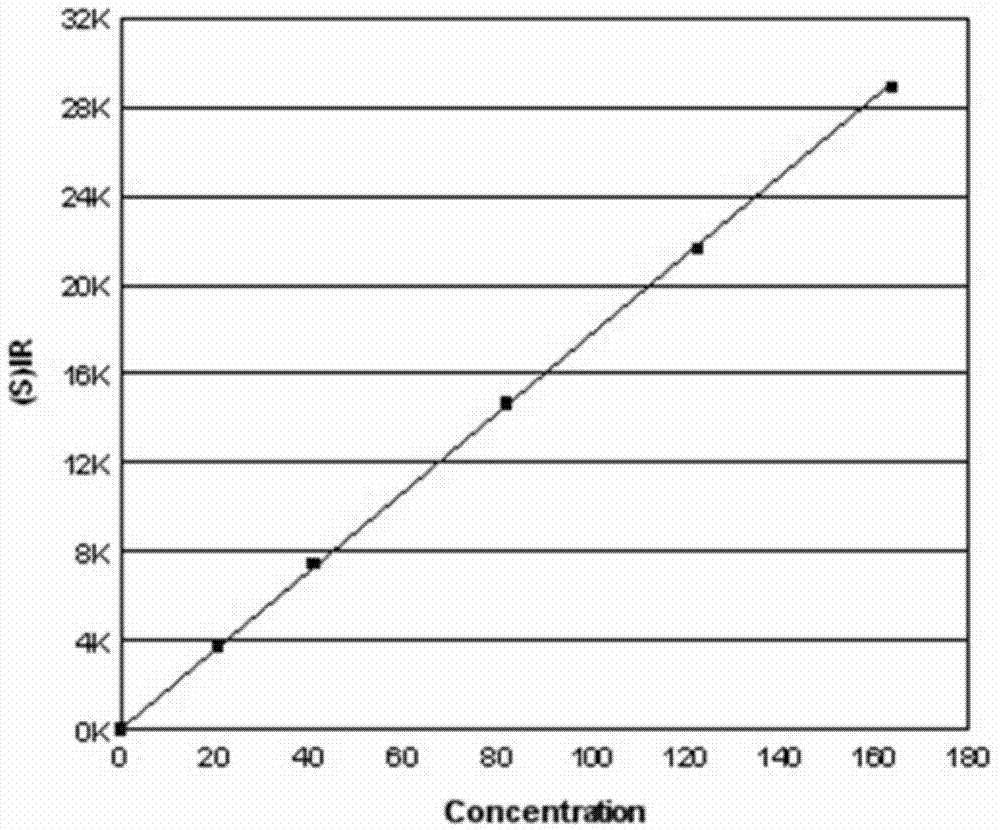

Measurement method for content of magnesium and content of aluminium in main component of pyrotechnic composition for fireworks and crackers

The invention discloses a measurement method for the content of magnesium and the content of aluminium in a main component of pyrotechnic composition for fireworks and crackers. The measurement method comprises the following steps: (1) taking inductively-coupled plasma emission spectrometer as a detecting instrument, selecting 279.0nm as a characteristic spectral line for detecting Mg element, and selecting 256.7nm or 237.3nm as a characteristic spectral line for detecting Al element; respectively making a Mg-element calibration curve and a Al-element calibration curve; and (2) preparing pyrotechnic composition sample liquid, detecting on a computer, displaying the characteristic spectral intensity on a recording instrument, reading a mass concentration value corresponding to Mg or Al according to the determined calibration curve by the characteristic spectral intensity; and calculating the mass percent concentration of elementary magnesium or aluminium according to the specific formula. The measurement method disclosed by the invention has the advantages that method is simple and the detection period is short; and the characteristic spectral line is adopted for detection by combination with the sample treatment method, the recovery rate is high (99.85%-103.07%) and the precision is high,.

Owner:广西出入境检验检疫局危险品检测技术中心

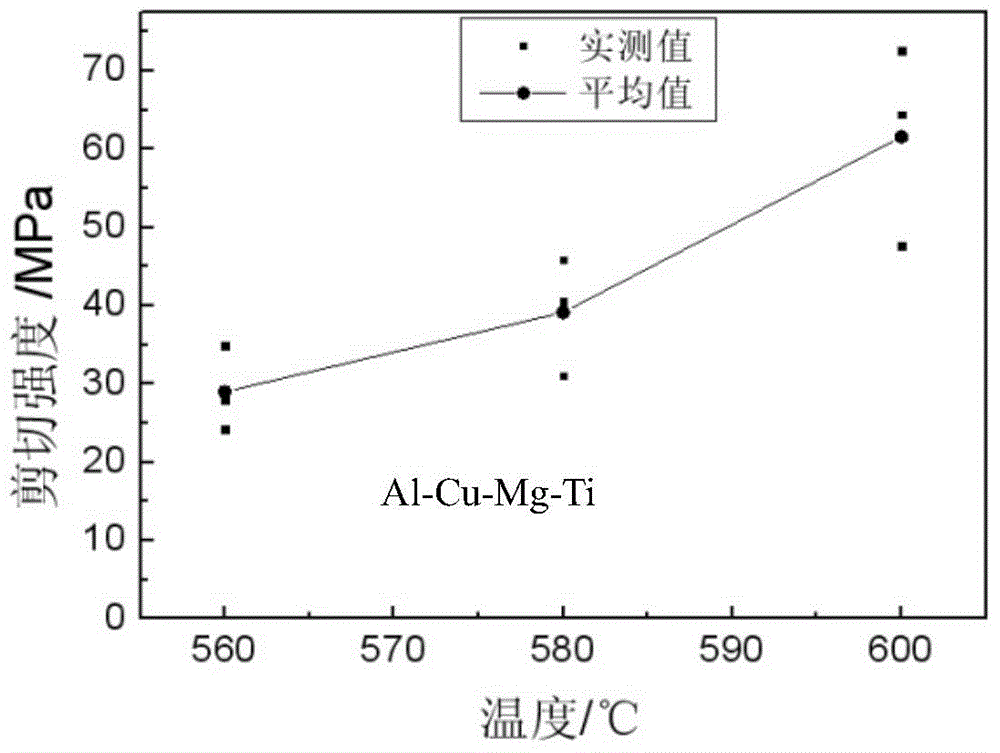

Al-Cu-Mg-Ti quaternary active solder for high-volume-fraction cast aluminum-based composite material, and preparation method for Al-Cu-Mg-Ti quaternary active solder

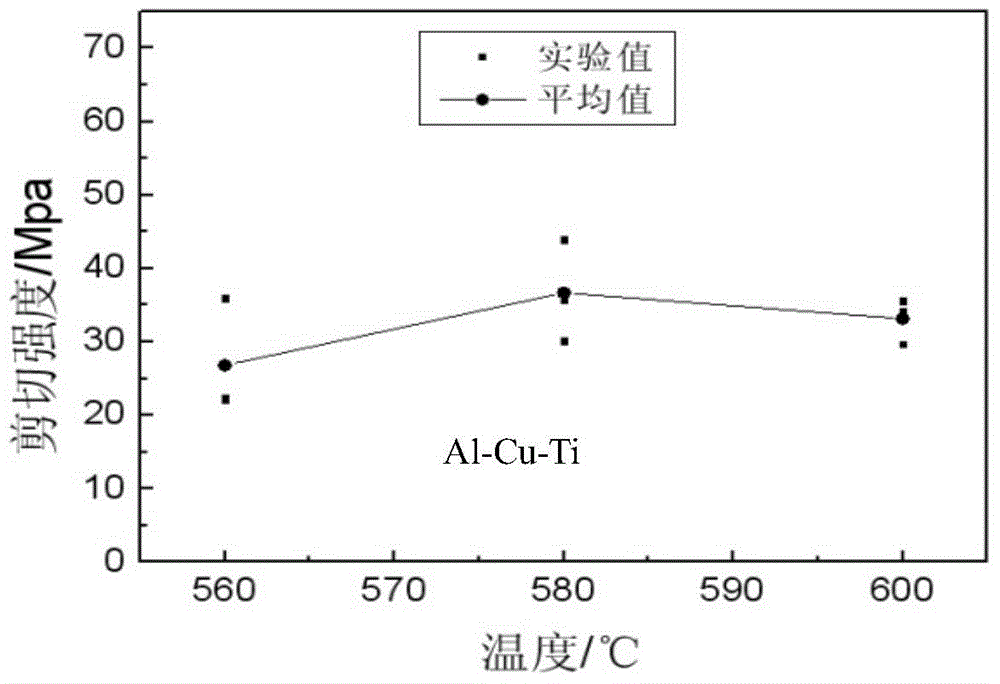

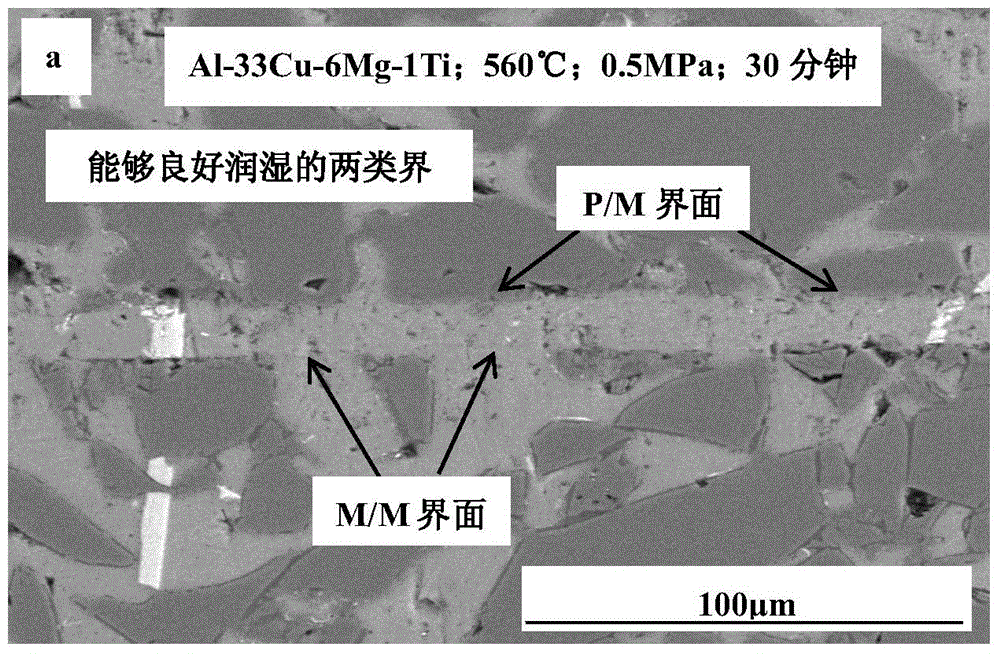

InactiveCN104646850AIncreased shear strengthProlong wetting reaction timeWelding/cutting media/materialsSoldering mediaCu elementMg element

The invention discloses Al-Cu-Mg-Ti quaternary active solder for a high-volume-fraction cast aluminum-based composite material, and a preparation method for the Al-Cu-Mg-Ti quaternary active solder. The Al-Cu-Mg-Ti quaternary active solder for the high-volume-fraction cast aluminum-based composite material consists of a Cu element, an Mg element, a Ti element and an Al element, wherein the Al-Cu-Mg-Ti quaternary active solder for the high-volume-fraction cast aluminum-based composite material comprises 18 to 40 mass percent of Cu element, 0.5 to 10 mass percent of Mg element and 0.1 to 10 mass percent of Ti element. According to the Al-Cu-Mg-Ti quaternary active solder, the wettability of the solder for a ceramic-reinforced phase can be effectively improved during welding, the shear strength of a soldered joint is strong, and the preparation method is simple.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com