Microwave dielectric ceramic with extra-high quality factors, medium-low dielectric constants and near zero temperature coefficients, and preparation method of microwave dielectric ceramic

A technology of microwave dielectric ceramics and magnesium tantalate is applied in the field of microwave dielectric ceramics to achieve the effect of low loss and meeting communication needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

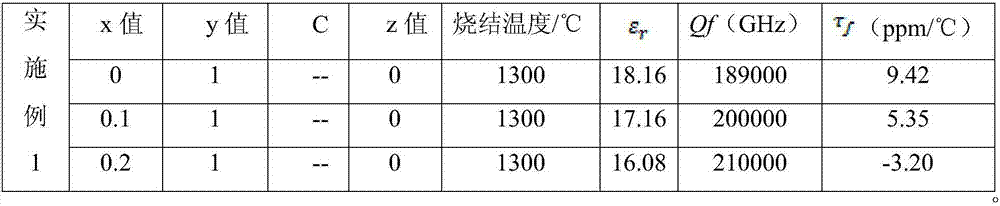

Embodiment 1

[0025] (1) MgO, Ta 2 o 5 , Nb 2 o 5 Weigh according to molar ratio 2.5:0.5:0.5, 2.6:0.5:0.5, 2.7:0.5:0.5 respectively, and then add equivalent 1wt% B 2 o 3 H 3 BO 3 , add zirconia balls and deionized water. Ball mill for 1 to 2 hours, and dry the ball-milled raw materials in a drying oven;

[0026] (2) Calcining the uniformly mixed powder at 1100°C for 4 hours;

[0027] (3) put the raw material calcined in step (2) into a ball mill jar and add zirconia balls and deionized water, ball mill for 1 to 2 hours, dry, and add a mass fraction of 3% PVA ( Polyvinyl alcohol) is used as binder granulation, and is pressed into cylindrical green body;

[0028] (4) Sinter the cylindrical green body at 1250°C to 1300°C for 4 hours to obtain the required low-loss temperature coefficient magnesium tantalate-based microwave dielectric ceramics;

[0029] (5) Use a network analyzer and a resonant cavity to test the microwave dielectric properties of the low-loss temperature coefficient ...

Embodiment 2

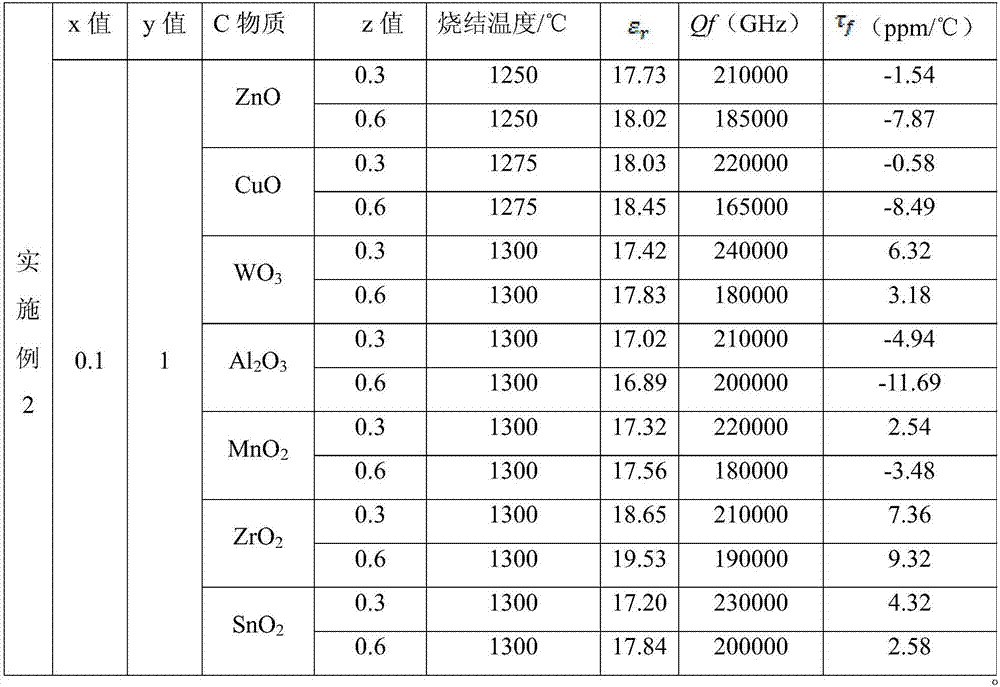

[0034] Following Example 1, on the basis of Example 1, select x=0.1, y=1 components to add zwt%C substances, and the rest are the same as Example 1. The test results are shown in Table 2.

[0035] Table 2 is the experimental result involved in embodiment 2:

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com