Measurement method for content of magnesium and content of aluminium in main component of pyrotechnic composition for fireworks and crackers

A technology of fireworks and firecrackers and measurement methods, which is applied in the field of analysis and testing, can solve problems such as cumbersome operation steps, insufficient operation proficiency, and long detection cycle, and achieve the effect of low requirements for operators, low labor intensity, and short detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

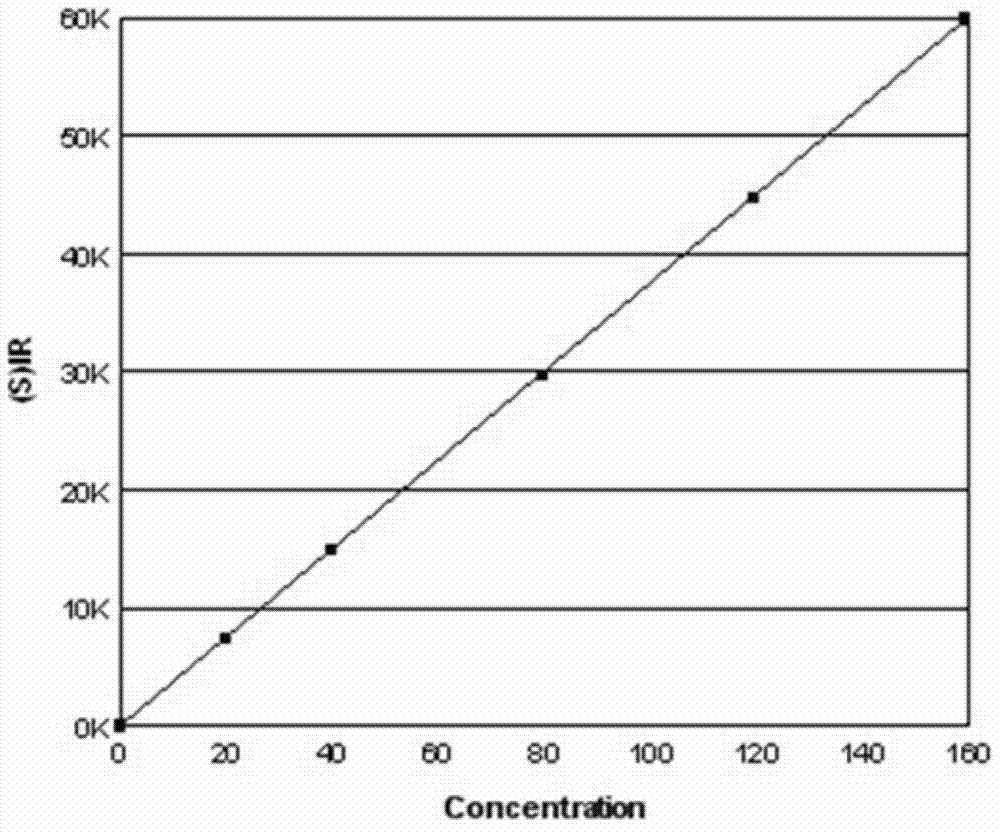

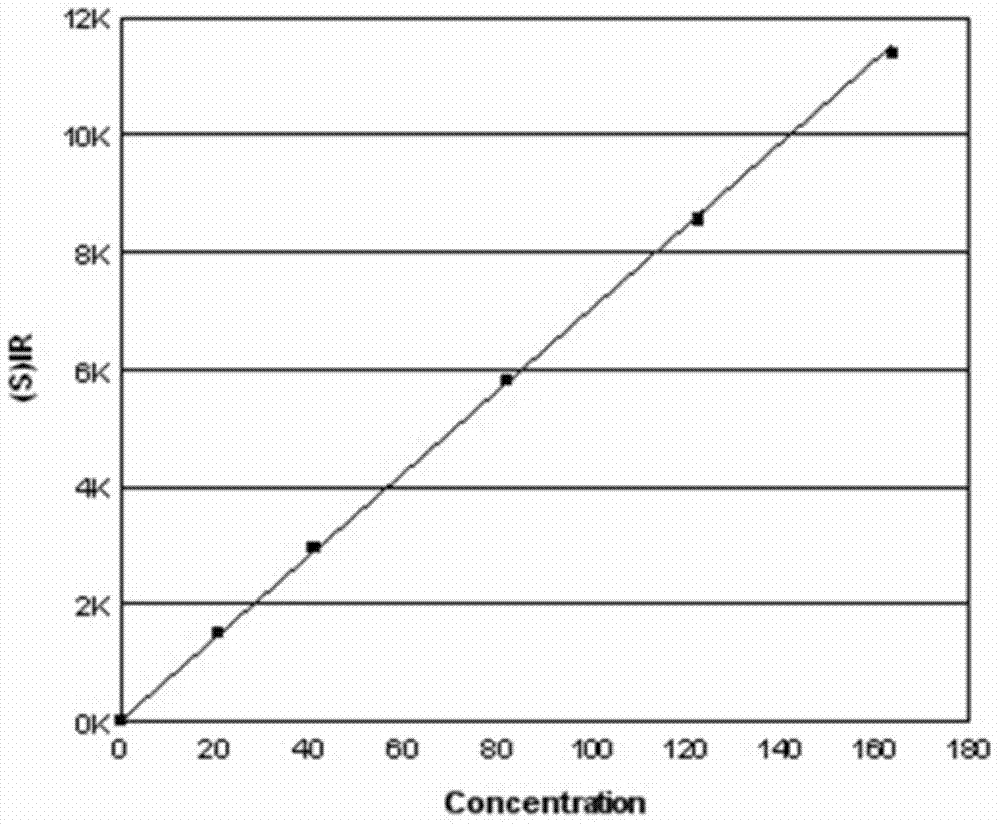

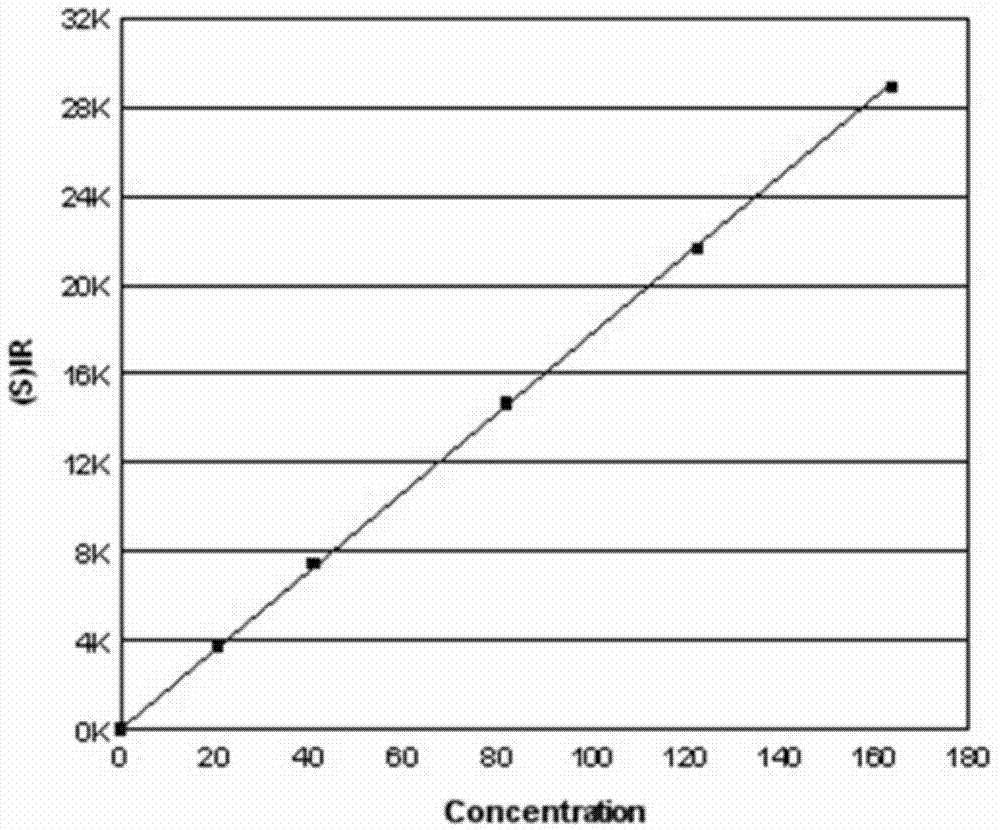

[0034] Example 1: Draw a calibration curve

[0035] 1) Prepare several parts of magnesium-aluminum working solution (the mass concentration of Mg in the obtained magnesium-aluminum working solution is required to be 20-160 mg / L, and the mass concentration of Al is 20-160 mg / L):

[0036] The specific preparation method is as follows:

[0037] Prepare 6 parts of magnesium-aluminum working solution: respectively pipette 0 mL, 2 mL, 4 mL, 8 mL, 12 mL and 16 mL of magnesium single standard solution and aluminum single standard solution with a mass concentration of 1000 mg / L and place them in six 100 mL volumetric flasks respectively. Use 2% mass of hydrochloric acid solution to set the volume to the scale, and number them respectively as Work 1, Work 2, Work 3, Work 4, Work 5 and Work 6. The concentrations of Mg and Al in them are shown in Table 1 respectively;

[0038] 2) Draw a calibration curve:

[0039] 2a) Using an inductively coupled plasma emission spectrometer (produced b...

Embodiment 2

[0049] Embodiment 2: adopting the method of the present invention to carry out the recovery test of addition of high-purity magnesium powder and high-purity aluminum powder with the actual pyrotechnic powder as the matrix

[0050] Contain magnesium, aluminum high-purity elemental pyrotechnic powder sample listed in Table 5 to carry out standard addition recovery test, wherein the Mg and Al nominal content of the pyrotechnic powder that is added with high-purity magnesium powder and high-purity aluminum powder are as shown in Table 5; Adopt When the method of the present invention is measured, the magnesium and aluminum content determination is carried out after the standard substance prepares the sample solution according to the following method.

[0051] 1) Preparation of sample solution:

[0052]Prepare the sample liquid with the pyrotechnic powder added with high-purity magnesium powder and high-purity aluminum powder of No. 1 as the sample, weigh 3 parts of 390-410 mg samp...

Embodiment 3

[0064] Embodiment 3: Adopt the method of the present invention to the precision test of the detection result of aluminum-marked pyrotechnic powder

[0065] In this embodiment, the aluminum-marked pyrotechnic powders numbered 1, 2, 3 and 4 in Table 5 were used as samples for testing.

[0066] 1) Preparation of sample solution:

[0067] Prepare the sample liquid with the pyrotechnic powder with high-purity magnesium powder and high-purity aluminum powder No. 1 as the sample, weigh 4 parts of 390-410 mg samples, and the accuracy of weighing is 0.1 mg, and put the first sample in a beaker Inside, add acetone (C 3 h 6 O content is 99% by mass), add absolute ethanol in the amount of 40mL / g sample to fully dissolve (to separate the organic binder in the pyrotechnic powder), filter, add hydrochloric acid in the amount of 20mL / g sample to the filter residue (HCl content is 36% by mass) to completely dissolve the filter residue, filter, add water to the filtrate to 1L to obtain the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com