Patents

Literature

113 results about "Aluminum high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

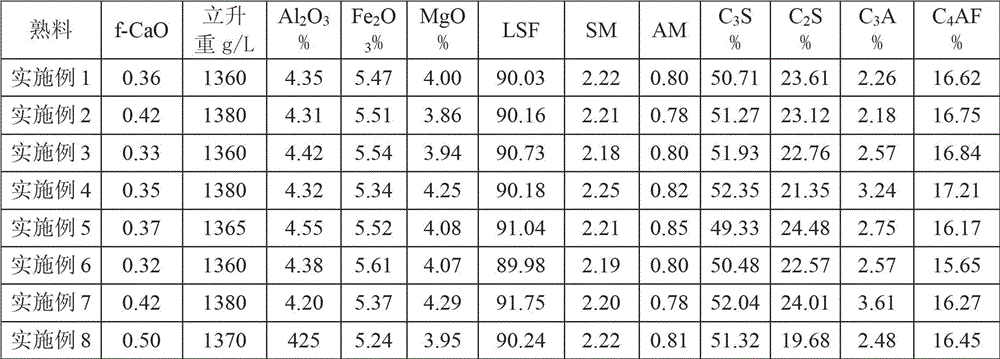

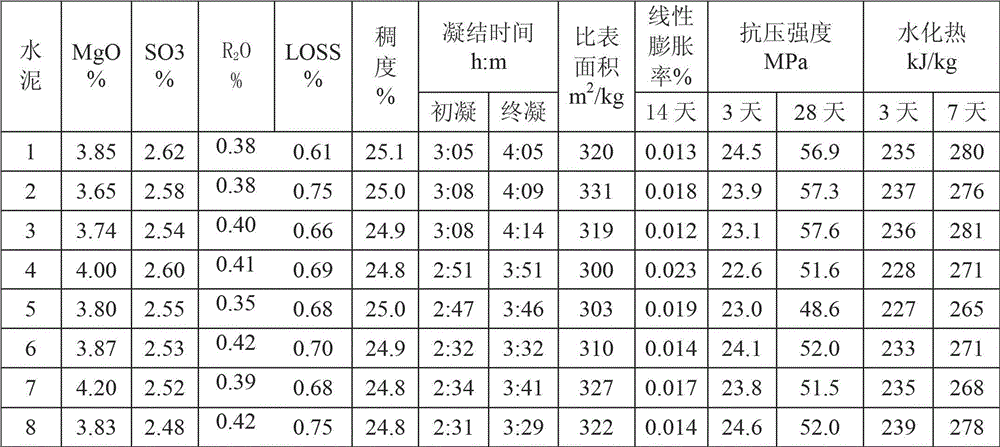

Micro-expansive moderate-heat Portland cement and production method thereof

InactiveCN102976641AHigh strengthHeat of hydration controlClinker productionHigh magnesiumPortland cement

The invention discloses a micro-expansive moderate-heat Portland cement and a production method thereof. The cement contains micro-expansive moderate-heat Portland cement clinker and gypsum in a weight ratio of 92:8-98:2, and also comprises grinding aid which accounts for 0-0.1 wt% of the sum of micro-expansive moderate-heat Portland cement clinker and gypsum. The raw meal of the micro-expansive moderate-heat Portland cement clinker is prepared from the following raw materials in percentage by weight: 65-80% of calcium raw material, 5-20% of silicon correction raw material, 5-15% of iron correction raw material and 3-10% of magnesium correction raw material. The micro-expansive moderate-heat Portland cement clinker is prepared by the following steps: grinding the raw meal, dehydrating the slurry, drying and crushing the filter cake, and firing to obtain the clinker. By adopting the low-aluminum high-iron high-magnesium low-saturation-ratio formula, the invention effectively controls the hydration heat of cement, displays the micro-expansive property, and can compensate the volume shrinkage in the concrete cooling process, thereby reducing or avoiding cracks.

Owner:GUANGXI YUFENG CEMENT

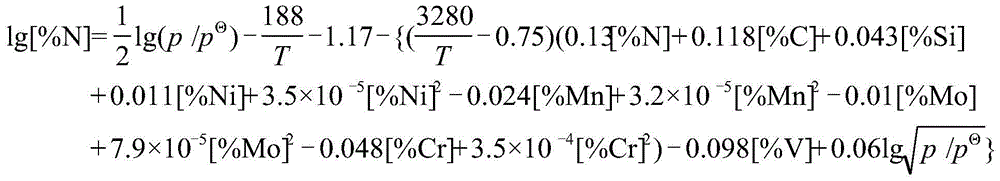

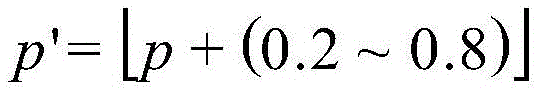

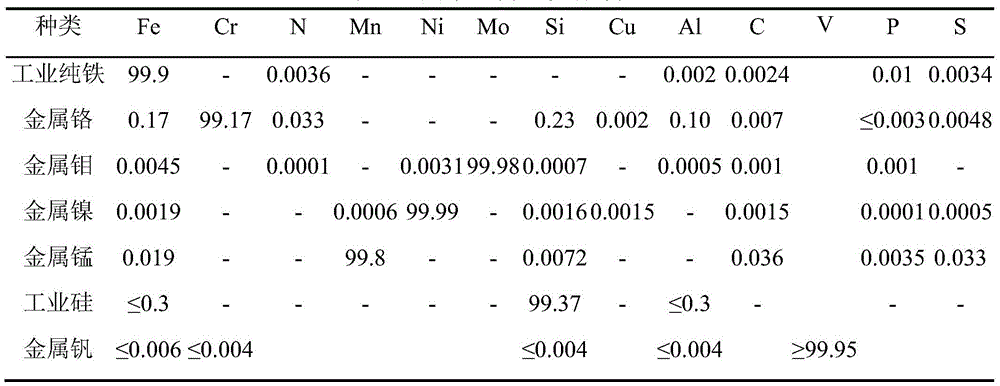

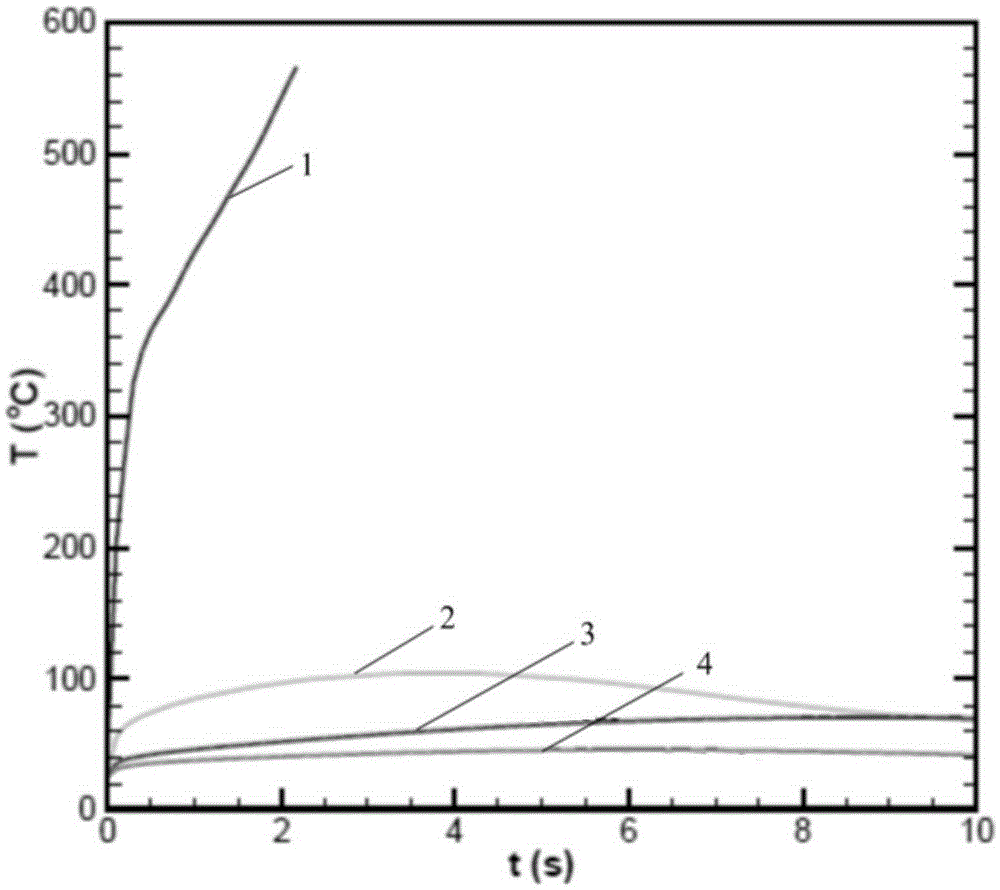

Method for smelting low-aluminum high-nitrogen martensitic stainless steel in pressurization and induction manner

The invention discloses a method for smelting low-aluminum high-nitrogen martensitic stainless steel in a pressurization and induction manner and belongs to the field of metallurgy, wherein the method is suitable for smelting. The low-aluminum high-nitrogen martensitic stainless steel comprises, 0.1%-0.6% of carbon, 0%-0.5% of manganese, 12%-24% of chromium, not larger than 1% of silicon, 0%-3% of molybdenum, 0.1%-0.6% of nitrogen, 0%-2% of nickel, 0%-1% of vanadium, not larger than 0.02% of aluminum, not large than 0.002% of sulfur and the balance iron and inevitable impurities. The method includes the specific steps of blending, material distribution, temperature increase after vacuumizing, high-pure argon filling after raw material melting-down, graphite adding for deoxygenation, industrial silicon adding for deoxygenation when the environment is vacuumized to 10 Pa, nitrogen filling and alloying, nickel magnesium alloy and rare earth adding for heat preservation for 5 min to 10 min, nitrogen charging and casting and the like.

Owner:NORTHEASTERN UNIV

Lithium battery electrode plate and manufacturing method therefor

ActiveCN106486639AThe coating process is simple and easyEase of mass productionSecondary cellsElectrode collector coatingLithium iron phosphateEngineering

The invention discloses a lithium battery electrode plate and a manufacturing method therefor. The lithium battery electrode plate comprises a positive electrode inner layer electrode plate and a positive electrode outer layer electrode plate, wherein the positive electrode inner layer electrode plate comprises a positive electrode inner layer active material; the positive electrode outer layer electrode plate comprises a positive electrode outer layer active material; the stability of the positive electrode inner layer active material is higher than that of the positive electrode outer layer active material, wherein the positive electrode inner layer active material comprises one or more of lithium iron phosphate, lithium cobalt oxide, a nickel-cobalt-manganese ternary material, a nickel-cobalt-aluminum high-nickel material and lithium titanate; and positive electrode outer layer active material comprises one or more of lithium iron phosphate, lithium cobalt oxide, the nickel-cobalt-manganese ternary material, the nickel-cobalt-aluminum high-nickel material and lithium titanate. The lithium battery electrode plate provided by the invention adopts a dual-layer electrode structure, so that relatively high safety performance can be obtained.

Owner:SHENZHEN BAK POWER BATTERY CO LTD +1

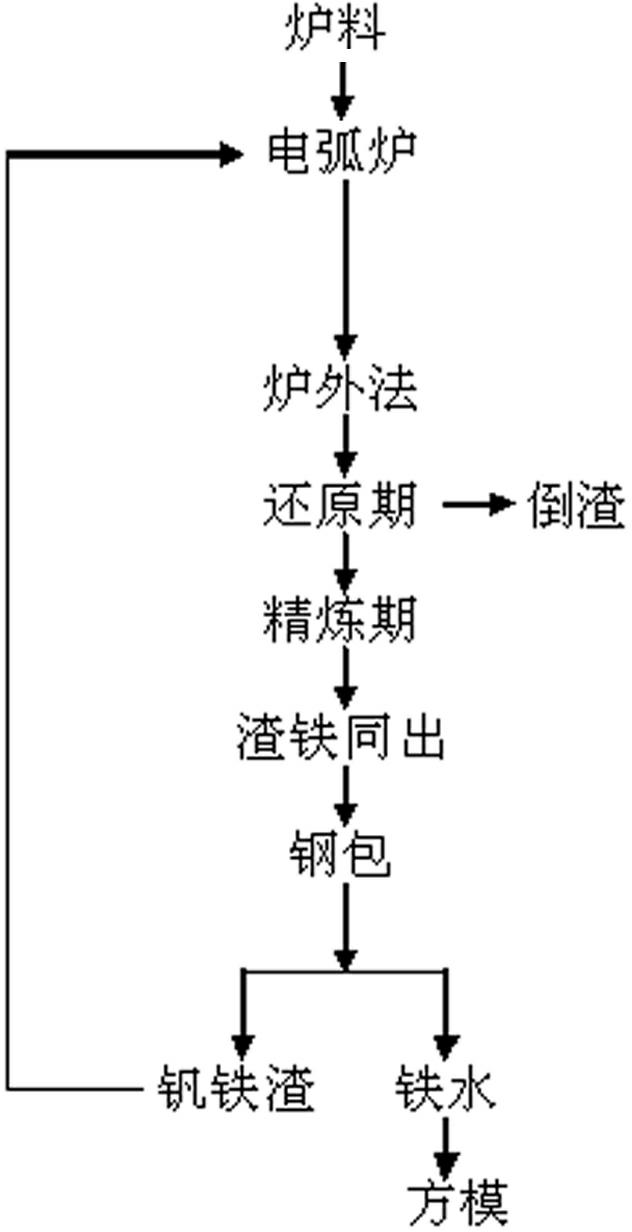

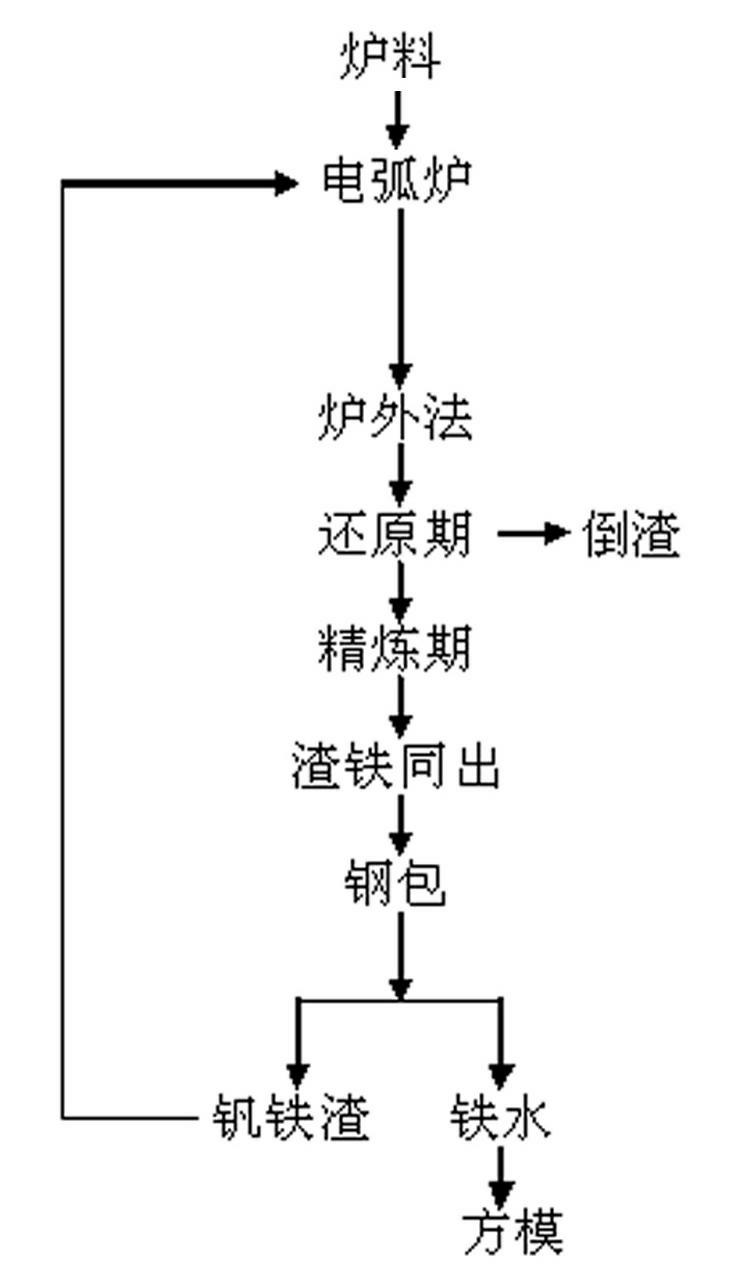

Method for smelting low-aluminum high-vanadium iron

ActiveCN102146527AReaction is easy to controlWide range of controlProcess efficiency improvementMolten stateElectric arc furnace

The invention discloses a method for smelting low-aluminum high-vanadium iron. The method comprises the following steps of: 1, smelting by adopting an outside furnace process, mixing vanadium pentoxide, aluminum powder, scrap steel, vanadium iron slag or lime, igniting and reacting to generate high-vanadium iron and furnace slag; and 2, uniformly mixing vanadium pentoxide and lime at a reducing stage by adopting an electric furnace process, putting the mixture into an electric arc furnace, adding scrap steel, adding industrial silicon and ferro-silico aluminum depleted furnace slag after the material is in a molten state, deslagging when the vanadium content of the furnace slag is below 0.5 percent, extracting an alloy sample and analyzing vanadium and silicon for monitoring before deslagging, putting vanadium pentoxide and lime into the furnace at a refining stage, electrifying to refine and pouring with a ladle after qualification is determined. The method has the advantages that aluminothermic process smelting is integrated with electro-silicothermic process smelting, chemical reaction heat of vanadium pentoxide and aluminum is fully utilized, furnace slag with high vanadium content is depleted, reduced and refined in a three-phase electric arc furnace to obtain high-vanadium low-aluminum qualified high-vanadium iron, the vanadium content of discharged furnace slag is lower than 0.5 percent, and the smelting yield is over 95 percent.

Owner:锦州钒业有限责任公司

Method for smelting low-silicon low-aluminum high-boron martensitic stainless steel

ActiveCN105296867AReduce manufacturing costIncrease productivityElectric arc furnaceMartensitic stainless steel

The invention relates to the field of steel smelting, in particular to a method for smelting low-silicon low-aluminum high-boron martensitic stainless steel. By total weight, the martensitic stainless steel comprises not larger than 0.1 % of Si, not larger than 0.015 % of Al and 0.015%-0.05 % of B. The method includes the steps that firstly, furnace charge is prepared; secondly, electric arc furnace rough smelting is conducted, wherein melting down, oxygen blowing and decarbonizaiton, pre-reduction, reduction and component adjustment are conducted; thirdly, LF furnace refinement is conducted, wherein reduction is conducted through a reducing agent and then components are adjusted; fourthly, VOD furnace refinement is conducted, wherein vacuum oxygen blowing and decarbonization, reduction and component adjustment are conducted sequentially; fifthly, LF furnace deep refinement is conducted, wherein reduction is conducted through the reducing agent, and then ferroboron is added; and sixthly, pouring is conducted. By means of the smelting method, the problem that the content of the Si, the content of the Al and the content of the B in the martensitic stainless steel are difficult to control by means of an existing electric arc furnace plus VOD process is solved, and the low-silicon low-aluminum high-boron martensitic stainless steel meeting the requirements of corresponding models is smelted.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

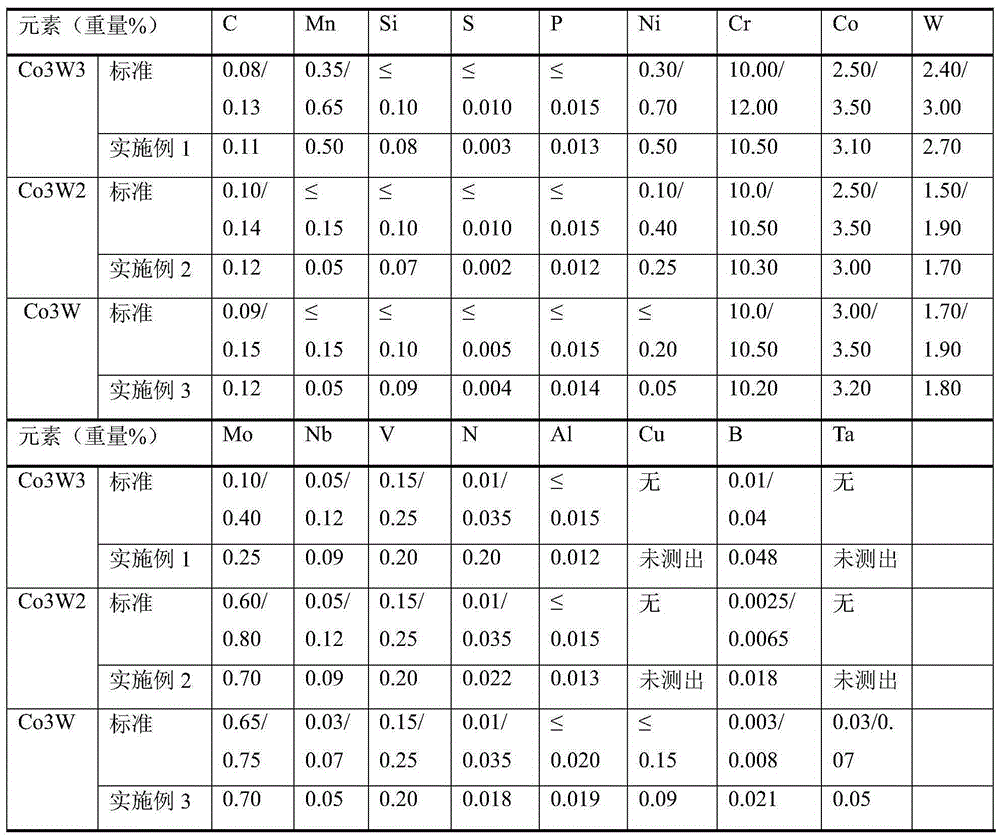

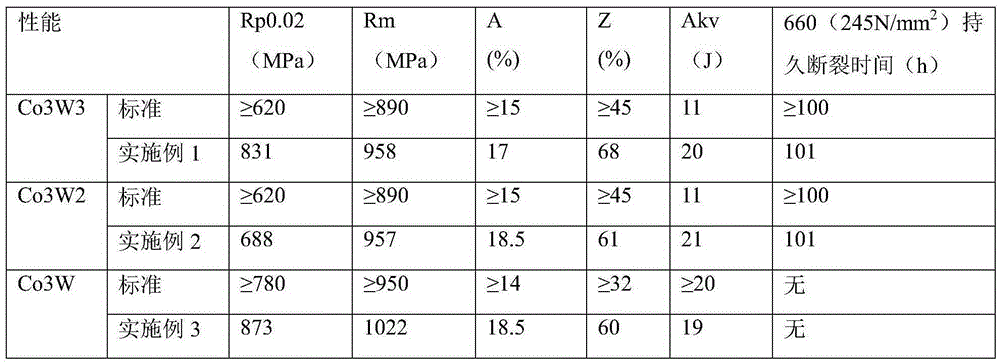

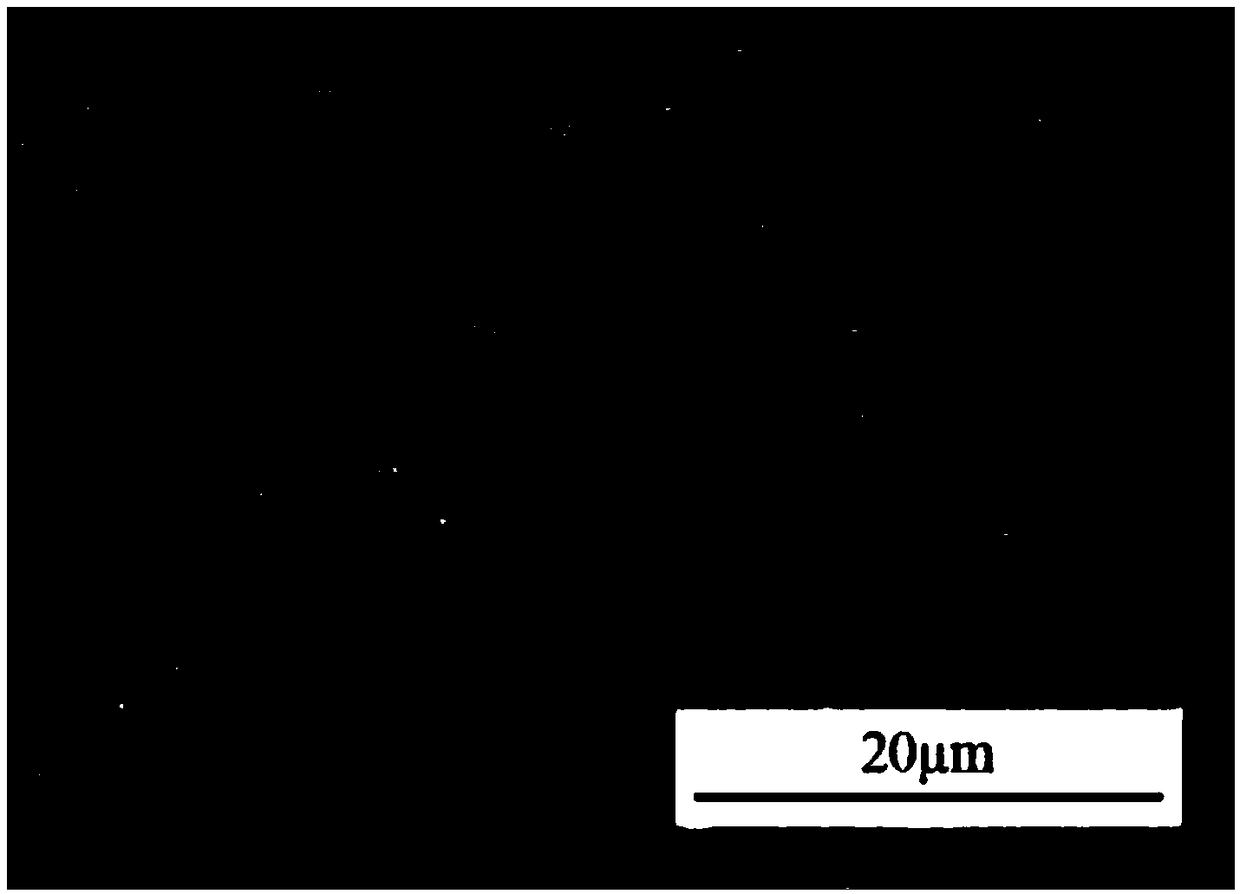

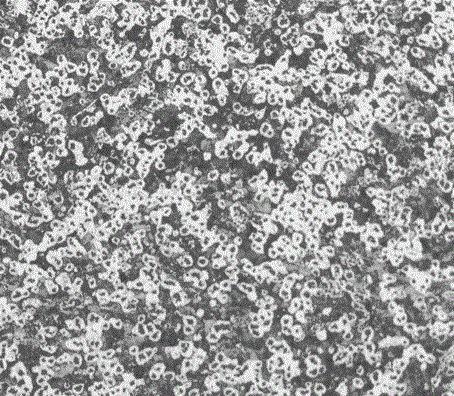

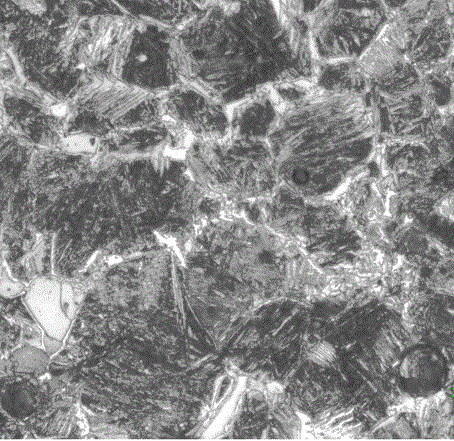

Novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel and preparation method thereof

ActiveCN108642402AHeat treatment window widthReduced tendency to overheat during heat treatmentMicro structureOxidation resistant

The invention discloses novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel and a preparation method thereof. Aluminum high-speed steel prepared by the preparation method adopts a novel powder metallurgical high-speed steel direct preparation process to lead in (0.05-5.0) AlN micro powder, and a material mixture is subjected to processes such as wet-milling, pelletizing, isostatic cool pressing and forming, hydrogen gas deoxidizing, hot-pressing composite sintering and vacuum thermal treatment, so that micro-level dispersion distribution of aluminum nitride particles is realized, and therefore, the defects that a conventional casting process easily generates a ledeburite structure, an aluminum nitride strengthening phase is difficulty led in by agas-atomizing-hot isostatic pressing method, and the like are overcome. The novel aluminum nitride dispersion strengthening powder metallurgical aluminum high-speed steel is short in process flow, islow in production cost, is low in impurity content, is high in compactness, and is remarkably improved in wear resistance, oxidization resistance and a micro structure after aluminum nitride is led in, and is novel mould material among conventional high-speed steel, a hard alloy and a ceramic material.

Owner:XIANGTAN UNIV

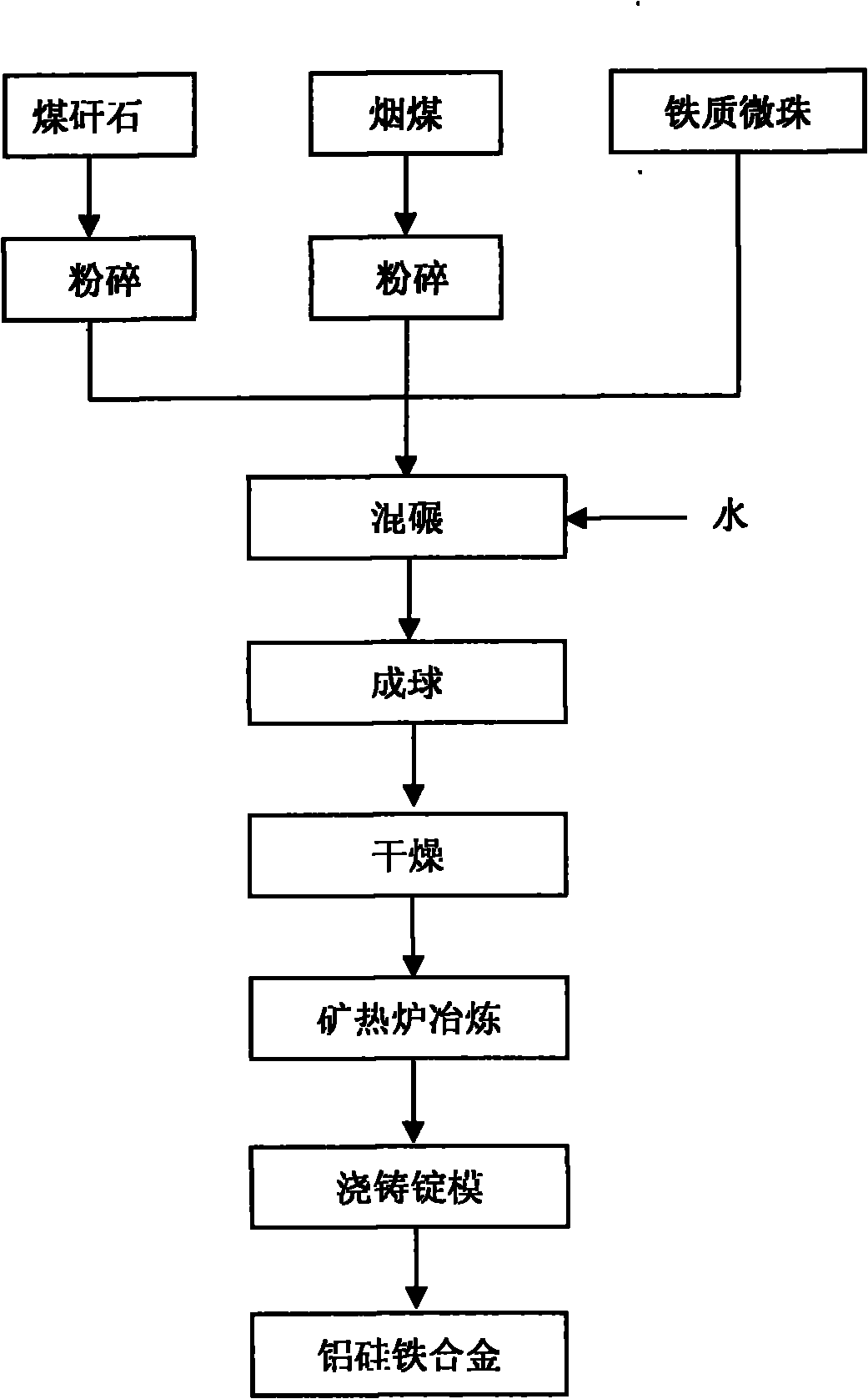

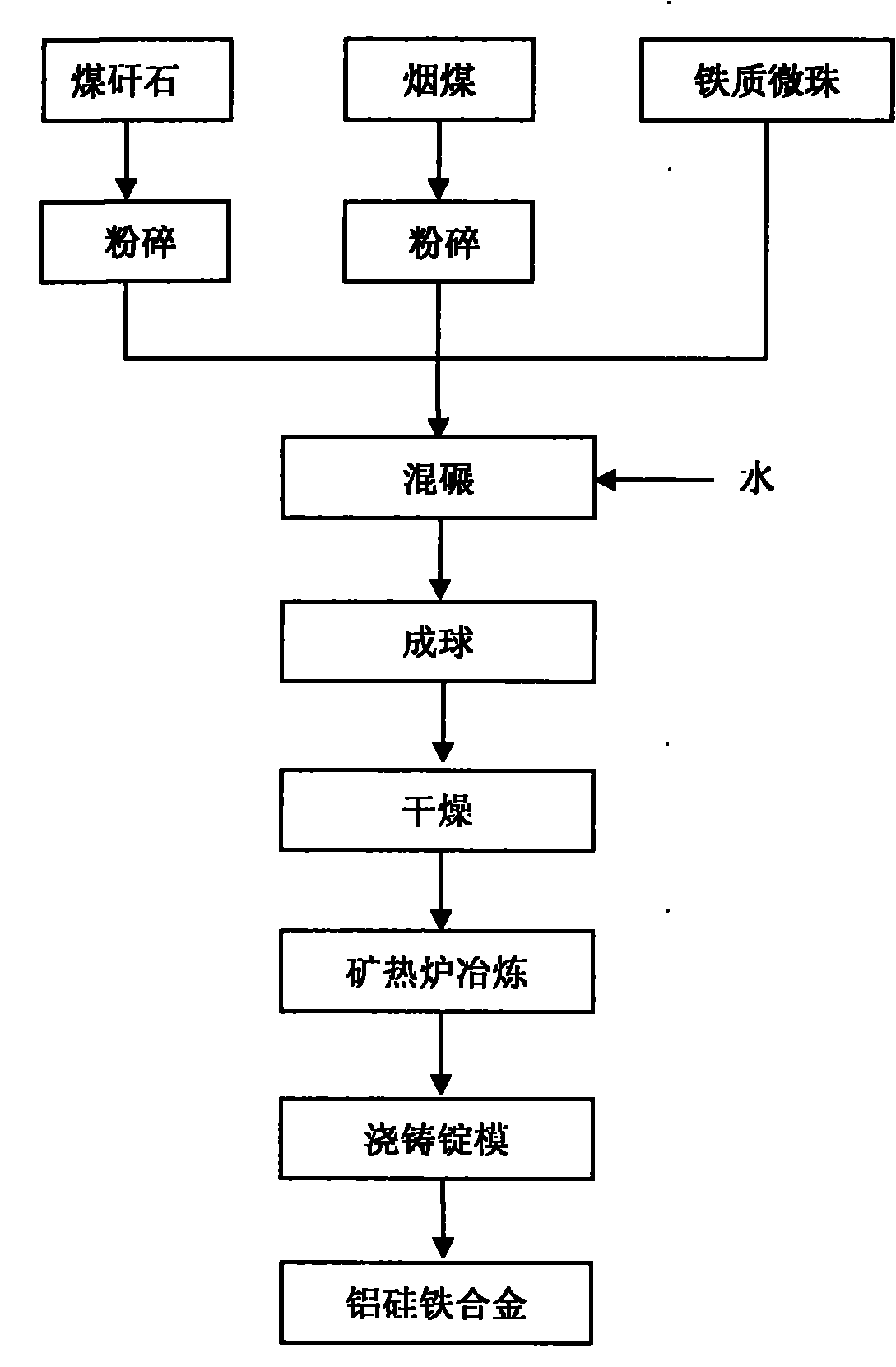

Method for preparing aluminum-silicon-ferrum alloy from coal gangue

InactiveCN101942561AImprove plasticityReduce manufacturing costProcess efficiency improvementSteelmakingFerrosilicon

The invention discloses a method for preparing an aluminum-silion-ferrum alloy from coal gangue, which relates to the technical field of aluminum-silion-ferrum production. The method comprises the following steps of: 1) crushing the raw material coal gangue and a reducing agent bituminous coal, and feeding the crushed material and coal ash ferric microballoons into a mixing mill; 2) adding water into the mixing mill, and mixing and rolling the material; 3) feeding the uniformly mixed and rolled material into a ball press for balling; 4) feeding balls discharged out of the ball press into a drying kiln for drying; 5) feeding the dried balls into a submerged arc furnace, and smelting the balls into molten iron at high temperature; and 6) discharging the molten iron out of the furnace and casting the molten iron into an ingot mould to prepare the aluminum-silion-ferrum alloy. As the coal gangue is mainly adopted as the raw material, the method has the advantages of vast raw material sources, low production cost and low energy consumption; and the prepared low-aluminum high-silicon aluminum-silion-ferrum alloy is applied to steelmaking deoxiders and magnesium-smelting reducing agents and can produce remarkable economic benefits.

Owner:TONGFANG ENVIRONMENT

Low-density ceramsite propping agent taking low-aluminum high-silicon alumyte as major raw material and preparation method thereof

ActiveCN102660252ASolve the problem of tight supplyReduce bulk densityFluid removalExpanded clay aggregateDolomite

The invention belongs to the technical field of solid propping agents for an oil / gas well fracturing technology, and discloses a low-density ceramsite propping agent taking low-aluminum high-silicon alumyte as a major raw material and a preparation method thereof. The low-density ceramsite propping agent is prepared from the following raw materials in percentage by mass: 90-96 percent of alumyte, 1-4 percent of manganese ore, 0.5-2 percent of hematite, 0-2 percent of clay and 0-2 percent of dolomite, wherein the alumyte is low-aluminum high-silicon alumyte; the mass percent of Al2O3 is 50-60 percent; and the mass percent of SiO2 is 12 percent. The method comprises the following steps of: smashing raw materials respectively; mixing according to a certain mixture ratio, grinding, and performing spray granulation; and sintering at the temperature of 1,320-1,380 DEG C for 0.5-2.5 hours. Crude low-aluminum high-silicon alumyte is adopted, so that the problem of supply tension of raw materials is solved, the production cost of alumyte is reduced by about 350 yuan / ton in comparison to alumyte of which the alumina content is over 65 percent, and the propping agent has a wide development prospect; and moreover, the bulk density and apparent density indexes of the ceramsite propping agent are reduced remarkably, and the cost of well fracturing is reduced simultaneously.

Owner:垣曲县方圆陶粒砂有限责任公司

High-damping and high-performance alloy cylinder sleeve and preparation technology thereof

ActiveCN105821294AHigh damping characteristicsReduce vibrationCylinder headsCylindersCavitationAlloy coating

The invention discloses a high-damping and high-performance alloy cylinder sleeve and a preparation technology thereof. The high-damping and high-performance alloy cylinder sleeve comprises a cylinder sleeve body and a zinc-aluminum high-damping alloy coating sprayed to the outer wall of a cylinder sleeve body. The thickness of the zinc-aluminum alloy coating is 0.3-1 mm. The cylinder sleeve body comprises, by weight, 3.2-3.5% of C, 2.8-3.3% of Si, 0-0.02% of P, 0-0.01% of S, 3.0-4.0% of Cu, 1.5-2.0% of Mn, 0.4-0.6% of Ni, 0.04-0.08% of Mg, 0.02-0.05% of Ce, and the balance Fe. The nodular cast iron cylinder sleeve obtained through the formula and preparation technology has high damping characteristics, vibration and noise of the engine cylinder sleeve can be effectively reduced, and a wearing surface on the inner wall of the cylinder sleeve has good wear resistance and anti-attrition performance, and the outer wall of the cylinder sleeves has the advantages of being high in strength, good in plasticity, good in corrosion resistance and anti-cavitation ability, short in run-in period with pistons and the like.

Owner:ZYNP GRP

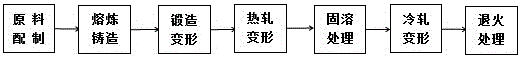

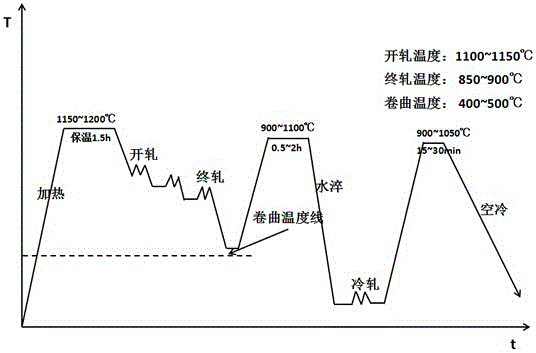

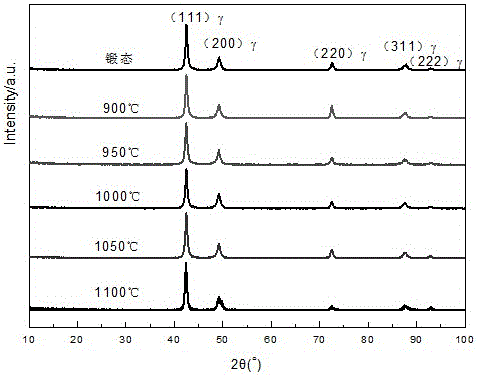

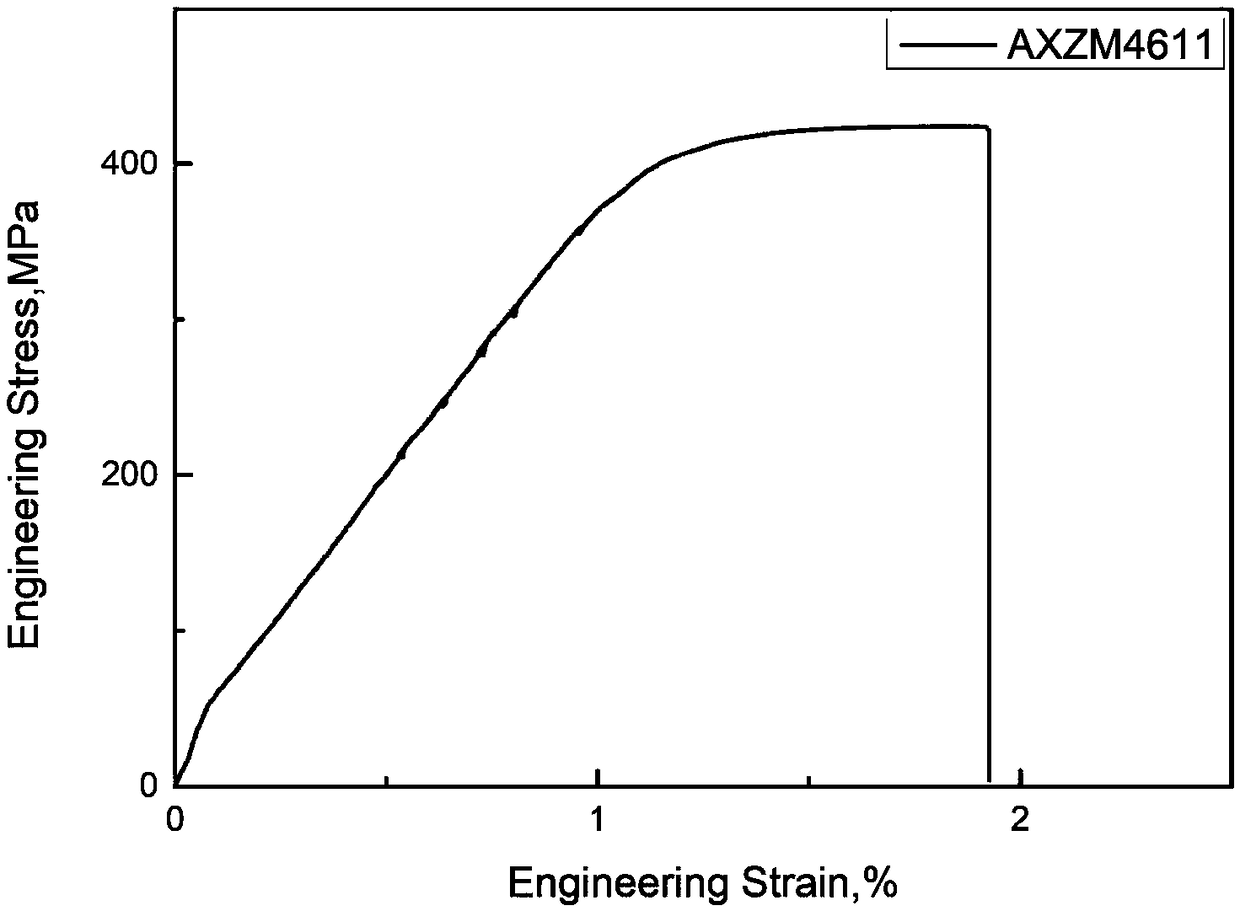

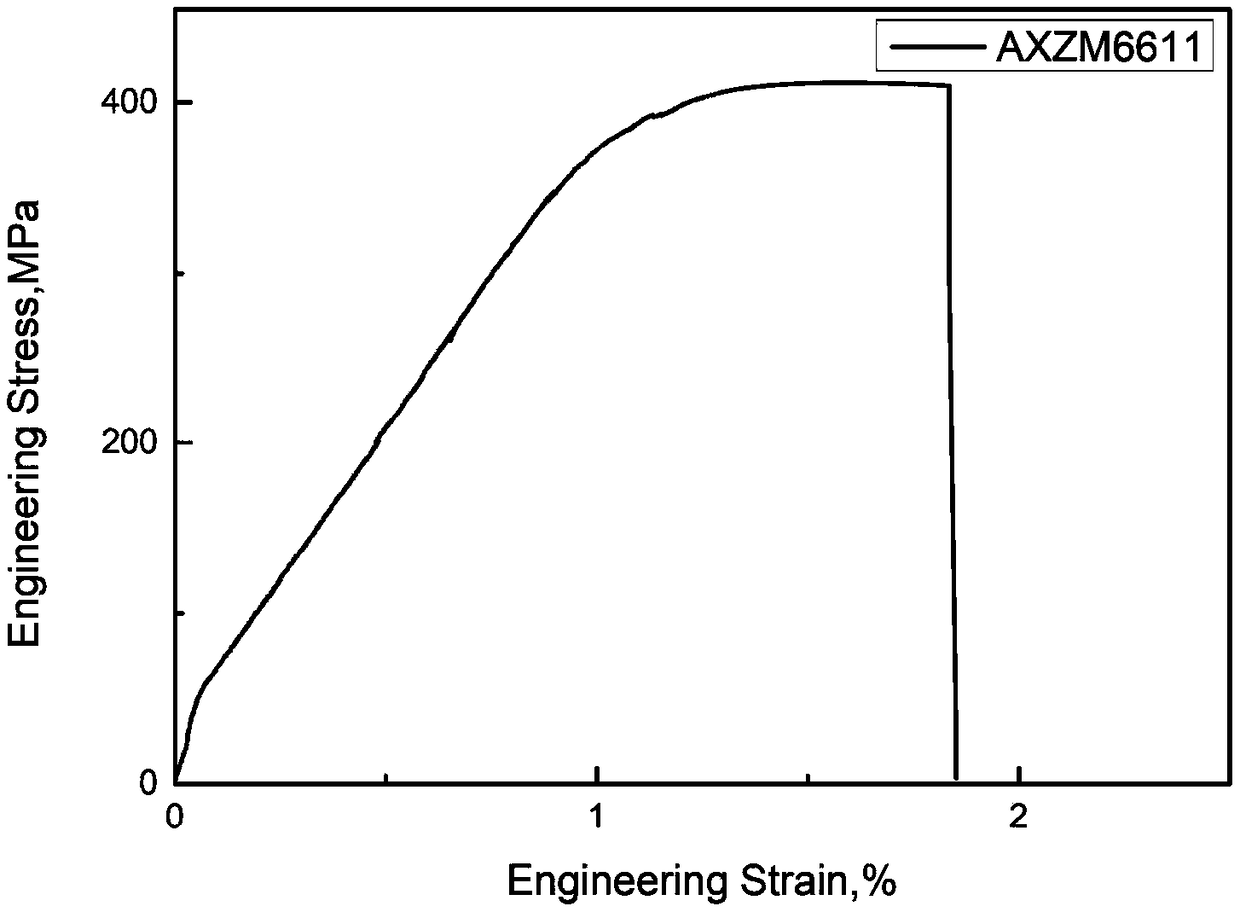

Microalloyed high-aluminum high-ductility steel plate and manufacturing method thereof

The invention relates to a microalloyed high-aluminum high-ductility steel plate and a manufacturing method thereof, and belongs to the field of alloy steel. The steel plate comprises the chemical components, by mass, including 0.8%-1.0% of C, 28%-30% of Mn, 8.0%-10% of Al, 0.02%-0.10% of Nb, 0.02%-0.10% of V, 0.02%-0.10% of Ti, 0.02%-0.08% of N, 0-0.003% of P, 0-0.003% of S and the balance Fe and inevitable impurities. The manufacturing method comprises the steps that firstly, raw materials are prepared according to the chemical components, then a plate billet is forged after smelting and casting, the plate billet is heated, homogenized and subjected to multi-pass hot rolling deformation with the accumulative deformation rate being 85%-90%, water cooling after rolling is conducted, and then the plate billet is air-cooled to the room temperature; secondly, the hot-rolled steel plate is subjected to solution treatment, fast heated to a solution treatment temperature for heat preservation for a period of time, and then water-quenched to the room temperature; thirdly, the steel plate subjected to the solution treatment is pickled, cold-rolled and subjected to multi-pass rolling deformation with the accumulative compression amount being 65%-80%; and fourthly, the cold-rolled steel plate is subjected to final annealing treatment, and then water-quenched to the room temperature, so that the microalloyed high-aluminum high-ductility steel plate is obtained. According to the steel plate manufactured through the manufacturing method, the strength and ductility product can reach 50 GPa*%, and the impact and collision resistance of the material is obviously improved.

Owner:KUNMING UNIV OF SCI & TECH

Aluminum high-pressure electrical porcelain and production process thereof

InactiveCN103253926ASmall coefficient of thermal expansionIntrinsic strain is smallClaywaresCalciteHigh pressure

The invention relates to aluminum high-pressure electrical porcelain. The aluminum high-pressure electrical porcelain comprises a raw material and a glaze material, wherein the raw material comprises the following components by weight percent: 57 percent of bauxite with aluminum content being more than 86 percent, 11 percent of green grass clay with aluminum content being 20 percent and magnesium content being 10 percent, 10 percent of black clay with aluminum content being 25 percent, 6 percent of feldspar powder and 16 percent of sulfonated soil with aluminum content being 22 percent; and the glaze material comprises 5 percent of manganese dioxide, 8 percent of zirconium oxide, 3 percent of chromium oxide, 5 percent of sulfonated soil, 9 percent of Triratna, 15 percent of moisture gauge, 5 percent of sodium humate, 15 percent of quartz, 5 percent of calcite, 25 percent of black clay and 5 percent of kaolin. The production process comprises the steps of batching, ball milling, screening, mixing, press filtering, smelting, aging, staling, clay refining, drying in shade, fettling, drying, glazing, sintering, cutting, grinding and cementing. By adopting the aluminum high-pressure electrical porcelain and the production process thereof, the problems of the existing high-pressure electrical porcelain product that the mechanical strength is low and the breaking strength is low can be solved. The advantages of low cost, high mechanical strength and high breaking strength can be achieved. The process is simple and easy to operate and control.

Owner:查府明

Advanced silica refractory and manufacturing technique thereof

The invention relates to a silicon refractory material with composition proportions of 3.0-1.0 mm and 30 to 55 percent of natural silica, 3.0 to 1.0mm and 0 to 15 percent of waste silica brick particles, 1.0 to 0.09mm and 10 to 25 percent of the natural silica, 3.0 to 1.0 mm and 0 to 15 percent of the waste silica brick particles, 10 to 25 percent of the natural silica plus waste silica brick powder plus calcinations silica less than 0.09mm, 1 to 5 percent of non-aluminum high C3S cement or calcium hydroxide powder, SiO2 no less than 98 percent, 0 to 5 percent of silica micropowder with median particle size D50 no more than 10 Mum, 1 to 5 percent of silica fume with SiO2 no more than 96 percent, 0.05 to 1.0 percent of high-efficiency water reducing agent and 0.03 to 1.0 percent of organic binder; 1 to 2 percent of fluorite, 0 to 6 percent of calcium sulfate, 0 to 4 percent of magnesium sulfate or magnesium oxide are doped as mineralizer. The production process comprises the process that after weighing, mixing and melting, forming and drying, the raw material is roasted as finished products under 1350 to 1460 DEG C for 10 to 36 hours. The invention has the advantages of good forming, rapid demoulding speed and excellent high temperature performance, which is suitable for silicon refractory material for glass manufacture, and large and special shaped silicon dioxide refractory material products.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

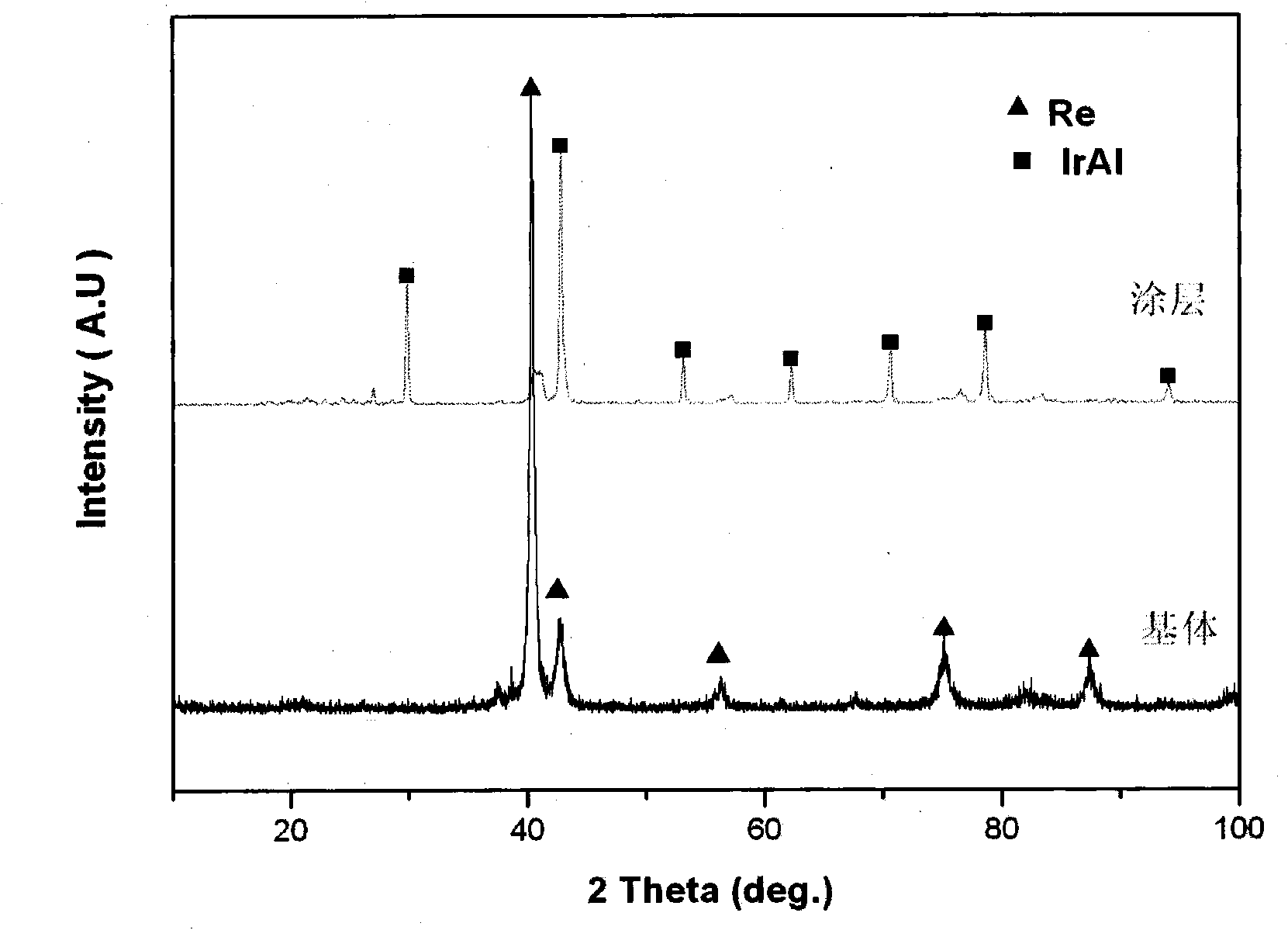

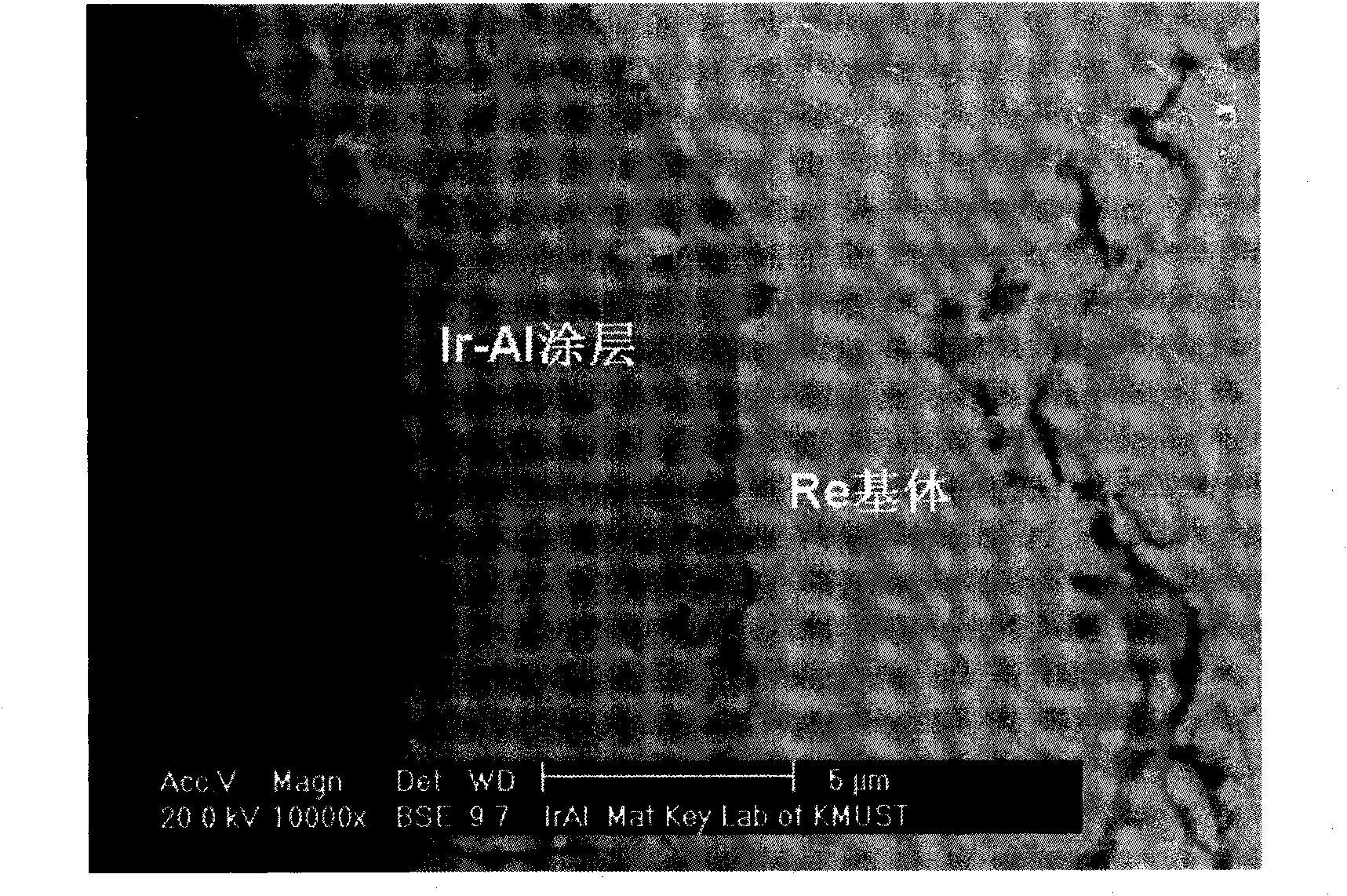

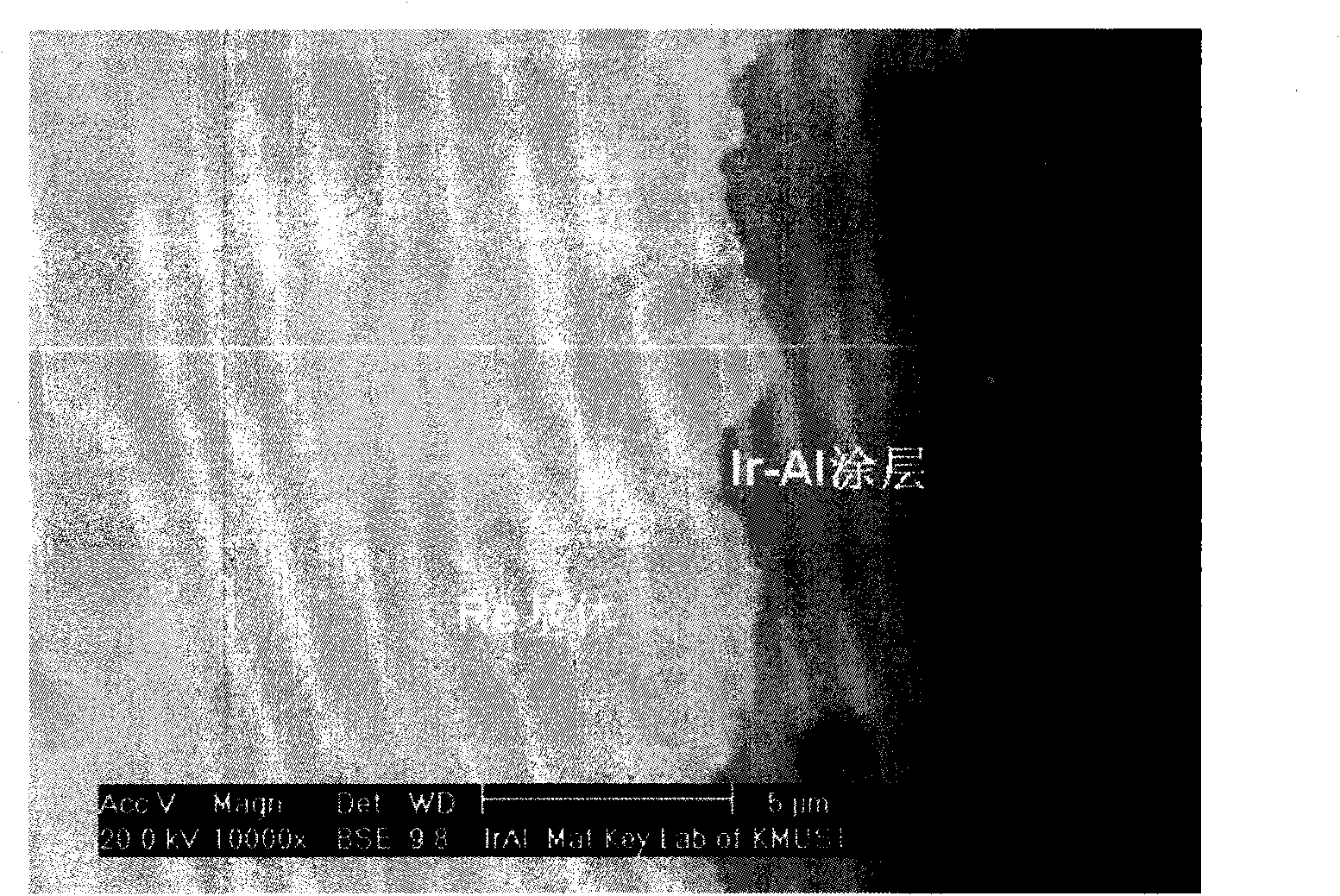

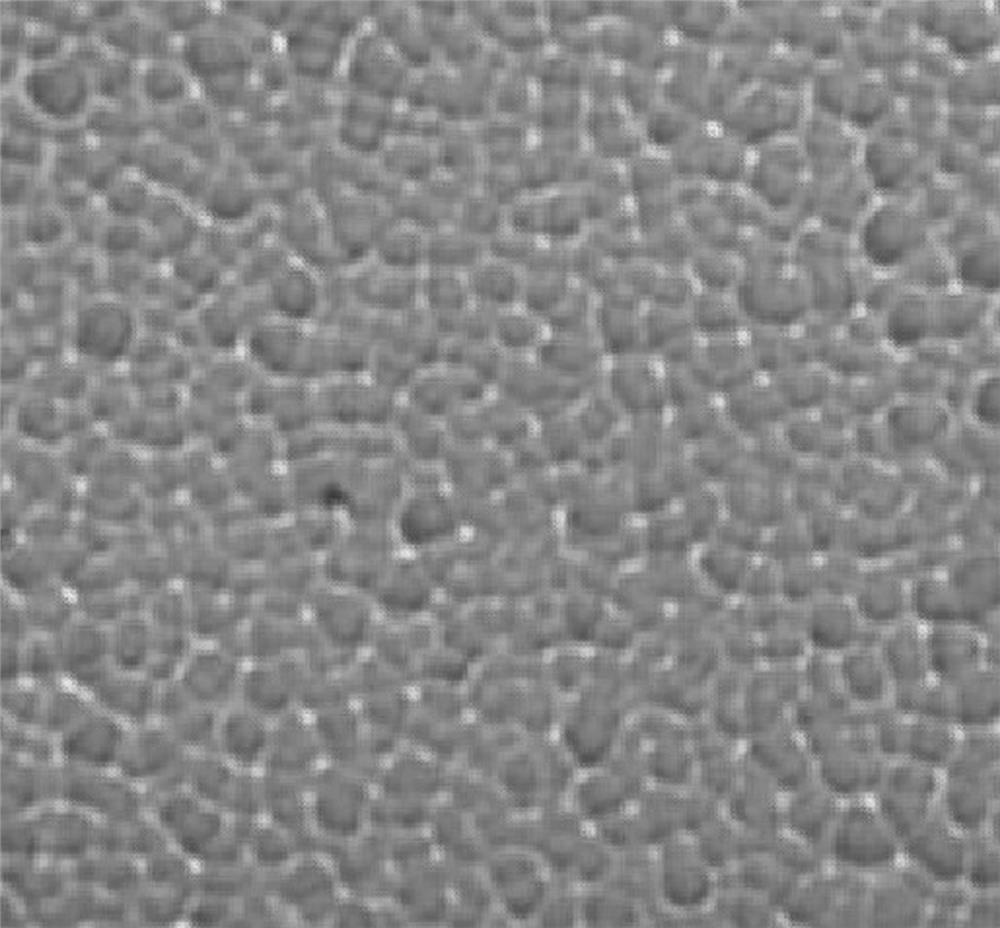

Preparation method of iridium-aluminum high temperature oxidation resistance coating

InactiveCN101643902AImprove bindingThickness is easy to controlSuperimposed coating processIridiumChemical treatment

The invention discloses a preparation method of iridium-aluminum coating, comprising the following steps: firstly performing surface cleaning and chemical treatment to the high temperature alloys or refractory metal substrates; then adopting electroplating process or chemical vapor deposition method to process the surface of the treated alloy to obtain a layer of pure iridium with a thickness of 0.5-10 microns; and finally performing pack cementation aluminizing at a certain temperature to obtain the iridium-aluminum coating. The bonding intensity between the iridium-aluminum coating and the substrate is high and the coating can be widely used in all kinds of high temperature alloys or refractory metals so as to increase the service life of the alloys or metals effectively and ensure the high temperature alloys or refractory metals to have excellent cold resistance, thermal shock resistance and high temperature oxidation resistance.

Owner:KUNMING INST OF PRECIOUS METALS

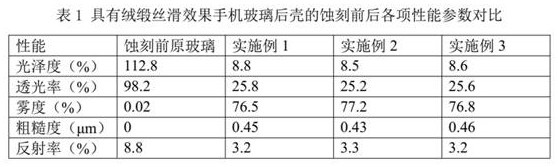

Etching solution with satin-like silky effect and process for manufacturing mobile phone glass rear cabinet with etching solution

ActiveCN111977984ASilky effect is obviousSimple processTelephone set constructionsAcid etchingPolyvinyl alcohol

The invention discloses an etching solution giving glass a satin-like silky effect and a process for manufacturing a process for manufacturing a mobile phone glass rear cabinet with the etching solution. The etching solution is prepared from the following raw materials in percentage by mass: 8-12 percent of NH4HF2, 3-6 percent of KHF2, 5-8 percent of HF, 15-25 percent of H3PO4, 8-12 percent of C6H8O7, 1-1.5 percent of K2HPO4, 5-10 percent of K2SO4, 0.8-1.5 percent of ZnCl2, 0.2-0.8 percent of sodium alkyl benzene sulfonate, 0.2-0.5 percent of polyacrylamide, 3-8 percent of polyvinyl alcohol, 3-6 percent of glycerinum and 25-40 percent of H2O. The process comprises the following steps: performing acid etching treatment on a mobile phone rear cabinet made of a high-aluminum high-silicon glass material and forming a corrugated concavo-convex etching layer with micro-level thickness, so that a silky fine texture and smooth hand-feeling touch effect is generated on the mobile phone rear cabinet glass surface, and the mobile phone rear cabinet glass has excellent characteristics of silky smoothness, scratch resistance, fingerprint resistance and the like.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

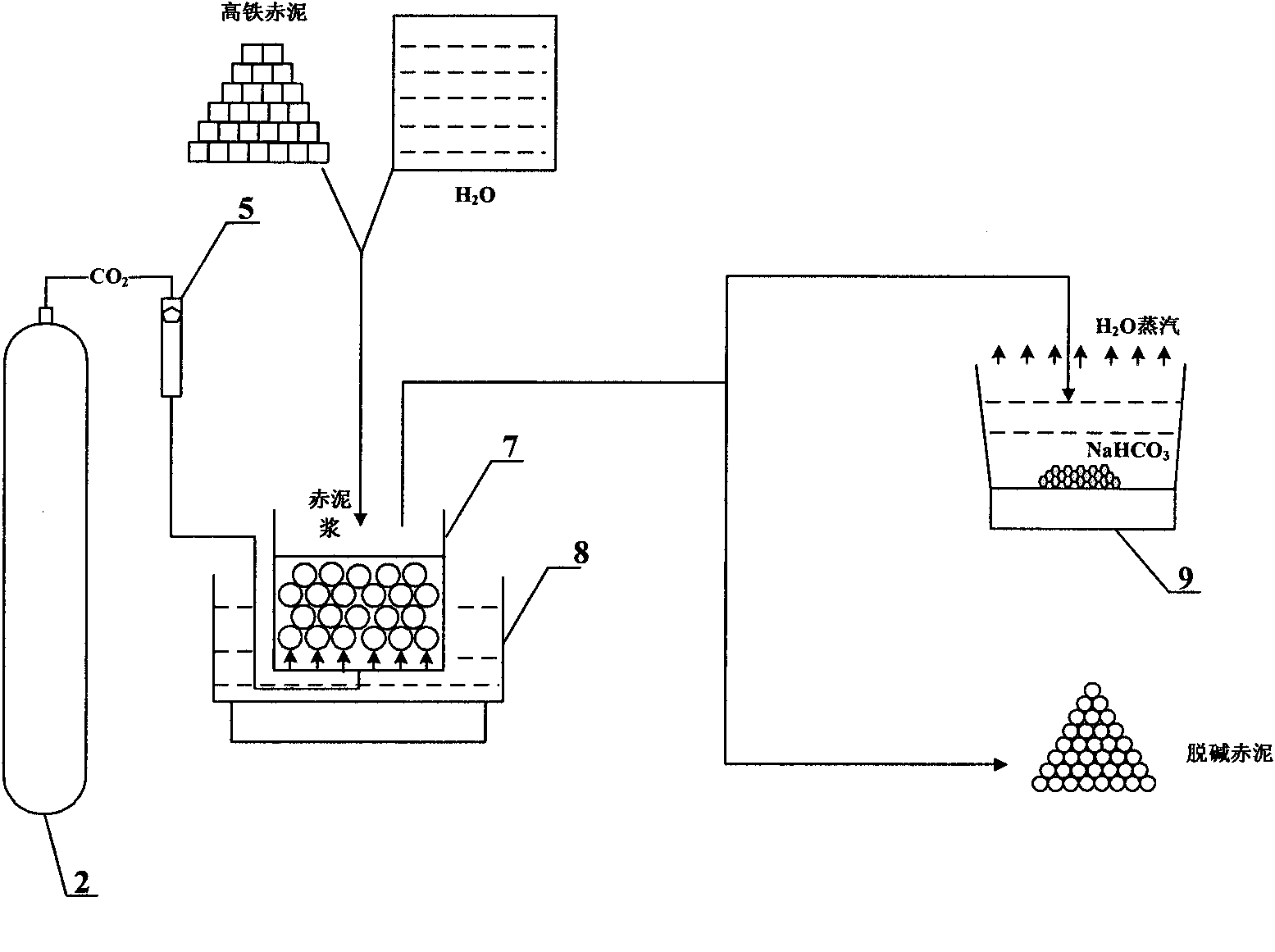

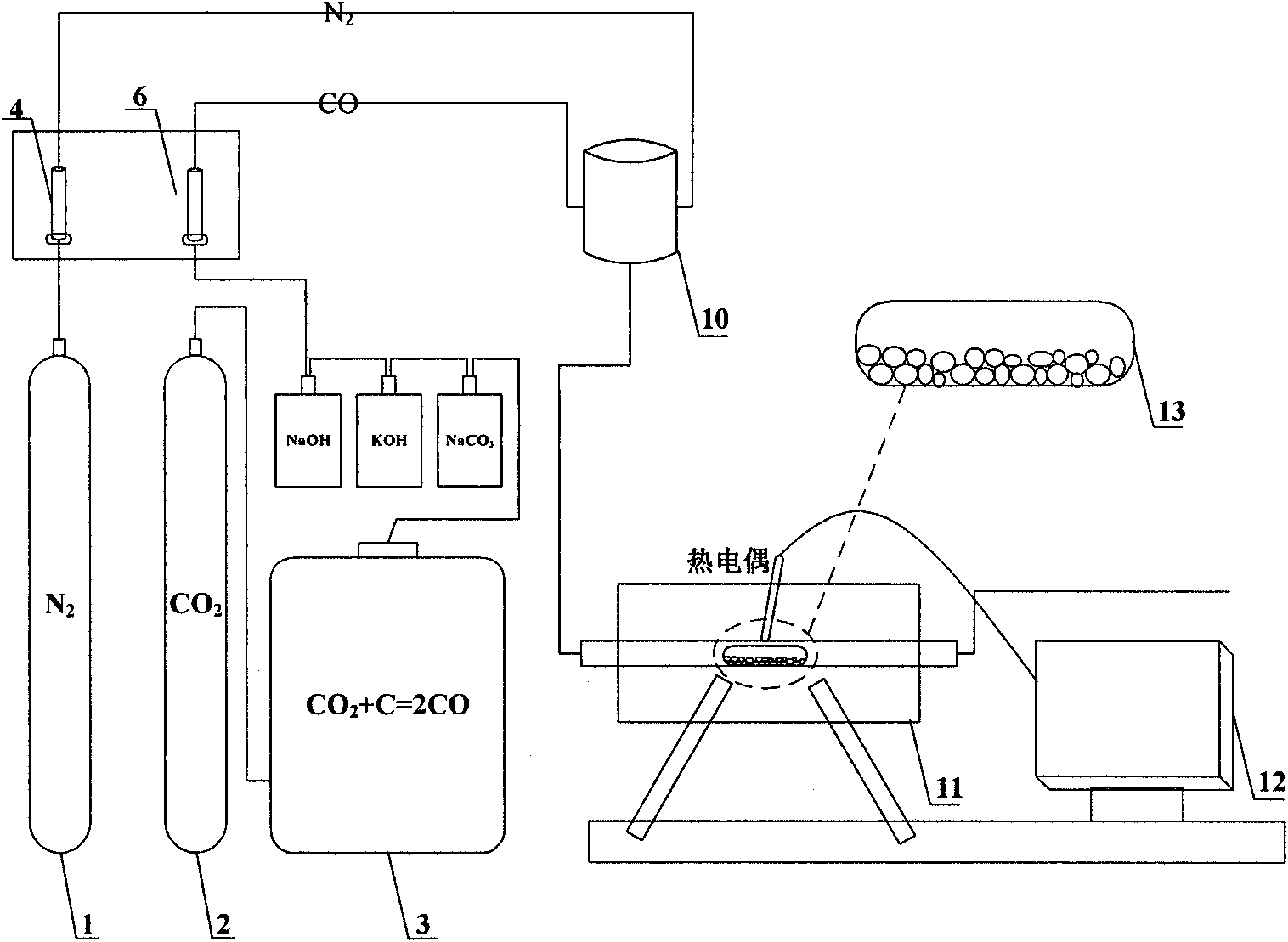

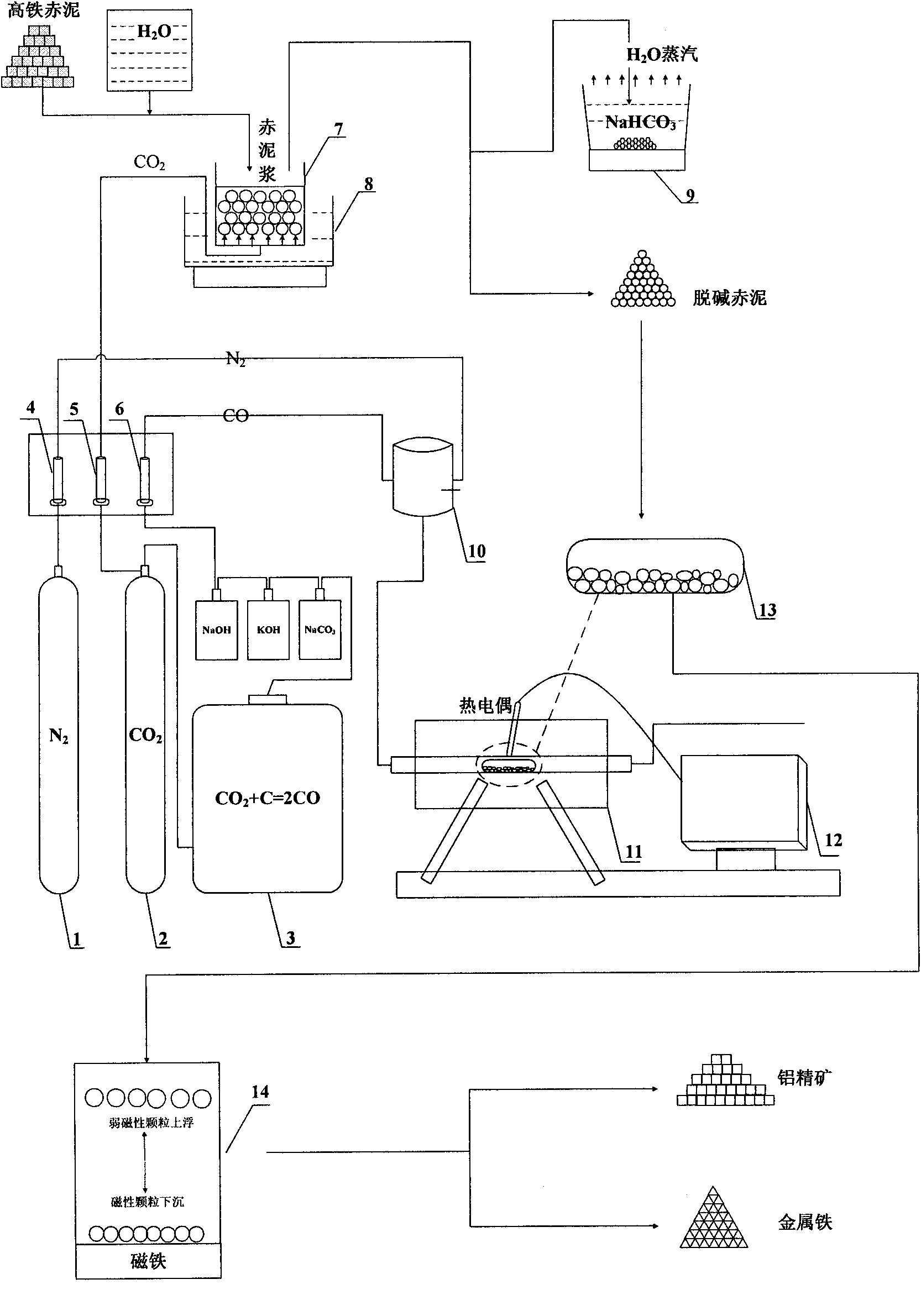

Method for directly preparing metallic iron and aluminum concentrate by using aluminum high-iron red mud as raw materials

InactiveCN102134646AEasy to separateRealize resource utilizationProcess efficiency improvementRed mudSeparation technology

The invention discloses a method for directly preparing metallic iron and aluminum concentrate by using aluminum high-iron red mud as raw materials, belonging to the field of recycling technology of solid wastes. The method is characterized by comprising the steps of: de-alkalizing wet aluminum high-iron red mud by adopting a CO2 de-alkalization technology, separating to obtain de-alkalized red mud and NaHCO3 solution and distilling the NaHCO3 solution to obtain NaHCO3 solid; treating the de-alkalized red mud by adopting an ultrafine grinding technology to obtain dry ultrafine powder; reducing the dry ultrafine powder by using a CO fine reduction technology so as to obtain a reduction product; and conducting magnetic separation to the reduction product by using a non-molten state separation technology so as to obtain the metallic iron and the aluminum concentrate with alumina as major component. The method of the invention has the advantages that the high-iron red mud is de-alkalized by CO2 at a temperature below 100DEG C and recycled to obtain NaHCO3; the oxide of the iron is reduced at a temperature below 900DEG C; and magnetic separation is carried out to obtain high-purity metallic iron and aluminum concentrate so that the full recycling of the aluminum high-iron red mud is realized.

Owner:李士琦

Compound rear earth additive for low-aluminum high-manganese CuAlMn low-temperature memory alloy

The invention discloses a compound rear earth additive for a low-aluminum high-manganese CuAlMn low-temperature memory alloy and belongs to the technical field of memory alloys. The additive is characterized in that the chemical composition comprises 20-28wt% of yttrium, 8-15wt% of lanthanum, 5-12wt% of cerium, 10-18% of niobium, praseodymium, europium, gadolinium, terbium, holmium, erbium, thulium and lutetium, 2-6wt% of wolfram, 2-5wt% of boron, 2-5wt% of zirconium and the balance copper. The compound rear earth additive is a lump-shaped alloy, the melting point range is from 800 DEG C to 1200 DEG C, and the adding amount range of the compound rear earth additive is in the range from 0.3wt% to 0.8wt%.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

Regenerated aluminum strong-magnetism iron-removing device and method thereof

InactiveCN103602822AEasy to removeSimple methodProcess efficiency improvementIron removalEngineering

A regenerated aluminum high-efficiency iron-removing device and a method thereof are characterized in that: 1) two hollow stirring rods are selected, the two stirring rods are allowed to be welded in parallel and be fixed on an iron-made sealed container, a water cooling circulation system is formed in the cavities of the stirring rods and the interior of the sealed container, the strong-magnetism iron-removing device with water cooling is prepared, and the exterior is coated with heat resistant asbestos cloth; 2) when iron removal of a regeneration aluminum molten liquid is required, the water cooling circulation system of the strong-magnetism iron-removing device is started, iron in the molten aluminum is absorbed and cleared up by utilizing a magnetic force of a strong magnet during stirring; and 3) the strong-magnetism iron-removing device can be recycled. The method is simple, is convenient for practical operation, good in iron removing effect and low in cost, and quite easily removes the impurity iron by utilizing magnetism adsorption. Moreover, with adopting of the water cooling circulation system, the magnetism of the magnet is ensured to not lose due to the high temperature, so that the strong-magnetism iron-removing device can be recycled.

Owner:ANHUI JINYING ALUMINUM

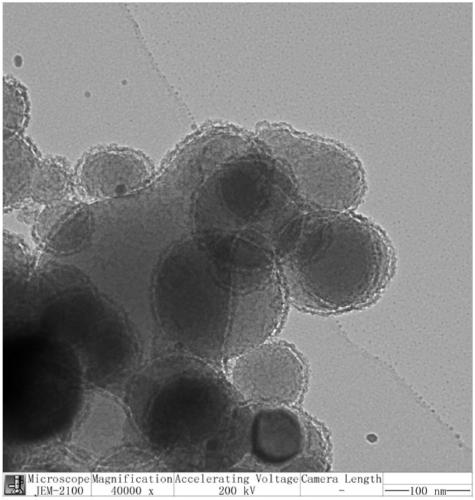

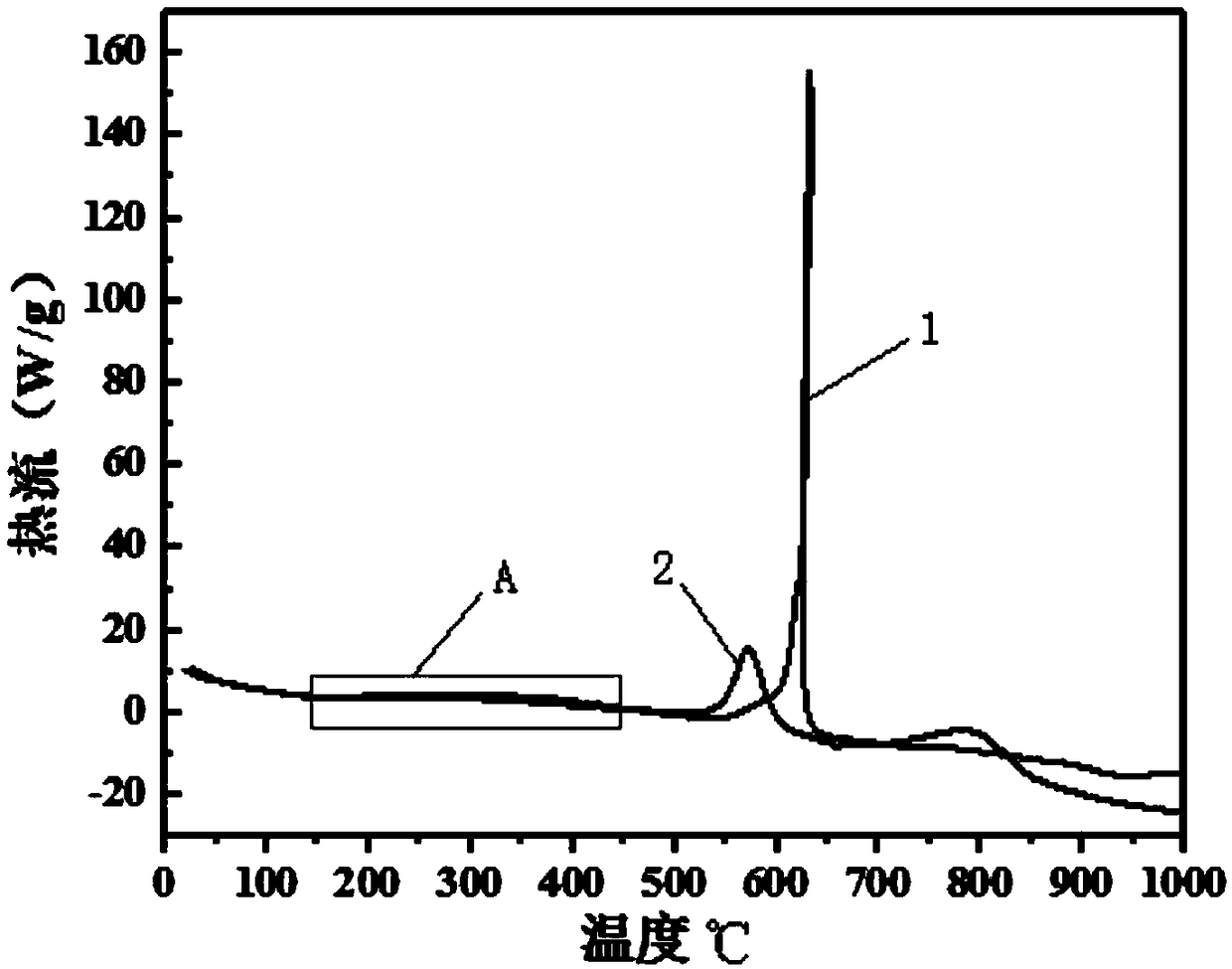

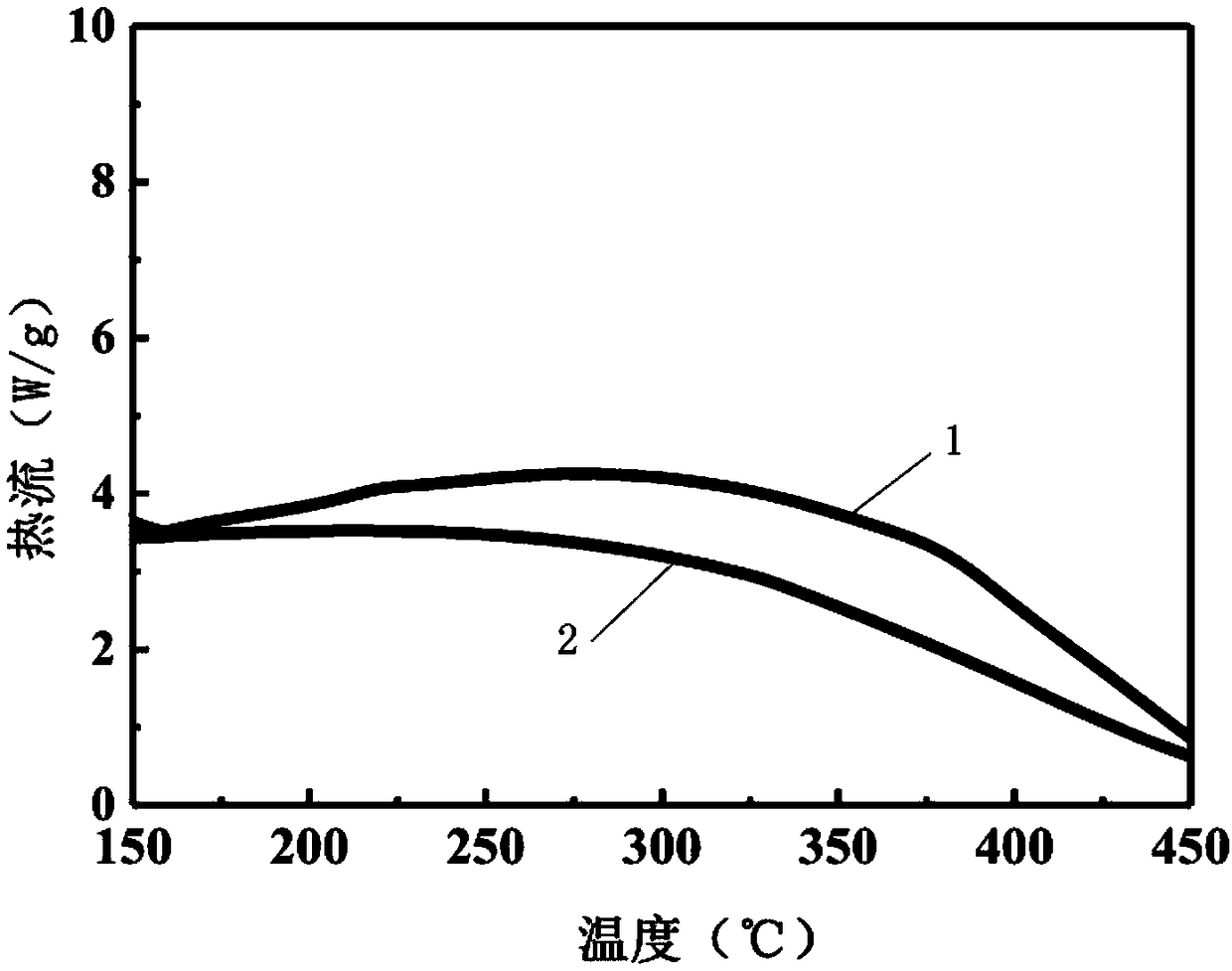

Nano fluorine-aluminum high energy release fuel and preparation method thereof

The invention relates to nano fluorine-aluminum high energy release fuel and a preparation method thereof and aims to solve the problem that existing preparation method of fluorine-aluminum compoundsare more applicable to micro aluminum powder, a fluorine-containing shell on the surface of the micro aluminum powder is about 100 nm thick, for nano aluminum powder, the fluorine-containing shell of100 nm is too heavy and affects the performance of the nano aluminum powder. The nano fluorine-aluminum high energy release fuel consists of a nano aluminum core with an oxidation film removed and a shell. The method comprises the steps as follows: 1, mixing an HF solution and a solvent to obtain a mixed solution; 2, adding nano aluminum powder to the mixed solution, and stirring the mixture at normal temperature to obtain a mixed solution containing aluminum powder; 3, adding a perfluorocarboxylic acid solution to the mixed solution containing aluminum powder, and performing stirring at normal temperature to obtain a crude product; 4, washing the crude product with absolute ethyl alcohol and performing filtration under reduced pressure to obtain the nano fluorine-aluminum high energy release fuel. The method is used for preparing the nano fluorine-aluminum high energy release fuel.

Owner:HARBIN INST OF TECH

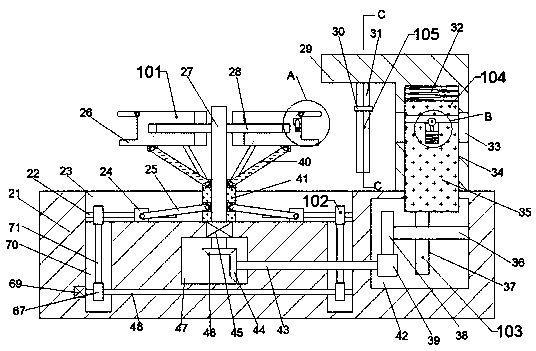

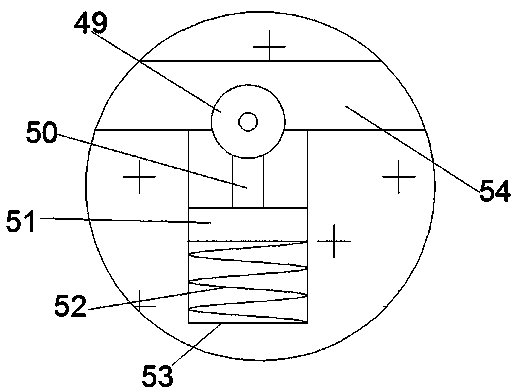

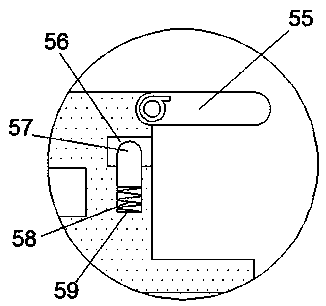

Aluminum high-voltage wire winding device

The invention discloses an aluminum high-voltage wire winding device. A machine body is included and internally provided with a top cavity opened upwards. An adjustable diameter packaging device usedfor bundled wires is arranged in the top cavity. An adjusting motor is started firstly, and accordingly a long shaft, symmetric belt wheels and short lead screws are driven to rotate. The device can wind an aluminum high-voltage wire into a bundle, then, the bundled wire can be automatically tailored and shorn, and accordingly wire bundling operation is finished. Meanwhile, compared with a traditional wire bundling device, in the device, wire collecting through replacement of discs different in diameter is not needed, the needed wire bundling diameter can be automatically changed, and accordingly the usage cost of the device is saved; and meanwhile, the work efficiency is improved, and the device can tidily arrange the wire during wire winding.

Owner:哈尔滨宾州奥特工业自动化有限公司

High-aluminum high-calcium content wrought magnesium alloy and preparation method thereof

The invention discloses a high-aluminum high-calcium content wrought magnesium alloy and a preparation method thereof and belongs to the field of wrought magnesium alloy materials. The high-aluminum high-calcium content wrought magnesium alloy comprises the following components in percentage by mass: 3.00-20.00% of aluminum, 2.00-15.00% of calcium, 0.10-5.00% of zinc, 0.10-3.00% of manganese, 0-5.00% of strontium, 0-5.00% of barium and the balance of magnesium and inevitable impurities. The preparation method comprises the following steps: firstly, melting pure magnesium cast ingots, sufficiently melting, further adding metals such as calcium, aluminum, zinc, manganese, strontium and barium, sufficiently stirring, casting so as to obtain cast ingots, further carrying out homogenization treatment on the cast ingots, and extruding by using a backward extrusion process, thereby obtaining a corresponding extrusion profile. The strength and the toughness of the high-aluminum high-calcium content wrought magnesium alloy are improved, and good mechanical properties are achieved.

Owner:NORTHEASTERN UNIV

Method for refining high carbon molten steel by using low aluminum steel casting residue

The invention relates to comprehensive utilization of casting residue, in particular to a method for refining high carbon molten steel by using low aluminum steel casting residue with the Al content of less than or equal to 0.0040 percent. The method comprises the following steps of: 1, preparing refinery residue: collecting aluminum steel casting residue with the alkalinity of 2.0 to 4.5 and the Al content of less than or equal to 0.0040 percent; crushing the residue; grinding the residue; adding an inorganic adhesive agent or an organic adhesive agent; pelletizing; and baking residue; 2, adding the refinery residue prepared in step 1 within 30 seconds after the deoxidizing alloying of the molten steel; and 3, controlling the time from pouring to the refining completion within 15 to 30 minutes, and controlling basicity of the residue after the refining completion to be 2.1 to 2.8. The method has the advantageous of realizing the comprehensive cyclic utilization of the low aluminum high carbon steel casting residue, and reducing the environmental pollution and field occupation along with simple and feasible technology, low cost, good slag formation, high slag formation speed, and short slag formation time. Though the refining time is relatively prolonged, the quality of the molten steel is improved.

Owner:武汉钢铁有限公司

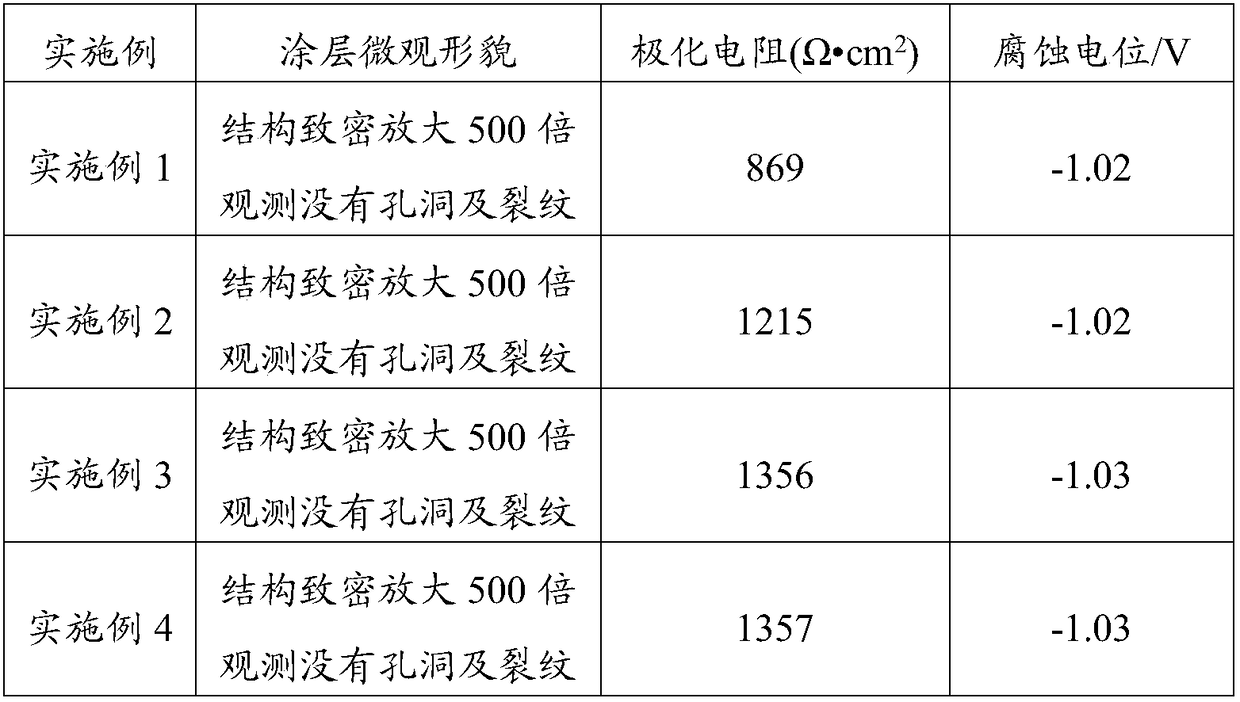

Plasma spraying zinc-aluminum high-strength steel as well as preparation method and application thereof

InactiveCN108265262AAvoid direct contactInhibit corrosion reactionMolten spray coatingElectrical resistance and conductanceRare earth

The invention provides a preparation method of plasma spraying zinc-aluminum high-strength steel. Zinc powder, aluminum powder and rare earth metal powder are subjected to ball grinding to obtain compound metal powder, wherein the mass ratio of the zinc powder to the aluminum powder to the rare earth metal powder is (84 to 87):(13 to 14.5):(0.2 to 0.6); the high-strength steel surface is sequentially subjected to pretreatment and shot blasting to obtain a high-strength steel substrate; the compound metal powder is sprayed and coated on the surface of the high-strength steel substrate by a plasma spraying method; a zinc-aluminum coating is formed at the surface of the high-strength steel substrate; the plasma spraying zinc-aluminum high-strength steel is obtained. The plasma spraying zinc-aluminum high-strength steel provided by the invention has good corrosion resistant performance and is applicable to severe conditions in marine environment. Experimental results of the embodiment showthat the polarization resistance of the plasma spraying zinc-aluminum high-strength steel provided by the invention reaches 1357 Omega.cm<2>, and the corrosion potential reaches -1.03V.

Owner:SHANGHAI UNIV

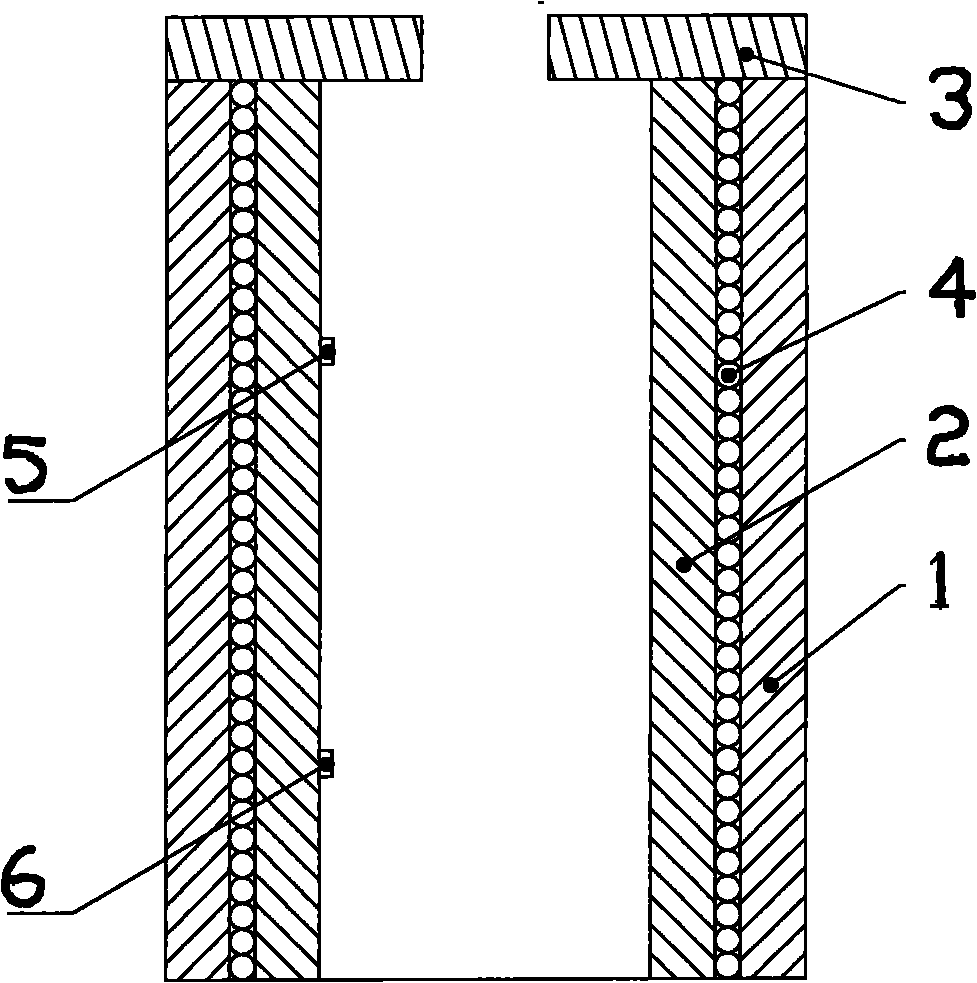

Crystal annealing device in growth furnace

InactiveCN101831712AImprove controllabilityTemperature Gradient RegulationAfter-treatment detailsThermocoupleAluminum high

The invention relates to a crystal annealing device in a growth furnace. The heating power of a heat chromium-aluminum high-temperature heating wire which is wound on an inner layer and an outer layer of heat insulating covers is adjusted by measuring the temperatures of two double platinum-rhodium thermocouples, and a heating source is provided; and an annealing space with the relatively small temperature gradient is formed in the upper heat insulating cover, and then the temperature gradients on a head part and a tail part of the crystal are smaller, so that an inner thermal stress of the crystal can be reduced. By using the method, the high-temperature crystal with the low internal stress can be grown, the crystal can be directly oriented and cut after annealing of crystal growth and crystal elements with all kinds of specifications are prepared without long-time annealing outside the furnace, so that the internal stress of the crystal is greatly reduced, the internal defects are reduced, the efficiency is greatly improved, and the device has simple structure and low manufacturing cost and is suitable for batch production.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Low-aluminum high-titanium welding wire steel and smelting method thereof

ActiveCN112011718AImprove continuous pouring performanceSolve the water outletSlag (welding)Iron powder

The invention provides low-aluminum high-titanium welding wire steel and a smelting method thereof. The smelting method comprises the following steps that S1, converter tapping deoxidation alloying iscarried out, specifically, high-silicon silicon manganese and high-purity silicon iron are sequentially added for deoxidation alloying during converter tapping, and then lime and fluorite are sequentially added; and S2, LF refining is carried out, specifically, lime and fluorite are added into an LF furnace according to the fluidity of refining slag; calcium carbide and ferrosilicon powder are added in batches for the first time of refining electrification for slag surface deoxidation; sampling and testing are carried out after electrifying is carried out for a period of time, and high-puritysilicon iron and manganese metal are added according to a test result to adjust components to target values; ferrosilicon powder is added to keep the reducibility of refining slag after an alloy is added until refining is finished; and in the later stage of refining, a ferrotitanium wire is fed at a time to enable the titanium content to reach a target value, soft blowing is carried out after sulfur wires are supplemented according to the sulfur content of the test result, and then machine continuous casting is carried out. According to the low-aluminum high-titanium welding wire steel and the smelting method thereof, the components of the low-aluminum high-titanium welding wire steel are stably controlled, meanwhile, the continuous pouring performance of the low-aluminum high-titanium welding wire steel is greatly improved, and the production cost is reduced.

Owner:JIANGSU YONGGANG GROUP CO LTD

Aluminum high molecular veneer composite door and window corner processing method

ActiveCN106273522AImprove splicing strengthImprove processing efficiencyDomestic articlesMilling equipment detailsData acquisitionEngineering

The invention relates to a door and window corner processing method and in particular to an aluminum high molecular veneer composite door and window corner processing method. The method comprises the steps of: data collecting and programming, material feeding and locating, milling-processing, welding heating, molding co-extrusion and the like. The method compensates the defects existing in current common processing, welding and corner-clearing and effectively solves the precision problem and the efficiency problem generated by multiple locating errors and repeated consumptions. Splicing end faces have a certain textures after being heated and molded so that the two end faces have strong occlusive force when being spliced, the door and window splicing strength is improved by 1.5-2 times, meanwhile the welding corner-clearing-free technology effectively guarantees the attractive appearance of group corners, guarantees the attractive appearance of door and window group corners, greatly improves the processing efficiency of doors and windows and provides an advanced technical support for processing and production of large-scale door and window group corners.

Owner:浙江瑞明节能门窗技术有限公司

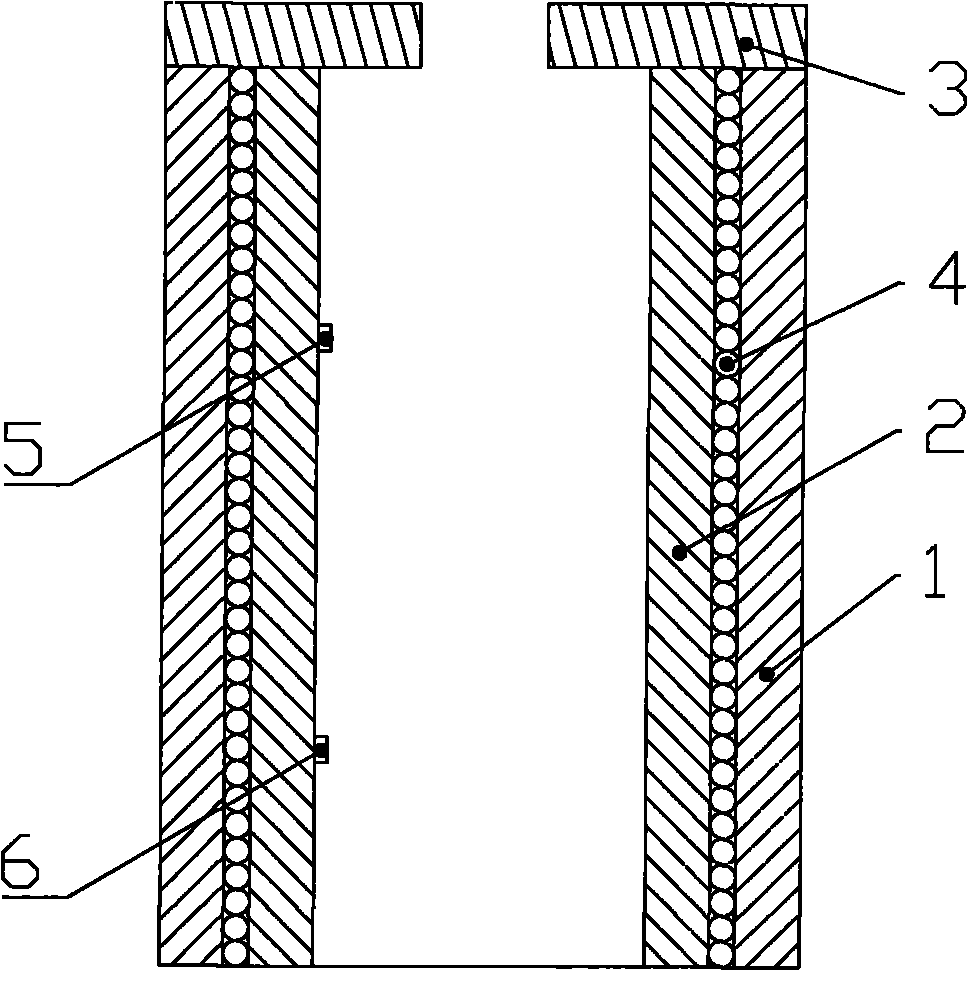

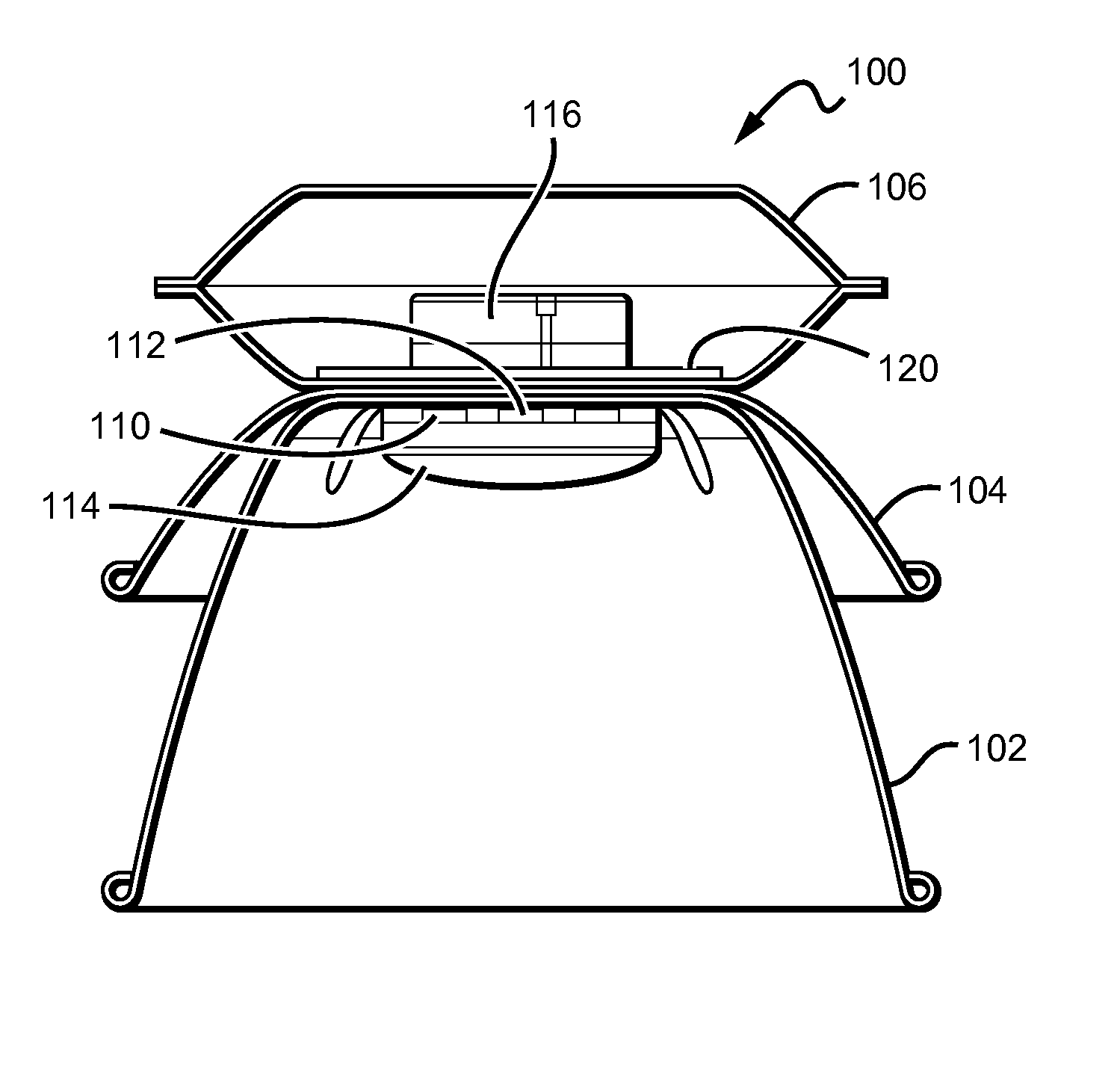

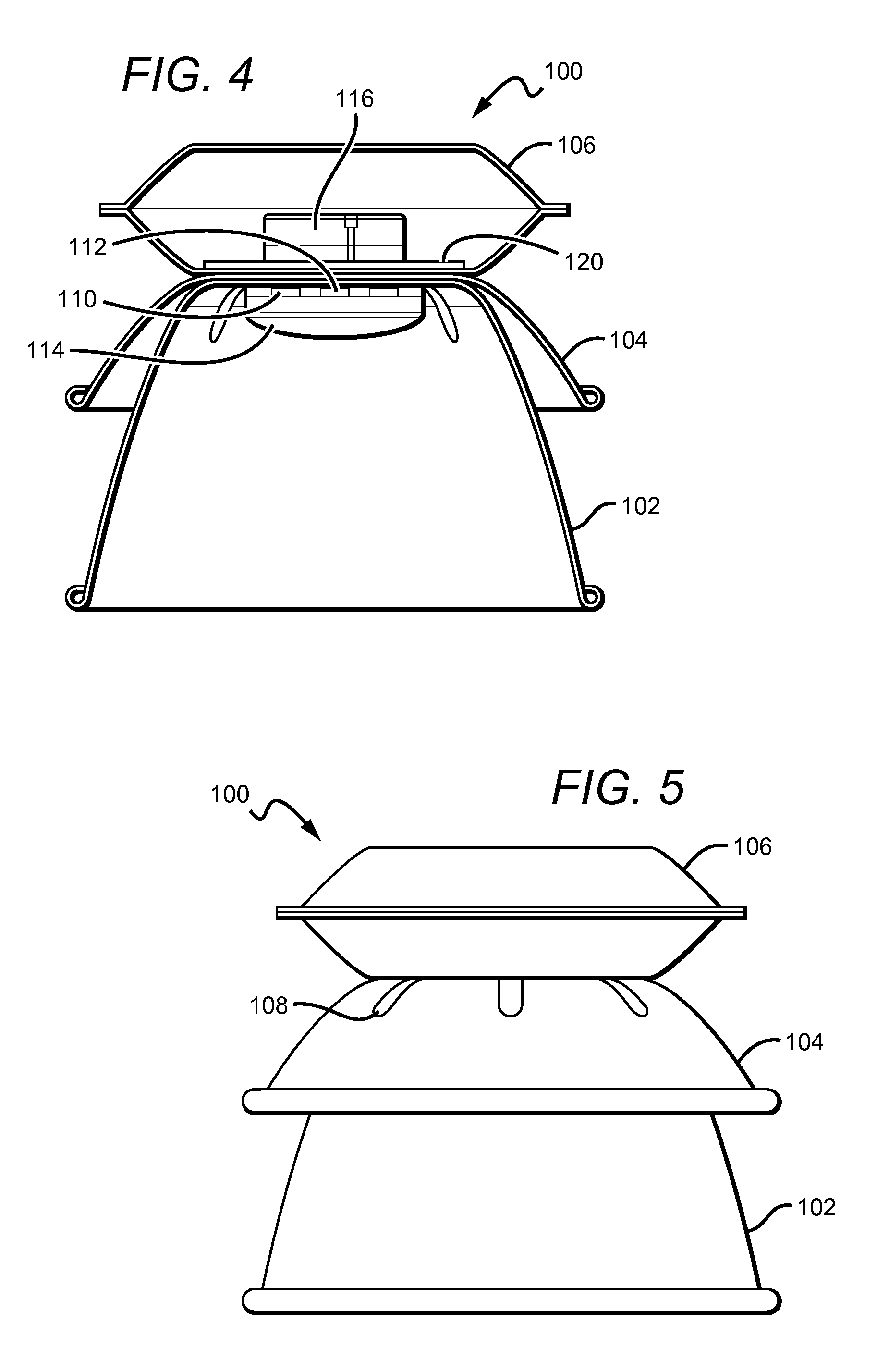

Aluminum high bay design

ActiveUS20140268745A1Efficiently dissipatedReduction height and weight and costNon-electric lightingLighting support devicesEffect lightEngineering

The present invention relates to different embodiments of high bay lighting fixtures comprising many improved features, such as the ability to dissipate heat from a light source in a non-traditional manner. One such example is the elimination of a traditional heat sink by placing housings and / or a heat spreader plate in thermal contact with the light emitting elements. By doing so, the housings and / or heat spreader plate can dissipate heat from the light emitting elements and spread it throughout the lighting fixture. Different embodiments also help dissipate heat from the light source by spreading out the light emitting elements. Other embodiments improve heat dissipation by using air slots, so that heat can more easily escape from the lighting fixture. Still another example of dissipating heat from the light source can be to use heat fins.

Owner:IDEAL IND LIGHTING LLC

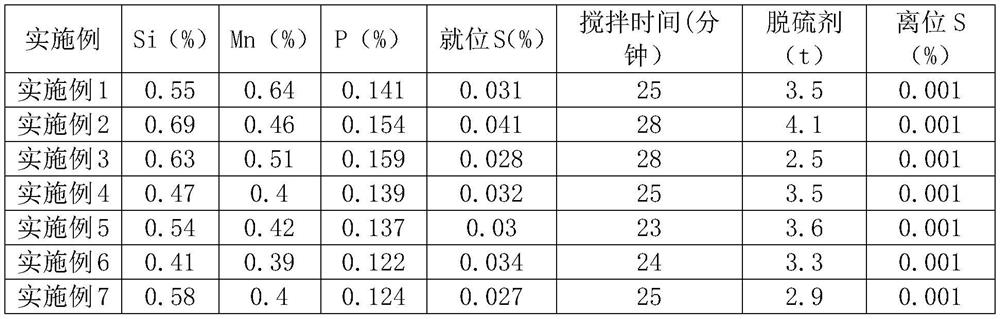

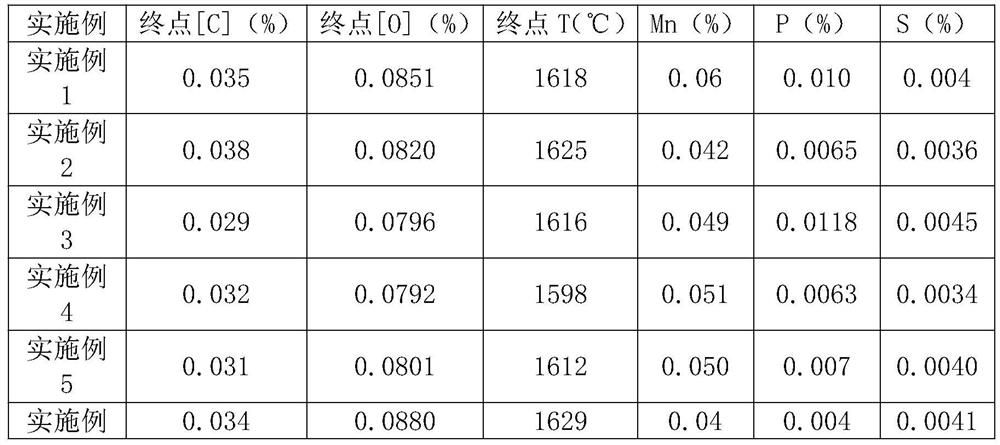

Production method of ultra-low-aluminum high-purity industrial pure iron

InactiveCN114318108AIncrease production costImprove purityManufacturing convertersProcess efficiency improvementSlagManganese

The invention discloses a production method of ultra-low-aluminum high-purity industrial pure iron. The production method comprises the following steps: (1) pre-desulfurizing molten iron; (2) a converter; (3) LF refining; (4) RH vacuum treatment; (5) continuous casting; the converter uses self-produced low-sulfur plain carbon waste steel and a double-slag dephosphorization and demanganization process, and low-temperature and high-oxygen content control is adopted at the end point; high oxidability of molten steel and slag is kept in the converter tapping and LF refining process, and phosphorus and manganese in steel are removed through LF refining oxidation; after RH vacuum decarburization, aluminum is added for deoxidation, the aluminum content of molten steel is 0.013-0.017%, the aluminum content in the steel is further reduced through the secondary oxidation effect of slag on the molten steel, the Al content in a finished product is within 0.005%, and the oxygen content is controlled to be below 0.005%; and the content of the industrial pure Fe element reaches 99.92% or above.

Owner:BAOTOU IRON & STEEL GRP

Solid heat storage material, and preparation method and application thereof

The invention belongs to the field of high temperature materials, and in particular, relates to a solid heat storage material, and a preparation method and an application thereof. The solid heat storage material comprises the following raw materials in parts by weight: 5-95 parts of iron ore, 5-50 parts of magnesium iron bricks, 5-20 parts of iron scales, 5-20 parts of a silicon carbide dedusting powder, 1-20 parts of aluminum nitride, 1-5 parts of beryllium nitride, 0.5-5 parts of boron mud, 1-2.5 parts of sodium hexametaphosphate, 1-2 parts of a magnesium aluminum high temperature cementing agent and 1-4 parts of water. The material is low in cost and high in specific heat; and the value of the thermal conductivity coefficient is adjusted according to different ingredient ratios, so as to meet the requirements of different heat storage devices.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

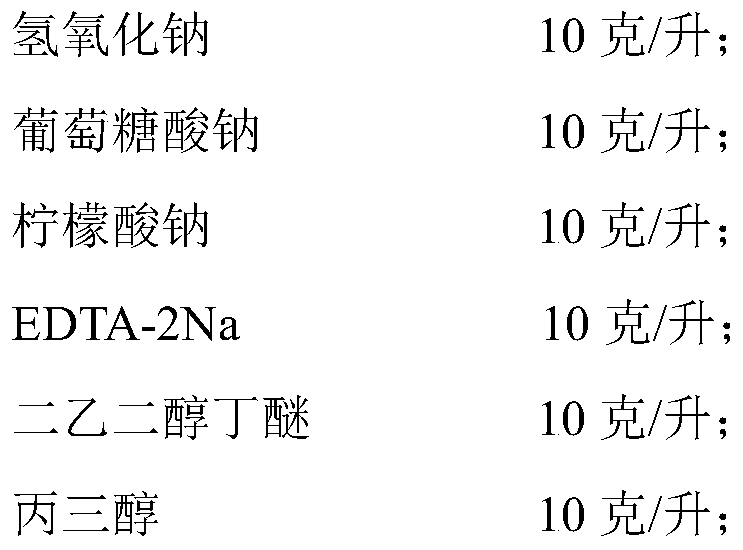

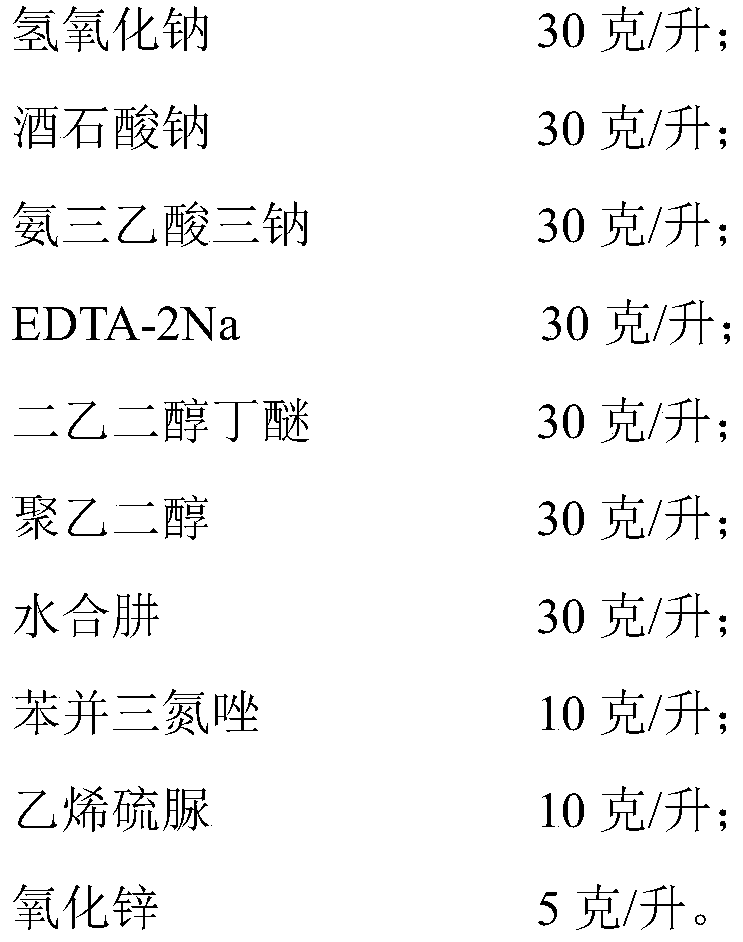

Film removal agent and film removal method for aluminum high light mobile phone middle frame surface anode oxide film

InactiveCN110804754AEasy to removeThe product surface is not damagedSurface reaction electrolytic coatingPhysical chemistryFluoride

The invention provides a film removal agent and a film removal method for a aluminum high light mobile phone middle frame surface anode oxide film. The film removal agent comprises the following massportion components of 1 part to 10 parts of inorganic base, 1 part to10 parts of complexing agent, 1 part to 10 parts of penetrating agent and 0.1 part to 1 part of brightener. The film removal methodcomprises the following steps of S1), degreasing and oil removing treatment, S2), anode oxide film removal treatment, S3), neutralization and ash removal treatment, and S4) drying treatment. According to the film removal agent and the film removal method for the aluminum high light mobile phone middle frame surface anode oxide film, not only the oxide film on a product surface is quickly removed,but also the product surface does not be damaged; after the film removal treatment is finished, the product surface has the advantages that the high gloss surface does not be damaged, over reaction does not cause corrosion to the aluminum alloy surface, and the requirements that the air tightness test is qualified in the enterprise production are met; and the film removal agent does not contain chromate, fluoride, nitrate, phosphate and other medicament that pollute the environment, the environmental protection requirements are fully met, and waste liquid can be discharged after simple neutralization.

Owner:东莞市新东明科技有限公司

Production method for copper-aluminum high-temperature compounding

PendingCN113026070ASolving difficult-to-prepare problemsSolve the strength problemMetal rolling arrangementsSemi solidSlurry

The invention discloses a production method for copper-aluminum high-temperature compounding. The production method comprises the following steps of (1) surface treatment of a copper strip; (2), electroplating and texturing treatment; (3) preparation of aluminum semi-solid slurry; (4) heat treatment and annealing; and (5) cold rolling. The method solves the problem that the copper-aluminum composite material is difficult to prepare due to the fact that the proportion of the copper layer obtained through an existing preparation method for copper-aluminum compounding is low, and also solves the problem that the peeling strength between the copper layer and aluminum layer of existing copper-aluminum compounding is low.

Owner:刘飞

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com