Film removal agent and film removal method for aluminum high light mobile phone middle frame surface anode oxide film

An anodic oxide film, mobile phone middle frame technology, applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve problems such as failure to meet air tightness test requirements, surface corrosion, aluminum alloy surface corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

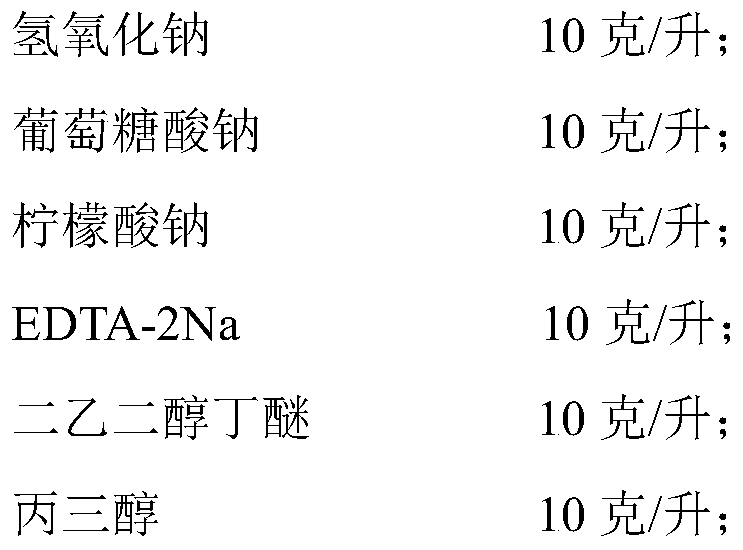

[0044] A release agent for anodized film on the surface of an aluminum high-gloss mobile phone middle frame, comprising the following components in parts by mass:

[0045]

[0046]

Embodiment 2

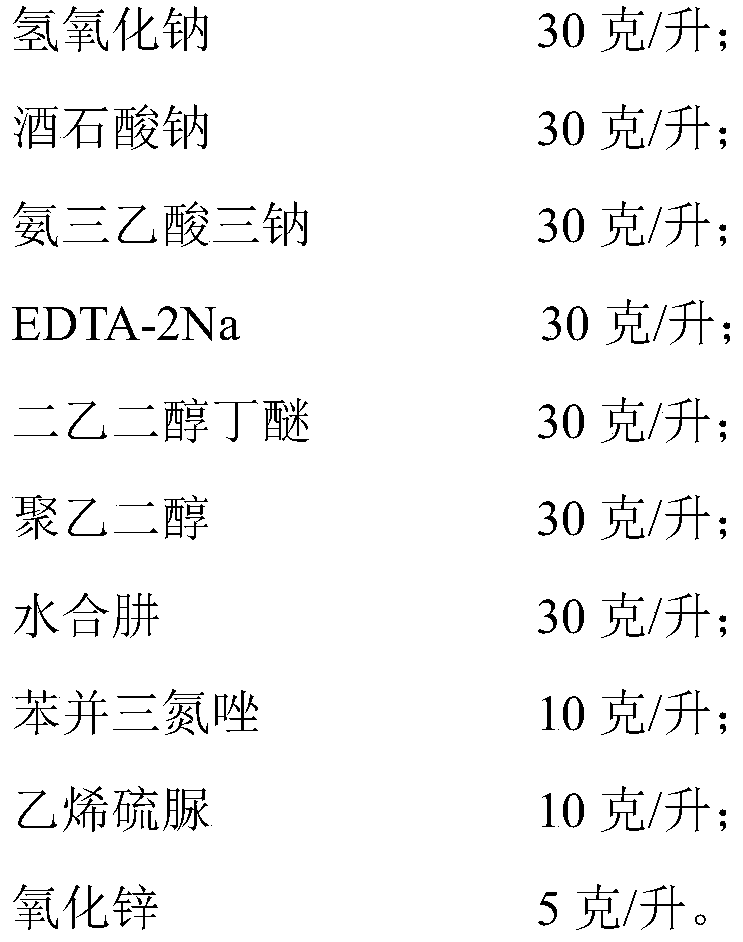

[0048] A release agent for anodized film on the surface of an aluminum high-gloss mobile phone middle frame, comprising the following components in parts by mass:

[0049]

Embodiment 3

[0051] A release agent for anodized film on the surface of an aluminum high-gloss mobile phone middle frame, comprising the following components in parts by mass:

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com