Patents

Literature

54results about How to "Improve splicing strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

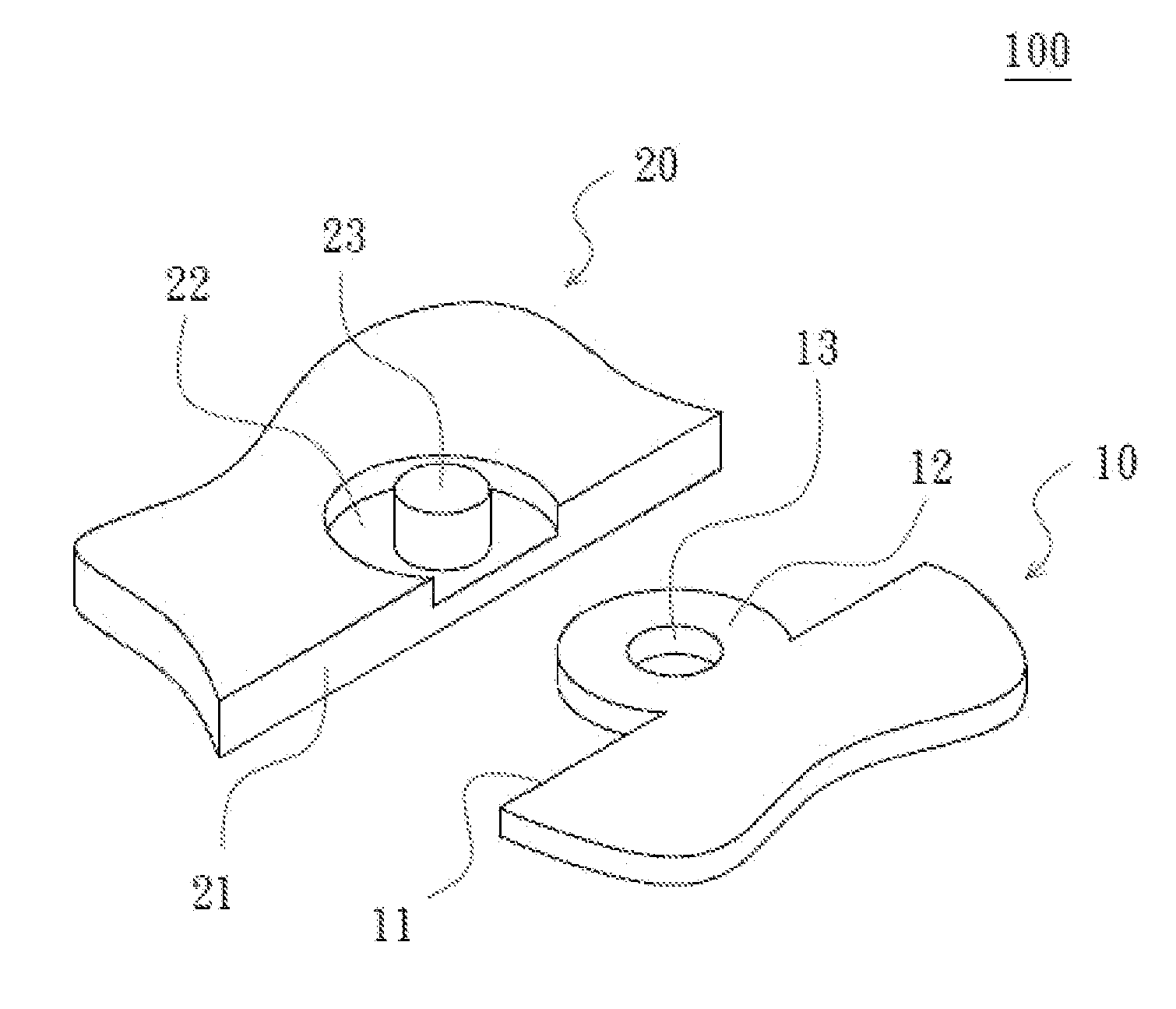

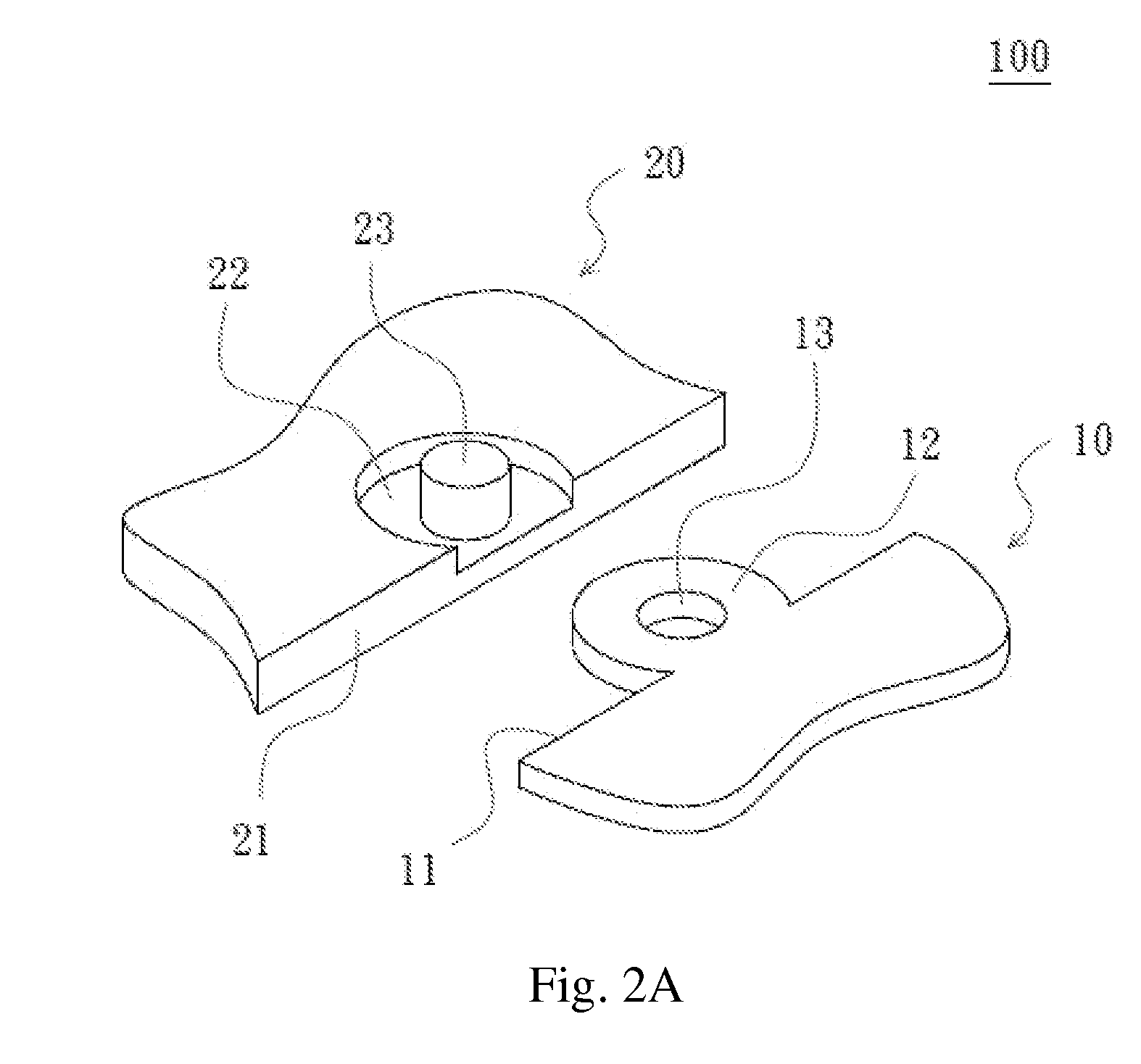

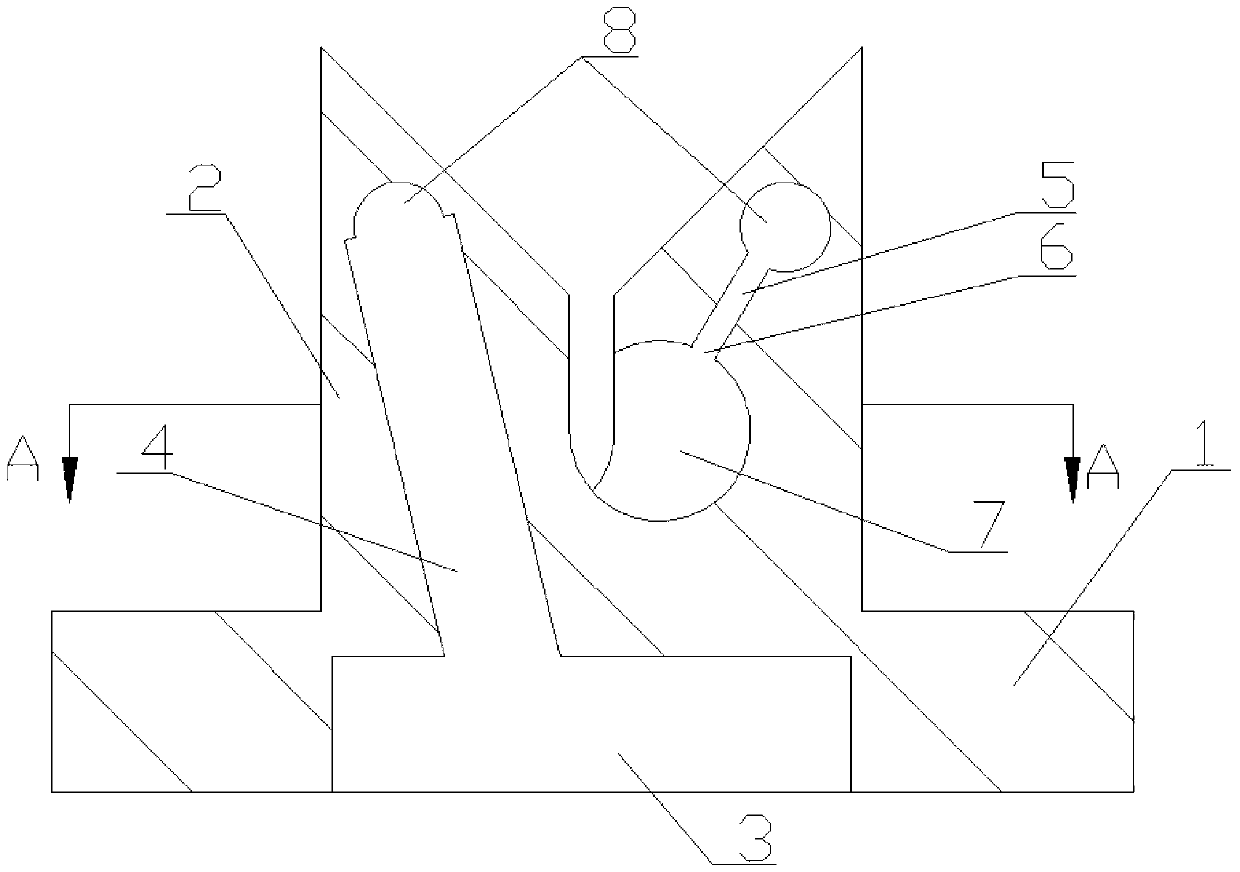

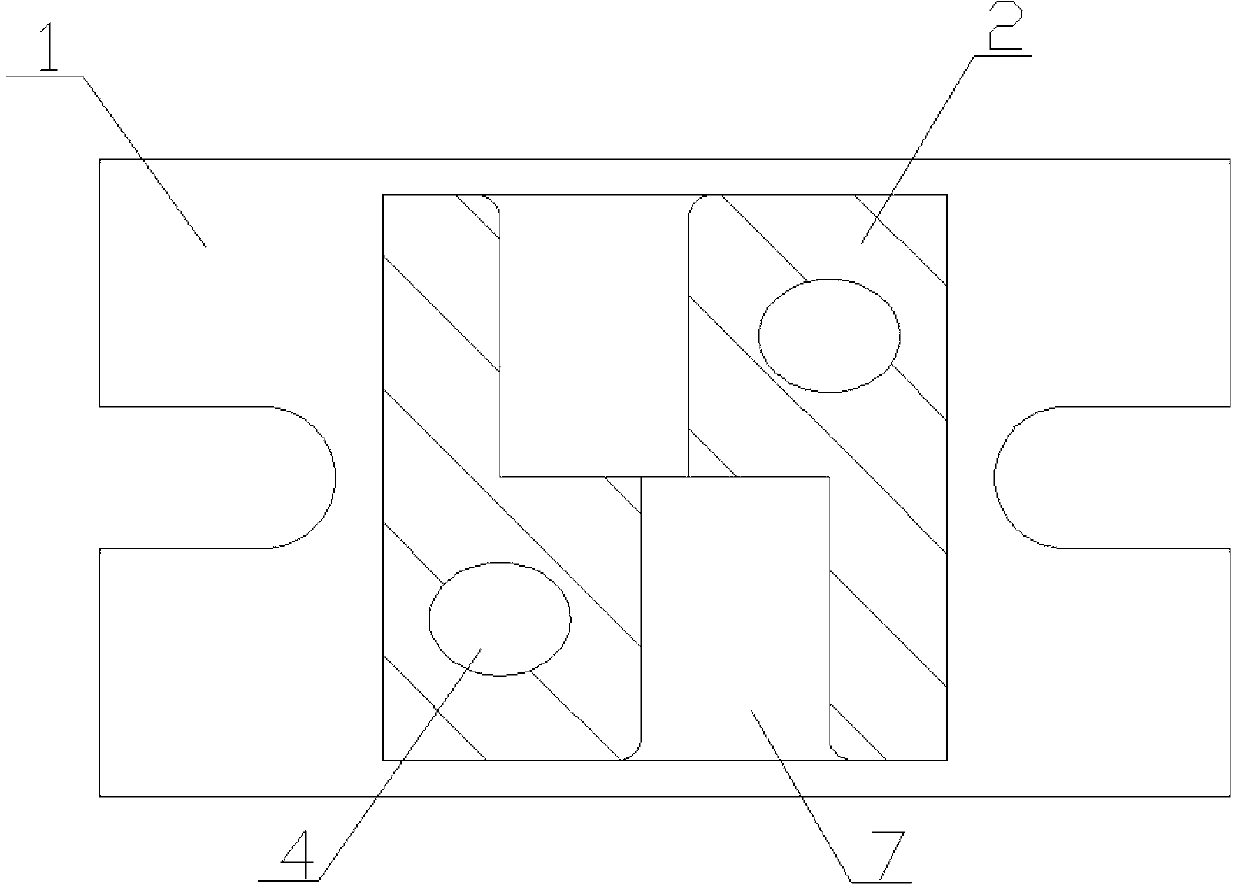

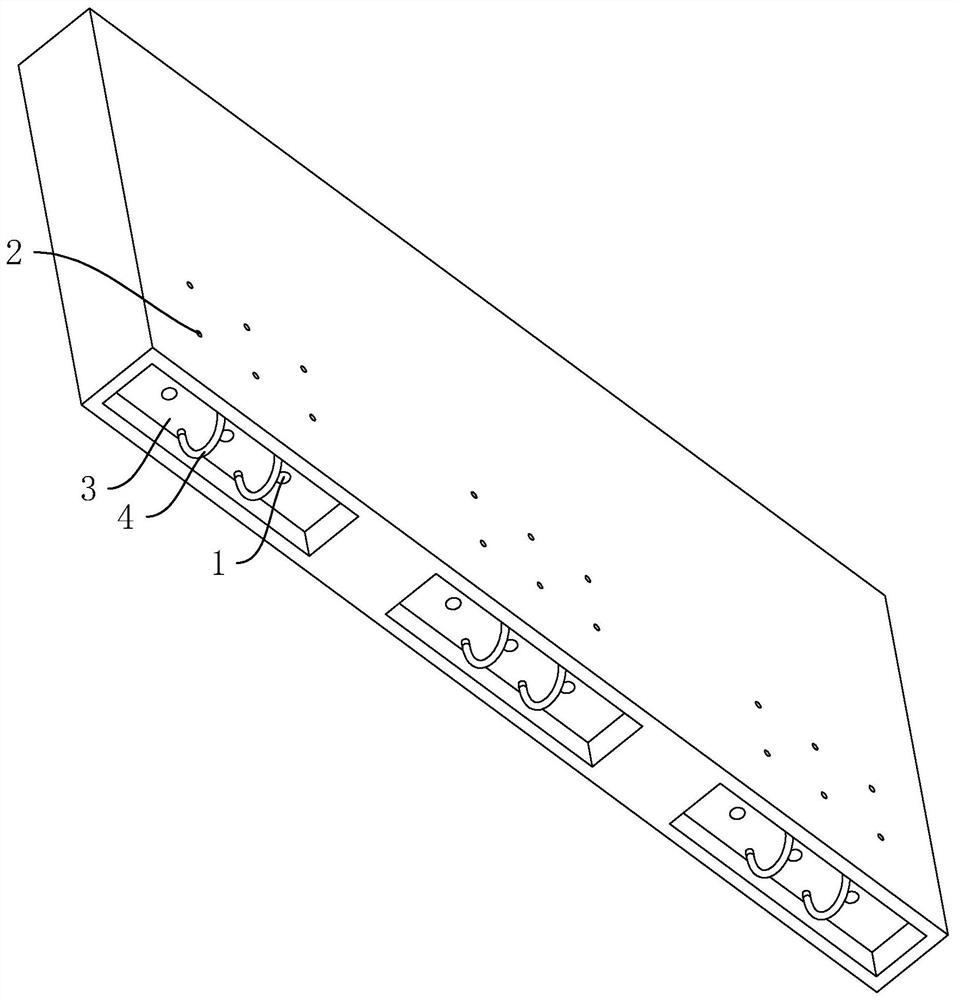

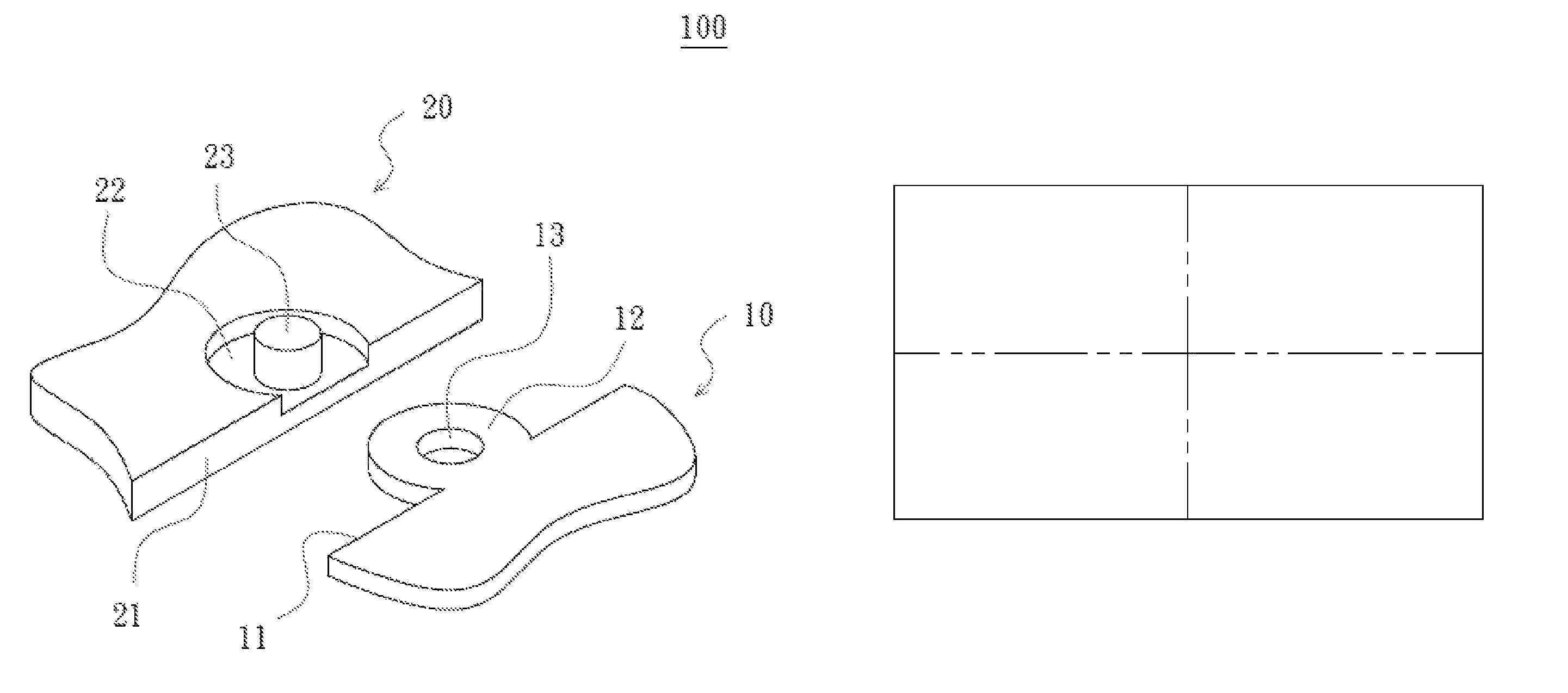

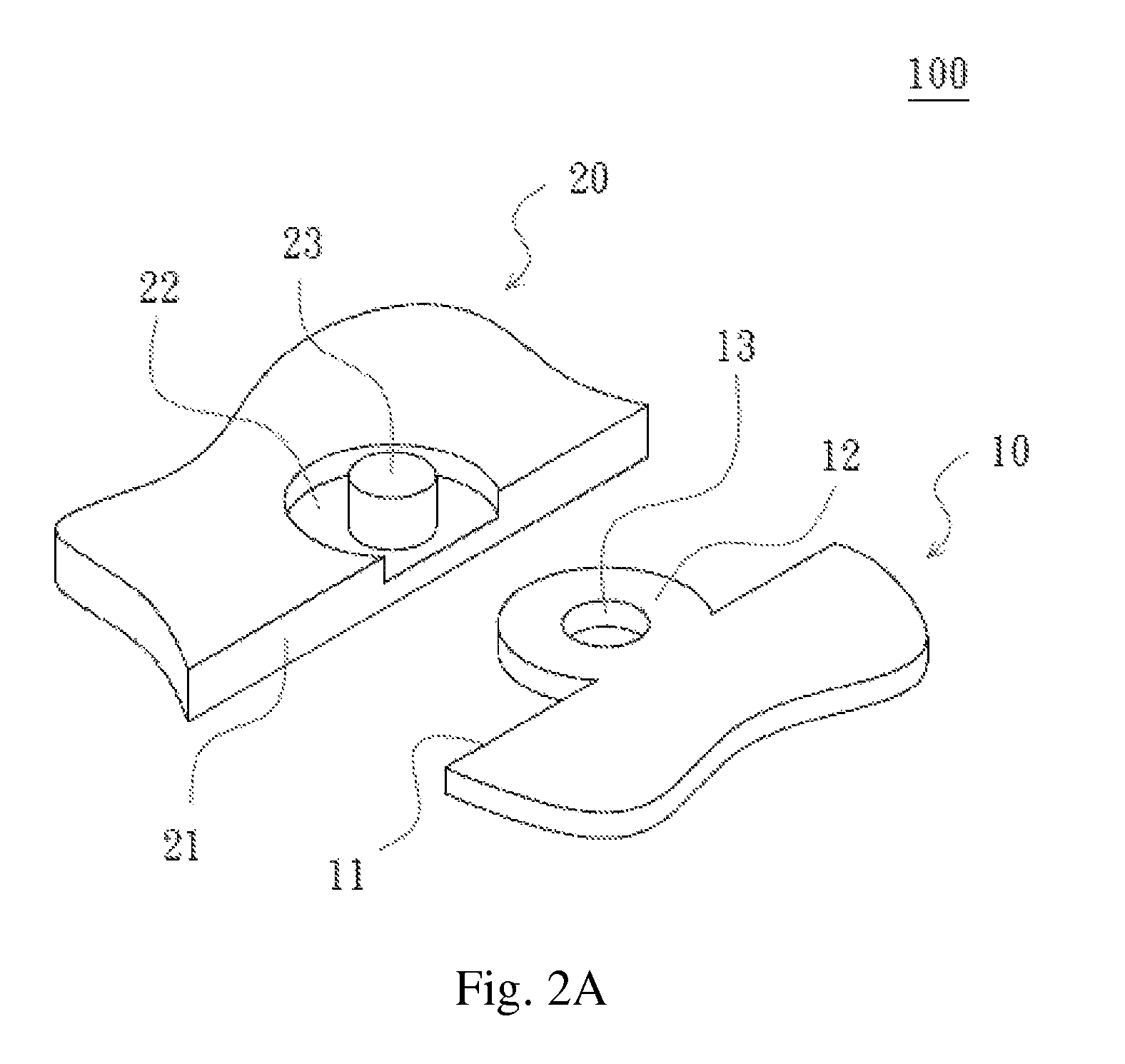

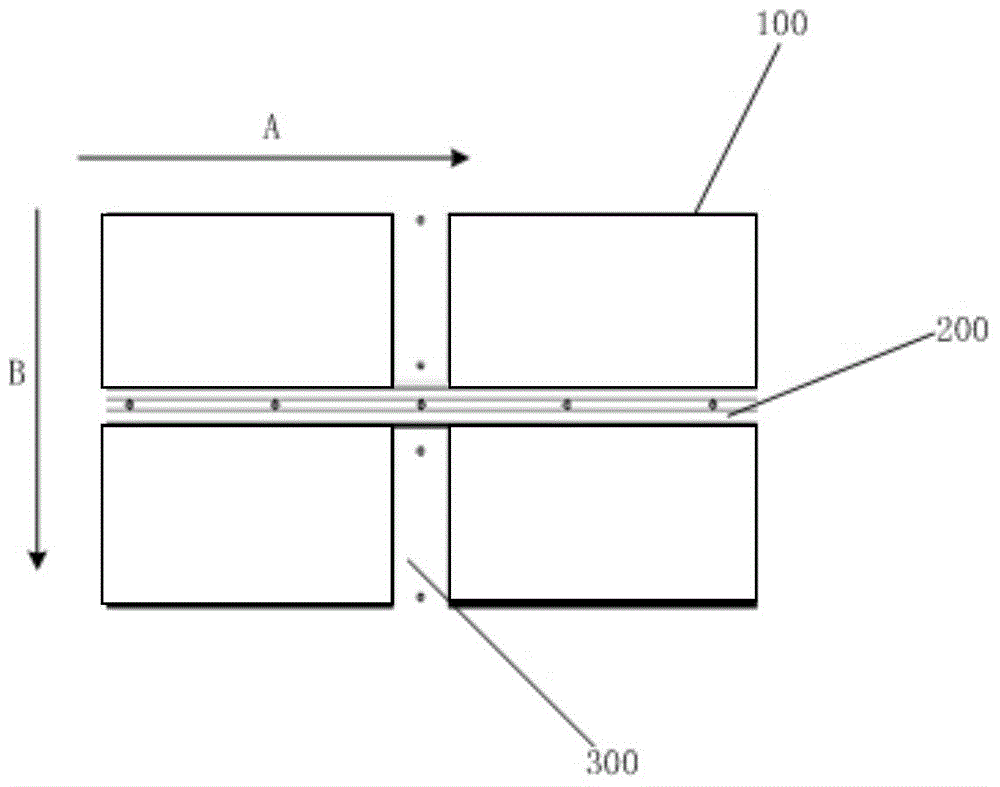

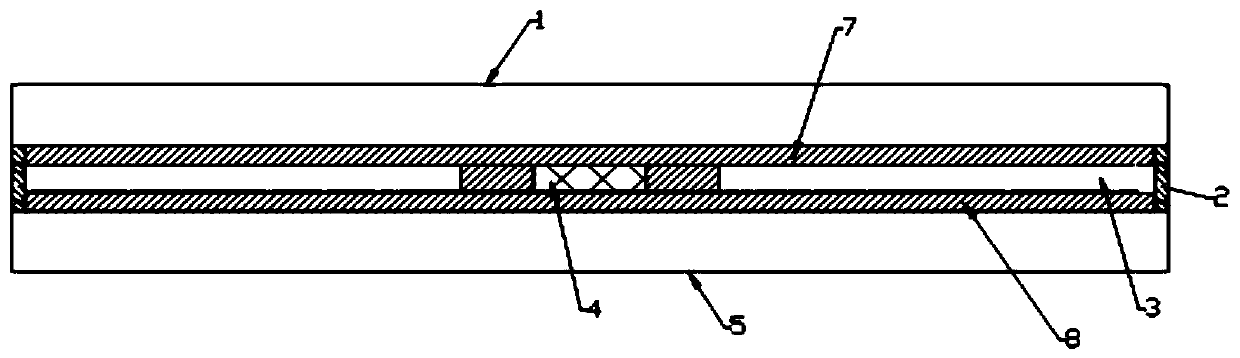

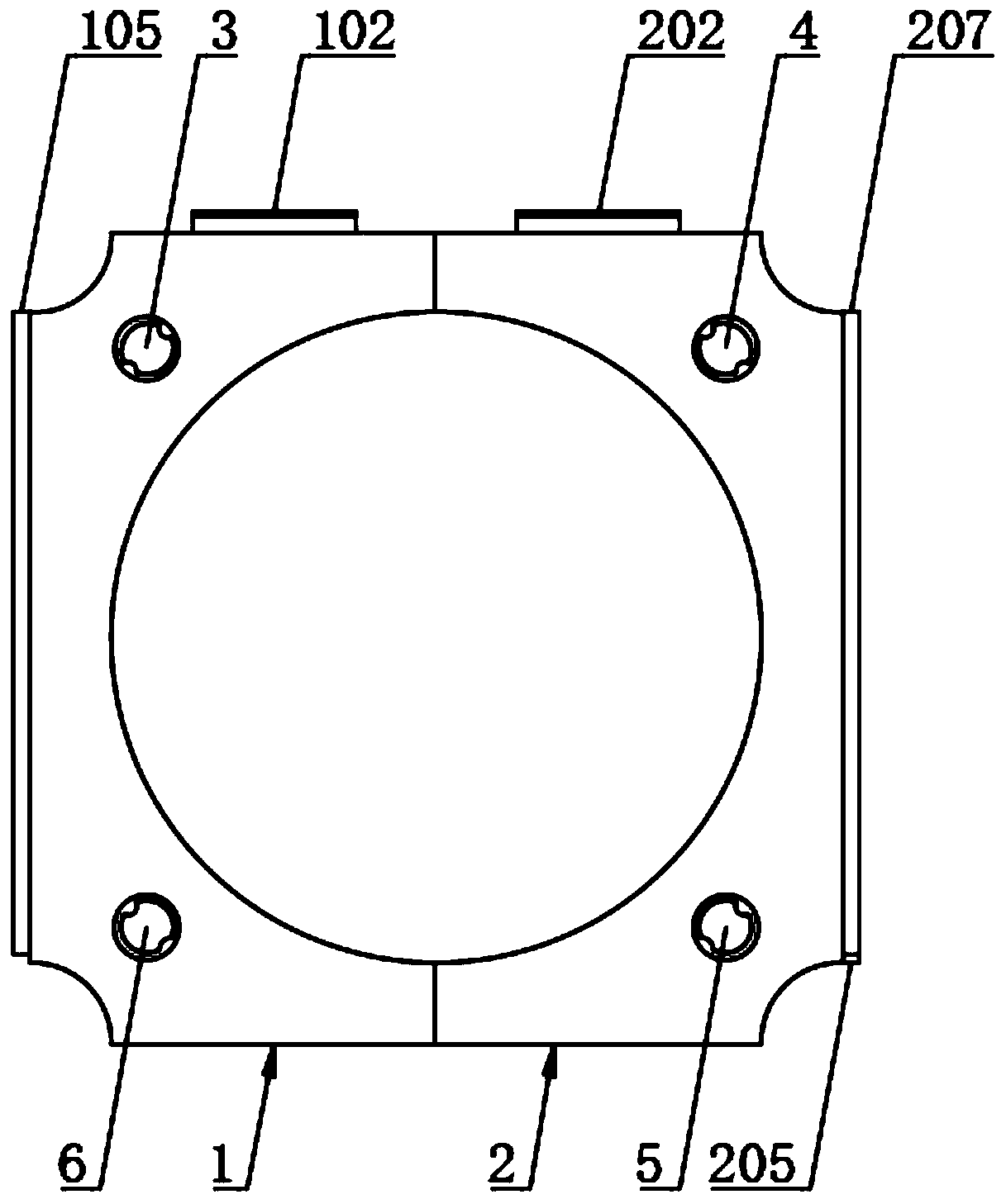

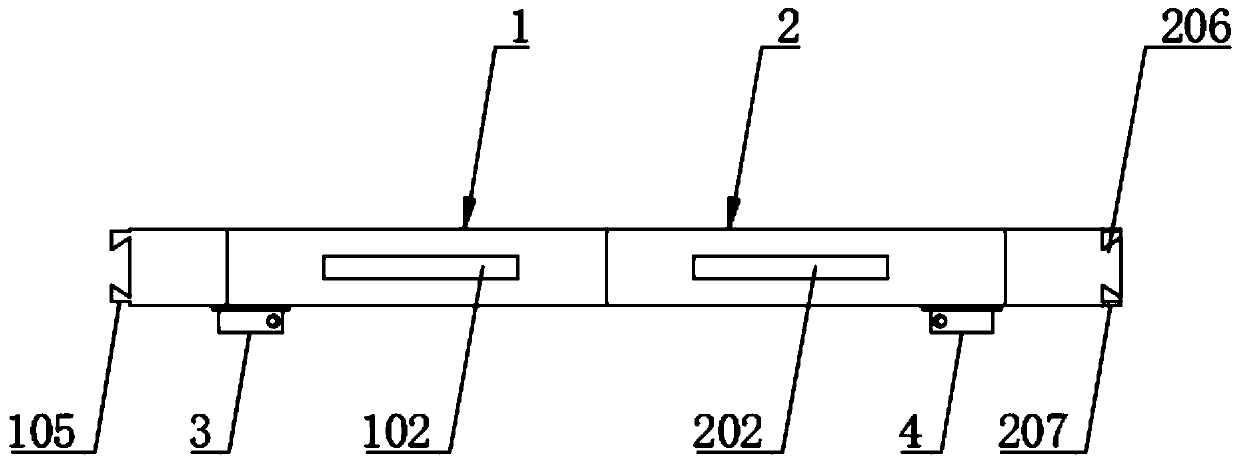

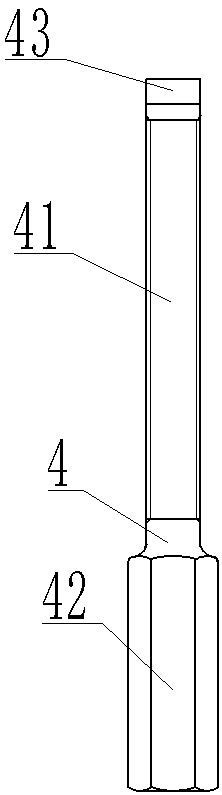

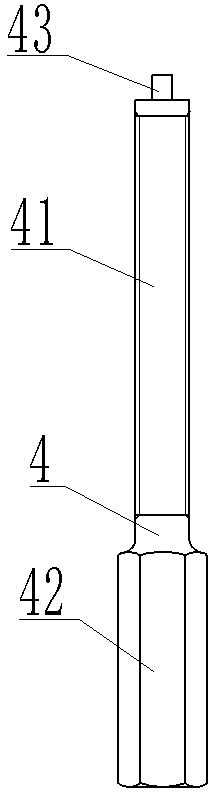

Backplane of liquid crystal module and splicing structure thereof

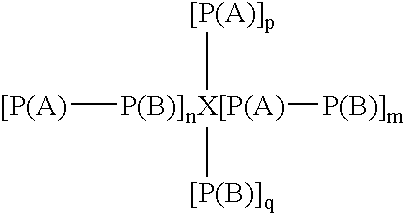

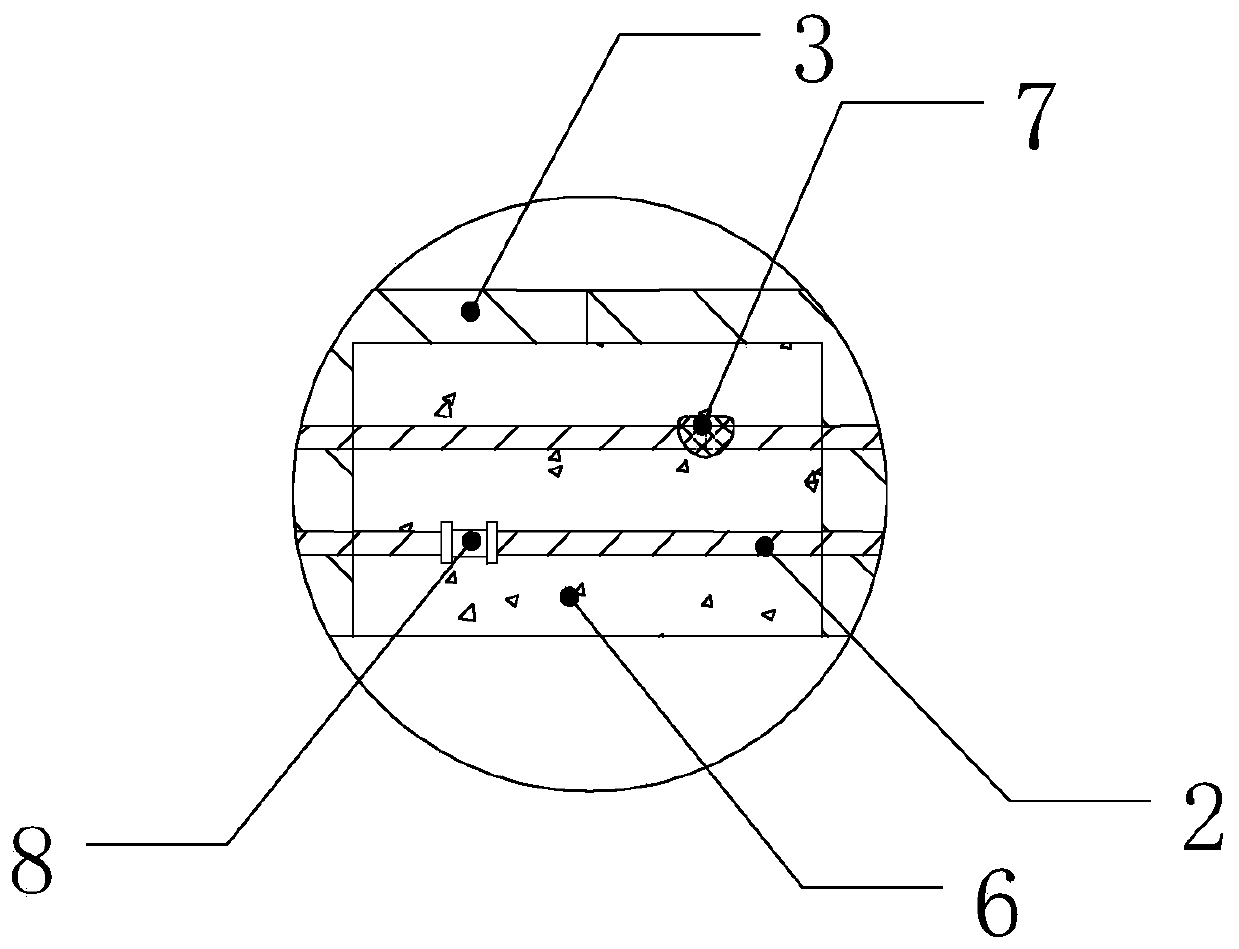

ActiveCN102402029ALow costImprove splicing strengthSheet joiningNon-linear opticsEngineeringUltimate tensile strength

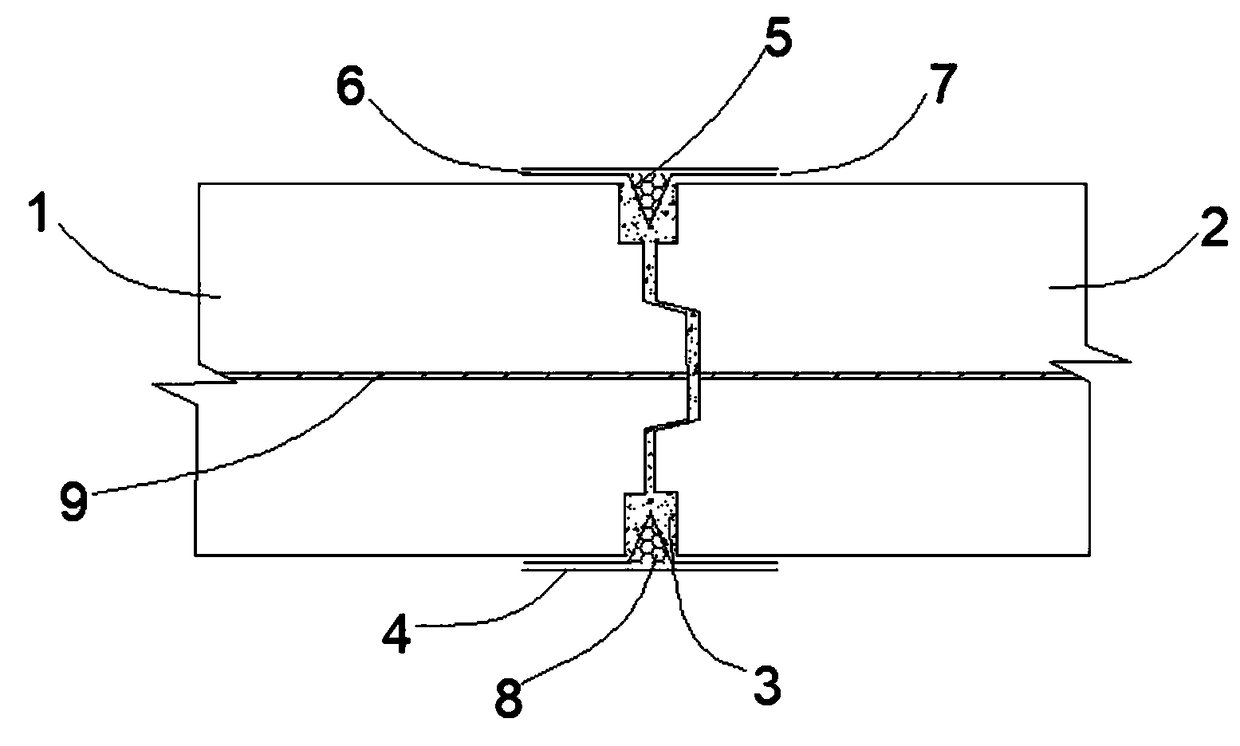

The invention discloses a backplane of liquid crystal module and splicing structure thereof, wherein the liquid crystal module backplane is spliced by at least a first backplane and a second backplane, at least one splicing structure is arranged between the first backplane and the second backplane, the shapes of the two sides of the splicing structures are corresponded and embedded with each other, a fixing hole is set on the protruding part, a fixed column is correspondingly set inside the concave step part, the fixed column pierces the fixed hole for some distance, the end of the fixed column are forced to deform and expand the diameter of the column so as to fix the first backplane and the second backplane. The invention that different materials are made and formed into the backplane of liquid crystal module by the splicing structures is characterized by reducing material cost, and strengthening the splice strength.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

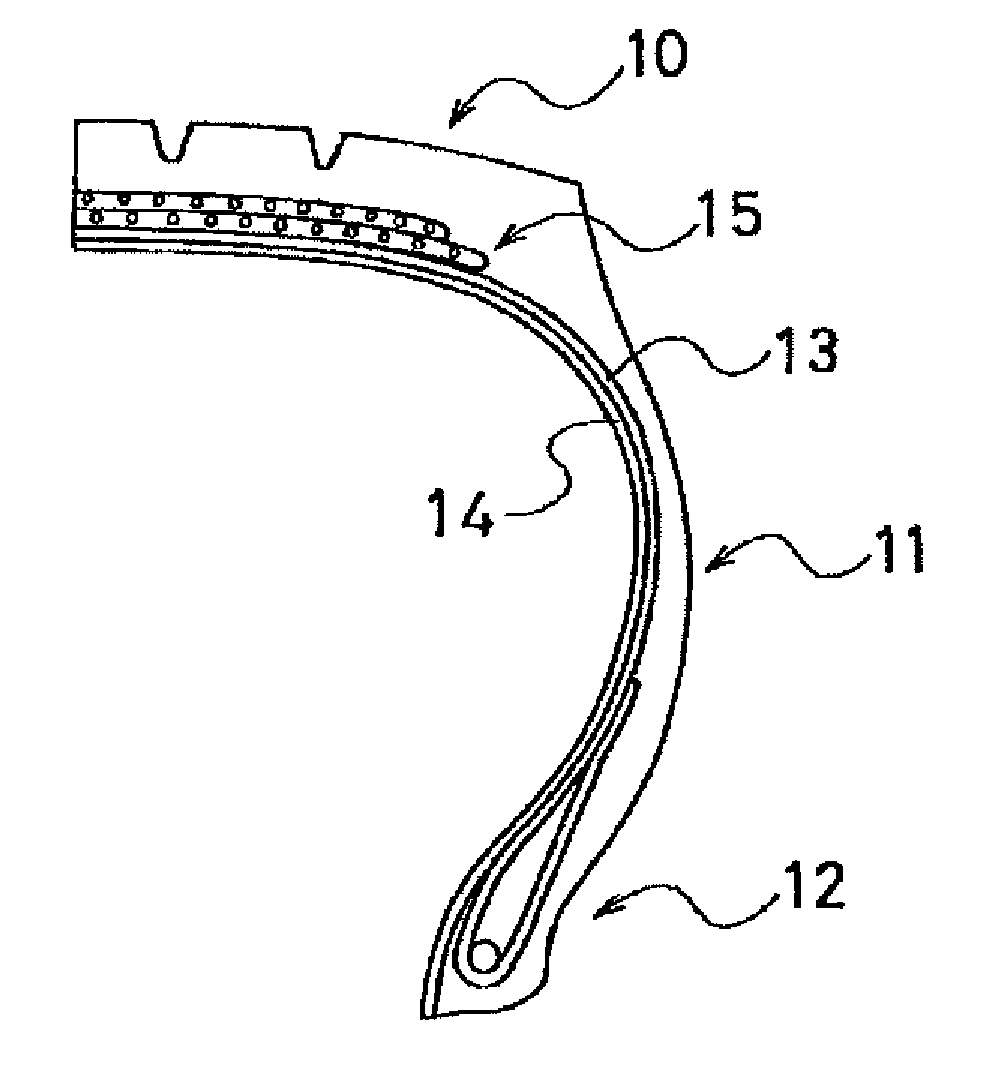

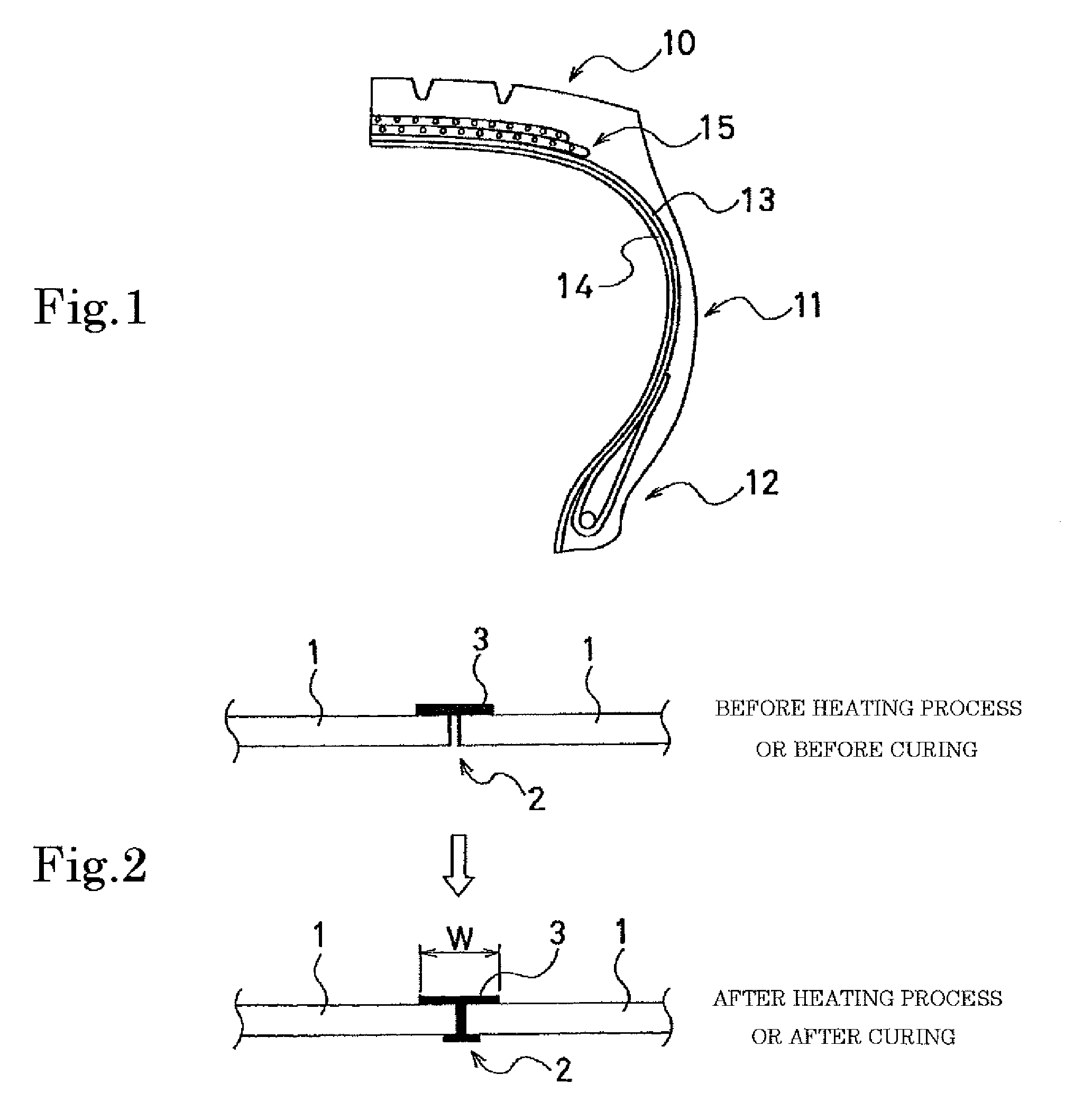

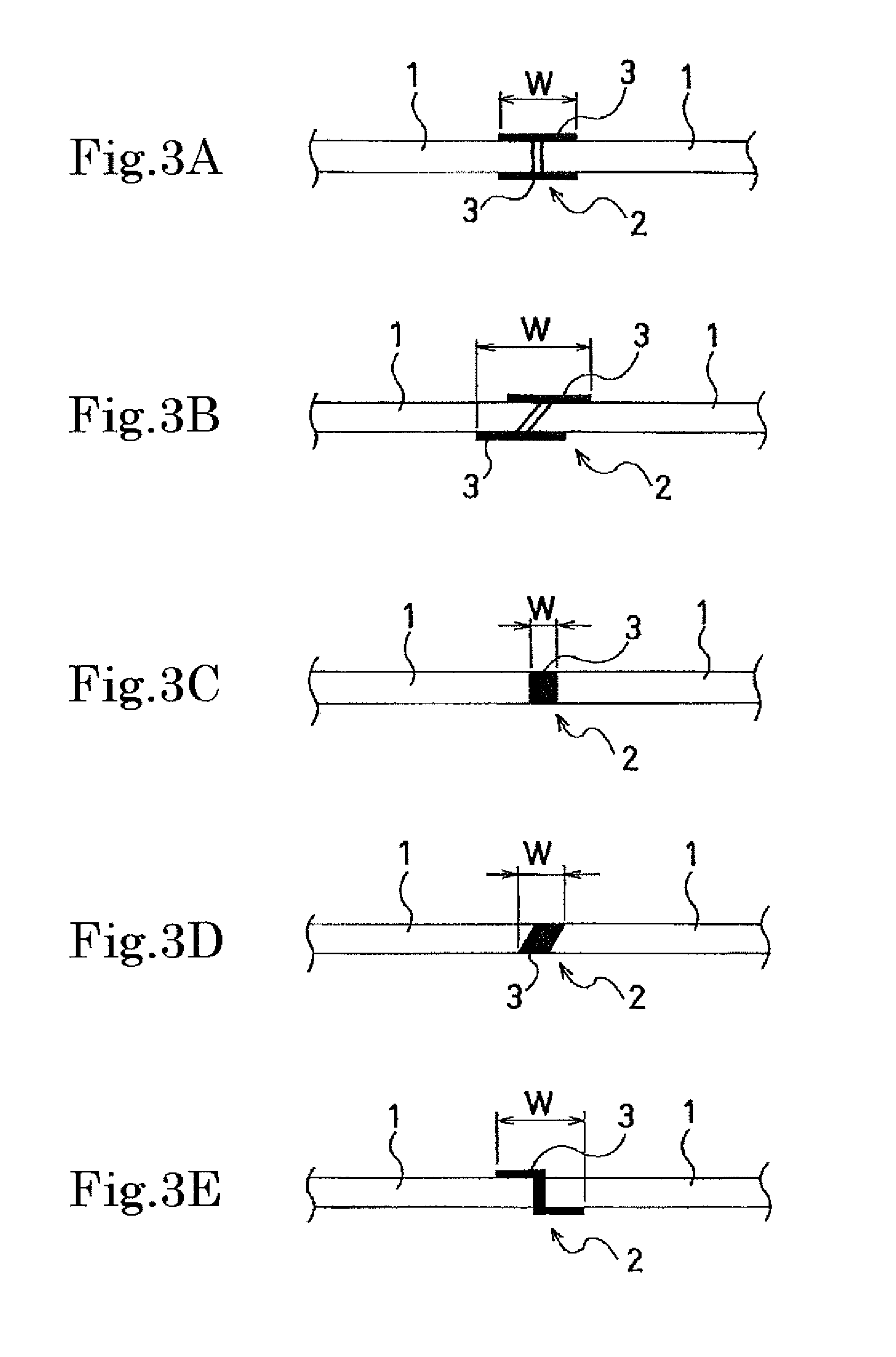

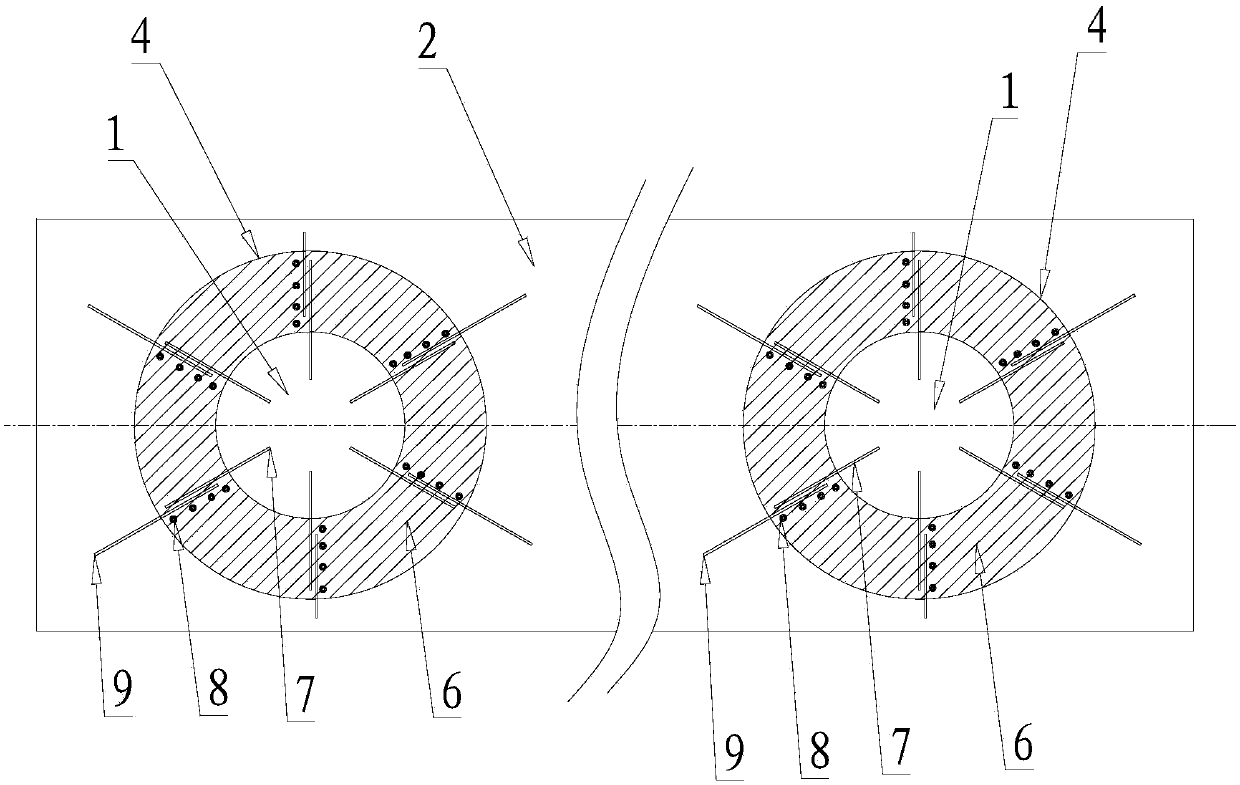

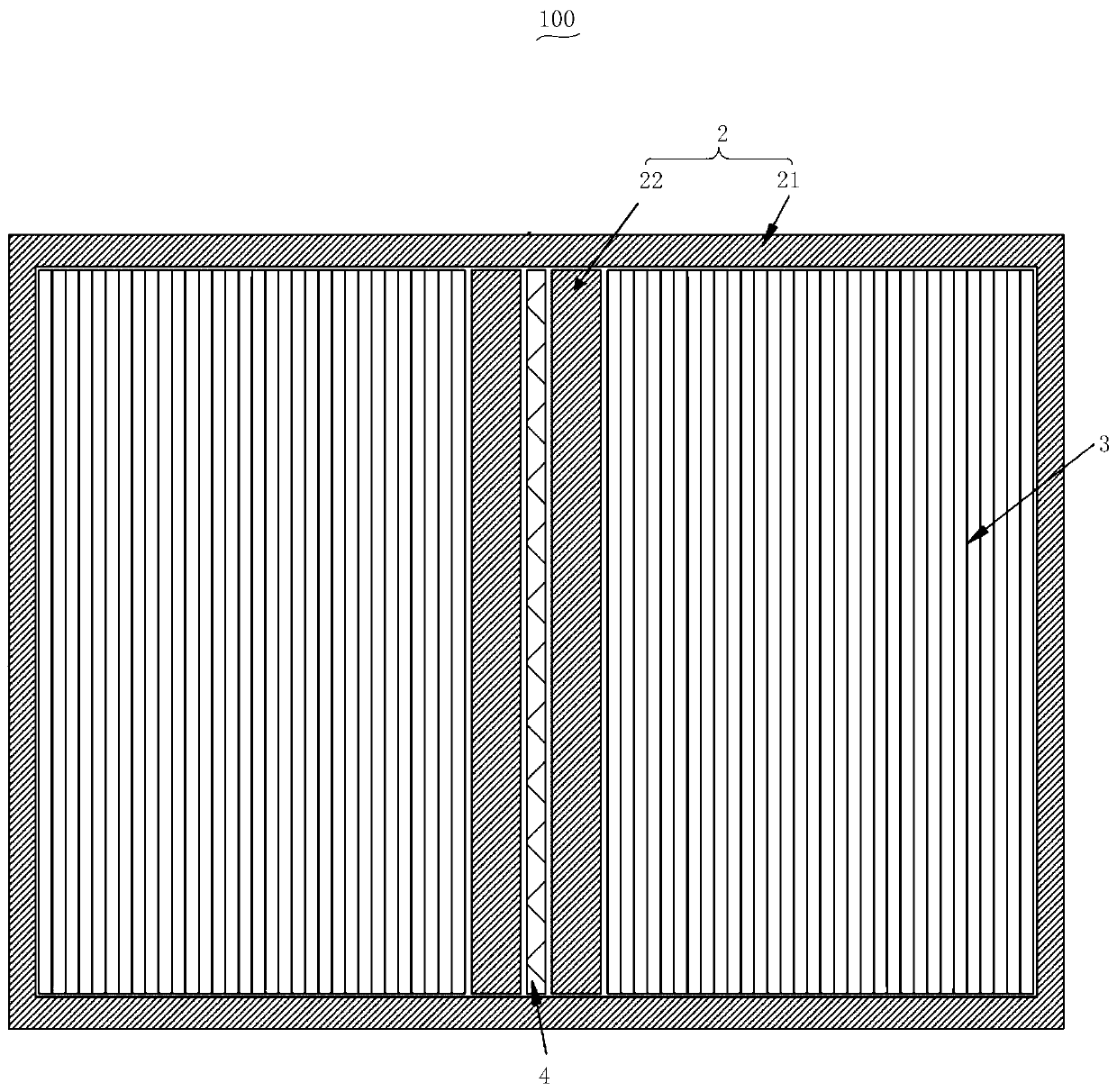

Pneumatic tire and process for producing the same

InactiveUS20110061783A1Enhance bonding strengthImprove durabilityWithout separate inflatable insertsSpecial tyresEngineeringThermoplastic elastomer

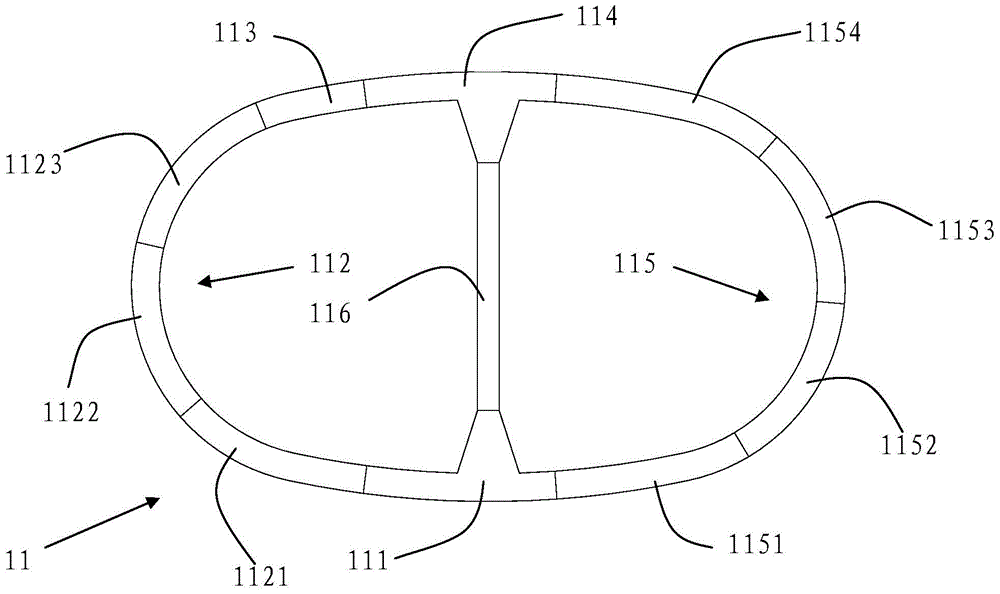

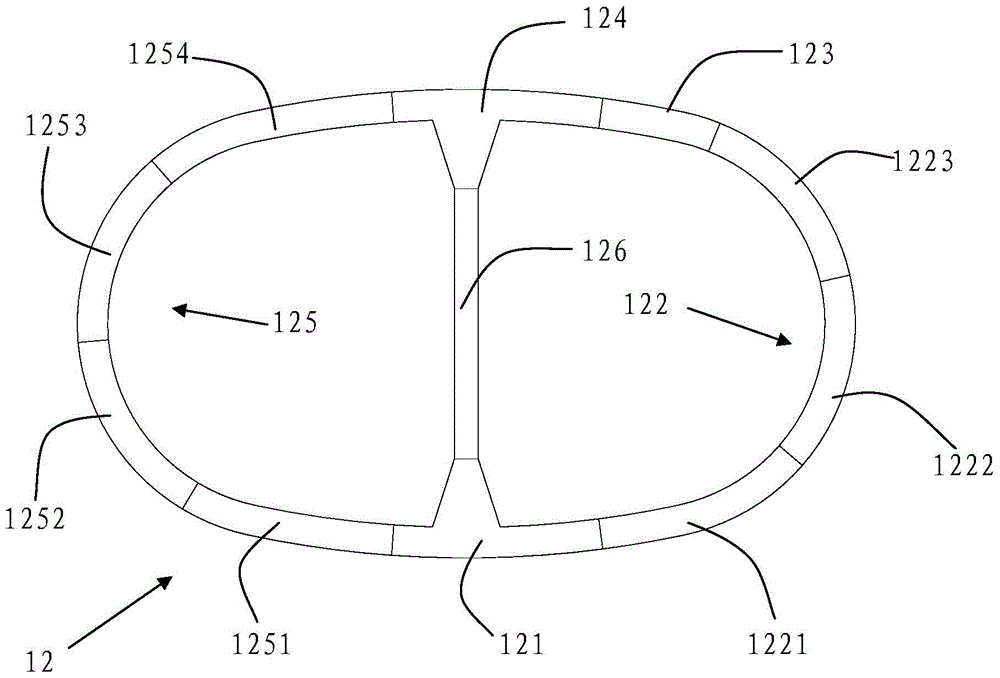

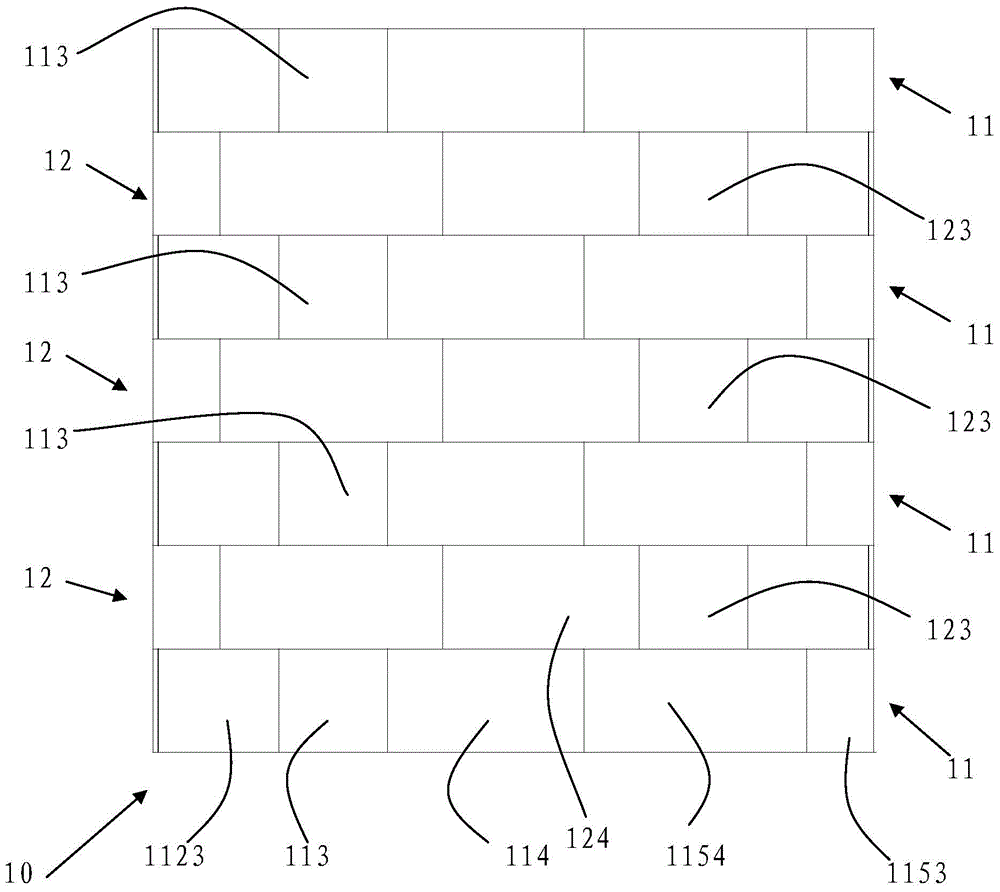

Provided is a pneumatic tire improved in the durability at a splice part (2) of a tire-constituting member (1) and in the uniformity of the tire, and a process for producing the same. The pneumatic tire includes a tire-constituting member (1) having a splice part (2) on which a thin film (3) made of a thermoplastic resin or a thermoplastic elastomer composition is coated and fusion-bonded. In addition, the process for producing the pneumatic tire includes a step of heating the thin films (3) each arranged at the splice part (2) of an inner liner layer (14) or the splice part (2) of a carcass layer (13) so as to thermally fusing the thermoplastic resin or the thermoplastic elastomer composition constituting the thin films (3).

Owner:YOKOHAMA RUBBER CO LTD

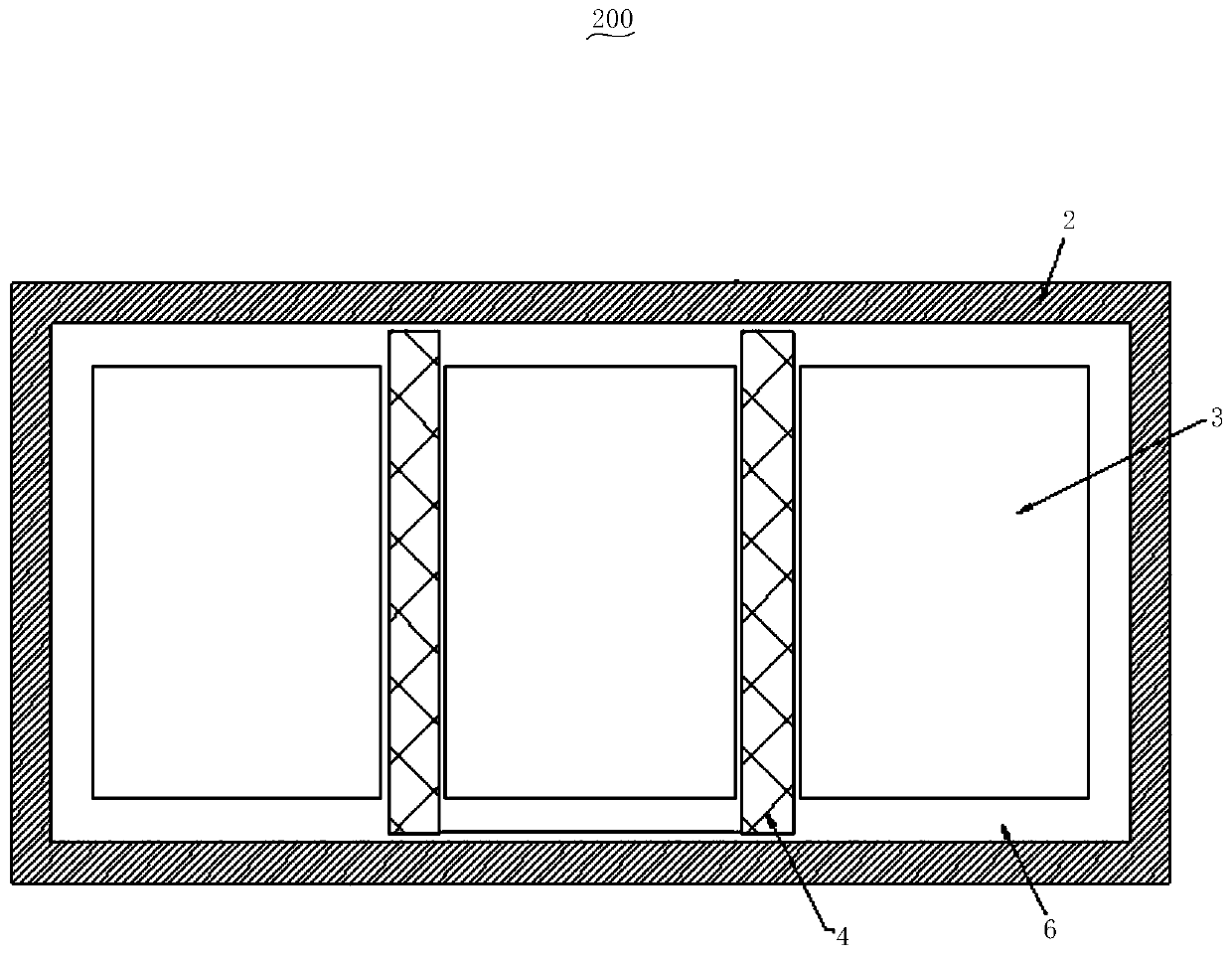

Connecting piece, back board and liquid crystal display device

InactiveCN102506395AImprove splicing strengthImprove versatilityLighting support devicesNon-linear opticsLiquid-crystal displayHigh intensity

The invention discloses a connecting piece, a back board and a liquid crystal display device. The connecting piece for a frame-type back board comprises at least two connecting parts which are respectively fixed with the support end parts of the frame-type backboard. Since the connecting piece is used for splicing supports, the connecting piece can be a high-strength structure which is integrally formed and the splicing strength of the supports is improved; since the connecting piece has a plurality of connecting parts and each connecting part is separately connected with one support, an interface can be standardized; and since the supports can be made into standard sections and cut according to different dimensions, the universality of the supports is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

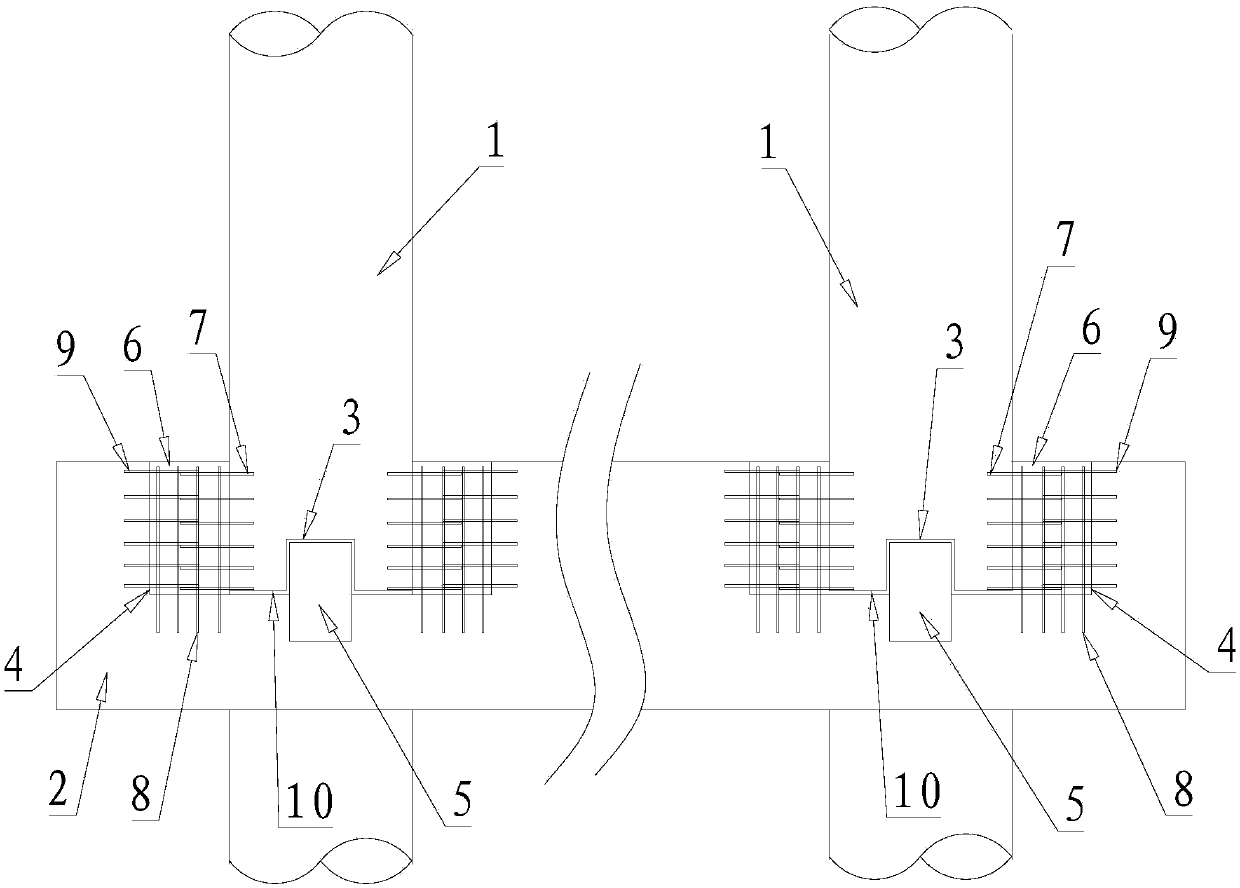

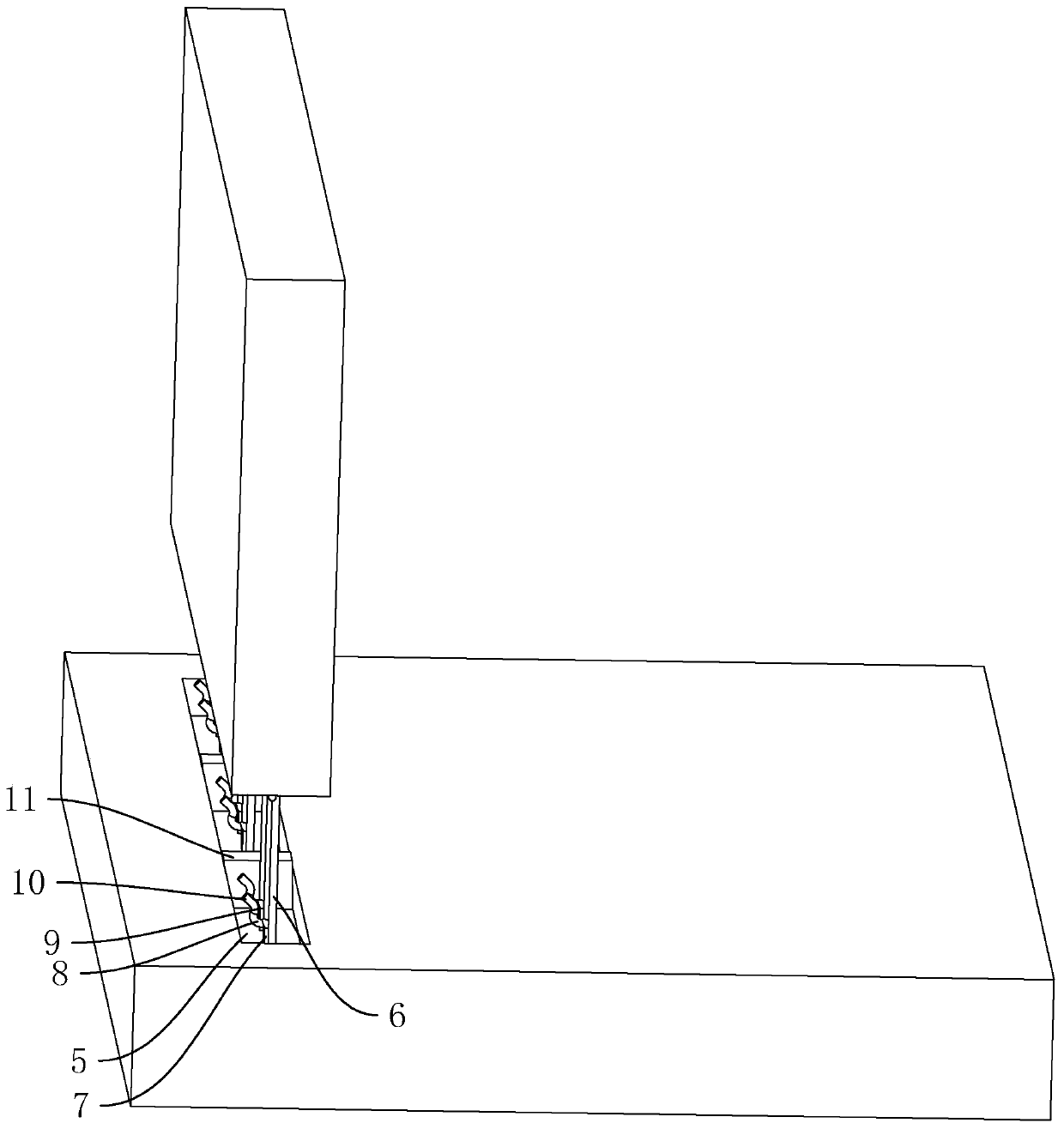

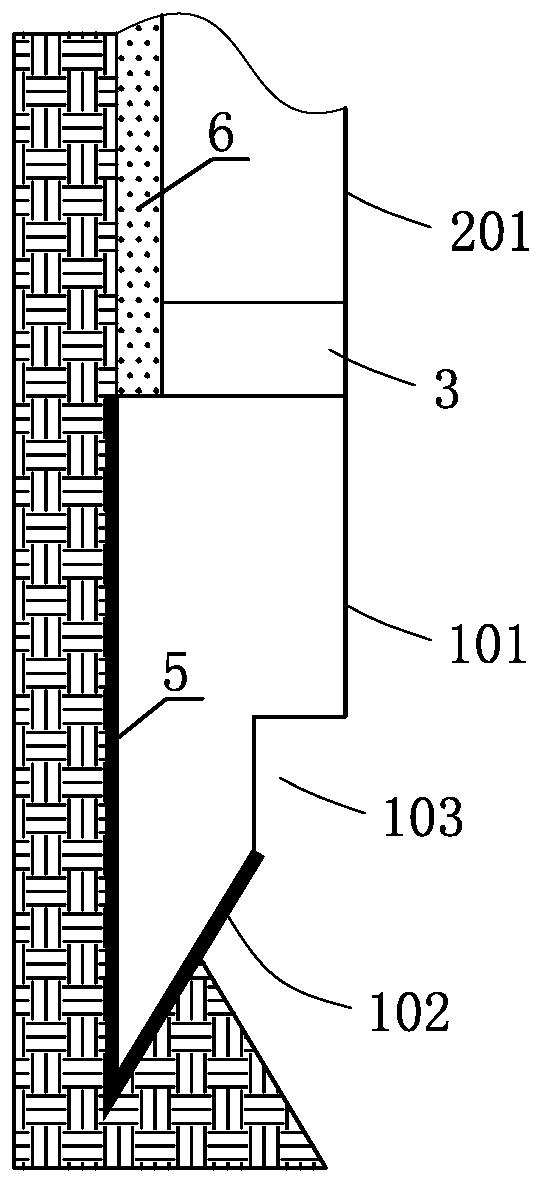

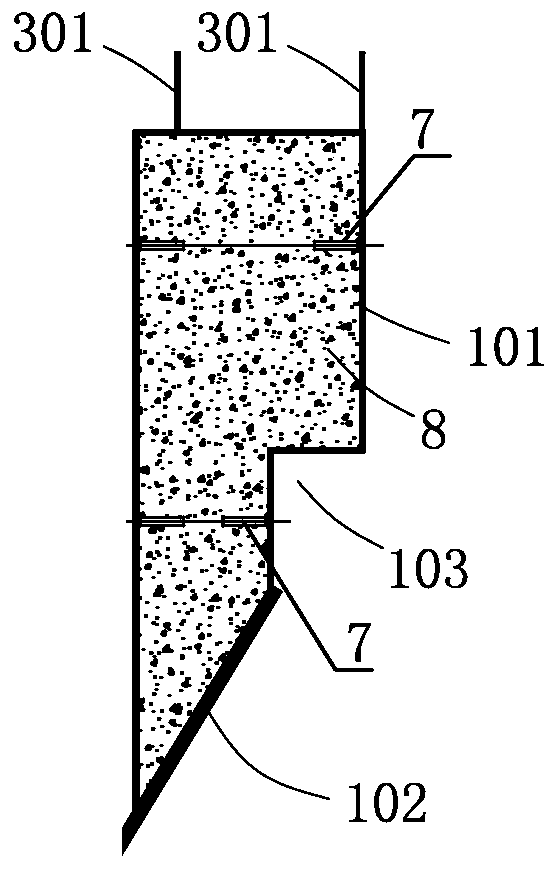

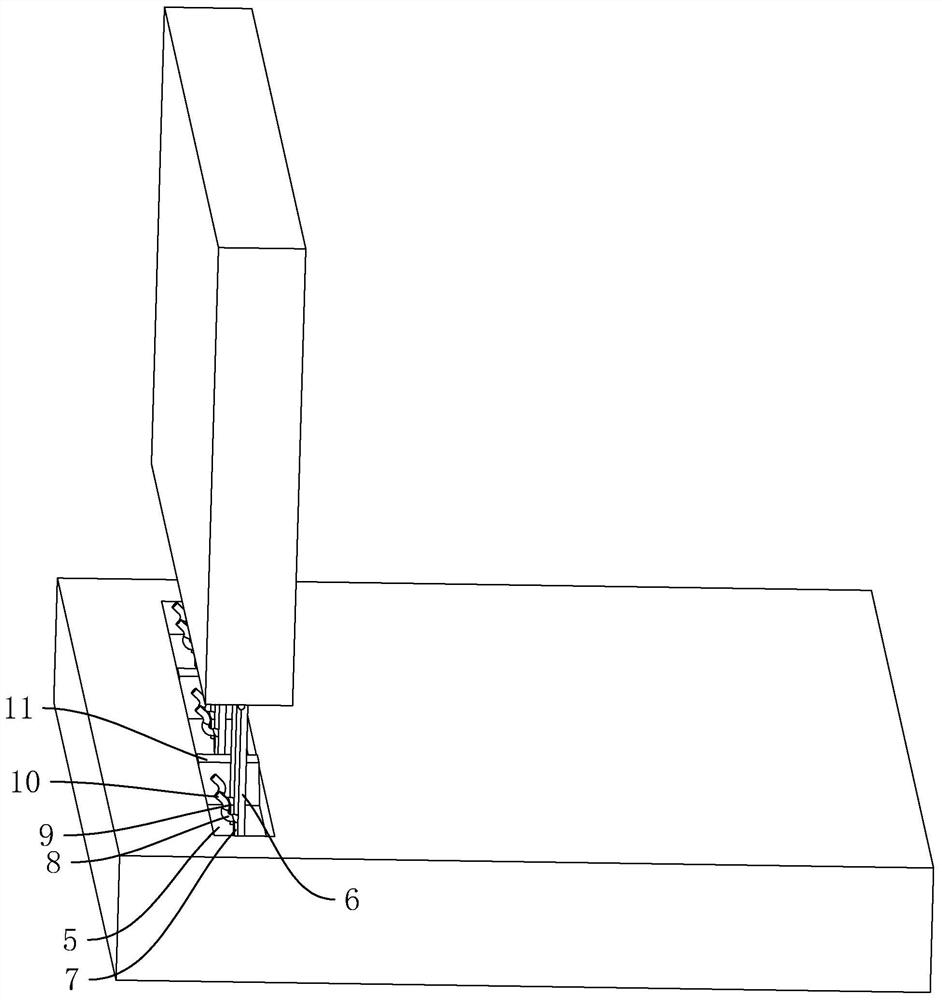

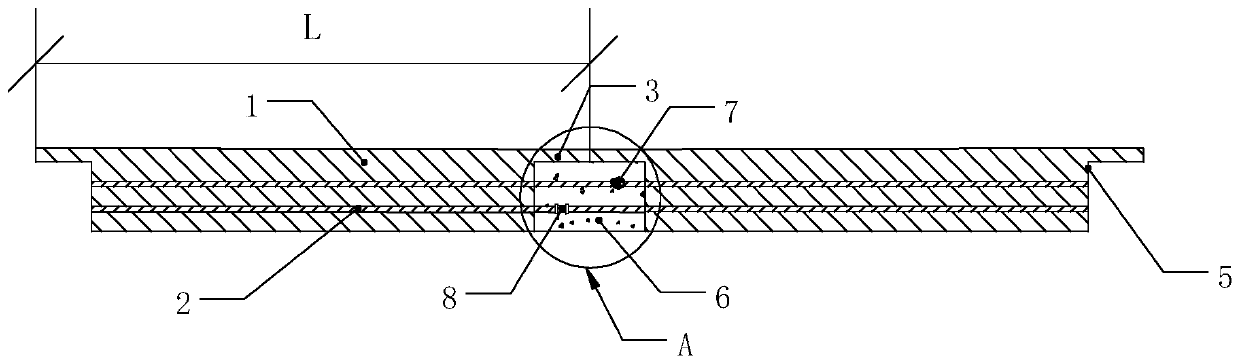

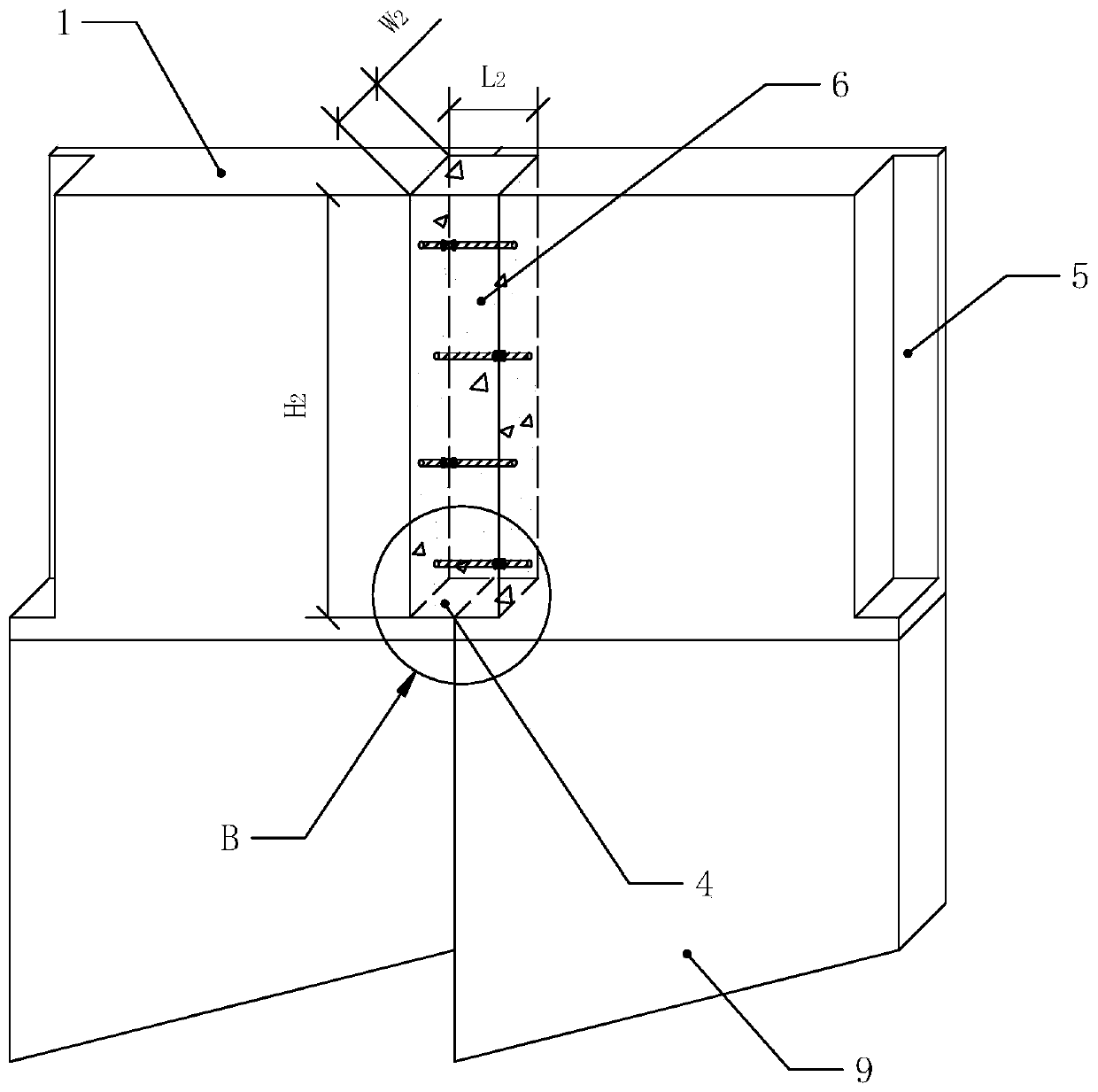

Splicing structure and splicing method of prefabricated bridge piers and prefabricated bearing platform

PendingCN108049305APrecise positioningShorten the construction periodBridge structural detailsFoundation engineeringShear capacityUltimate tensile strength

The invention provides a splicing structure and a splicing method of prefabricated bridge piers and a prefabricated bearing platform. By utilizing the joggling of hollow steel tubes in first concave grooves in the bottoms of the prefabricated bridge piers and concrete filled steel tube tenons enclosed by the inner walls of annular grooves in the top of the prefabricated bearing platform, on one hand, favorable positioning effects are achieved for the mounting, on the bearing platform, of the prefabricated bridge piers, and on the other hand, the shear capacity and the flexural capacity at splicing positions are improved; post-poured concrete is poured into the annular grooves to enwrap the splicing positions of the prefabricated bridge piers and the prefabricated bearing platform; the prefabricated bridge piers and the prefabricated bearing platform are connected into a whole; an overall stress structure is ameliorated; the splicing strength of the prefabricated bride piers and the prefabricated bearing platform is greatly improved, and is not less than the strength of a cast-in-place bridge pier. By adopting a way of splicing the prefabricated bride piers and the prefabricated bearing platform, the field pouring workload of concrete is effectively reduced; the field operation is facilitated; a road is not occupied; influences on an urban traffic environment during the operation are effectively relieved, and meanwhile, a construction period of a bridge is shortened.

Owner:FUJIAN UNIV OF TECH

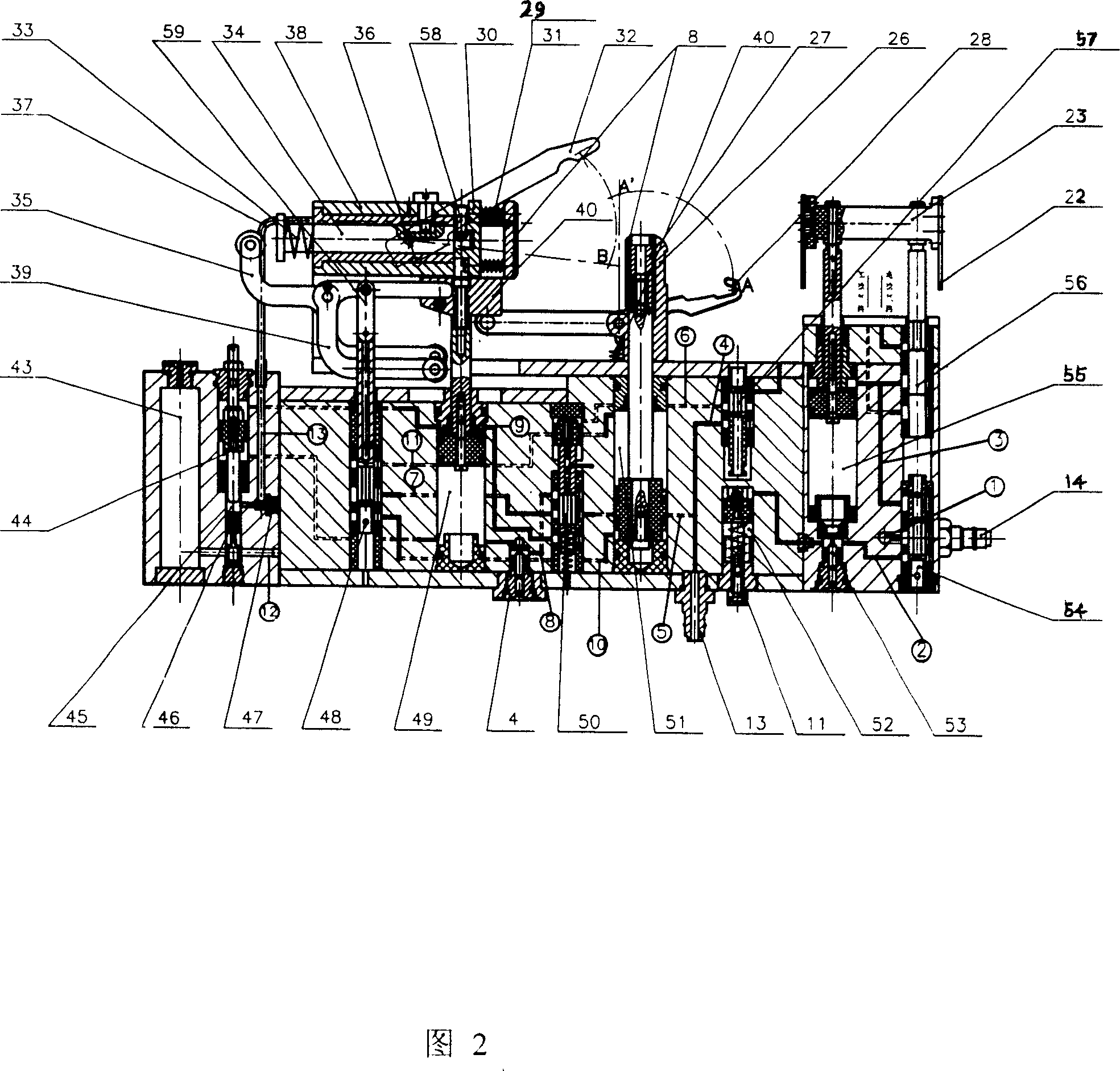

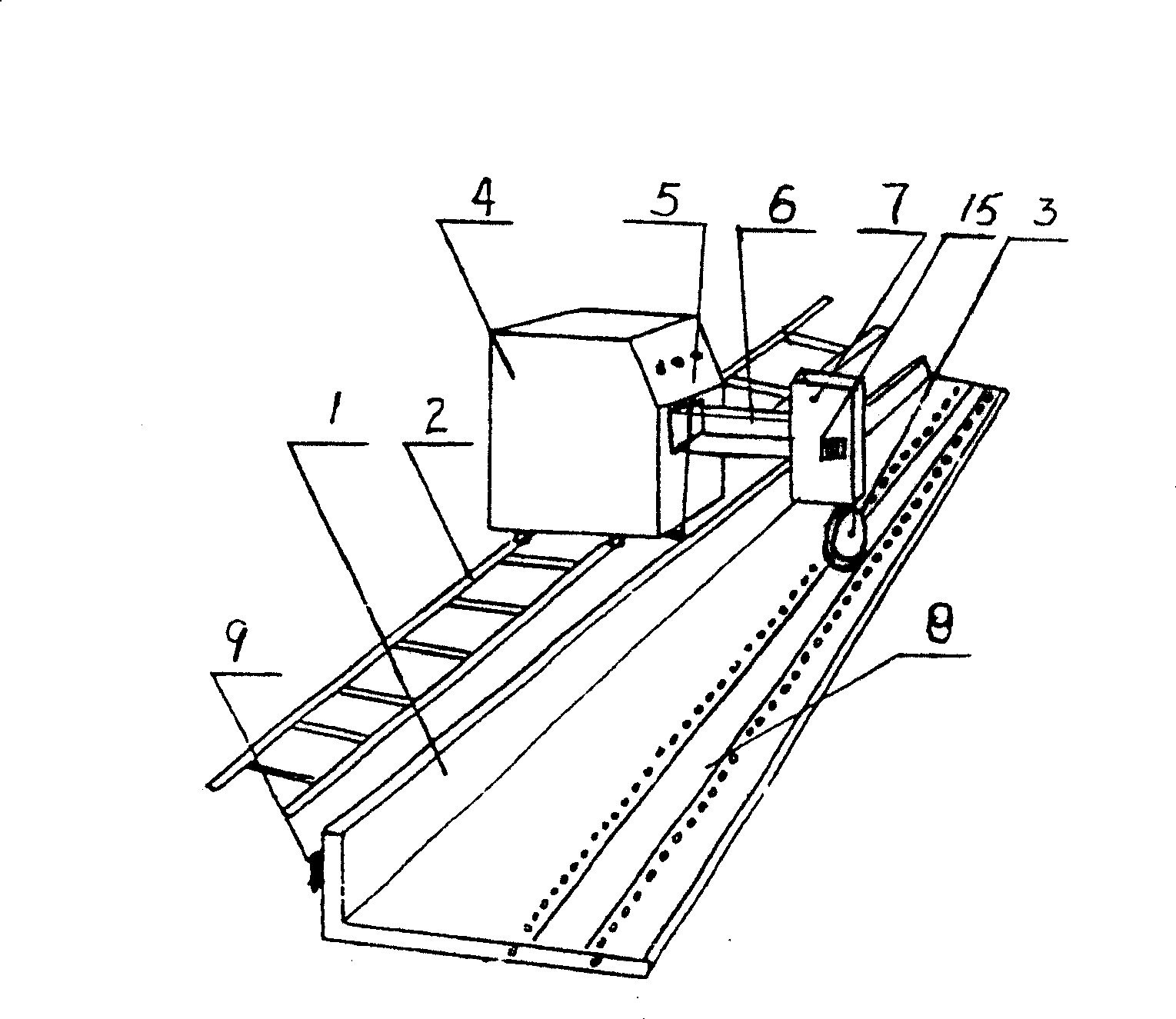

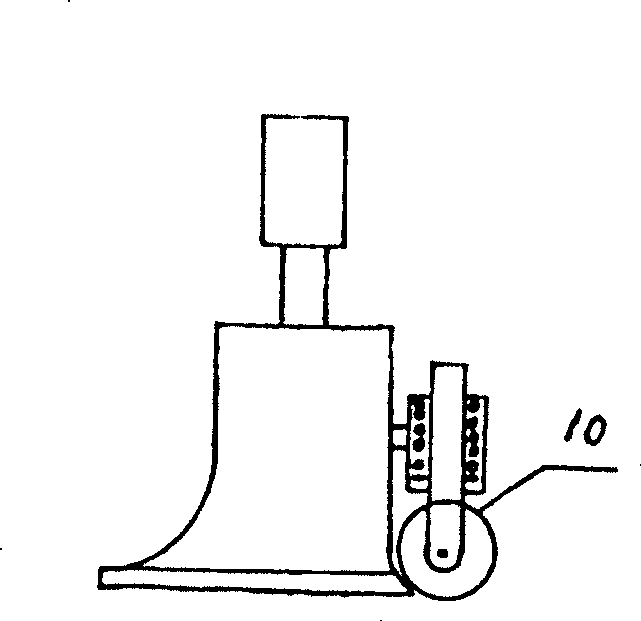

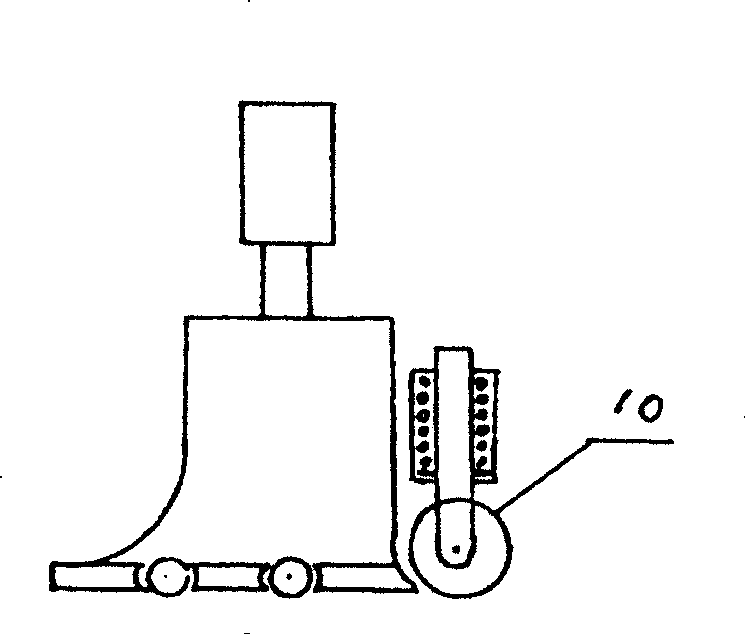

Process to yarn making non-knot twist contecting and thread rolling device using said method

The present invention relates to new yarn twisting method, and is especially knotless joining method suitable of coarse yarn, open-end yarn and strand in spooler and double twister. The present invention also relates to one kind of wet air yarn twister operating on the said method. The wet air yarn twister has increased yarn twisting unit and water supplying unit. The present invention has raised yarn twisting strength.

Owner:上海梅花刺轴有限公司

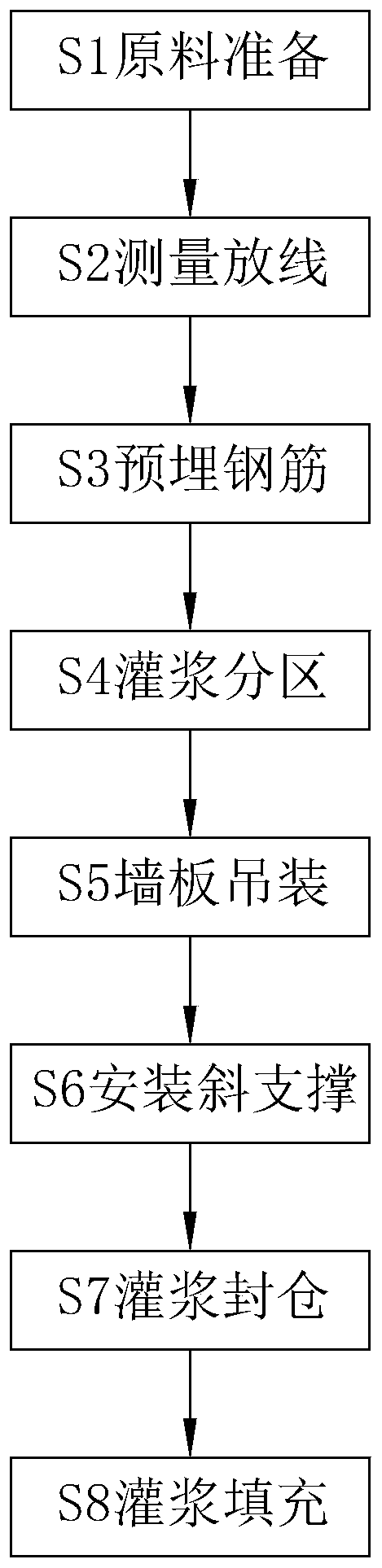

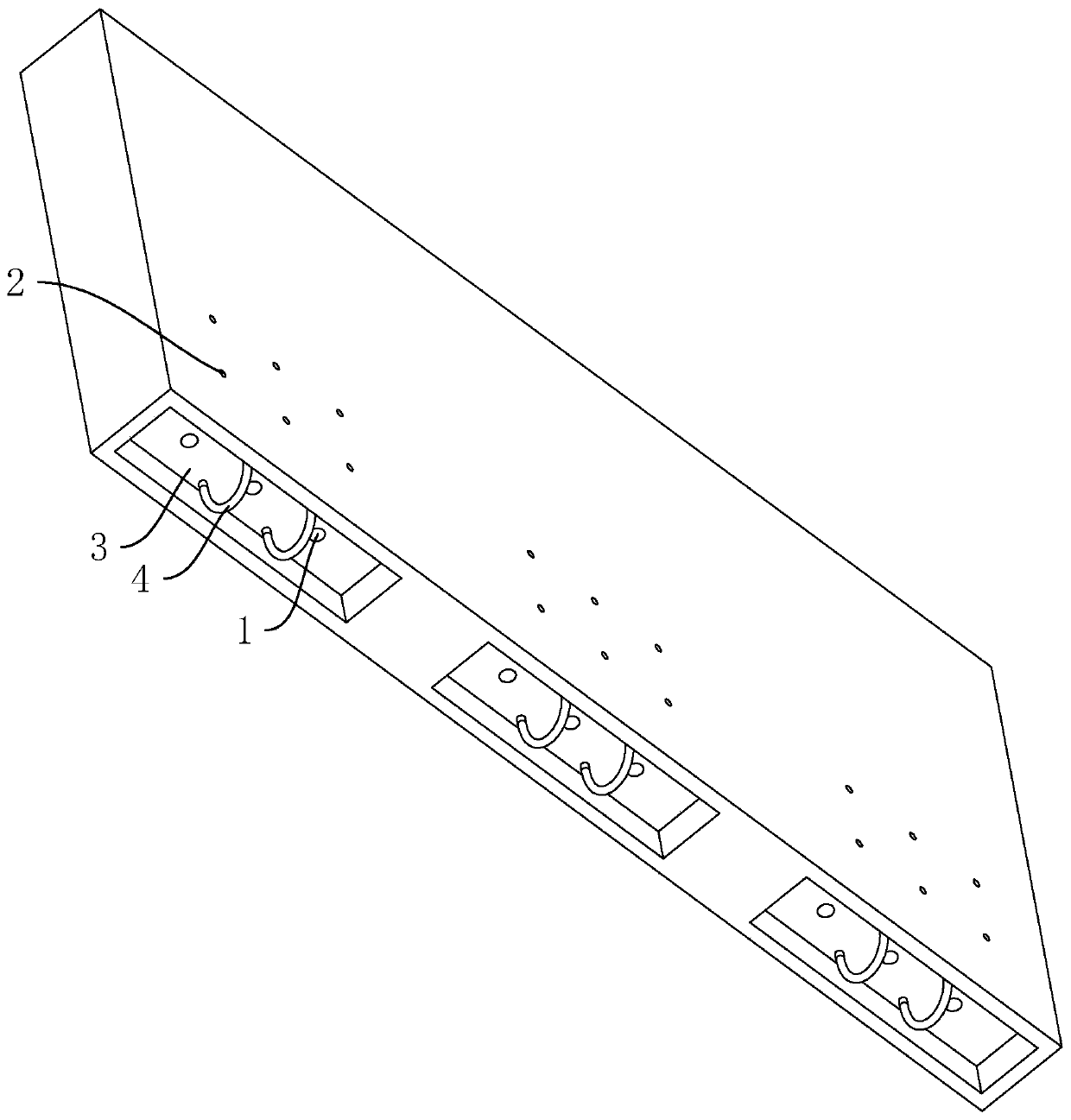

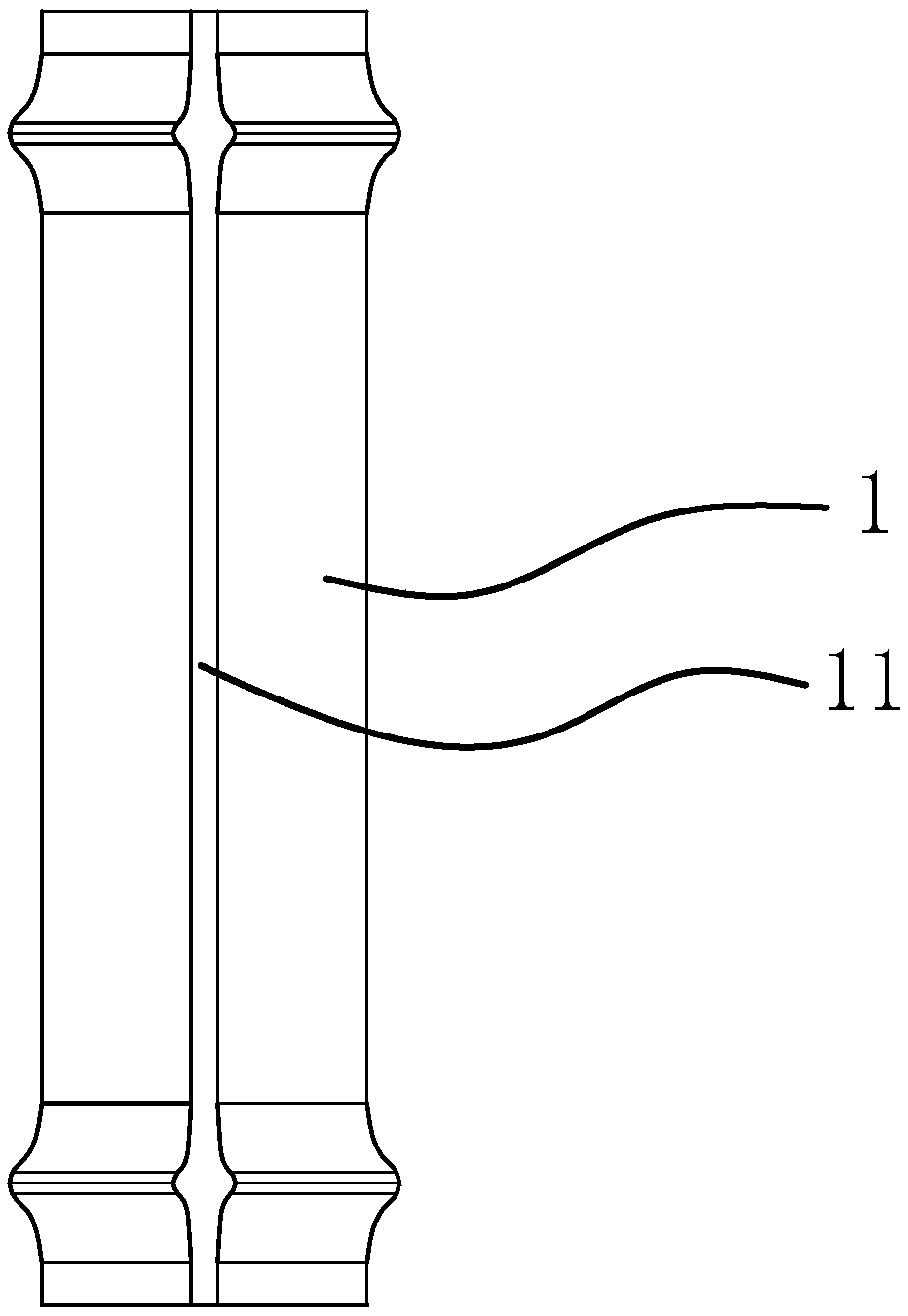

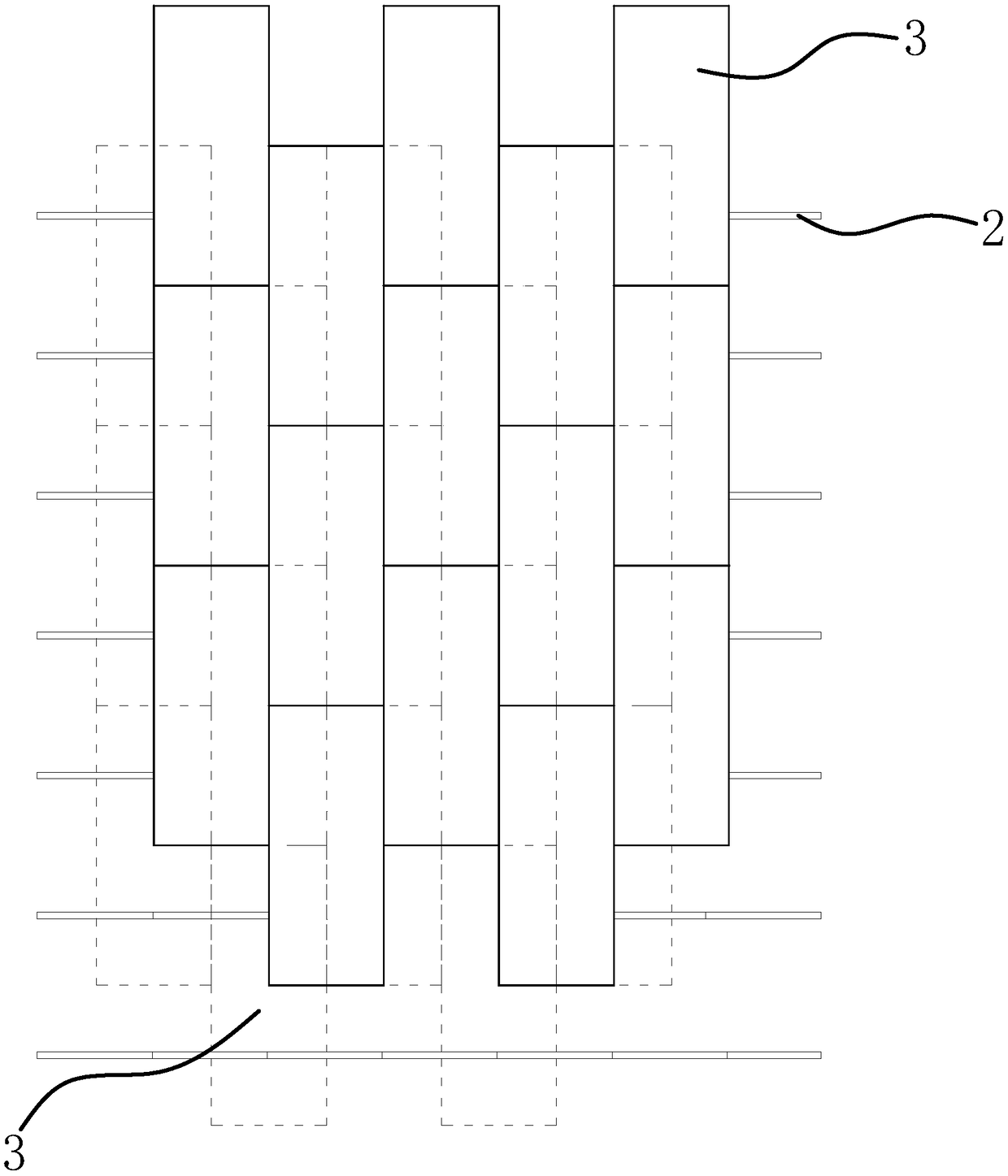

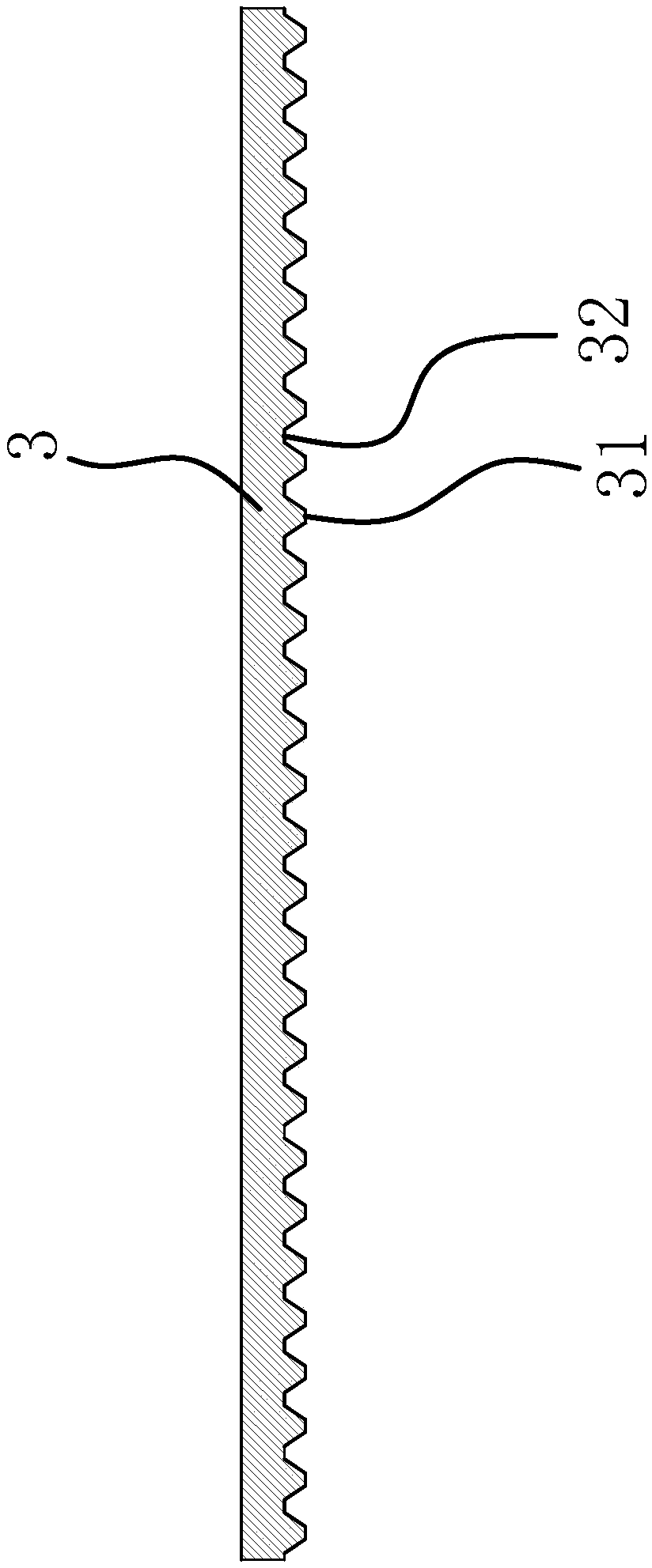

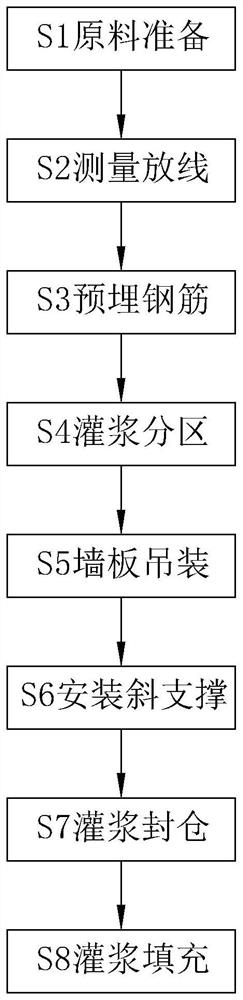

Construction method of prefabricated wallboard

ActiveCN111206698AReduce usageEasy to installWallsBuilding material handlingArchitectural engineeringCement grout

The invention discloses a construction method of a prefabricated wallboard and relates to the field of assembly type buildings. The construction method comprises the following steps of S1, preparing raw materials, wherein the lower end face of the adopted prefabricated wallboard is provided with a plurality of groove openings, one end face of the prefabricated wallboard is provided with a plurality of mortar holes communicating with the groove openings, and each groove opening communicates with two mortar holes in the vertical direction; S2, conducting measuring and setting out; S3, pre-burying reinforcing steel bars; S4, conducting grouting partitioning; S5, hoisting the wallboard, wherein the groove openings on the lower end face of the prefabricated wallboard are aligned with the embedded straight reinforcing steel bars and then the straight reinforcing steel bars are inserted into the groove openings; S6, installing diagonal braces; S7, conducting grouting sealing; and S8, conducting grouting filling, wherein cement mortar is injected through the mortar holes, the mortar holes are plugged through plugs, and after being injected, the mortar is solidified to fix a base face and the wallboard. According to the construction method, the groove openings, the mortar holes and the embedded reinforcing steel bars are arranged, the cement mortar is injected into the groove openings through the mortar holes, after the cement mortar is solidified, the cement mortar achieves connection between the base face and the prefabricated wallboard, so that the number of used reinforcing pieces is reduced, and the overall installation is firmer.

Owner:HAIDA CONSTR GRP

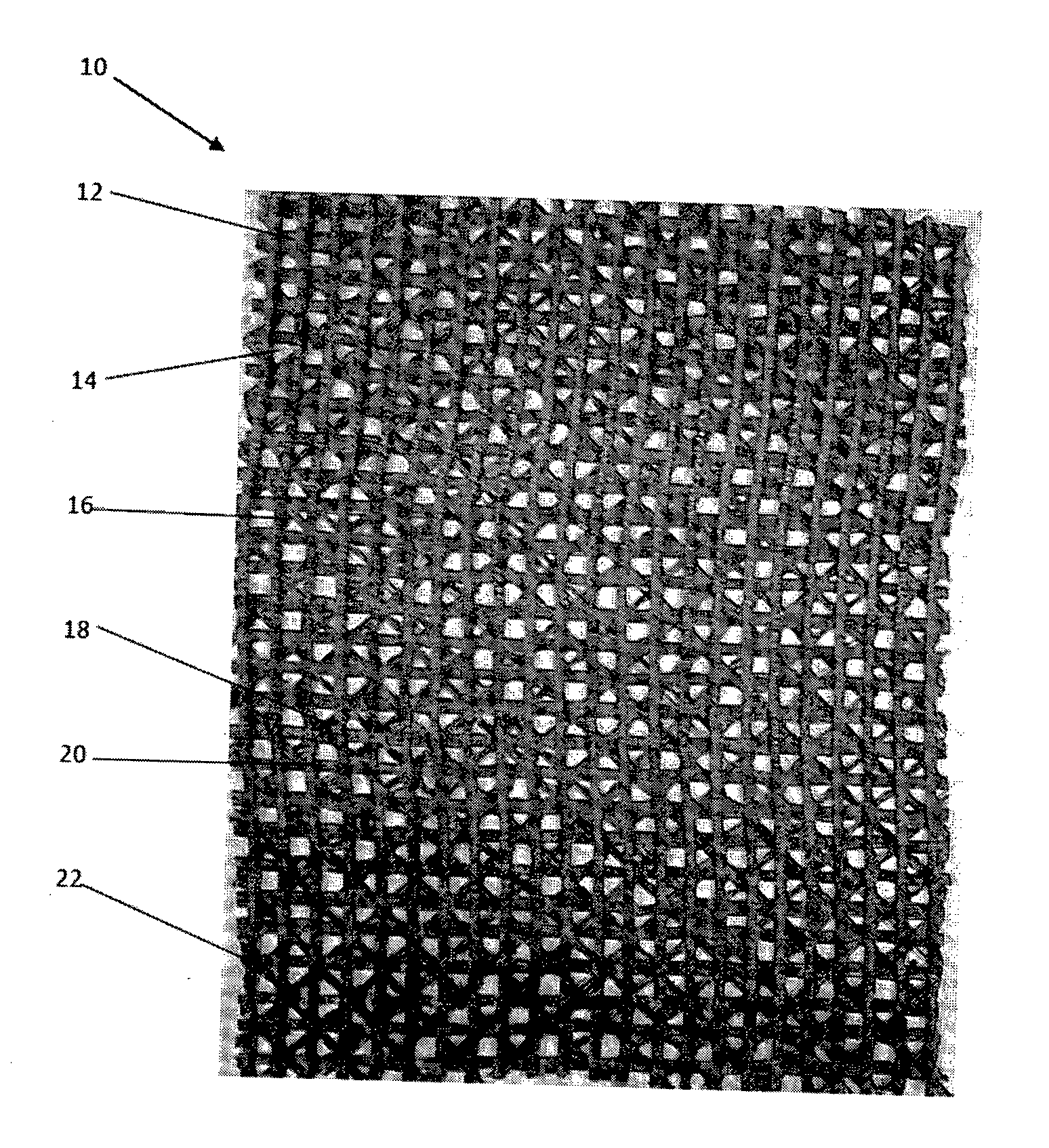

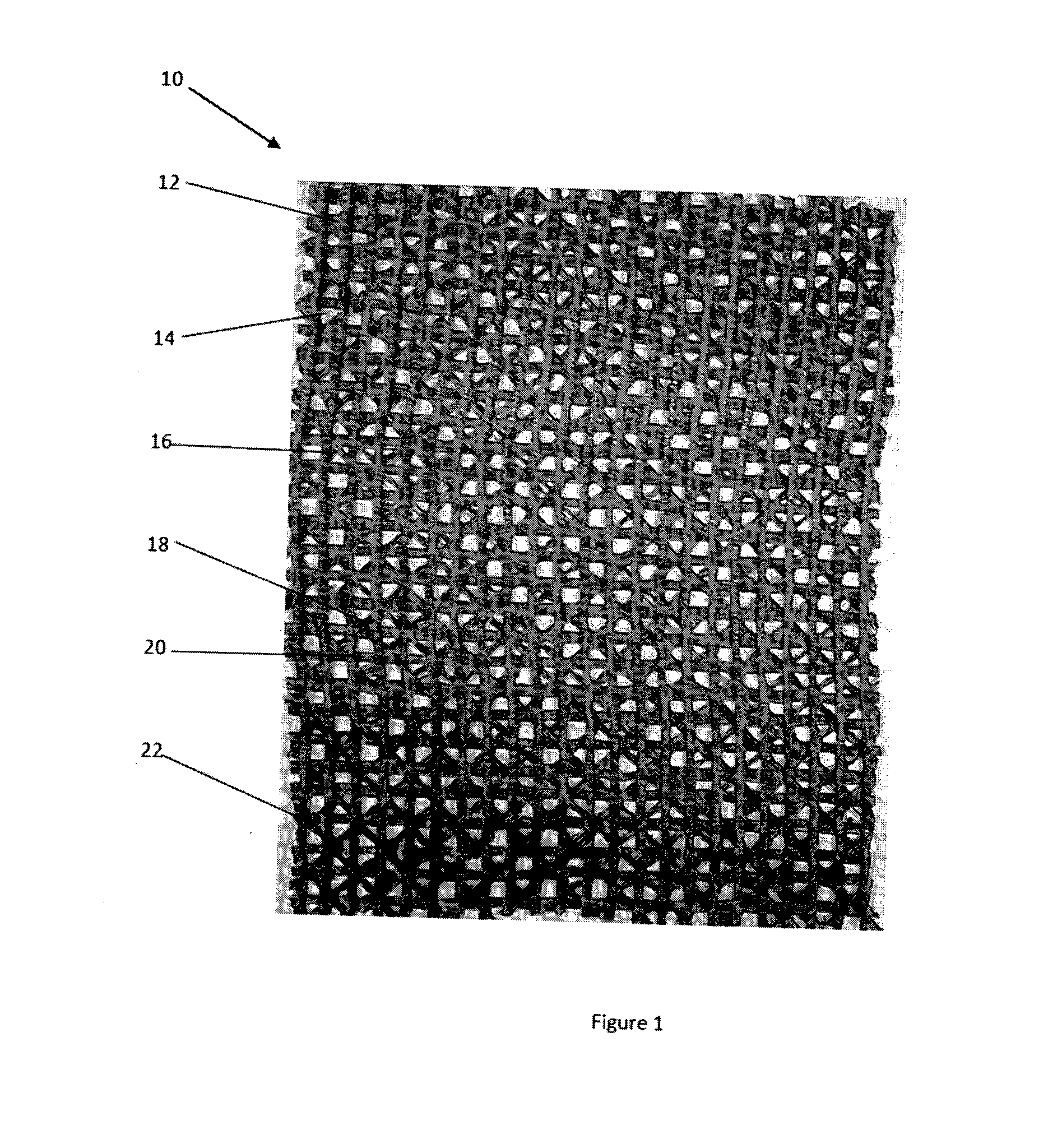

Reinforced rubberised transport systems

InactiveUS20150202837A1Improve splicing strengthReduce splicing failureLayered productsTyresYarnTransport system

An aramid carcass highly bondable to vulcanized rubber, and which includes a multiaxial composite fabric made of layers of parallel yarns laid in different orientations layer-by-layer and stitched together, the layers of the yarn creating a mesh like fabric through which vulcanized rubber can penetrate, the multiaxial composite fabric treated with RFL (Resorcinol Formaldehyde Latex) adhesive.

Owner:COETZEE FREDERICK JAMES

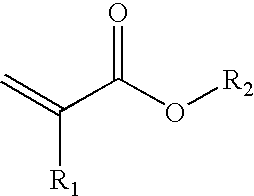

Repulpable PSAs

InactiveUS7067581B2Improve splicing strengthFilm/foil adhesivesLayered productsCopolymerPressure sensitive

Owner:TESA SE

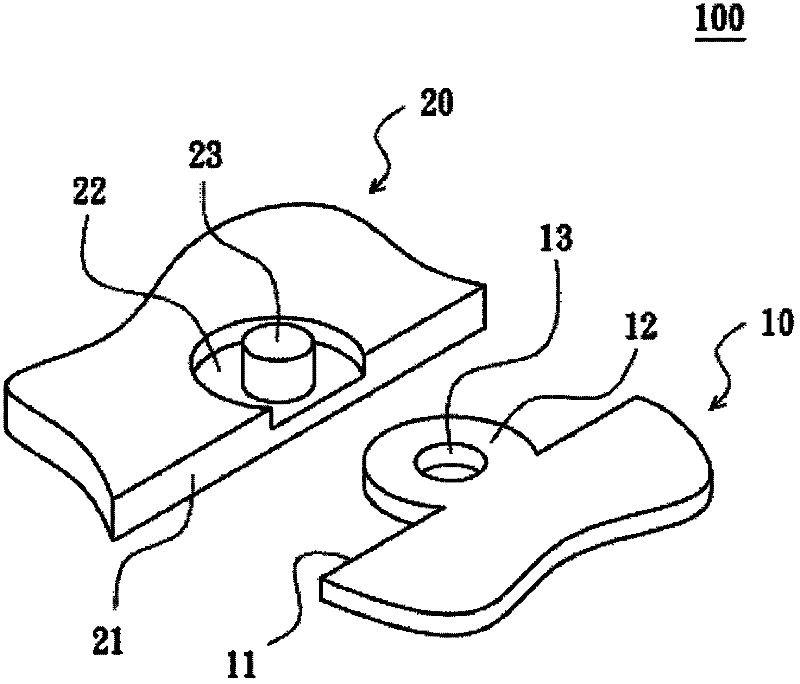

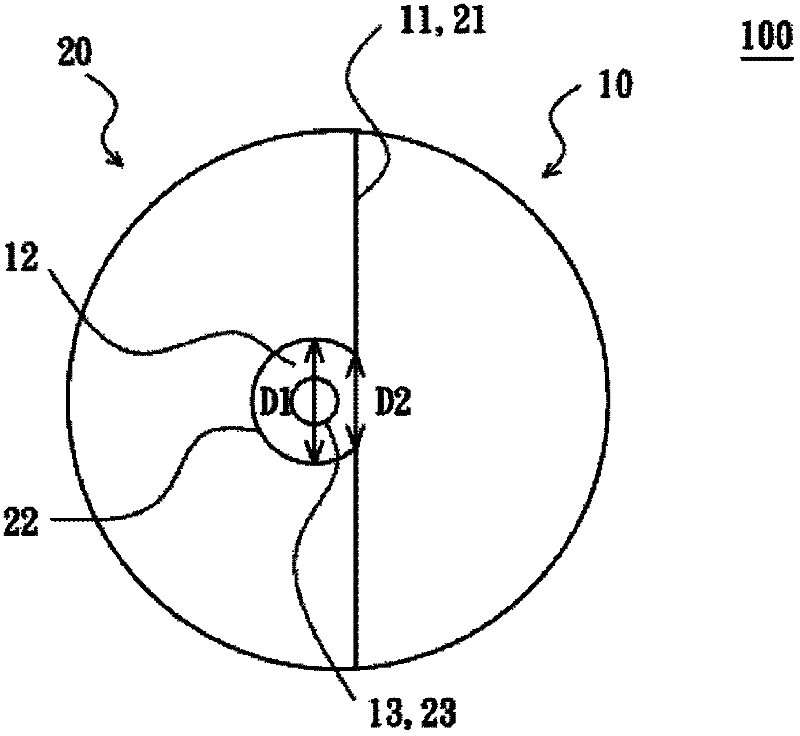

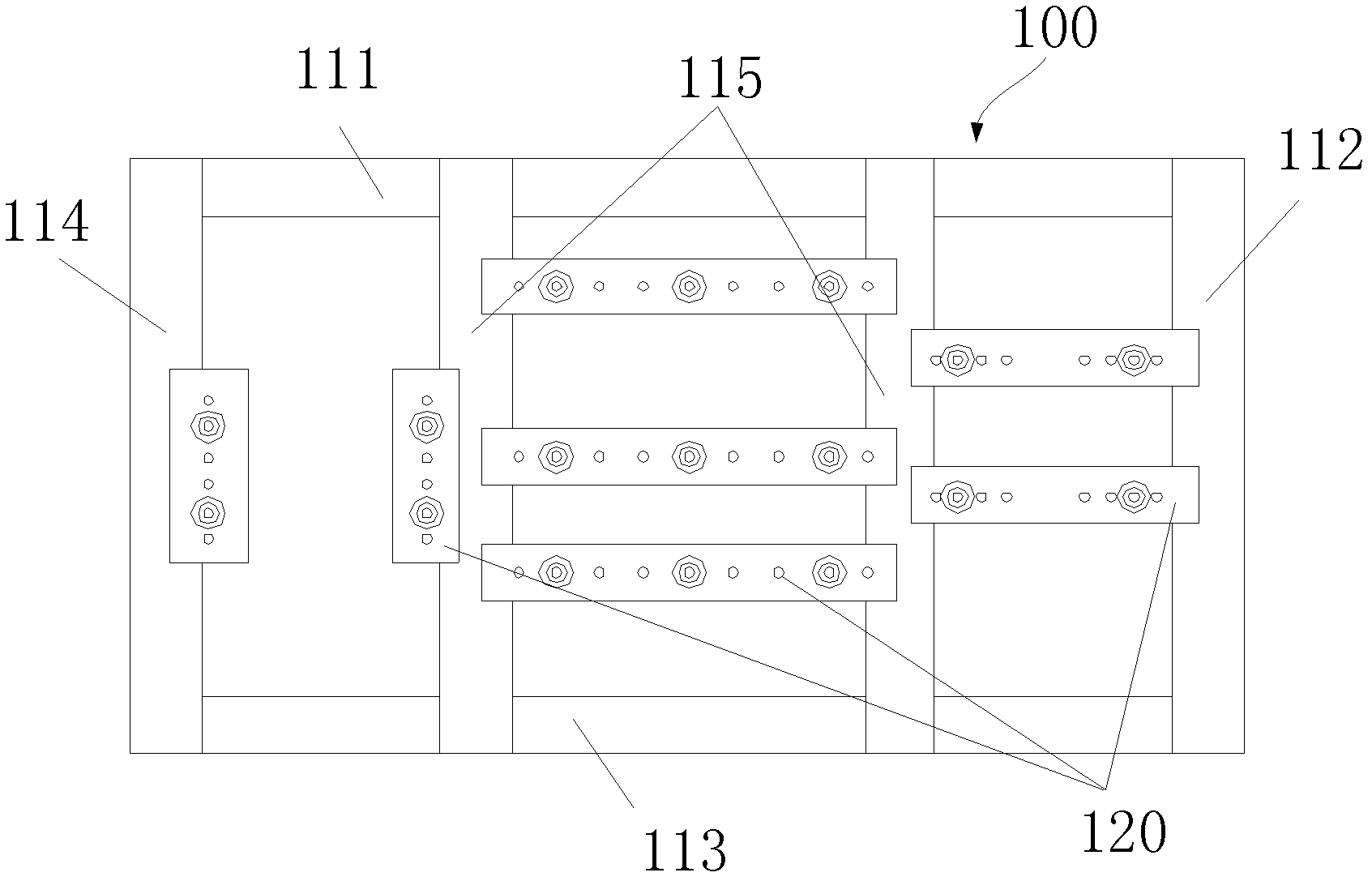

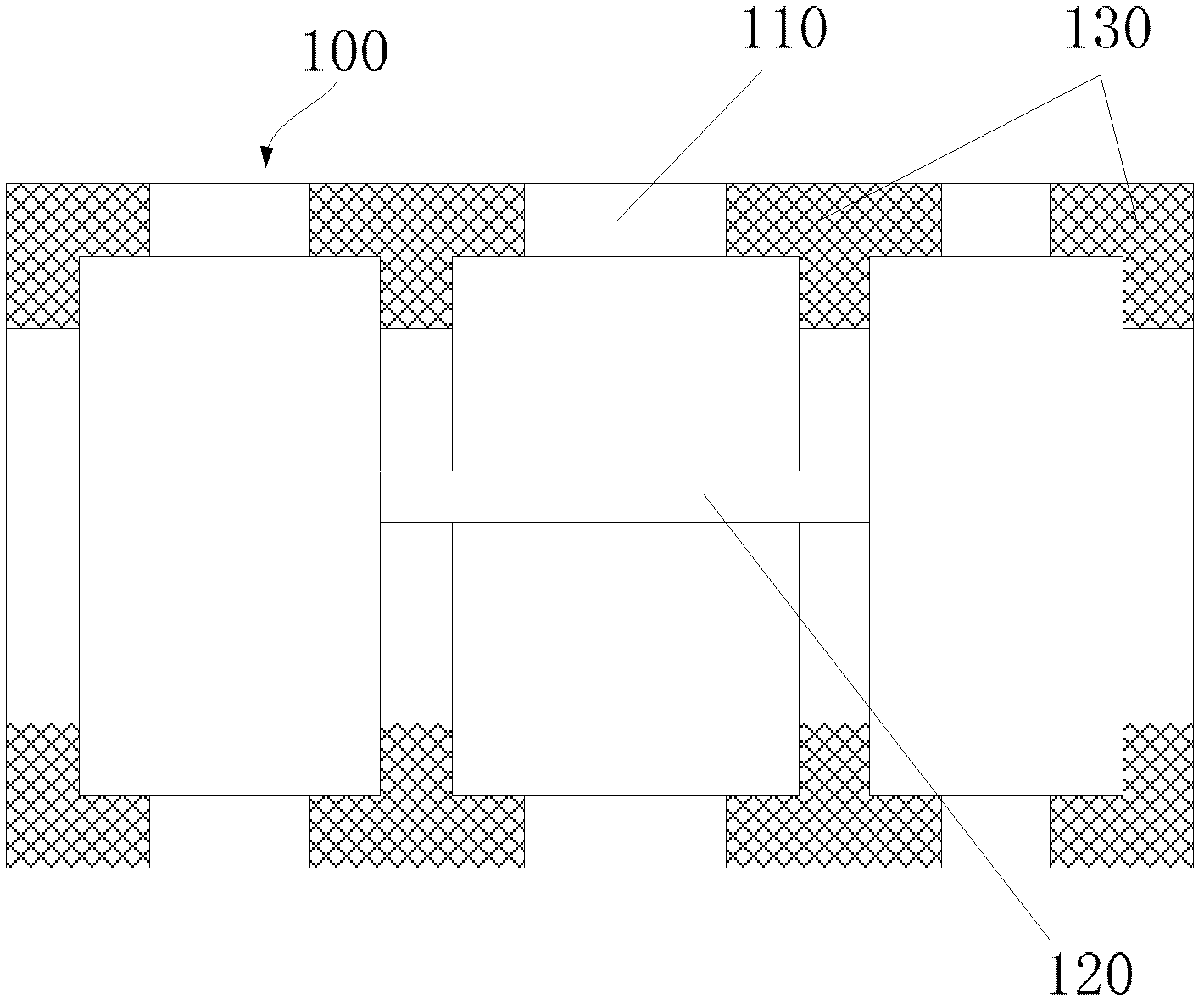

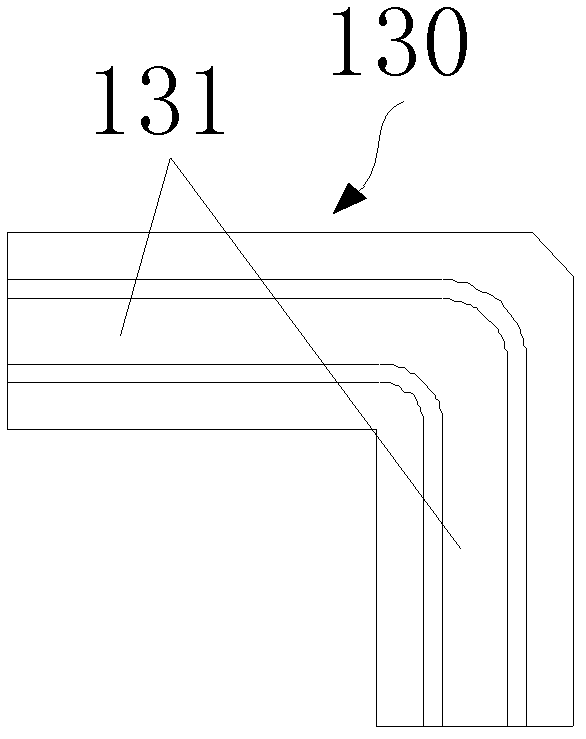

Back plate of liquid crystal display module and splice structure thereof

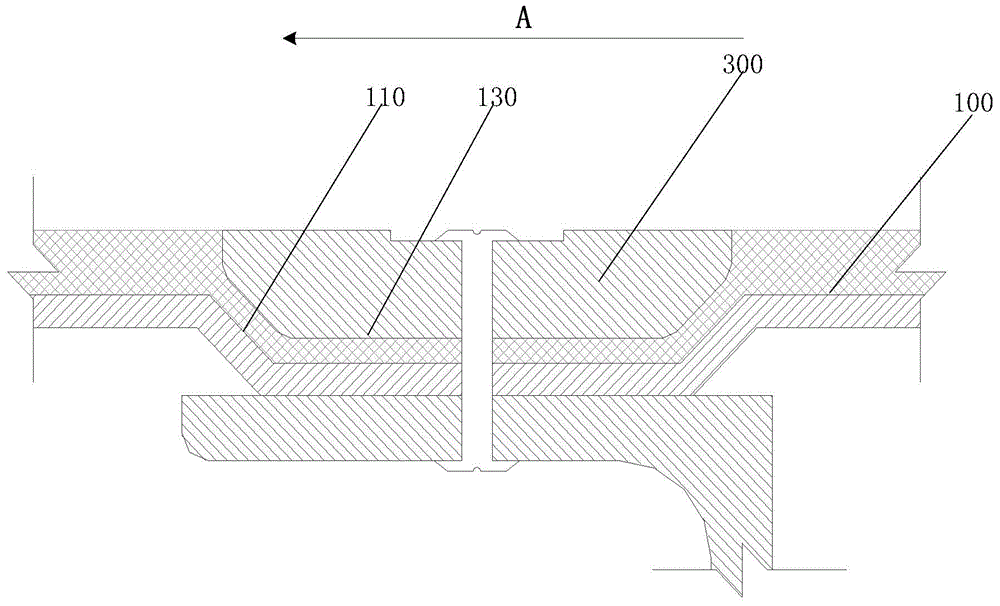

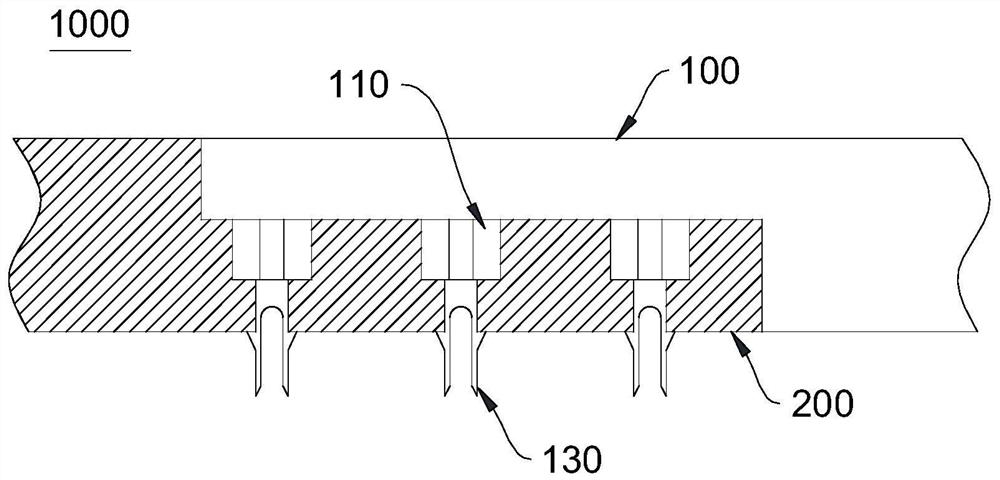

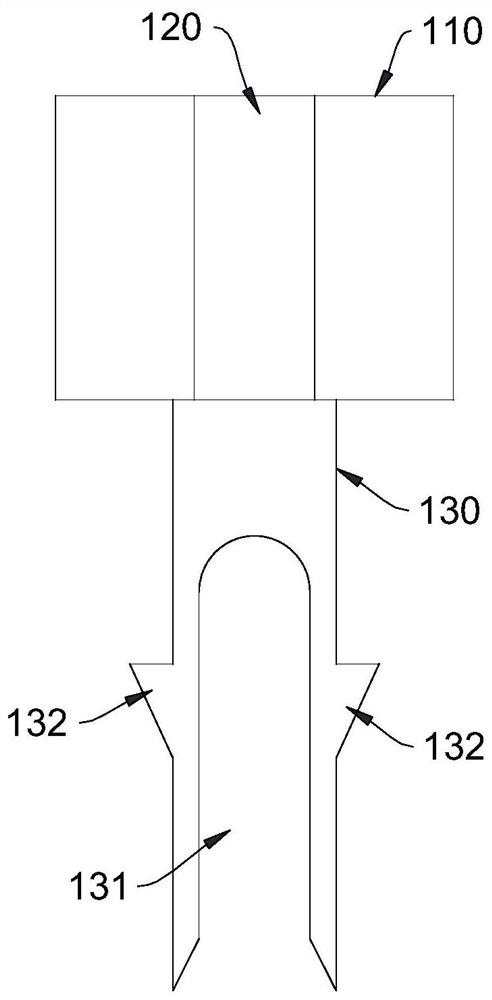

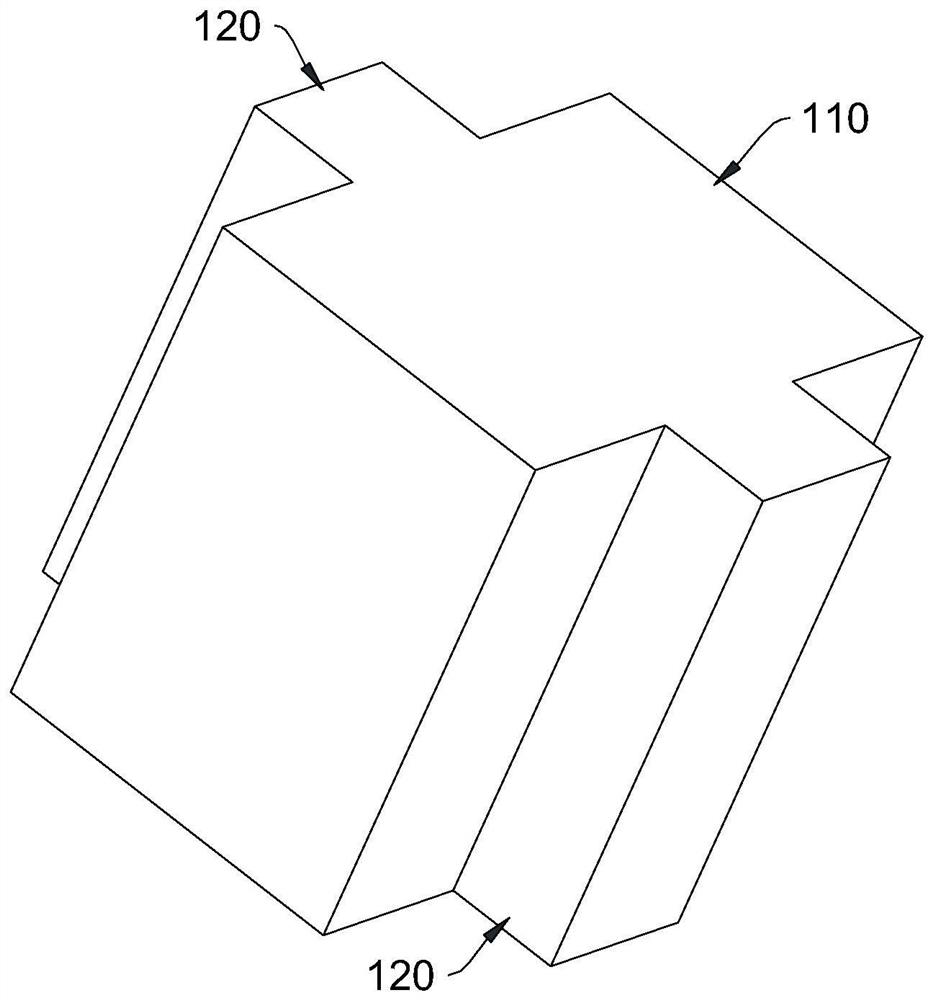

ActiveUS20130119216A1Improve splicing strengthReduce material costsTelevision system detailsCandle holdersLiquid-crystal displayUltimate tensile strength

The present invention discloses a back plate of a liquid crystal display (LCD) module and a splice structure thereof. The back plate is assembled at least by a first back plate portion and a second back plate portion, wherein at least one splice structure is defined between the first back plate portion and the second back plate portion, and the shapes of two sides of the splice structure are correspondingly engaged with each other. Besides, the convex portion is provided with a fixing hole thereon, and the concave step portion is correspondingly provided with a fixing pillar therein. The fixing pillar passes through the fixing hole to fix the first back plate portion and the second back plate portion. The present invention can use different type of material to assemble into the back plate, so as to intensify the splicing strength except for decreasing the material cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

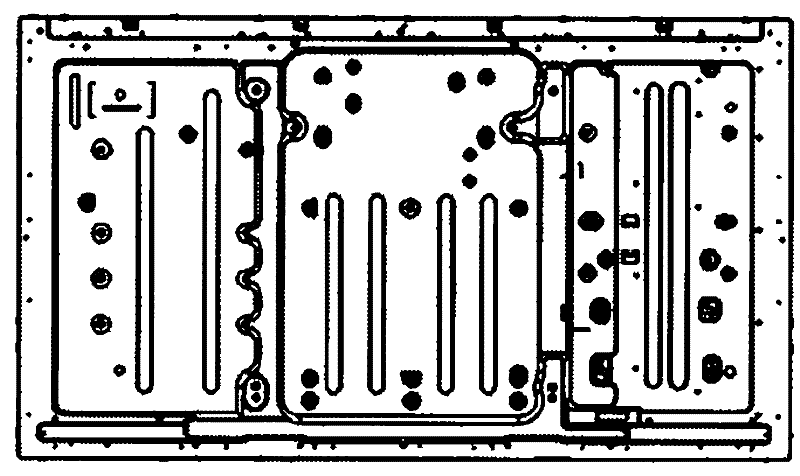

Continuous high-frequency welding machine and welding method

InactiveCN100460188CGuaranteed complete fusion bondingMake up for the problem of uneven local gapsEngineeringCopper

The present invention is developed on the basis of available continuous HF fusion welding machine and fusion welding method and has improved long non-ferrous metal electrode plate. Structurally, the present invention has flexible material inside the longitudinally open-mouthed section, conducting copper sheet on the flexible material and insulating layer on the conducting copper sheet; as well as wheel protecting belt below the movable HF electrode plate heat jointing and settling assembly. The present invention has the advantages of the complete fusion and adhering of the jointed material, no adhesion between the HF electrode plate heat jointing and settling assembly and the jointed material and high welding quality.

Owner:杭州中凌广告器材有限公司

Partition board waterproof and anti-seepage joint structure and construction method thereof

InactiveCN108824655AImprove performanceImprove splicing strengthWallsBuilding insulationsFiberArchitectural engineering

The invention discloses a partition board waterproof and anti-seepage joint structure. The partition board waterproof and anti-seepage joint structure comprises a left wall panel and a right wall panel, and a vertical joint structure body is formed between the left wall panel and the right wall panel; the joint structure further comprises a caulking mortar layer, a water stop plate and a crack-proof fiber mesh belt layer, and the joint structure body is filled with the caulking mortar layer in a solid mode; the water stop plate comprises a V-shaped plate, a first horizontal plate and a secondhorizontal plate, and the first horizontal plate is laterally connected to one end of the V-shaped plate, the second horizontal plate is laterally connected to the other end of the V-shaped plate, theincluded angled tip end of the V-shaped plate is pre-buried in the joint structure body, and the first horizontal plate and the second horizontal plate are correspondingly and symmetrically laid on the surfaces of the left wall panel and the right wall panel; and the crack-proof fiber mesh belt layer is adhered to the surface of the water stop plate, the width of the crack-proof fiber mesh belt layer is greater than the width of the first horizontal plate and the second horizontal plate of the water stop plate, and the water stop plate is covered by the crack-proof fiber mesh belt layer fromtop to bottom. The invention further discloses a construction method of the joint structure. The construction is convenient and simple, the connection is tight and firm, and a joint of partition boards can meet the waterproof and anti-seepage requirements.

Owner:南宁积家市场建设有限公司

Rectangular staggered joint shield based capping segment and post segment assembling structure and method

ActiveCN104695976AImprove molding qualityAvoid the problem of not being able to insertUnderground chambersTunnel liningHeight differenceEngineering

The invention discloses a rectangular staggered joint shield based capping segment and post segment assembling structure and method. The method comprises steps as follows: lower T-shaped segments at the bottom of assembling space as well as left waist segments and right waist segments located on two sides of each lower T-shaped segment respectively are assembled; a first assembling zone is reserved at the top of the assembling space; a second assembling zone is reserved on the left side or the right side of the top of the assembling space; upper T-shaped segments are assembled in the first assembling zone; capping segments are assembled in the second assembling zone; post segments are assembled between the upper T-shaped segments and the lower T-shaped segments. The upper T-shaped segments, the capping segments and the post segments are sequentially mounted, and the capping segments and the abutted waist segments are not staggered, the ring height difference between adjacent rings and an assembling gap between the adjacent segments are effectively controlled, the problem that the capping segments cannot be inserted into the gaps is solved, a gap between the upper and lower T-shaped segments is easier to control, and the longitudinal insertion stability of the middle post segments is high.

Owner:SHANGHAI TUNNEL ENG CO LTD +2

Composite non-off-bridge assembly tube structure

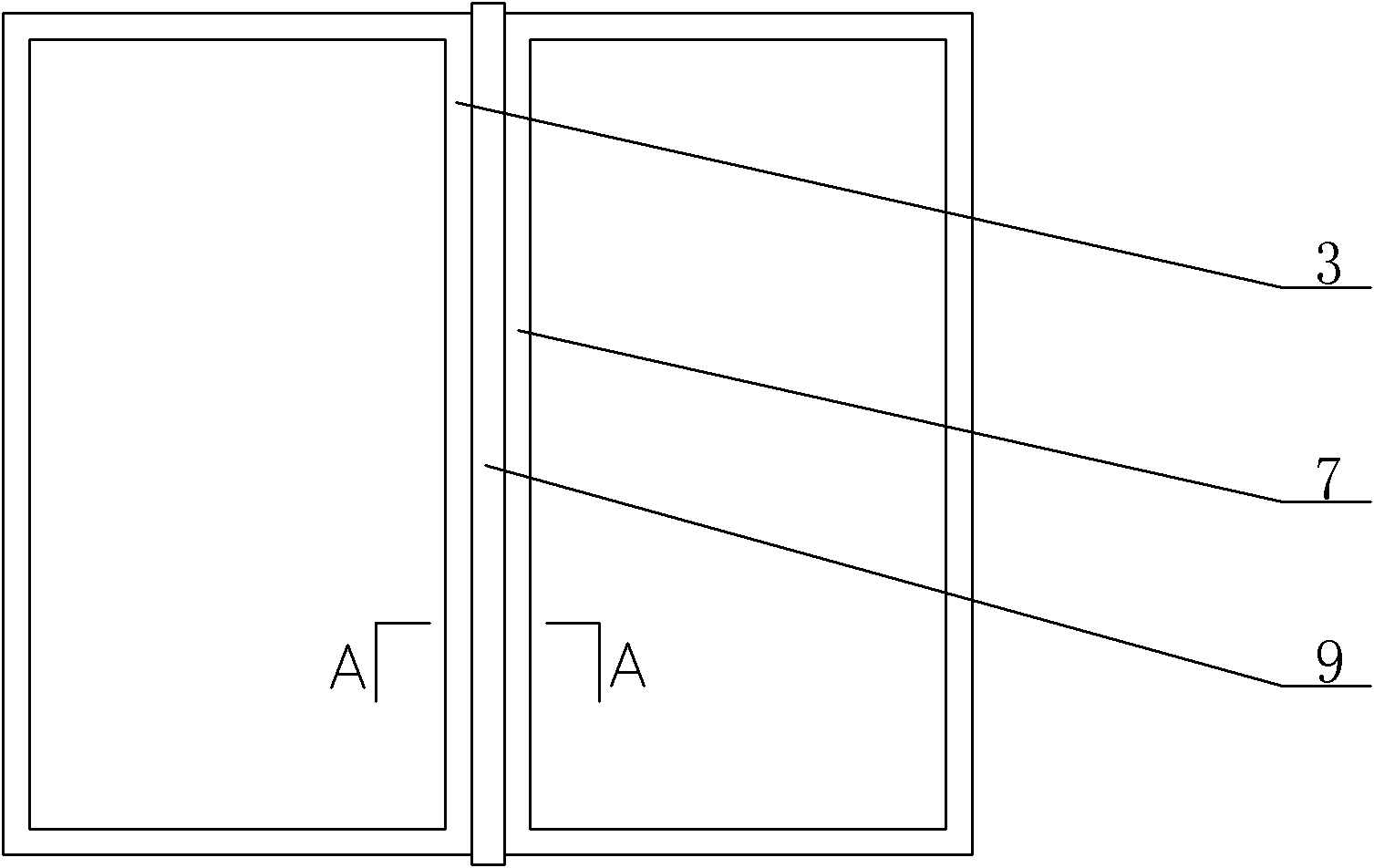

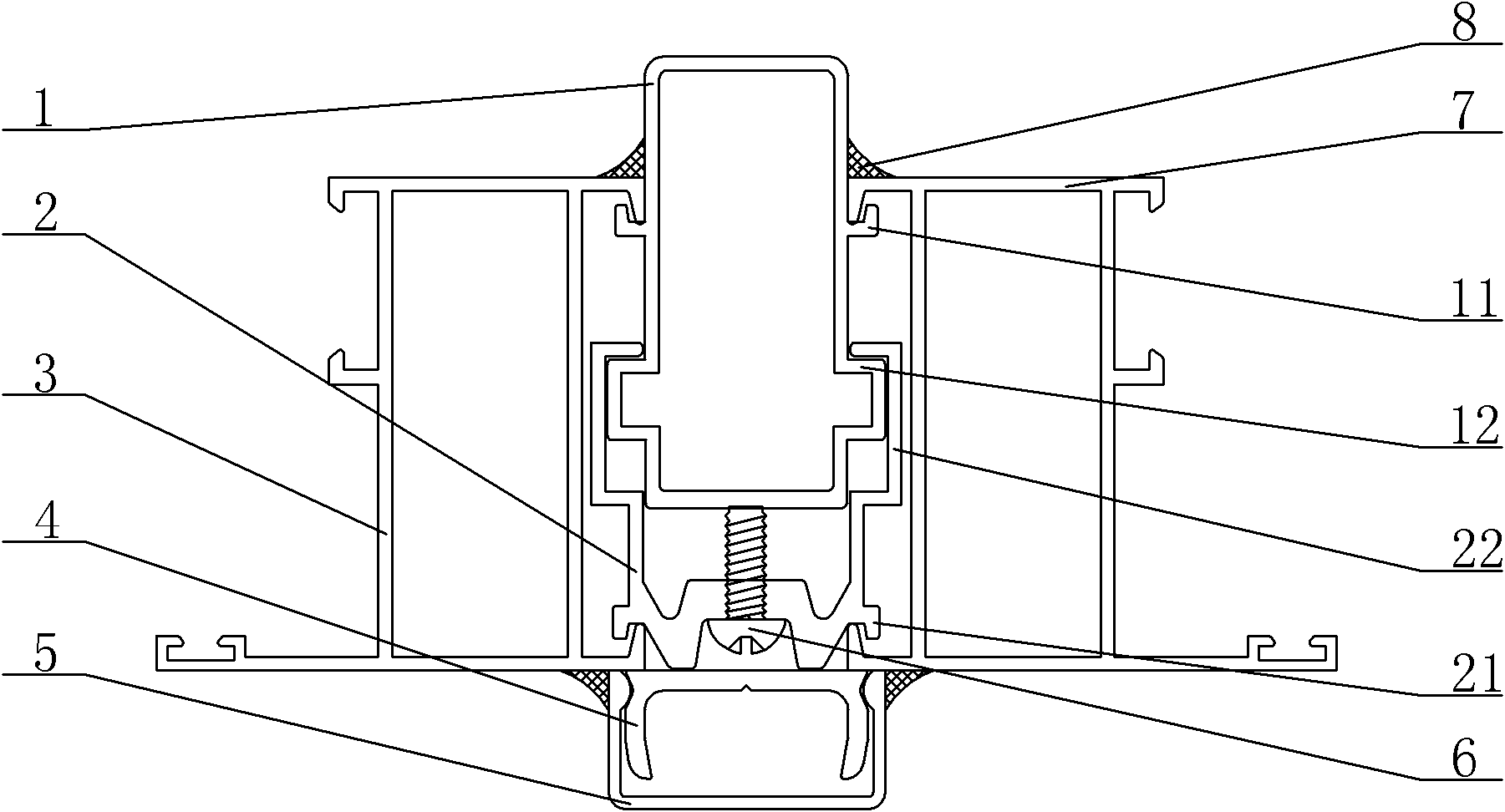

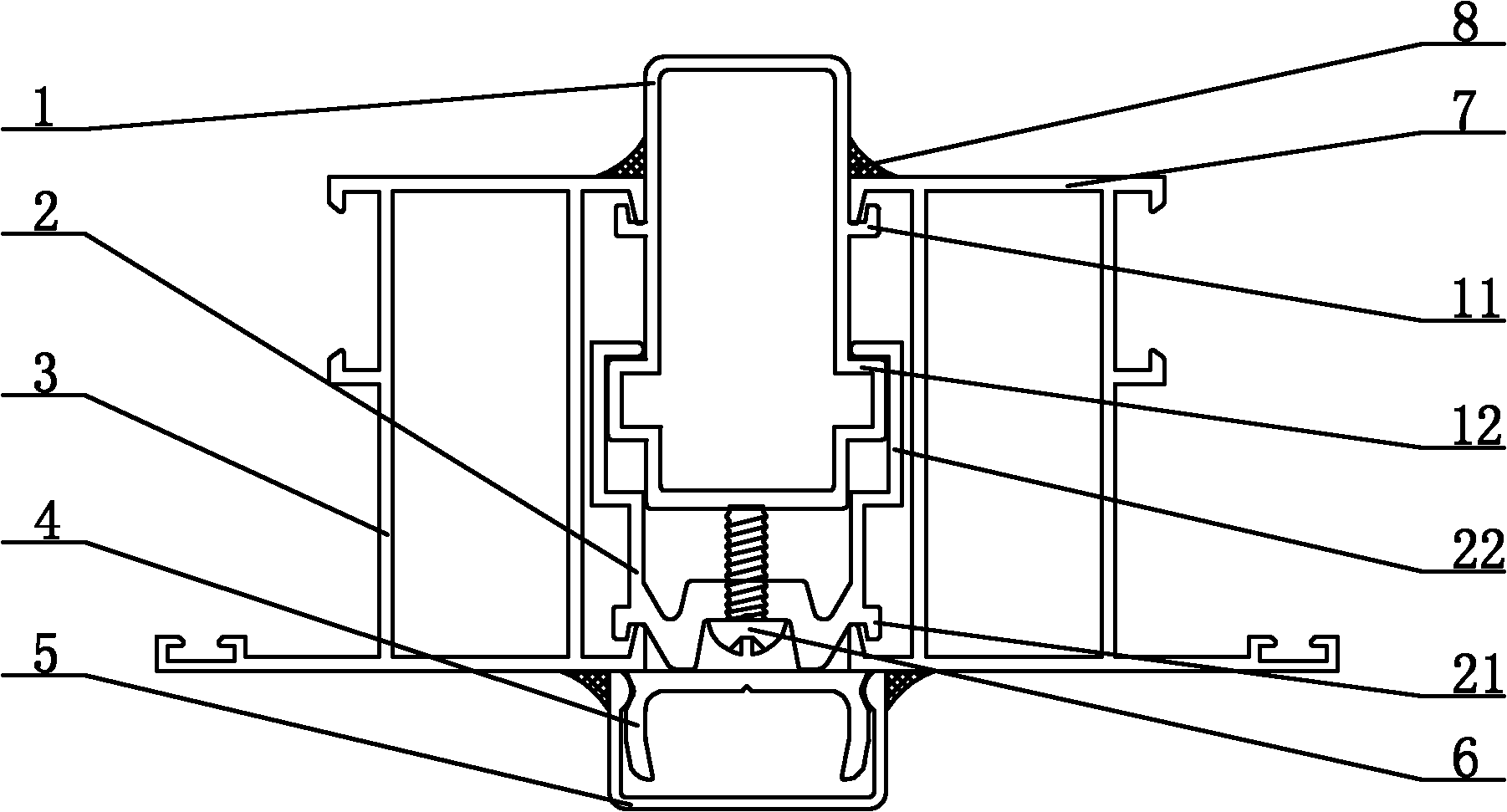

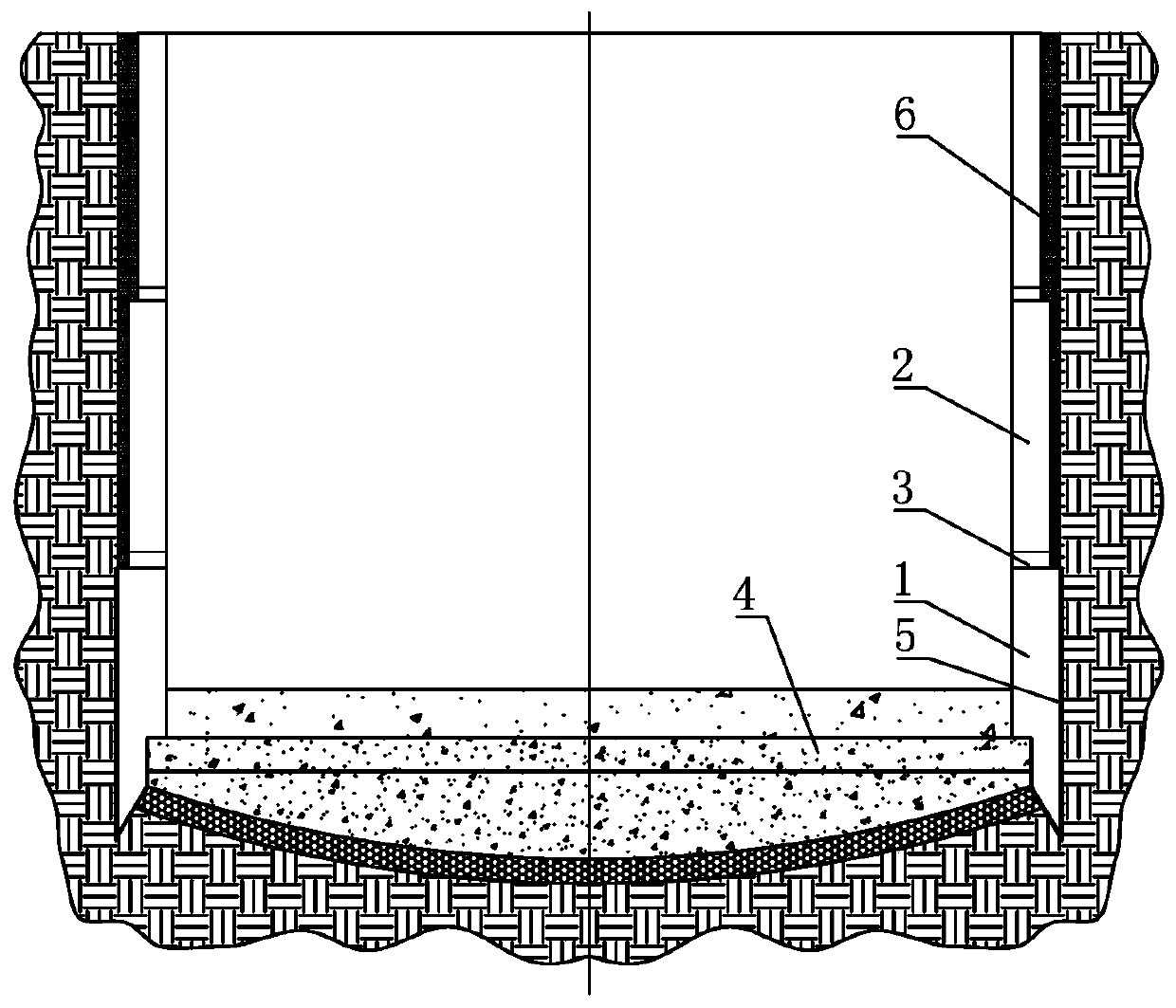

ActiveCN102128002APrevent intrusionEasy to operateSealing arrangementsWing framesInsertion depthMechanical engineering

The invention relates to a connecting component in the field of door and window manufacturing, in particular to a composite non-off-bridge assembly tube structure. A main body of the composite non-off-bridge assembly tube structure is an assembly tube which is connected with a left frame and a right frame; the assembly tube comprises a tubular assembly tube plug-in connector and a tubular assembly tube sleeve; the assembly tube plug-in connector is inserted into the assembly tube sleeve vertically; two sides of the assembly tube plug-in connector are symmetrically provided with two plug-in connector bayonets; two sides of the split tube sleeve are symmetrically provided with two sleeve bayonets; an adjusting screw which adjusts the inserting depth of the assembly tube plug-in connector is arranged on the split tube sleeve; and the assembly tube plug-in connector is pushed to exit the assembly tube sleeve by the adjusting screw, and the plug-in connector bayonets and the sleeve bayonets on two sides are combined and clamped with bayonets of the left frame and the right frame. The movable bayonets are adjusted by the adjusting screw, so that the bayonets of the assembly tube are clamped with the bayonets of the frames, and the structure is easy and convenient to mount and operate.

Owner:浙江瑞明节能门窗技术有限公司

Aluminum high molecular veneer composite door and window corner processing method

ActiveCN106273522AImprove splicing strengthImprove processing efficiencyDomestic articlesMilling equipment detailsData acquisitionEngineering

The invention relates to a door and window corner processing method and in particular to an aluminum high molecular veneer composite door and window corner processing method. The method comprises the steps of: data collecting and programming, material feeding and locating, milling-processing, welding heating, molding co-extrusion and the like. The method compensates the defects existing in current common processing, welding and corner-clearing and effectively solves the precision problem and the efficiency problem generated by multiple locating errors and repeated consumptions. Splicing end faces have a certain textures after being heated and molded so that the two end faces have strong occlusive force when being spliced, the door and window splicing strength is improved by 1.5-2 times, meanwhile the welding corner-clearing-free technology effectively guarantees the attractive appearance of group corners, guarantees the attractive appearance of door and window group corners, greatly improves the processing efficiency of doors and windows and provides an advanced technical support for processing and production of large-scale door and window group corners.

Owner:浙江瑞明节能门窗技术有限公司

Construction method of stereo garage foundation open caisson

InactiveCN109736612AReduce volumeVibration compaction is easyArtificial islandsProtective foundationSoil horizonDrainage ditch

A construction method of a stereo garage foundation open caisson comprises the following steps that S1, an underground wall body is vertically divided into a plurality of layers in the height direction, and the thickness of the upper-layer underground wall body is smaller than that of the lower-layer underground wall body; S2, the position of an open caisson is determined; S3, a drainage ditch isarranged; S4, a blade foot layer is installed, specifically, first sand grains are packed between a blade foot steel foundation unit and a soil layer along with the sinking process of the blade foot layer; S5, a module layer is installed, specifically, second sand grains are packed between a module steel foundation unit and the soil layer along with sinking of the module layer; S6, the module steel foundation unit is continuously hoisted, and the space between the module steel foundation unit and the soil layer is filled with second sand grains along with sinking of the module layer; S7, the step S6 is repeated to install other module layers until a shaft sinks to a preset depth layer by layer; and S8, bottom sealing of the open caisson is carried out. The technical problems that an underground stereo garage is long in construction period, difficult to construct, low in structural strength and high in manufacturing cost are solved, and the construction method is widely applied to stereo garage construction.

Owner:SHANDONG JIANZHU UNIV +1

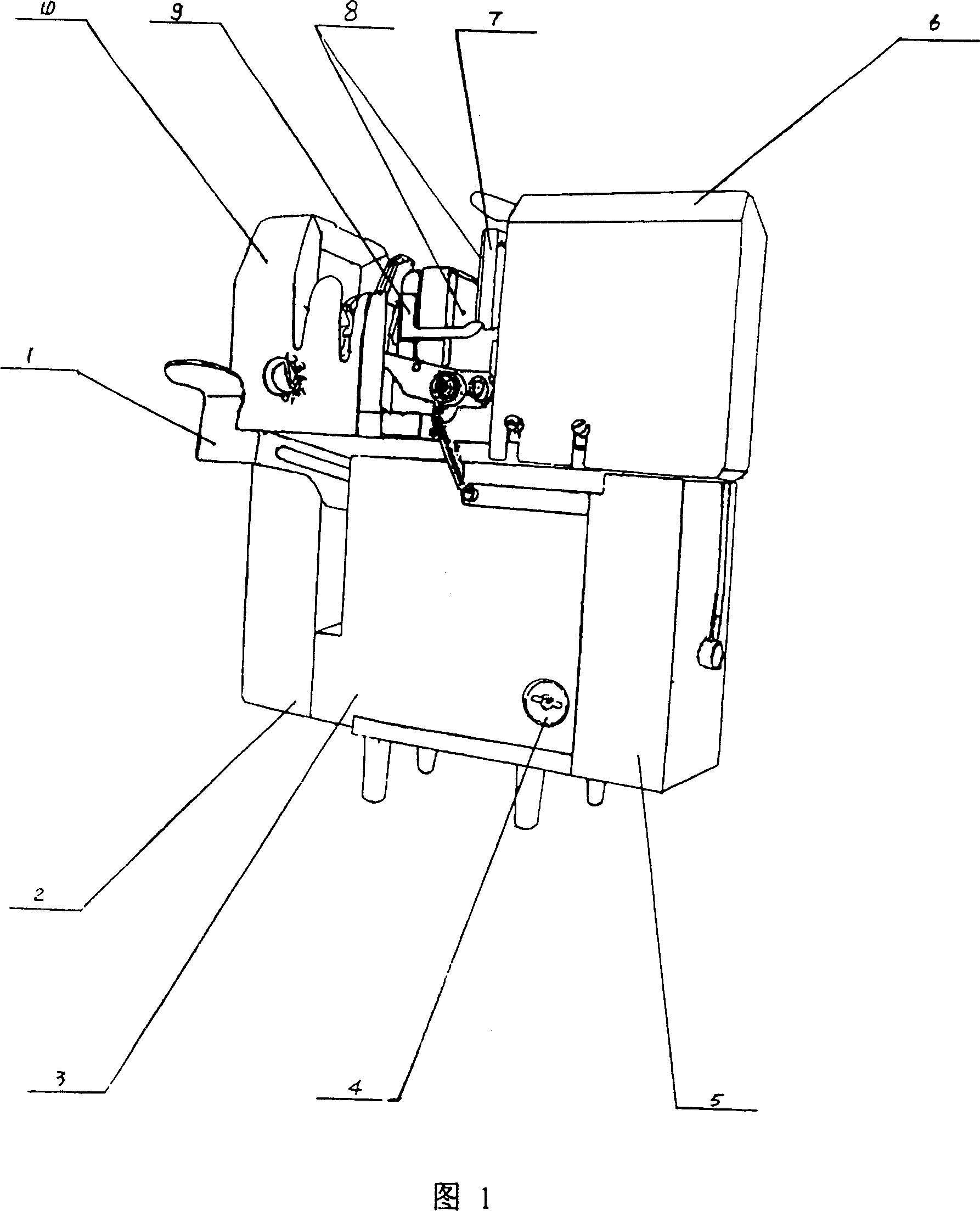

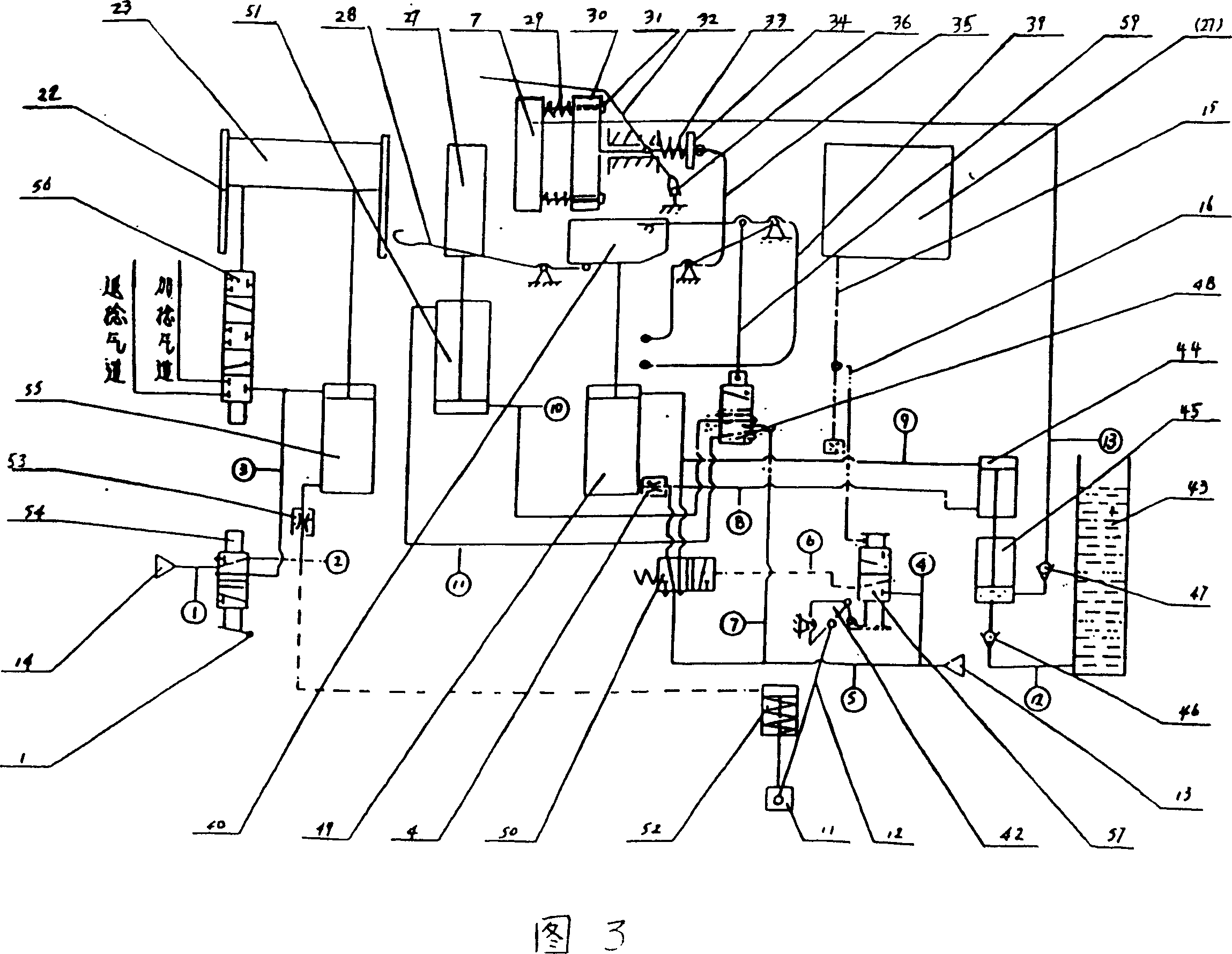

Sectional type air splicing chamber

InactiveCN103343411AAvoid replacementIncrease productivityPiercing arrangementsContinuous wound-up machinesYarnAgricultural engineering

The invention provides a sectional type air splicing chamber which comprises a base, a splicing chamber body, an air bag, air way pipes, air conveying pipes, air outlets and a splicing chamber hole. The splicing chamber body is fixed on the upper end face of the base, the air bag is arranged in the base, the air way pipes and the air conveying pipes are arranged in the splicing chamber body, the air outlets are formed in the inner side of the splicing chamber hole, the air way pipes are communicated with the air bag, the air conveying pipes are connected with the air outlets, transverse air pipes are arranged in the splicing chamber body, the air way pipes and the air conveying pipes are communicated through the transverse air pipes, the splicing chamber hole is divided into two sections, each air outlet is formed in each section of splicing chamber hole, and the two air outlets, the air way pipes corresponding to the air outlets, the transverse air pipes corresponding to the air outlets, and the air conveying pipes corresponding to the air outlets are arranged on different sides of the splicing chamber hole respectively. Due to the fact that a sectional type chamber body structure is adopted by the sectional type air splicing chamber, the sectional type air splicing chamber is applicable to splicing of a plurality of types of yarn, and free of replacement in production, improves production efficiency, reduces cost, and improves splicing strength.

Owner:WUXI SANDA TEXTILE ACCESSORY

Method for processing plate with expanded bamboo as raw material

InactiveCN108818800AImprove compactnessHigh strengthWood treatment detailsCane mechanical workingEngineeringLongitudinal strength

The invention provides a method for processing a plate with expanded bamboo as a raw material, and belongs to the technical field of bamboo processing. The method comprises the steps that taking a bamboo tube with bamboo knots being retained as a base material, after expansion, the bamboo knot parts are removed for standby application; positioning bulges and positioning grooves are formed in one side of the bamboo inner skin of the plate with the bamboo knots being removed; the plate of a two-layer structure is formed in overlapped and spliced modes; and after being expanded, the bamboo knot parts form reinforcing strips used for being embedded into two-side plate structures so as to reinforce the transverse and longitudinal strength of the plate. The method has the advantages that the smoothness of the bamboo plate can be improved, the utilization rate of the bamboo is increased, the strength of the plate is reinforced, the service life of the plate is prolonged, and the appearance ofthe plate is optimized.

Owner:永新县福新木业有限公司

Construction method of prefabricated wall panels

ActiveCN111206698BReduce usageEasy to installWallsBuilding material handlingArchitectural engineeringCement slurry

The invention discloses a construction method of a prefabricated wall panel, which relates to the field of prefabricated buildings, and comprises the following steps: S1, raw material preparation, the lower end surface of the prefabricated wall panel used is provided with a number of notches, one end surface of the prefabricated wall panel There are several grout holes connected with the notch; each notch has two grout holes connected vertically; S2, measuring and setting out; S3, pre-embedded steel bars; S4, grouting partition; S5, wallboard hoisting , so that the notch on the lower end of the prefabricated wall panel is aligned with the pre-embedded straight steel bar and then inserted; S6, install the oblique support; S7, grouting to seal the warehouse; S8, grouting filling, inject cement mortar through the grout hole, and through the plug The grout hole is blocked, so that the mortar is filled and solidified to fix the base surface and wallboard. Set notches, grout holes and pre-embedded steel bars, inject cement slurry into the notch through the grout holes, and after the cement slurry solidifies, the cement slurry realizes the connection between the base surface and the prefabricated wallboard, thereby reducing the use of reinforcements and making the overall The installation is more secure.

Owner:HAIDA CONSTR GRP

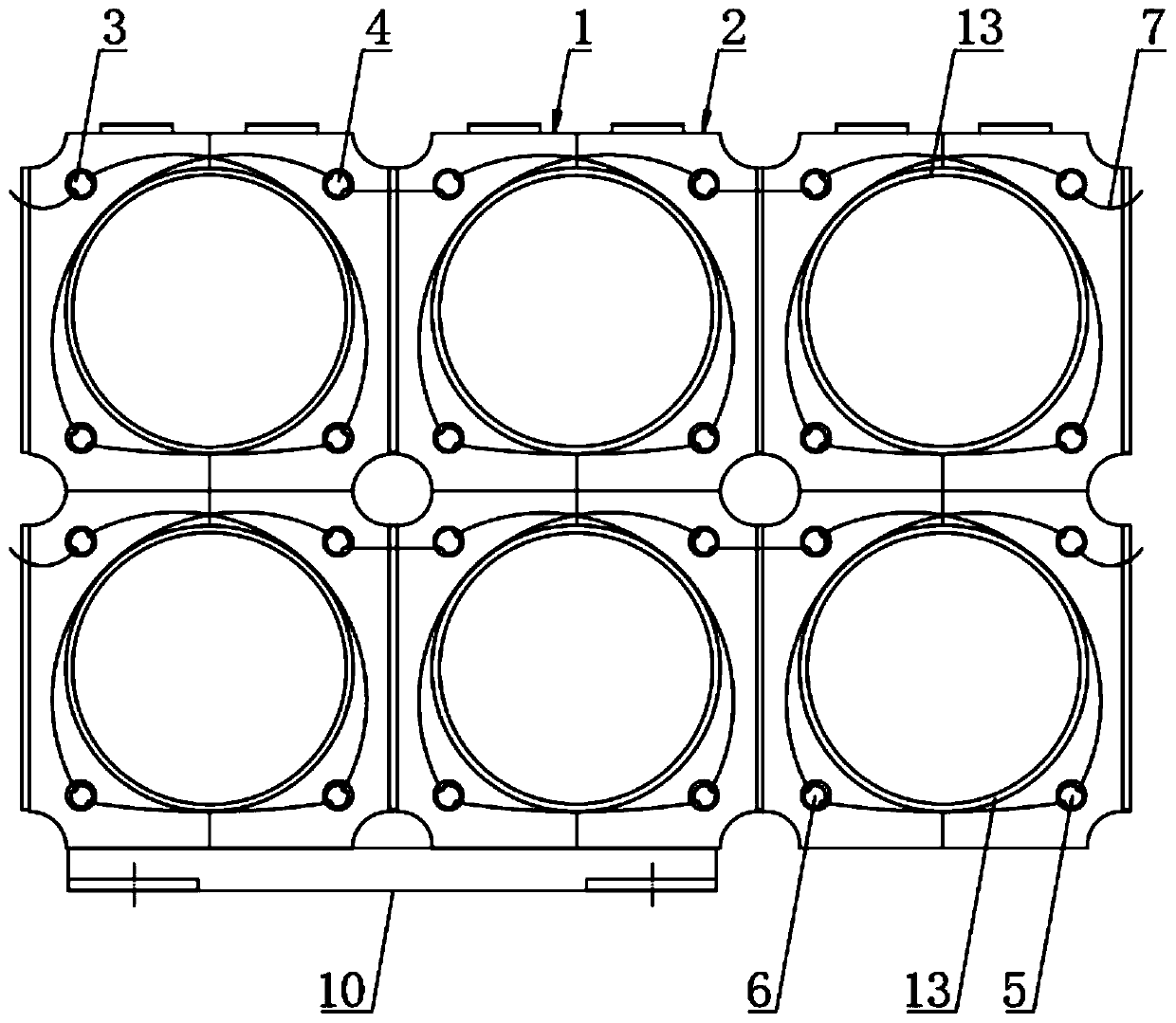

Pool wall prefabricated block splicing structure suitable for static pressure assembled pool and construction method thereof

InactiveCN110725595AImprove anti-seepage performanceGuaranteed stiffnessBulk storage containerArchitectural engineeringRebar

The invention discloses a pool wall prefabricated block splicing structure suitable for a static pressure assembled pool and a construction method thereof. The splicing structure comprises a prefabricated block which is spliced along the circumferential direction to form a pool wall, a steel bar which penetrates through the prefabricated block and extends out from the circumferential end part of the prefabricated block, a splicing block which is positioned at the circumferential end part of the prefabricated block to form the outer wall of the pool and a soil retaining block which is positioned at the bottom of the prefabricated block, and the splicing block and the soil retaining block are enclosed to form a connecting groove for circumferential splicing, when the prefabricated blocks are assembled along the circumferential direction, two opposite steel bars in the connecting grooves of the adjacent prefabricated blocks are fixedly connected with each other, and concrete is filled inthe connecting grooves to form cast-in-place blocks. The construction method comprises the following steps of determining the size and the quantity of the prefabricated blocks according to the size of the water pool; manufacturing the prefabricated block, pressing the prefabricated block into a soil body, and butting the steel bars; pouring concrete to form the cast-in-place blocks. According tothe splicing structure and the construction method, the prefabricated block and the cast-in-place block are assembled to form the pool wall, and the prefabricated structure and the cast-in-place structure are combined, so that the anti-seepage performance of the pool wall is improved, and the integral rigidity of the structure is guaranteed.

Owner:HOHAI UNIV

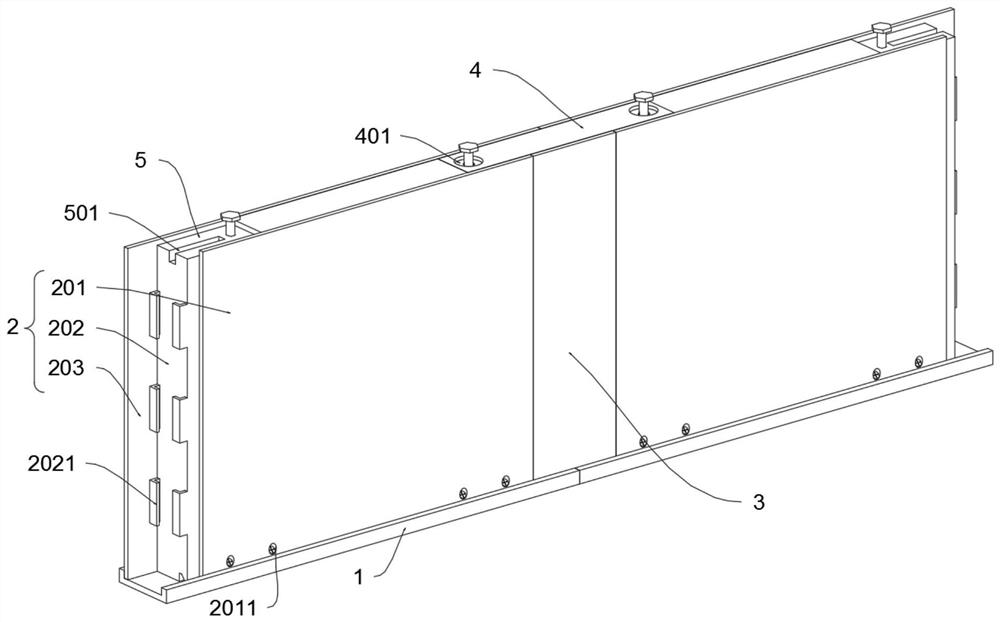

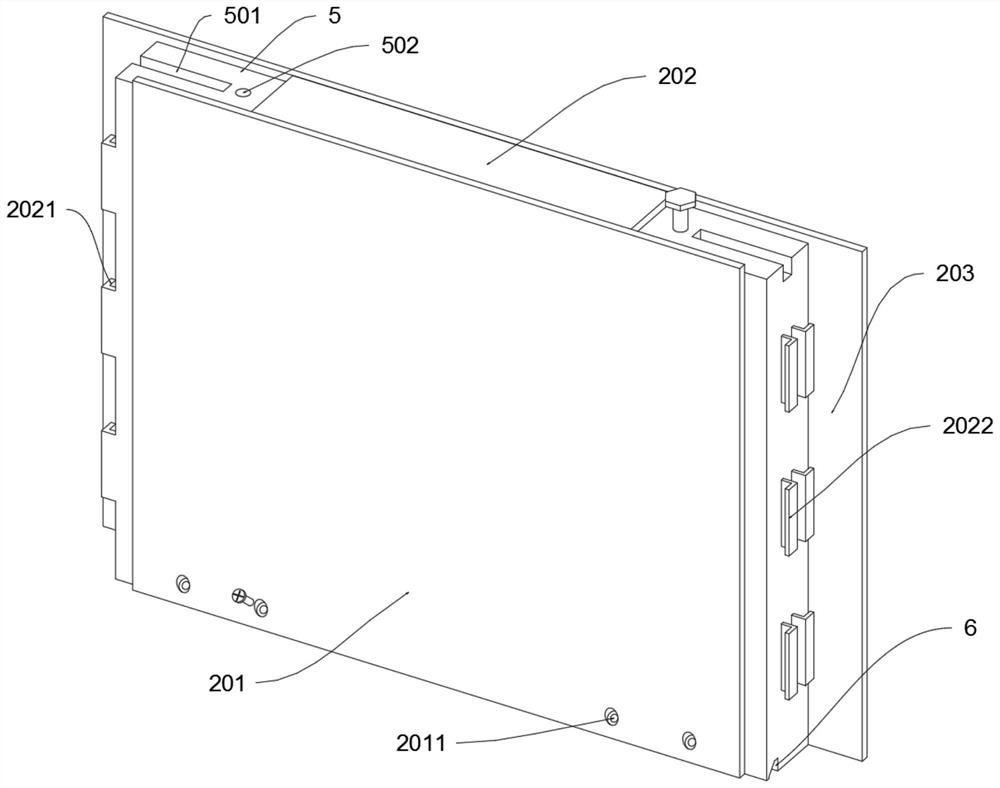

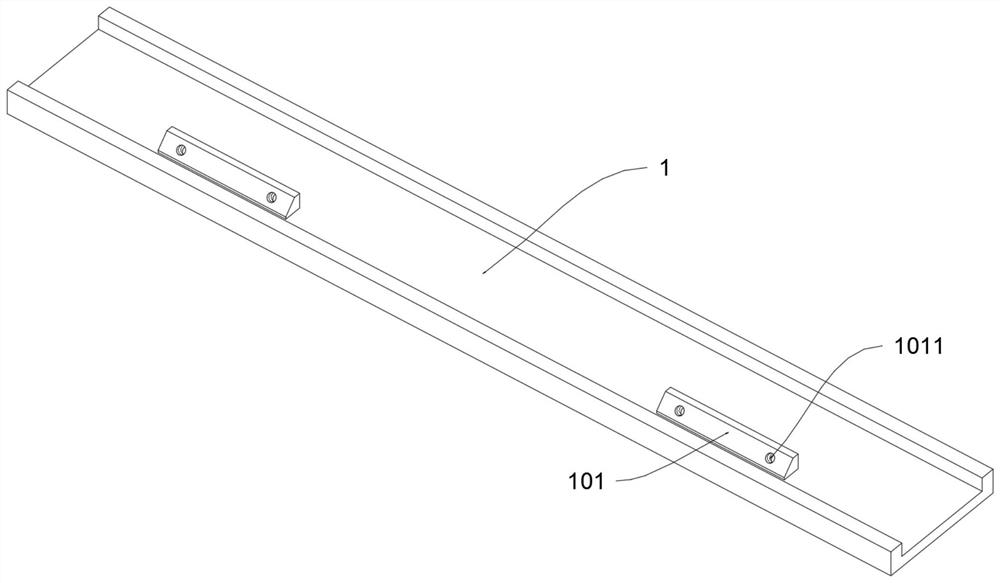

Steel structure building wallboard unit structure easy to assemble

InactiveCN112609892AImprove stabilityReinforced Relative Connection StrengthConstruction materialBuilding material handlingUnit structureUltimate tensile strength

The invention provides a steel structure building wallboard unit structure easy to assemble. The steel structure building wallboard unit structure comprises a mounting underframe, a connecting column, an upper gland, upper positioning grooves and lower positioning grooves, wherein walls are fixedly connected to the upper portion of the mounting underframe, and the lower surfaces of the walls are located in a mounting underframe groove; the connecting column is movably connected between the two sets of walls; the upper positioning grooves are formed in the left sides and the right sides of the upper surfaces of the walls correspondingly in two positions; the upper gland is fixedly connected to the upper portions of the upper positioning grooves through screws; the lower positioning grooves are formed in the lower surfaces of the walls; the mounting underframe is an arched groove body, and a lower reinforcing block of a trapezoidal structure is connected to the upper surface of the mounting underframe in a welded mode; and a lower fixing hole is formed in front of the lower reinforcing block and is an internal threaded hole. Therefore, the connecting mode of the spliced walls is improved, a middle connecting mechanism is improved, and the problems of stress concentration and insufficient airtightness of the wall connecting positions are reduced while the connecting strength is ensured.

Owner:黄海湖

Back plate of liquid crystal display module and splice structure thereof

ActiveUS8444099B1Improve splicing strengthReduce material costsTelevision system detailsCandle holdersLiquid-crystal displayUltimate tensile strength

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Jet stream acoustic lining protective panel

The invention discloses a jet stream acoustic lining protective panel, which includes a plurality of acoustic panel absorbers, external pressing strips and hidden pressing strips, wherein first relative parallel edges of the acoustic panel absorbers are buckling edges, second relative parallel edges of the acoustic panel absorbers are straight edges; the adjacent buckling edges of the acoustic panel absorbers in the first direction are butted to form grooves; the hidden pressing strips are embedded in the grooves in a pressing manner; the adjacent straight edges of the acoustic panel absorbers in the second direction vertical to the first direction are butted; the external pressing strips are pressed and attached to the butted parts of the straight edges. The jet stream acoustic lining protective panel guarantees the splicing strength of splicing parts of the acoustic panel absorbers and the flatness to adapt to the jet flow environment, and abandons and changes the bi-directional external pressing manner into the hidden pressing technology in the direction vertical to the air flow to guarantee low flow resistance, thereby reducing the influence on airflow and sound field, and enhancing the splicing intensity of panels at the same time.

Owner:上海声望声学科技股份有限公司

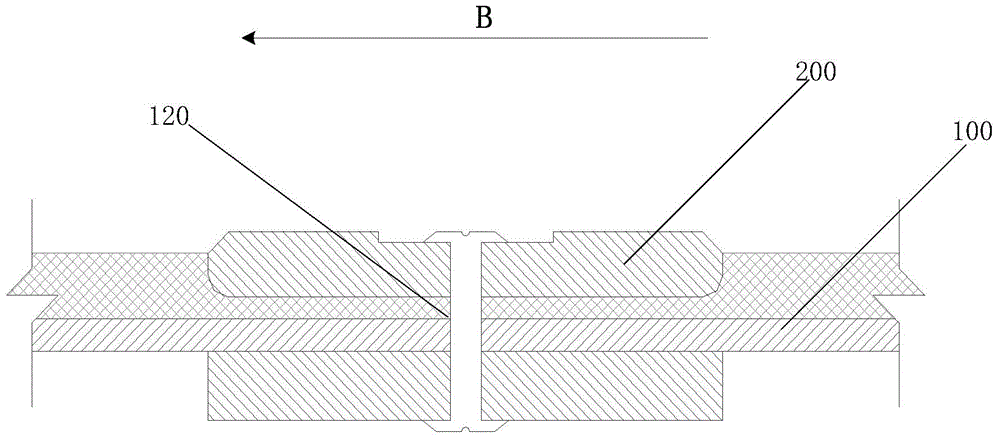

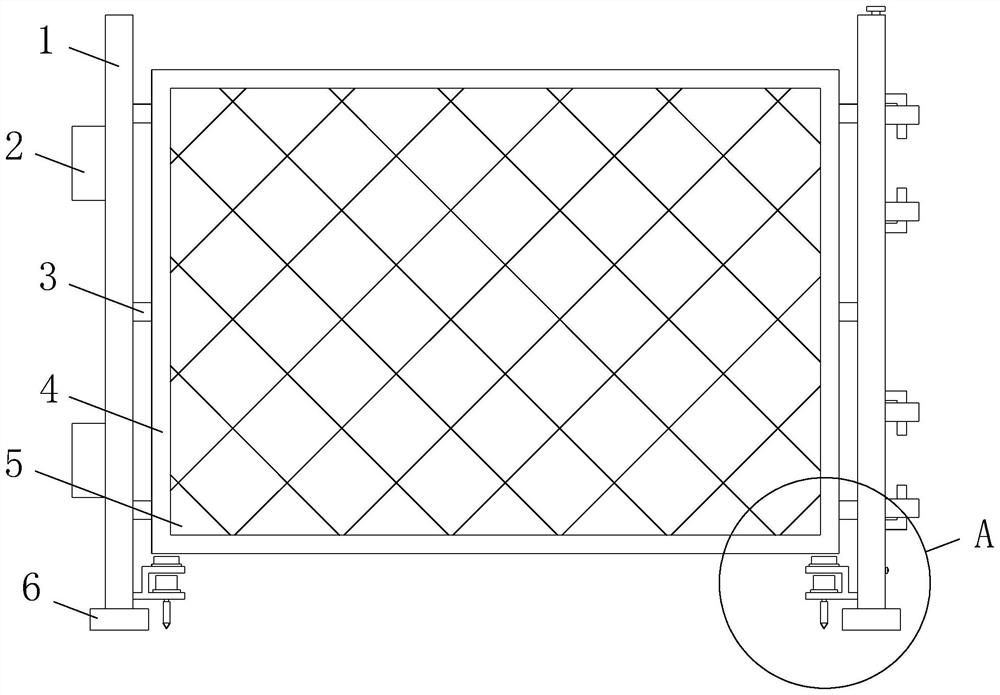

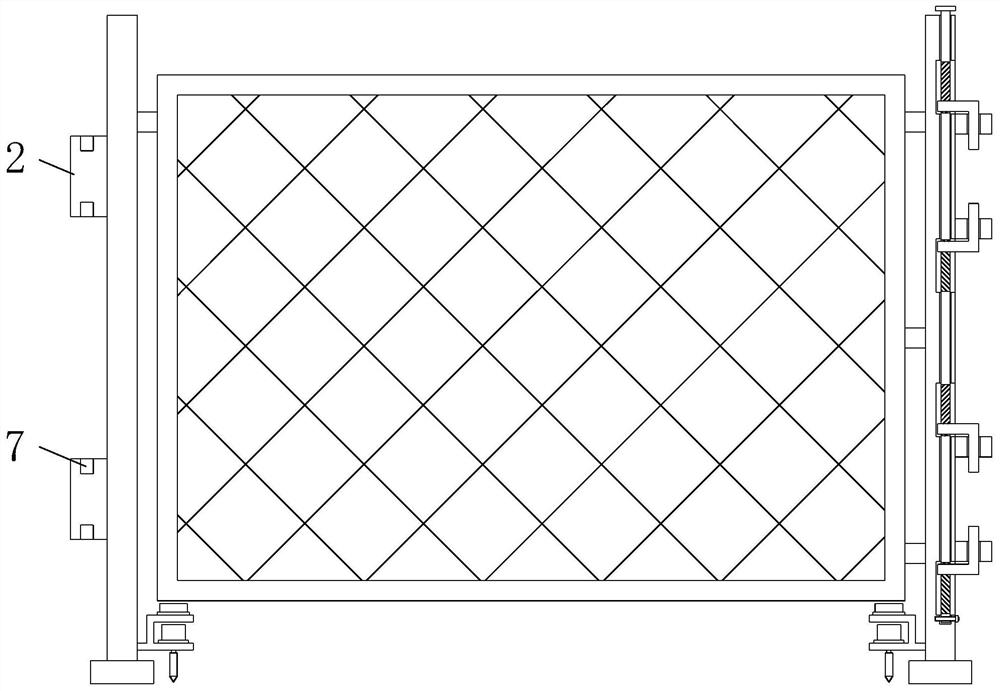

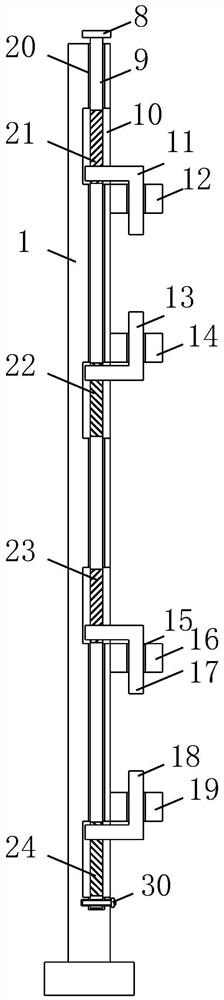

Safety protection fence for building engineering construction and using method thereof

PendingCN112647759AImprove splicing strengthImprove the safety of useBatteries circuit arrangementsFencingStructural engineeringInternal connection

The invention discloses a safety protection fence for building engineering construction, and belongs to the technical field of building engineering construction. The safety protection fence comprises two supporting rods; a frame is arranged in the middles of the two supporting rods; a filling net is connected to the interior of the frame; two sides of the frame are connected with the supporting rods on the corresponding sides through a plurality of connecting blocks; and the upper side and the lower side of the side, away from the frame, of one supporting rod are connected with large splicing blocks. By arranging the upper large splicing block, the lower large splicing block, splicing holes, a first small splicing block, a second small splicing block, a third small splicing block, a fourth small splicing block, splicing through holes, a first splicing rod, a second splicing rod, a third splicing rod and a fourth splicing rod, splicing of adjacent safety protection fences can be achieved through connection of the upper sides and the lower sides by virtue of mutual cooperation of structures; and the splicing strength between the safety protection fences is improved, so that the use safety of the safety protection fences is improved.

Owner:NANTONG XINHUA CONSTR GROUP

Solar cell module and preparation method thereof

PendingCN111509071AImprove splicing strengthEliminate stitching gapsPhotovoltaic energy generationSemiconductor devicesPhysicsElectrical battery

The invention provides a solar cell module and a preparation method thereof. The solar cell module comprises: a front plate; a back plate arranged opposite to the front plate; a water vapor blocking piece clamped between the front plate and the back plate, wherein the water vapor blocking piece is matched with the front plate and the back plate to form a closed containing space; at least two solarcells accommodated in the containing space, wherein two adjacent solar cells in the at least two solar cells are arranged at intervals; and an isolation glue arranged between the adjacent solar cells, wherein the isolation glue is bonded and fixed with the back plate and the front plate. The solar cell module can resist the influence of water vapor and improve the splicing strength.

Owner:上海祖强能源有限公司

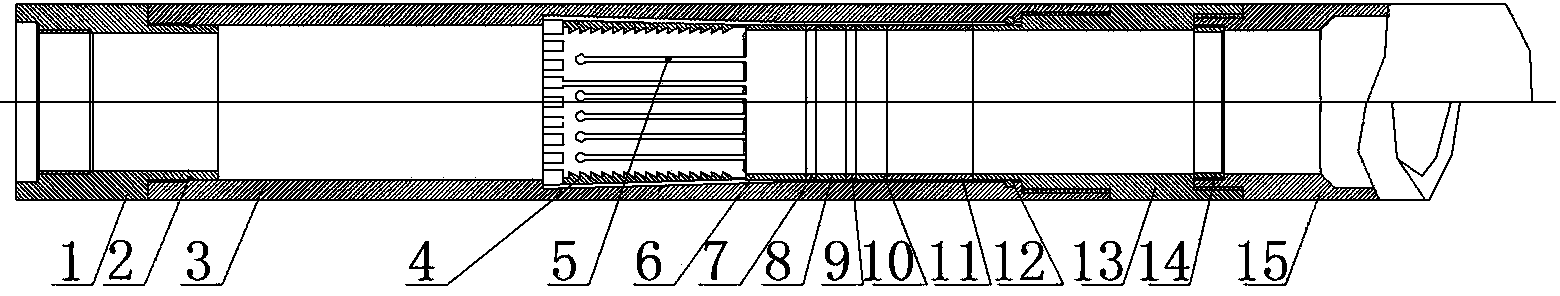

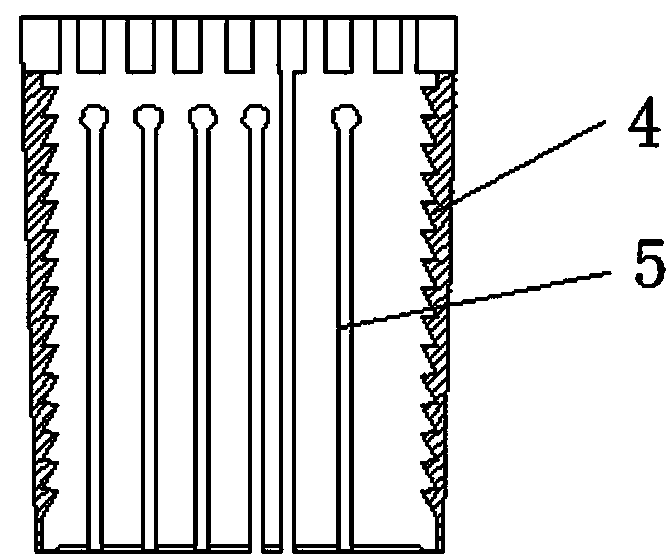

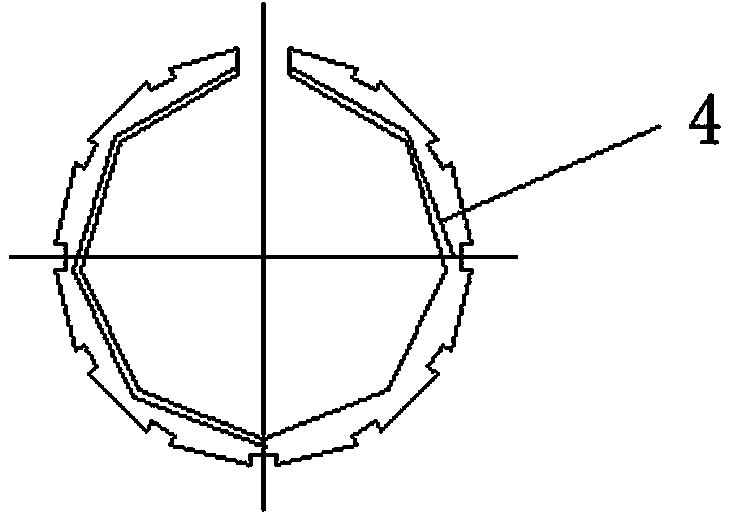

Multifunctional bushing self-sealing repair and connection device

InactiveCN103643914AAchieve secondary sealingImprove sealingBorehole/well accessoriesUpper jointUltimate tensile strength

The invention relates to the technical field of oil filed oil well repair tools and particularly relates to a multifunctional bushing self-sealing repair and connection device. The repair and connection device comprises a grappling component and a sealing component. The grappling component comprises an upper joint, a guiding shoe, an outer cylinder and a connection cylinder which are arranged between the upper joint and the guiding shoe successively and a slip connected internally with the outer cylinder. Locating keys on the inner wall of the outer cylinder are snapped in grooves of the slip, and a milling ring is arranged at the connection position of the connection cylinder and the guiding shoe. According to the device, the structure is used, so that the inner drift diameter is kept unchanged; meanwhile, the primary seal is achieved through lead rings, and the secondary seal is achieved through cementing well cementation, so that the device is good in seal performance, convenient to operate and use and capable of effectively improving the repair and connection strength and prolonging the service life. Besides, the device has the advantages of being reasonable in design, simple in structure, low in manufacture cost and the like.

Owner:JIANGSU JUNXINYI GASOLINEEUM MACHINERY

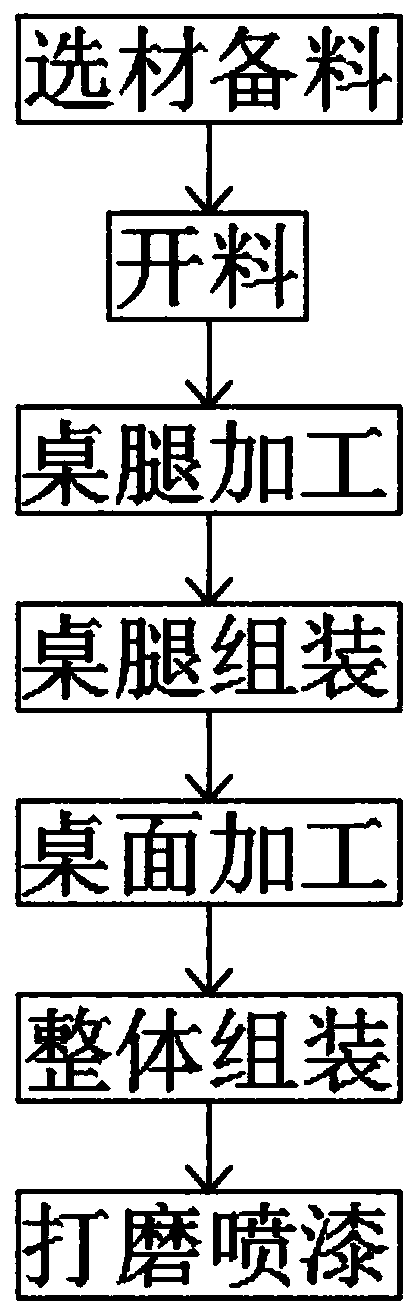

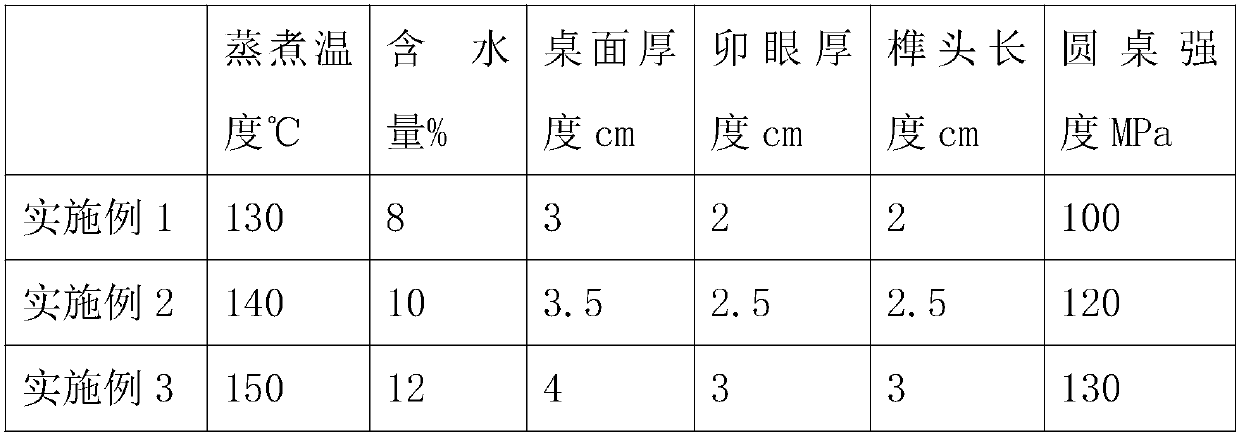

Solid wood round table processing technology

The invention discloses a solid wood round table processing technology. The solid wood round table processing technology comprises the specific steps that material selection and preparation are carried out, specifically, wood without white skin of heartwood is selected, the wood is placed in a wood cooking tank for cooking and sterilization and then is put in a wood drying box for drying, and thewood is discharged from the box for preparation; and material cutting is carried out, specifically, the dried wood in the first step is placed on a material cutting machine for cutting. According to the solid wood round table processing technology, when the wood is selected, the wood without the white skin of heartwood is selected, the situations of wormhole and decay on the wood can be reduced, and the wood strength is increased; meanwhile, wood plate breaking during processing is avoided, in the process of desktop processing, a biscuit tenon is adopted for splicing to increase the splicing strength of wood plates, the connection is more stable, the strength of desktops is improved, the precision requirement is not high, and operating is facilitated; and when polishing and painting are carried out, sprayed paint is waterborne polyurethane paint which is environment-friendly, volatile matter is non-toxic and tasteless, the water resistance, abrasion resistance and aging resistance of the desktops are improved, and better application prospects are brought.

Owner:YINGSHANG CHENJIA CRAFT FURNITURE

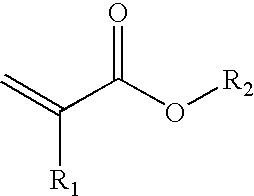

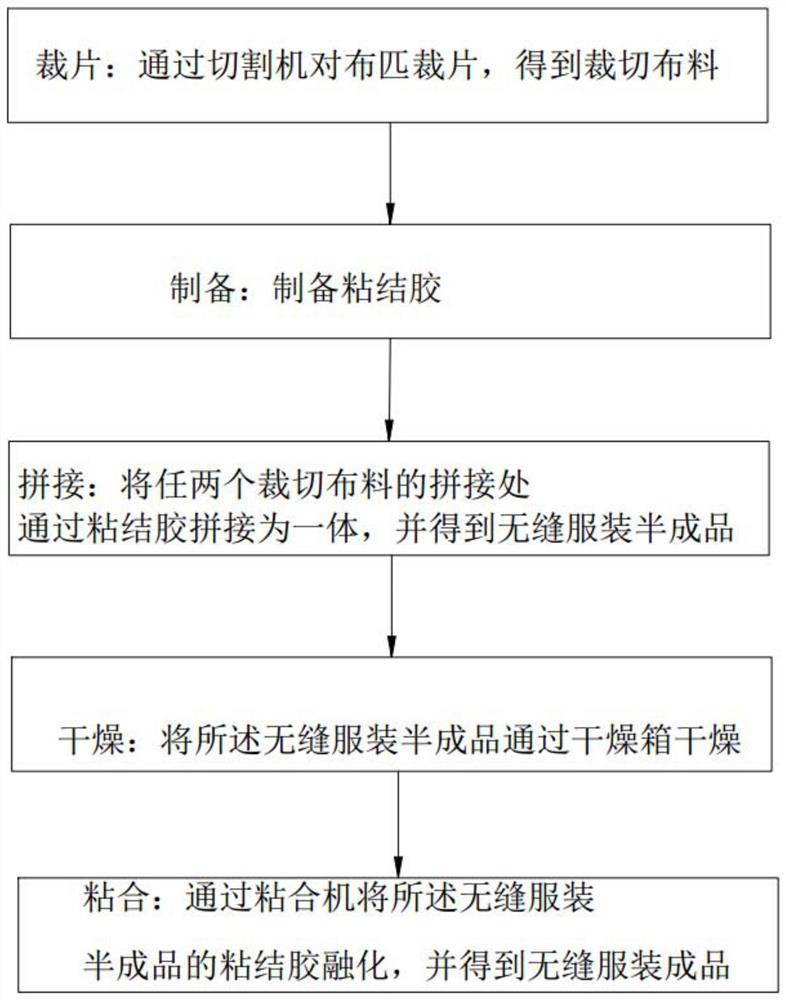

Bonding glue and manufacturing method of seamless clothes

InactiveCN111732900AHigh bonding strengthImprove splicing strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveDichloropropanePolymer science

The invention discloses a bonding glue and a manufacturing method of seamless clothes. The bonding glue comprises the components in parts by weight: 40 to 50 parts of bisphenol F epoxy resin, 10 to 18parts of a silane coupling agent, 8 to 20 parts of diatomite, 4 to 12 parts of dimethyl carbonate, 6 to 12 parts of dichloropropane, 8 to 20 parts of methyl methacrylate, 9 to 21 parts of N-beta-(aminoethyl)-gamma-aminopropyltrimethoxysilane, 10 to 16 parts of dibutyltin dilaurate, 8 to 20 parts of organic bentonite and 10 to 20 parts of kaolin. The adopted bonding glue is high in bonding strength, so that high bonding strength between cloth of the clothes is guaranteed, gaps are not prone to being reserved, the phenomena of dampness, mildewing and the like are avoided, and the splicing strength between the cloth is further improved.

Owner:JIANGXI INST OF FASHION TECH

Bundling type anti-falling device for power pipe transportation

The invention discloses a bundling type anti-falling device for power pipe transportation. The device comprises a pipe body fixing frame and a rigid rope, wherein the pipe body fixing frame is formedby splicing a plurality of pipe body fixing units in a rectangular shape, the pipe body fixing unit comprises a left fastener and a right fastener which are used for clamping a power pipe, a first arcgroove is formed in the left fastener, a second arc groove is formed in the right fastener, the first arc groove and the second arc groove are matched with the power pipe, a first positioning columnand a fourth positioning column are arranged on the front side wall of the left fastener, a second positioning column and a third positioning column are arranged on the front side wall of the right fastener, the first positioning column, the second positioning column, the third positioning column and the fourth positioning column are arranged in a rectangular shape, and the rigid rope penetrates through the first positioning column, the second positioning column, the third positioning column and the fourth positioning column and is wound around the power pipe clockwise. The bundling type anti-falling device for power pipe transportation can achieve the purposes of stably storing the power pipes and improving the transportation reliability.

Owner:江苏通亚工程材料有限公司

Steel pylon inclination correction bolt and pylon connection rectifying device applying same

PendingCN108223539AIncrease lift heightImprove installation qualityScrewsFoundation engineeringMechanical engineeringEngineering

The invention discloses a steel pylon inclination correction bolt which comprises an upper bolt portion and a lower nut portion. The upper bolt portion and the lower nut portion are of an integrated structure, and the top of the upper bolt portion is provided with a connector. The inclination correction bolt is in the integrated design, accordingly, connection strength can be improved, space limitation does not need to be considered in the installation process, and installation quality of the connection rectifying device is further improved.

Owner:STATE GRID CORP OF CHINA +1

Novel geogrid structure

ActiveCN112681281AAchieve lockingAvoid shrinkage elastic deformationSoil preservationStructural engineeringGeogrid

The invention provides a novel geogrid structure, and relates to the technical field of engineering construction. A first matching part is arranged at one end of the novel geogrid structure, and a second matching part used for being matched with a first matching part of another novel geogrid structure is arranged at the other end of the novel geogrid structure. The first matching part is provided with matching blocks distributed in an array mode, and matching columns are arranged at the ends of the matching blocks. The matching columns are provided with notches, the end walls of the notches are sunken in the axial direction of the notches to form the notches, and the notches further penetrate through the side walls of the two opposite sides of the matching columns. Clamping blocks are further arranged on the side walls of the matching columns in a protruding mode. The matching columns are made of elastic materials. The second matching part is provided with matching grooves used for being matched with the matching blocks, and matching through holes used for being matched with the matching columns are formed in the groove bottoms of the matching grooves. The novel geogrid structure is simple in structure and easy to operate and implement, the splicing strength can be effectively improved, the matching strength between the novel geogrid structure and a geotechnical layer is optimized, the overall stability and reliability are effectively improved, and the engineering safety degree is further improved.

Owner:GUANGDONG CONSTR CO LTD OF CHINA RAILWAY NO 3 ENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com