Jet stream acoustic lining protective panel

A technology of high-speed airflow and protective panels, applied in aerodynamic tests, measuring devices, instruments, etc., can solve the problems of airflow and sound field influence, affect the accuracy and reliability of data acquisition in wind tunnel tests, and achieve enhanced splicing strength , reduce the impact, reduce the effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

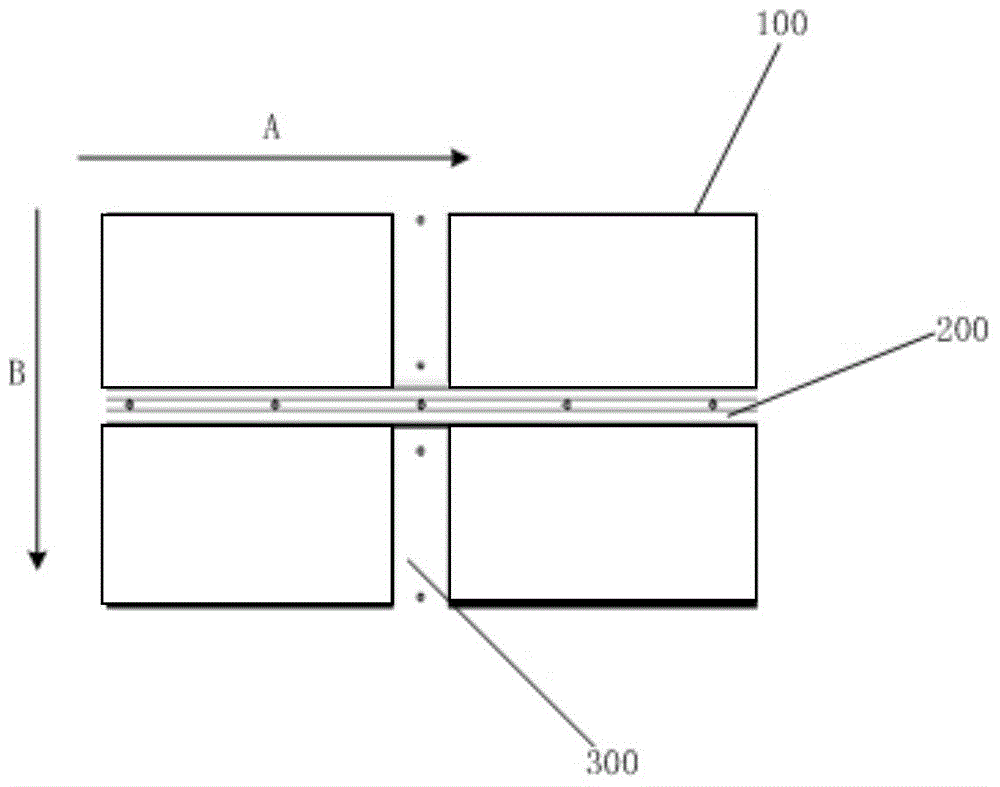

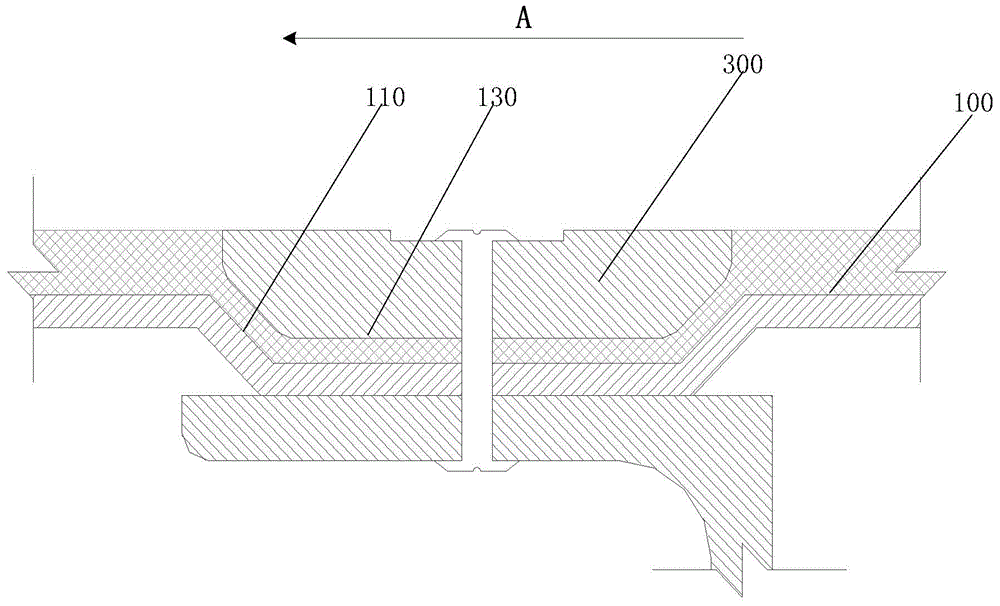

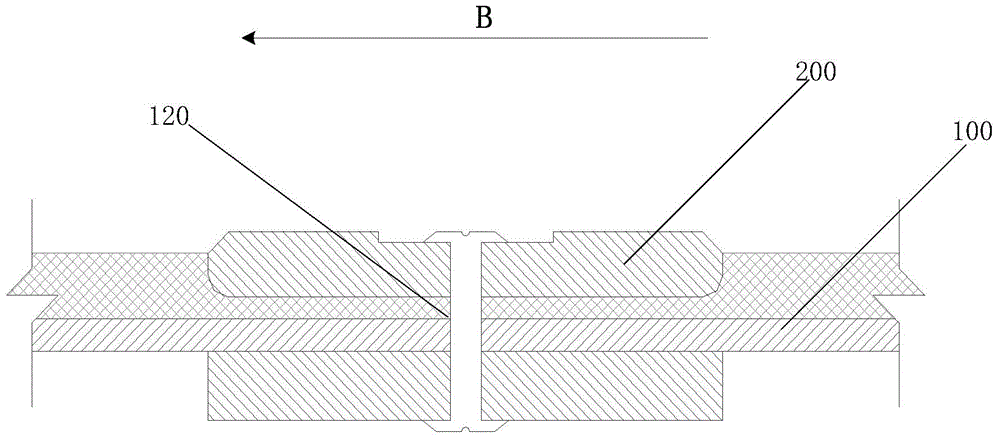

[0016] Considering that in the prior art, in a high-speed airflow environment such as a wind tunnel, the two-way surface pressure splicing used to install and fix the sound-absorbing protective panel on the wall of the wind tunnel has seriously affected the sound-absorbing panel into a complete protective panel. The flow of airflow is prone to turbulence and increased wind noise, which in turn affects technical issues such as the accuracy of data collection in wind tunnel testing. This invention adopts a new process suitable for seam splicing under high-speed airflow, and abandons the two-way surface pressure method. , The open pressure splicing method is adopted in the direction along the high-speed air flow, and the dark pressure splicing method is used in the direction perpendicular to the high-speed air flow, thereby reducing the impact on the high-speed air flow and increasing the splicing strength.

[0017] In order to make the purpose and features of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com