Patents

Literature

277results about How to "Improve the bending capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

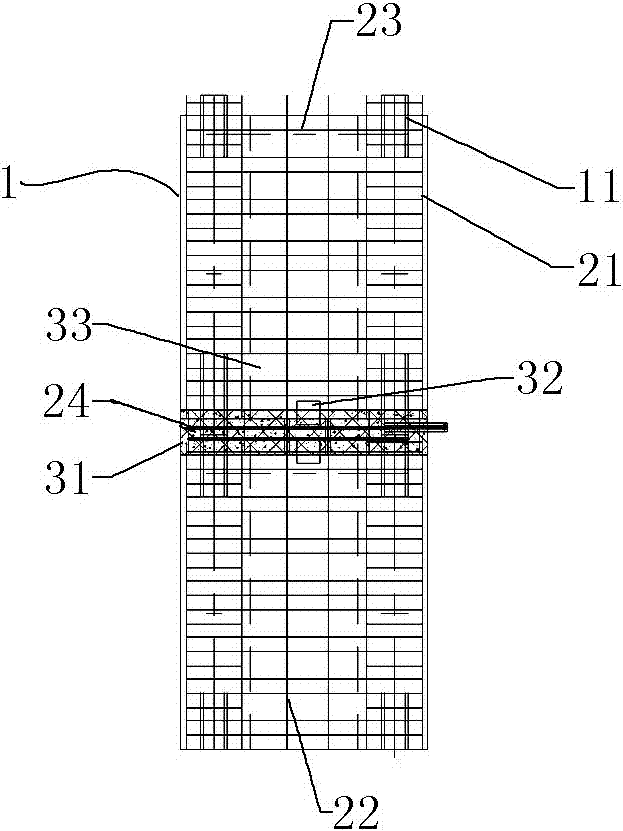

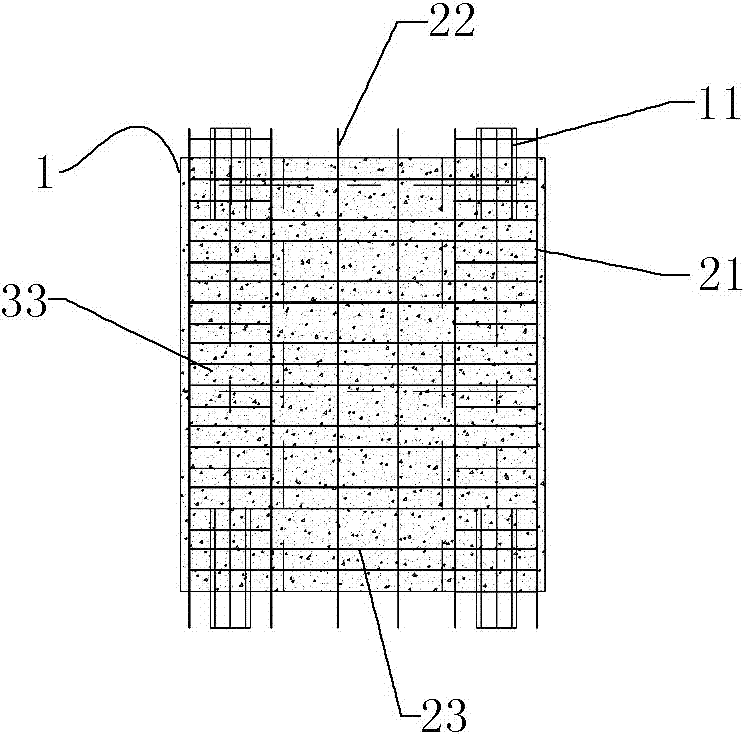

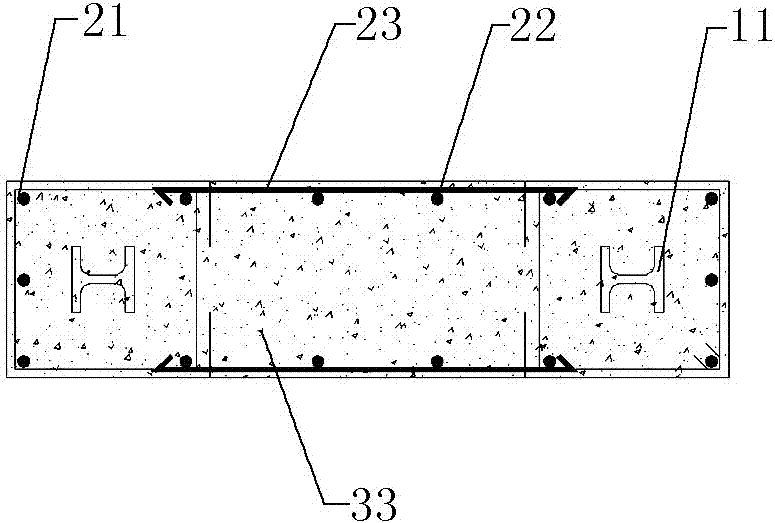

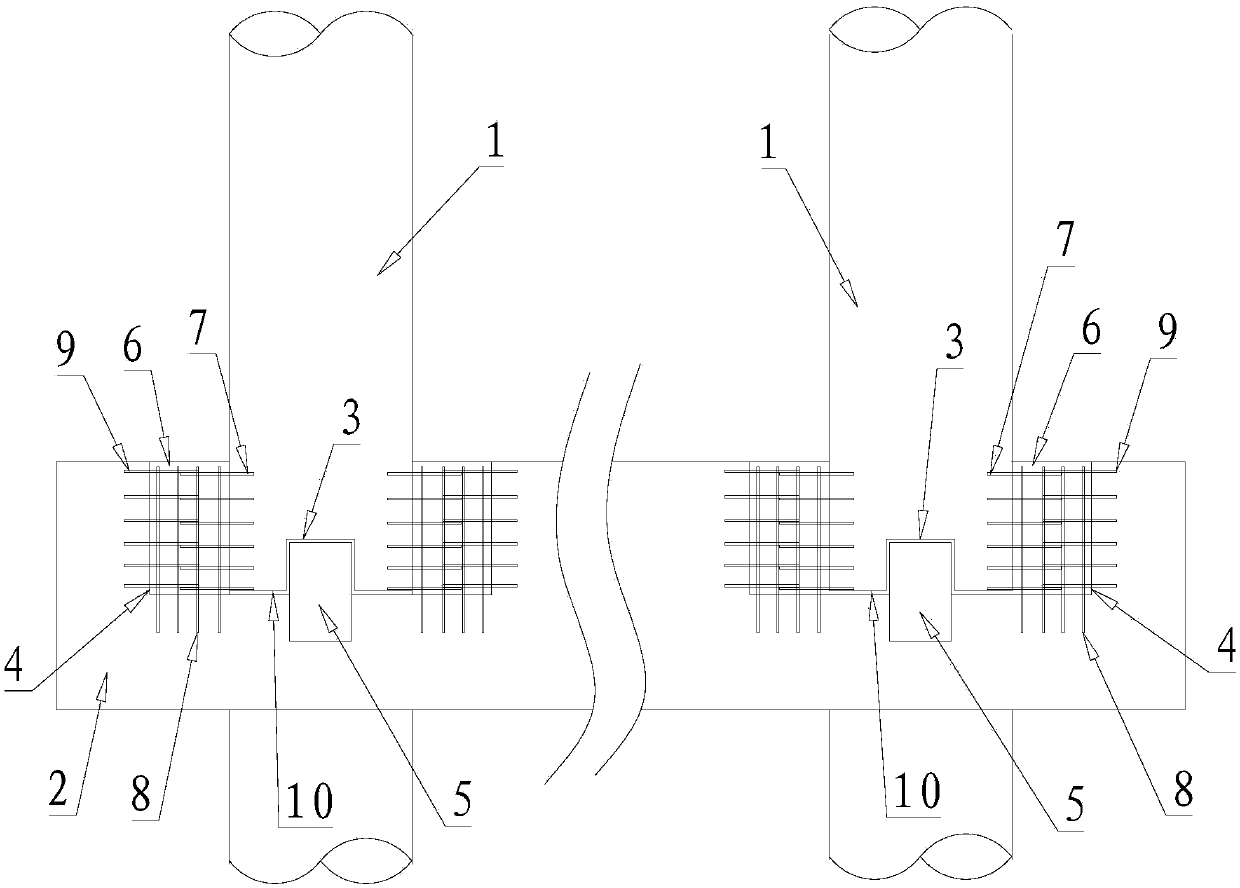

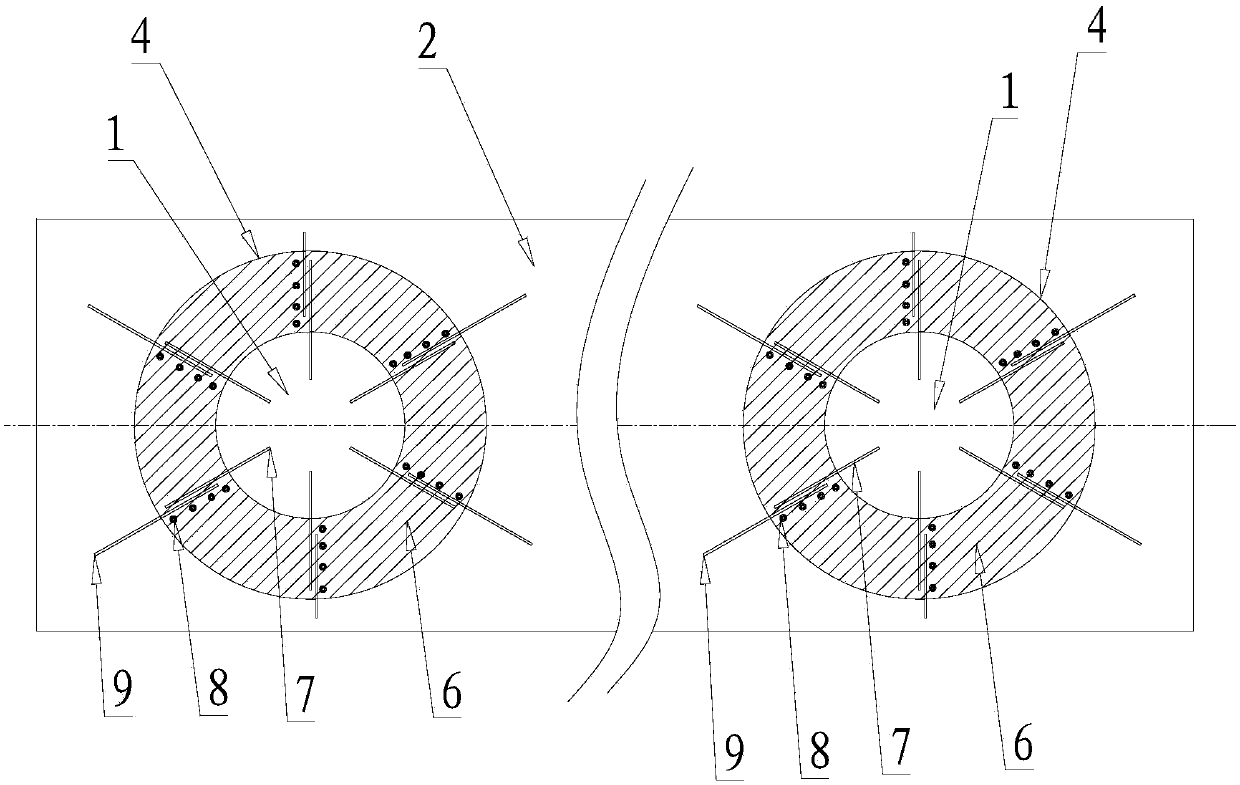

Reinforced type prefabricated steel bar concrete shear wall, structural system and construction method thereof

PendingCN107090925AIncreased shear strengthImprove the bending capacityWallsBrickReinforced concrete

The invention relates to the technical field of structural systems of shear walls, and discloses a reinforced type prefabricated steel bar concrete shear wall, a structural system and a construction method thereof. The reinforced type prefabricated steel bar concrete shear wall is composed of a prefabricated wallboard connected from up to down, and comprises reinforced vertical steel bones, steel bars and poured concrete wall bodies, wherein the reinforced vertical steel bricks and steel bars are located in the edge area of the prefabricated wallboards. The vertical steel bones are arranged discontinuously and are arranged at the connection nodes of the upper and lower ends of the prefabricated wallboards; edge longitudinal bars are fixed by horizontal hooped reinforcements or tie bars and arranged outside the reinforced vertical steel bones in a sleeved mode. The outer sides of the reinforced vertical steel bones are connected with the edge longitudinal bars in a lapped, anchored or welded mode, one end extends out of the concrete walls; the height of the concrete walls is not higher than the height of the edge longitudinal reinforcements and wall body vertical steel bars; the upper and lower adjacent prefabricated wallboards are connected by the corresponding reinforced vertical reinforcements, edge longitudinal reinforcements and walls body vertical steel bars, and connecting gaps are poured at the connection nodes. The reinforced type prefabricated steel bar concrete shear wall, the structural system and the construction method thereof have the advantages of being low in cost and convenient in construction; having excellent shear strength at the connections; being convenient to control the construction quality.

Owner:姚攀峰

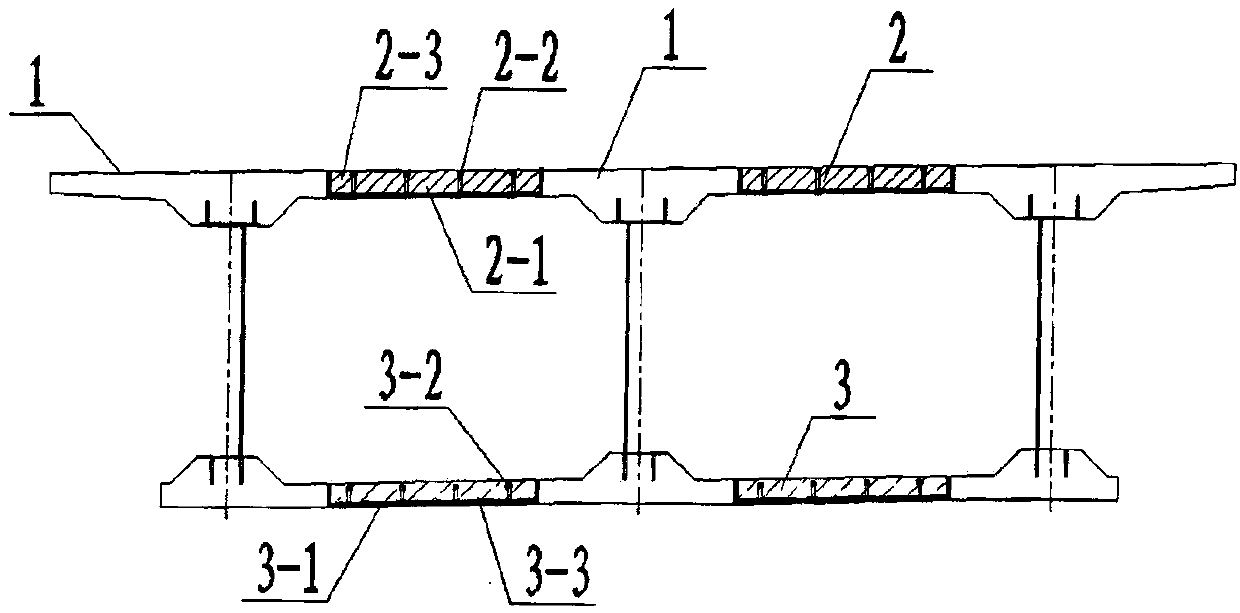

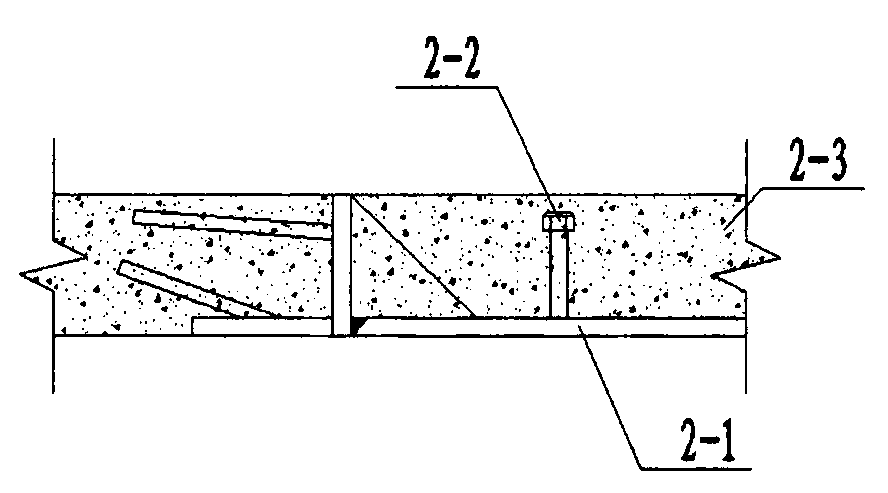

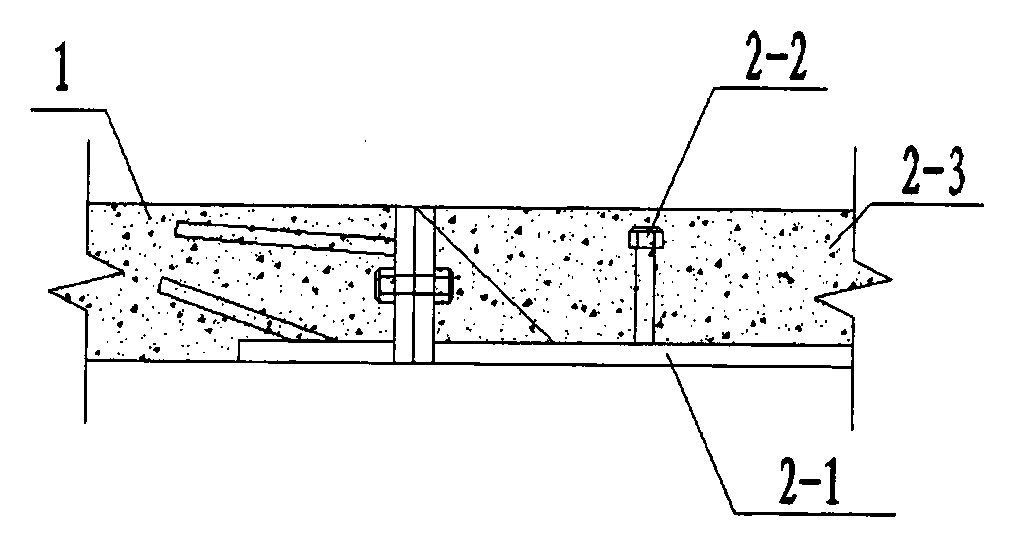

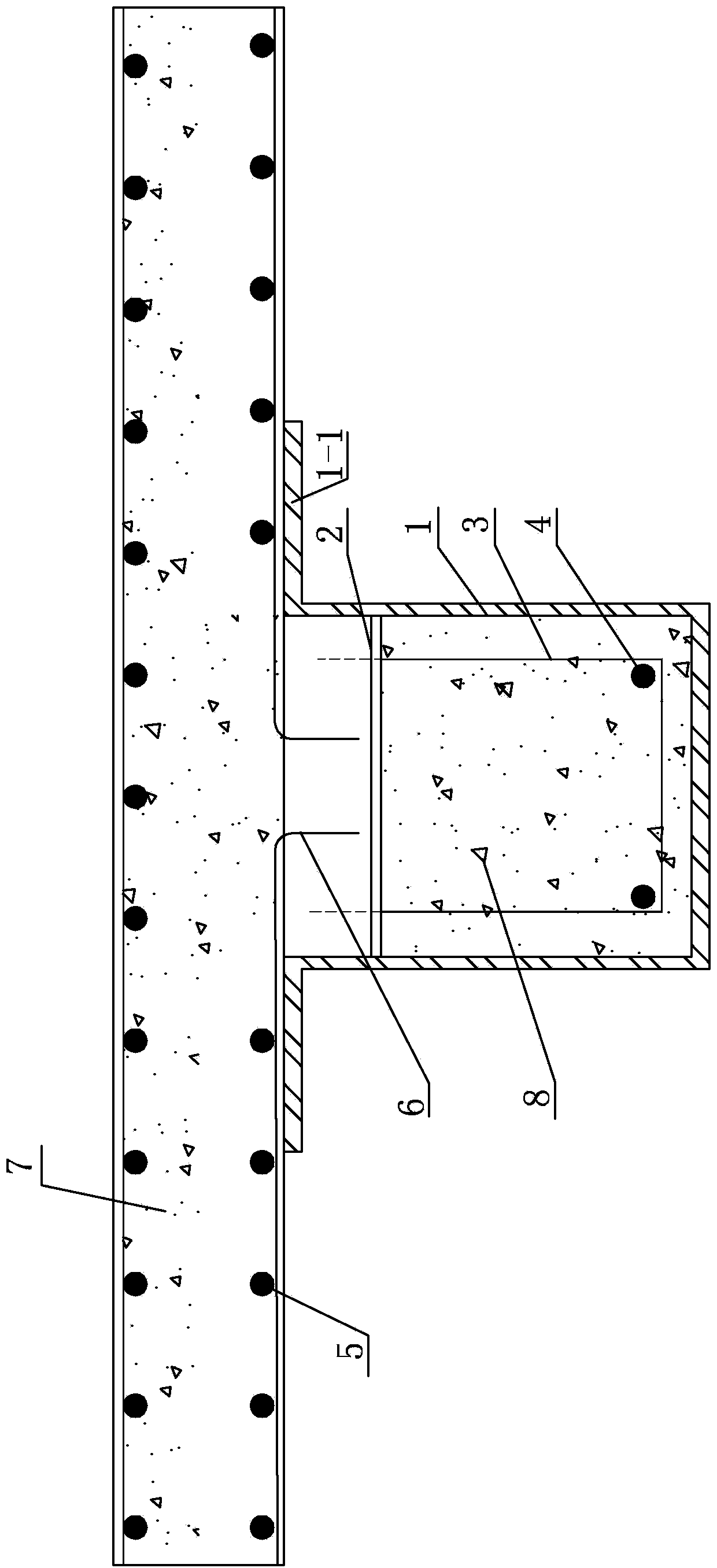

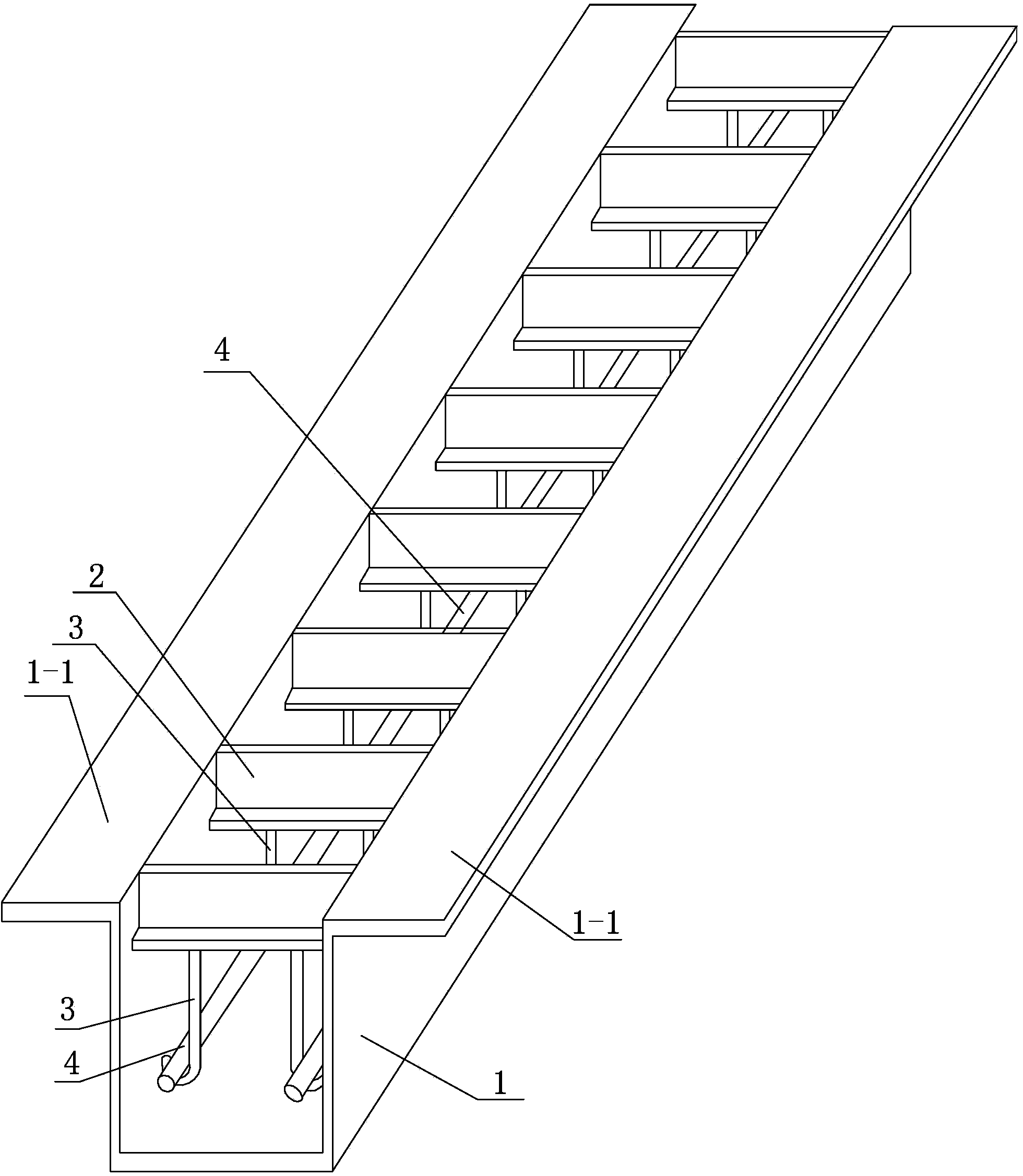

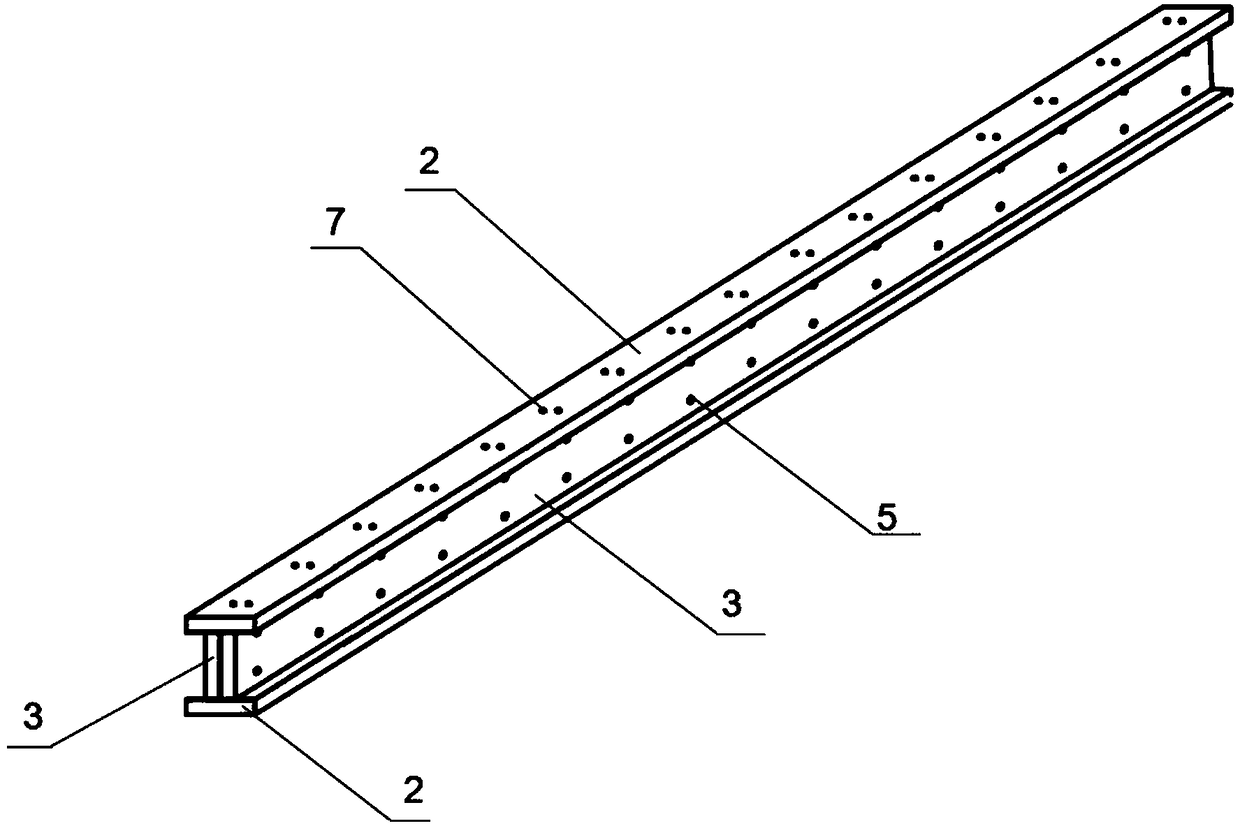

Horizontal splicing corrugated steel web plate combined box girder and construction method

InactiveCN103388303AReduce adverse effectsIncrease spacingBridge erection/assemblySheet steelAbutment

The invention discloses a horizontal splicing corrugated steel web plate combined box girder comprising a combined box girder formed by horizontally splicing multiple precast I-shaped girder units (1); and a top plate lower edge steel plate (2-1) and a bottom plate lower edge steel plate (3-1) are respectively connected to the lower end faces of a top plate wet jointing seam (2) and a bottom plate wet jointing seam (3) of two adjacent precast I-shaped girder units (1). The construction method comprises the steps of mounting the multiple precast I-shaped girder units onto a bridge pier abutment, fixing the top plate lower edge steel plates connected with shearing force nails to the top plate wet jointing seams of every two adjacent precast I-shaped girder units, and pouring top plate wet jointing seam concrete (2-3) by taking the top plate lower edge steel plates as support templates; and then fixing the bottom plate lower edge steel plates connected with the shearing force nails to the bottom plate wet jointing seams of every two adjacent precast I-shaped girder units, and pouring bottom plate wet jointing seam concrete (3-3) by taking the bottom plate lower edge steel plates as the support templates. The horizontal splicing corrugated steel web plate combined box girder and the construction method achieve the aims of simplifying the operation process, reducing work amount, shortening construction period, reducing weight and ensuring construction quality.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

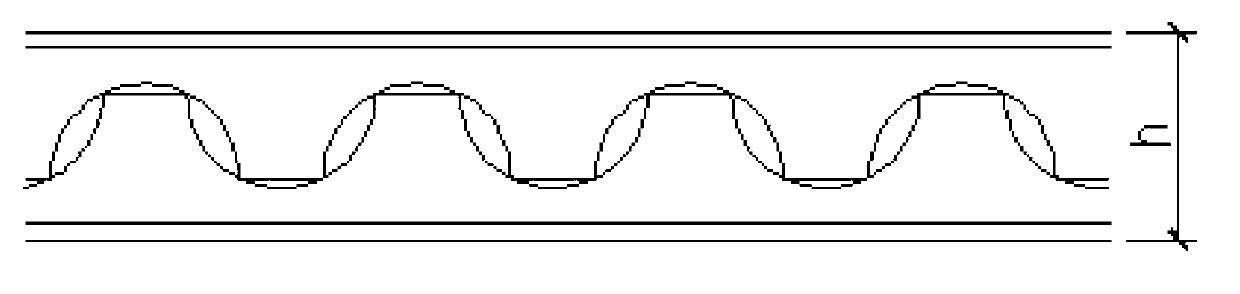

Steel box girder matched with cellular steel web plate

InactiveCN103132649AImprove the bending capacityIncreased bending stiffnessGirdersJoistsMetallurgyBox girder

The invention discloses a steel box girder matched with a cellular steel web plate. The steel box girder comprises two H-shaped steel or I-shaped steel used as web plate components of the steel box girder, further comprises a steel top plate, a steel bottom plate, a clapboard and a reinforcing rib and is characterized in that a plurality of through holes of the same shapes and intervals are formed in two web plates; the steel top plate and the steel bottom plate of the steel box girder are fixedly connected with upper flanges or lower flanges of the web plate components respectively; and a certain number of transverse clapboards and the reinforcing rib are configured. Compared with a solid web steel box girder, the cellular steel box girder disclosed by the invention has the advantages that the resistance capacity and bending resistance rigidity can be increased by about 30% under the condition of same steel use amount; the torsional rigidity of the cellular steel box girder is also greatly increased; simultaneously, the overall stability of the web plate cellular component and the local stability of an overhung flange of the box girder are improved; the use amount of steels is reduced, so that the cost is reduced; and furthermore, the steel box girder disclosed by the invention is attractive in appearance and convenient to maintain.

Owner:GUANGXI UNIV +1

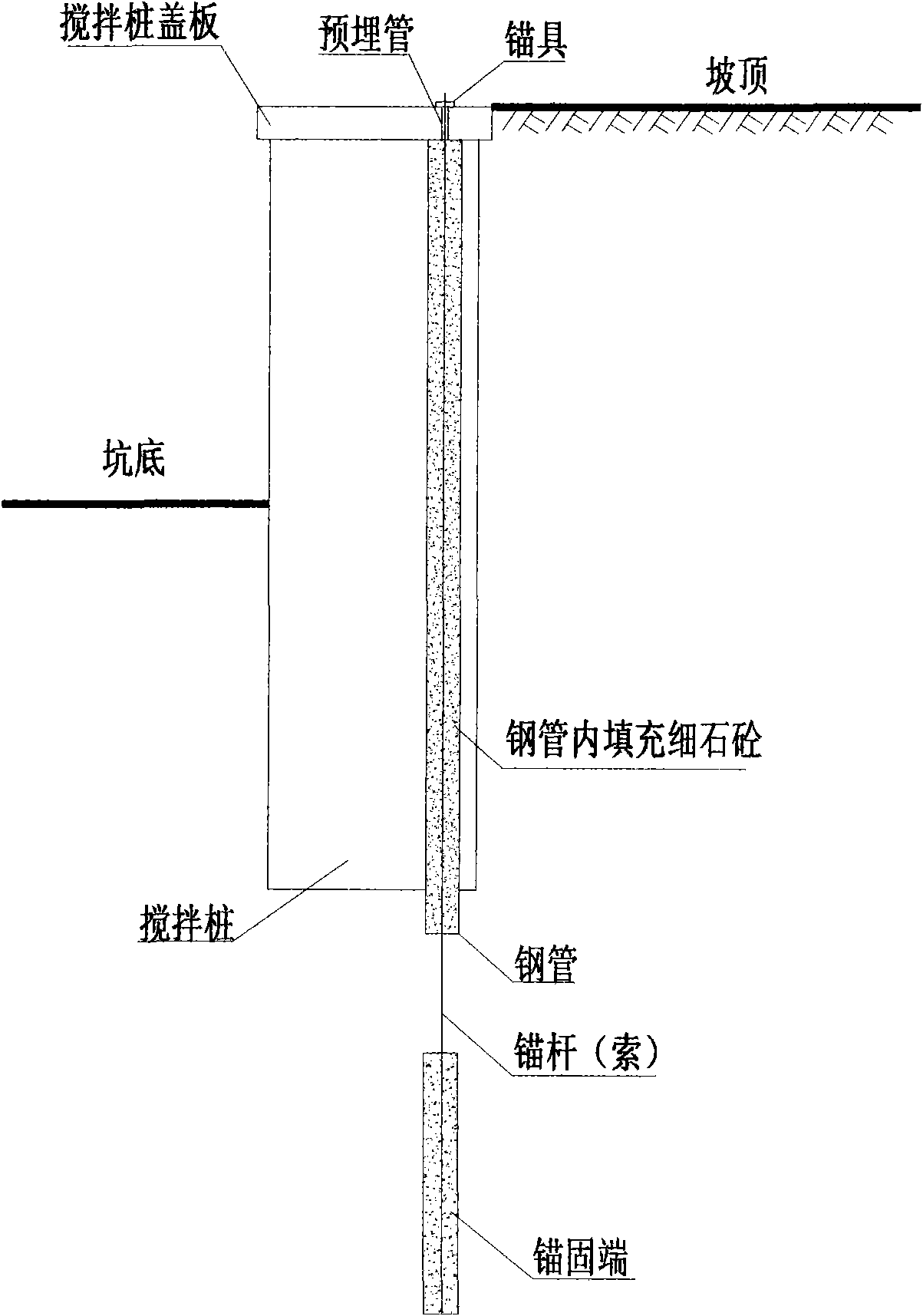

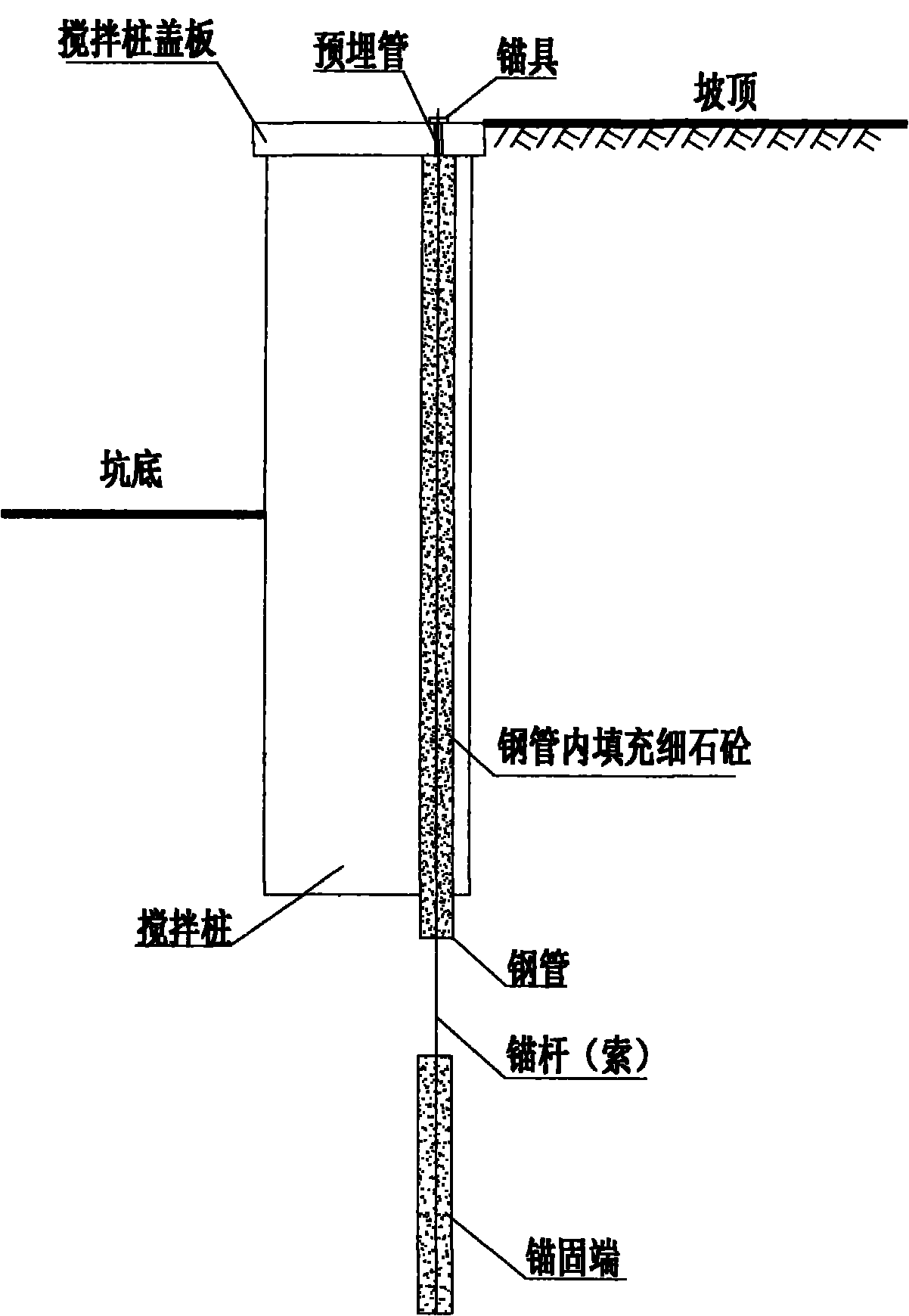

Deep mixing pile-micro pre-stressed steel pipe concrete pile-vertical anchor rod composite foundation pit support method

InactiveCN101851925AImprove overturning resistanceImprove slip resistanceExcavationsBulkheads/pilesLow noisePre stress

The invention provides a deep mixing pile-micro pre-stressed steel pipe concrete pile-vertical anchor rod composite foundation pit support method. The method comprises the following steps: (1) constructing the deep mixing pile; (2) grouting at an anchoring end; and (3) forming the micro pre-stressed steel pipe concrete pile. The method has the advantages that as the deep mixing pile is equipped with the micro pre-stressed steel pipe pile and an anchor rod or an anchor rope, the bending and shearing bearing capacity thereof is improved; the antidumping and anti-slip capability of the wall body of the mixing pile is improved under the condition of not exceeding a land red line; and meanwhile the combined support method has the advantages of short construction period, low noise, no pollution and no soil squeezing and is very beneficial to environmental protection during the construction process, thus being a novel combined support member and a method which are worth to be popularized and applied.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

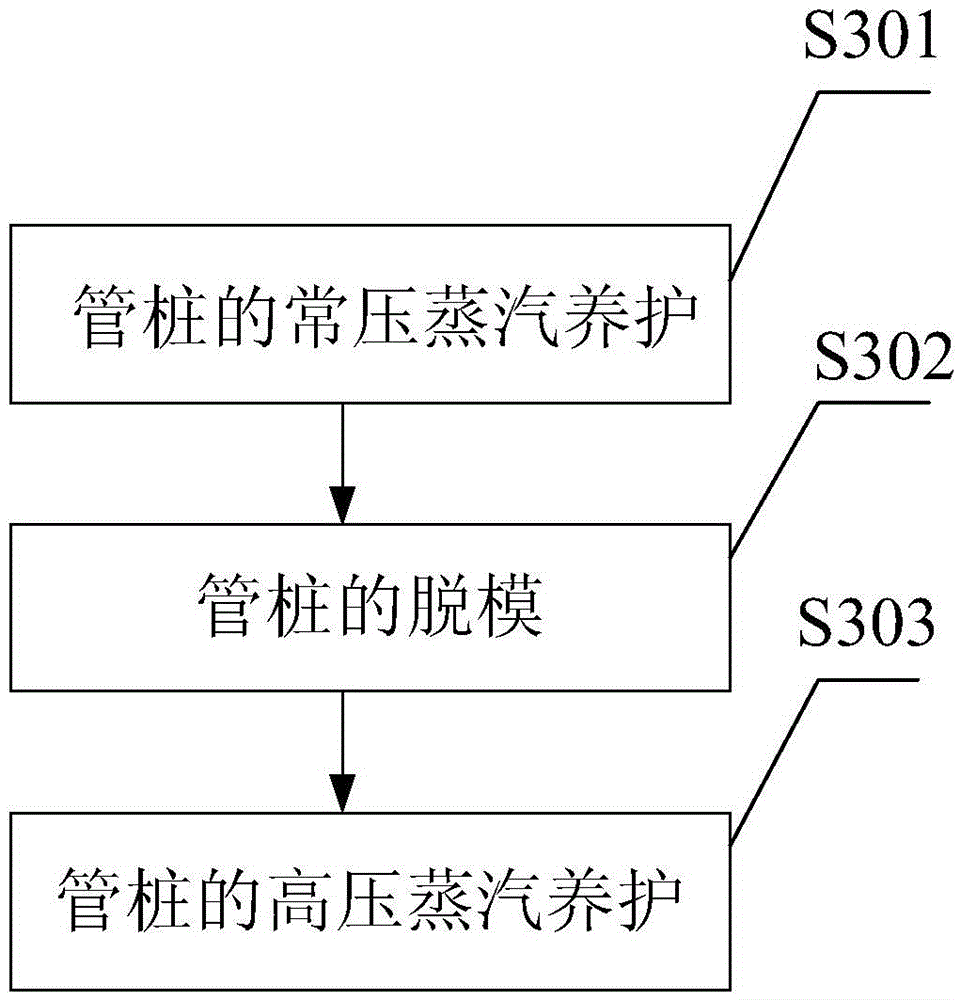

Production method of pretensioning prestressed concrete dynamic load piles

ActiveCN102166788AImprove performanceImprove the bending capacityCeramic shaping apparatusBulkheads/pilesPre stressPre stressing

The invention discloses a production method of pretensioning prestressed concrete dynamic load piles, comprising the following steps: arranging a welded non-prestressed steel reinforcement framework cage in a prestressed steel reinforcement cage; cleaning a corresponding steel die; coating a separant; suspending the double-layer steel reinforcement framework cage in a lower die body of the steel die; respectively arranging the end plates of a connected hooping plate at the two ends of the double-layer steel reinforcement framework cage; casting concrete material to the lower die body of the steel die; carrying out die assembly and pre-stressed tensioning; performing centrifugal shaping; pouring out the surplus starch solution on the inner wall; and carrying out steam curing and secondary steam curing. The production method provided by the invention aims to overcome the shortages in the prior art. The invention provides a method for producing a pretensioning prestressed concrete dynamic load dynamic load pile with horizontal anti-bending bearing capacity, high shearing resistance, high bearing capacity of a single pile, and strong shock resistance.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

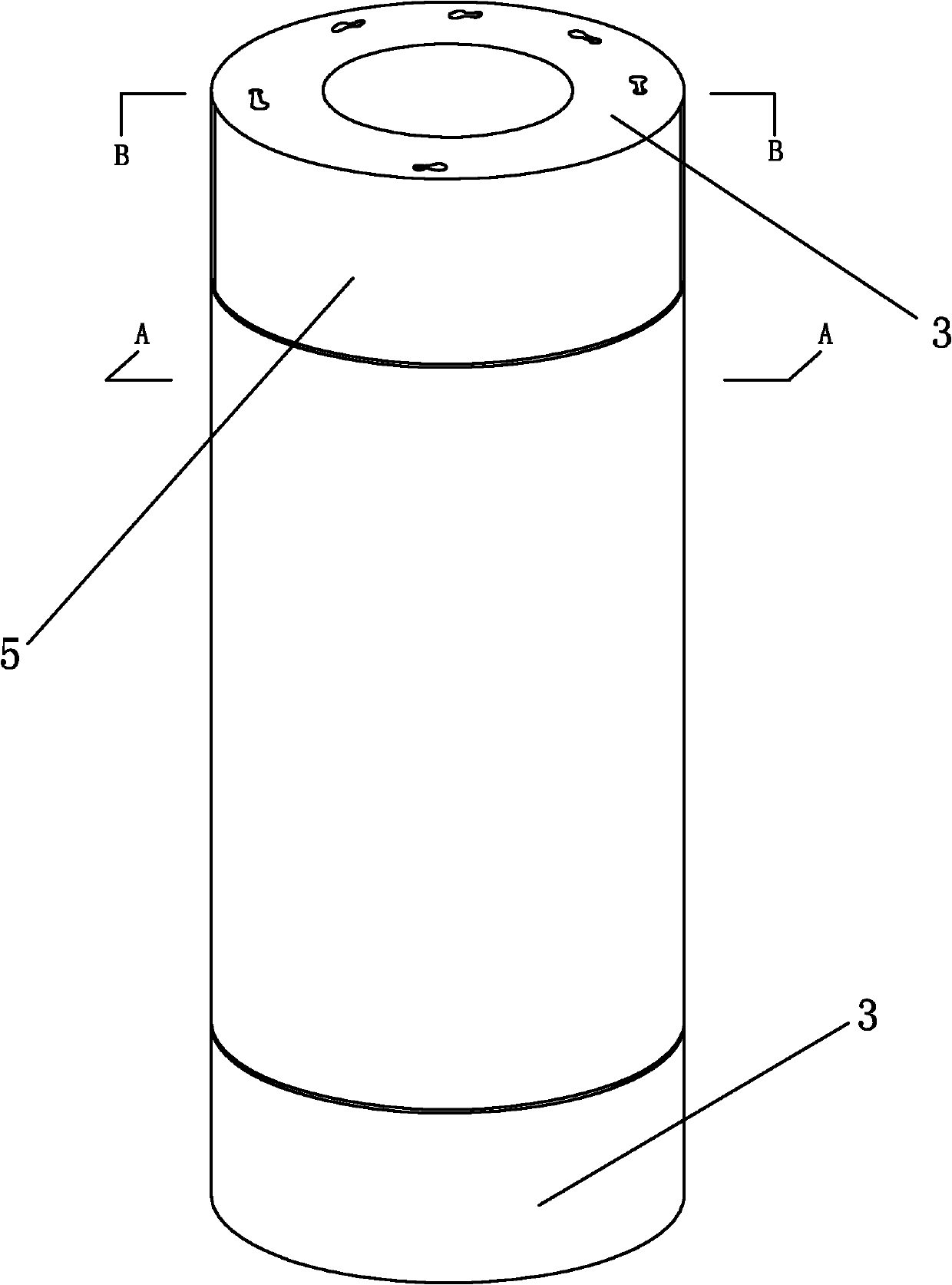

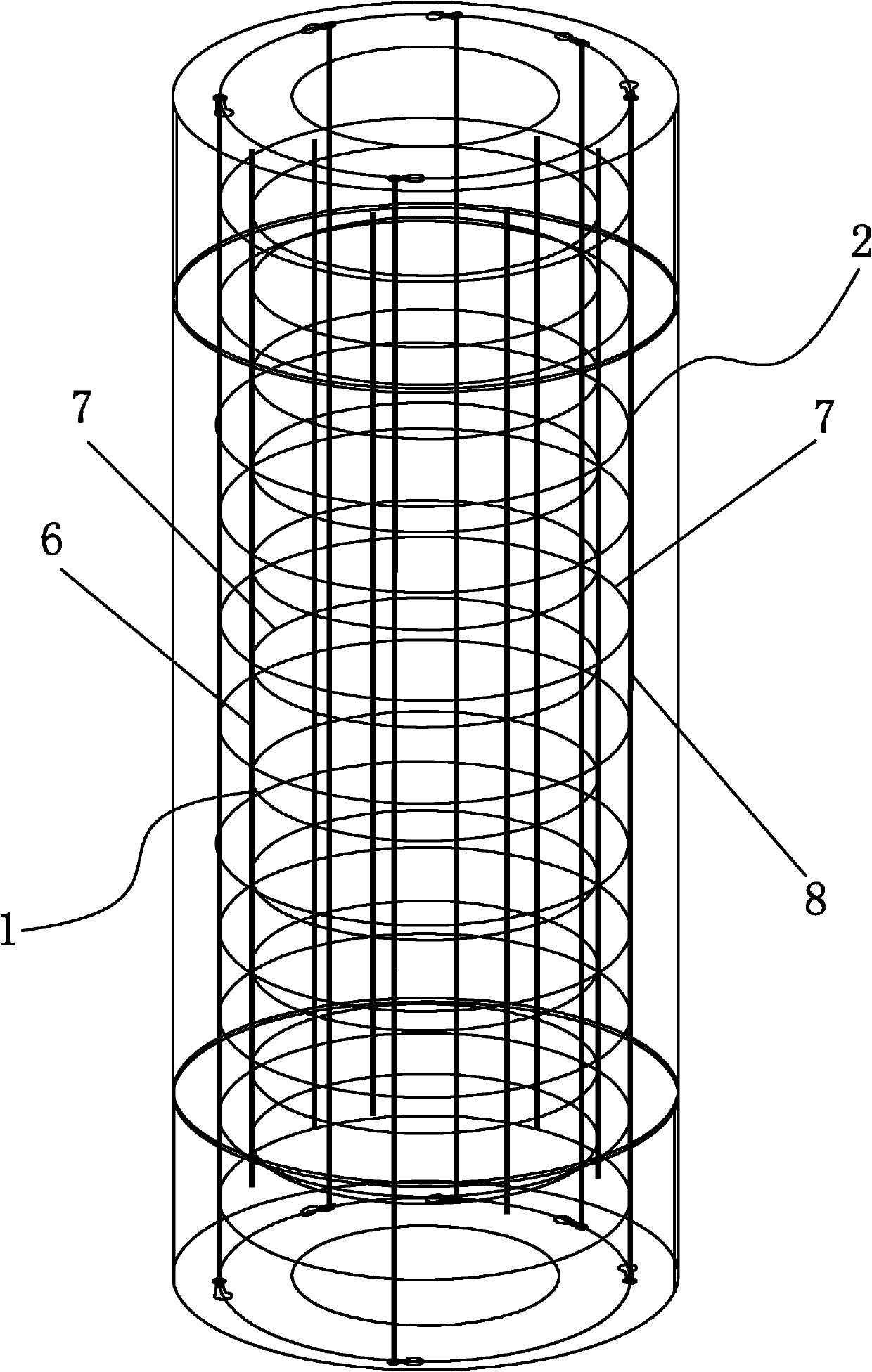

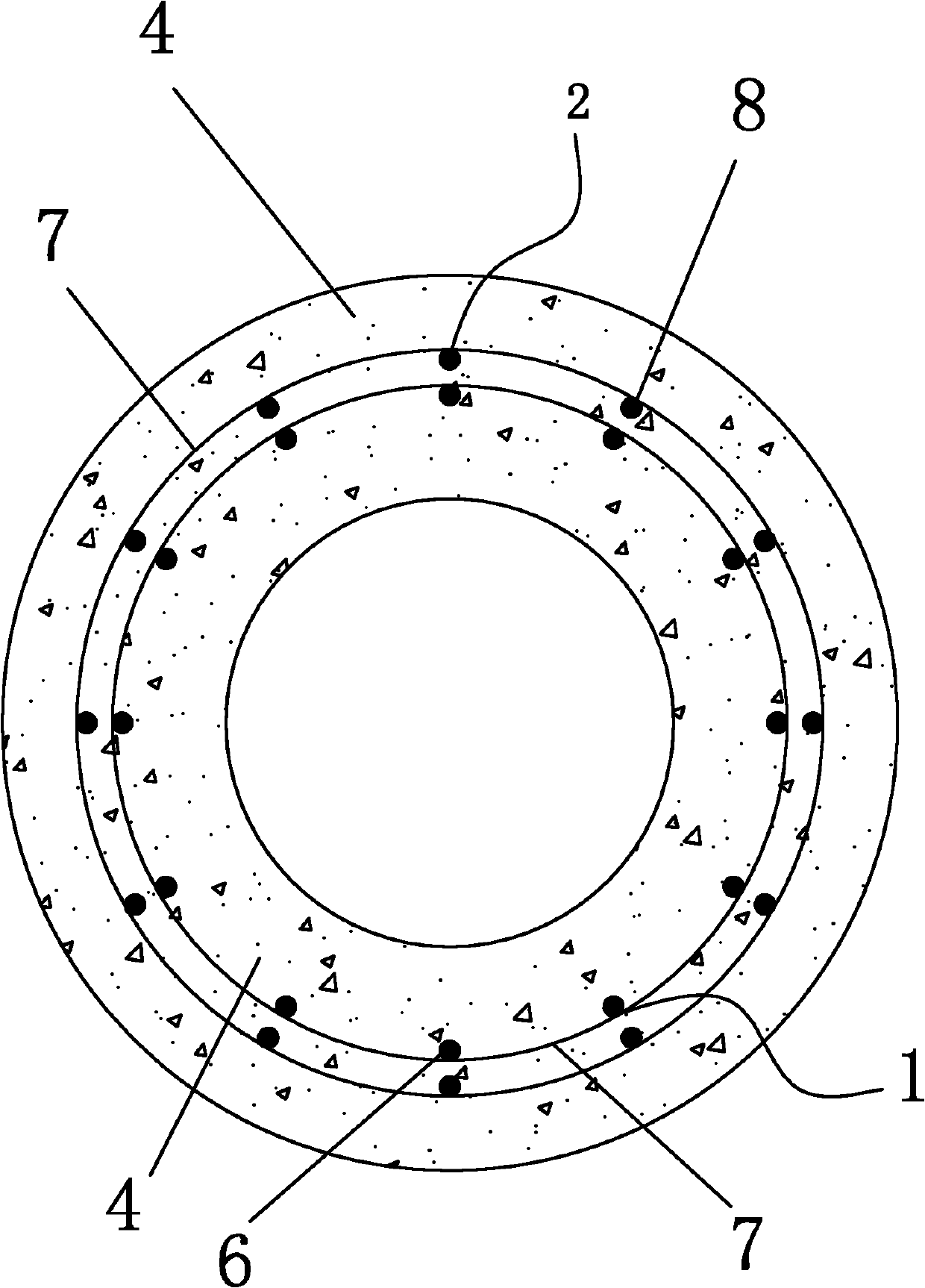

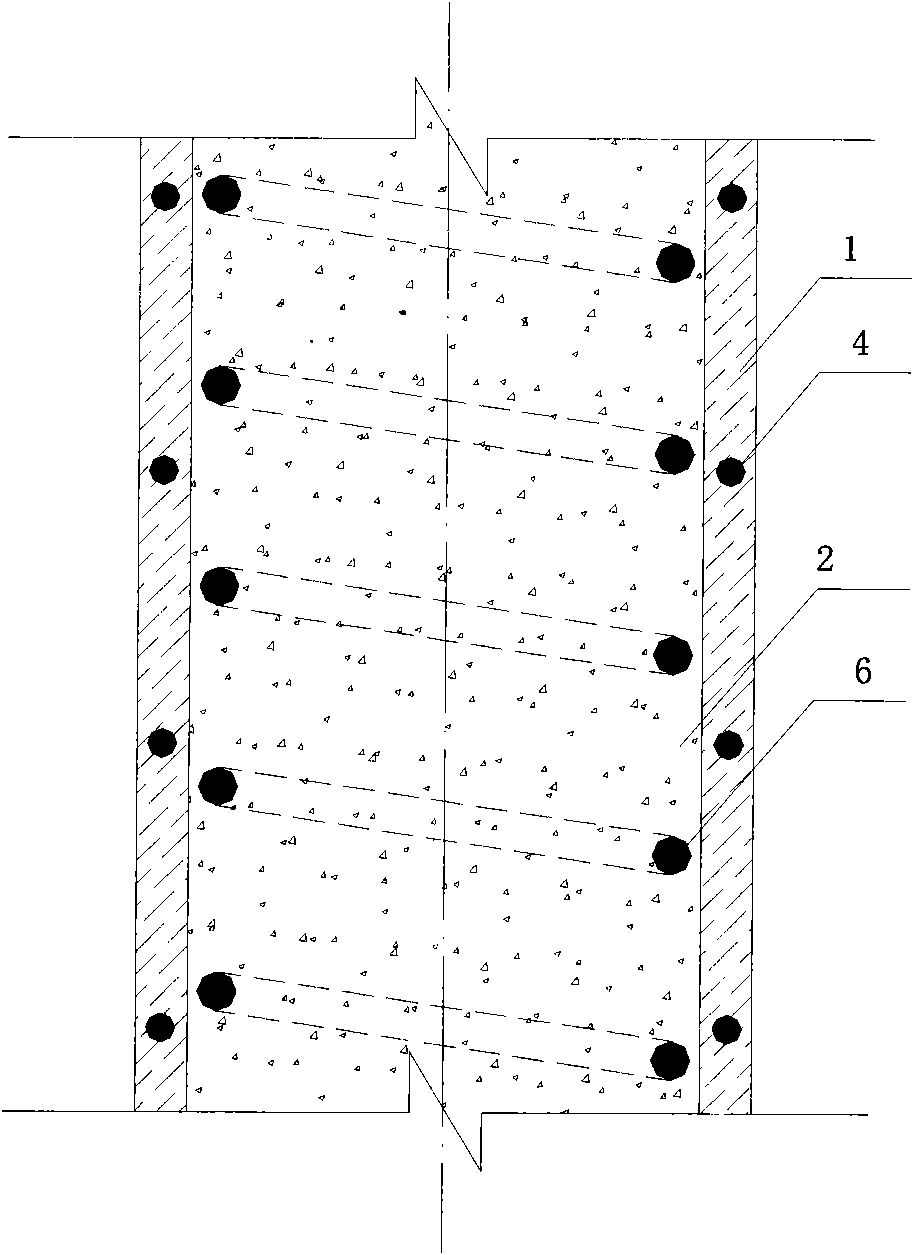

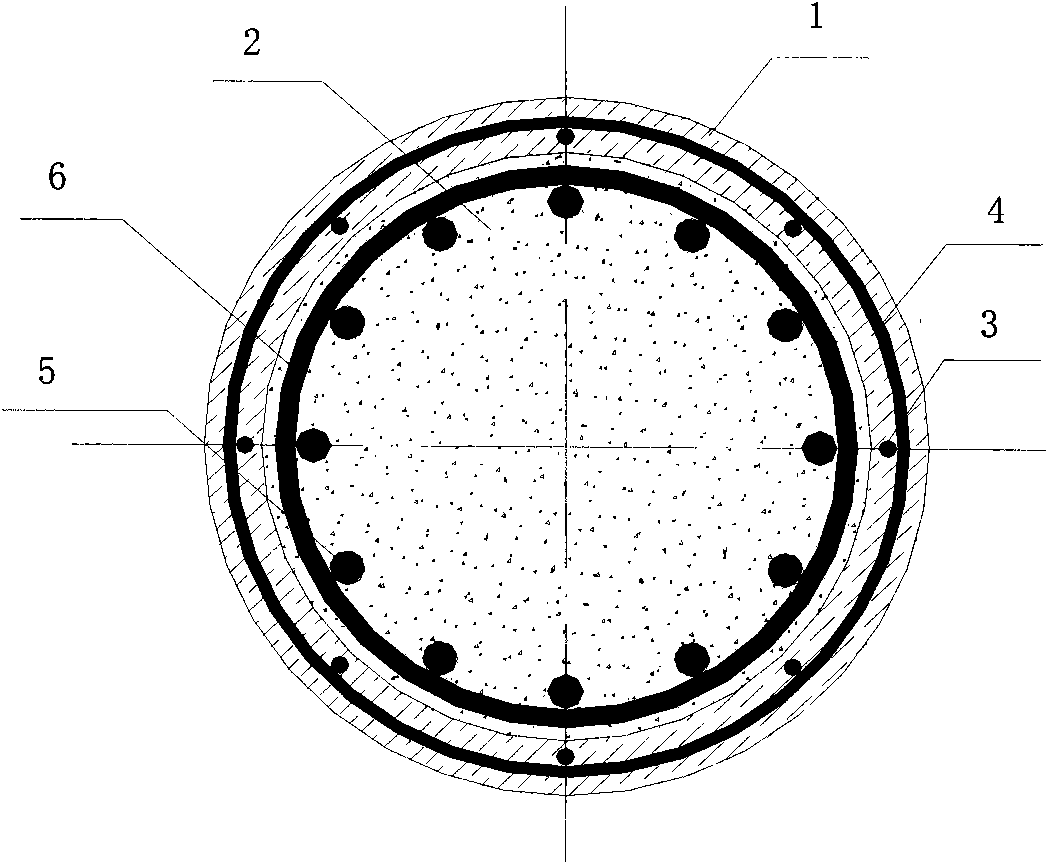

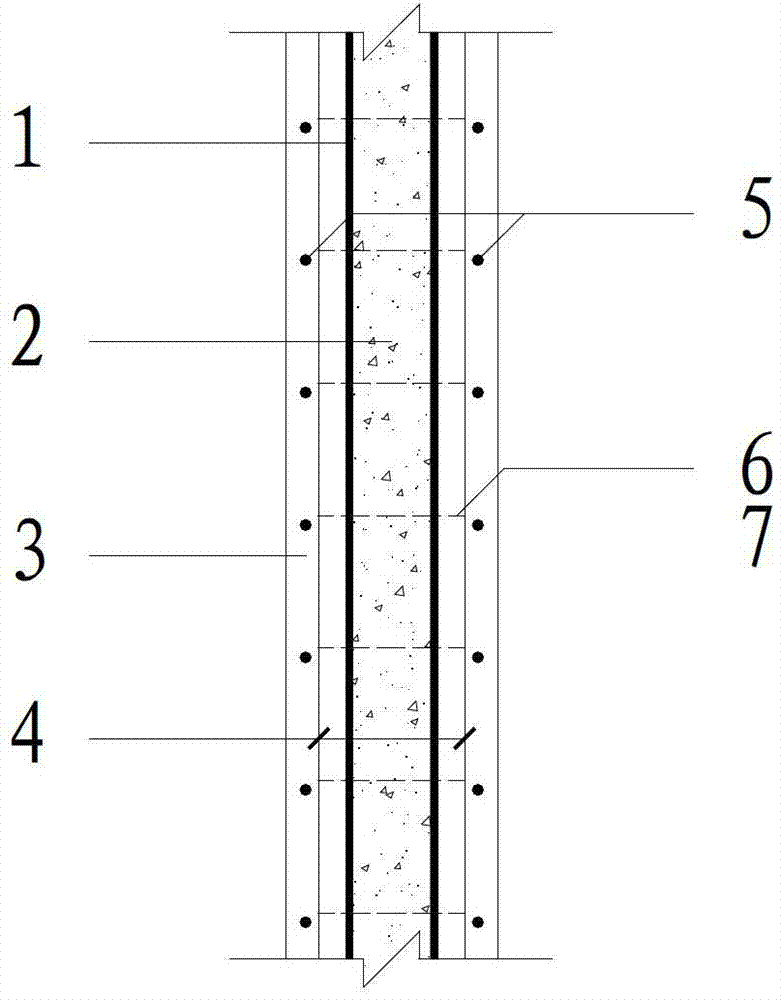

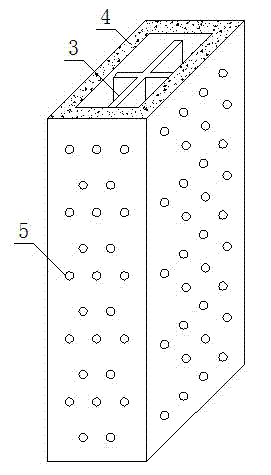

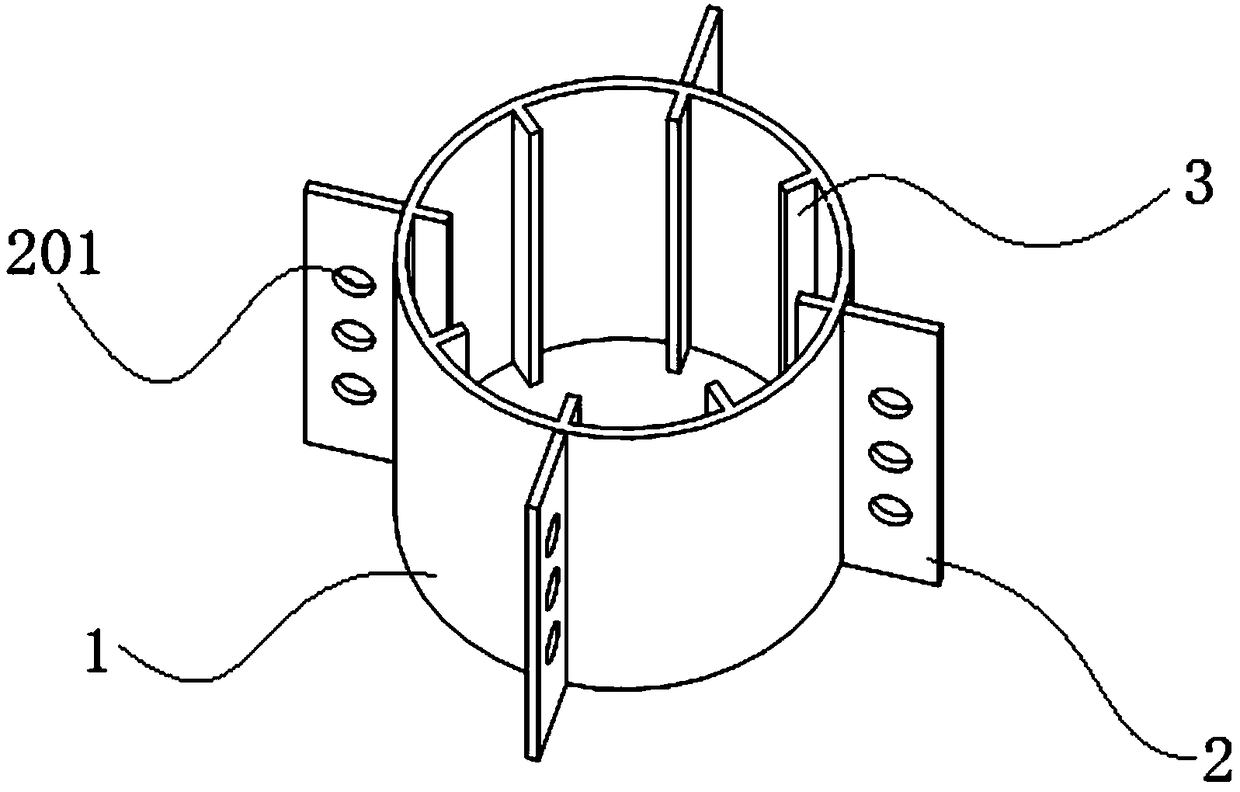

Sleeve reinforced concrete column

InactiveCN102102423AGive full play to the material performanceEasy constructionStrutsPillarsReinforced concrete columnShock resistance

The invention discloses a sleeve reinforced concrete column. The sleeve reinforced concrete column is characterized in that: a sleeve (1) of a reinforced concrete column (2) is a prefabricated active powder concrete sleeve. The sleeve reinforced concrete column has the advantages of convenience for construction, low cost, high axial bearing capacity, good shock resistance, predominant fireproof performance, excellent durability and the like, meanwhile, saves more resources and energy, and accords with the requirements of sustainable development.

Owner:HUNAN UNIV

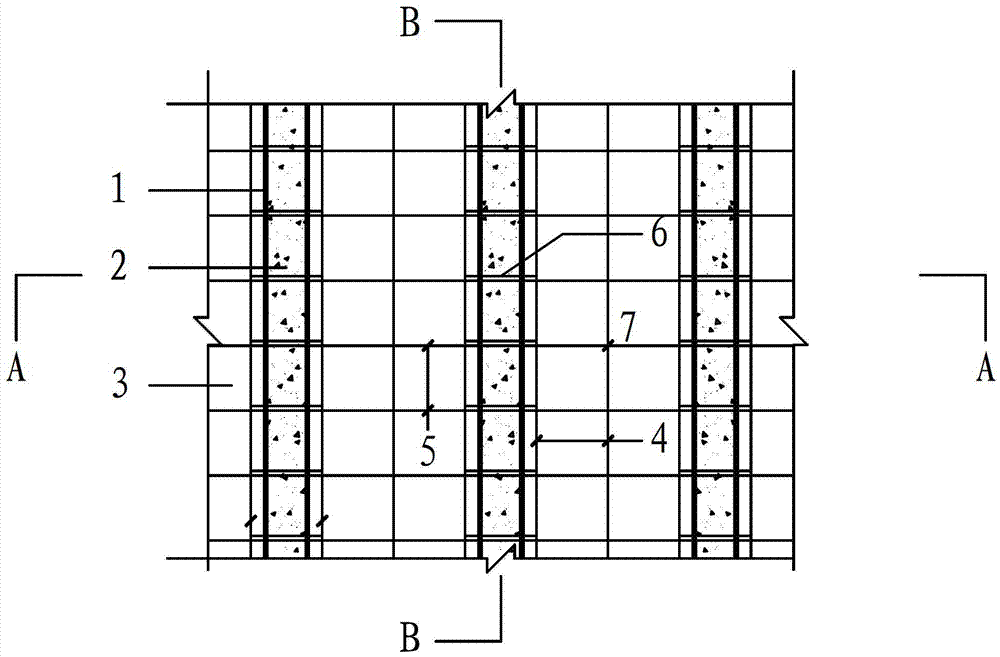

Concrete-filled steel tube combined shear wall and construction process thereof

InactiveCN102900169AHigh strengthImprove ductilityWallsBuilding material handlingReinforced concreteShear capacity

The invention relates to a concrete-filled steel tube combined shear wall and a construction process thereof. The shear wall comprises steel tubes which are distributed uniformly along the section of the shear wall, concrete filled into the steel tubes, concrete poured outside the steel tubes, square stirrups arranged outside the steel tubes, and vertically-distributed steel bars and horizontally-distributed steel bars which are arranged on front and rear sides of the steel tubes, tie steel bars which are tied between the steel tubes and the vertically-distributed steel bars and between the steel tubes and the horizontally-distributed steel bars, and longitudinal steel bars which are arranged at the positions of restraint members on edges of two sides of the steel bars. According to the concrete-filled steel tube combined shear wall, the steel tubes are embedded into the ordinary reinforced concrete shear wall, and the bearing capacity of the concrete is improved under the restraint action of the steel tubes, so that the sectional dimensions of the members are reduced, the dead weight of a structure is reduced, a seismic effect is reduced, and more usable areas are provided for buildings under the condition of the same design axial force; and anti-seismic properties of the flexural capacity, shear capacity, damage ductility and the like of the shear force are improved effectively by utilizing the high bearing capacity and high ductility of the concrete-filled steel tubes.

Owner:TSINGHUA UNIV

Fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column

ActiveCN103899040AEnhanced binding effectDelayed bucklingStrutsBuilding reinforcementsFiberReinforced concrete

The invention aims at providing a fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column which comprises a steel tube, a hoop rib, an FRP reinforced rib and a longitudinal reinforcement, wherein the hoop rib and the FRP reinforced rib are arranged in the steel tube; the inner wall of the steel tube is provided with fixed angle iron; the end part of the FRP reinforced rib is fixed on the angle iron; the FRP reinforced rib is provided with a hole, and the hoop rib passes through the hole in the FRP reinforced rib; the longitudinal reinforcement is fixed on the hoop rib; the steel tube is filled with concrete. An FRP reinforced rib plate internally provided with the hoop rib and the longitudinal reinforcement is arranged in the FRP reinforced concrete-filled steel tube combination column, and the concrete can be separated again, so that the restraint effect of the concrete is improved, the bearing capacity of the concrete is improved, and the tube wall on the stressed side is effectively prevented from being bended. By adopting a structure of enabling reinforced concrete, the FRP reinforced rib and the steel tube to cooperative work, the FRP reinforced concrete-filled steel tube combination column is simple in structure and convenient to construct, and has the characteristics of being light in weight, high in carrying capacity and good in ductility and shock resistance.

Owner:HARBIN ENG UNIV

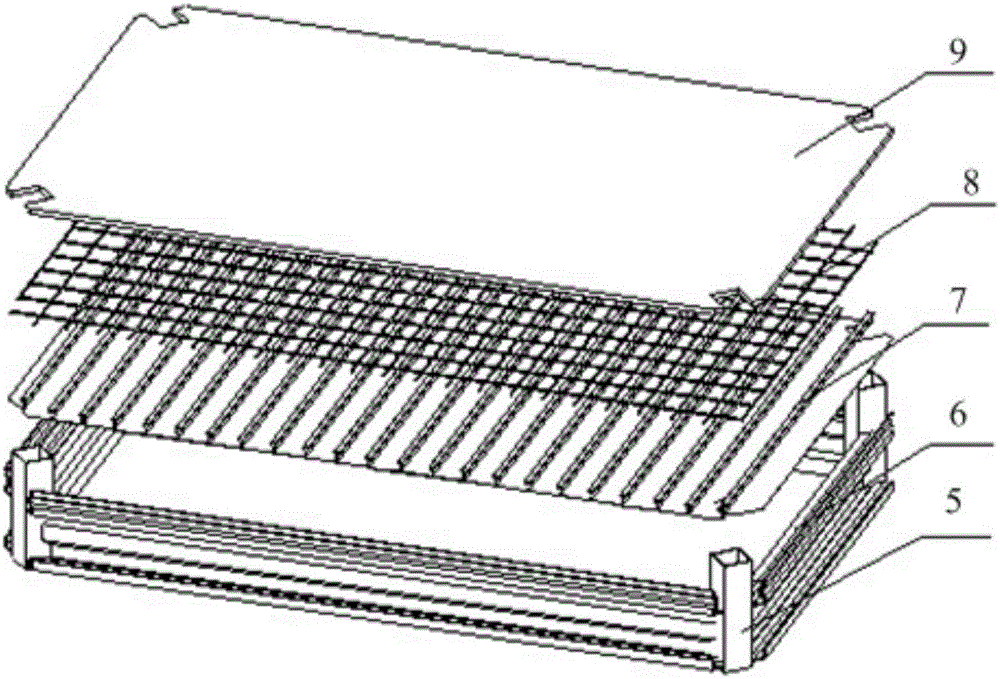

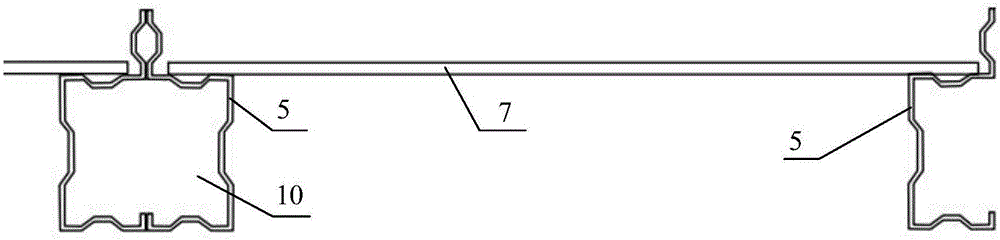

U-shaped steel-concrete composite beam

ActiveCN103835435AIncreased bending stiffnessImprove the bending capacityLoad-supporting elementsSteel barFire resistance

The invention discloses a U-shaped steel-concrete composite beam, relates to a composite beam, and solves the problems that the conventional I-shaped steel-concrete composite beam has poor fire resistance and poor overall stability, an outsourcing steel-concrete laminated plate composite beam has low anti-shear bearing capacity, the complete cooperative work of a steel beam and concrete is not guaranteed easily. The U-shaped steel-concrete composite beam comprises a concrete plate, U-shaped steel, a plurality of pieces of angle steel, a plurality of longitudinal stress reinforcing steel bars, a plurality of erect reinforcing steel bars and the concrete; each web plate of the U-shaped steel is fixedly connected with a flange plate which is arranged horizontally; the U-shaped steel and the flange plate are integrated; the plurality of pieces of angle steel are fixedly connected in the U-shaped steel along the length direction of the U-shaped steel; an erect reinforcing steel bar is welded on the side surface of each piece of angle steel; the longitudinal stress reinforcing steel bars are fixedly connected with the corresponding erect reinforcing steel bars along the length direction of the U-shaped steel; the concrete plate is arranged on the top of the U-shaped steel; the reinforcing steel bars in the concrete plate are bent and then extend into the U-shaped steel; the concrete is cast in the U-shaped steel. The U-shaped steel-concrete composite beam is applied to civil engineering construction.

Owner:JIANGSU ZHONGBAO STEEL STRUCTURE

High-strength concrete prefabricated pile doped with fiber-reinforced plastic bar

The invention discloses a high-strength concrete prefabricated pile doped with a fiber-reinforced plastic bar, which comprises a steel reinforcement cage framework. The high-strength concrete prefabricated pile is characterized in the fiber-reinforced plastic bar is arranged in the steel reinforcement cage framework; end plates are respectively arranged at two ends of the steel reinforcement cage framework; concrete is cast on the steel reinforcement cage framework and the fiber-reinforced plastic bar, so that the steel reinforcement cage framework, the fiber-reinforced plastic bar and the end plates are integrated; and a central round hole penetrating through the whole pipe body is formed in the middle of the integrated pile body. The invention aims at overcoming the defects in the prior art and providing the high-strength concrete prefabricated pile doped with the fiber-reinforced plastic bar, which has the advantages of favorable horizontal bending resistant bearing capacity, high pullout-resistant bearing capacity, high single-pile vertical bearing capacity, strong anti-seismic capability and suitability for projects having higher requirements for bending resistance and pullout resistance.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Novel combined stone beam

InactiveCN101696589AImprove the bending capacityImproved brittle failure propertiesBuilding repairsGirdersPre stressBending stiffness

The invention discloses a novel combined stone beam. The stone beam comprises a stone beam body, wherein a tensile region of the stone beam body is provided with a groove in the longitudinal direction of the stone beam body; a reinforcement material under a certain horizontal prestressing force is arranged in the groove in the longitudinal direction; the reinforcement material is fixed in the groove in a bonding way through a bonding material; and both ends of the reinforcement material are firmly fixed on both longitudinal ends of the stone beam body respectively through anchor devices. Compared with the prior art, the combined stone beam substantially increases the cracking moment, bending rigidity and anti-bending bearing capacity of the stone beam by embedding the high-strength tensile reinforcement material in the tensile region of the stone beam body and applying prestressing force and anchoring. Moreover, the combined stone beam can be applied in a beam-type stone-structure member of larger span and has the advantages of great width, high bearing capacity, no damages to stone-structure style and features and beauty, and the like; and therefore, the combined stone beam can be used in a newly-built stone-structure project and the reinforcement of an existing stone structure.

Owner:HUAQIAO UNIVERSITY

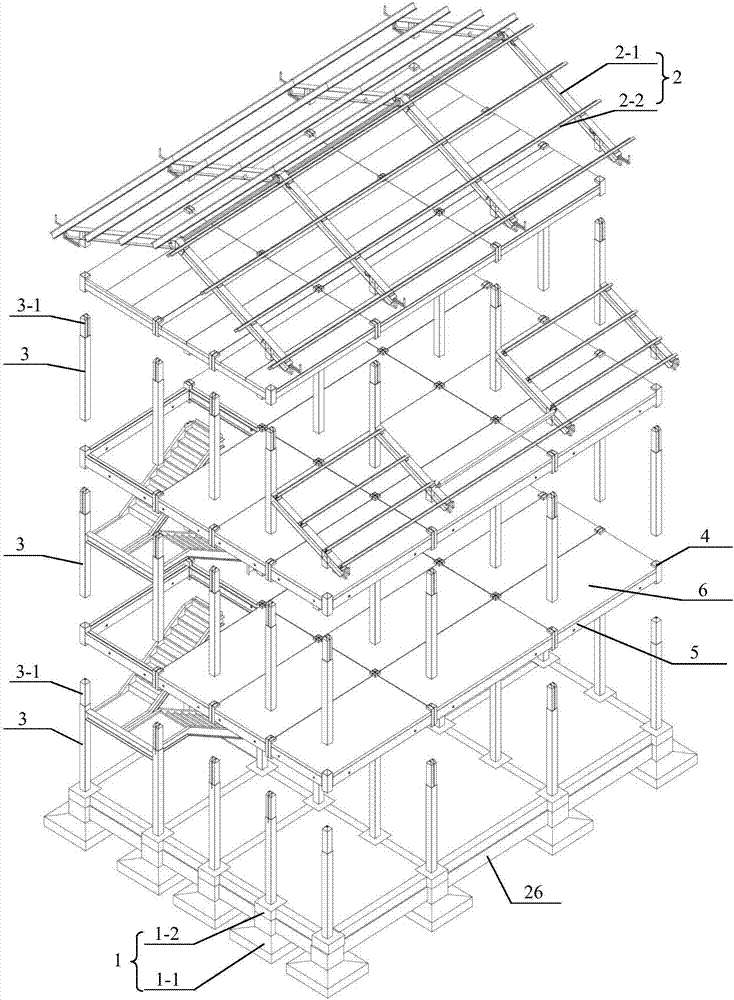

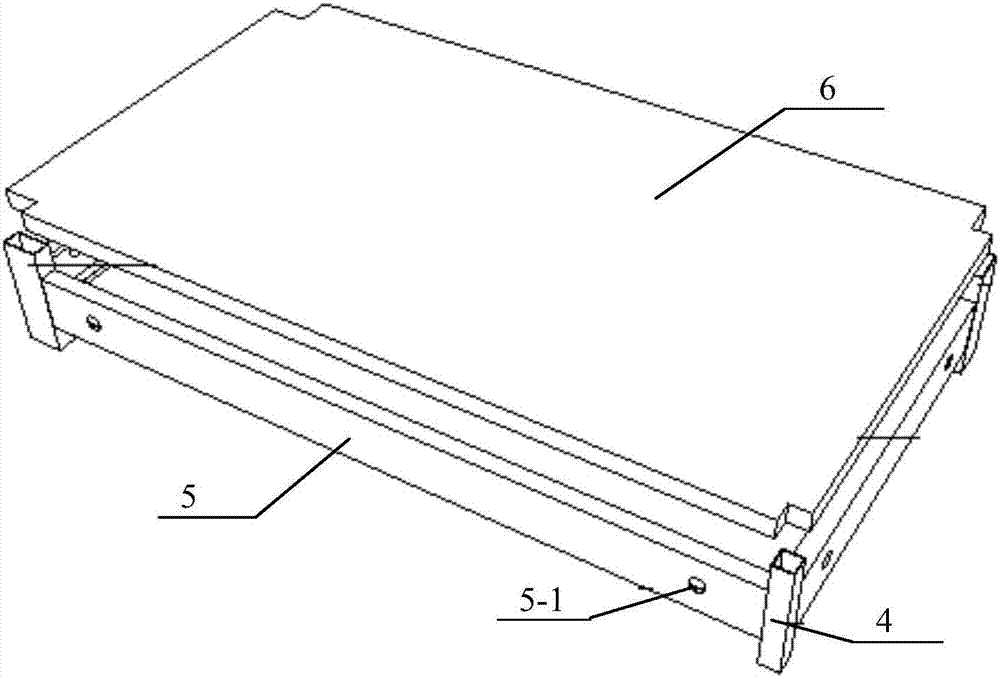

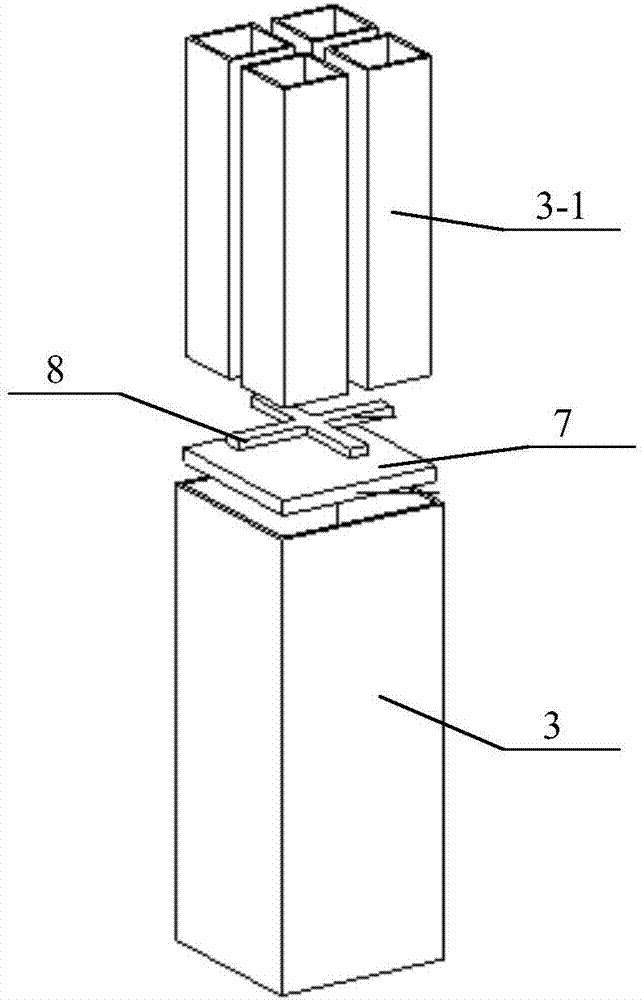

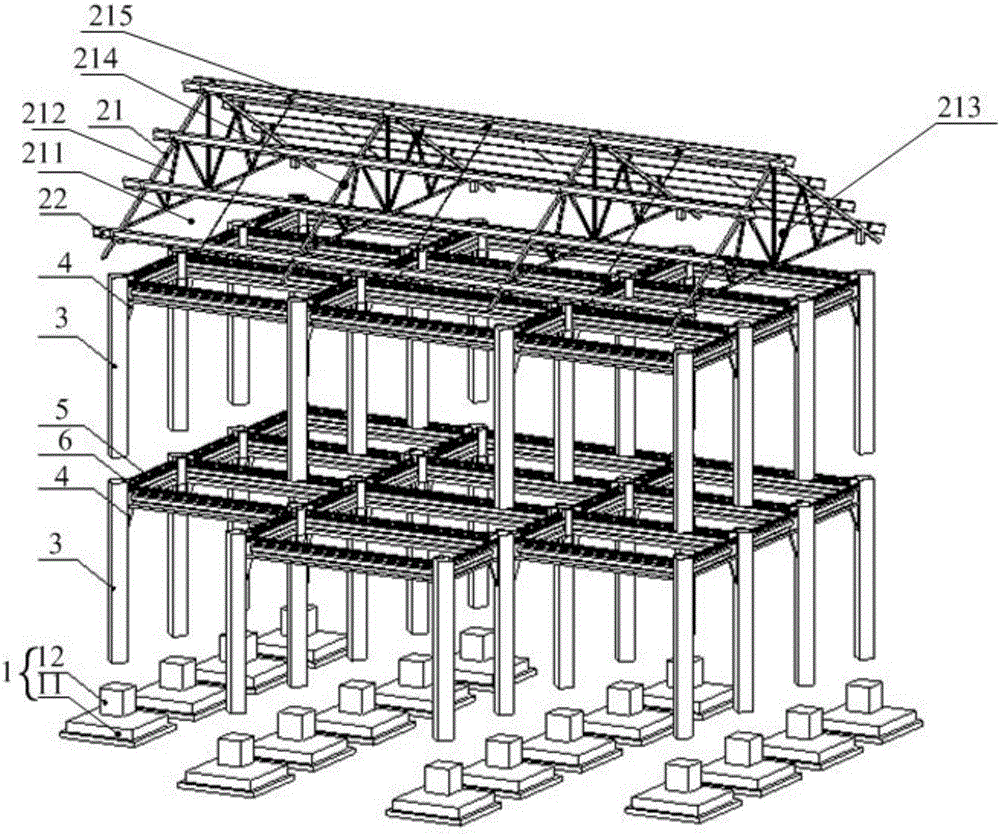

Prefabricated building main body structure

PendingCN107366356AReasonable connectionEasy to installBuilding constructionsFloor slabArchitectural engineering

The invention discloses a prefabricated building main body structure, and relates to the technical field of constructional engineering structures. The prefabricated building main body structure comprises an independent foundation; at least one layer of floor slabs is fixedly arranged above the independent foundation; a supporting structure is arranged under each layer of the floor slabs; a roof frame structure is fixedly arranged above the top layer of the floor slabs; the floor slabs comprise a plurality of combination beam plates; the supporting structure of each layer comprises a plurality of square pipe columns; tenon pipes connected with the combination beam plates in an inserting manner are arranged on the square pipe columns; a stairway is arranged between every two vertically adjacent layers of floor slabs; the combination beam plates comprise four-corner components; steel beams are fixedly connected between the adjacent four-corner components; the upper edges of the steel beams are spaced from the top ends of the four-corner components by a certain distance; concrete slabs are poured on the steel beams; reinforcement meshes are arranged in the concrete slabs; reserved pipeline holes are formed in the side surfaces of the steel beams; and the four-corner components are sleeves matched with the tenon pipes in an inserting manner. The beam and column connection is reasonable, the mounting is convenient and the flexural capacity is high.

Owner:北京善筑科技股份有限公司

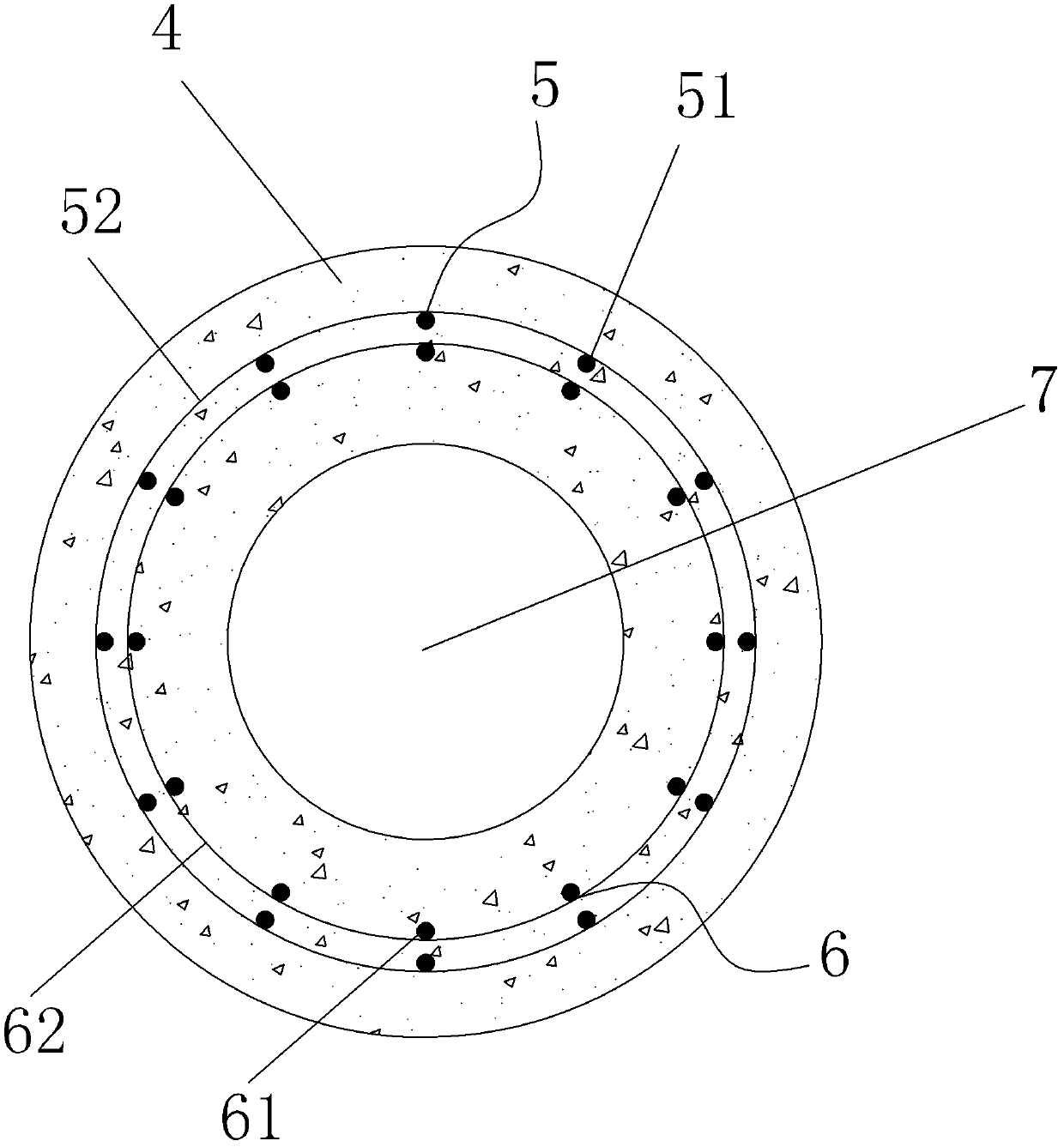

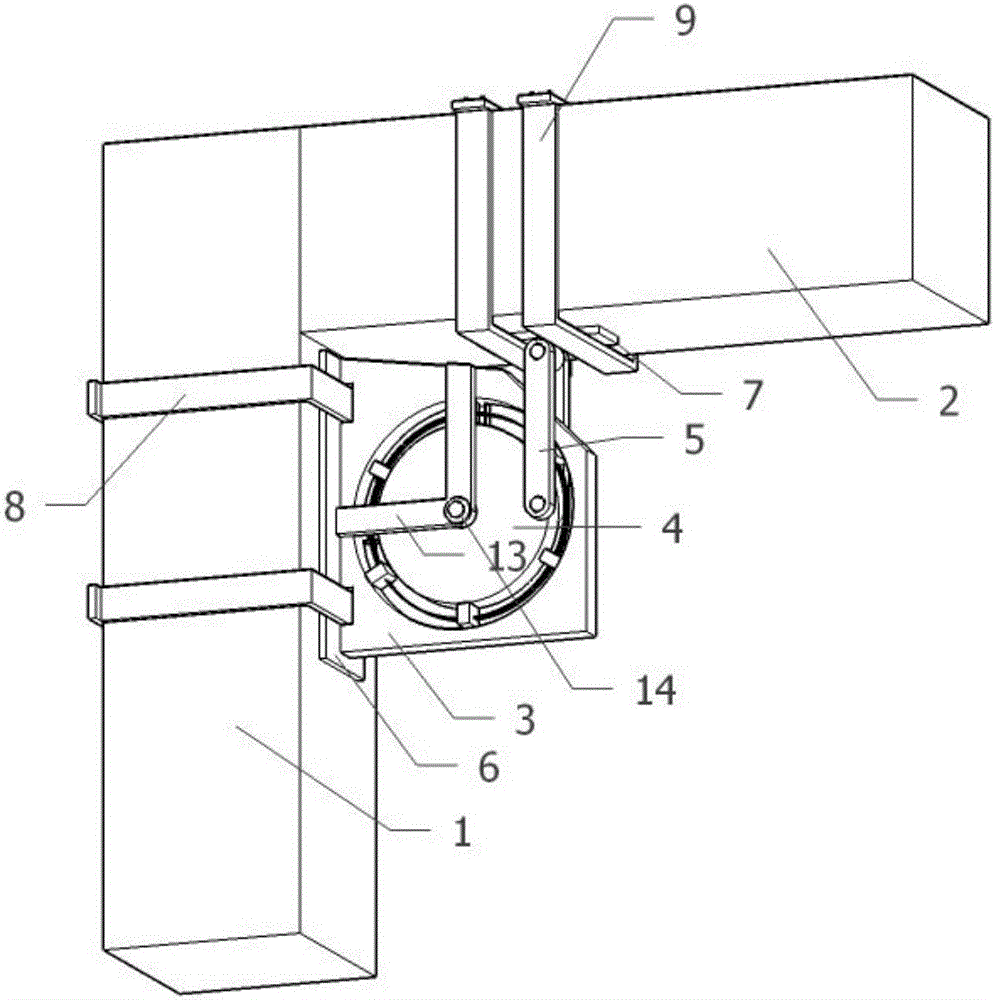

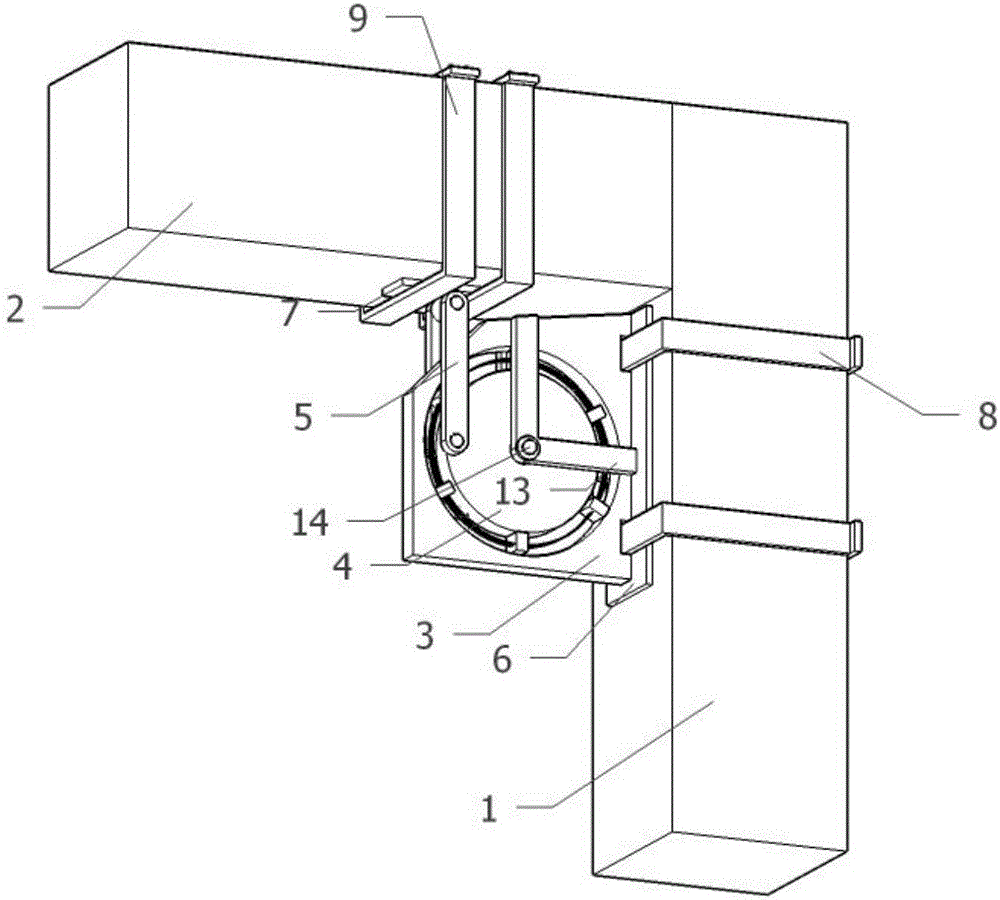

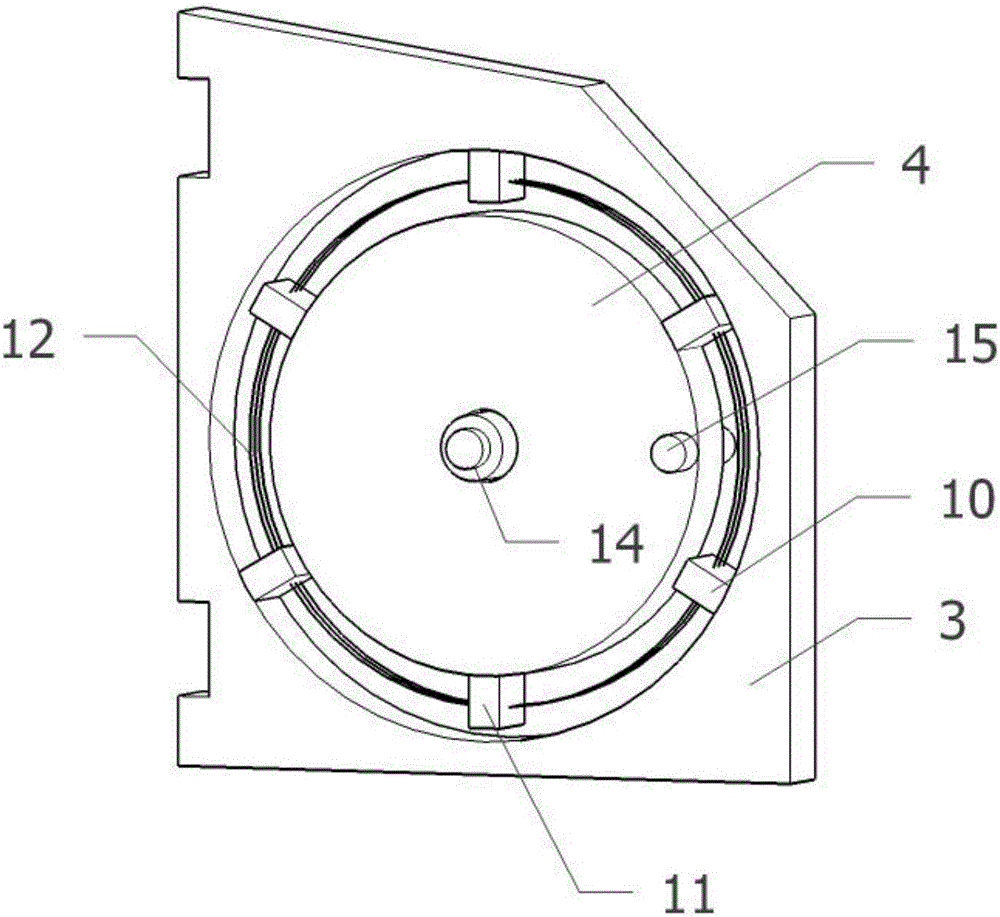

Disc-shaped memory alloy damper

ActiveCN106481132AIncreased shear capacityImprove the bending capacityProtective buildings/sheltersShock proofingCircular discShape-memory alloy

The invention discloses a disc-shaped memory alloy damper. The disc-shaped memory alloy damper comprises a wood column and a wood beam connected with the wood column and is characterized in that a base is connected to a corner where the wood column is connected with the wood beam, a rotary disc which can rotate along the base is arranged in the base, and the base is fixed on the inner side of the wood column through a vertical connecting steel plate and a wood column hoop; the rotary disc is respectively connected with the vertical connecting steel plate and the wood beam through an L-shaped fixing steel plate, the rotary disc is connected with the bottom surface of the wood beam through a rigid tie bar, a super-elasticity shape memory alloy wire is arranged at the gap between the base and the rotary disc, and the rotary disc is driven to move in a reciprocating manner through the vertical reciprocating movement of the rigid tie bar to allow the super-elasticity shape memory alloy wire to be repeatedly stretched and reset to bear the internal force the wood column and the wood beam. The disc-shaped memory alloy damper has the advantages that a node reinforcing manner is used to limit interlayer sidesway, the energy consumption and self-resetting ability of the structure under earthquake action are increased evidently, building inclination and collapse caused by the dynamic response generated by vibration, and secondary rectification and reinforcement of a building after the earthquake is avoided.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

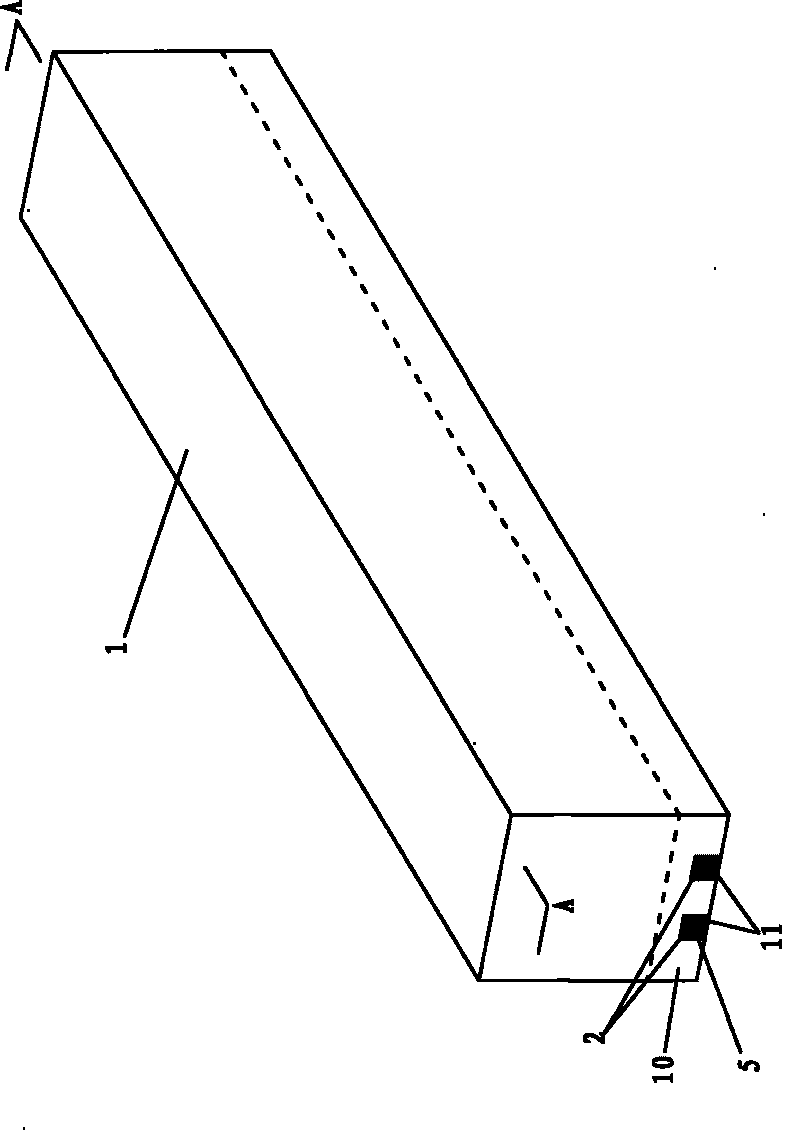

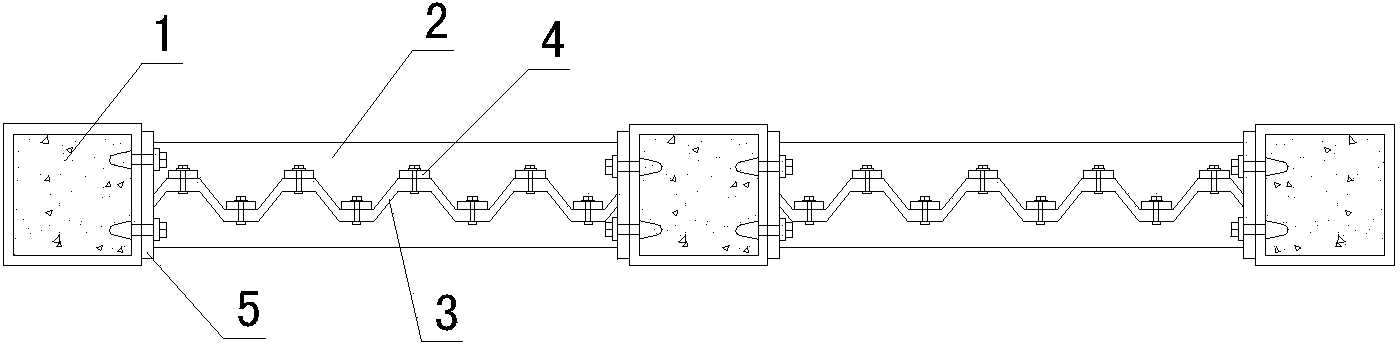

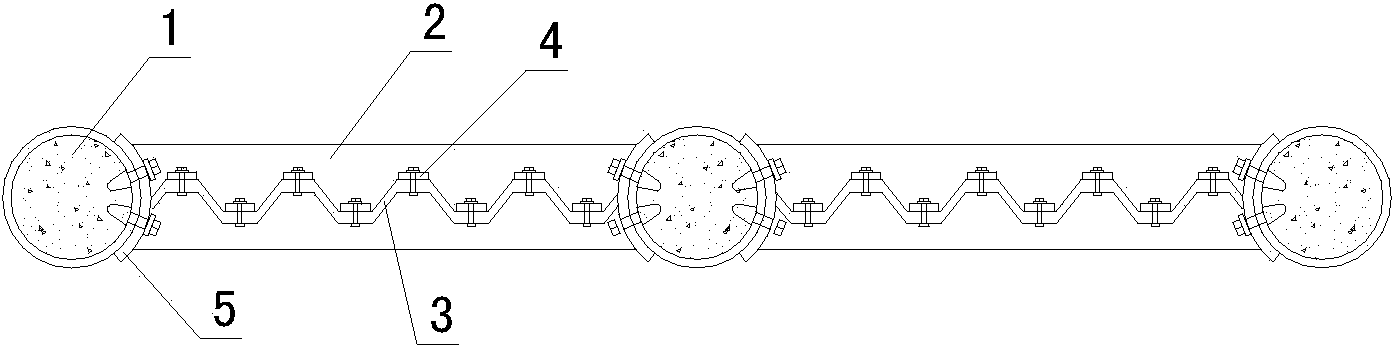

Energy dissipation, shock absorption and anti-liquefaction rigid and flexible slide-resistant pile and construction method

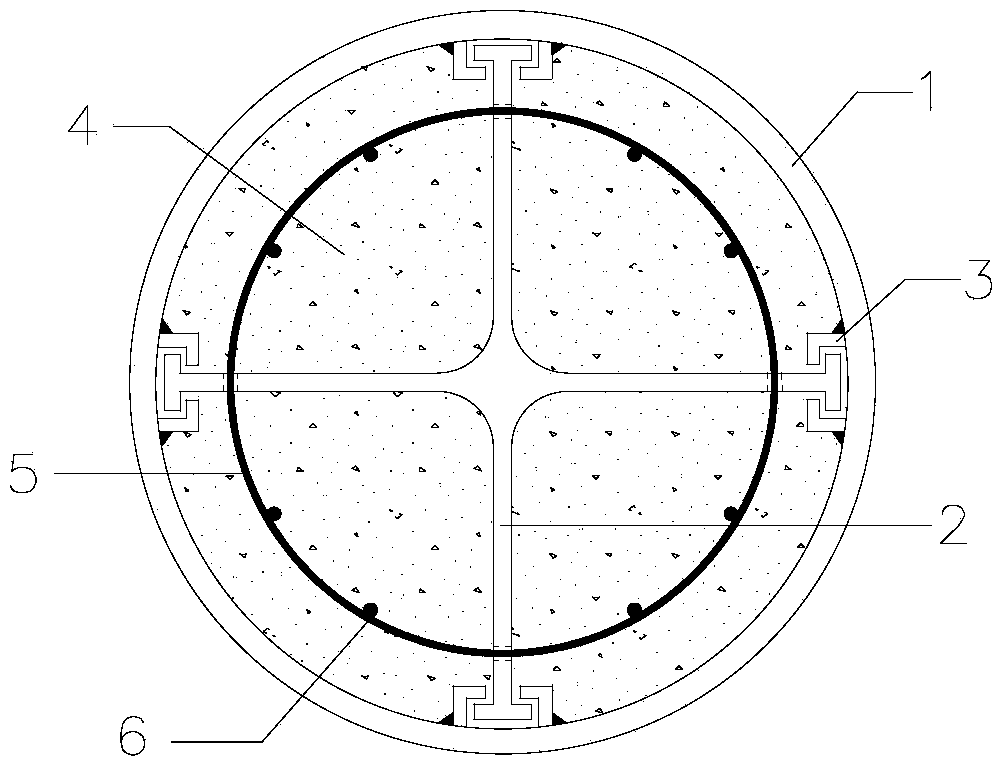

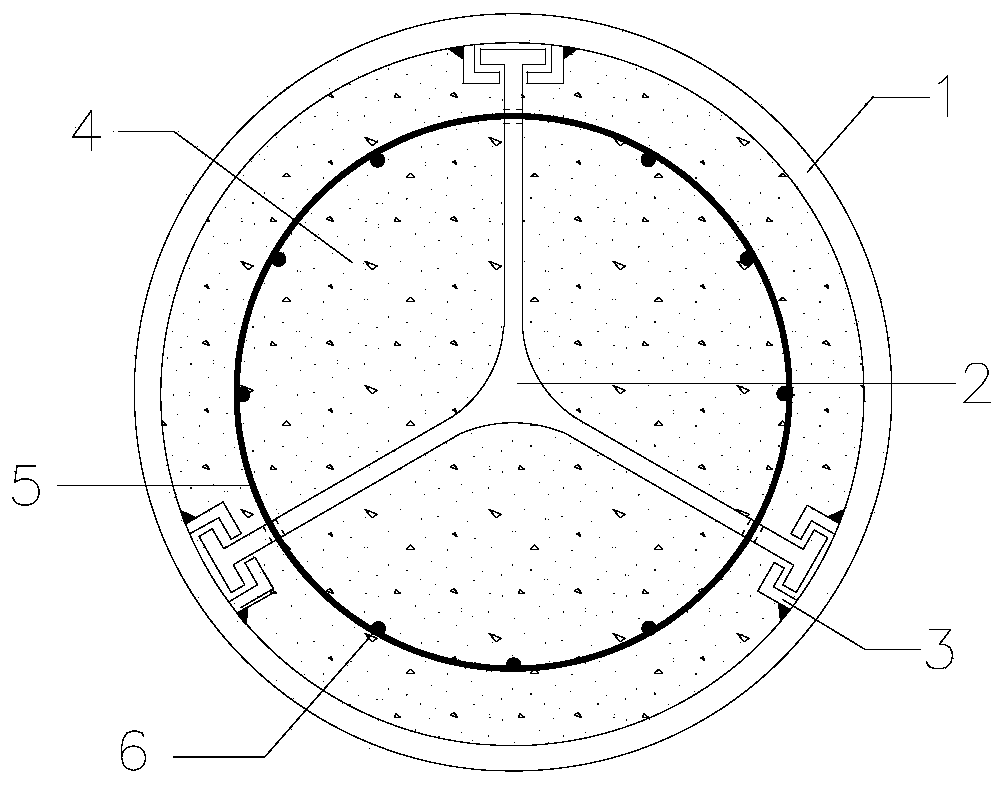

ActiveCN104762980AImprove ductilityImprove the bending capacityProtective foundationExcavationsRebarReinforced concrete

An energy dissipation, shock absorption and anti-liquefaction rigid and flexible slide-resistant pile and a construction method belong to the slope supporting technology field. The energy dissipation, shock absorption and anti-liquefaction rigid and flexible slide-resistant pile is composed of a hollow tubular pile, broken stones, anchor cables and air cushions, wherein the hollow tubular pile comprises first-type hollow tubular piles and second-type hollow tubular piles, which are all prefabricated with reinforcement concrete; crossed plates are embedded in an external barrel; water permeating holes are formed in the external barrel in a plum blossom shape; anchor cables penetrate through the hollow tubular piles and the air cushions are covered at the outer side; one first-type hollow tubular pile and many second-type hollow tubular piles are arranged in sequence in the pile holes of a slope body; the tops and the bottoms of the hollow tubular piles are embedded with one another; the hollow tubular pile is filled with the broken stones and a cover plate is arranged on the top; the anchor cables are anchored on the bottom plate and the cover plate through an anchorage device and the air cushions are full of gas. The slide-resistant pile is prefabricated, assembled and formed to be a rigid and flexible body, has high load-bearing capacity, plays a role in well dissipating energy under earthquake condition, has good drainage capacity and prevents soil around the pile from being liquefied; the construction method is simple and quick and the engineering cost is low.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Assembly type main structure of building

InactiveCN106759900AReasonable connectionEasy to installFloorsFoundation engineeringCold formedEngineering

The invention discloses an assembly type main structure of a building, and relates to the technical field of building engineering structures. The assembly type main structure of the building comprises isolated foundations, at least one layer of supporting beam group and at least one layer of cold-formed thin-walled steel composite beam plates are arranged on the isolated foundations, and a roof frame structure is arranged on the top supporting beam group, wherein each layer of supporting beam group comprises a plurality of square tubular columns, and the upper portion of each square tubular column is provided with a beam support; each cold-formed thin-walled steel composite beam plate comprises a lipped channel stiffened structural beam, a profiled steel sheet, a reinforcing mesh and a concrete plate, and the end of each lipped channel stiffened structural beam is provided with a sleeve; each lipped channel stiffened structural beam comprises a vertical plate, a first transverse plate and a second transverse plate, a vertical baffle is arranged above each first transverse plate, and stiffened structures are arranged on the first transverse plates, the second transverse plates, the vertical plates and the vertical baffles respectively. The assembly type main structure is reasonable in beam-column connection, convenient to install, high in flexural capacity and suitable for large-span commercial complex buildings.

Owner:北京善筑科技股份有限公司

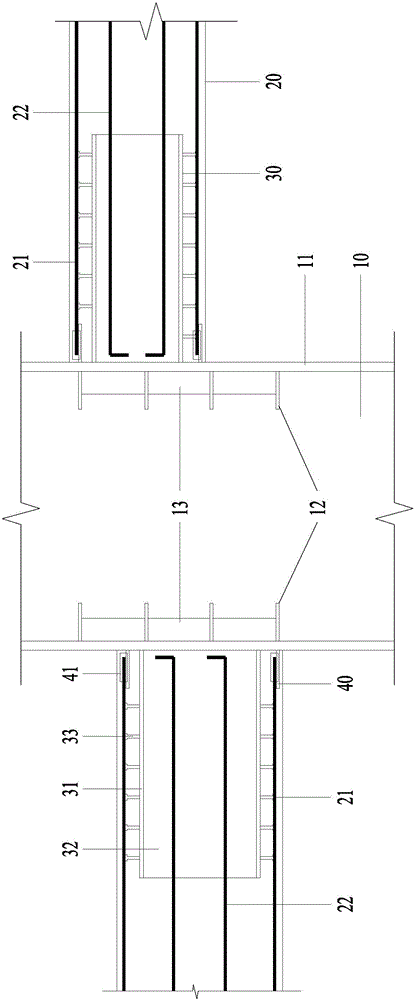

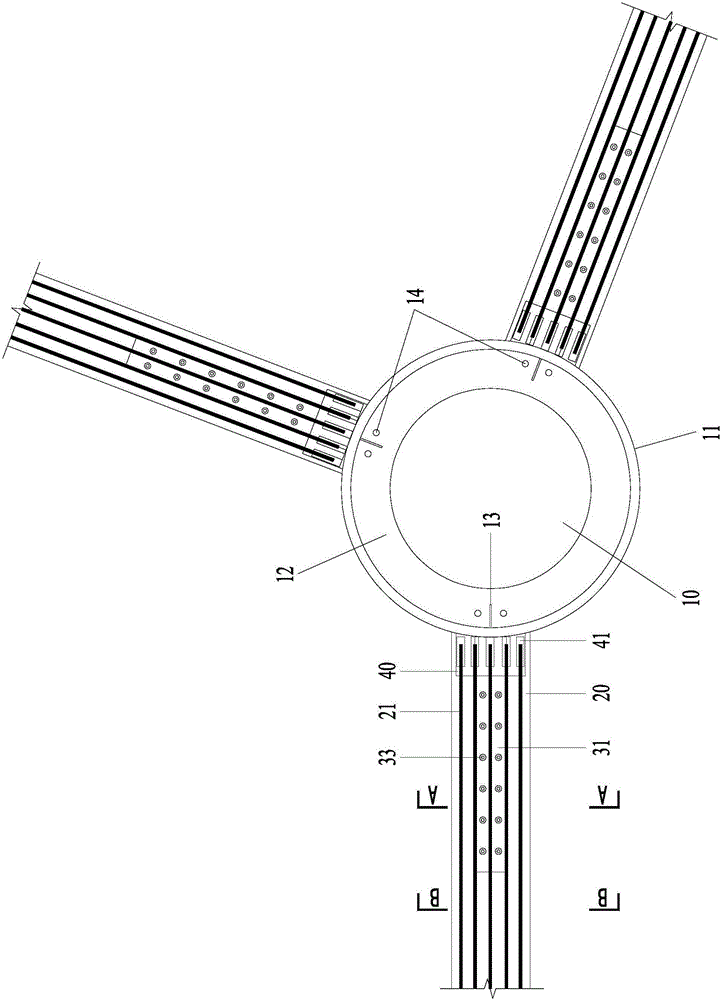

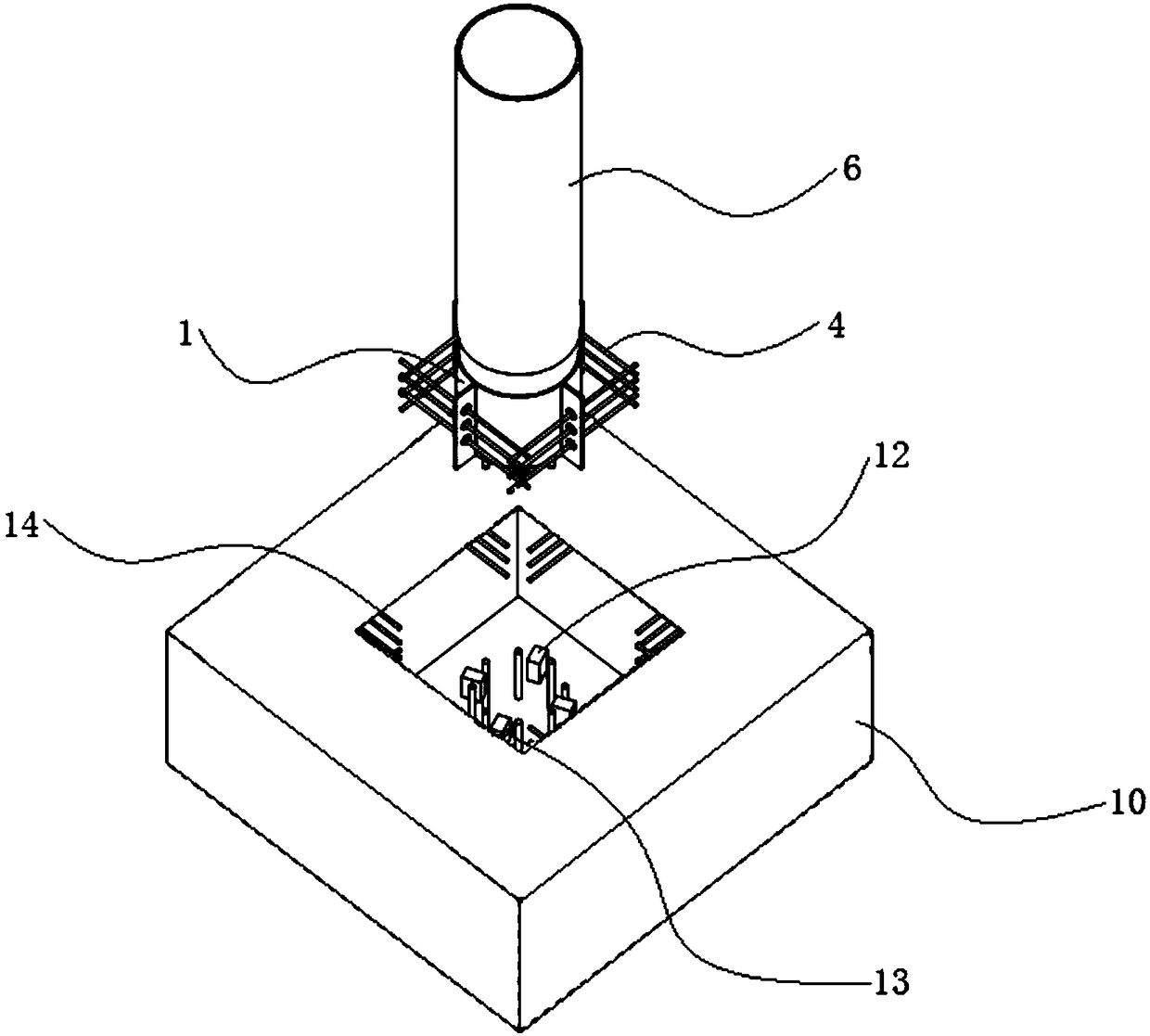

Splicing structure and splicing method of prefabricated bridge piers and prefabricated bearing platform

PendingCN108049305APrecise positioningShorten the construction periodBridge structural detailsFoundation engineeringShear capacityUltimate tensile strength

The invention provides a splicing structure and a splicing method of prefabricated bridge piers and a prefabricated bearing platform. By utilizing the joggling of hollow steel tubes in first concave grooves in the bottoms of the prefabricated bridge piers and concrete filled steel tube tenons enclosed by the inner walls of annular grooves in the top of the prefabricated bearing platform, on one hand, favorable positioning effects are achieved for the mounting, on the bearing platform, of the prefabricated bridge piers, and on the other hand, the shear capacity and the flexural capacity at splicing positions are improved; post-poured concrete is poured into the annular grooves to enwrap the splicing positions of the prefabricated bridge piers and the prefabricated bearing platform; the prefabricated bridge piers and the prefabricated bearing platform are connected into a whole; an overall stress structure is ameliorated; the splicing strength of the prefabricated bride piers and the prefabricated bearing platform is greatly improved, and is not less than the strength of a cast-in-place bridge pier. By adopting a way of splicing the prefabricated bride piers and the prefabricated bearing platform, the field pouring workload of concrete is effectively reduced; the field operation is facilitated; a road is not occupied; influences on an urban traffic environment during the operation are effectively relieved, and meanwhile, a construction period of a bridge is shortened.

Owner:FUJIAN UNIV OF TECH

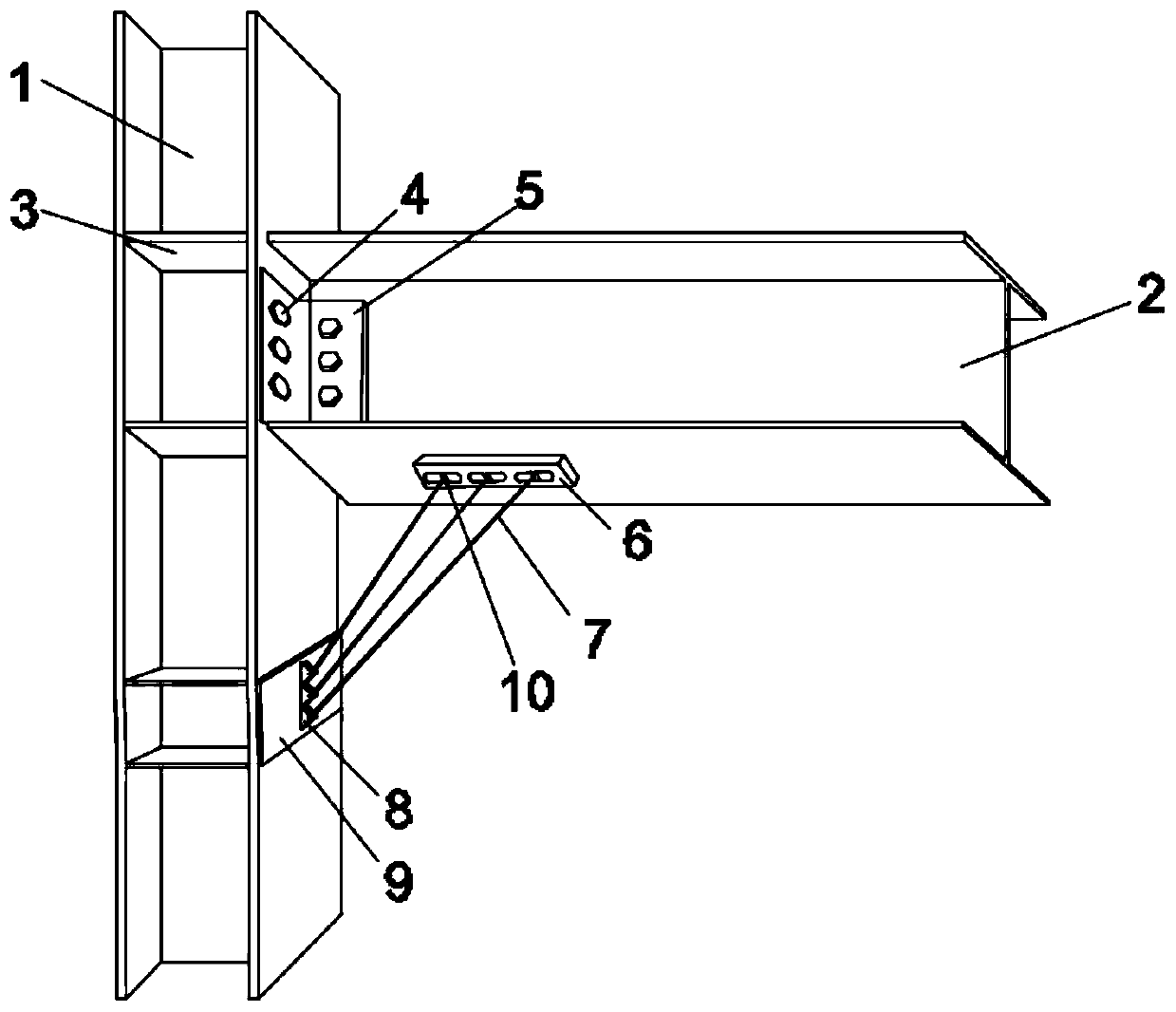

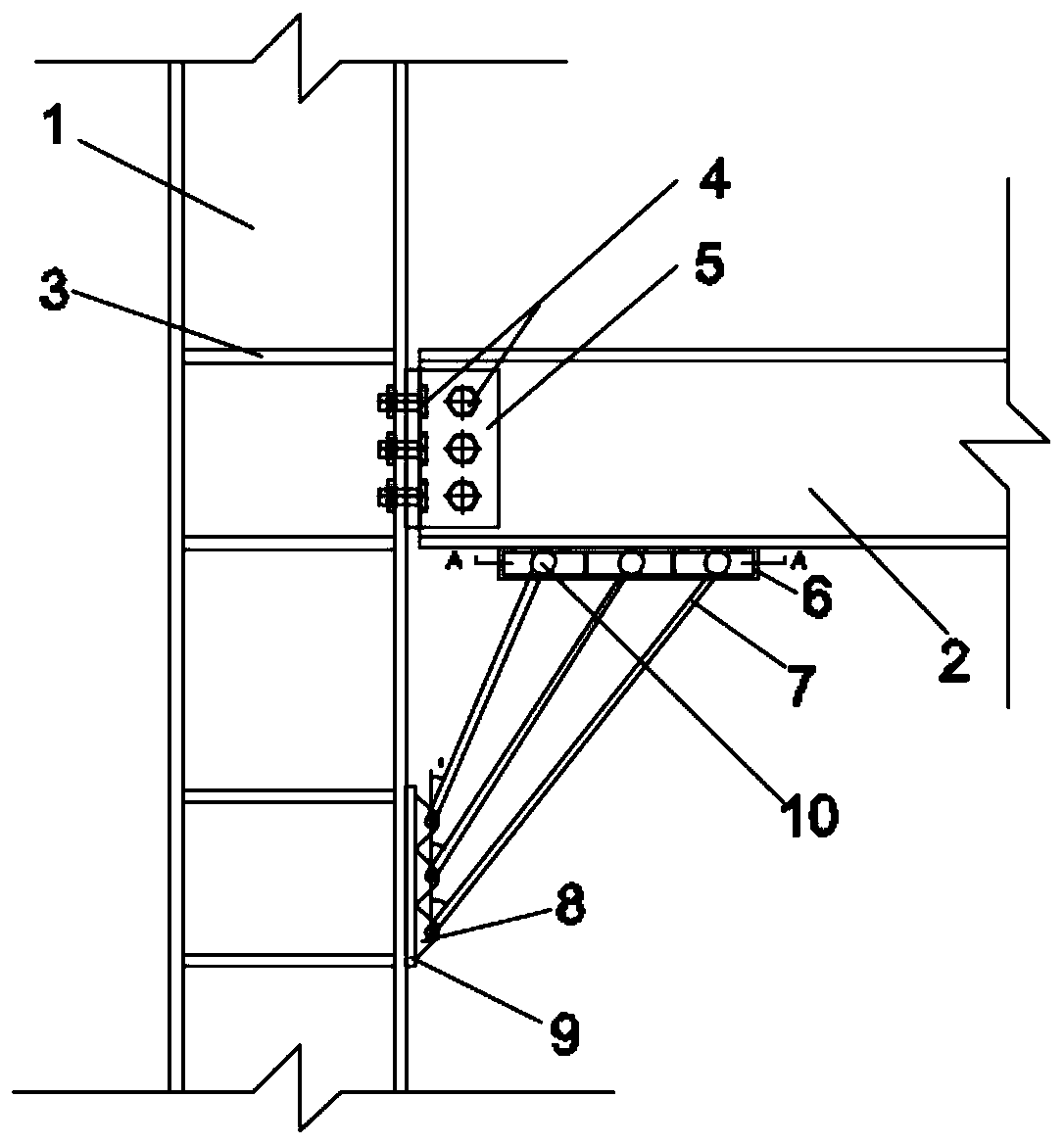

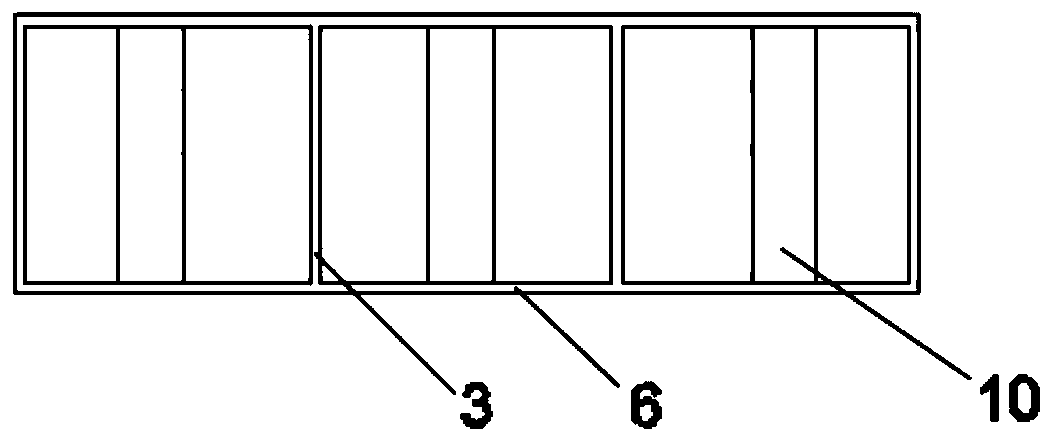

Connecting structure of concrete-filled steel tube column and reinforced concrete beam

ActiveCN105735468AImprove the bending capacityIncreased shear capacityBuilding constructionsReinforced concreteSteel bar

The invention discloses a connecting structure of a concrete-filled steel tube column and a reinforced concrete beam. The connecting structure comprises the concrete-filled steel tube column made of a steel tube and concrete and the reinforced concrete beam made of a reinforcing steel bar and concrete; a boom extending steel beam is welded on the outer side surface of the steel tube and consists of flanges and a web plate; pull and tie plates parallel to the flanges are symmetrically welded on the two sides of the web plate; bar penetration holes are formed in the pull and tie plates; the reinforcing steel bar comprises longitudinal bars arranged on the upper side and the lower side, lumbar bars arranged on the left side and the right side, a first stirrup connected onto the longitudinal bars and the lumbar bars in a bundling manner and a pull and tie bar with two ends respectively colluded on the crossed lumbar bars and the first stirrup; one end of the reinforced concrete beam is inserted into the boom extending steel beam; the pull and tie bar is cut into two sections by the web plate of the boom extending steel beam, and the cut ends of the pull and tie bar are inserted into the bar penetration holes. Through the overlap joint of the reinforcing steel bar and the boom extending steel beam, the anchorage and the force transmission of the reinforcing steel bar are realized. The connecting structure disclosed by the invention has the advantages of being strong in bending and shear bearing capacity, small in welding workload, simple in mounting process and convenient and quick to construct.

Owner:筑博设计股份有限公司

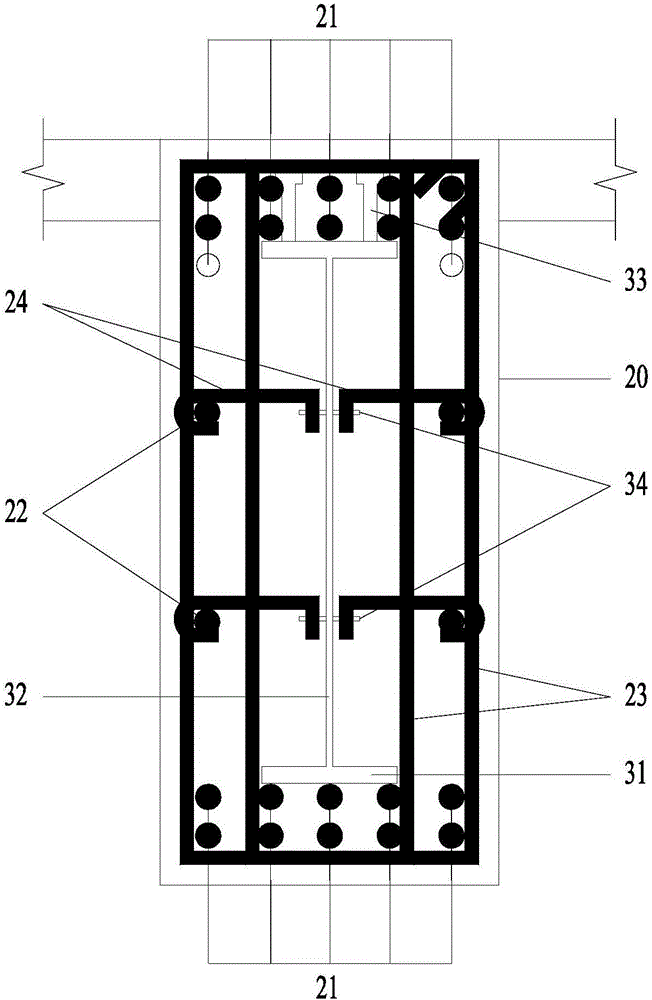

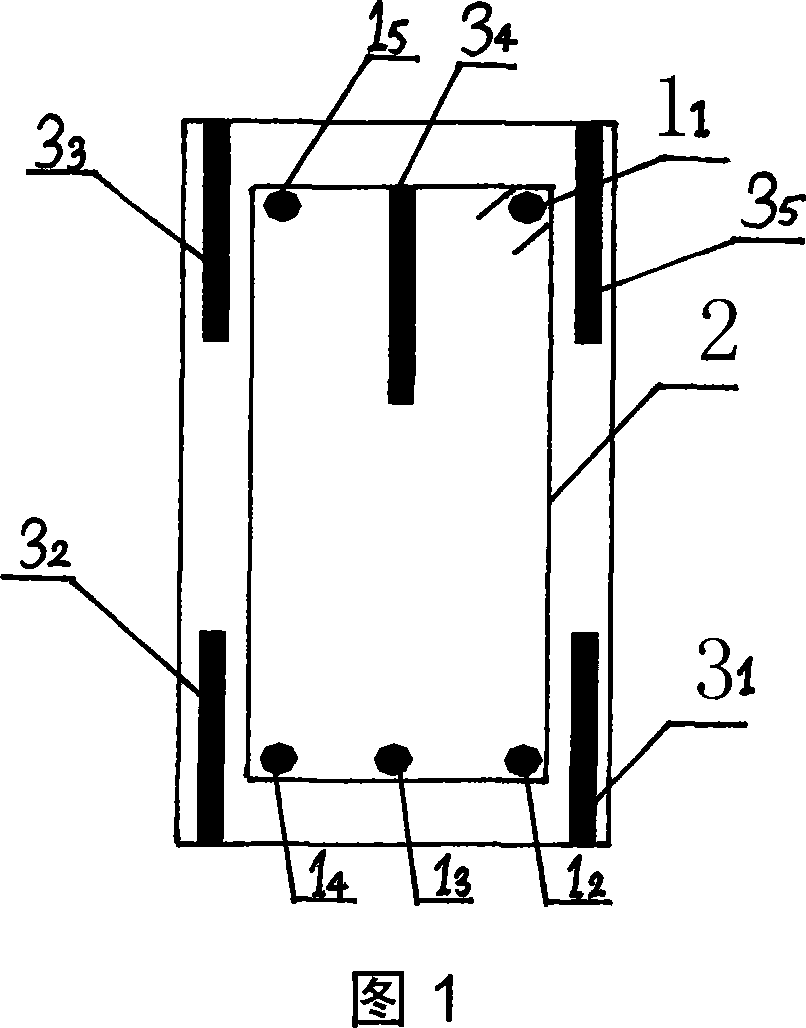

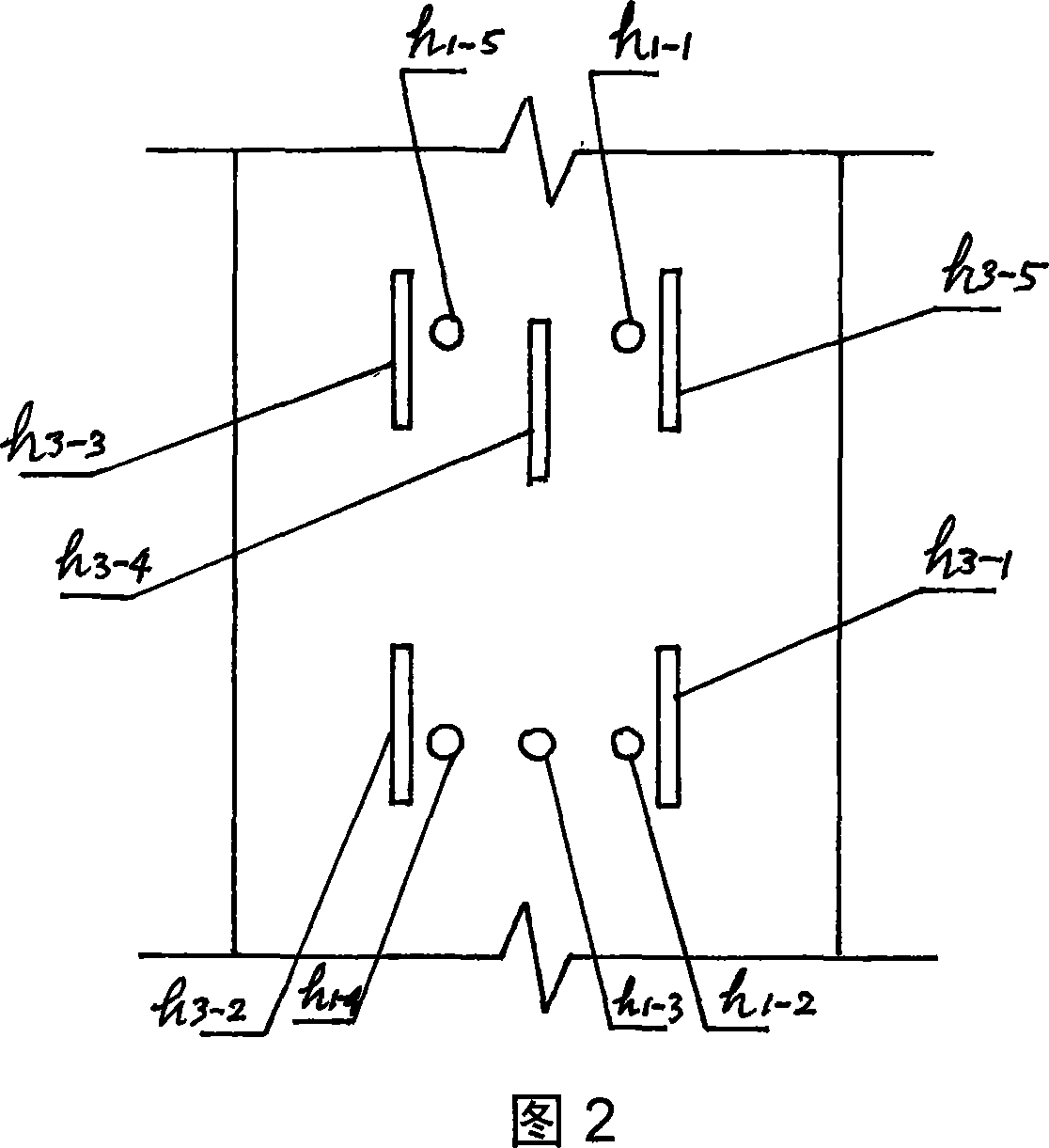

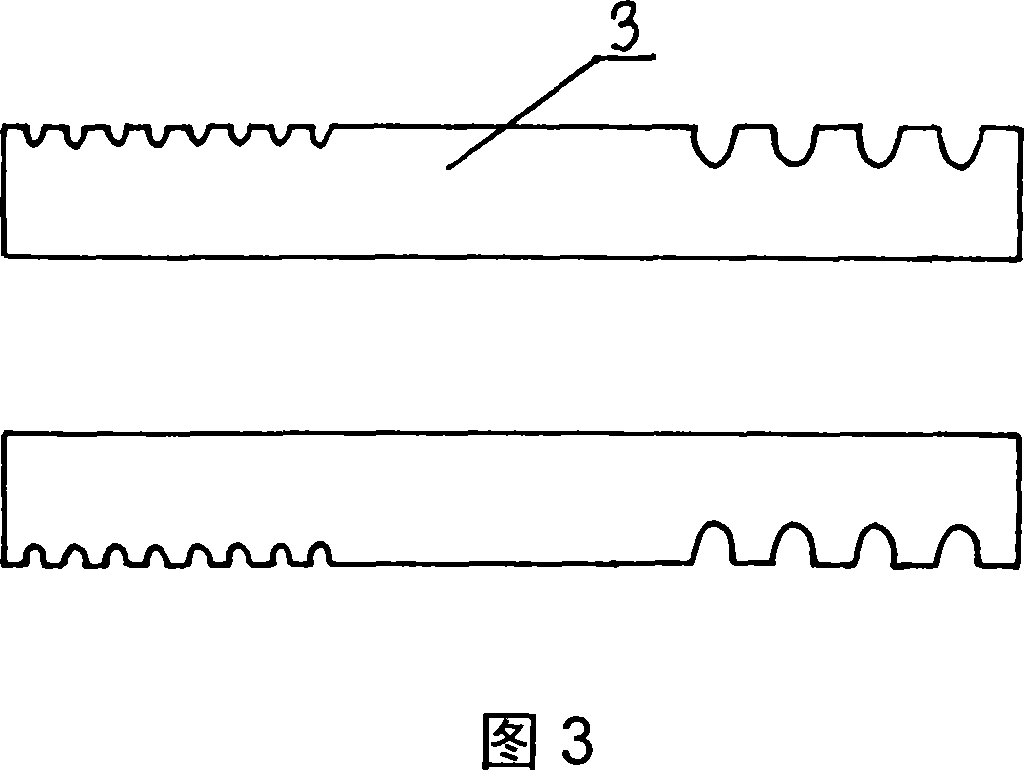

Connecting structure for steel tube concrete beam and column node

InactiveCN101059000AImprove mechanical performanceGuaranteed integrityBuilding constructionsSEMI-CIRCLEConcrete beams

Steel pipe concrete beam-column joints connecting structure, and it aims at improving the shear and flexural strength of beam-column joints and ensuring the steel plate and node work together. The cross section of steel pipe 4 in steel pipe concrete column is rectangular, the steel beam 31, 32, 33, 34, 35 in beam and the reinforcing bar 11, 12, 13, 14, 15 cross through the rectangular hole h3-1, h3-2, h3-3, h3-4, h3-5 and round hole h1, h2, h3, h4, h5 separately, two ends of the steel plate 31, 32, 33, 34, 35 are opened 8-16 semi-circle holes separately.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

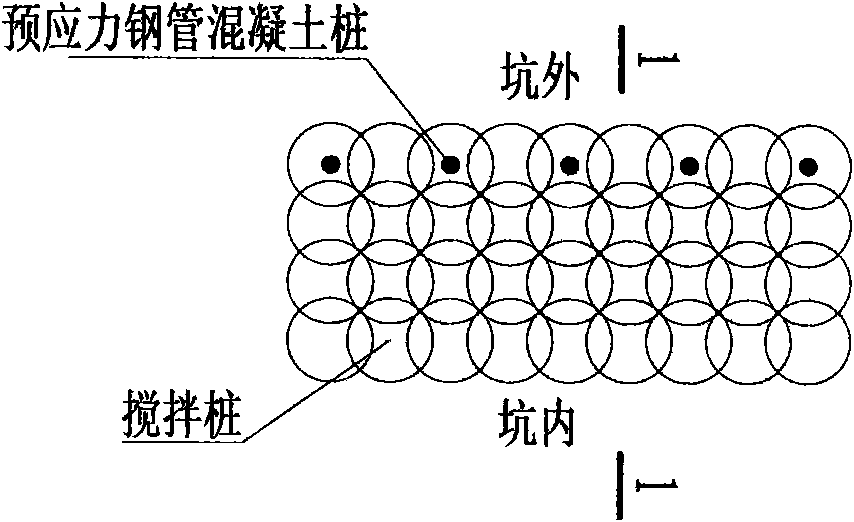

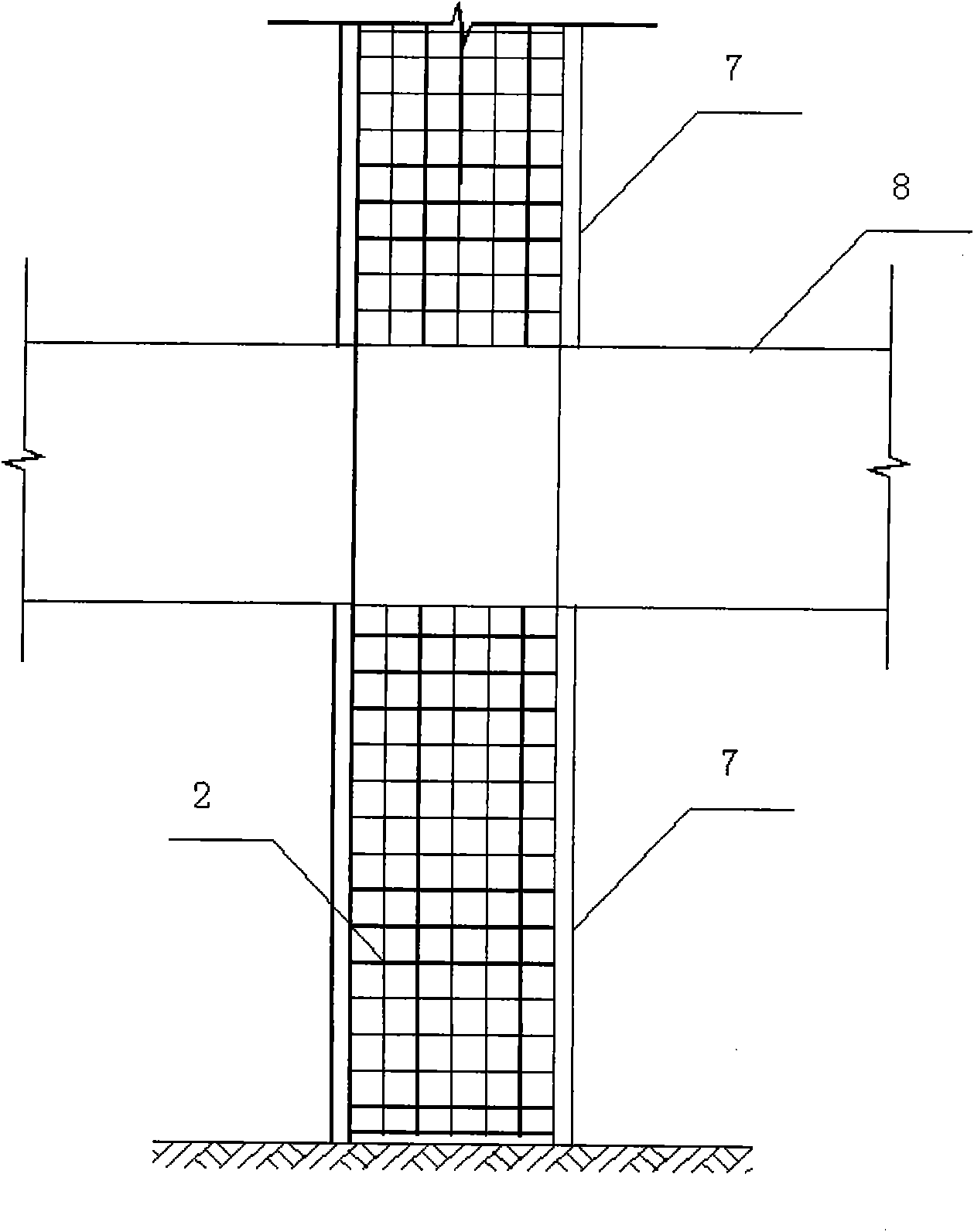

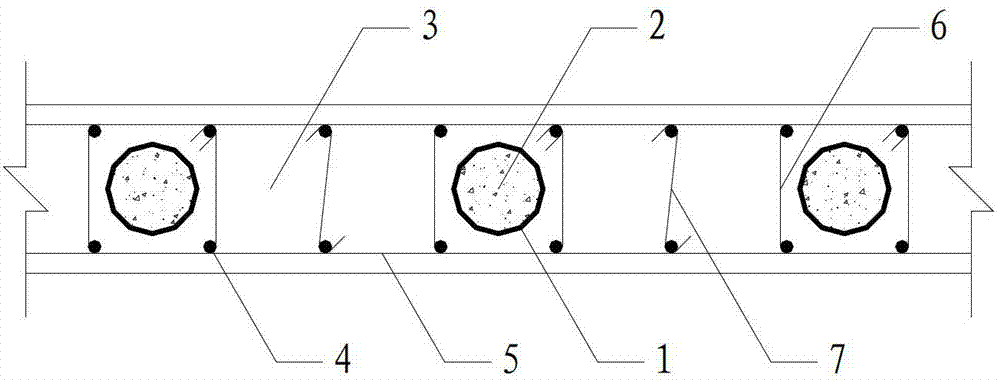

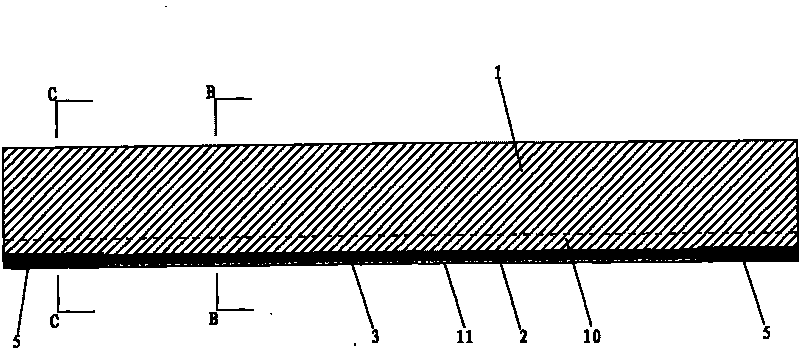

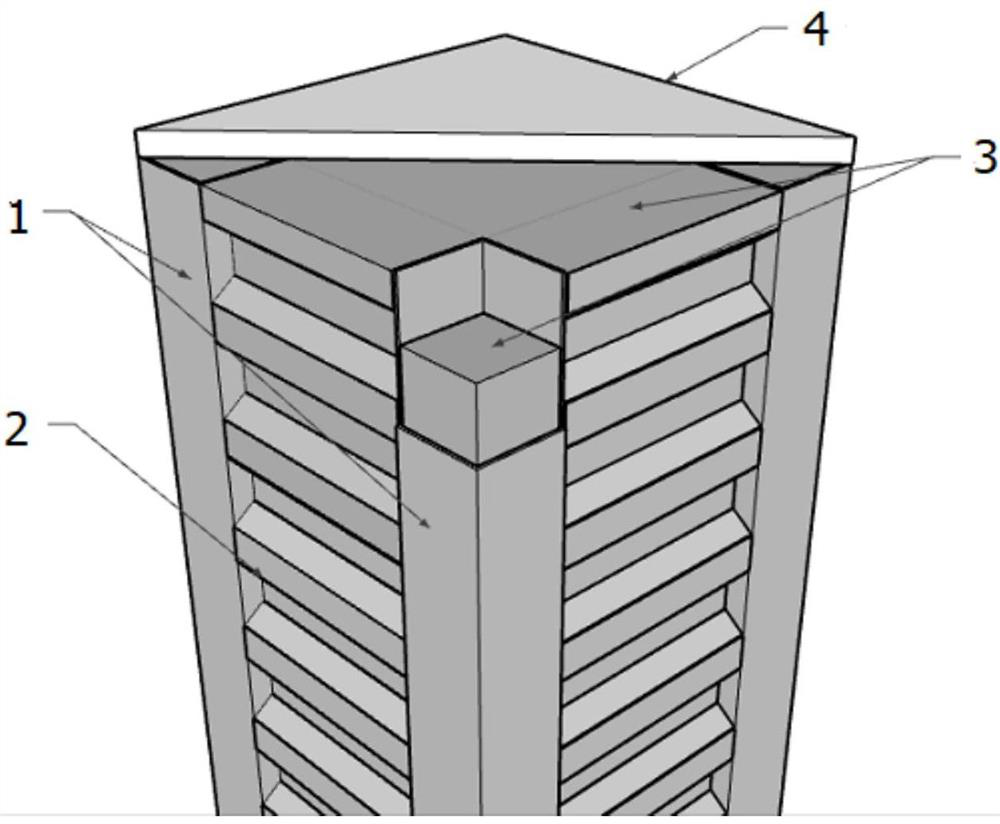

Method for supporting and protecting building foundation pit by employing transverse-diaphragm prestressing concrete pipe pile

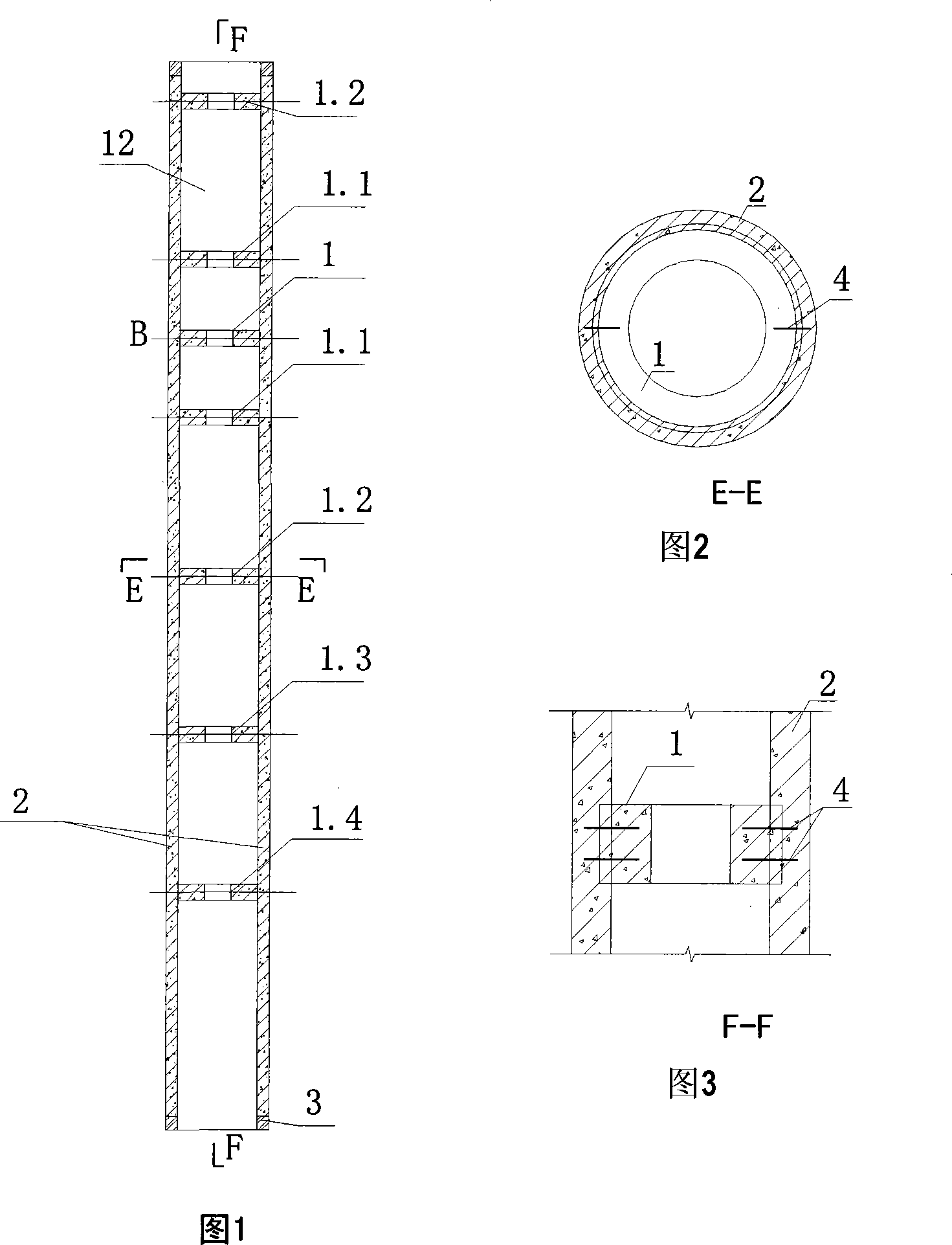

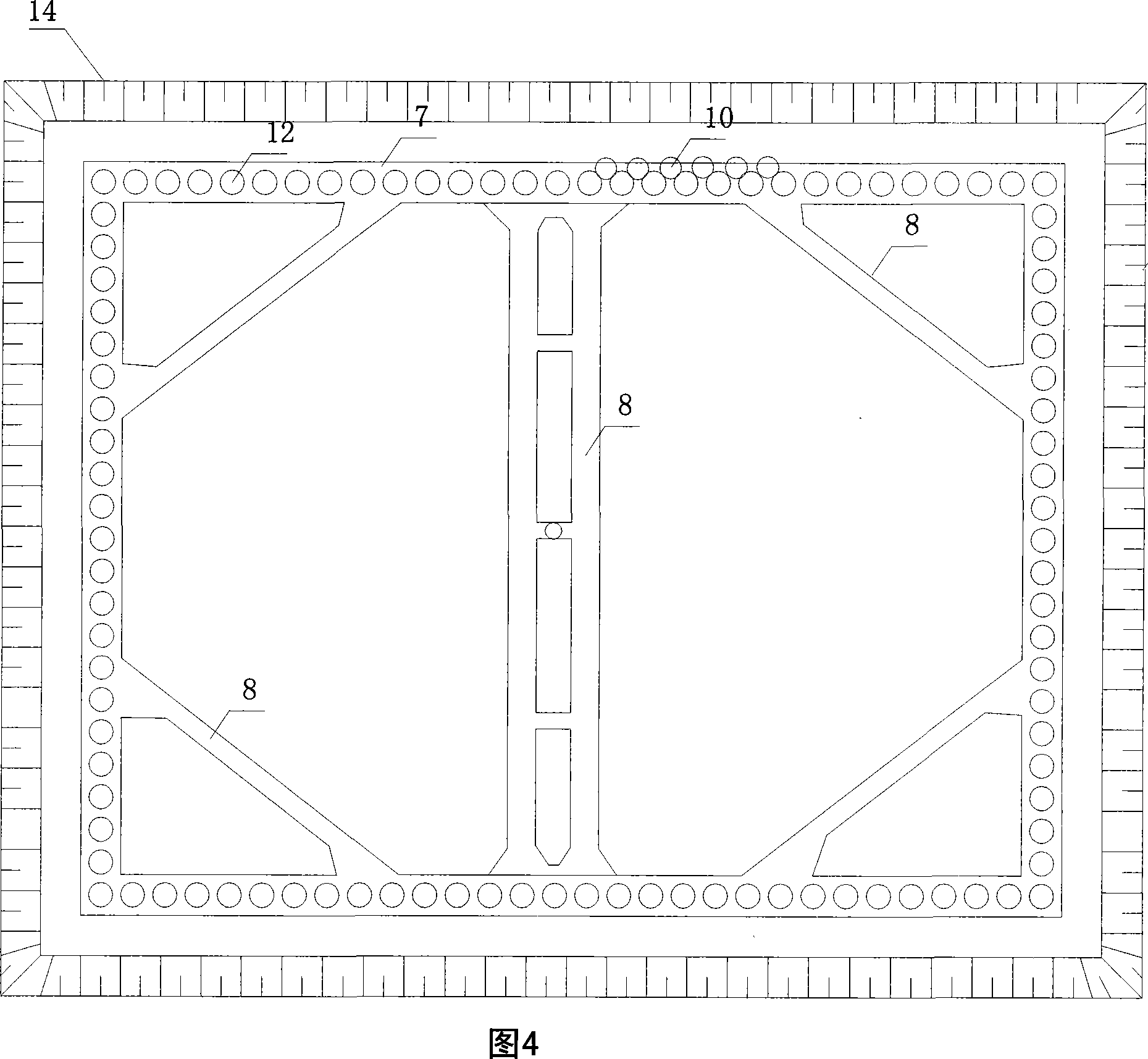

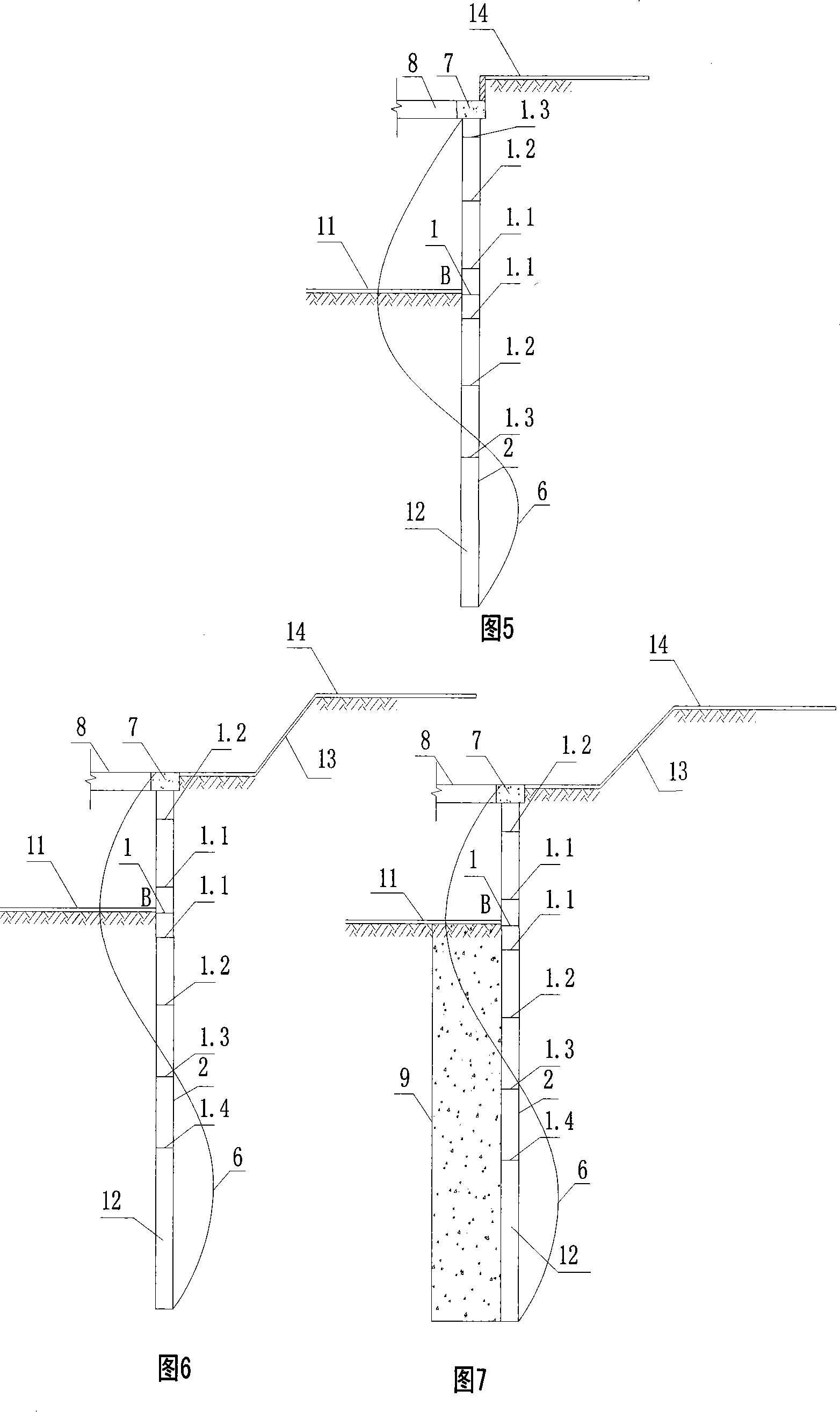

InactiveCN101105033APrecise layoutImprove the bending capacityShaping reinforcementsExcavationsReinforced concretePre stress

The invention discloses a method for supporting a building foundation pit by using transverse partition-type pre-stressed concrete pipe pile. The method comprises the following steps: (A) calculating and determining the axial position of inner transverse partitions (1, 1.1, 1.2, 1.3, 1.4) of a transverse partition-type pre-stressed concrete pipe pile (12) and the diameter and length of the pipe pile (12); (B) fabricating the pipe pile (12); (C) measuring and lining to determine the position of the pipe pile (12); (D) statically settling the pipe pile (12); (E) welding anchoring tendons at the top of piles and fabricating and installing reinforced concrete top ring beams (7) and supporters (8). The method further comprises driving concrete-stirring piles (9, 10) respectively inside and outside the pipe pile (12) and grouting concrete (5) inside the pipe pile (12). The method has the advantages of wide application range, high construction quality, short construction cycle, relatively-low construction cost for foundation pit support, and no noise and vibration pollution.

Owner:HUAFENG CONSTR CO LTD +1

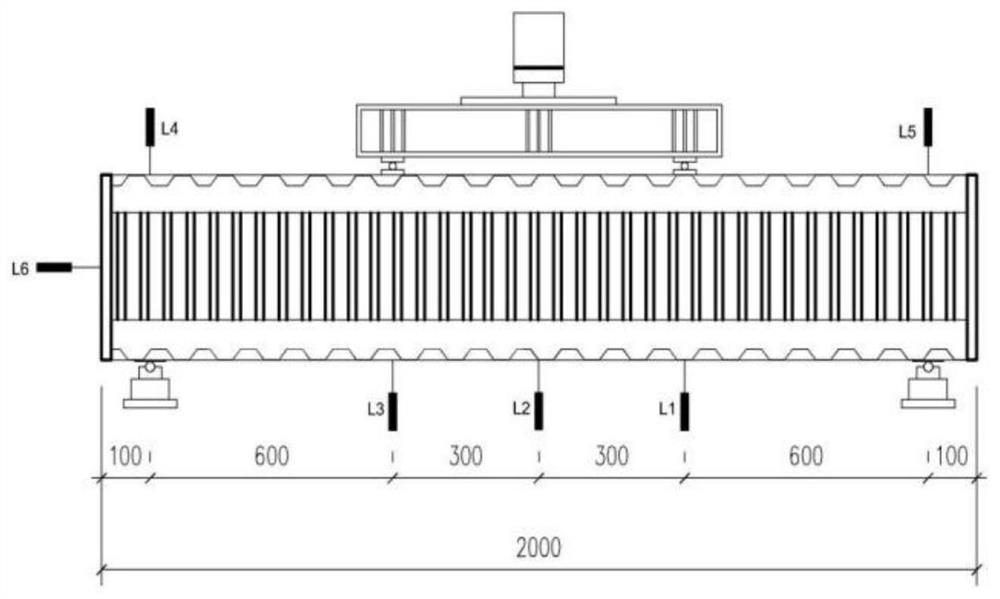

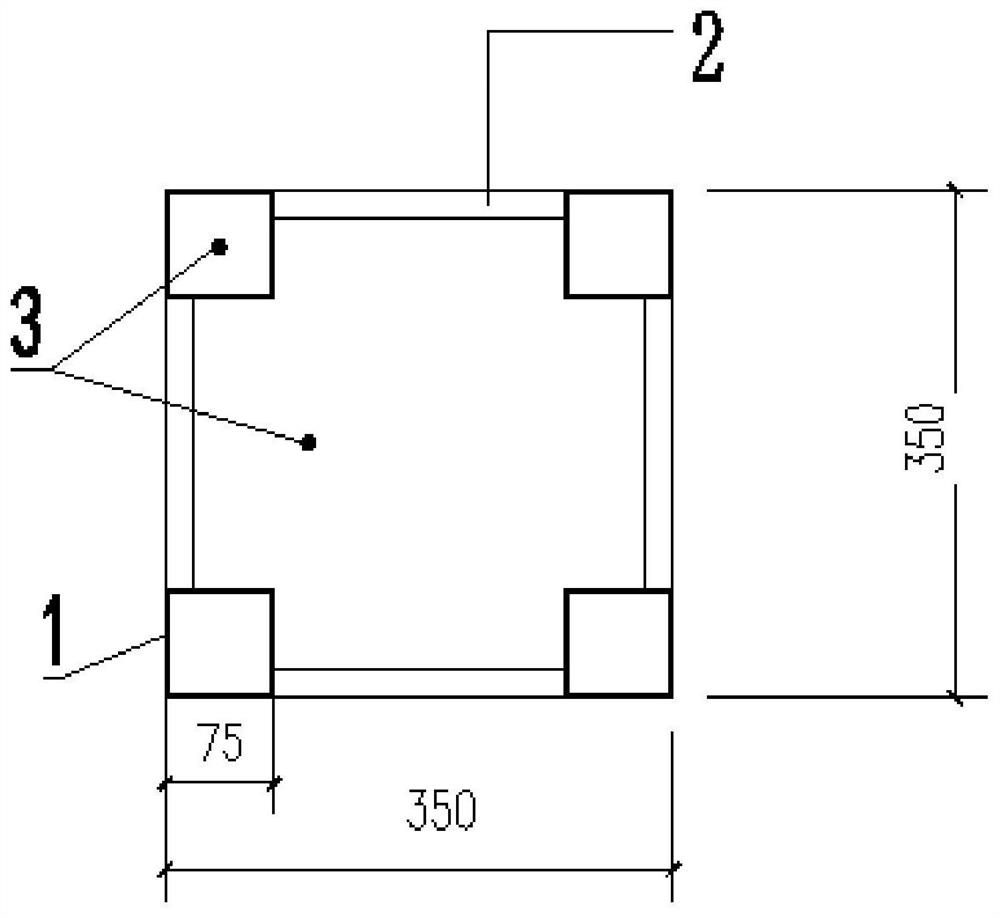

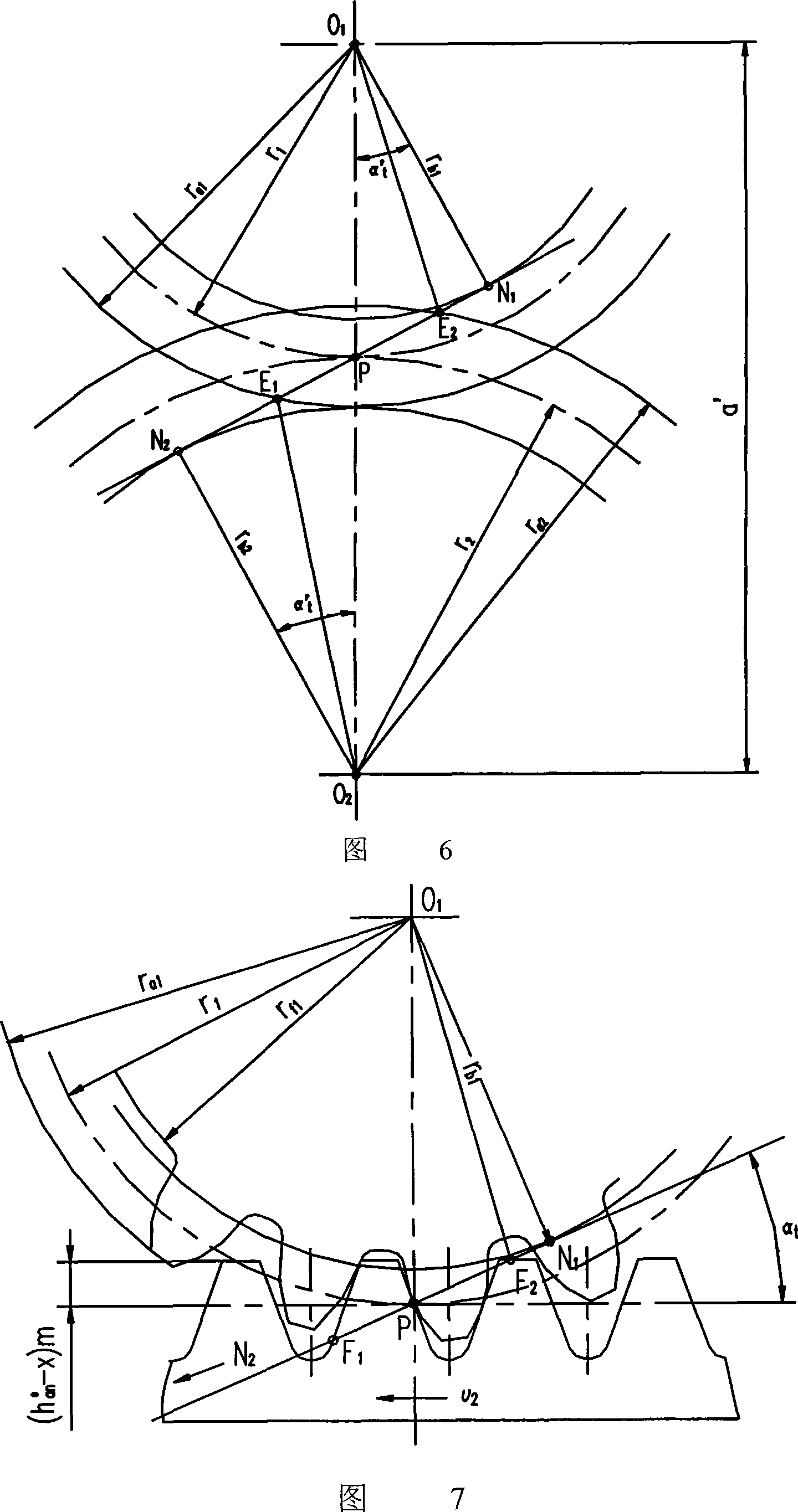

Method for calculating flexural capacity of variable cross-section column

PendingCN111753351AAnti-bending capacity design formula, accurate calculationAccurate calculationGeometric CADDesign optimisation/simulationElement analysisClassical mechanics

The invention discloses a method for calculating the flexural capacity of a variable cross-section column. The method comprises the following steps: S1, calculating and determining a hoop coefficienttheta of a component; and S2, substituting the parameters into a formula to solve the ultimate flexural capacity. The influence of the corrugated plates, the area conversion of the irregular concretesection, the enhancement of the structural constraint effect and other factors are considered, the steel pipe, the corrugated plates and the concrete can be synergistically stressed under the pure bending load, the overall working performance of the combined column is good, and the deflection and cracks of the combined column can be effectively controlled; and the influence of the concrete strength grade on the flexural capacity of the component under the pure bending load is small. The mean value of the ratio of the crustacean column flexural capacity obtained through a calculation formula tothe ultimate bending moment obtained through finite element analysis is 0.999, the variance is 0.009, and the flexural capacity of the crustacean column can be accurately calculated.

Owner:JIANGNAN UNIV

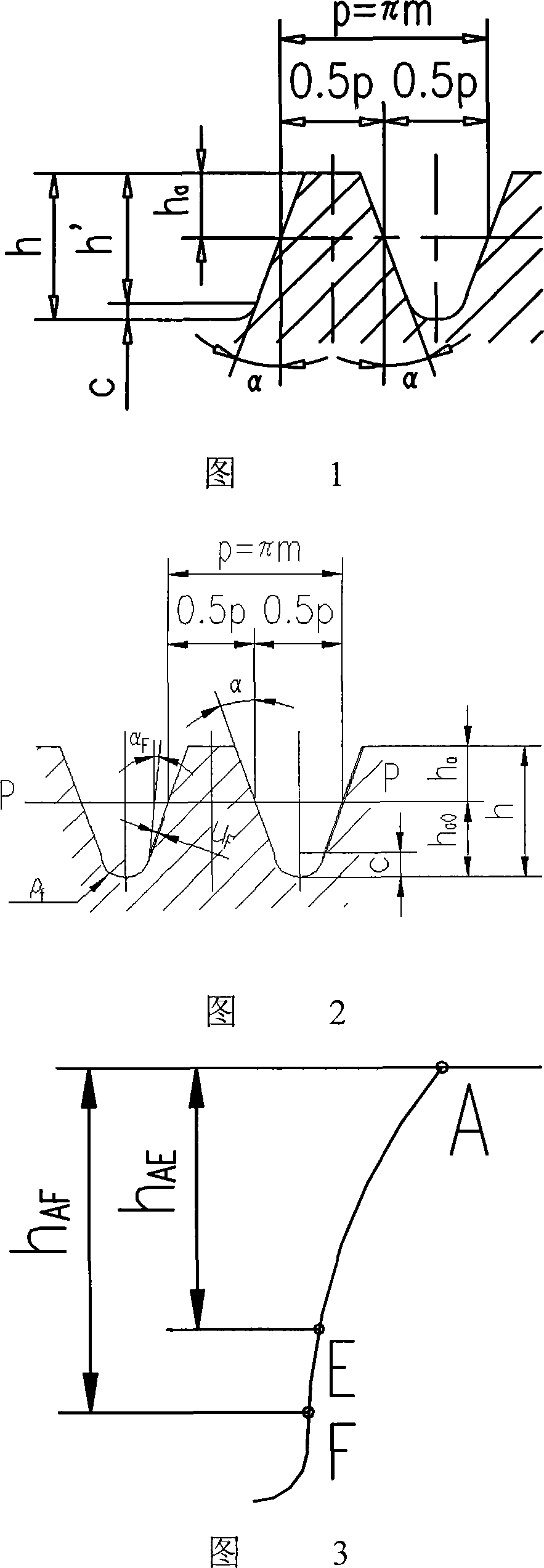

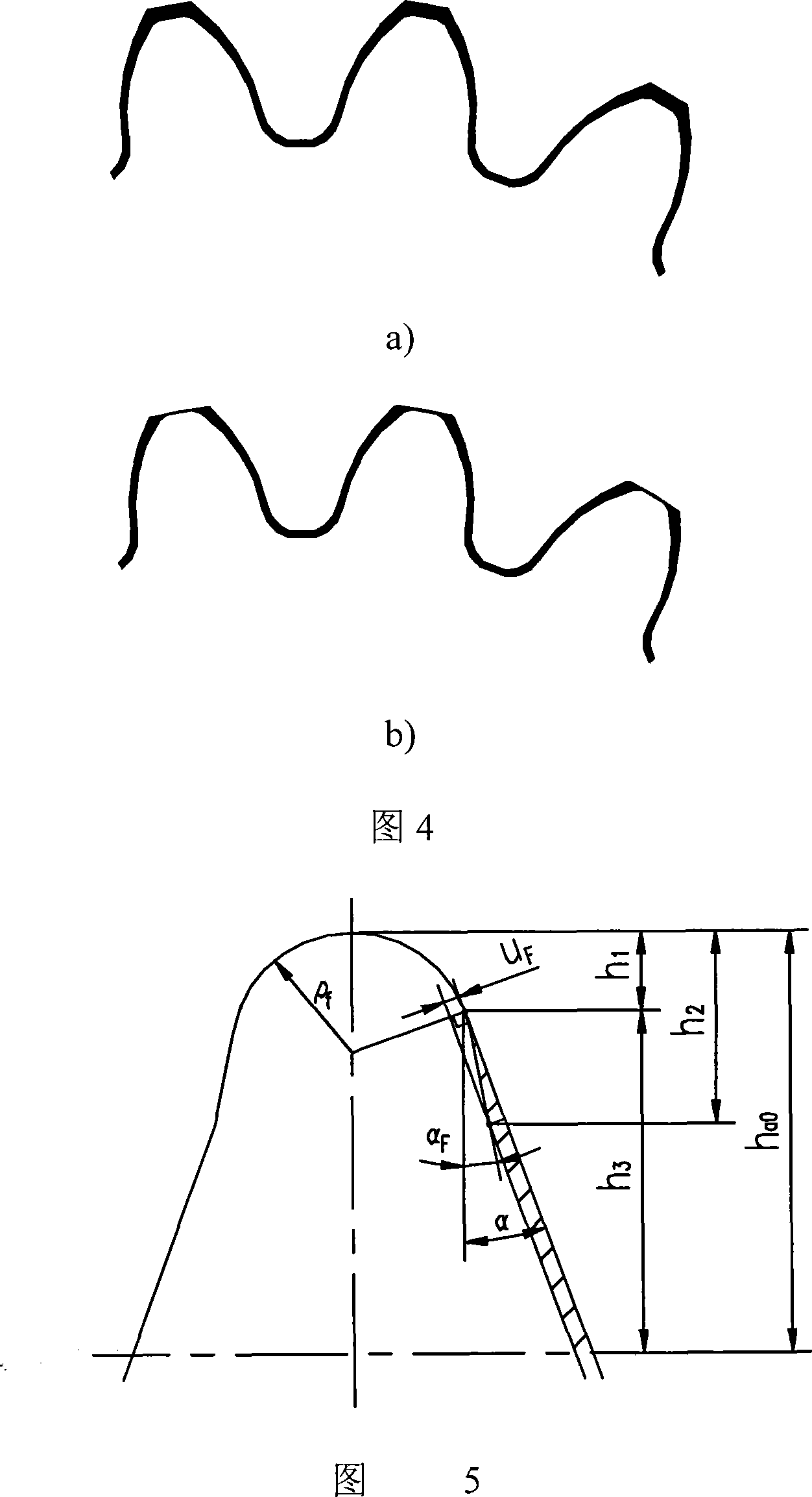

Gear wheel with changed tooth height

InactiveCN101182880AImproved face alignmentHigh coincidencePortable liftingGearing elementsCarrying capacityGear wheel

The invention relates to a gear with inconstant addendum and belongs to the technical field of mechanical transmission. The gear is provided with gear teeth uniformly distributed on the circumference of the gear. Involute profiles are arranged on both sides of the gear teeth. The relation between the addendum ha of the basic tooth profile of the gear and the modules of the gear is that ha is more than or equal to 1.05 m and is less than or equal to 1.25 m. The structure of the invention is improved based on the prior science; the action line length is improved by about 15 percent; the touch carrying capacity is improved by more than 10 percent; the bending carrying capacity is improved by 5 percent to 9 percent; the noise is significantly reduced on the premise that the material cost of the gear is hardly increased; the cutter of the gear is not changed; the process is not changed; the difficulty of the manufacture is not improved basically. Accordingly, the invention has remarkable substantial characteristics and remarkable improvement.

Owner:宝钢苏冶重工有限公司

Manufacturing method of internally arranged thin-wall H-shaped steel and wood composite beam

InactiveCN108824698AImprove bearing capacityMake full use ofMaterial gluingLoad-supporting elementsEpoxyEngineering

The invention discloses a manufacturing method of an internally arranged thin-wall H-shaped steel and wood composite beam. The manufacturing method comprises the steps that epoxy resin adhesives are brushed on the two sides of a thin-wall H-shaped steel web and the inner sides of web wood plates, the thin-wall H-shaped steel web and the web wood plates are bonded and connected through web connecting bolts, and then thin-wall H-shaped steel and webs on the two sides are closely pasted through pre-tightening opposite-pulling devices; epoxy resin adhesives are brushed on the surfaces of thin-wallH-shaped steel flanges and the inner sides of flange wood plates, the thin-wall H-shaped steel flanges and the flange wood plates are bonded and connected through flange shear-resistant connecting toggle pins, and then the thin-wall H-shaped steel and the flange wood plates are closely pasted through the pre-tightening opposite-pulling devices; and finally, the internally arranged thin-wall H-shaped steel and wood composite beam is formed. According to the manufacturing method of the internally arranged thin-wall H-shaped steel and wood composite beam, efficient steel and wood compositing canbe achieved, the steel and wood composite beam with more excellent properties of bearing capacity, rigidity, durability and the like is formed, and industrial production and standardized constructionof the steel and wood composite beam in a steel and wood composite structure are facilitated.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Fully-prefabricated cold-formed steel house modular unit and assembly connection method

ActiveCN105275089AReduce on-site construction workloadHigh degree of industrializationBuilding material handlingModular unitAbnormal shaped

The invention discloses a fully-prefabricated cold-formed steel house modular unit and an assembly connection method. The fully-prefabricated cold-formed steel house modular unit comprises split special-shaped column units, wall body units and connection wall board units, wherein the split special-shaped column units and the wall body units are in assembly connection; and the places where the split special-shaped column units and the wall body units are connected are in assembly connection via the connection wall board units. The unit and the method of the invention have the advantages of simple and convenient construction operation, high industrial degree, little field construction quantity and the like, quick fully-prefabricated construction on the house structure can be realized, and cold-formed steel house structure construction is facilitated.

Owner:SOUTHEAST UNIV

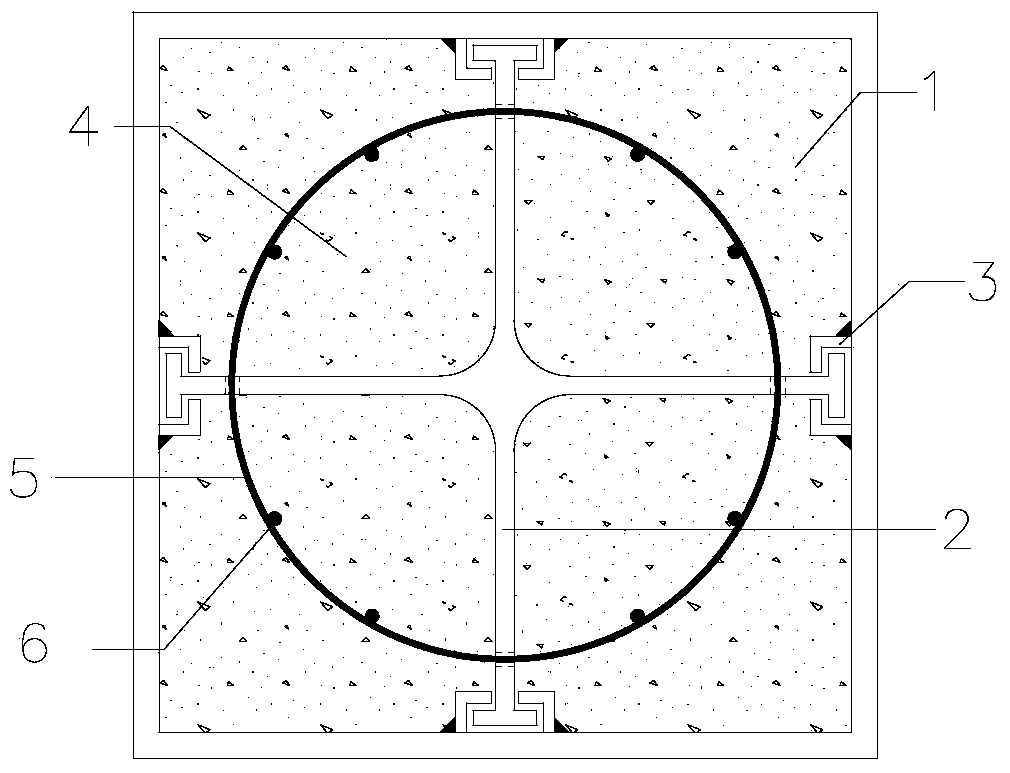

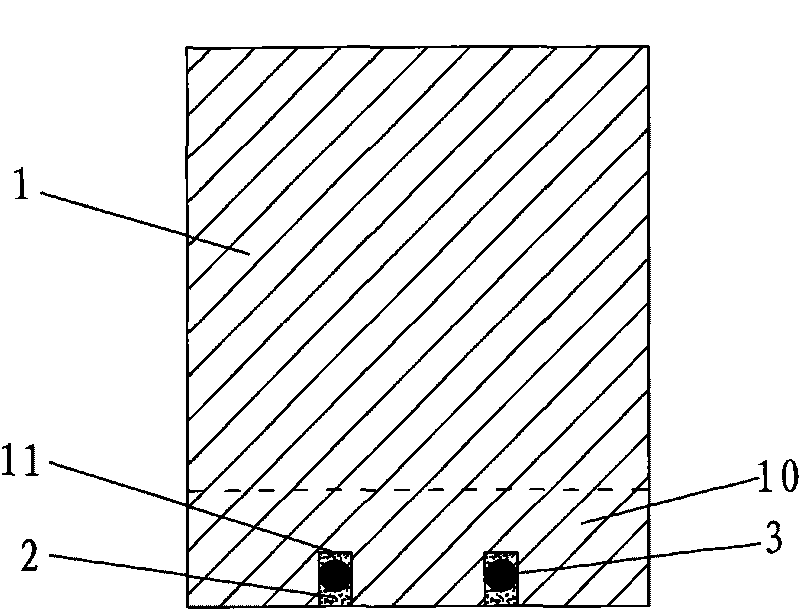

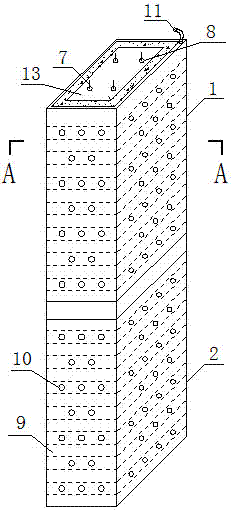

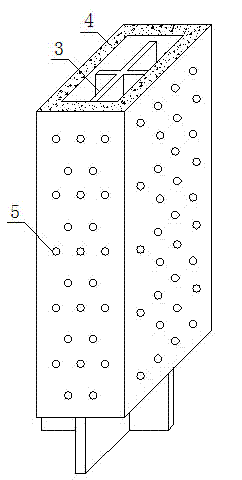

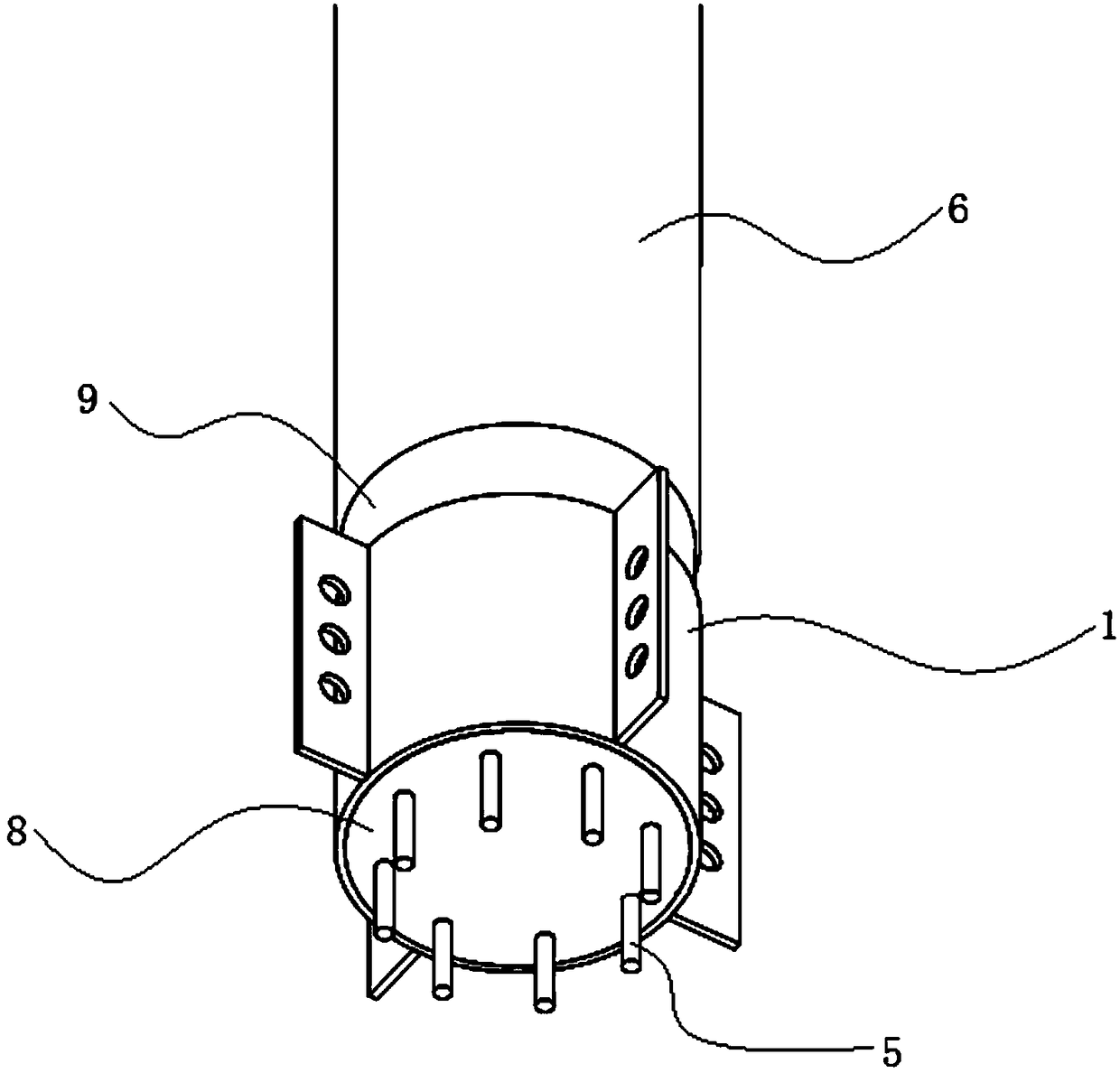

Connecting joint of prefabricated steel pipe restraining reinforced concrete pier and bearing platform

ActiveCN108360370ASimple molding processFast constructionBridge structural detailsBridge erection/assemblyReinforced concreteEngineering

The invention provides a connecting joint of a prefabricated steel pipe restraining reinforced concrete pier and a bearing platform and a construction method thereof. The connecting joint connects a prefabricated bridge pier and a bearing platform. The prefabricated bridge pier includes a steel pipe joint, an upper steel pipe and concrete. The steel pipe joint includes a lower steel pipe, a perforated steel plate and a connecting steel plate. The upper steel pipe is arranged above the lower steel pipe. The construction method of the connecting joint includes manufacturing a steel pipe joint, arranging longitudinal steel bars, pouring bridge pier concrete, hoisting a prefabricated pier and pouring filling concrete and the like. The connecting joint simplifies the formwork process. The construction speed is fast. The construction quality is improved. The construction environment is improved. The labor cost and the construction cost are saved. The bearing capacity of the connecting jointof the prefabricated pier and the bearing platform is improved on the basis of ensuring that the outer-wrapped steel pipe does not bear vertical load and greater lateral binding force on the core concrete is provided.

Owner:CHONGQING UNIV

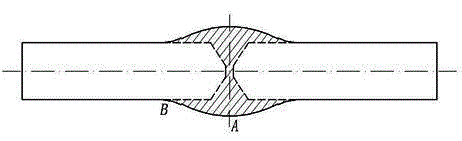

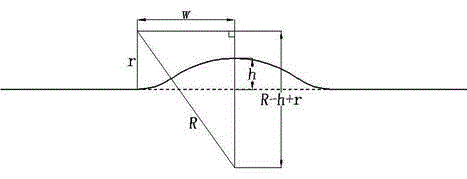

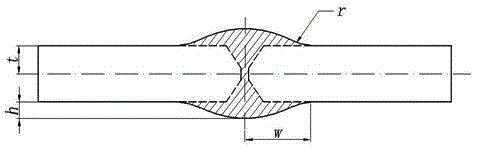

Joint shape design method for realizing equal bending bearing of low-match butt-joint joint with base metal

InactiveCN103143853ALower the preheat temperatureImprove working environmentWorkpiece edge portionsButt jointStrength of materials

The invention provides a joint shape design method for realizing equal bending bearing of low-match butt-joint joint with base metal and relates to a butt-joint joint design method. The method comprises the following steps that 1, the yield strength matching ratio of a low-match joint is calculated; 2, the height h of the welding seam surplus height is obtained through calculation by a material mechanical formula according to the equal bending bearing condition; 3, the cover surface weld pass half width w is determined; 4, the weld toe radius r is determined; and 5, the low-match joint geometrical shape parameter required by the equal bending bearing is obtained according to the solved height h of the welding seam surplus height, the cover surface weld pass half width w and the weld toe radius r. The joint shape design method is suitable for the low-match flat plate butt-joint joint of the X-shaped grooved double-side welding. The high-intensity welding structure can adopt the low-match joint assembly mode. The high-intensity welding adopts the low-match welding joint, the bending bearing capability can be enabled to be not lower than that of the base metal, and in addition, the ductility and toughness and the like are obviously improved through being compared with those of a matched welding joint.

Owner:HARBIN INST OF TECH

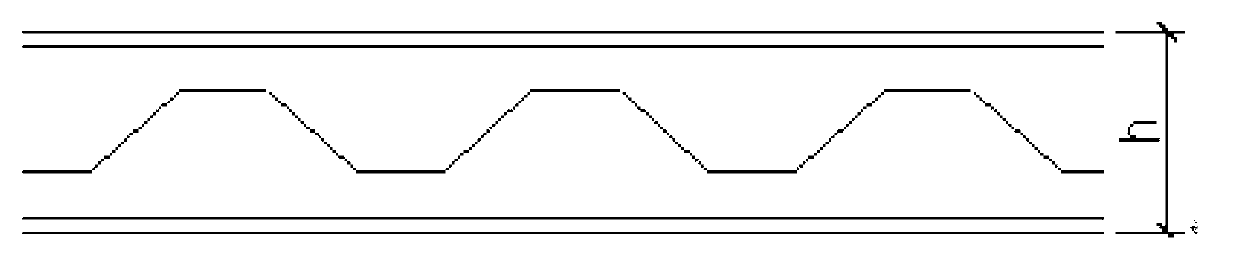

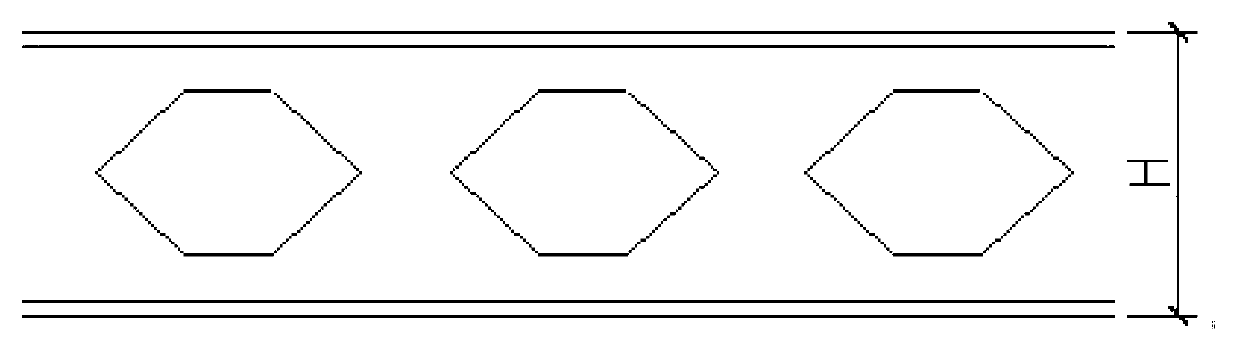

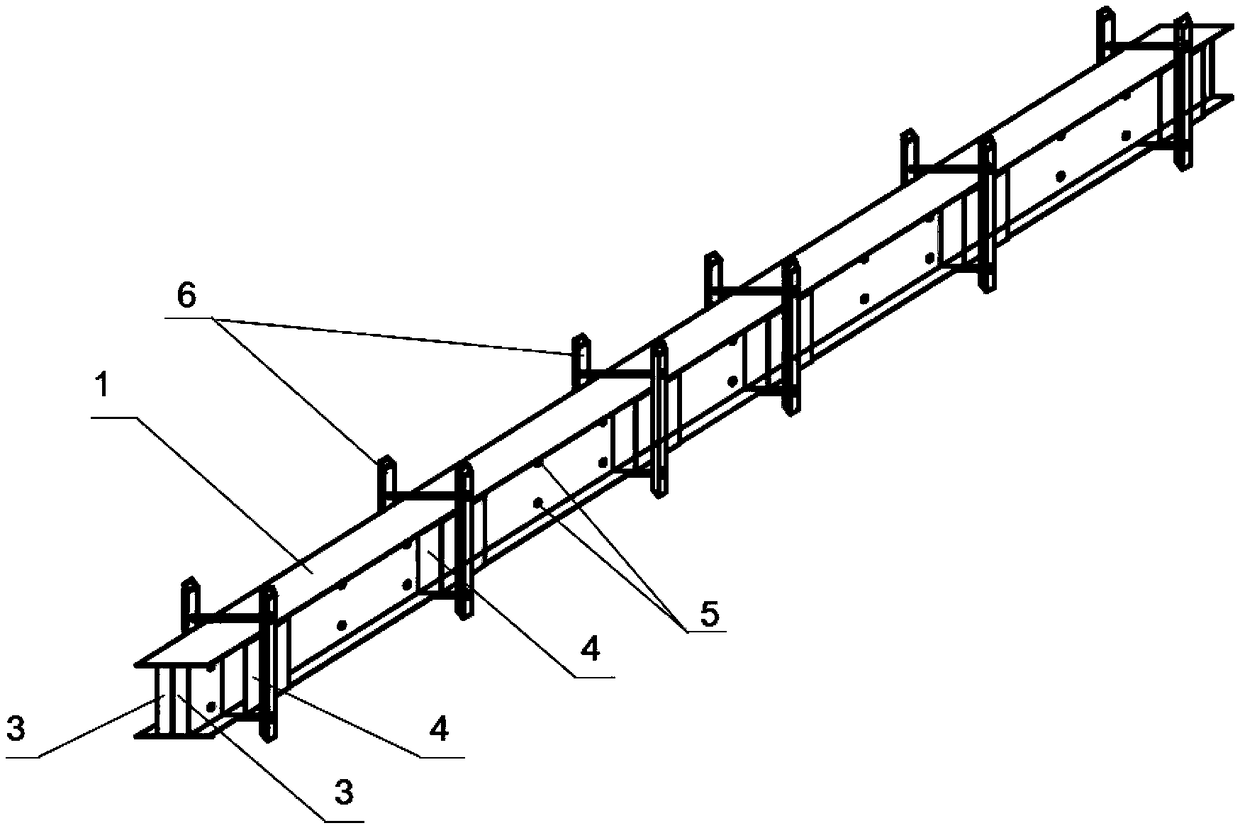

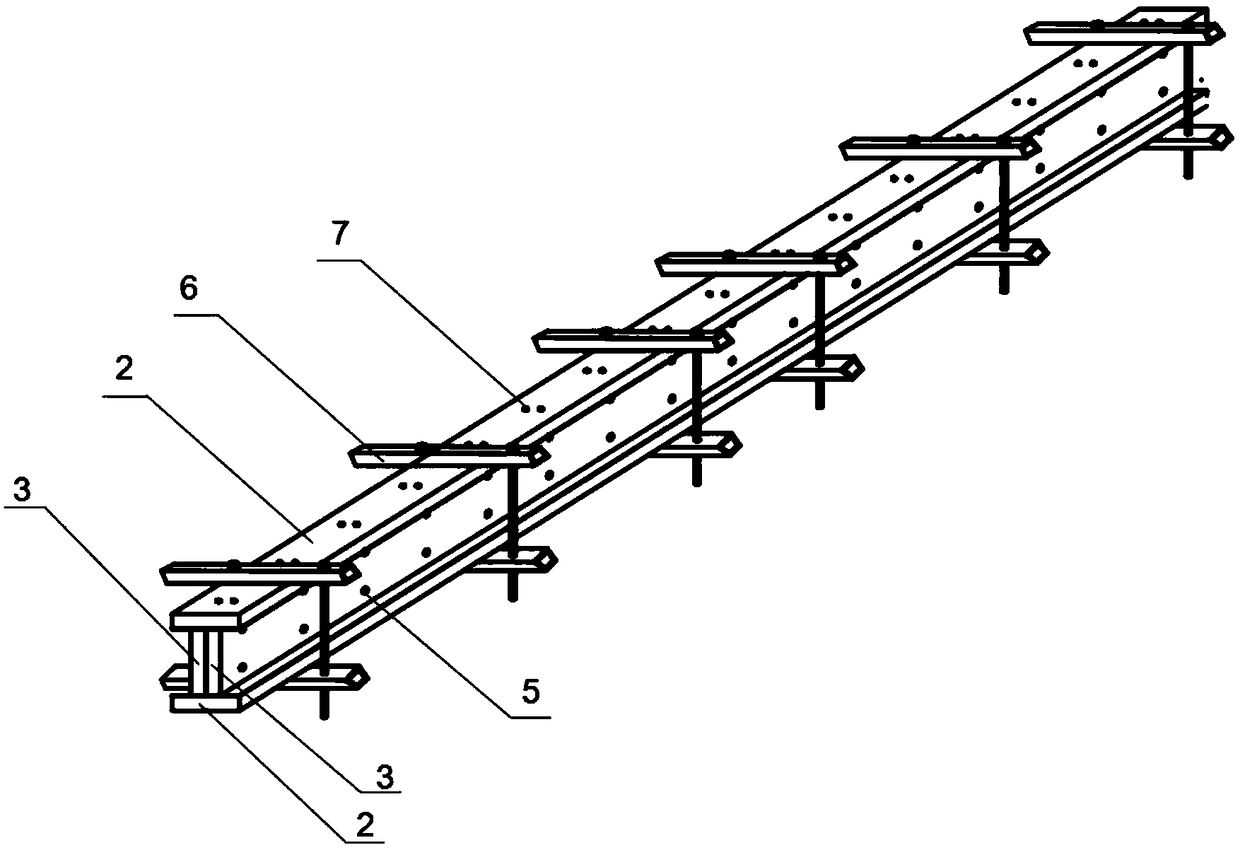

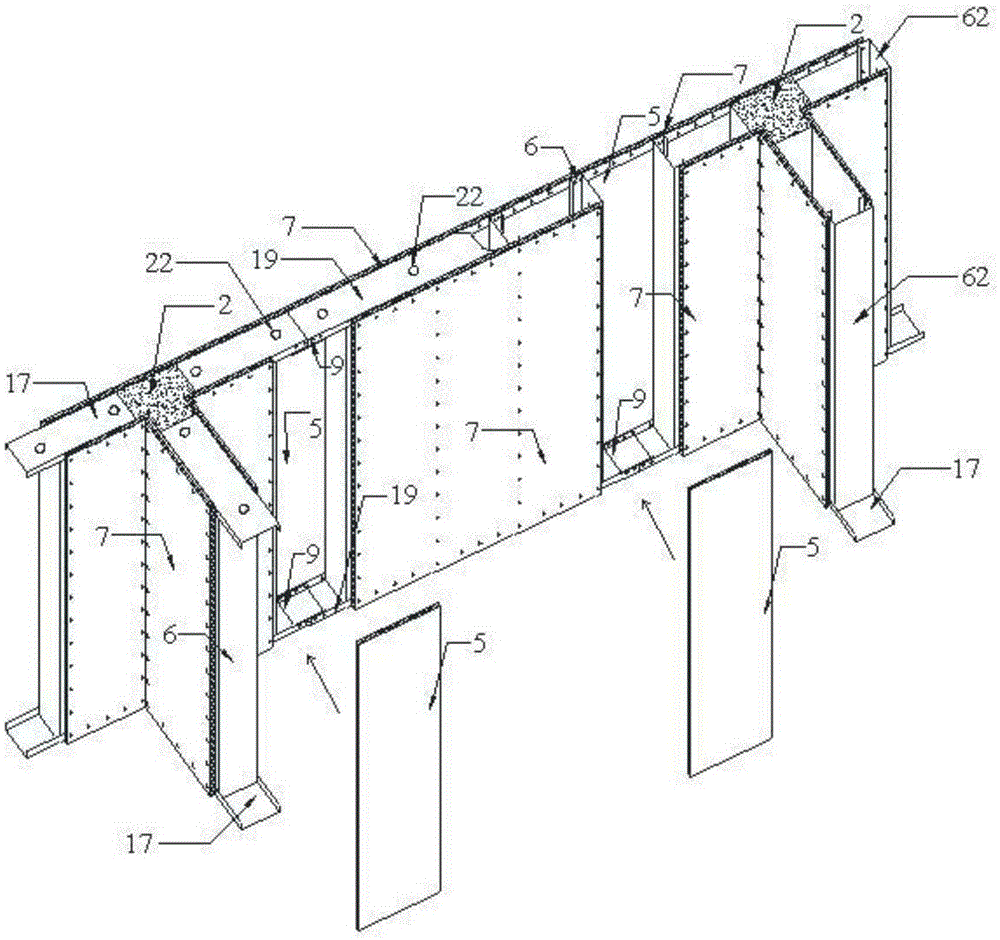

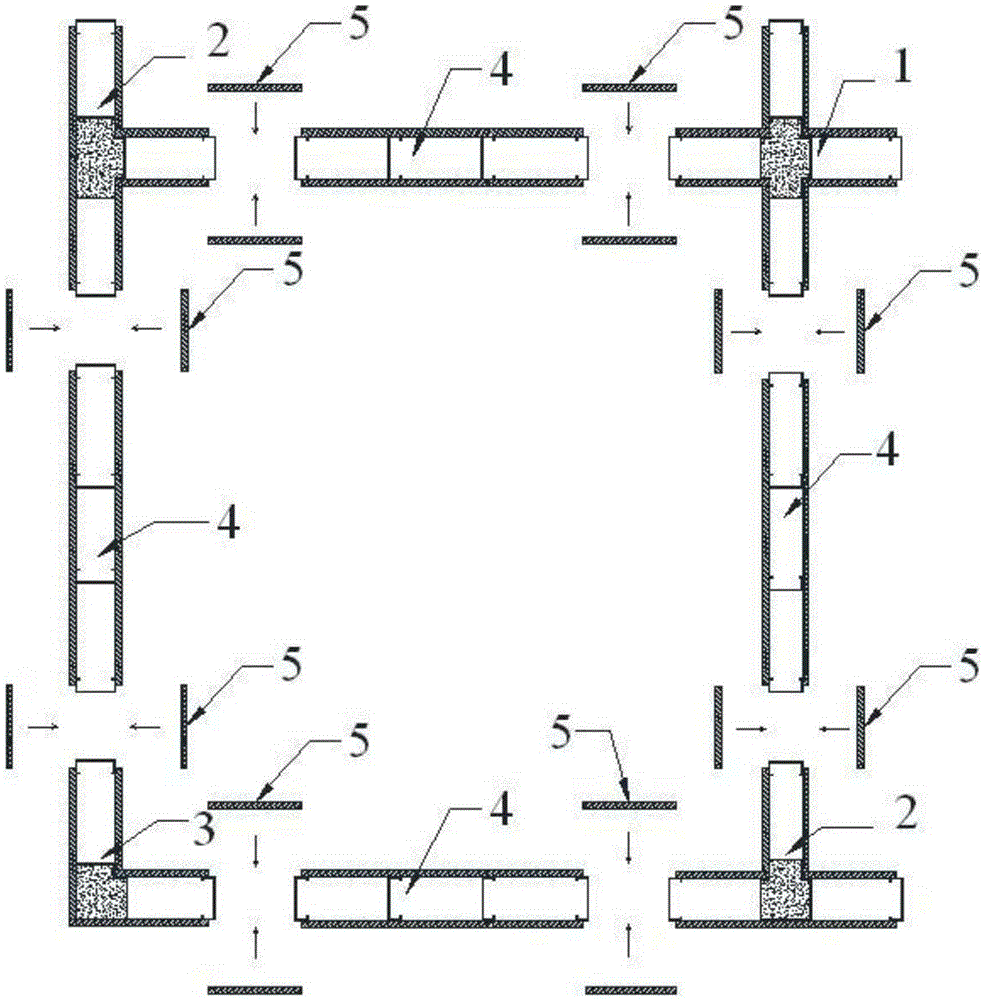

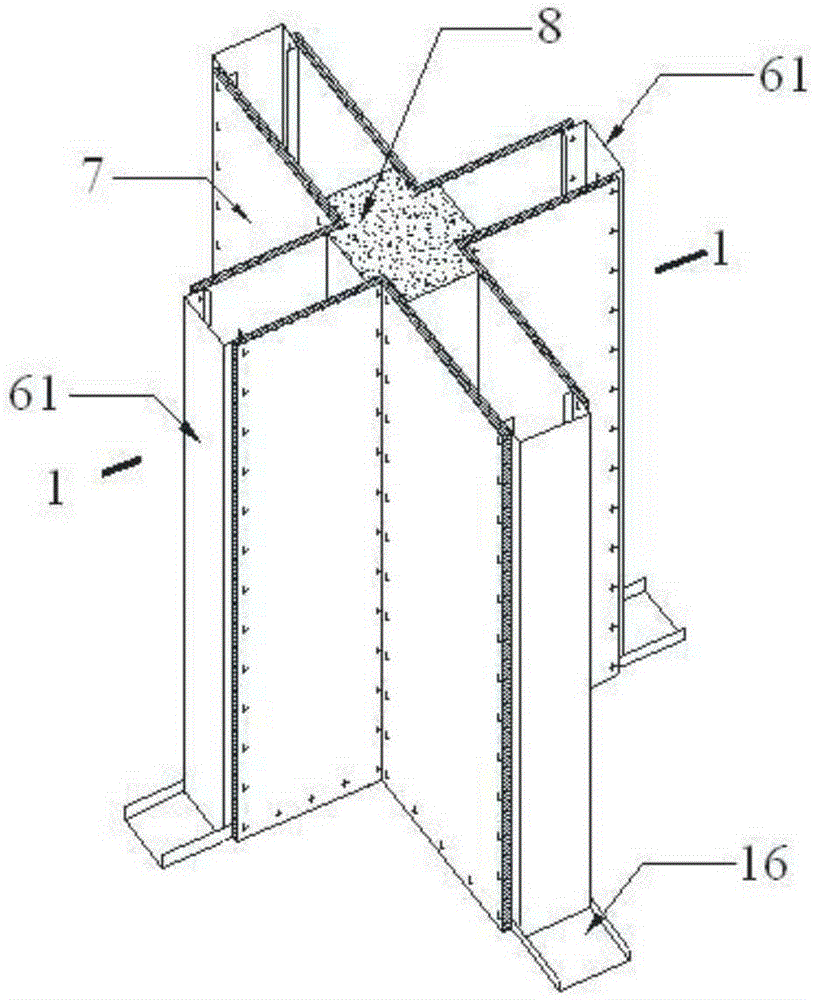

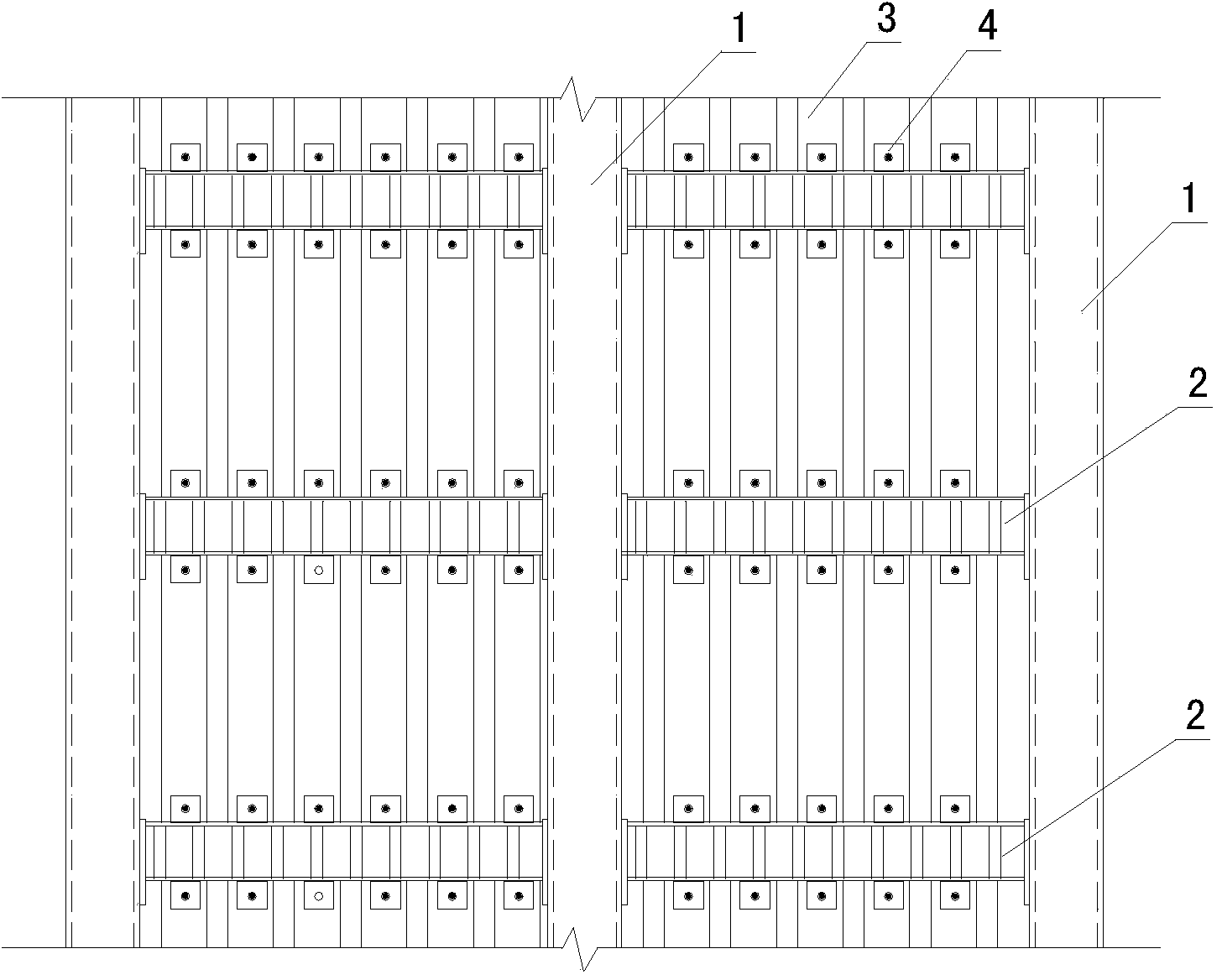

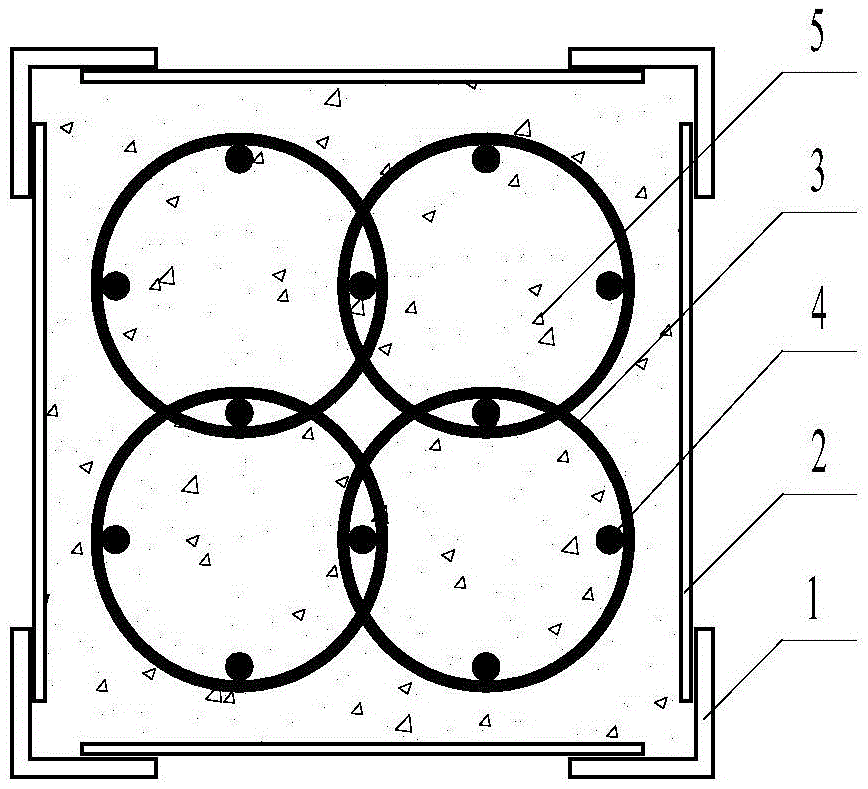

Assembling and energy consuming structural system with combined fluted frameworks and shear walls

The invention discloses an assembling and energy consuming structural system with combined fluted frameworks and shear walls. The system is characterized in that the system comprises concrete-filled steel tubular columns, fluted web plate beams and fluted steel plate shear walls; the concrete-filled steel tubular columns, the fluted web plate beams and the fluted steel plate shear walls are connected through bolts; the cross section of each fluted web plate beam is of an H shape; flange plates comprising the fluted web plate beams with the H-shaped cross sections are smooth steel plates; web plates are fluted steel plates; the fluted steel plate shear walls are made of fluted steel plates. The assembling and energy consuming structural system with the combined fluted frameworks and the shear walls is an assembly type high-rise steel-structure energy consuming building system which has the advantages that the construction progress is fast, the force transmission path is simple, and the energy consuming capacity is high.

Owner:HEFEI UNIV OF TECH

Steel structure reinforcing joint part with multiple anti-seismic progressive-collapse-resisting defensive lines

PendingCN110670900AIncrease dampingImprove seismic performanceBuilding repairsProtective buildings/sheltersEngineeringSteel columns

The invention discloses a steel structure reinforcing joint part with multiple anti-seismic progressive-collapse-resisting defensive lines. The steel structure reinforcing joint part comprises a steelbeam, a steel column, a steel groove and truss chord members. The end of the steel beam is fixed to the steel column, the steel groove is fixed to the lower surface of a bottom flange of the steel beam, the side face of the steel column is provided with hinge supports, friction sliding blocks are arranged in the steel groove, through holes are formed in the bottom face of the steel groove, one ends of the truss chord members penetrate through the through holes to be connected with the friction sliding blocks, and the other ends of the truss chord members are connected with the hinge supports.According to the part, the problem that a traditional steel structure joint is poor in anti-seismic progressive-collapse-resisting capacity, and the structure is in brittle failure can be effectivelysolved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

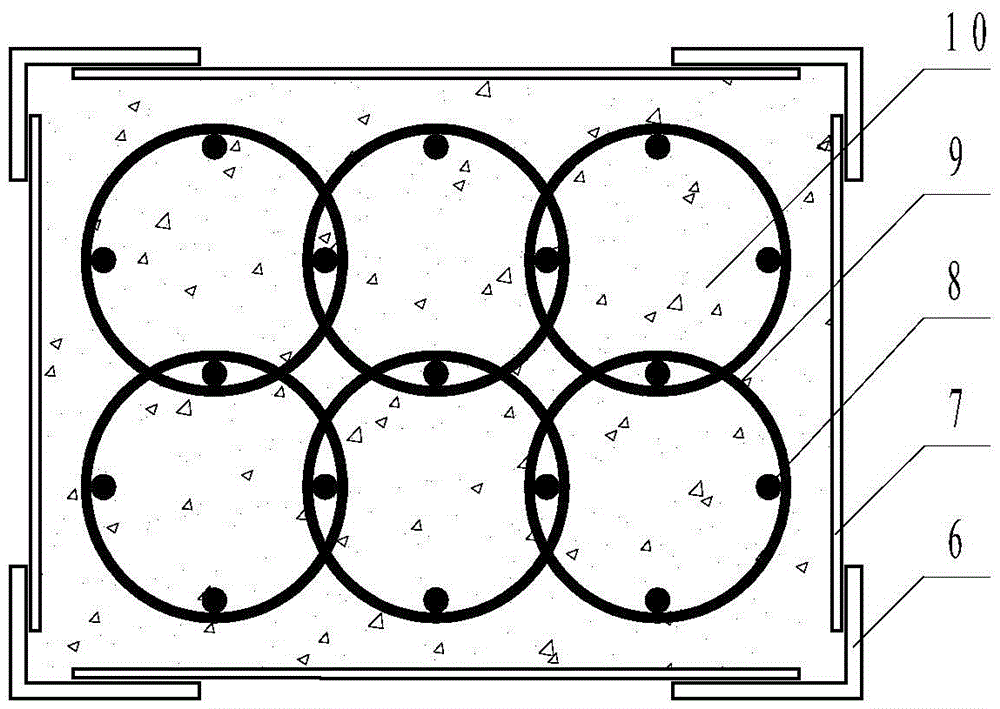

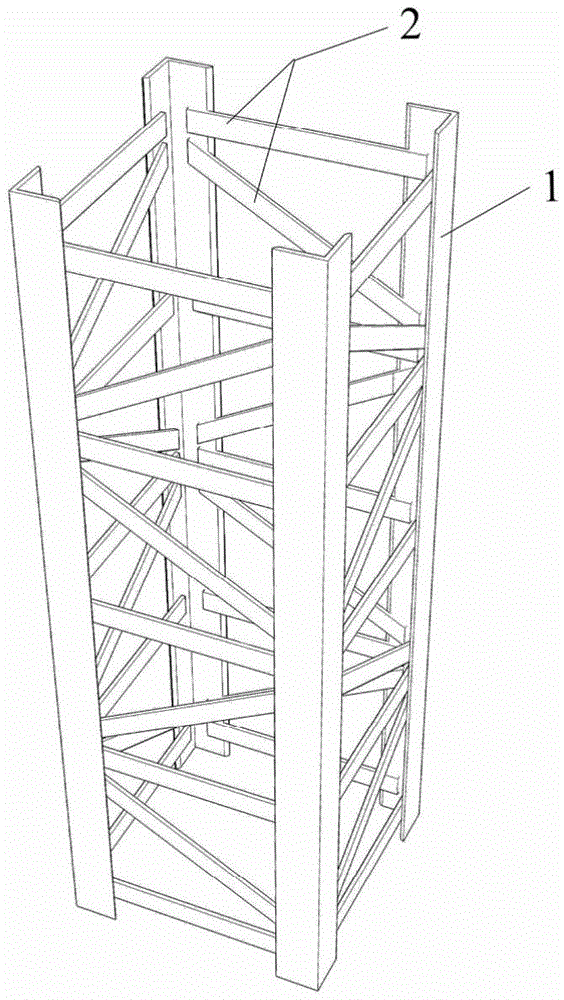

Steel reinforced concrete combination pillar with built-in bunched spiral stirrups and manufacturing method

InactiveCN105484429AImprove bearing capacityImprove ductilityStrutsPillarsReinforced concreteSteel bar

The invention discloses a steel reinforced concrete combination pillar with built-in bunched spiral stirrups. The combination pillar comprises angle steel, steel lacing and batten elements, the spiral stirrups, longitudinal reinforcing steel bars and concrete. The section of the combination pillar is in a square or rectangular shape. The spiral stirrups are arranged side by side and bundled with the longitudinal reinforcing steel bars to form a reinforcement cage. The reinforcement cage is wrapped with the concrete. The concrete is wrapped with a section steel truss. The section steel truss is formed by welding the angle steel and the steel lacing and batten elements. Due to the fact that the concrete is wrapped with the section steel, the problem that the concrete is cracked and peeled off early, and therefore the bearing capacity is lowered is effectively solved. The spiral stirrups arranged side by side produce a restriction effect on the concrete inside therein, and the problem that the spiral stirrup concrete pillar is weak in restriction ability under the bending effect is solved. The flexural rigidity, flexural capacity and anti-seismic property of the combination pillar are effectively improved through the section steel truss. Reinforcing steel bars in a frame node area middle beam can penetrate through the section of the pillar, and construction is convenient and fast. The steel reinforced concrete combination pillar is particularly applicable to a structural pillar with the high requirement for anti-seismic property or a heavy-load pillar bearing large vertical loads.

Owner:GUANGXI UNIV

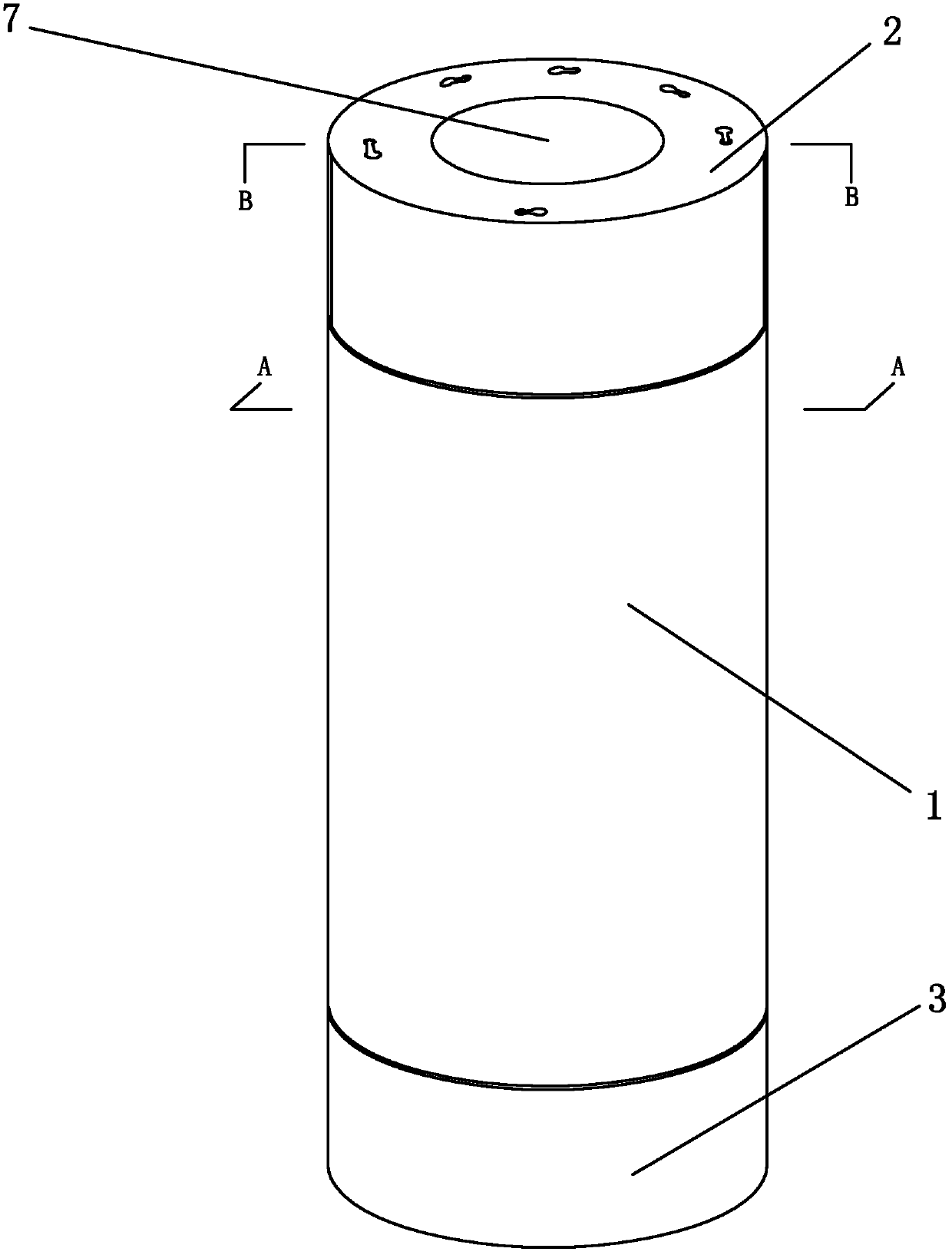

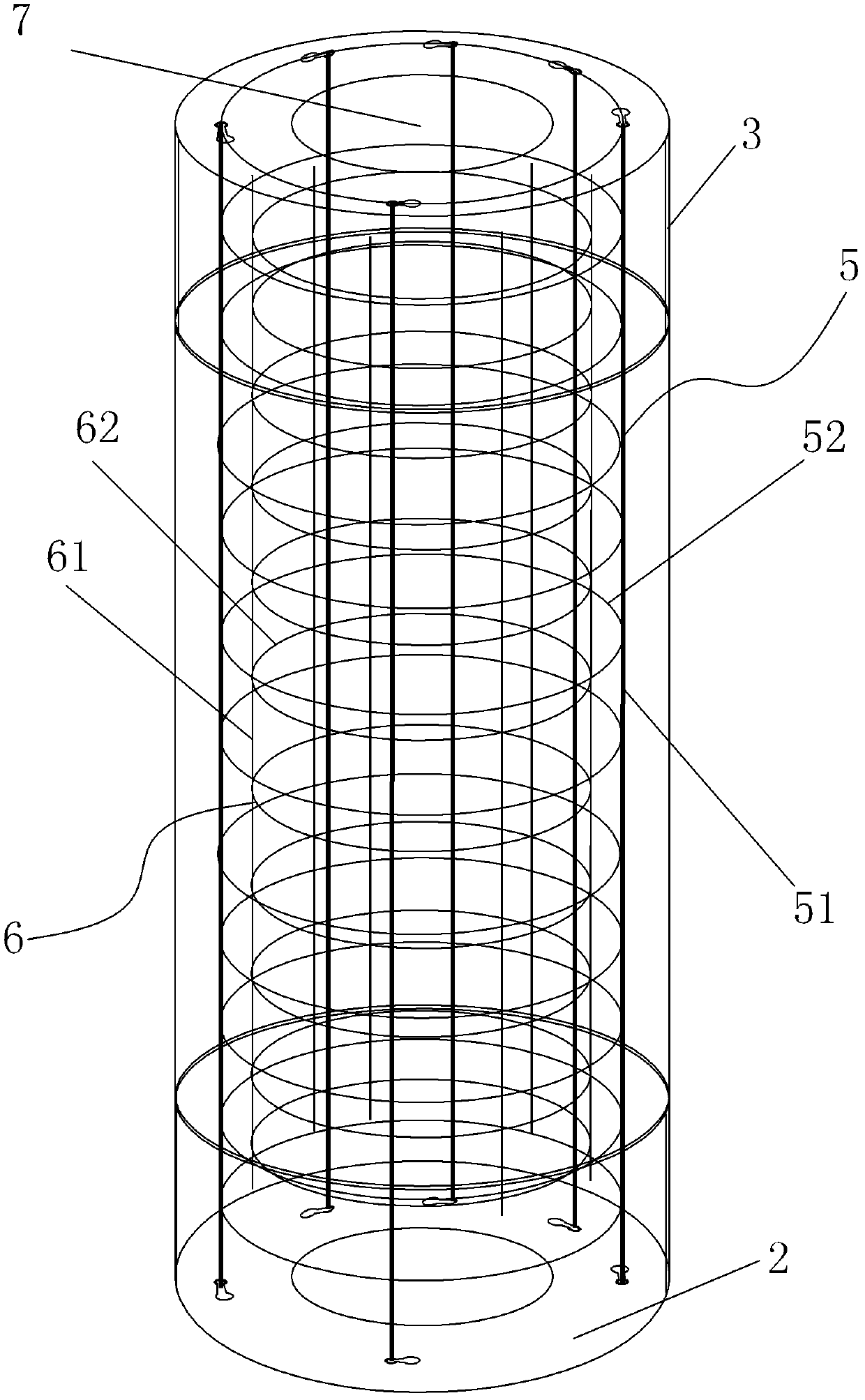

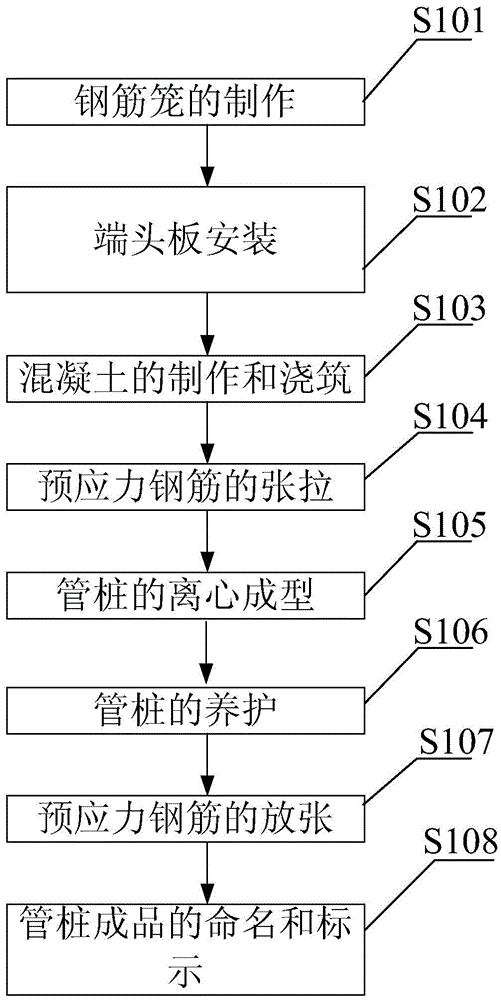

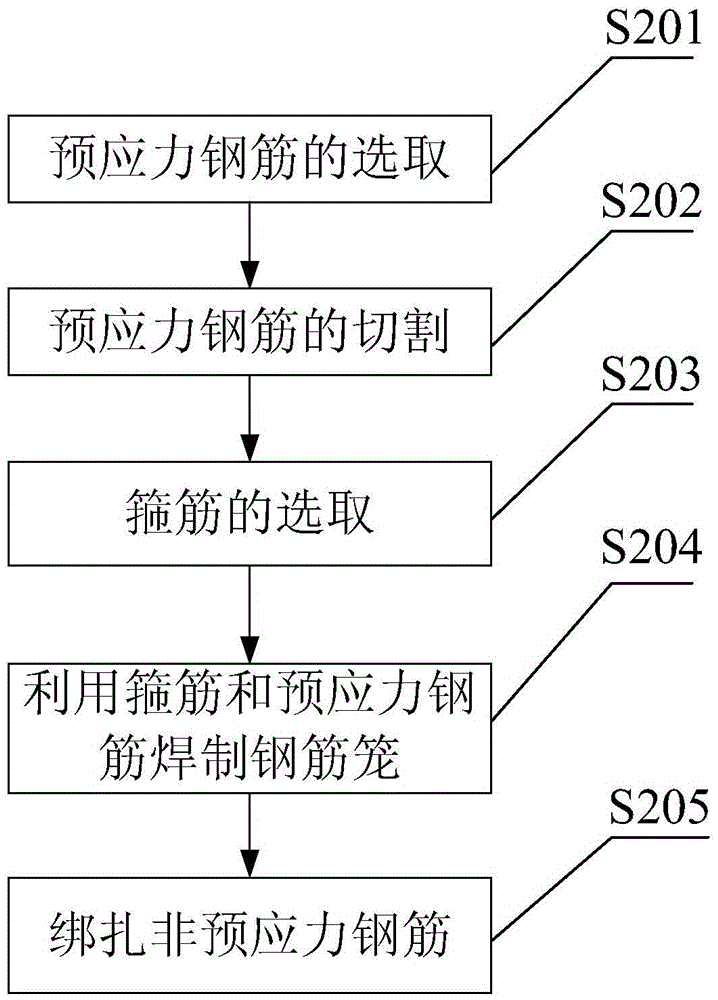

Anti-seismic tubular pile production method

InactiveCN105599132AImprove ductilityImprove the bending capacityShaping reinforcementsBulkheads/pilesPre stressRebar

The invention provides an anti-seismic tubular pile production method and aims at solving the problems of poor flexural performance, fragile-form damage, low anti-seismic performance and limited application existing in the prior art. The anti-seismic tubular pile production method comprises the steps of reinforcement cage manufacturing, end plate installation, concrete manufacturing and casting, prestressed steel bar tensioning, centrifugal tubular pile shaping, tubular pile maintenance, tensioning and arrangement of prestressed steel bars and naming and marking of tubular pile products. The anti-seismic tubular pile production method has the advantages that the ductility and flexural bearing capacity of anti-seismic tubular piles produced by means of the anti-seismic tubular pile production method are improved, the anti-seismic tubular piles have good adaptability to geological conditions, pile bodies are high in concrete strength, compact and beating-resistant, and the anti-seismic tubular piles have stronger penetrability, have better adaptability to the geological condition of large bearing stratum fluctuation change and are suitable for regions having higher requirements for the horizontal bearing capacity of the tubular piles.

Owner:TIANJIN BAOFENG BUILDING MATERIALS CO LTD

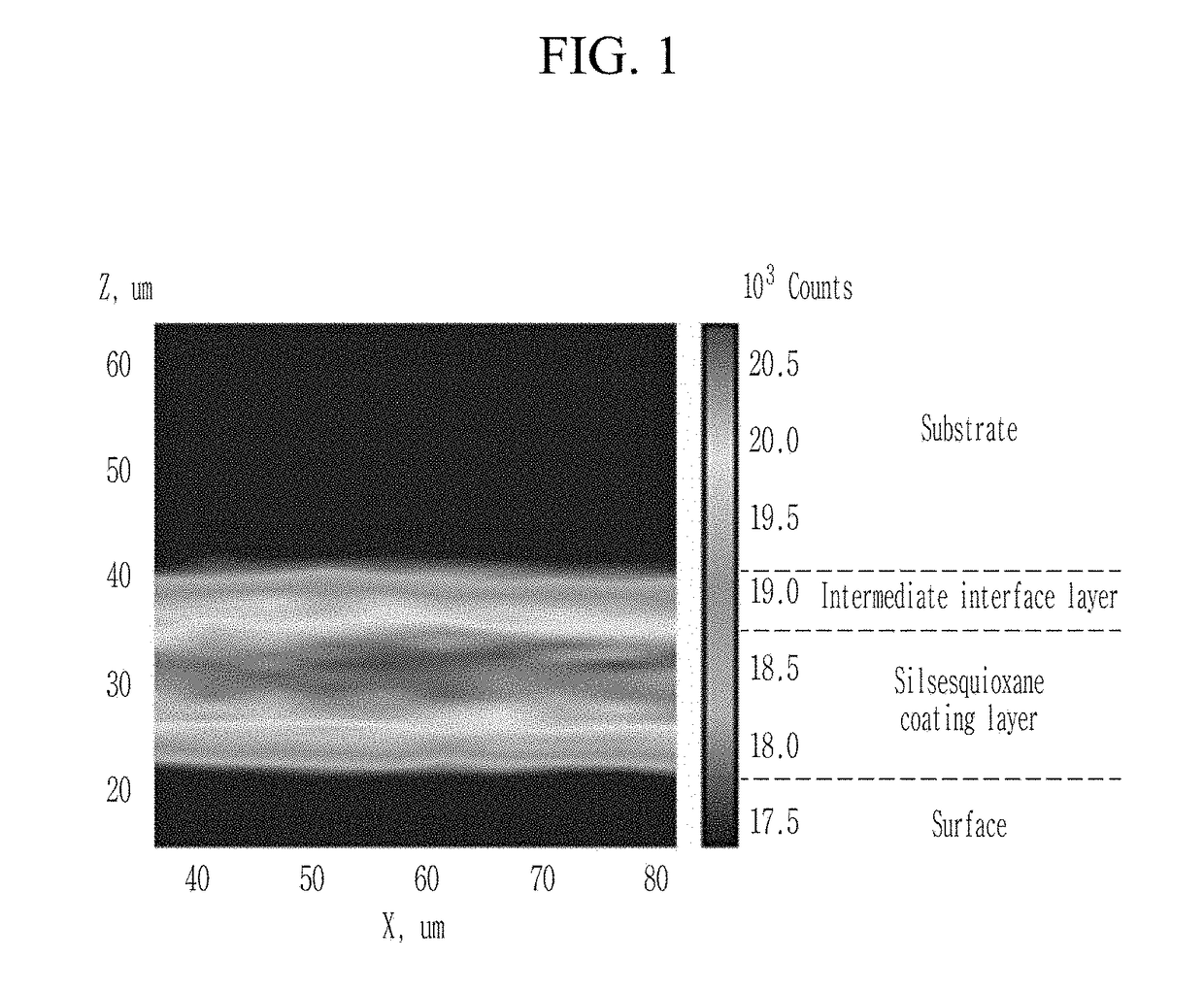

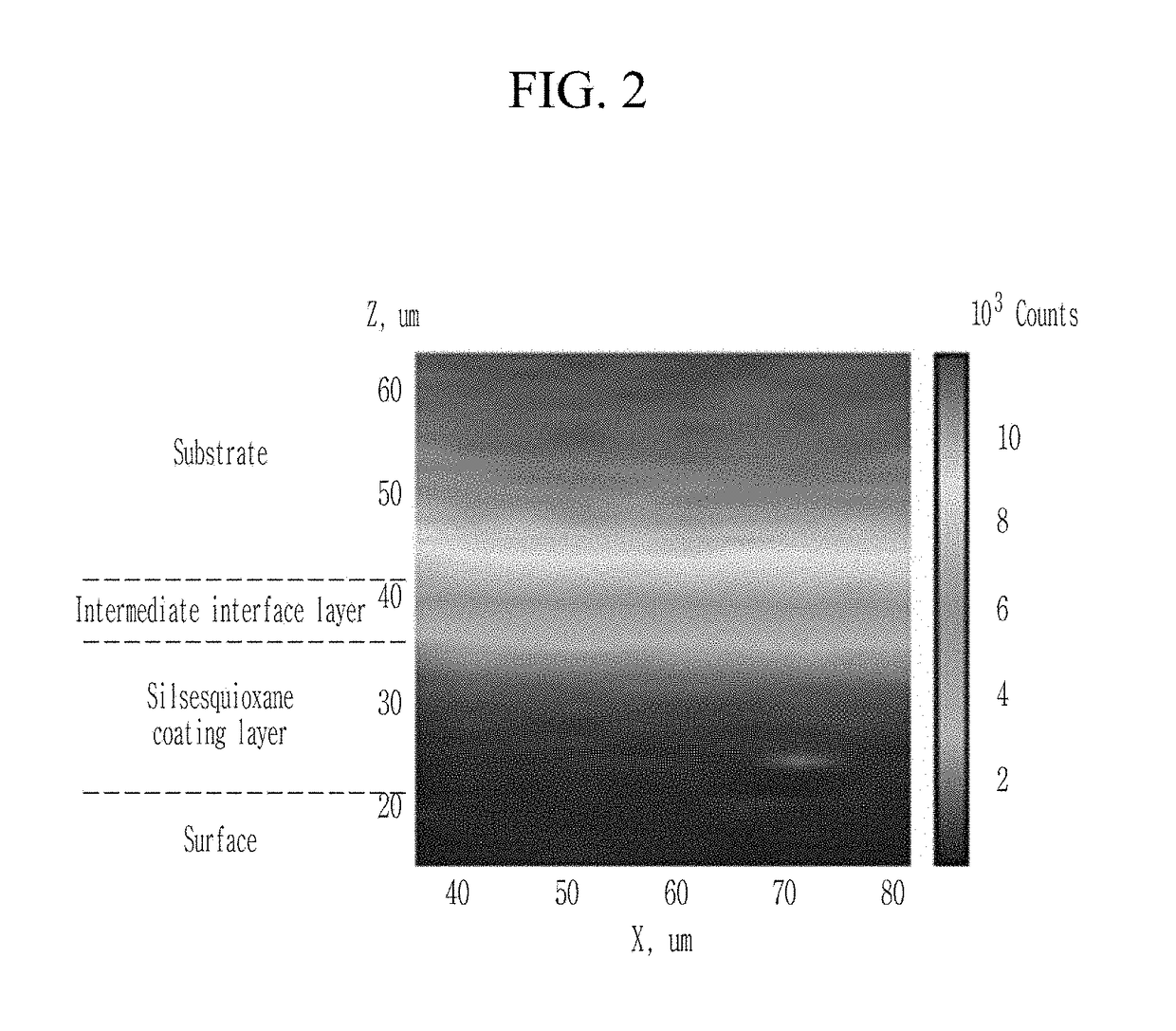

Laminate and method for producing same

ActiveUS20180237658A1Improve the bending capacityHigh transparencyPretreated surfacesCoatingsInterface layerHardness

The present invention relates to a laminate including a coating layer, which includes an Si—O group-containing material and an intermediate interface layer, and to a method for producing the same, and more specifically, to a laminate which includes an intermediate interface layer, which is a mixture of materials constituting a substrate and materials constituting a coating layer, between the substrate and the coating layer, which includes an Si—O group-containing material, and thus can significantly improve bending capabilities, transparency, and adhesion between the substrate and the coating layer, and further enhances scratch resistance, water repellent properties, anti-fouling properties, fingerprint resistance, thermal stability, gloss properties, and surface hardness by a silsesquioxane coating, and a method for producing the laminate.

Owner:DONGJIN SEMICHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com