Horizontal splicing corrugated steel web plate combined box girder and construction method

A technology of corrugated steel webs and combined boxes, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., which can solve the difficulties of construction, increased spacing, and the width limitation of horizontally assembled corrugated steel webs combined box girder bridges, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

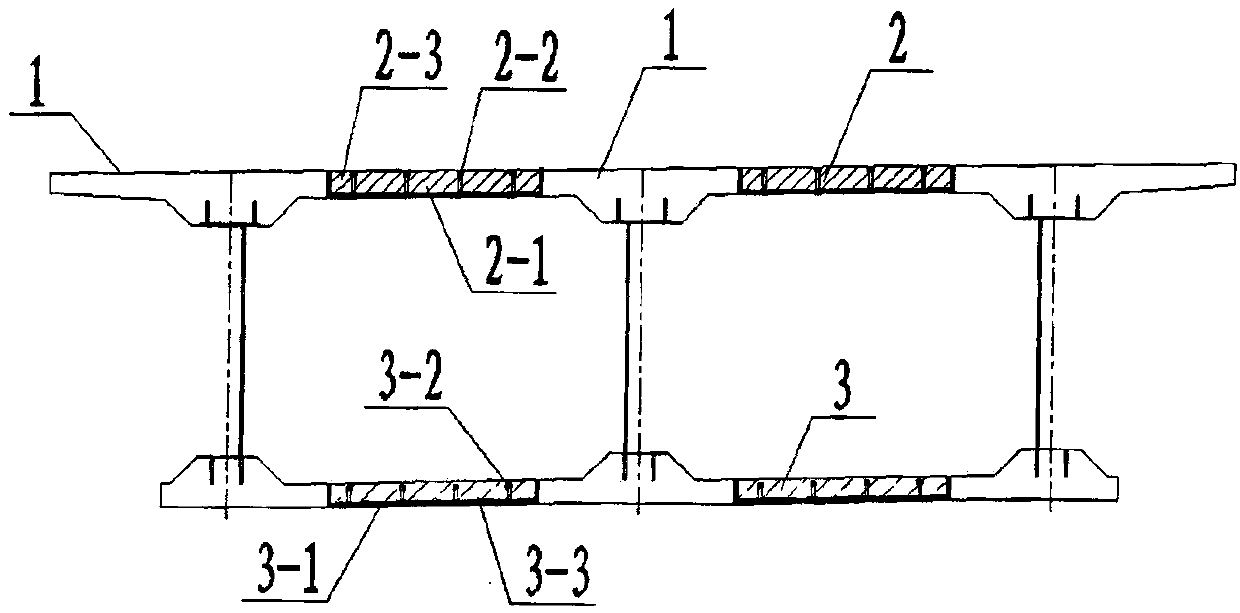

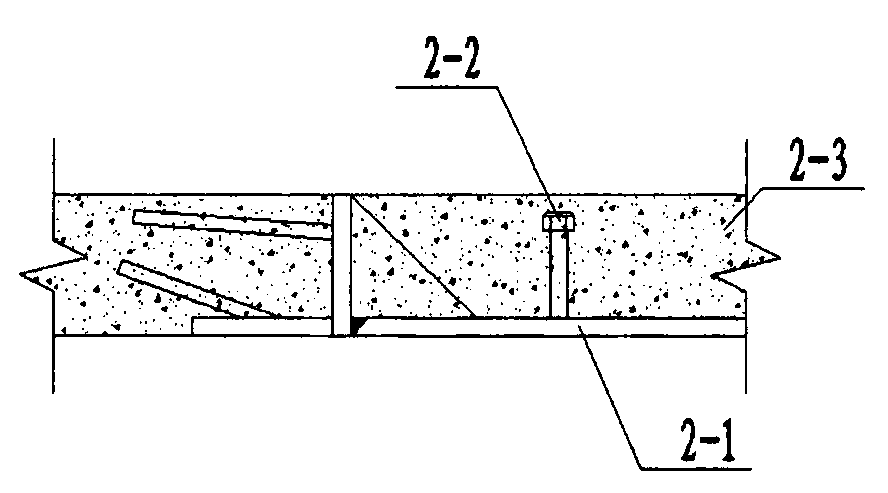

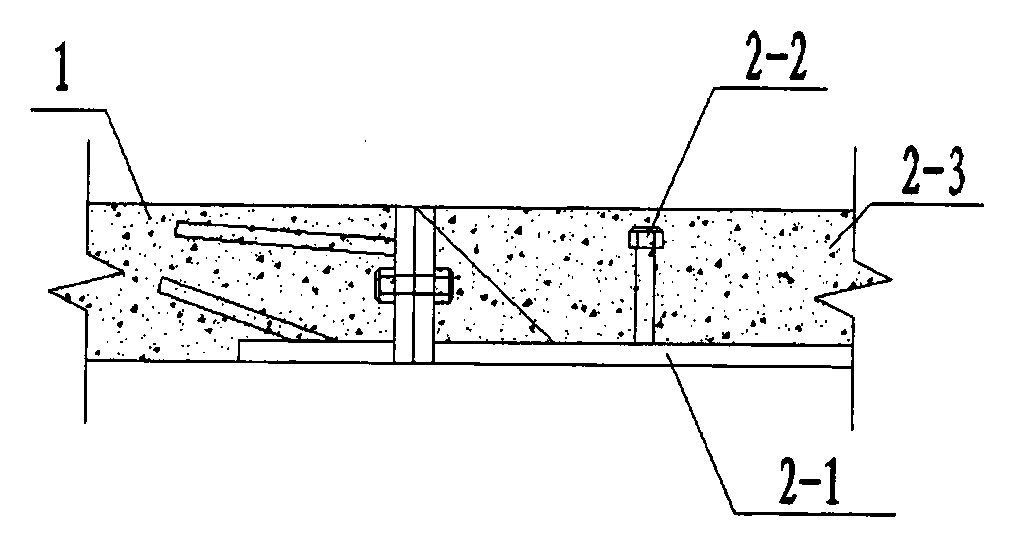

[0024] Such as Figure 1-2 As shown: the horizontal roof and bottom plate of this embodiment adopt a steel-concrete composite structure of a horizontally assembled corrugated steel web composite box girder, including a composite box girder composed of a plurality of prefabricated I-beam units 1 laterally assembled. The prefabricated I-beam unit 1 is a construction prefabricated corrugated steel web I-beam, and the I-beam adopts pre-tensioning or post-tensioning. The structure and specific construction steps of the prefabricated corrugated steel web I-beam 1 refer to the Chinese patent "A prestressed concrete I-beam with corrugated steel web" (ZL 2011 2 0098202.6) that the applicant has applied for. The lower edge steel plate 2-1 of the top plate and the lower edge steel plate 3-1 of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com