Steel box girder matched with cellular steel web plate

A steel web, steel box girder technology, applied in joists, girders, trusses and other directions, can solve the problems of easy instability, low rigidity, and failure to give full play to the strength of steel, so as to improve the flexural bearing capacity, The effect of increased torsional stiffness and enhanced overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

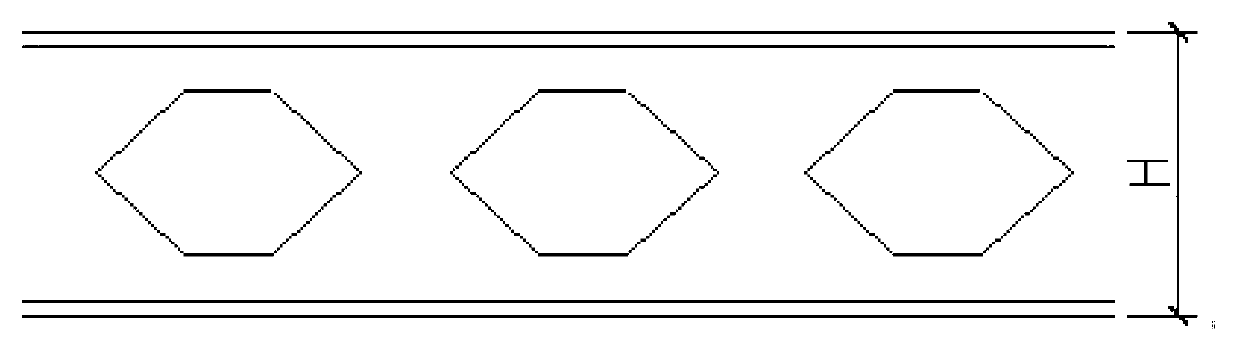

[0021] The box-shaped steel girder equipped with honeycomb steel webs of the present invention is similar in appearance to ordinary box girders, and its essence is to use honeycomb steel members instead of ordinary solid-web steel plates as the box girder webs.

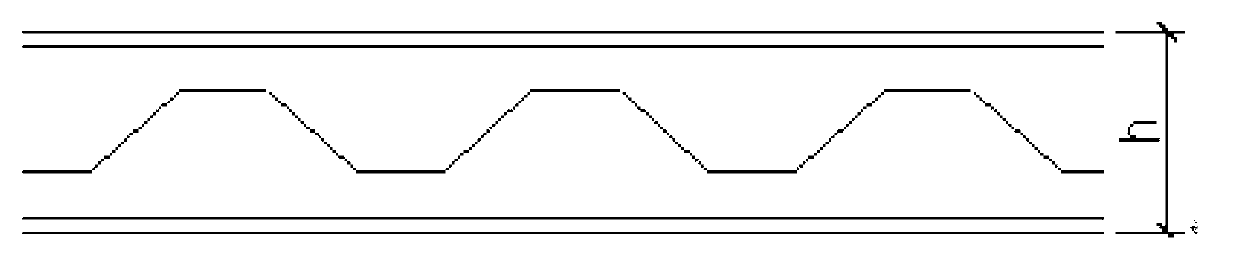

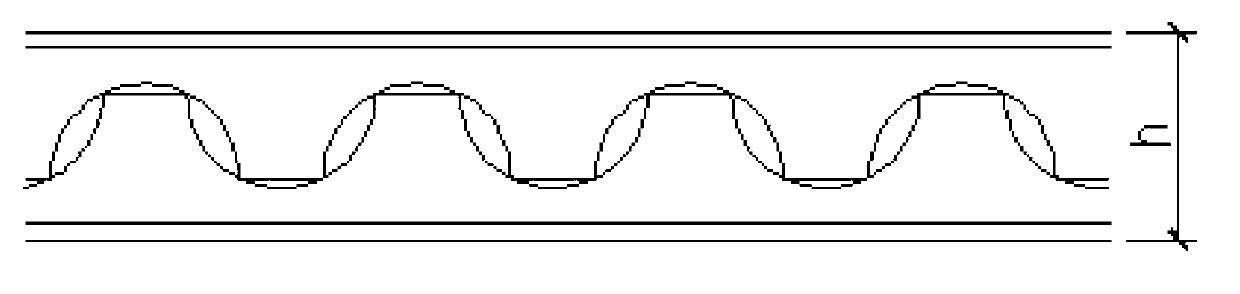

[0022] Depending on the set cutting line shape, the shape of the through hole is different; the through hole of the honeycomb steel web can be a rectangular hole, a hexagonal hole, an octagonal hole, a round hole, an elliptical hole and other shapes. The ratio of the section height H of the honeycomb steel member to the section height h of the original solid-web steel is called the expansion ratio, and the reasonable value range of the expansion ratio is between 1.4 and 1.6.

[0023] The honeycomb steel web technology is applied to the steel box girder structure to make a "steel box girder with honeycomb steel web", which is a perfect combination of two different components. It makes full use of the advantages of reas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com