Steel reinforced concrete combination pillar with built-in bunched spiral stirrups and manufacturing method

A technology of stirrup-shaped steel and spiral stirrups, which is applied to the field of built-in and bundled spiral stirrup-shaped steel-concrete composite columns and the production field, can solve the problems of limited cross-sectional form and poor restraint effect of the spiral stirrups, and can solve the problems of reducing bearing capacity, The construction is convenient and fast, and the effect of cross-section form and size is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

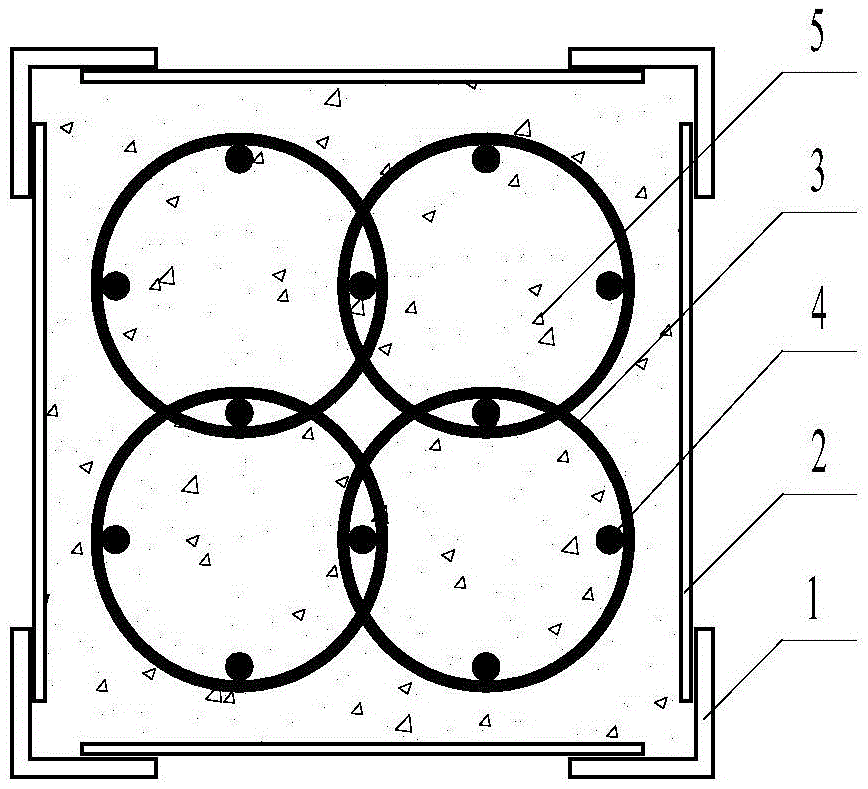

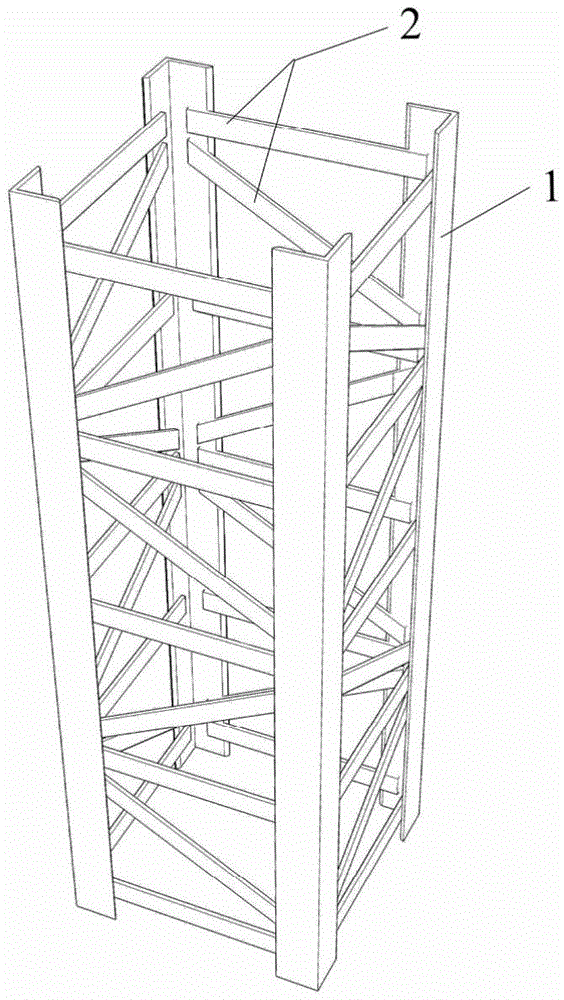

[0033] Such as figure 1 , image 3 with Figure 4 As shown, the steel-concrete composite column with built-in bundled spiral stirrups includes the angle steel 1 of embodiment 1, steel embellishments 2, spiral stirrups 3, longitudinal steel bars 4, and concrete 5. Spiral stirrups 3 and longitudinal steel bars 4 are bound to form a reinforcement cage, which is wrapped in concrete 5, and the concrete 5 is wrapped with a steel truss; The distance from the outer edge of the outermost spiral stirrup to the inner edge of the steel trim is 30mm-50mm, which facilitates the installation of reinforcement cages and steel trusses, as well as the pouring of concrete.

[0034] The cross-section of the steel-concrete composite column with built-in bundled spiral stirrups in this embodiment is a square, and the angle steel is an equilateral angle steel, which is arranged at the four corners of the column. Four spiral stirrups 3 are arranged in the column, and the four spiral stirrups are in ...

Embodiment 2

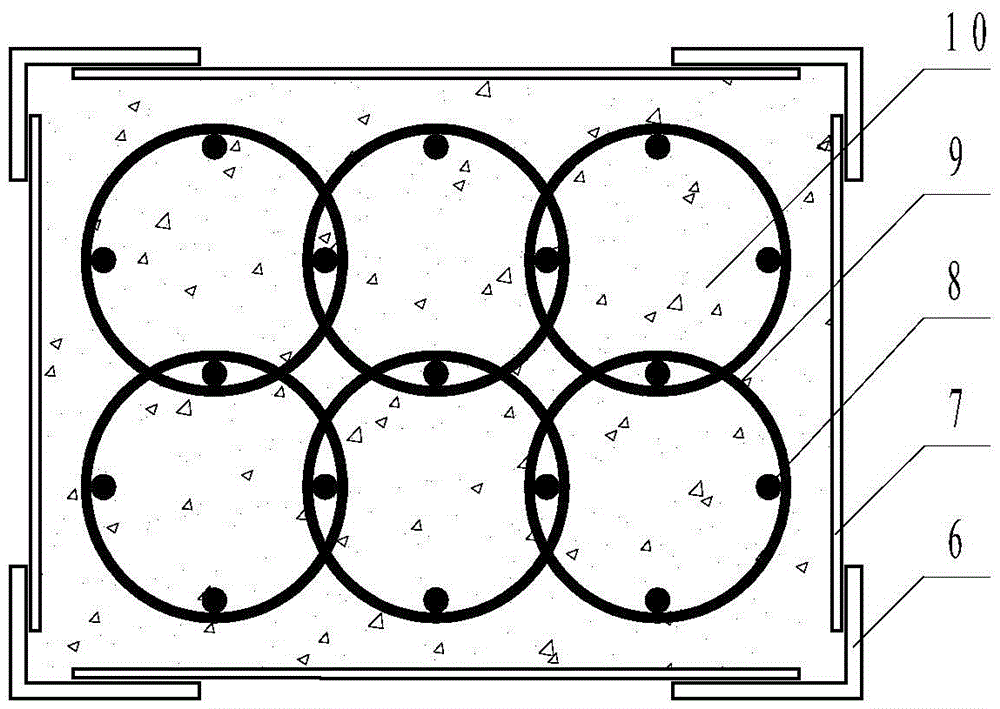

[0042] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that its structure is as figure 2 , Figure 5 with Image 6 As shown, the section of the steel-concrete composite column with built-in bundled spiral stirrups is rectangular, and 6 spiral stirrups 9 are arranged in the column, and the 6 spiral stirrups are arranged side by side in a rectangular shape, which can improve the compression-bending mechanical properties of the composite column. Angle steel 6 is unequal angle steel, which is set at the four corners of the composite column. The long leg of the angle steel is located on the long side of the composite column section, and the short leg of the angle steel is located on the short side of the composite column section, so as to improve the bending resistance of the composite column. Mechanical properties and shock resistance. This embodiment 2 also has the steel embellishment 7, the longitudinal reinforcement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com