Patents

Literature

126results about How to "Tight seams" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Installation construction method for large all-steel formwork at internal corner of shear wall

InactiveCN102704672ATight seamsIncrease stiffnessForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSheet steelShear wall

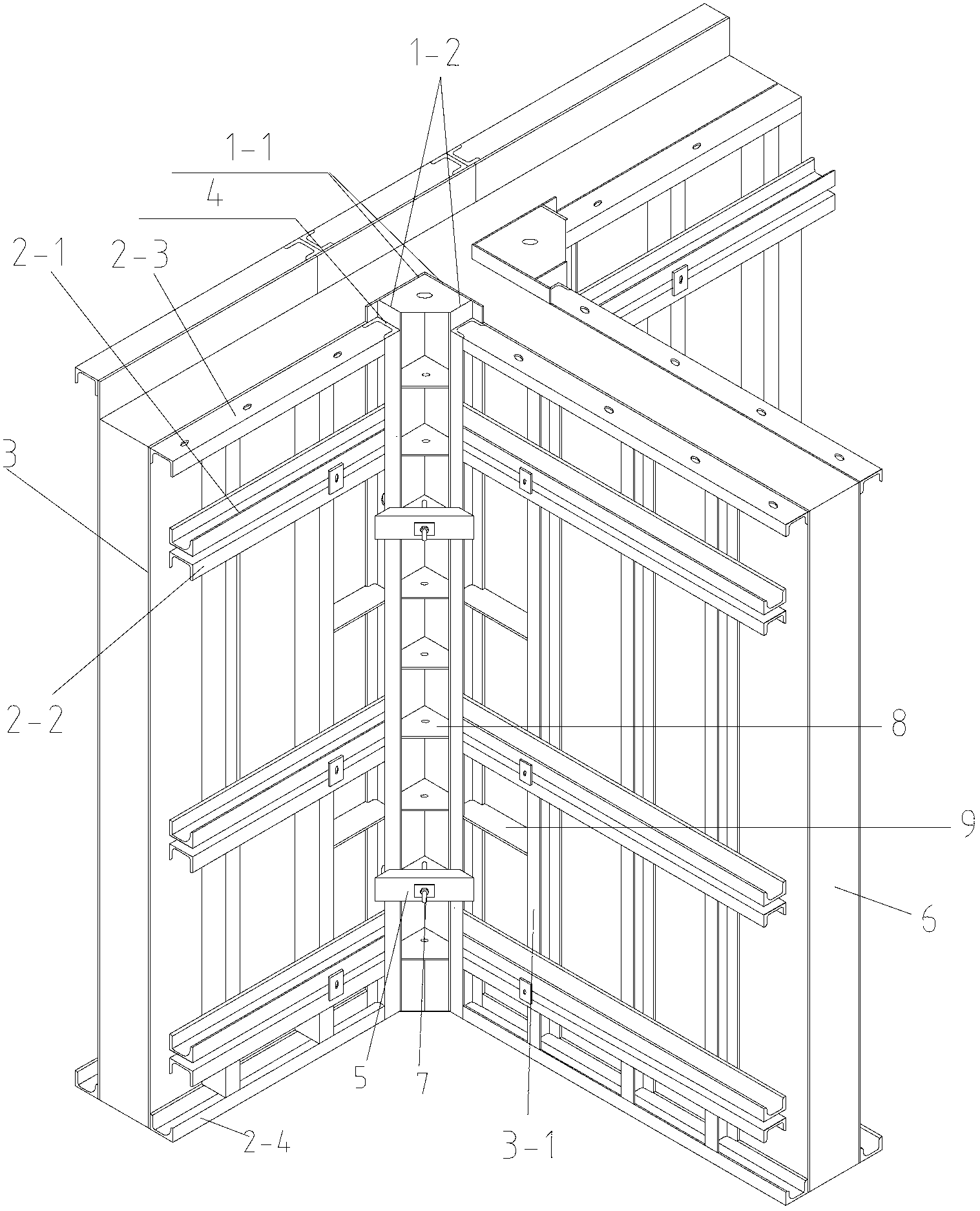

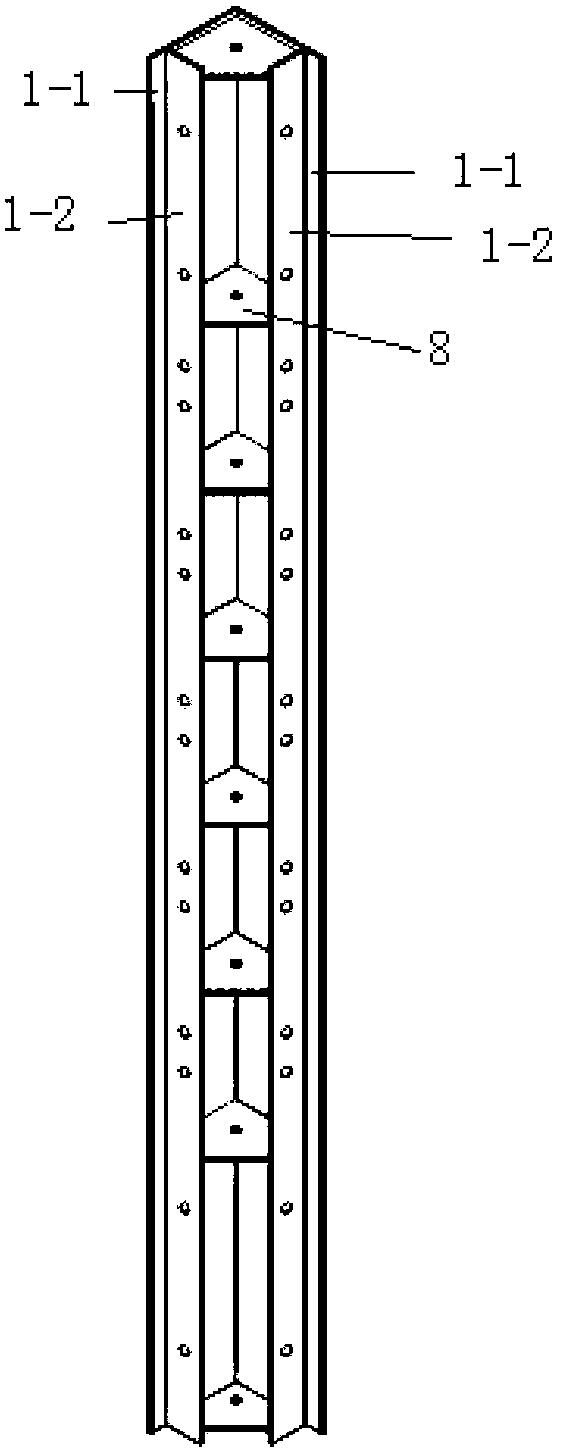

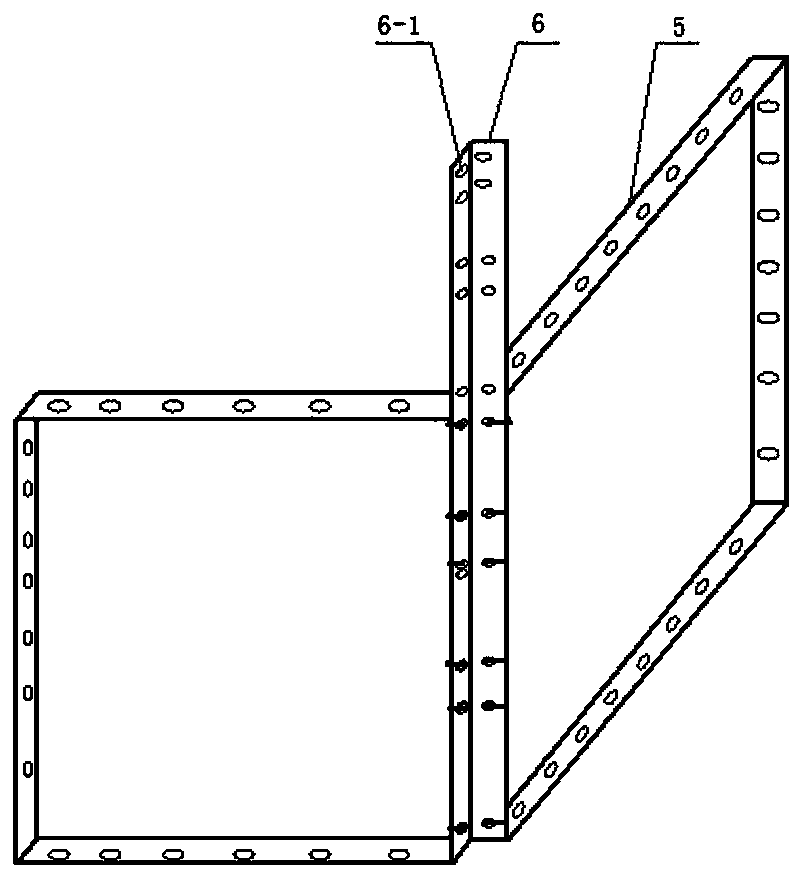

The invention discloses an installation construction method for a large all-steel formwork at the internal corner of a shear wall. The installation construction method comprises the following steps of: (1) installing an internal corner steel formwork at the internal corner of the wall, wherein the internal corner steel formwork comprises two vertical steel plates which are welded at a right angle, multiple reinforcing ribs are connected between the two vertical steel plates at intervals, two connecting steel plates are respectively welded at the two sides of each reinforcing rib, and each connecting steel plate is respectively and vertically connected with the vertical steel plate at the corresponding side; (2) respectively connecting and installing a groove type steel plate at the outer side edge of each connecting steel plate along the vertical direction through a lead screw; (3) installing large steel formworks at the two sides of the internal corner of the wall; (4) connecting formwork back ribs on the large steel formworks at intervals; (5) connecting internal corner rolling grooves corresponding to each reinforcing rib with holes arranged on the reinforcing ribs through internal corner hook bolts; and (6) pouring concrete into the shear wall. According to the installation construction method provided by the invention, a formwork system at the internal corner of the shear wall firmly and reliably forms a stable integral system.

Owner:天津住宅集团建设工程总承包有限公司

Method for making spatial multi-curved-surface as-cast finish concrete stay in place formwork by using plywood

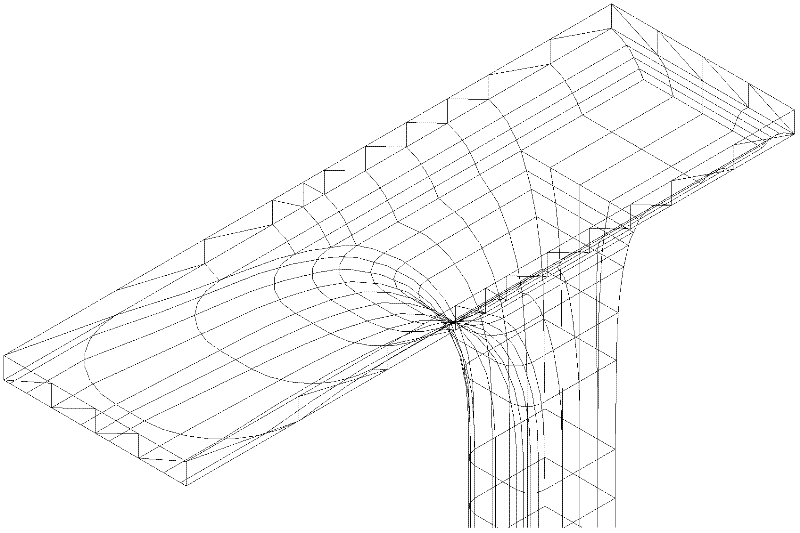

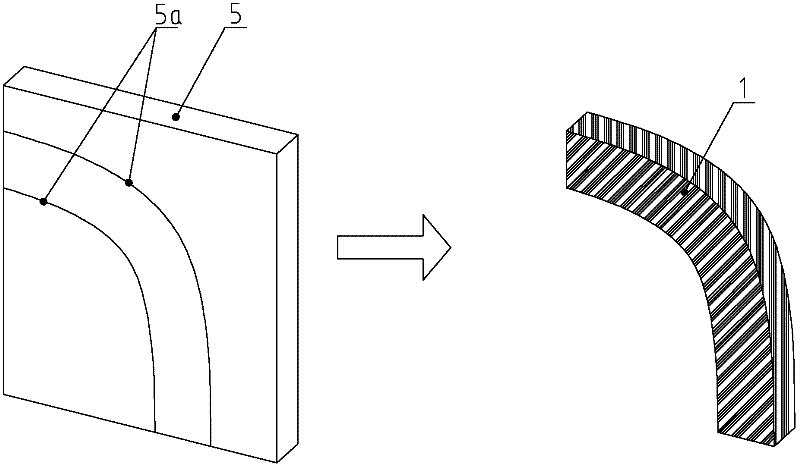

The invention discloses a method for making a spatial multi-curved-surface as-cast finish concrete stay in place formwork by using plywood. The method comprises the following steps of: (1) establishing a three-dimensional model of a spatial multi-curved-surface as-cast finish concrete structure; (2) simulating concrete force analysis in a computer, computing a back lining keel distance, and arranging a bottom framework; (3) introducing three-dimensional coordinate data of the three-dimensional model into an electronic total station for field lofting, and lofting an arc-shaped locus intersecting with a spatial curved surface; (4) lofting a wood back lining keel according to curves at different height sections of a building drawing; (5) paving curved plywood on the back lining keel for serving as a bottom framework; and (6) paving thin plywood on an opposite surface between the bottom framework and as-cast finish concrete for serving as a panel. The method for making the spatial multi-curved-surface as-cast finish concrete stay in place formwork by using plywood provided by the invention has the advantages of low manufacturing cost, convenience and rapidness for constructing, flat, smooth, attractive surface of the made as-cast finish concrete structure and the like, and has remarkable economic benefit and social benefit.

Owner:广州市第三建筑工程有限公司

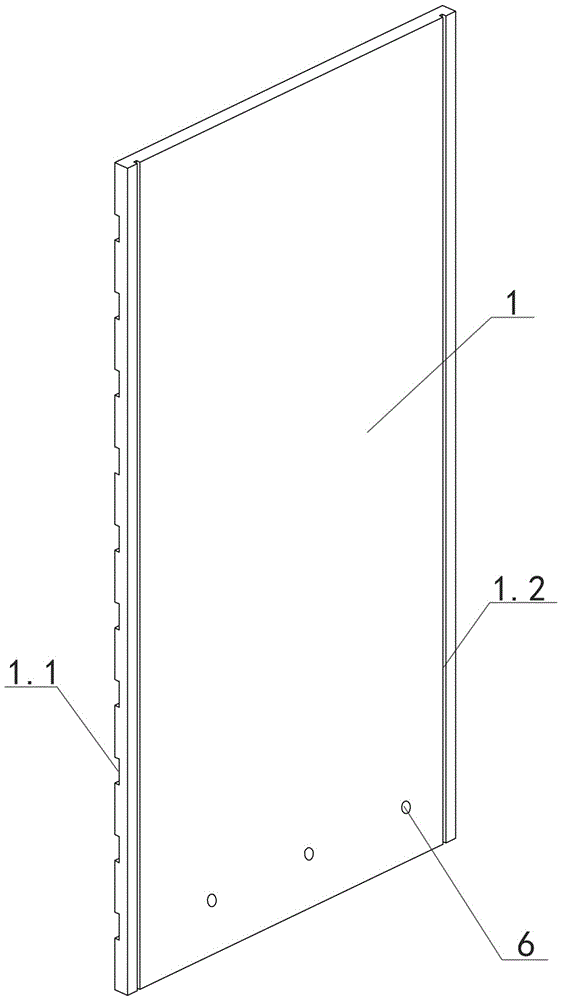

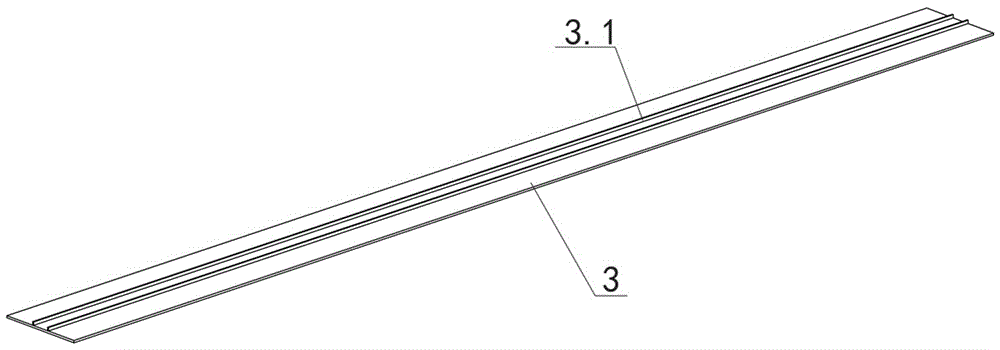

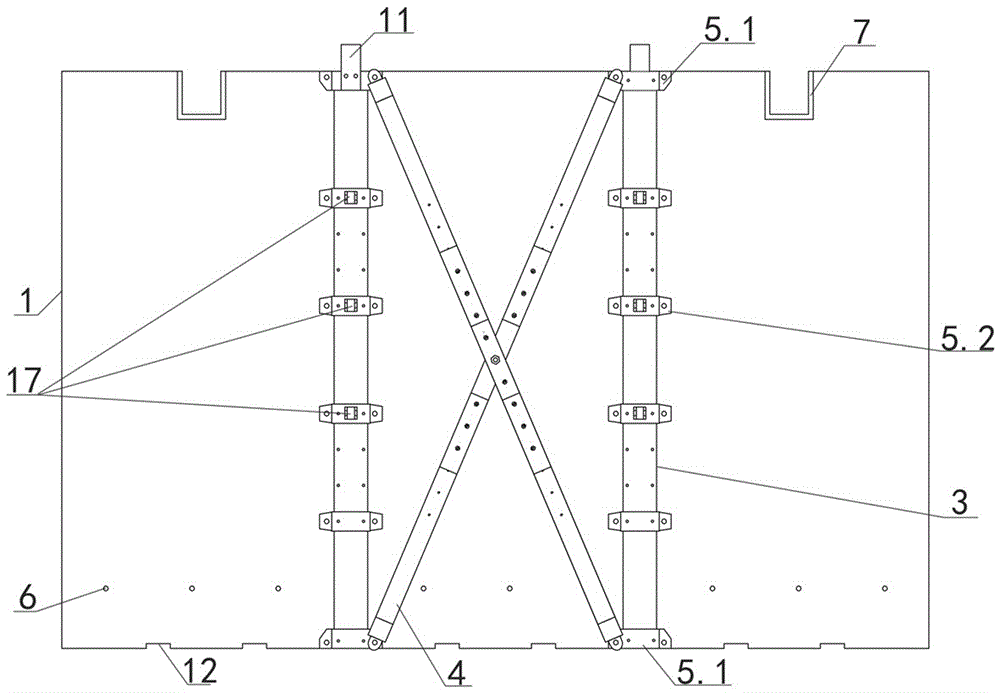

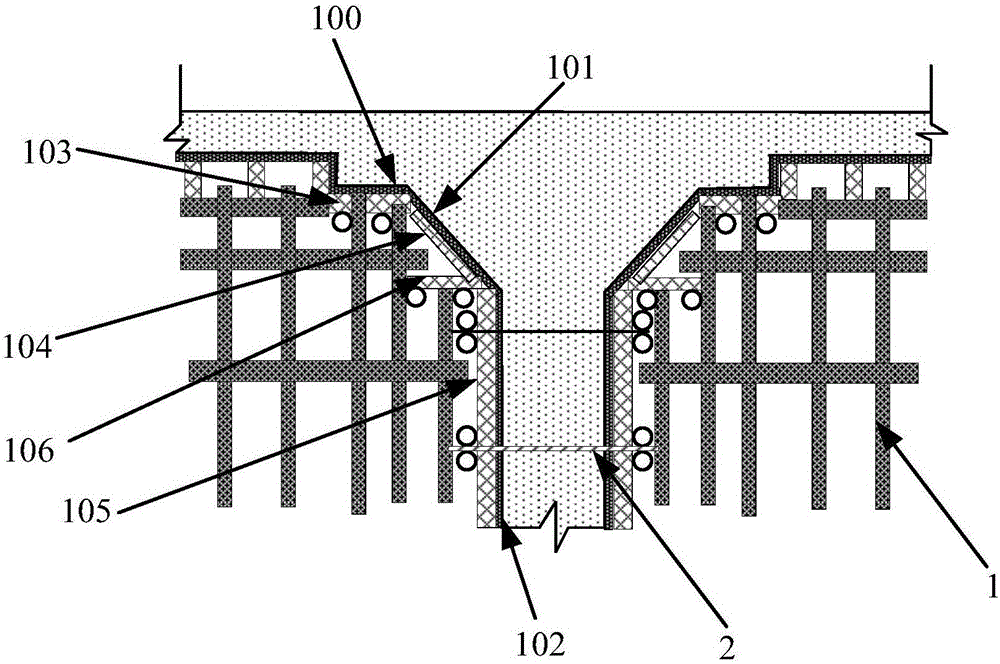

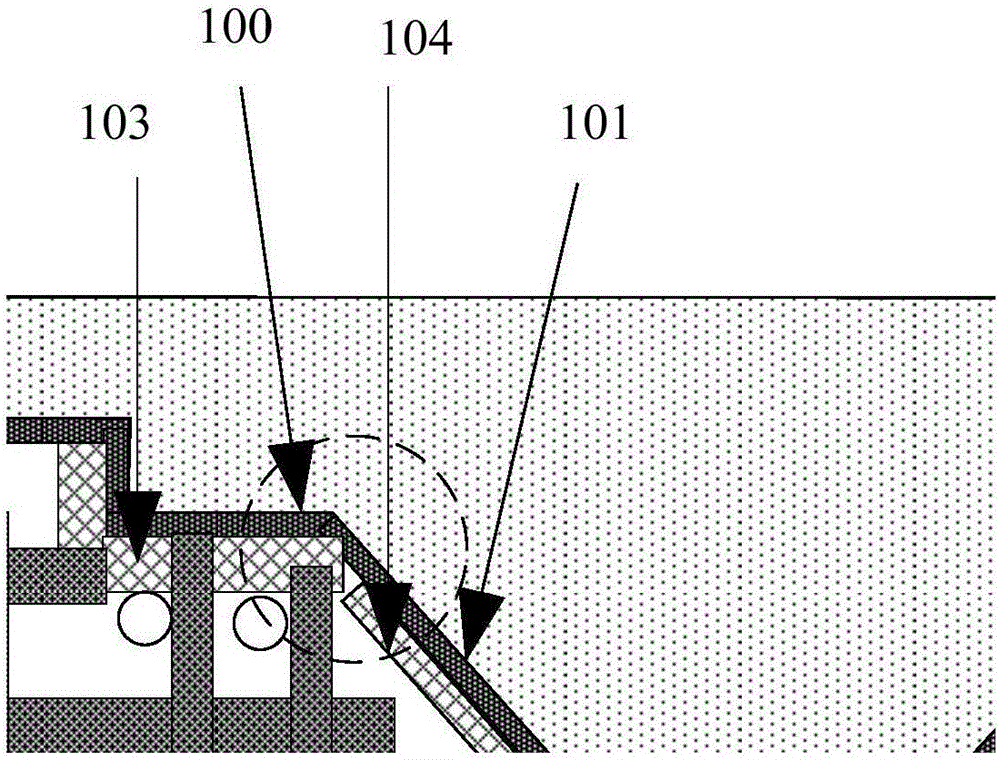

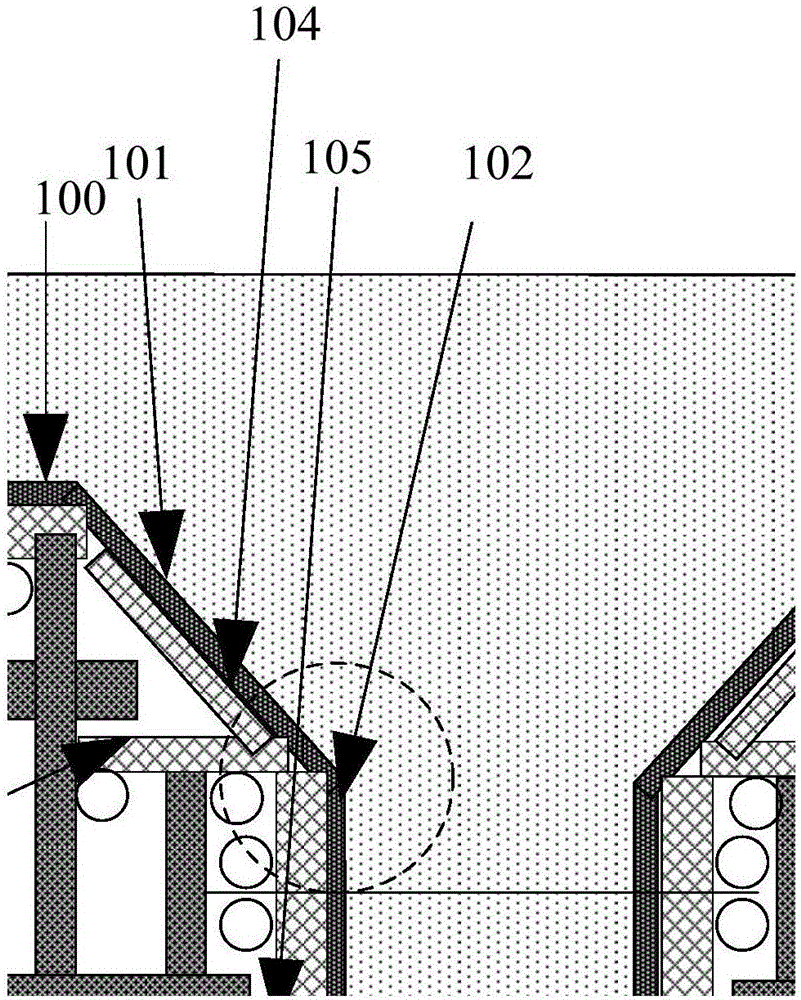

Glass fiber cement non-removal formwork system, connection structure and construction method of connection structure

The invention discloses a glass fiber cement non-removal formwork system, a connection structure and a construction method of the connection structure. The formwork system comprises a panel group, a support frame structure and a split bolt, wherein transverse interlocked strengthening grooves are formed in the inner side surface of a panel unit at intervals; the support frame structure comprises a frame steel sheet strip, a cross-panel connection assembly and a telescopic panel-attached brace; the frame steel sheet strip is arranged in a full length along the height direction of the panel unit; the cross-panel connection assembly comprises a one-way cross-panel connector; and the split bolt passes through the one-way cross-panel connector and tightens the formwork system from front to back. The connection structure comprises a floor, a formwork bottom locating assembly, a formwork top locator and the glass fiber cement non-removal formwork system. The glass fiber cement non-removal formwork system is simple in form, relatively large in combination rigidity, high in manufacturing accuracy, tight in seam, safe and reliable in structure, good in overall performance, relatively high in turnover frequency, energy-saving and environment-friendly. According to the connection structure and the construction method thereof, the construction efficiency of formwork engineering is improved and the construction cost is reduced.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

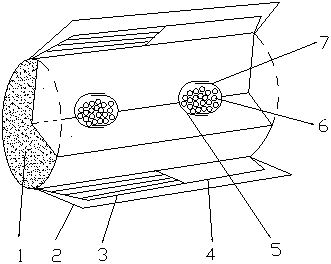

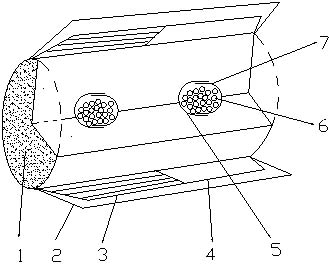

Filter tip and filter stick pre-buried with solid capsules

InactiveCN102669817ASatisfy productivityFulfil requirementsTobacco smoke filtersAbsorbent materialHuman health

The invention provides a filter tip and a filter stick pre-buried with solid capsules. The filter tip comprises forming paper, a filter element and the solid capsules, wherein the forming paper wraps the periphery of the filter element, and the solid capsules are pre-buried in the filter element. The solid capsule is composed of a large hemispherical shell, a solid medical material and a small hemispherical shell; and the solid capsule presents a sphere shape, an ellipsoid shape or a medical capsule shape. The solid medical material has the ingredients of a natural flavour, an artificial flavour or Chinese herbal medicines or an absorbent material. When the filter tip is kneaded by fingers of a human body, the large hemispherical shell and the small hemispherical shell are deformed, and an obvious gap is generated therebetween, and the smell of the solid medical material can be emitted, or an adsorption effect is generated simultaneously. A filter stick pre-buried with solid capsules is formed in the case that a plurality of filter tips are integrally connected. According to the invention, the solid medical material is slowly released and slowly sucked, thus meeting requirements on the production and the storage life of the filter tip; and the solid medical material is good for exerting effects by the kneading during sucking. According to the filter tip and the filter stick pre-buried with solid capsules provided by the invention, the flavour of a cigarette can be added, the adsorption capacity of the filter tip is improved, and the harm on human health is reduced.

Owner:NANTONG CIGARETTE FILTER

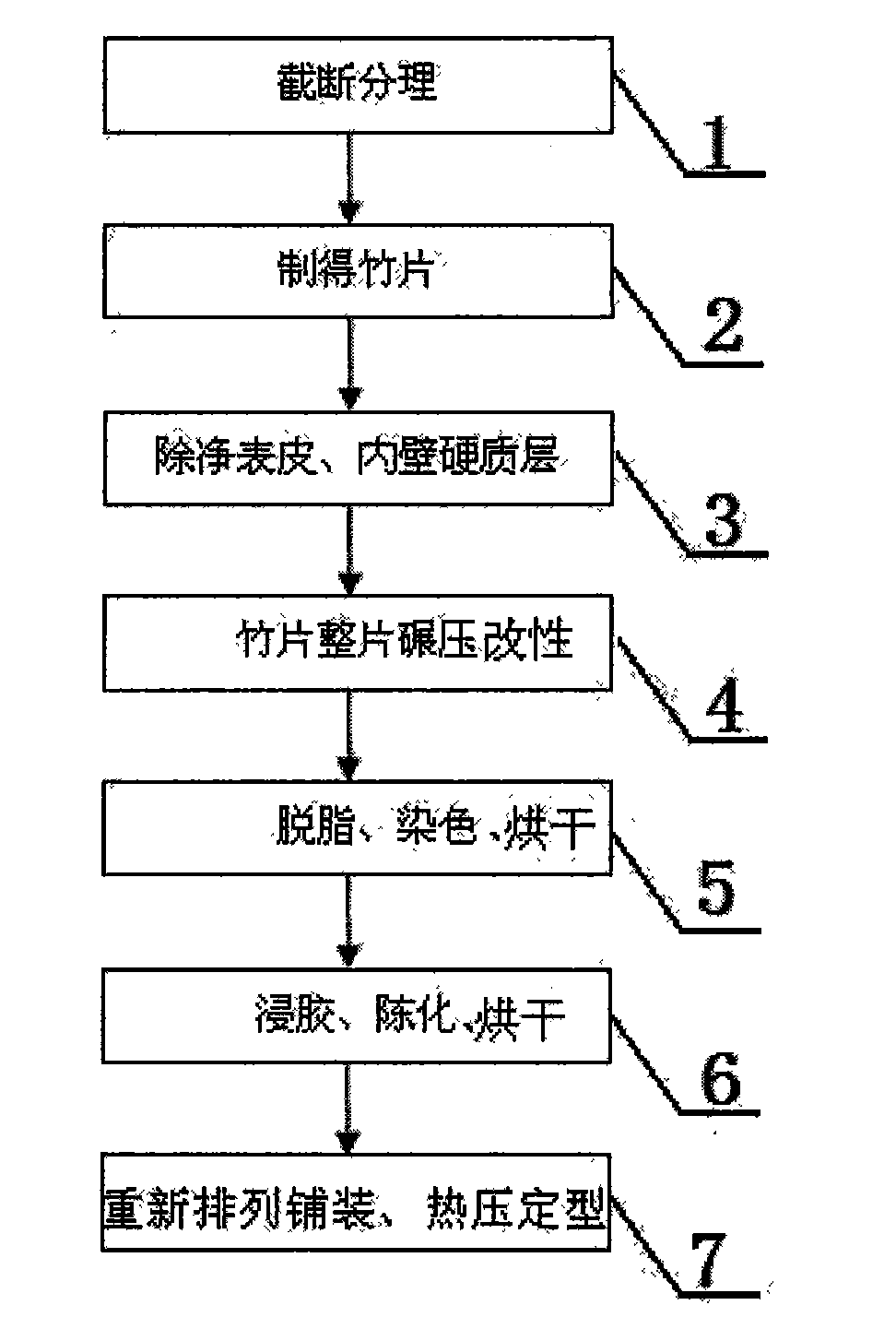

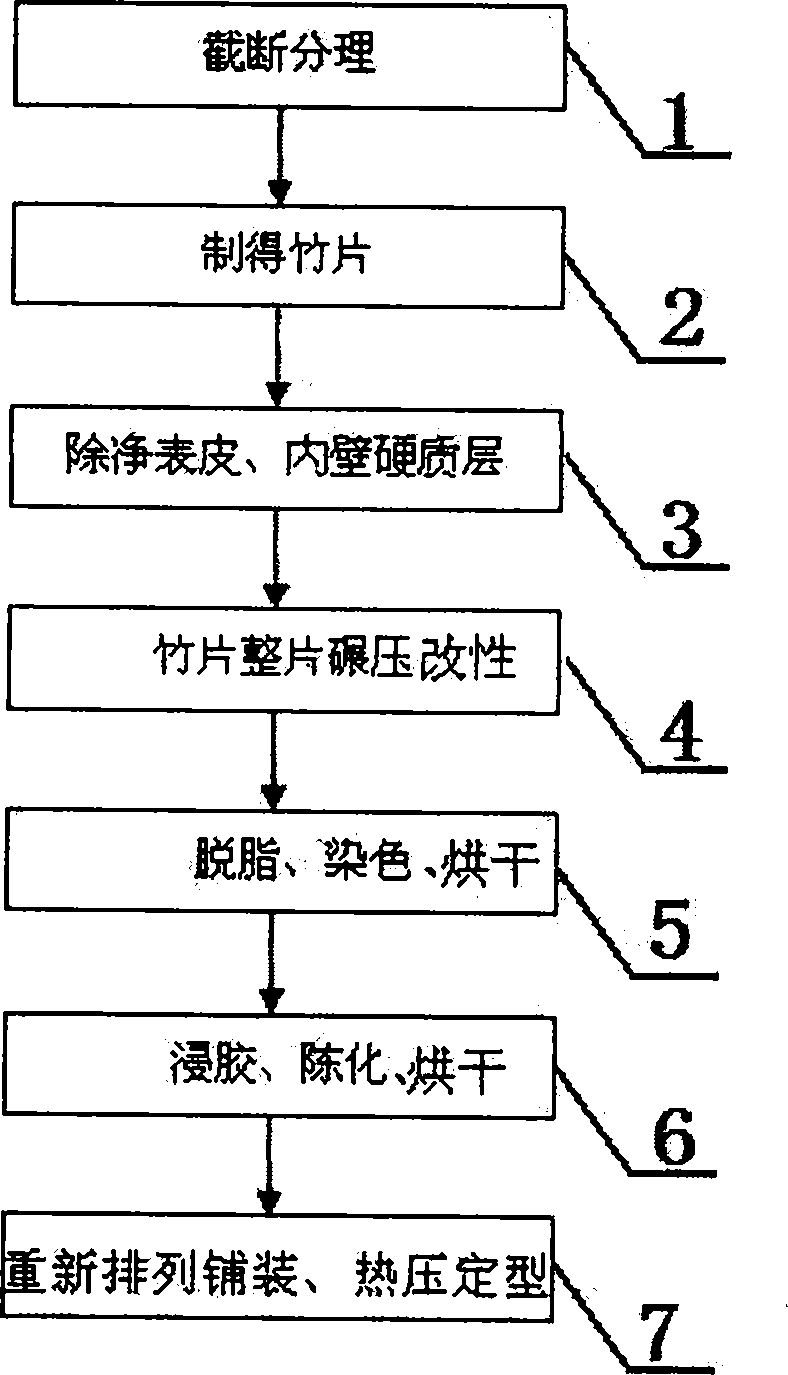

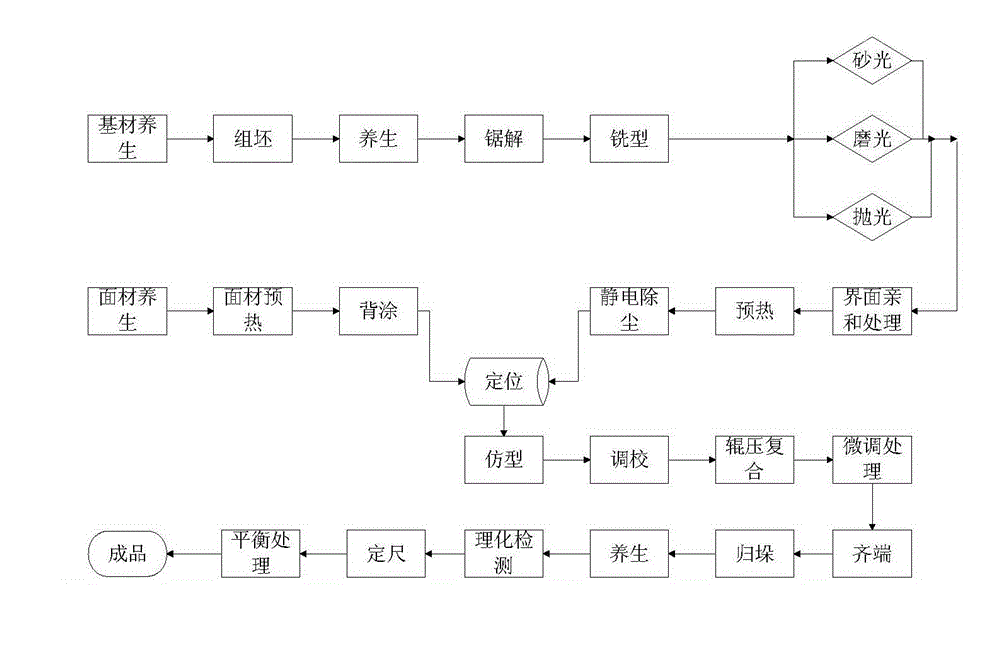

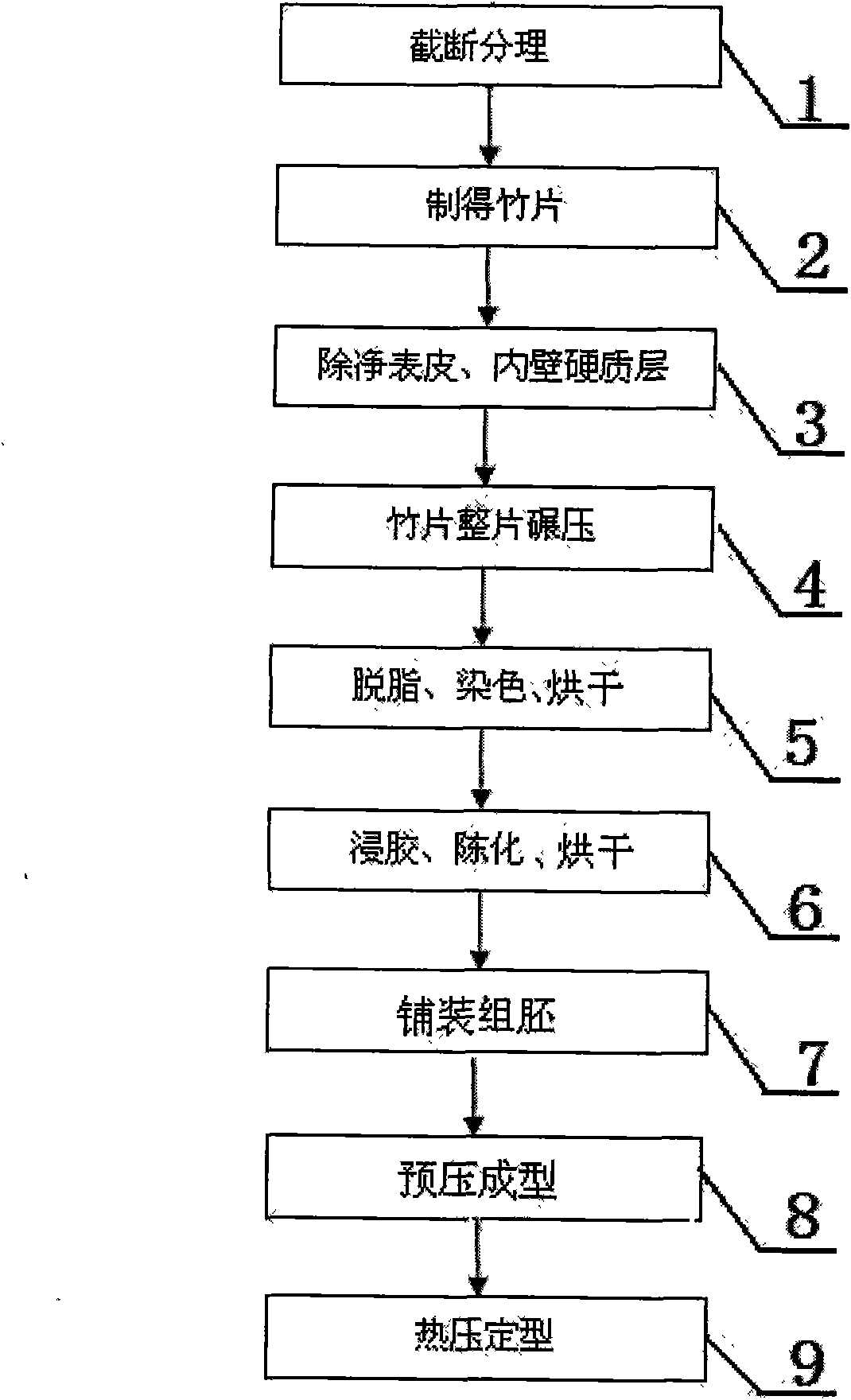

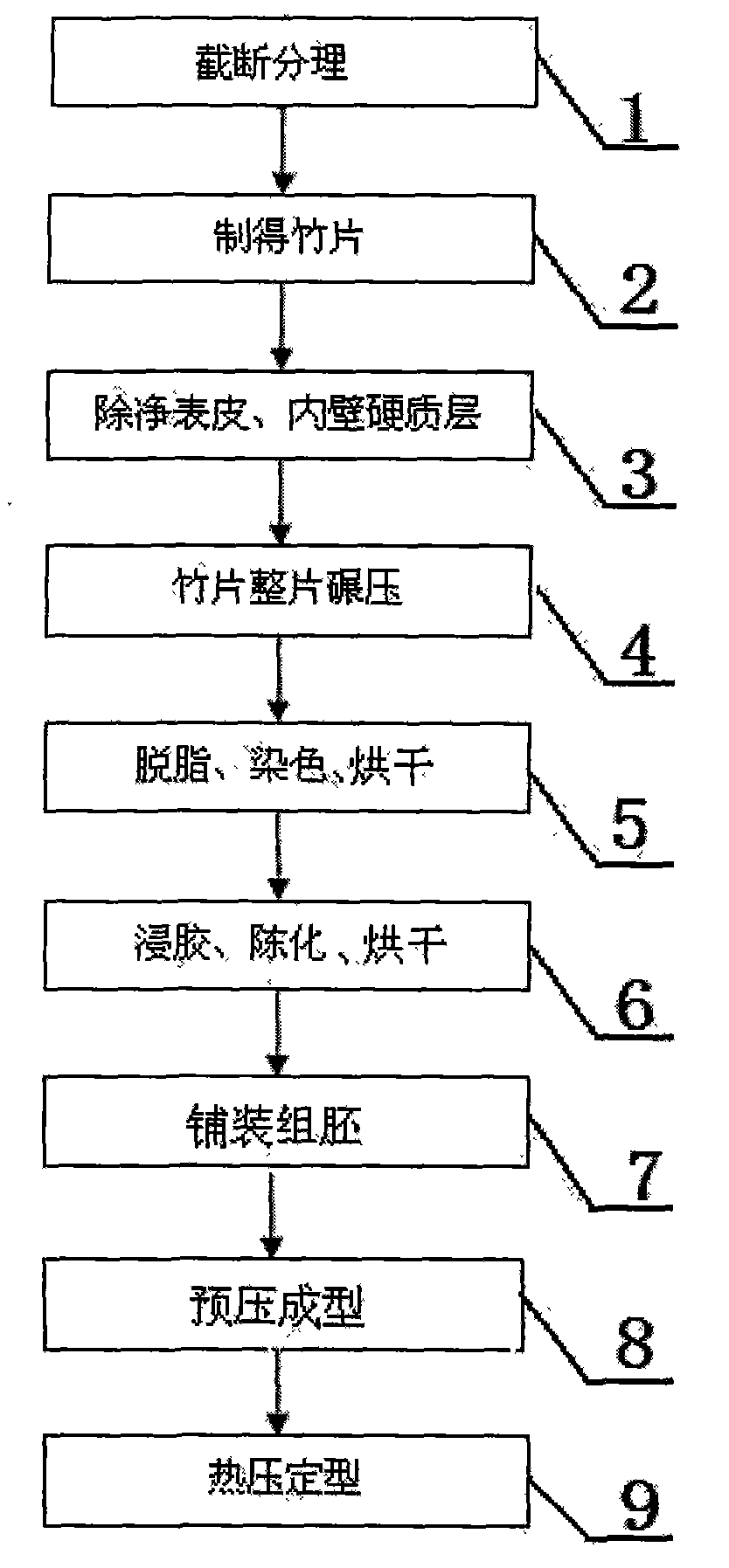

Process for manufacturing large-breadth plates by using all-bamboo modified material

The invention discloses a process for manufacturing large-breadth plates by using an all-bamboo modified material, which comprises the following steps of: (1), fully clearing way a surface wax layer and an inner hard layer; (2), modifying and laminating bamboo sheets into sheet bamboo materials which are in strips, filaments and fibres and are cracked but not fragile; (3), degreasing, dying and drying the bamboo material; (4), impregnating, ageing and drying the bamboo material; and (5), rearranging and laying the bamboo material to form blanks, and performing hot pressing on the blanks to mold the blanks into the large-breadth plates of the all-bamboo modified material. The large-breadth plates of the all-bamboo modified material are fine and smooth in vein and compact in structure and are applied to the application field of manufacturing all-bamboo furniture, floors, decoration materials and engineering, construction and military materials, and can effectively and greatly save raw materials, energy, labour cost, production field and storage field. At the same time, because the bamboo material is modified, 10 kinds of bamboos can be selected as processing raw materials.

Owner:上海缘竹实业有限公司 +2

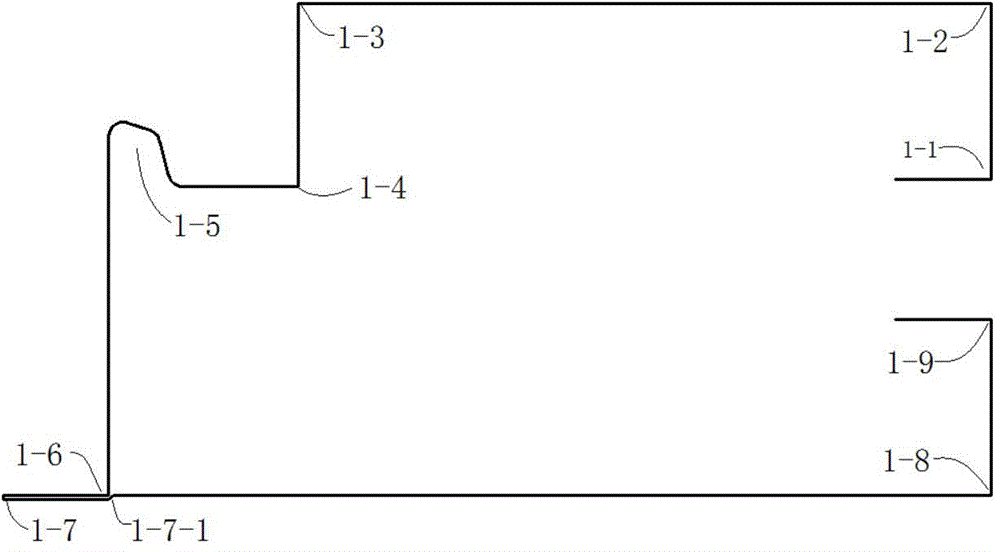

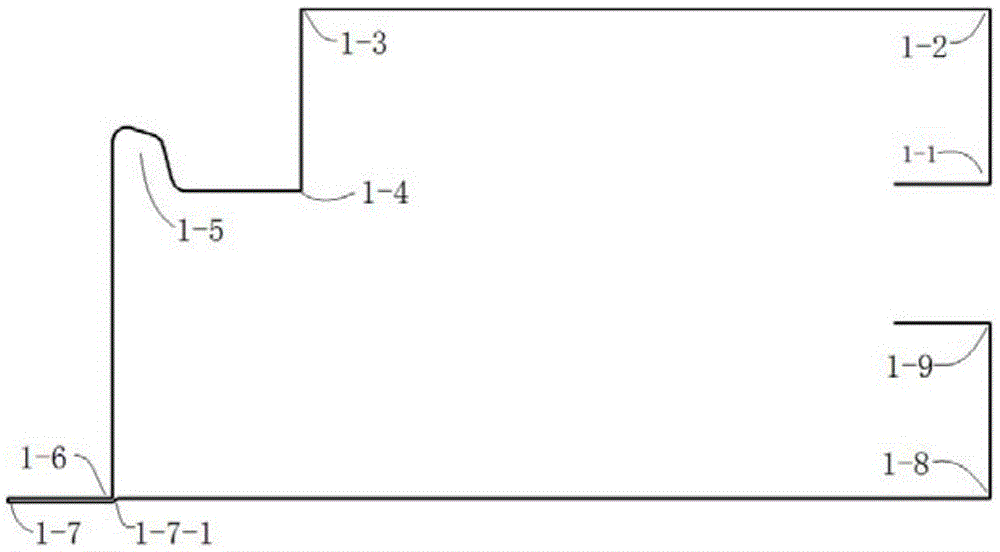

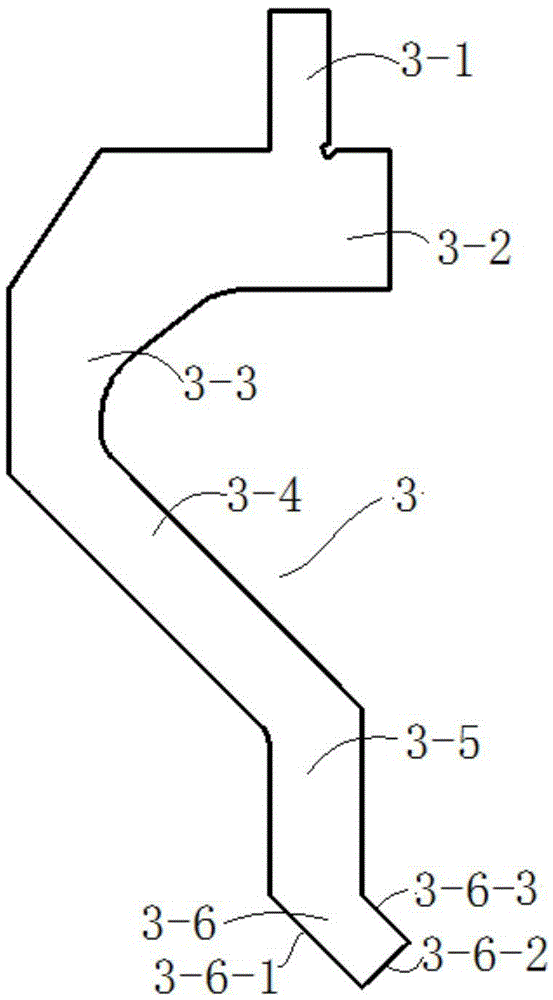

Door frame, door frame bending die and bending method

ActiveCN104438489ATight seamsGood sound insulationShaping toolsWindow/door framesEngineeringInterference phenomenon

The invention discloses a door frame and a door frame bending die and bending method and belongs to the technical fields of dies and bending. The door frame bending die comprises a lower die, a right-angle upper die, a 45-degree upper die, an edge folding upper die and a flattening upper die, wherein a lower die edge folding groove of the lower die is matched with the edge folding upper die and used for bending a folded edge protrusion. A lower die pre-folding groove is matched with the 45-degree upper die and used for folding a transition section and pre-bending a flatly-folded section. A first V-shaped groove and a second V-shaped groove of the lower die are matched with the right-angle upper die. The door frame bending die is reasonable in structural design, the matching performance of the upper dies and the lower die is good, reasonable avoiding can be achieved, forming effect is good, only four upper dies are used for machining the complicated structure, and machining cost is low. The door frame bending method is reasonable in machining sequence arrangement, no interference phenomenon occurs in the machining process, machining efficiency is high, and a machined door frame is tight in closing and good in sound insulation effect.

Owner:ANHUI CHANGJIANG MACHINE TOOL MFG GRP

Prefabricated toilet and construction and installation method thereof

The invention discloses a prefabricated toilet and a construction and installation method thereof. The prefabricated toilet includes a bottom plate unit, four wall surface units and a ceiling plate unit which are mutually and fixedly connected; the bottom plate unit, the wall surface units and the ceiling plate unit are constructed by reinforced concrete; doors and windows are arranged on the wall surface units; at least one wall surface unit or a part of one wall surface unit of the four wall surface units is of a semi-prefabricated structural wall, the thickness of the semi-prefabricated structural wall is less than the whole thickness of a building structural wall, a plurality of raised columns are arranged on an outer side surface of the semi-prefabricated structural wall in the normal direction thereof, the height of the raised columns plus the thickness of the semi-prefabricated structural wall equals the whole thickness of the building structural wall, top surfaces of the plurality of raised columns are parallel to the outer side surface of the semi-prefabricated structural wall, and bolts for accurately positioning and installing cast-in-situ wall templates are arranged on the top surface of each raised columns. The prefabricated toilet is easy to construct and install, is firm and stable in structure, and can greatly improve the efficiency of on-site construction.

Owner:YAU LEE WAH CONSTRUCTION MATERIALS (HUIZHOU) COMPANY LIMITED

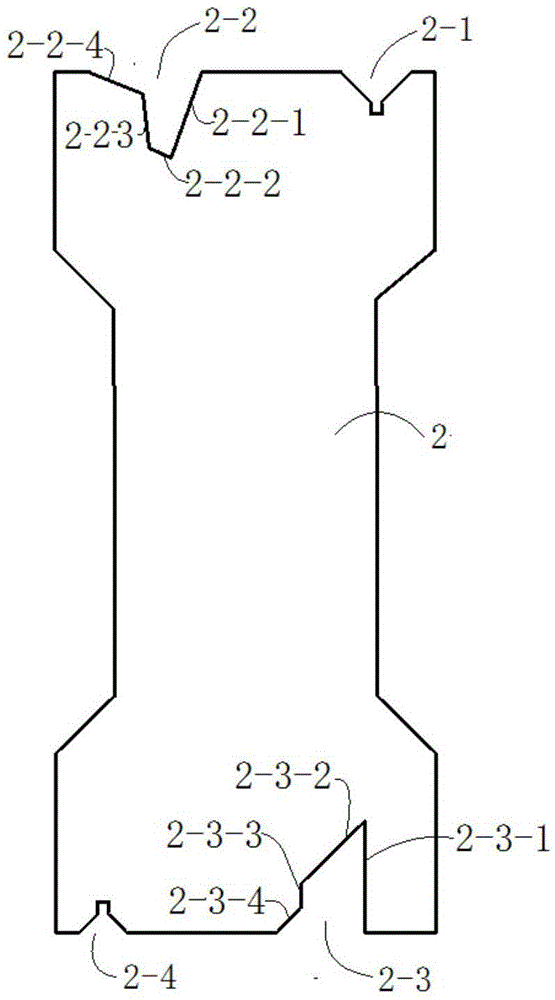

Building construction all-steel mold plate and manufacturing and assembling method thereof

ActiveCN102182302ATight seamsFlexible assembly and disassemblyForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringTorsional deformation

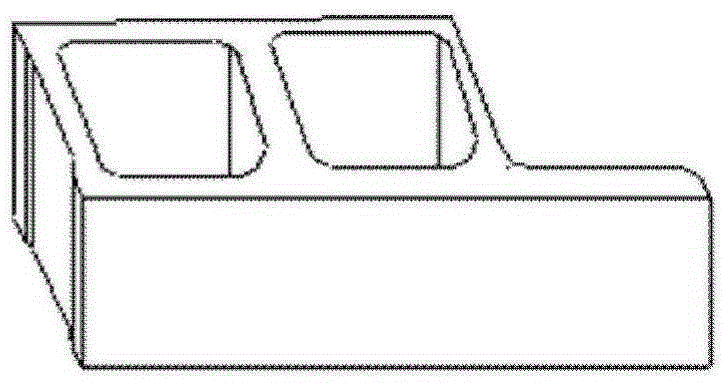

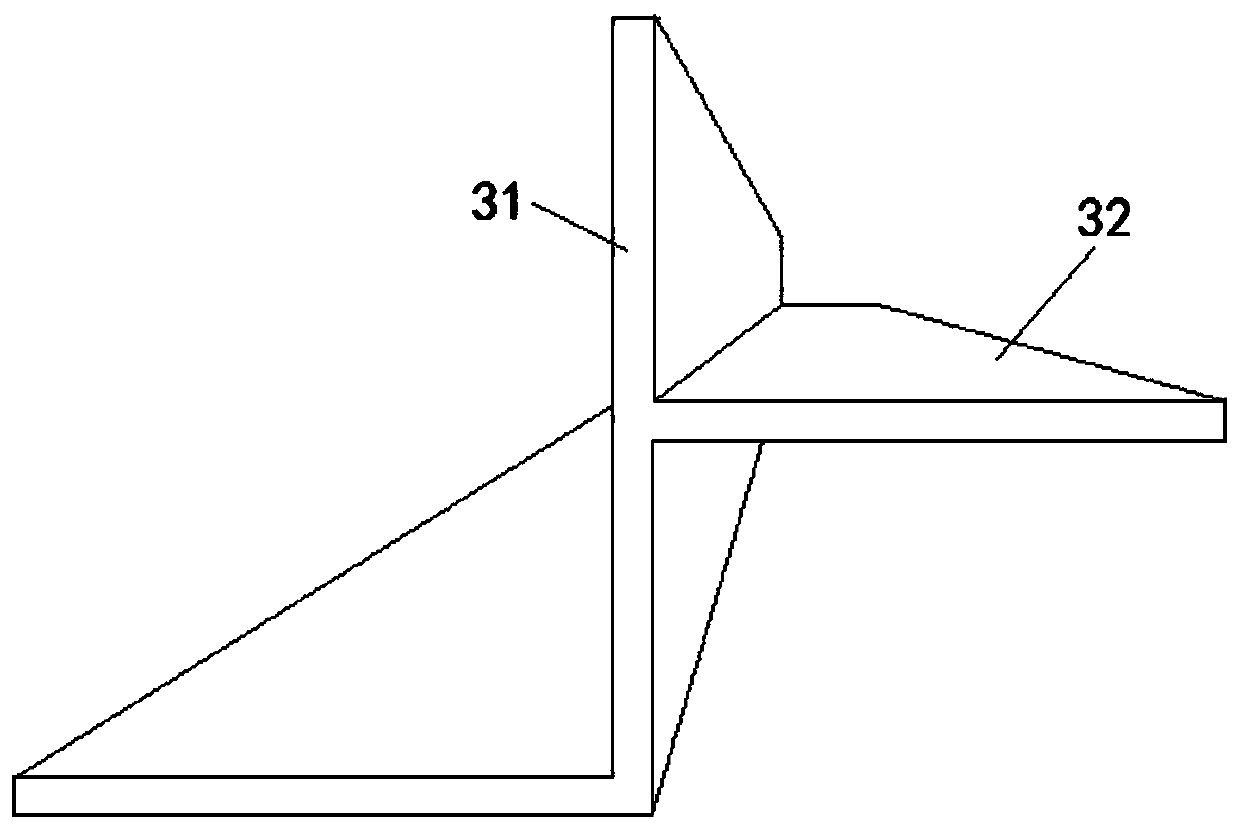

The invention relates to a building construction all-steel mold plate, which belongs to the field of building construction. The building construction all-steel mold plate comprises two major parts, namely a mold plate and auxiliary accessories, wherein the mold plate comprises a flat plate, an external corner, an internal corner, a special-shaped plate and a stunt head; the auxiliary accessories comprise a double-back arris, a double-back arris hook, an oblique back arris, an oblique back arris hook, a wall-penetrating bolt, a hook head bolt, a fastening bolt, a fastener, an operation platform frame, an oblique support, a mold plate hanging hook and a door hole mold right angle; and the building construction all-steel mold plate is characterized in that the flat plate is formed by weldinga planar plate with a framework, the framework is formed by assembly welding of rectangular steel pipes, the planar plate is surrounded by the framework, a plurality of horizontal and vertical reinforcing ribs are arranged on one side of the planar plate, the reinforcing ribs are the rectangular steel pipes, and connecting holes are arranged on the framework and the reinforcing ribs. Joint seams are tight, the assembly and the disassembly are flexible, the transportation is convenient, the whole hoisting can be realized by a tower hoist, and bulk assembly and bulk disassembly can also be performed. The torsional deformation due to loading can be avoided, when the mold plates are combined for use, the concrete leakage phenomenon at the junctions can be avoided.

Owner:CHINA CHEM ENG SECOND CONSTR +1

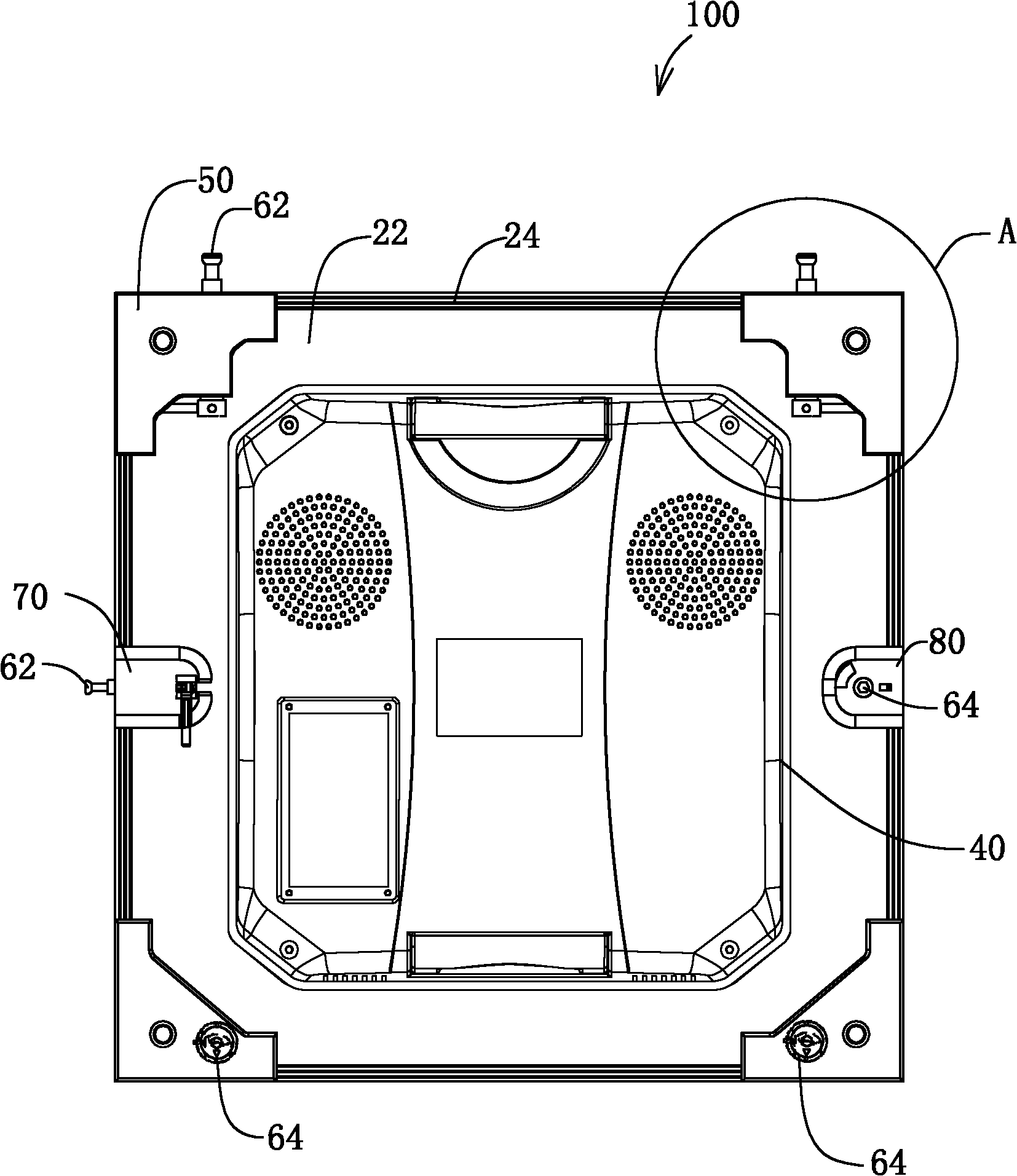

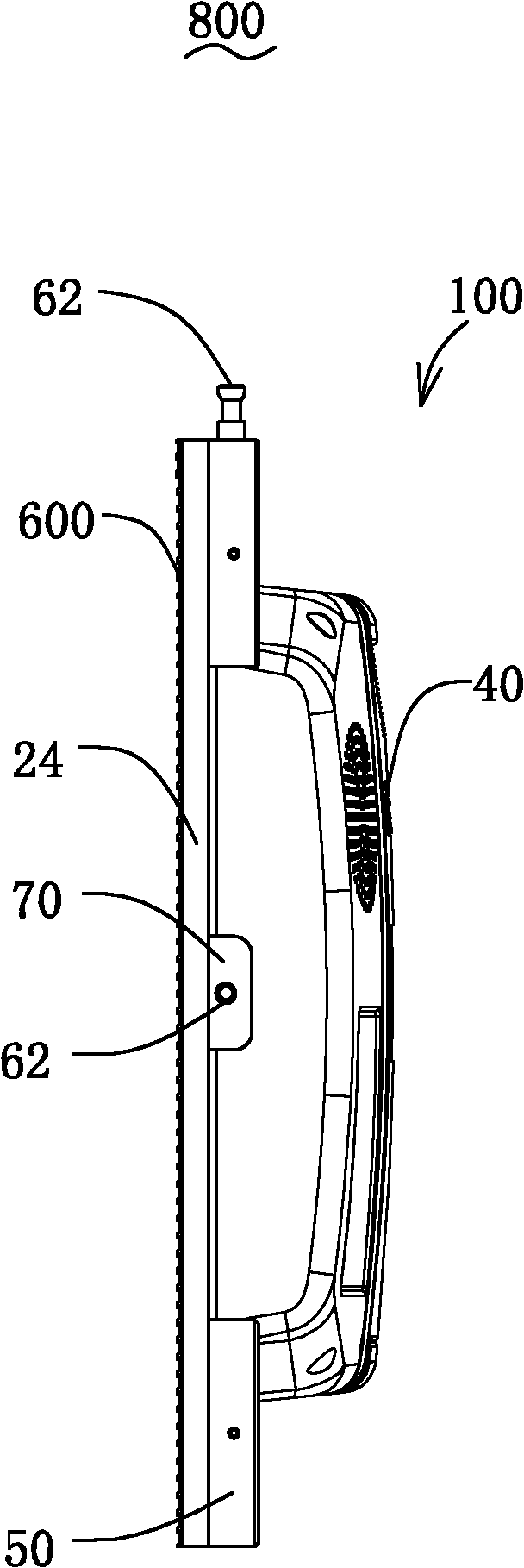

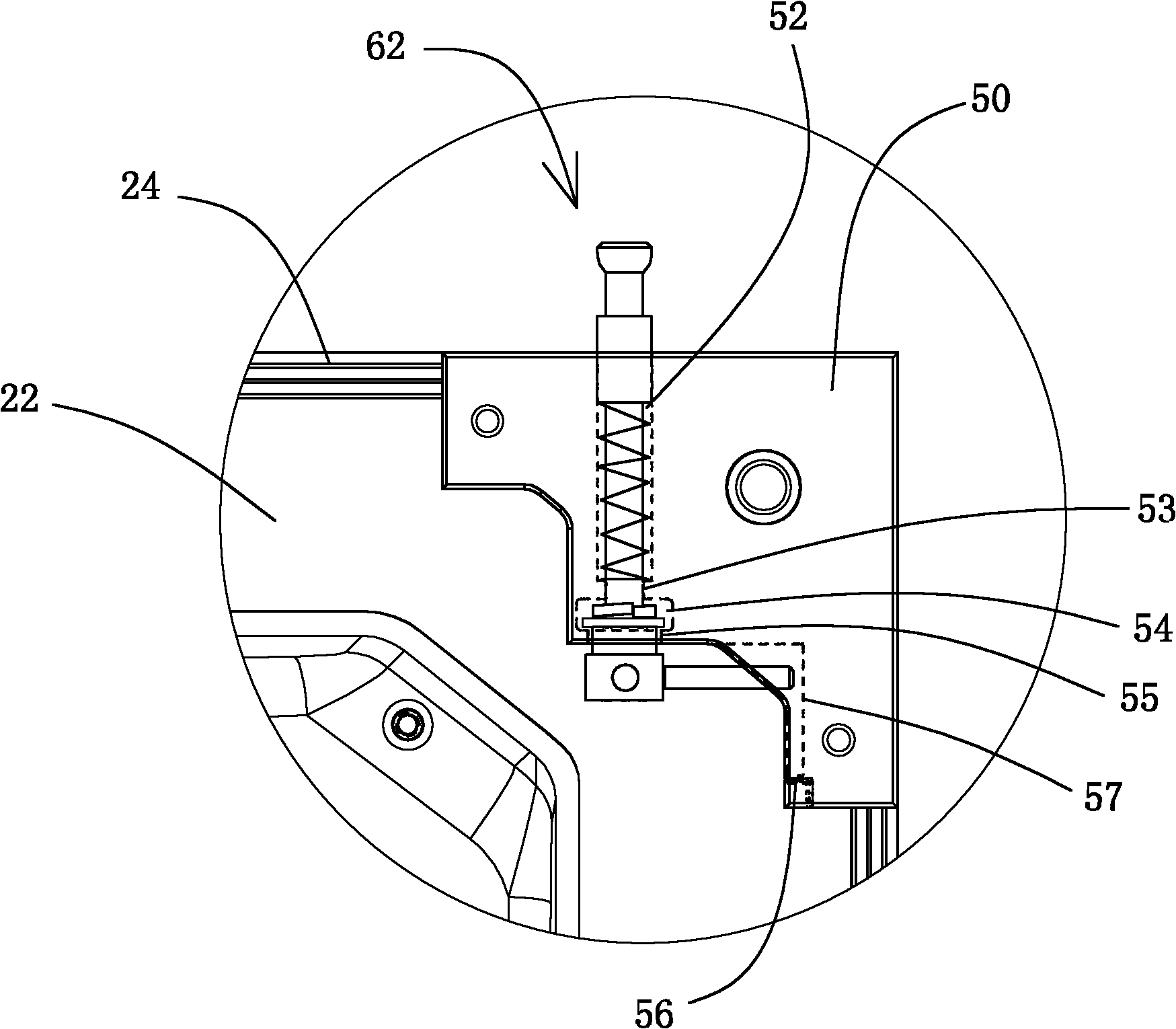

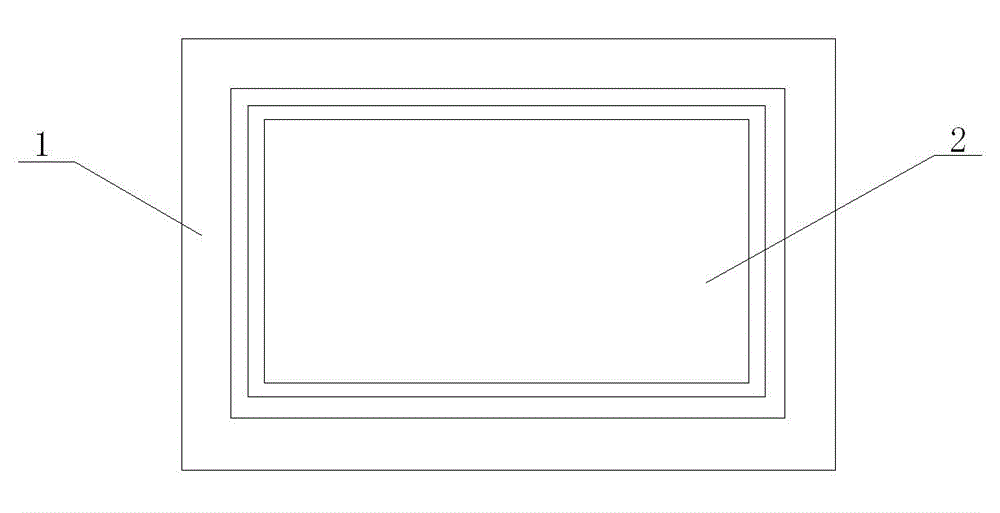

Display unit of display screen, and display screen

InactiveCN102087817AGuaranteed sizeGuaranteed accuracyIdentification meansElectrical apparatus casings/cabinets/drawersComputer engineering

The invention relates to a display unit of a display screen, and a display screen composed of the same. The display unit of the display screen comprises a polygonal metal plate and sectional materials connected at each side of the metal plate. Each corner at the back of the display unit of the display screen is further provided with a fixing block and a connecting piece for connecting a pluralityof display units. The display unit of the display screen provided by the invention is composed of a monolithic metal plate and non-flexible sectional materials, so that precision of the size and the angle of the display unit of the display screen can be ensured, and tidy and close abutted seams can be formed while splicing the display unit of the display screen. With the fixing block arranged on each corner at the back of the display unit of the display screen, the display unit of the display screen can be firmer, and the size of the display unit can be more controllable. Additionally, the display unit of the display screen is small in volume, thin in thickness and easy to mount in quick speed.

Owner:SHENZHEN LAMP TECH

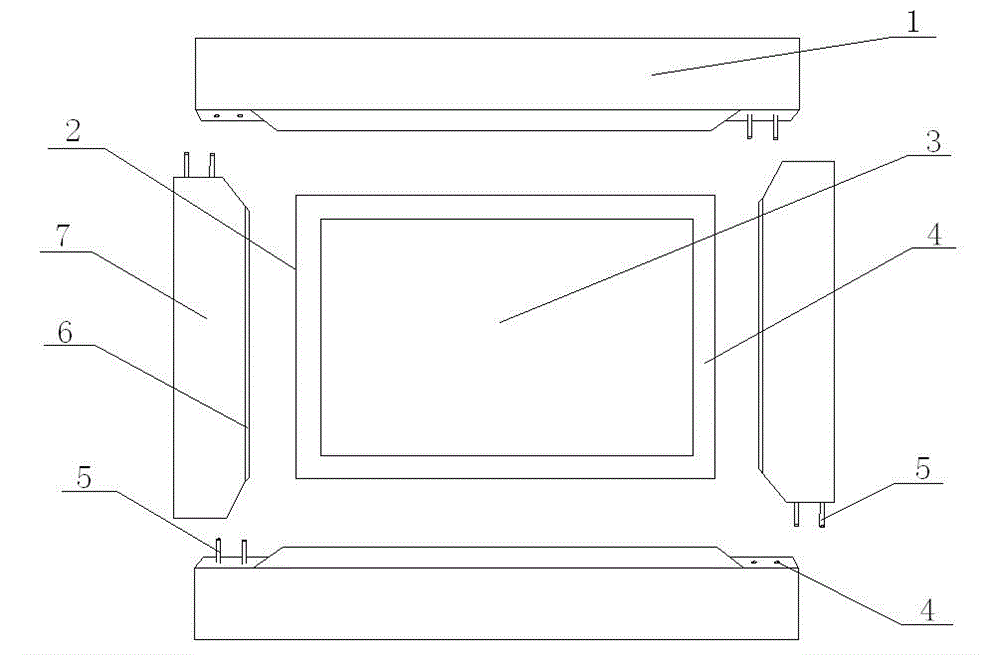

Indoor suspended ceiling gusset plate and cladding process thereof

The invention relates to an indoor suspended ceiling gusset plate and a cladding process thereof, wherein the suspended ceiling gusset plate comprises a peripheral frame and an internally-arranged core plate; the core plate is embedded into the frame; the frame is of a rectangular structure formed by sequentially-combined four lines and the adjacent lines are integrally connected through pins; the frame and the core plate are connected via clamping; and the cladding process comprises the steps of respectively preprocessing a base material and a plane materiel, controlling certain process conditions and obtaining a cladded product through a cladding machine. The suspended ceiling gusset plate disclosed by the invention has the advantages that the structure is simple and a separated type structure of the core plate and the frame is adopted, so that the suspended ceiling gusset plate can be separately produced and the industrial volume production is easy to realize; the environmental protection performance is good and PVC (Poly Vinyl Chloride) membranes with various textures, colors and structures or other cladding materials can be adopted to clad, so that the suspended ceilings with various different styles can be formed in the room; in the meantime, the suspended ceiling gusset plate has the performances of good water resistance, moisture resistance, ageing resistance, deformation resistance and the like.

Owner:朱志迁 +3

Combined box type steel sheet pile construction method of dock wall

InactiveCN1869340ASolve quality control difficultiesSave painting costsFoundation engineeringEngineeringSheet pile

The invention supplies a boatyard dock wall combination type steel sheet piling construction method that includes the following steps: fixing guiding frame, inserting pile into the frame and locating to form folding screen type pitching of pile; after one group pile pitching, pitching the first pile of the next group next to the last pile to make part of the first pile on ground being used as the location pile and removing guiding frame; fixing the second guiding frame according to the first pile, and taking steel sheet piling, repeating the process. The invention could make the appearance of the combination type steel sheet piling flat and water seal.

Owner:SHANGHAI NO 7 CONSTR

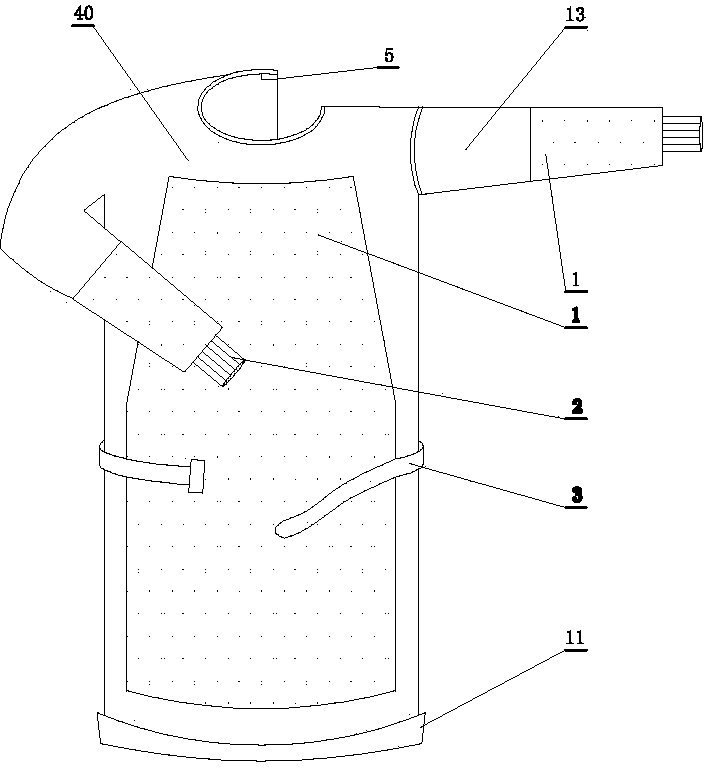

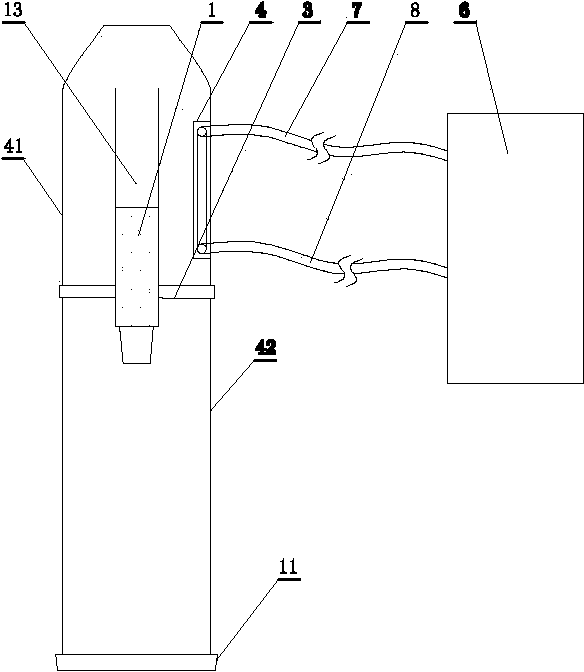

Operating garment with antibiosis effect, anti-static effect and plasma-resistant effect

InactiveCN104188189AAntibacterialHas antibacterial propertiesProtective garmentSpecial outerwear garmentsFiberSocial benefits

An operating garment with the antibiosis effect, the anti-static effect and the plasma-resistant effect comprises an operating garment body and sleeves. An elastic band is arranged at the wrist portion of each sleeve. The operating garment body and the sleeves are respectively formed by breathable film composite non-woven fabrics in a spliced mode. The operating garment is characterized in that a cooling interlayer is arranged on the back of the operating garment body, dyed medical dressing layers are arranged on the outer surfaces of the arm portions of the operating garment and the outer surface of the chest area of the operating garment body, and a lotus root fiber fabric layer is arranged on the inner surface of the chest area of the operating garment body. The cooling interlayer is internally provided with a water inlet pipe and a water outlet pipe, wherein the head of the water inlet pipe and the head of the water outlet pipe are closed, a plurality of branch pipes are arranged between the water inlet pipe and the water outlet pipe and are connected with the water inlet pipe and the water outlet pipe in parallel, and the tail end of the water inlet pipe and the tail end of the water outlet pipe are connected with an inlet terminal of a refrigerating machine and an outlet terminal of the refrigerating machine respectively. The adsorption function is powerful, the water pressure resistance is high, wire-free wireless ultraviolet welding is adopted in the production process, the operating garment has the advantages of being breathable, flexible, light in weight, recyclable and the like, and the operating garment has great economic benefits and social benefits.

Owner:宏昌生物医疗科技(仙桃)有限公司

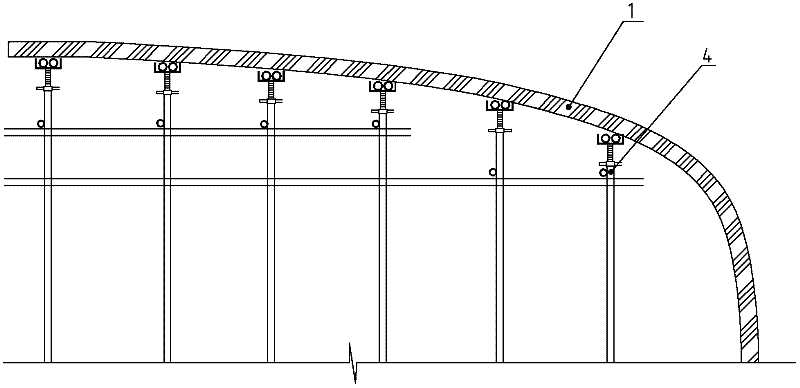

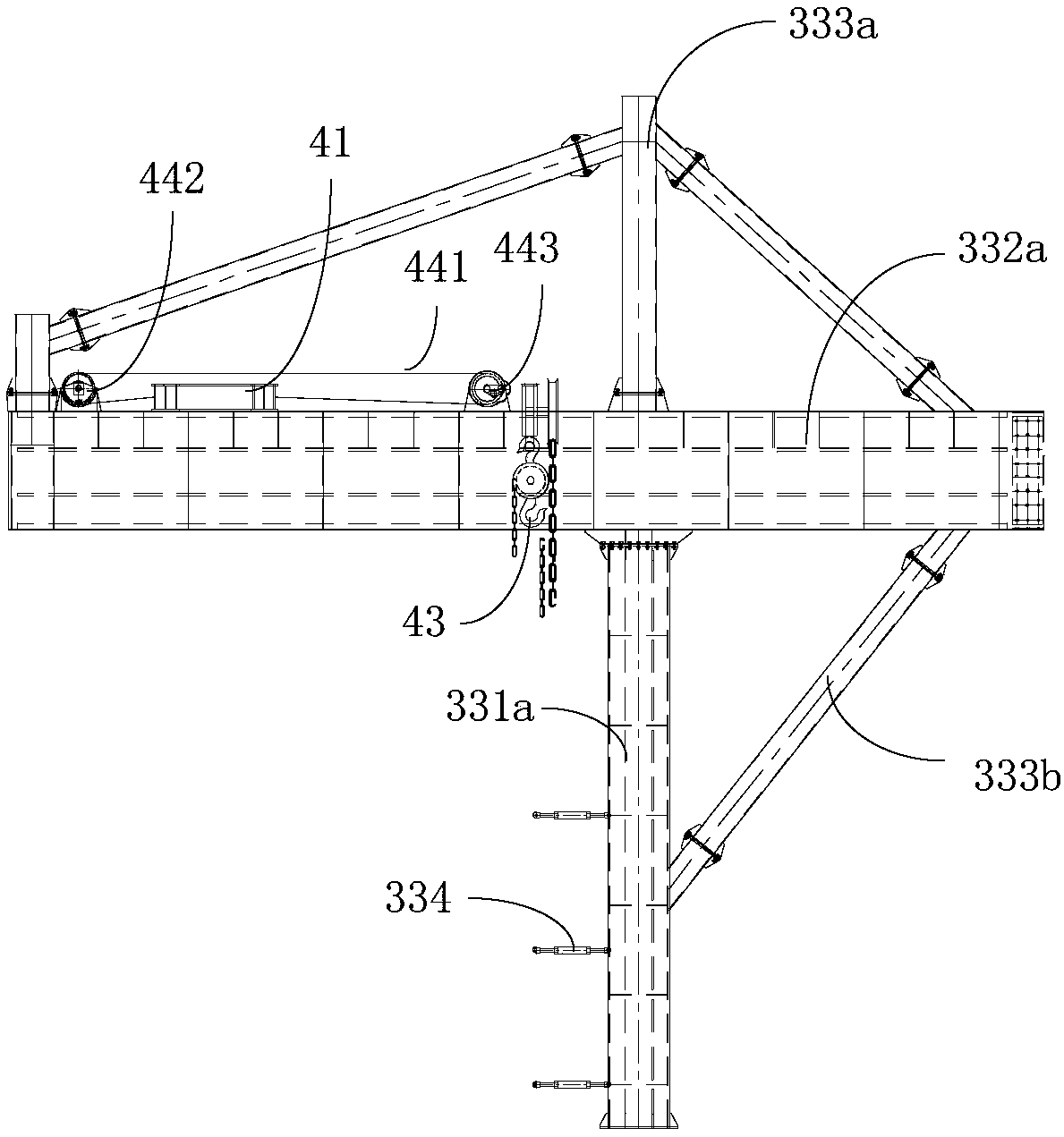

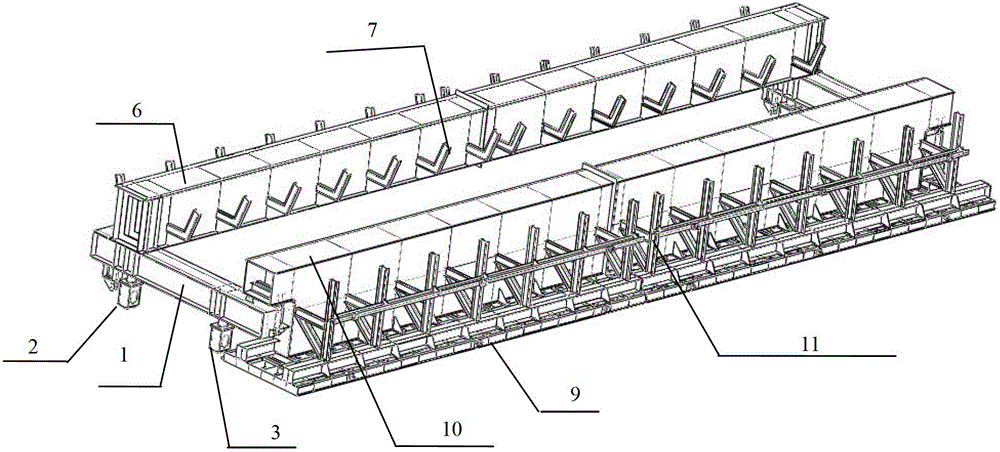

Curve PC track beam prefabrication construction method

InactiveCN109808050ATight seamsImprove construction efficiencyDischarging arrangementCeramic shaping plantsSteel barPrefabrication

The invention discloses a curve PC track beam prefabrication construction method. The curve PC track beam prefabrication construction method comprises the operations of steel bar cage binding, template adjusting, steel bar cage placing, concrete pouring and demolding. According to the curve PC track beam prefabrication construction method, a steel cage prefabrication and suspension line positioning device is adopted to assist side template measurement positioning and side template automatic adjustment, the disadvantage of low manual template adjustment efficiency in traditional track beam prefabrication is broken, the automation degree of a template system is improved, and the quantity of operators is reduced.

Owner:THE SECOND CONSTR OF CTCE GROUP +2

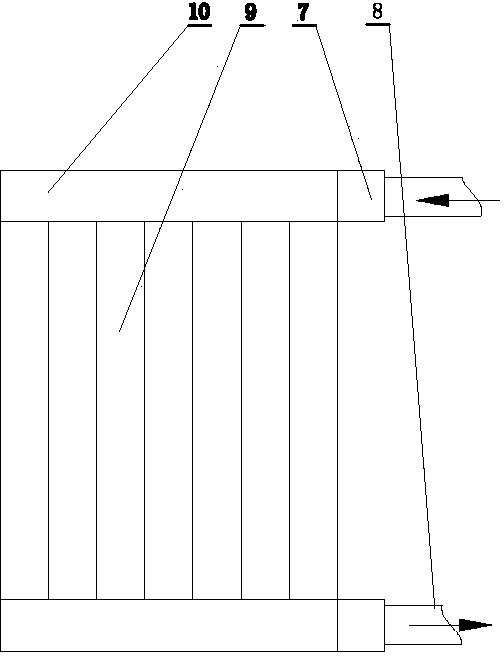

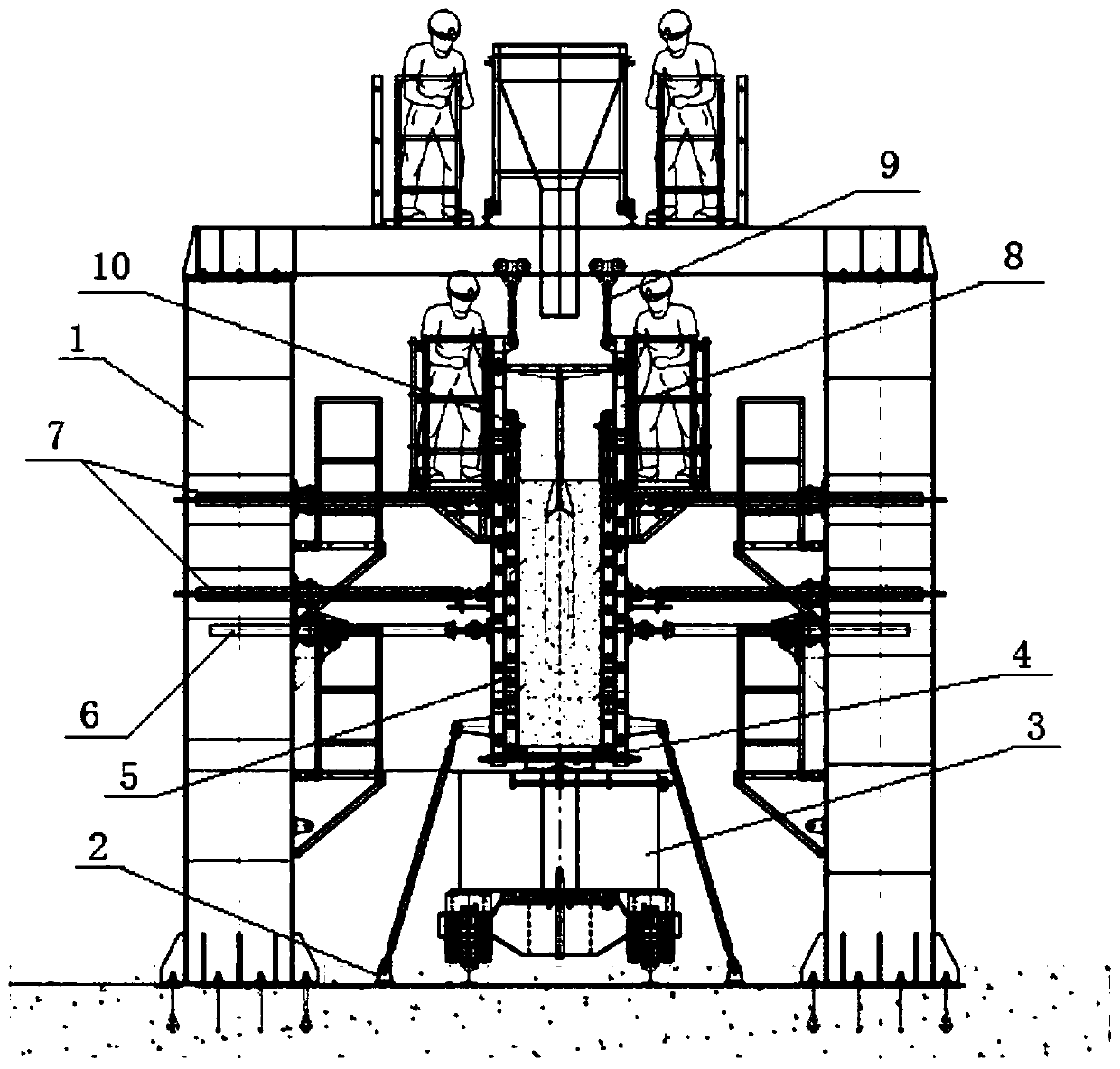

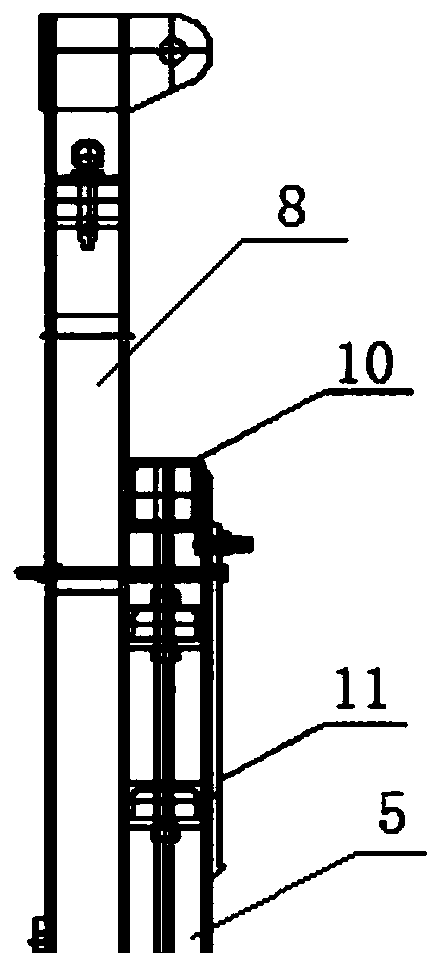

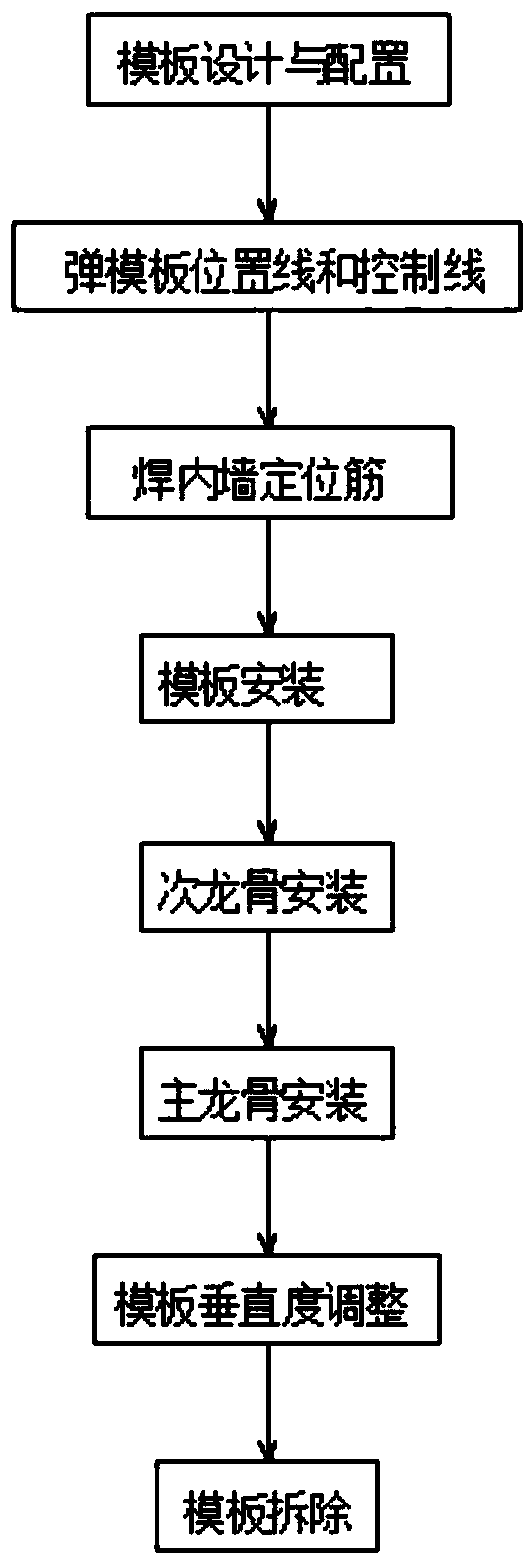

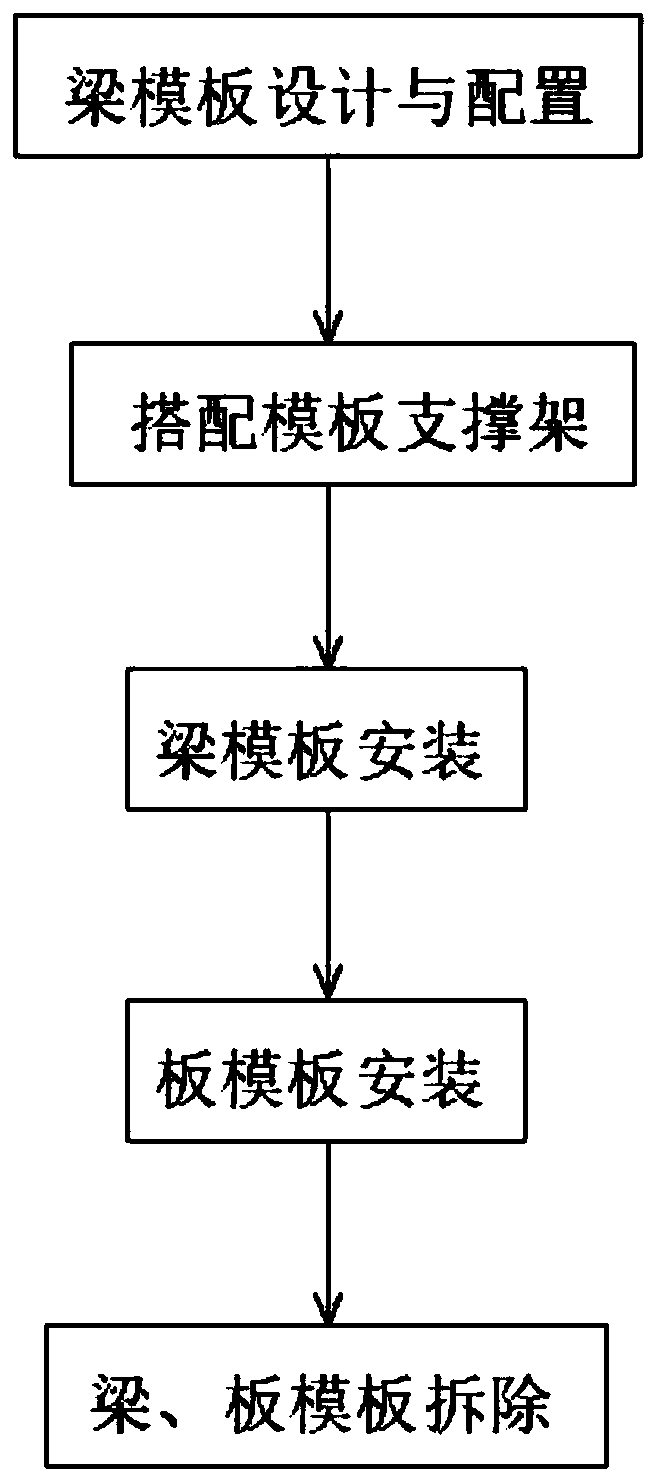

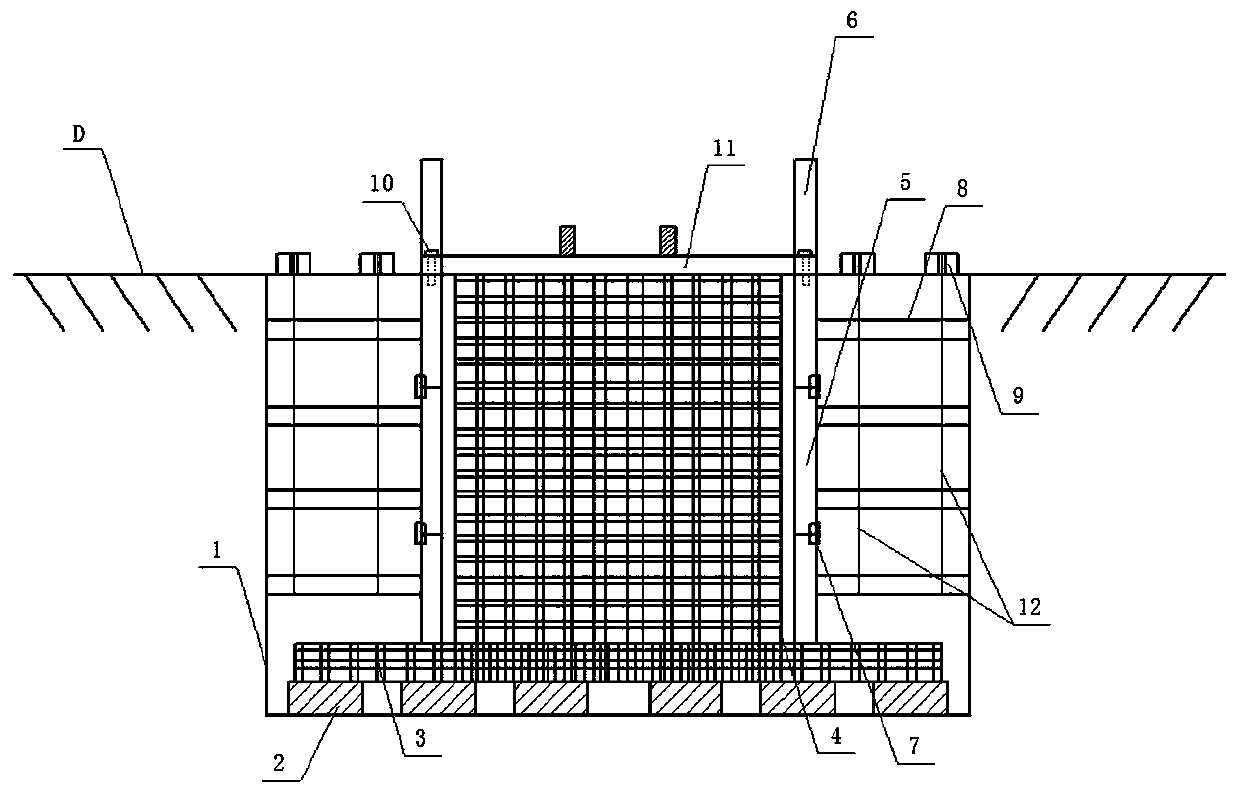

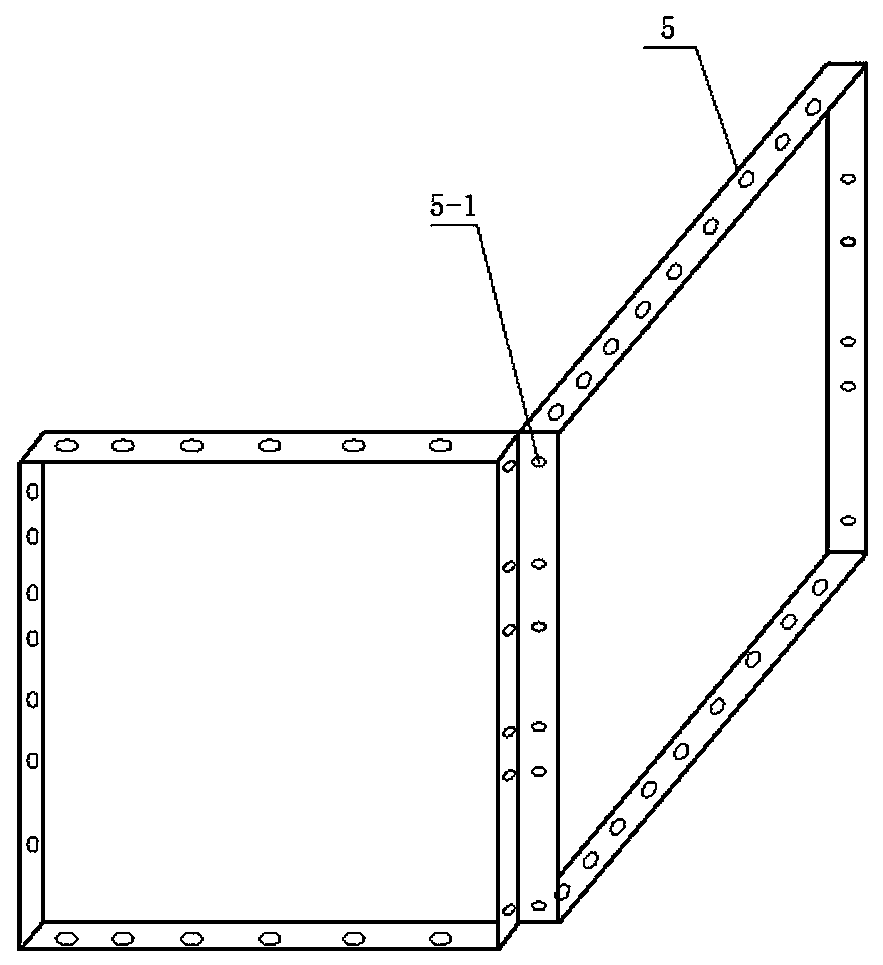

Novel construction method of profile steel keel steel wood combined formwork

InactiveCN108894488AImprove the quality of look and feelPut an end to empty drumsForms/shuttering/falseworksForming/stuttering elementsTemplate designKeel

The invention provides a novel construction method of a profile steel keel steel wood combined formwork, which comprises the construction steps of the wall and column formwork and beam and plate formwork of a steel wood formwork, wherein the construction steps of the wall and column formwork are as follows: formwork design and preparation, snapping the position line and control line of the formwork, welding of an inner wall positioning rib, wall formwork splicing, installation of formwork and wall bolts, secondary keel installation, main keel installation, verticality adjustment of the formwork and formwork removal. The construction steps of the beam and plate formwork are as follows: design and preparation of beam and plate formwork, erection of a formwork supporting frame, installation of the beam formwork, installation of the plate formwork, removal of the beam and plate formwork; according to the steel wood formwork construction system, the profile steel is used as the main and secondary keels of the formwork, bolts or pins are used for connection, the wood formwork is used as the concrete contact surface, the integral rigidity of the formwork system is ensured, the joint seamis tight, and the smoothness of the concrete contact surface is also guaranteed.

Owner:CHINA MCC17 GRP

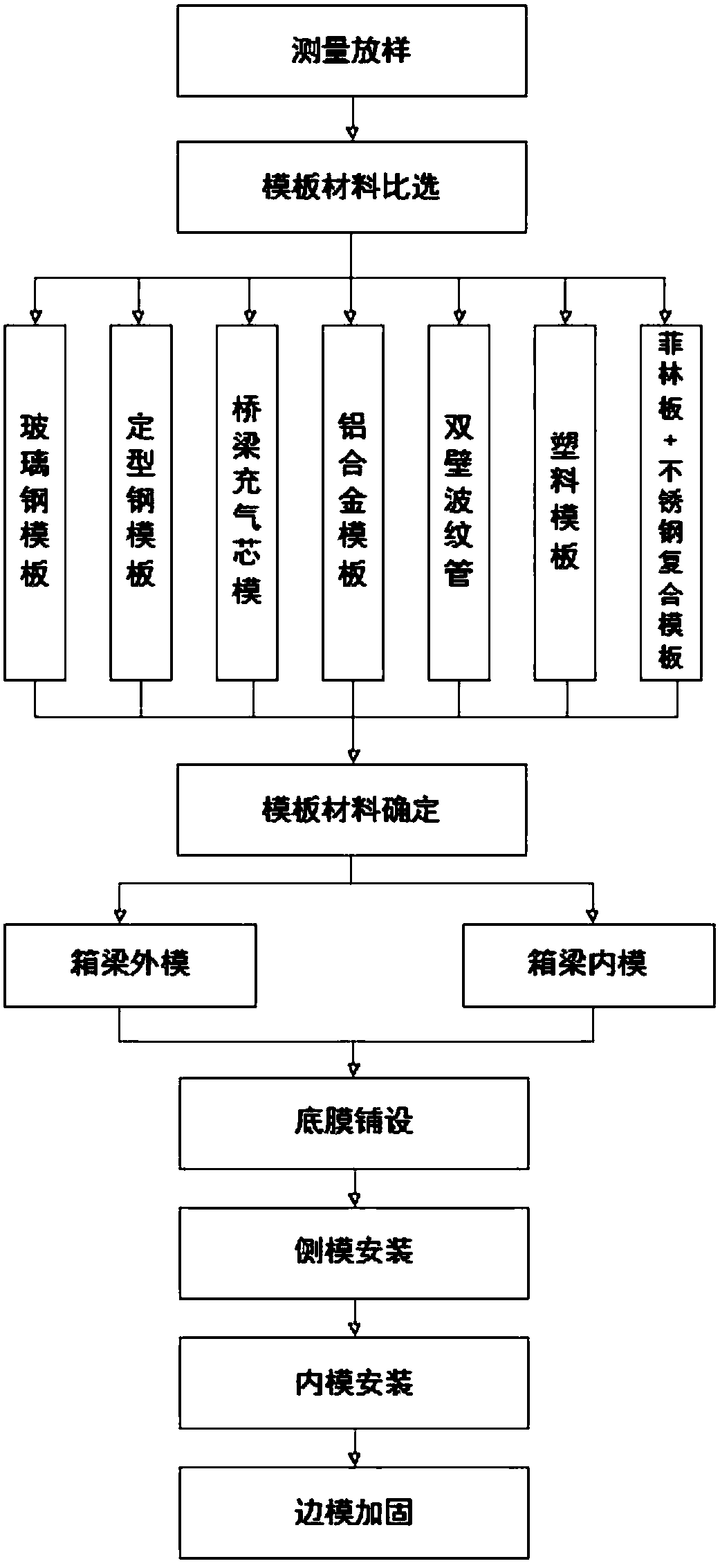

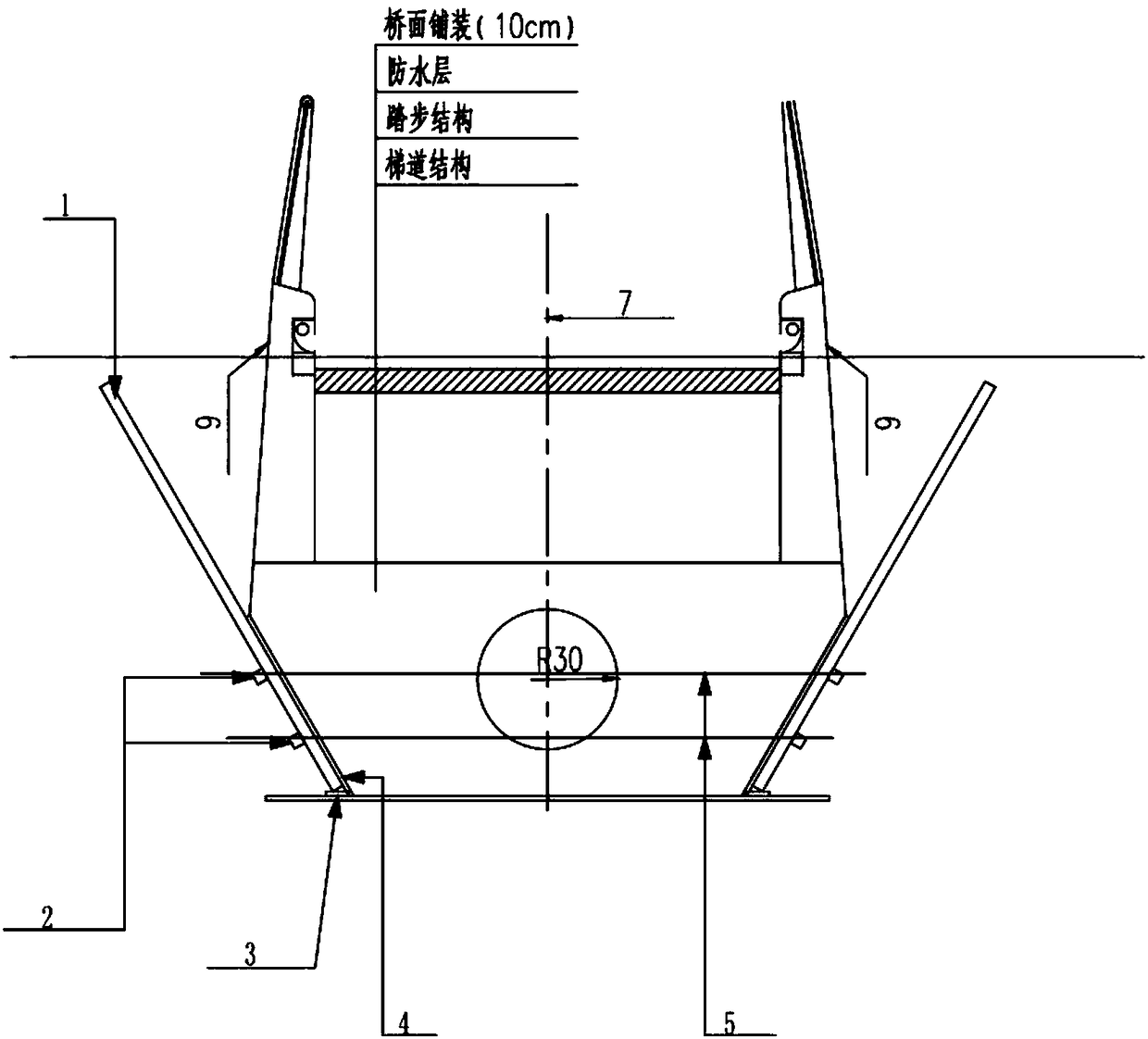

Forming method of arc-shaped box girder formwork

The invention discloses a forming method of an arc-shaped box girder formwork. The forming method comprises the following steps that (1) survey and setting out are conducted, specifically, coordinatesare determined, and field on-site setting out is conducted; (2) formwork materials are compared and selected, specifically, the formwork materials comprising a fiberglass formwork, a set-shaped steelformwork, a film plate and stainless steel composite formwork, a bridge inflatable core mould, an aluminum alloy formwork, a double-wall corrugated pipe and a plastic formwork are compared and selected; (3) the formwork materials are selected, specifically, the formwork materials comprising a box girder outer mould and a box girder inner mould are selected, the characteristics of an arc-shaped box girder are combined, the box girder outer mould adopts the film plate and stainless steel composite formwork, and the box girder inner mould adopts the double-wall corrugated pipe; (4) a bottom mould is laid; (5) side moulds are mounted; (6) an inner mould is mounted; and (7) edge moulds are mounted for reinforcement. The construction speed is high, the overall appearance quality and geometricaldimension precision of the arc-shaped box girder are remarkably improved, meanwhile, the construction safety is guaranteed, and the construction cost is saved.

Owner:GUANGZHOU NO 2 MUNICIPAL ENG CO LTD

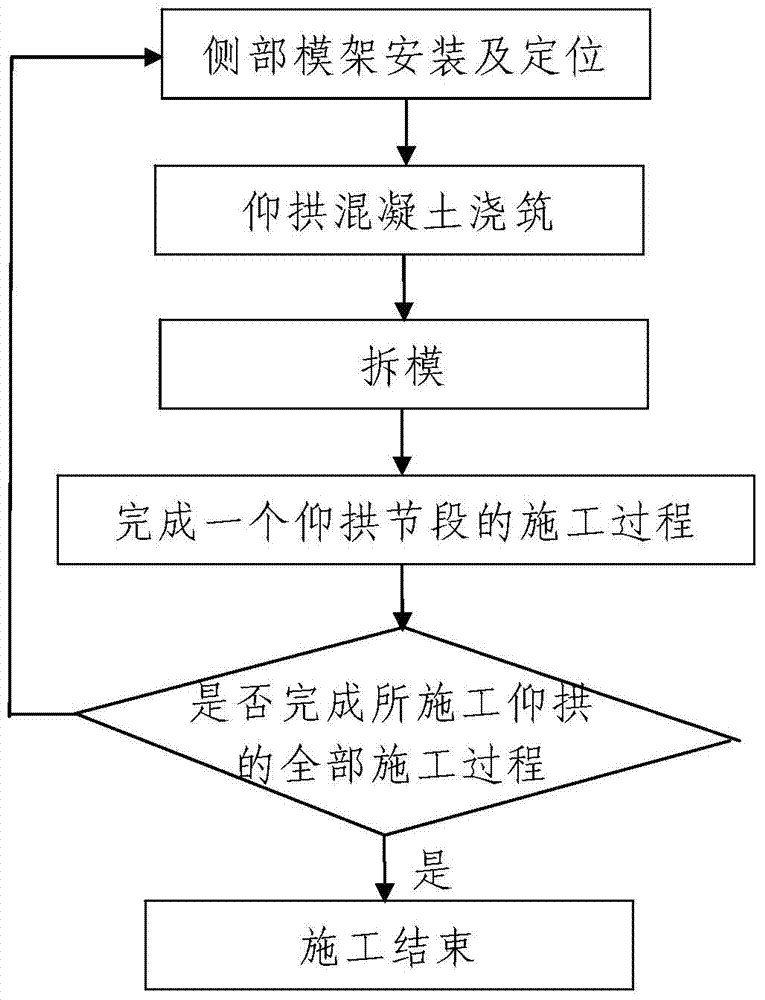

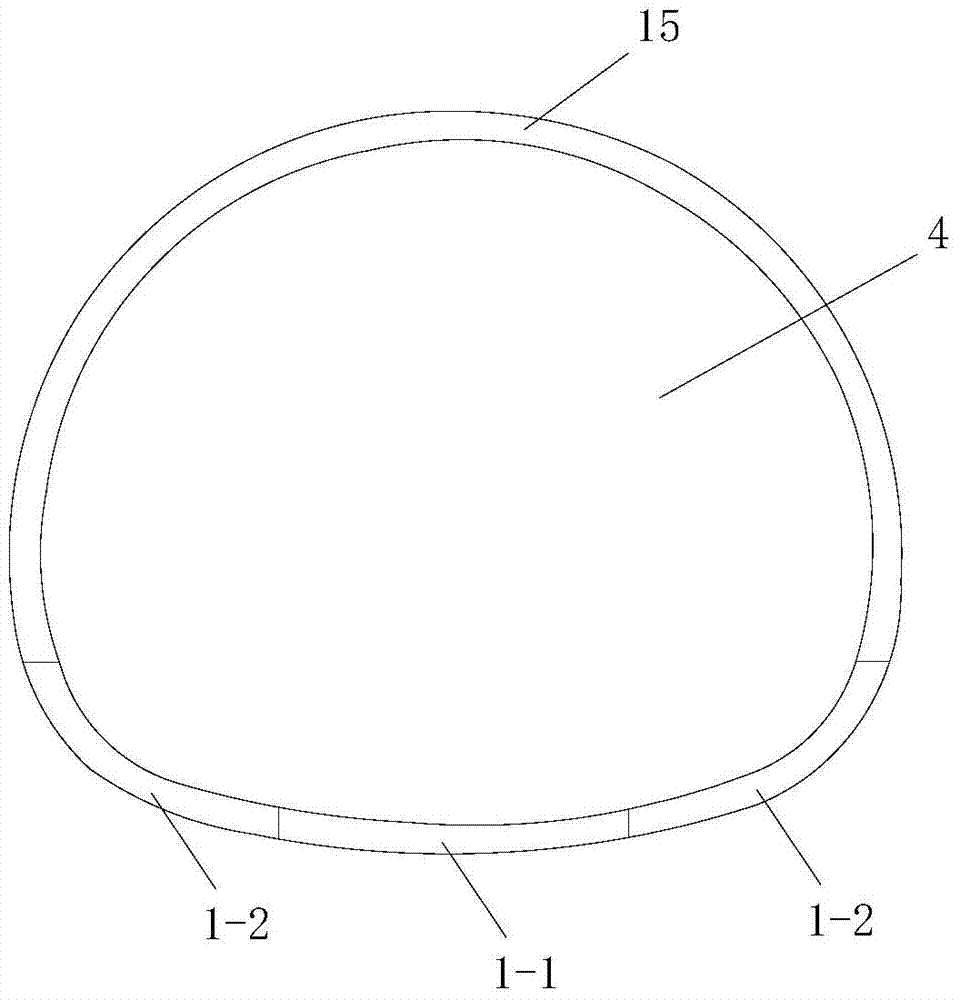

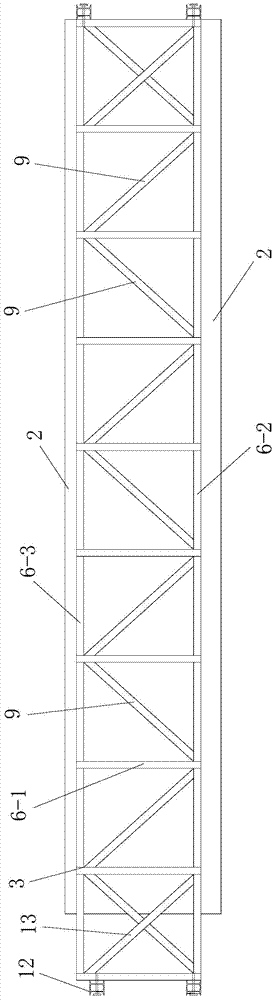

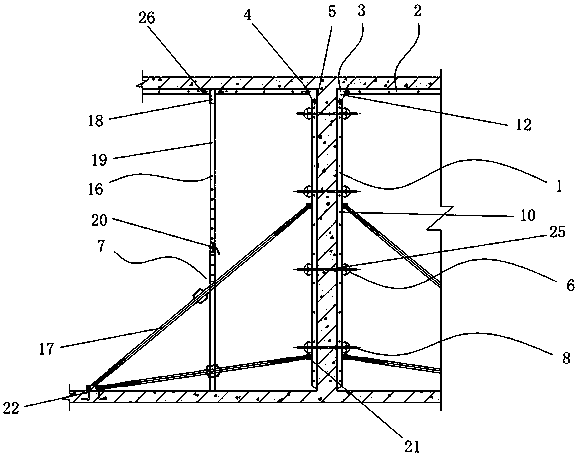

Tunnel inverted arch construction die carrier and tunnel inverted arch construction process

ActiveCN104500106ASimple structureReasonable designUnderground chambersTunnel liningBuilding constructionEngineering

The invention discloses a tunnel inverted arch construction die carrier and a tunnel inverted arch construction process. The die carrier comprises two side die carriers used for respectively constructing two side arch sections of a constructed inverted arch, wherein each side die carrier comprises an arc-shaped steel template for performing shaping construction on the upper surfaces of the side arch section, a template support which is positioned above the arc-shaped steel template and used for supporting the arc-shaped steel template and a front supporting and positioning mechanism positioned at the front side of the arc-shaped steel template. The adopted tunnel inverted arch construction process comprises the following steps of: 1, performing construction of a first inverted arch section, namely installing and positioning the side die carriers, casting inverted arch concrete and detaching a die; 2, performing construction of the other inverted arch section; 3, repeating the step 2 multiple times until the whole construction process of the constructed inverted arch is finished. The tunnel inverted arch construction die carrier is reasonable in design, convenient to realize, and simple and convenient in construction process; in the construction process, the templates are not deviated, the construction effect is god, not only can the tunnel inverted arch construction progress be quickened, but also the construction quality of the constructed and molded inverted arch is easily ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP +1

Combined set-shaped steel formwork and modeling method thereof

InactiveCN110273539AGenerate accuratelyRealize the establishmentGeometric CADForms/shuttering/falseworksHigh turnoverEngineering

The invention discloses a combined set-shaped steel formwork. The combined set-shaped steel formwork comprises a formwork assembly, connecting assemblies, a supporting assembly and fasteners, wherein the formwork assembly is used for forming a closed surface required for the construction of a concrete structure and ensuring a plate piece for forming of a building structure during concrete pouring; the formwork assembly comprises a plurality of single formwork bodies, and the single formwork bodies comprise single standard plates and single internal corner pieces; the single standard plates are provided with standard plate bevel angles, and the single internal corner pieces are provided with internal corner piece bevel angles; the connecting assemblies are used for connecting the single formwork bodies into a connector of a model; the supporting assembly is a stabilizer used for supporting the formwork assembly during the construction of the concrete structure; and the fasteners are members used for shaping the structure, width and size modeled by the formwork assembly. The invention further discloses a method for modeling using the combined set-shaped steel formwork. The combined set-shaped steel formwork and the modeling method have the advantages of light weight, high turnover usage rate, recyclability, high work efficiency, flexible assembly, high versatility, high machining precision, accurate forming size, uniform corner angles, flat and smooth surface and wide application range.

Owner:XINJIANG SUZHONG CONSTR ENG

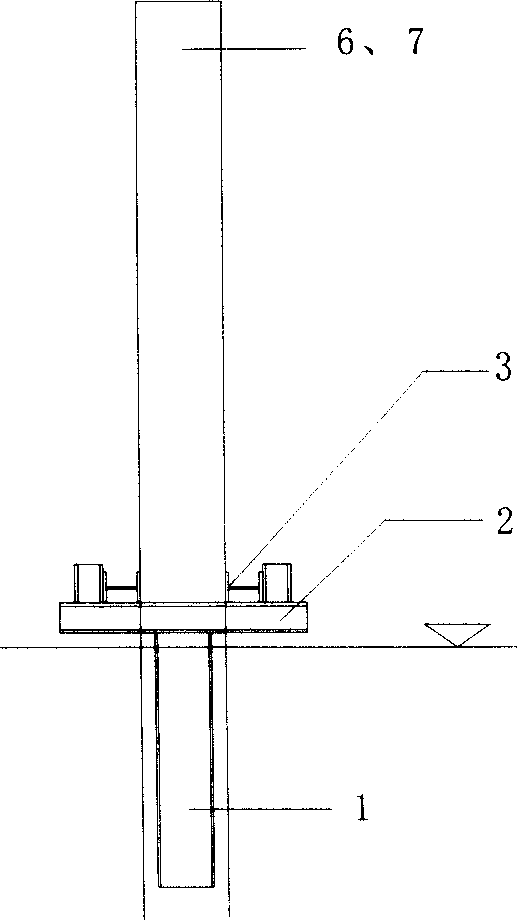

Electric transmission line iron stand foundation and construction method

PendingCN110984210APlay a tight roleGuaranteed surface qualityFoundation engineeringArchitectural engineeringRebar

The invention discloses a construction method of an electric transmission line iron stand foundation. The electric transmission line iron stand foundation is mainly composed of bottom plate ribs and stand column ribs, formworks are arranged outside the stand column ribs, the two adjacent stand columns ribs are fixedly connected together through a right-angle fixing plate, the upper and lower formworks are fixedly connected together through an iron wire, ejector rods are mounted between the outer walls of the formworks and the inner wall of a foundation pit, the ejector rods are arranged on a supporting plate in a sleeving manner through a rope, and the ejector rods are sequentially sleeved together and fixedly connected. The construction method comprises the specific operation steps of firstly, foundation pit and grounding pit excavation; secondly, rebar binding and formwork erecting; thirdly, formwork mounting; fourthly, foundation bolt mounting; fifthly, foundation pouring; sixthly,formwork stripping for backfill; and seventhly, site cleaning. Construction of the iron tower foundation is subjected to comprehensive control, various problems appearing after later-period construction are solved, the whole construction quality is ensured, the construction period is shortened, smooth finishing of the iron tower foundation construction is facilitated, and the foundation is laid for safe, stable and reliable running of a power line.

Owner:POWER CHINA HENAN ENG CO LTD

Reinforcement system of cylindrical wood formwork and splice joint fastener

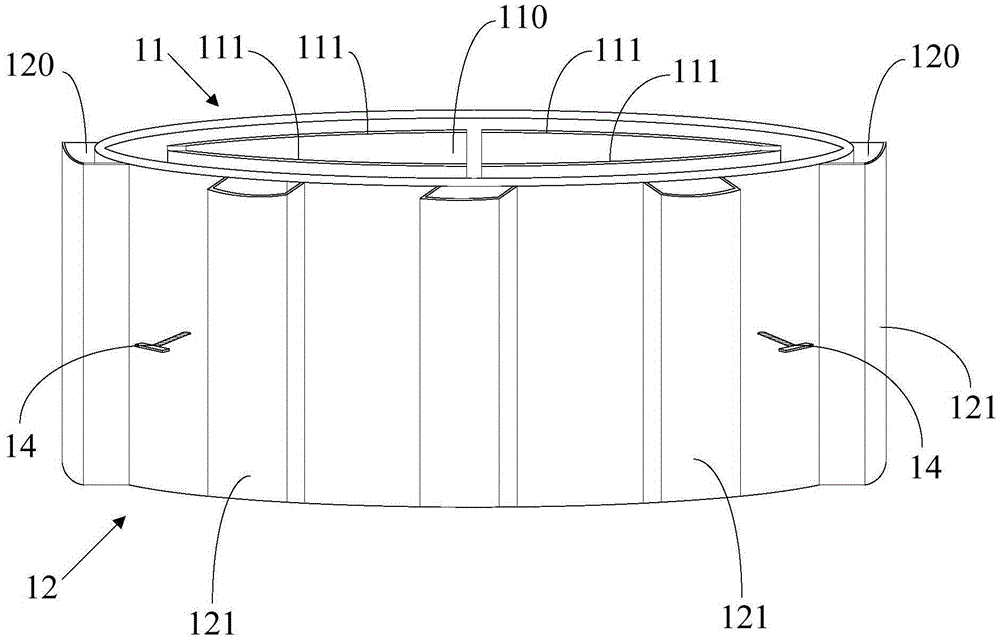

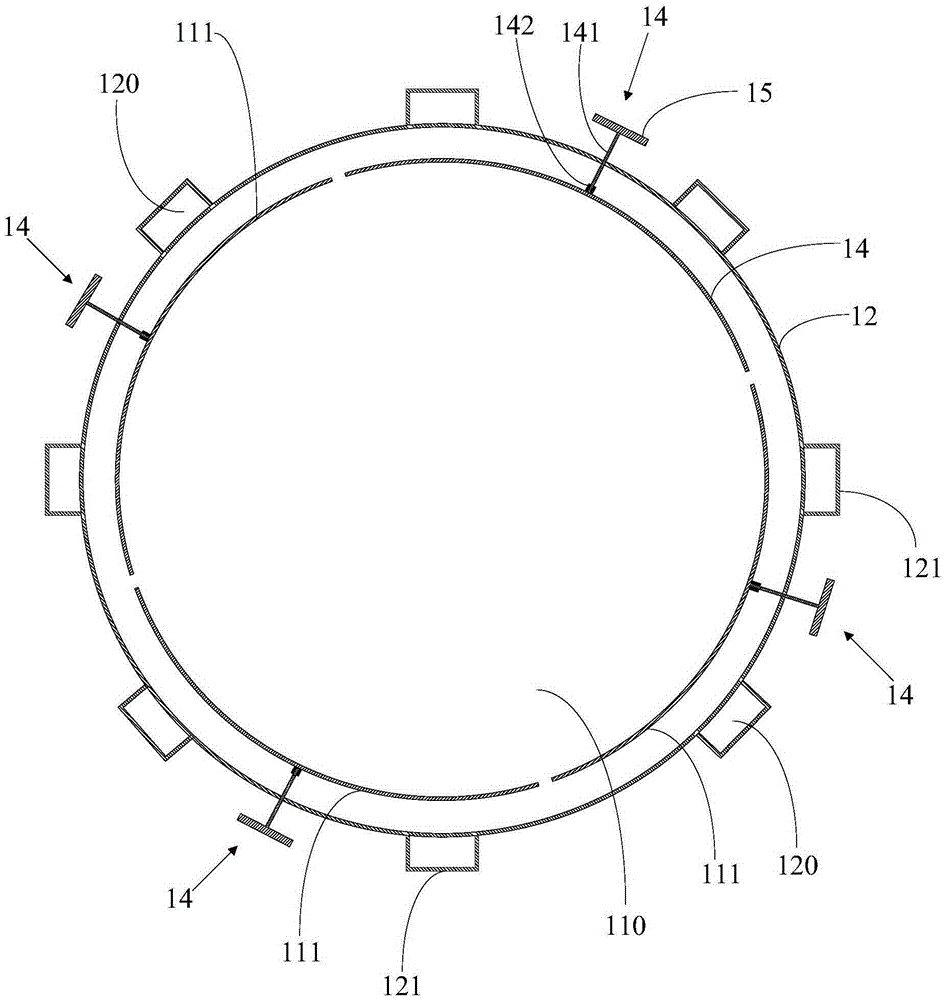

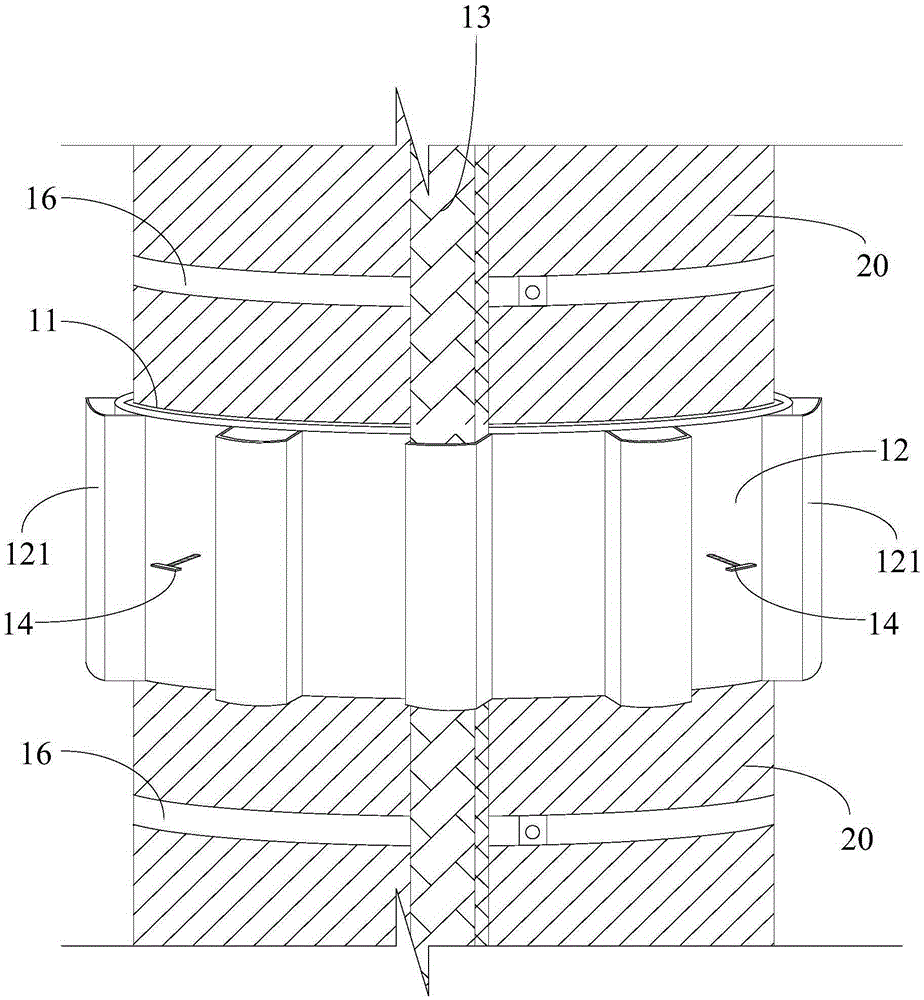

ActiveCN105421764AReinforced, safe and reliableImprove the effectForms/shuttering/falseworksFastenerDual layer

The invention discloses a reinforcement system of a cylindrical wood formwork and a splice joint fastener. The splice joint fastener comprises an inner side column loop and an outer side column loop. The inner side column loop comprises a plurality of arc-shaped plate bodies, a containing space for containing the cylindrical wood formwork is defined by the arc-shaped plate bodies, and an adjusting fastening structure for adjusting the arc-shaped plate body to control the containing space is arranged outside each arc-shaped plate body. The outer side column loop is arranged outside the inner side column loop in a sleeving mode. A plurality of positioning clamping grooves which are formed in the height direction of the cylindrical wood formwork and used for inserting positioning inserts are formed in the outer wall of the outer side column loop. The inner side column loop and the outer side column loop form a dual-layer column loop structure; on one hand, the problems that vertically-adjacent cylindrical wood formworks are not firm in splice joint and not easy to reinforce are solved through the inner side column loop with the adjusting fastening structure; on the other hand, the perpendicularity of the vertically-adjacent cylindrical wood formworks is controlled through the outer side column loop with the positioning clamping grooves and the positioning inserts.

Owner:中建八局西北建设有限公司

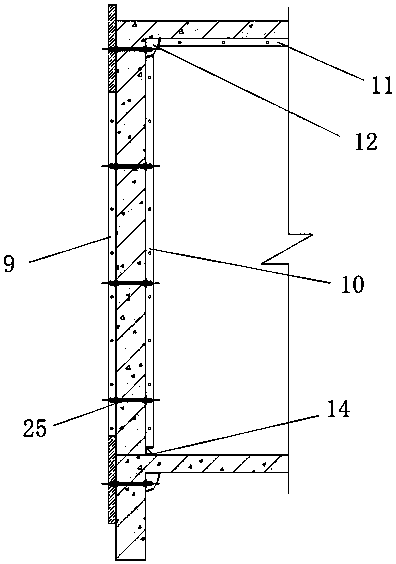

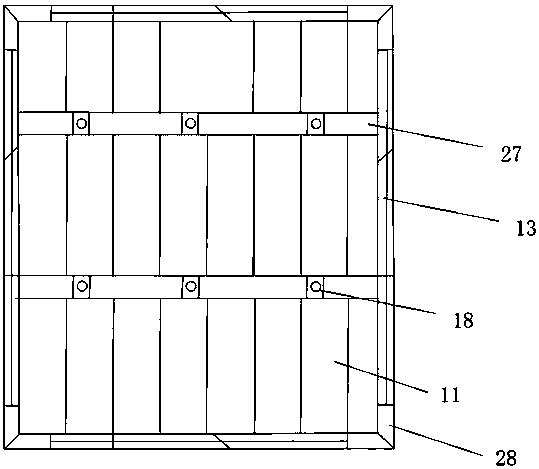

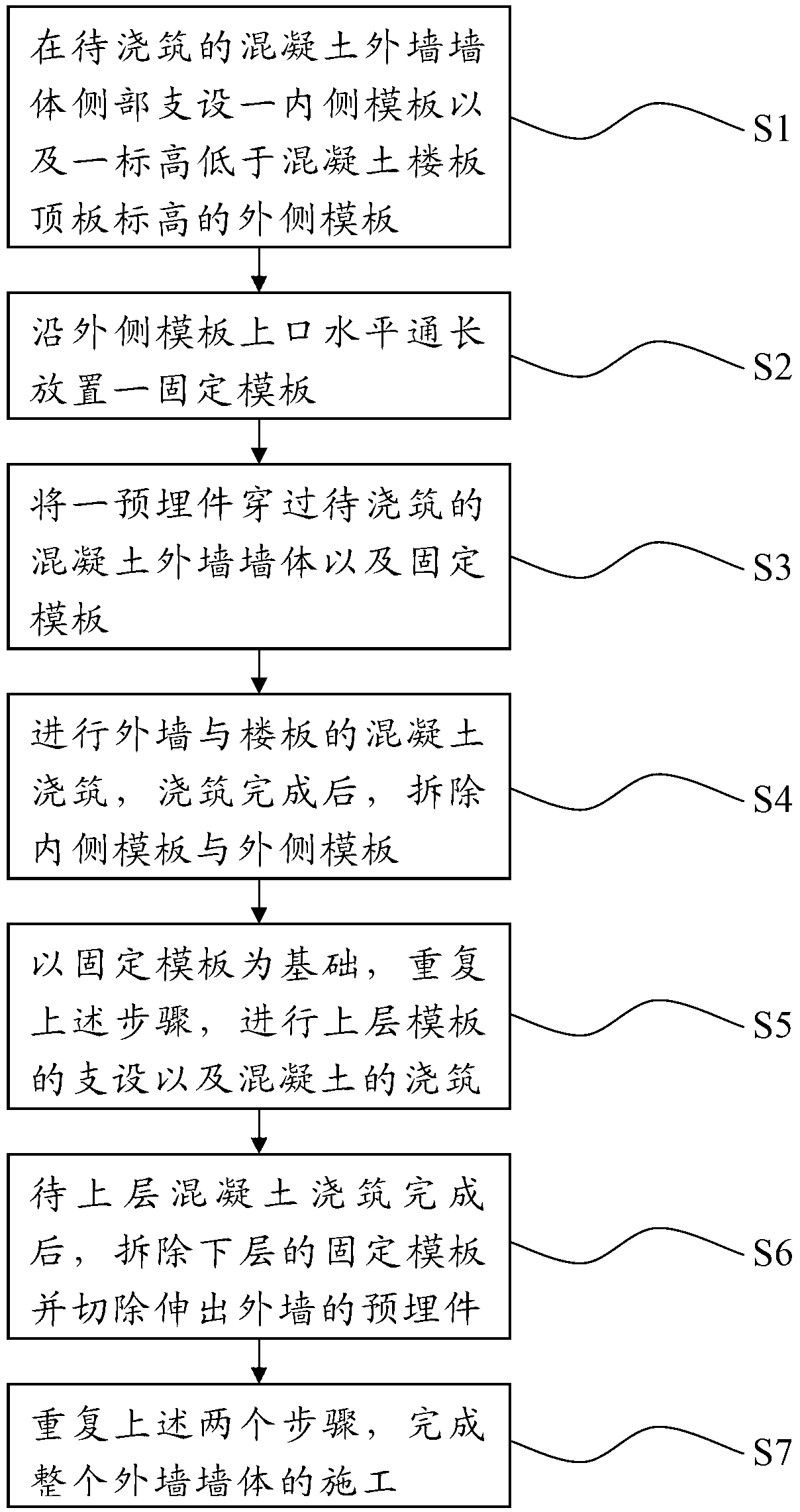

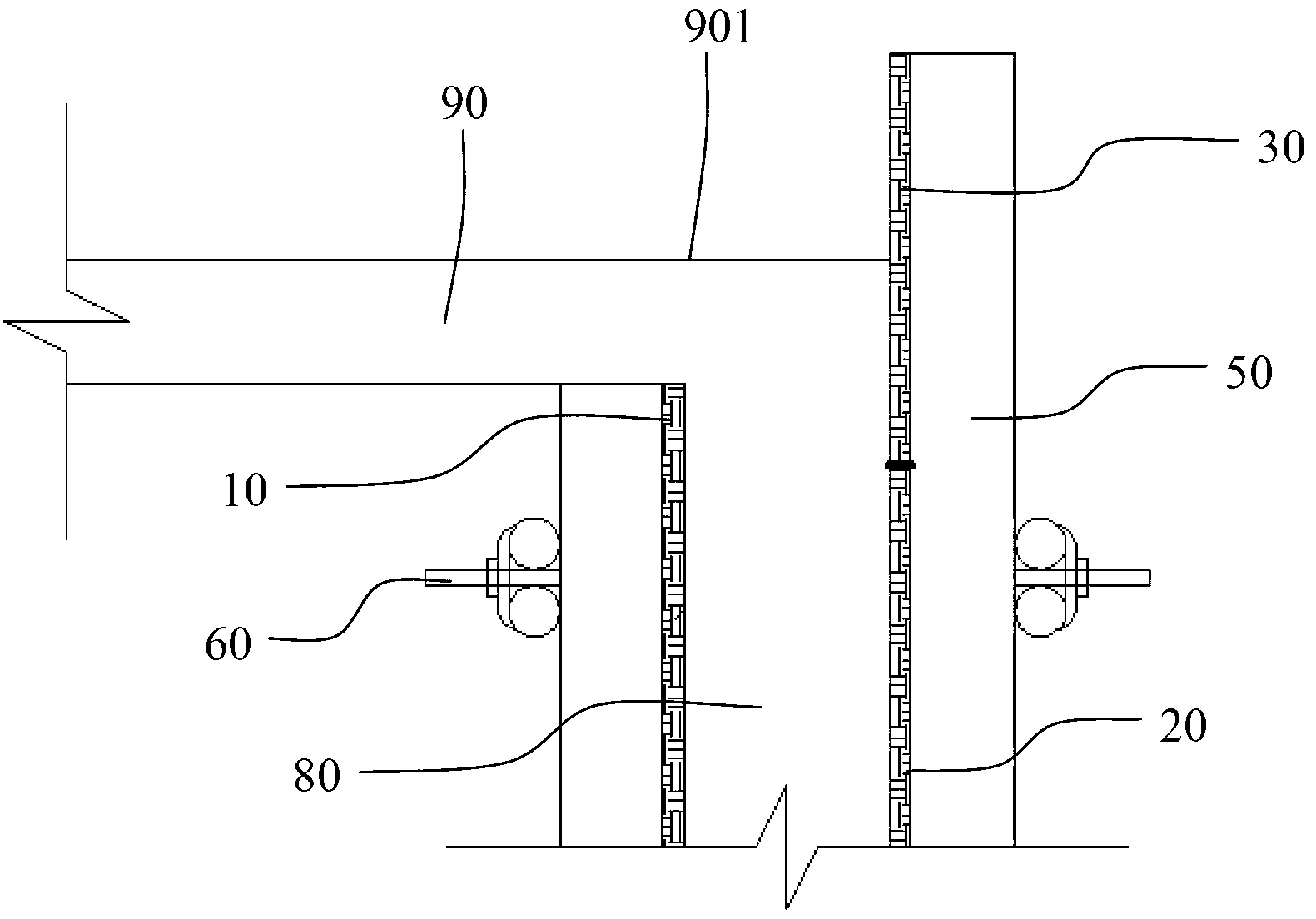

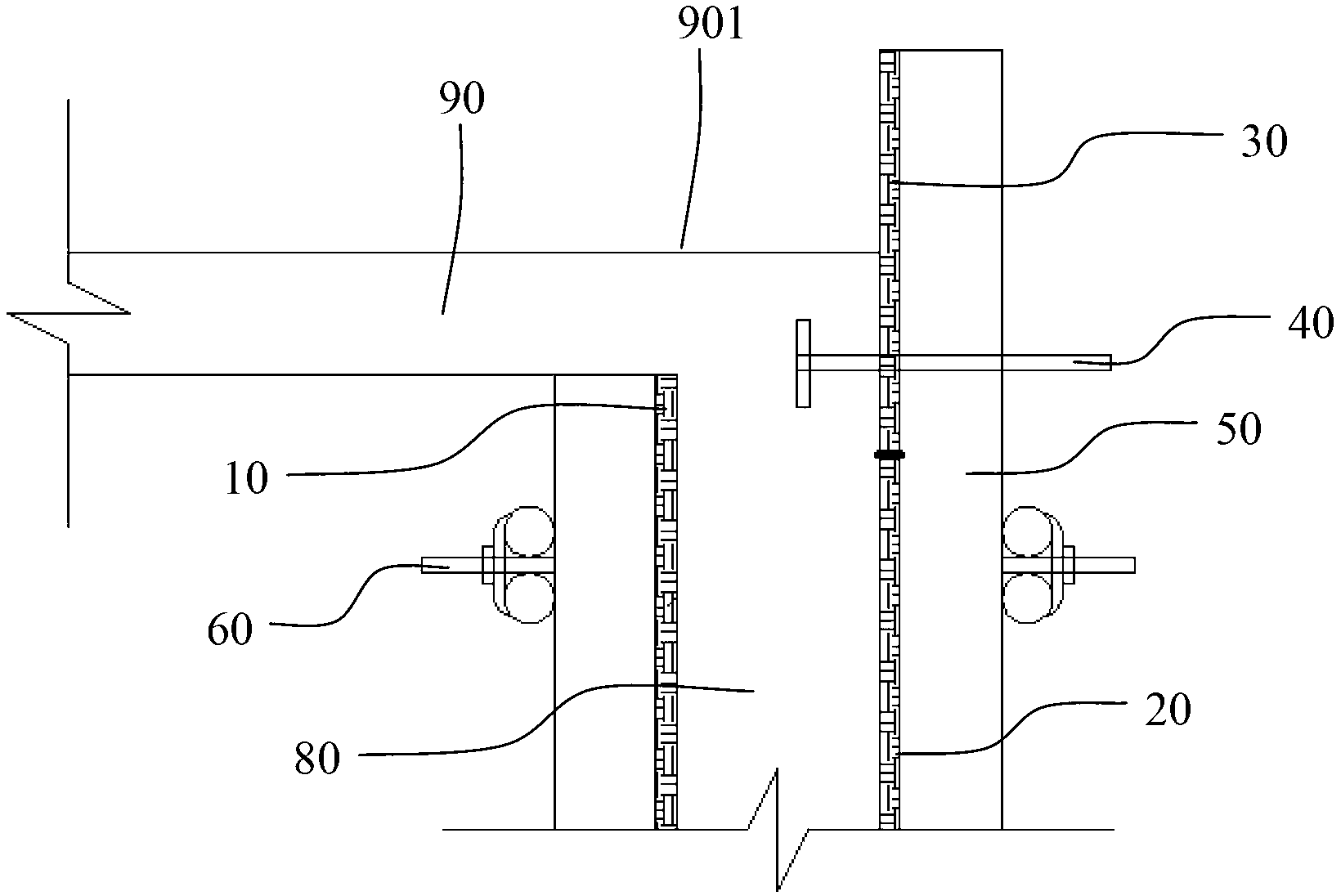

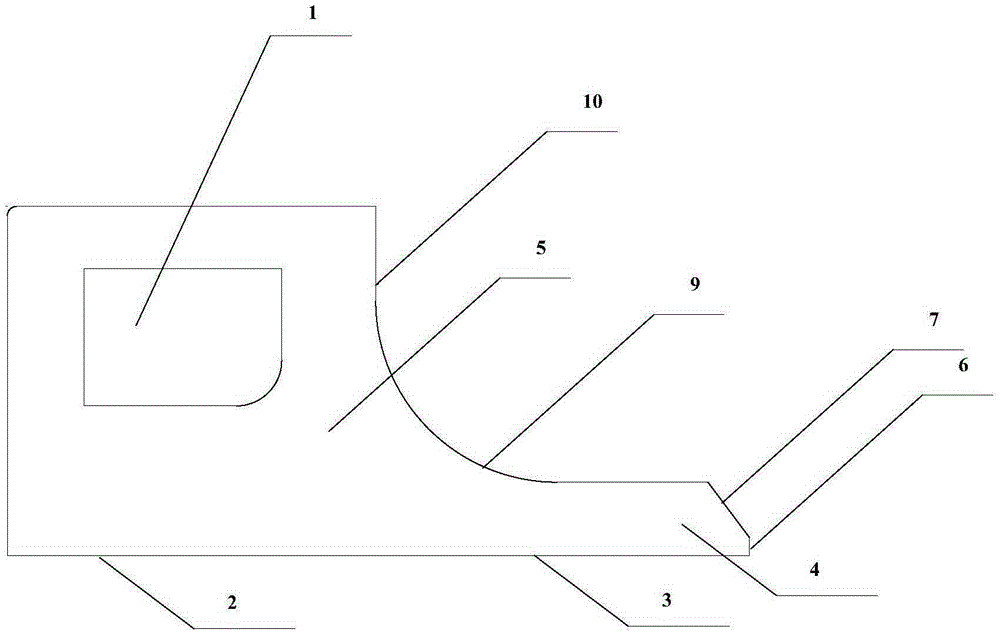

Erecting method and structure of piece-by-piece assembling formworks at position of interlayer outer wall construction joint

ActiveCN103321403AGuaranteed to be firmGuaranteed seamless integrationWallsForms/shuttering/falseworksFloor slabEngineering

The invention discloses an erecting method of piece-by-piece assembling formworks at the position of an interlayer outer wall construction joint. The method comprises the following steps of (1) erecting an inner side formwork and an outer side formwork with elevation lower than that of a concrete floor slab top plate at the side portion of a concrete outer wall body to be poured, (2) placing a fixed formwork along the horizontal pass length of an upper port of the outer side formwork, (3) enabling an embedded part to penetrate the concrete outer wall body to be poured and the fixed formwork, (4) performing concrete pouring of an outer wall and a floor slab and dismounting the inner side formwork and the outer side formwork after the pouring is finished, (5) using the fixed formwork as a basis, repeating the steps to perform erection of the upper-layer formworks and the concrete pouring, (6) dismounting the lower-layer fixed formwork and cutting off the portion of the embedded part extending out of the outer wall after the upper-layer concrete pouring is finished, (7) repeating the steps (5) and (6) to finish construction of the whole outer wall body. By means of the erecting method of the piece-by-piece assembling formworks at the position of the interlayer outer wall construction joint, joint-free combination of wall bodies is ensured, and grout leakage and slab staggering are avoided.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

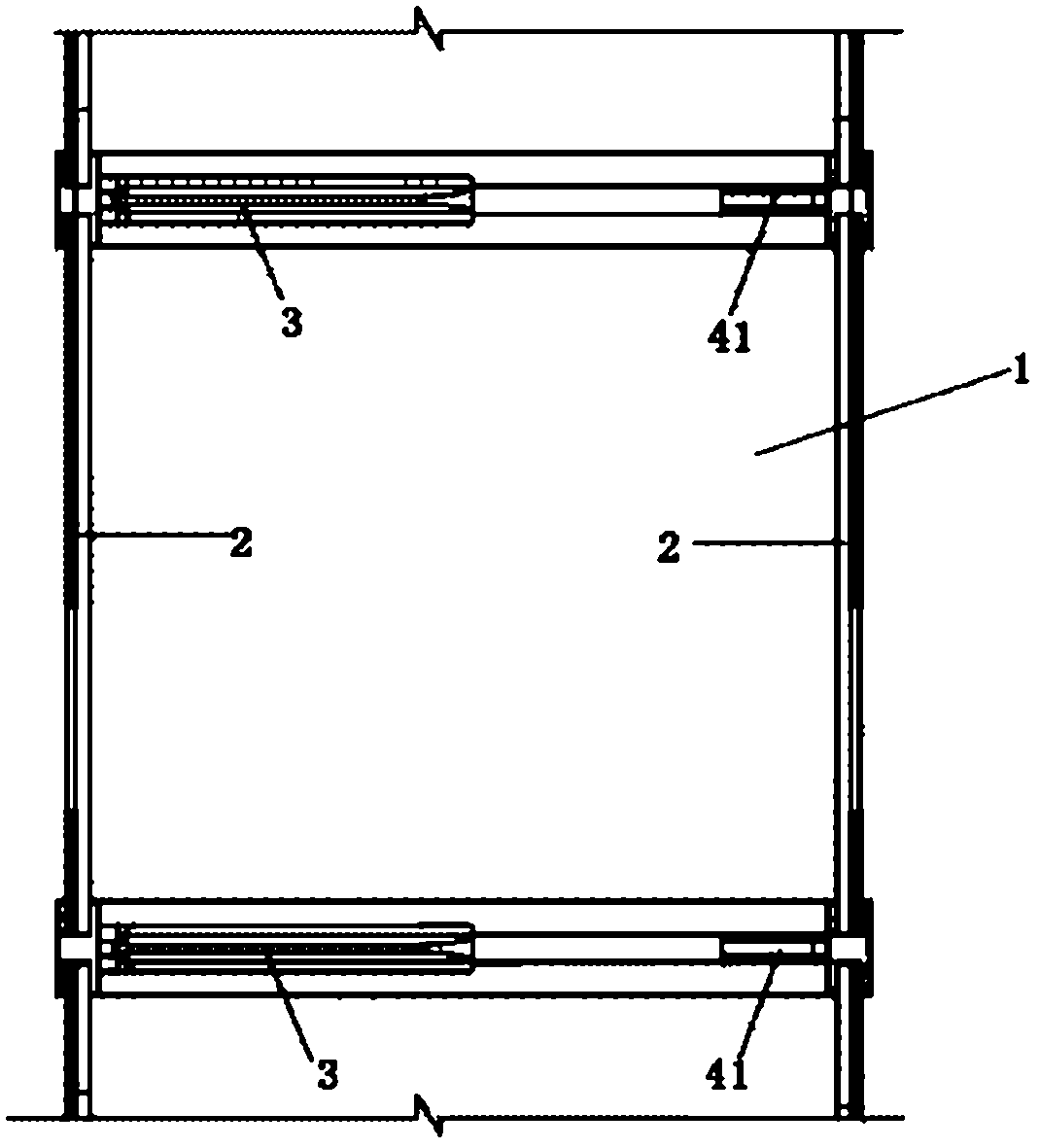

Building block material unit and butt joint structure thereof

InactiveCN105350701AEliminate reinforcement and difficult operationTroubleshoot template issuesBuilding componentsRear quarterElectricity

The invention relates to a building block material unit which comprises a hollow building body (1) formed by connecting side plates, and a concrete side plate die (3) outwards extending in one or more directions along the side plates of the hollow building body. The building block material units can be in effective group building through the outwards extending side plates. Various kinds of butt joint of at least two building block material units can be conducted to build block walls in different directions. A core column built through the building block material unit replaces a traditional constructional column, and the trouble that up-down brick sleeving and building of interlocking building blocks in the core column is eliminated. Meanwhile, use of a wood mould and a diagonal bracing is avoided, construction is easy and convenient, operation is easy, and work efficiency is high. Grooves do not need to be formed, water and electricity holes do not need to be chiseled and wire pipes and wire boxes do not need to be arranged on the building block walls, and the situations that plastering is carried out on grooved portions and steel wire meshes are additionally arranged on original building block walls are avoided. The walls using the building block material unit is good in quality and flat in appearance, materials and labor are saved by 16%, and manufacturing cost of each project is saved by 28.46%.

Owner:CHENGDE MINGDE BUILDING MATERIAL MFG CO LTD

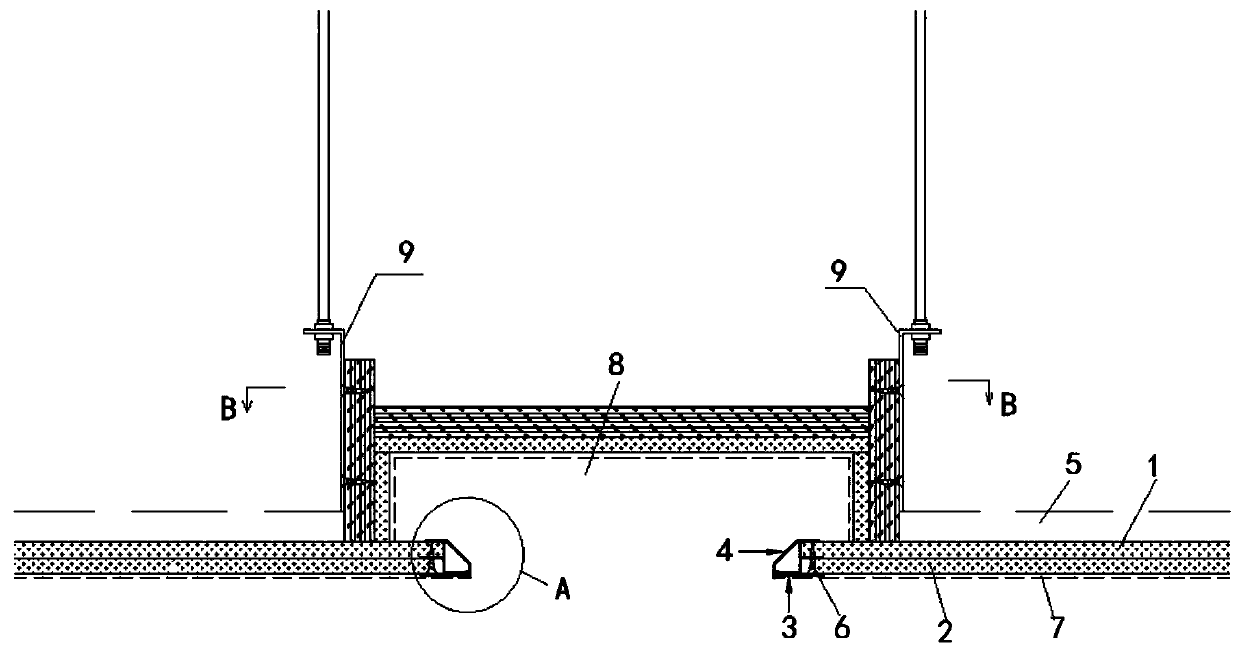

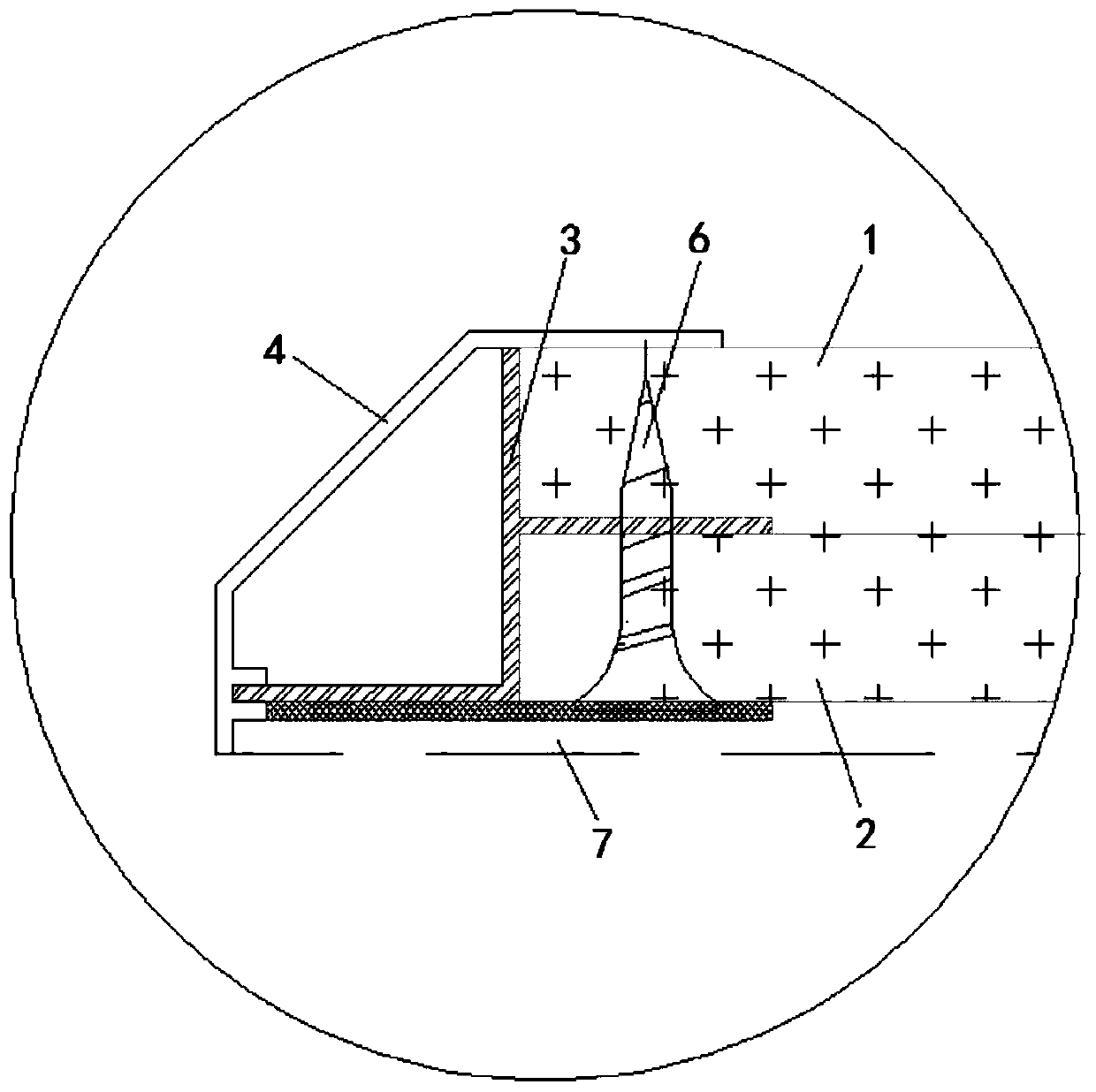

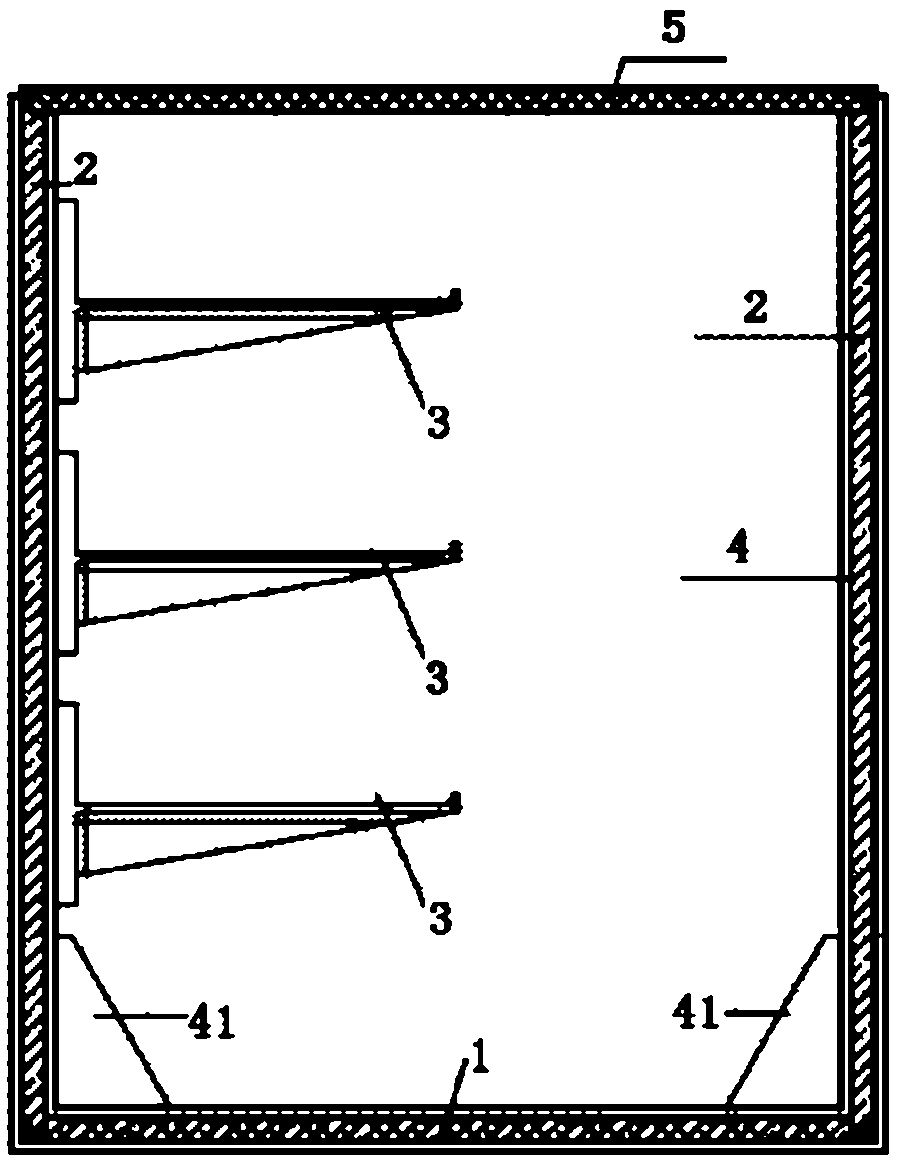

Ceiling lamp trough edge closing structure and ceiling lamp trough applying same

ActiveCN111088869AStitching natureAvoid deformationCeilingsLighting support devicesEngineeringStructural engineering

The invention discloses a ceiling lamp trough edge closing structure and a ceiling lamp trough applying the same. The edge closing structure comprises a ceiling bottom plate fixed to the lower end face of a lamp trough base plate, a ceiling panel bonded to the lower end face of the ceiling bottom plate, a base arranged at the end of the ceiling bottom plate and the end of the ceiling panel, and aclosing panel fixedly connected with the base, wherein the base is fixed to the ceiling panel and the ceiling bottom plate through a fastener screwed into the ceiling panel and the ceiling bottom plate from bottom to top, and the lower end face of the ceiling panel is coated with a coating layer. According to the ceiling lamp trough edge closing structure and the ceiling lamp trough applying the same, the structure is simple, installation and use are convenient, during construction, only the base, the closing panel, the ceiling bottom plate and the ceiling panel need to be assembled, splicingof an arc-shaped and special-shaped GRG lamp trough can be more natural, and the quality problems of cracking, dislocation, deformation and the like of the GRG lamp trough are avoided.

Owner:SHANGHAI BUILDING DECORATION ENG GRP

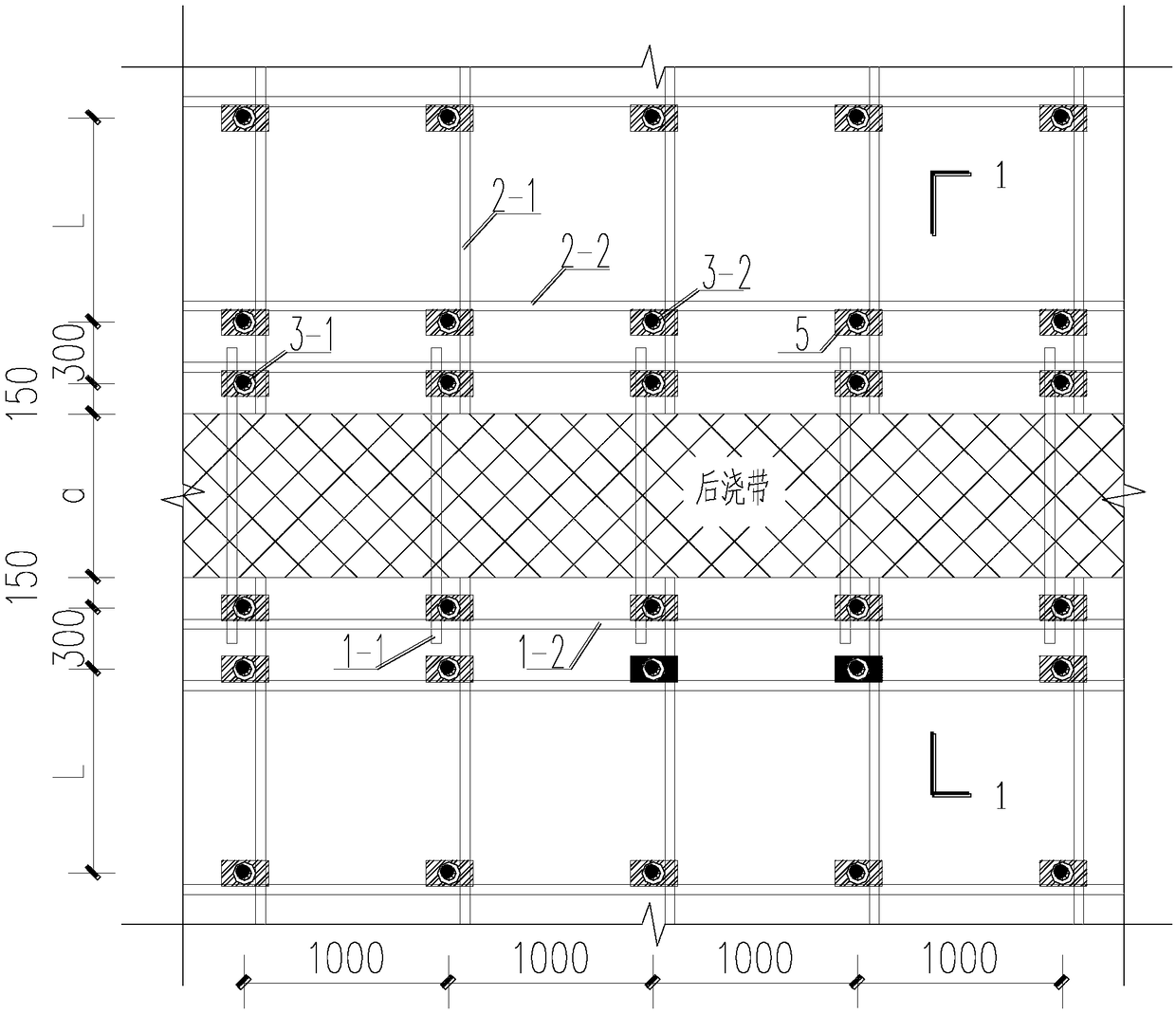

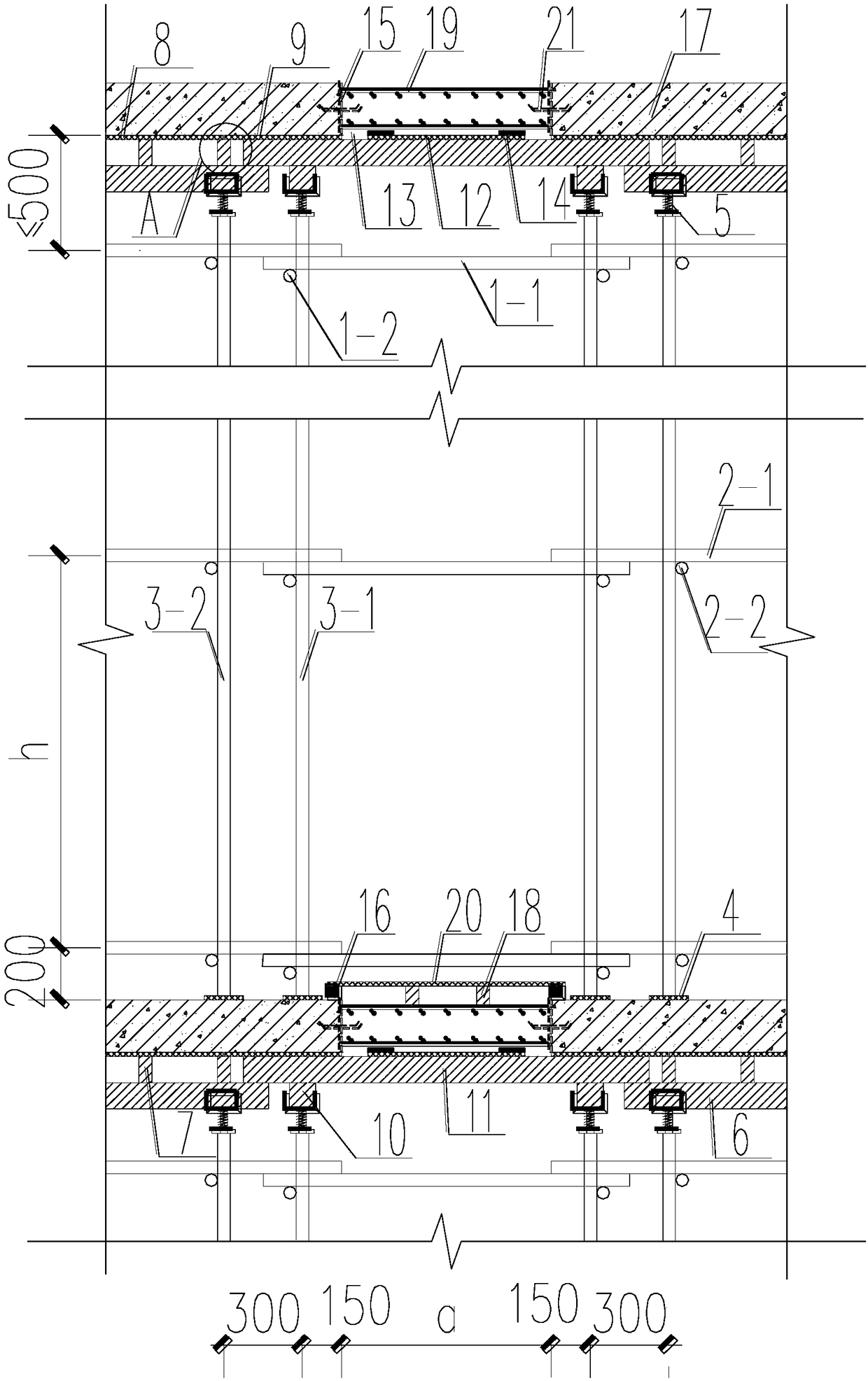

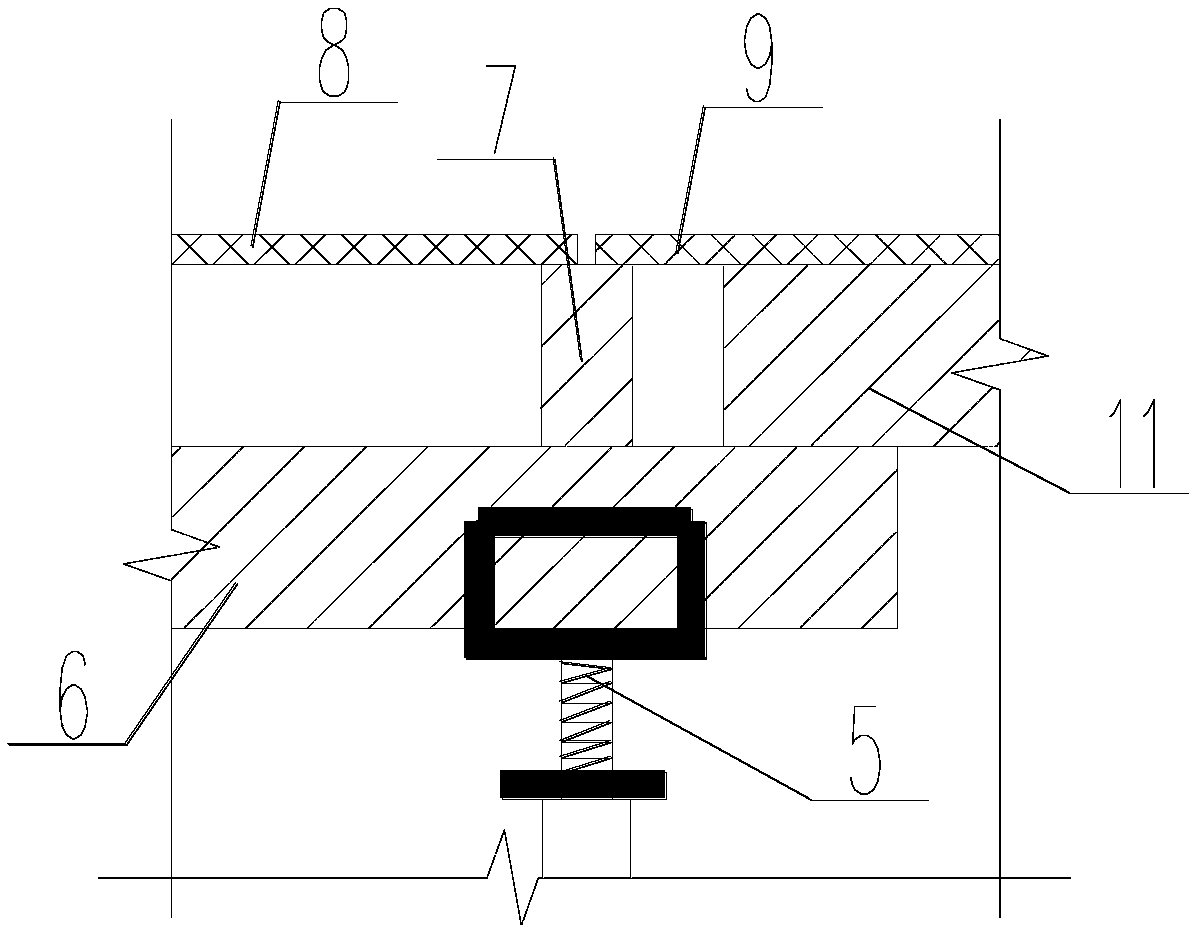

Floor post-cast strip template support system

The invention discloses a floor post-cast strip template support system, and the support system comprises a post-cast strip part support system, a floor slab full support system at two sides of a post-cast strip, and a post-cast strip top protection system. The post-cast strip part support system comprises a post-cast strip part support system vertical rod, a post-cast strip part support system lateral horizontal rod, a post-cast strip part support system longitudinal horizontal rod, a longitudinal main beam, a lateral secondary beam, a post-cast strip part independent template, a through longmoving template, and a quick and easy close-up mesh. The floor slab full support system comprises a floor slab full support system vertical plate, a floor slab full support system lateral horizontalrod, a floor slab full support system longitudinal horizontal rod, a lateral main beam, a longitudinal secondary beam, a floor slab post-cast strip side independent template, and a floor slab template. The post-cast strip top protection system comprises a brick setting water blocking platform, a protection wood brace, and a protection template. The system provided by the invention can avoid the phenomena of large height difference or unevenness of cracks and seams, and can avoid the slag inclusion after the pouring of concrete.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

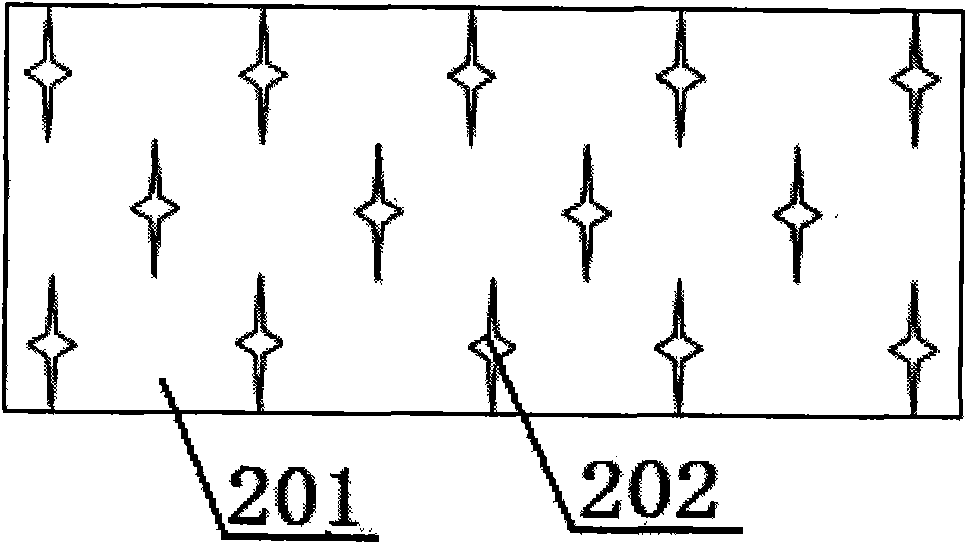

Process for manufacturing full-bamboo embossed pattern plate

InactiveCN101890748AImprove deep processingIncrease profitDecorative surface effectsWood treatment detailsHigh intensityManufacturing engineering

The invention discloses a process for manufacturing a full-bamboo embossed pattern plate. In the process, modified bamboo fibers, bamboo filaments and bamboo strips are paved and arranged in a bundle shape on a pattern template with a customized pattern and are made into a wide high-strength high-density embossed pattern-face embryonic plate through high temperature and high pressure. The process for manufacturing the full-bamboo embossed pattern plate can increase specifications and varieties of materials and save the materials and labor.

Owner:葛会龙 +1

Door jamb bending method

ActiveCN105598266AImprove cohesionImprove processing efficiencyShaping toolsWindow/door framesMarking outEngineering

The invention discloses a door jamb bending method, and belongs to the technical field of moulds and bending. According to the door jamb bending method, adopted bending moulds comprise a lower mould, an upper right-angled mould, an upper 45-degree mould, an upper flanging mould and an upper flattening mould. The method comprises the bending steps that materials are selected and marked out; a plurality of right-angled sections are bent out through the upper right-angled mould; a flanged protrusion is machined through the upper flanging mould; a right-angled section is bent out through the upper right-angled mould; then pre-bending is carried out through the upper 45-degree mould, finally the pre-bent corner is flattened through the upper flattening mould, and a door jamb workpiece is machined. According to the door jamb bending method, the bending moulds are reasonable in structural design, the cooperation performance of the upper moulds and the lower mould is good, the machining sequence is set reasonably, no interference phenomenon occurs in the machining process, machining efficiency is high, and the machined door jamb is tight in joint closing and good in sound insulation effect.

Owner:ANHUI CHANGJIANG MACHINE TOOL MFG GRP

Full-glass-reinforced-plastic box-type cable chute

InactiveCN102593780AShort construction periodShorten the timeCable installations on groundPipe supportsWorking environmentElectrical performance

The invention relates to a full-glass-reinforced-plastic box-type cable chute. The cable chute is made from glass reinforced plastic and comprises a U-type column, a bottom plate, side plates, a cover plate and a bracket, wherein the lower end of the U-type column is fixed on the bottom plate; the left side and the right side of the U-type column are fixed on the side plates; the bracket is fixed on the U-type column; and the cover plate is fixed at the upper end of the U-type column. Compared with the prior art, the cable chute has the advantages of short construction cycle, neat appearance of finished product, excellent electrical performance, good cable working environment and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Material-saving type inclination linking and supporting plate column cap wood formwork and construction method thereof

InactiveCN106639306AReduce inputReduce loss rateForms/shuttering/falseworksResource utilizationPlate column

The invention discloses a material-saving type inclination linking and supporting plate column cap wood formwork and a construction method thereof. The material-saving type inclination linking and supporting plate column cap wood formwork comprises four horizontal supporting plates, four inclination reverse moulds and four frame column formworks which are supported by steel pipe supporting frames composed of steel pipes. The four frame column formworks are vertically arranged and form a square-shaped upright column. The inclination reverse moulds extend outwards and obliquely upwards from the four sides of the top of the square-shaped upright column. The horizontal supporting plates are connected with the upper ends of the inclination reverse moulds and extend outwards in the horizontal directions. According to the column cap wood formwork and the construction method thereof, under the condition that the mounting construction process of the column cap formwork is met, whole wood formwork cutting is avoided as far as possible, and maximization, rationalization and economization utilization of the formworks and cants which are purchased newly and in the stipulated turnover frequency and repeatable resource utilization of the waste formworks and cants can be achieved.

Owner:徐仁贵

Stable installation structure of stone and aluminum plate modeling on common space super-high wall surface

ActiveCN107938980ATight seamsImprove sealingCovering/liningsClimate change adaptationCommon spaceStructural engineering

The invention provides a stable installation structure of a stone and aluminum plate modeling on a common space super-high wall surface. The stable installation structure comprises a stone plate and an aluminum plate, wherein the stone plate is fixedly arranged on the wall surface, the aluminum plate is fixedly arranged on the wall surface, and the stone plate and the aluminum plate are connectedthrough a connecting portion; and the connecting portion is provided with a z-shaped connecting plate, one end of the connecting plate is connected with the aluminum plate, the other end of the connecting plate is provided with a tooth-shaped surface, and the tooth-shaped surface is meshed with a gear embedded in the end part of the stone plate. According to the stable installation structure of the stone and aluminum plate modeling on the common space super-high wall surface, the problem that a splicing gap is large between the stone plate and the aluminum plate in the prior art and the overall coordination is poor is solved.

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

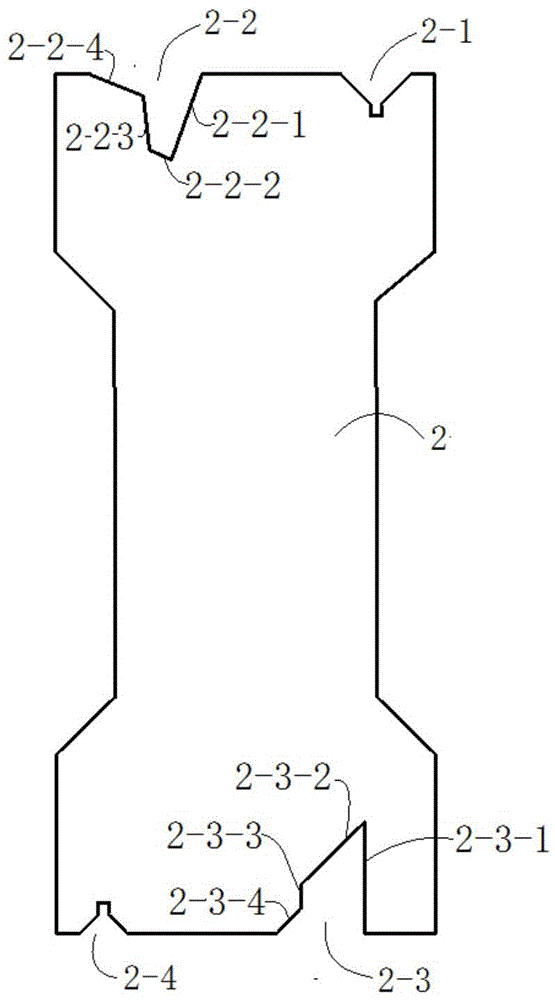

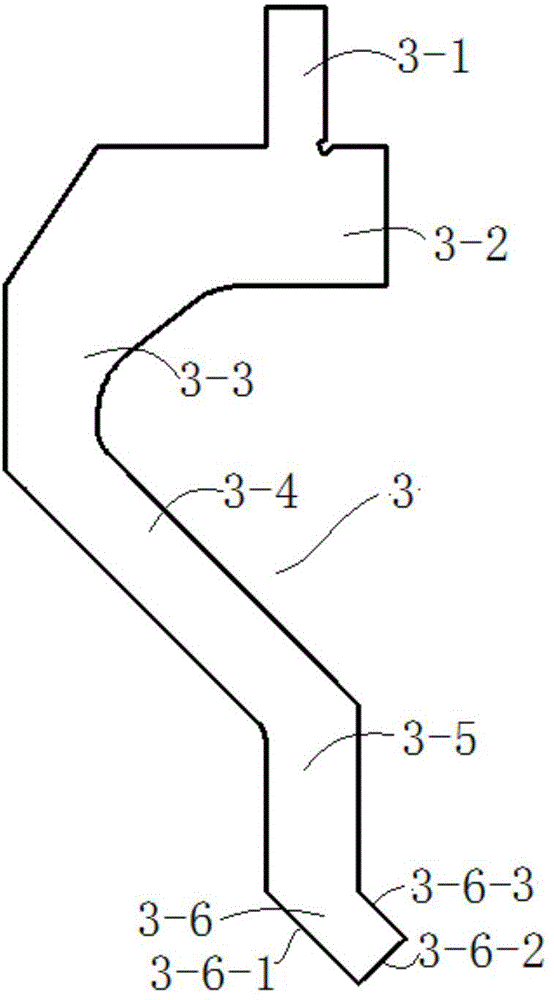

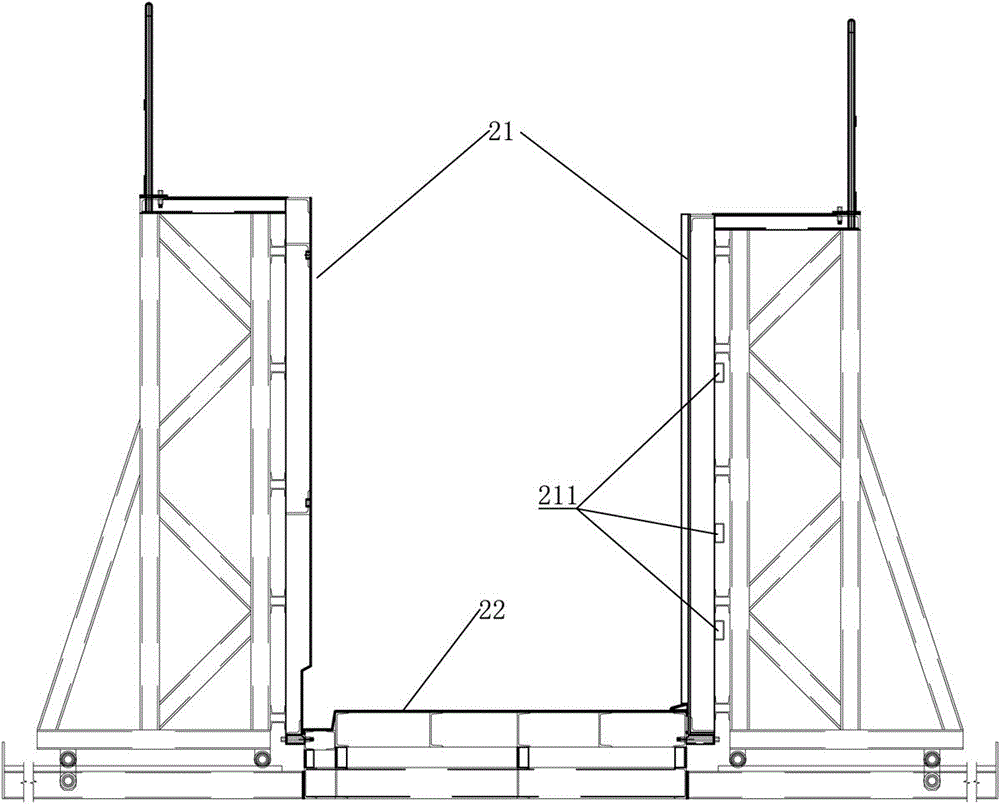

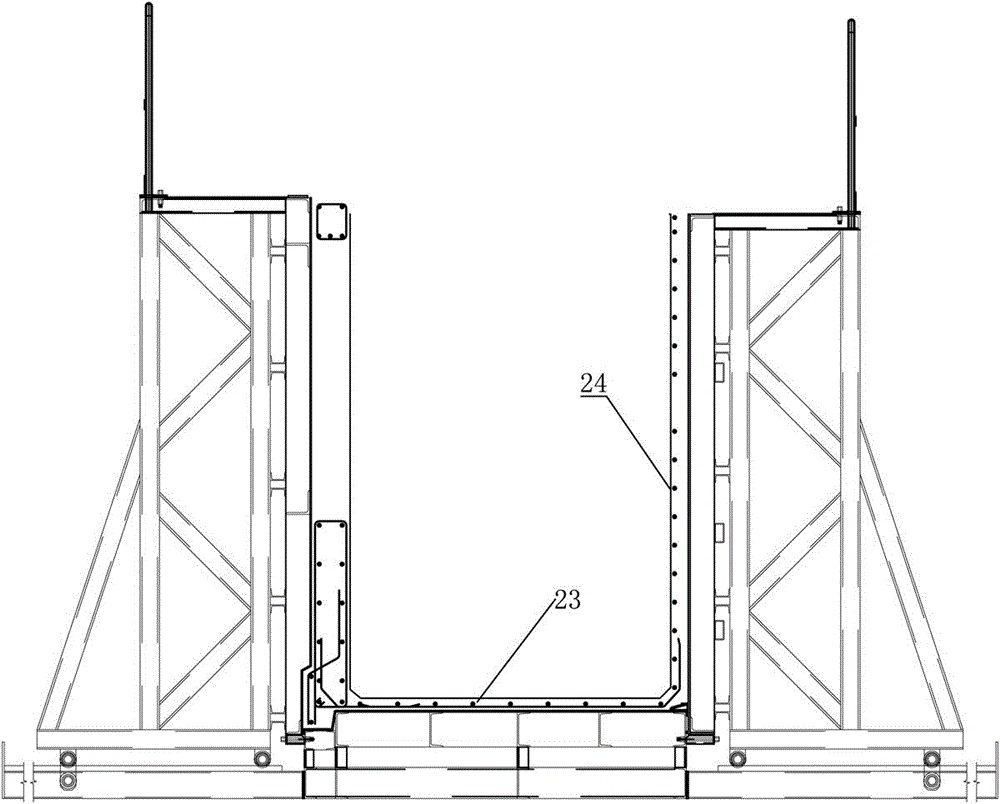

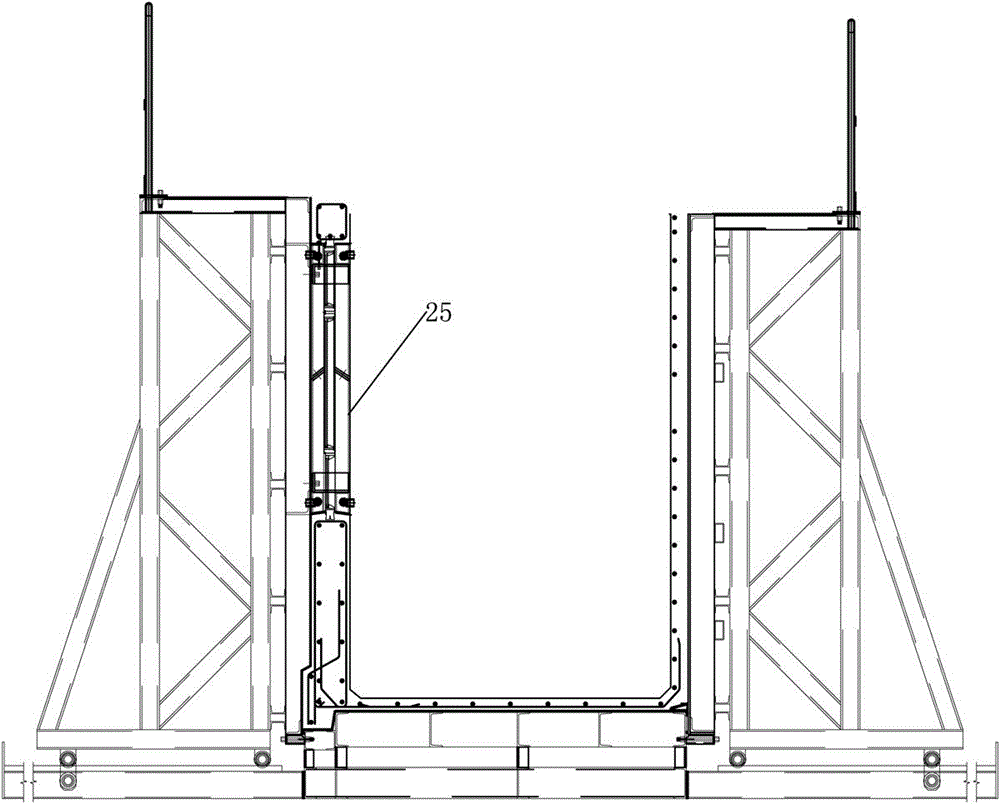

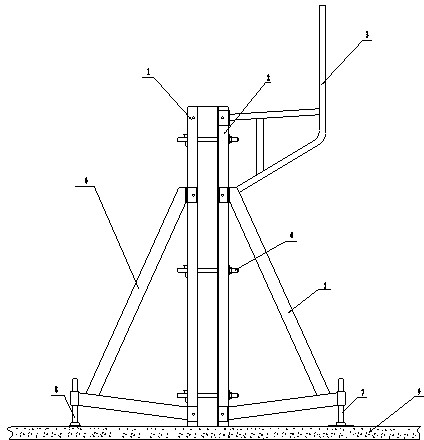

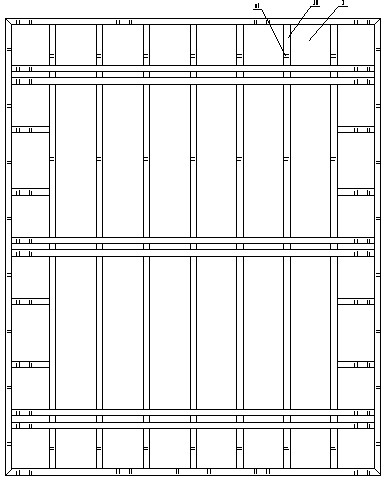

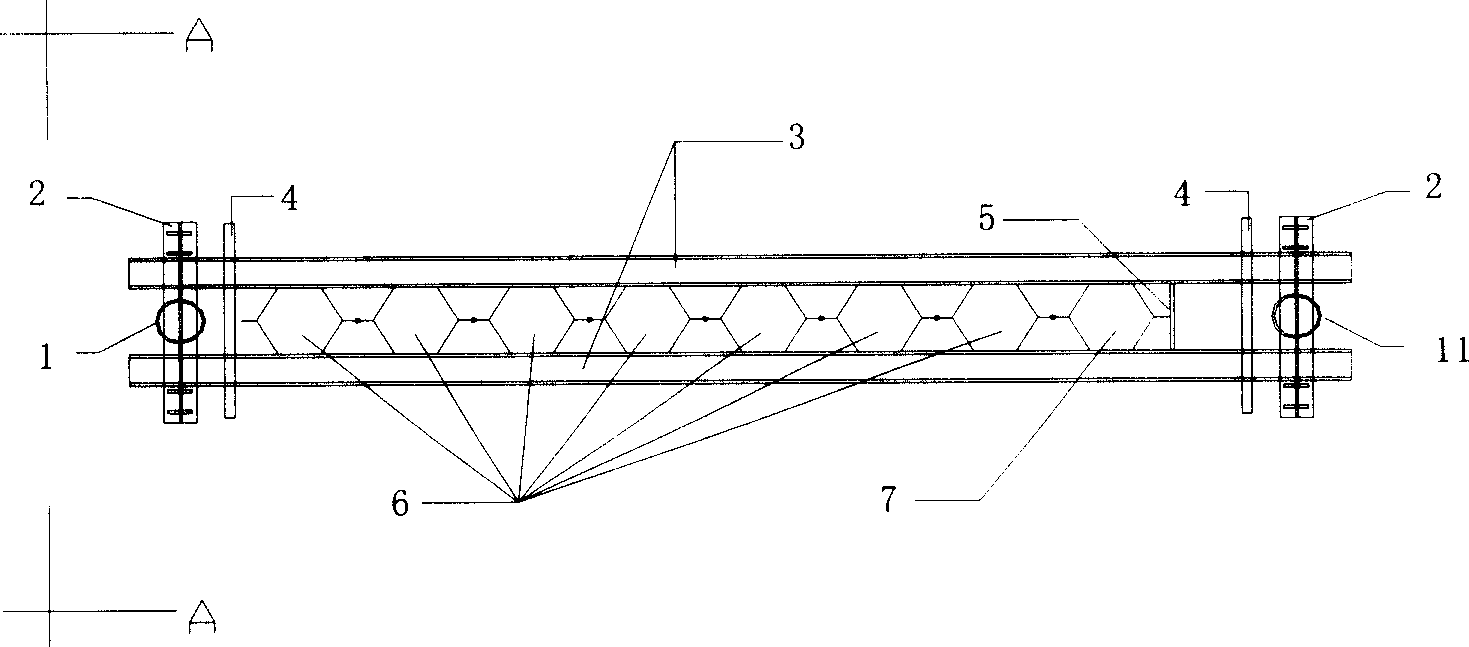

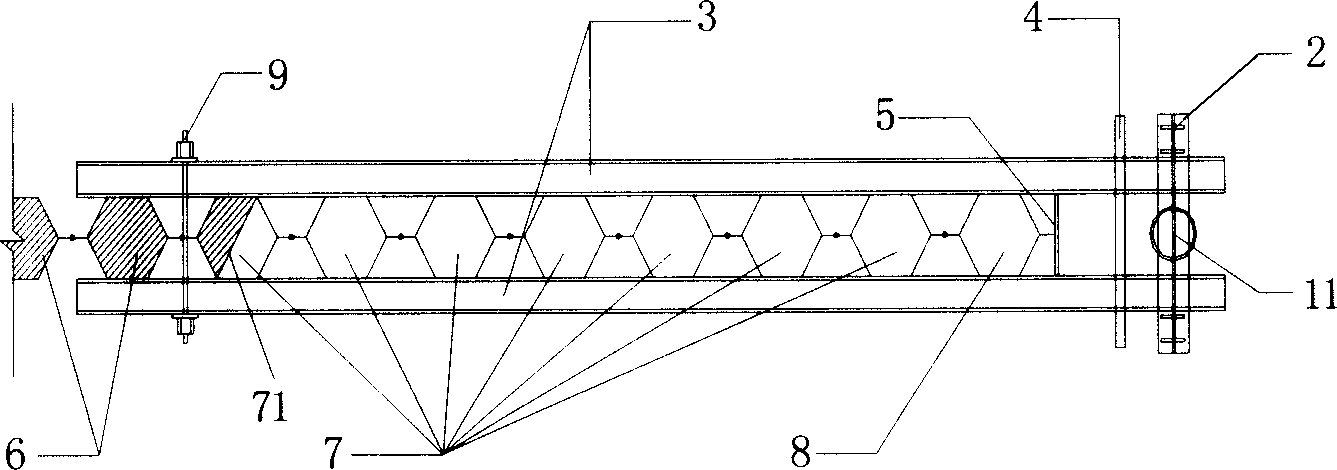

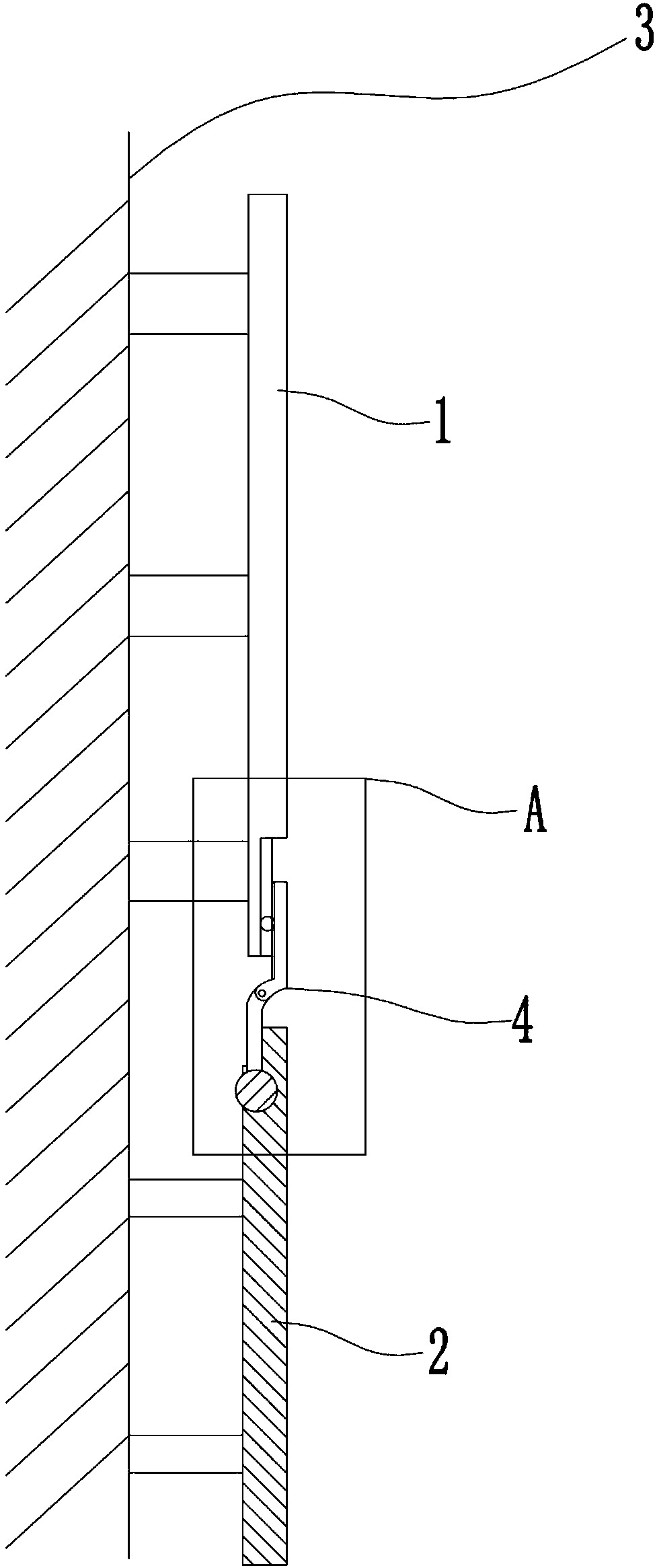

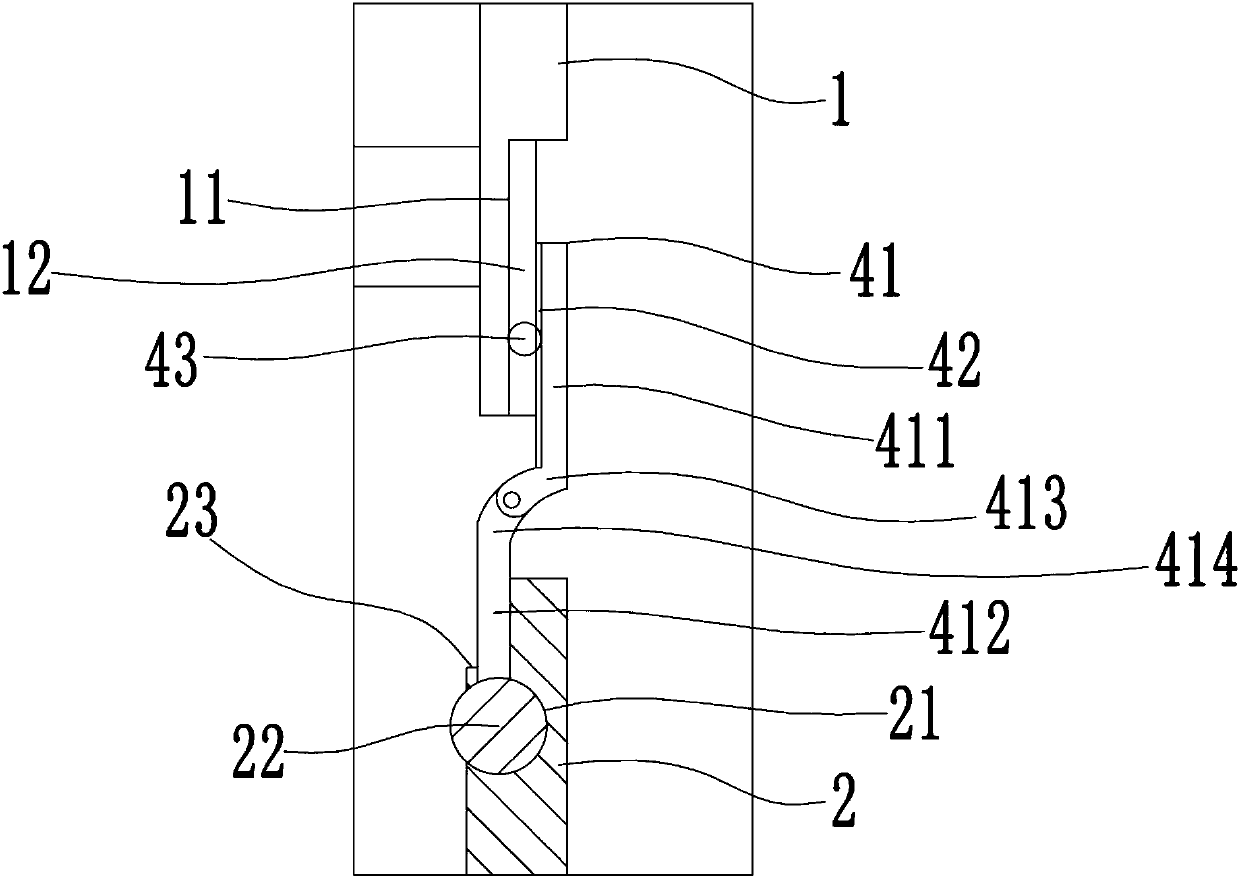

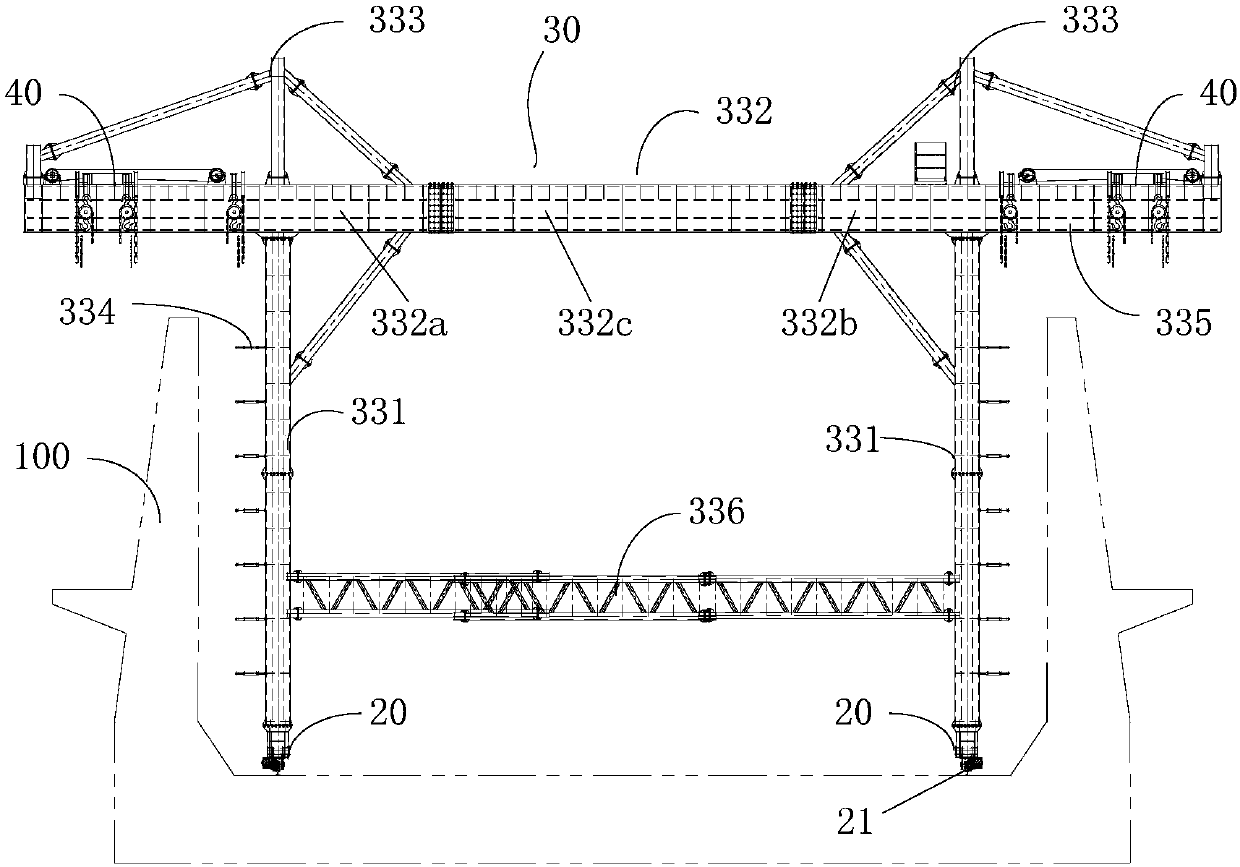

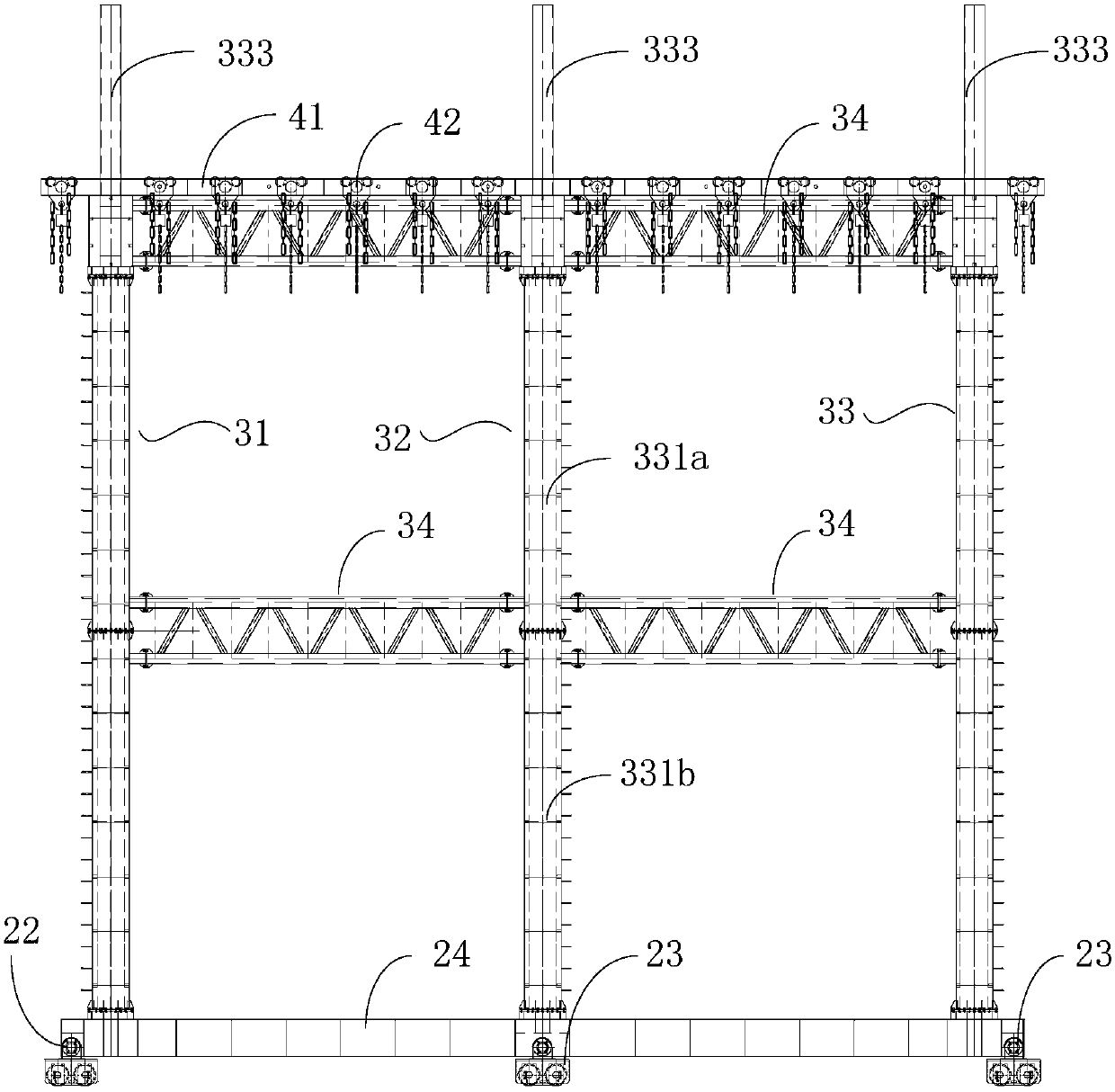

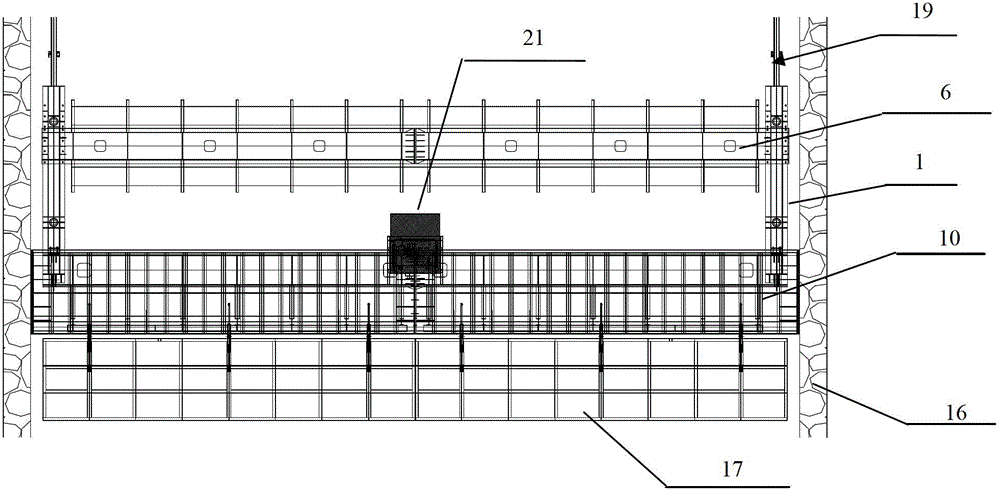

Adjusting type light movable formwork support and steel formwork capable of guaranteeing tightness of joint of new concrete and old concrete of lock chamber

PendingCN107816028ATight seamsNo root rotDry-docksClimate change adaptationRoot rotUltimate tensile strength

The invention discloses an adjusting type light movable formwork support and a steel formwork capable of guaranteeing tightness of a joint of new concrete and old concrete of a lock chamber. The steelformwork comprises an outer side formwork body and an inner side formwork body; a first retaining piece is arranged at the bottom of the inner side formwork body; a first open groove for storing a first rubber sealing piece is formed in the first retaining piece; and part of the first rubber sealing piece protrudes out of the first open groove and is attached to the inner side concrete wall of awall chamfer of the lock chamber. By adopting the steel formwork, the tightness of the joint of the new concrete and the old concrete in the connection position of the wall body chamber and a wall body can be guaranteed, on one hand, construction according to the structure design is guaranteed, and on the other hand, the phenomena of root rot and mortar leakage are avoided after the steel formworkis mounted. Gantries of the light movable formwork support adopt combined splicing structures of box beams and truss arms, the structural strength requirement is met, safety risks are reduced, the structural weight is decreased, the dimension of the formwork support is adjustable, and the characteristics of recycling, saving of the construction cost and the like are achieved.

Owner:安徽建工路港建设集团有限公司

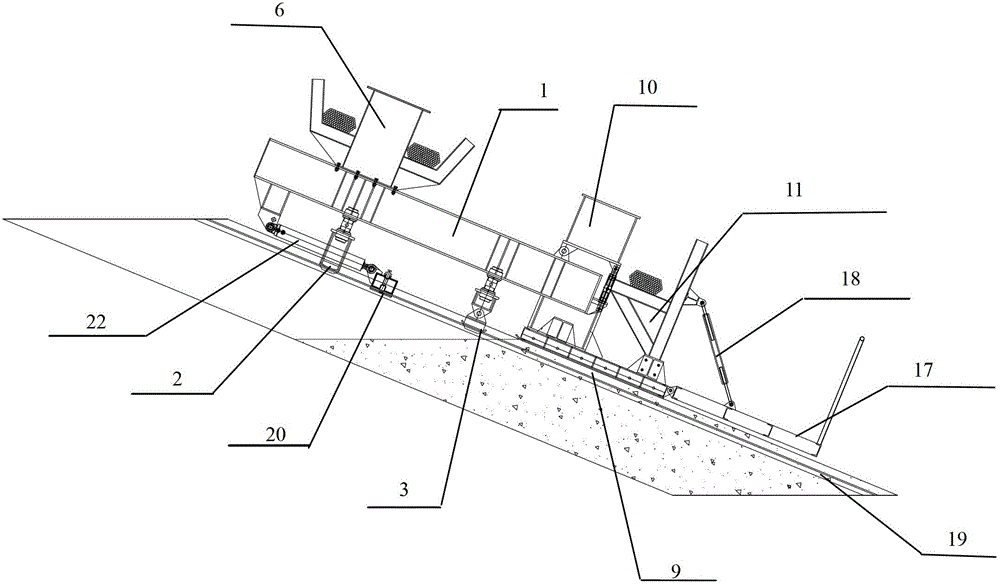

Slope hydraulic self-propelled concealed-rail drag mold

ActiveCN102720162ASolve problems limited by slope slopeFast constructionCoastlines protectionHydraulic pumpEngineering

The invention provides a slope hydraulic self-propelled concealed-rail drag mold, which comprises travel beams, a balance beam, a template system, a working platform, a hydraulic system and the like, wherein each travel beam consists of a crossbeam, a front sliding seat, a back sliding seat, adjusting screws and a cylinder block; the front sliding seat is in rigid connection with the crossbeam, and the back sliding seat is hinged with the crossbeam; the template system consists of a template, a bearing beam and a template system support frame; the bearing beam is parallel to the balance beam; two ends below the bearing beam and the balance beam are respectively provided with a travel beam in the vertical direction; the rear end of the template is provided with the template system support frame; the working platform is parallel to a rail, and is obliquely tensioned on the template system support frame through a spiral lock button; the hydraulic system mainly comprises a hydraulic pump station, advancing cylinders, a hydraulic pipeline and the like; the hydraulic pump station is arranged in the middle of the bearing beam; and an advancing cylinder is arranged below each of two travel beams. The drag mold is not limited to the slope gradient, can ensure that concrete can be continuously poured in large cube amount and large area, and ensures high pouring speed and good quality.

Owner:SINOHYDRO BUREAU 7 CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com