Electric transmission line iron stand foundation and construction method

A transmission line and basic technology, applied in infrastructure engineering, construction, etc., can solve the problems of difficult natural conditions, heavy workload, increased maintenance costs, etc., and achieve the effect of ensuring construction quality, tight joints, and shortening construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

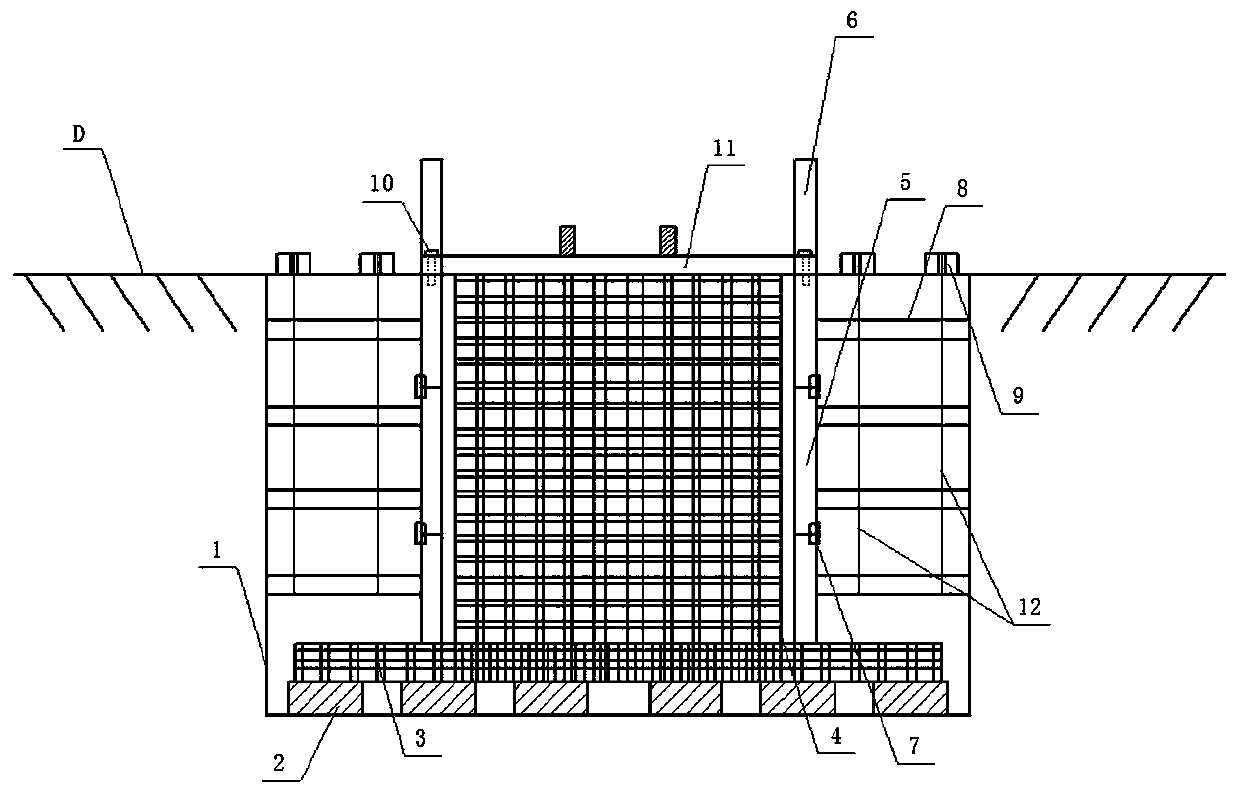

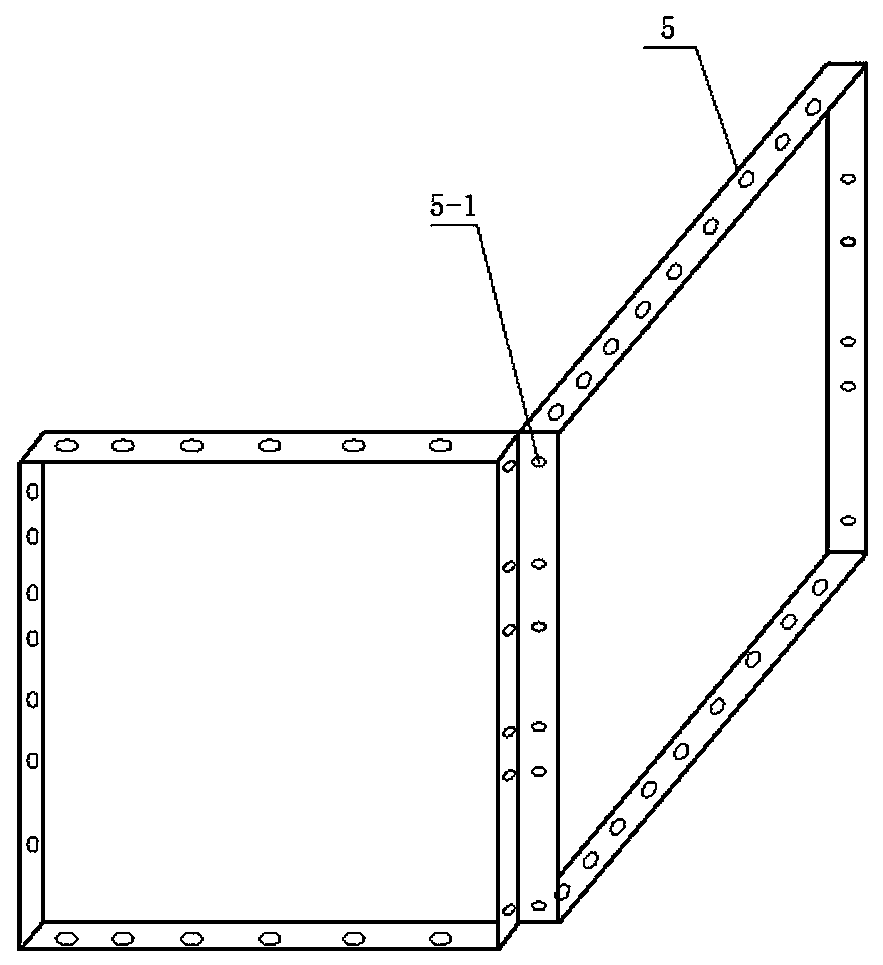

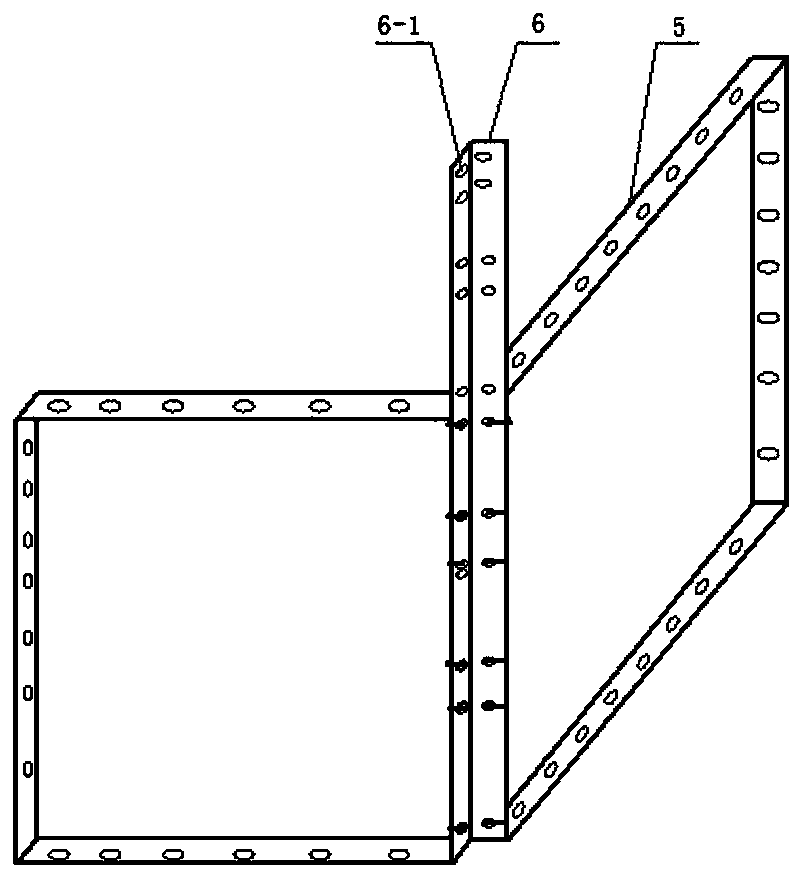

[0054] Example 1: An iron frame foundation for a transmission line, including floor reinforcement 3 and column reinforcement 4. Bricks 2 are arranged at the bottom of the floor reinforcement 3, and the column reinforcement 4 is placed at the center of the floor reinforcement 3 There are four sets of support templates set around the four sets of support templates, each set of support templates are vertically stacked on top and bottom of at least three templates 5; a right-angle fixed plate 6 is set at the corner between the adjacent two sets of support templates At least three top rods 8 are provided between the outside of each group of supporting formwork and the inner wall of the foundation pit 1, and a supporting plate 9 is provided above the opening of the foundation pit. The supporting plate 9 and the top rod 8 are sequentially sheathed by a soft rope The outer part of the top rod and the supporting plate 9 are fixed together; the upper middle part of the four groups of supp...

Embodiment 2

[0055] Embodiment 2: The construction method of the iron frame foundation of the transmission line includes the following steps:

[0056] B. Construction preparation:

[0057] 1) Tool preparation: select measuring instruments suitable for construction use, including theodolite, steel tape, tower ruler, flower pole, level ruler, scientific calculator; complete foundation pit excavation, backfilling, foundation pouring, grounding trench excavation and Various tools for backfilling; in addition, small nails, string, paint, hammer, plumb should be prepared as auxiliary materials; the measuring instruments and measuring tools should be checked and corrected before use;

[0058] 2) Line retest: check straight line and angle of rotation, check pole position height difference and gear distance, check crossover position and elevation, check wind deflection influence points; check pole and tower position comprehensively, including: basic protection Scope, the height difference of the pole tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com