Concrete vibrator for easy support and working method thereof

A vibrator and concrete technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the inconvenience of adjusting the height of the scraping teeth, the inclination angle of the vibrating rod, and the auxiliary scraping of concrete with different heights equality issue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

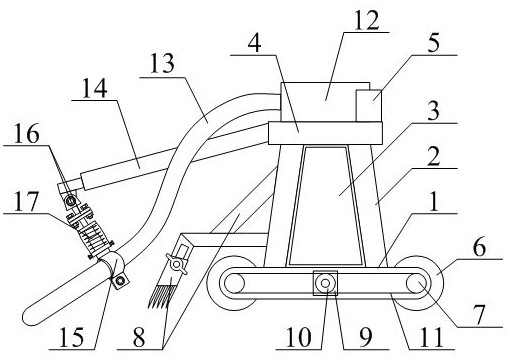

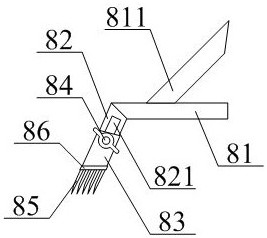

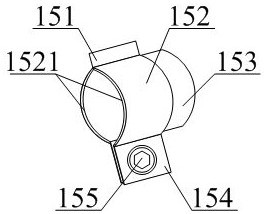

[0043] as attached figure 1 And attached figure 2 shown

[0044] The present invention provides a concrete vibrator that is easy to support, including a transverse bottom plate 1, support legs 2, a tool storage frame 3, a transverse plate 4, a junction box 5, a moving wheel 6, a driven wheel 7, and an adjustable auxiliary scraping frame structure 8. Drive motor 9, driving wheel 10, transmission belt 11, vibrating motor 12, vibrating rod 13, mounting frame 14, clamping fixed frame structure 15, angle adjustment fixed frame structure 16 and buffer bracket structure 17, the support The bolts of leg 2 are installed on the left and right sides of the upper part of the transverse bottom plate 1; the screws of the tool storage frame 3 are installed on the inner side of the supporting leg 2; the bolts of the transverse plate 4 are installed on the upper part of the supporting leg 2; the junction box 5 screws are installed on the upper right side of the transverse plate 4; the movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com