Patents

Literature

850results about How to "Easy to adjust the length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-rotation link

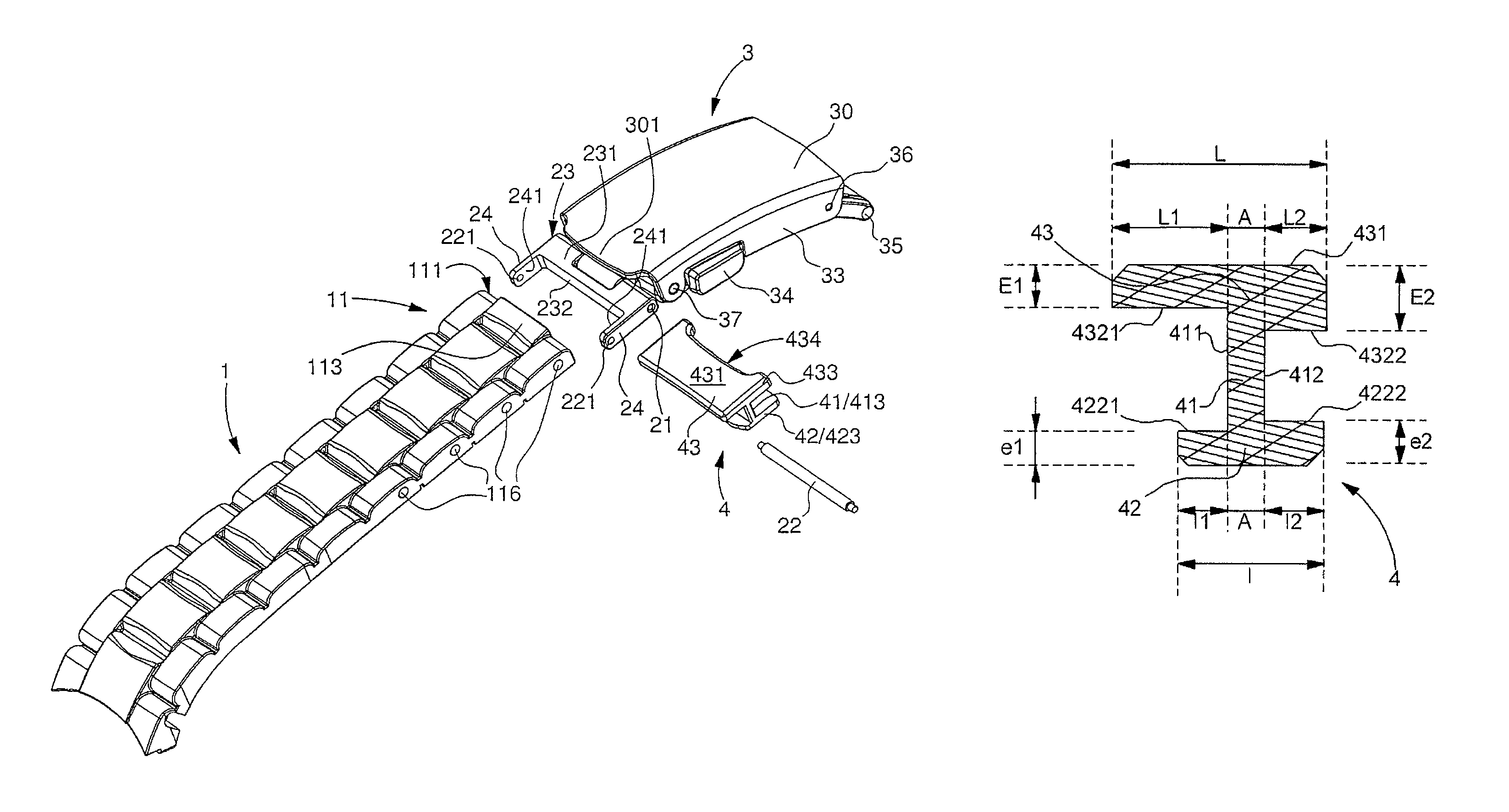

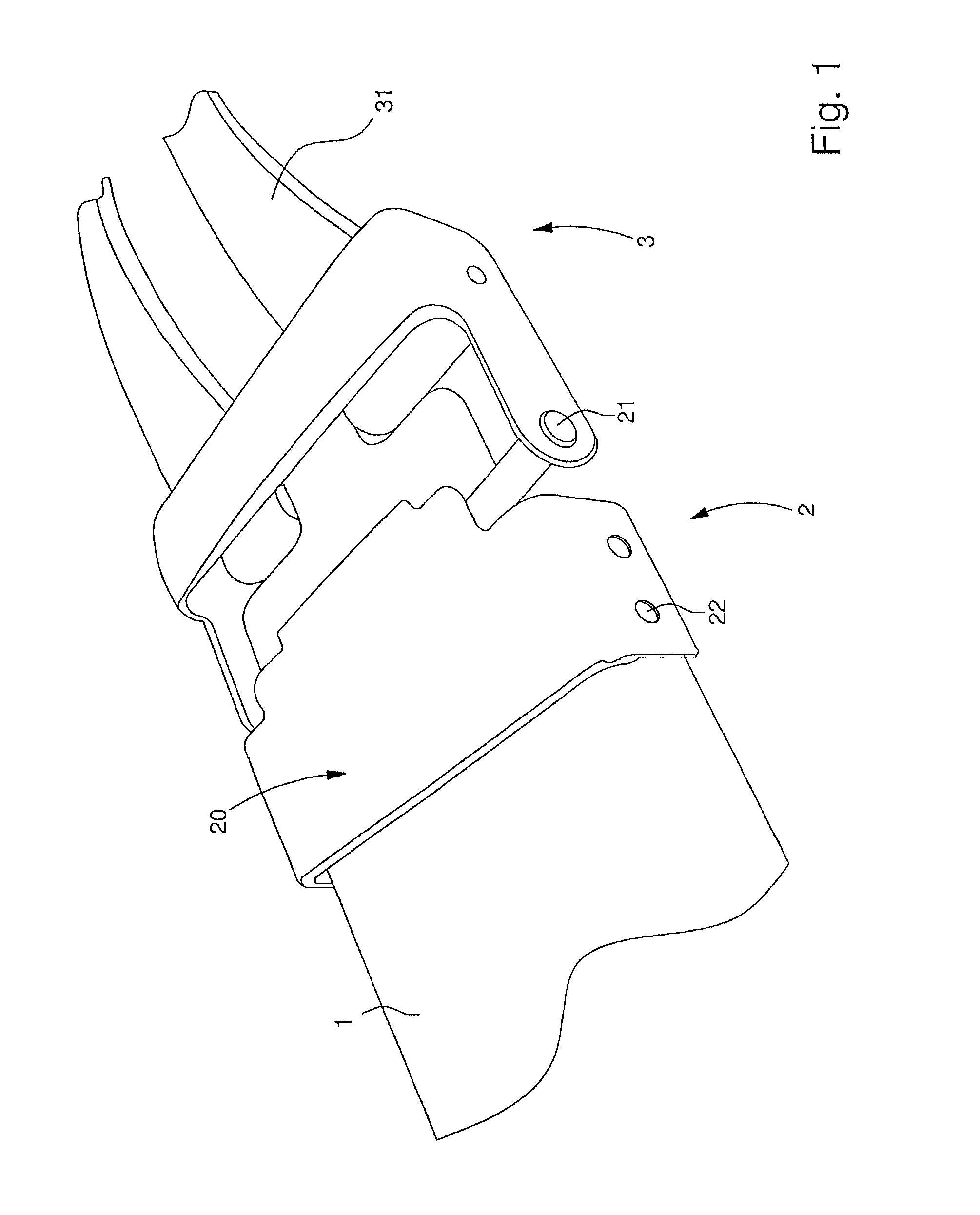

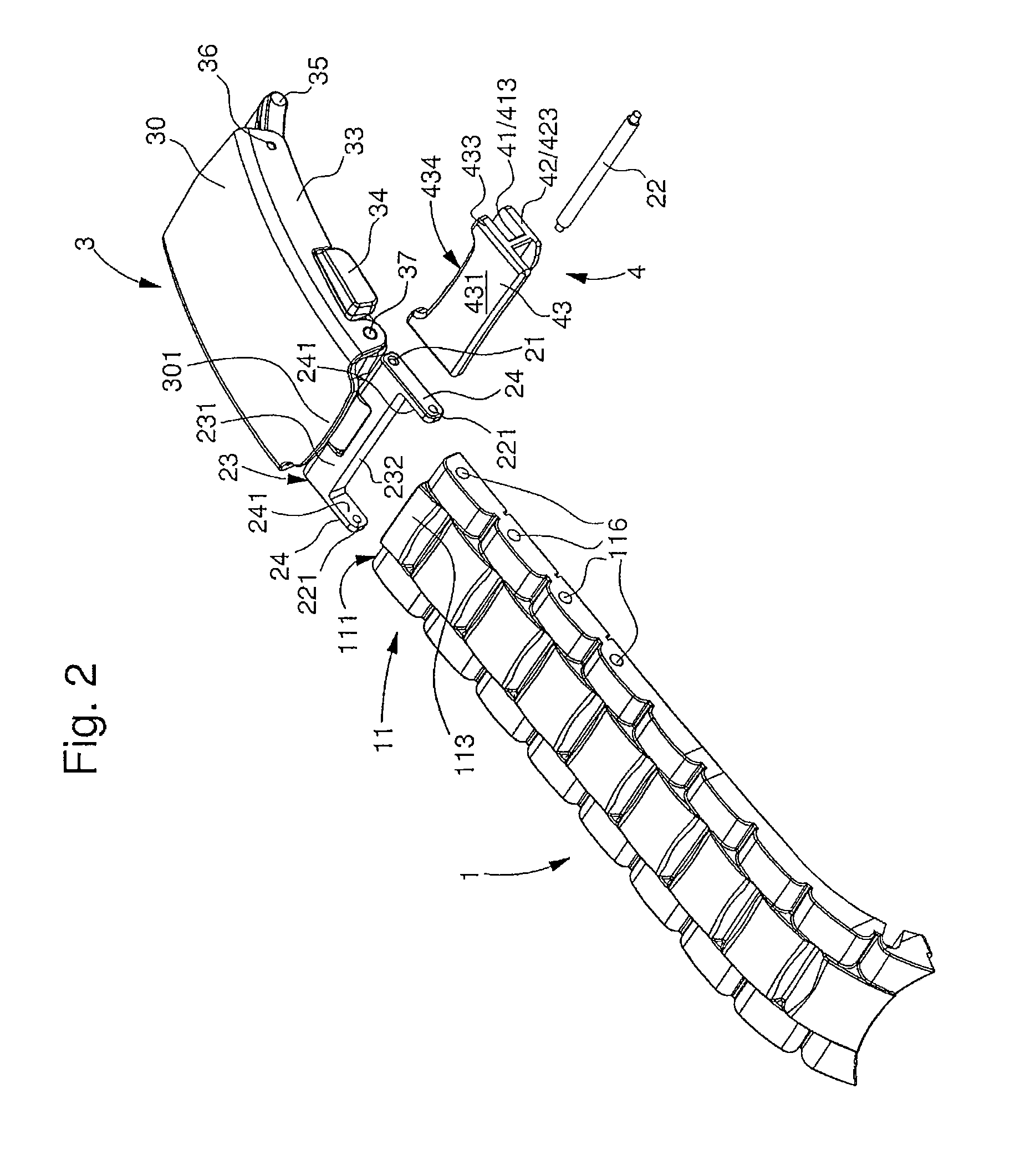

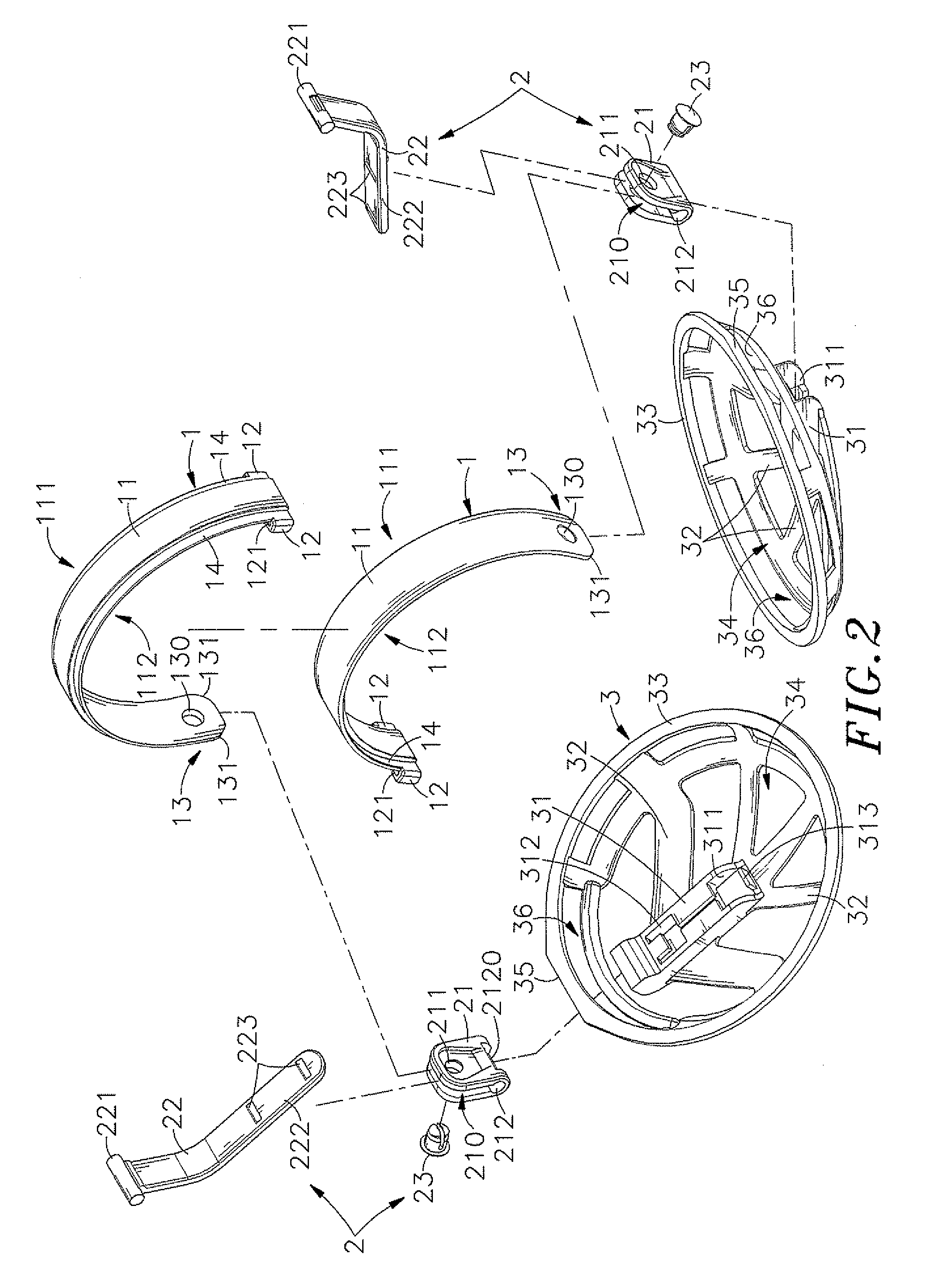

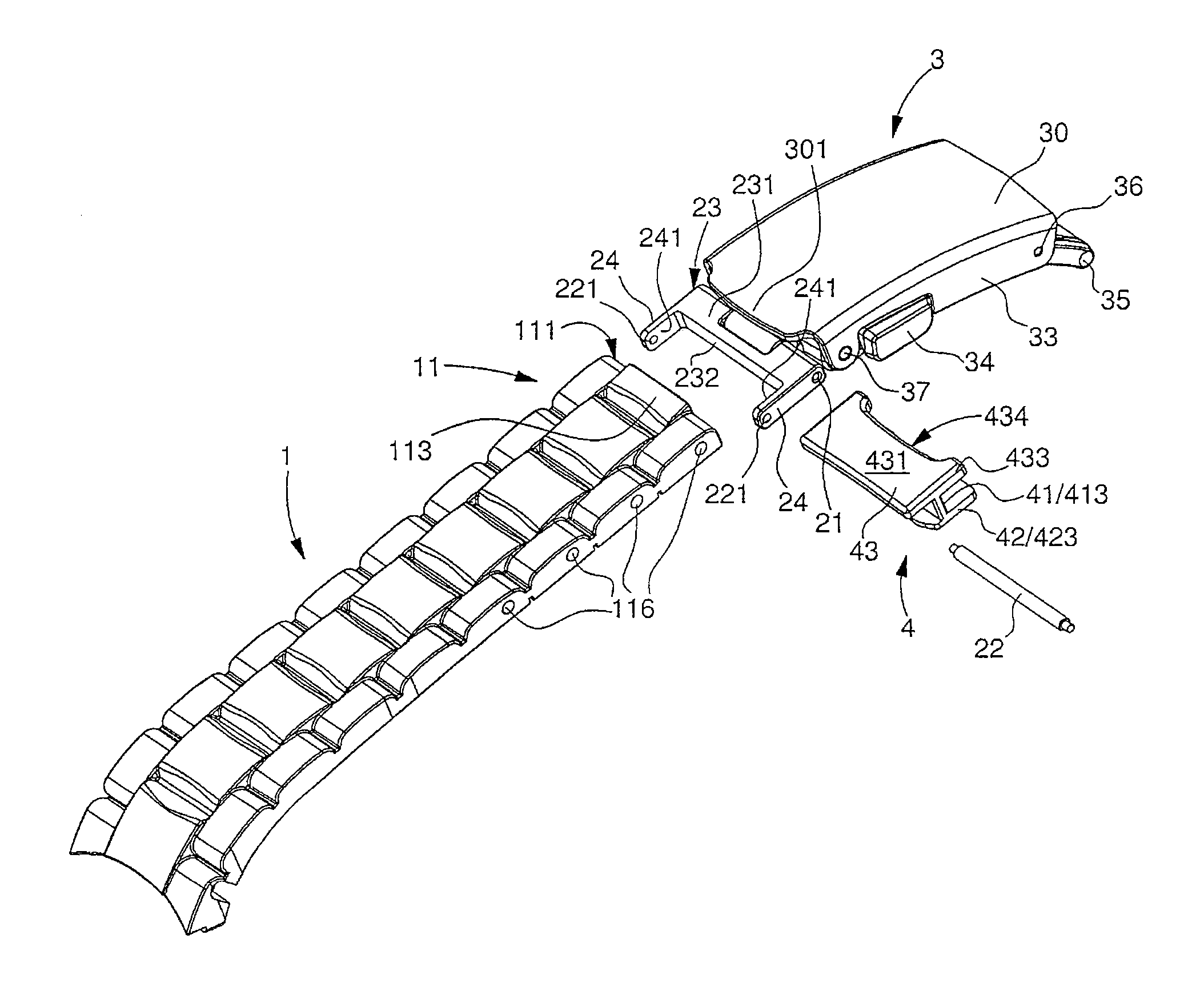

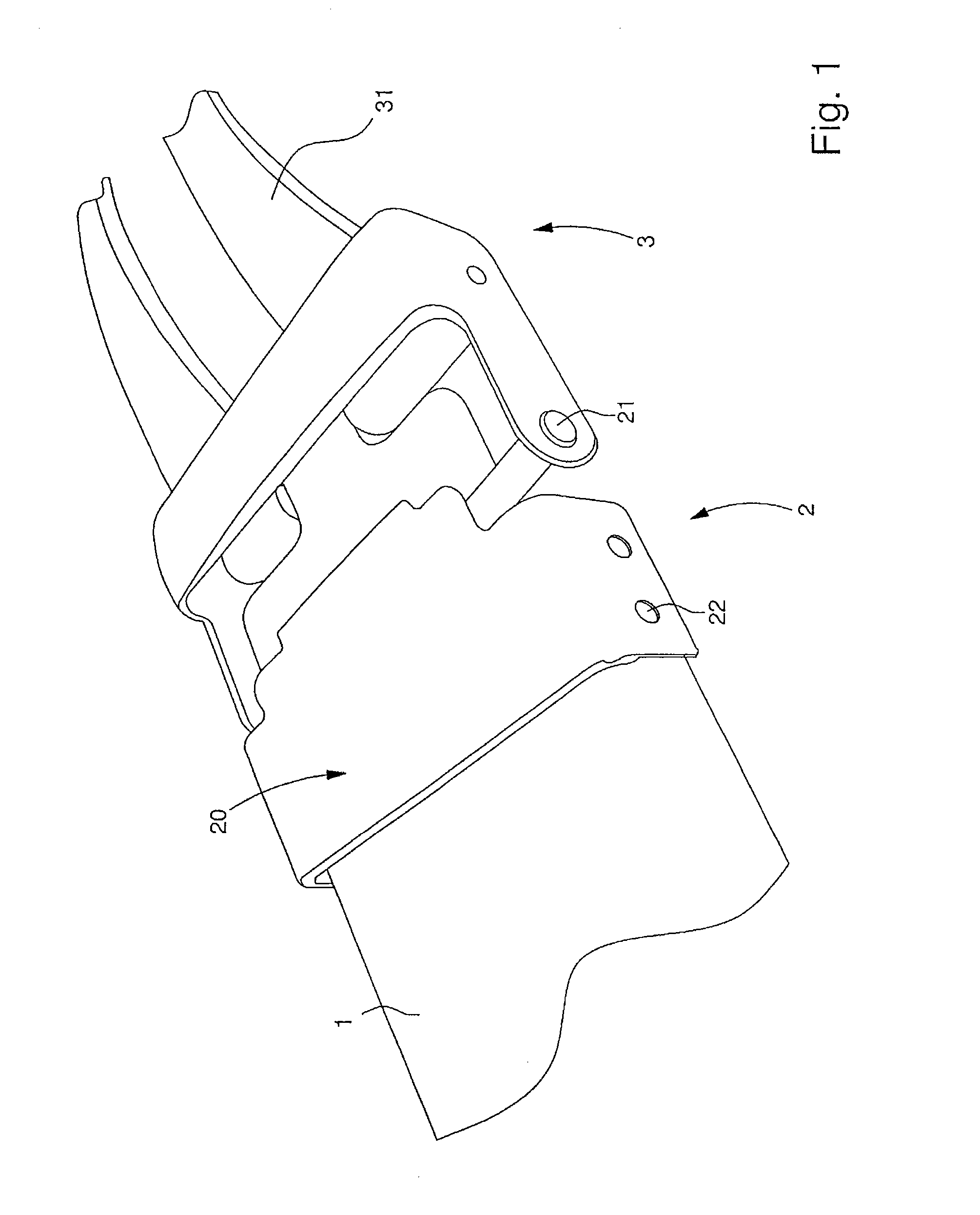

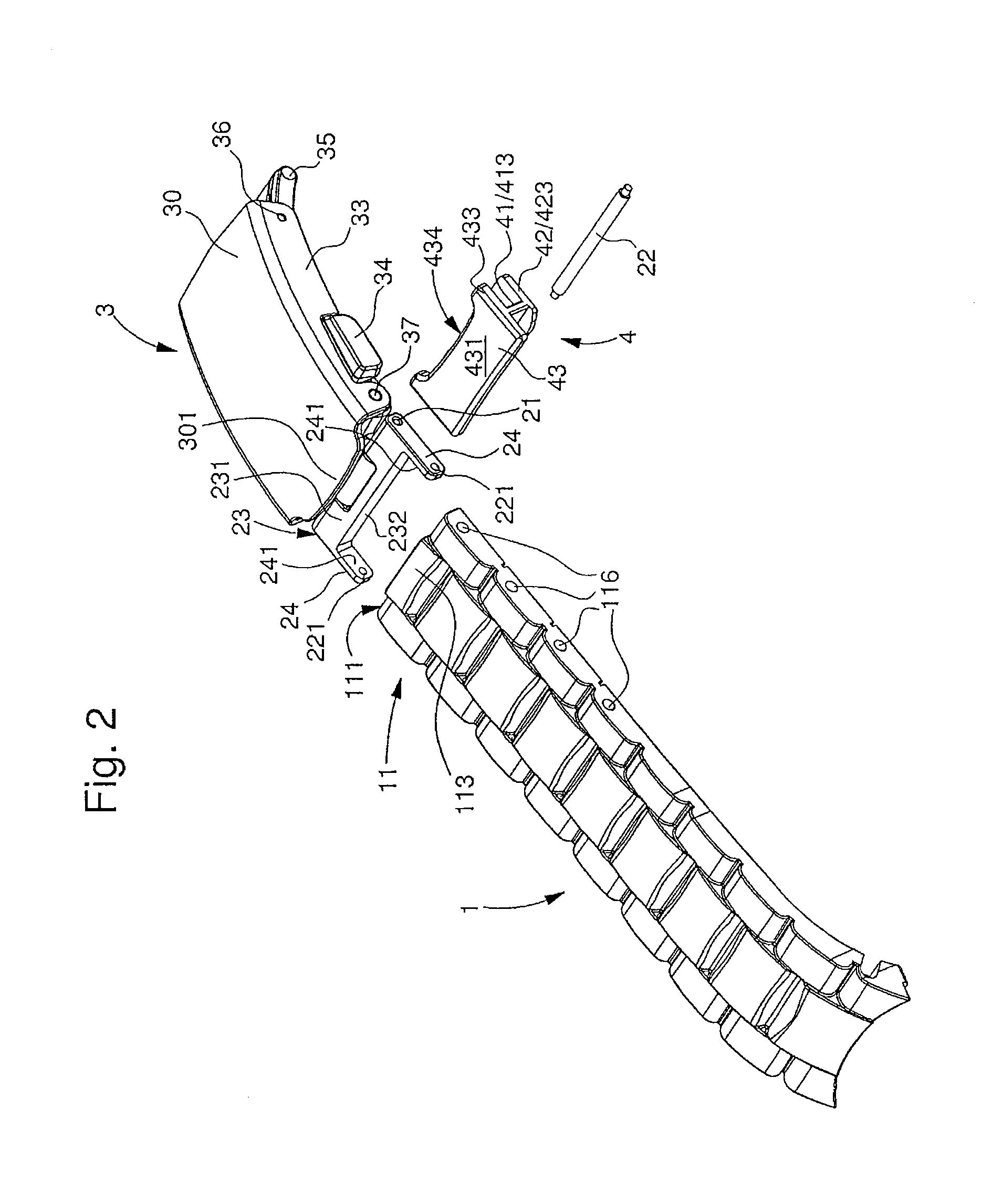

ActiveUS8601784B2Easy to adjust the lengthImprove aestheticsBraceletsWrist-watch strapsLower wingUpper wing

Link for a wristwatch, characterized in that it comprises a central core connecting a lower wing and an upper wing.

Owner:THE SWATCH GROUP MANAGEMENT SERVICES

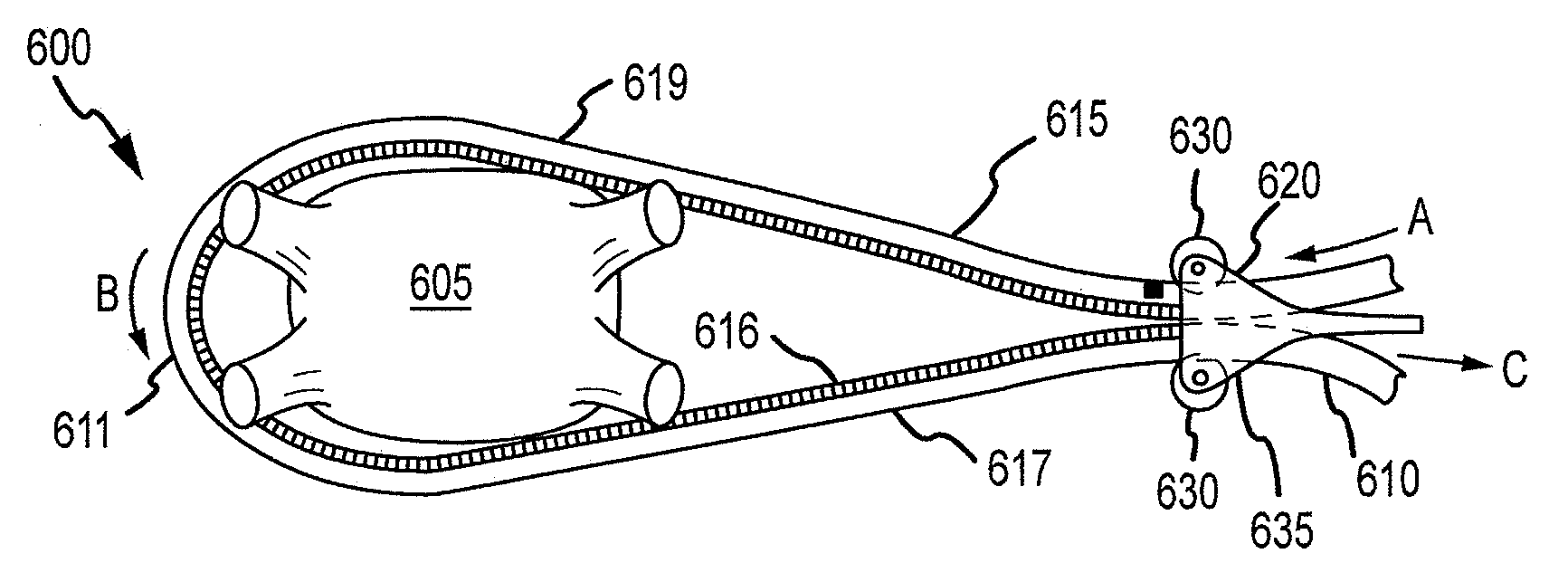

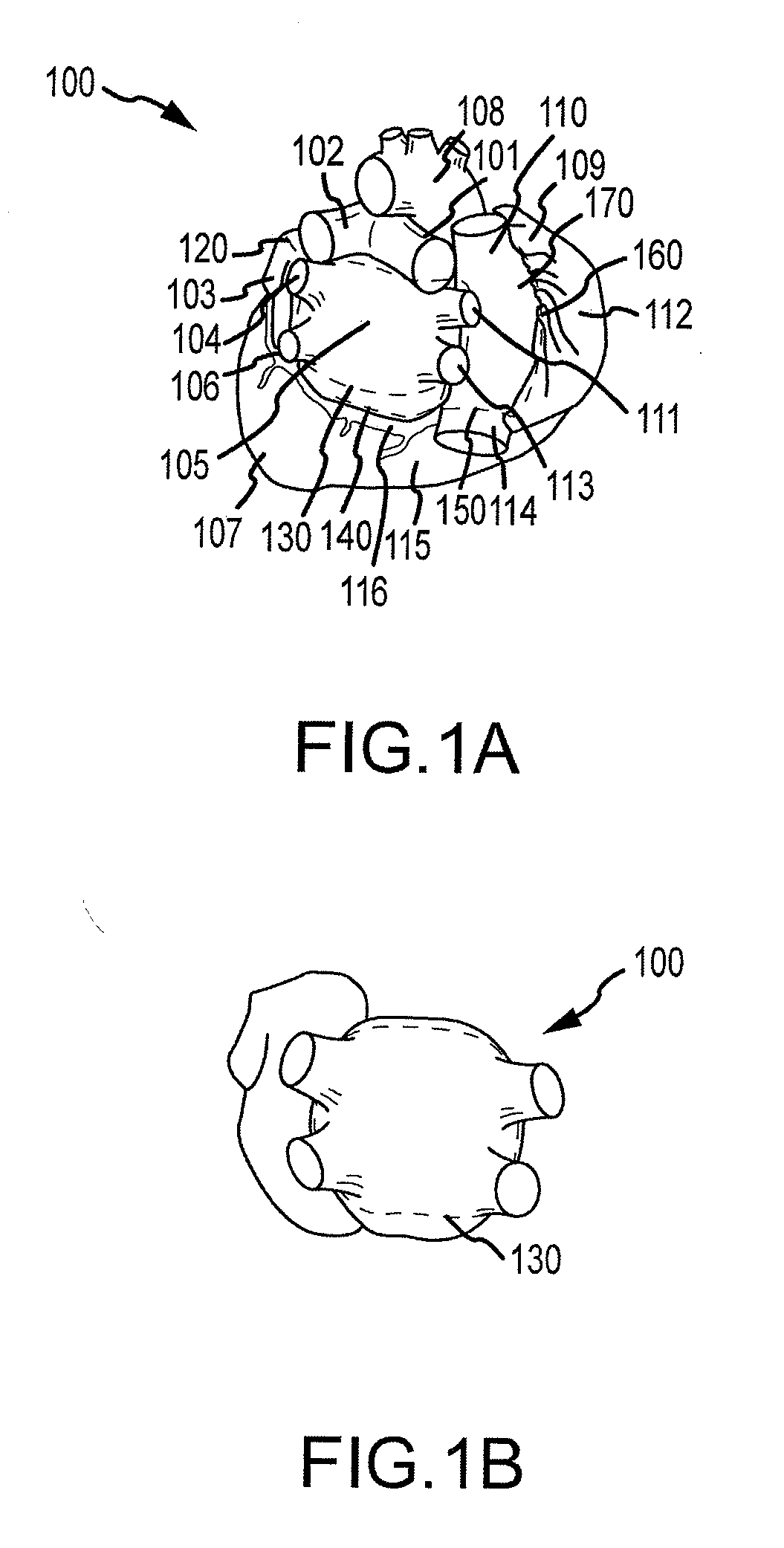

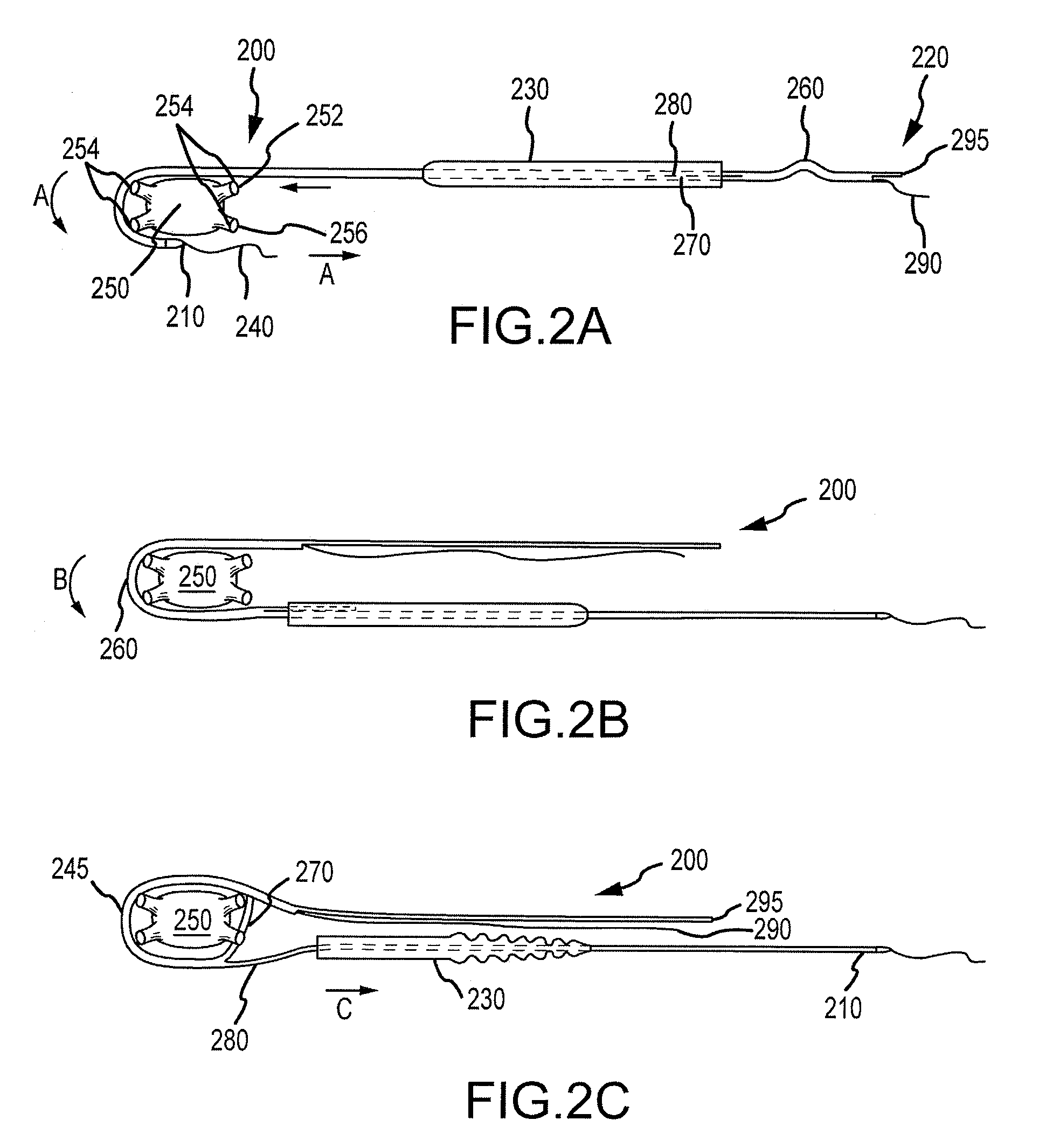

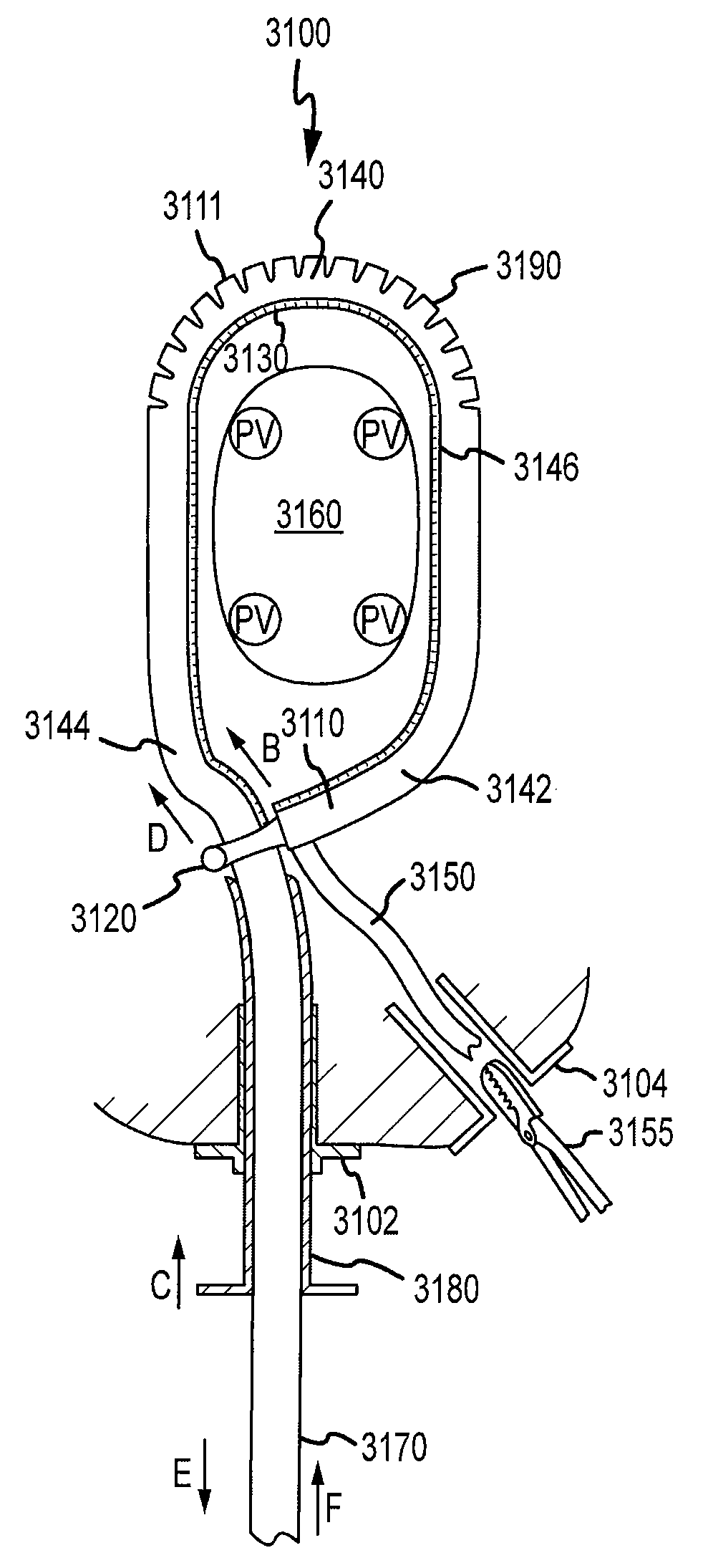

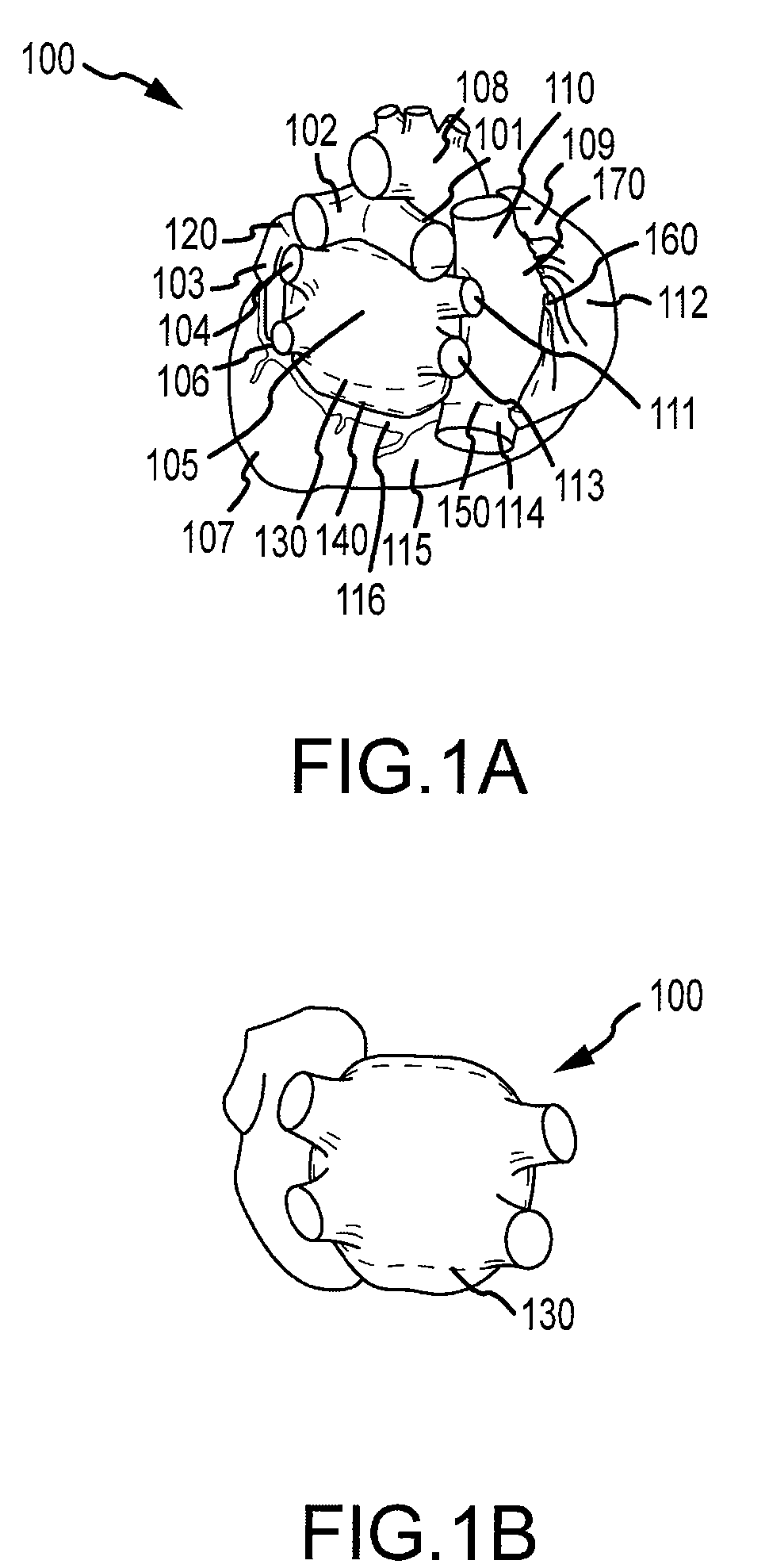

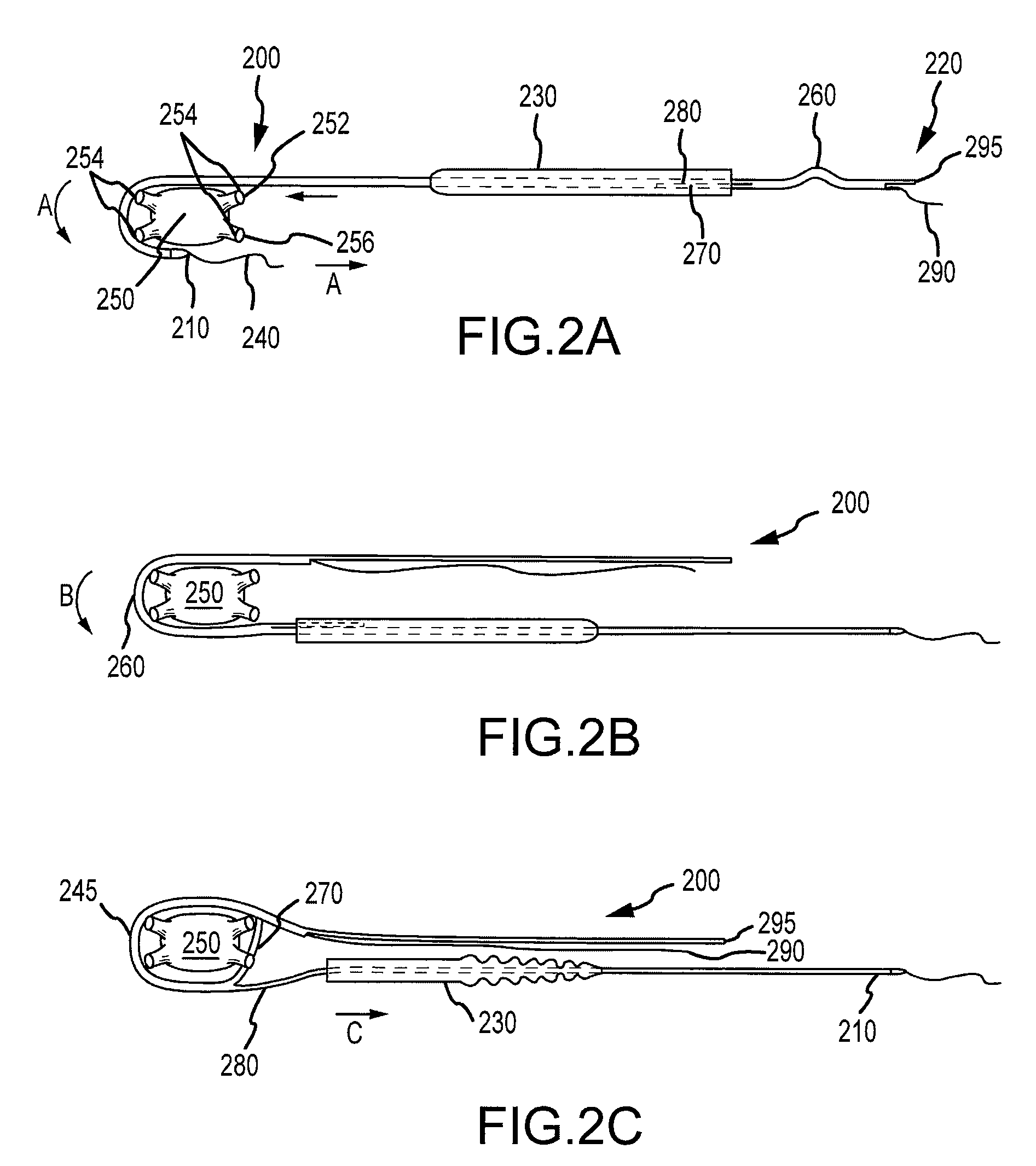

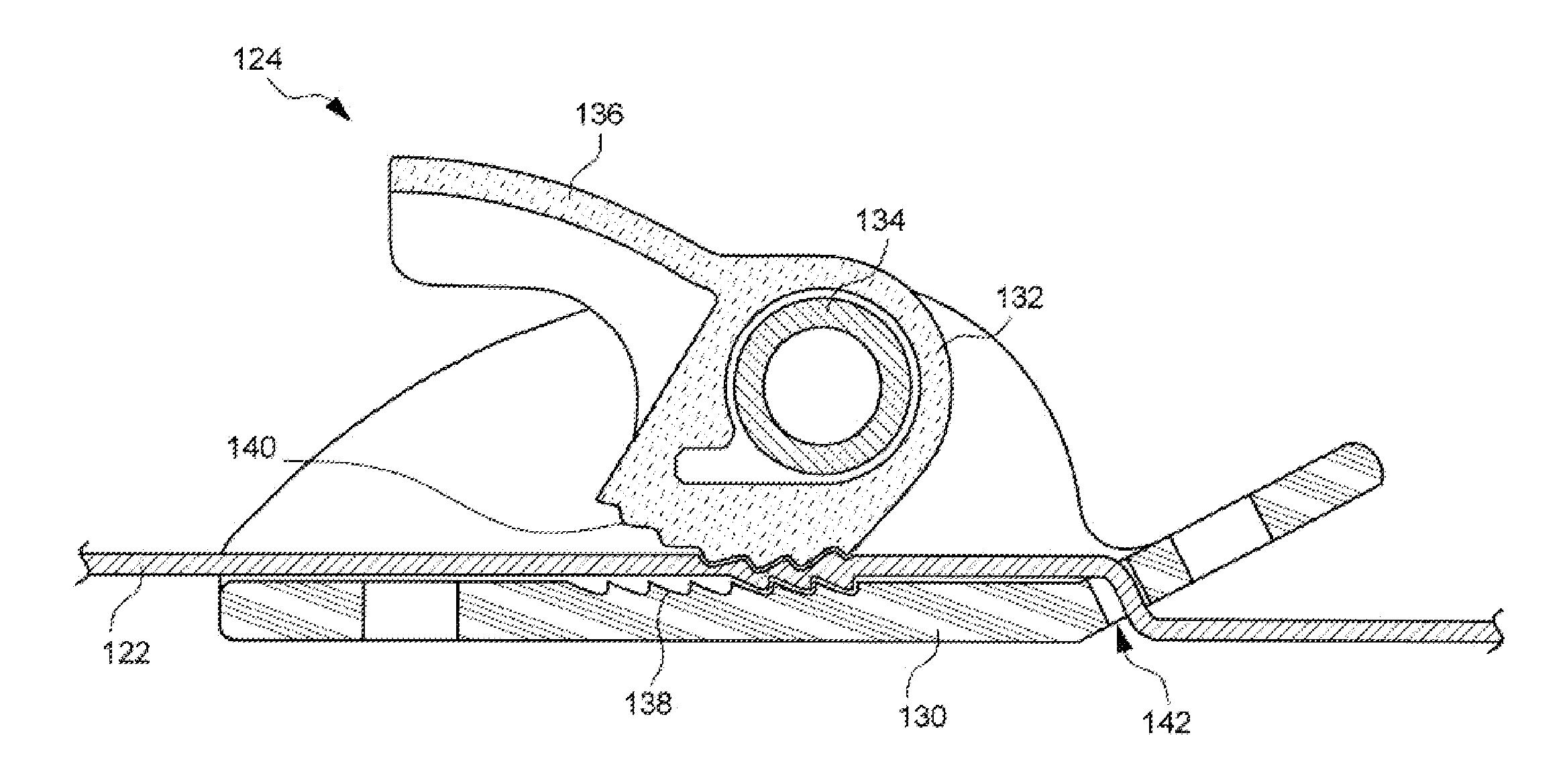

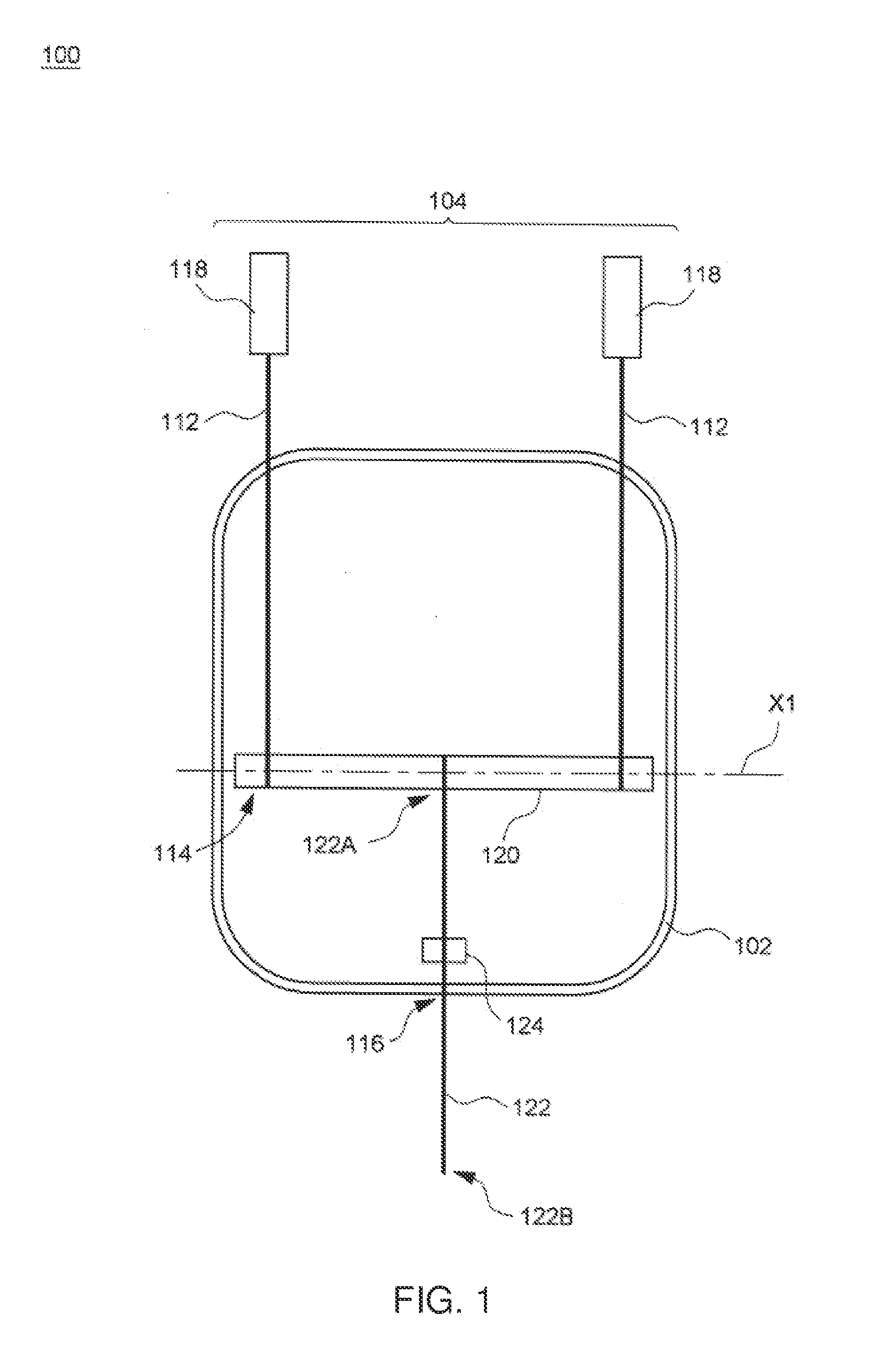

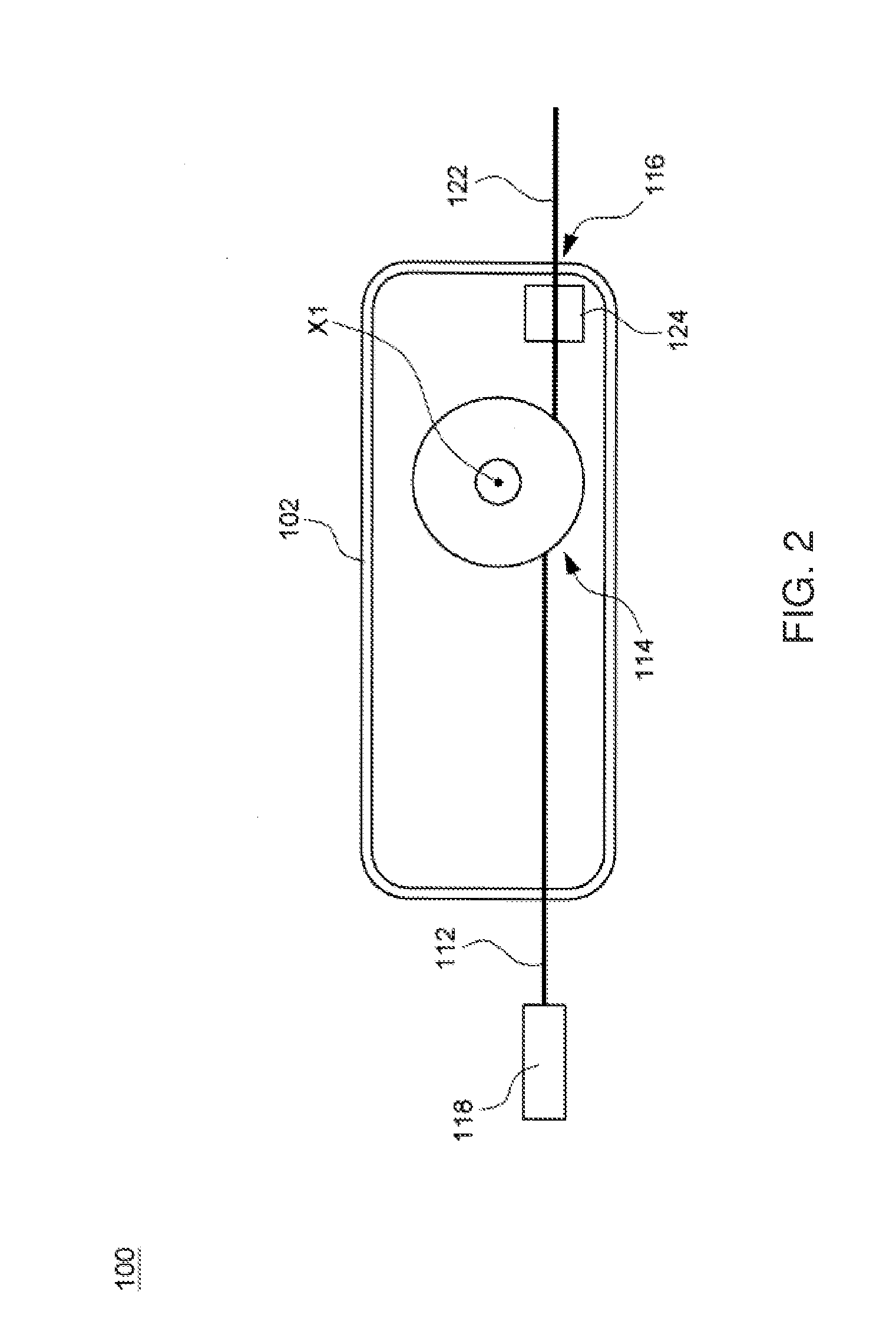

Cardiac ablation systems and methods

ActiveUS20090048591A1Rapid and effective ablative lesionEasy to adjust the lengthSurgical instruments for heatingCardiac AblationBiomedical engineering

Cardiac ablation systems and methods of their use and manufacture involve an ablation mechanism, a stabilizer mechanism, and a cinching mechanism that urges the ablation mechanism toward a patient tissue. Embodiments encompass methods for administering epicardial and endocardial lesions, including box lesions and connecting lesions, to patient tissue.

Owner:ATRICURE +1

Cardiac ablation systems and methods

ActiveUS20080294154A1Rapid and effective ablative lesionEasy to adjust the lengthChiropractic devicesEye exercisersBiomedical engineeringCardiac Ablation

Cardiac ablation systems and methods of their use and manufacture involve an ablation mechanism, a stabilizer mechanism, and a cinching mechanism that urges the ablation mechanism toward a patient tissue. Embodiments encompass methods for administering epicardial and endocardial lesions, including box lesions and connecting lesions, to patient tissue.

Owner:ATRICURE +1

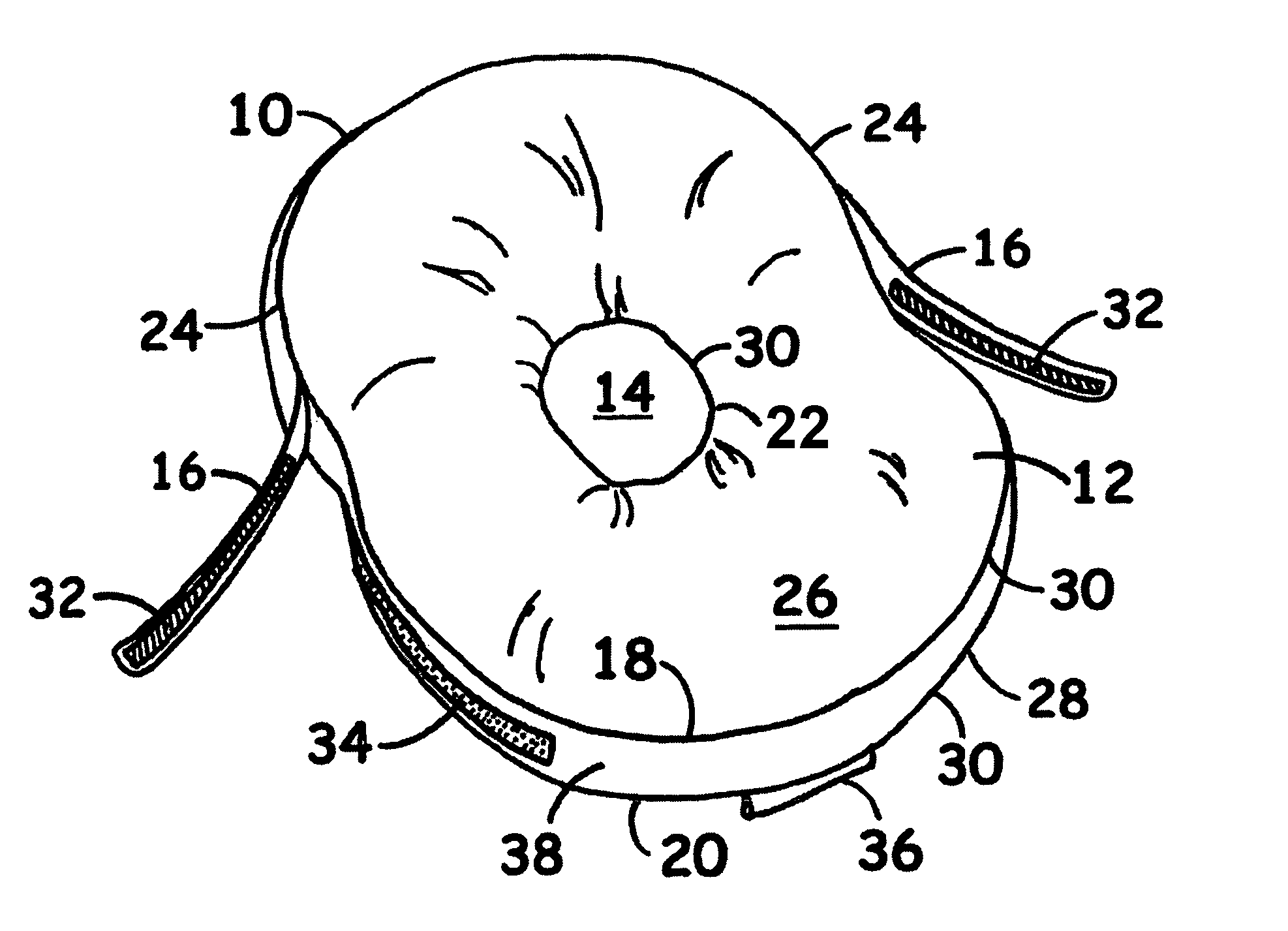

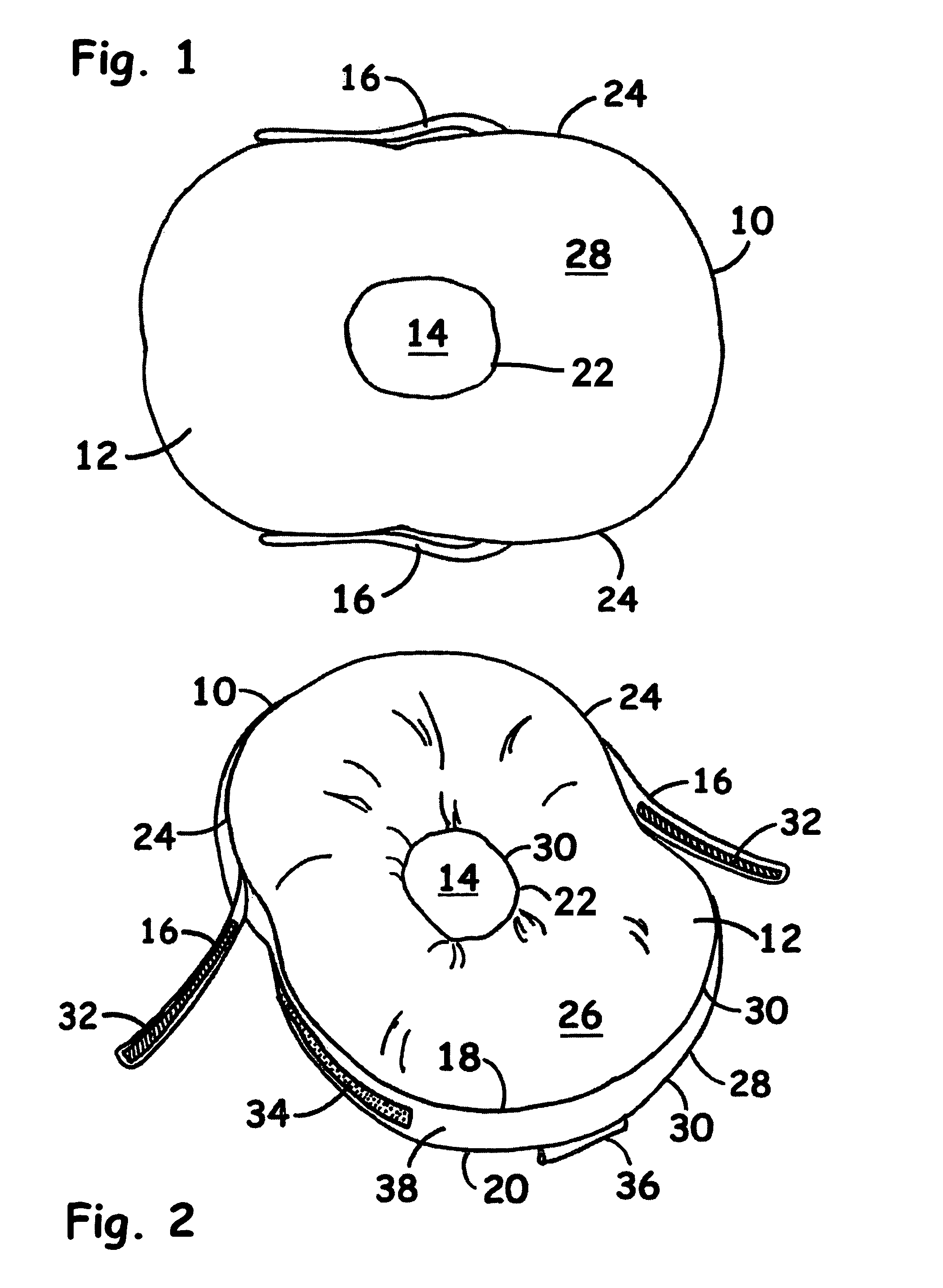

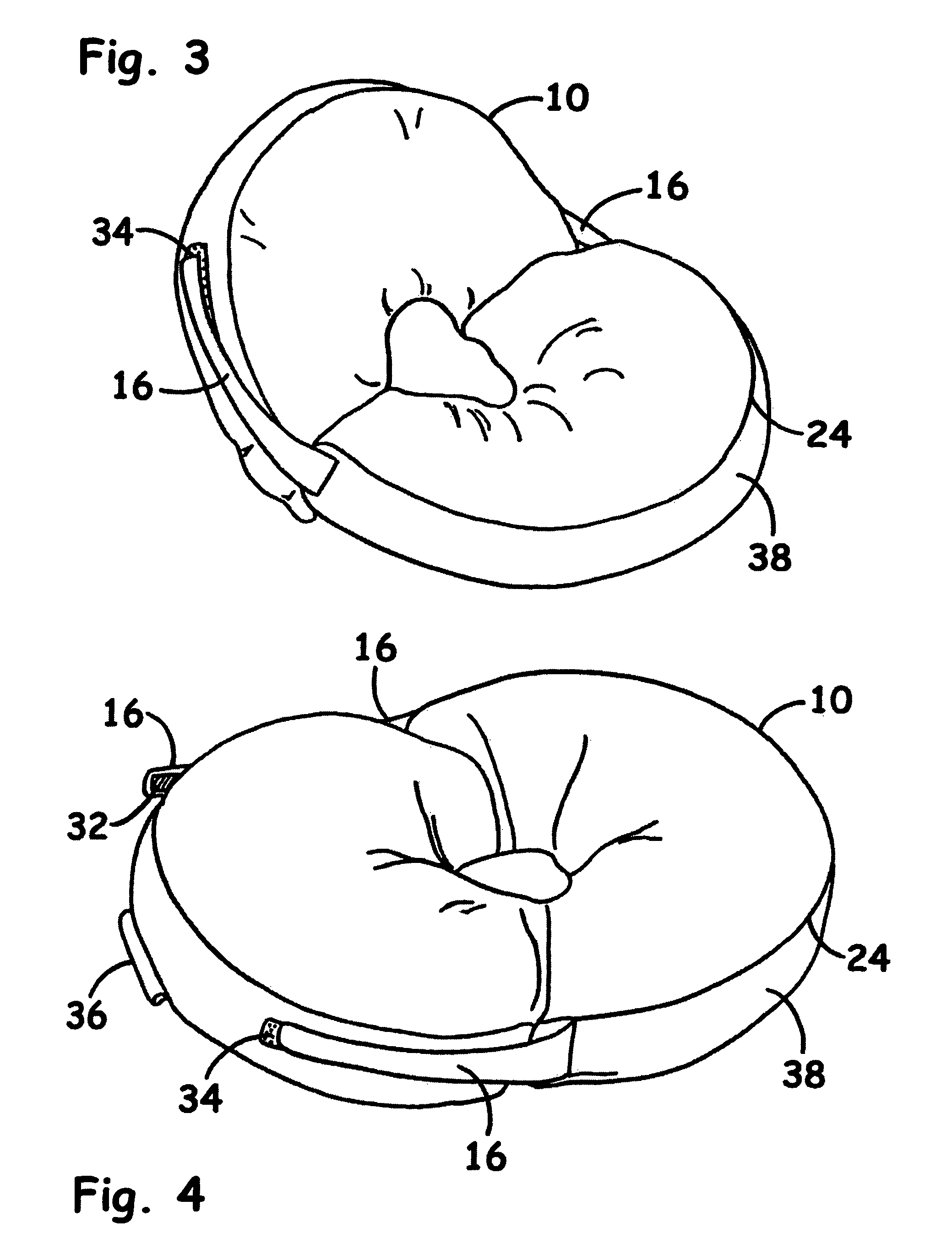

Adjustable contoured baby bathing or pet cushion

A contoured adjustable baby or pet bathing cushion with a substantially oval shaped outer portion and a depressed central portion, the substantially oval shaped outer portion being provided with adjustable tabs to facilitate adjustment of the length of the cushion to accommodate an infant, a larger baby, or a pet.

Owner:LEACH JAMIE S

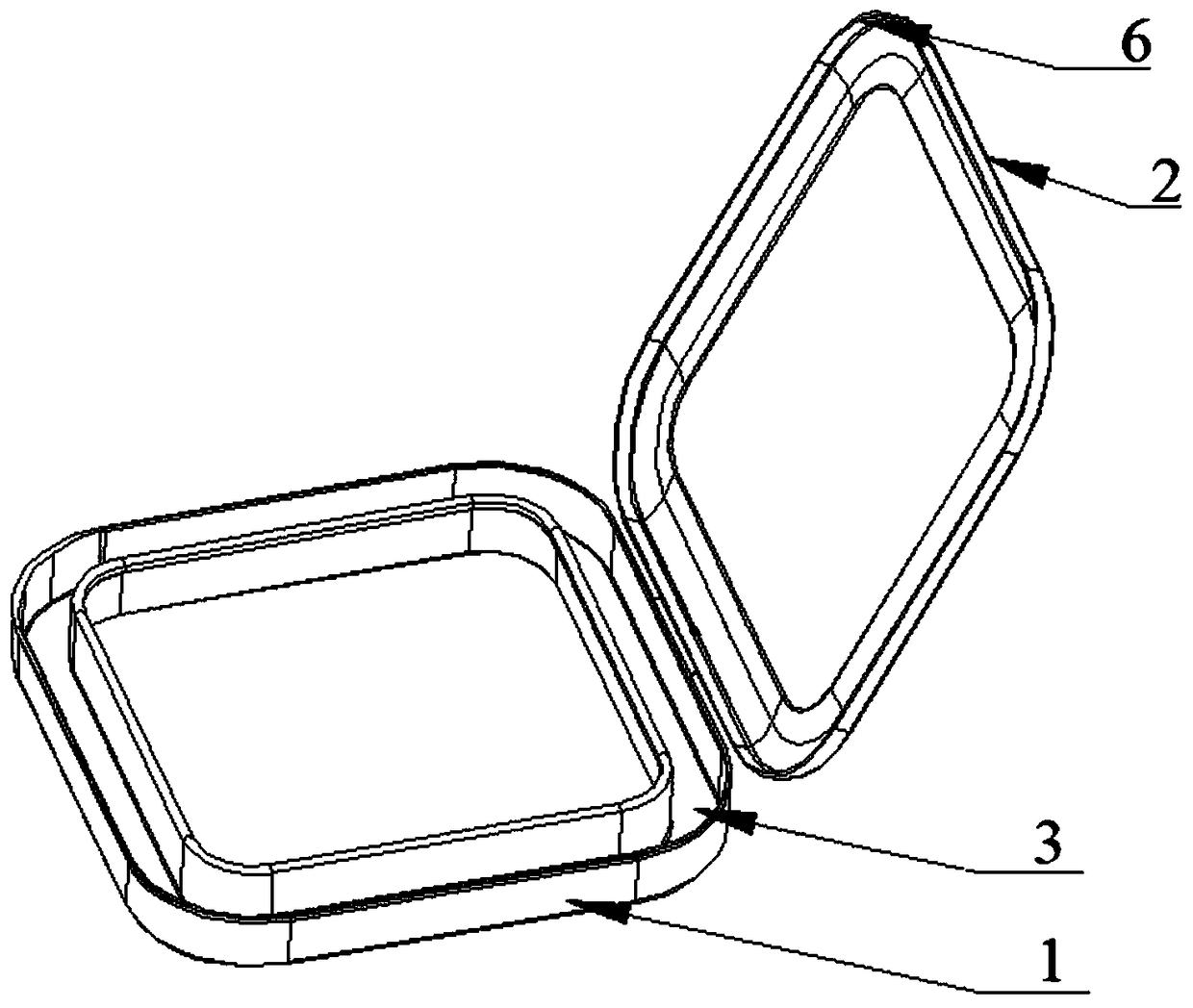

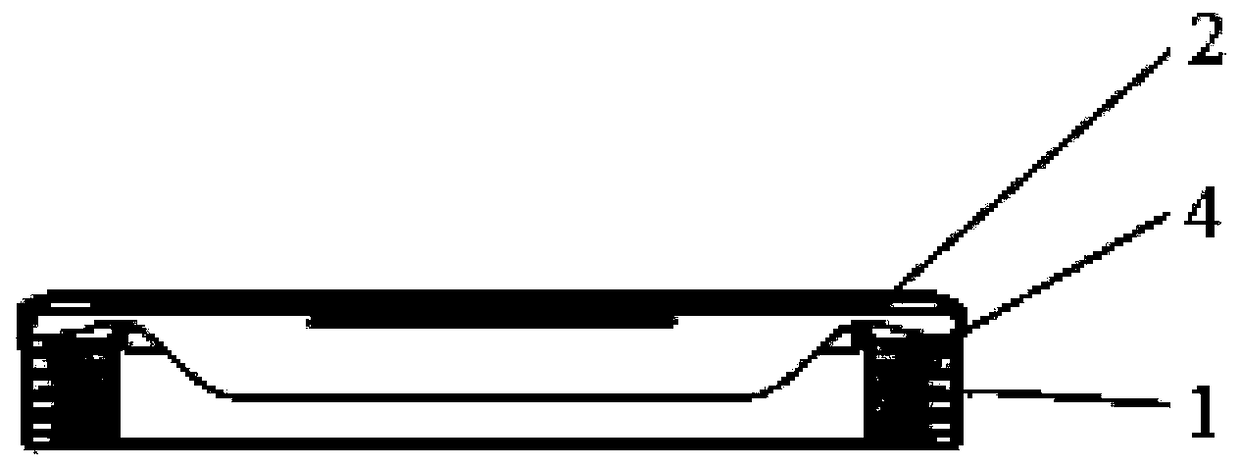

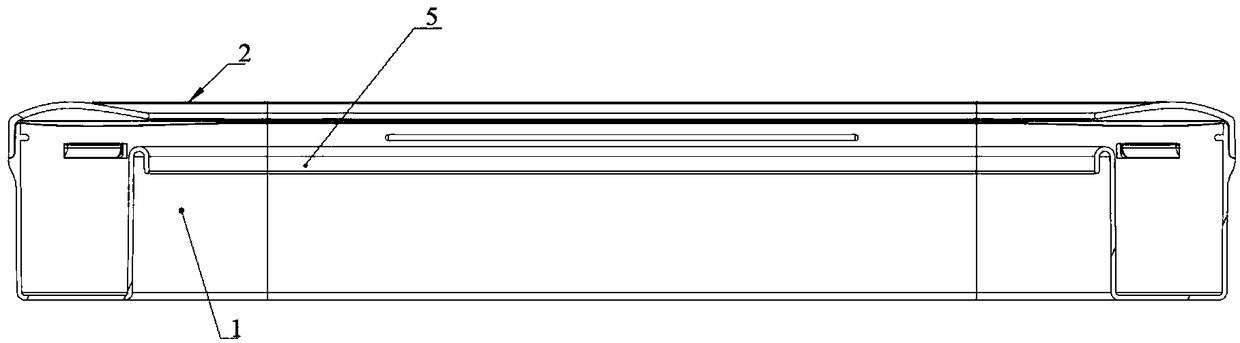

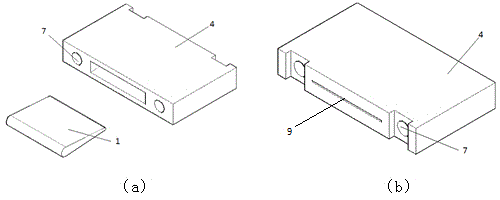

Trash bag component and intelligent trash bin

PendingCN108974704AImprove automationImprove the level of intelligenceRefuse receptaclesEngineeringAutomation

The application relates to the technical field of intelligent trash bins, in particular to a trash bag component and an intelligent trash bin. The trash bag component includes a storage body and a cover; the storage body is provided with a first through hole and a circular channel arranged around the first through hole and used for storing a trash bag; the cover is provided with a second through hole corresponding to the first through hole; an opening of the circular channel is covered; a gap is provided between the cover and one sidewall of the circular channel so as to form a trash bag outlet. The trash bag component with these settings has the advantages that the trash bag component can be applied to intelligent trash bins so as to conveniently implement the function of full-automatic laying and packing of trash bags, thereby further increasing trash bin automation level and intelligence level; damage to trash bags during production, storage and transport of the trash bags is effectively avoided; trash bag changing is simple so that efficiency can be improved; the trash bag component is of integrate structure, is convenient to assemble and helps reduce production and mounting costs.

Owner:SHANGHAI TOWNEW INTELLIGENT TECH CO LTD

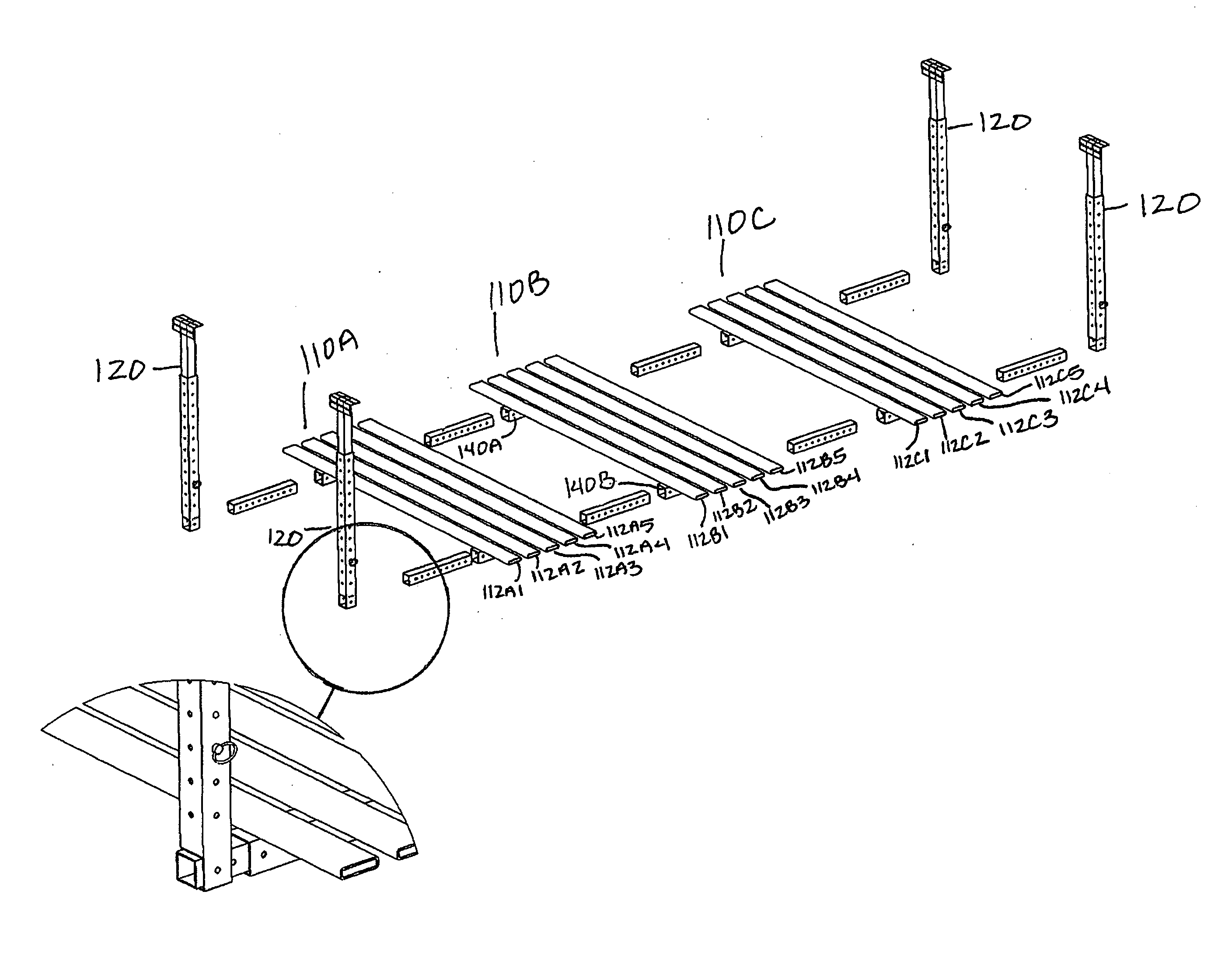

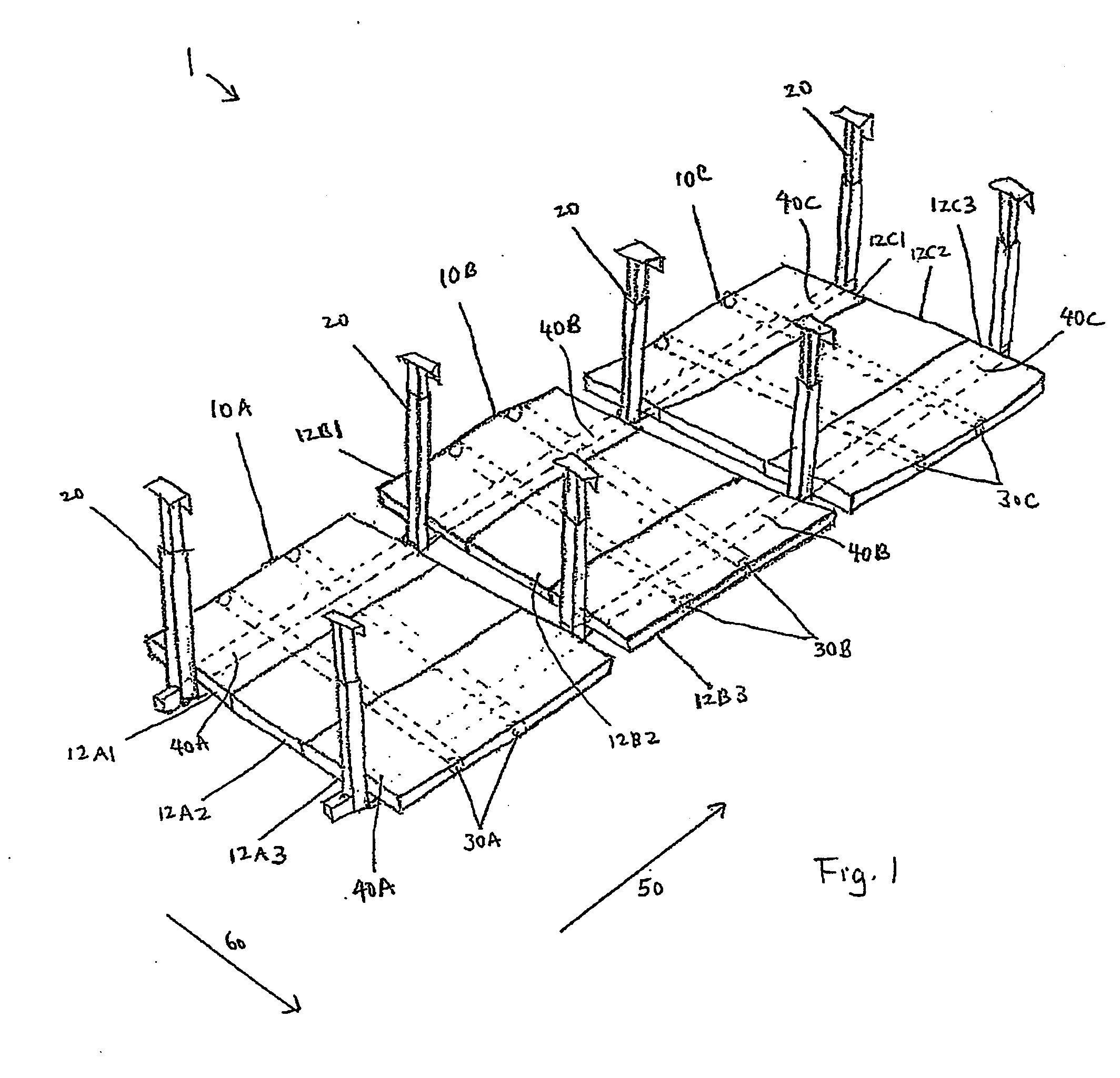

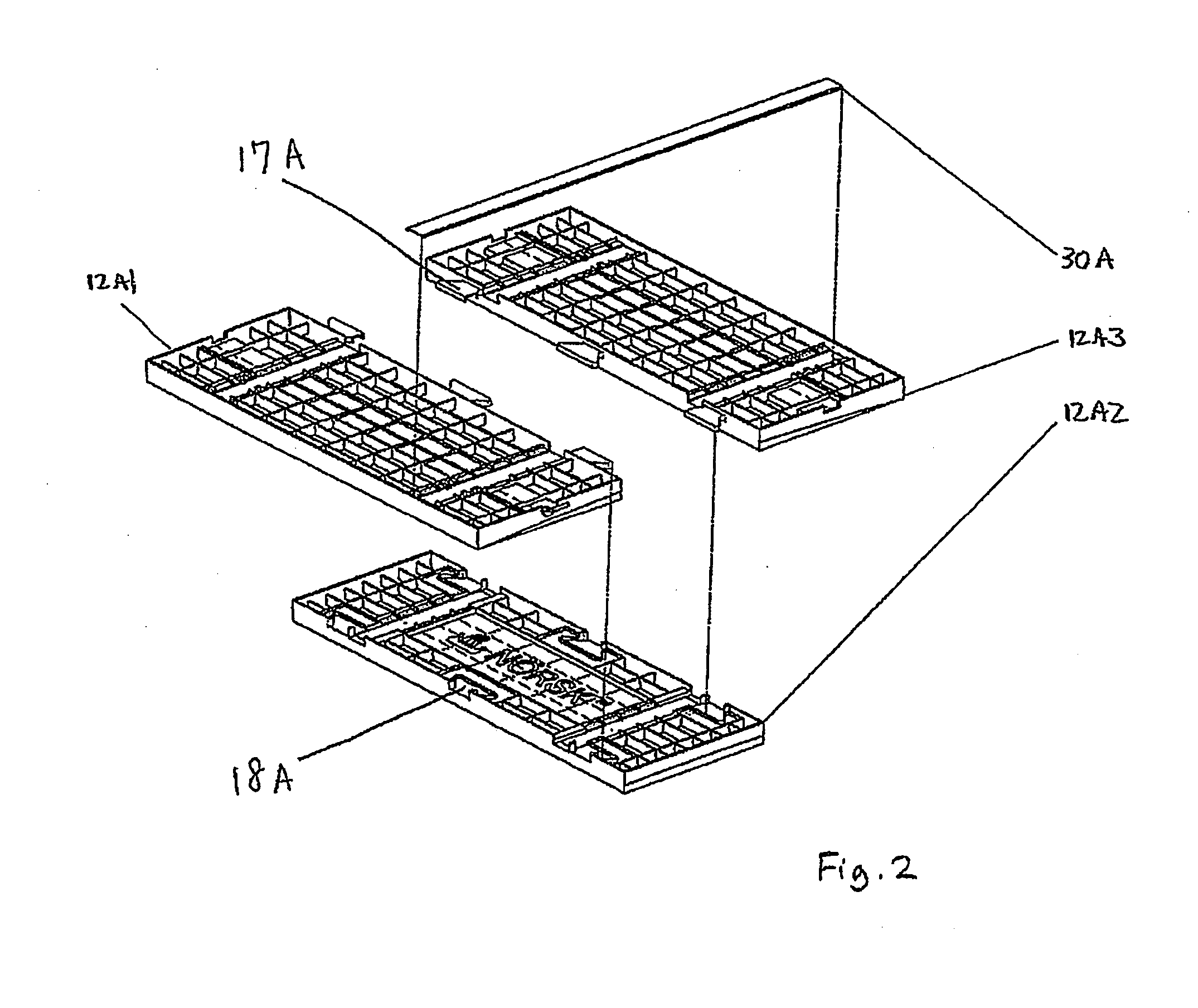

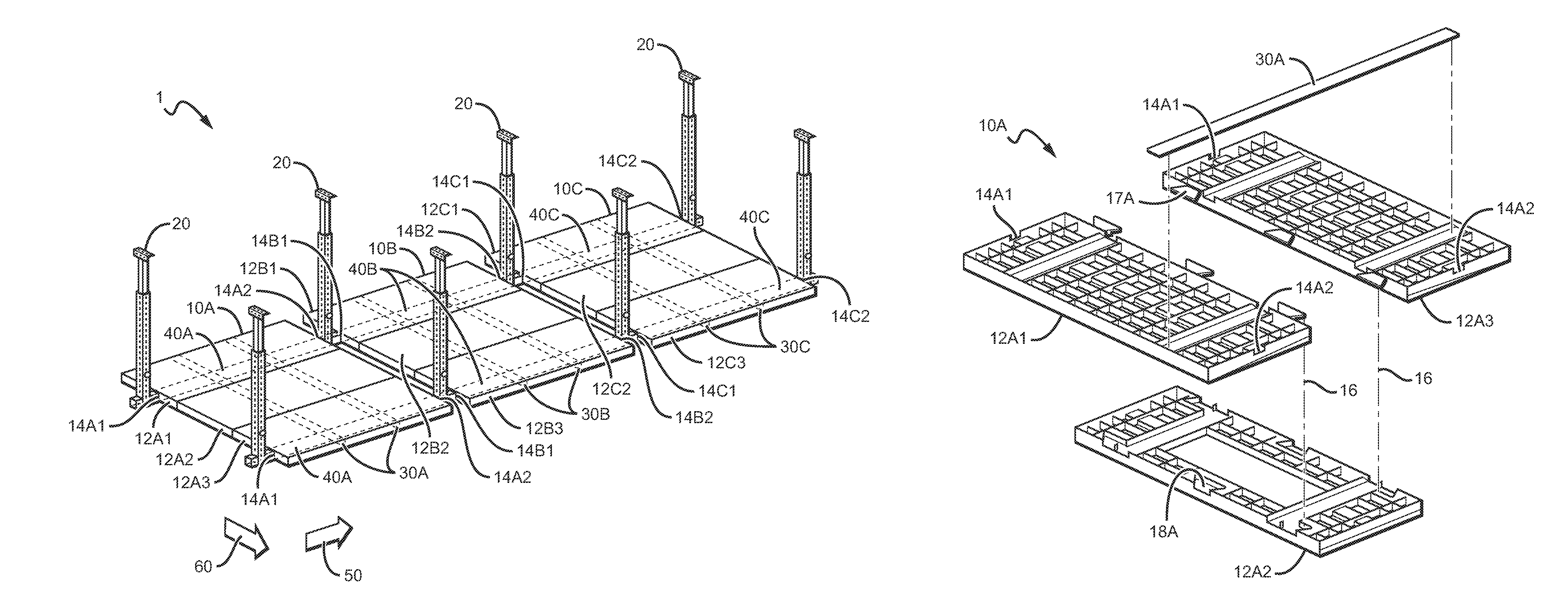

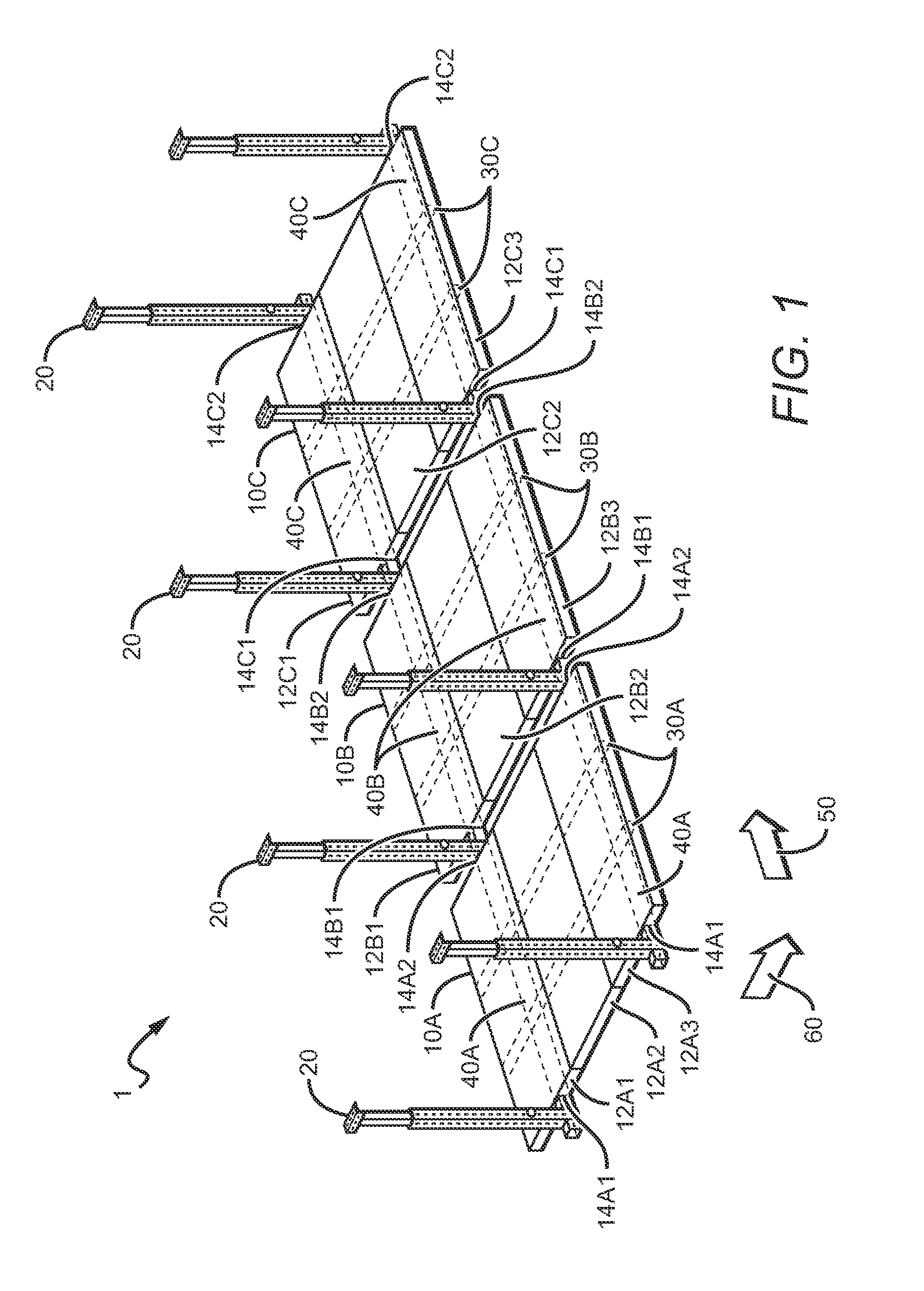

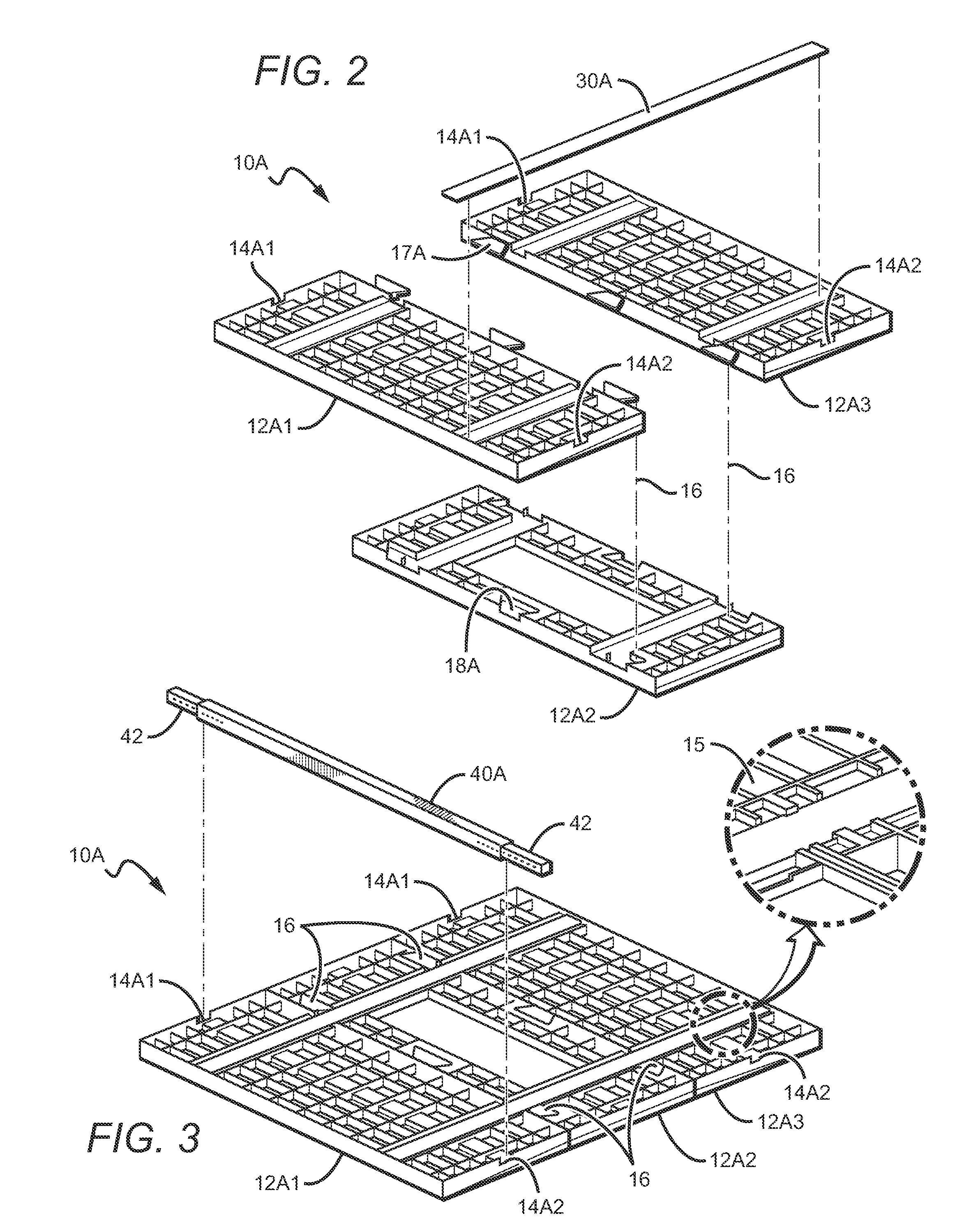

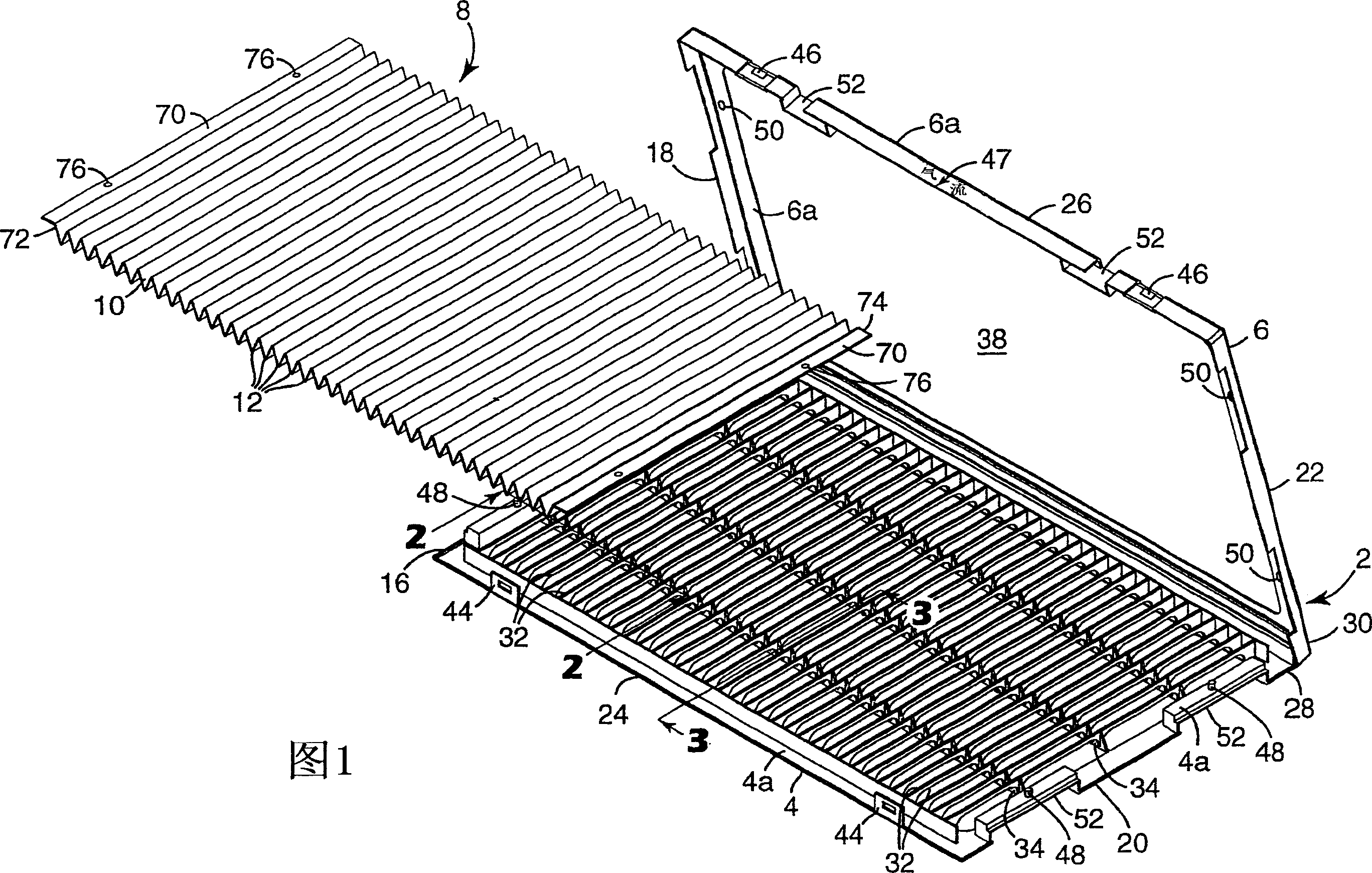

Modular overhead storage

InactiveUS20070007223A1Easy to adjust the lengthReduce noiseFurniture partsFolding cabinetsCouplingMultiple platform

A storage system comprises a rack of multiple platforms connectable to one another in a first direction, where each of the platforms has segments that connect to one another along a direction other than the first direction, via a user-operable coupling. The platforms are preferably rectangular, and are connected at their long ends. The segments of each platform are also preferably rectangular, but they are connected along their long sides. In such embodiments, the connection between platforms is perpendicular to the length of the rack, while the connection between segments is parallel to the length of the rack. The segments of individual platforms are preferably coupled together with snap fit connections, and supported from their undersides by transverse supports, and the transverse supports are supported from their undersides by longitudinal supports. The transverse supports are preferably perpendicular to the longitudinal supports.

Owner:PARALLAX GROUP INT

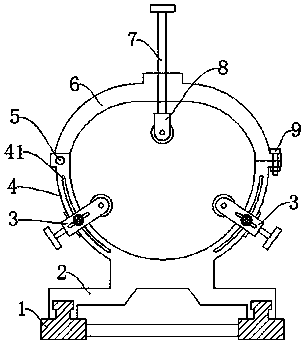

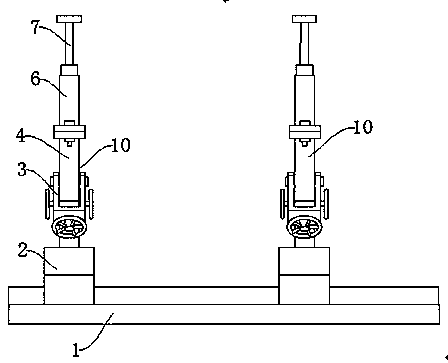

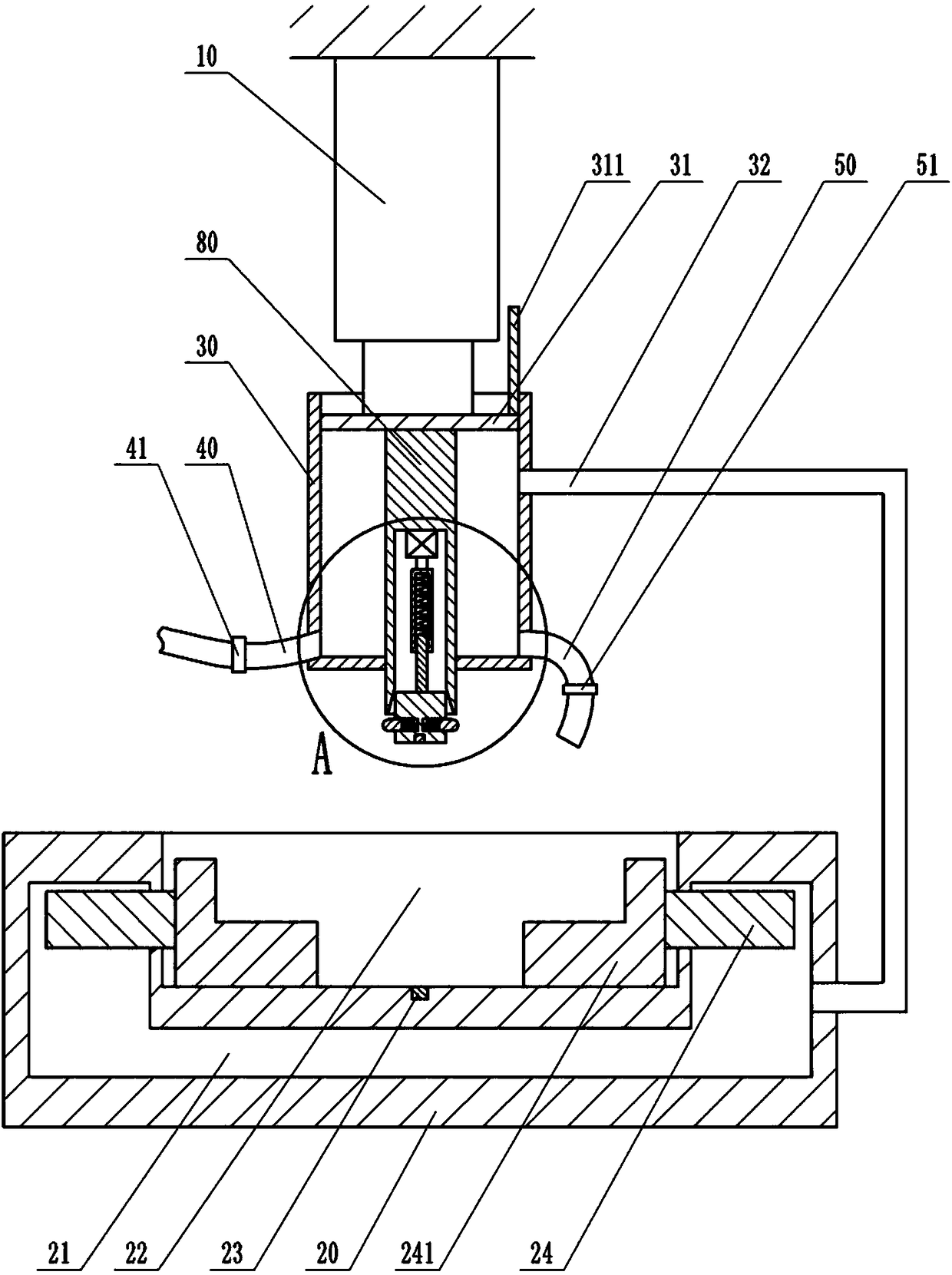

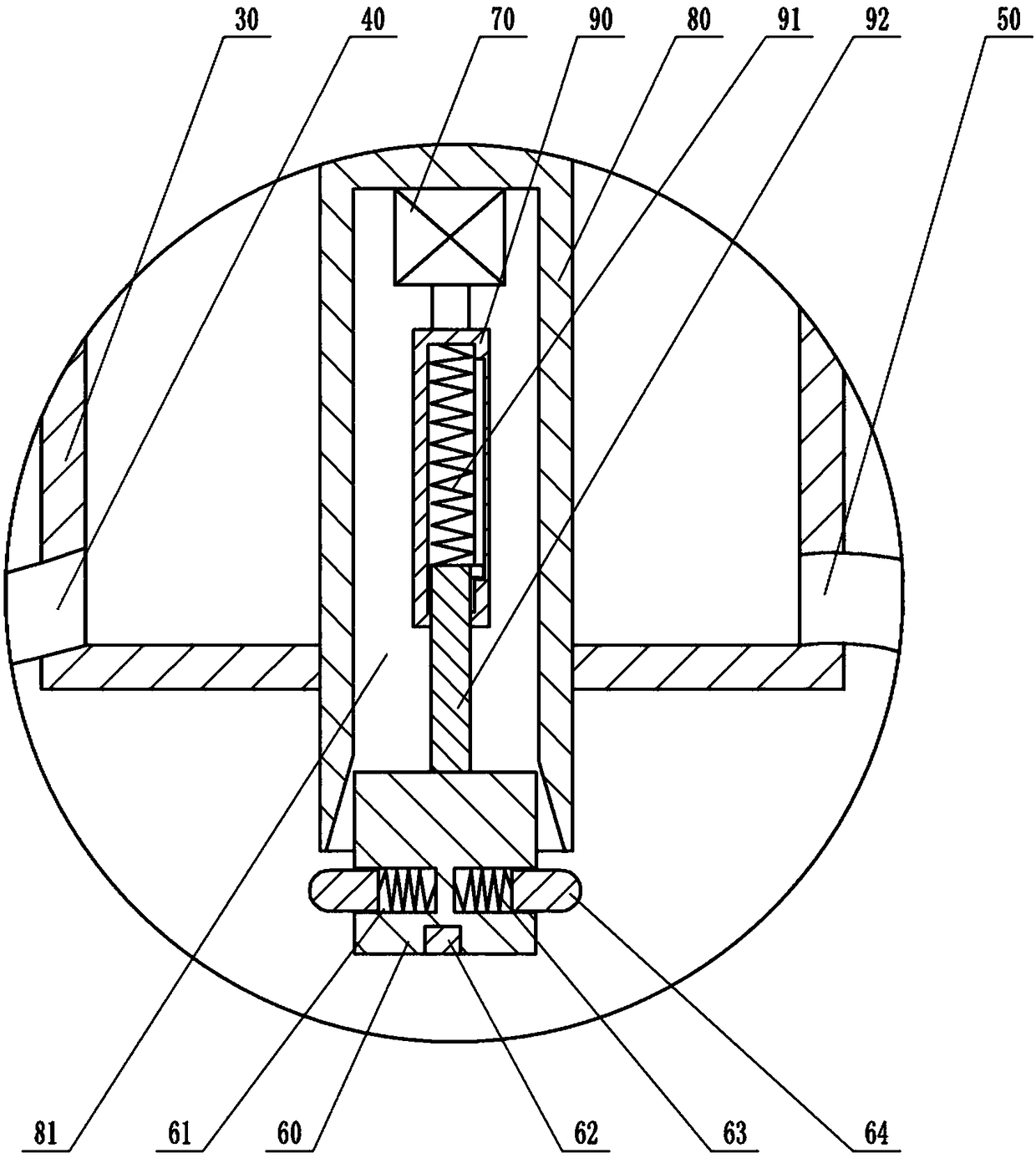

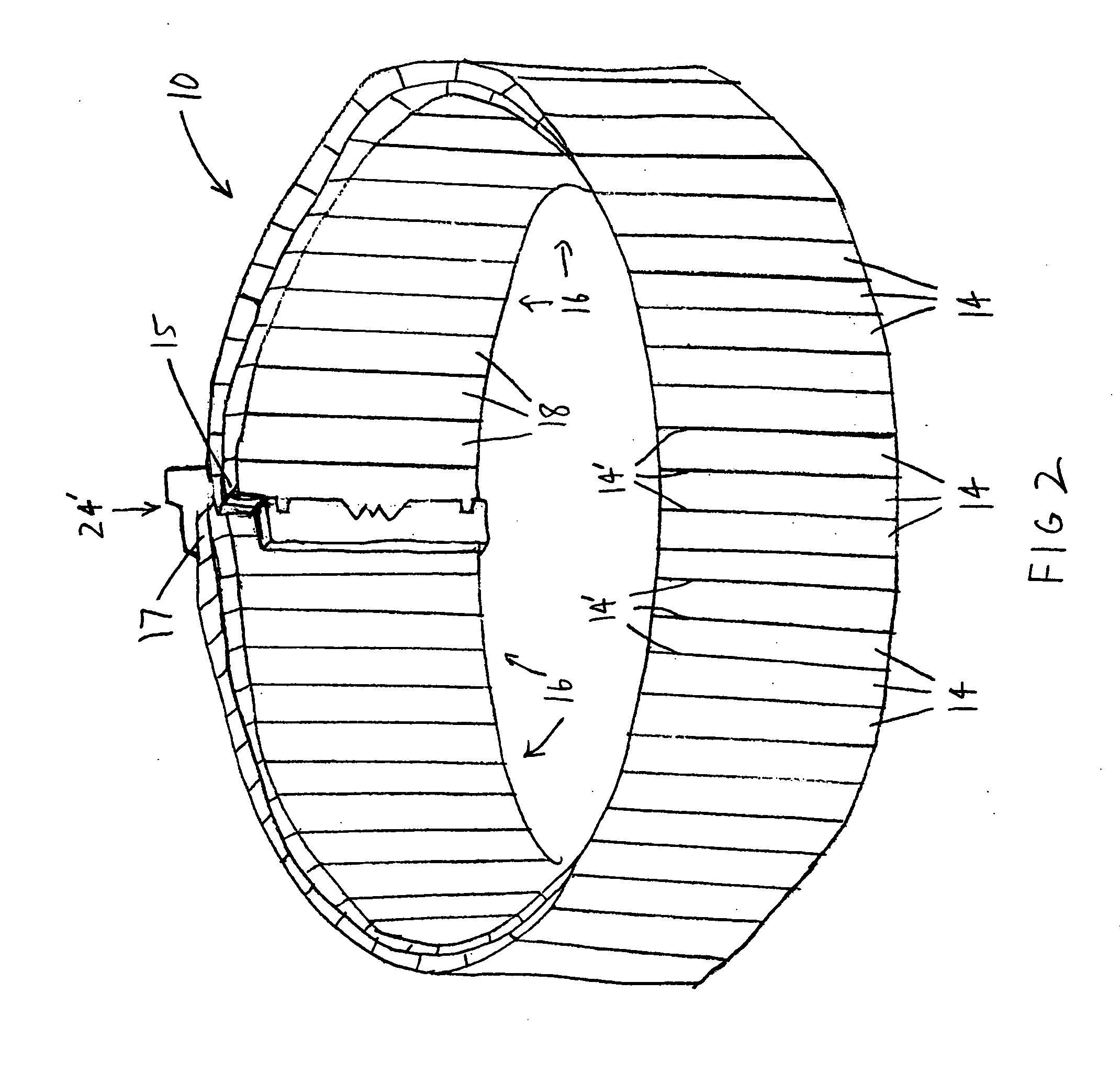

Special fixture for arc-shaped plate

ActiveCN107932117AAchieve clamping and fixingEasy to adjustWork holdersPositioning apparatusEngineeringMechanical engineering

The invention discloses a special fixture for an arc-shaped plate. The special fixture comprises a guide rail and a plurality of clamping mechanisms. The multiple clamping mechanisms are arranged on the guide rail, and each clamping mechanism comprises a base, two arc-shaped supporting plates and a supporting arm, wherein the bases are slidably mounted on the guide rail, every two arc-shaped supporting plates are arranged above the corresponding base, and each arc-shaped supporting plate is one fourth of a round ring. The special fixture for the arc-shaped plate has the beneficial effects thatthe arc-shaped plate is jacked up through two tight jacking devices arranged at the bottom of the arc-shaped plate, a compressing device is arranged on the inner side of the arc-shaped plate, a compressing wheel is utilized to compress the arc-shaped plate to the jacking device from the inner side, and accordingly clamping and fixing of the arc-shaped plate are achieved. A first slide groove formed in the arc-shaped plate is convenient for adjusting the positions of the tight jacking devices, and accordingly the arc-shaped plates with different outline radius sizes can be clamped conveniently. A second slide groove is convenient for adjusting the length of a supporting wheel extending into the inner sides of the arc-shaped supporting plates so as to clamp the irregular arc-shaped plates.

Owner:青岛自动化仪表有限公司

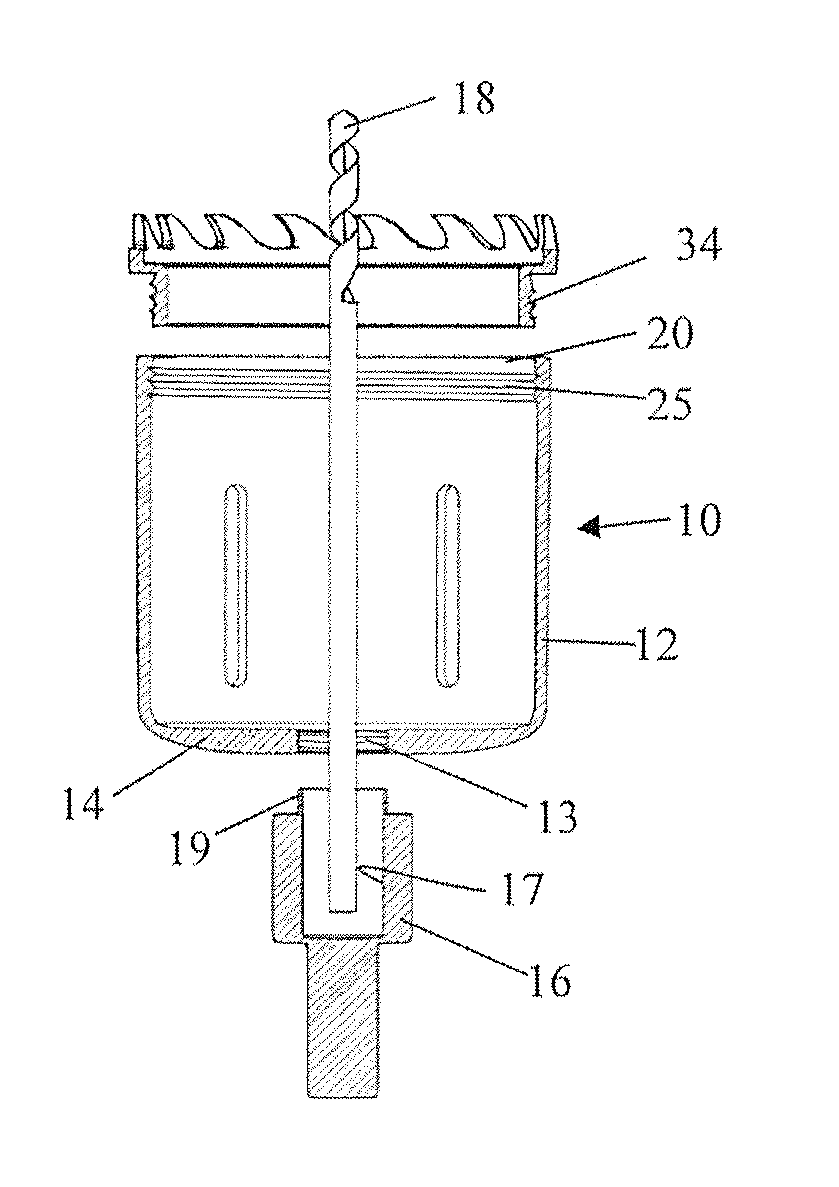

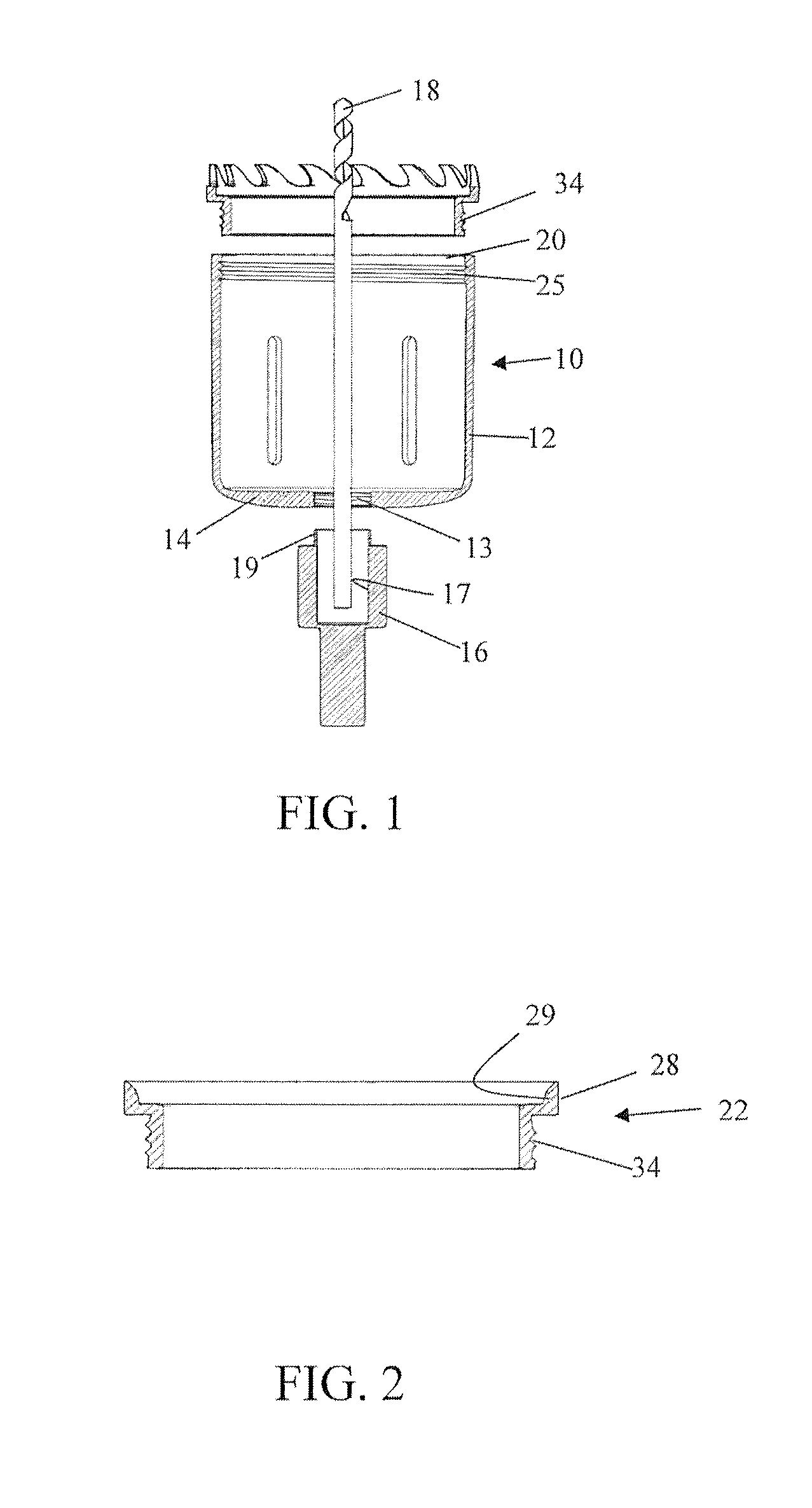

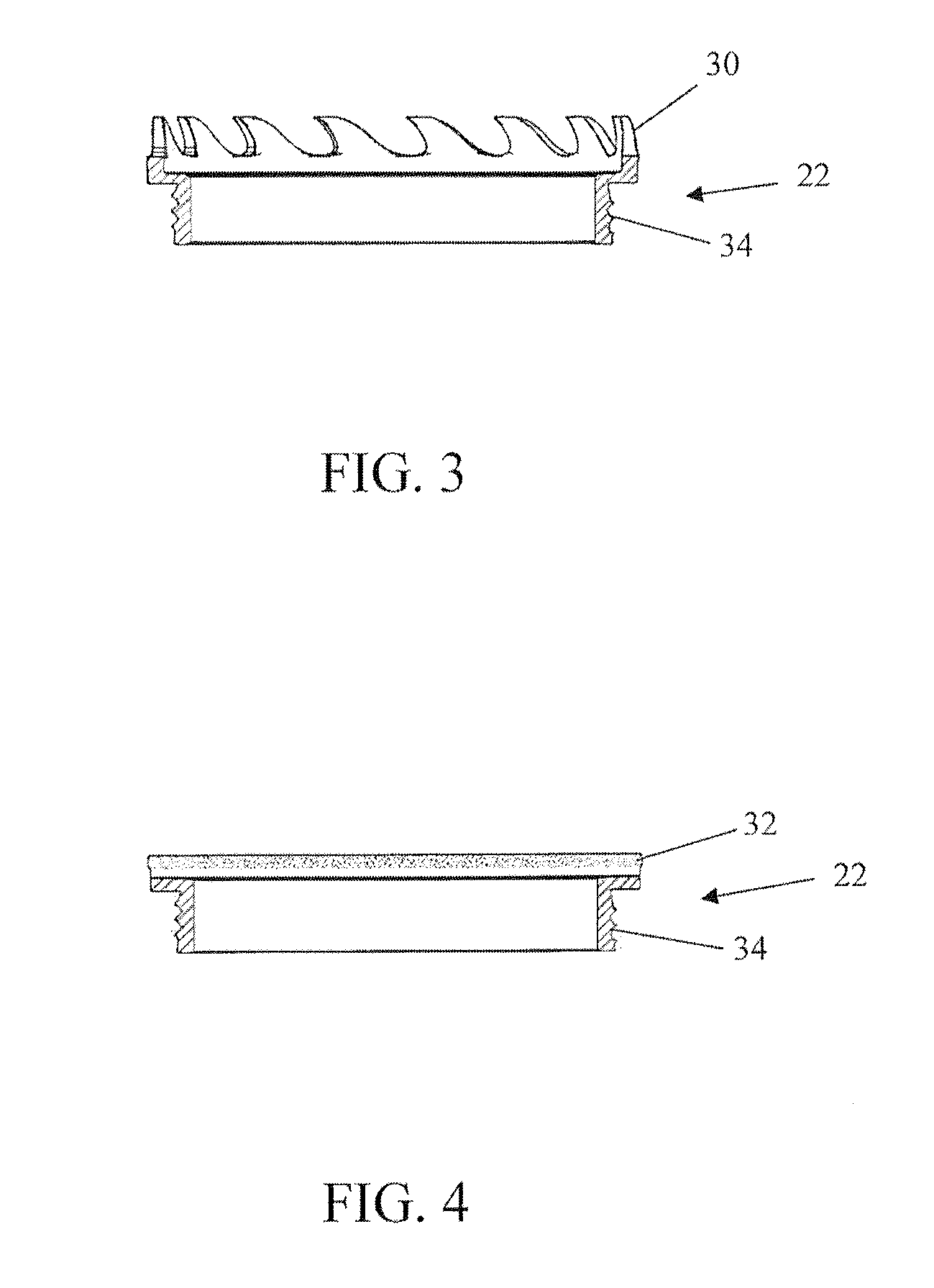

Adjustable Depth Hole Saw Assembly

InactiveUS20110052340A1Easy to adjust the lengthPrecise cuttingTransportation and packagingCircular sawsVariable thicknessHole saw

A hole saw cup member includes a tubular saw cup member having a closed end arranged to be coupled to a rotary power source and an open end arranged to detachably secure an annular cutting ring member. The invention may include at least one saw cup extension member positioned between the saw cup member and the annular cutting ring member to lengthen the saw cup member to facilitate cutting of substrates having variable thickness.

Owner:COMBINED PRODS

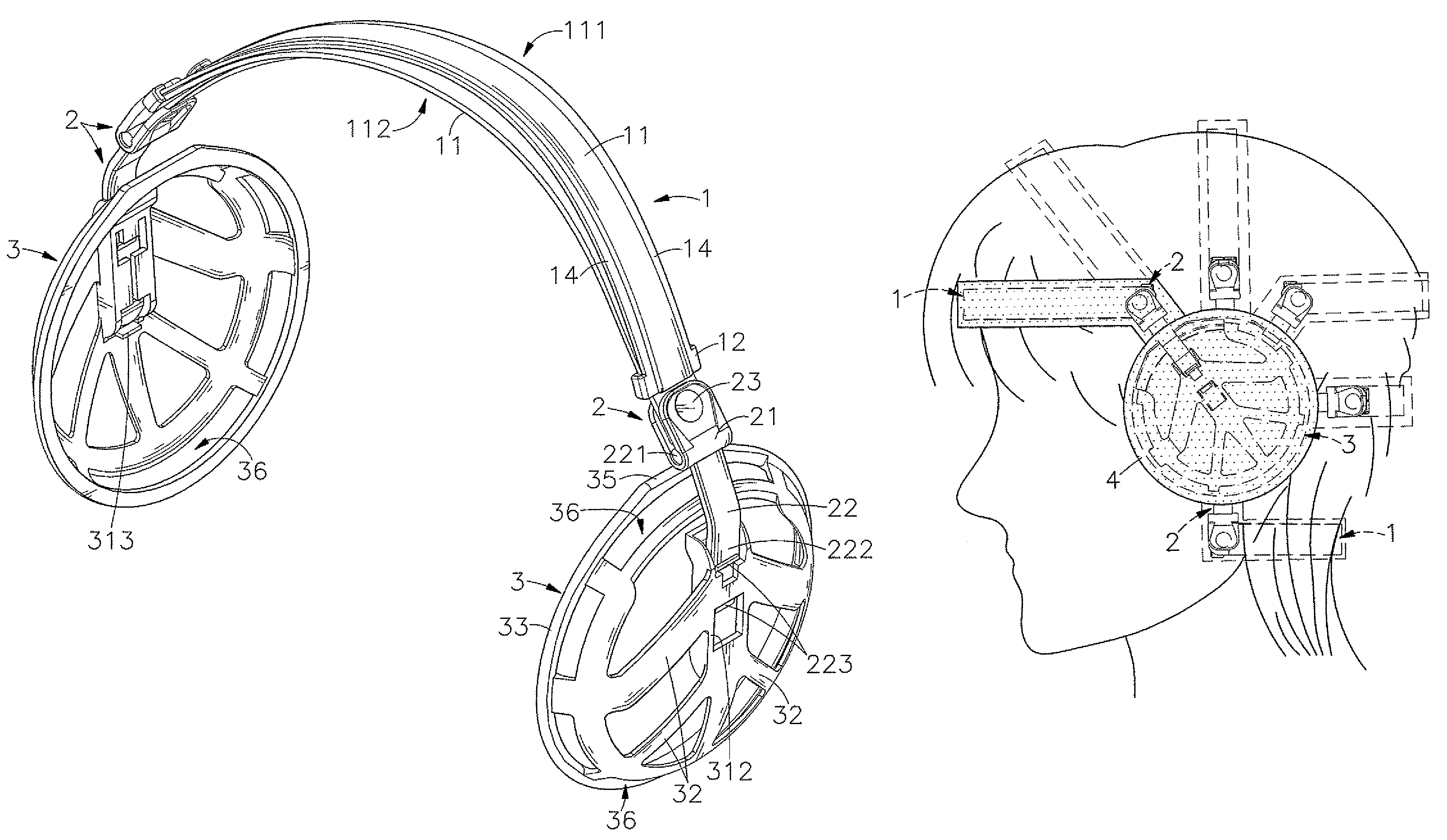

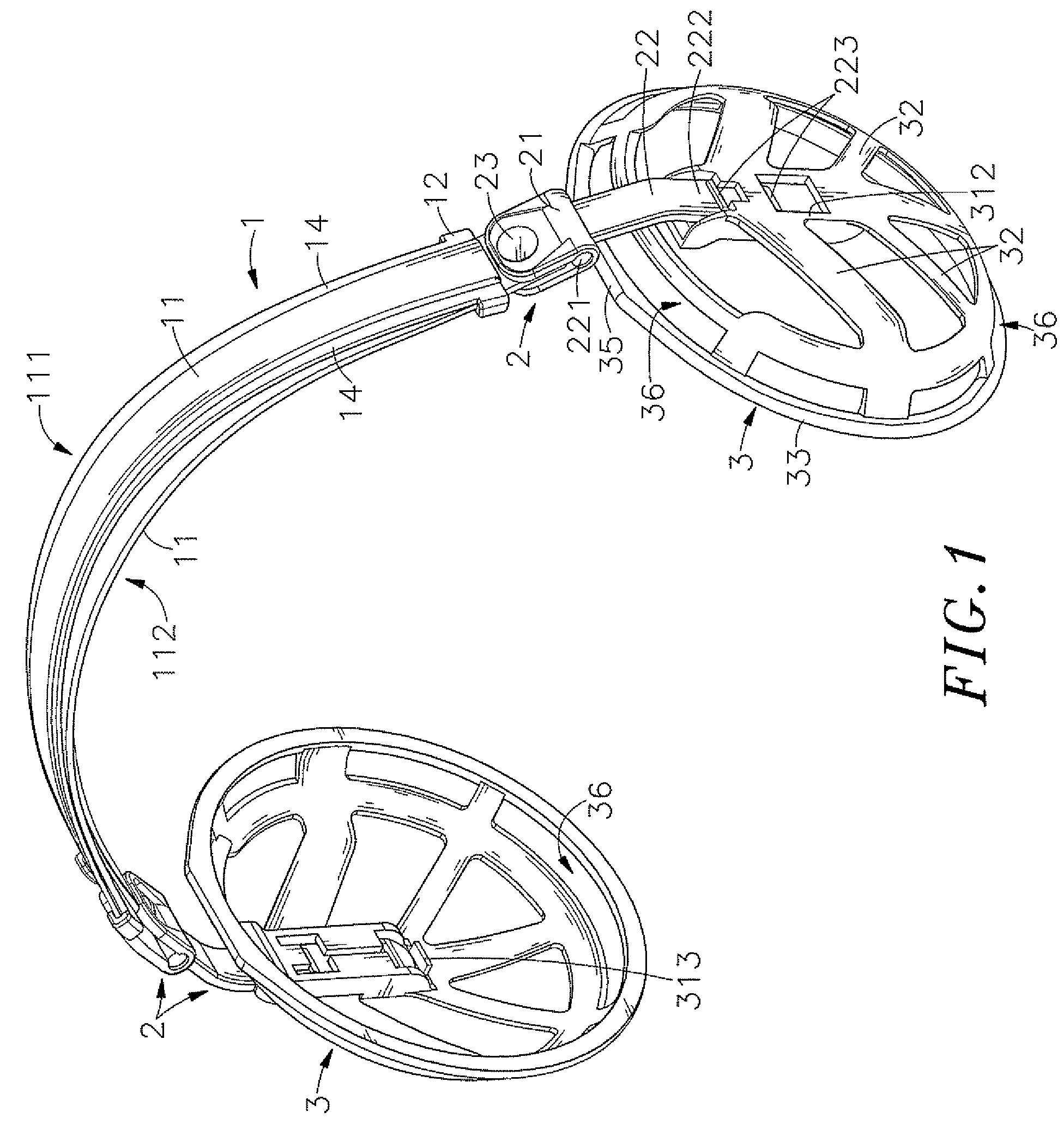

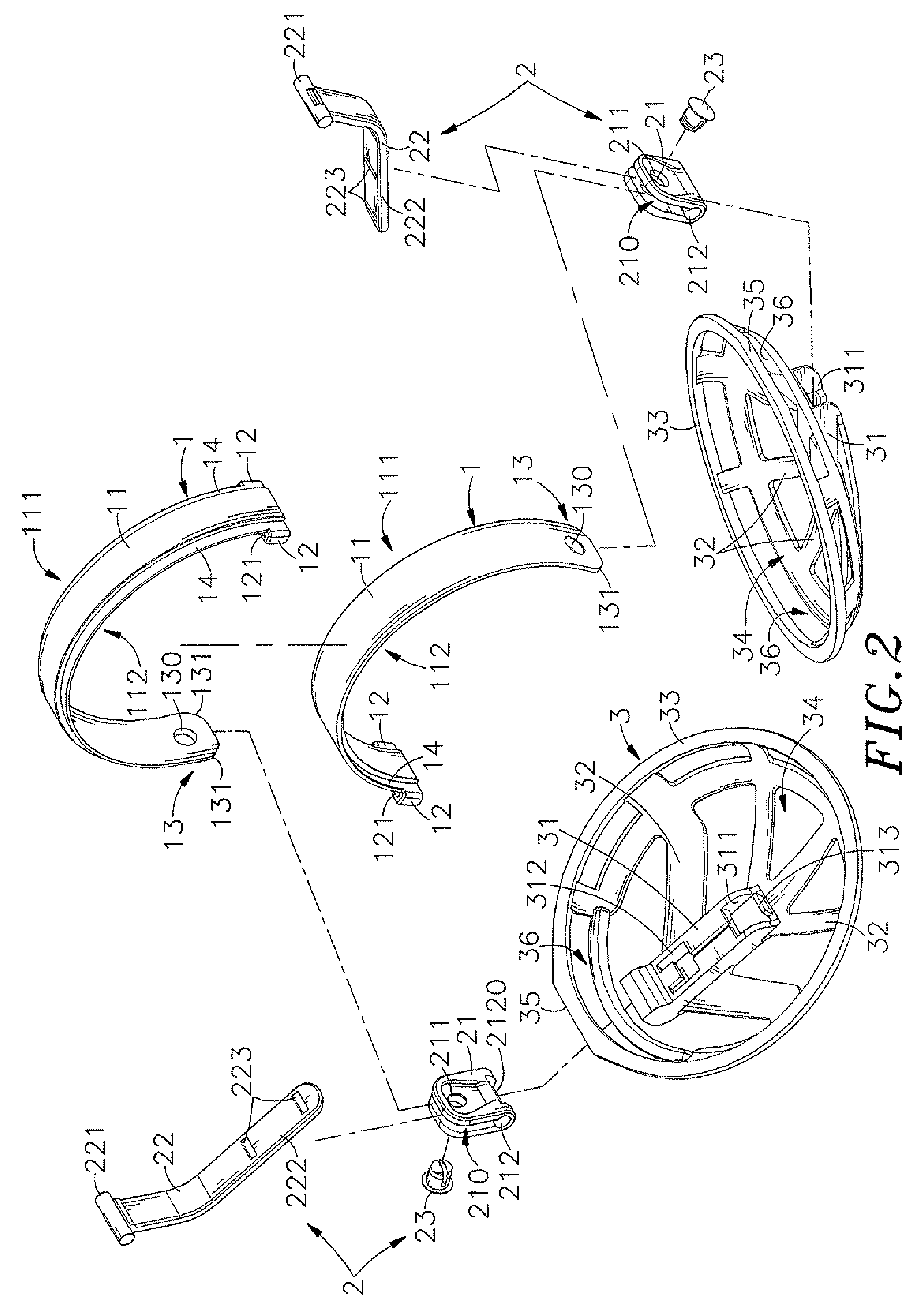

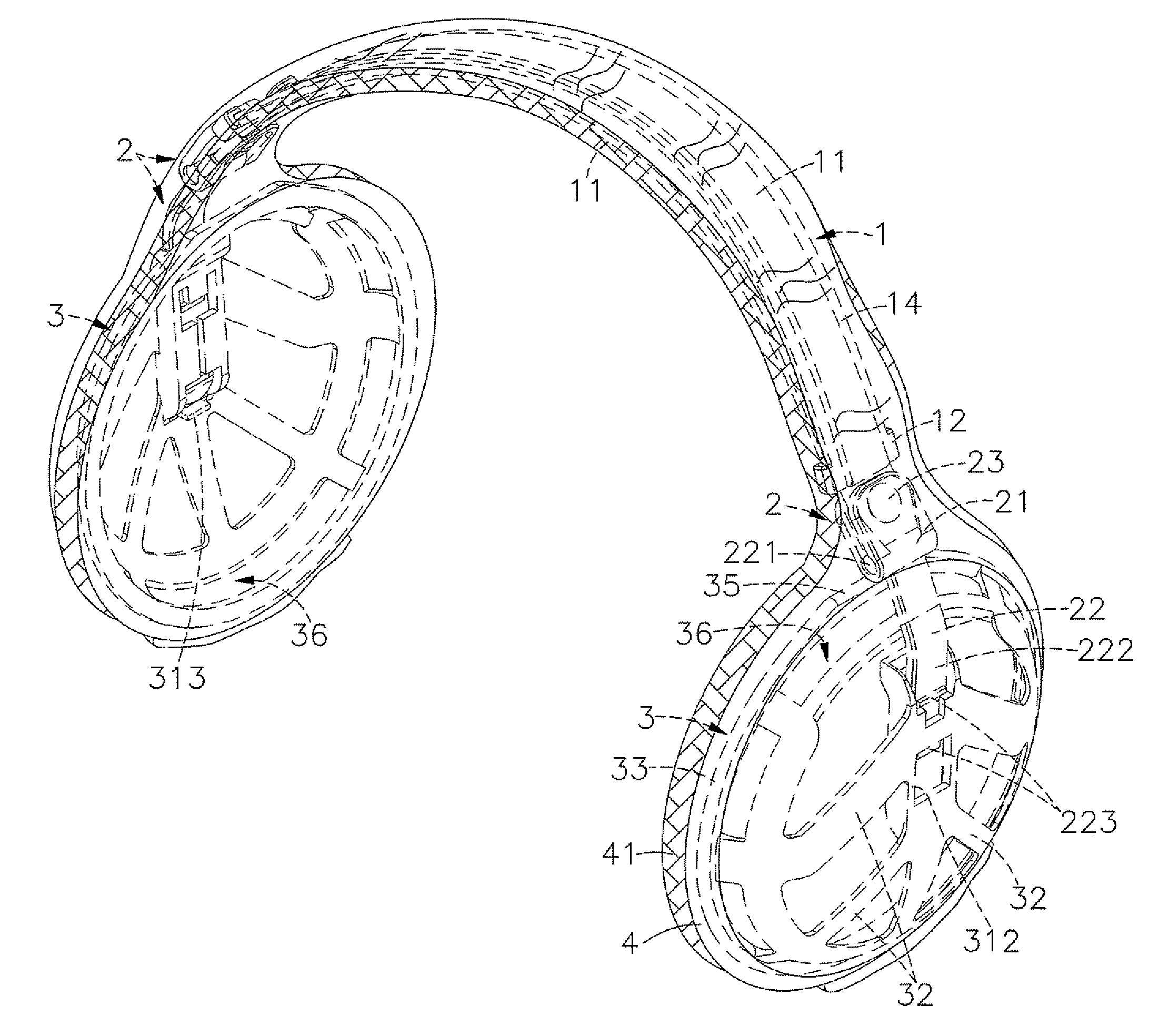

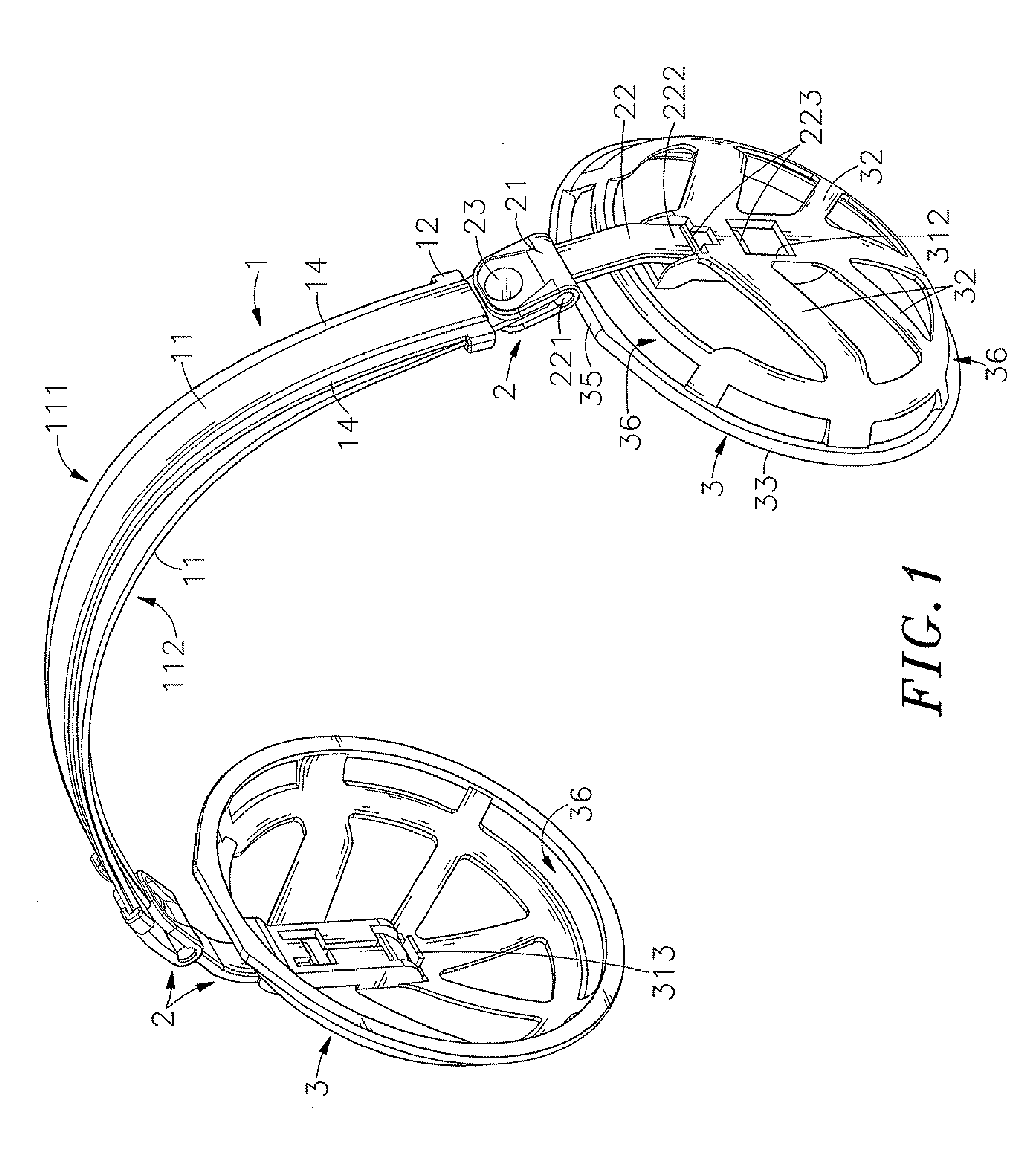

Earmuff assembly

An earmuff assembly includes a headband consisting of two headband elements each having two constraint lugs bilaterally located on one end and a coupling portion located on the opposite end, the coupling portion of one headband element being inserted through a groove on each constraint lug of the other headband element for allowing adjustment of the length of the headband, two ear cups, two connection devices that connect the coupling portions of the headband elements to the ear cups such that the angular positions of the ear cups are adjustable in the X-axis direction as well as in the Y-axis direction relative to the headband, and a soft fabric material covering the ear cups for optimal wearing comfort.

Owner:SOUND TEAM ENTERPRISE

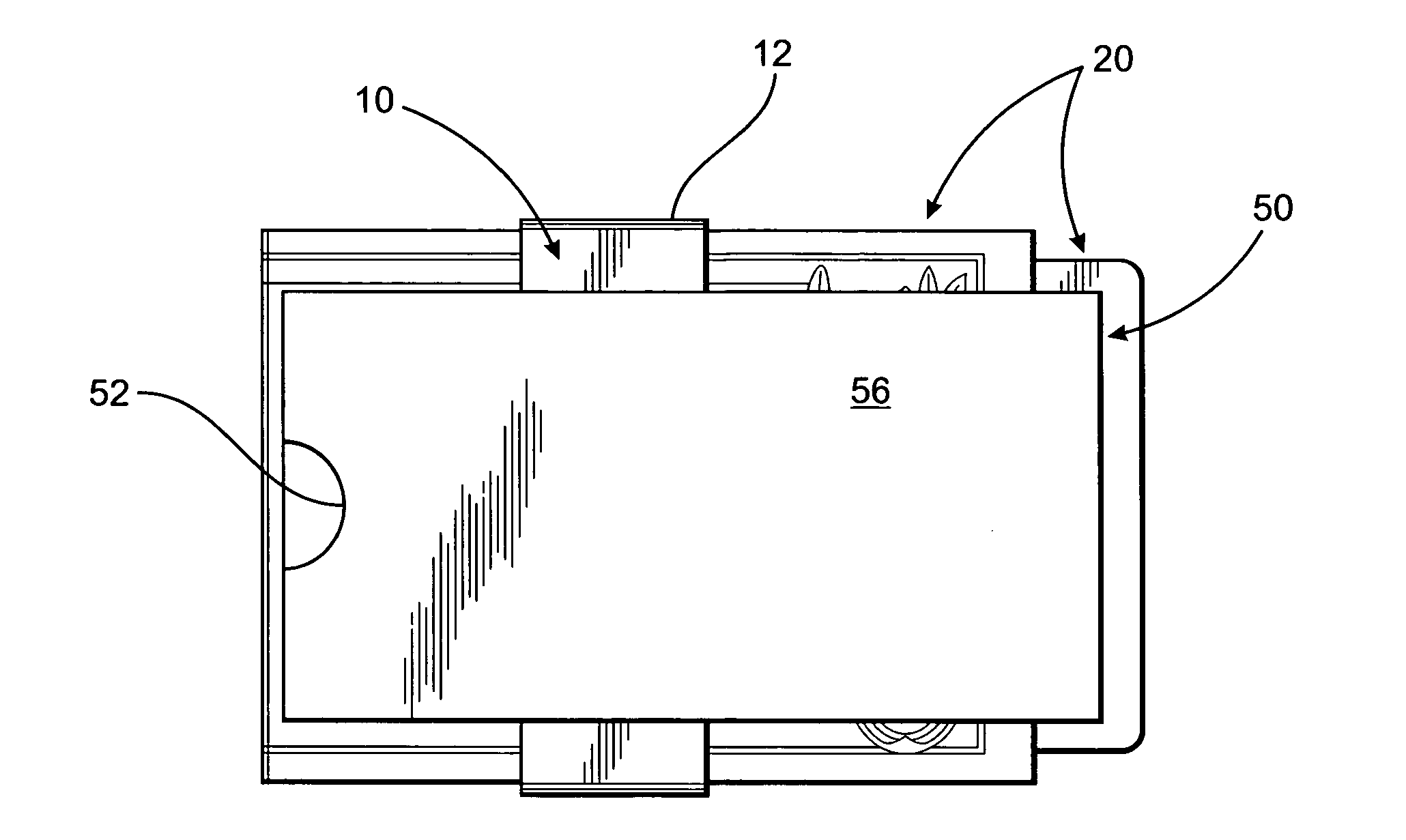

Modular overhead storage

ActiveUS8657130B2Easy to adjust the lengthReduce noiseCeilingsMachine supportsMultiple platformCoupling

A storage system comprises a rack of multiple platforms connectable to one another in a first direction, where each of the platforms has segments that connect to one another along a direction other than the first direction, via a user-operable coupling. The platforms are preferably rectangular, and are connected at their long ends. The segments of each platform are also preferably rectangular, but they are connected along their long sides. In such embodiments, the connection between platforms is perpendicular to the length of the rack, while the connection between segments is parallel to the length of the rack. The segments of individual platforms are preferably coupled together with snap fit connections, and supported from their undersides by transverse supports, and the transverse supports are supported from their undersides by longitudinal supports via recesses on the segments. The transverse supports are preferably perpendicular to the longitudinal supports.

Owner:PARALLAX GROUP INT

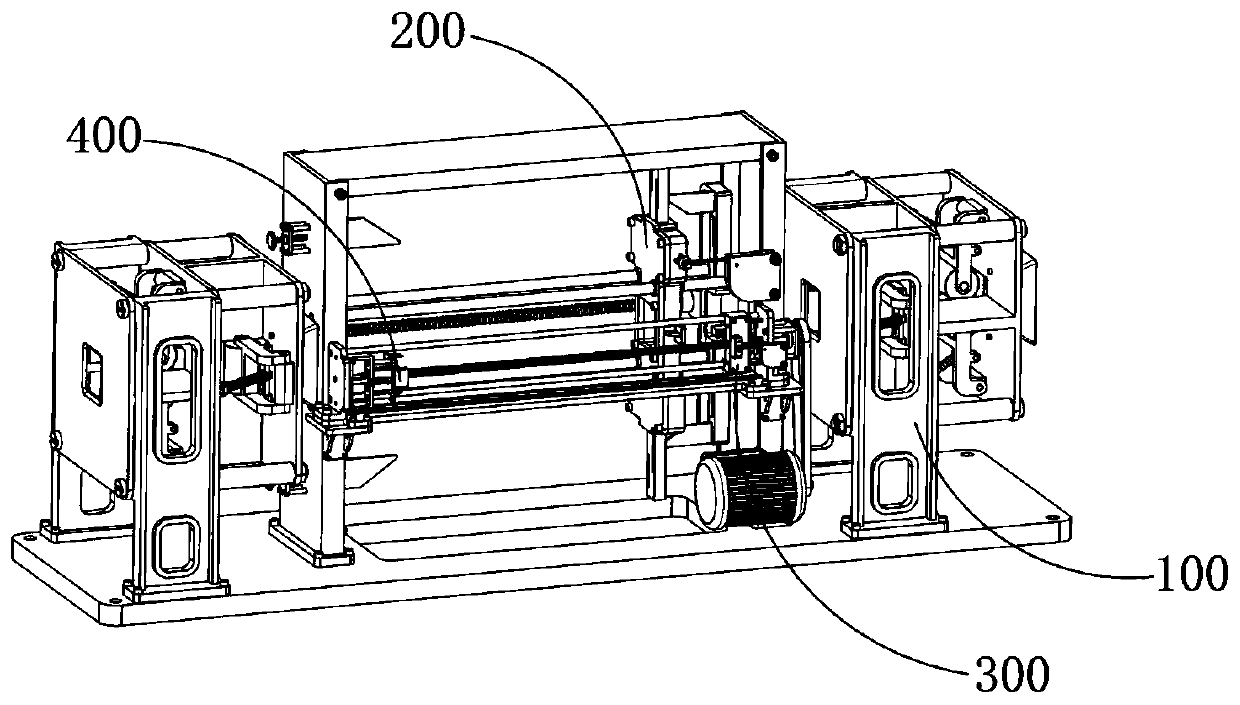

Punching and grinding integrated device

InactiveCN108500129AImprove efficiencyEasy to processEdge grinding machinesShaping toolsPunchingEngineering

The invention belongs to the technical field of punching device, and specifically discloses a punching and grinding integrated device. The device comprises a worktable, a controller, a punch and a sliding barrel, wherein a groove is formed in the upper surface of the worktable, and an infrared emitter is arranged in the groove; an empty cavity is formed in the worktable, and two pushing columns are connected into the empty cavity in a sliding manner; L-shaped clamping plates are arranged on the pushing rods; a piston is connected into the sliding barrel in a sliding manner, and the punch is fixed to the piston; a water inlet pipe, a water draining pipe and a communicating pipe are connected to the sidewall of the sliding barrel; an inner concave cavity is formed in the lower surface of thepunch, and a plunger piston is connected into the inner concave cavity and a motor is arranged in the inner concave cavity; a telescoping rod is connected to an output shaft of the motor and is connected to the plunger piston; a chute is formed in the sidewall of the plunger piston; a grinding bump is connected into the chute in a sliding manner; an infrared receiver is embedded into the lower surface of the plunger piston; and the infrared receiver and the infrared emitter are electrically connected to a controller. According to the technical scheme, the device is capable of punching, grinding and processing a workpiece, and the processing efficiency is improved.

Owner:宁波鑫神泽汽车零部件有限公司

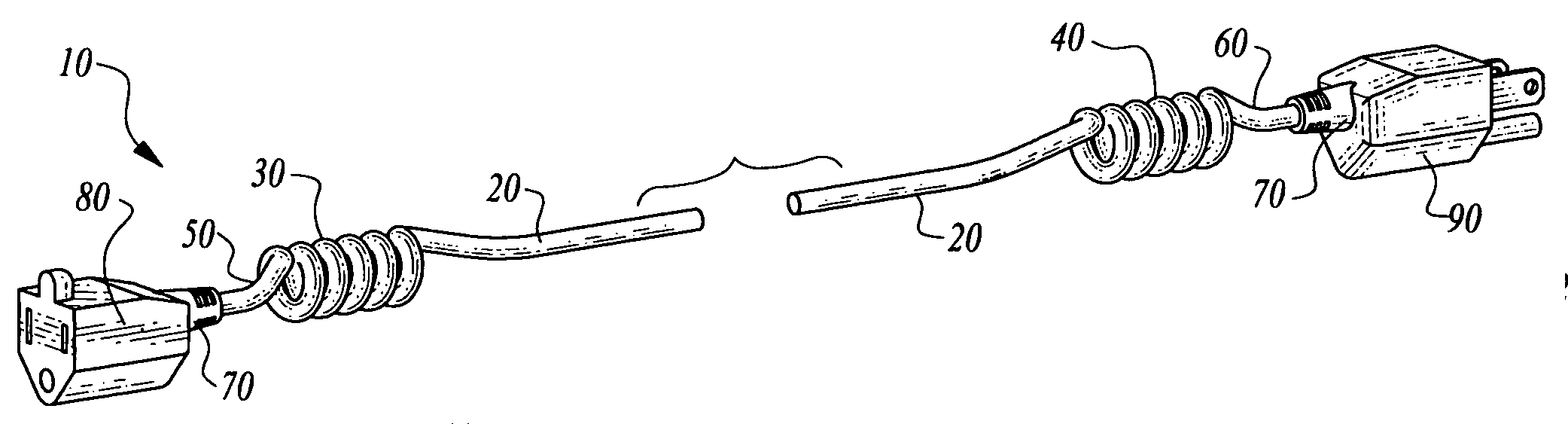

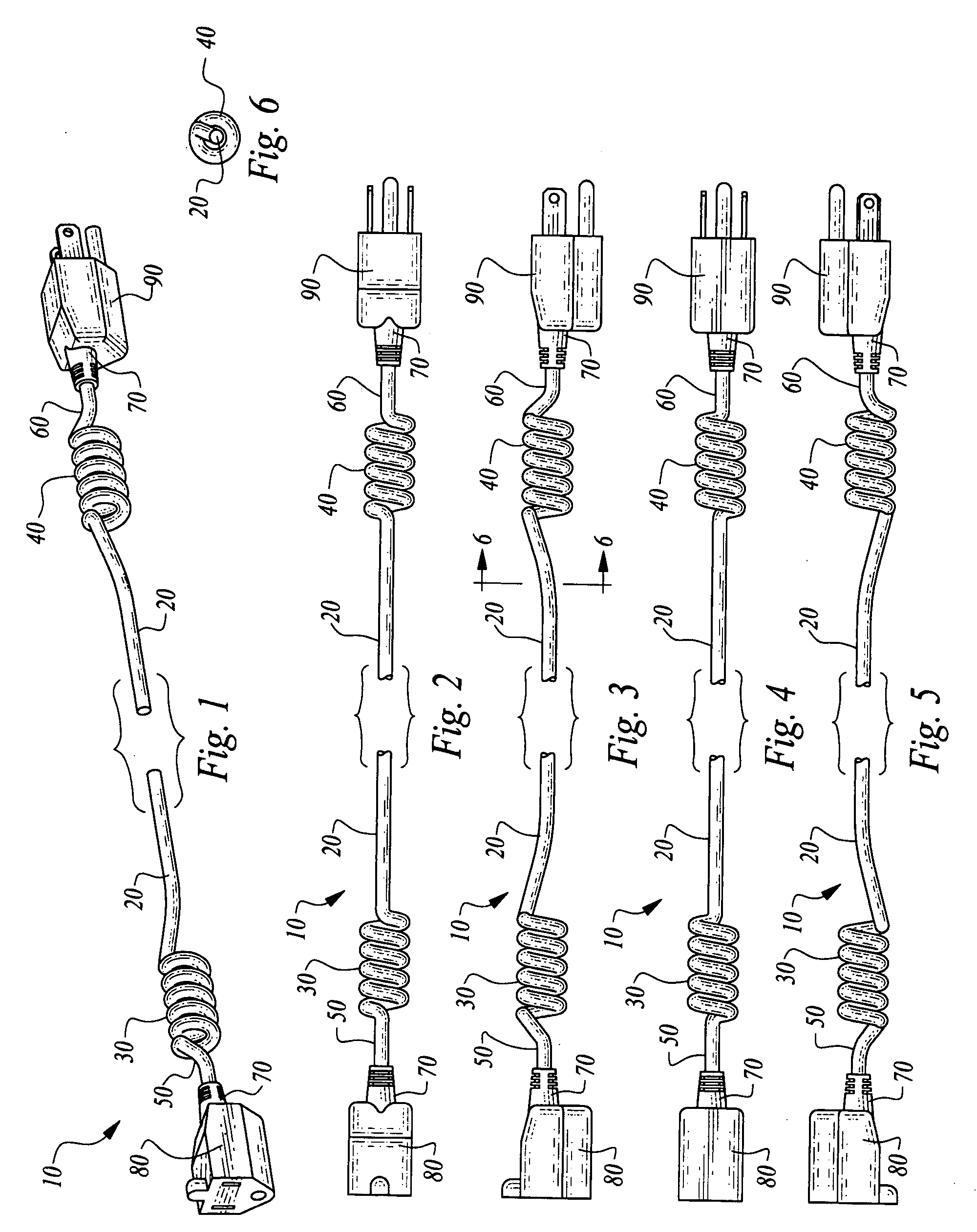

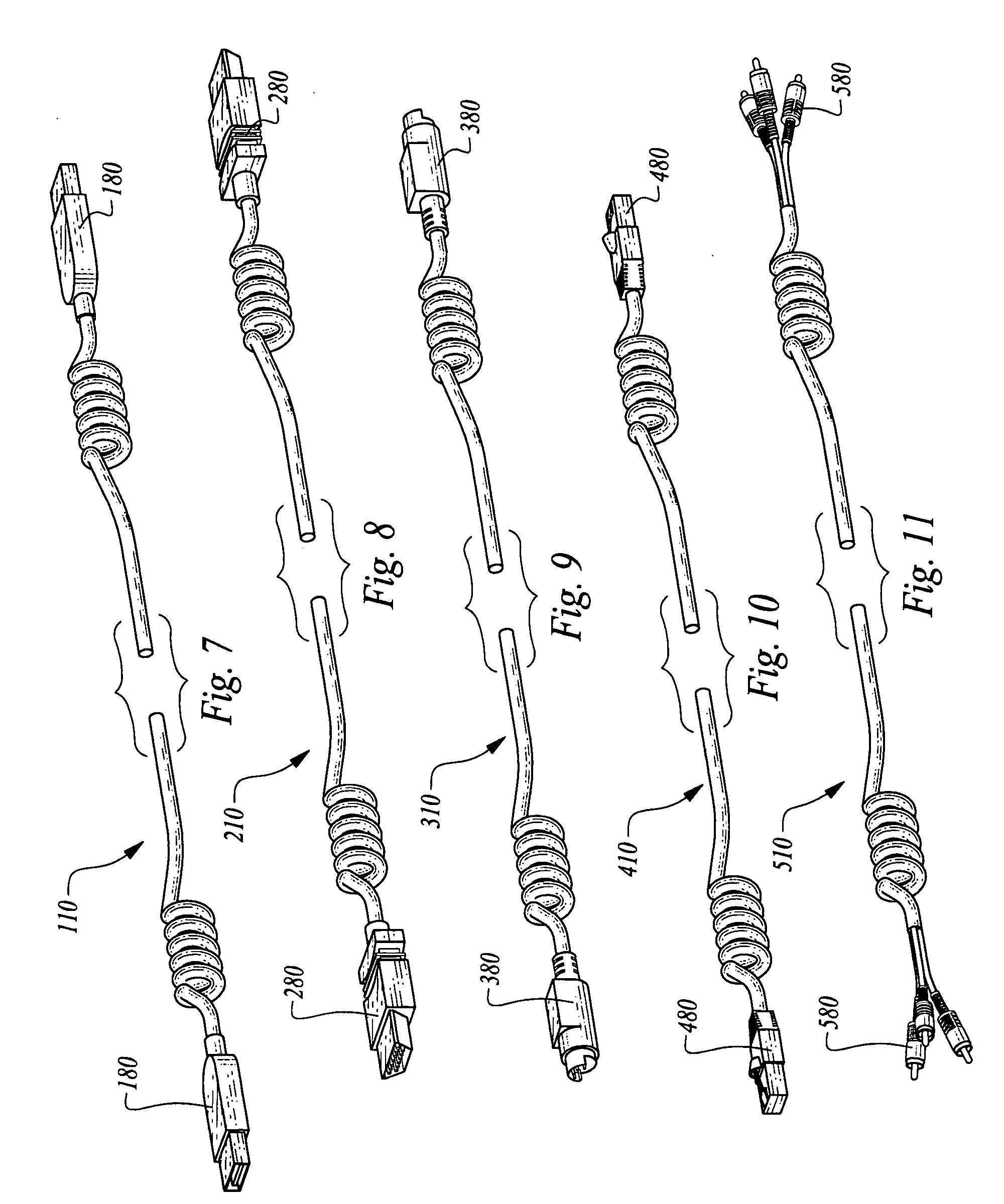

Extension cord featuring length adjustable ends

InactiveUS20090104811A1Prevent kinkingAdjustable lengthTwo-part coupling devicesFlexible lead accommodationPower cableSCSI

An extension cord is provided with a central portion which is uncoiled, this central portion bounded on either end by a first coil and a second coil. Each of these coils are length adjustable while the central portion is substantially non-extendible. The extension cord can be fixed in position at a point along the central portion or routed through a narrow space at the central portion and still facilitate length adjustability at two different locations adjacent ends of the cord. Connectors are provided at ends of the cord. The connectors can be male and female power plug connectors for delivery of electric power or can be data cables or combined data and power cables. For instance, USB extension cords, SCSI extension cords, S-VIDEO extension cords, ethernet extension cords, RCA extension cords and power strip extension cords can provide various different connectors for the length adjustable extension cord of this invention.

Owner:SUMIDA WESLEY K

Multifunctional support for sleeping in travel

InactiveCN103204170AEasy to installEasy to adjust the lengthVehicle seatsSeating furnitureEngineeringCushion

The invention relates to a multifunctional support for sleeping in travel. The support comprises a head cushion plate, a seat cushion plate, one or a plurality of support pipes and a base. The head cushion plate is a plate body used for supporting the head. One end of the seat cushion plate is cushioned under a seat. Grains are carved on the surface of one support pipe connected with the seat cushion plate and used for fixing other parts. The base is connected with a lowest support pipe in the support pipes or integrated with the support pipe. The support further comprises a chest cushion plate which is a plate body for supporting the chest and further comprises a package box. A hole is arranged on one lateral face of the package box, and the seat cushion plate can be inserted in the hole. The support can help passengers sitting on hard seats of a train to sleep. The passengers can rest comfortably even the passengers do not buy sitting tickets.

Owner:陈健全

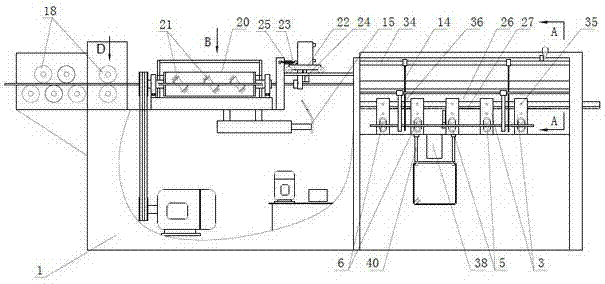

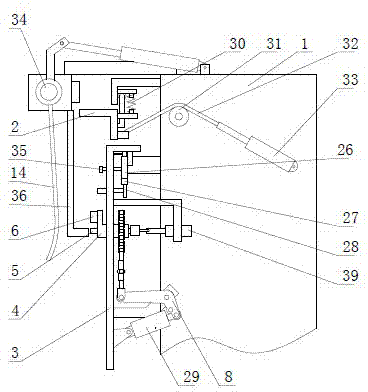

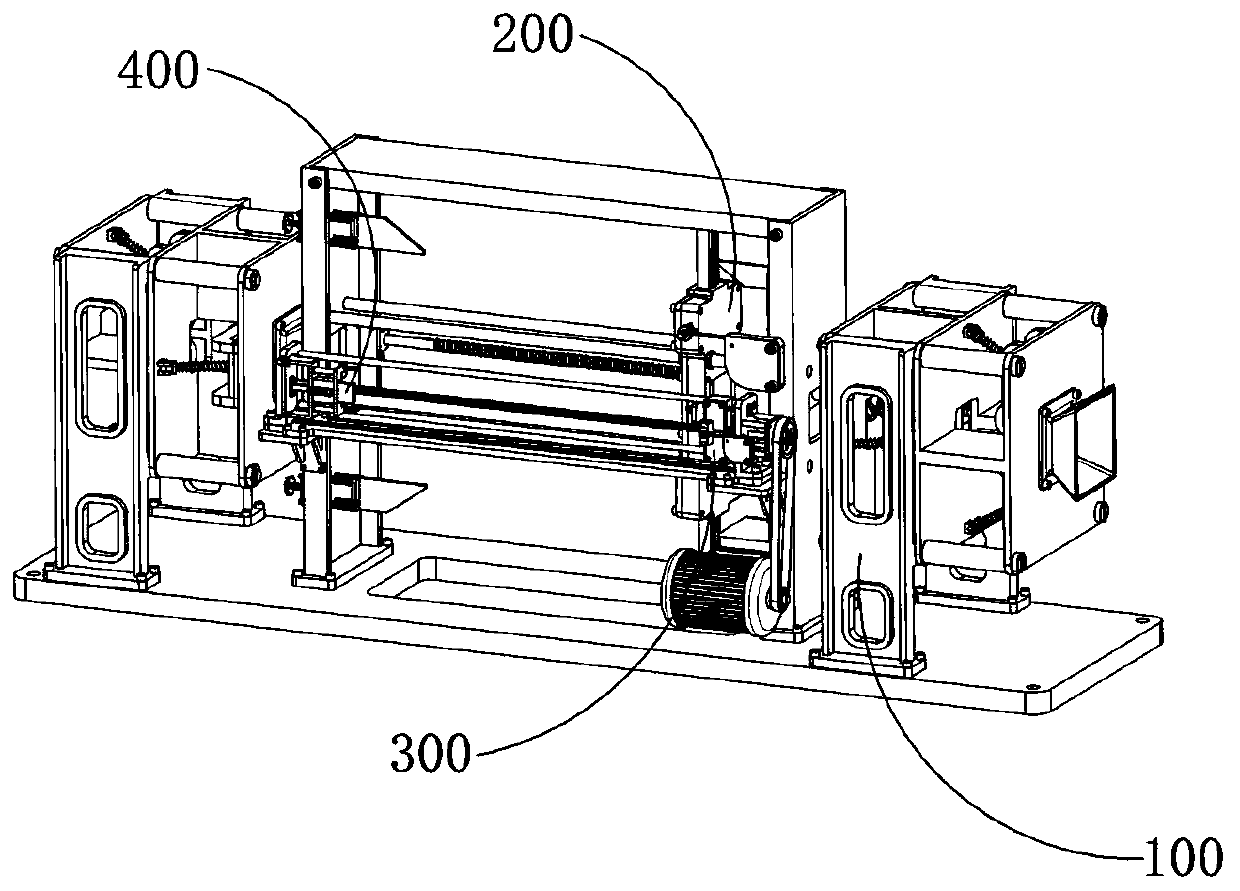

Multifunctional full-automatic steel bar bending and forming machine

The invention discloses a multifunctional full-automatic steel bar bending and forming machine which comprises a machine frame. A feeding device, a steel bar straightening device and a steel bar cutting-off device are installed on the machine frame, multiple bending devices are connected onto the machine frame, and a steel bar clamping device is connected onto one bending device. Each bending device comprises a bending frame connected onto the machine frame in a sliding mode, wherein a supporting shaft sleeve and a telescopic shaft are installed on the bending frame, the supporting shaft sleeve is further provided with a bending roller, a bending power device is installed on the bending frame, the supporting shaft sleeve is in power connection with a transmission chain wheel, a bending crank arm and a fixing column are further installed on the bending frame, a transmission chain is installed on the transmission chain wheel in a winding mode, two free ends of the transmission chain are respectively connected onto one supporting arm of the bending crank arm and the fixing column, a reset spring is installed between the transmission chain and the fixing column, the other supporting arm of the bending crank arm is in power connection with the bending power device, and the telescopic shaft is driven by a pulling power device. The multifunctional full-automatic steel bar bending and forming machine has the advantages of being high in labor efficiency and enabling a bending angle and the length to be adjustable quickly and conveniently.

Owner:WEIFANG HUAYAO MAGNETOELECTRIC MACHINERY

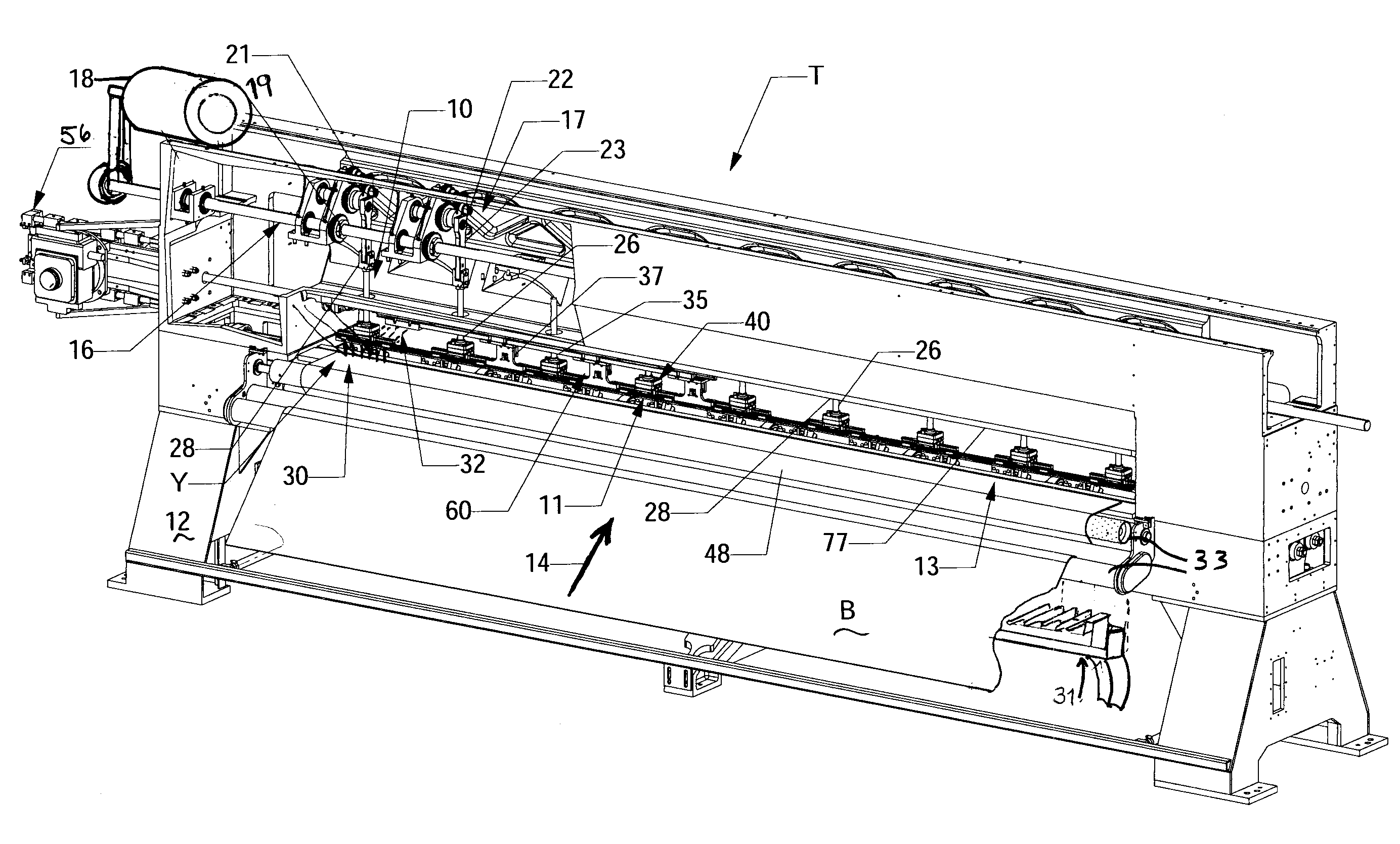

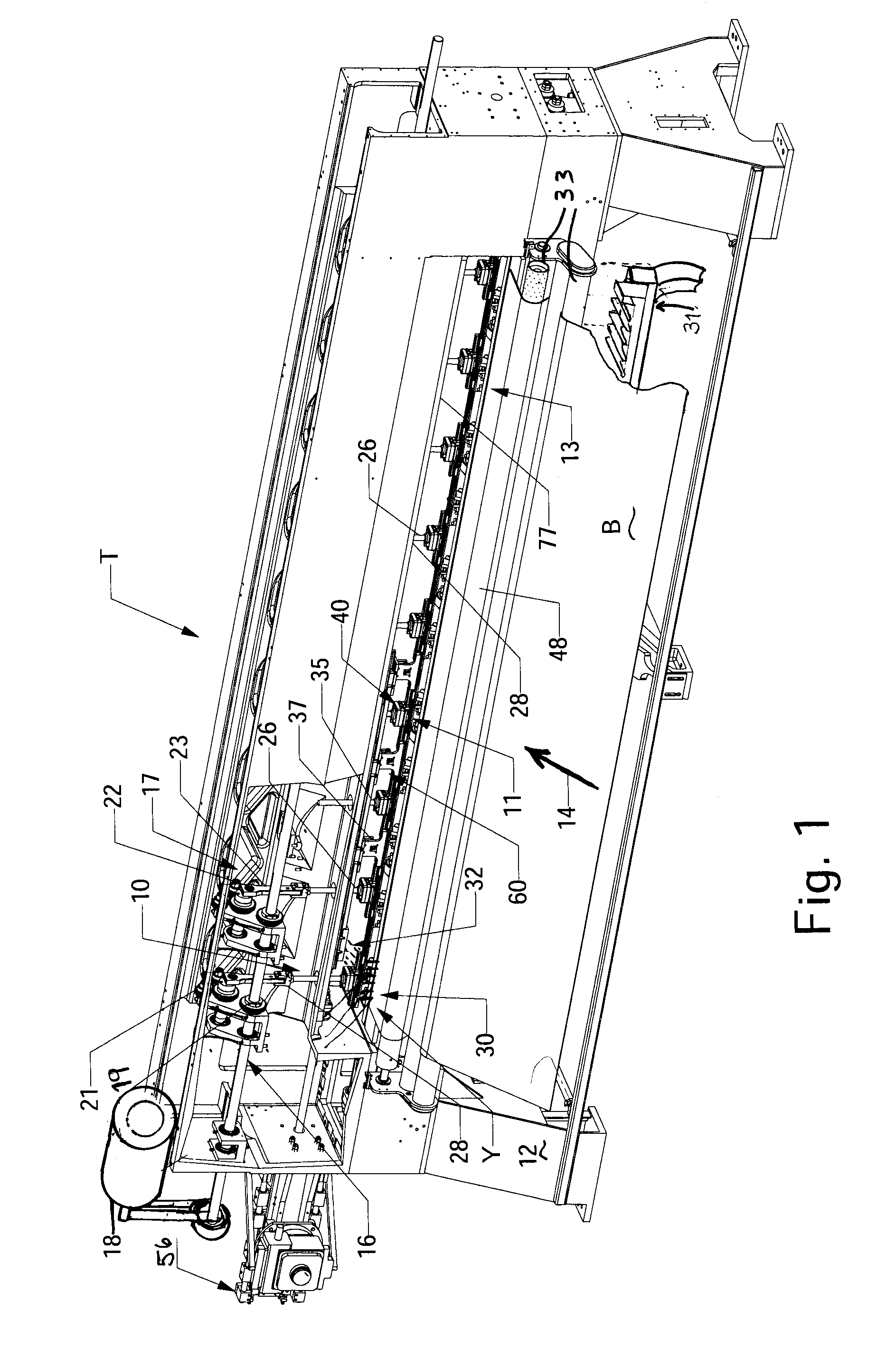

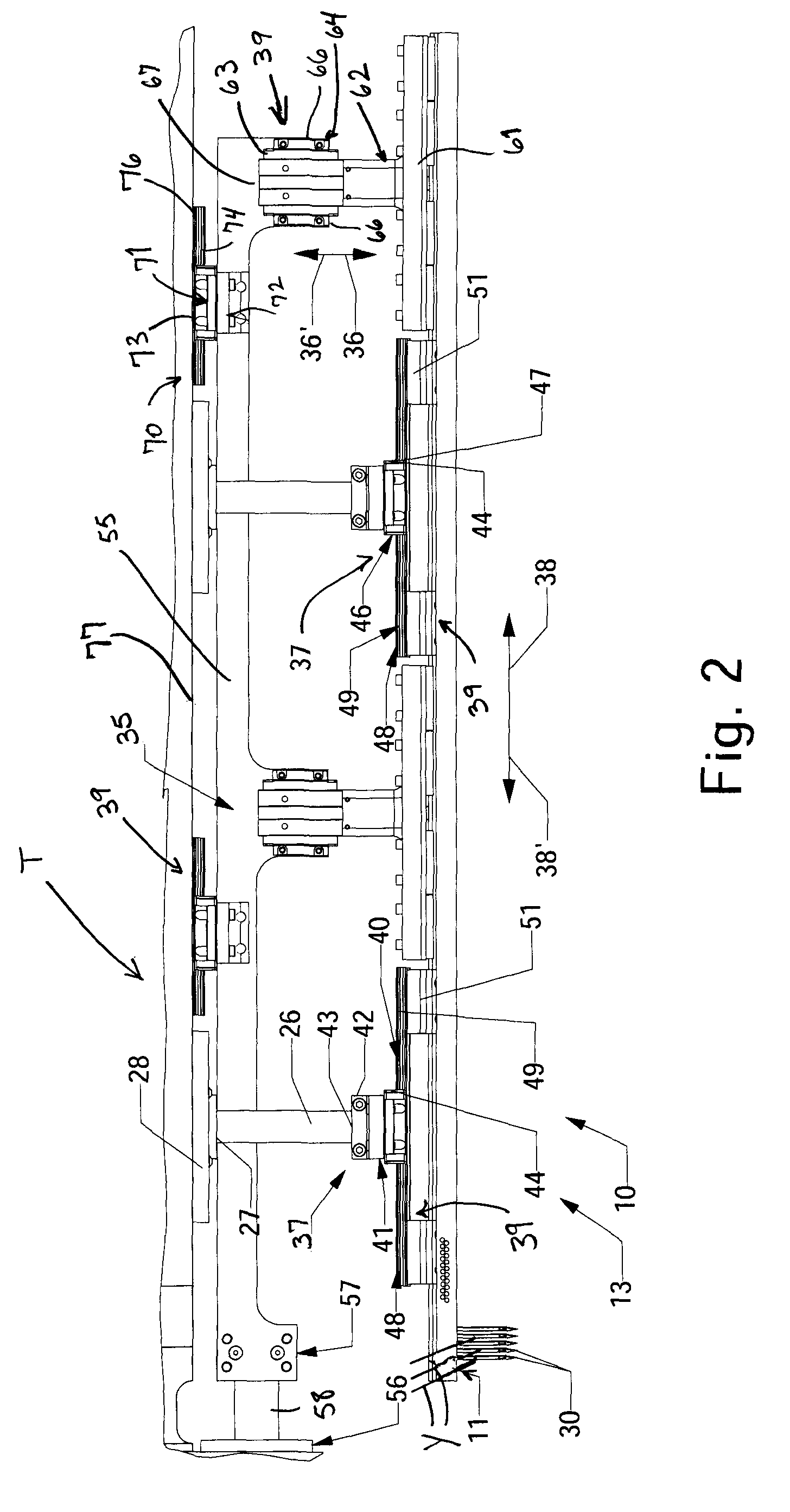

Tufting machine drive system

InactiveUS9260810B2Enhanced rigidity and dimensional stabilityHigh precisionTufting apparatusReciprocating motionLateral movement

A tufting machine has a needle bar for carrying a plurality of needles for reciprocating into and out of a base material. A sliding needle bar shift mechanism may shift the needle bar laterally according to a pattern. The needle bar is mounted for reciprocation and for lateral movement relative to the direction of reciprocation by a drive system including a first directional drive component having a foot secured to a respective push rod of the tufting machine and a second directional drive component connected to the shift mechanism. The first and second drive components will connect to the needle bar through linear bearings or bushings so that the motion of the needle bar in multiple different directions is controlled while permitting greater machine operating and needle bar shifting speeds.

Owner:CARD MONROE

Child Seat

A child seat includes a seat shell, a retractor assembly connected with the seat shell, two anchor strap portions extending outward from a rear of the seat shell, and an adjustment strap extending outside the seat shell. Each of the two anchor straps is provided with a fastener operable to attach with an anchor structure of a vehicle. The two anchor strap portions extend outward from a rear of the seat shell, and are provided with two fasteners operable to attach with an anchor structure of a vehicle, the anchor strap portions being connected with the retractor assembly. The adjustment strap is operable to actuate the retractor assembly to retract the anchor strap portions toward an interior of the seat shell.

Owner:WONDERLAND SWITZERLAND AG

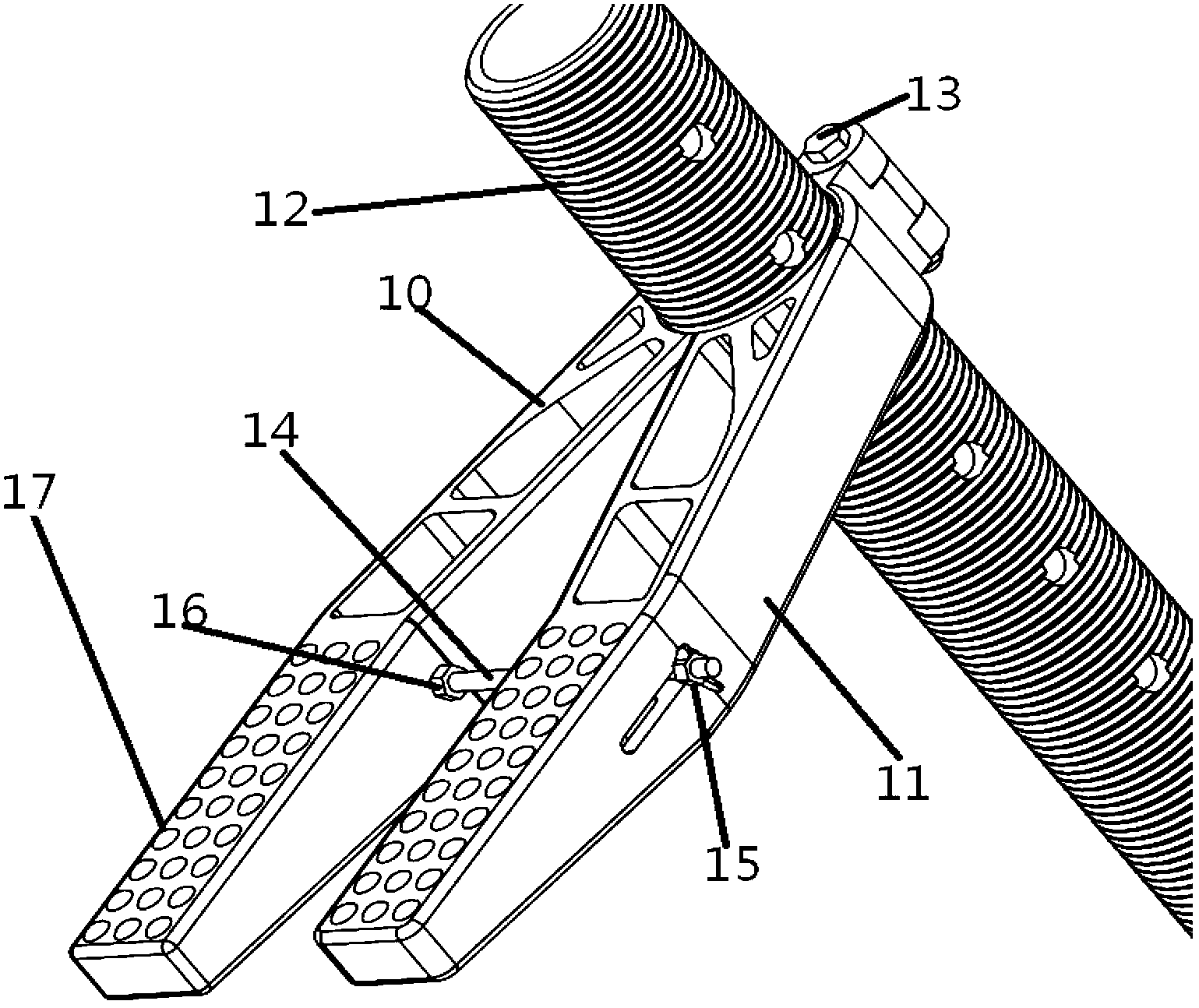

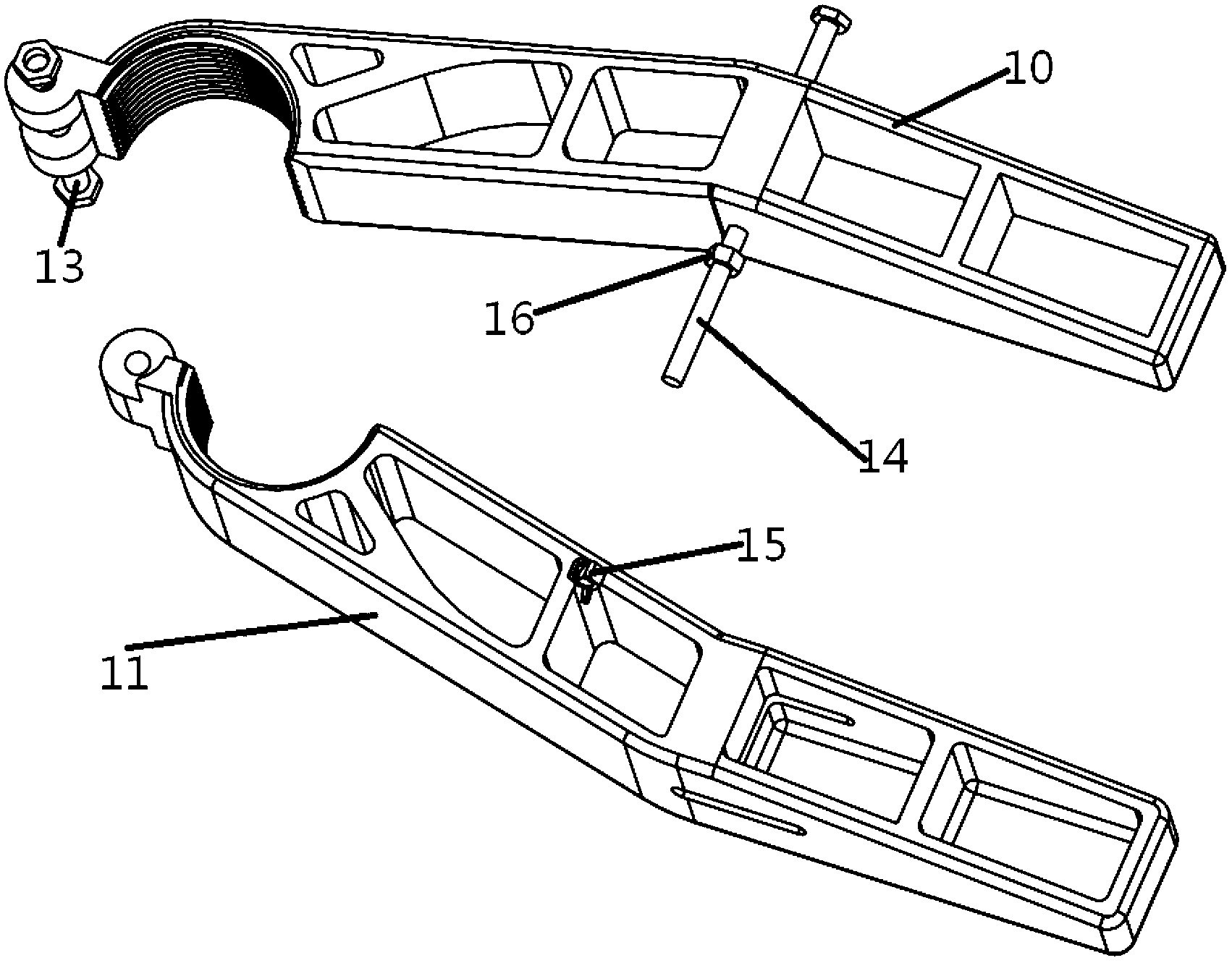

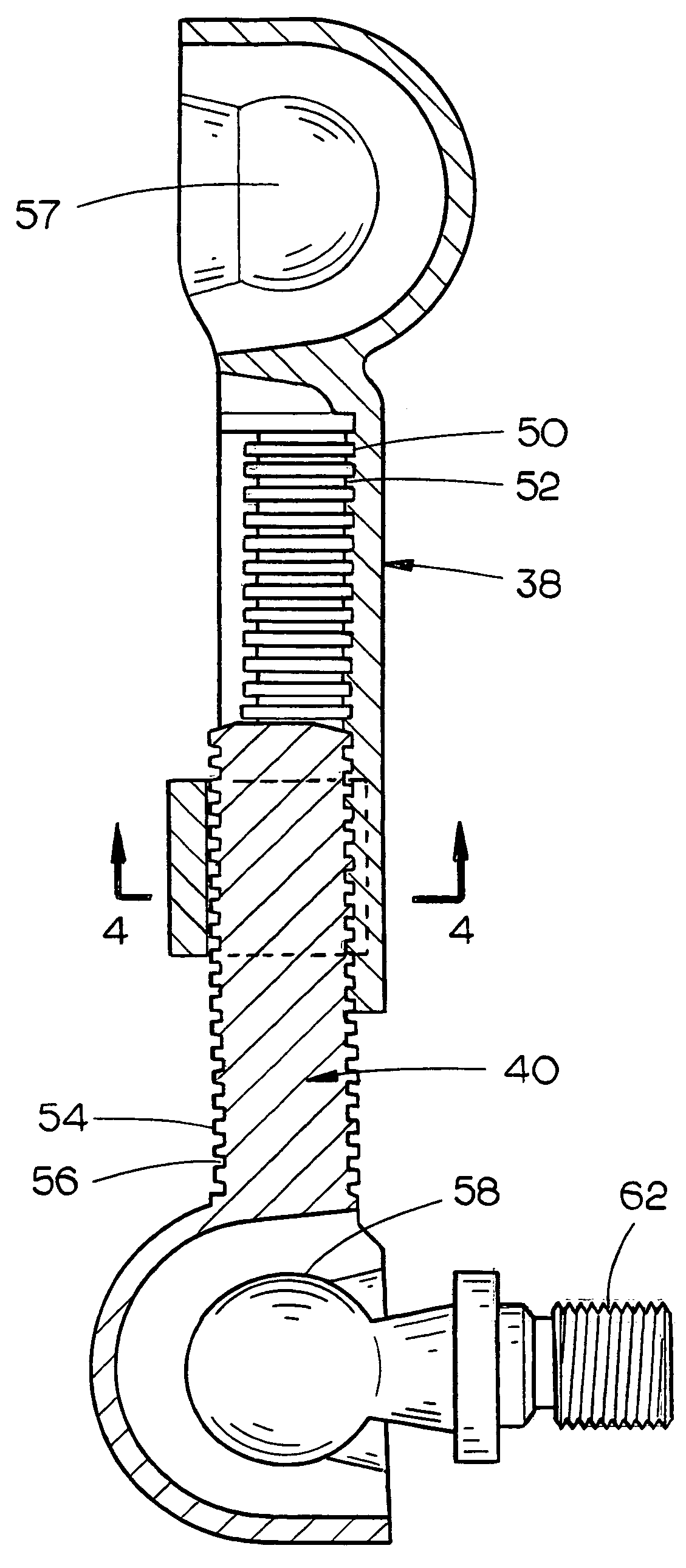

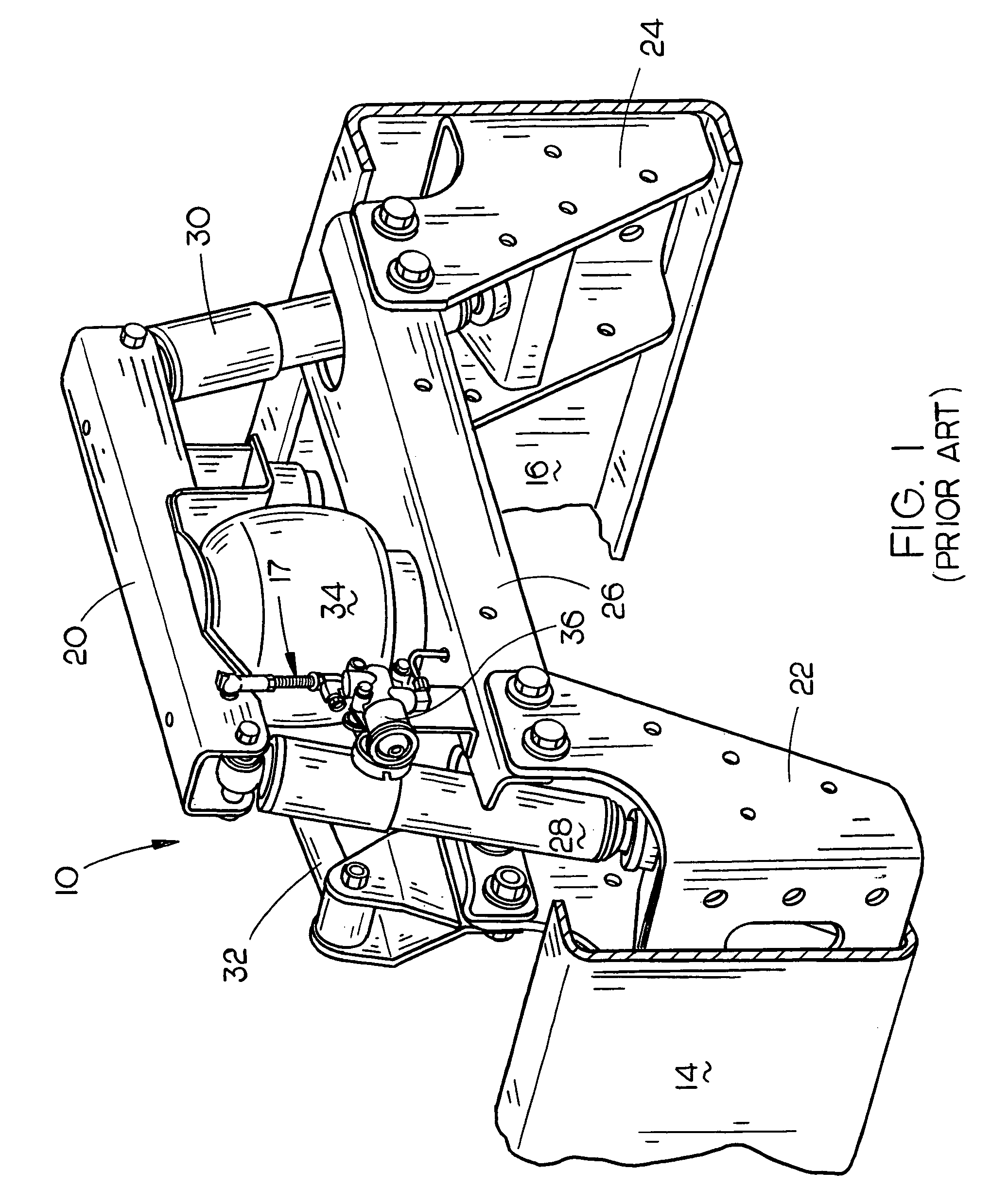

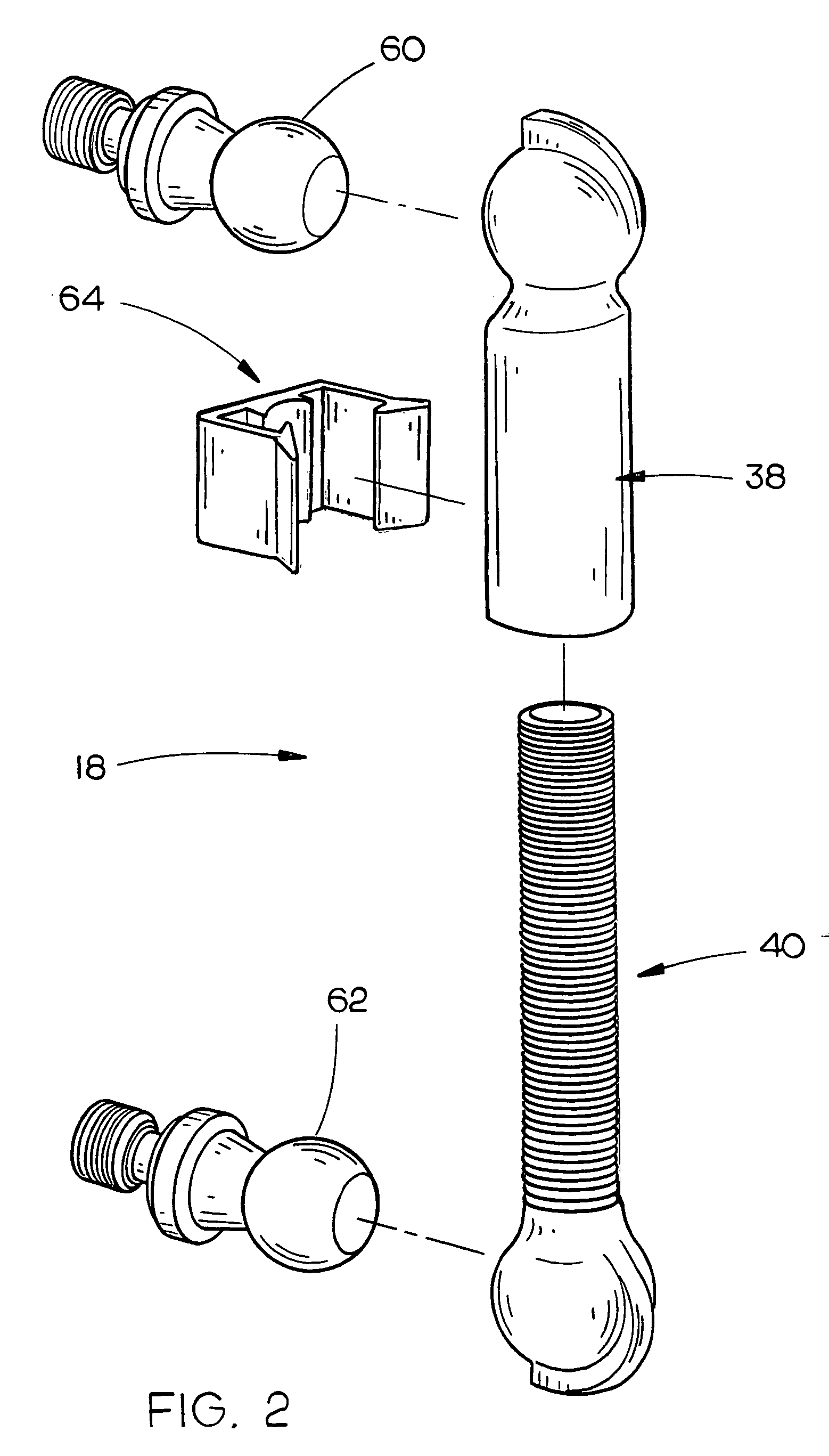

Height control linkage for a vehicle cab suspension

ActiveUS7216925B1Easy to adjust the lengthReduce manufacturing costVehicle seatsVehicle body-frame connectionsPlastic materialsMechanical engineering

Owner:LINK MFG

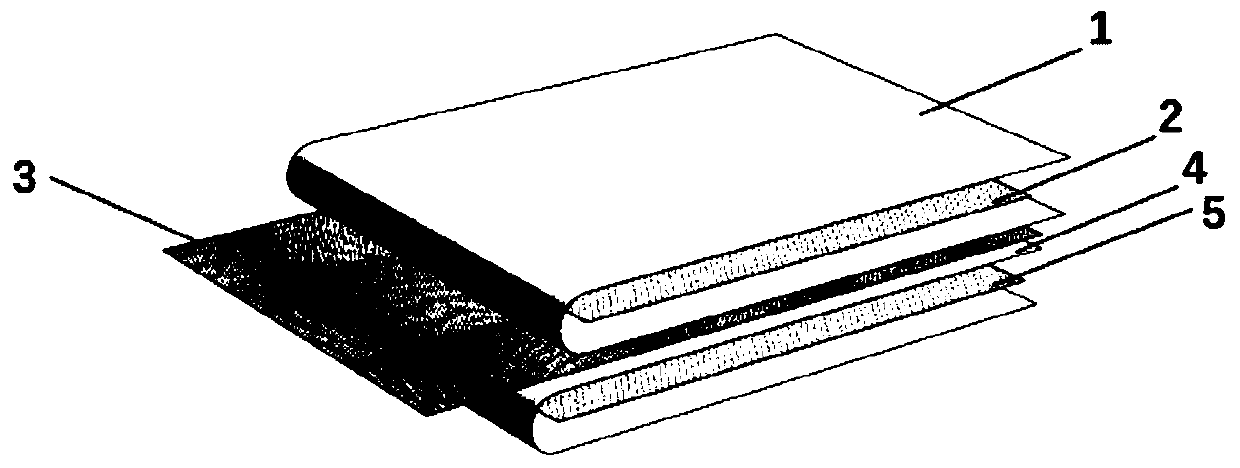

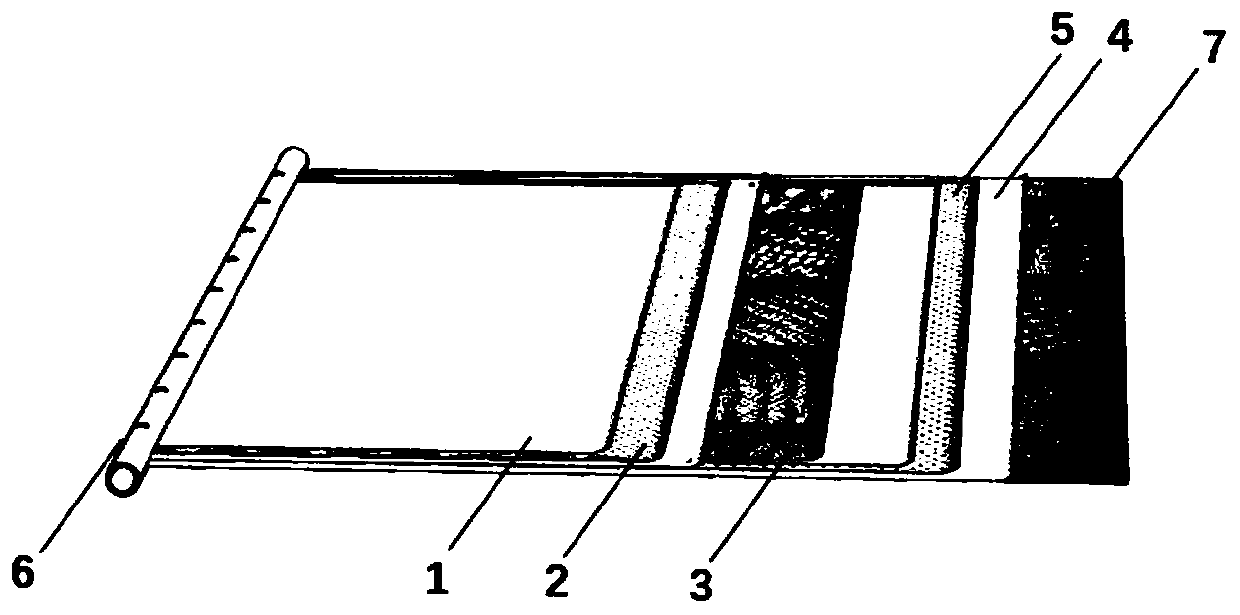

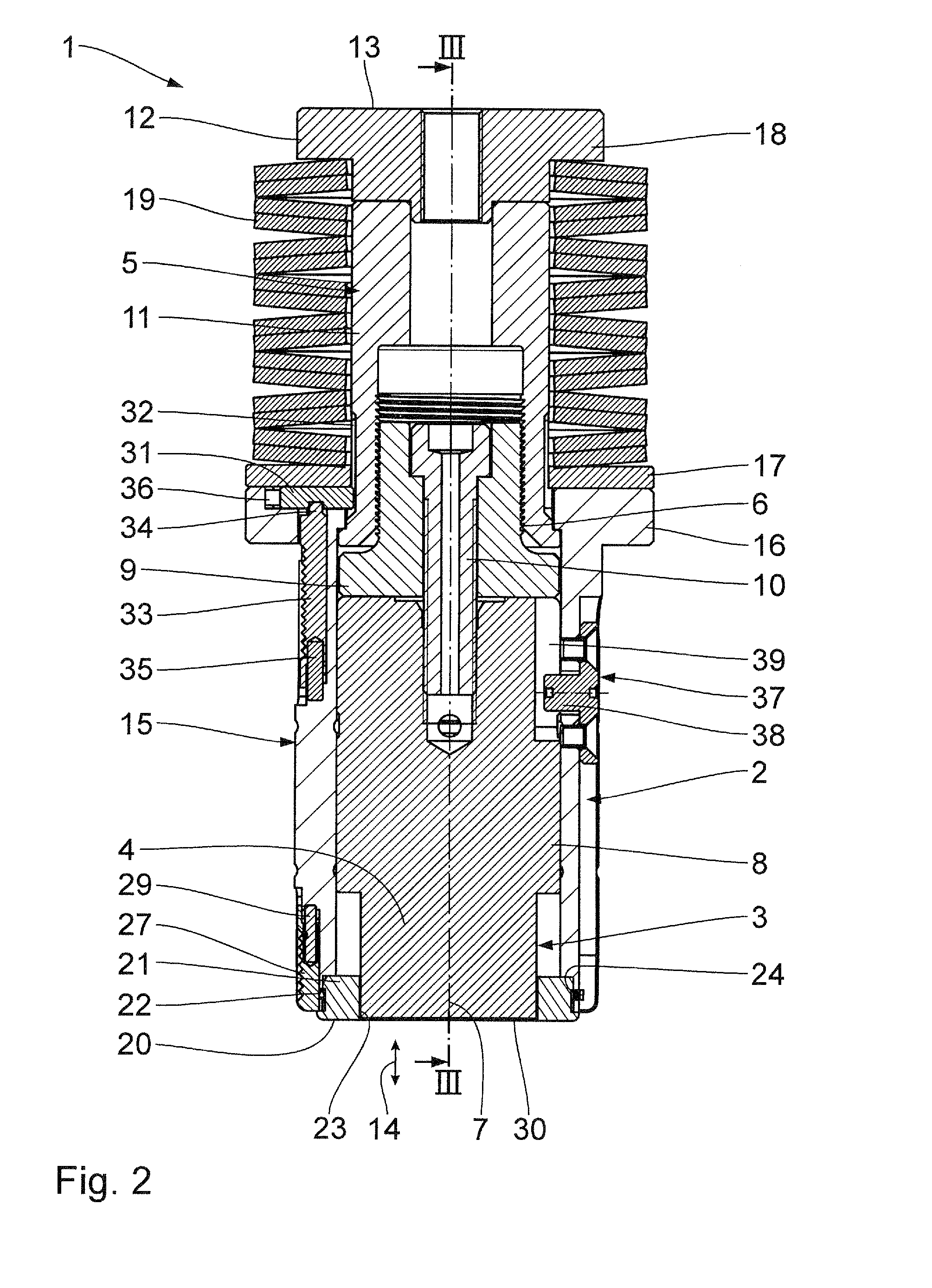

Composite membrane element suitable for water different in quality and manufacturing method

PendingCN110885112AKeep healthyEasy to adjust the lengthSemi-permeable membranesGeneral water supply conservationHigh fluxReverse osmosis

The invention discloses a composite membrane element suitable for water different in quality and a manufacturing method. The element includes a central tube, a reverse osmosis membrane assembly and ananofiltration membrane assembly. The reverse osmosis membrane assembly includes a reverse osmosis membrane, a dense water flow path cloth of the reverse osmosis membrane assembly and a pure water flow path cloth. The nanofiltration membrane assembly includes a nanofiltration membrane, a dense water flow path cloth of the nanofiltration membrane assembly and a pure water flow path cloth. This composite membrane element has a wide range of application, ensures healthy water drinking and no scaling, and has a high flux, the rejection rate of calcium and magnesium ions is higher than that of a single nanofiltration membrane, and the service lifetime of the composite membrane element is effectively prolonged.

Owner:BEIJING ORIGIN WATER FILM TECH

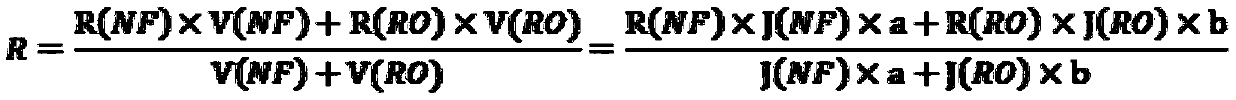

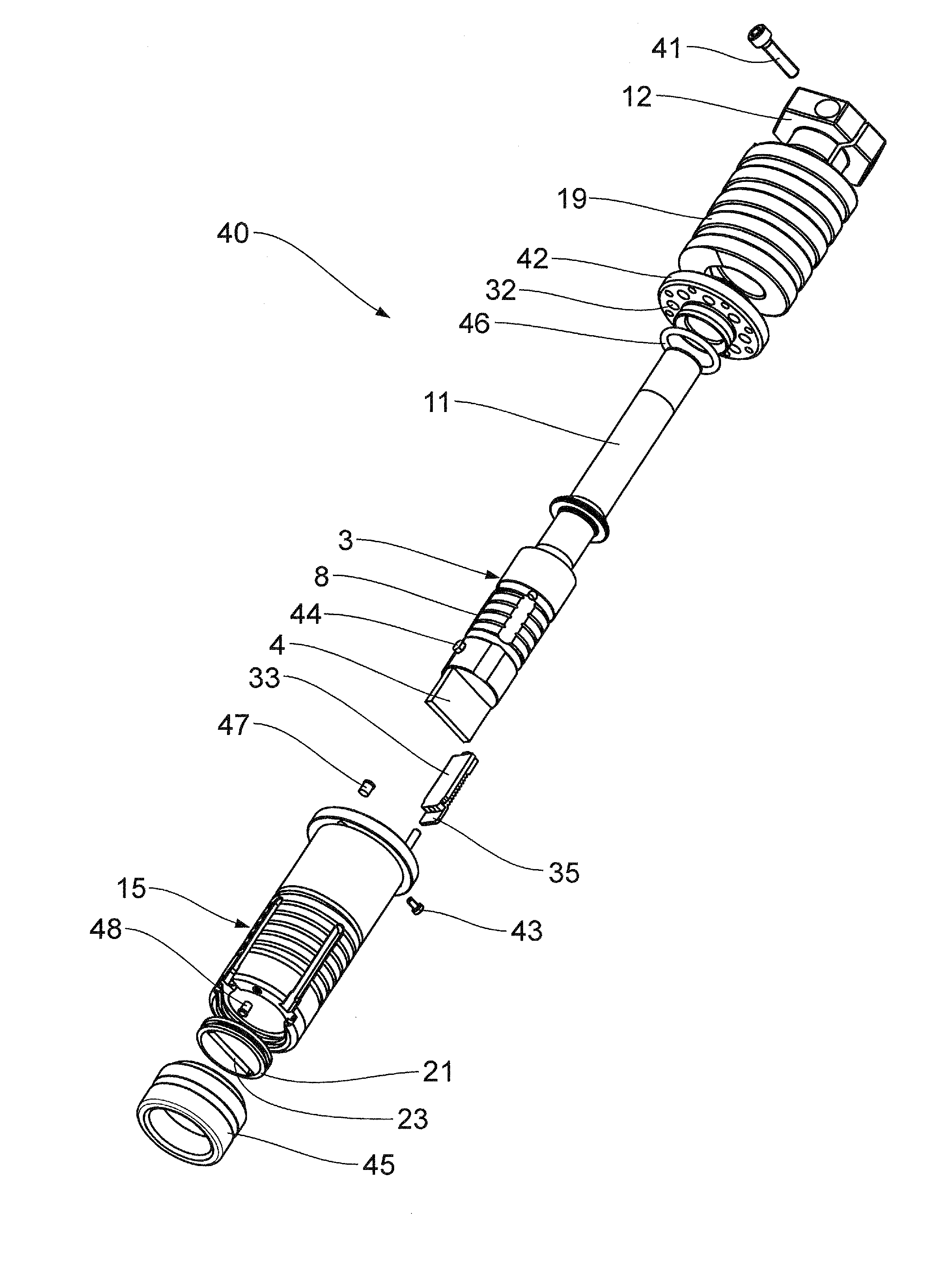

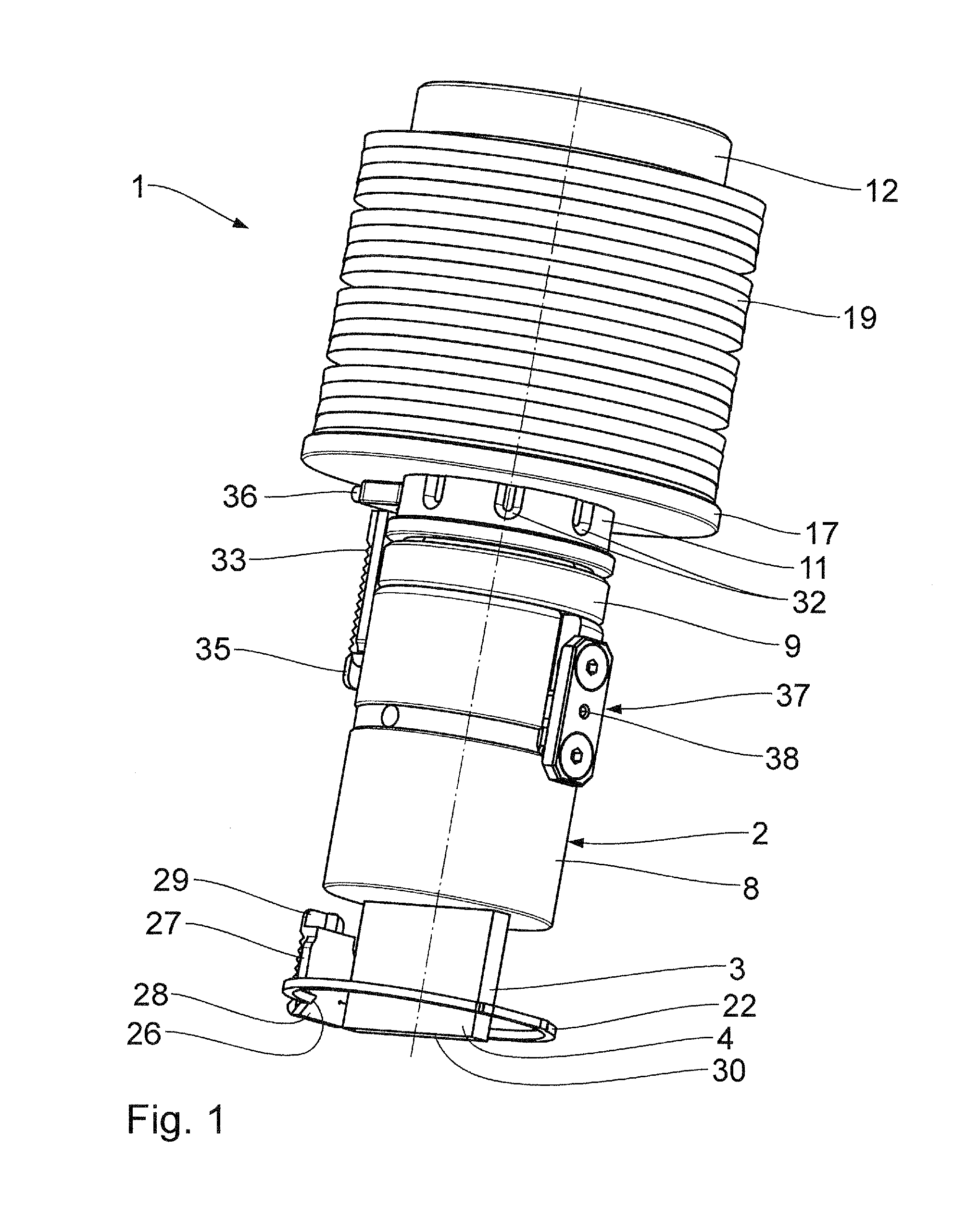

Stamping tool

InactiveUS20100206150A1Easy constructionOperational dependabilityPerforating toolsMetal working apparatusScrew positionEngineering

A stamping tool has a stamping punch for forming at least one punched hole in a workpiece. The stamping punch is guided in a guide housing along a stamping displacement movement. The stamping punch has a stamping element and a head element, which is connected with the stamping element by means of a screw connection. A length of the stamping punch between a head front face and a stamping surface, which closes off the stamping element at the front, can be set by means of the screw-in depth of the screw connection. An unlocking body, which is freely accessible from outside of the guide housing can be displaced between a locked position, in which the screw connection is blocked, and a screwing position, in which the screw connection is released. The result is a stamping tool with a simplified length adjustment.

Owner:PASS STANZTECHN

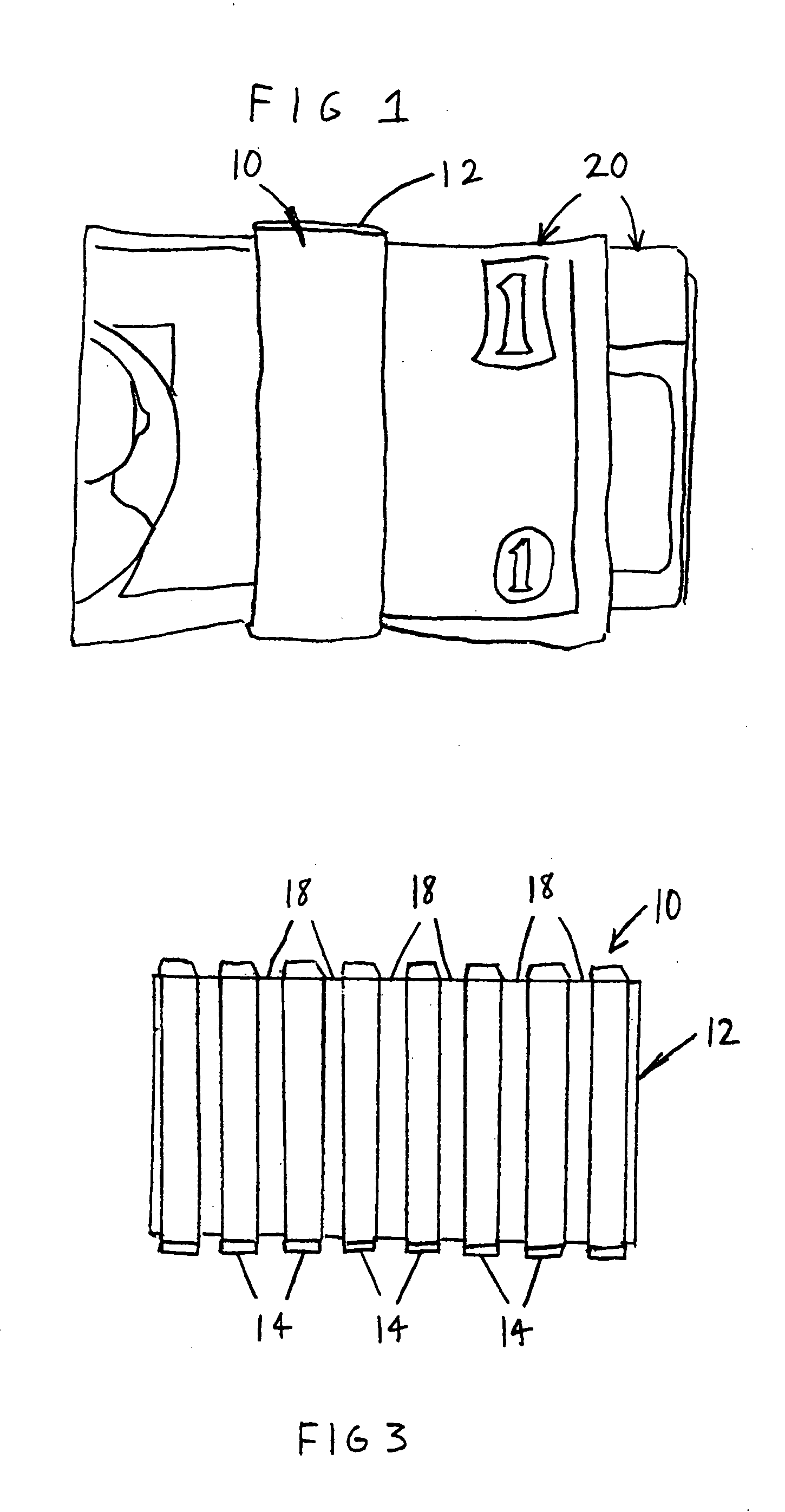

Holder assembly for currency, credit cards and like objects

A holder assembly for paper currency, credit cards and other type of currency including an elongated band comprising a plurality of movably interconnected segments extending along a length thereof. A connecting assembly, which may be formed of a shape memory alloy of the type demonstrating pseudo-elastic properties, interconnects the plurality of segments and is structured to facilitate expansion or contraction of the band as well as to normally bias the band, as well as the plurality of segments, into a contracted orientation. In at least one embodiment a coupling assembly is connected to the band and is disposed and structured to vary the length of the band such that the longitudinal dimension thereof is adjustable whether the band is in the expanded or contracted orientation. In addition, a container may be connected to the band and structured to removably contain one or more card type objects.

Owner:GLICKFIELD ADAM

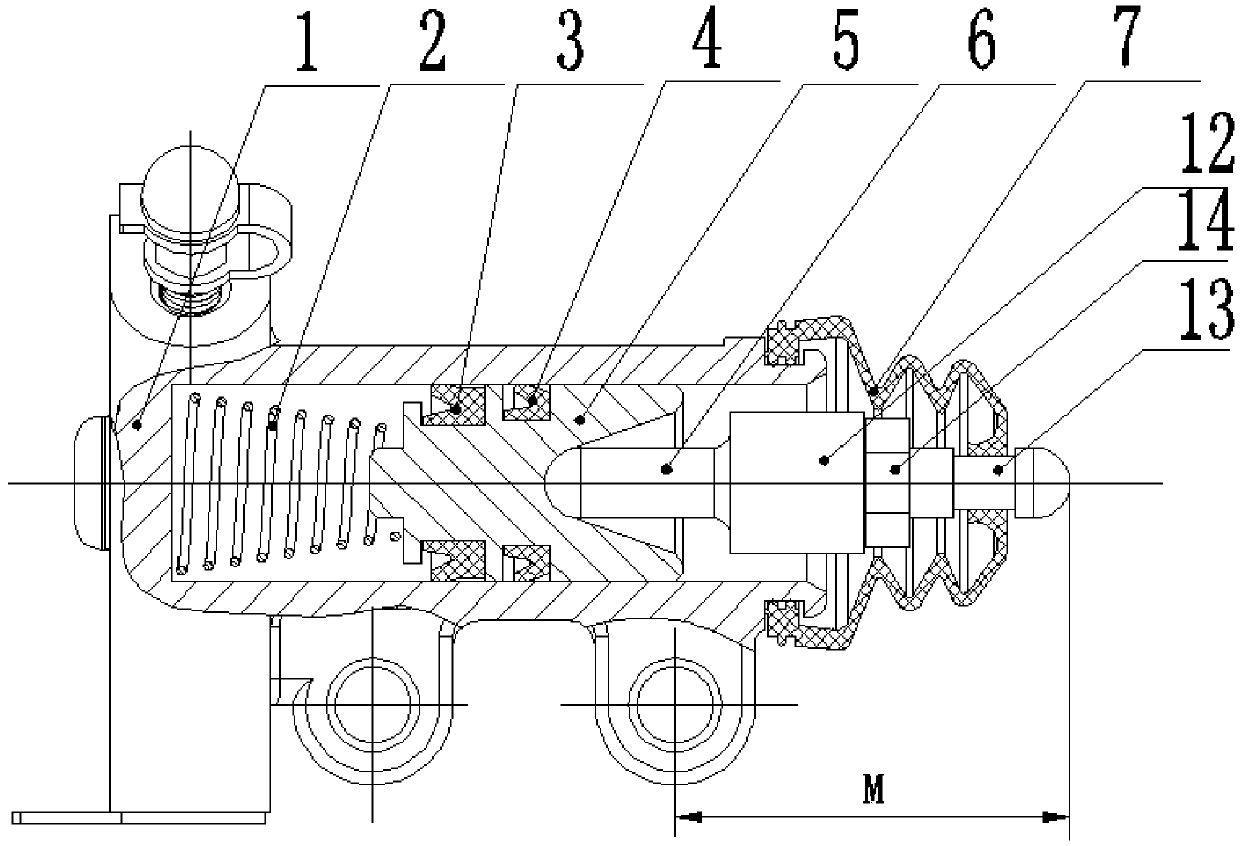

Clutch slave cylinder

InactiveCN102996666ASimple pump structureImprove reliabilityFluid actuated clutchesMaster cylinderEngineering

The invention discloses a clutch slave cylinder which is arranged between a clutch master cylinder and a clutch shifter. As an execution mechanism for separating a clutch, the clutch slave cylinder comprises a cylinder of which one end is opened; an oil intake channel and an exhaust channel which are communicated with the inner chamber of the cylinder are respectively arranged on the cylinder; and a spring, a piston and a top rod component are arranged inside the inner chamber of the cylinder from inside to outside in sequence. According to the clutch slave cylinder, the top rod is designed into a length adjustable structure, and the problems that the initial position of the top rod of the clutch slave cylinder is corrected, the clutch pedal travel is increased because of slight abrasion of the automobile clutch, and the like, are mainly solved.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

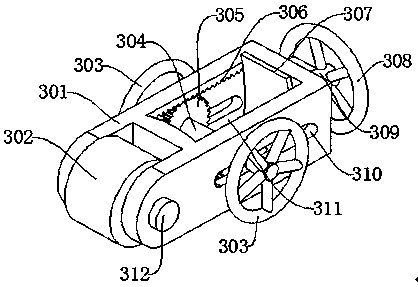

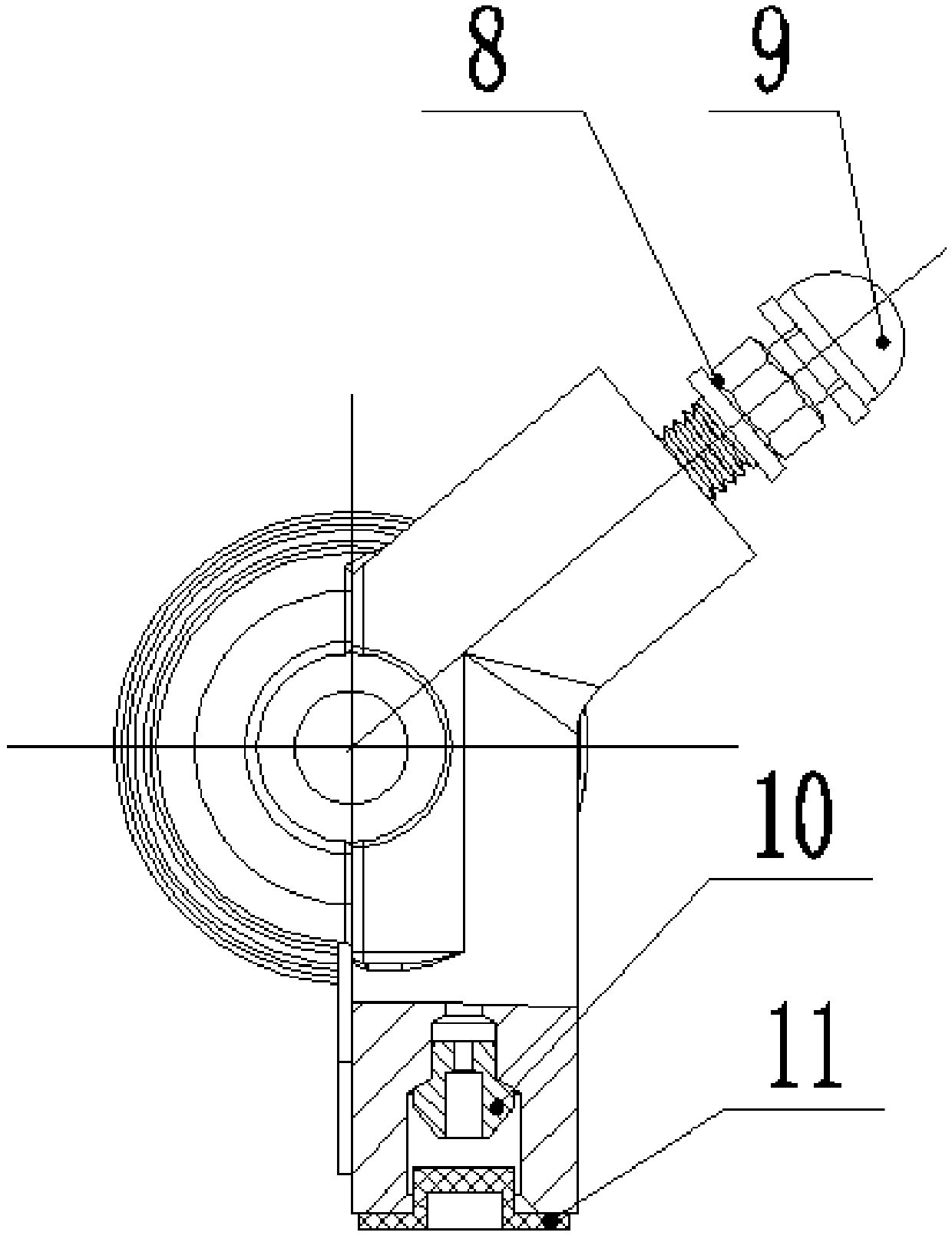

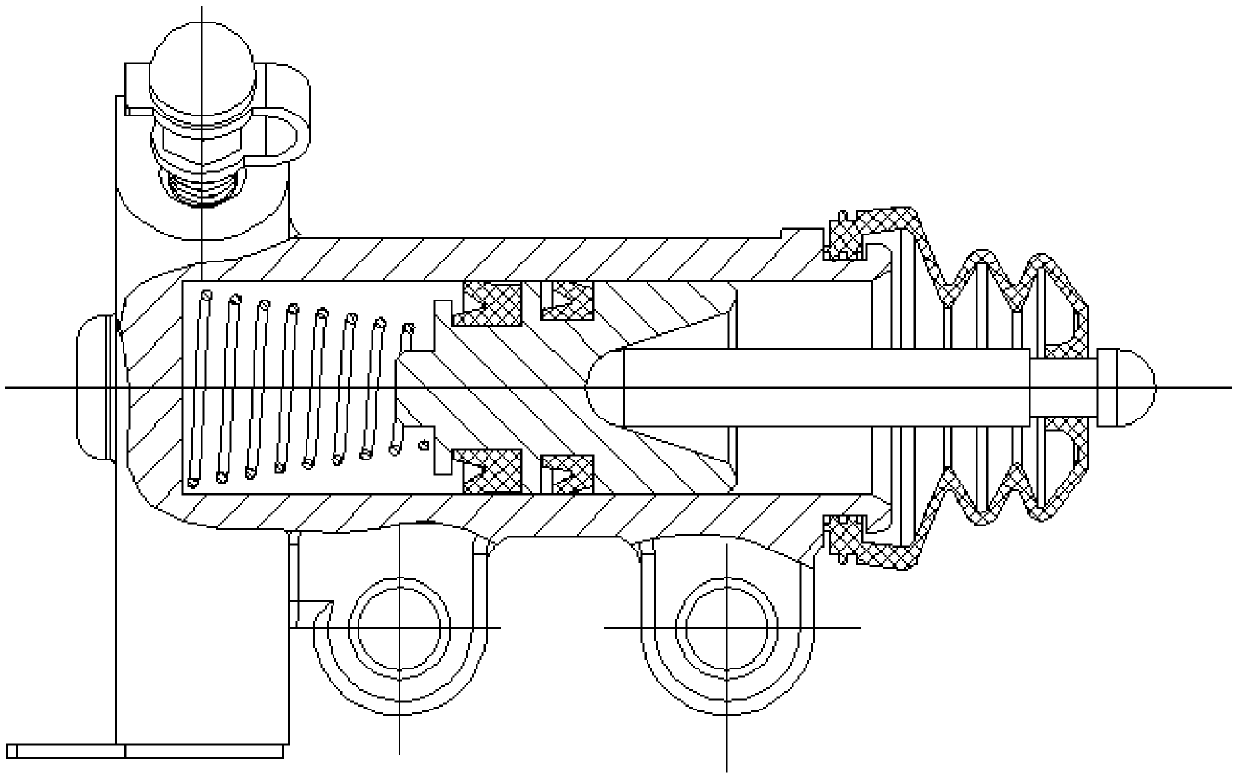

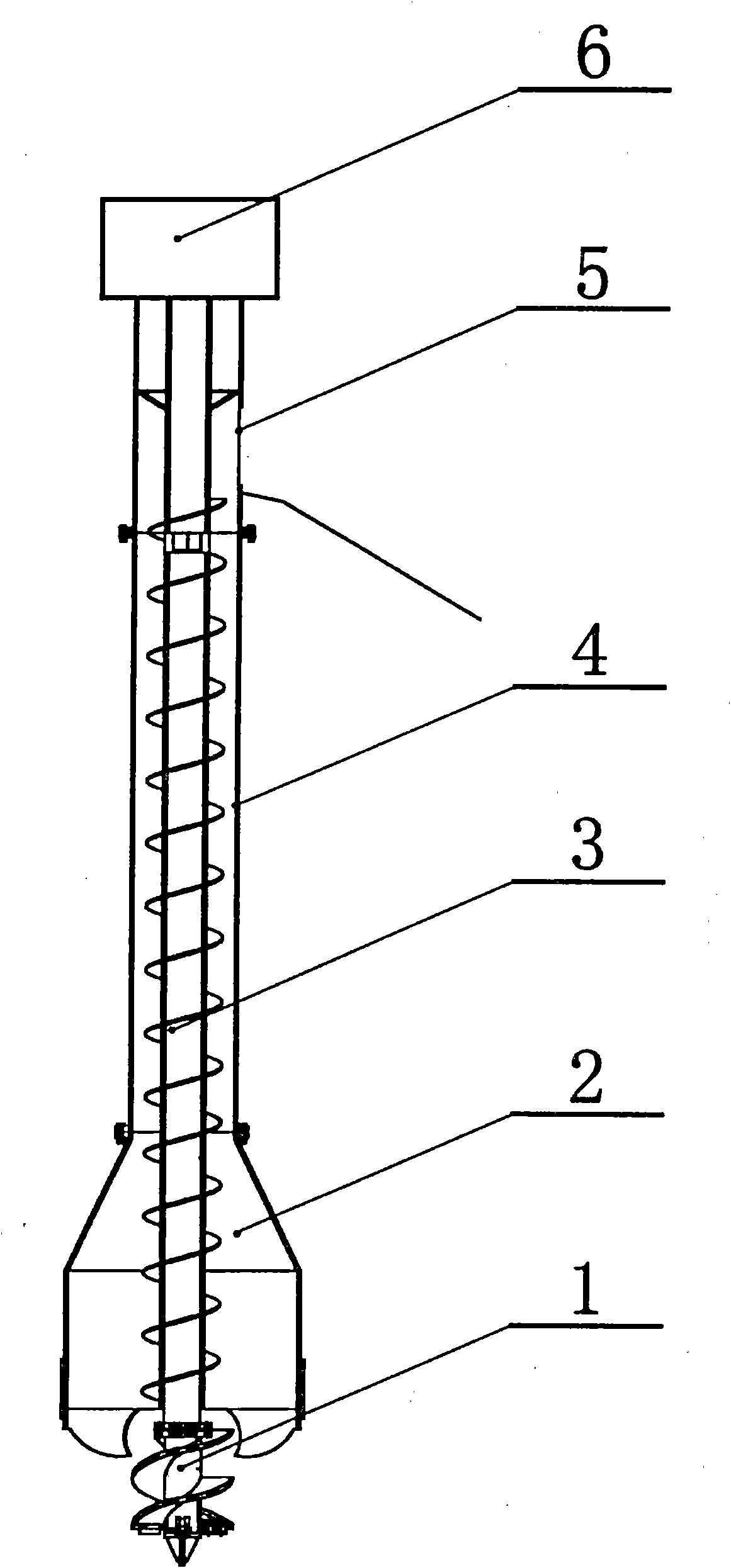

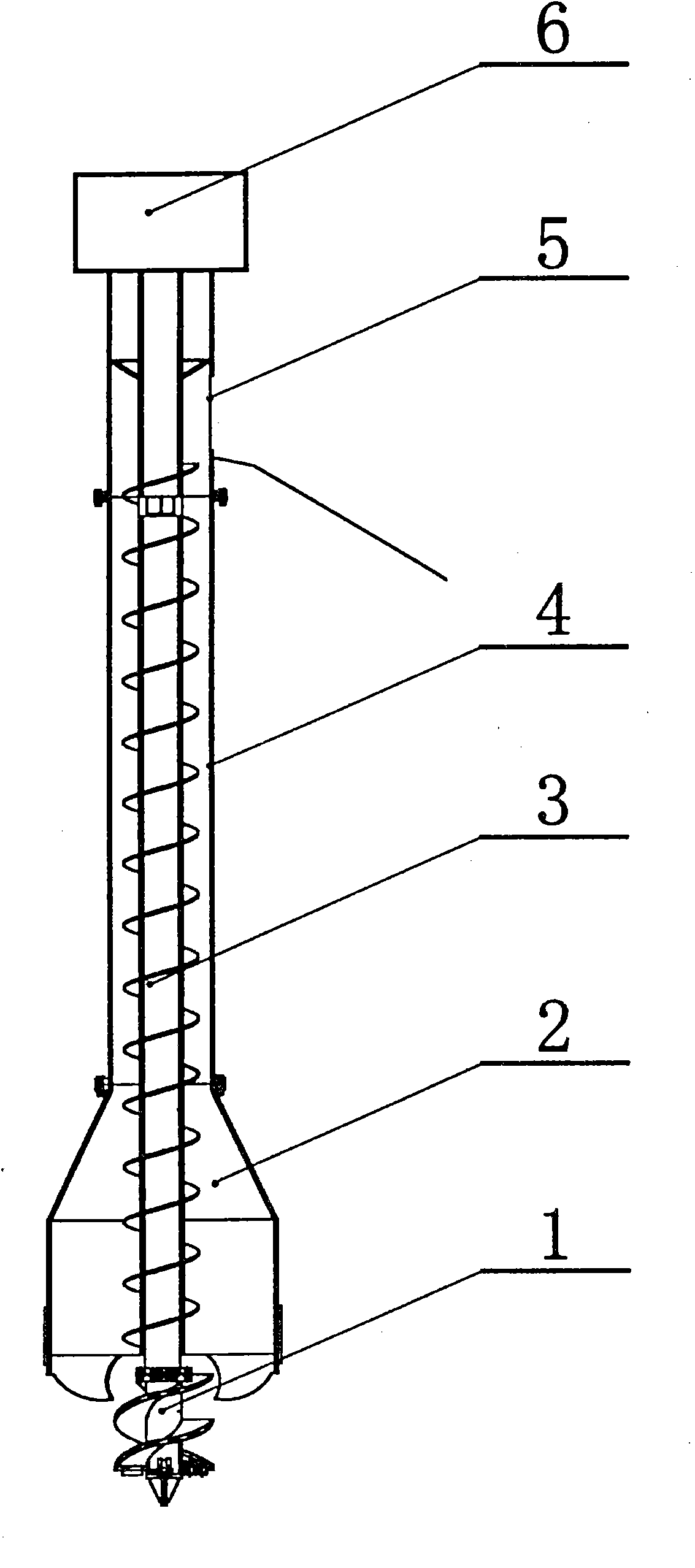

Compound rotary drilling rig drilling mechanism

The invention relates to a compound rotary drilling rig drilling mechanism which is provided with a long tube shape coat drill pipe of which the upper part is provided with a mud discharging port. The lower end of the coat drill pipe is fixedly connected with a heavy-calibre drill by a flange bolt; a spiral drill pipe coaxially rotating is arranged in the coat drill pipe; the bottom end of the rotary drill pipe is connected with a guiding drill; the coat drill pipe and the spiral drill pipe are in sectioned connection structure; two ends of the coat drill pipe and the spiral drill pipe are respectively provided with a quick-change connector capable of quickly splicing and installing; the upper part of the spiral drill pipe is connected with a motor; and meanwhile, the motor is meshed and connected with the gear on the coat drill pipe in a driving mode. The compound rotary drilling rig drilling mechanism has the construction function of a common drilling mechanism, can conveniently adjust the length of the drill pipe and carry out heavy-calibre drilling construction, can pump drilled mud and sand out of the drill pipe, effectively improves progress of works, solves the problem of poor stability caused by an over-high rotary drilling rig and is convenient to transport the rotary drilling rig.

Owner:毛杰

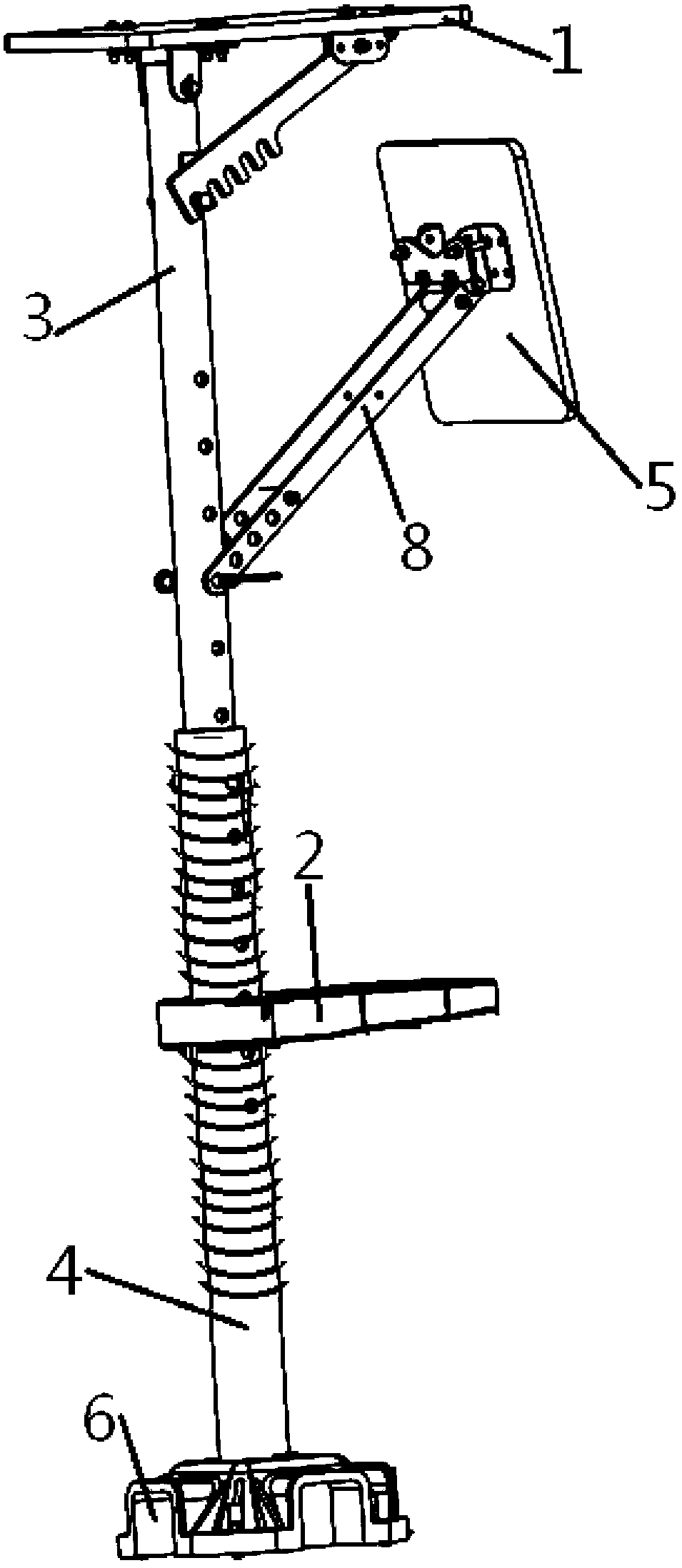

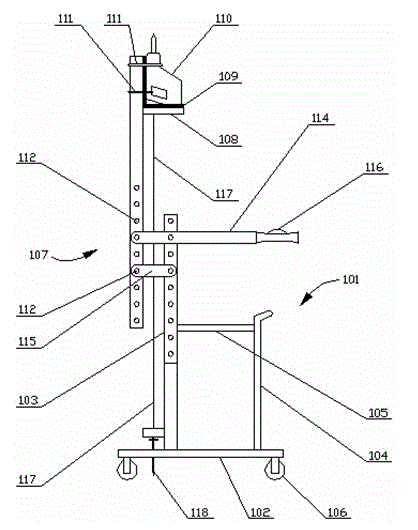

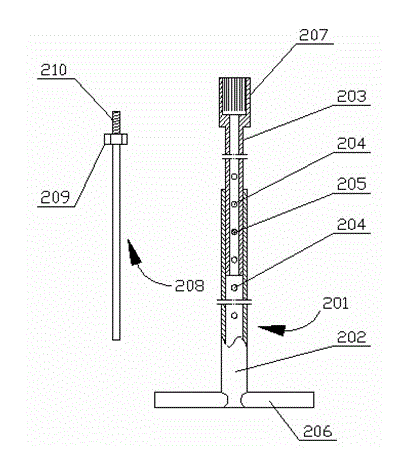

Method for rapidly positioning and installing hanging bars

The invention discloses a method for rapidly positioning and installing hanging bars, wherein perpendicular corresponding points of drilling points designed on a ceiling are marked on the ground; a mobile precise-positioning hanging bar drilling device is used for not only positioning the drilling points on the ceiling through the perpendicular corresponding points, but also drilling; and a convenient hanging bar installer is used for installing the hanging bars in eye holes at the drilling points. The method for rapidly positioning and installing the hanging bars has the beneficial effects of simple structure and rational design, known according to the descriptions of the scheme. Operations such as positioning, drilling and installation are performed by operators on the ground, so that the potential safety hazards are reduced. The operators can drill the ceiling and install the hanging bars on the ceiling even on the ground, without standing on a herringbone ladder; since the operators do not need to move, adjust or climb the herringbone ladder, the working efficiency is increased. Furthermore, the operators do not work in high-places resulting in operation inconvenience, so that the working quality is improved.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

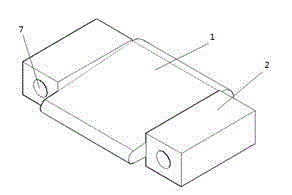

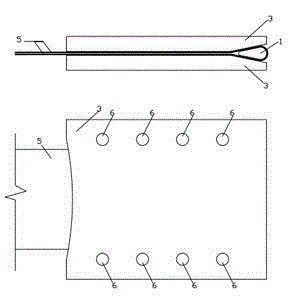

Fiber belt-anchoring device having wedge plate

ActiveCN105275219AEasy to operateImprove anchoring performanceBuilding repairsBridge erection/assemblyFiberEngineering

The invention discloses a fiber belt-anchoring device having a wedge plate. The fiber belt-anchoring device comprises the wedge plate and anchoring components which can be accessories on two sides, two clamping plates or an anchoring box. Fiber belts continuously bypass the thick head of the wedge plate or extend far towards the direction of the thin head or are folded by utilizing the two clamping plates or respectively clamped between the wedge plate and an inner surface of the anchoring box and then penetrate out together. The fiber belt-anchoring device having the wedge plate has following beneficial effects: the fiber belt-anchoring device is used for structural strengthening and is advantaged by being convenient in installation and reliable in effect; and cost is saved and a construction period is shortened.

Owner:周朝阳

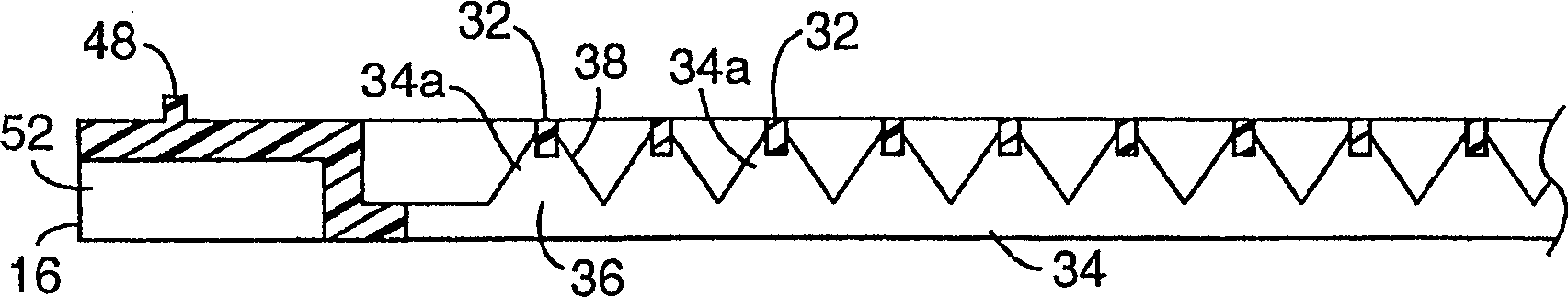

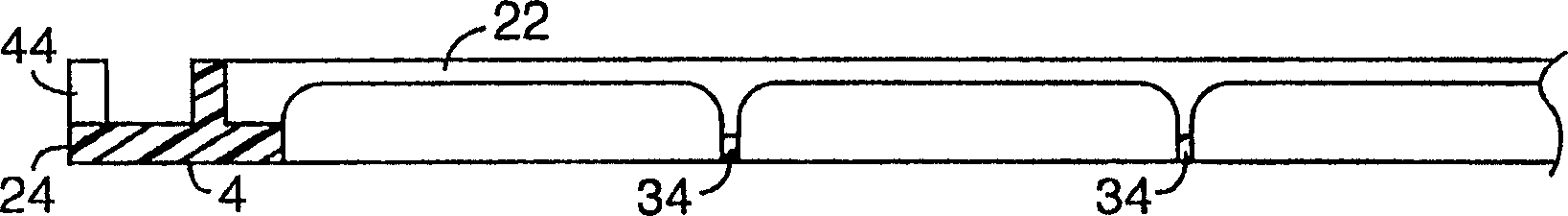

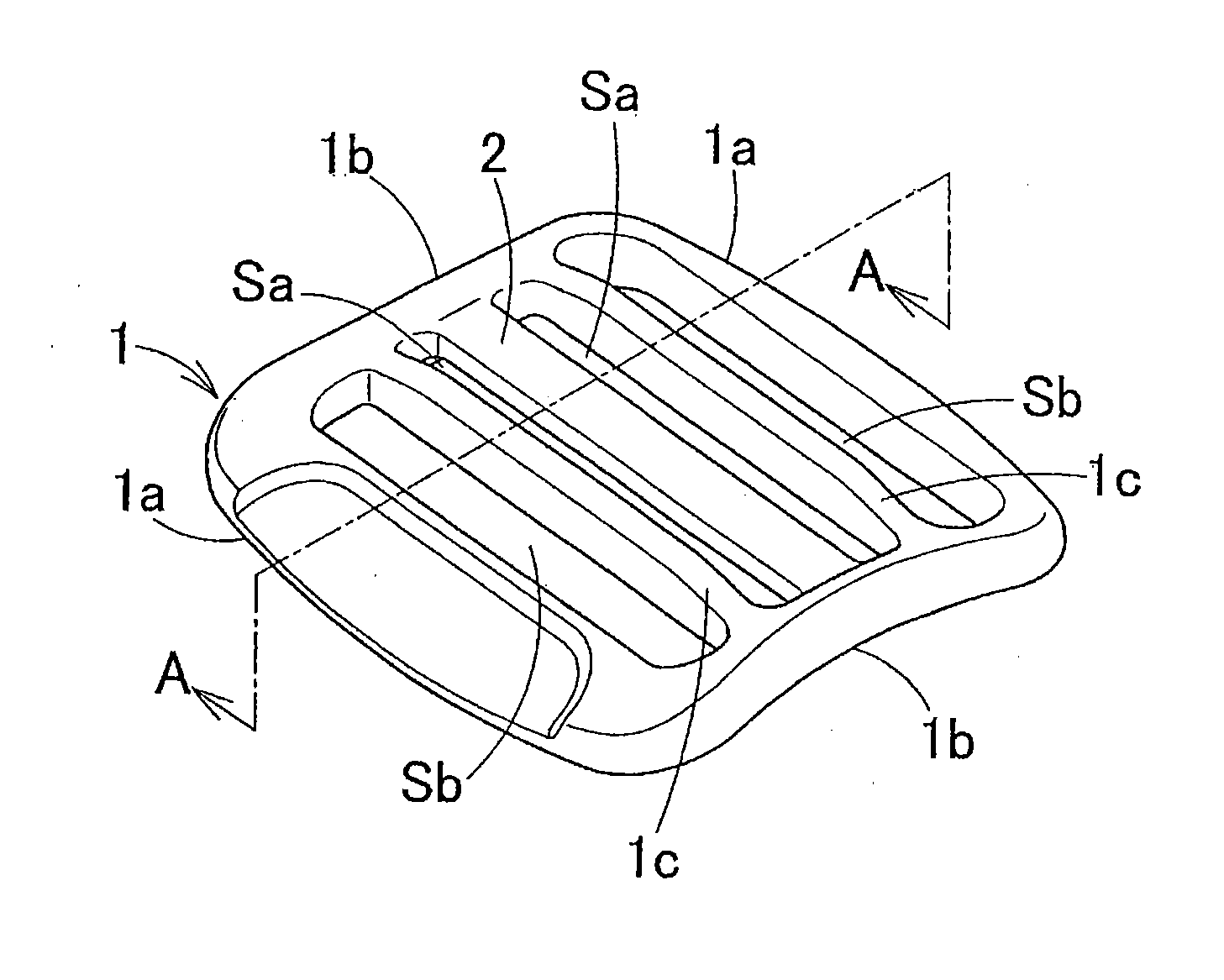

Filter assembly

InactiveCN1898007ALow costSpread evenly and evenlyDispersed particle filtrationTransportation and packagingPleatWaste management

A filter assembly includes a reusable filter frame and a replaceable, pleated, reversibly expandable, self-spacing filter removably arranged in the frame. The self-spacing pleated filter expands uniformly with equal pleat spacing to allow the filter to be easily installed in the reusable filter frame without the aid of a secondary spacing structure. When the filter is expanded to the length of the filter frame, the filter is under tension, thereby allowing the length of the filter to be readily adjusted to match the length of the frame and allowing the pleats to be aligned with corresponding ribs provided in the frame.

Owner:3M INNOVATIVE PROPERTIES CO

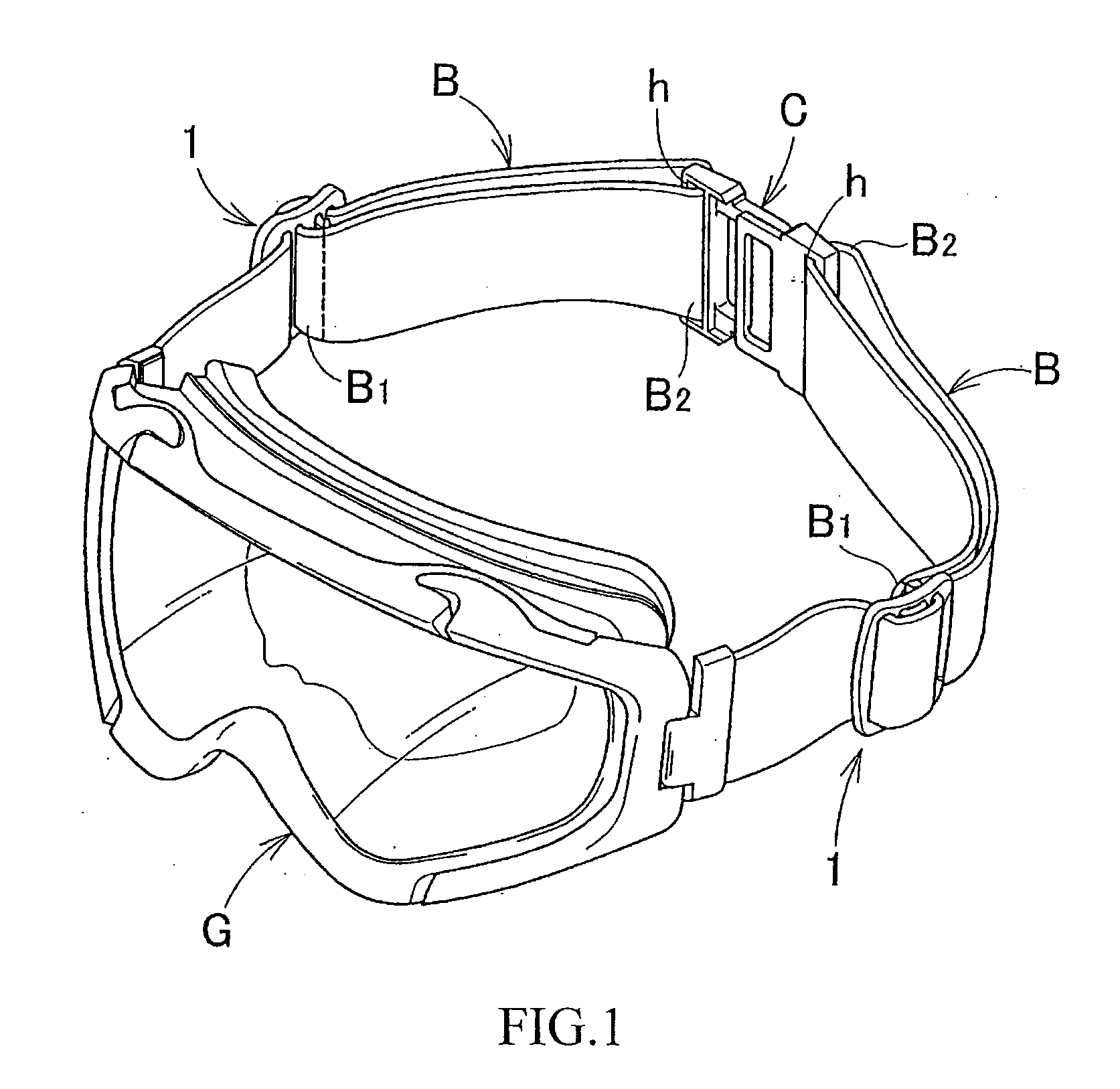

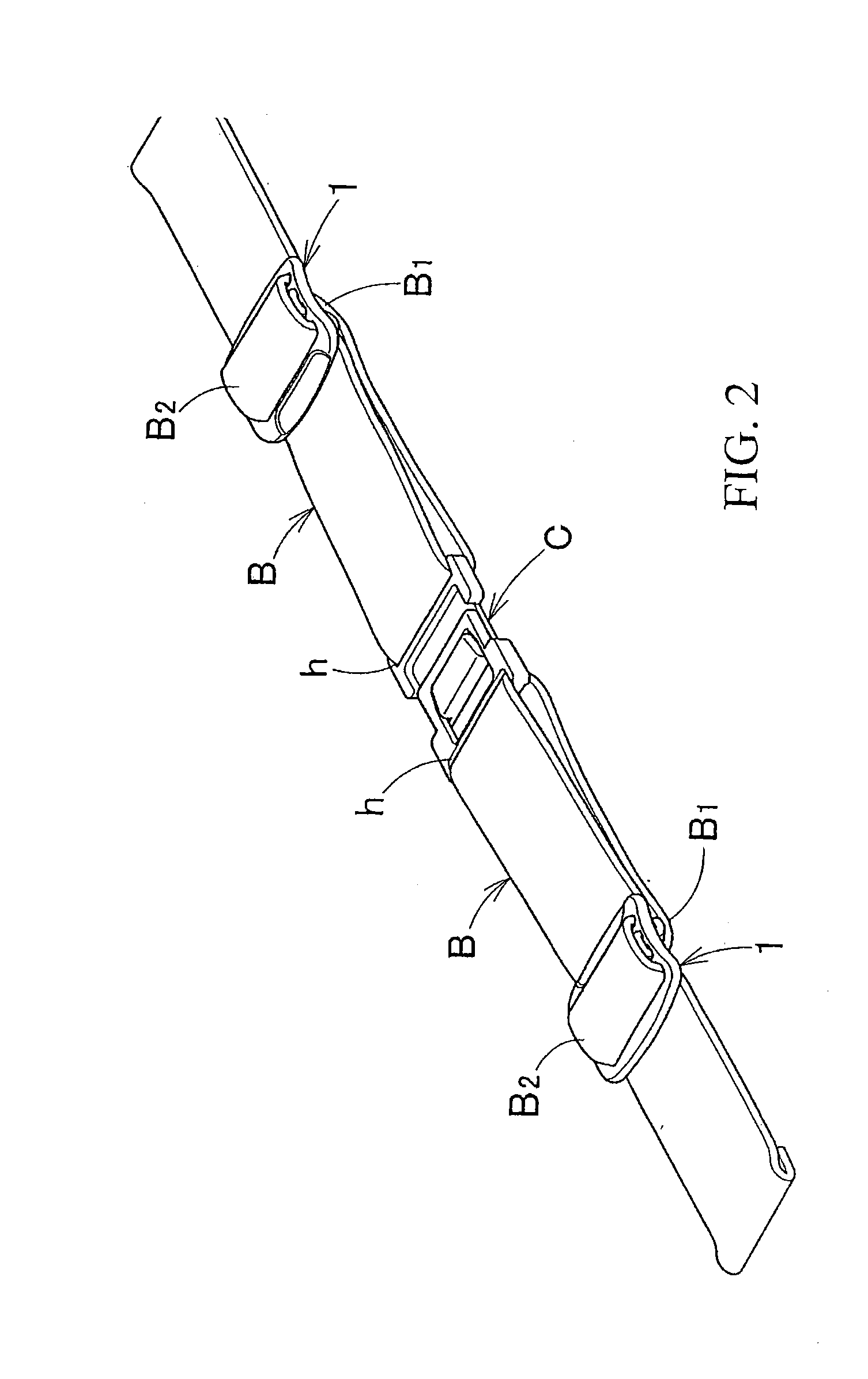

Belt length adjuster

ActiveUS20110239416A1Easy to adjust the lengthEasy to manufactureSnap fastenersClothes buttonsBraced frameEngineering

A belt length adjuster includes a frame body with two outer frames and two connecting frames, and a support frame provided between the two outer frames and stretching to and between the two connecting frames. The support frame supports one end part of the belt member to be used with the belt length adjuster. Two inner frames are respectively provided between the support frame and the respective outer frames and stretching to and between the two connecting frames. The support frame and the respective inner frames provide first insertion spaces into which the one end part of the belt member is inserted, while the respective inner frames and the respective outer frames provide second insertion spaces into which the other side of the belt member is inserted. Furthermore the one end part of the belt member is easily attached to the frame body.

Owner:SWANS

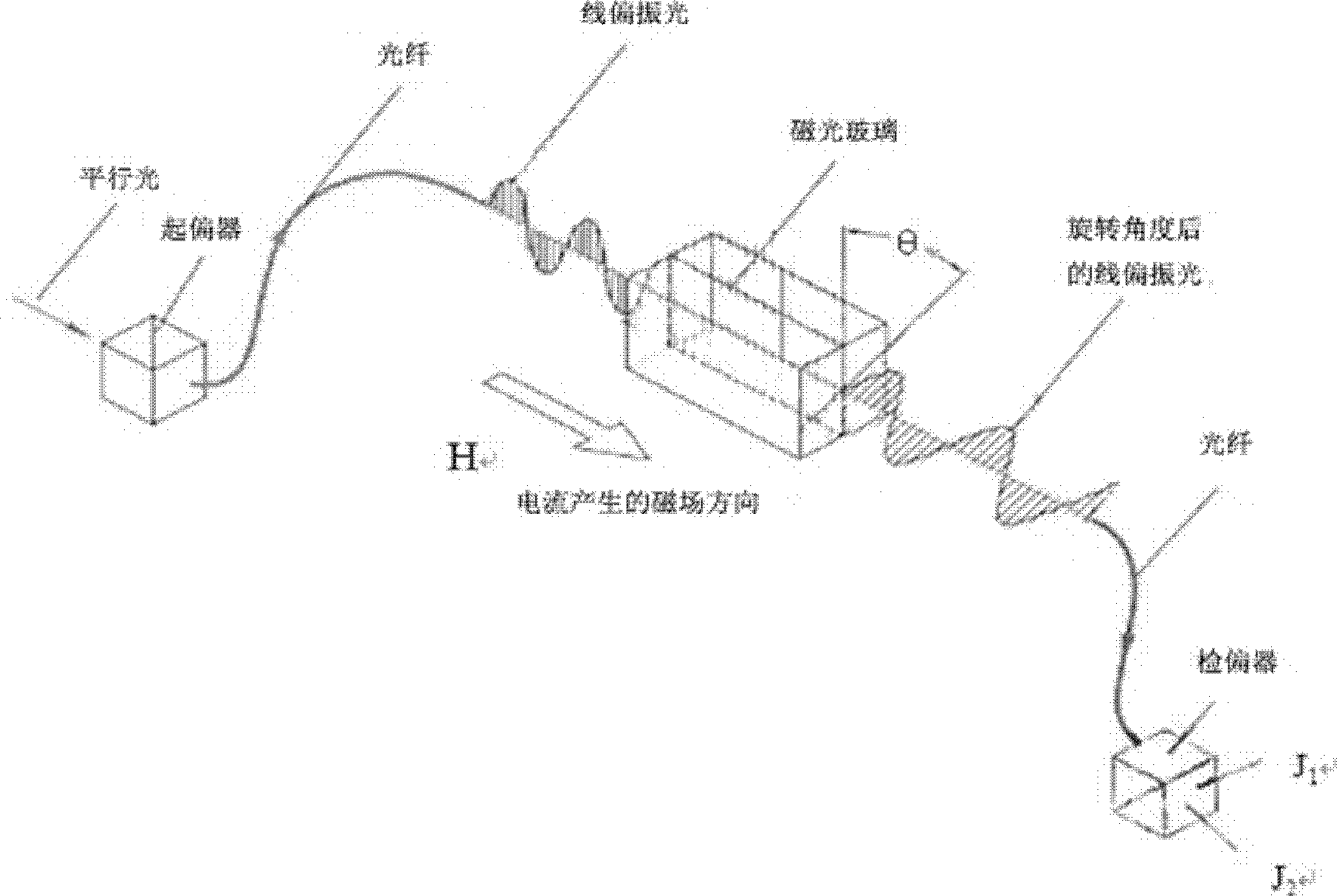

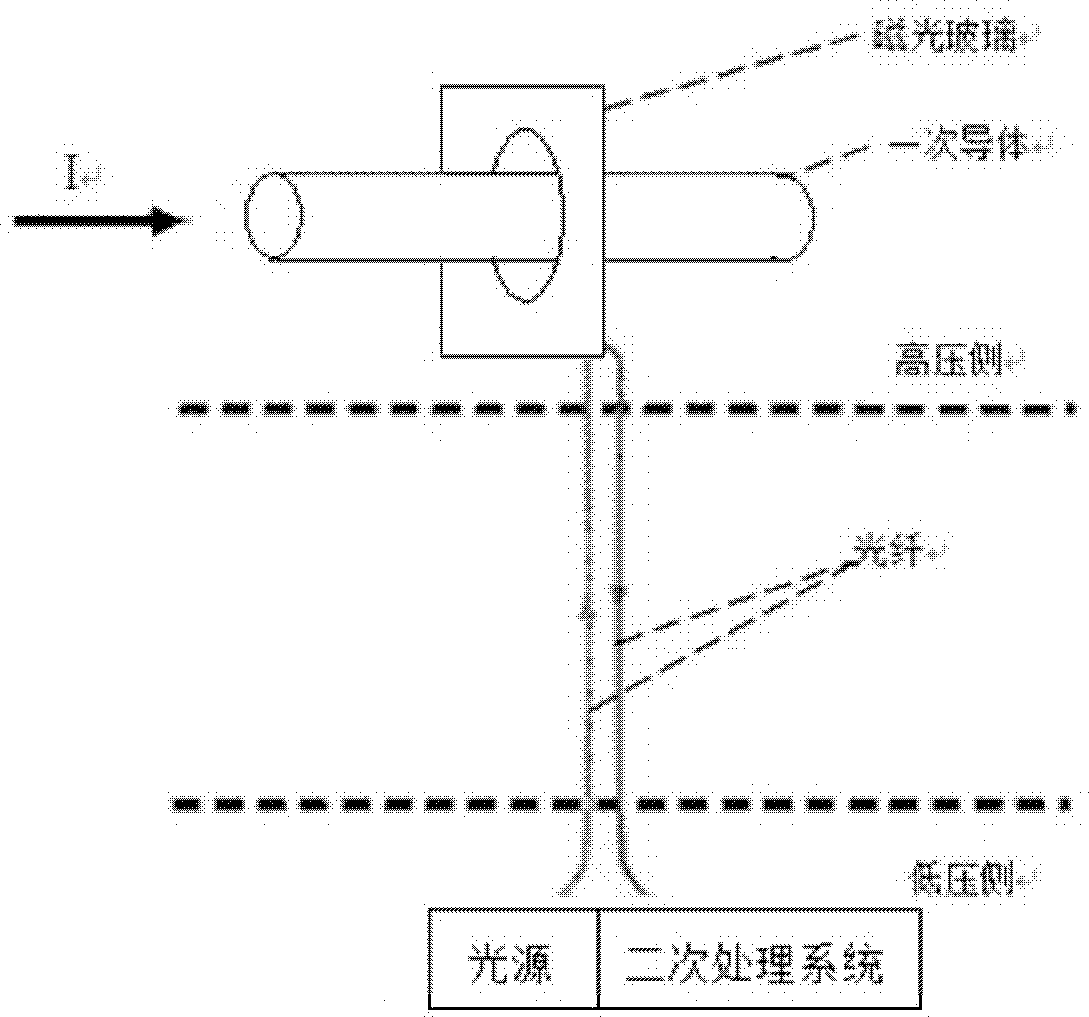

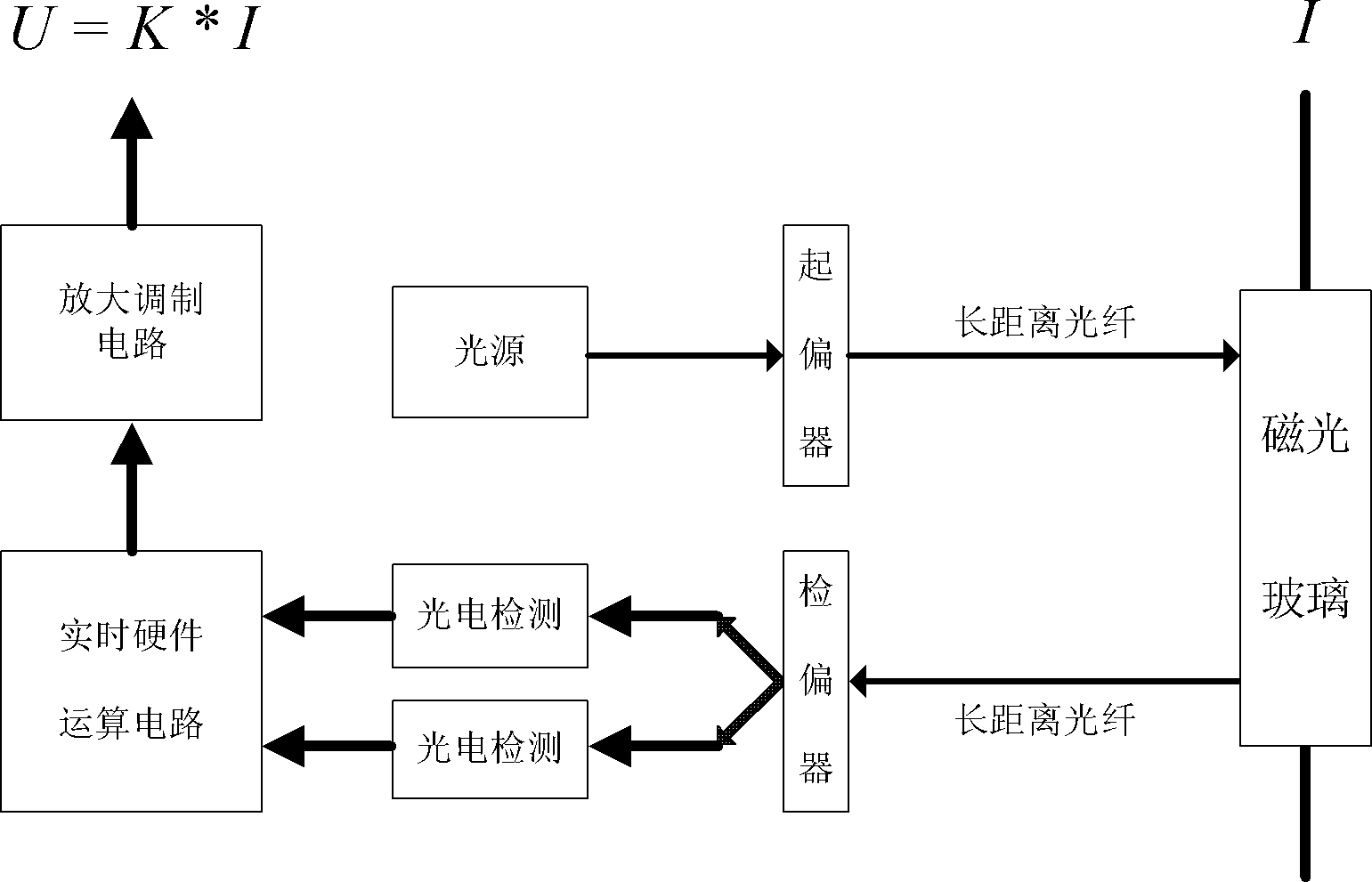

Traveling wave distance measurement device based on passive magnetooptic glass current transformer principle

InactiveCN102323516AImprove reliability and flexibilityNo bit errors will occurFault locationComplex programmable logic deviceCurrent amplitude

The invention relates to a traveling wave distance measurement device based on a passive magnetooptic glass current transformer principle. A small voltage signal reflecting primary side current amplitude of a transmission line is obtained by adopting a passive magnetooptic glass electronic current transformer, and a high-speed acquiring circuit is controlled by a CPLD (Complex Programmable Logic Device) for recording and sampling 625KHz travelling wave data and starting the sampling of 20KHz criterion data. When the transmission line fails, the travelling wave distance measurement device judges whether the transmission line fails through the sampled 20KHz data, and controls a 625KHz high-speed sampling part to completely record high-speed sampled data comprising travelling signals and sends data to a background computer through communication, and the background computer automatically computes and recognizes a failed travelling wave head through a wavelet algorithm after obtaining dual-end circuit data, and realizes failure location of the transmission line according to different moments of the wave head arriving at a dual-end bus.

Owner:CHINA ELECTRIC POWER RES INST +1

Earmuff assembly

An earmuff assembly includes a headband consisting of two headband elements each having two constraint lugs bilaterally located on one end and a coupling portion located on the opposite end, the coupling portion of one headband element being inserted through a groove on each constraint lug of the other headband element for allowing adjustment of the length of the headband, two ear cups, two connection devices that connect the coupling portions of the headband elements to the ear cups such that the angular positions of the ear cups are adjustable in X-axis direction as well as in Y-axis direction relative to the headband, and a soft fabric material covering the ear cups for an optimal wearing comfort.

Owner:SOUND TEAM ENTERPRISE

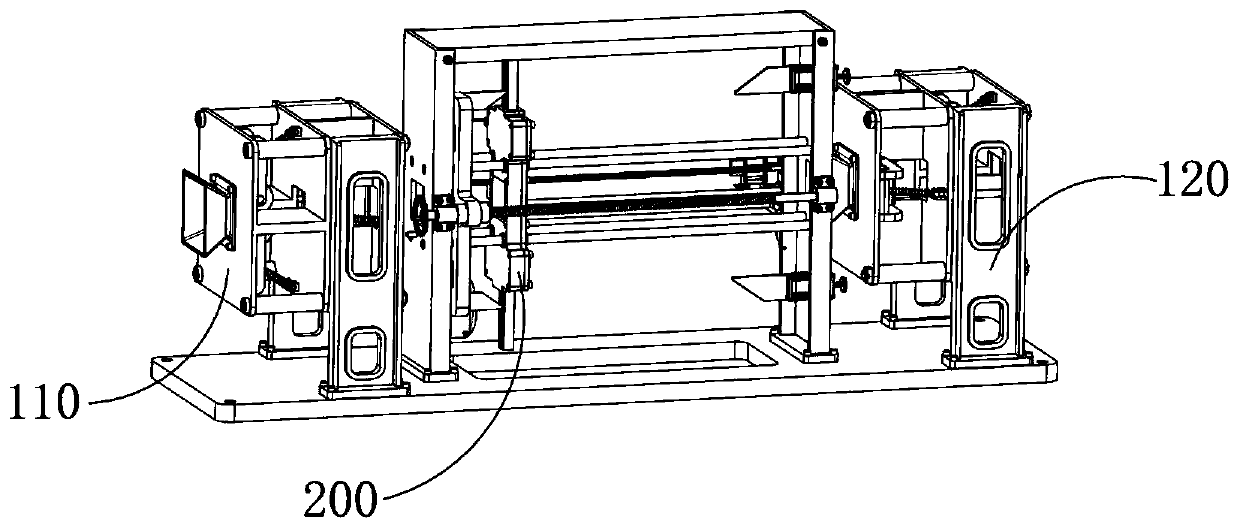

Fixed-length intermittent propelling machining technology for construction steel pipe

ActiveCN109968092ARealize continuous fixed-length feedingEasy to adjust the lengthMetal working apparatusButt jointEngineering

The invention provides a fixed-length intermittent propelling machining technology for a construction steel pipe. The technology includes the following steps that firstly, the output end of an outputguiding mechanism is butt-jointed with the feeding position of machining equipment, a bar is inserted from the input end of an input guiding mechanism and extends to the output end of the output guiding mechanism through an intermittent propelling device; then the inserted bar is clamped by a clamping end opening of the intermittent propelling device, power is transmitted to the intermittent propelling device by a power driving device, and the clamped bar is driven to be pushed to the output end; next, after the bar is propelled by clamping blocks, power output of the power driving device is cut off by a withdrawing and resetting device, and the power driving device is pulled to reset automatically, meanwhile, the clamping blocks are switched by a triggering component to the loosened stateand move reversely to reset, and the clamping blocks are switched to the clamping state automatically after resetting; and finally, the step 2 and the step 3 are repeated, and the bar is intermittently propelled and fed into the machining equipment communicating with the output opening of the output guiding mechanism.

Owner:广西北部湾粮油技术研究有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com