Clutch slave cylinder

A technology of clutch sub-pump and clutch master cylinder, which is applied to clutches, fluid-driven clutches, and non-mechanical-driven clutches, etc., can solve the problem of larger clutch pedal stroke, and achieve the effects of improving reliability performance, facilitating component processing and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below with reference to the accompanying drawings.

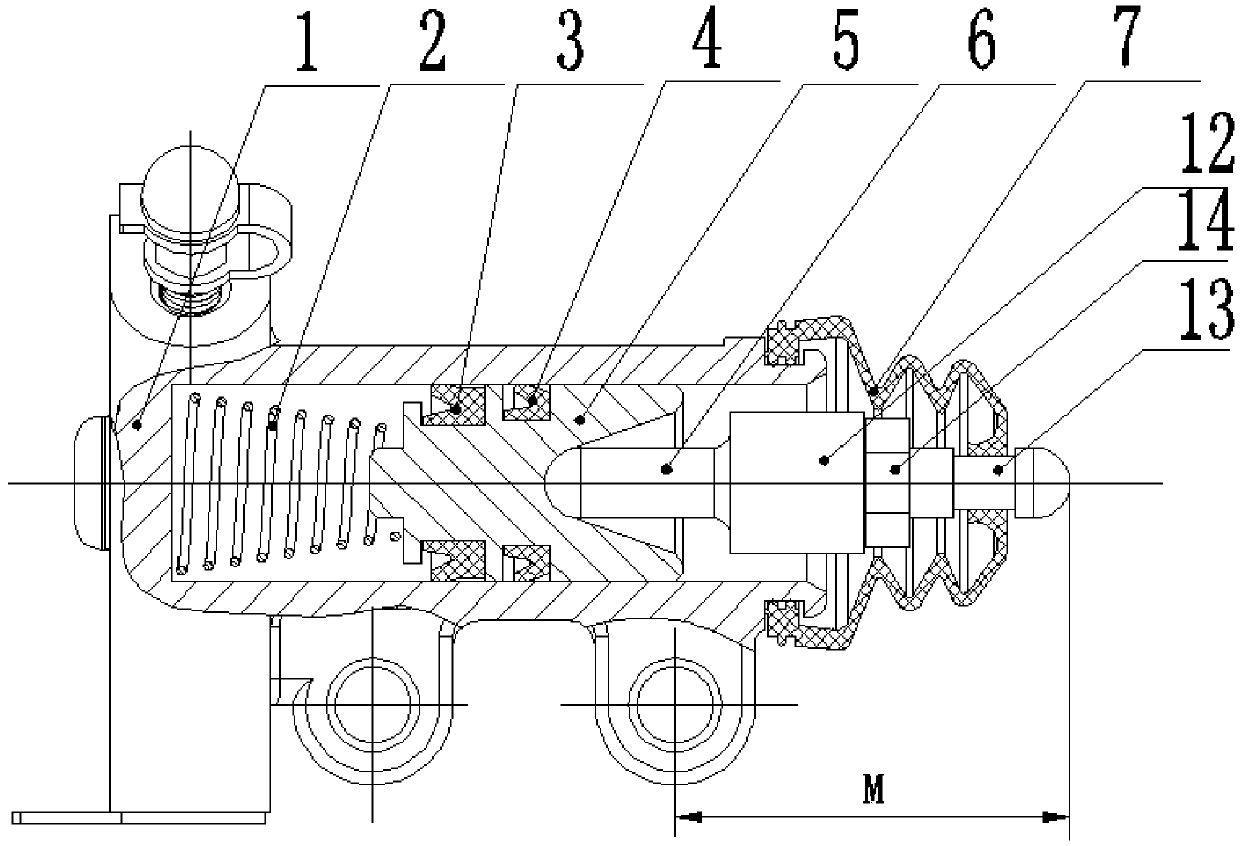

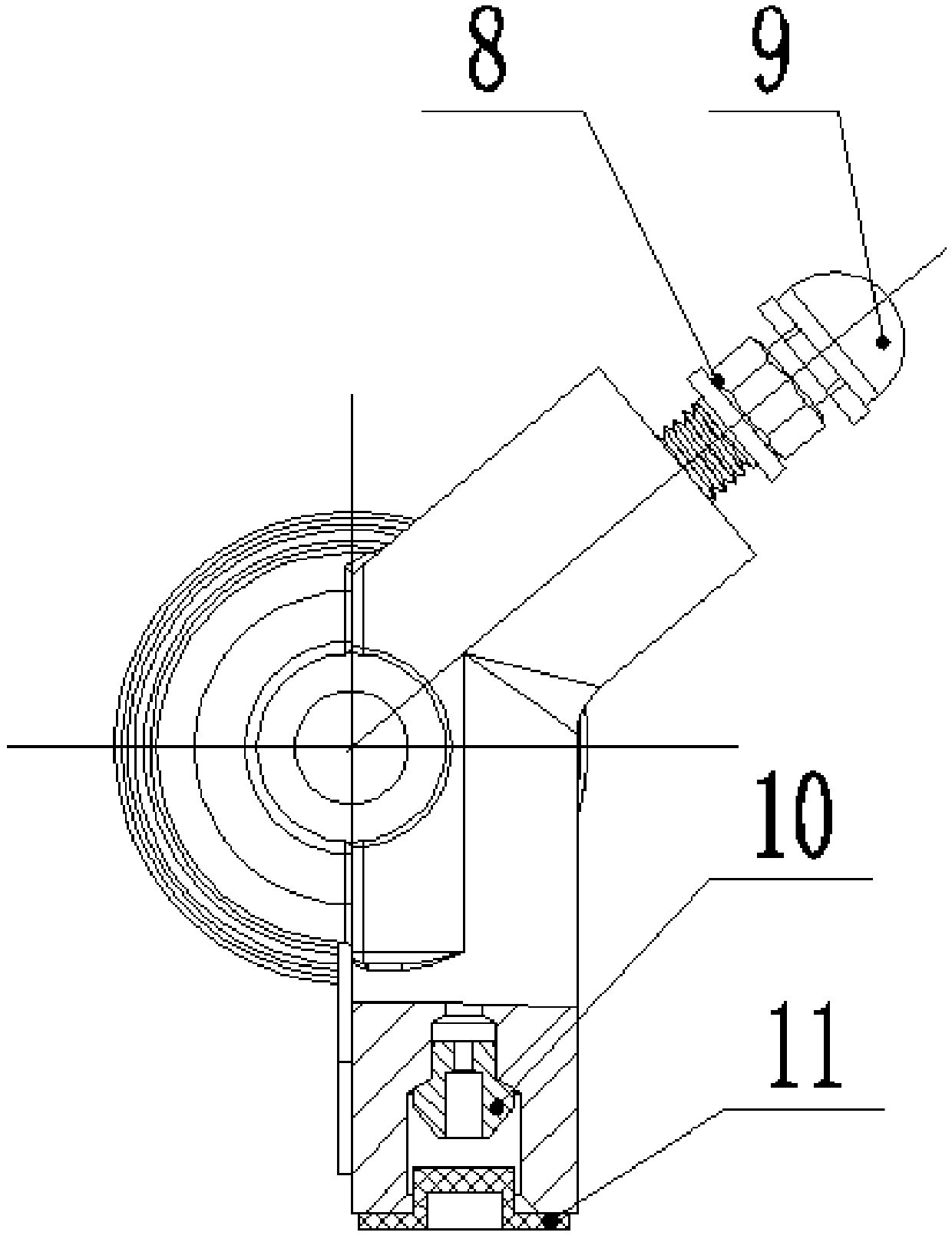

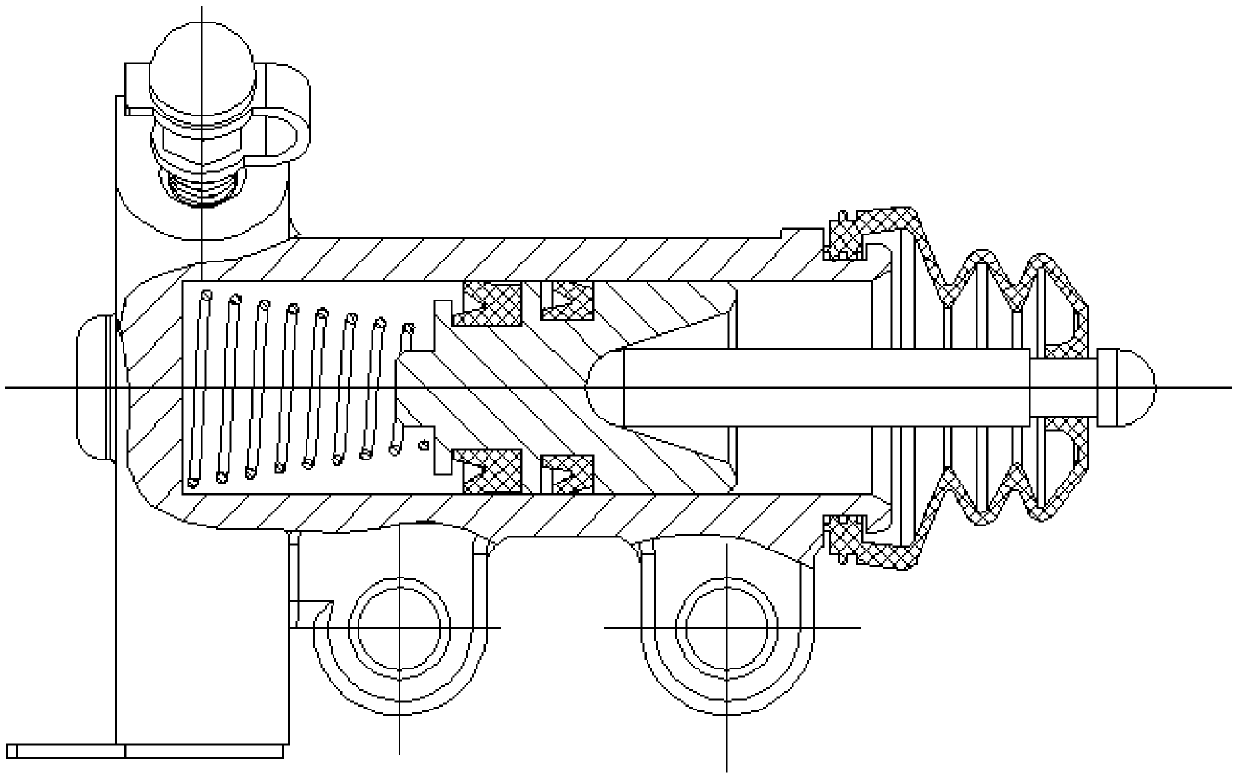

[0028] Such as Figure 1-2 As shown, the embodiment of the present invention provides a clutch slave cylinder, which is arranged between the clutch master cylinder and the clutch fork as an actuator for clutch separation. The clutch slave cylinder includes a cylinder 1 with an open end. The cylinder body 1 is respectively provided with an oil inlet passage and an exhaust passage connected with its inner chamber, and the inner chamber of the cylinder body 1 is provided with a spring 2, a piston 5 and a ejector rod assembly 6 sequentially from the inside to the outside, and the ejector rod Assembly 6 is a length-adjustable structure.

[0029] The clutch cylinder of the present invention is simple in structure, and the length of the ejector rod assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com