Filter assembly

A filter assembly and filter technology, applied in membrane filters, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of increasing filter material costs and manufacturing costs, achieve sufficient cross-network stability, reduce material cost, effect of eliminating spacer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

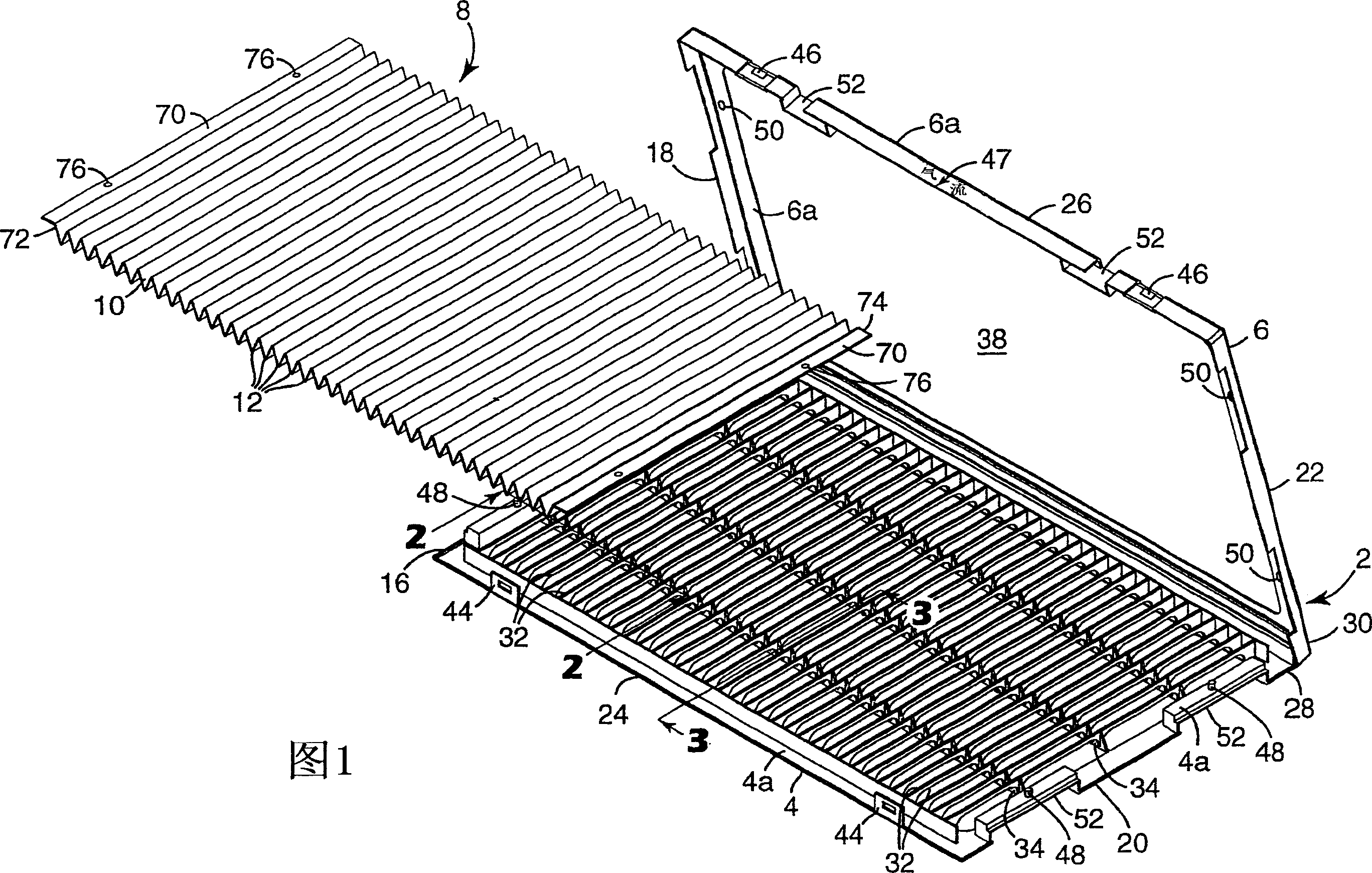

[0028] Referring now to the drawings, wherein like reference numerals indicate like or corresponding parts throughout the several views, FIGS. 1-5 show a reusable, self-spaced, pleated filter 8 A filter frame 2 comprising a base body 4 and an optional cover 6 , the filter 6 being suitably sized and configured to fit into the base body 4 . Alternatively, the functions of the base body 4 and the cover 6 can also be reversed, so that the filter 8 is arranged in the cover 6 and the base body 4 is closed by the cover 6 . The filter frame 2 has a substantially flat rectangular configuration and is especially suitable for use in air ducts or boilers of residential air-conditioning systems.

[0029] Filter 8 generally includes filter media 10 having a plurality of pleats 12 . reference below Figure 6-9 Filter 8 will be described more fully.

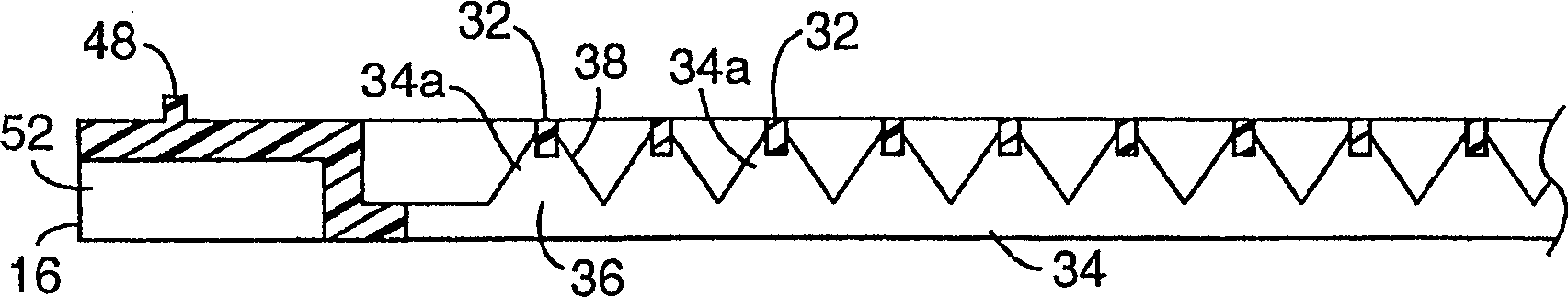

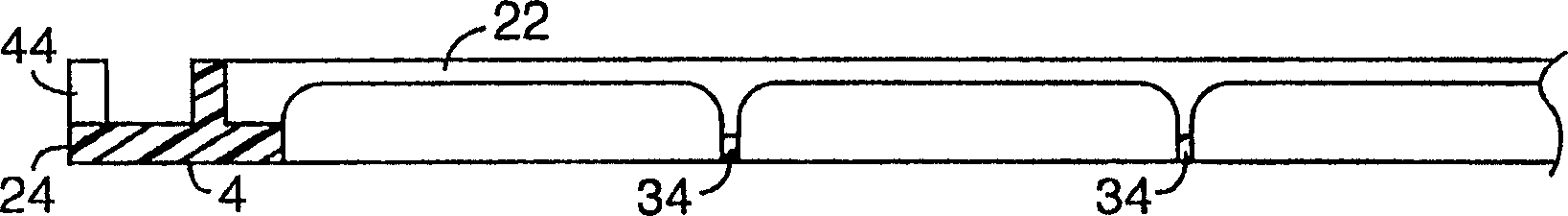

[0030] The base body 4 and the cover 6 respectively comprise a peripheral structure 4a, 6a having respective first 16, 18 and second 20, 22 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com