Compound rotary drilling rig drilling mechanism

A technology of rotary drilling rig and drilling mechanism, which is applied in the directions of rotary drilling rig, rotary drilling, drilling equipment and method, etc., can solve the problems of poor stability of rotary drilling machine, etc. less stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

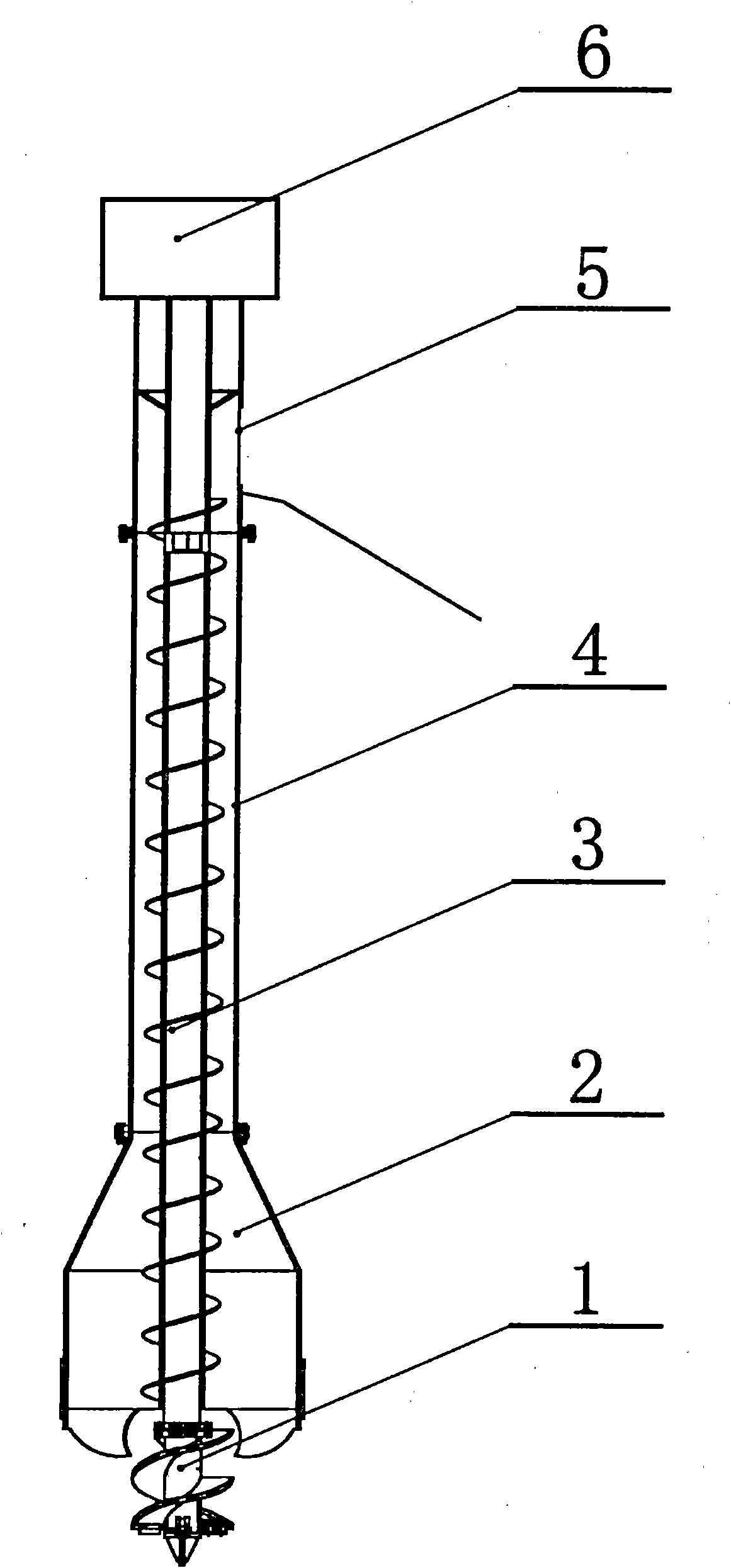

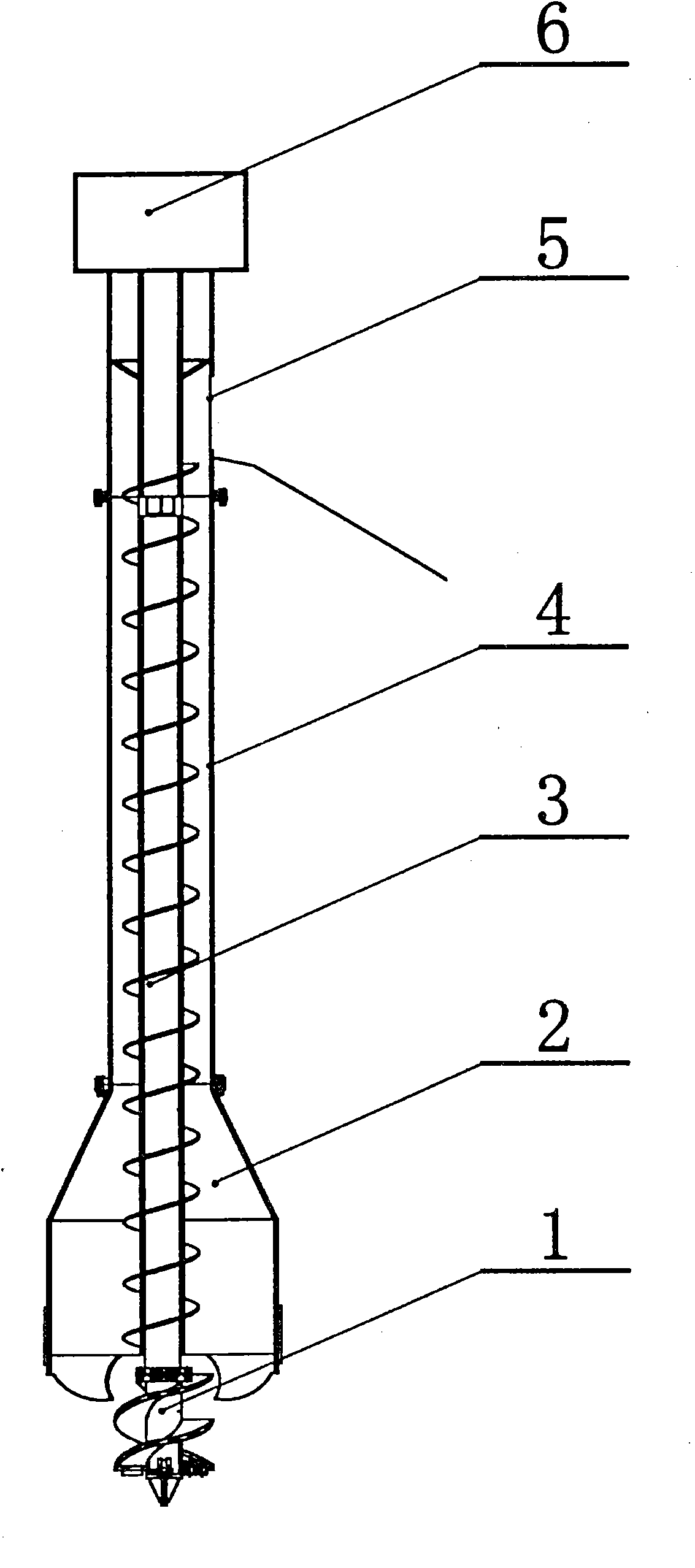

[0009] in the attached figure 1 Among them, the drilling mechanism of this kind of composite rotary drilling rig includes a pilot drill bit 1, a large-diameter drill bit 2, an auger drill rod 3, a jacket drill rod 4, a mud outlet 5 and a motor 6; the mechanism has a long tube-shaped jacket Drill rod 4, the upper part of the jacket drill rod 4 is provided with a mud outlet 5; the lower end of the jacket drill rod 4 is fixedly connected to the large-diameter drill bit 2 with rotary cutting blades at the bottom by flange bolts, and the drill bit can be drilled according to different drilling methods. It needs to be easily replaced; the casing drill rod 4 is provided with a coaxially rotating auger rod 3; the bottom end of the auger rod 3 is connected with a guide bit 1; the casing drill rod 4 and the auger rod 3 are a one-piece One section of segmented structure, the two ends of the jacket drill pipe 4 and the auger drill pipe 3 are respectively equipped with quick-change joints ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com