Patents

Literature

463 results about "Screw position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

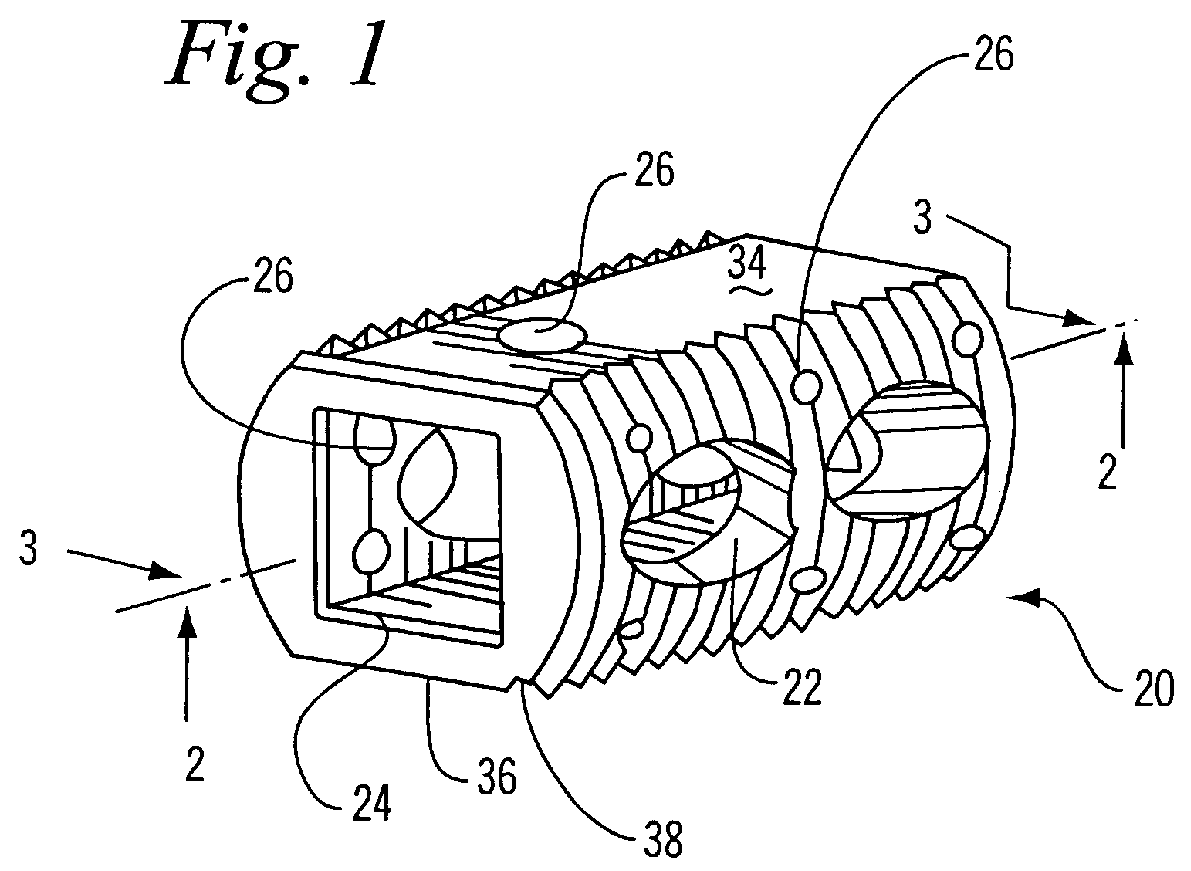

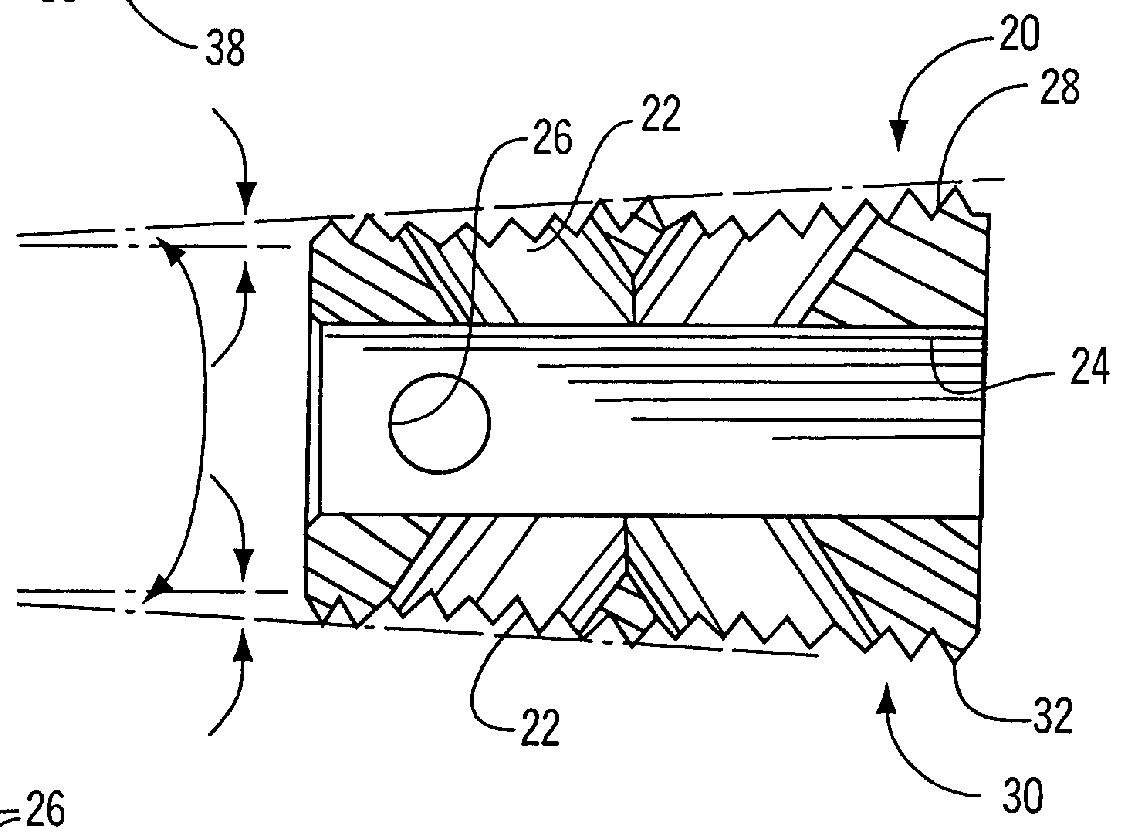

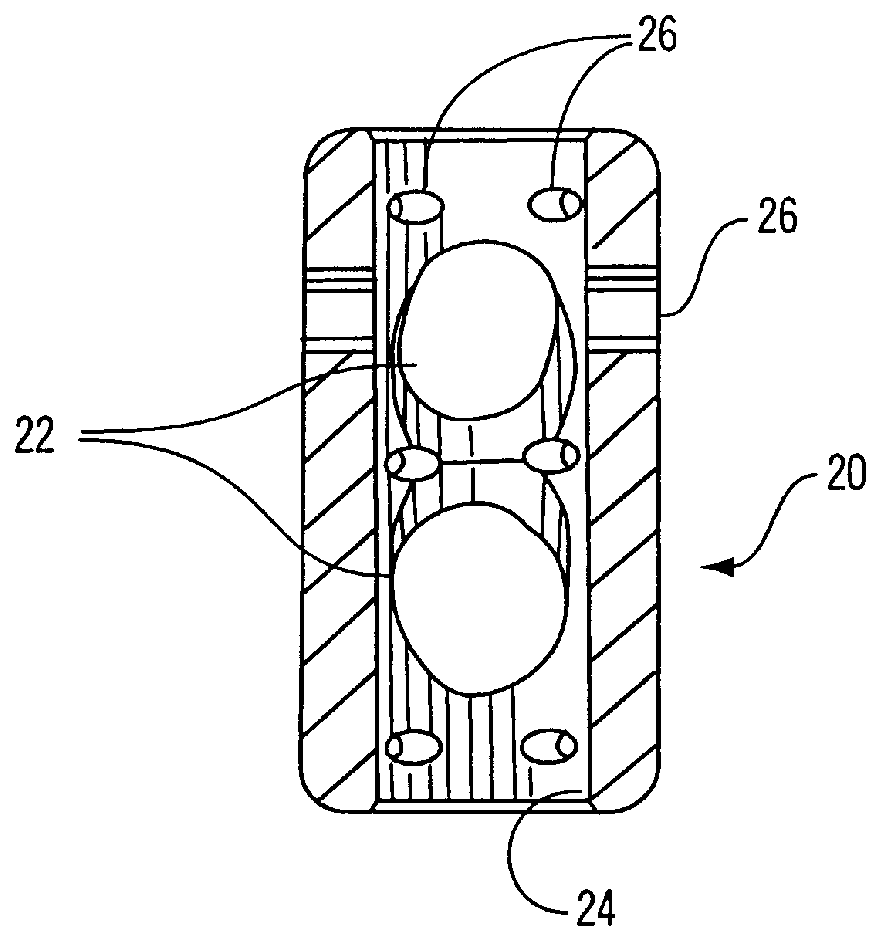

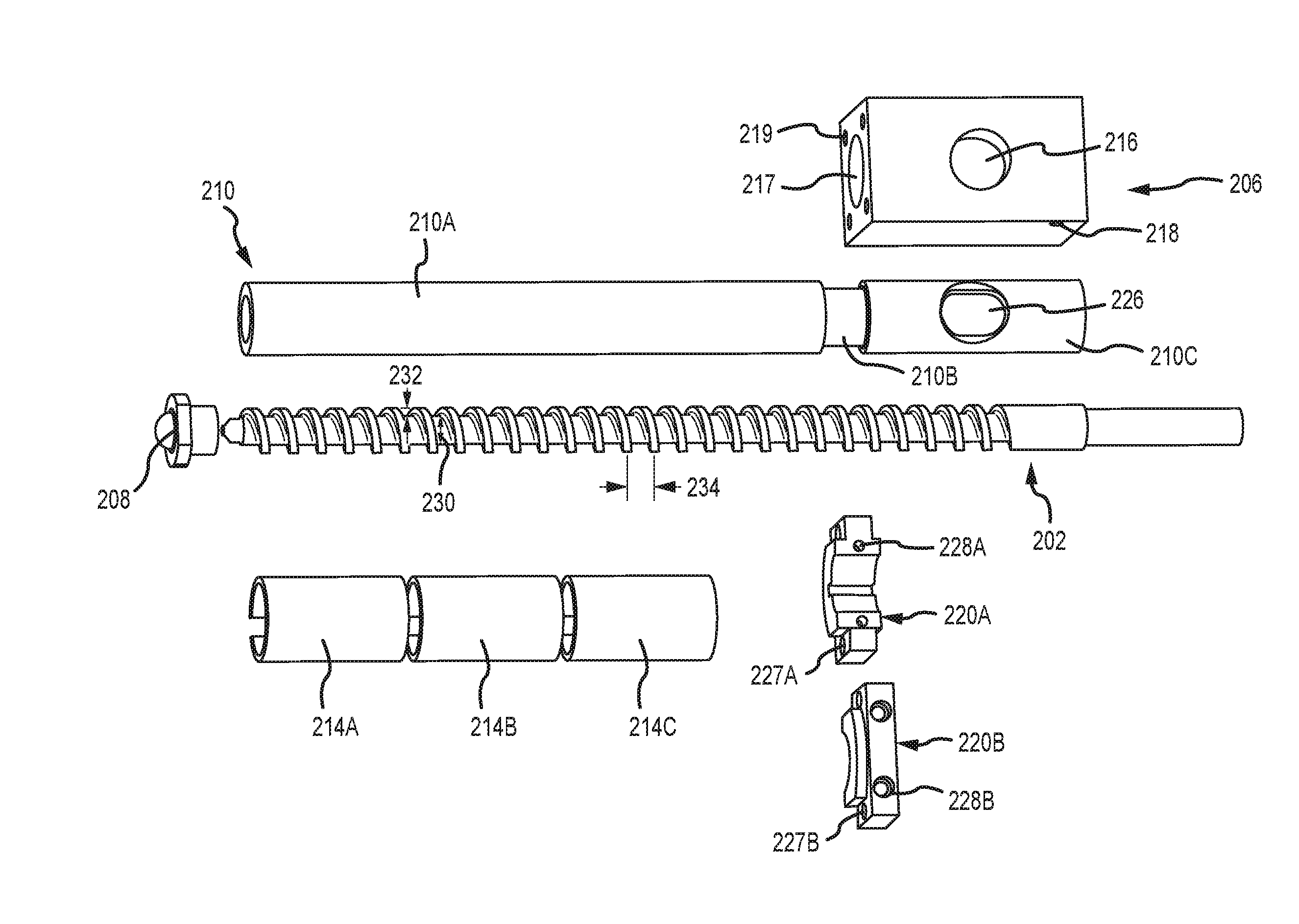

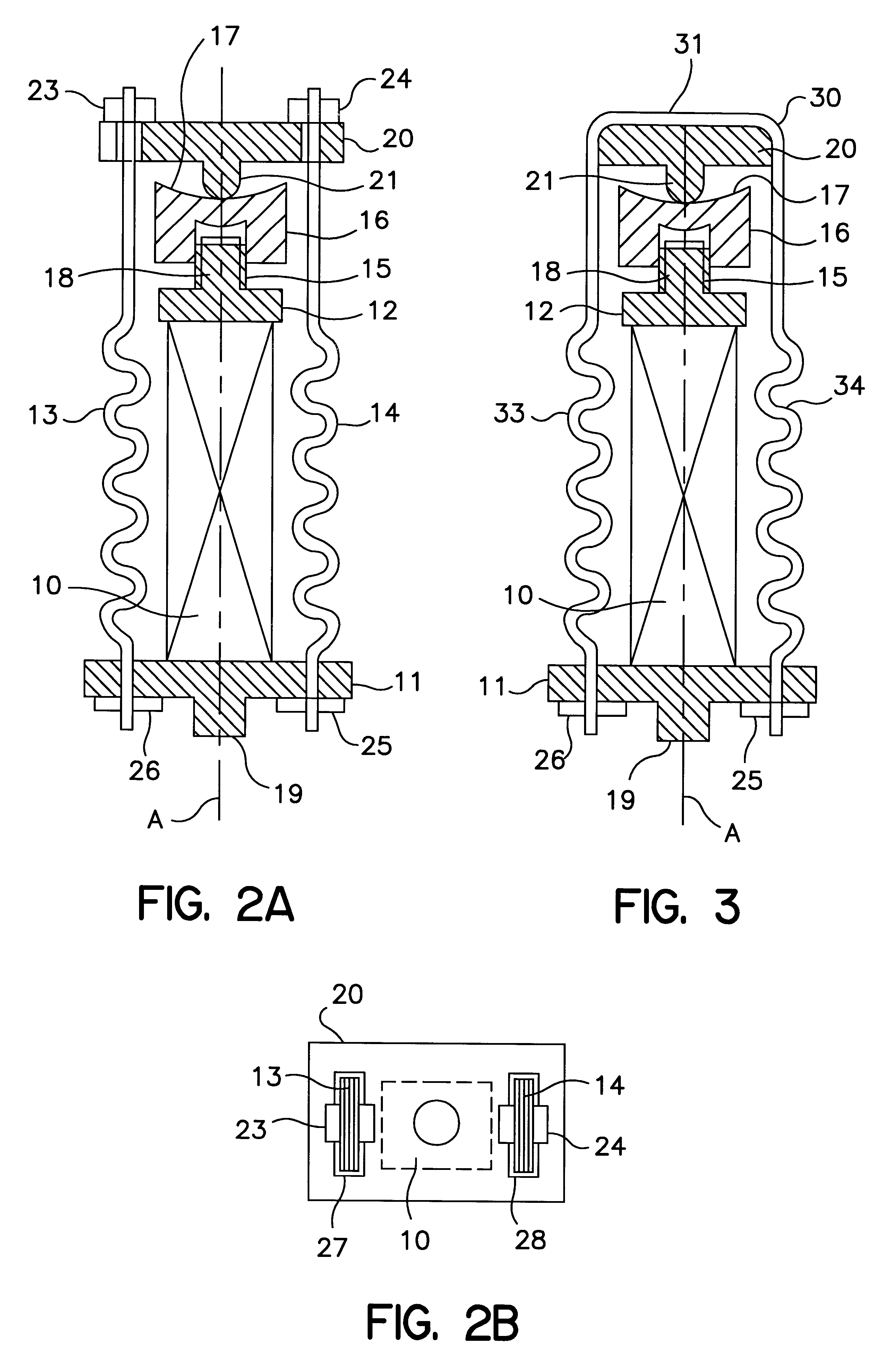

Method and device for fixing and correcting spondylolisthesis anteriorly

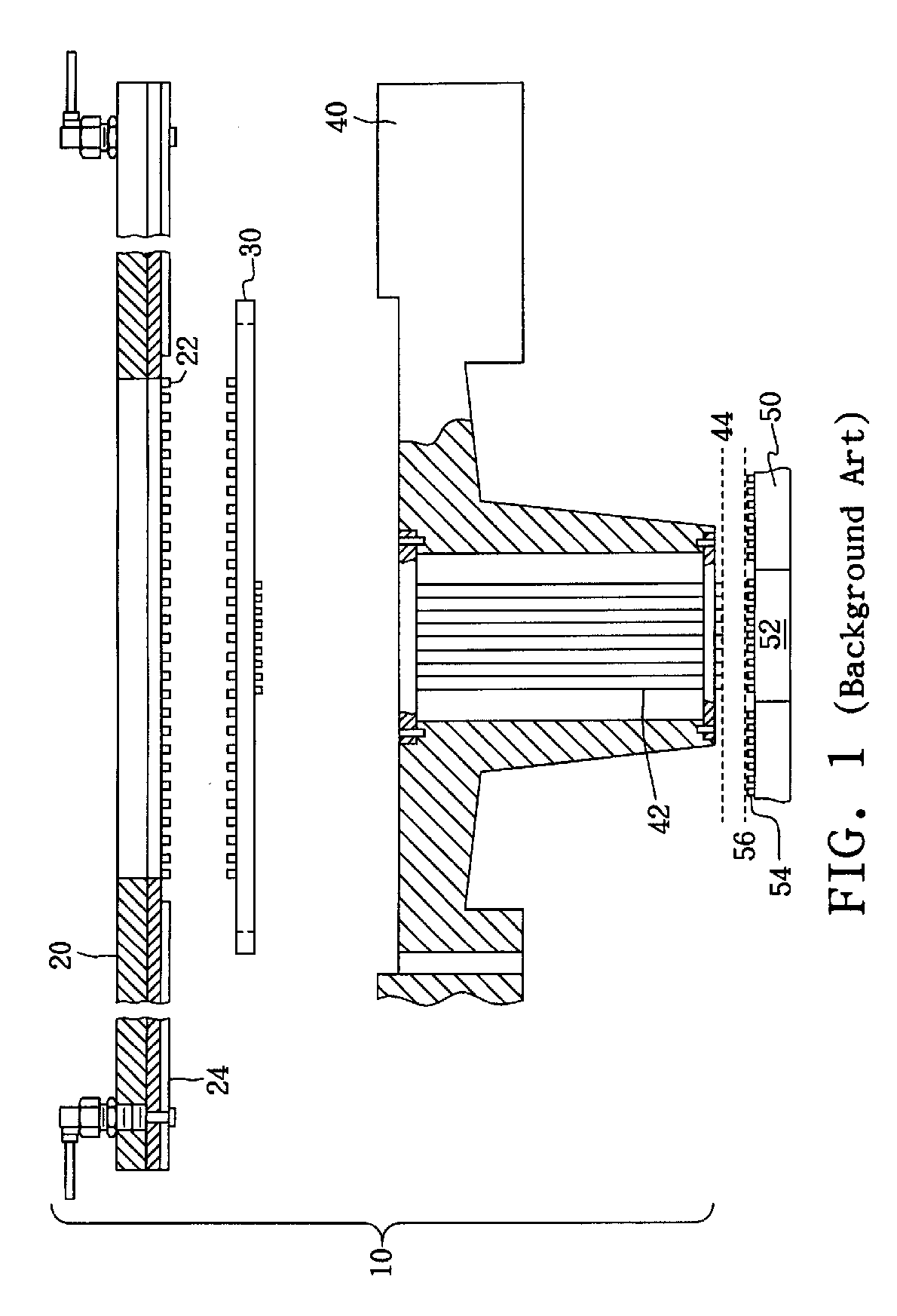

A method and apparatus for fixation and correction of spondylolisthesis anteriorly includes a disk cage which is inserted into the space between adjacent vertebrae, a drill guide for guiding and aligning a drill bit to angle an opening anteriorly between adjacent vertebrae, a distractor for temporarily aligning the vertebrae to position a disk cage and an elongated hollow screw positioned in said drilled opening through one vertebra, said disk cage and into said adjacent vertebra.

Owner:SPINEOLOGY

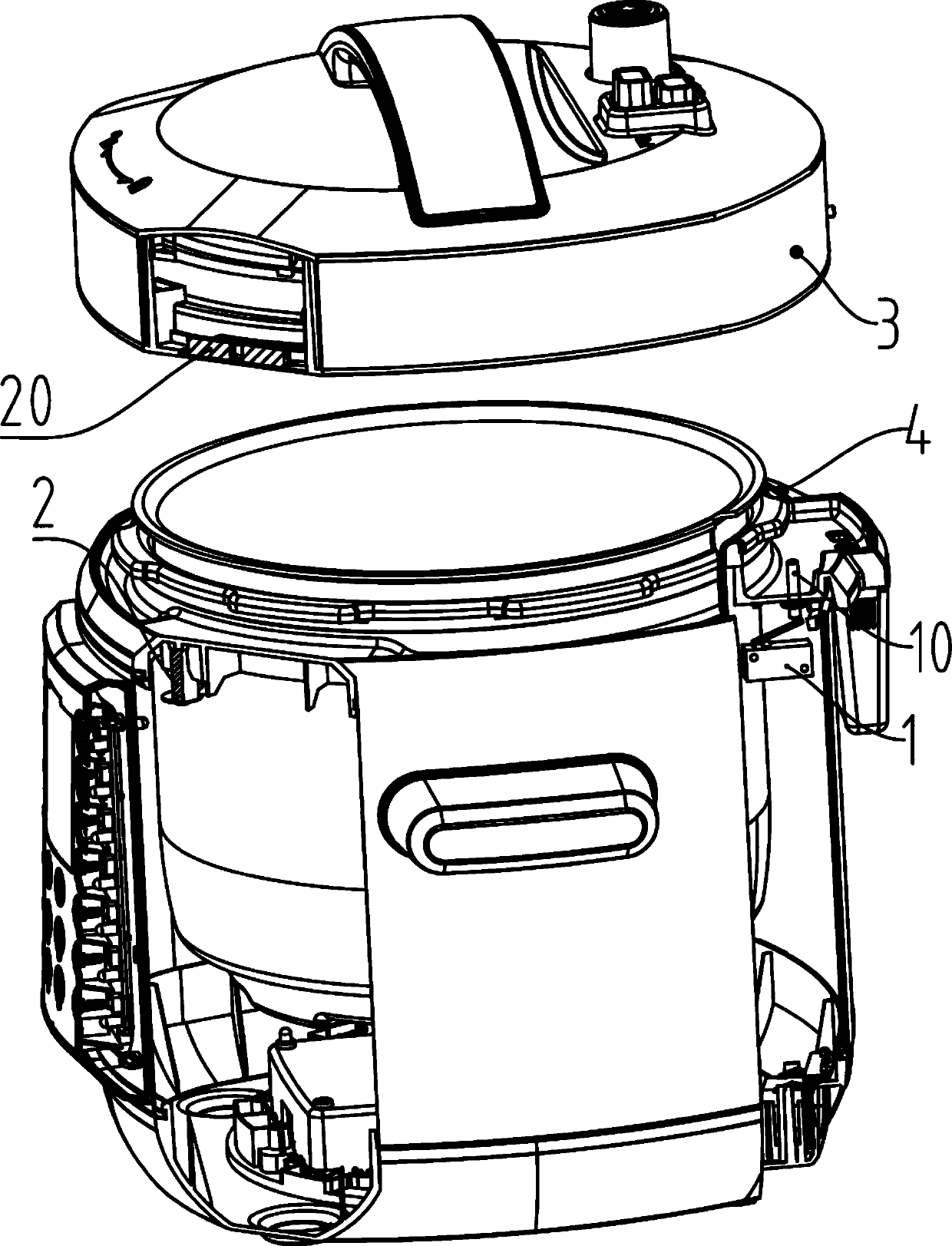

Cooking control method based on closing state of electric pressure cooker cover

The invention relates to a cooking control method based on the closing state of an electric pressure cooker cover. A pressure cooker comprises a cooker base, a cooker cover capable of being screwed onthe cooker base and a central control unit, and also comprises two position sensors capable of responding to the screwing position of the cooker cover on the cooker base, and the two position sensorsinclude the first position sensor and the second position sensor, wherein the first position sensor is used for responding to a position signal when the cooker cover is not screwed in place and providing a first position signal for the central control unit, and the second position sensor is used for responding to a position signal when the cooker cover is screwed in place and providing a second position signal for the central control unit; after the pressure cooker is powered on and started, the central control unit determines whether the pressure cooker is permitted to start follow-on work or not according to whether the first position signal or the second position signal is received or not as a logical judgment. Intelligent control of multiple cooking states can be achieved through combination of multiple logical judgments, the safety is greatly improved, and intellectualization can also be conveniently achieved through software.

Owner:DEA GENERAL AVIATION HLDG CO LTD

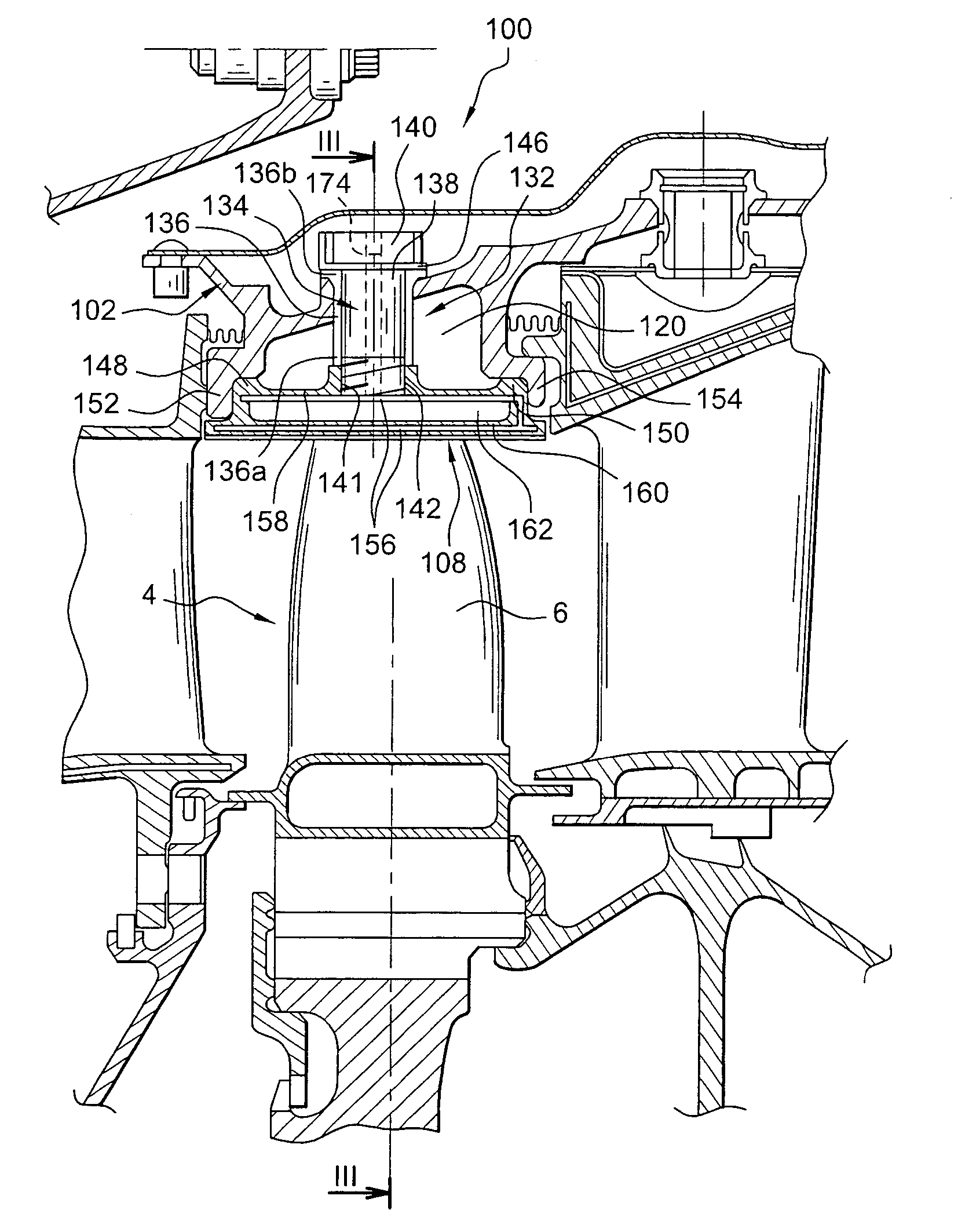

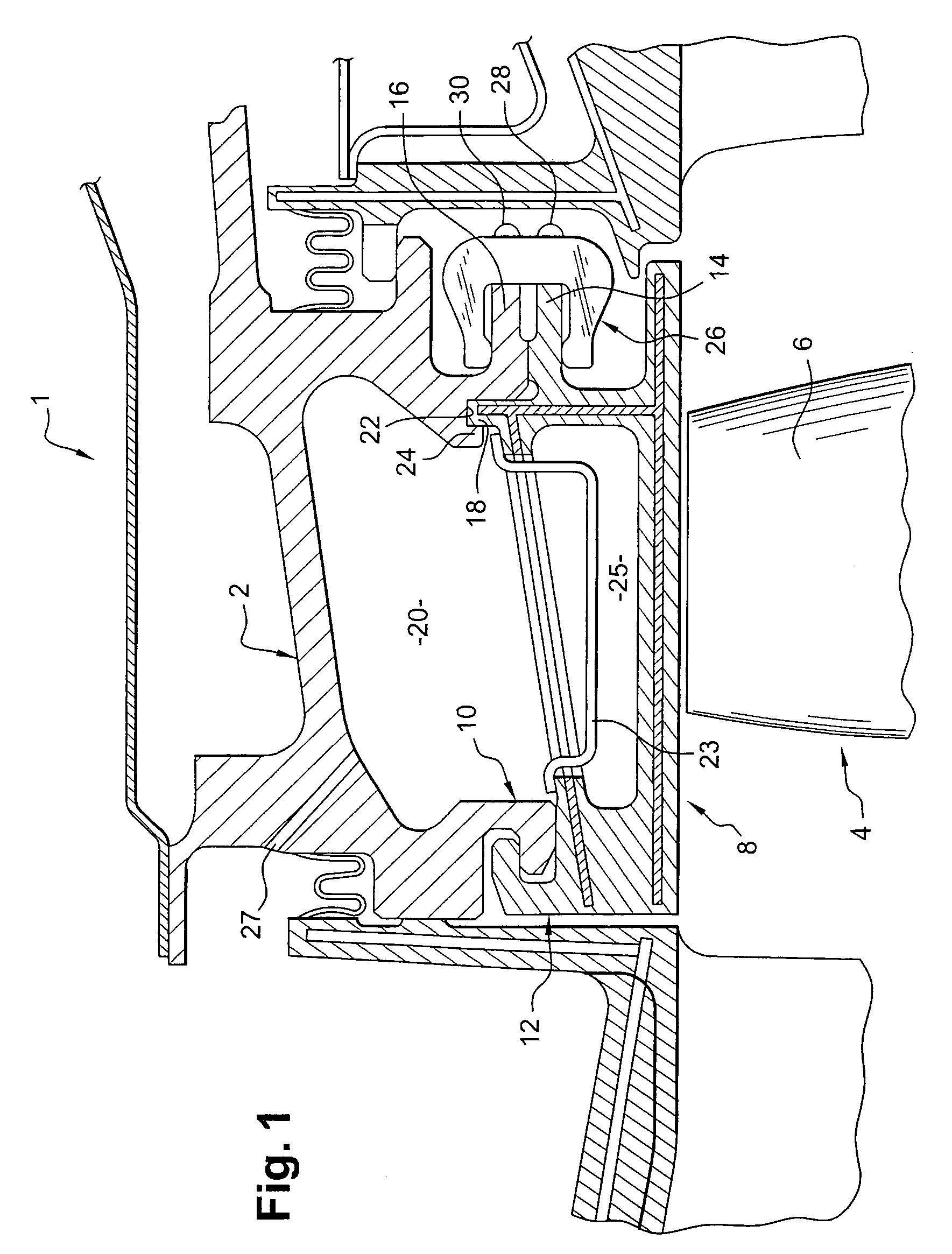

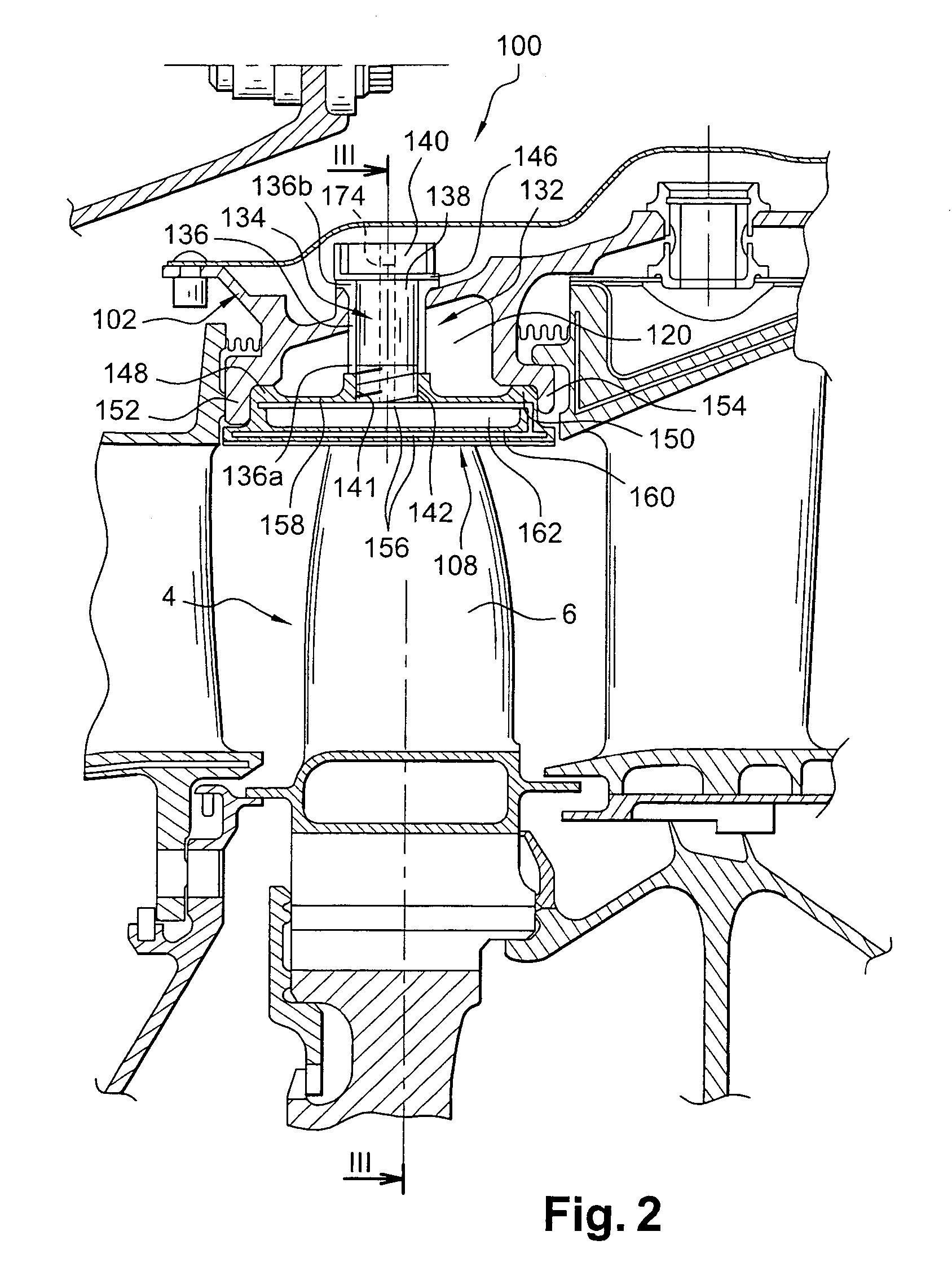

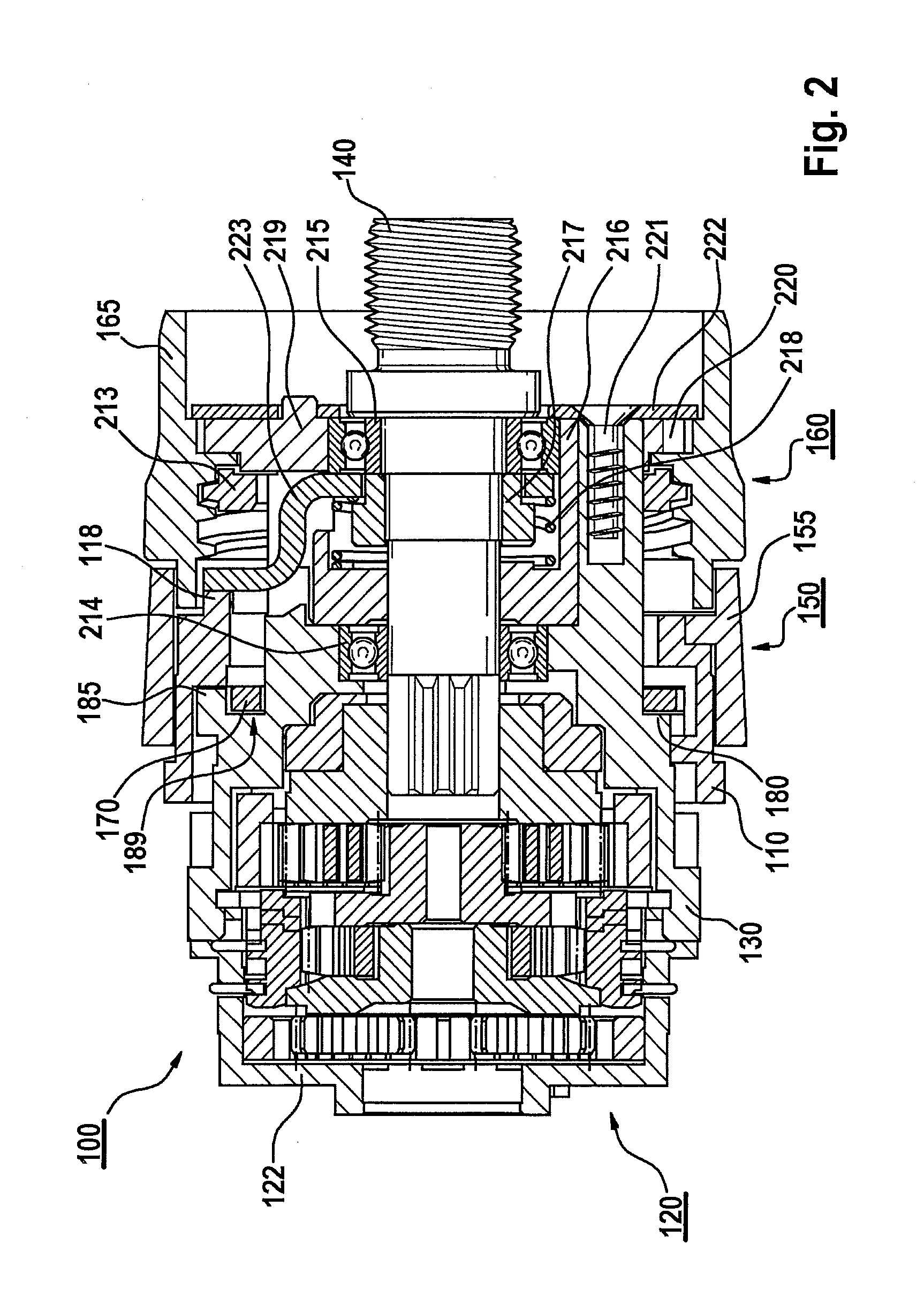

Turbomachine with cooled ring segments

ActiveUS7011493B2Precise positioningSimple designPump componentsTurbine/propulsion engine coolingScrew positionEngineering

A turbomachine includes a casing, a rotor, and a plurality of cooled ring segments installed between the casing and the rotor, each ring segment containing a main cooling cavity and being attached to the casing by a fastening device. The fastening device can include a clamping screw positioned more or less radially and pinning the ring segment against the casing. The clamping screw is crossed through by a cooling airway that communicates with the main cooling cavity of the ring segment.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

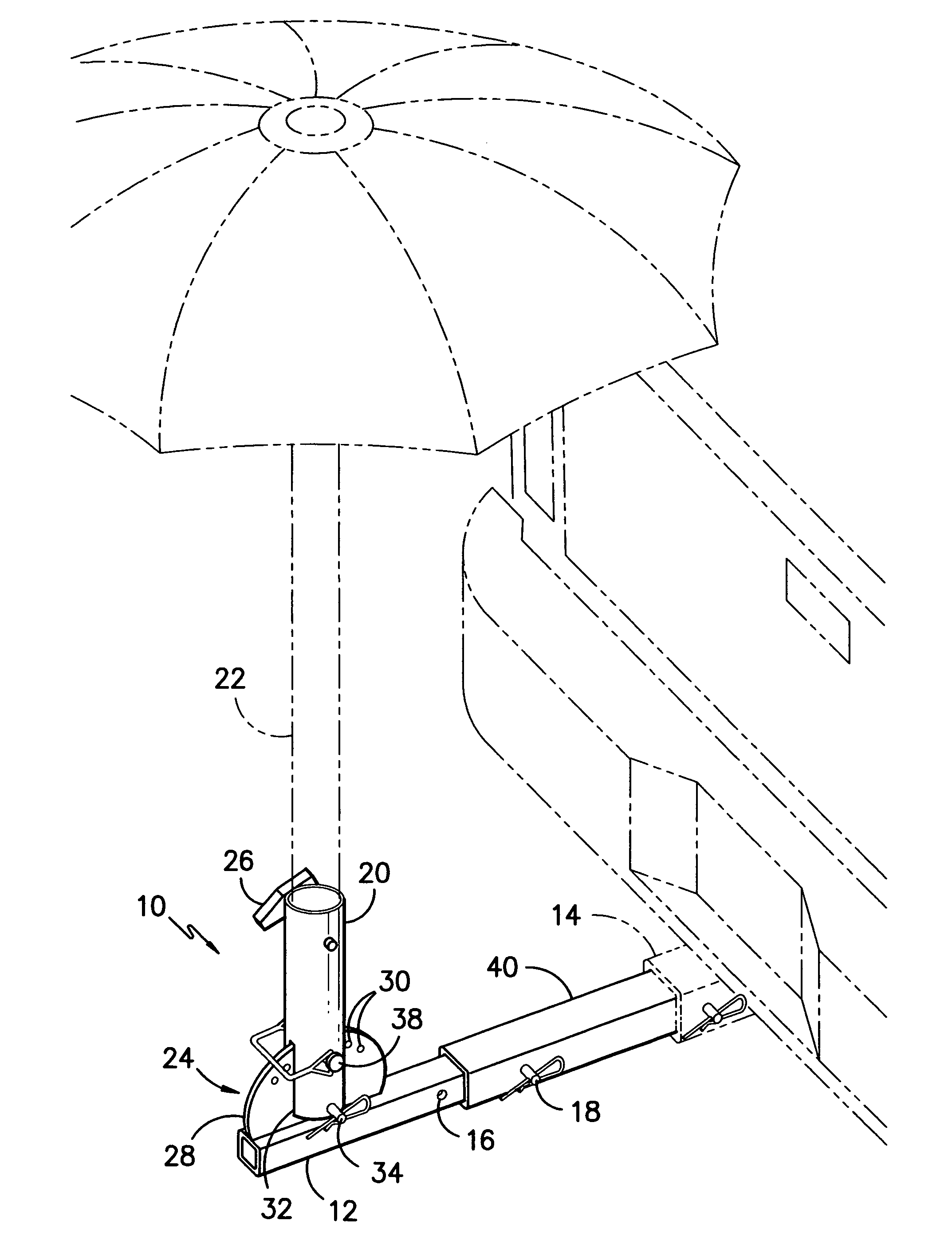

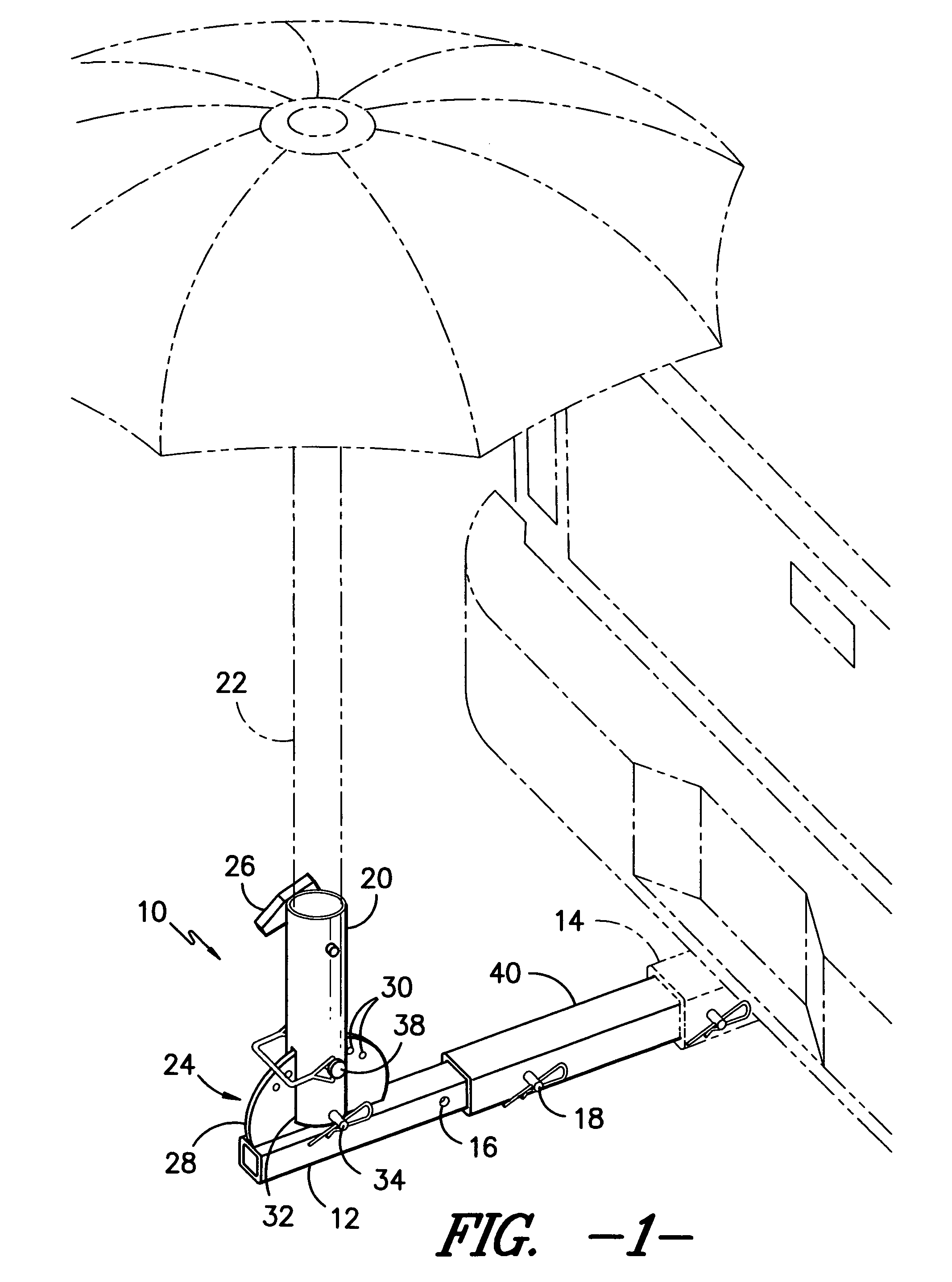

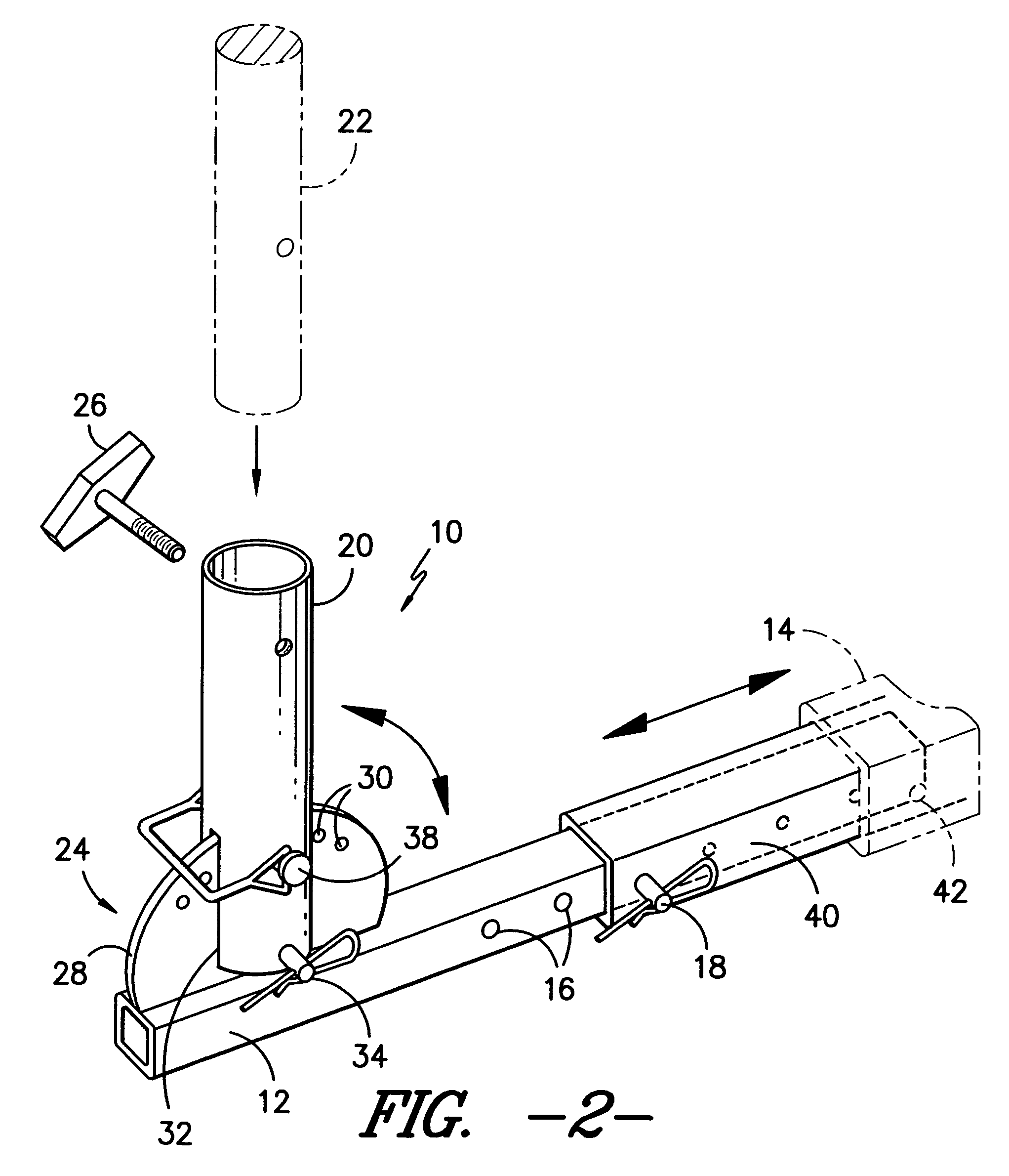

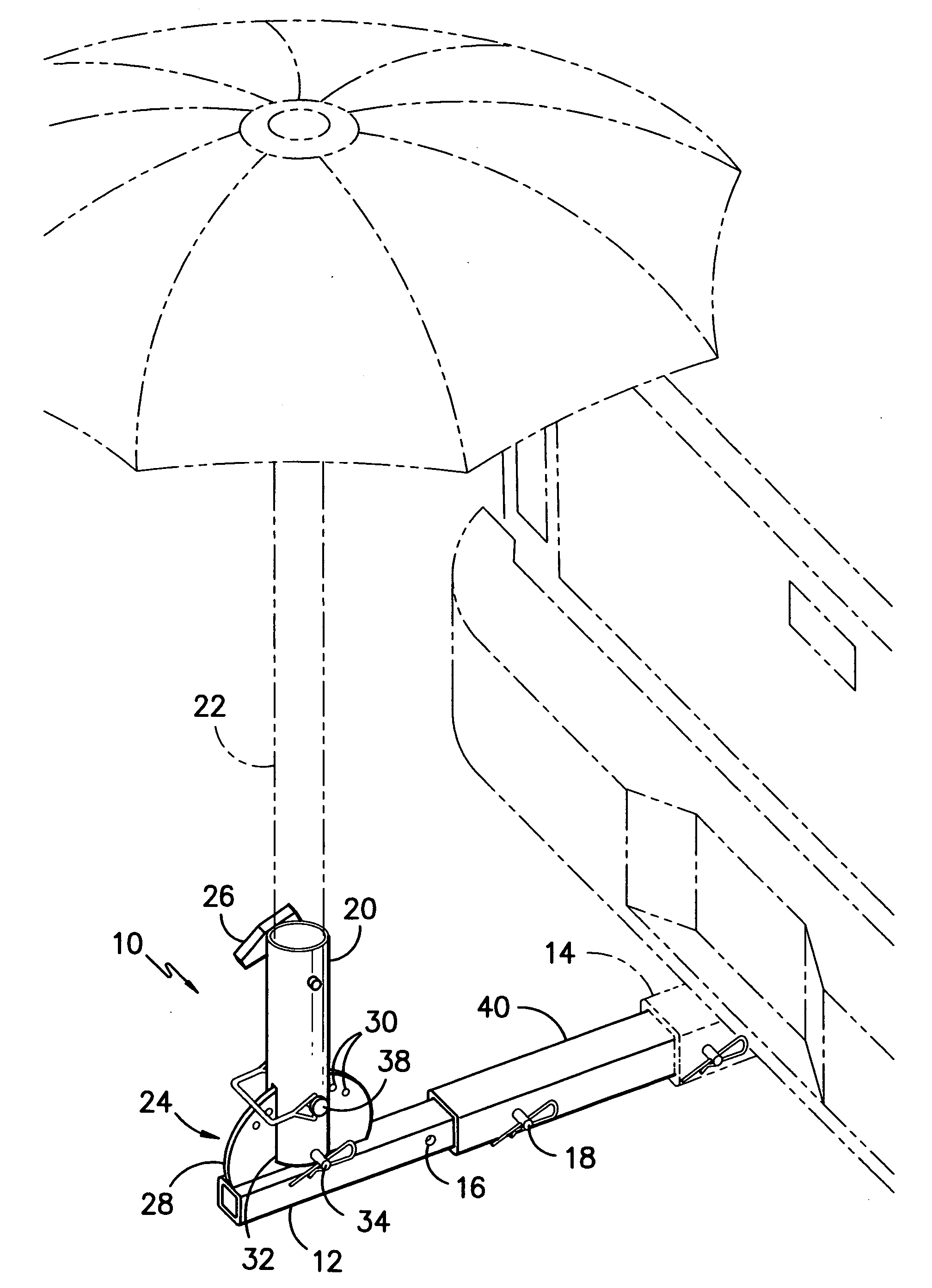

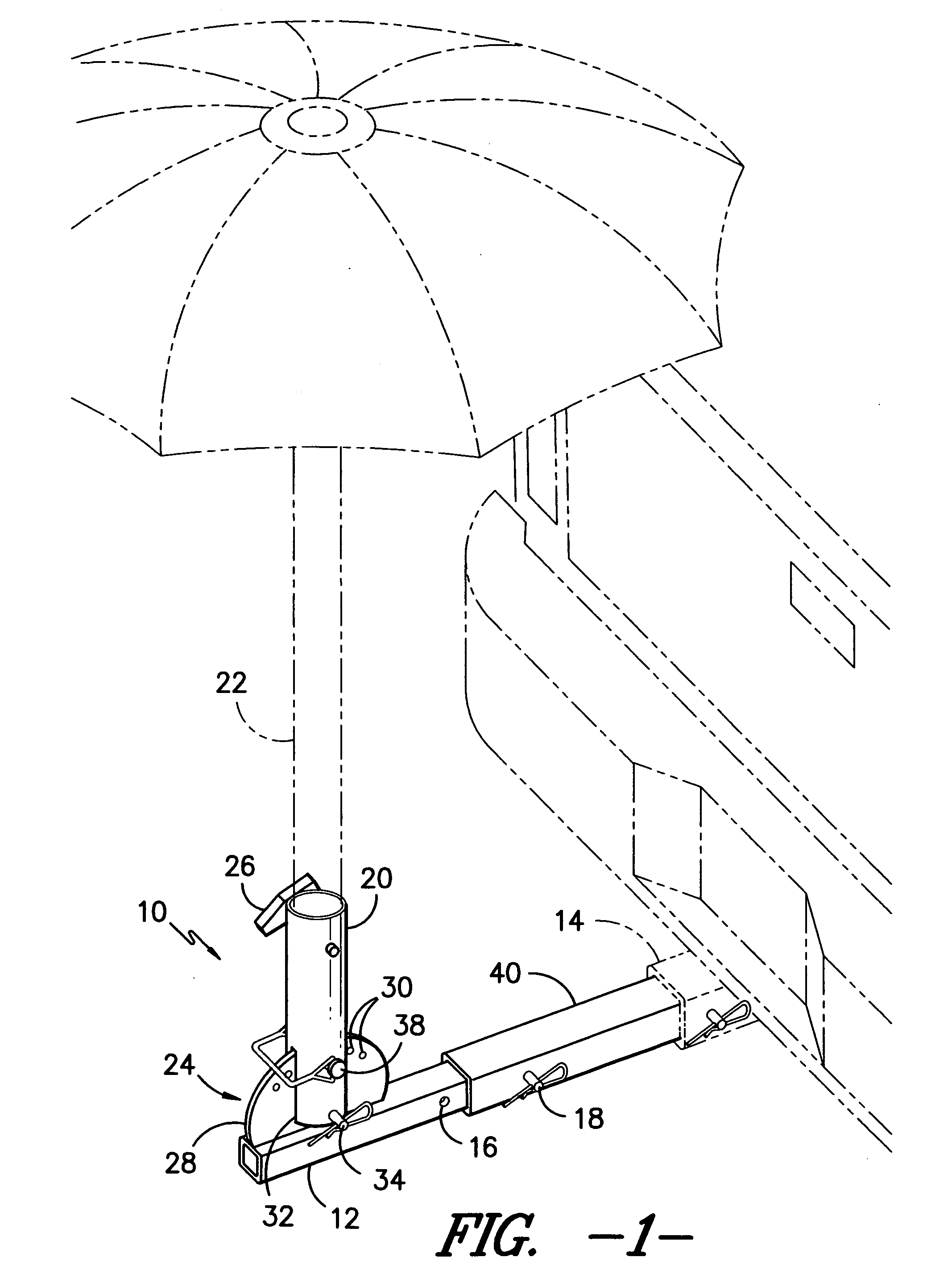

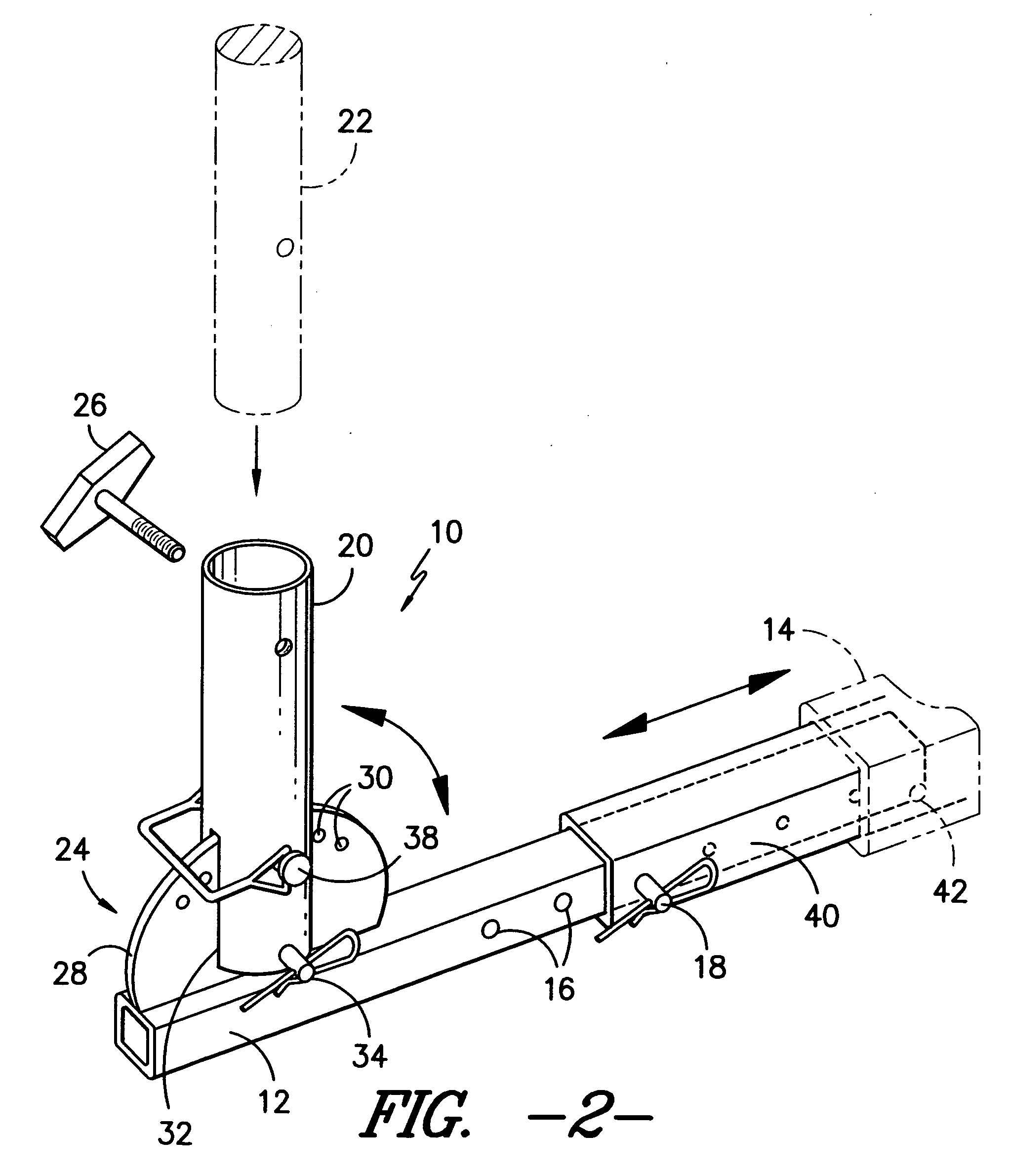

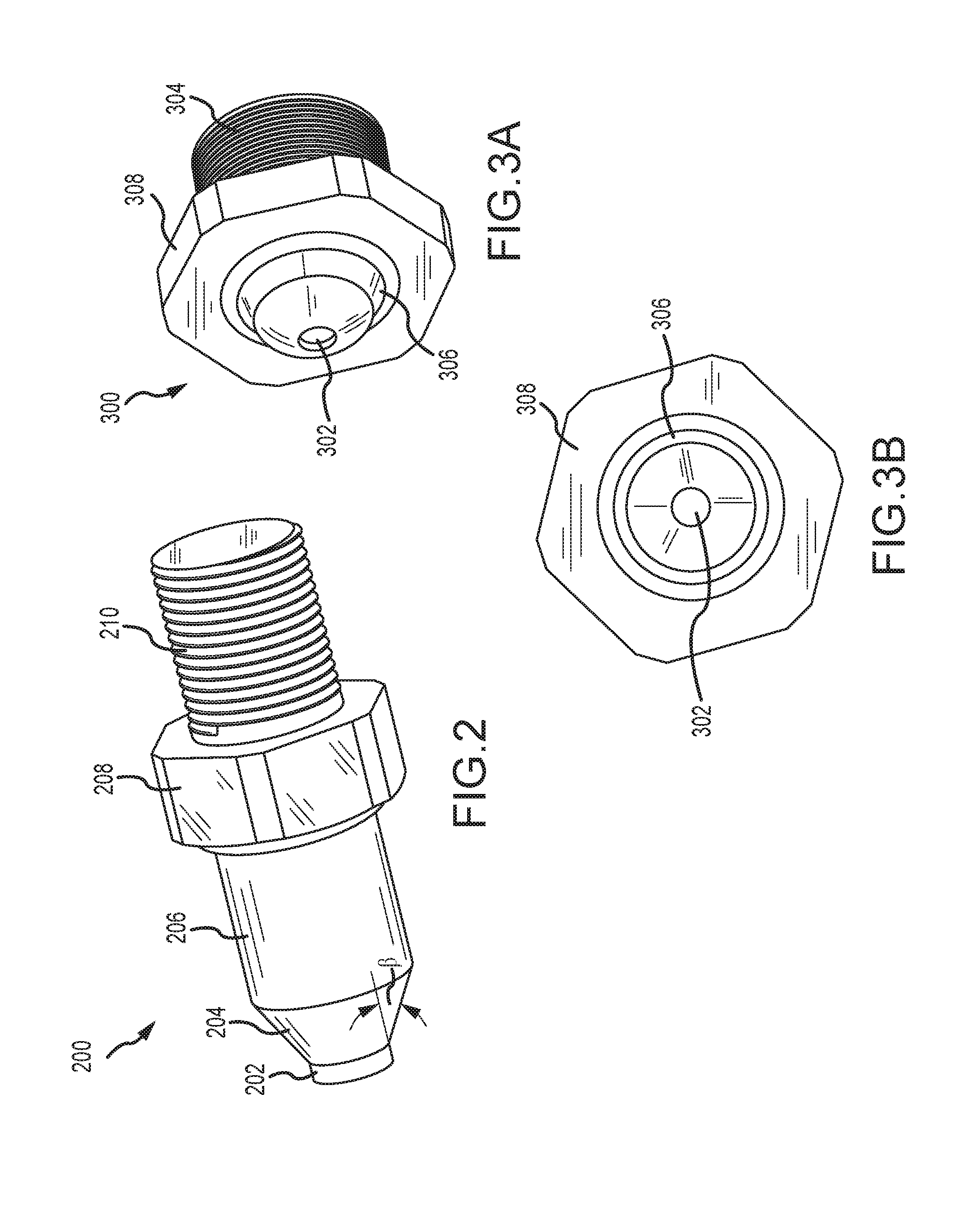

Adjustable trailer hitch mount for an umbrella

InactiveUS7819128B2Increase distanceDesired lengthWalking sticksUmbrellasSquare cross sectionScrew position

The trailer hitch mount for an umbrella includes a square cross-section shaft that is adapted to slide into a standard sleeve-style trailer hitch receiver that is currently available on many vehicles. The shaft includes a series of holes along the sides thereof to receive a pin in order to secure the shaft to the trailer hitch receiver in a telescopic relationship. The series of holes allows the shaft length to be adjusted, so that the distance between the trailer hitch receiver and the opposed end of the shaft may be shortened or lengthened, as desired. The shaft includes two ends, one of which slides into the trailer hitch receiver, and the other end includes a hollow pivoting cylindrical tube that is used to receive the bottom end of an umbrella pole. The pivoting tube includes adjustment means, so that the pivoting tube may be tilted to a desired angle and secured in that position. For travel or storage purposes, the pivoting tube may be folded down and secured into a compact position parallel with the shaft. At an upper end of the pivoting tube is receiving and securing means for the umbrella pole. The umbrella pole, in a preferred embodiment, slides into the hollow pivoting tube and a hand screw positioned on the side of the pivoting tube at its upper end may be tightened against the umbrella pole and secured thereby.

Owner:CLARK SCOTTY OBRIAN +1

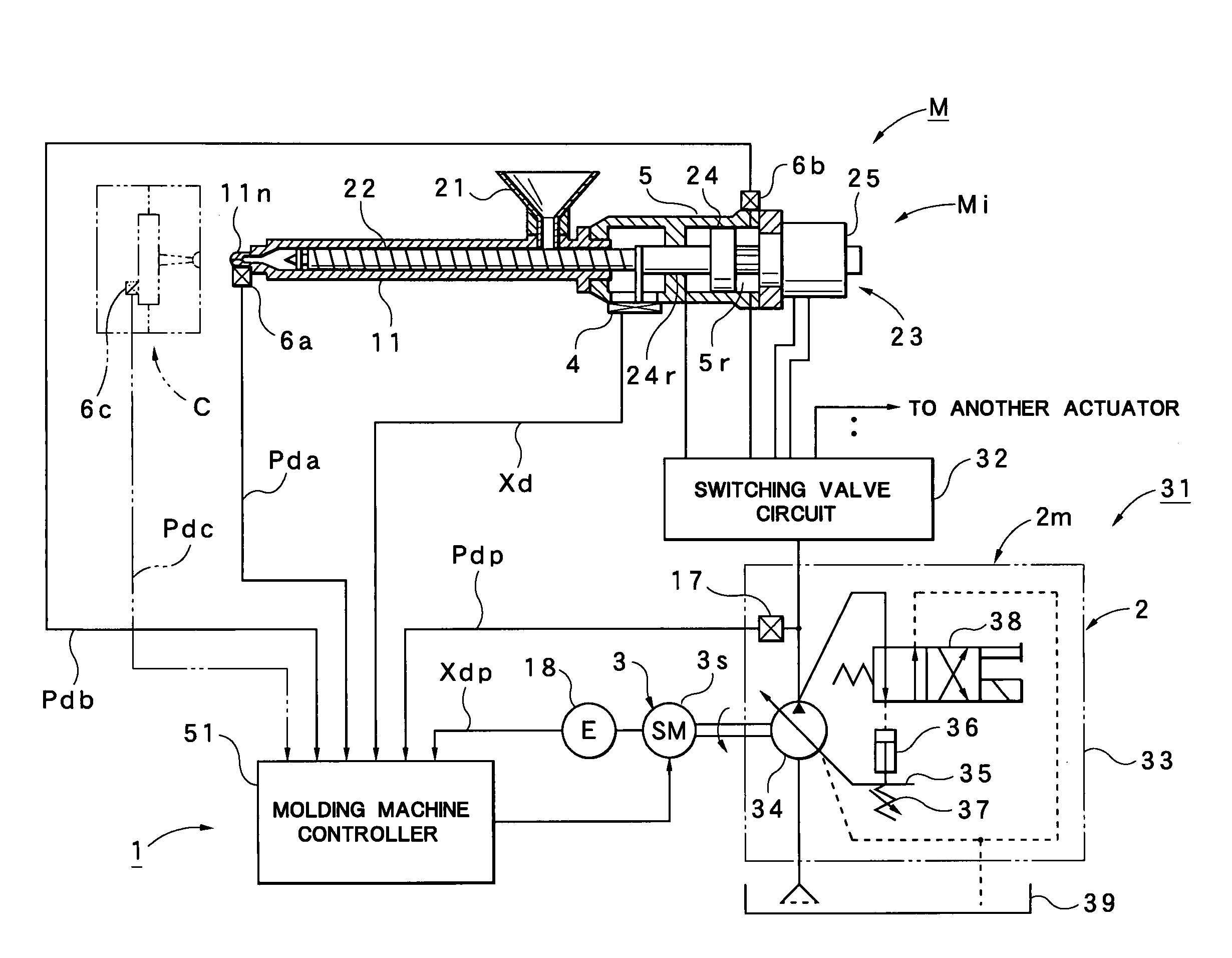

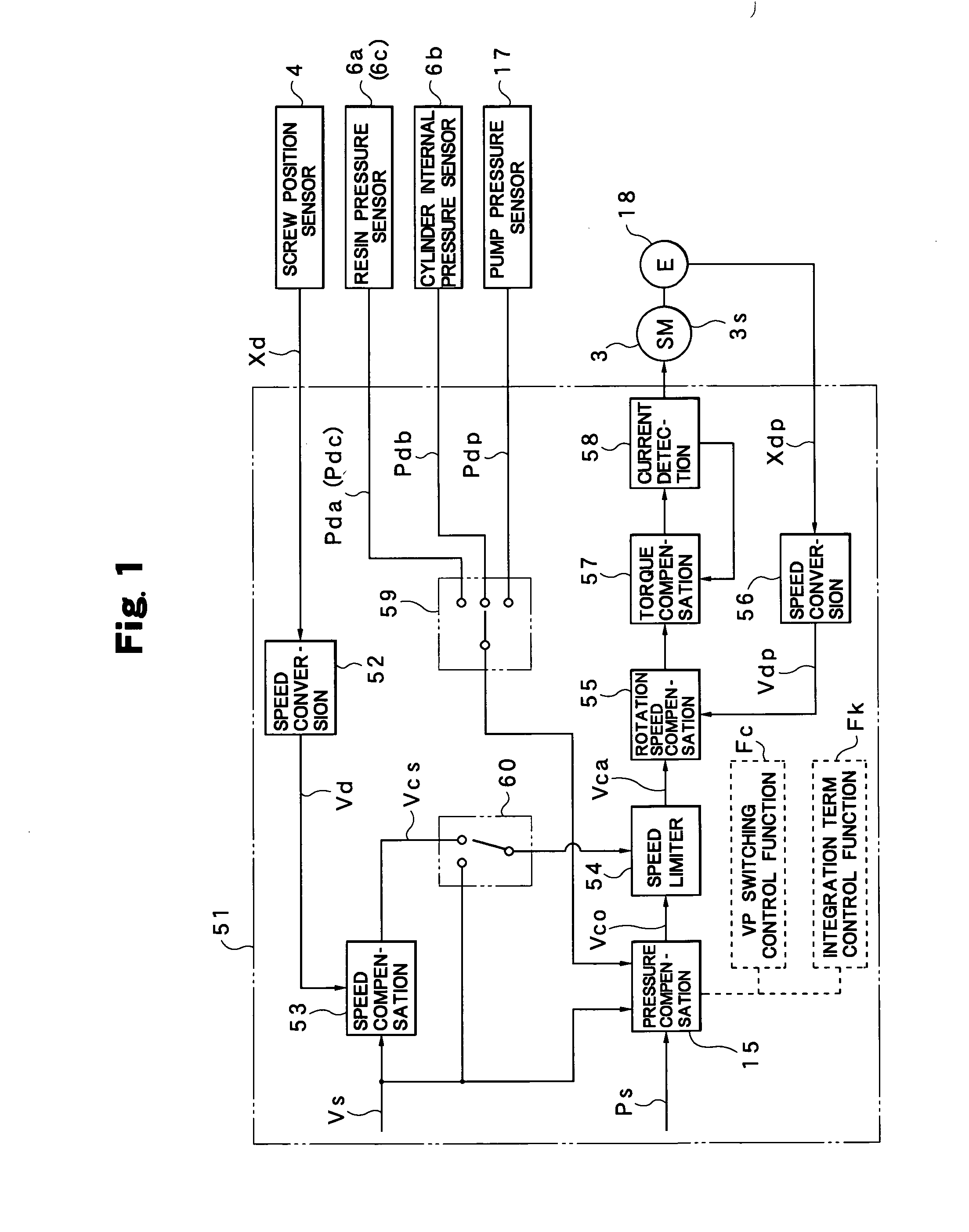

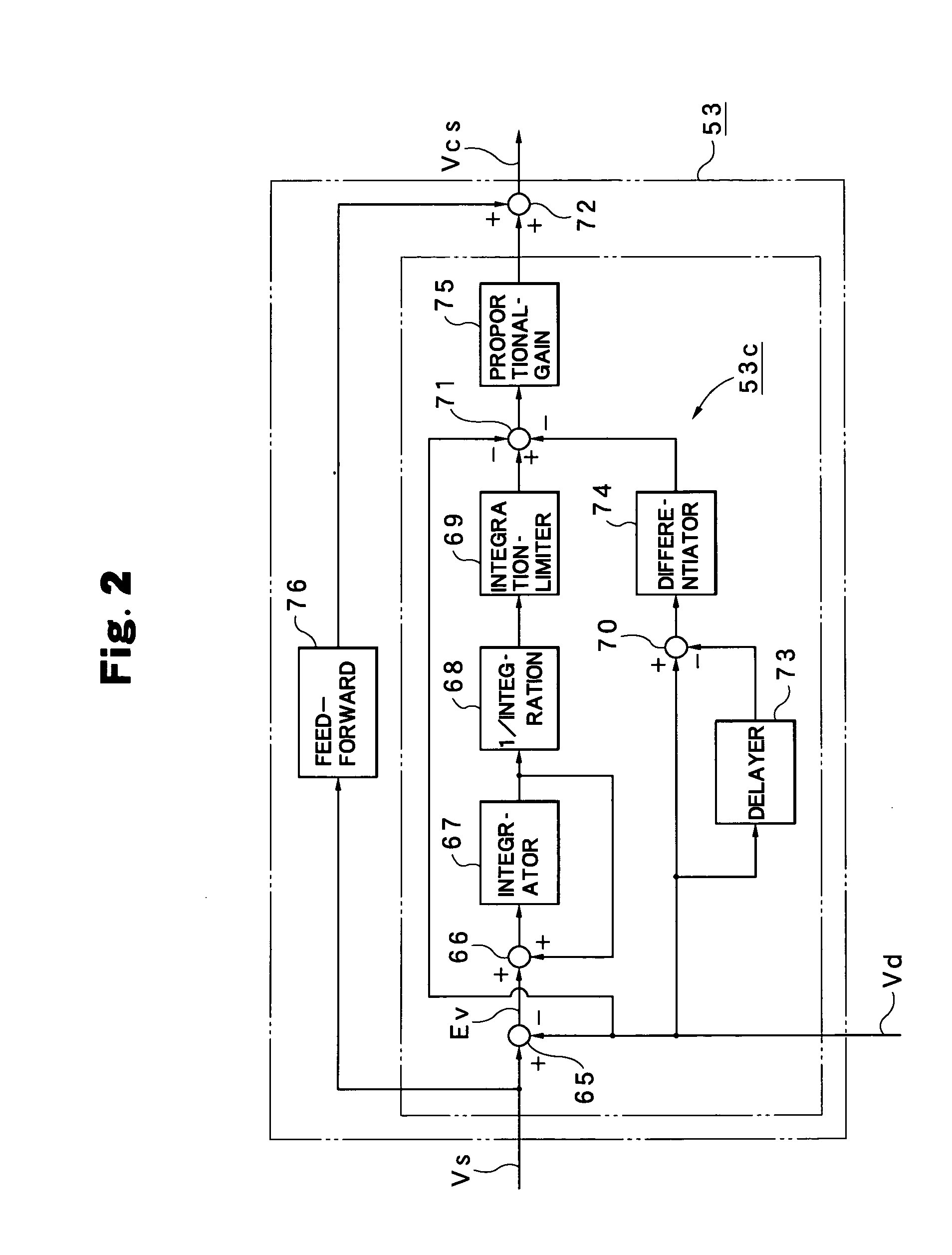

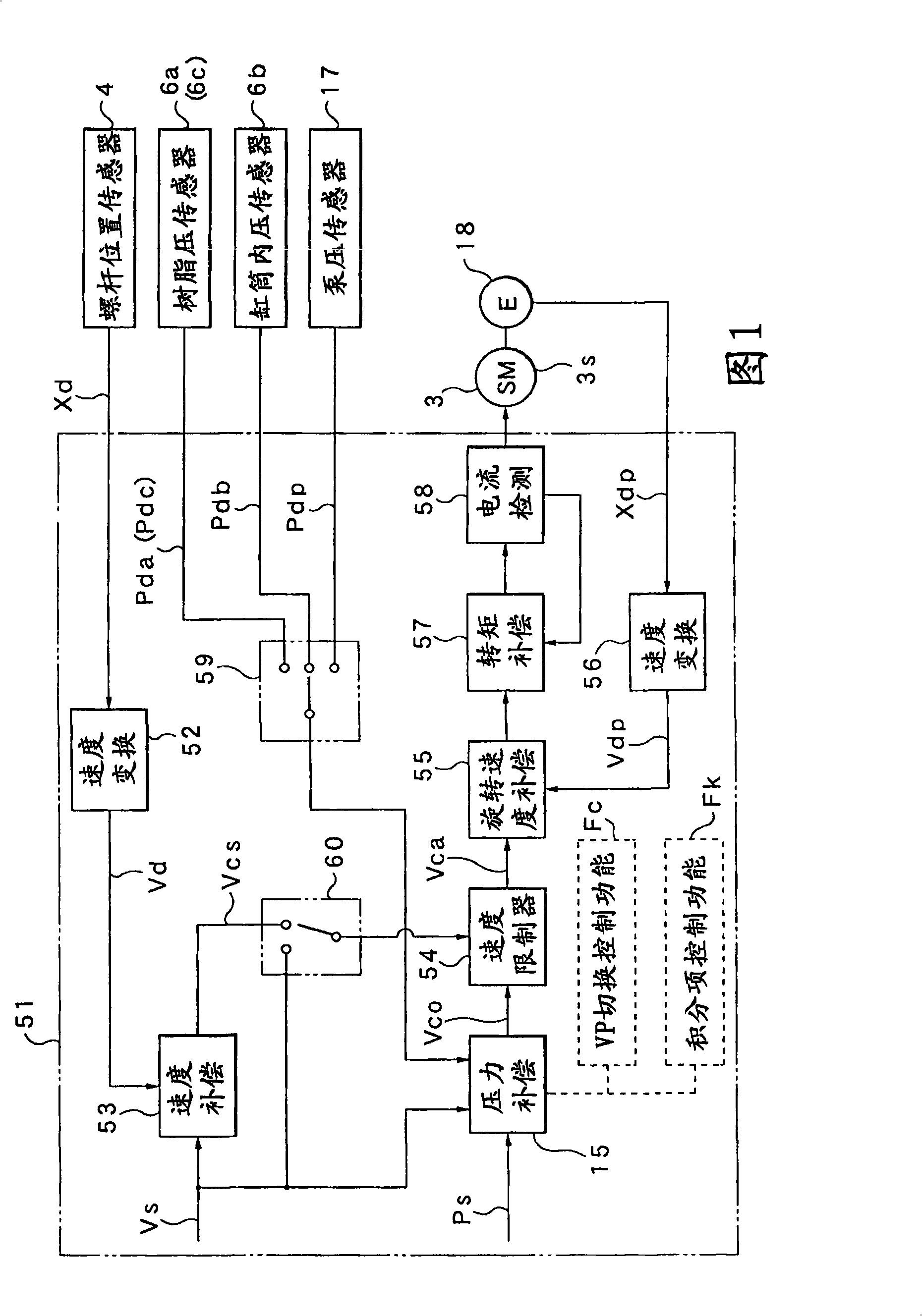

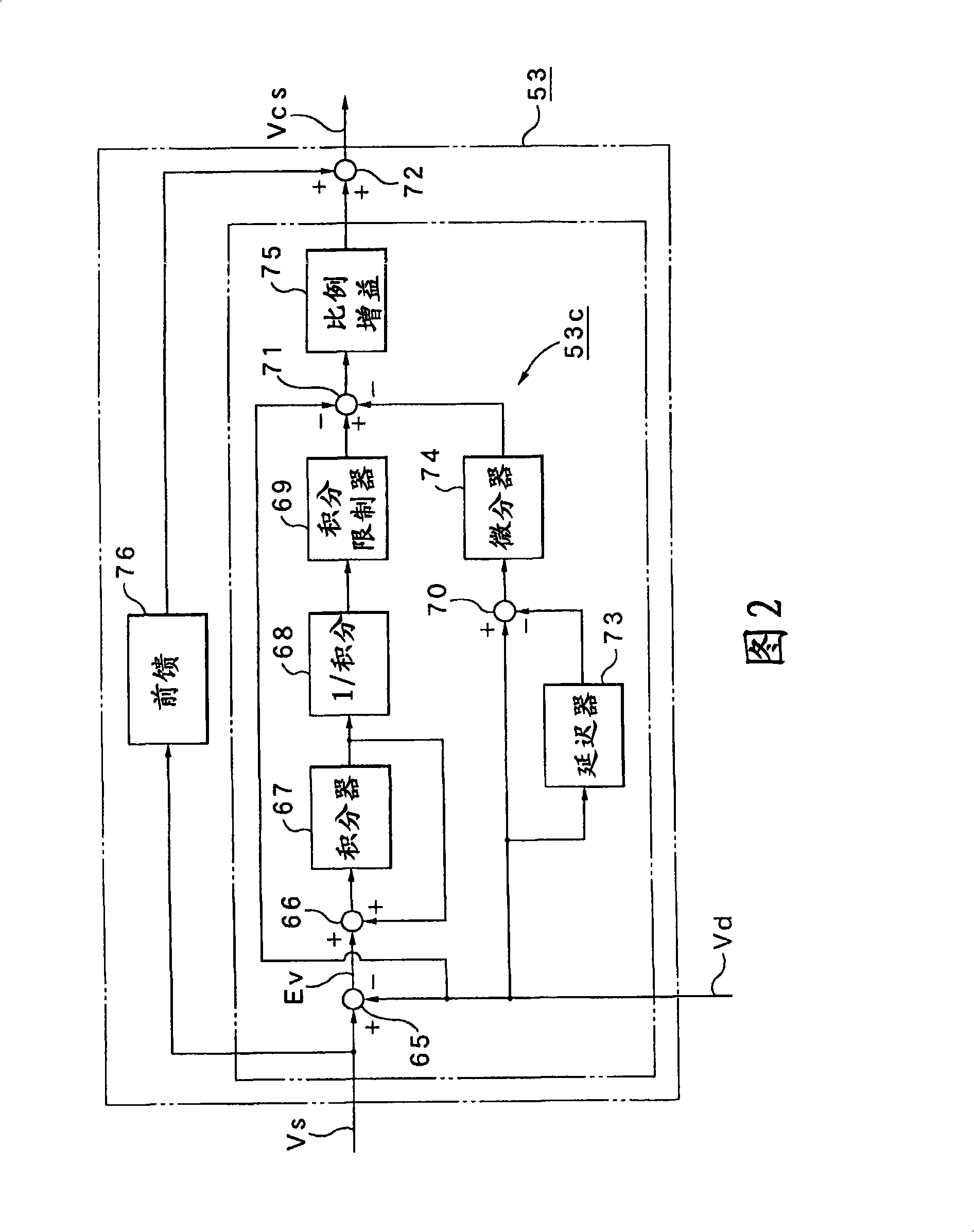

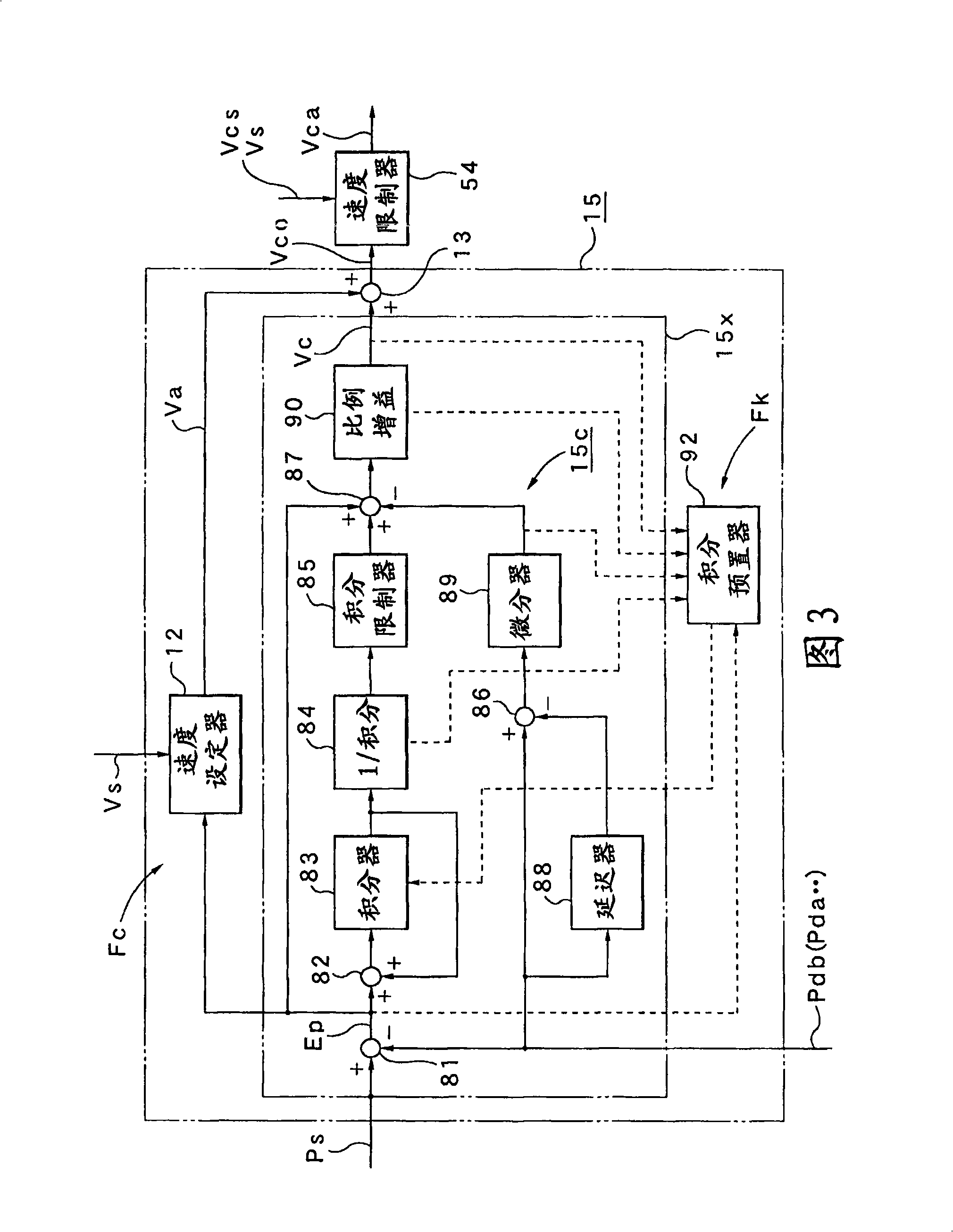

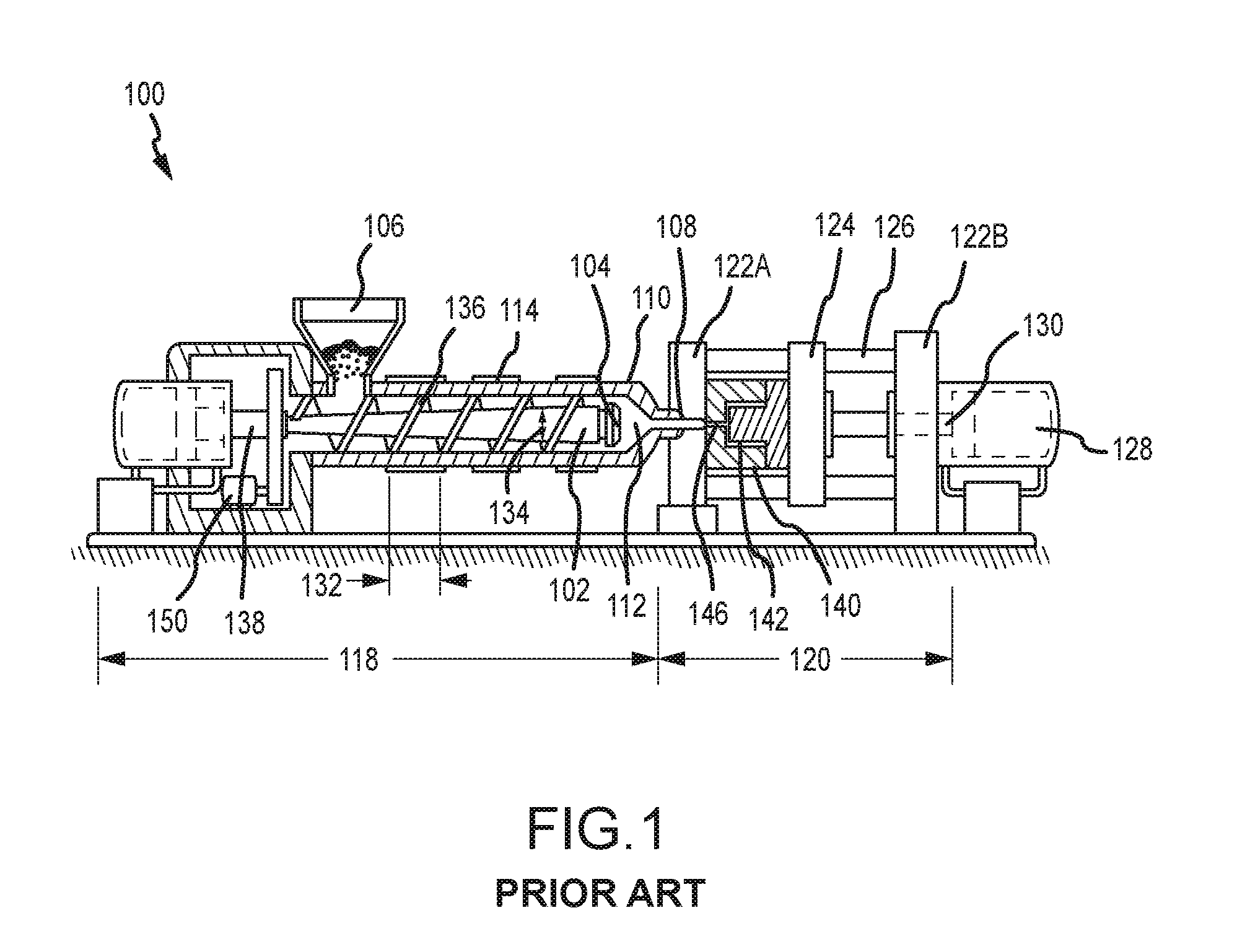

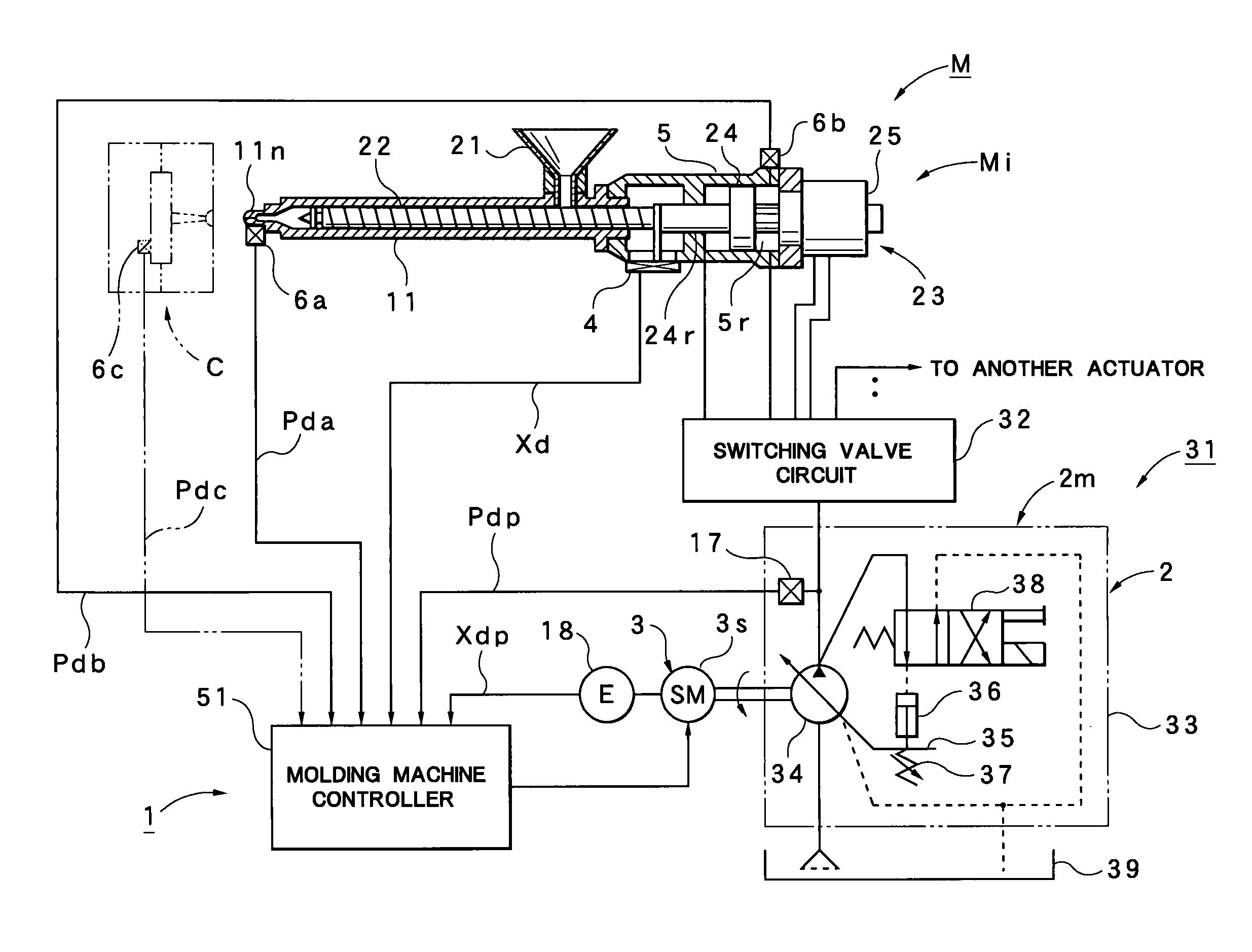

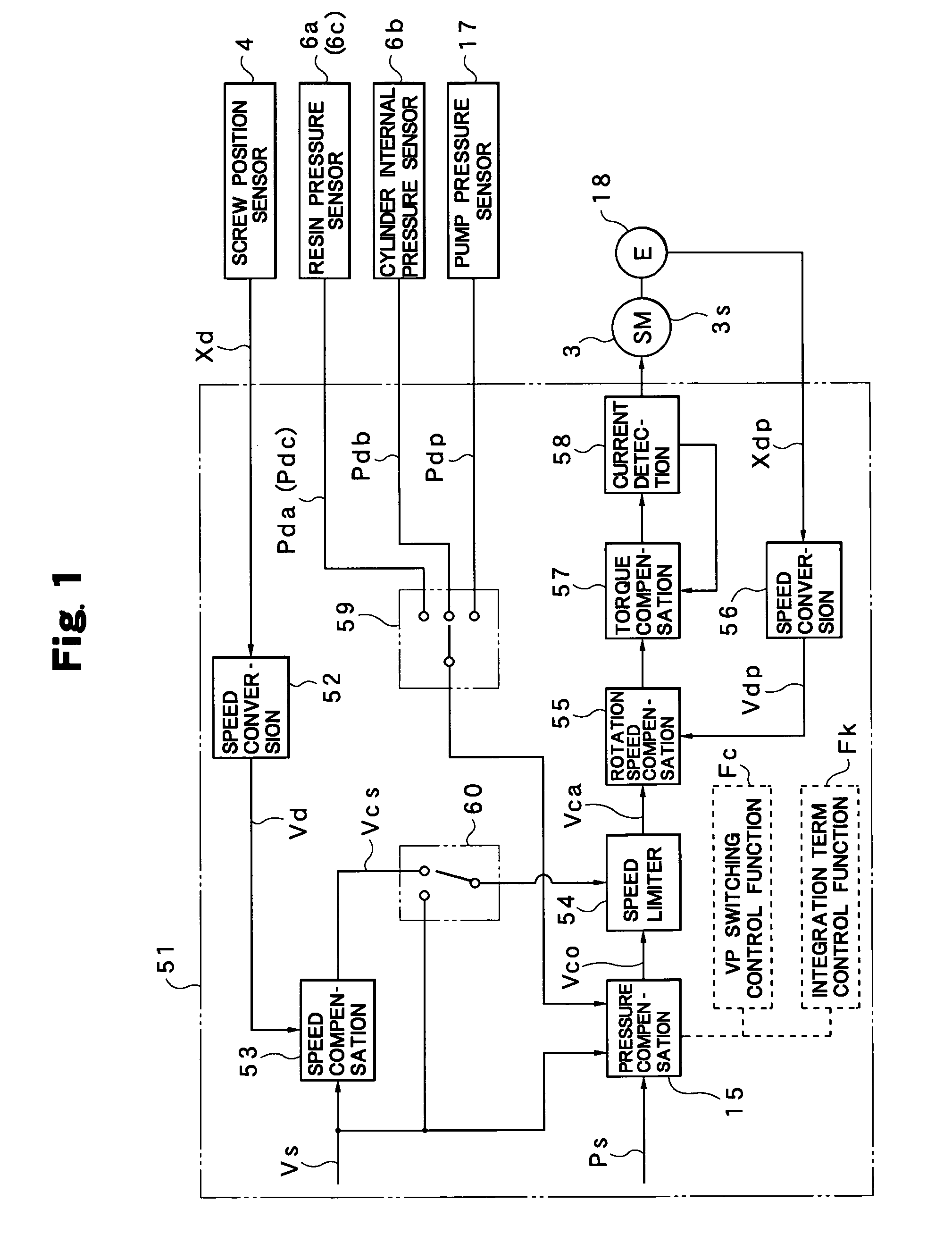

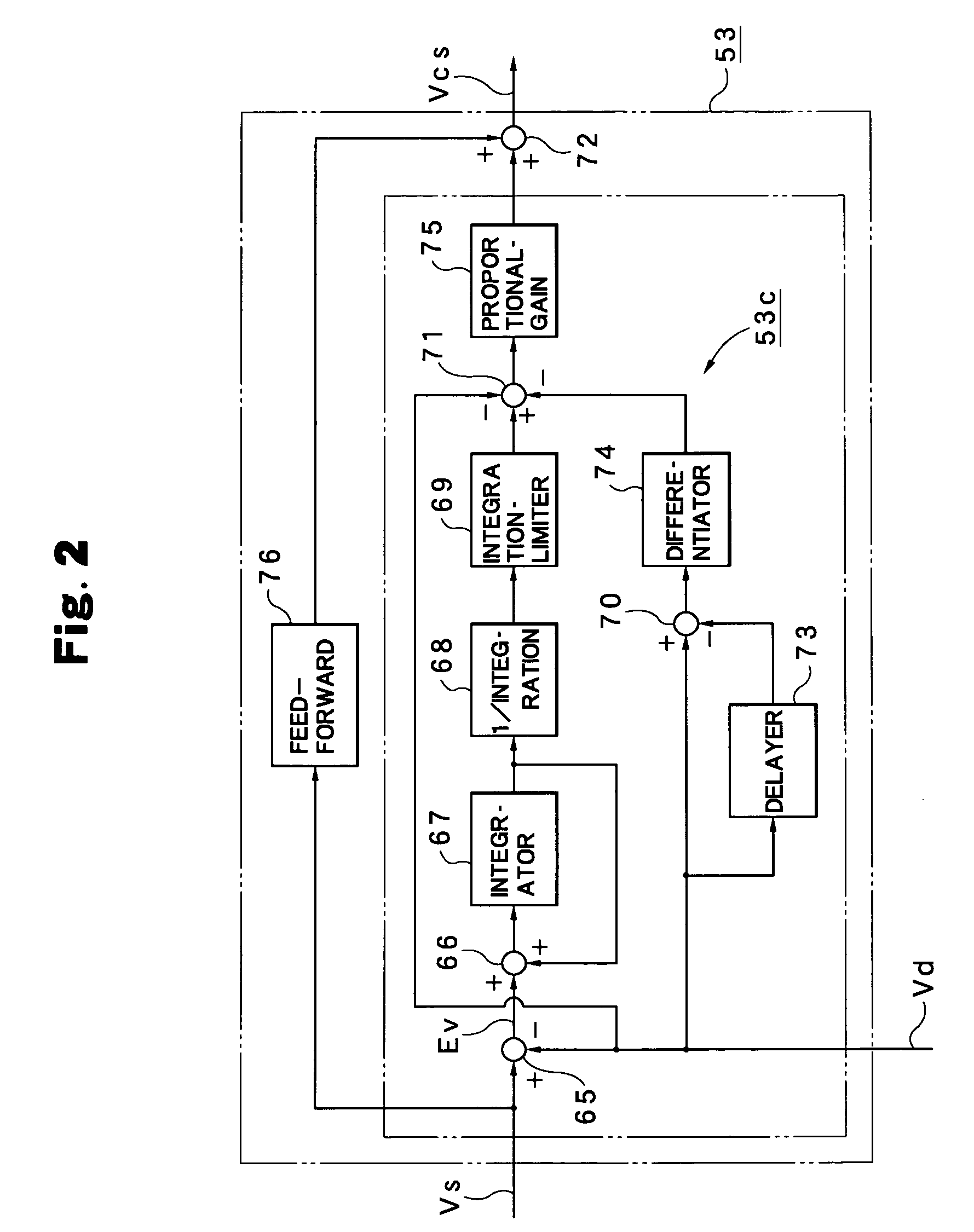

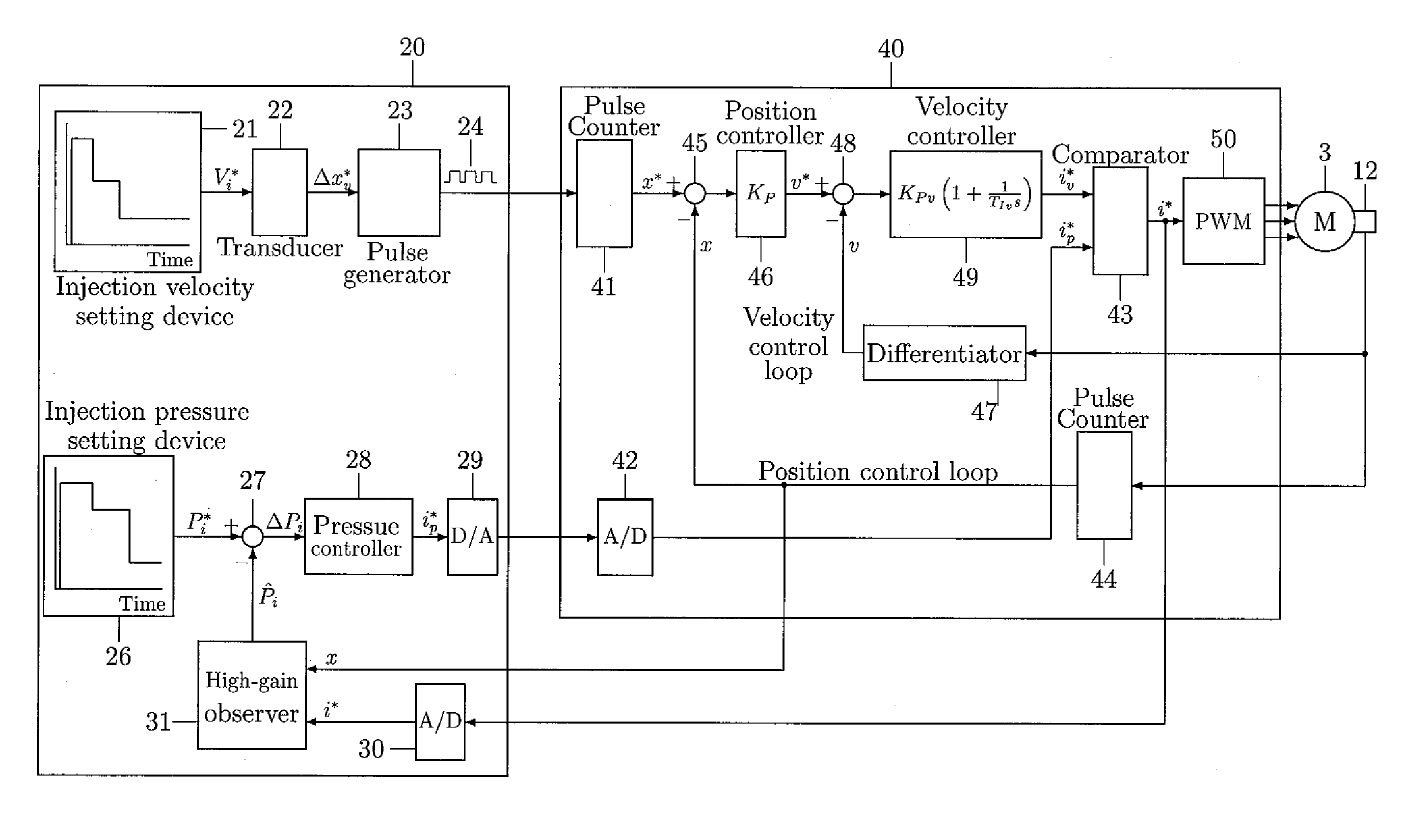

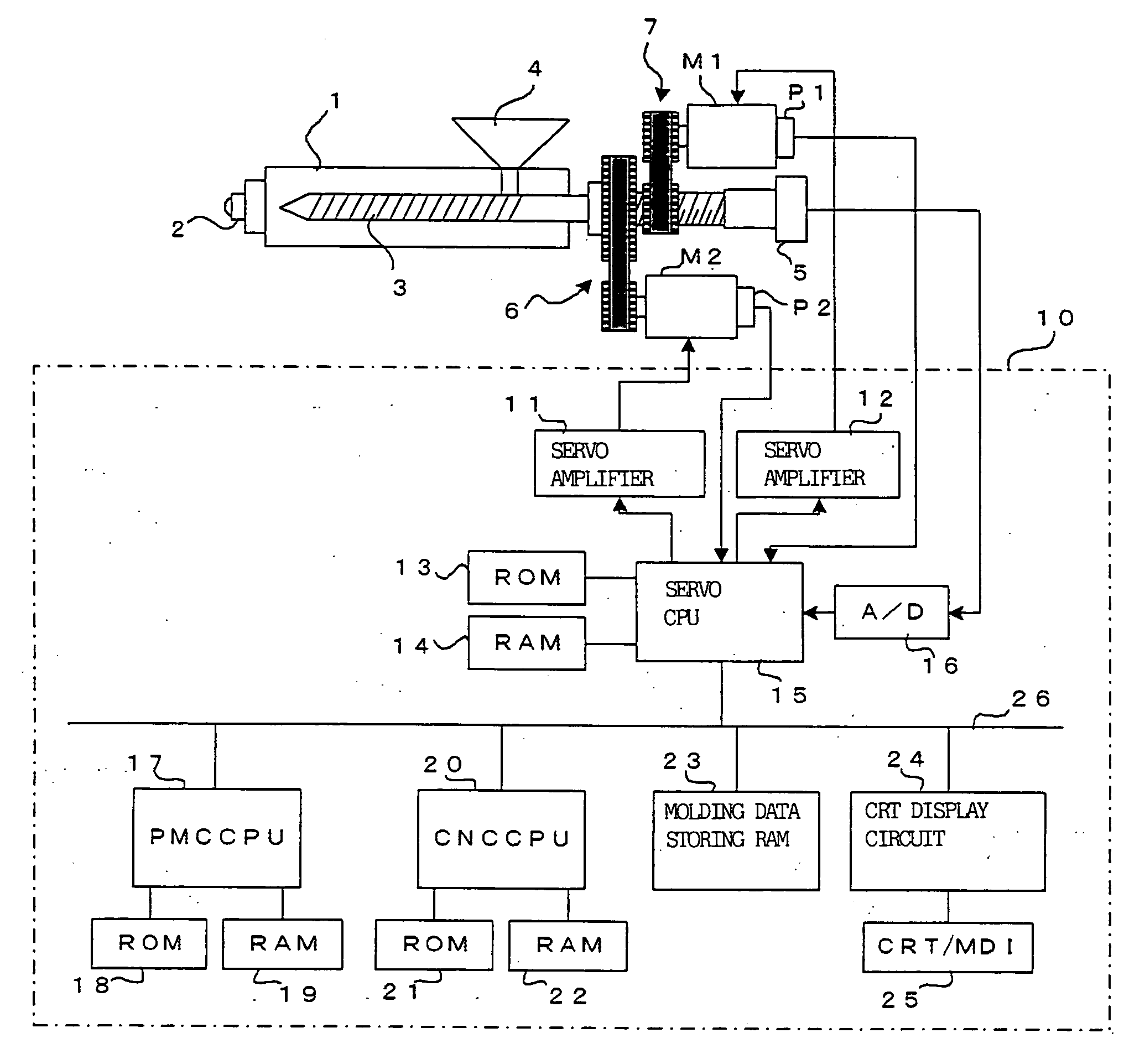

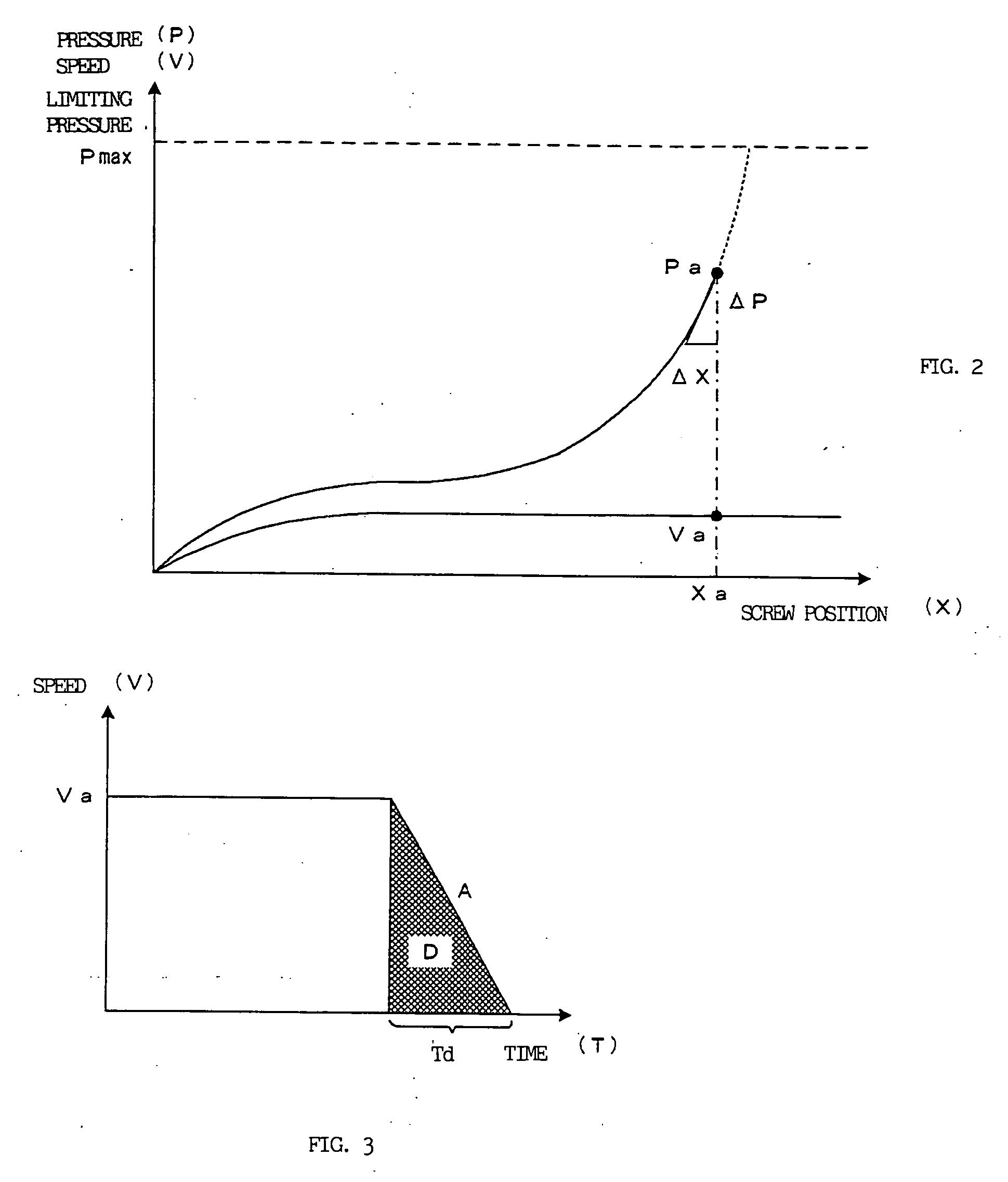

Controller of injection molding machine

ActiveUS20090087510A1Significant changeSolve unqualifiedAuxillary shaping apparatusInjection pressureScrew position

The present invention comprises a speed feedback control system for carrying out speed feedback control on the basis of a speed detected value Vd obtained by converting a position detected value Xd obtained from a screw position sensor 4, a pressure feedback control system for carrying out a pressure feedback control on the basis of a pressure detected value Pdb obtained from an injection pressure sensor 6b, and a VP switching control function portion Fc for carrying out switching from a speed control region to a pressure control region Zp when a pressure deviation Ep between a preset pressure set value Ps and the pressure detected value Pdb becomes a preset switching determination value Eps or less and carrying out the switching to the pressure control region Zp after control of a speed command value in the speed control region Zv by a predetermined control pattern Dp at this switching.

Owner:NISSEI PLASTIC IND CO LTD

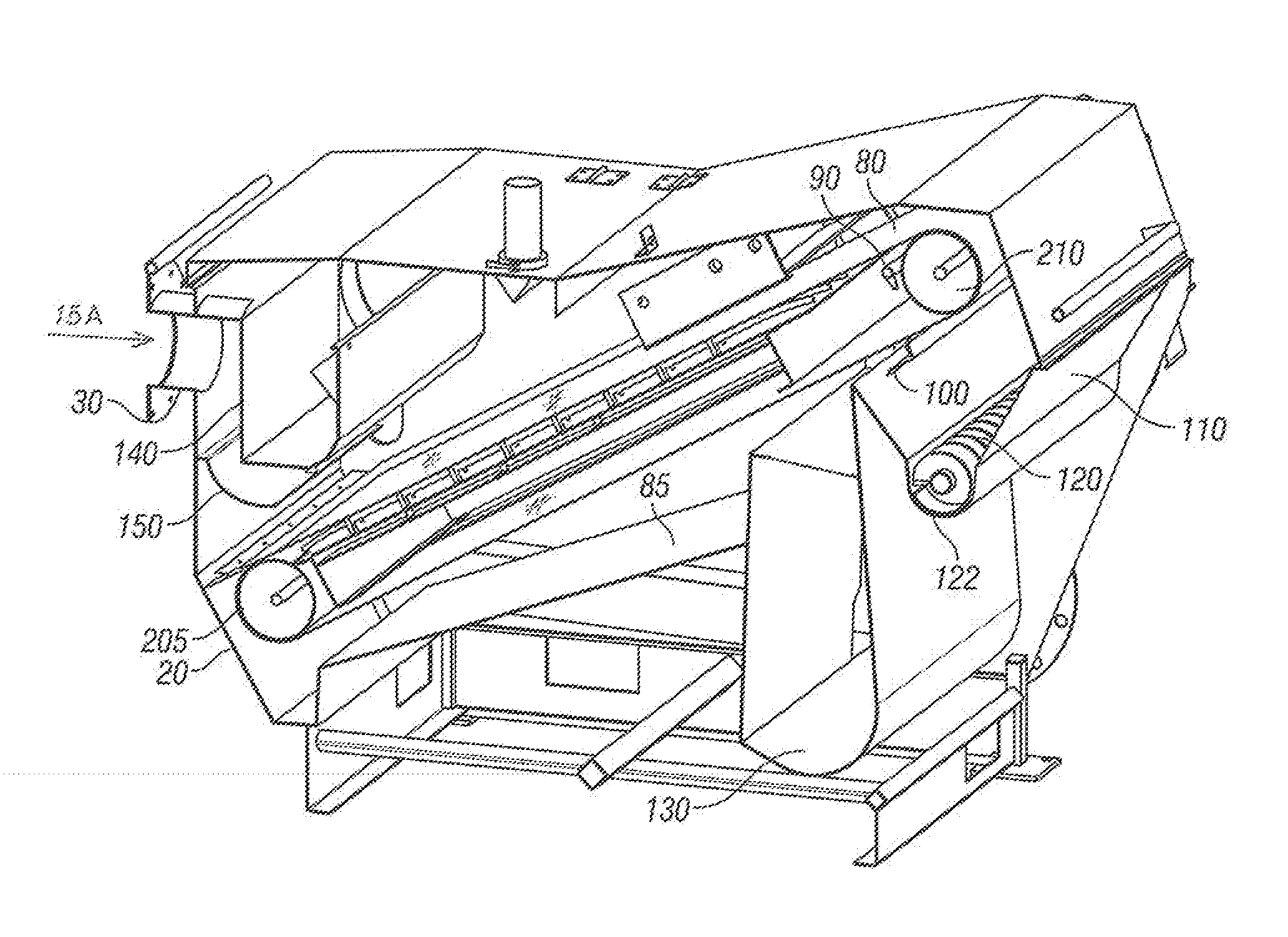

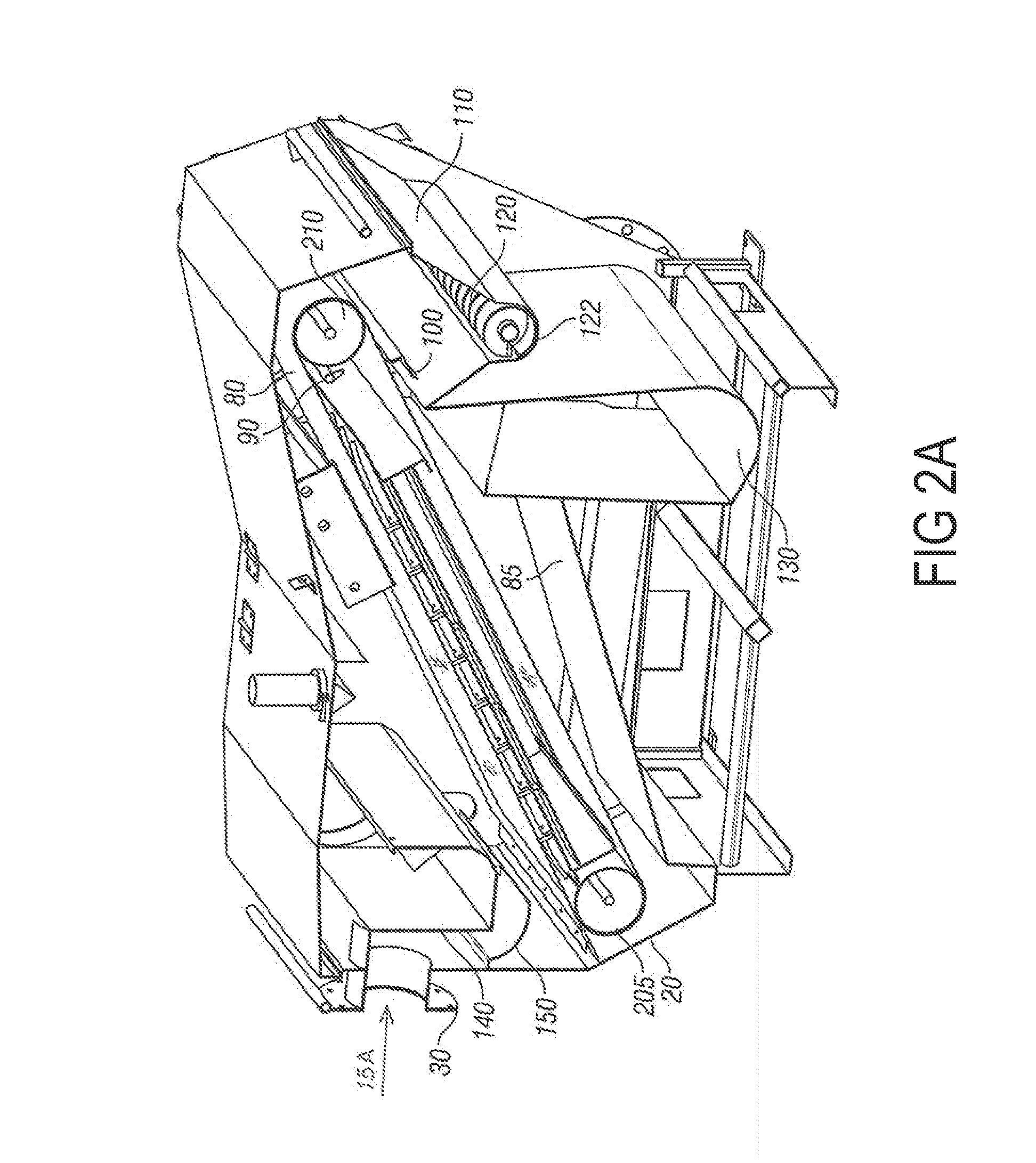

Industrial separator and dewatering plant

ActiveUS8302780B1Avoid pollutionReduce input energy requirementWater/sewage treatmentLoose filtering material filtersScrew positionWash water

An industrial separator and dewatering plant has a filtering portion using an inclined conveyor belt for carrying away a watery cake from an aqueous mixture containing solid matter. The filtering portion further has a wash water spray nozzle directed at the conveyor belt so as to dislodge the watery cake penetrated within the conveyor belt. A dewatering portion has a compression auger screw positioned for receiving the dislodged watery cake and the wash water. An auger screw receives the wash water and cake which is transported to a compression cage where compression drives water out of the cake leaving a semi-solid cake which is pressed against a door where it exits the plant.

Owner:HYDRO INTERNATIONAL AG

Archery sight with zero pin spacing capability

An Archery Sight with Zero Pin Spacing Capability consisting of a mounting assembly and a fixed pin assembly. The fixed pin assembly consists of channel containing a plurality of horizontal sight pins each mounted to a vertical support. The stack of the plurality of vertical supports are held rigid by friction from a compression force from screws positioned through the sides of a channel. The sight pin vertical supports may be separated by separating components that are fixed in the vertical direction so that moving one sight pin does not affect other sight pins. The sight pins are moved by finger pressure or by adjusting screw when the compression force is released by loosening other screws. With the above configuration, the pins may be moved so that they touch one another. The fixed pin assembly can be adjusted horizontally and vertically by means in the mounting assembly.

Owner:SHELIGA DOUGLAS J

Controller of injection molding machine

The present invention discloses a control device of an injection molding machine, which comprises a speed feedback control system for carrying out speed feedback control on the basis of a speed detected value Vd obtained by converting a position detected value Xd obtained from a screw position sensor 4, a pressure feedback control system for carrying out a pressure feedback control on the basis of a pressure detected value Pdb obtained from an injection pressure sensor 6b, and a VP switching control function portion Fc for carrying out switching from a speed control region to a pressure control region Zp when a pressure deviation Ep between a preset pressure set value Ps and the pressure detected value Pdb becomes a preset switching determination value Eps or less and carrying out the switching to the pressure control region Zp after control of a speed command value in the speed control region Zv by a predetermined control pattern Dp at this switching.

Owner:NISSEI PLASTIC IND CO LTD

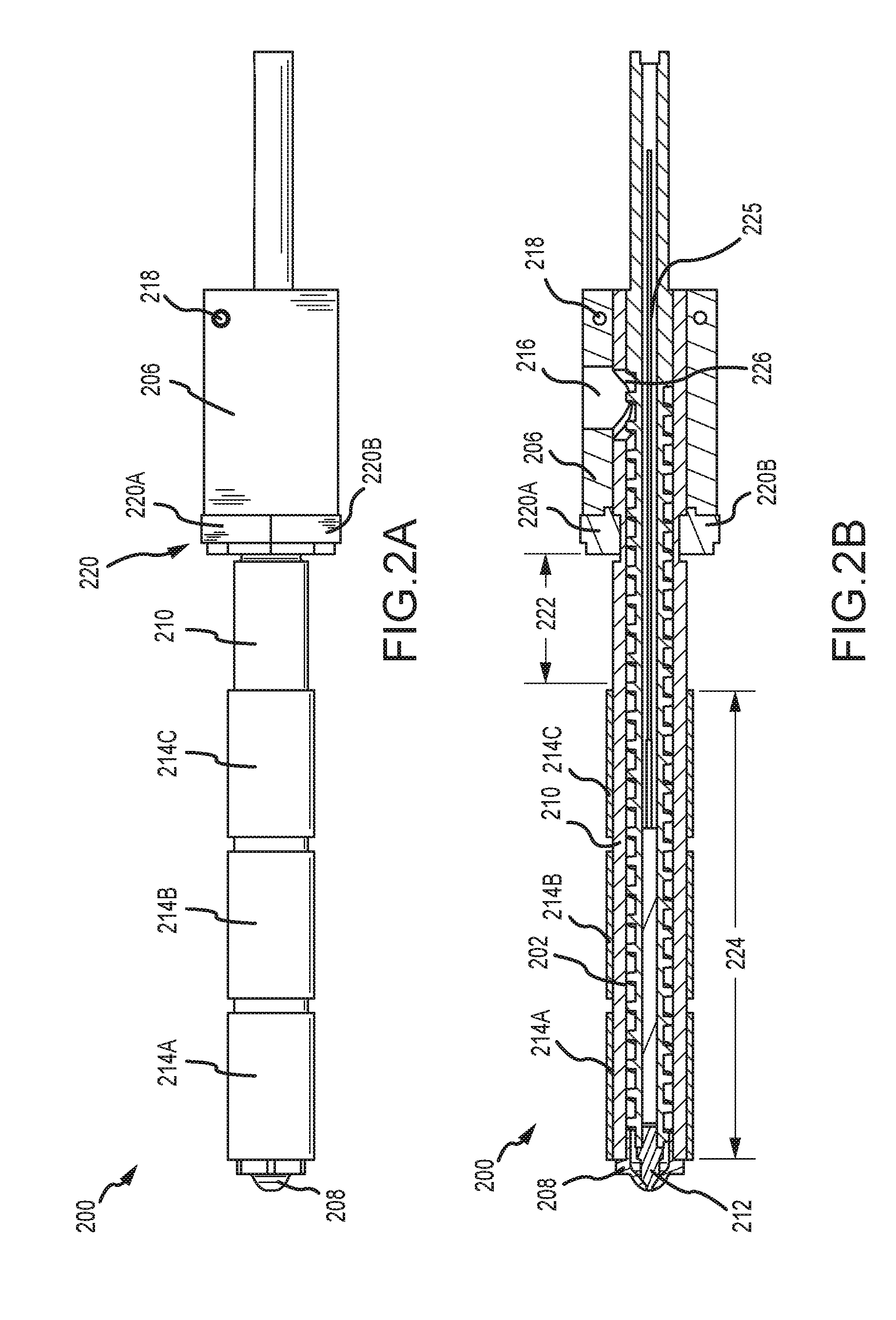

Molding system and method of heating a material inside a molding system

The present disclosure provides a molding system and a method of heating a material inside a molding system. The molding system may include a thermally-insulative barrel, a screw received inside the barrel and rotatable relative to the barrel, and a heat source received inside the barrel for heating an annular space defined between the barrel and the screw. The method of heating a material inside a molding system may include applying inductive heat to a magnetic screw positioned inside an insulative barrel to prepare a material for extrusion.

Owner:EXTRUDE TO FILL

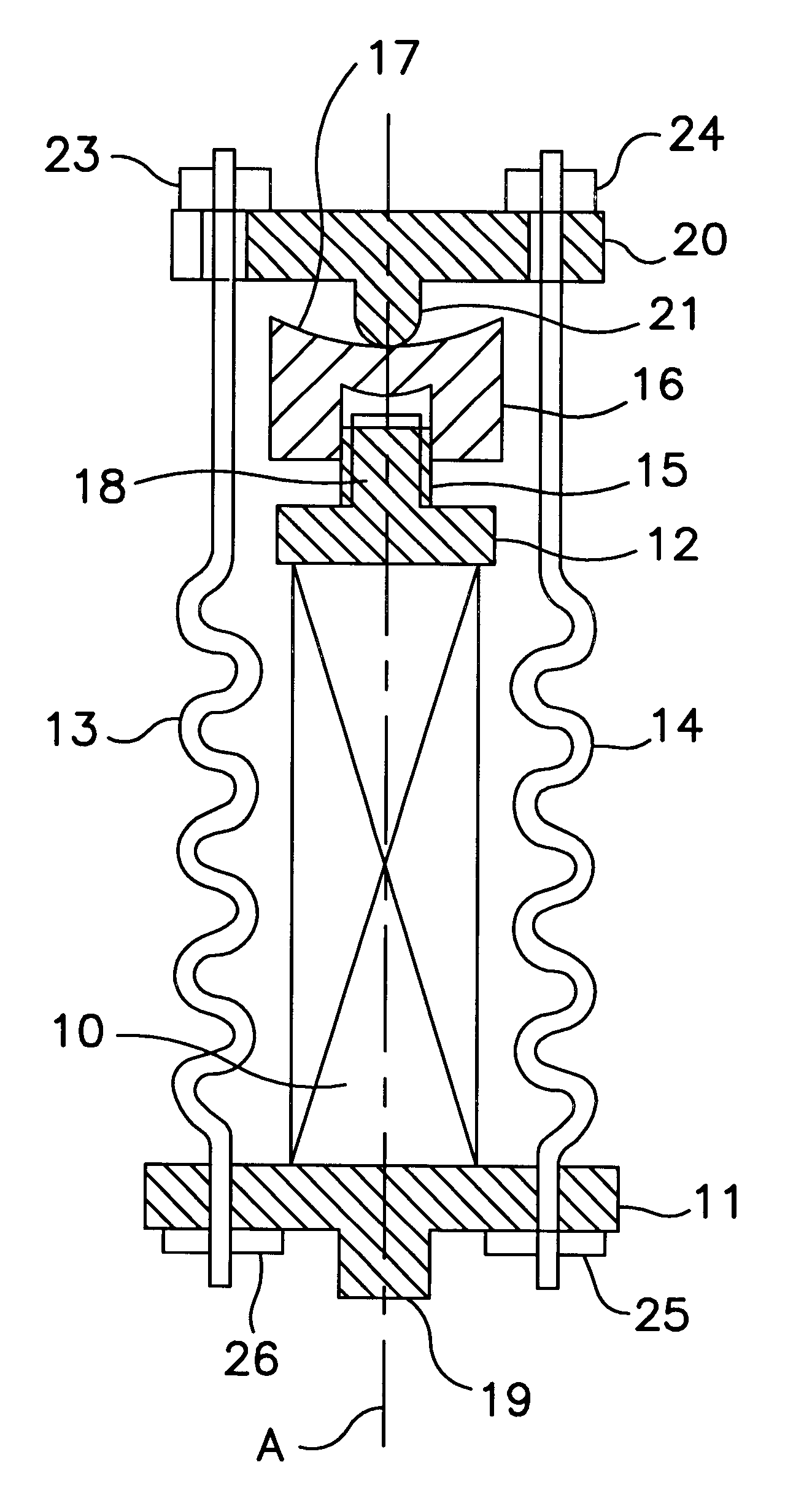

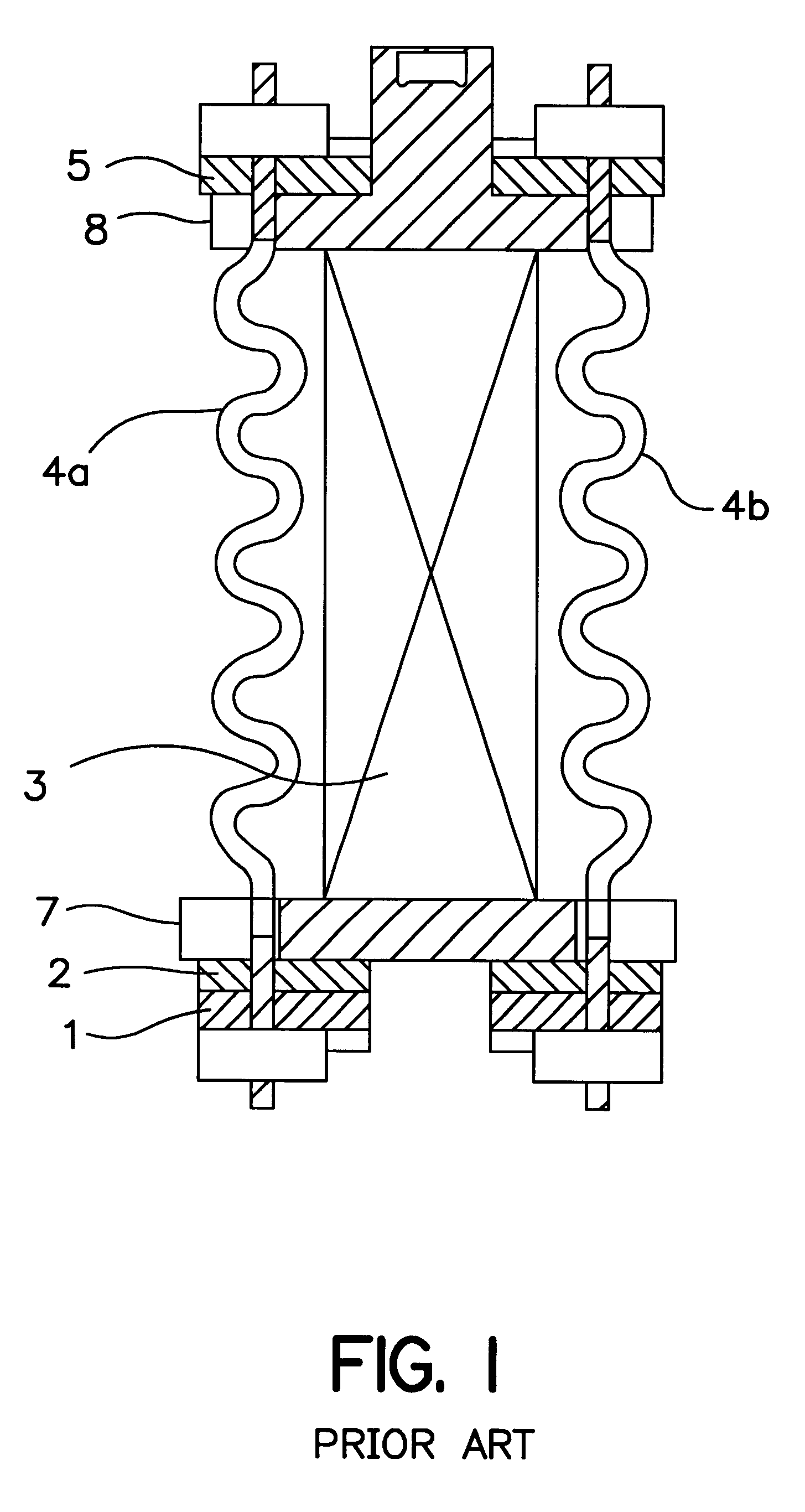

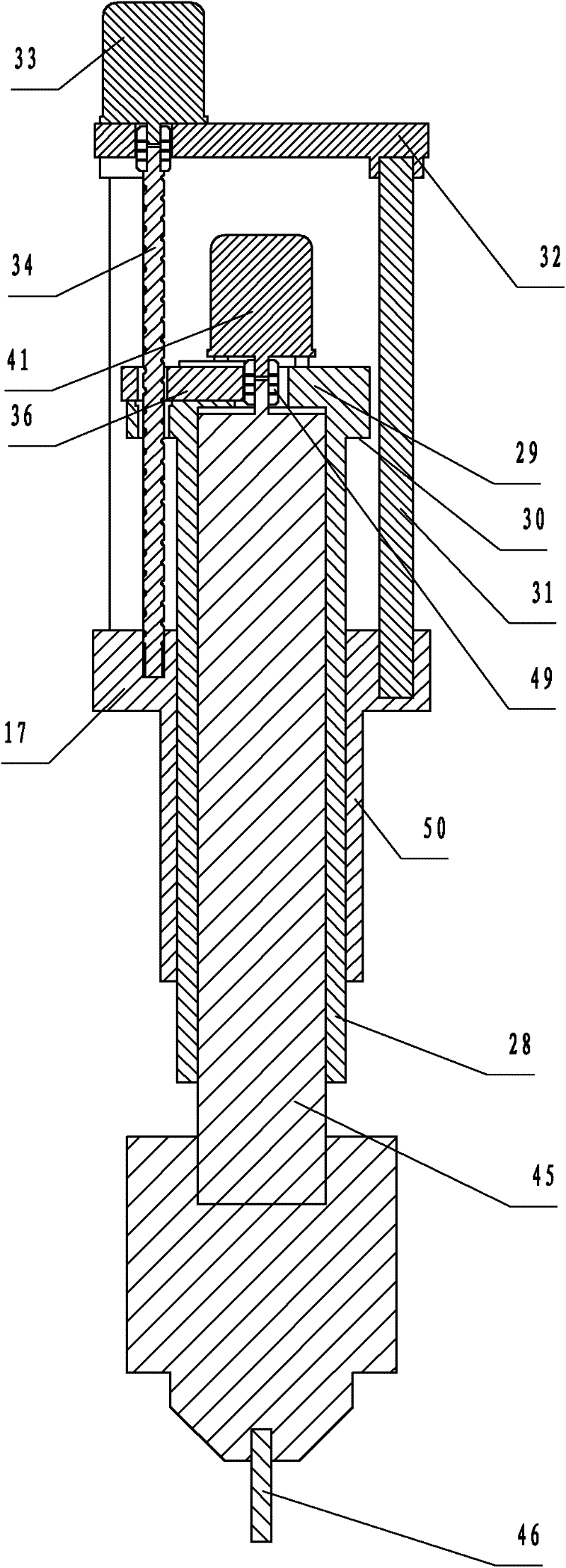

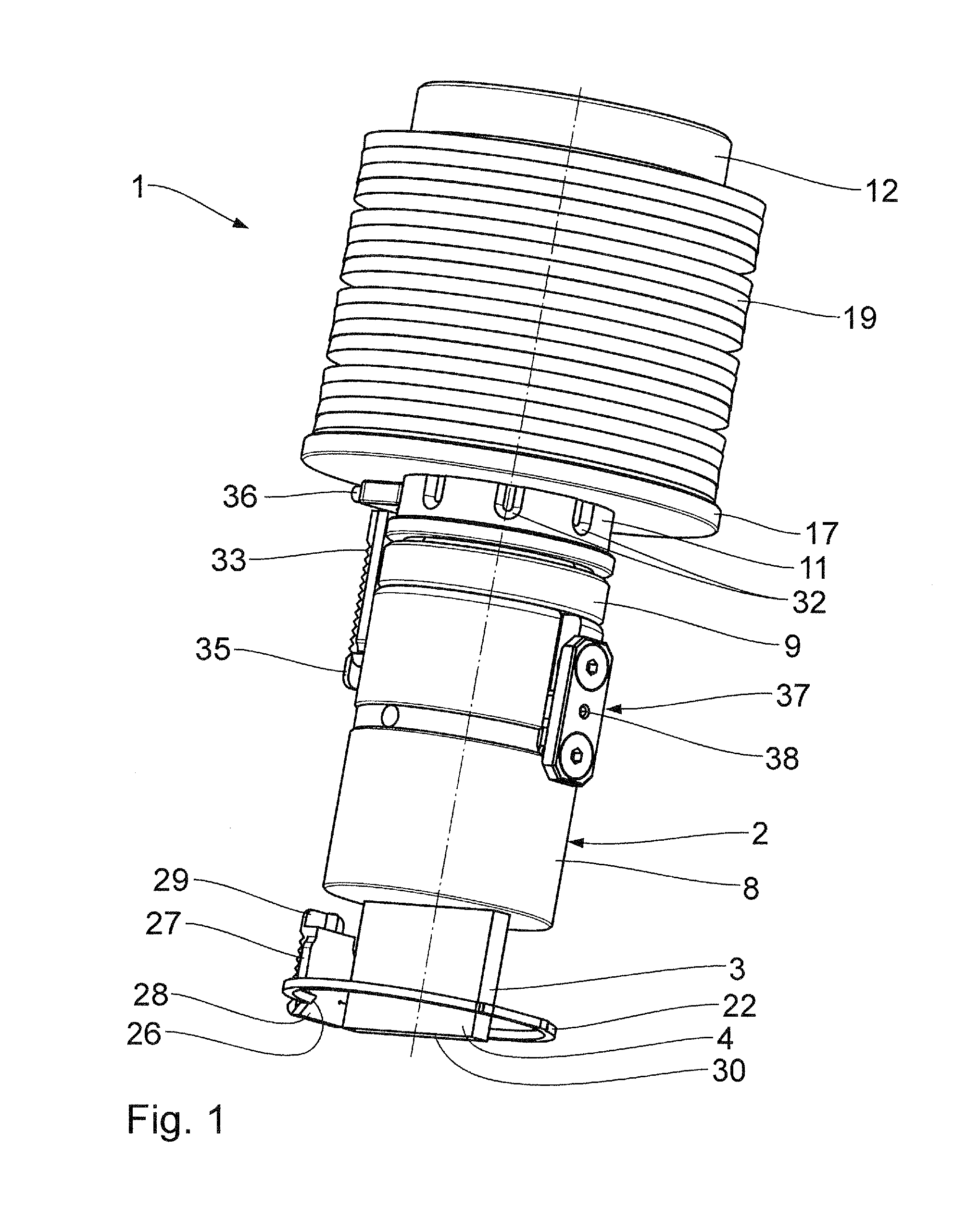

Piezoelectric actuator

InactiveUS6326717B1Easy to adjustImproved compensating elementPiezoelectric/electrostriction/magnetostriction machinesFuel injection apparatusElectrically conductiveScrew position

A piezoelectric actuator, in particular for actuating control valves or injection valves in motor vehicles, having an actuator body embodied in the form of a multilayered laminate made up of stacked layers of piezoelectric material with intervening metallic or electrically conductive layers that function as electrodes. The piezoelectric actuator include end faces, between a bottom plate oriented toward the valve and an opposing top plate, which are elastically prestressed by two spring bands that are disposed in the longitudinal direction on opposite sides of the actuator body and whose prestressing force can be adjusted by an adjusting nut. The piezoelectric actuator is constituted so that the adjusting nut engages in screw fashion with an external thread provided on a central, axial extension bolt of the top plate and which, depending on a screwed position, adjusts the prestressing force of the spring bands.

Owner:ROBERT BOSCH GMBH

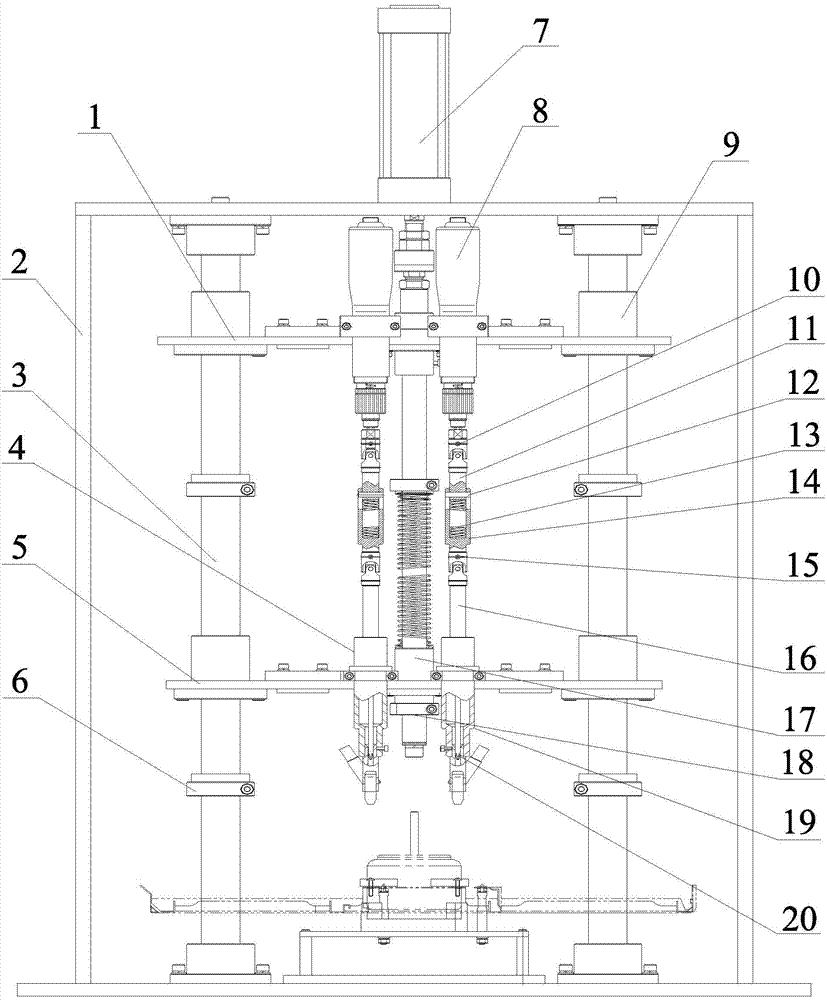

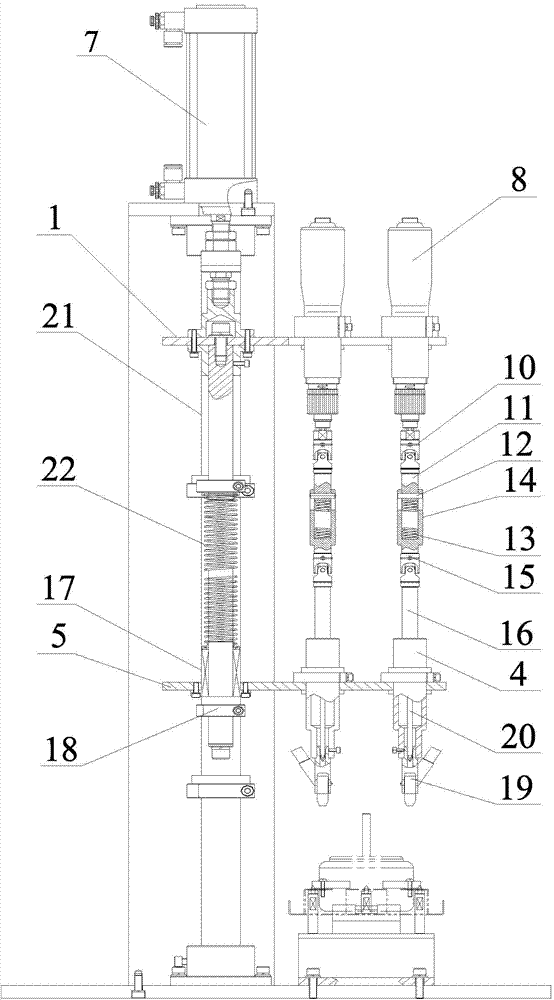

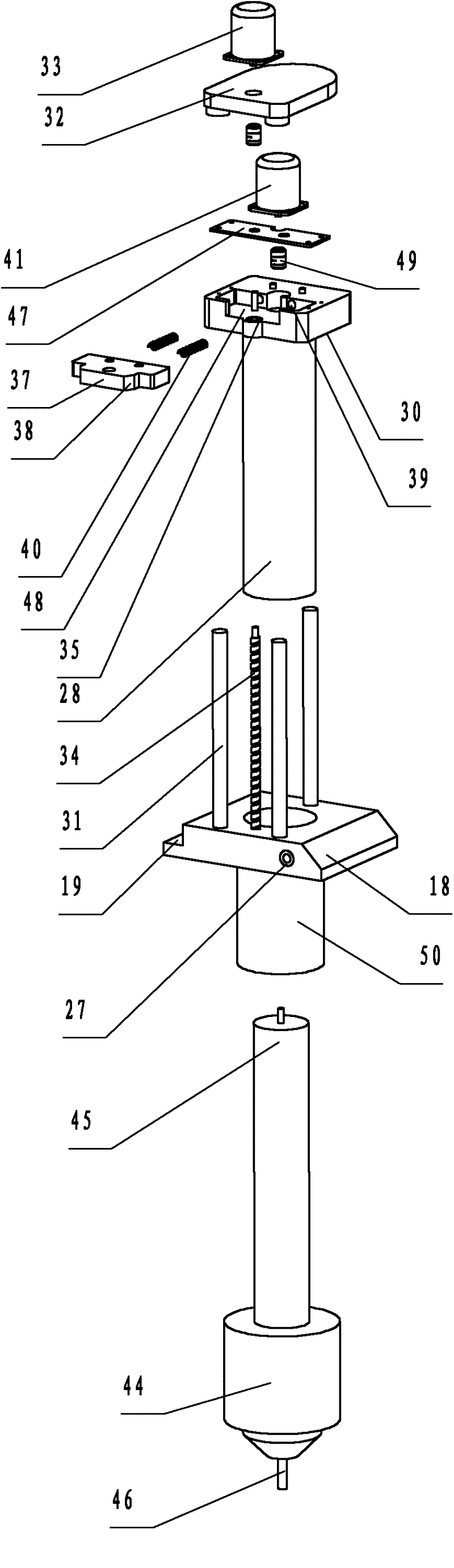

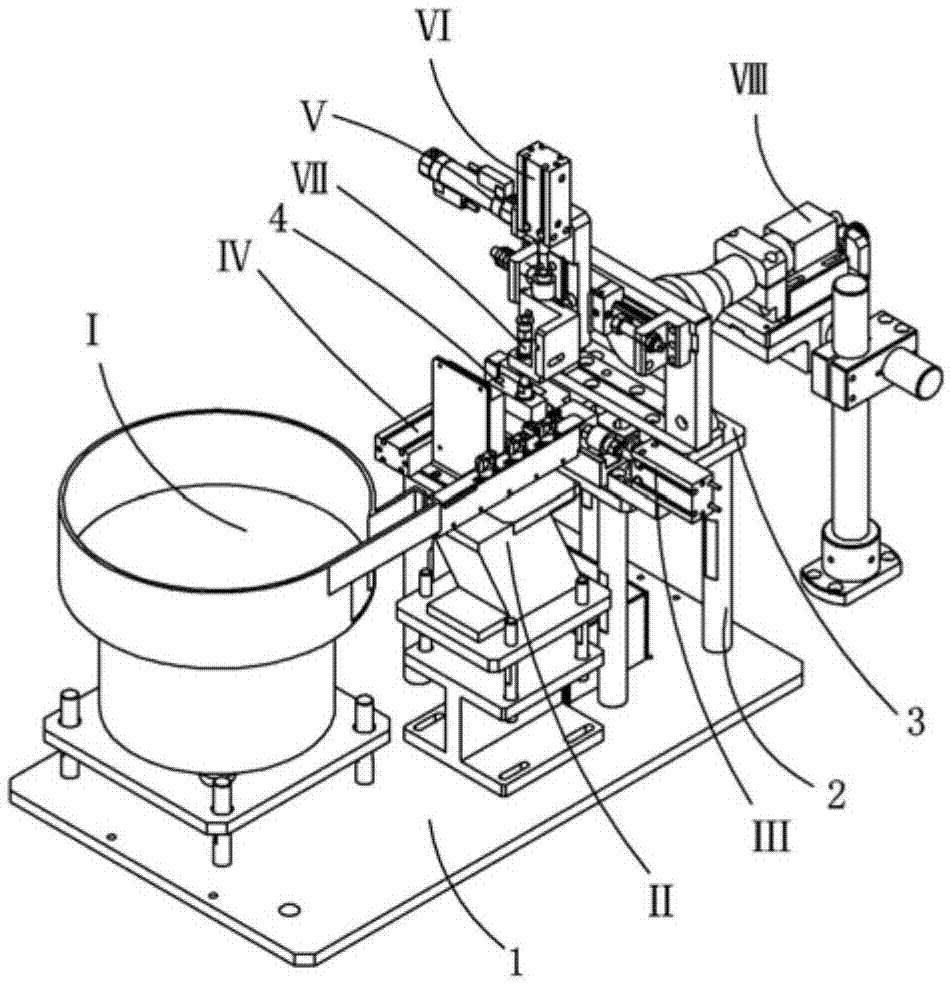

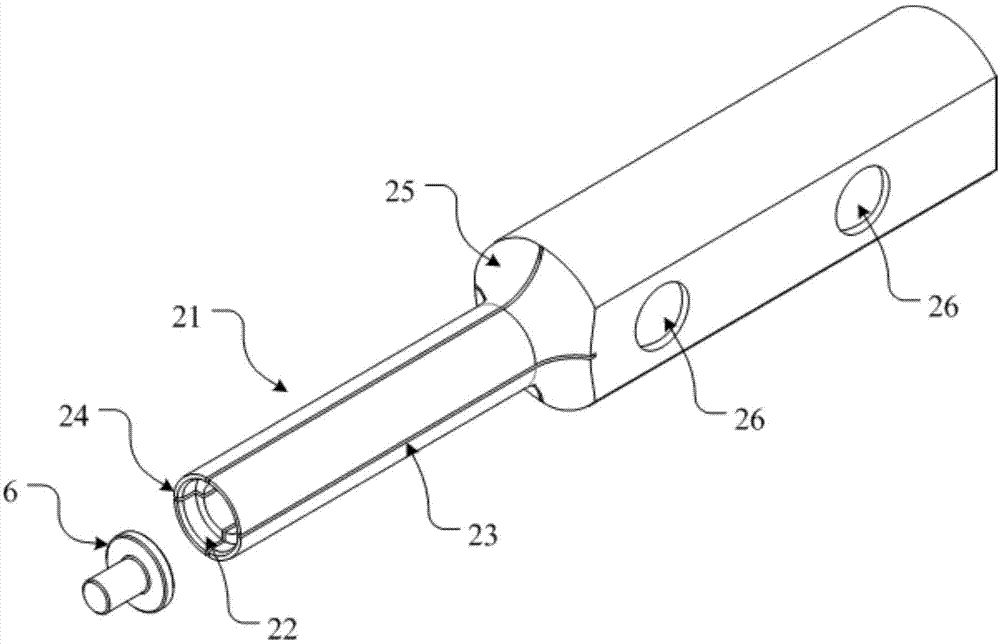

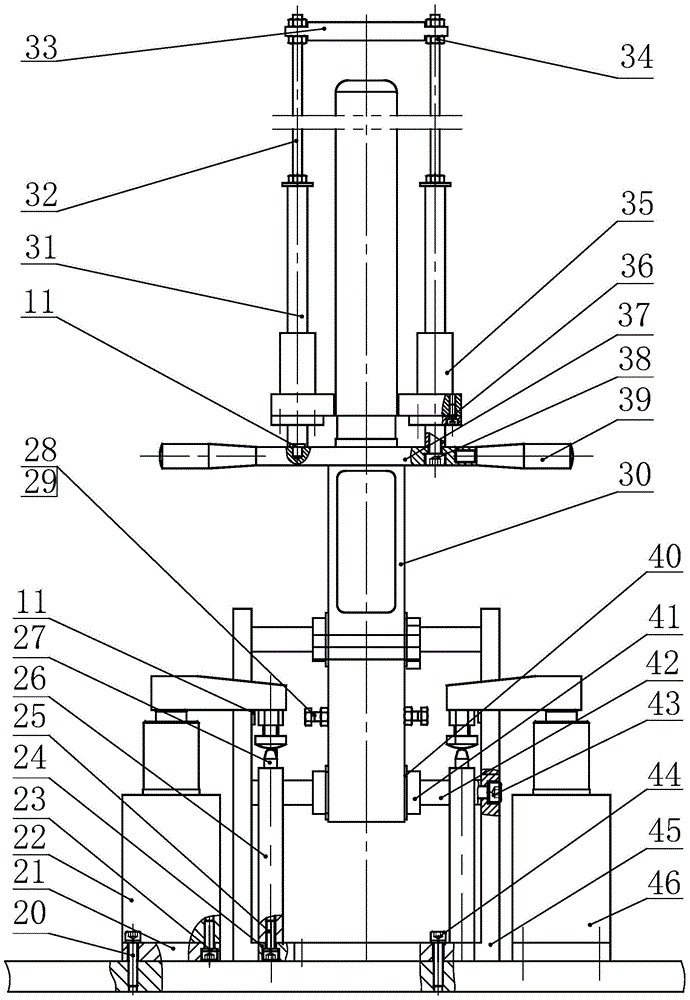

Bunching screw automatic locking device of multi-axle buffering

ActiveCN104325281ARealize automatic lockingAvoid bruisesMetal working apparatusScrew positionLocking mechanism

The invention discloses a bunching screw automatic locking device of multi-axle buffering. The device is characterized in that the device comprises a machine body (2), an air cylinder (7) and an upper movable board (1), wherein the air cylinder (7) is arranged on the machine body (2), the upper movable board (1) is connected onto the flexible rod of the air cylinder (7), and the upper movable board (1) is respectively provided with a limit mechanism and at least two locking mechanisms. The bunching screw automatic locking device is simple in structure and low in cost, the at least two locking mechanisms are arranged, and the automatic locking of bunching screws is realized, so that the assembling production efficiency is greatly improved, the labor productive force cost is reduced, and the production quality is improved; the limit mechanism can limit the movement of the locking mechanisms close to the screw position of a workpiece, the device can be prevented from damaging the workpiece, and the device is suitable for popularization and use.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

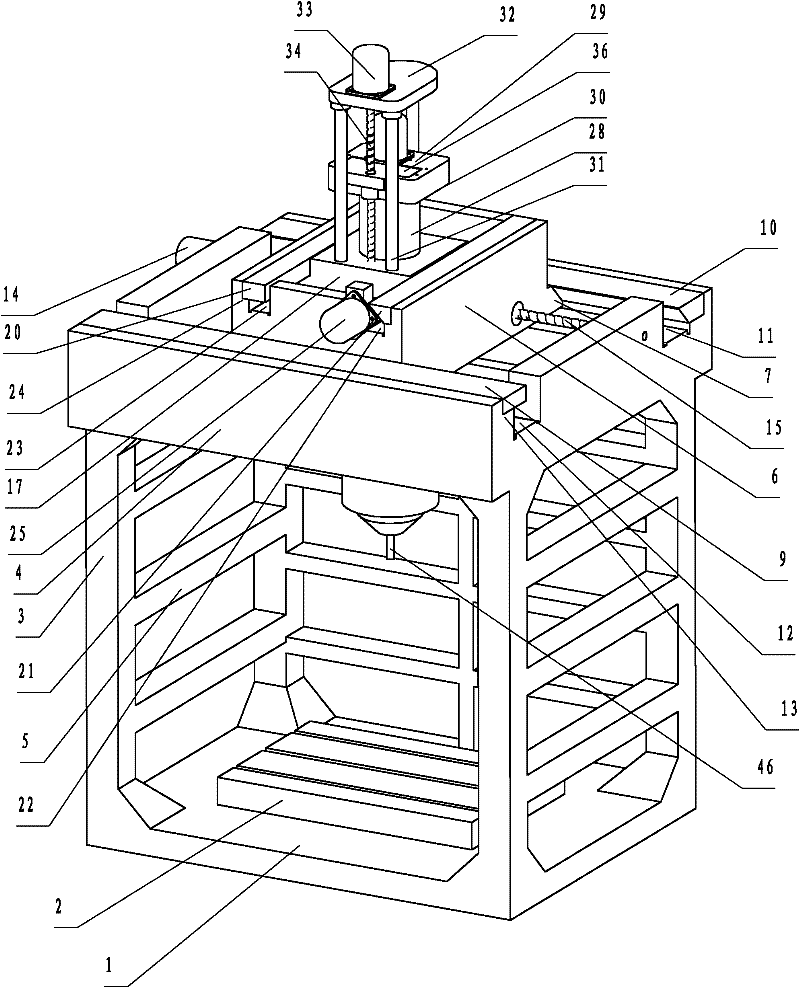

Numerical control equipment, machining process, numerical control production line and automatic article storage system

InactiveCN102528567AImprove carrying capacityImprove rigidityFeeding apparatusLarge fixed membersProduction lineNumerical control

Numerical control equipment comprises a main frame, a workpiece clamping device, an X-directional sliding seat, a first driving device, Y-directional sliding seat, a second driving device and a Z-directional guide device. The main support frame is of a closed-loop structure with a vertical opening; an X-directional front guide rail and an X-directional rear guide rail which are matched with each other are arranged between the main support frame and the X-directional sliding seat; the first driving device drives the X-directional sliding seat to move back and forth and comprises an X-directional lead screw positioned between the X-directional front guide rail and the X-directional rear guide rail; the second driving device drives the Y-directional sliding seat to move back and forth; the Z-directional guide device is mounted on the Y-directional sliding seat and comprises a Z-directional guide rod capable of vertically moving, and a third driving device for driving the Z-directional guide rod to vertically move; and a main machining head is arranged at the lower end of the Z-directional guide rod. The numerical control equipment has the advantages of fine stability, accuracy in positioning and smoothness in movement, and iron scraps falling after machining a workpiece basically cannot enter the guide rail above the machining head without special protection.

Owner:杨东佐

Controller of injection molding machine

Owner:NISSEI PLASTIC IND CO LTD

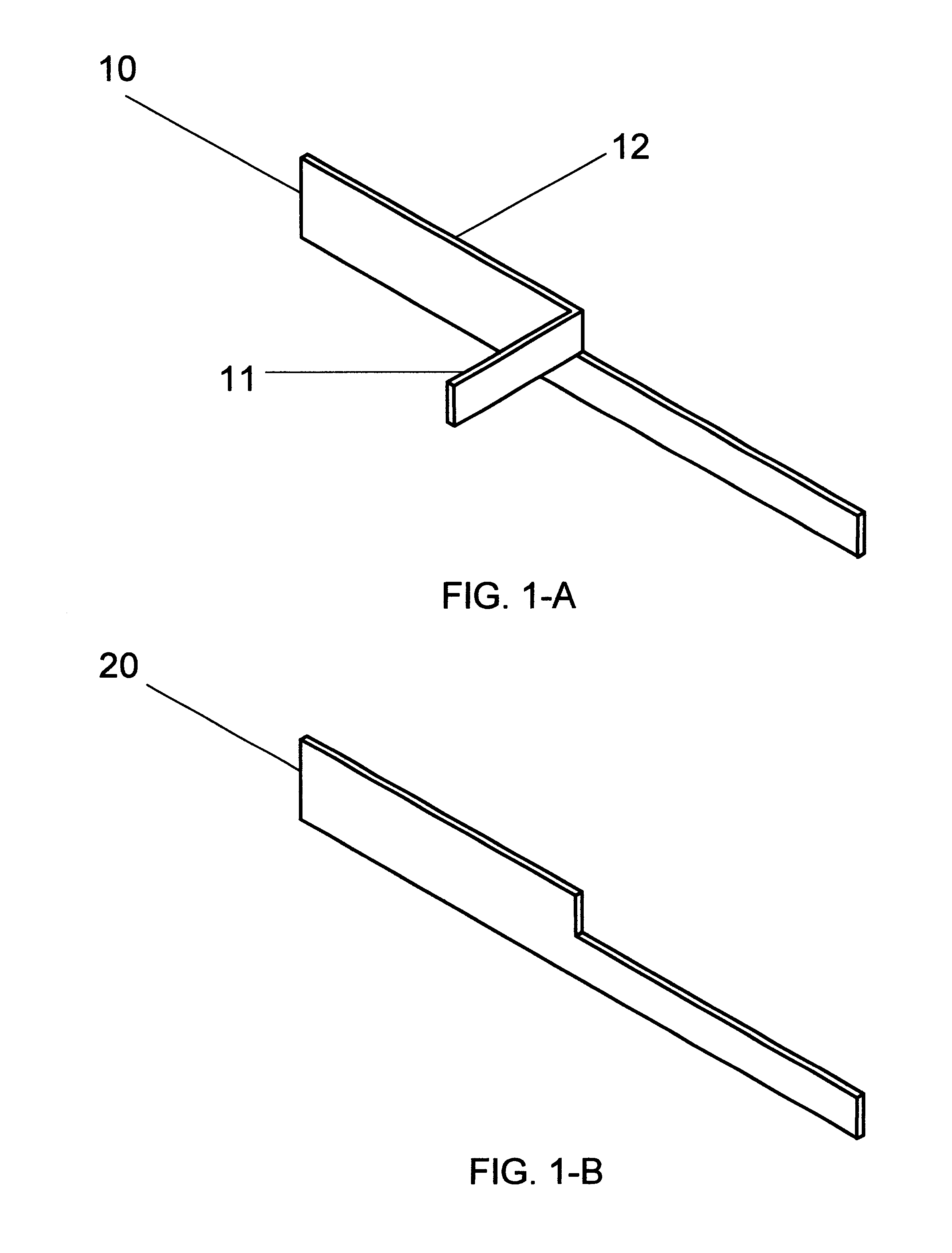

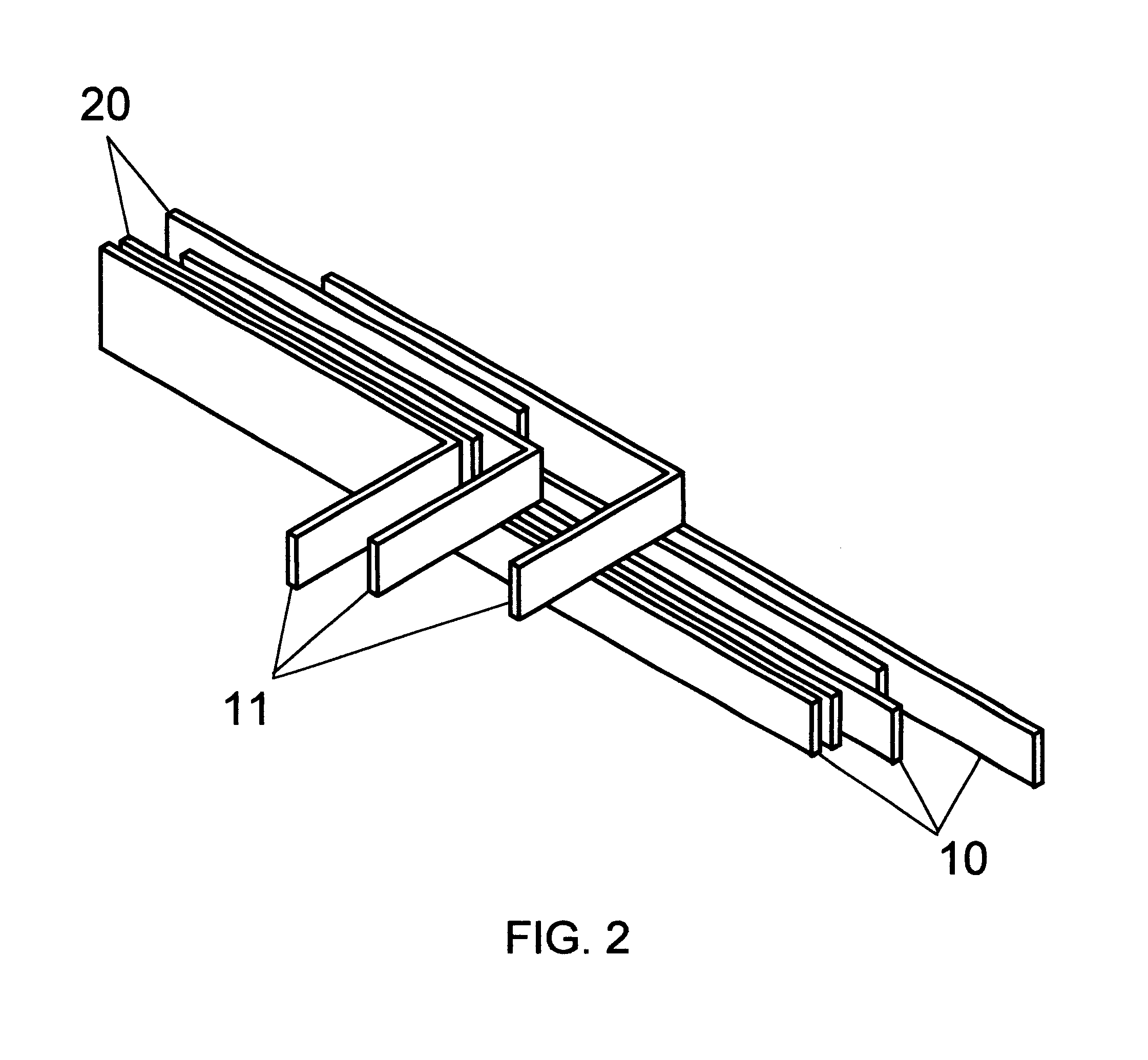

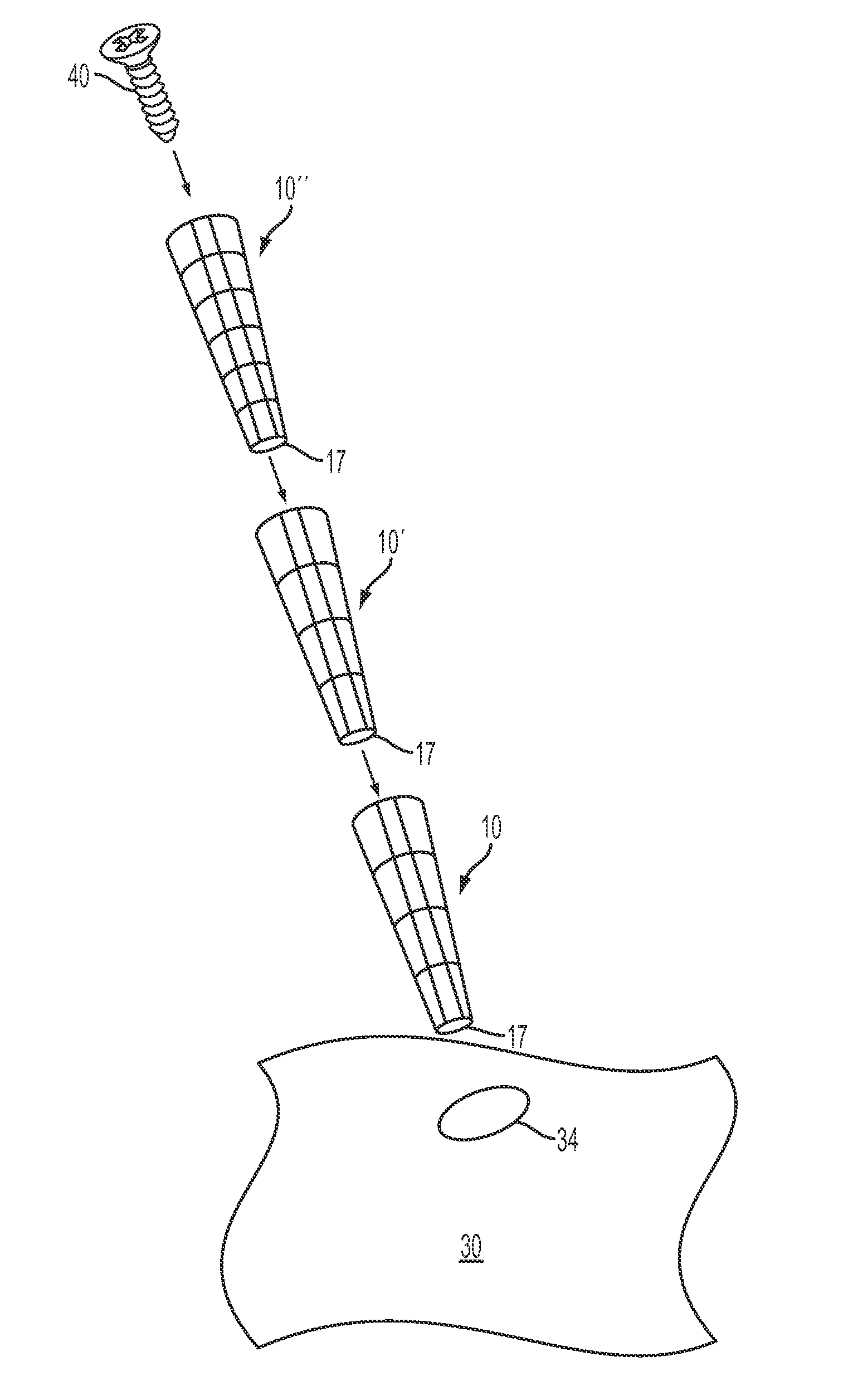

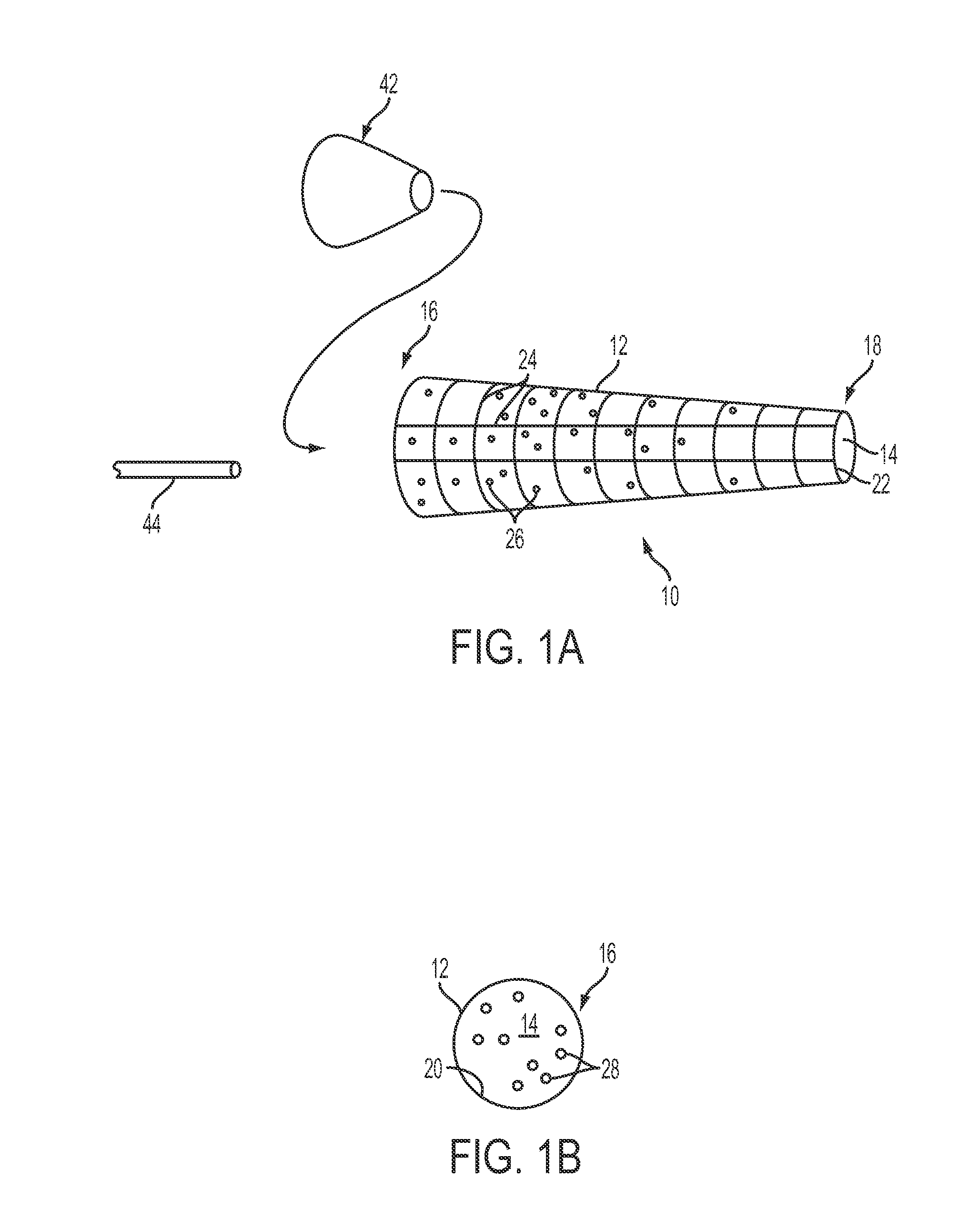

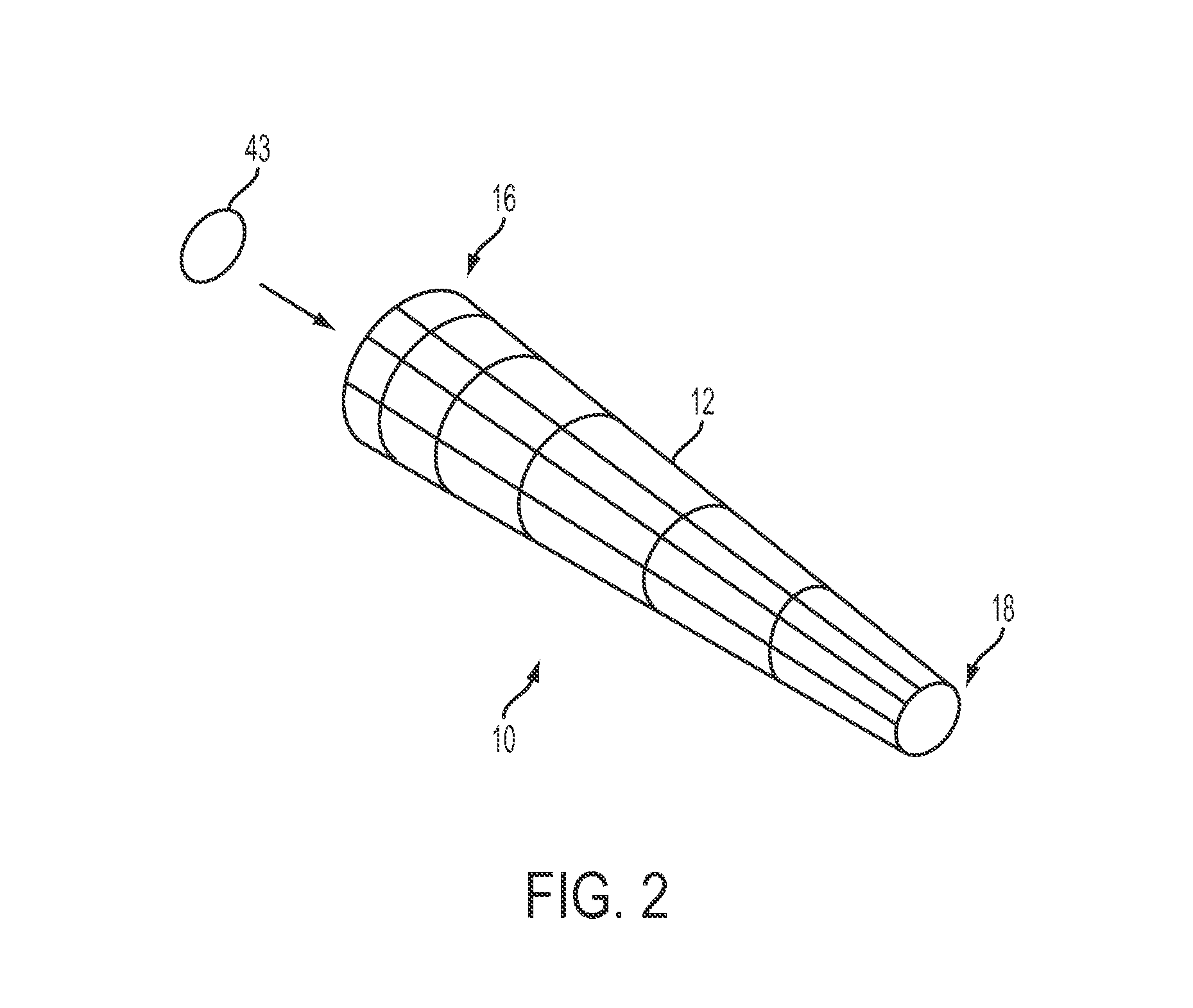

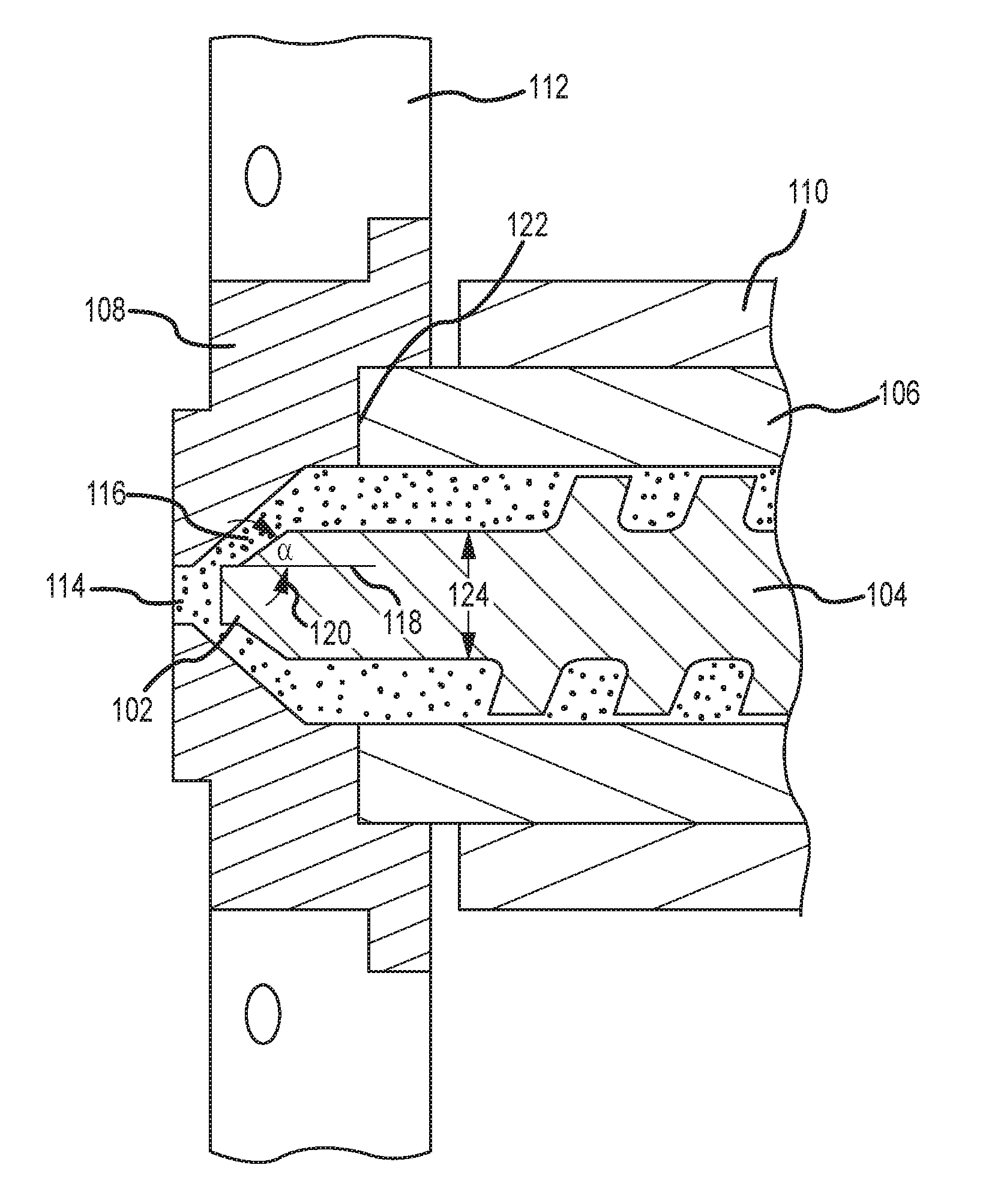

Surgical screw hole liner devices and related methods

A sleeve system for lining a hole of a surgical screw in a bone or tissue of a subject includes a woven sleeve having a first end, a second end, and an elongated body. The elongated body has an interior portion. The first end includes an aperture that accesses the interior portion. The sleeve system also includes a protective tip that may be inserted through the aperture of the first end of the sleeve. The protective tip at least partially protects tissue of the subject from a screw positioned within the sleeve.

Owner:WOVEN ORTHOPEDIC TECH

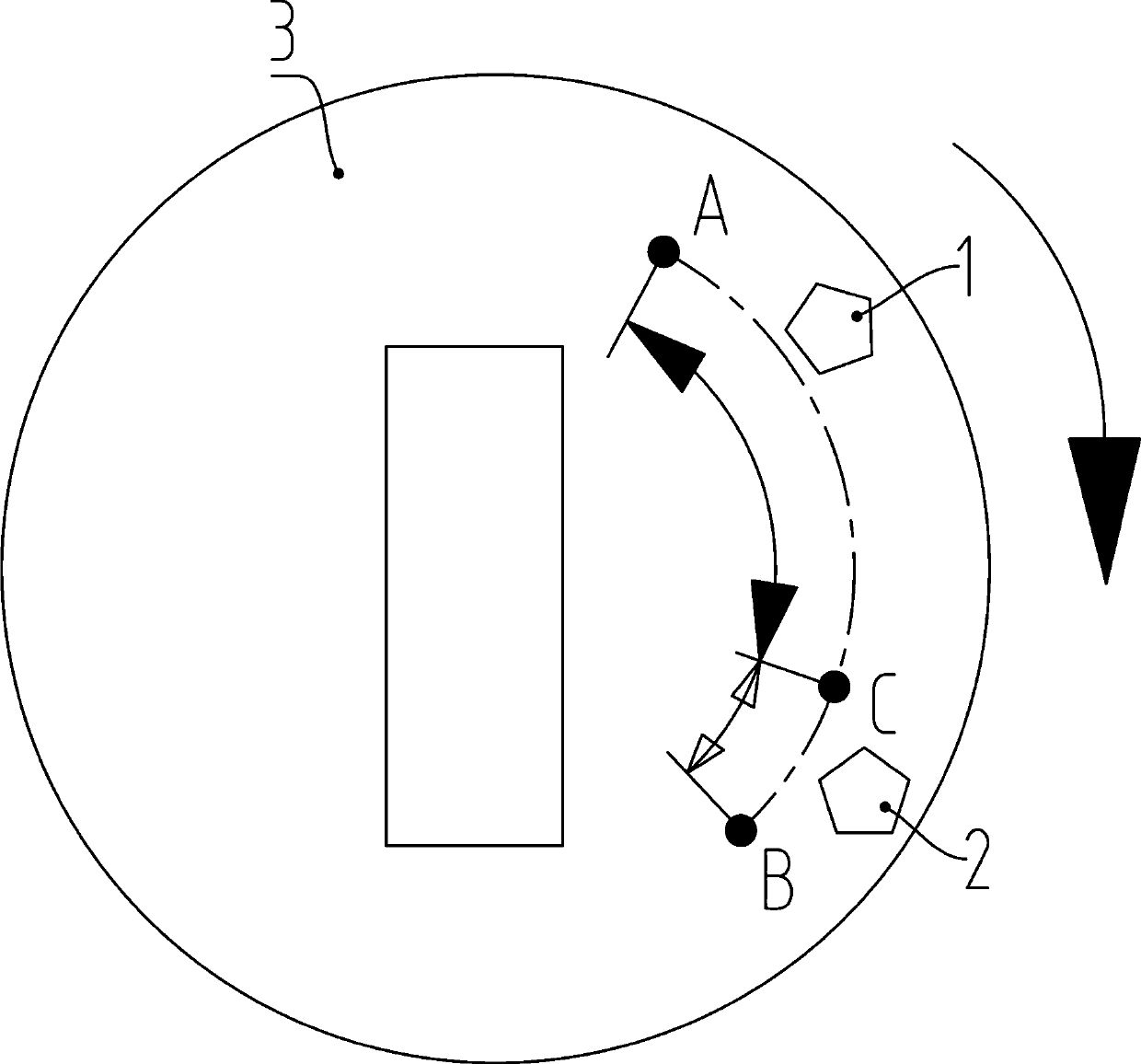

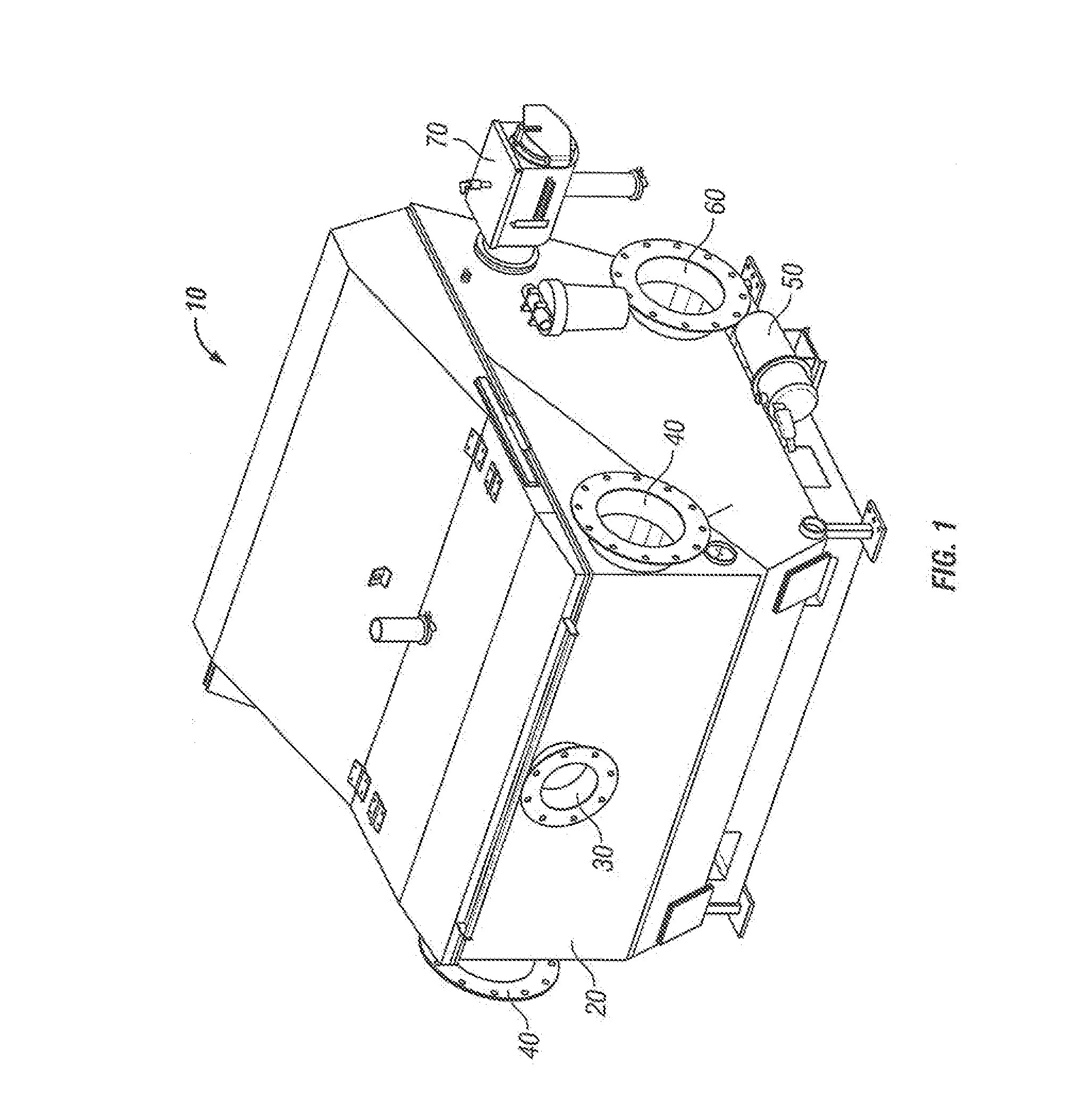

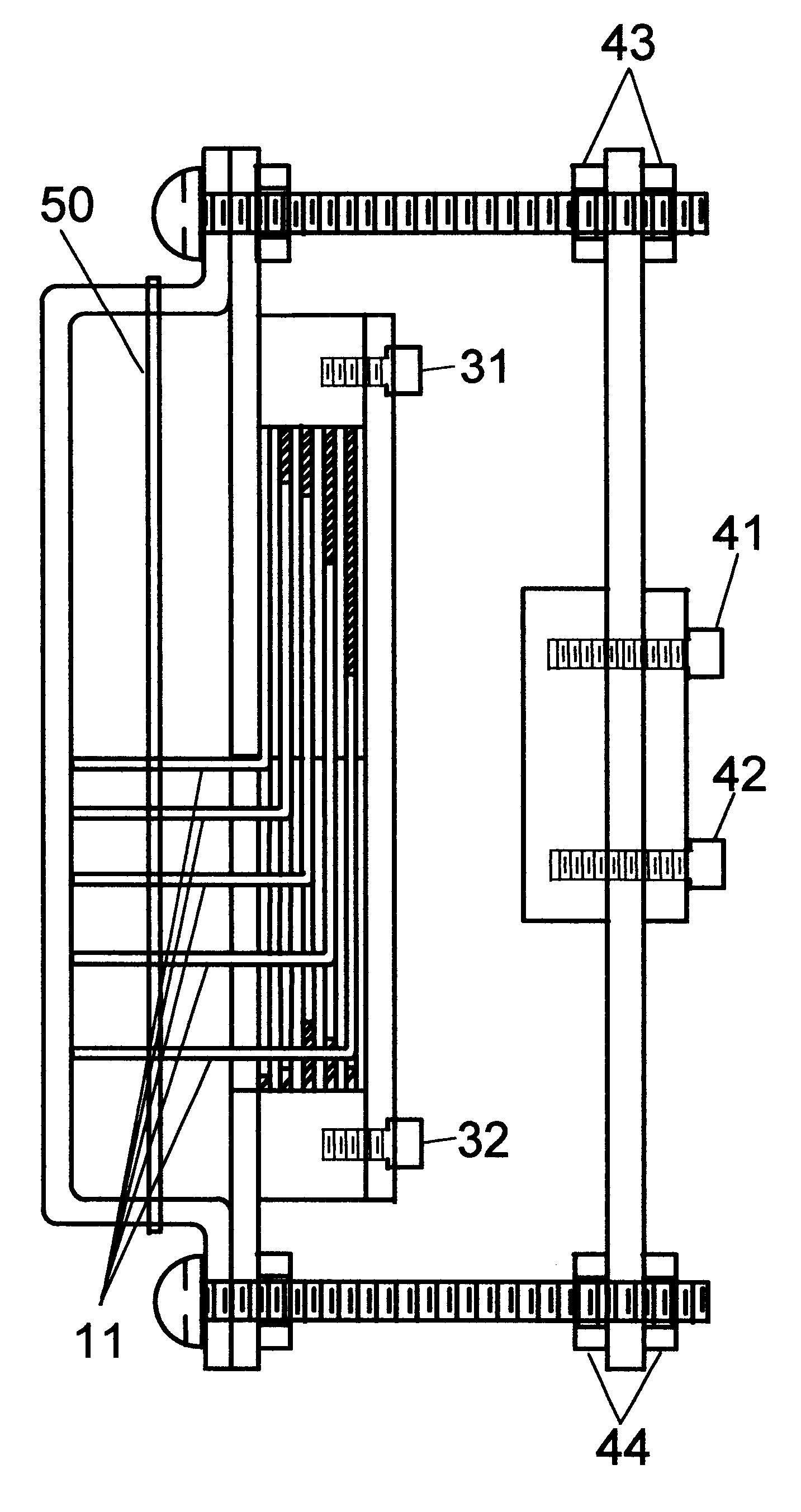

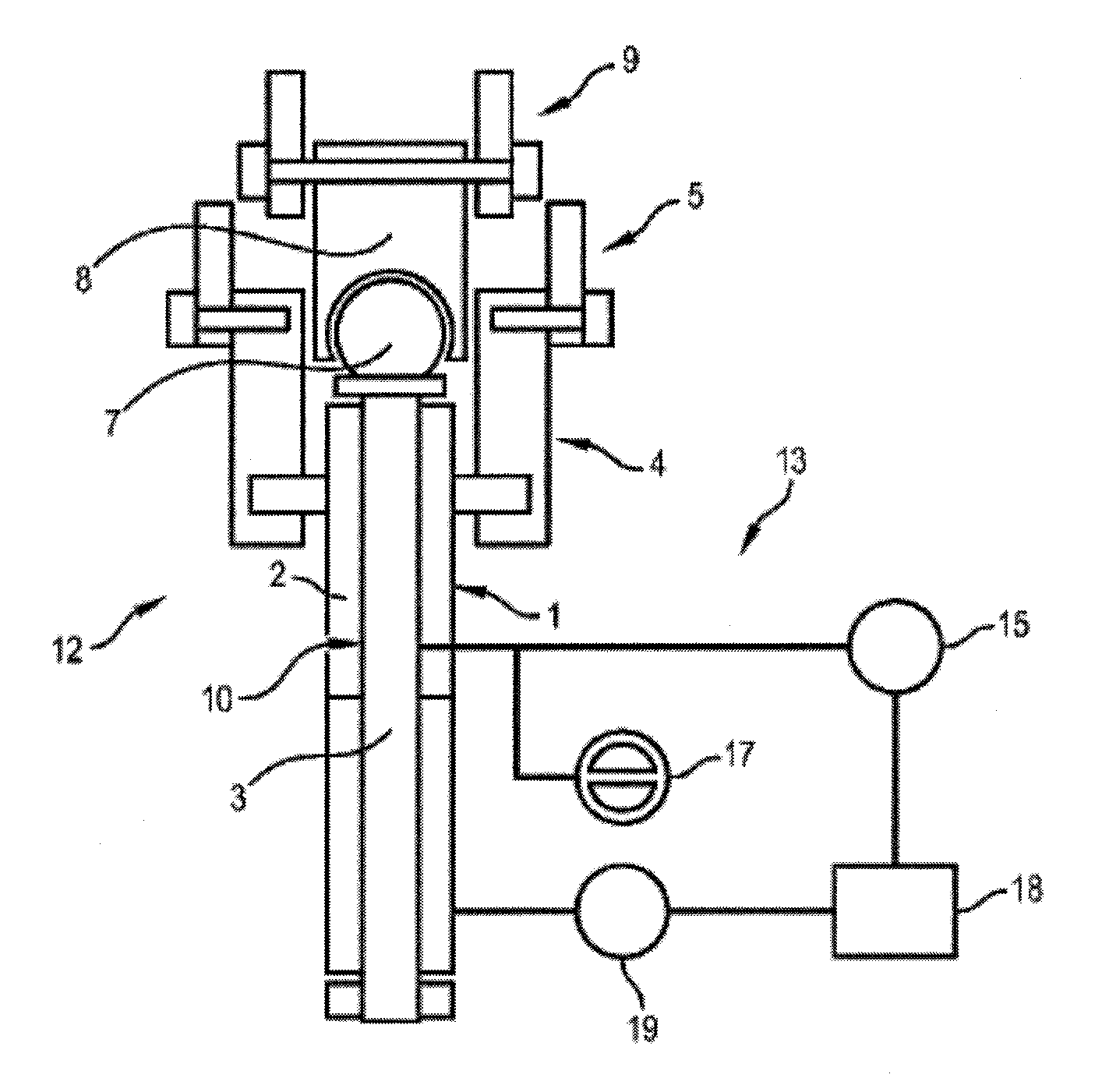

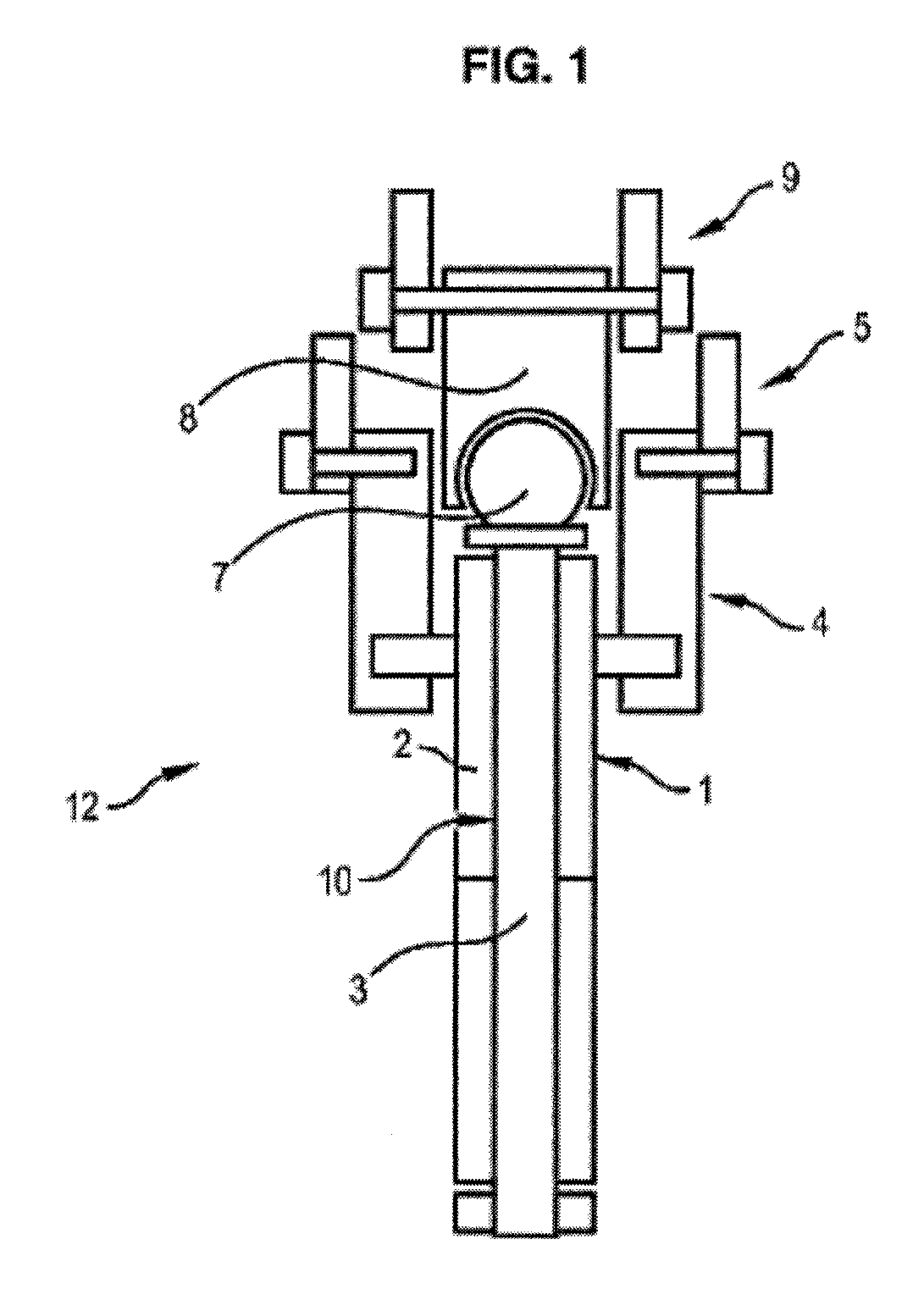

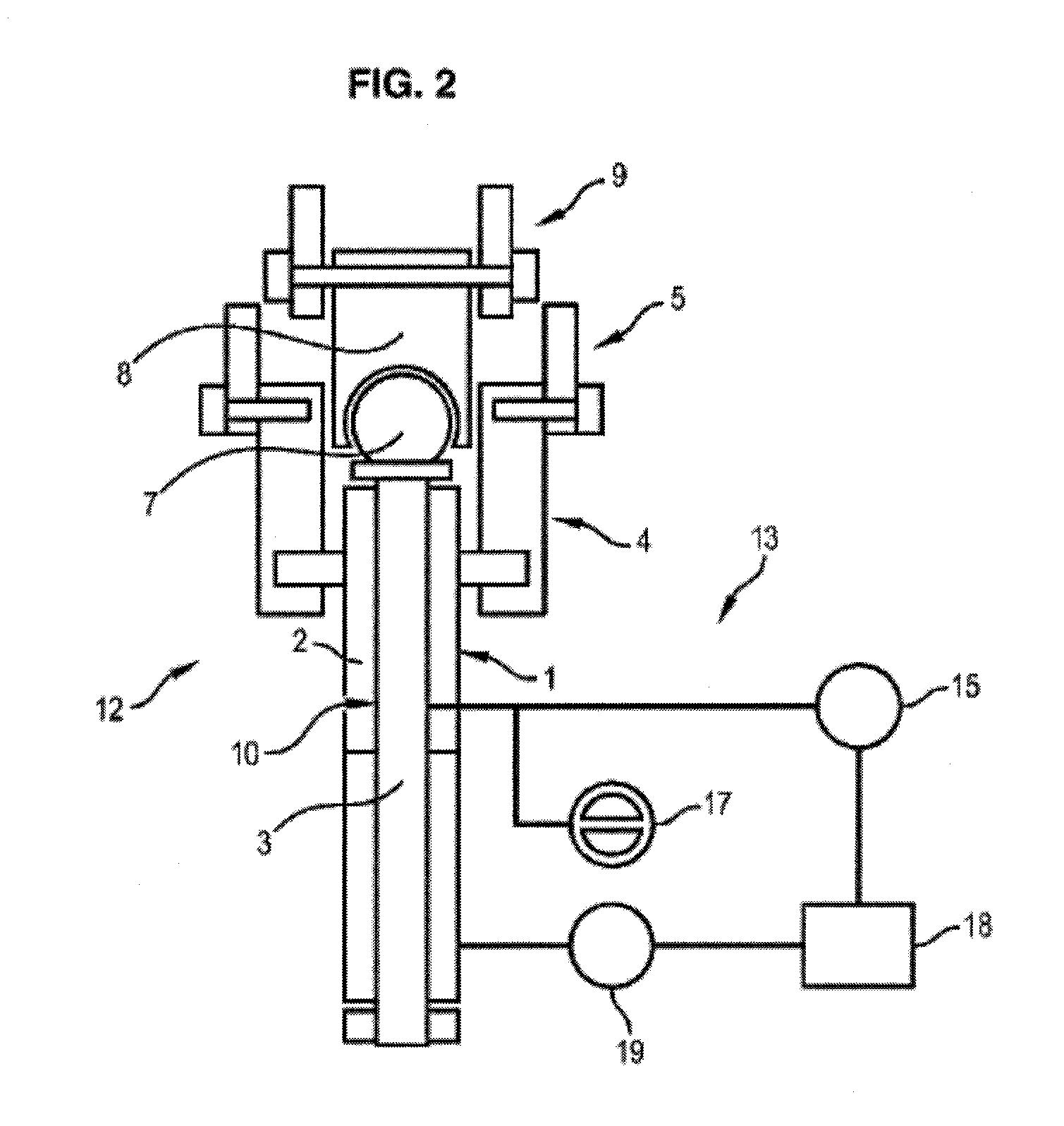

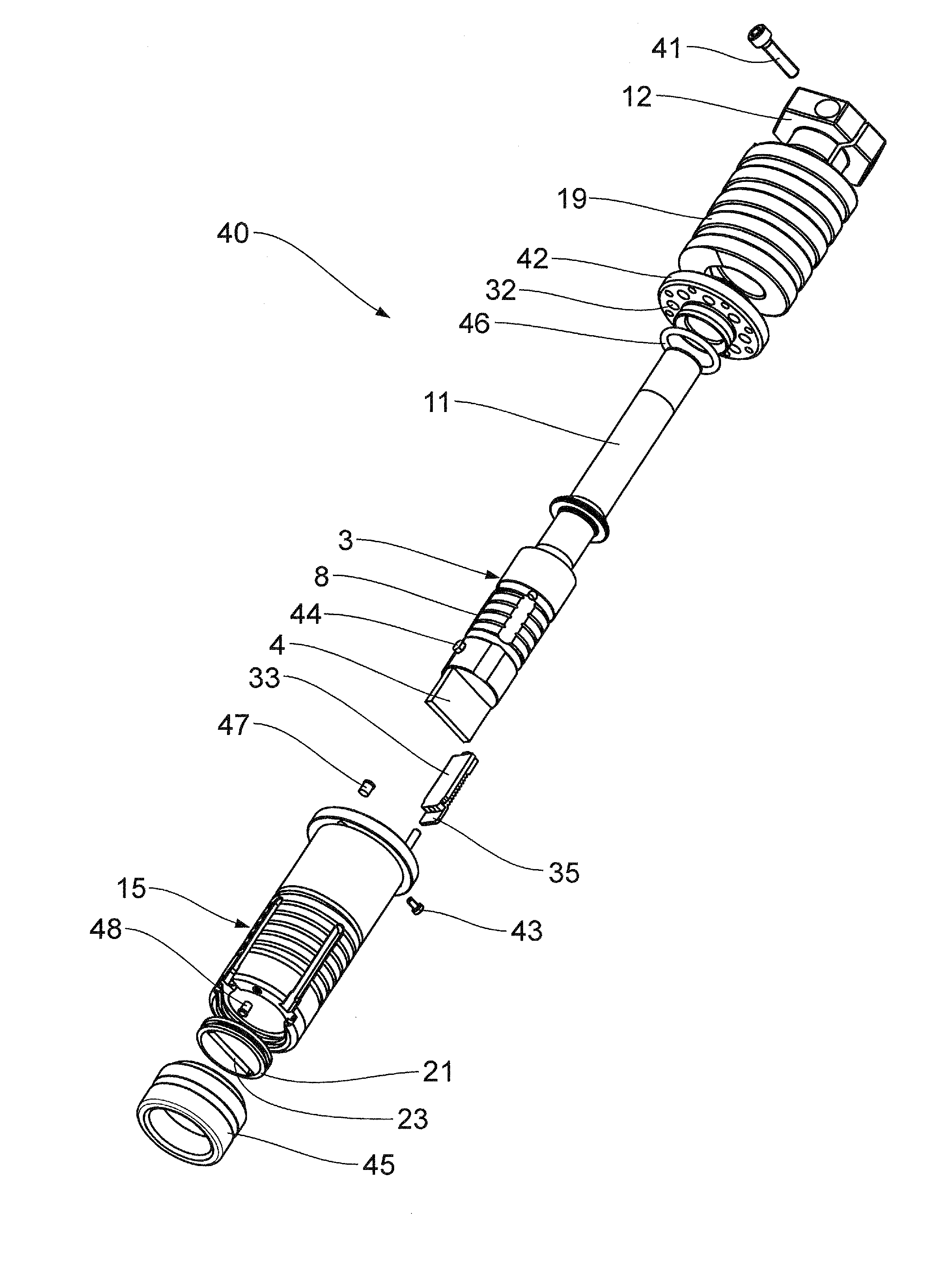

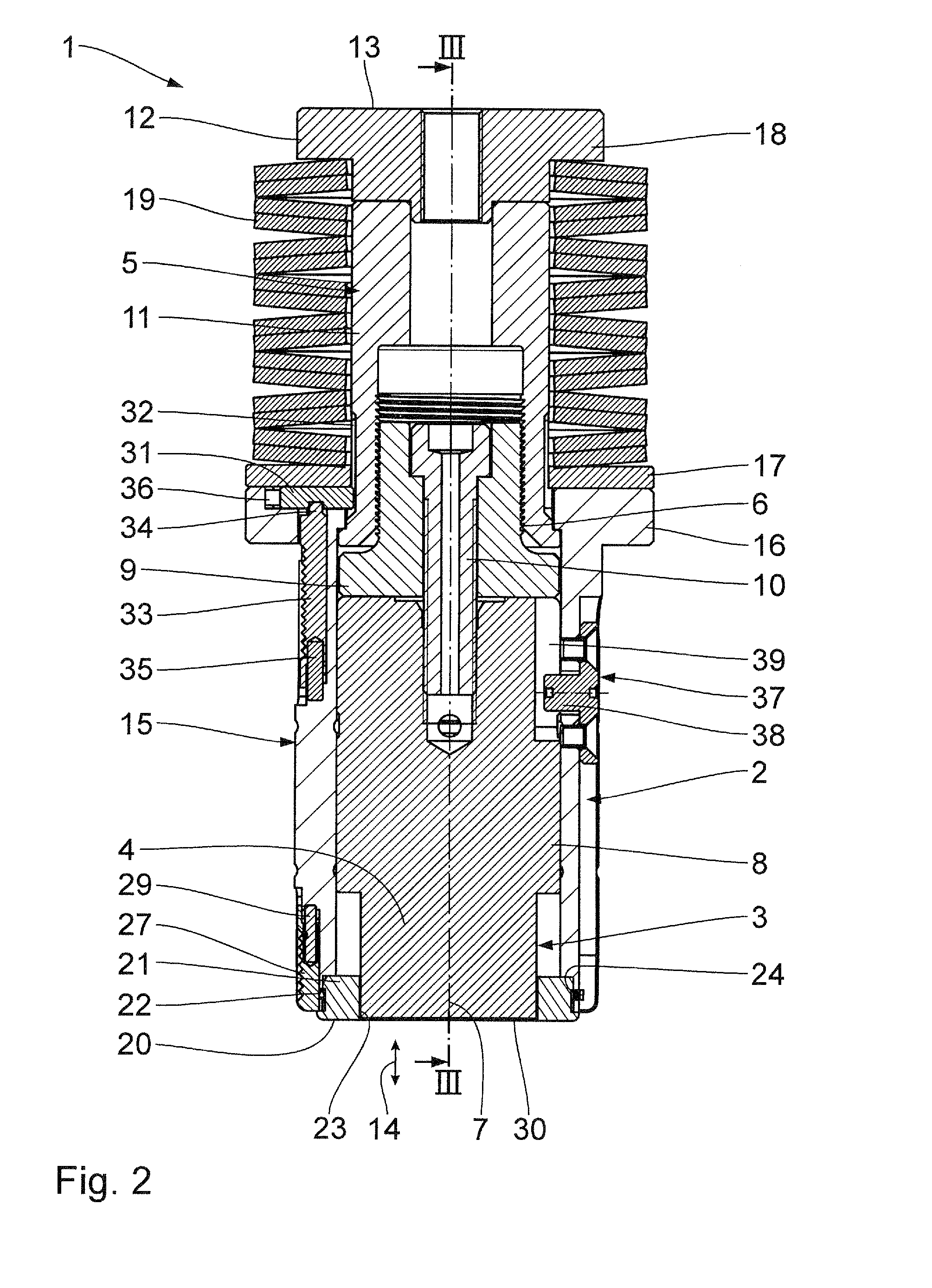

Device for detecting breakage of a primary path in a flight control actuator

ActiveUS20130105623A1Simple and low-cost solutionNegligibly increasing massAircraft stabilisationWithout power ampliicationFly controlScrew position

A device (13) for detecting the breakage of a primary path in a flight control actuator, said actuator having a primary path (1) comprising a rotary hollow screw (2), a secondary path (10) comprising a safety rod (3) that reacts the load passing through the screw (2), said device (13) being characterized in that it comprises a position sensor (15), connected to the screw (2), to measure information representative of the angular position thereof, and a disconnection system (17) able to disconnect the screw (2) position sensor (15) in the event of relative movement of the rod (3) with respect to the screw (2) if there is a break in the primary path (1).

Owner:GOODRICH ACTUATION SYST

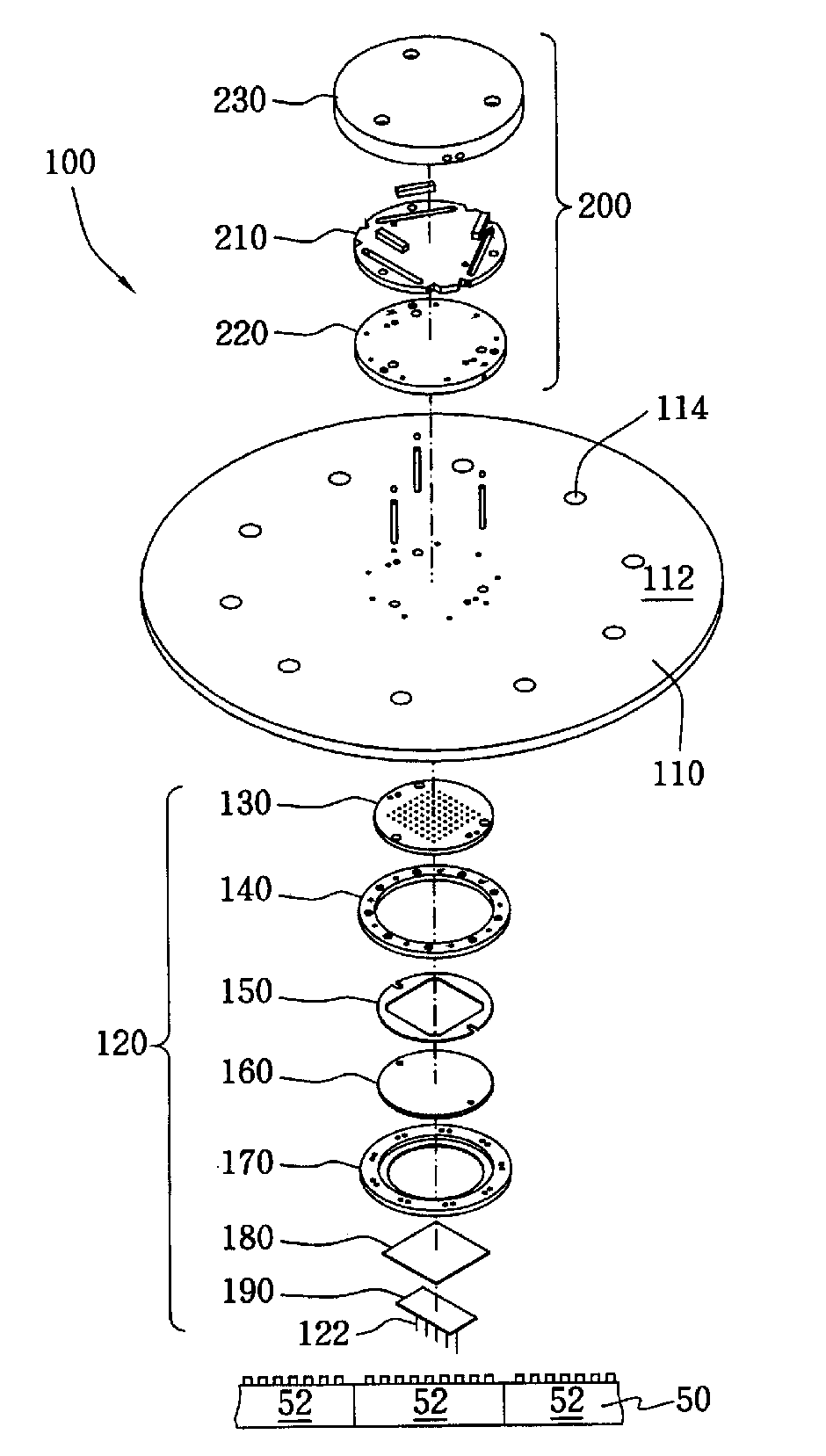

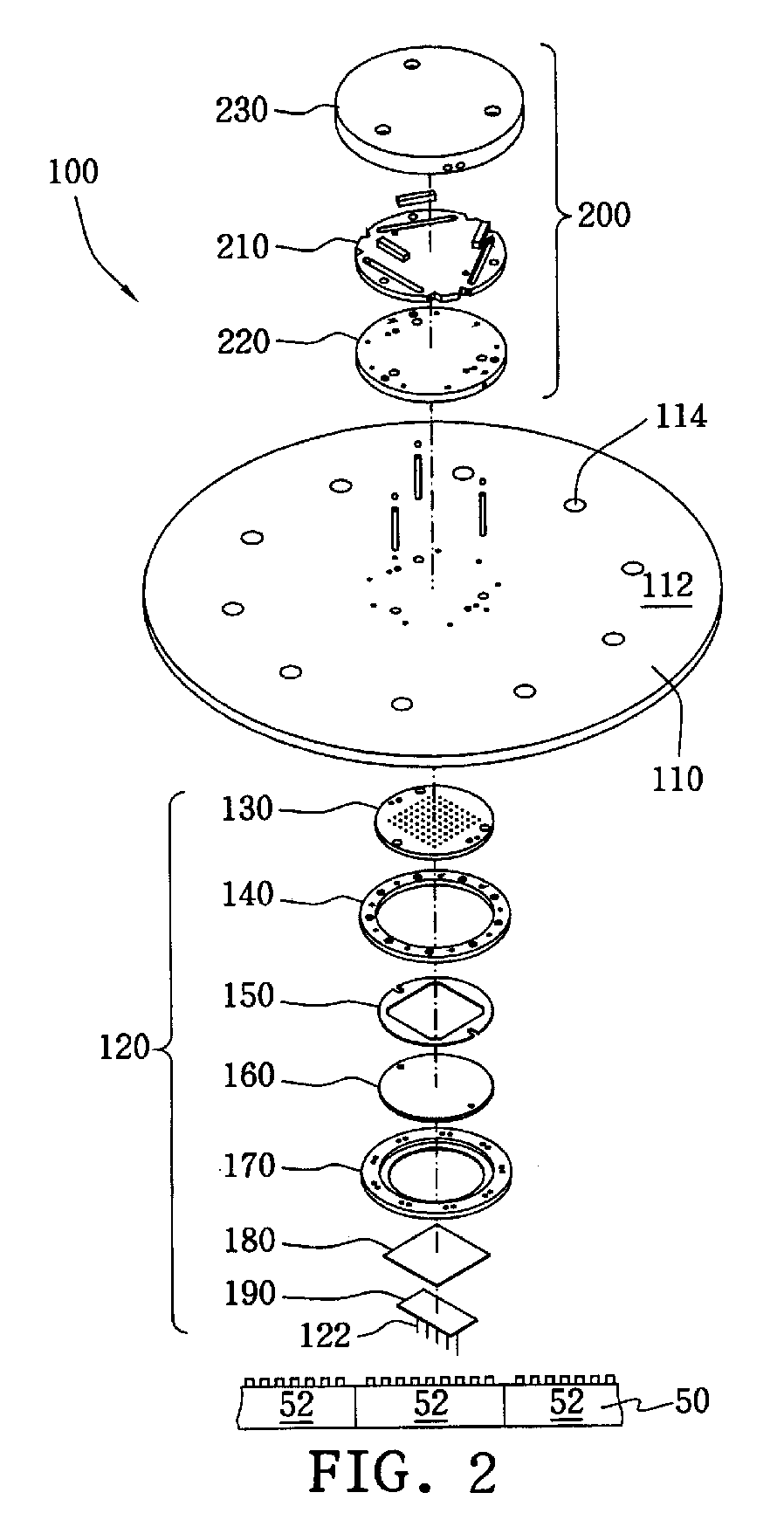

Integrated circuit probe card

InactiveUS20060022686A1Coplanarity easilyEasy to adjustElectrical measurement instrument detailsElectrical testingProbe cardScrew position

The probe card comprises a primary circuit board with a plurality of signal contacts, a probe assembly including a plurality of probes electrically connected to the signal contact and an adjusting assembly for adjusting the coplanarity between the probe assembly and a device under test. The adjusting assembly comprises a groove plate with a plurality of grooves, a wedge positioned in the groove, at least one adjusting pin connecting the wedge and the probe assembly and at least one screw positioned at one side of the wedge. The wedge comprises an inclined surface, and one end of the adjusting pin contacts the inclined surface of the wedge and the other end contacts the probe assembly. The circuit probe card moves the wedge laterally to further move the adjusting pin upwards and downwards, so that to the coplanarity between the probe assembly and the device under test can be adjusted.

Owner:MICROELECTRONICS TECH INC

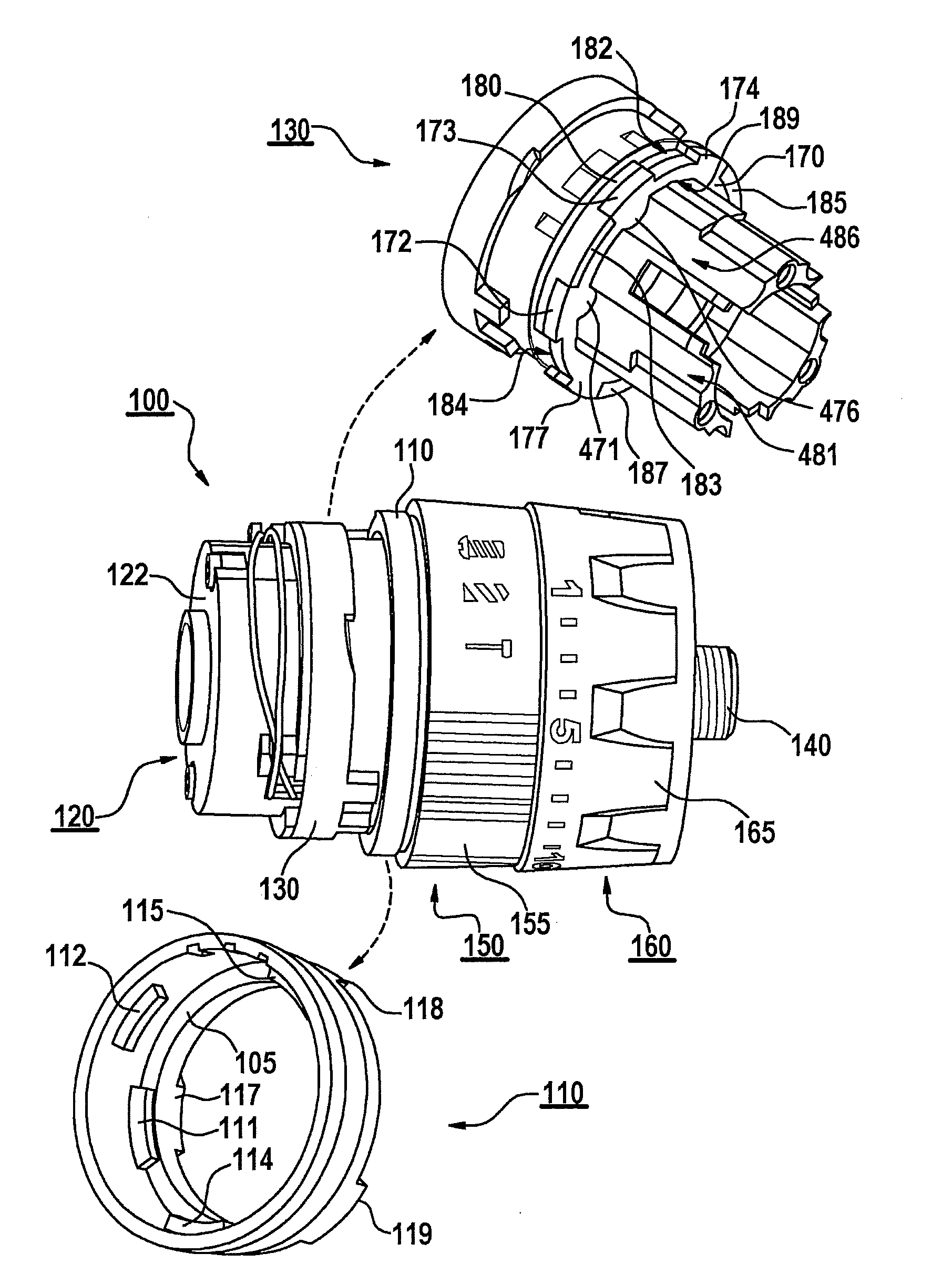

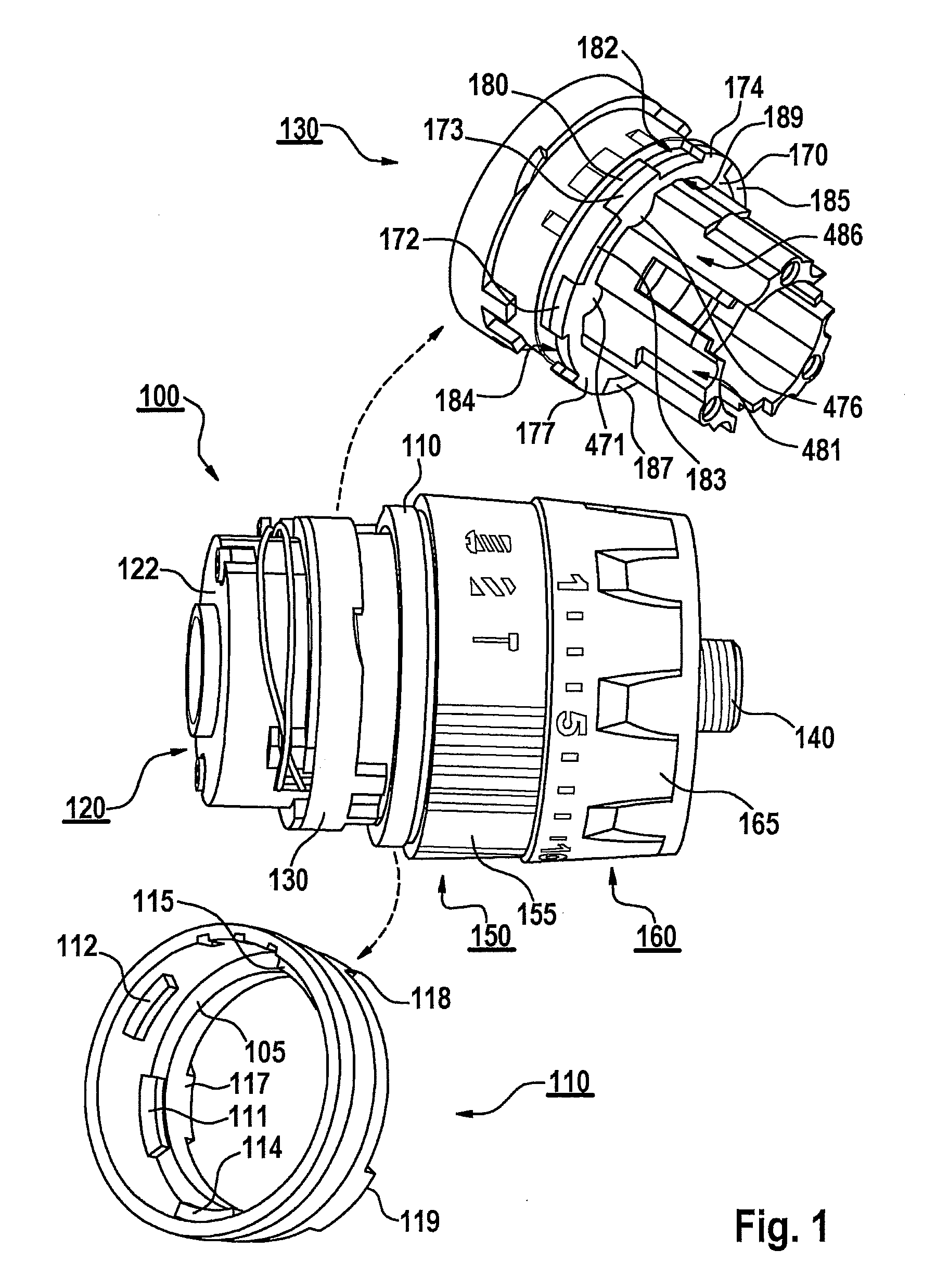

Hand-held power tool

A hand-held power tool having hammer-drilling, drilling and screwing modes, including a mode-setting device having an actuating element, a setting element, and a gear unit for driving an output shaft, in which the actuating and setting elements are interconnected in a rotatably fixed manner, and, in an operating mode(s), the setting element is coupled to a transmission element supported at a coupling housing assigned to the gear unit and axially displaceable at the coupling housing in a screwing position associated with the screwing mode and is axially fixed in position at the coupling housing in hammer-drilling and drilling positions of the corresponding modes; the transmission element is connected to the coupling housing in a rotatably fixed manner, a predefined operating mode being settable by rotating the setting element; the setting and transmission elements being rotatable relative to one another, the setting element embracing at least sections of the transmission element.

Owner:ROBERT BOSCH GMBH

Adjustable trailer hitch mount for an umbrella

InactiveUS20100059093A1Increase distanceDesired lengthWalking sticksUmbrellasSquare cross sectionScrew position

The trailer hitch mount for an umbrella includes a square cross-section shaft that is adapted to slide into a standard sleeve-style trailer hitch receiver that is currently available on many vehicles. The shaft includes a series of holes along the sides thereof to receive a pin in order to secure the shaft to the trailer hitch receiver in a telescopic relationship. The series of holes allows the shaft length to be adjusted, so that the distance between the trailer hitch receiver and the opposed end of the shaft may be shortened or lengthened, as desired. The shaft includes two ends, one of which slides into the trailer hitch receiver, and the other end includes a hollow pivoting cylindrical tube that is used to receive the bottom end of an umbrella pole. The pivoting tube includes adjustment means, so that the pivoting tube may be tilted to a desired angle and secured in that position. For travel or storage purposes, the pivoting tube may be folded down and secured into a compact position parallel with the shaft. At an upper end of the pivoting tube is receiving and securing means for the umbrella pole. The umbrella pole, in a preferred embodiment, slides into the hollow pivoting tube and a hand screw positioned on the side of the pivoting tube at its upper end may be tightened against the umbrella pole and secured thereby.

Owner:CLARK SCOTTY OBRIAN +1

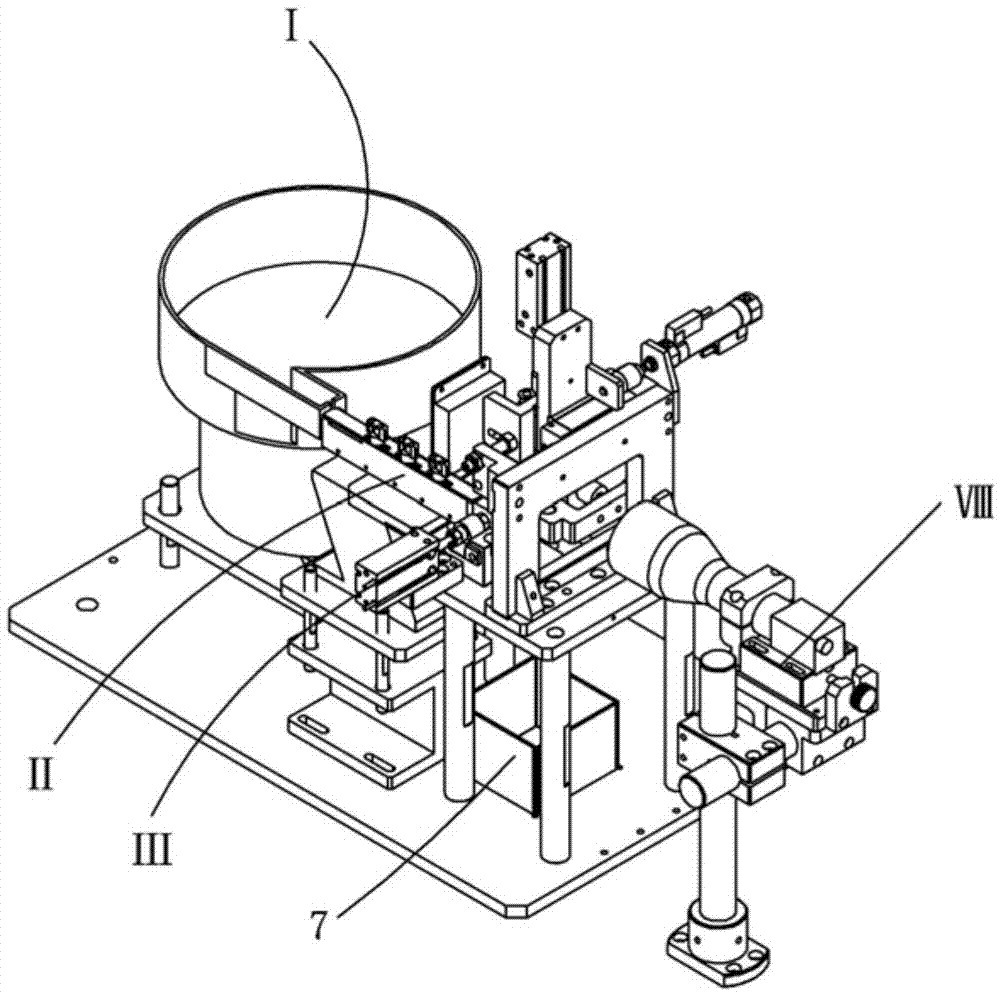

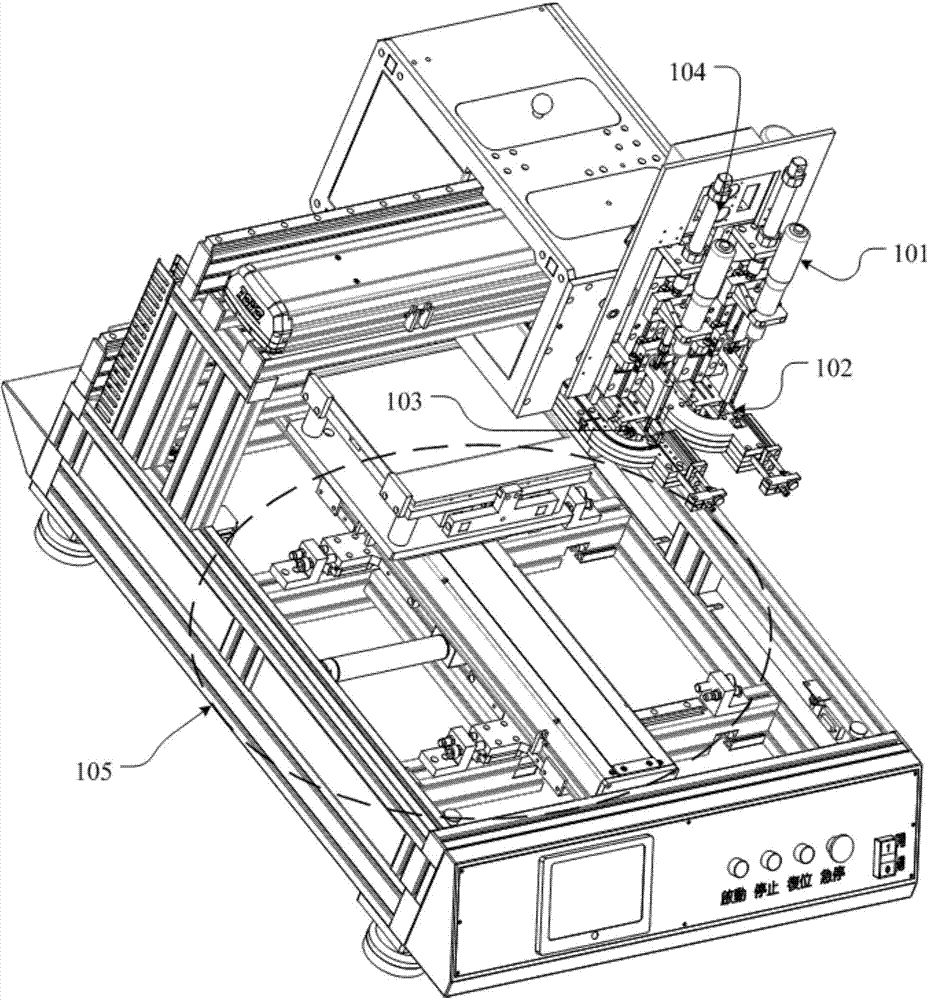

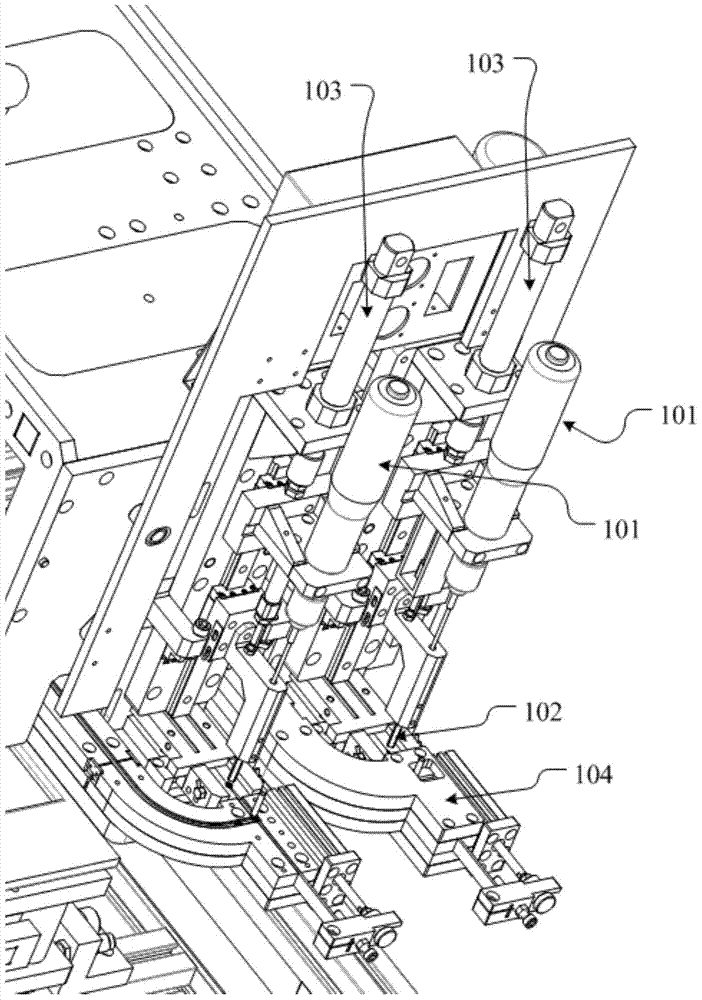

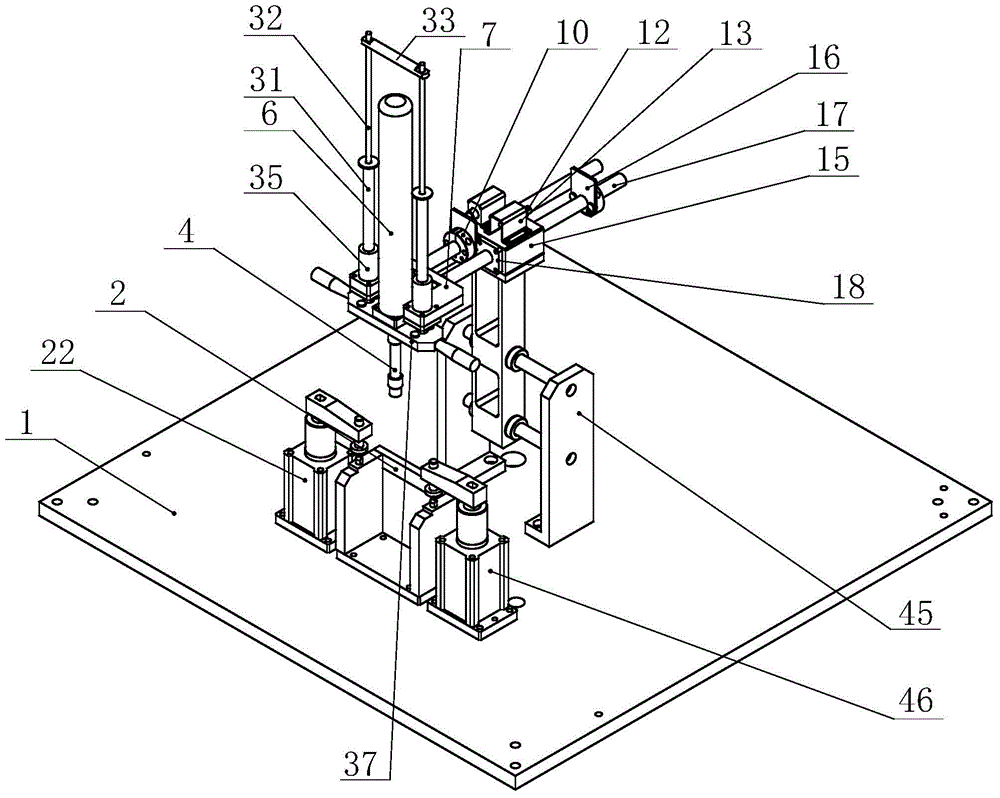

Screw feeding mechanism

ActiveCN105438768AAvoid material jamsEfficient exclusionConveyorsConveyor partsScrew positionLocking mechanism

The invention relates to a screw feeding mechanism. A feeding assembly is used for feeding. A staggering air cylinder of a staggering mechanism acts to drive a staggering sliding block to move, screws are staggered one by one in cooperation with a screw abutting block and moved to an adsorption position. A transverse movement device and a vertical movement device act respectively to move a suction nozzle to the to-be-sucked screw position to suck screws, then the screws are moved to the position above a material dropping block. The similarity, the length and the diameter of screw threads are detected through a CCD, and if the screws are flawless, the screws are directly put down through the suction nozzle, the screws penetrate a through hole in a material dropping base and directly drop down in a material dropping guiding element a to be supplied to a locking mechanism along a gas pipe; and if the screws are flawed, the material separation mechanism acts to stagger the material dropping block, the suction nozzle puts the screws down, and the screws penetrate the through hole in the material dropping base and fall into a waste material box from a material dropping guide element b. By the adoption of the screw material separation mechanism, non-defective products and defective products can be separated, and the non-defective products are selected to be supplied to the locking mechanism.

Owner:BOZHON PRECISION IND TECH CO LTD

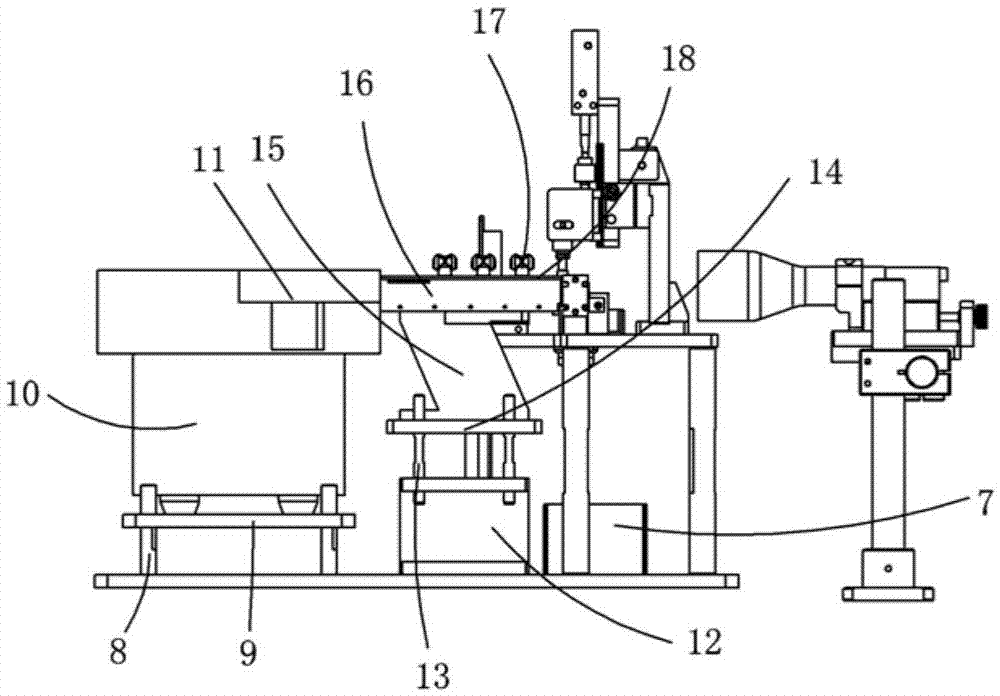

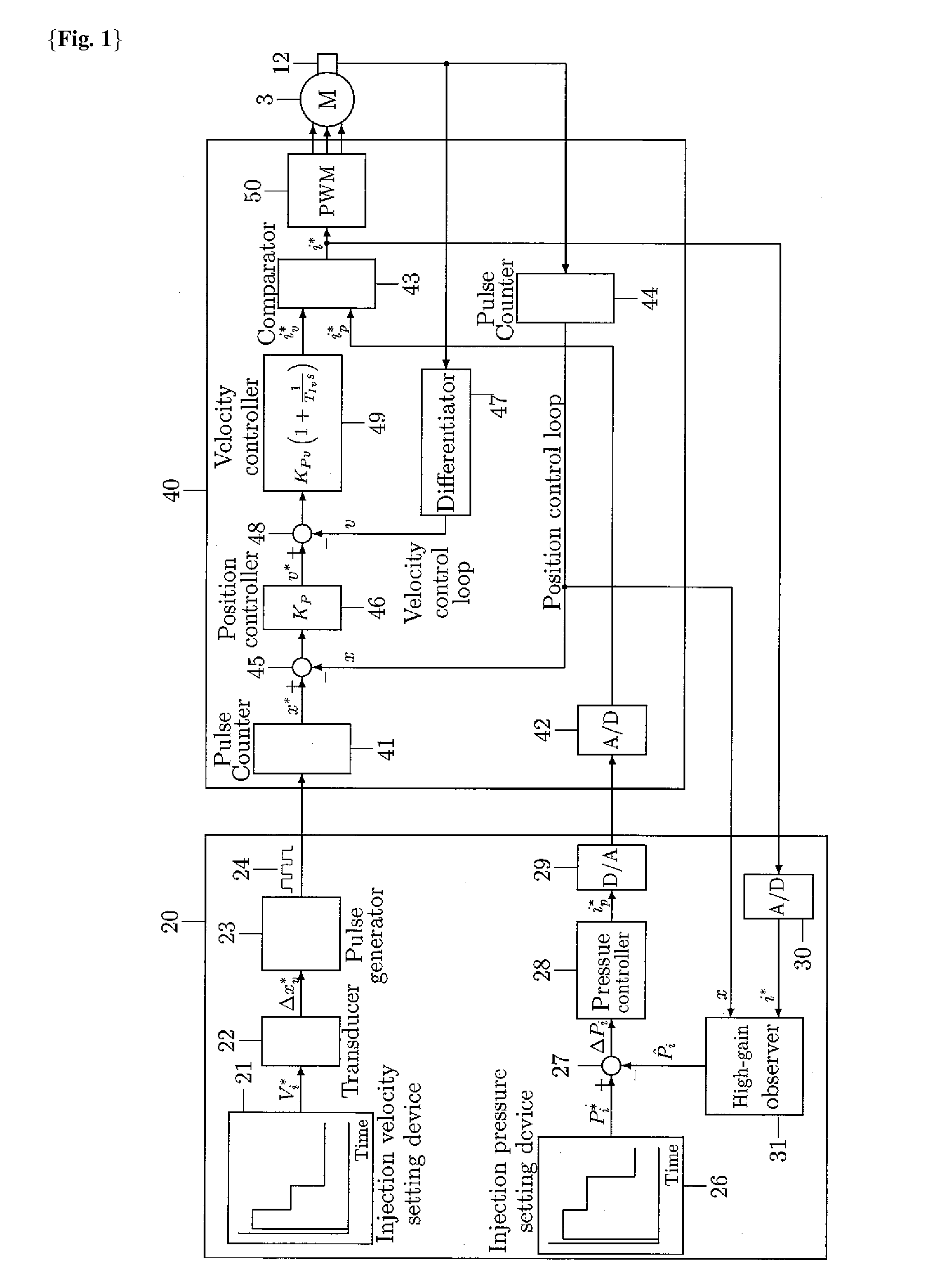

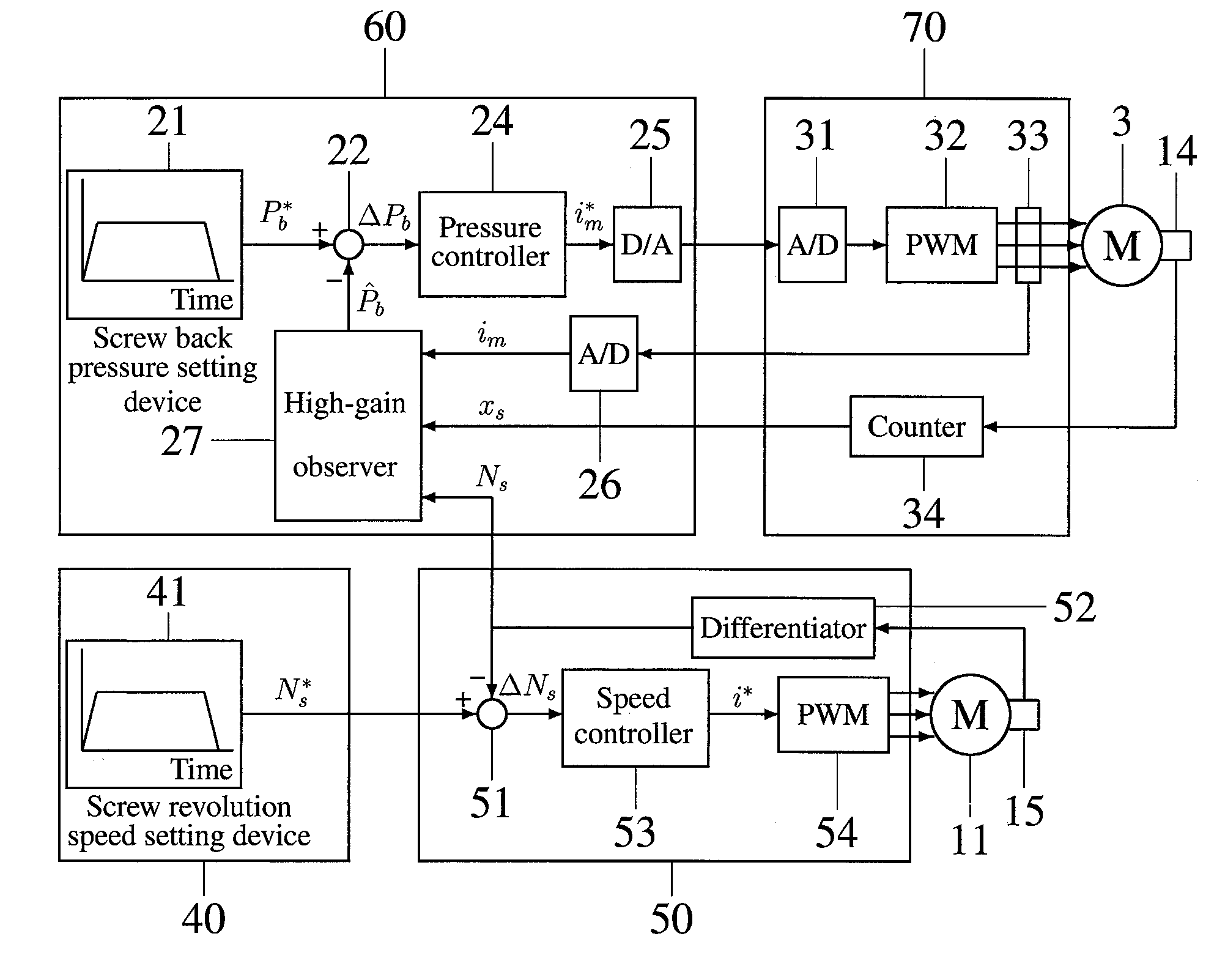

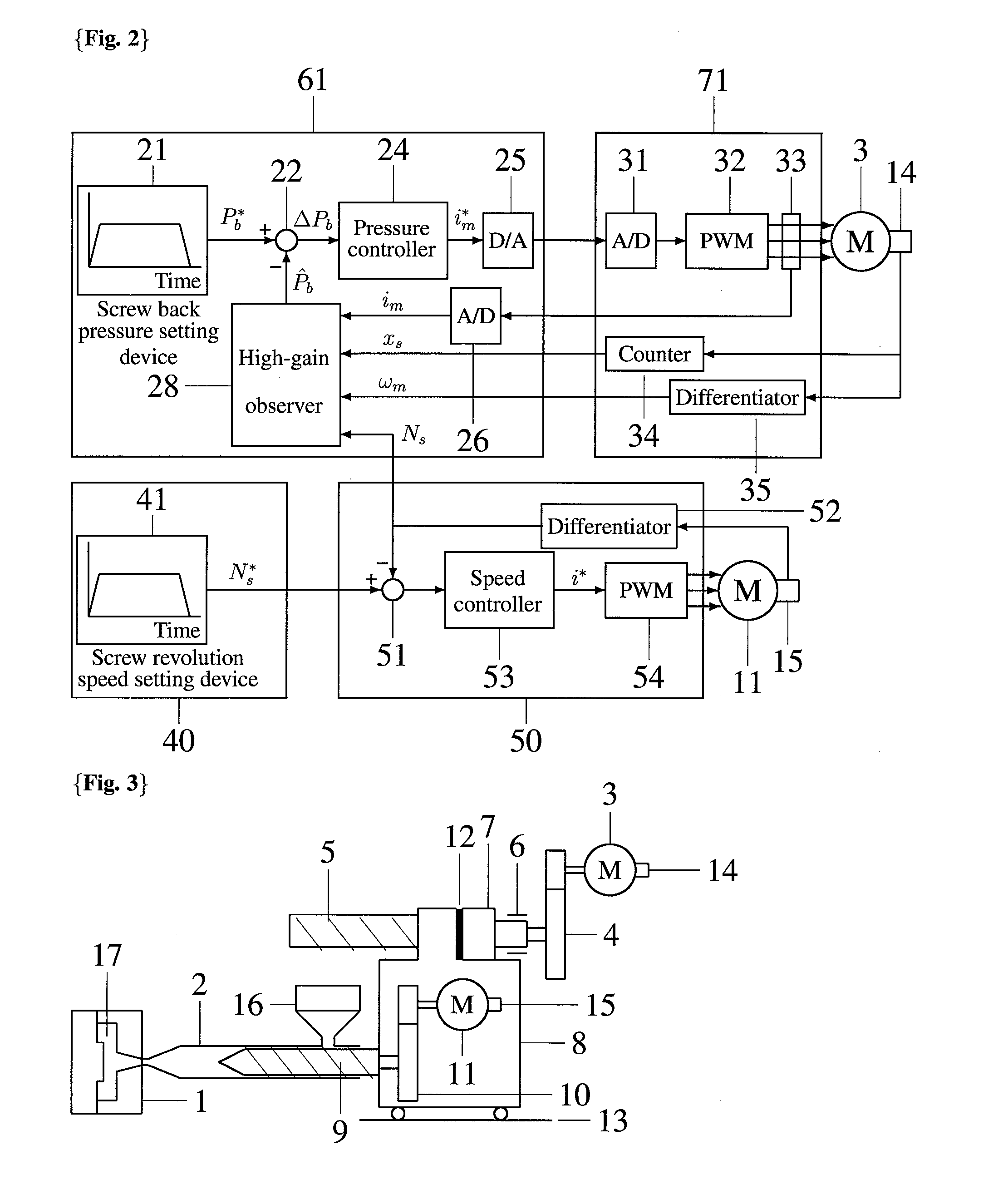

Device and method for pressure control of electric injection molding machine

ActiveUS20110175248A1Small time lagSatisfies requirementLaminationLamination apparatusTime lagMathematical model

The exact method with small time-lag of detecting injection pressure for controlling pressure in an electric-motor driven injection molding machine without using a pressure detector has been asked for because the pressure detector is very expensive, necessitates troublesome works for mounting, an electric protection against noise and the works for zero-point and span adjustings and causes a complicate mechanical structure. The present invention uses a high-gain observer which contains the discrete-time arithmetic expressions derived from a mathematical model of an injection and pressure application mechanism in an electric-motor driven injection molding machine consisting of state equations and outputs an estimate of injection pressure, which is one of the state variables of the above state equations, by using a screw position signal and a servomotor current demand signal or actual motor current signal as inputs. The high-gain observer obtains the exact injection pressure estimate with very small time-lag without using a pressure detector. Thus the estimate of injection pressure fed by the high-gain observer can be adopted as a feedback signal of actual injection pressure for controlling injection pressure.

Owner:AKASAKA NORIYUKI

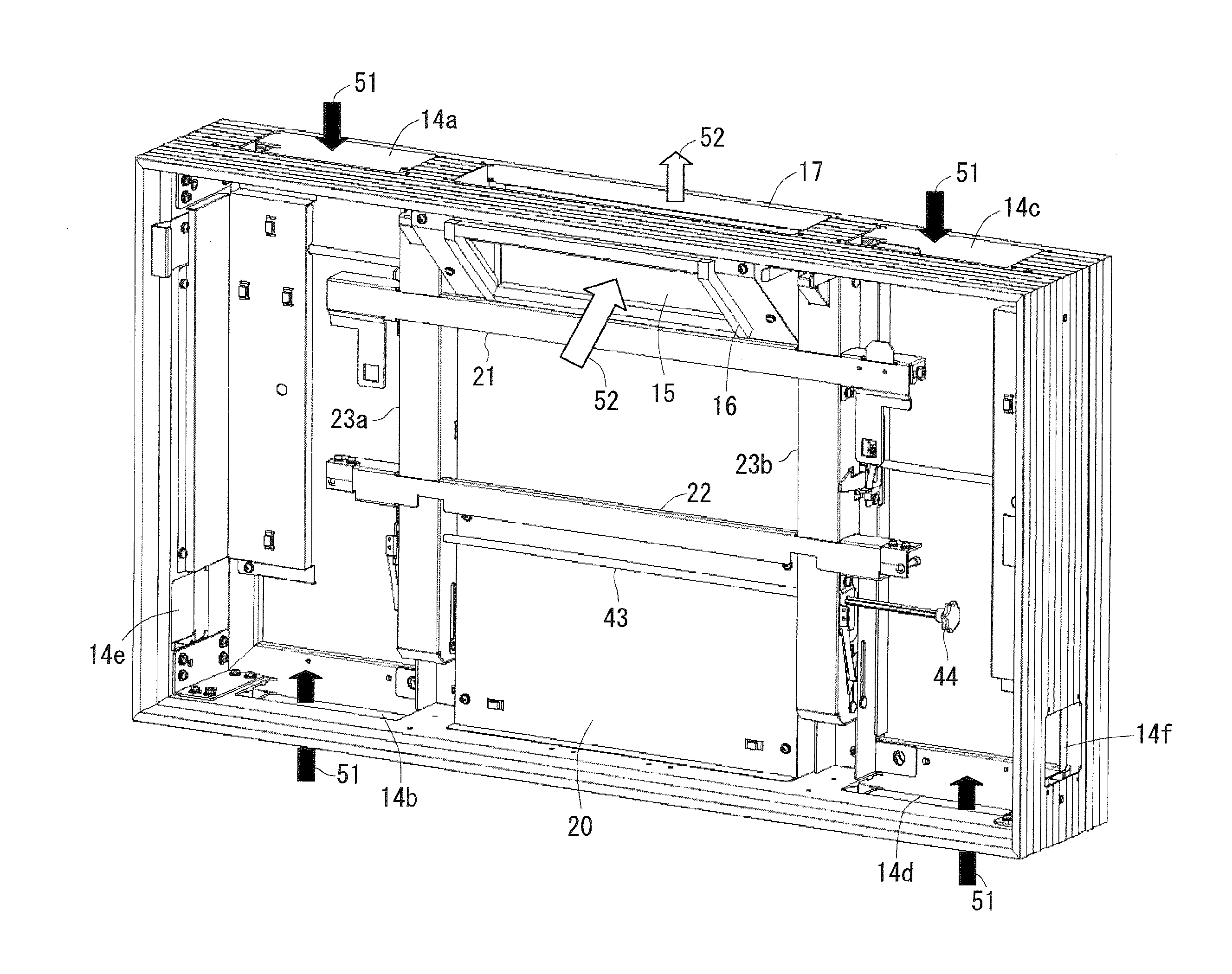

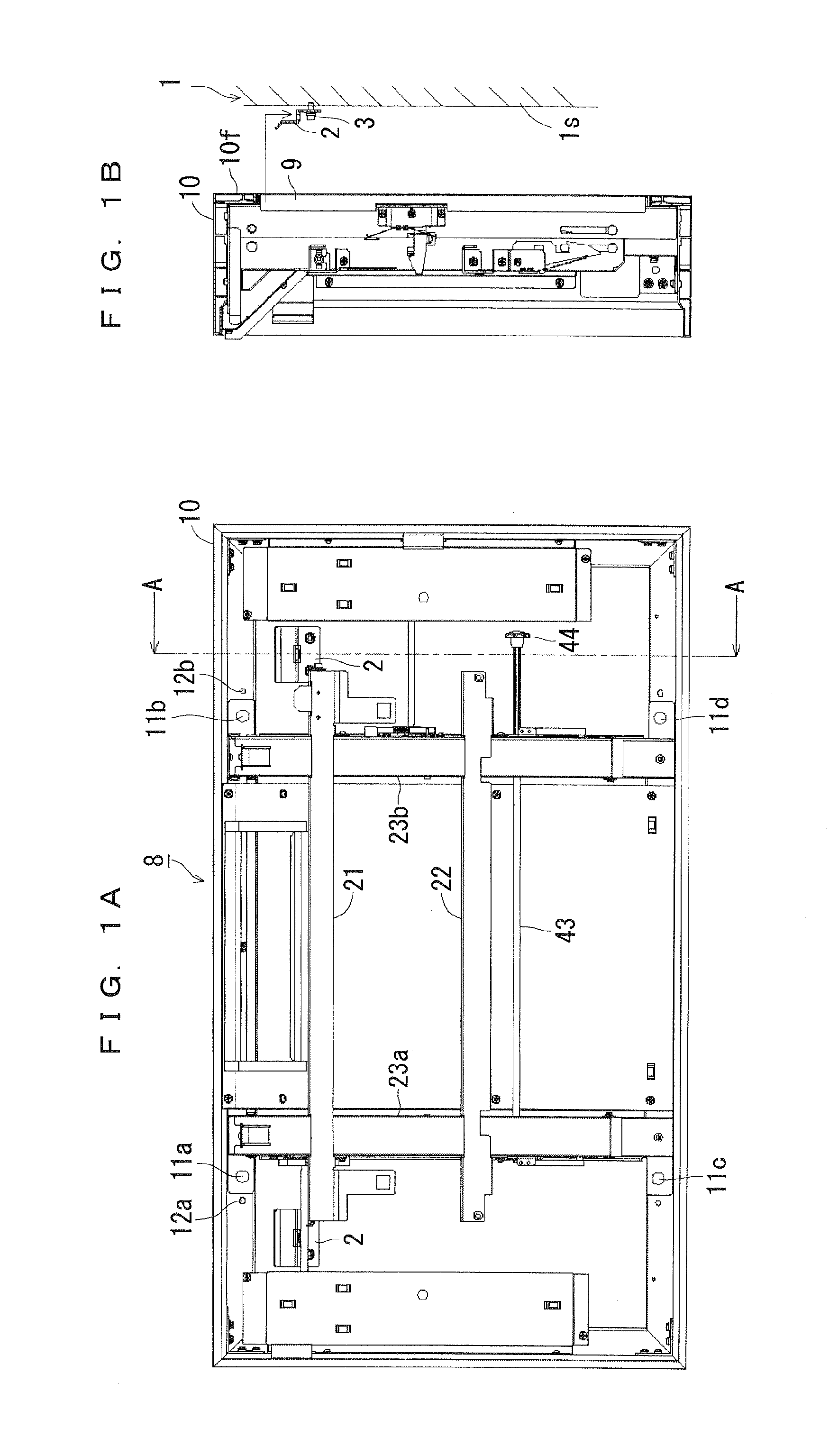

Wall-mounted attaching apparatus

InactiveUS20110101185A1Convenience to workFixed and accuratePipe supportsCandle holdersScrew positionEngineering

A mount portion has a rectangular outside shape, and has an opening in its center part that can be fitted by hanging on mounting brackets fixed on a wall surface. An installation surface has mount fixing holes in its upper part and mount fixing holes in its lower part. Default positioning holes are provided adjacent to the mount fixing holes. In screwing, the mount fixing holes have given screwing position freedom. The regions of the default positioning holes have smaller opening areas than the regions of the mount fixing holes.

Owner:MITSUBISHI ELECTRIC CORP

Automatic screw locking machine

InactiveCN104259840AAvoid locking failureMagnetic properties are not requiredMetal working apparatusScrew positionEngineering

The embodiment of the invention discloses an automatic screw locking machine which is used for avoiding the situation that the screw position is inclined, and locking is failed due to the fact that the screw hole cannot be aligned. The automatic screw locking machine has no requirement for the magnetic force feature of screws, and various types of screws can be locked on a locked object. The automatic screw locking machine comprises an electric screw driver, an elastic clamp head, a clamping pneumatic claw, a locking hole sliding platform, a downwards-pressing air cylinder, and a program controller, wherein the elastic clamp head is arranged on the electric screw driver, the head of the elastic clamp head is provided with a clamping position for being clamped with a screw head of a screw in a matched mode, and the clamping position is used for fixing the screw to the elastic clamp head by clamping the screw head; the clamping pneumatic claw is used for clamping a screw rod of the screw to fix the screw; the locking hole sliding platform is used for conveying a screw hole required to be locked currently in the locked object to the position below the elastic clamp head by moving the locked object; the downwards-pressing air cylinder is used for driving the electric screw driver and the elastic clamp head on the electric screw driver to move downwards; the program controller is used for controlling the electric screw driver, the clamping pneumatic claw, the downwards-pressing air cylinder and the locking hole sliding platform through a preset operation process.

Owner:KUNSHAN FUXIN LIWEI AUTOMATION TECH

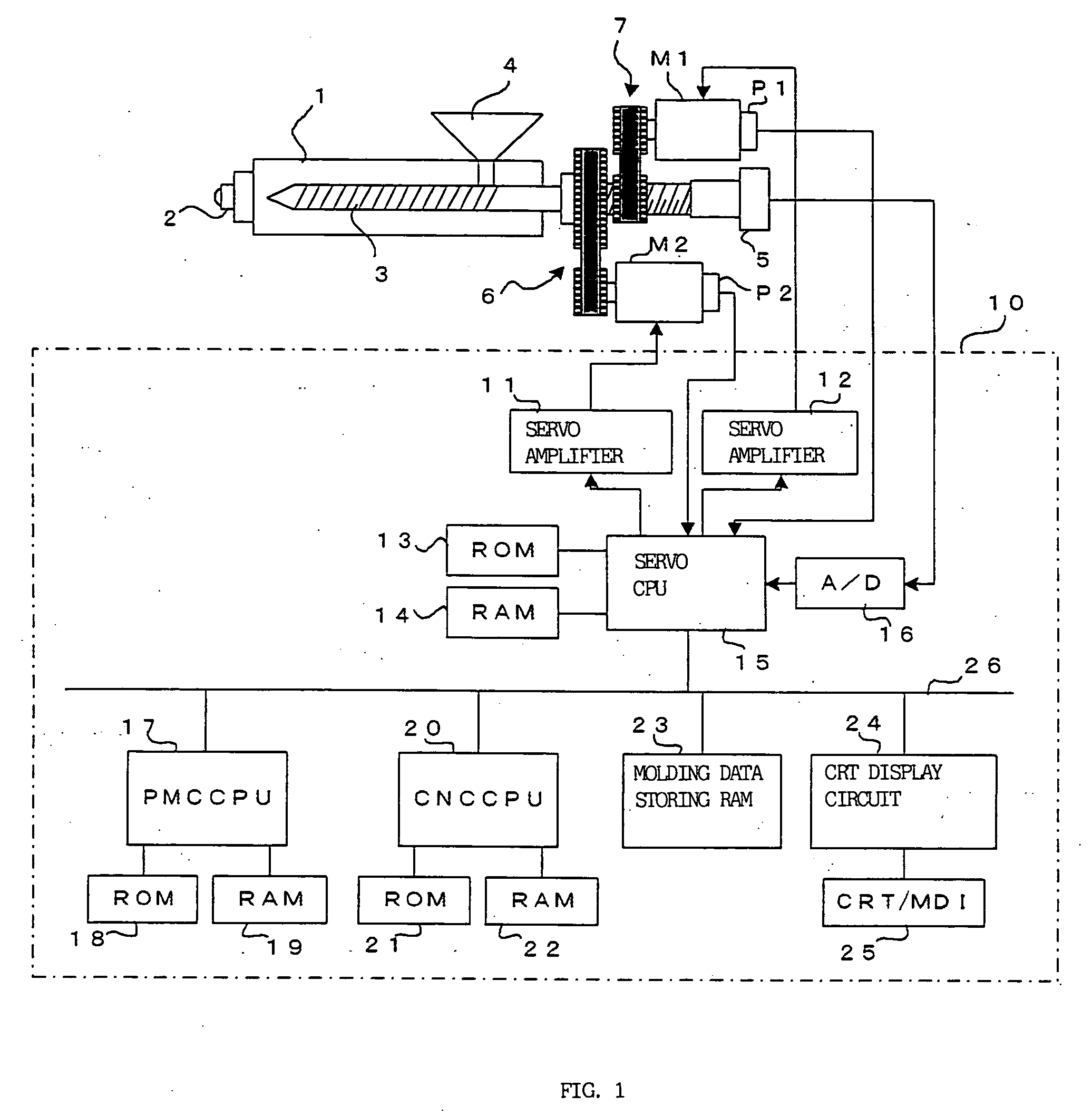

Pressure abnormality detecting device for injection molding machine

ActiveUS20060191347A1Accurate predictionAvoid failureFluid pressure measurement by mechanical elementsInjection pressureScrew position

An injection screw position Xa, injection speed Va, and injection pressure Pa are read. A deceleration distance D the injection screw moves from the point where the injection operation has been stopped at the current moment to be decelerated by maximum deceleration till the point where the injection speed is reduced to zero is determined from a corrected deceleration in which the amount of correction α is added to a predetermined deceleration A inherent in the machine and the read injection speed Va. The determined deceleration distance D is multiplied by the amount of change in injection pressure with respect to the amount of change in the injection screw position to determine a predicted increment in pressure (D·ΔP / ΔX). The predicted increment in pressure is added to the current injection pressure Pa to determine an injection pressure Pa* predicted when the screw is suddenly decelerated at the current moment. If the predicted injection pressure Pa* exceeds the predetermined limit pressure Pmax, the injection operation is stopped to decelerate the screw.

Owner:FANUC LTD

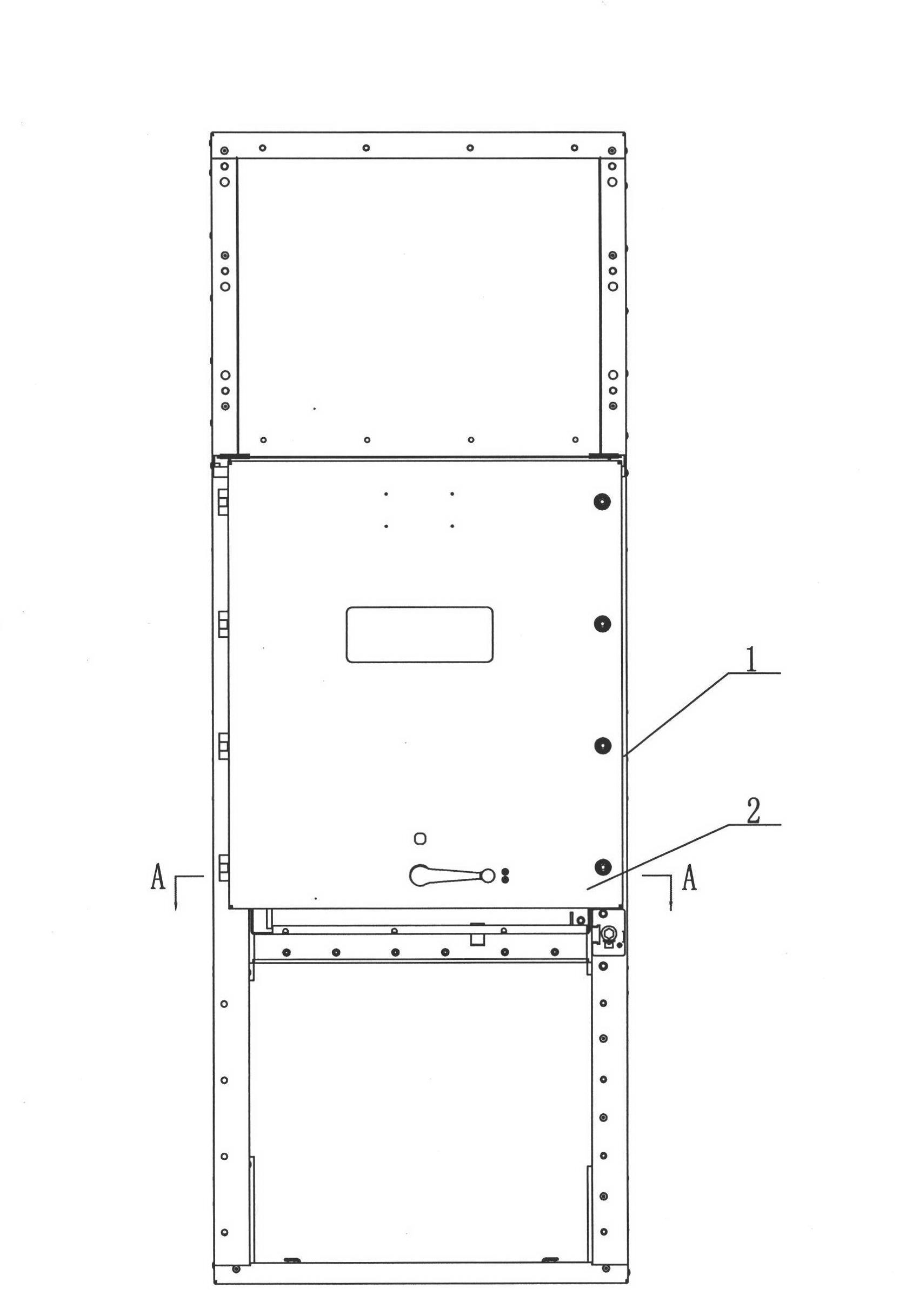

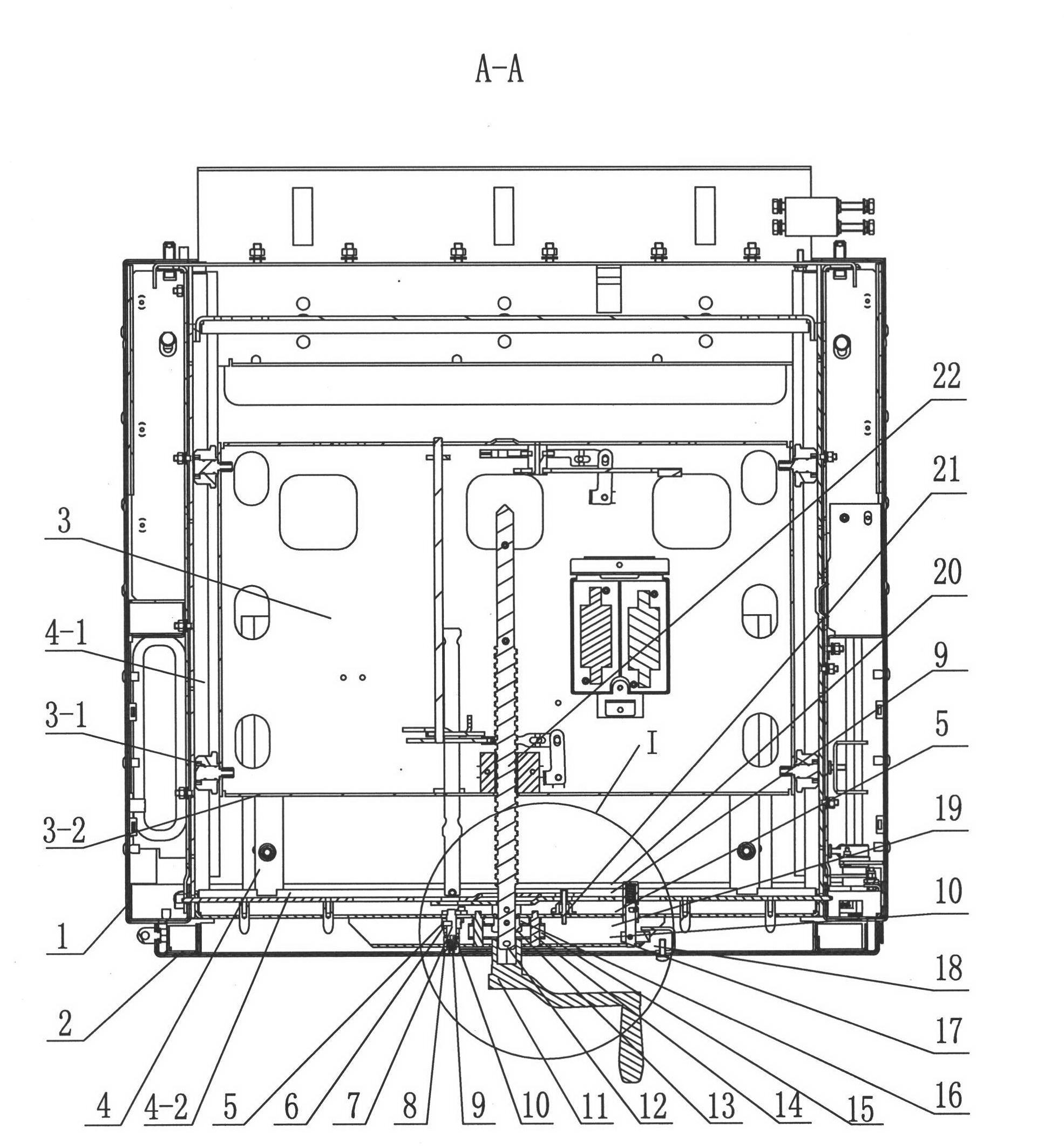

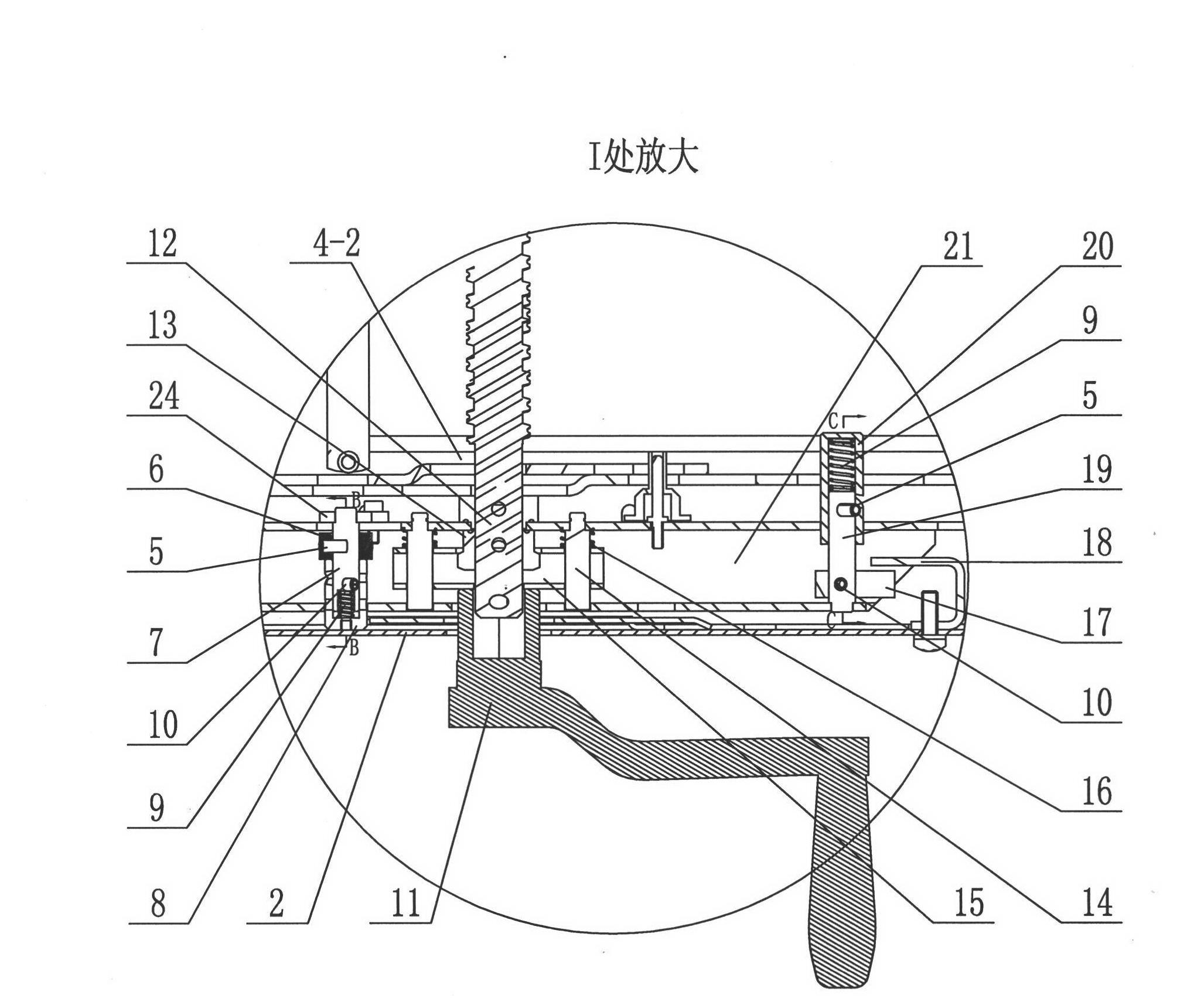

Device for interlocking chassis vehicle with cabinet door of circuit breaker chamber

ActiveCN102324708AAccurately control the working strokeEasy to controlSwitchgear with withdrawable carriageScrew positionFree state

The invention relates to a device for interlocking a chassis vehicle with a cabinet door of a circuit breaker chamber. A front baffle plate of a positioning frame is provided with a locking plate; an elastic member is sleeved on a connector; an external supporting plate covers the locking plate and is connected with the front baffle plate; a first stop block of a lead screw position-limiting mechanism is connected with a first rotary shaft through a first connecting shaft; a second connecting shaft installed on the first rotary shaft is arranged in a spiral guide groove of a first sleeve; an offsetting spring is installed between the first rotary shaft and the first sleeve; the first sleeve in a free state drives the first stop block to be installed between the locking plate and the frontbaffle plate; a second rotary shaft of a cabinet door position-limiting mechanism is installed on the external supporting plate; a second stop block is connected with the second rotary shaft through the first connecting shaft; the second connecting shaft installed on the second rotary shaft is arranged in a spiral guide groove of a second sleeve; an offsetting spring is installed between the first rotary shaft and the second sleeve; and the second sleeve in a free state drives the second stop block to be installed in a position-limiting groove of the cabinet door baffle plate. The device forinterlocking the chassis vehicle with the cabinet door of the circuit breaker chamber has the advantages of rational and compact structure, reliability for interlocking, and reduction of production cost.

Owner:EATON ELECTRICAL EQUIP CO LTD

Stamping tool

InactiveUS20100206150A1Easy constructionOperational dependabilityPerforating toolsMetal working apparatusScrew positionEngineering

A stamping tool has a stamping punch for forming at least one punched hole in a workpiece. The stamping punch is guided in a guide housing along a stamping displacement movement. The stamping punch has a stamping element and a head element, which is connected with the stamping element by means of a screw connection. A length of the stamping punch between a head front face and a stamping surface, which closes off the stamping element at the front, can be set by means of the screw-in depth of the screw connection. An unlocking body, which is freely accessible from outside of the guide housing can be displaced between a locked position, in which the screw connection is blocked, and a screwing position, in which the screw connection is released. The result is a stamping tool with a simplified length adjustment.

Owner:PASS STANZTECHN

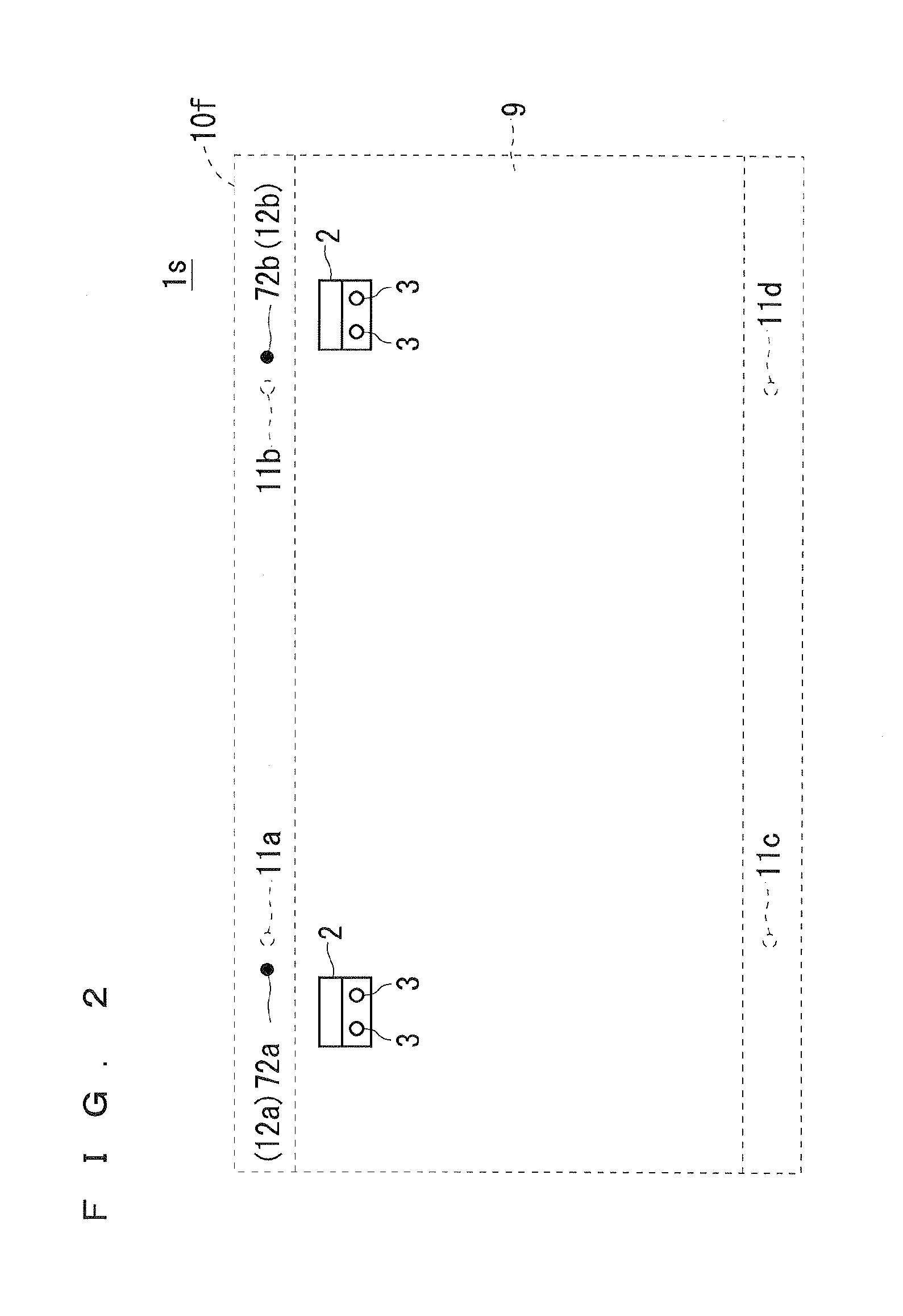

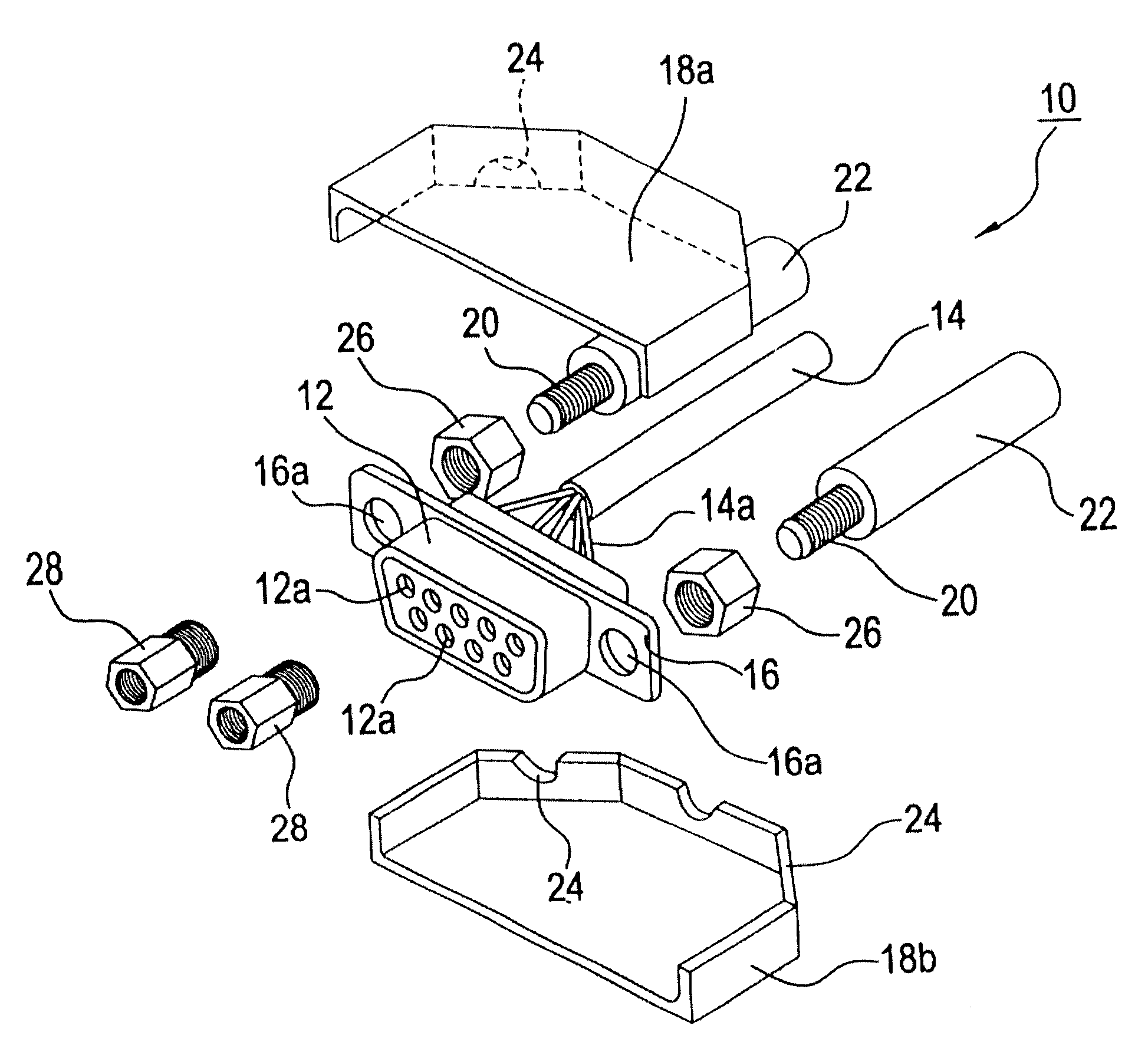

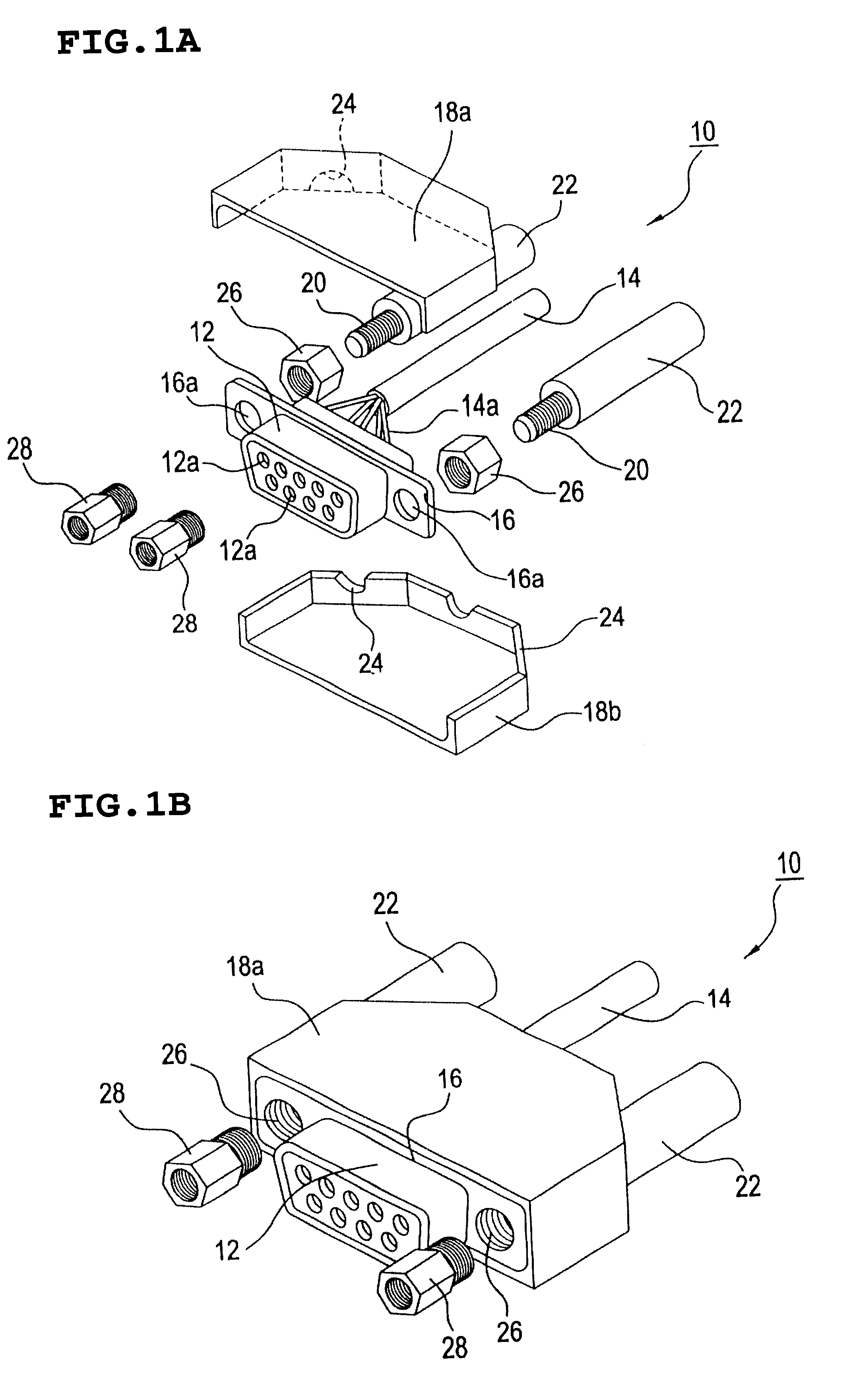

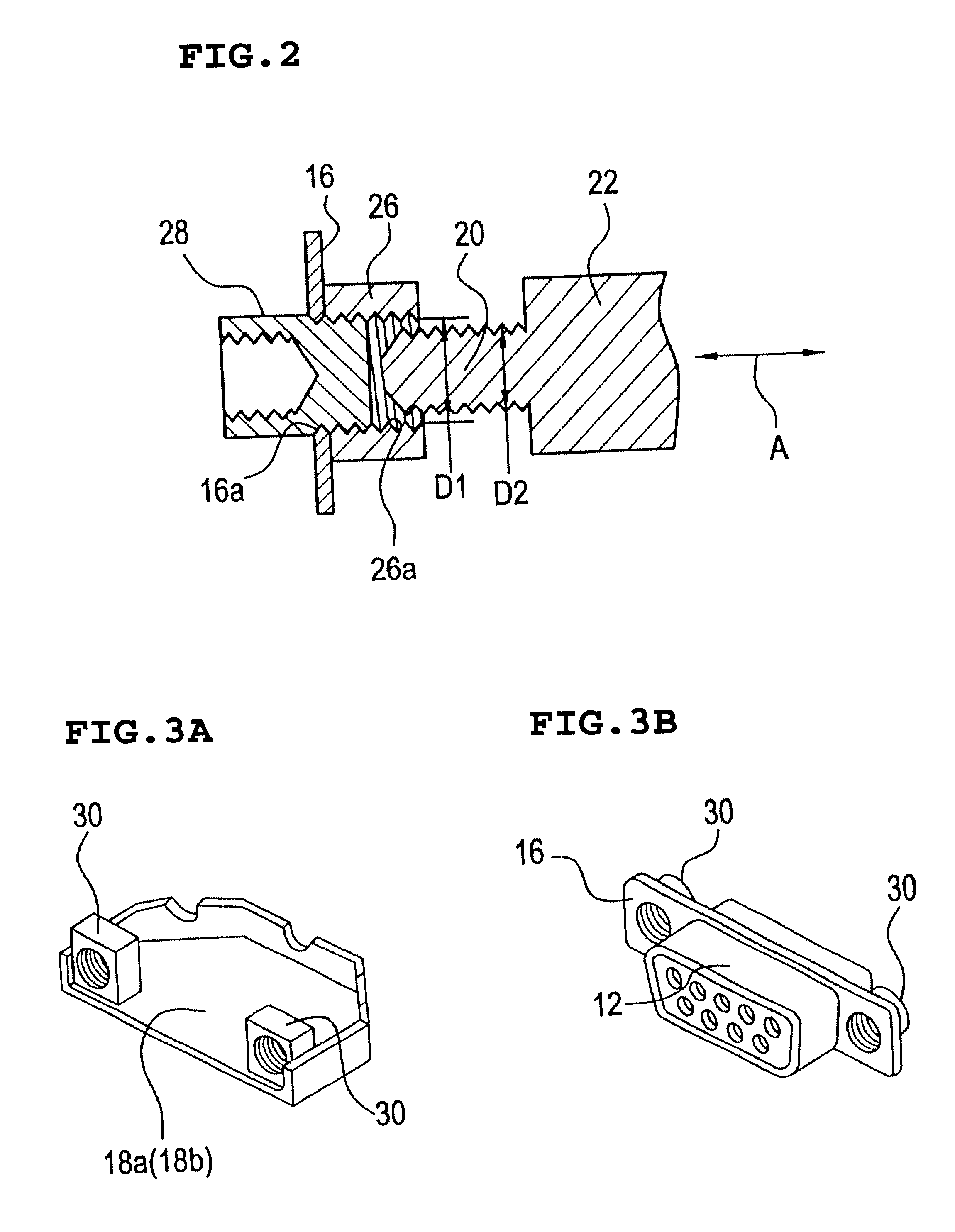

Connector device, interface module using the connector device, and adapter for changing the number of cores of a connector

Owner:MURATA MFG CO LTD

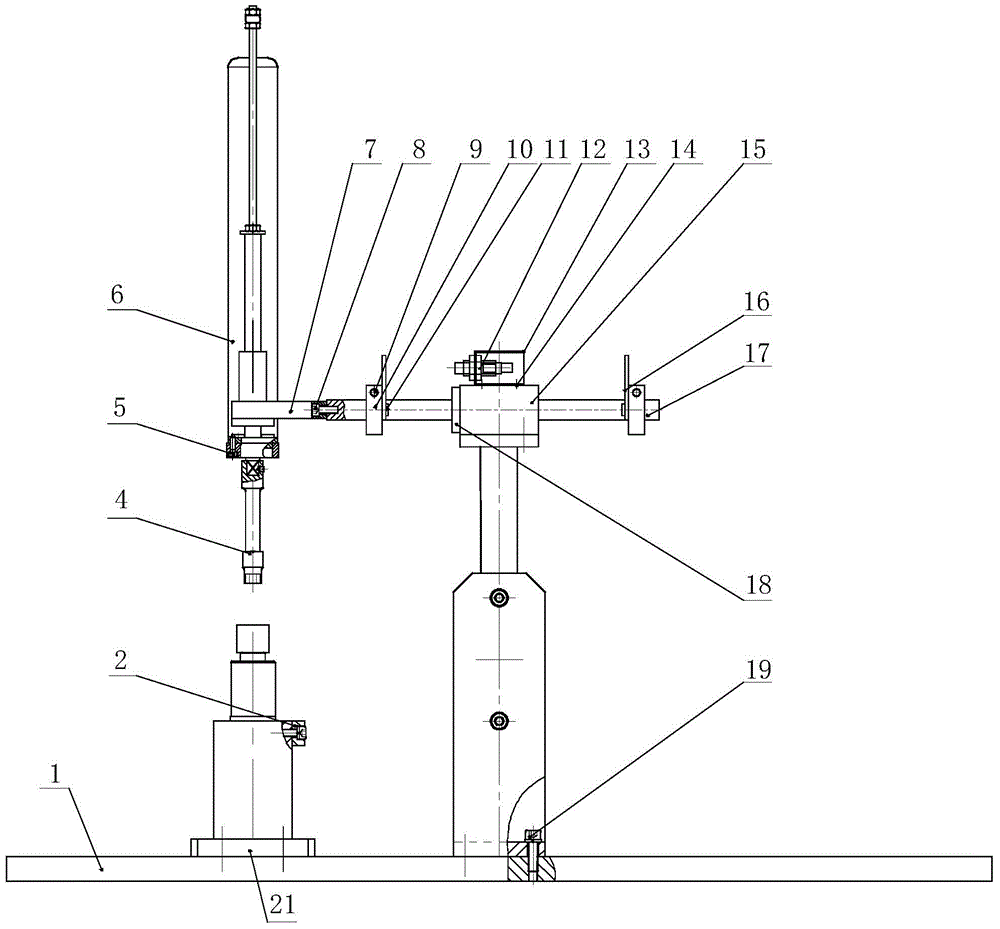

Assembling tool of electric caliper transmission assembly

ActiveCN104440068AHigh tightening precisionImprove securityMetal working apparatusScrew positionCalipers

The invention relates to an assembling tool of an electric caliper transmission assembly. The assembling tool comprises a workbench. A clamp device is connected to the upper end of the workbench. A three-freedom-degree adjusting device is disposed at the rear of the clamp device and fixed on the workbench. A bolt screwing device is mounted on the three-freedom-degree adjusting device. The assembling tool has the advantages that the clamp device is used to compress a workpiece, three-freedom-degree motion of the bolt screwing device can be achieved by the three-freedom-degree adjusting device, screwing positions can be changed conveniently, bolt screwing is then performed through the bolt screwing device, and the assembling tool is applicable to bolt assembling of various positions; the problem of poor performance caused by threaded assembling can be eliminated, thread screwing precision is increased by a torque-rotary angle control method, high bolt axial pre-tightening force precision is achieved, large bolt axial pre-tightening force can be acquired, the three-freedom-degree motion can be achieved, and convenient and fast adjustments can be performed according to the assembling position changes of the to-be-assembled workpiece.

Owner:WUHU HIT ROBOT TECH RES INST

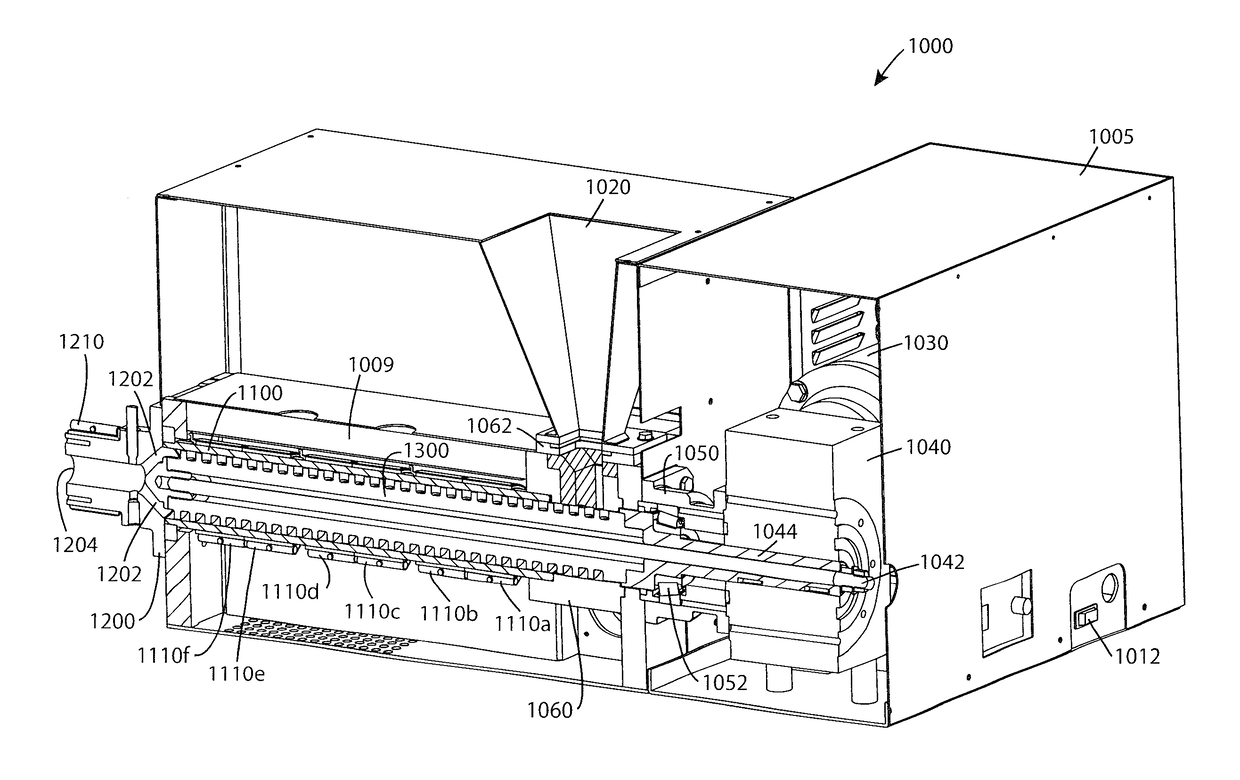

Extruder

ActiveUS20180236705A1Reduced strain orientationReduce and minimize amount of heatTubular articlesScrew positionEngineering

An extruder has a barrel extending from a feed inlet end to an extruder outlet end. The barrel has an inner surface, an outer surface, and a wall thickness between the inner and outer surfaces. The extruder also has at least one heating member positioned provided on the barrel; a screw drive motor drivingly connected to a rotatably mounted screw positioned within the barrel, whereby the screw is rotatable at various revolutions per minute (RPM); and a controller is operably connected to the screw drive motor to adjust the RPM of the screw based upon a temperature of material passing through and / or being extruded from the barrel. Methods for operating an extruder filling a mold are also provided.

Owner:OMACHRON INTPROP

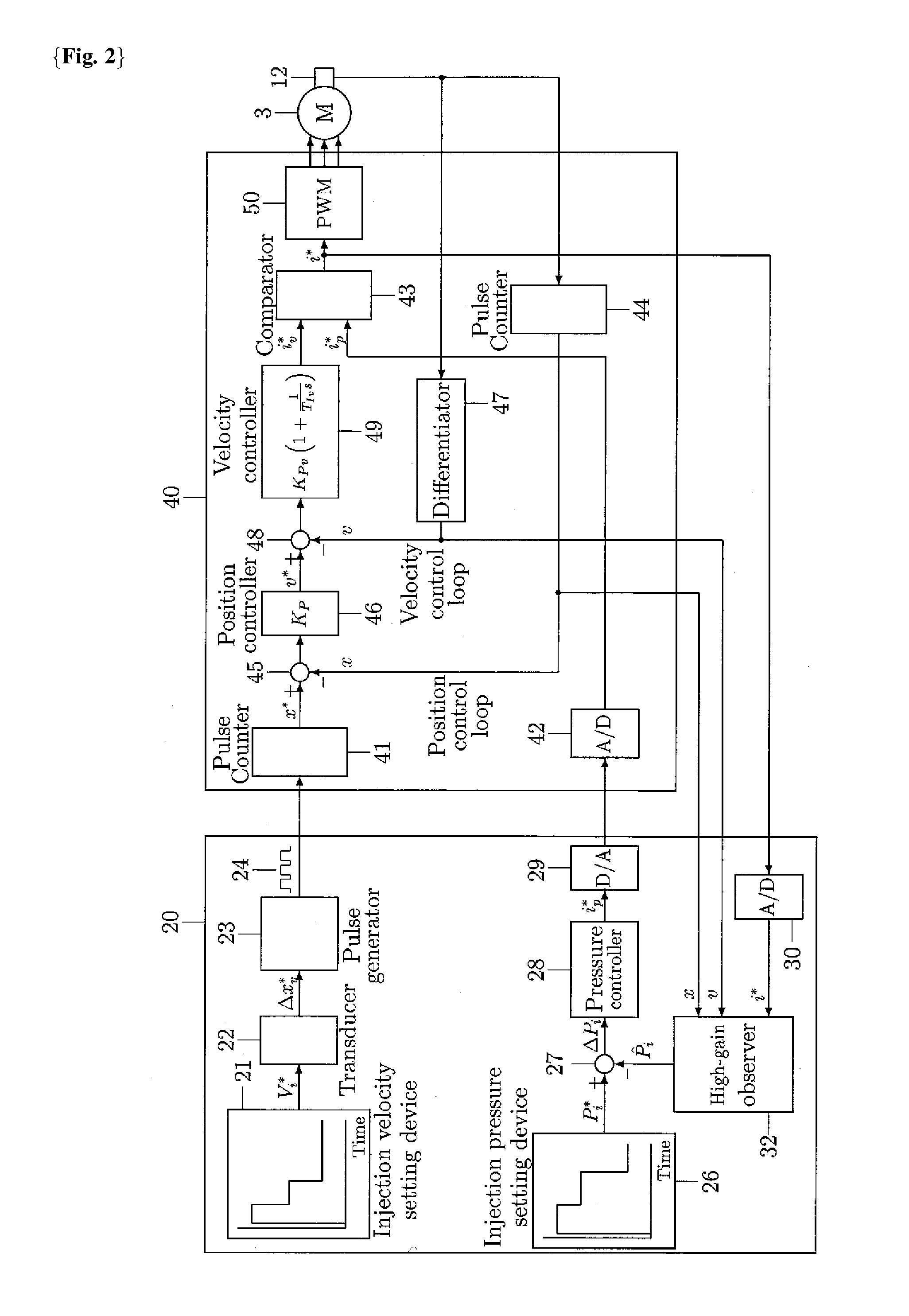

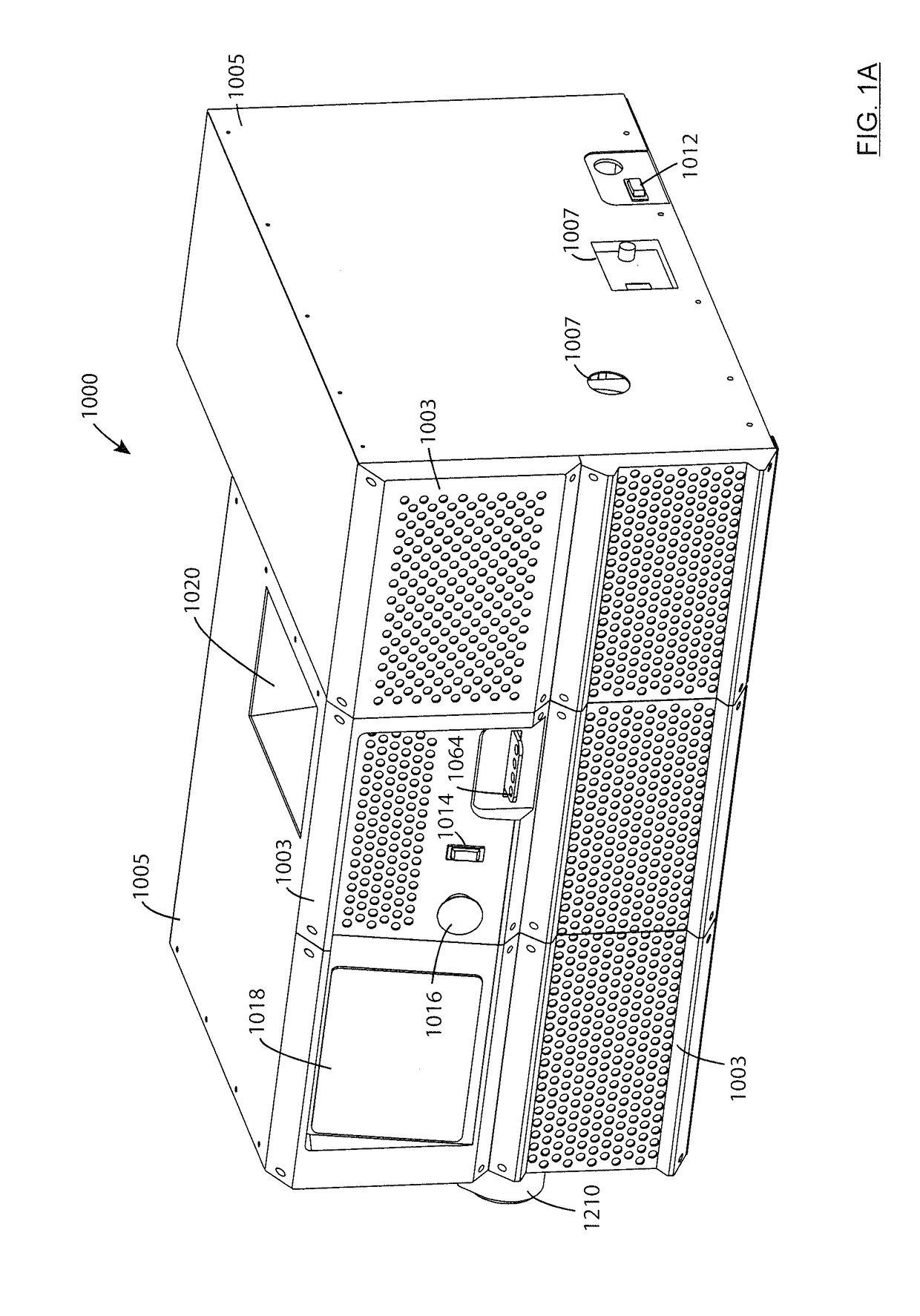

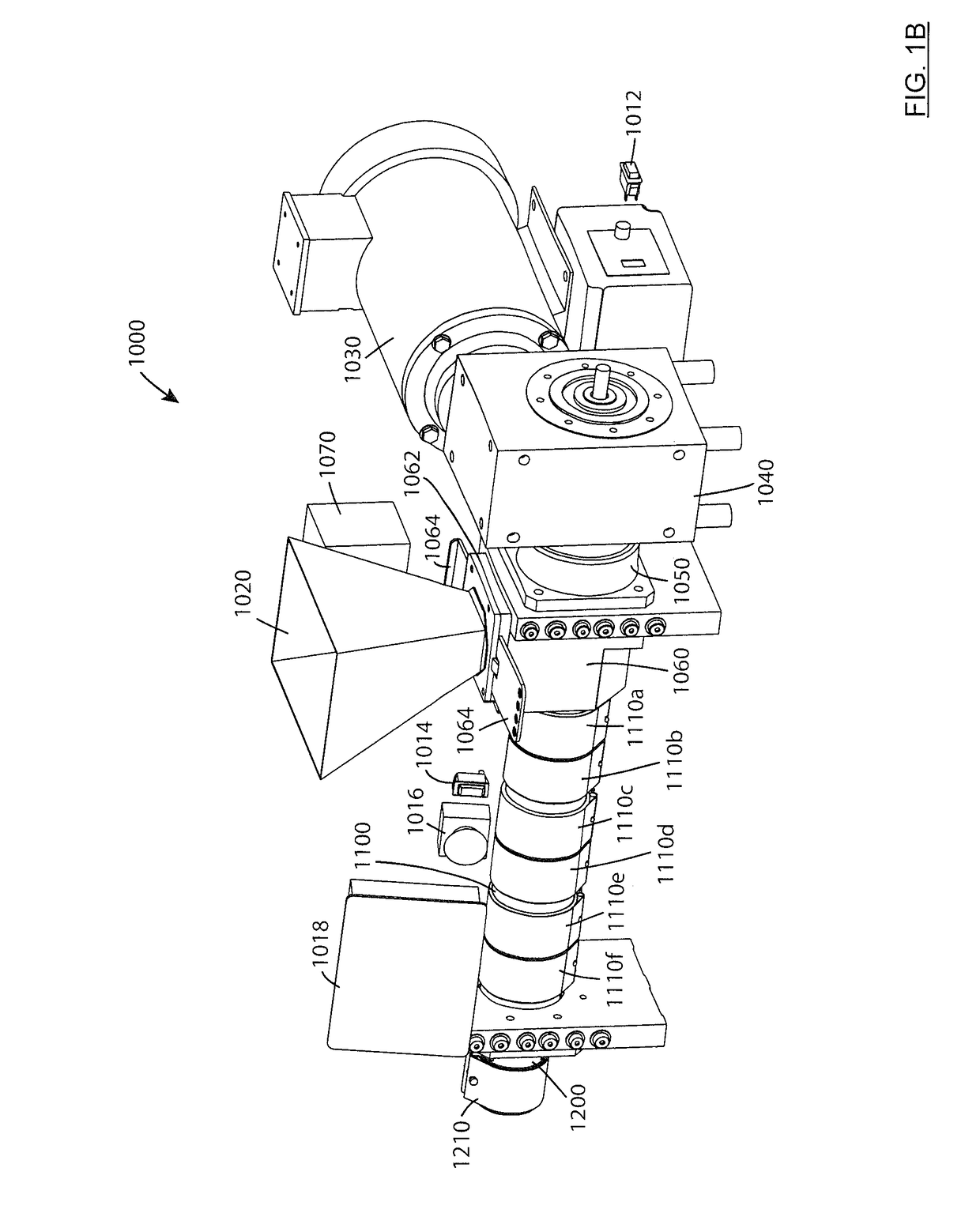

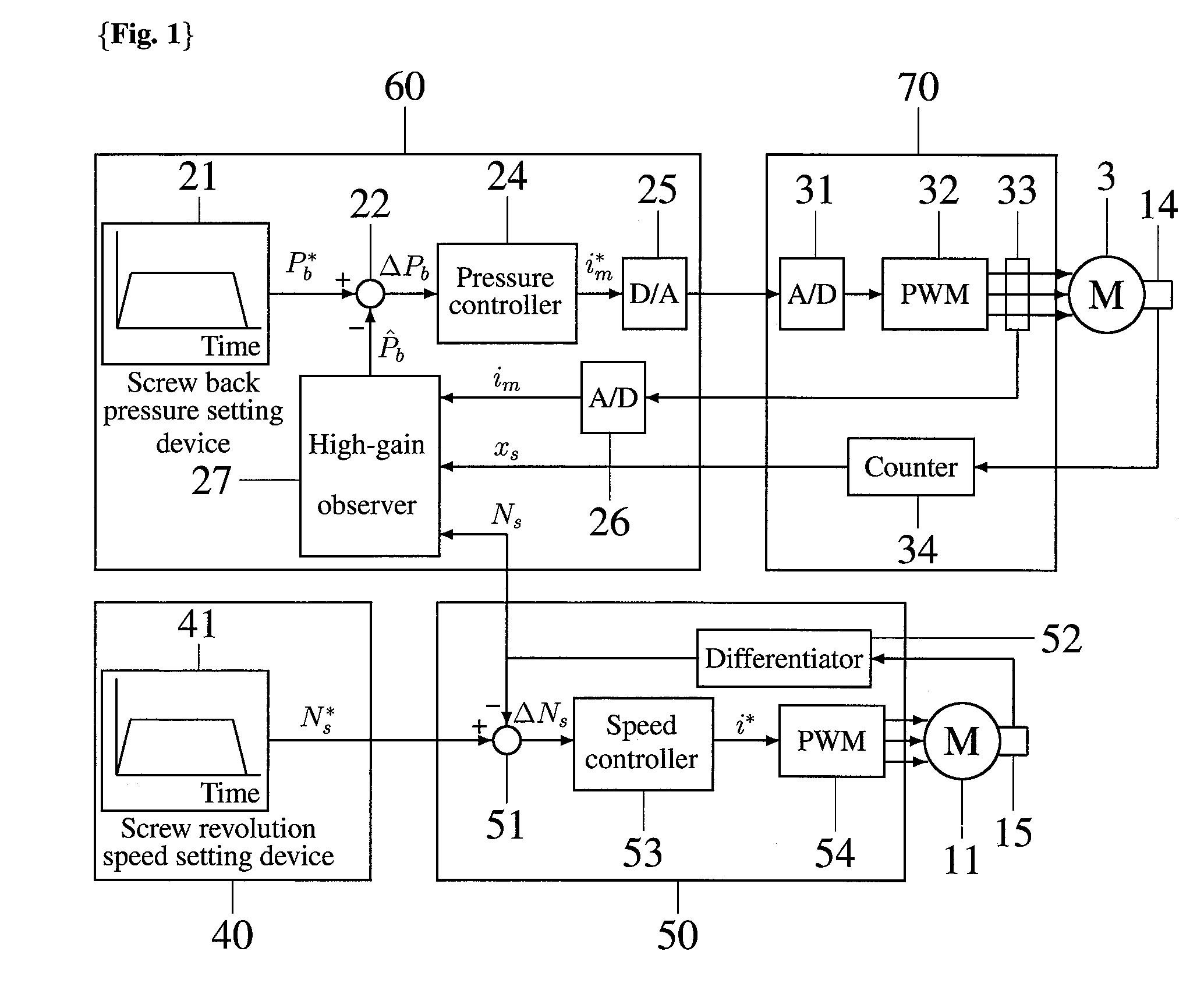

Device and Method for Plasticization Control of Electric Injection Molding Machine

ActiveUS20110298146A1Small time lagSufficient back pressureAuxillary shaping apparatusTime lagMathematical model

The exact method with small time-lag of detecting screw back pressure for controlling the screw back pressure in the plasticizing process of an electric-motor driven injection molding machine without using a pressure detector has been asked for because the pressure detector is very expensive, necessitates troublesome works for mounting, an electric protection against noise and the works for zero-point and span adjustings and causes a complicate mechanical structure.The present invention uses a high-gain observer which contains the discrete-time arithmetic expressions derived from a mathematical model of a plasticizing mechanism in an electric-motor driven injection molding machine consisting of state equations and outputs an estimate of screw back pressure, which is one of the state variables of the above state equations, by using a screw position signal, a servomotor current demand signal or actual motor current signal and a screw revolution speed signal as inputs. The high-gain observer obtains the exact screw back pressure estimate with very small time-lag without using a pressure detector. Thus the estimate of screw back pressure fed by the high-gain observer can be adopted as a feedback signal of actual screw back pressure for controlling the screw back pressure in the plasticizing process.

Owner:AKASAKA NORIYUKI

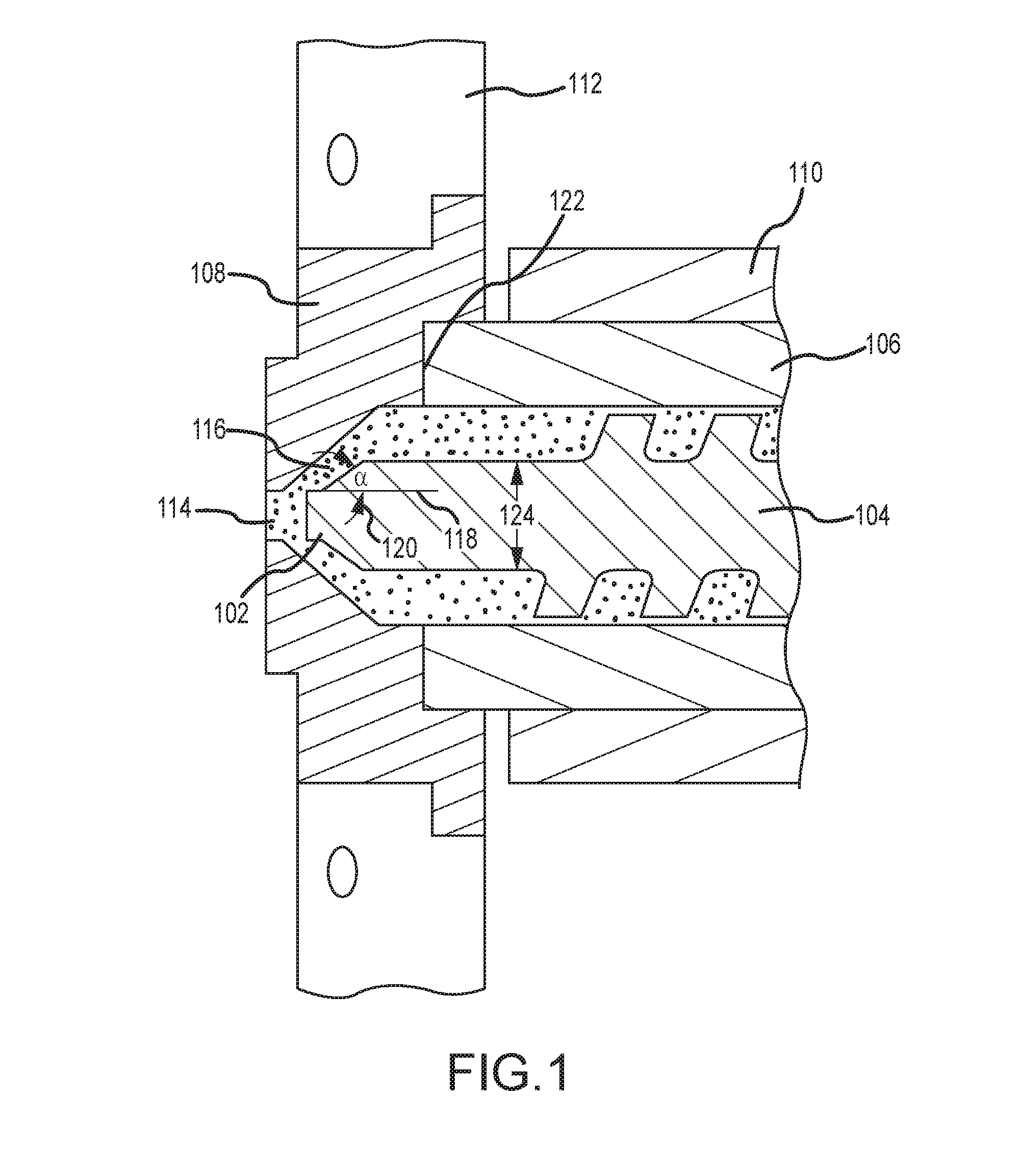

Nozzle shut off for injection molding system

ActiveUS20160158981A1Reduce injection pressureEffective heat conductionProgramme controlFood shapingScrew positionInjection molding machine

An injection molding apparatus and method of fabricating a molded part are provided. The apparatus may include a barrel, a nozzle enclosing an end of the barrel and defining an opening in fluid communication with an inside of the barrel, and an extrusion screw positioned at least partially inside the barrel and rotatable relative to the barrel. The extrusion screw may include a screw tip. Relative axial movement between the barrel and the extrusion screw may open or close the opening of the nozzle to permit or prevent, respectively, material flow through the opening of the nozzle. The method may include clamping a mold, opening a nozzle, rotating the extrusion screw to pump a molten material into the mold until the mold is filled, closing the nozzle, and unclamping the mold to release a molded part.

Owner:EXTRUDE TO FILL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com