Screw feeding mechanism

A feeding mechanism and screw technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems affecting the locking effect, and achieve the effect of preventing material jamming, ensuring the quality of locking, and eliminating waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

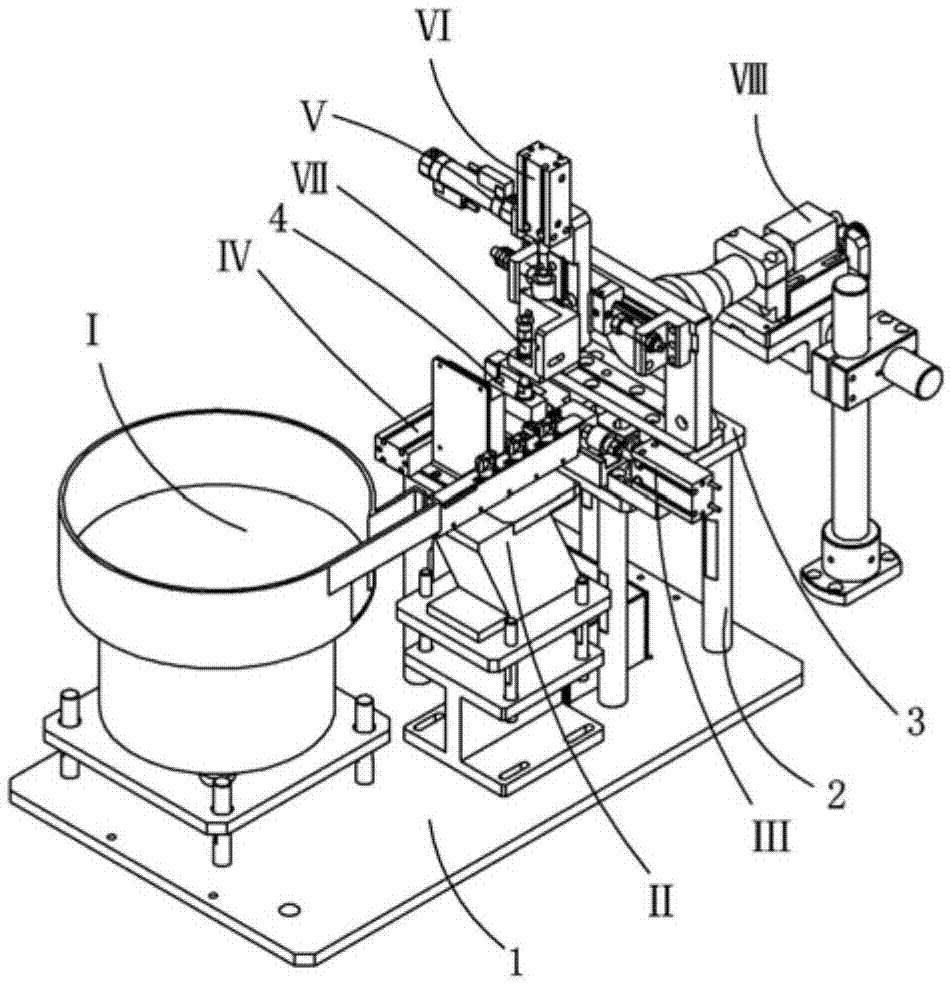

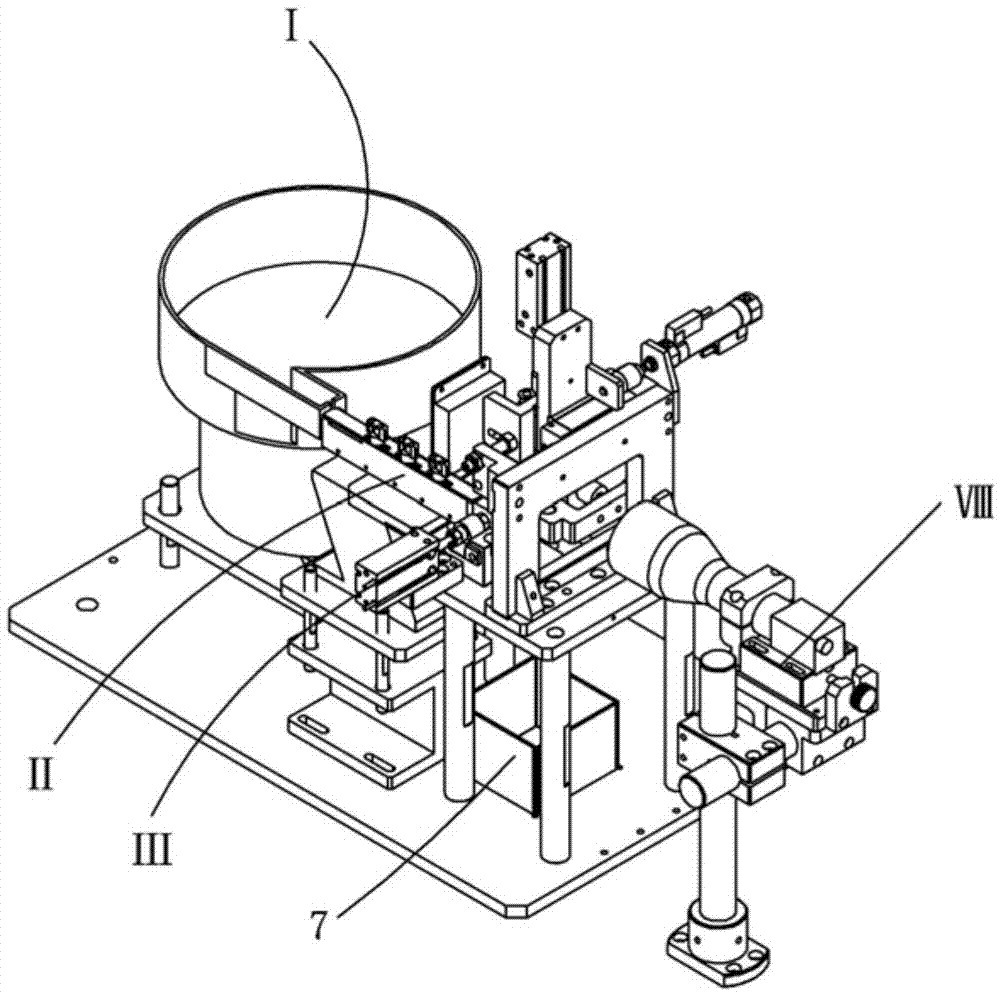

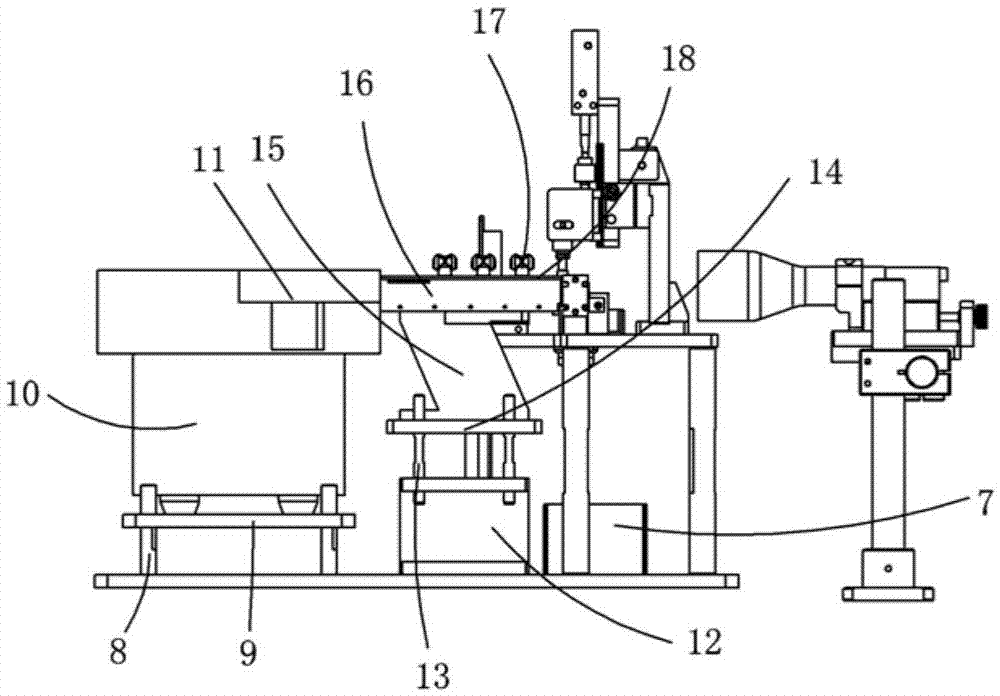

[0040] Examples, see attached Figure 1-19, a screw feeding mechanism, including a bottom plate 1, a feeding assembly I is installed on the bottom plate, a direct vibration assembly II is installed on the right side of the feeding assembly on the bottom plate, the feeding track of the feeding assembly and the direct vibration assembly The direct vibration track is connected; the base plate is equipped with a material distribution base plate 3 through the material distribution pillar 2, there are four material distribution pillars, and the material distribution base plate is installed on the four material distribution pillars; the material distribution base plate is respectively installed There are dislocation mechanism III and material distribution mechanism IV; the distribution base plate is equipped with a horizontal movement device V, a vertical movement device VI is installed on the horizontal movement device, and a suction nozzle assembly VII is installed on the vertical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com