Slender material automatic loading device

An automatic feeding and slender body technology, which is applied in loading/unloading, conveyor objects, transportation and packaging, etc., can solve the problems of prone to reverse material, the output of e-cigarettes cannot meet the demand, and high labor intensity, etc. tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

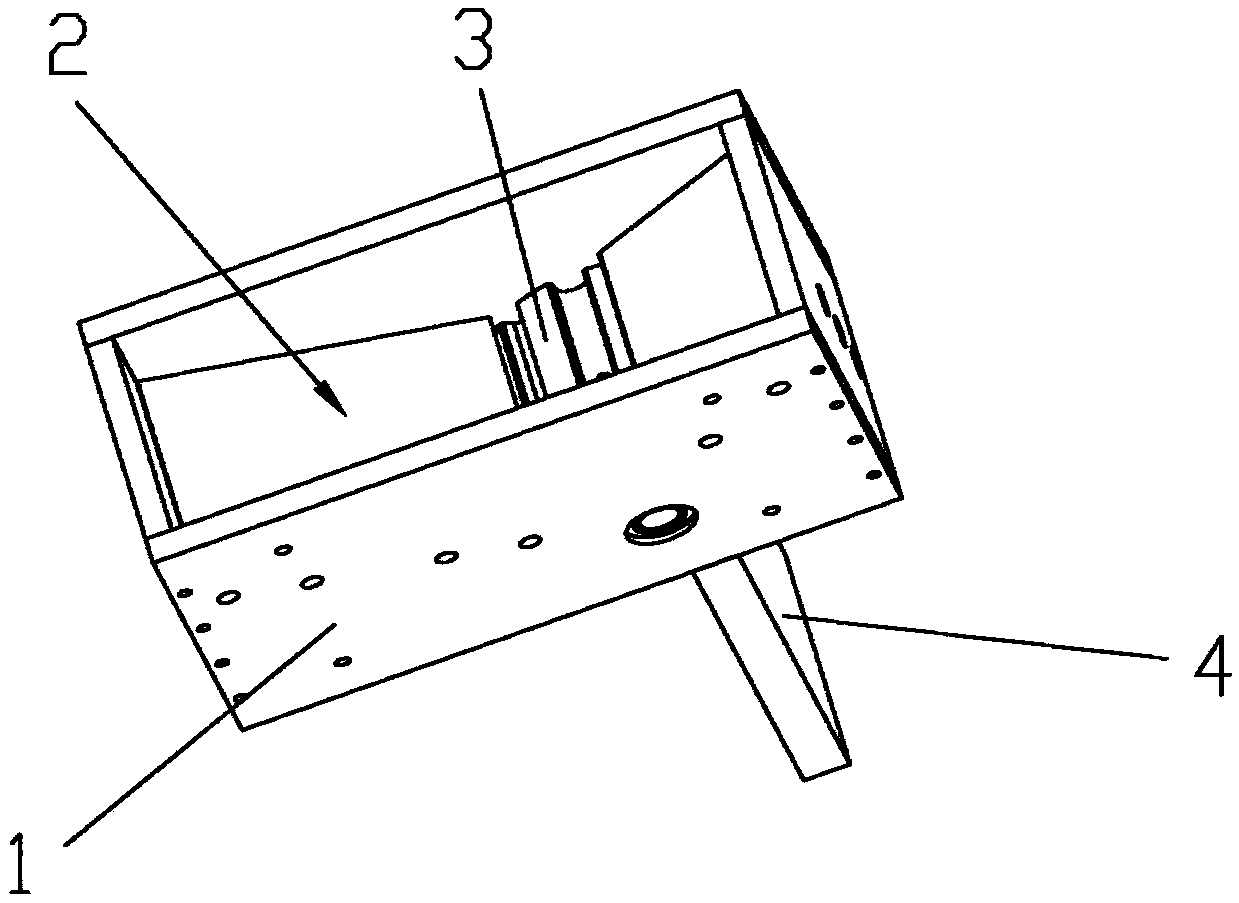

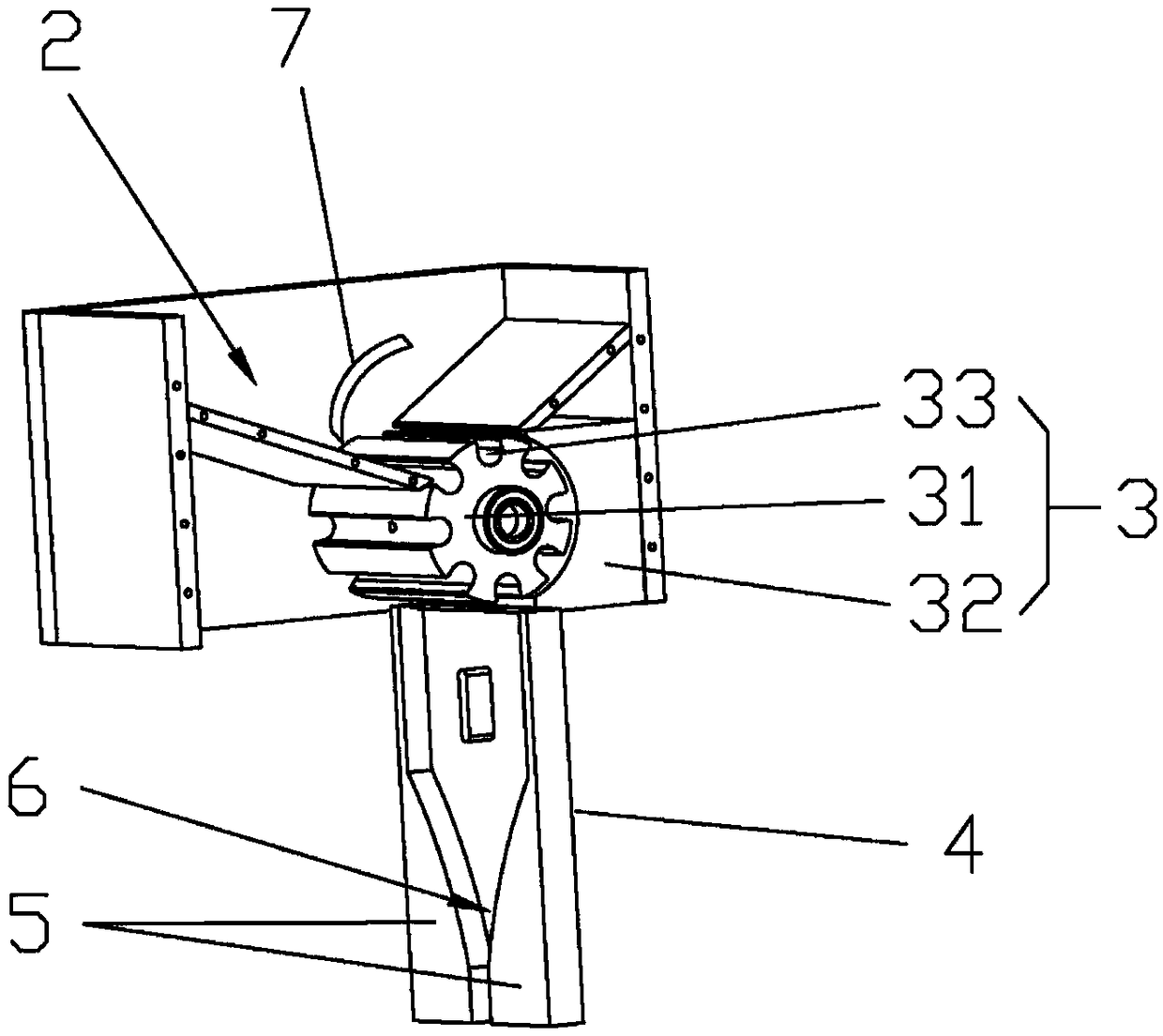

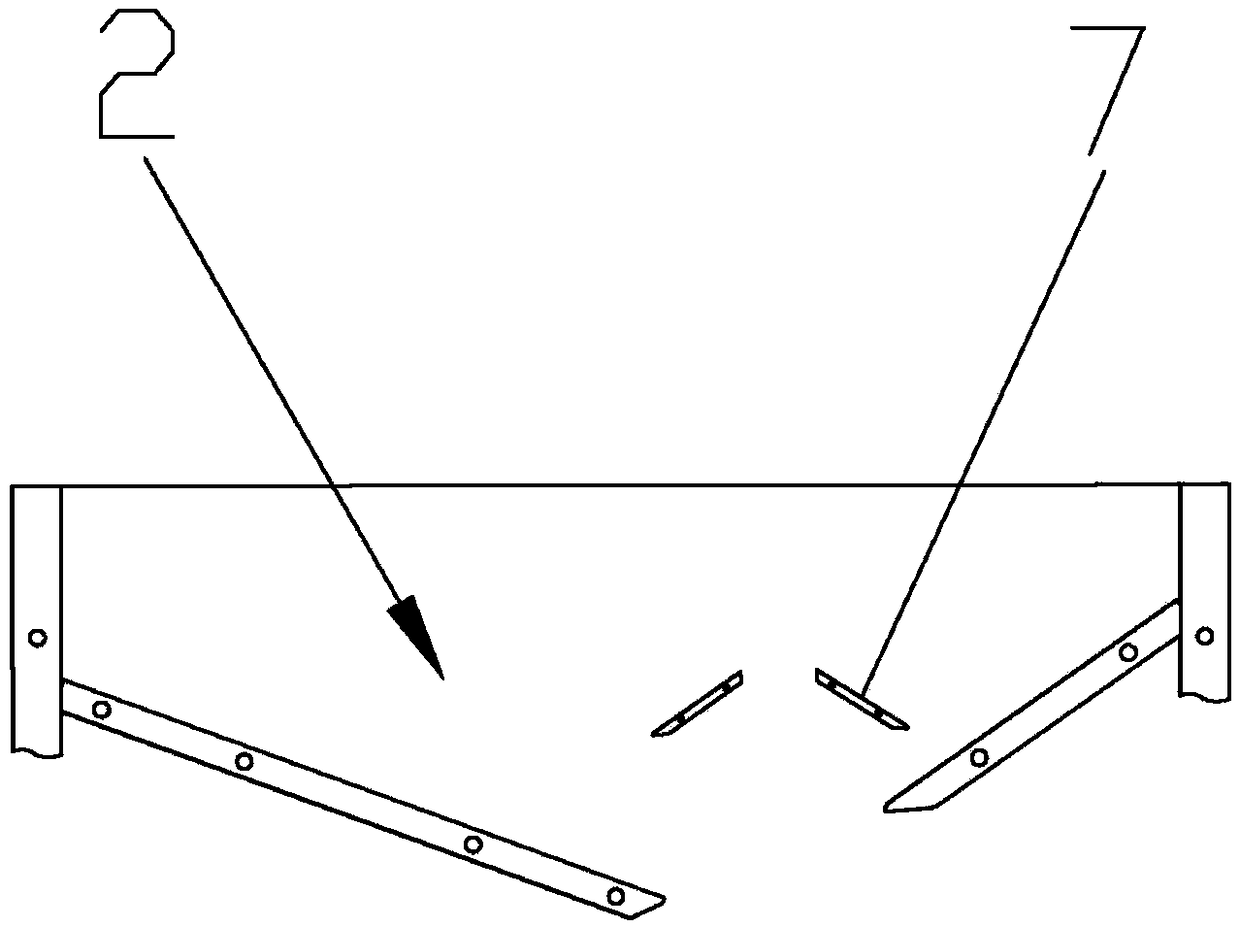

[0042] Please refer to the attached Figure 1-5 , an automatic feeding device for slender body materials, comprising a body 1, a storage bin 2 installed inside the body 1, a discharge mechanism 3 and a correction device 4 installed below the body 1, the discharge mechanism 3 Located below the storage bin 2 and above the straightening device 4, the discharge mechanism 3 is used to transport the elongated material at the outlet of the storage bin 2 to the entrance of the straightening device 4, and the entrance of the straightening device 4 is connected to the discharge mechanism 3 The lengths of the outlets are the same, and they are arranged parallel to each other. A correction block 41 is installed in the middle of the correction device 4, and the distance between the correction block 41 and the left and right sides of the correction device 4 is equal.

[0043] Further, two arc-shaped plates 5 are installed at the lower end of the correcting device 4, and a gap 6 is provided ...

Embodiment 2

[0052] The difference between embodiment 2 and embodiment 1 is that the number of the partitions 7 is two, and the two partitions 7 are arranged axially symmetrically.

Embodiment 3

[0054] The difference between embodiment 3 and embodiment 1 is that the number of the partitions 7 is two, and the two partitions 7 are arranged randomly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com