Safety rail capable of automatically winding and unwinding warning belt

A safety fence, automatic retractable technology, applied in the direction of fences, roads, building types, etc., can solve the problems of labor time waste, construction progress impact, increase the labor intensity of safety fences, etc., to achieve convenient handling and placement, convenient layout, The effect of shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

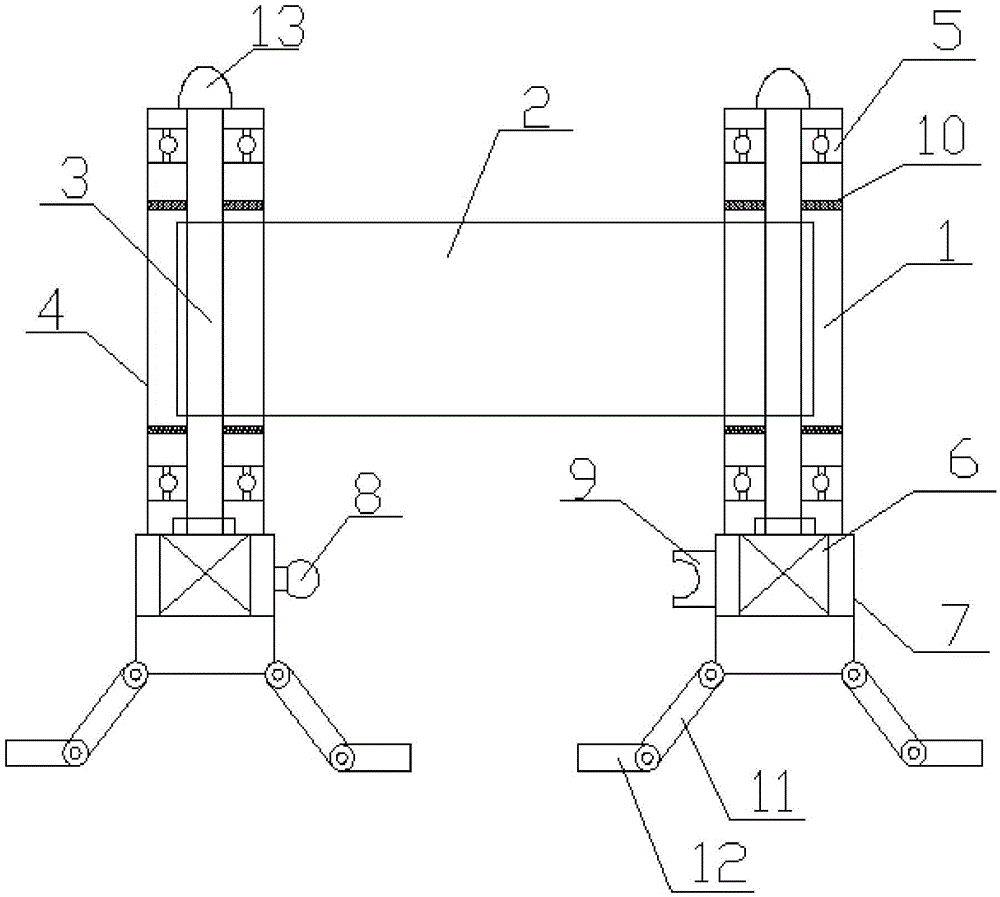

[0020] Specific embodiment one: please refer to figure 1 As shown, a safety fence that can automatically retract the warning tape includes two fence posts 1 and a warning tape 2, and the warning tape 2 is stretched between the two fence posts 1, and the fence post 1 includes a rotating Shaft 3 and shaft sleeve 4, the rotating shaft 3 is arranged in the shaft sleeve 4, the upper and lower ends of the rotating shaft 3 are fixed in the shaft sleeve 4 through bearings 5, and the lower end of the rotating shaft 3 is connected with a drive motor 6. The drive motor 6 is externally provided with a fixed casing 7 for fixing the motor, the lower end of the shaft sleeve 4 is fixed on the fixed casing 7, and the outer side of the lower end of the fixed casing 7 is provided with a support frame mechanism for supporting the ground, The warning tape 2 is wound on the rotating shaft 3, the side of the fixed shell 7 is provided with a spherical boss 8, and the adjacent fixed shell is provided ...

specific Embodiment 2

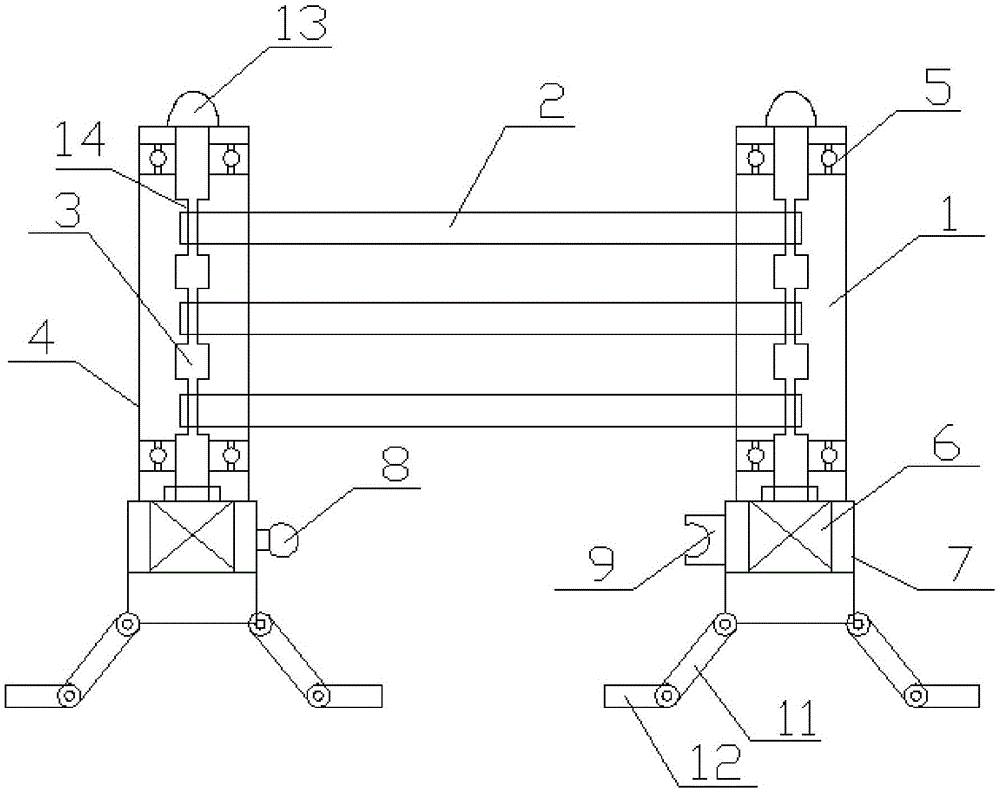

[0021] Specific embodiment two: please refer to figure 2 As shown, a safety fence that can automatically retract the warning tape includes two fence posts 1 and a warning tape 2, and the warning tape 2 is stretched between the two fence posts 1, and the fence post 1 includes a rotating Shaft 3 and shaft sleeve 4, the rotating shaft 3 is arranged in the shaft sleeve 4, the upper and lower ends of the rotating shaft 3 are fixed in the shaft sleeve 4 through bearings 5, and the lower end of the rotating shaft 3 is connected with a drive motor 6. The drive motor 6 is externally provided with a fixed casing 7 for fixing the motor, the lower end of the shaft sleeve 4 is fixed on the fixed casing 7, and the outer side of the lower end of the fixed casing 7 is provided with a support frame mechanism for supporting the ground, The supporting frame mechanism includes a first leg 11 and a second leg 12, the first leg 11 is connected to the second leg 12 through a hinge, and the first le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com