Loading device

The technology of a silo and a material guide block is applied in the field of the feeding device for distinguishing the positive and negative electrodes of the battery, which can solve problems such as scratches on the surface of the battery, and achieve the effect of preventing wrong material feeding and avoiding mutual scratches.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

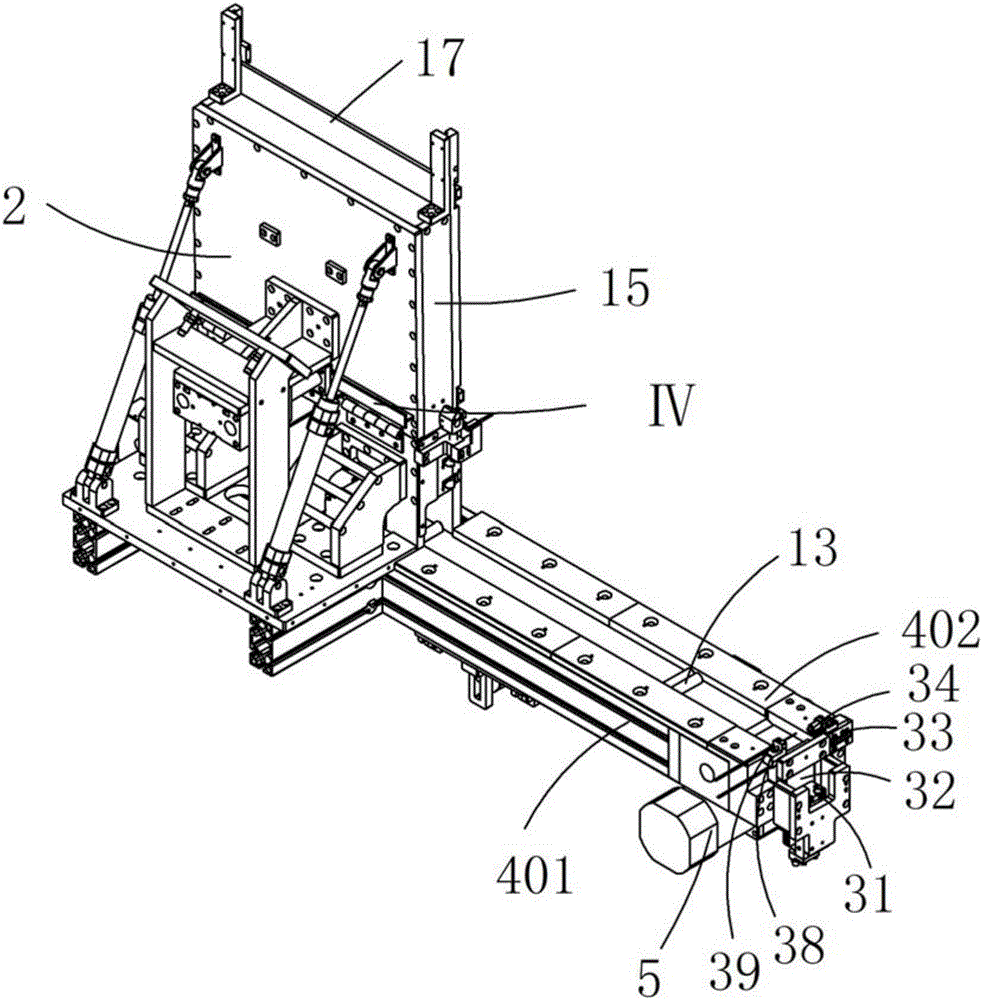

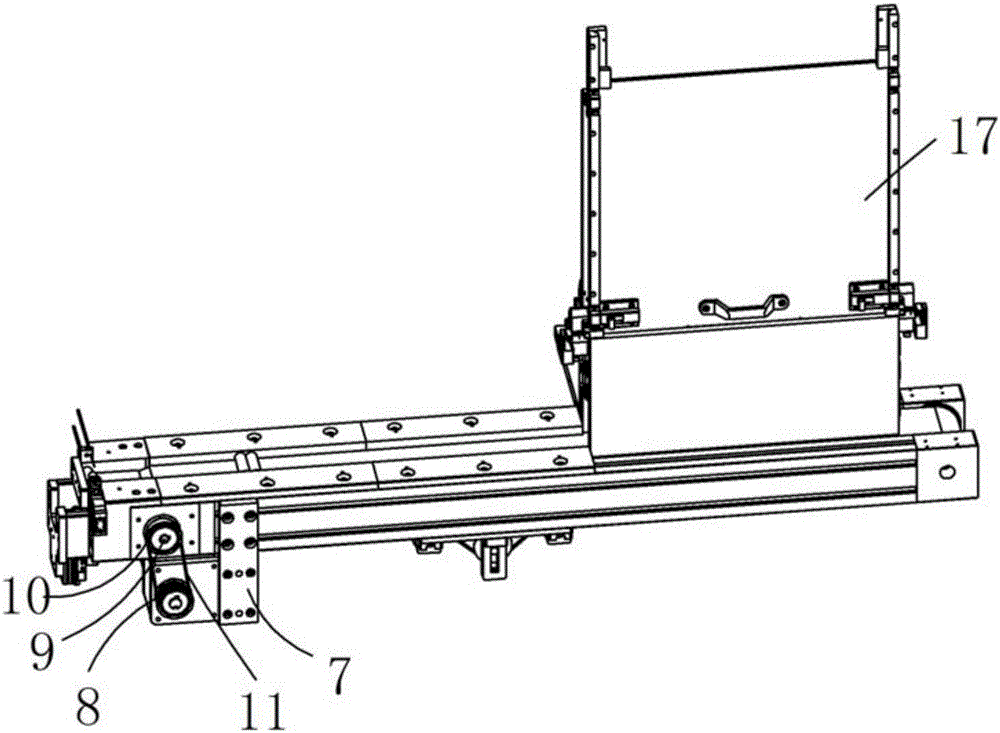

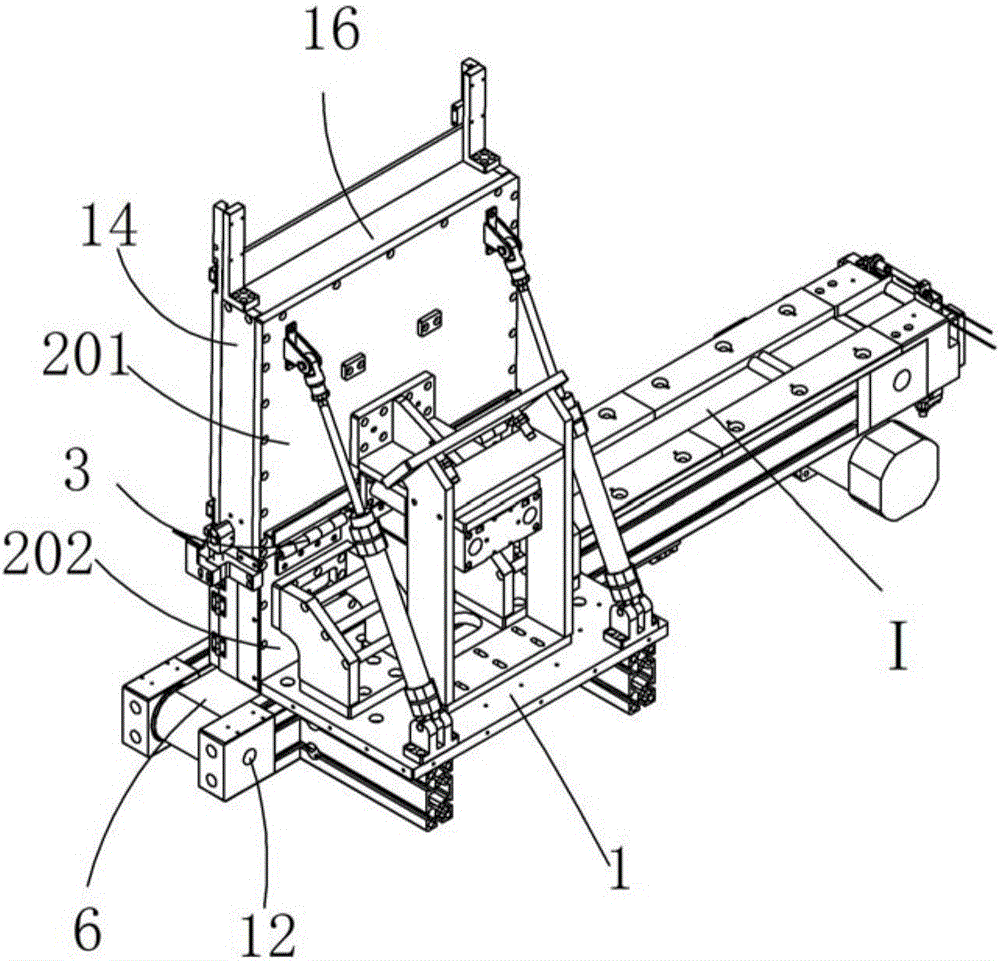

[0036] Examples, see attached Figure 1-10 , a feeding device, comprising a bottom plate 1 and a silo vertical plate 2 installed on the rear side of the bottom plate, the bottom plate 1 is a flat plate structure, and the silo vertical plate includes an upper silo vertical plate 201 hingedly connected by a hinge 3 and a blanking material The bin vertical plate 202 and the upper material bin vertical plate 201 can be flipped relative to the lower material bin vertical plate 202, and the lower material bin vertical plate and the bottom plate are supported and positioned by the connecting component V.

[0037] The bottom of the base plate is provided with a transfer assembly line assembly 1 capable of transporting batteries; the transfer assembly line assembly includes an assembly line workbench 4, an assembly line drive motor 5 and a belt 6, and the assembly line workbench includes a symmetrically arranged front assembly line workbench 401 and a rear assembly line assembly. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com