Automatic PCB detaching, overturning and pasting integrated machine

A technology of PCB board and all-in-one machine, which is applied in the field of automatic all-in-one machine for dismantling, flipping and sticking of PCB boards, can solve the problems of increasing the electrostatic hazard of electronic products and increasing processing costs, and achieves the goal of reducing production costs, improving processing efficiency, and improving the degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

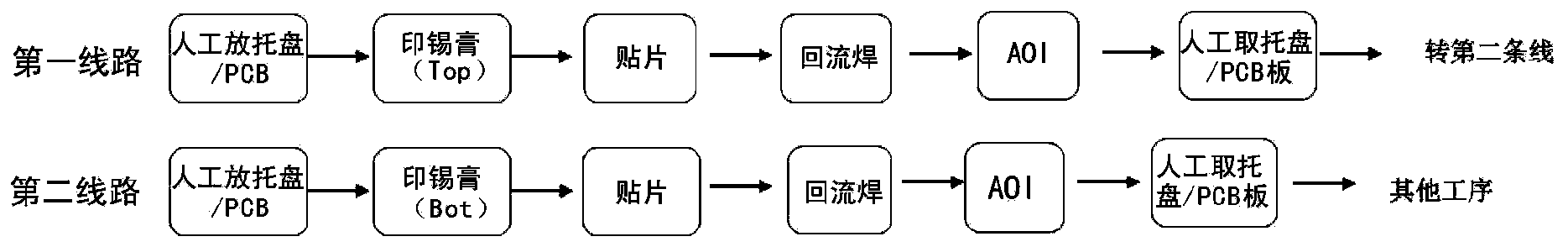

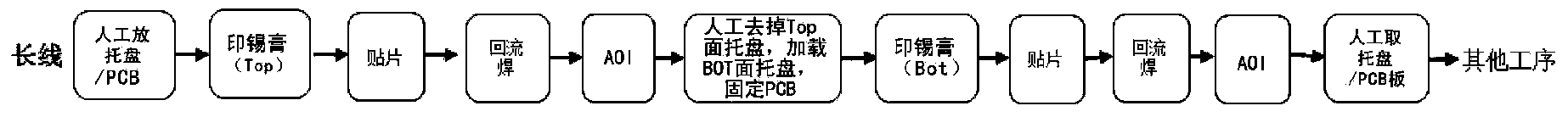

[0030] Such as figure 1 , figure 2 As shown, the SMT production line for front and back processing of PCB boards is generally divided into short-line and long-line processing. The short-line processing uses two lines to complete the front and back processing of the PCB board, and each line completes one side of the PCB board. Processing, while long-line processing is a long line that completes the entire SMT line process of the PCB board. Whether long-line processing or short-line processing is used, the PCB board needs to be flipped, disassembled, and reassembled before entering the other side of the PCB board for processing. fit.

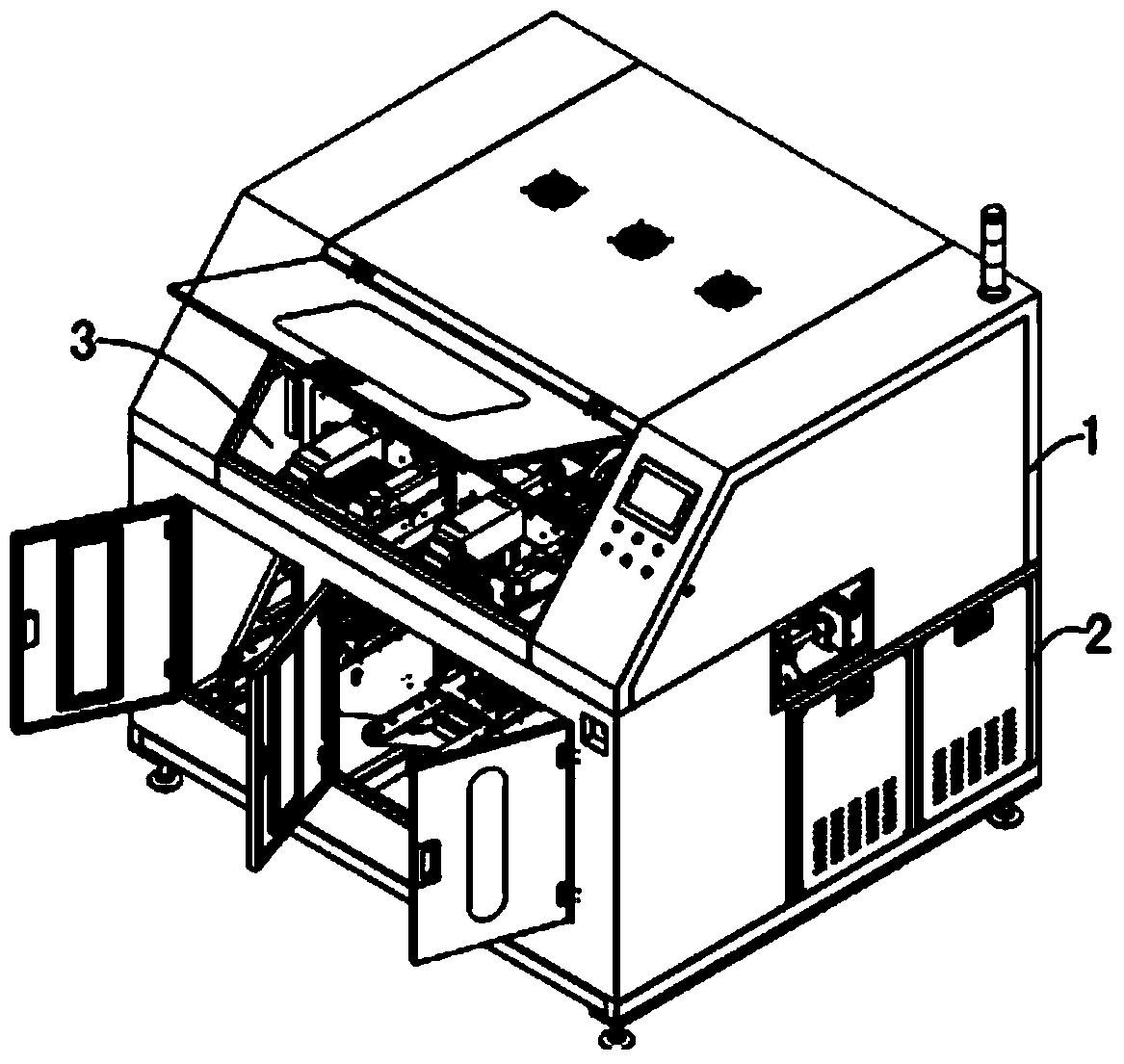

[0031] The automatic all-in-one machine for removing, flipping and pasting PCB boards disclosed by the present invention is mainly to automatically re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com