Precast constructional double-dovetailed steel-concrete combined beam in adoption of stud connection

A prefabricated concrete slab and prefabricated assembly technology, which is applied in the direction of load-bearing elongated structural members, joists, girders, etc., can solve the problems of large amount of materials, difficult construction, complex structure, etc., and achieve large ductility and deformation capacity, guaranteeing construction quality, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail in conjunction with the accompanying drawings and a specific installation method.

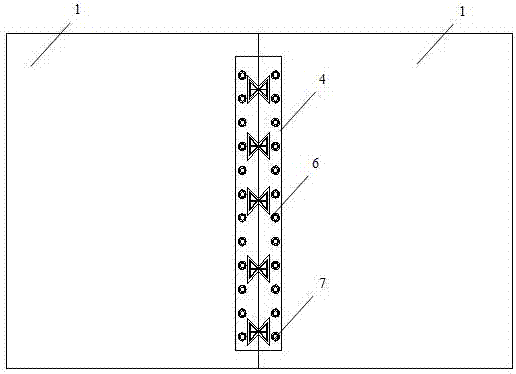

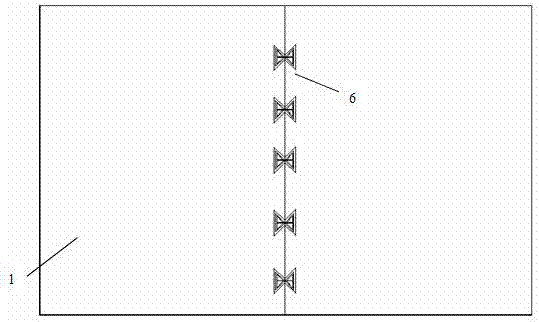

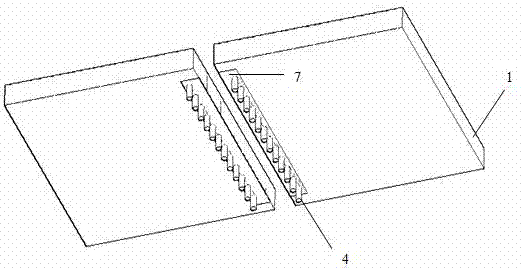

[0028] like figure 1 , 2 ,, 4,, 5, Figure 11 As shown, a prefabricated double dovetail steel-concrete composite beam connected by studs includes a precast concrete slab 1, and the prefabricated concrete slab 1 and steel beam 2 are assembled and connected by pre-embedded shear studs 4, The part below the upper flange of the steel beam 2 is connected and fastened with the steel beam 2 by the nut 2, and the precast concrete panels 1 on the left and right sides are connected by inserting double dovetail connectors 6 into the reserved holes of the wedge-shaped steel parts. The holes reserved in the prefabricated thin-walled steel plate 7 are consistent with those reserved in the steel beam 2, and the shear studs 4 penetrate into the reserved holes in the prefabricated thin-walled steel plate 7, and spot welding is used to make the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com