Patents

Literature

393results about How to "Realize blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

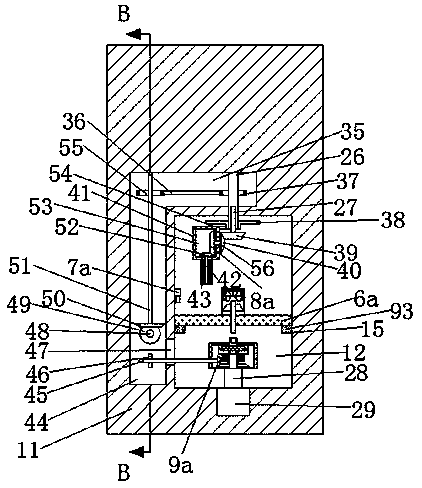

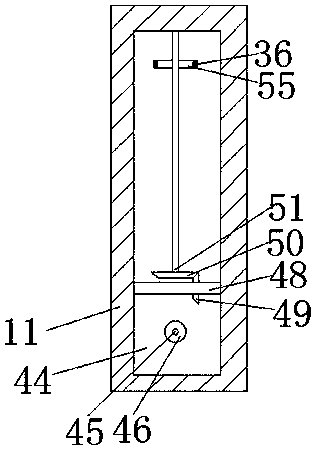

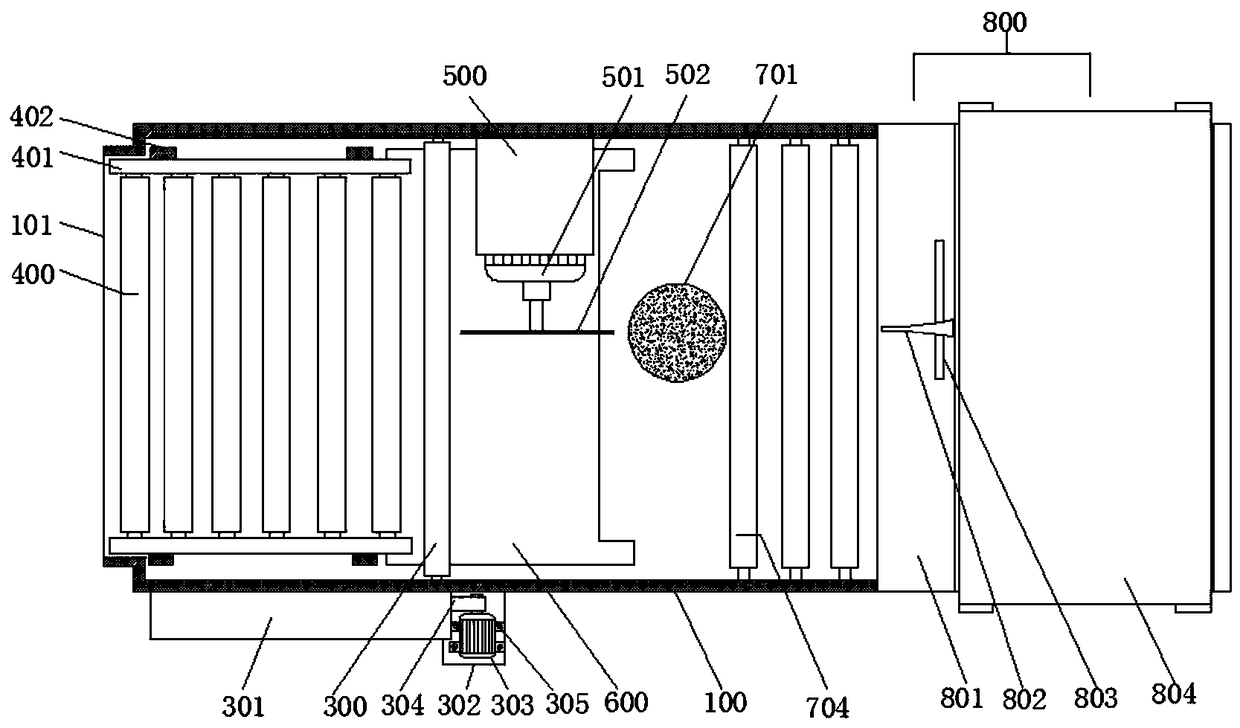

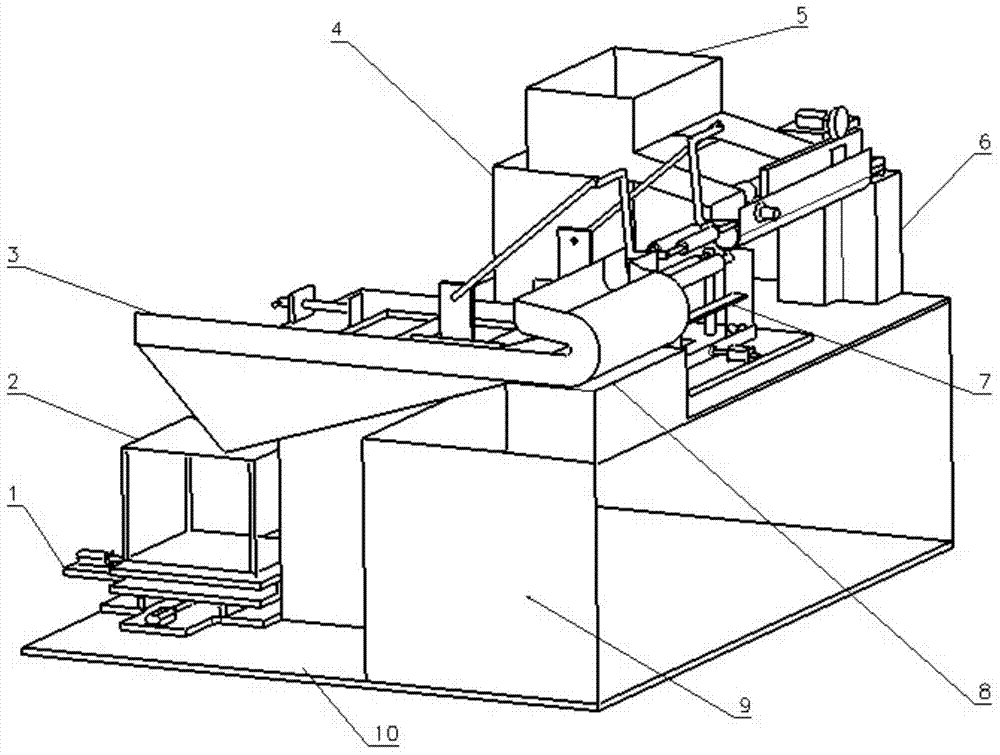

Assembly line for gas valves

PendingCN105855870ARealize blankingAutomate operationAssembly machinesAssembly lineElectromagnetic valve

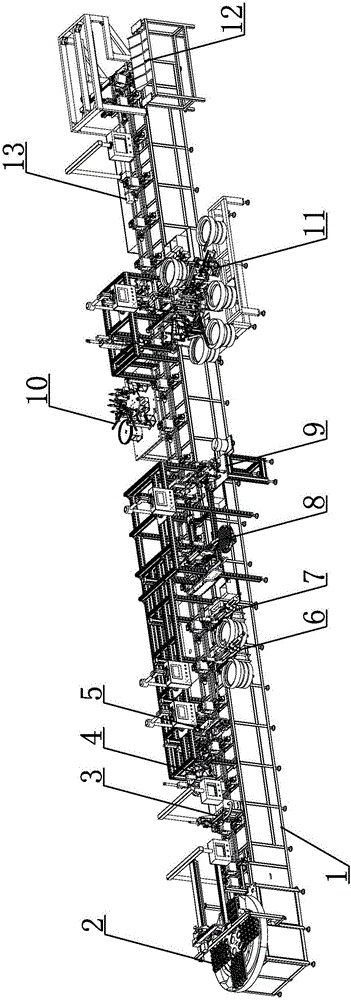

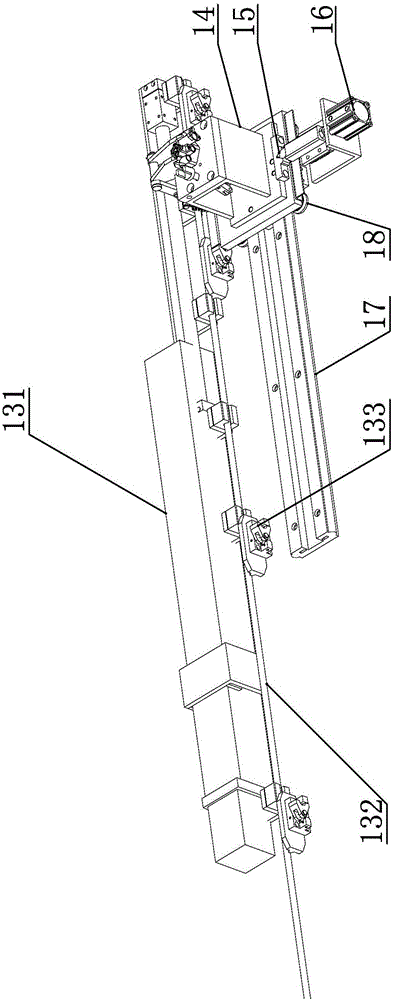

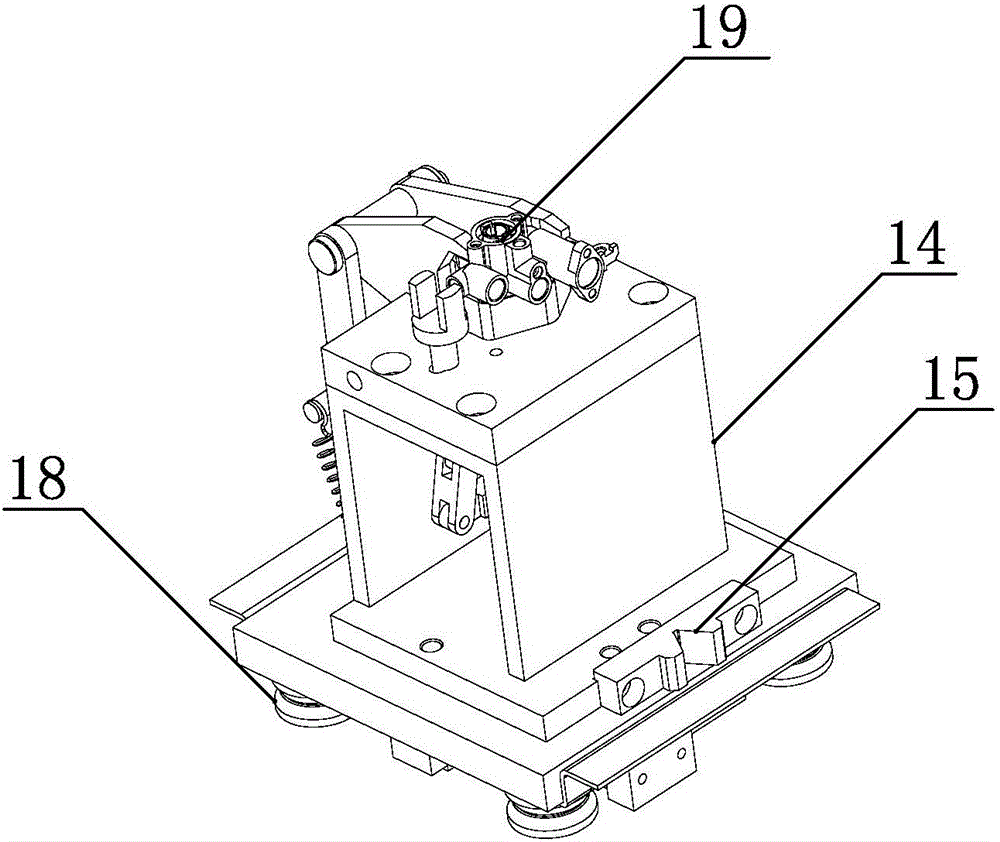

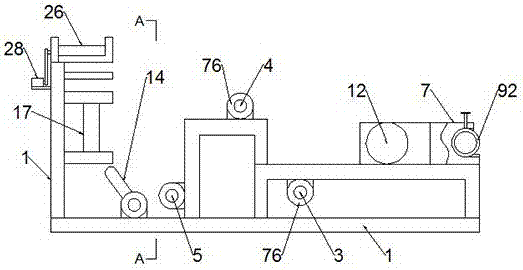

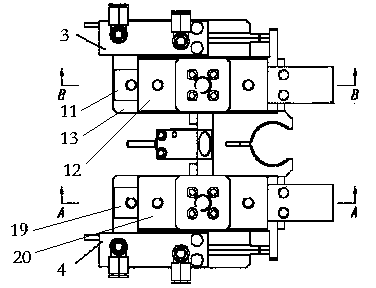

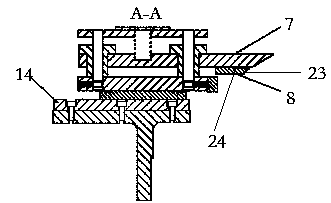

The invention discloses an assembly line for gas valves, relates to an industrial assembly line for assembling gas valves, and aims to provide a full-automatic valve assembly line capable of improving the assembling efficiency of the gas valves and promoting large-scale production. The assembly line for the gas valves comprises a rack, wherein a main slide is arranged on the rack, a main assembly line is mounted on the rack, a pallet capable of moving horizontally is arranged on the main assembly line and is used for fixing valve bodies of the valves, and following stations are sequentially arranged on the main assembly line: a valve body front feeding station, a body dust collection station, a closed direction-distinguishing and oiling station, a closed oiling and rotating station, a cock direction-distinguishing and assembling station, a small screw locking station, a large screw locking station, a short copper joint locking station, a long copper joint locking station, an electromagnetic valve assembling and locking station, a fine-adjustment valve core assembling and locking station, a valve core assembly assembling station, a switch axle assembly assembling station, a cover plate assembling and locking station and a finished product discharging station.

Owner:NANJING AIMEIQING INTELLIGENT TECH CO LTD

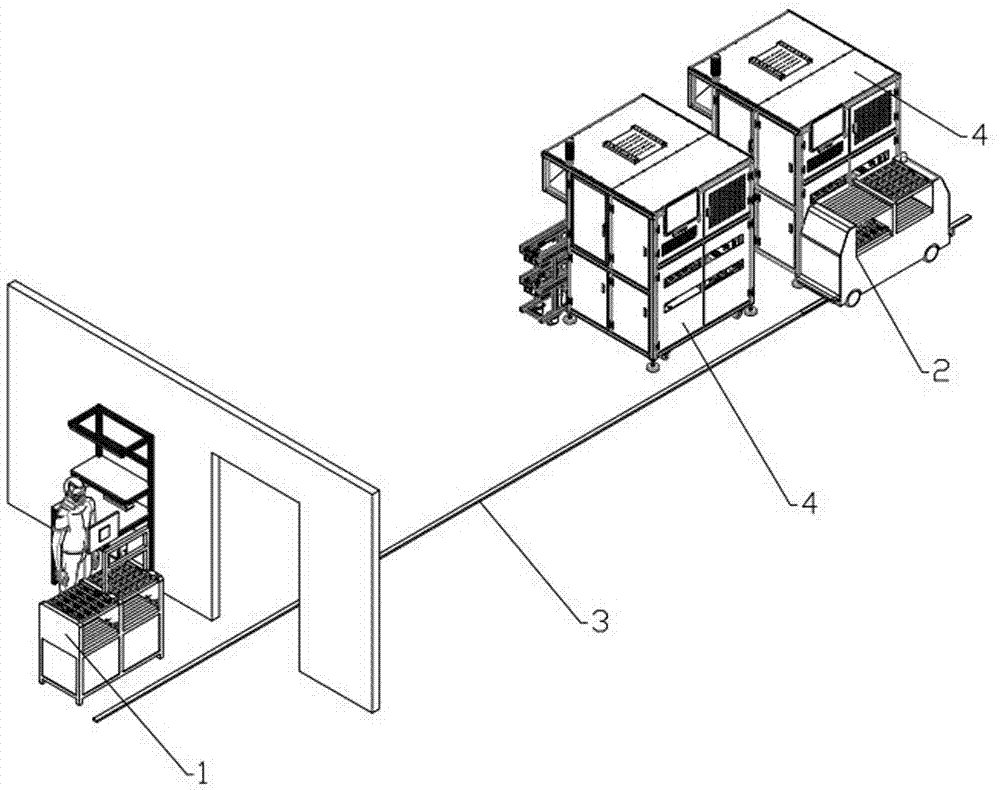

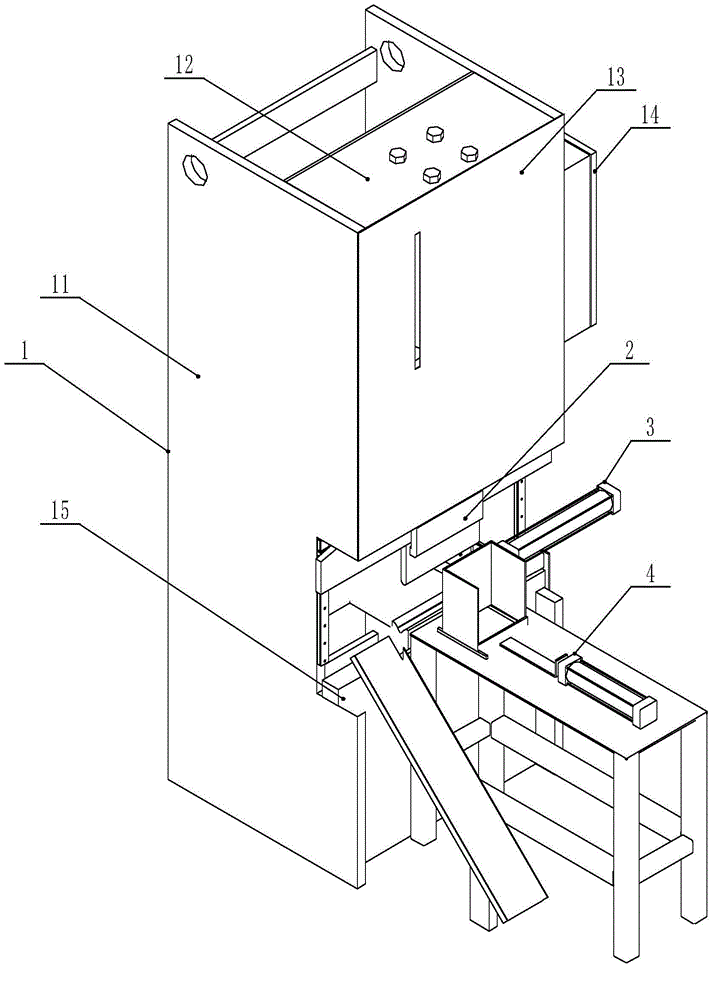

Automated material distributing system

PendingCN107336962ARealize automatic feeding processRealize blankingControl devices for conveyorsStorage devicesEngineeringMechanical engineering

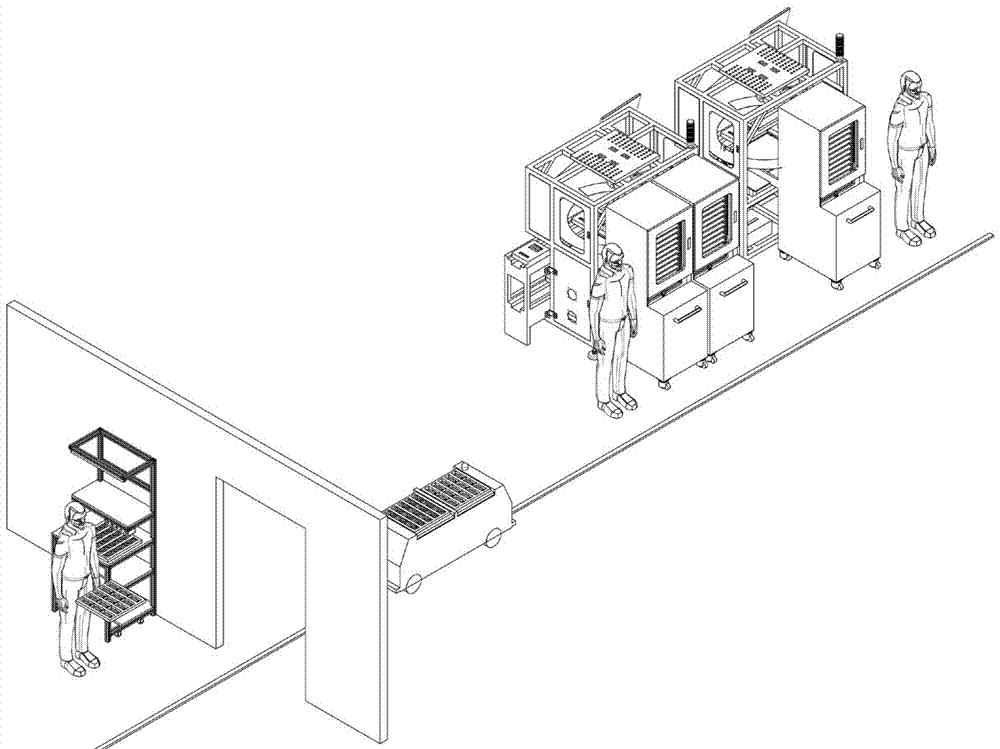

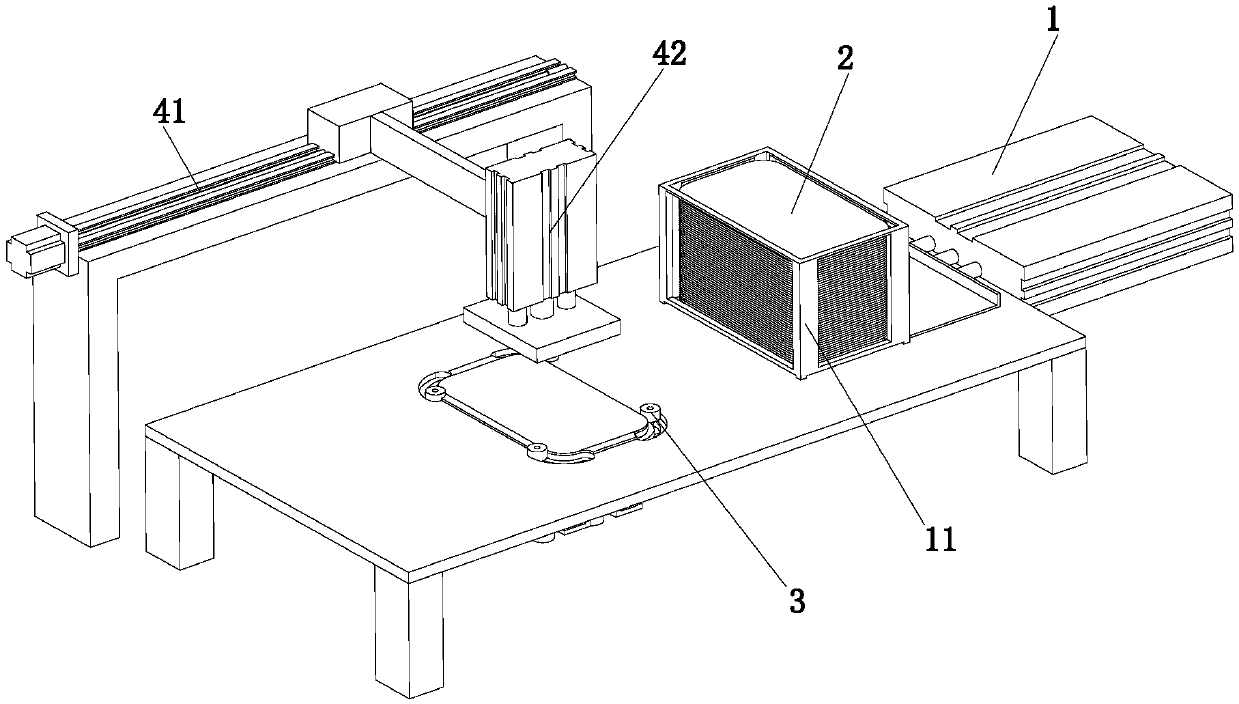

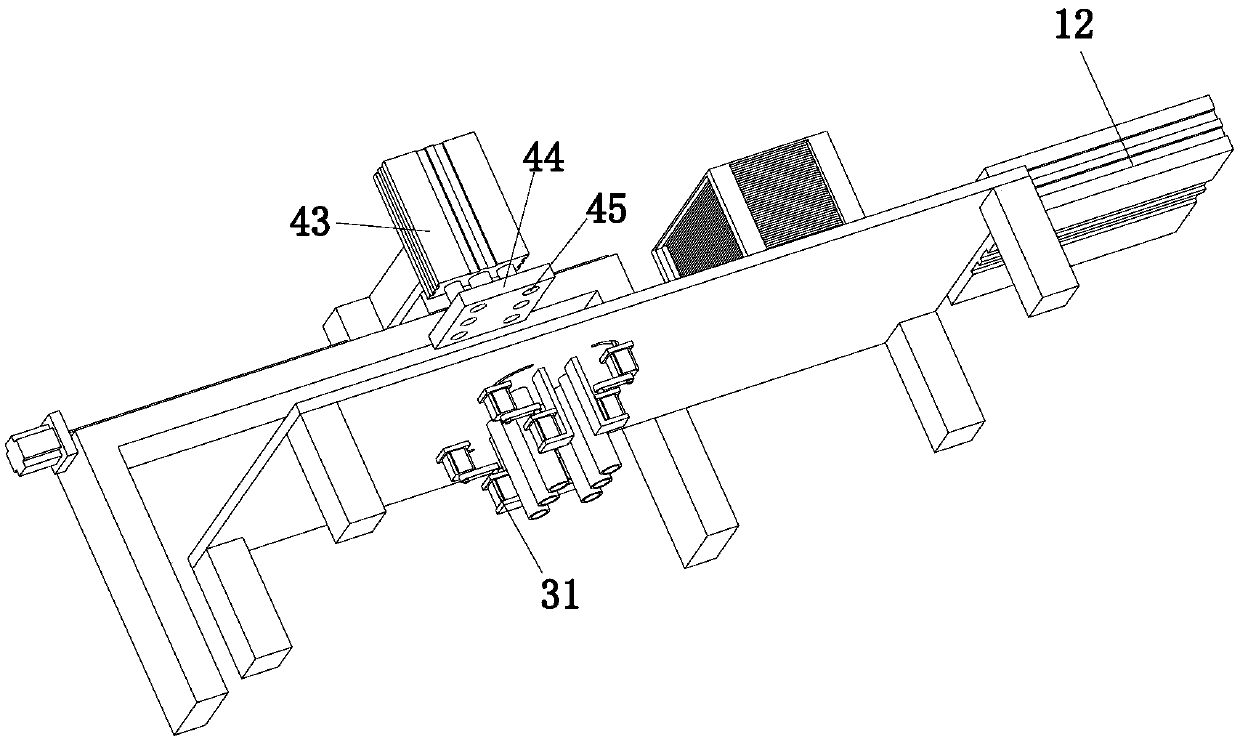

The invention provides an automated material distributing system. The automated material distributing system comprises an AGV inspection conveyor, an AGV trolley, an AGV trolley track, three-dimensional feeding mechanisms and a central controller, wherein the AGV inspection conveyor comprises multiple first horizontal conveying mechanisms, trays used for containing materials are arranged on the first horizontal conveying mechanisms, and the AGV trolley is provided with second horizontal conveying mechanisms which are connected with the first horizontal conveying mechanisms in a butted manner; and each three-dimensional feeding mechanism comprises a stock bin, a butting platform, a vertical lifting mechanism and a horizontal conveying mechanism, wherein the stock bin is used for enabling the trays to be stored in a stacked manner, the butting platform is fixed to the vertical lifting mechanism, the horizontal conveying mechanism is arranged at the bottom end of the butting platform, and the butting platform is driven by the vertical lifting mechanism and the horizontal conveying mechanism to enable the trays to move between the stock bin and the AGV trolley. According to the automated material distributing system, automatic feeding and discharging of materials can be achieved, and artificial burdening and material changing are reduced; and meanwhile, automatic conveying is achieved, artificial distribution is reduced, the tool efficiency can be effectively improved, and the labor cost is reduced.

Owner:SHENZHEN HYTERA COMM

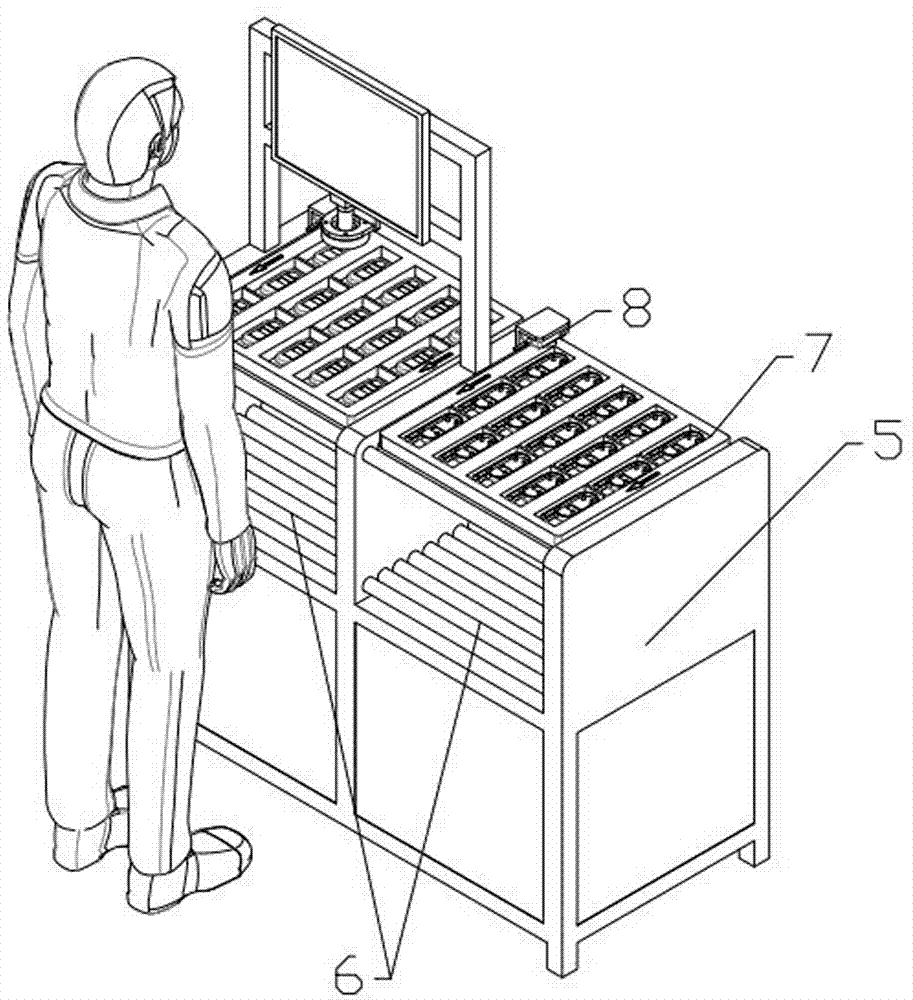

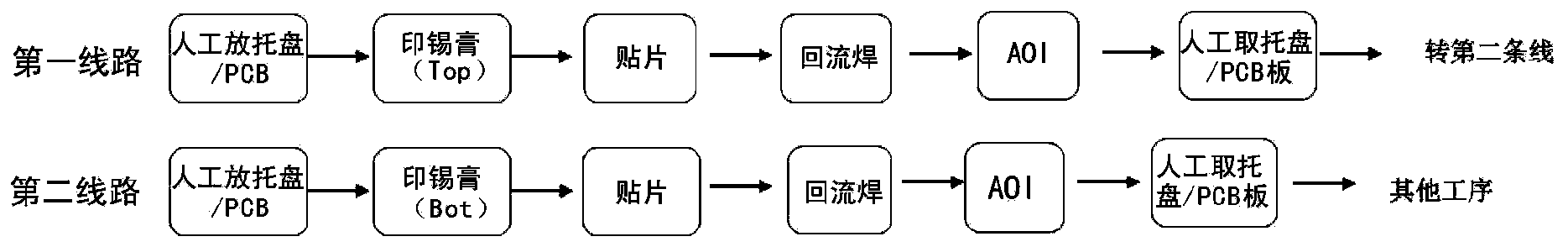

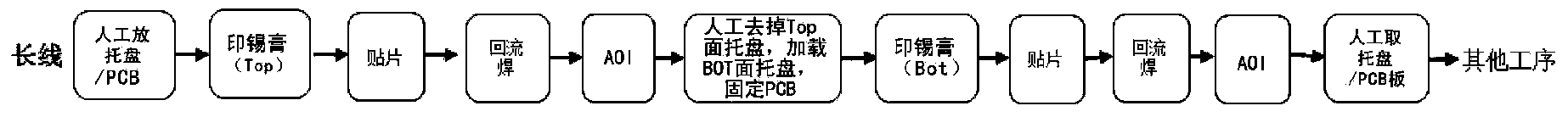

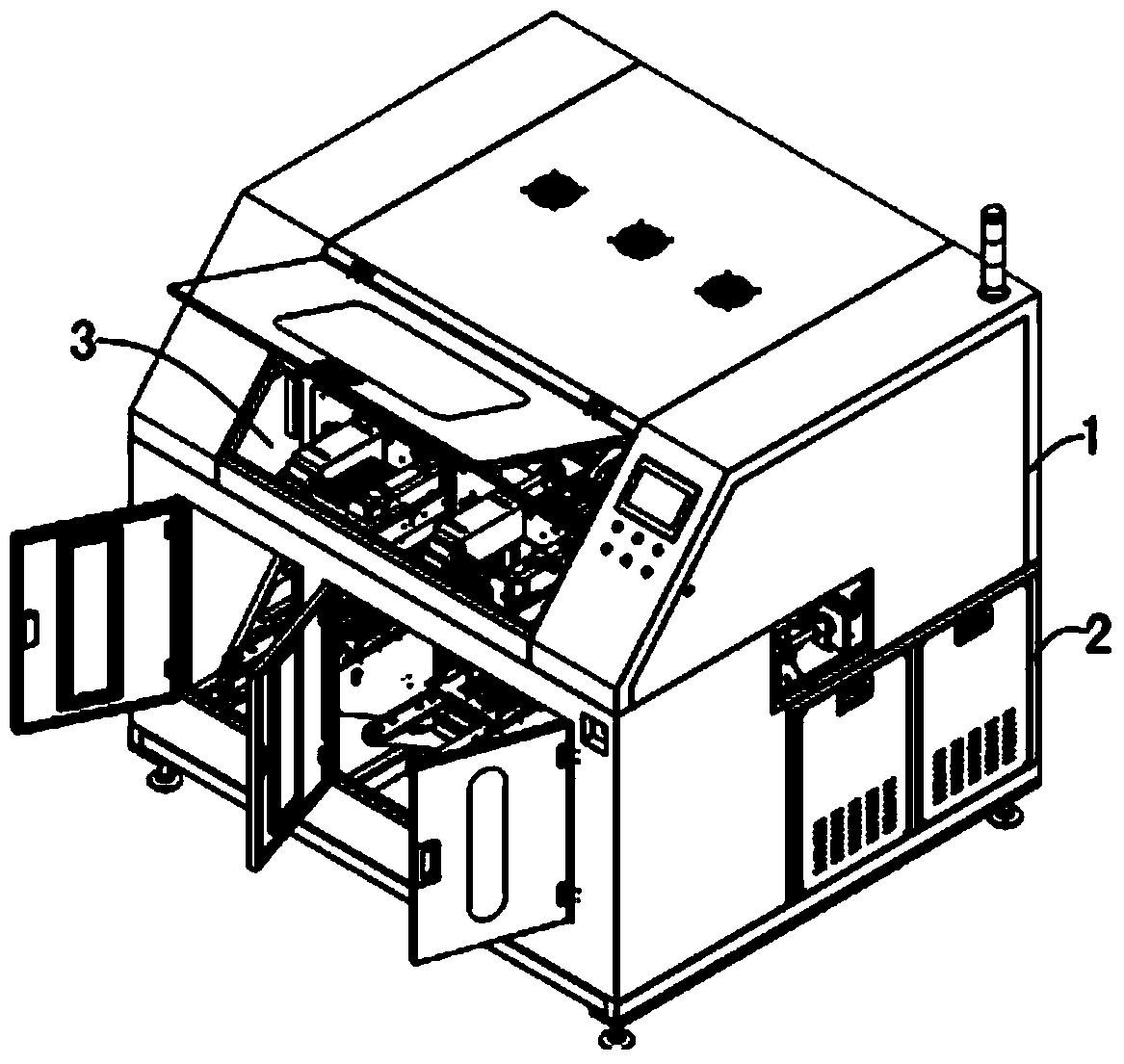

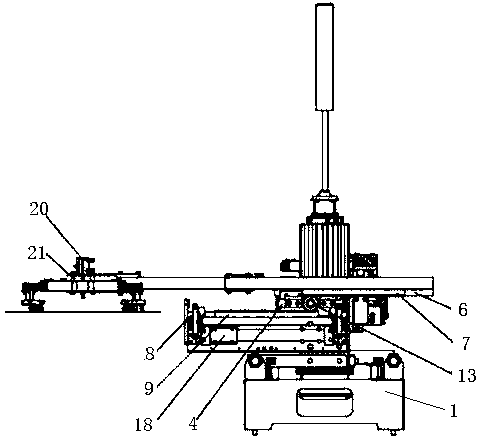

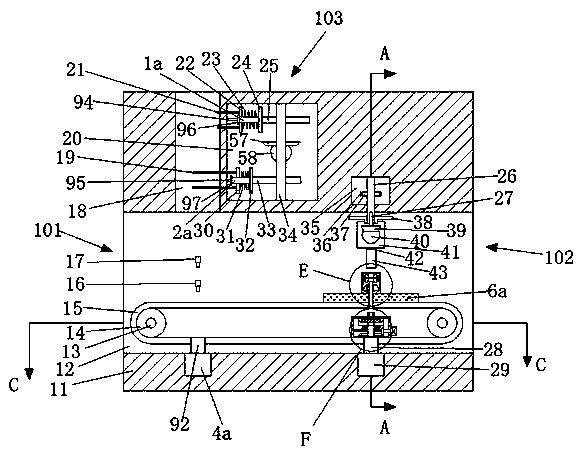

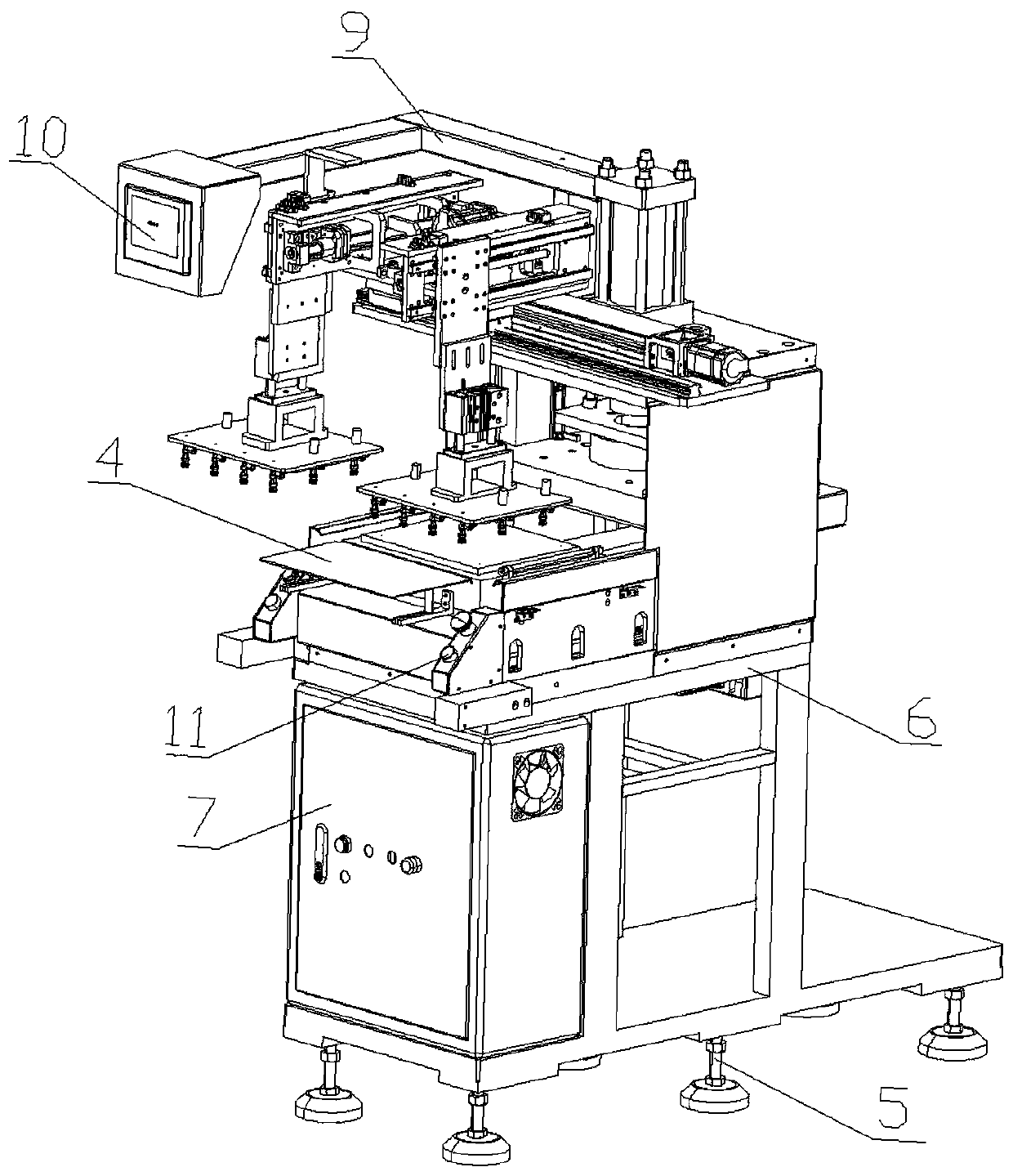

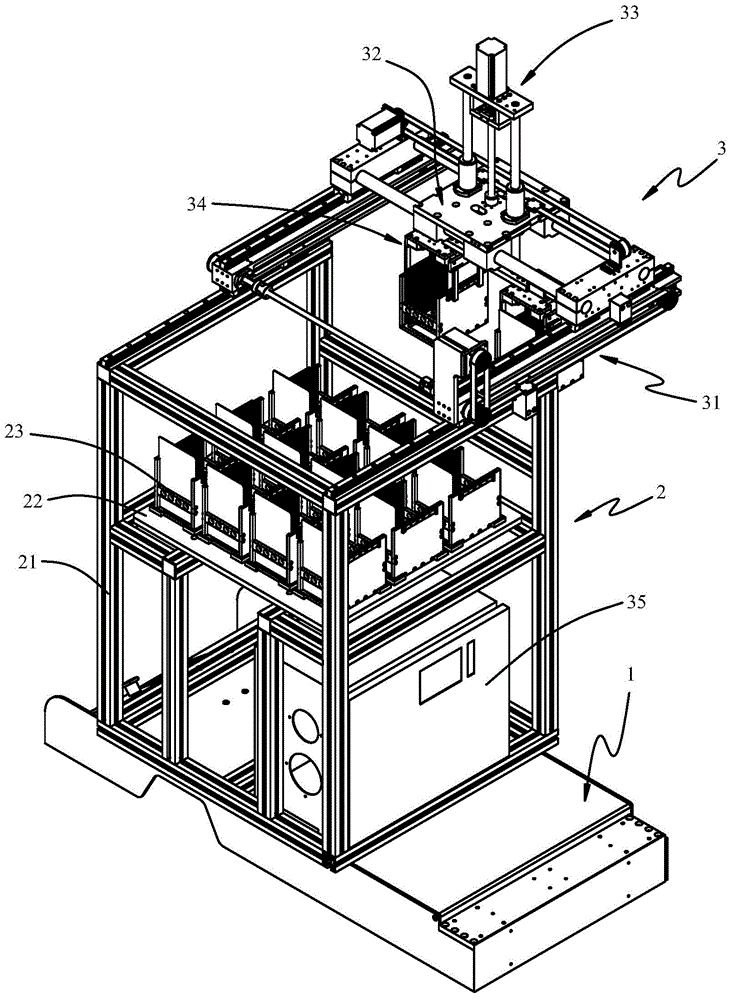

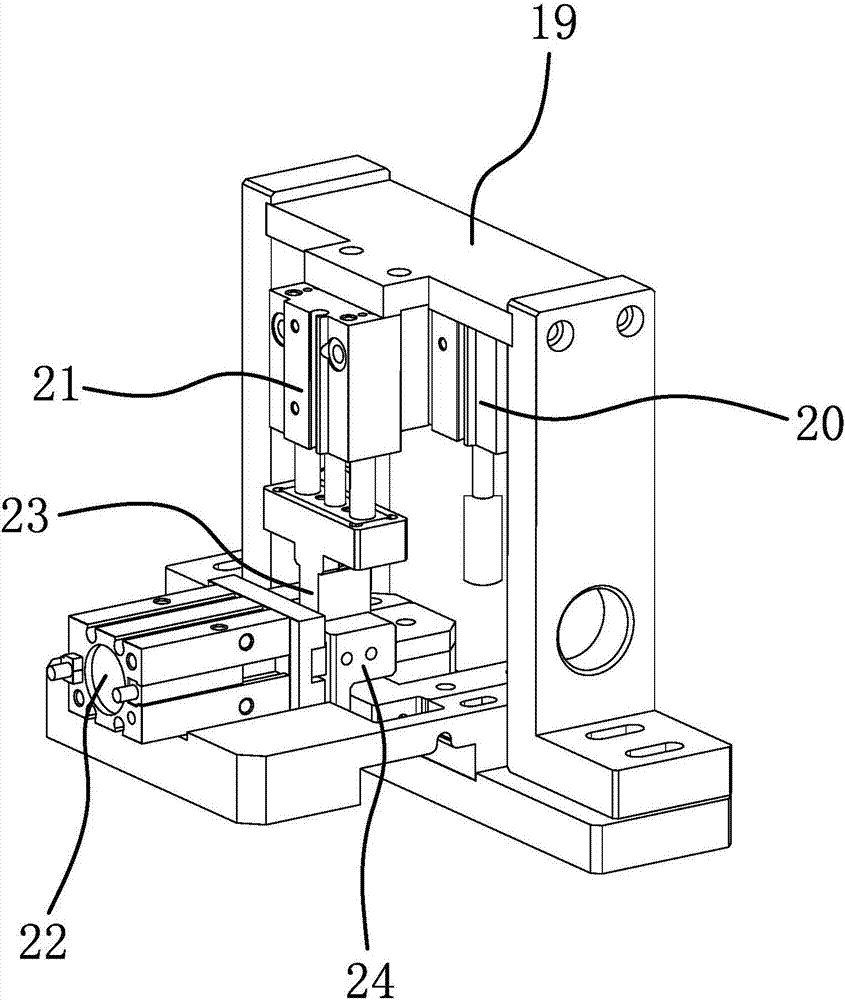

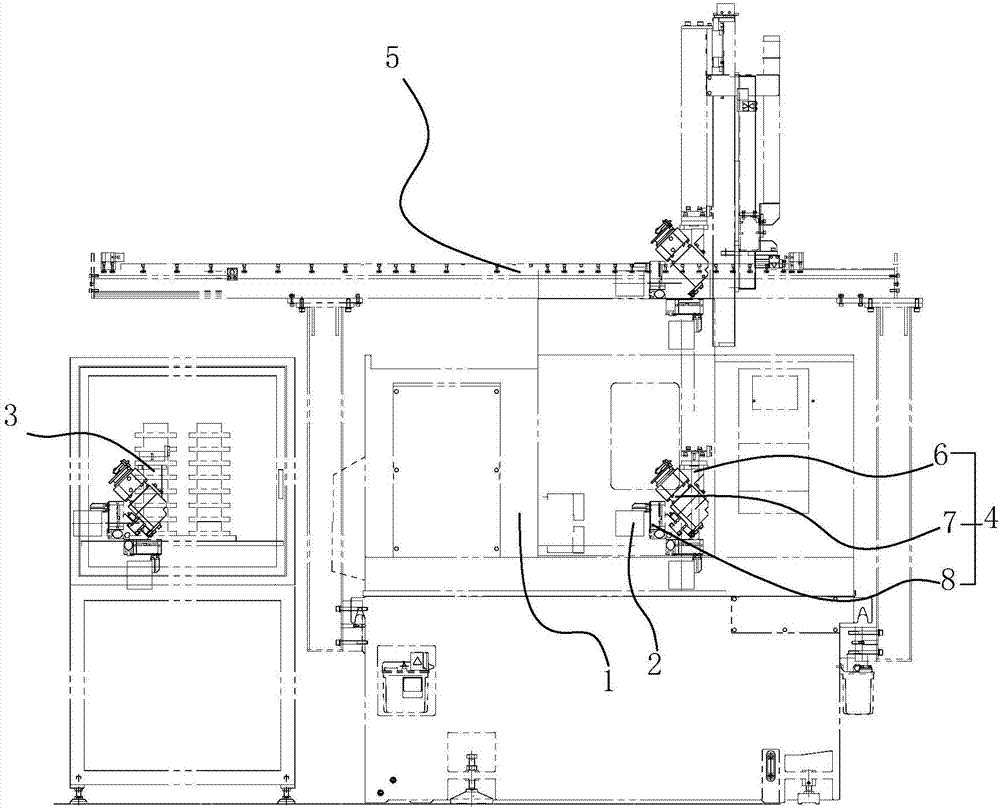

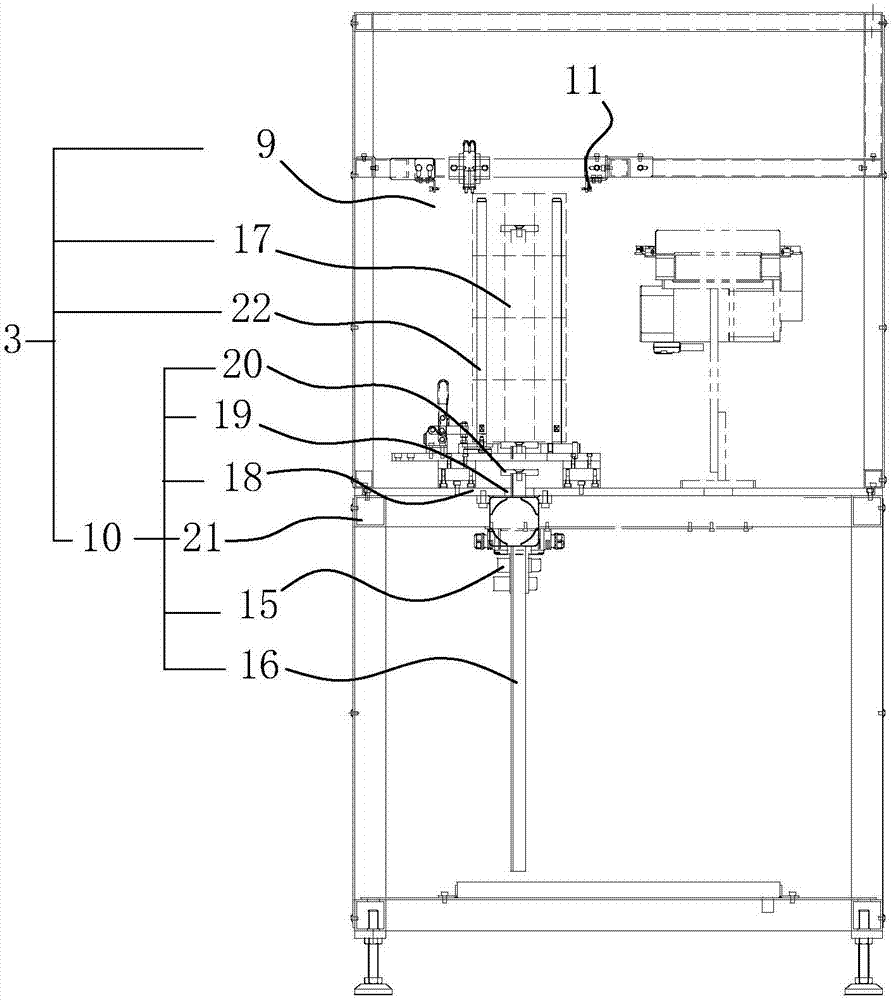

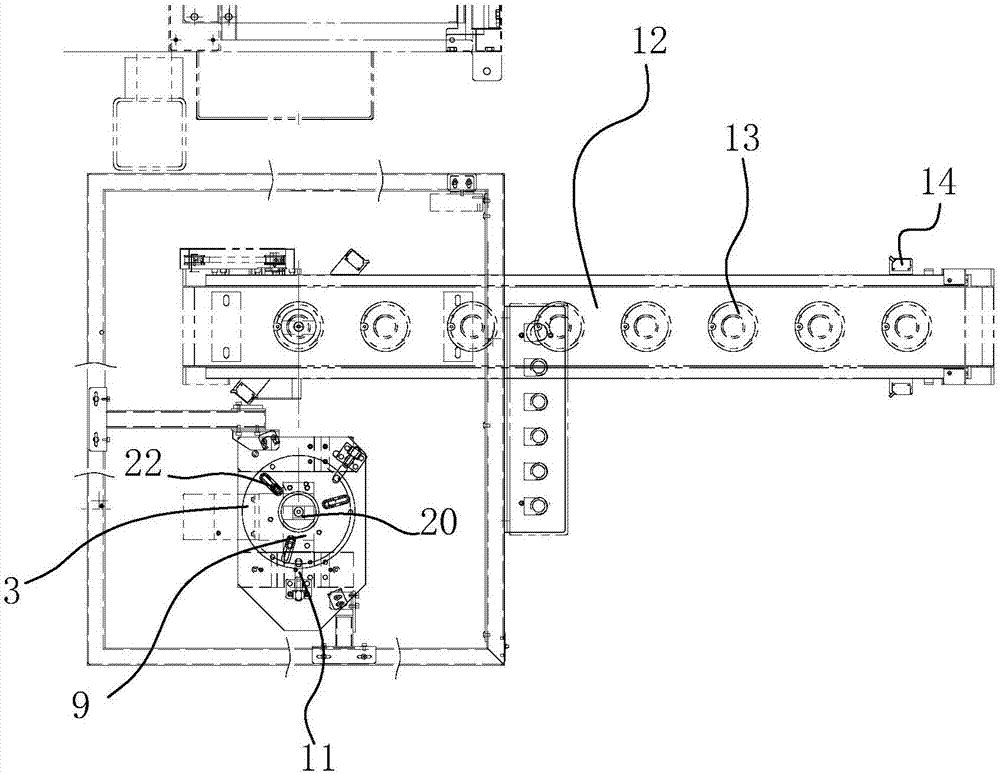

Automatic PCB detaching, overturning and pasting integrated machine

ActiveCN103763866AAchieve disassemblyImprove processing efficiencyPrinted circuit assemblingEngineeringMechanical engineering

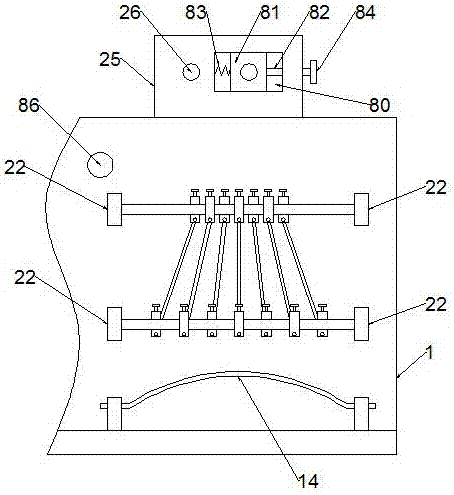

The invention discloses an automatic PCB detaching, overturning and pasting integrated machine which comprises an equipment body, a machine hood arranged on the equipment body in a sleeved mode and a rack for supporting the equipment body. The equipment body comprises a conveying mechanism, a large gantry mechanism, small gantry mechanisms and automatic feeding and discharging mechanisms. At least two working stations are arranged on the large gantry mechanism and the small gantry mechanisms are arranged on one side of the large gantry mechanism in parallel. The small gantry mechanisms and the large gantry mechanism are matched for automatically detaching, overturning and pasting a PCB again. The automatic feeding and discharging mechanisms are arranged on one side below the conveying mechanism in parallel and used for conveying cover plates or carriers to all the working stations. According to the automatic PCB detaching, overturning and pasting integrated machine, unloading of an old carrier and cover plates, overturning of the PCB and repeated pasting of the PCB and a new carrier are performed automatically and the machining efficiency of the PCB is improved. Meanwhile, labor force and labor cost are saved, cost is reduced and in addition, automatic feeding and discharging are achieved, especially materials can be automatically replaced in a non-stopping state.

Owner:SUZHOU INTELLIGENT AUTOMATION EQUIP CO LTD

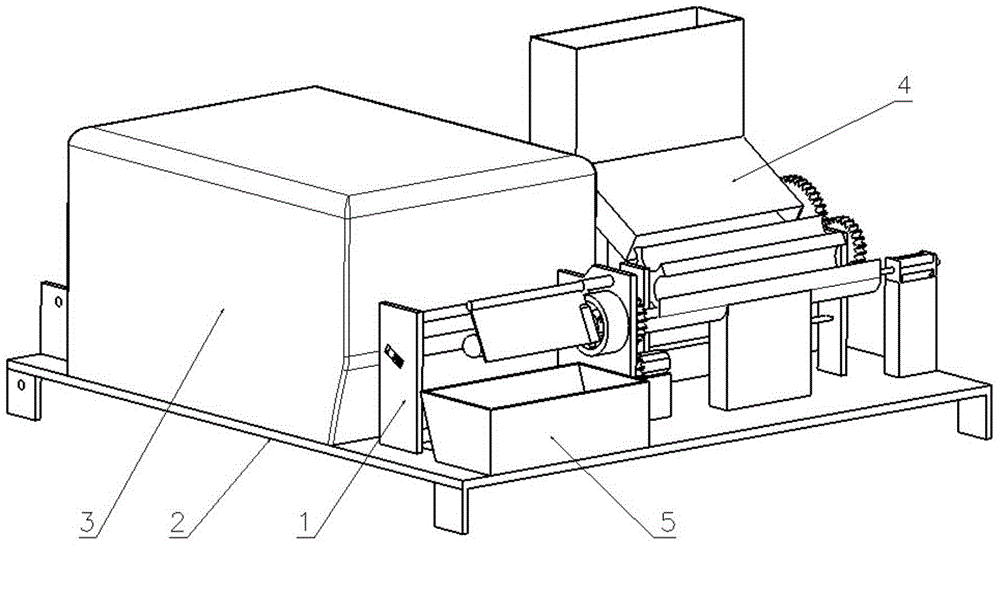

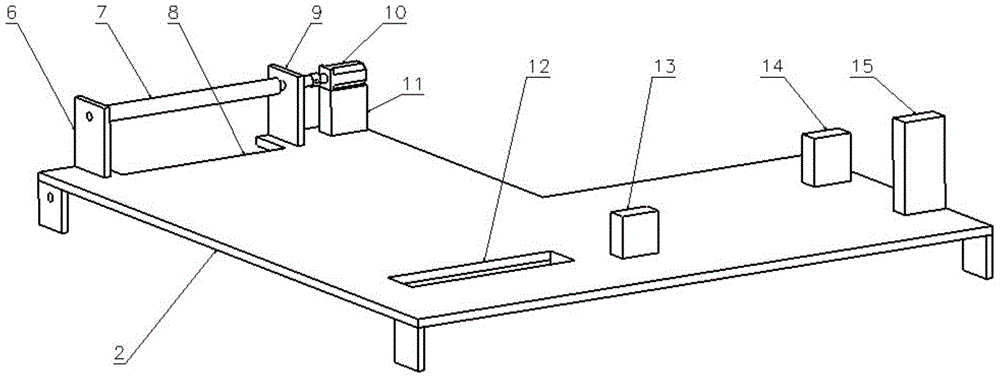

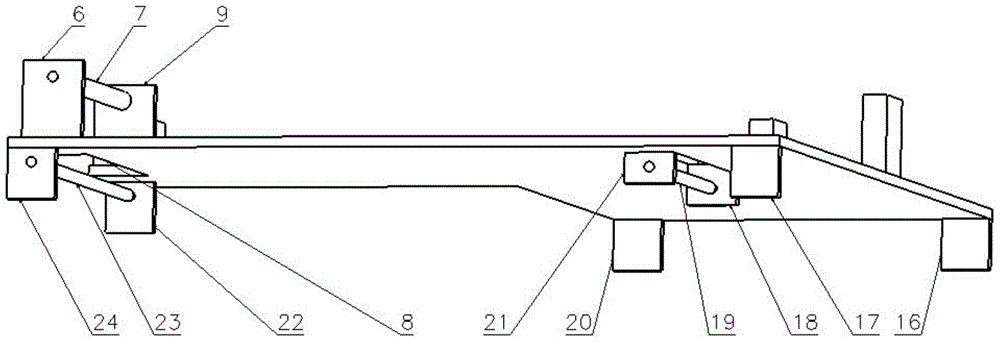

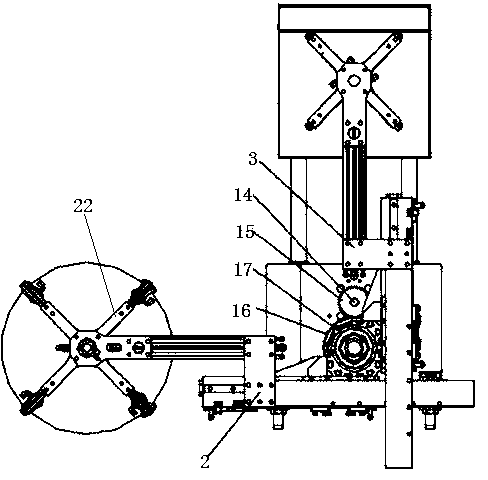

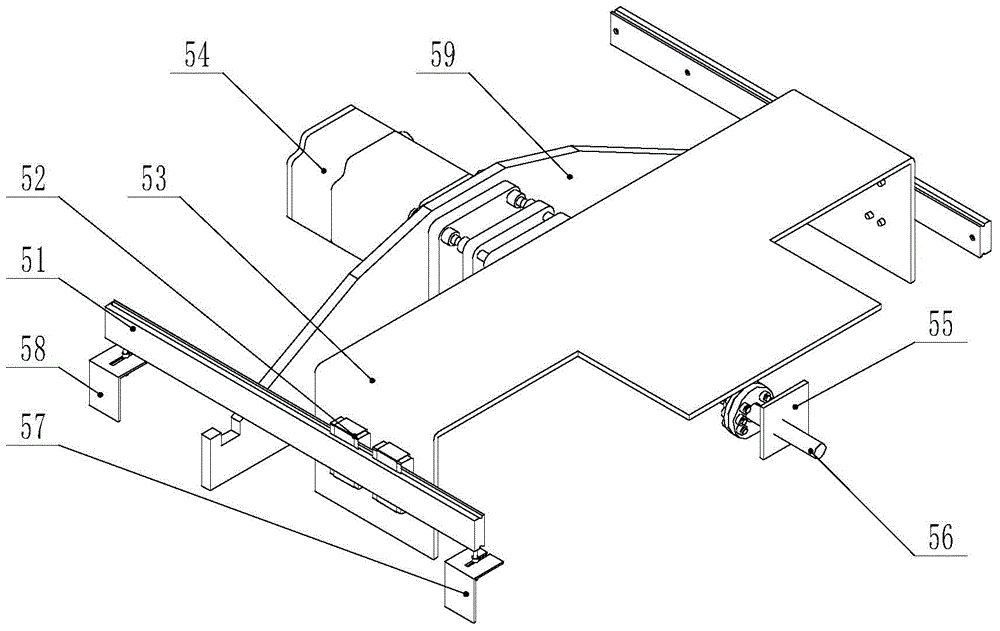

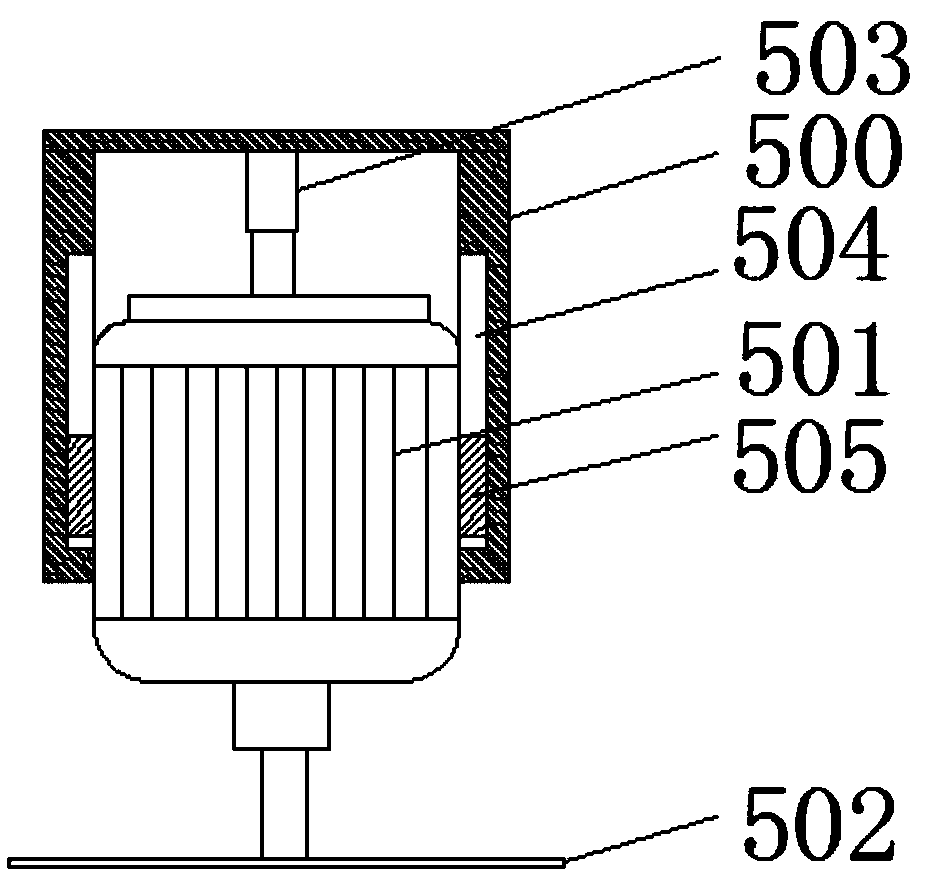

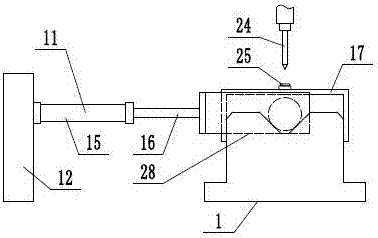

Test tube labeling machine with capabilities of automatic feeding and blanking

InactiveCN104691880ARealize automatic feeding processRealize blankingLabelling machinesLabelling elongated objectsDrive motorEngineering

The invention belongs to the field of labeling, relates to a test tube labeling machine with the capabilities of automatic feeding and blanking and aims at solving the problem of low efficiency of a labeling machine in the prior art. The test tube labeling machine mainly comprises a labeling mechanism, a bottom plate, a feeding mechanism and a blanking cabin, wherein the labeling mechanism consists of a turntable mechanism, a label pressing mechanism, a rotation mechanism and a rack assembly; the turntable mechanism consists of a turntable, a gear ring, a turntable driving gear, a turntable driving motor and a driving motor support seat; the feeding mechanism consists of a plate pushing mechanism, a rotary wheel mechanism and a feeding cabin mechanism which are fixed to the bottom plate sequentially. According to the test tube labeling machine, automatic feeding and blanking of a test tube can be realized, the labeling efficiency can be improved, test tubes with different diameters can be clamped, the test tubes stored in a feeding cabin can successfully enter the rotary wheel mechanism without the blockage phenomenon by adopting a cam mechanism, and the test tubes in a feeding cabin can singly and orderly enter a U-shaped groove for labeling by adopting the rotary wheel mechanism, the structure is simple, the debugging is convenient, the cost is low and the operation is convenient.

Owner:JILIN UNIV

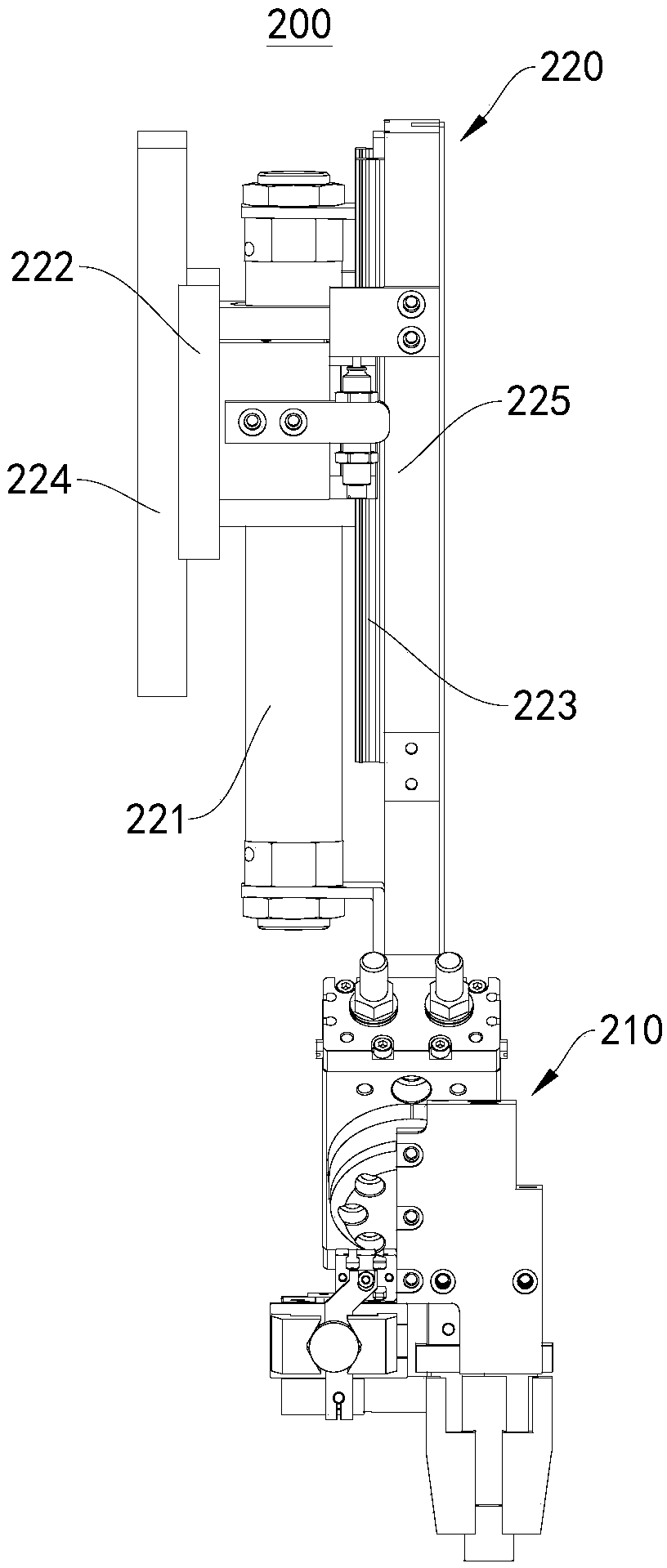

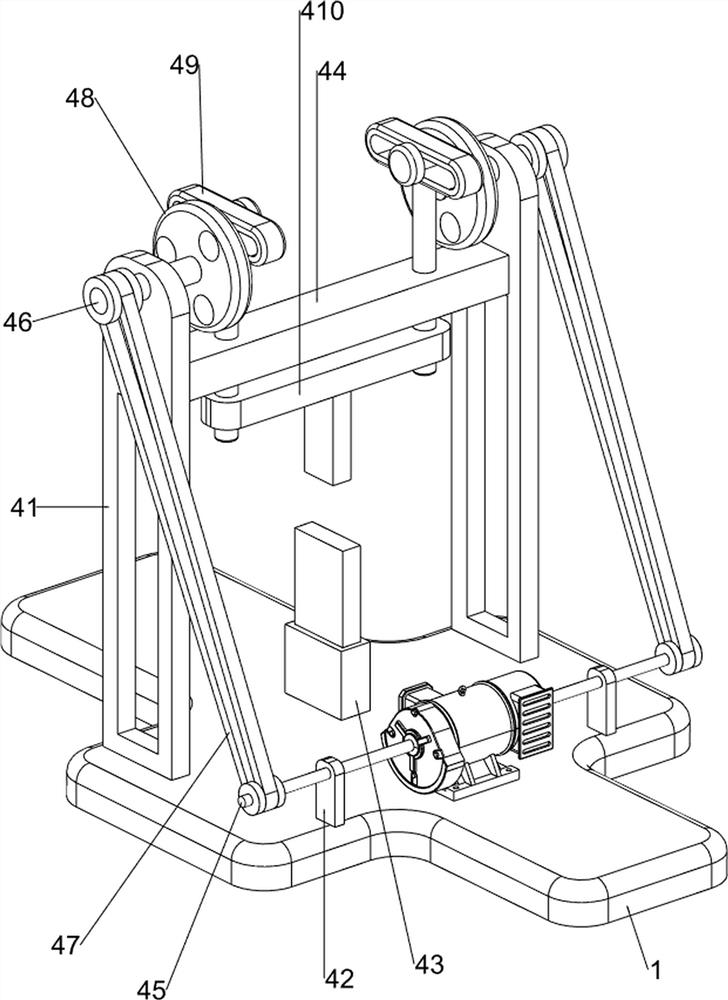

Mechanical arm

The invention discloses a mechanical arm. The mechanical arm comprises a base, a driving device, a rotating mechanism, a telescopic mechanism and a material taking device, wherein the driving device, the rotating mechanism, the telescopic mechanism and the material taking device are arranged on the base. The driving device is connected with the rotating mechanism and used for driving the rotating mechanism to rotate. The telescopic mechanism is connected with the rotating mechanism and driven by the rotating mechanism to rotate. The telescopic mechanism is connected with the material taking device. The telescopic mechanism comprises at least one mechanical arm body, sliding boards and mechanical arm installation bases connected with the rotating mechanism, wherein the sliding boards correspond to the mechanical arm bodies one to one. The mechanism arm bodies are connected with the mechanical arm installation bases through the sliding boards. The sliding boards are controlled to slide by a drive part. The mechanical arm is capable of automatically taking and placing materials, easy and convenient to operate, high in production efficiency, wide in machining range and large in telescopic range.

Owner:GUANGZHOU DAZHENG ADVANCED MATERIAL TECH CO LTD

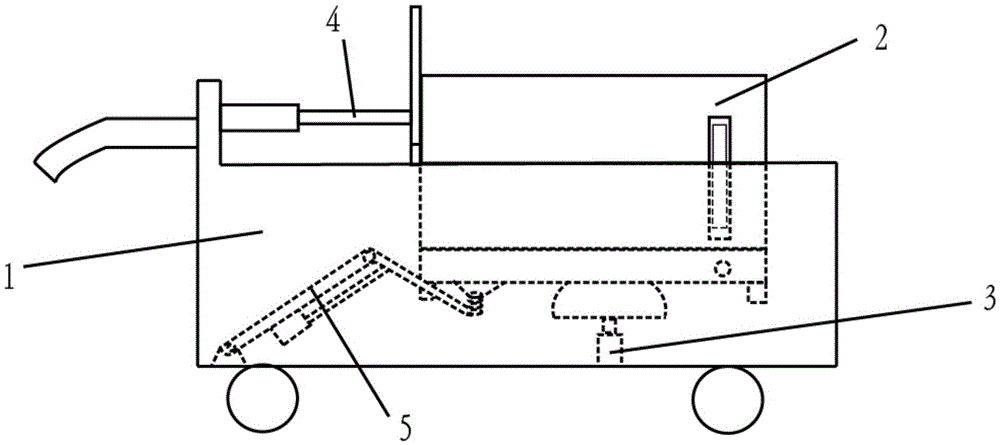

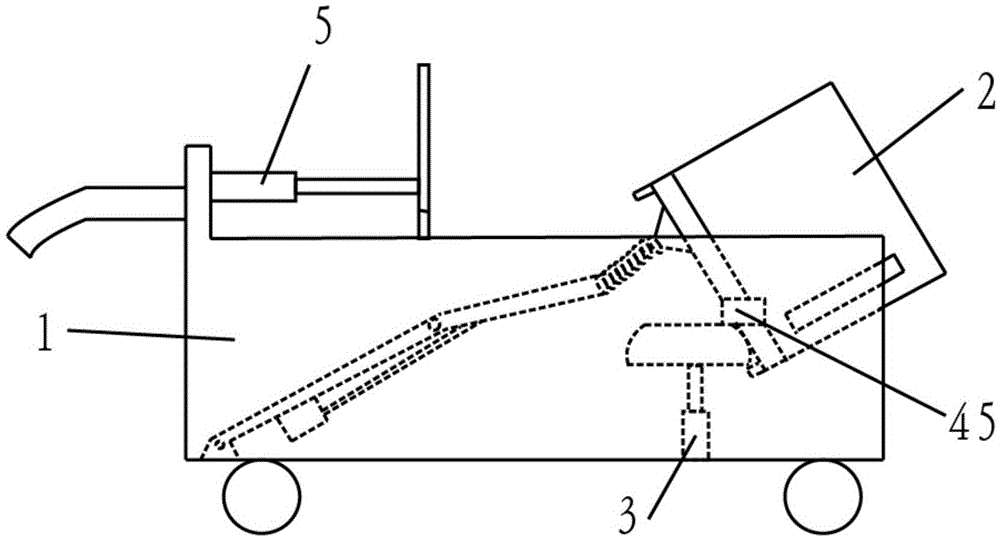

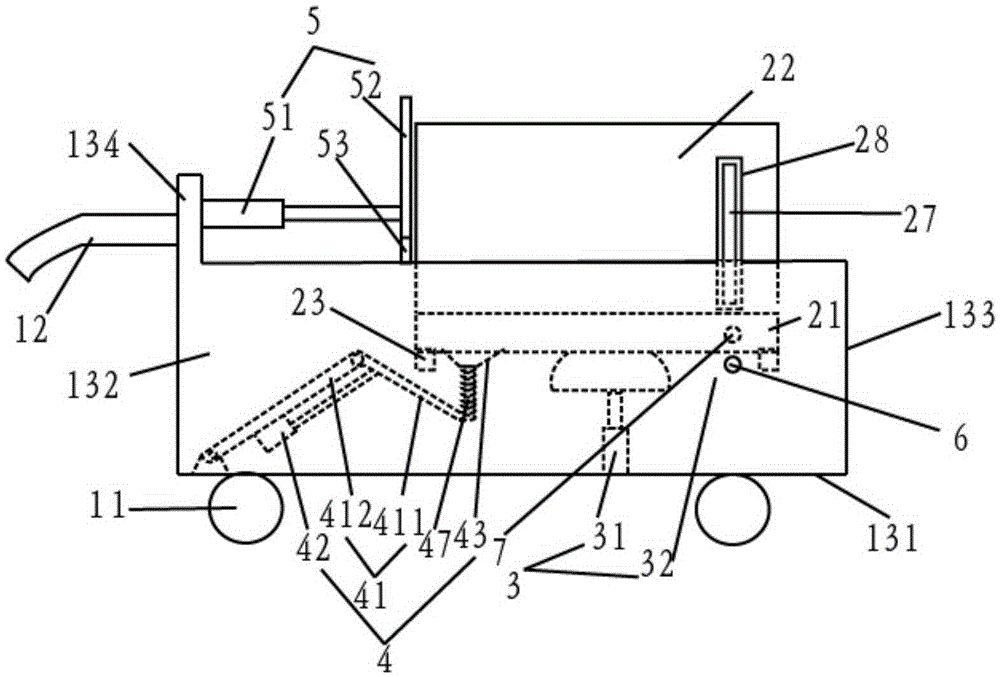

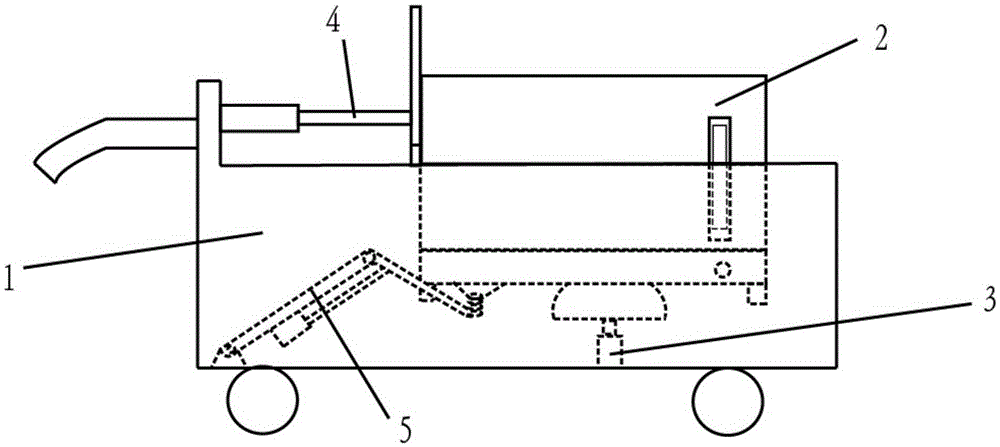

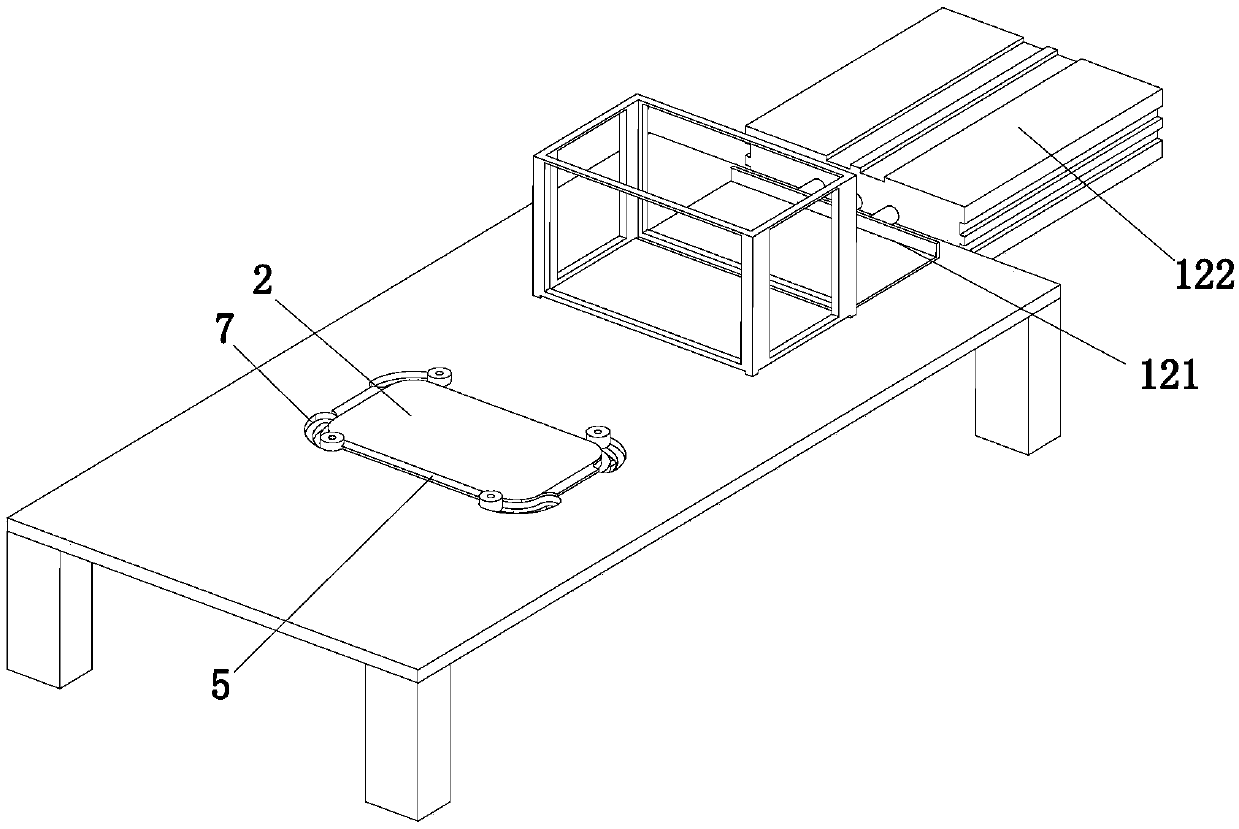

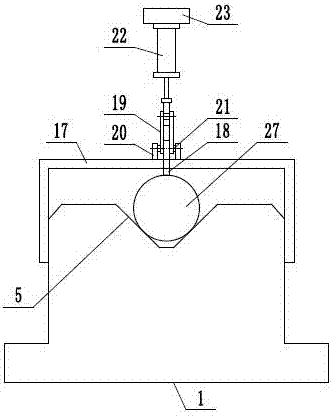

Tray box transfer device with pushing-out and discharging functions

InactiveCN105460528ARealize blankingHinder progressConveyor partsMechanical conveyorsMechanical engineeringEngineering

The invention discloses a tray box transfer device with the pushing-out and discharging functions. The tray box transfer device comprises a transfer trolley and a tray box. The tray box is arranged in an inner cavity of the transfer trolley. The transfer device further comprises a lifting mechanism and a pushing-out mechanism. The lifting mechanism comprises a lifting oil cylinder and a hemispherical-table-shaped supporting board with the top smaller than the bottom. The pushing-out mechanism comprises a pushing oil cylinder, the cylinder body end of the pushing oil cylinder is fixed to the inner wall of a rear baffle, and the piston rod end of the pushing oil cylinder extends forwards and can push the tray box. The tray box comprises a tray frame and a side board assembly. The side board assembly comprises a left side board, a right side board, a rear side board and a front side board assembly. A structure with the open top, the closed periphery and the closed bottom can be jointly defined by the left side board, the right side board, the rear side board, the front side board assembly and the tray frame. The tray box transfer device has the advantages of being simple in structure, convenient to operate and capable of transferring materials and unloading the materials as well.

Owner:全椒县富民优质粮种植专业合作社

Efficient production equipment of automatic loading/unloading workpiece end surface

ActiveCN105538141AAchieve grindingIncrease productivityGrinding feedersPlane surface grinding machinesEngineeringMechanical engineering

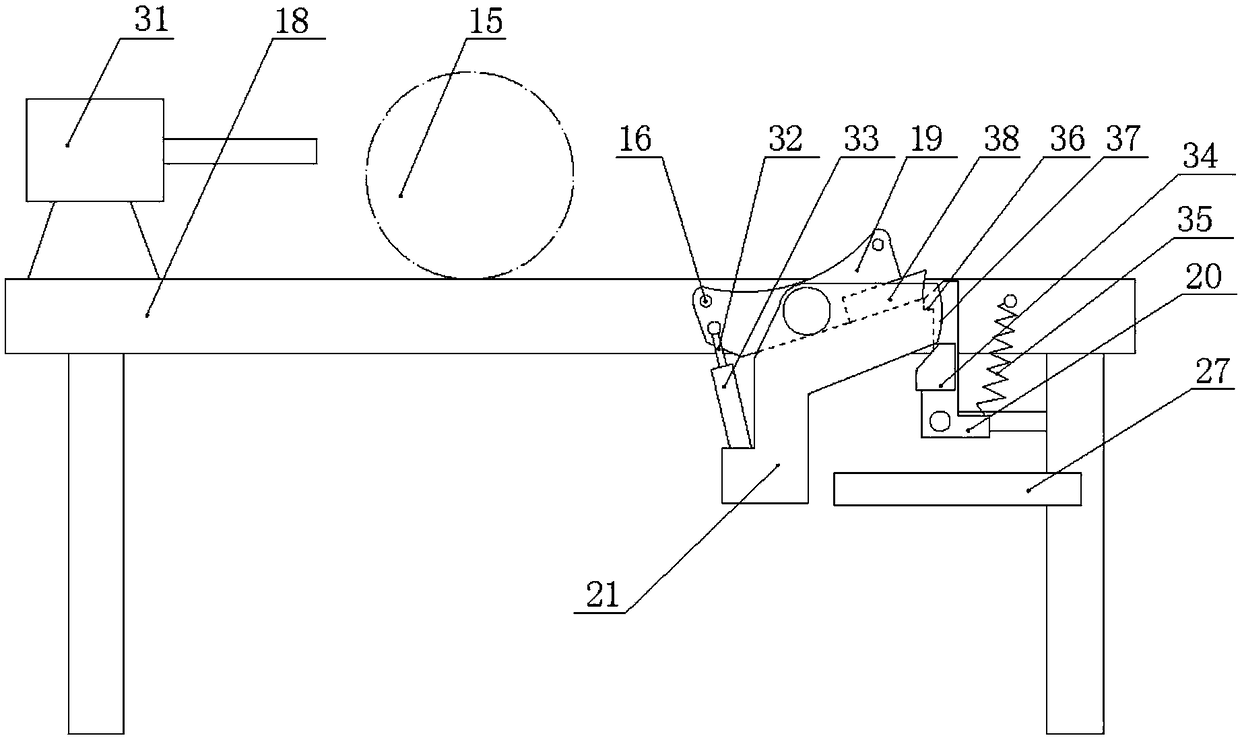

The invention discloses efficient production equipment of an automatic loading / unloading workpiece end surface. The equipment comprises a collecting container, a polishing table, a loading table, a pushing mechanism, a driving mechanism, an ejecting mechanism and a polishing mechanism; the collecting container, the polishing table, the loading table and the pushing mechanism are arranged in sequence in the horizontal direction; a loading channel and an unloading channel are formed in the polishing table; extending directions of the loading channel and the unloading channel are on the same straight line; a clamping groove is formed in the polishing table between the loading channel and the unloading channel; in the extending direction of the loading channel, a baffle plate and a conveying mechanism are respectively arranged on two sides of the loading table; the ejecting mechanism is positioned below the polishing table for ejecting a workpiece in the clamping groove out of the clamping groove; the pushing mechanism is used for pushing the workpiece on the loading table into the clamping groove along the loading channel and pushing the workpiece ejected out of the clamping groove into the collecting container; and the polishing mechanism is positioned above the polishing table, and is driven by the driving mechanism to lift up and down. The equipment greatly improves the workpiece productivity.

Owner:TIANCHANG CYLINDER HEAD

Full-automatic numerical control bending machine

ActiveCN104307944ARealize automatic feeding processAchieve positioningShaping toolsMetal-working feeding devicesNumerical controlUltimate tensile strength

The invention discloses a full-automatic numerical control bending machine and belongs to the field of engineering machines. The full-automatic numerical control bending machine mainly comprises a rack, wherein a conveying device, a bending device and a discharging device which are mutually matched are arranged at the bottom part of the rack; the conveying device comprises a conveying platform, a conveying air cylinder is arranged on the conveying platform and the conveying air cylinder is connected with a conveying push plate; the bending device comprises an upper working platform, a lower working platform and a pressure cylinder, the upper working platform is connected with a piston of the pressure cylinder, the lower working platform is correspondingly connected with the conveying platform, the pressure cylinder and an upper die are arranged on the upper working platform, and a lower die matched with the upper die is arranged on the lower working platform; the discharging device comprises a discharging air cylinder and a discharging slide way. The full-automatic numerical control bending machine has the advantages that the structure is simple, the efficiency is high, the energy consumption is low, the automatic charging, positioning, bending and discharging of parts are realized, the labor intensity of workers and the production cost are reduced, and safety accidents are prevented from occurring. The full-automatic numerical control bending machine is mainly used for bending parts.

Owner:SHANDONG LINGONG CONSTR MACHINERY

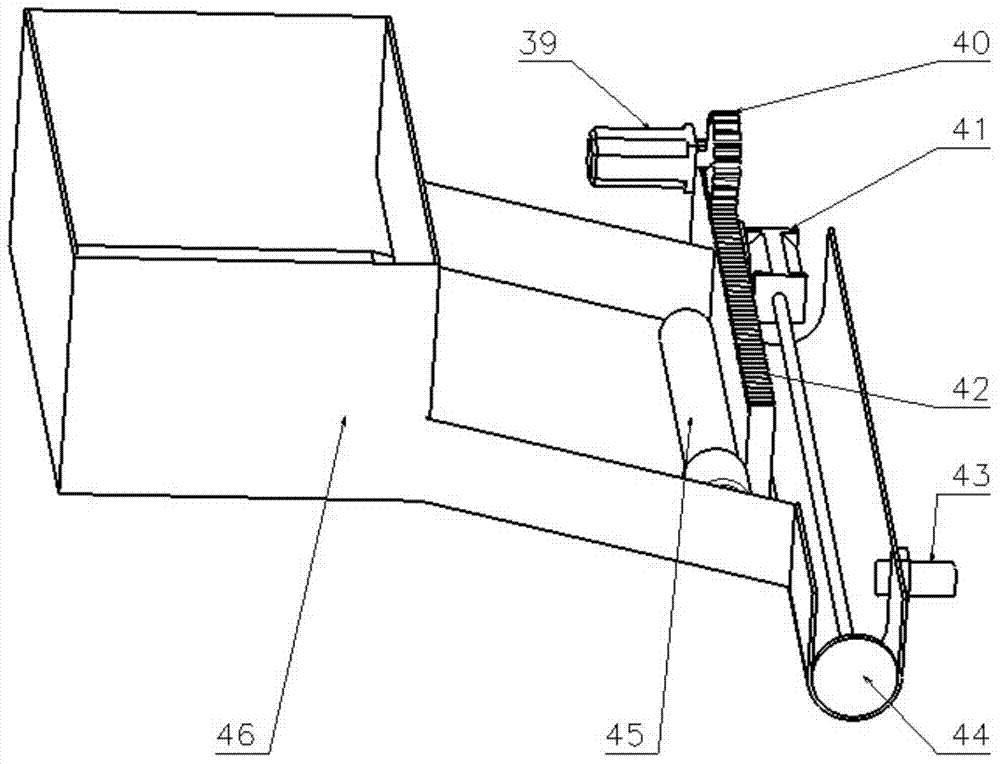

Device for grinding outer surface of circular plastic circular pipe

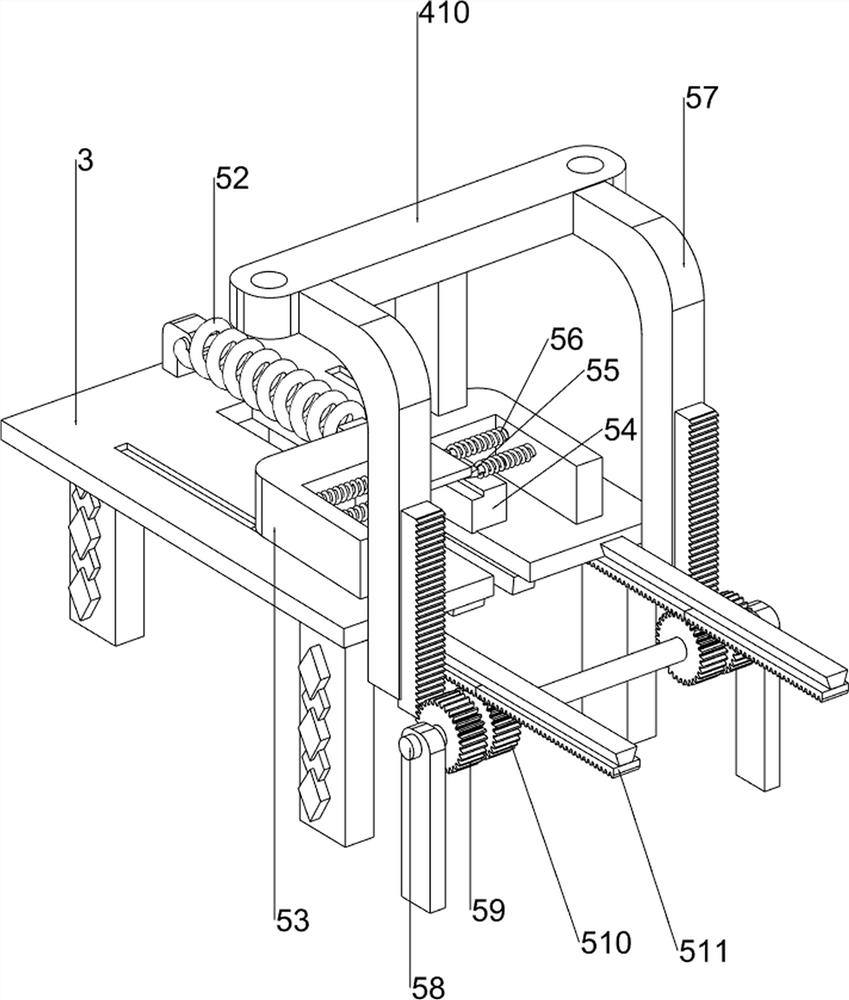

InactiveCN110722427ARealize blankingAchieve clampingEdge grinding machinesGrinding drivesGear wheelEngineering

The invention discloses a device for grinding the outer surface of a circular plastic circular pipe. The device includes a machine frame, and the machine frame is internally provided with a conveyingdevice; the conveying device includes a conveying cavity formed in the lower end of the machine frame in a left-right penetrating mode, conveying rods in left-right symmetry are rotatably arranged between the front wall and the rear wall of the conveying cavity, and conveying gears attached to the front wall and the rear wall of the conveying cavity are fixedly arranged at the front ends and the rear ends of the conveying rods on the two sides; roller slideways are fixedly arranged on the front wall and the rear wall of the conveying cavity, rollers are arranged in the roller slideways in a rolling mode, and the outer circular surfaces of the conveying gears on the two sides mesh with the rollers; and the rollers are provided with part placing plates, sliding of the part placing plates isdriven by rolling of the rollers, a grinding device body is arranged on the upper wall of the conveying cavity, and a grinding gear box is arranged in the grinding device body. The device enables paper cutting and paper feeding to be powered by one power source and to carry out intermittent movements synchronously, the accuracy of paper cutting is ensured, and cut waste paper can be recycled and reused, so that waste of resources is avoided.

Owner:YONGKANG BENYUAN PLASTIC PROD CO LTD

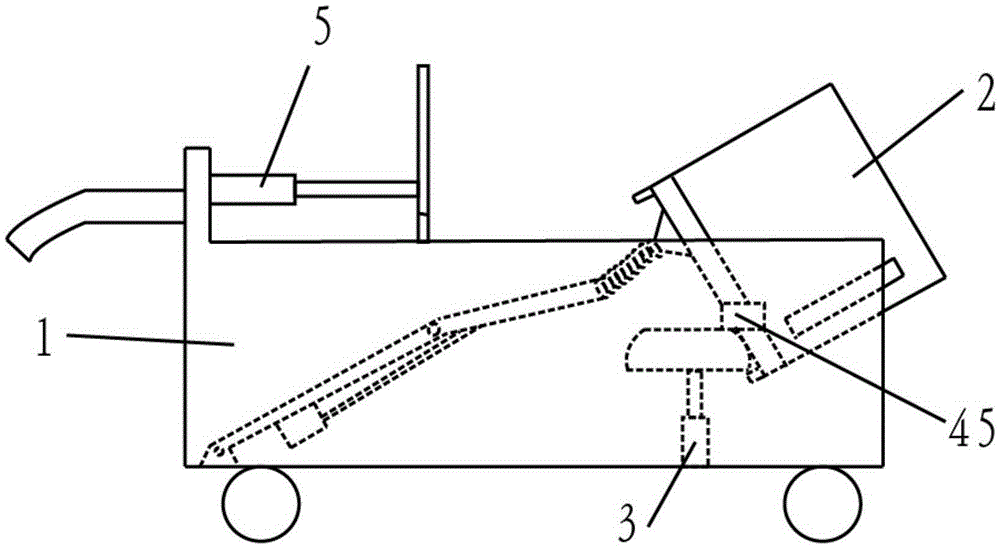

Discharge mechanism of pallet box transfer device

The invention discloses a discharge mechanism of a pallet box transfer device. The discharge mechanism comprises a transfer body, an elevating mechanism arranged on the transfer body, an overturning mechanism and an ejecting mechanism. A fixed end of the elevating mechanism is arranged on the bottom wall of a cavity of the transfer body. An elevating end of the elevating mechanism extends upwardly and is connected with the bottom of a pallet box. A connecting end of the overturning mechanism is hinged onto the bottom wall of the cavity of the transfer body. A free end of the overturning mechanism can be adhered to the bottom of the pallet box. A fixed end of the ejecting mechanism is arranged on the back wall of the cavity of the transfer body. A telescopic end of the ejecting mechanism extends forward and is close to the pallet box. The discharge mechanism of the pallet box transfer device has following advantages: based on softness and brittleness of material, different discharge methods are selected.

Owner:全椒县富民优质粮种植专业合作社

Pallet box transferring device

ActiveCN105417041AAddress flexibilitySolve the shortage restricted by the transshipment siteConveyor partsMechanical conveyorsEngineeringPallet

The invention discloses a pallet box transferring device. The pallet box transferring device comprises a transferring cart, a pallet box, a lifting mechanism, a turnover mechanism and a push-out mechanism. The pallet box is arranged in an inner cavity of the transferring cart; the fixed end of the lifting mechanism is disposed on the bottom wall of the inner cavity; the lifting end of the lifting mechanism upwards extends and is used for supporting the pallet box; the connecting end of the turnover mechanism is hinged to the bottom wall of the inner cavity; the free end of the turnover mechanism can be attached to the bottom of the pallet box; the fixed end of the push-out mechanism is disposed on the rear wall of the inner cavity; the retractable end of the push-out mechanism forwards extends and is close to the pallet box. The pallet box transferring device has the advantages of being good in flexibility and stability, large in bearing load, high in transferring efficiency and capable of safely blanking materials.

Owner:淮北市宇控信息技术有限公司

Sheel metal stacker

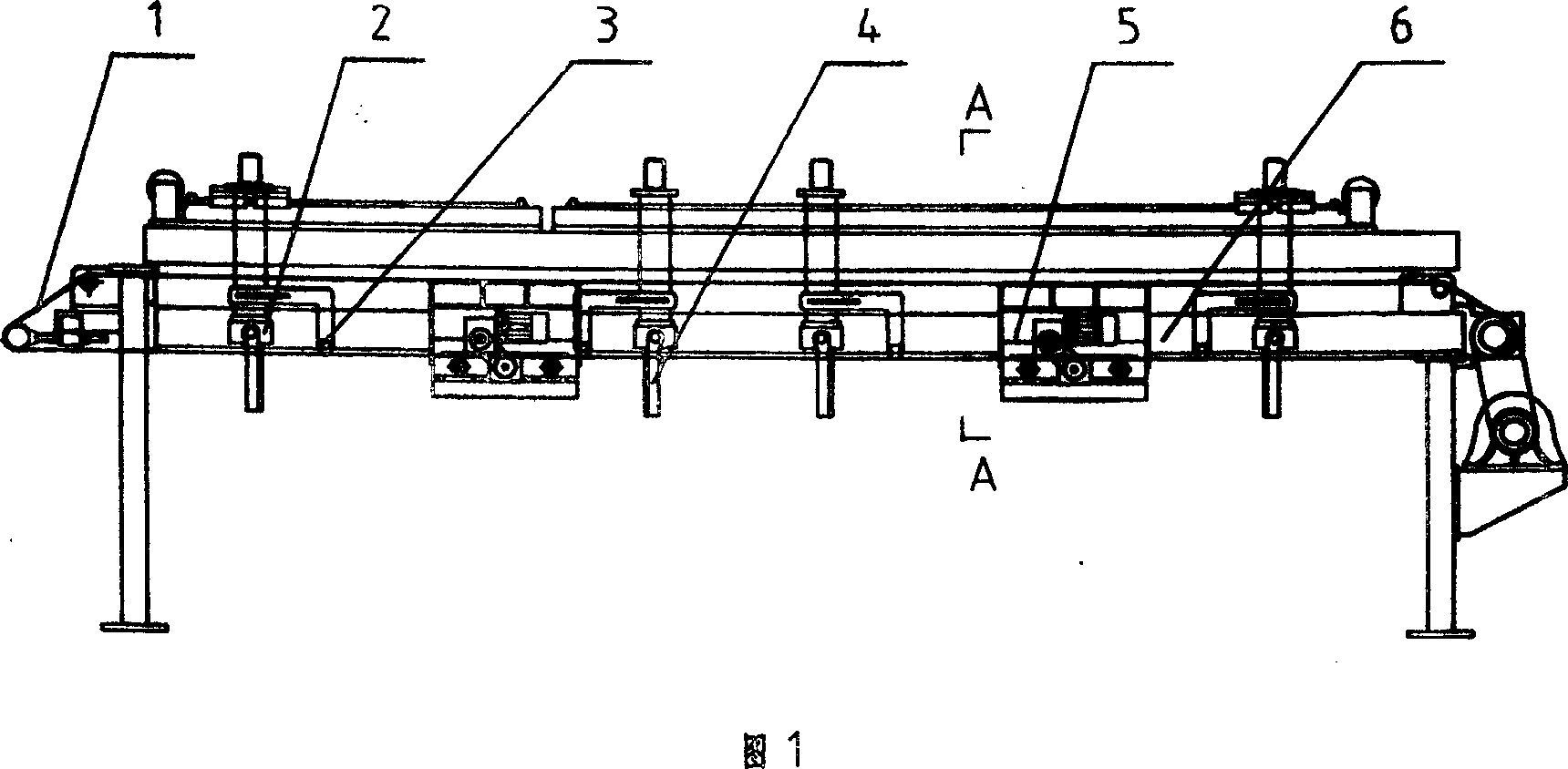

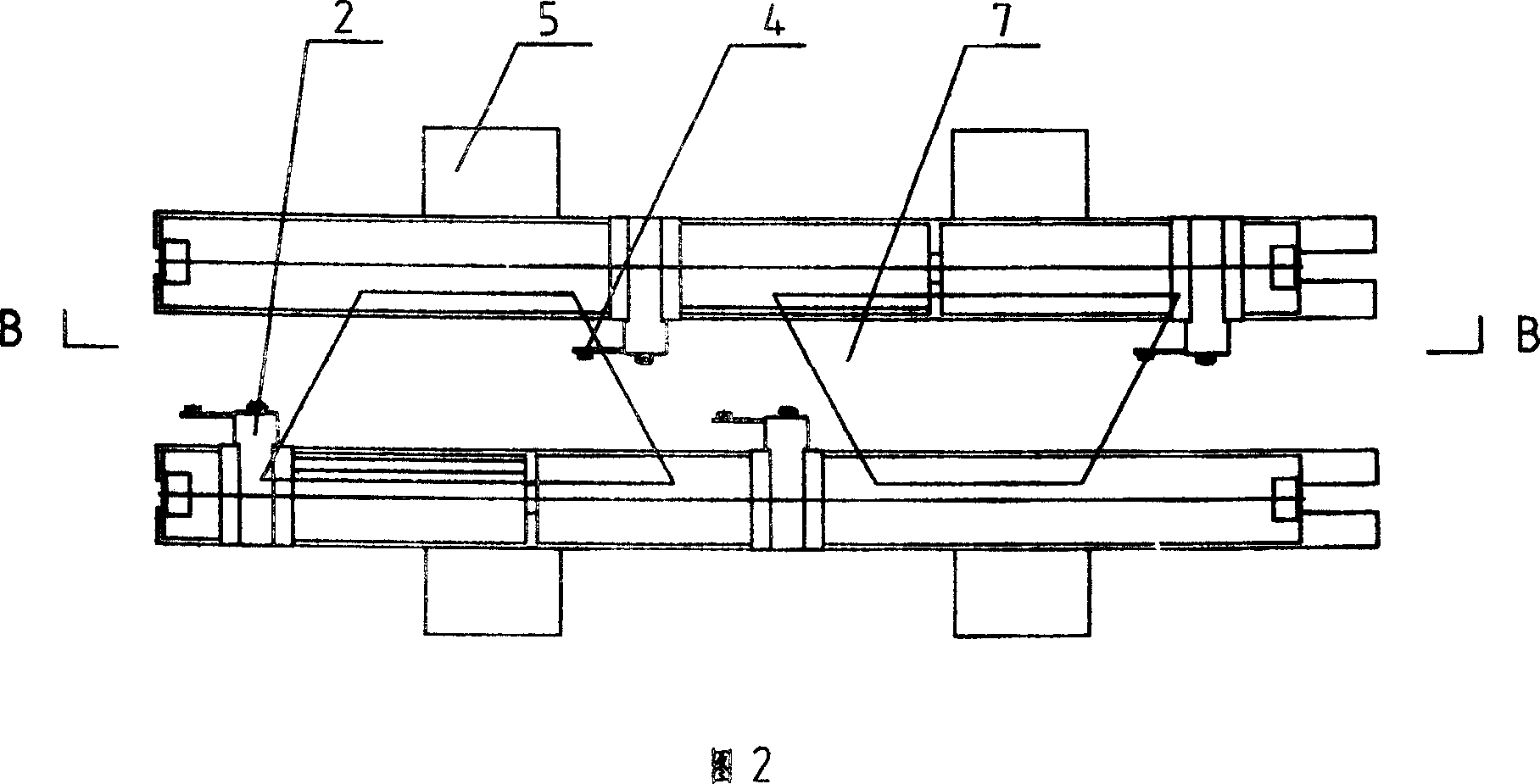

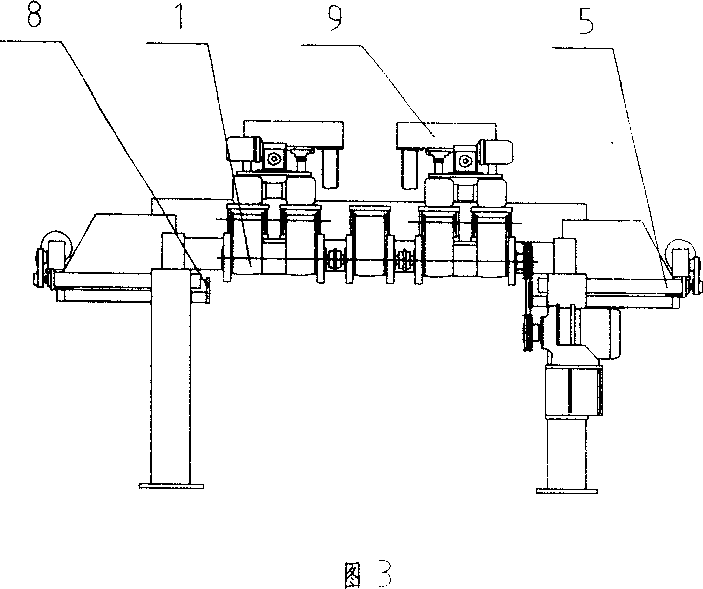

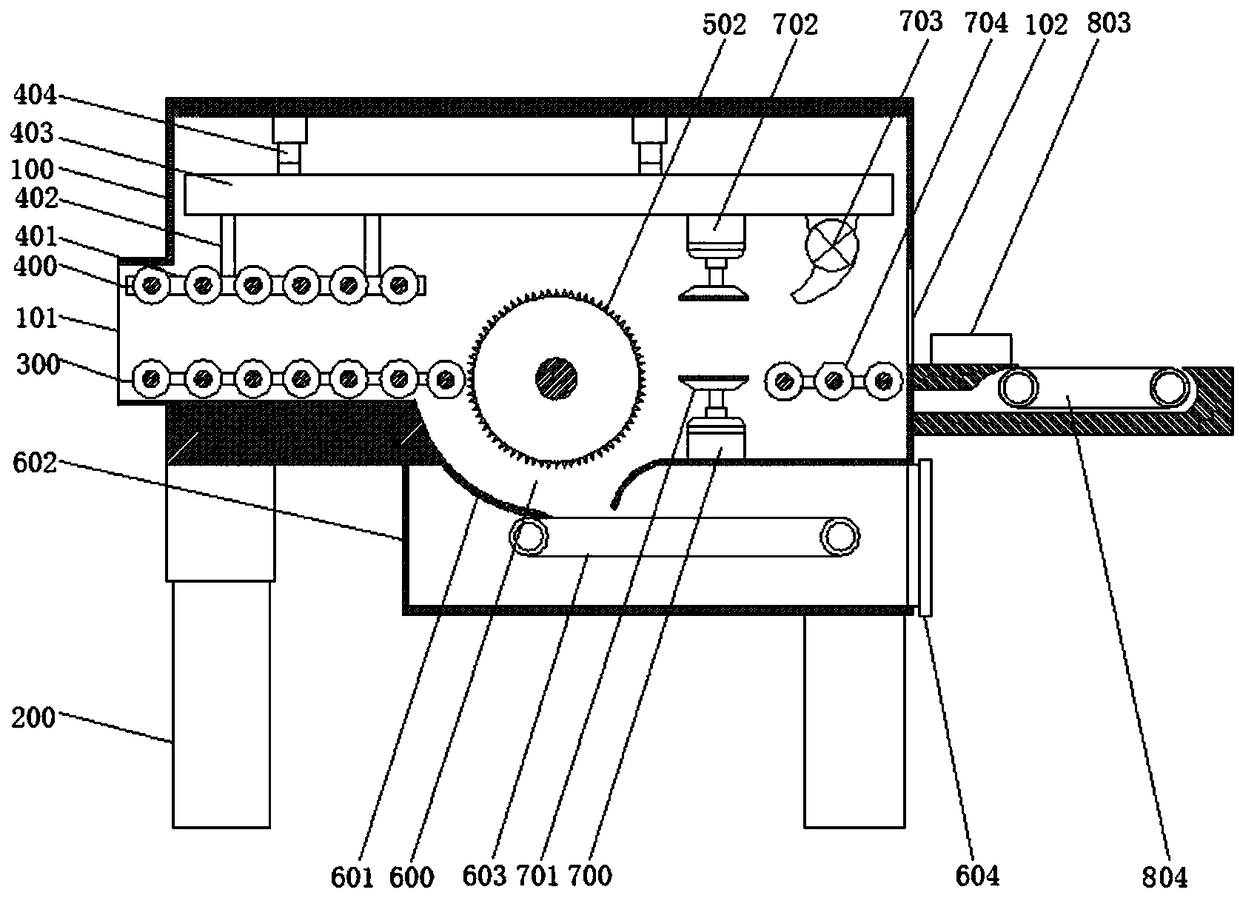

ActiveCN101045505APrecise positioningRealize blankingPile receiversArticle deliveryInductorEngineering

A plate stacking machine for the shaped plates is composed of a moving, locating and plate lowering system consisting of machine frame, parallel two longitudinal beams, driver unit, controller, conveying belt, electromagnetic suction block, and automatic locating block, an automatic lifting-lowering platform, coaxial two horizontal stop blocks under the plate inlets and perpendicular to longitudinal beam, another two stop blocks on said longitudinal beams, and an inductor between said another two stop blocks and connected electrically to said controller.

Owner:JIANGSU YAWEI MACHINE TOOL

Cutting and polishing machine for solid wood floor

ActiveCN109366620AStable structure deliveryEffective sandingPolishing machinesCircular sawsSolid woodEngineering

The invention discloses a cutting and polishing machine for a solid wood floor. The cutting and polishing machine comprises a box body; a feeding opening is formed in the right side surface of the boxbody; a driving roller set is arranged on the right side of the lower end of the feeding opening; one end of the driving roller set is rotationally connected with a bearing on the inner side wall ofthe box body; the other end of the driving roller set penetrates through the outer side wall of the box body to be inserted in a driving box; a motor fixing plate is arranged on the right side of thedriving box; a driving motor is fixed to the motor fixing plate; power is transmitted to the driving roller set through a belt by an output shaft of an output shaft of the driving motor; a compressionroller set is arranged right above the driving roller set; cross slabs are arranged at the front end and the rear end of the compression roller set; and compression rollers on the compression rollerset are rotationally connected with bearings arranged on the cross slabs. The cutting and polishing machine is simple in structure, realizes the integration of automatic cutting and polishing, can effectively recover wood chips in the processes of cutting and polishing, improves the entire environment, and is higher in practicability.

Owner:安徽可尔海思新材料科技有限公司

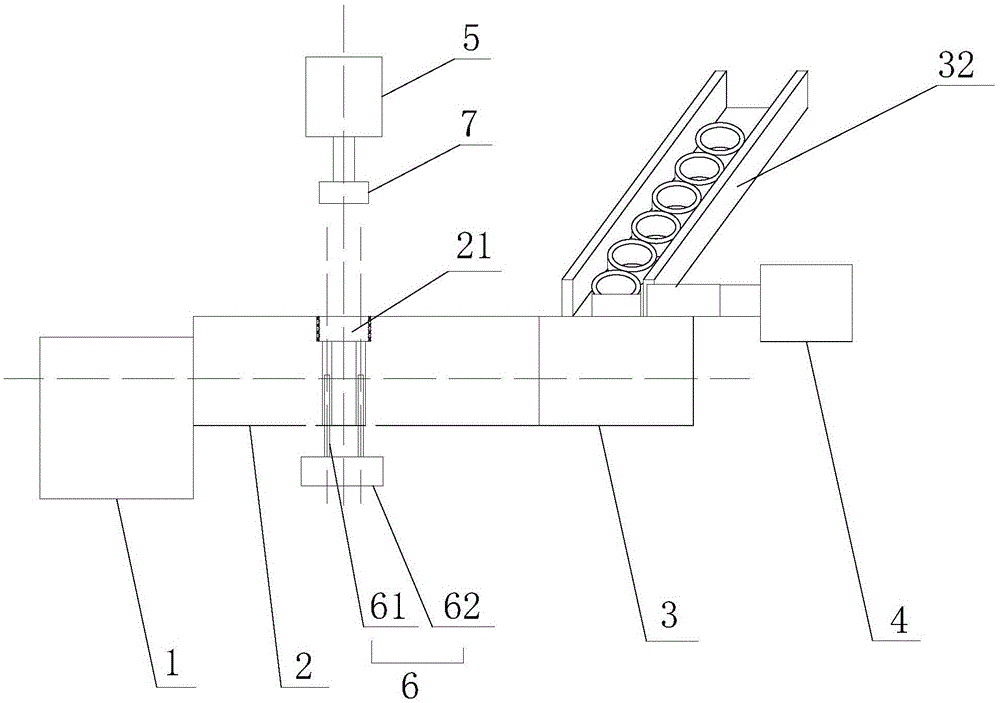

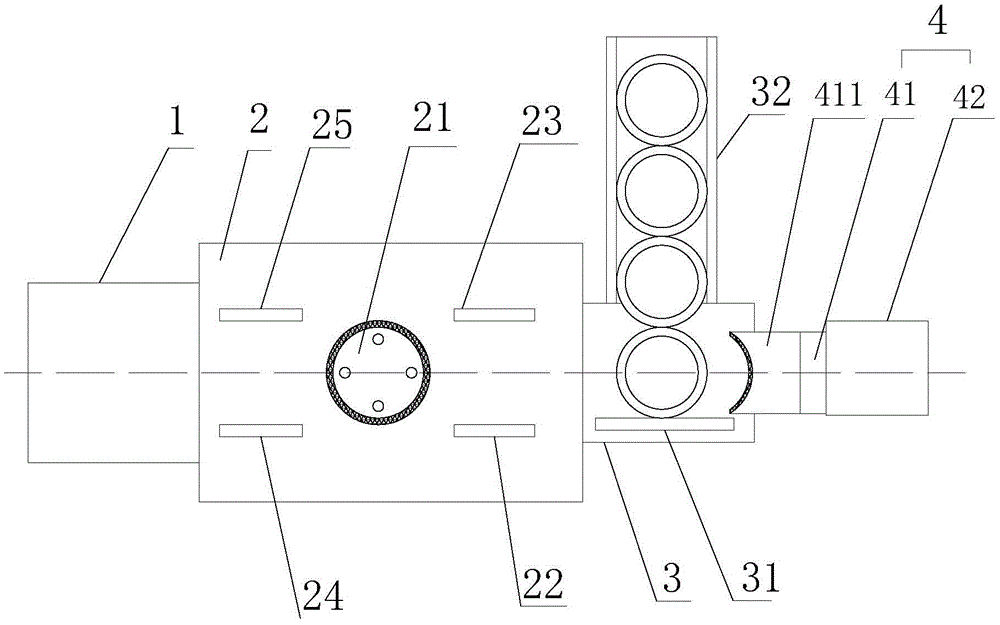

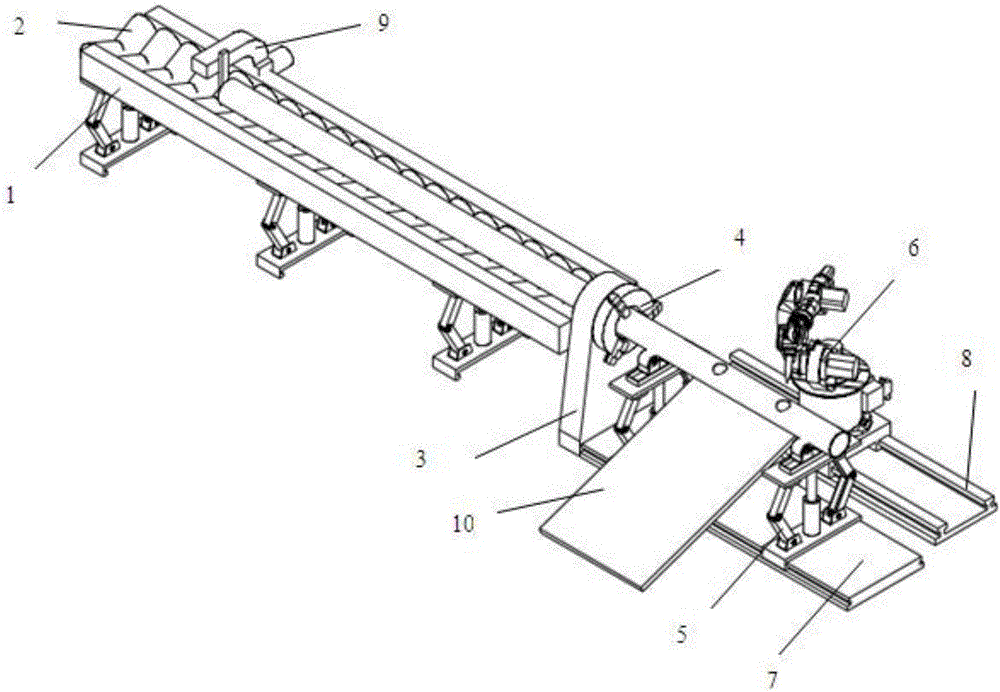

Circular tube intersecting line cutting production line

InactiveCN106670660ARealize automatic feeding processAchieve reductionLaser beam welding apparatusProduction lineEngineering

The invention discloses a circular tube cutting device. The circular tube cutting device comprises a feeding part, a cutting part and a discharging part, and is mainly composed of a lifting conveying platform, a dislodgement machine, a hollow chuck, liftable brackets, a laser cutting robot and a slope discharging rolling path; automatic feeding, cutting and discharging of circular tubes can be achieved; and the circular tube cutting device can adapt to different tube diameters, the production efficiency can be greatly improved, and the manpower cost is reduced.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Medical bed sheet-cutting machine

PendingCN107298333ARealize blankingAchieve foldingSevering textilesFolding thin materialsEngineeringMechanical engineering

A medical bed sheet-cutting machine comprises a rack and a feed mechanism, a transverse folding mechanism, a cutting mechanism and a longitudinal folding mechanism which are arranged on the rack. The feeding mechanism is located right ahead of the transverse folding mechanism, and the transverse folding mechanism, the cutting mechanism and the longitudinal folding mechanism are arranged from right to left in sequence. The medical bed sheet-cutting machine is low in manufacturing cost and convenient in use; the feed mechanism is used for conveying of cloth, the transverse folding mechanism is used for folding the cloth transversely, the cutting mechanism is used for cutting the cloth which is folded through the transverse folding mechanism, the longitudinal folding mechanism is used for folding the cloth longitudinally, and cutting and folding of the cloth are finally performed.

Owner:崔春彦

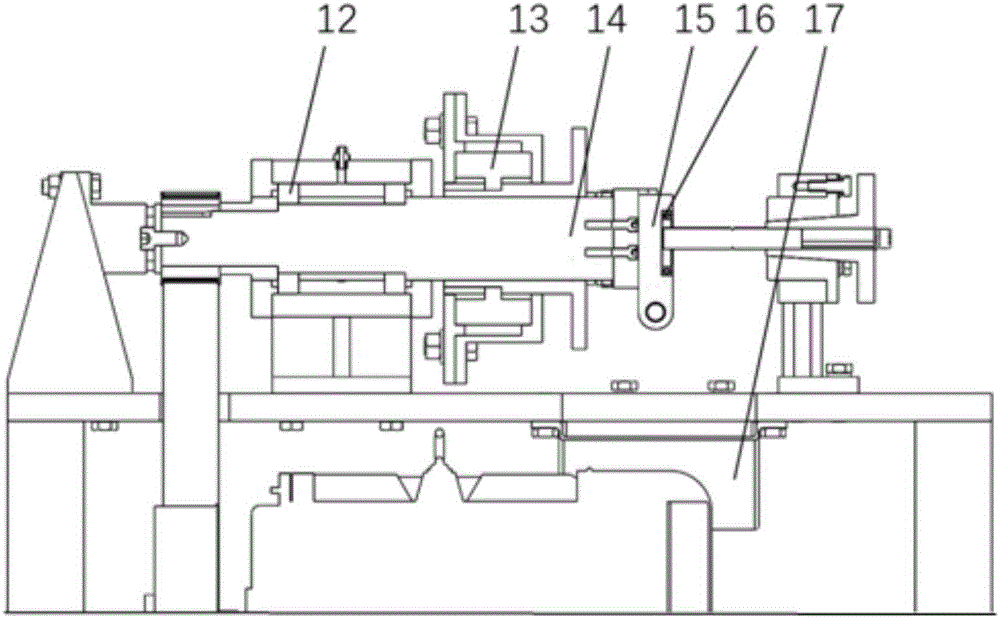

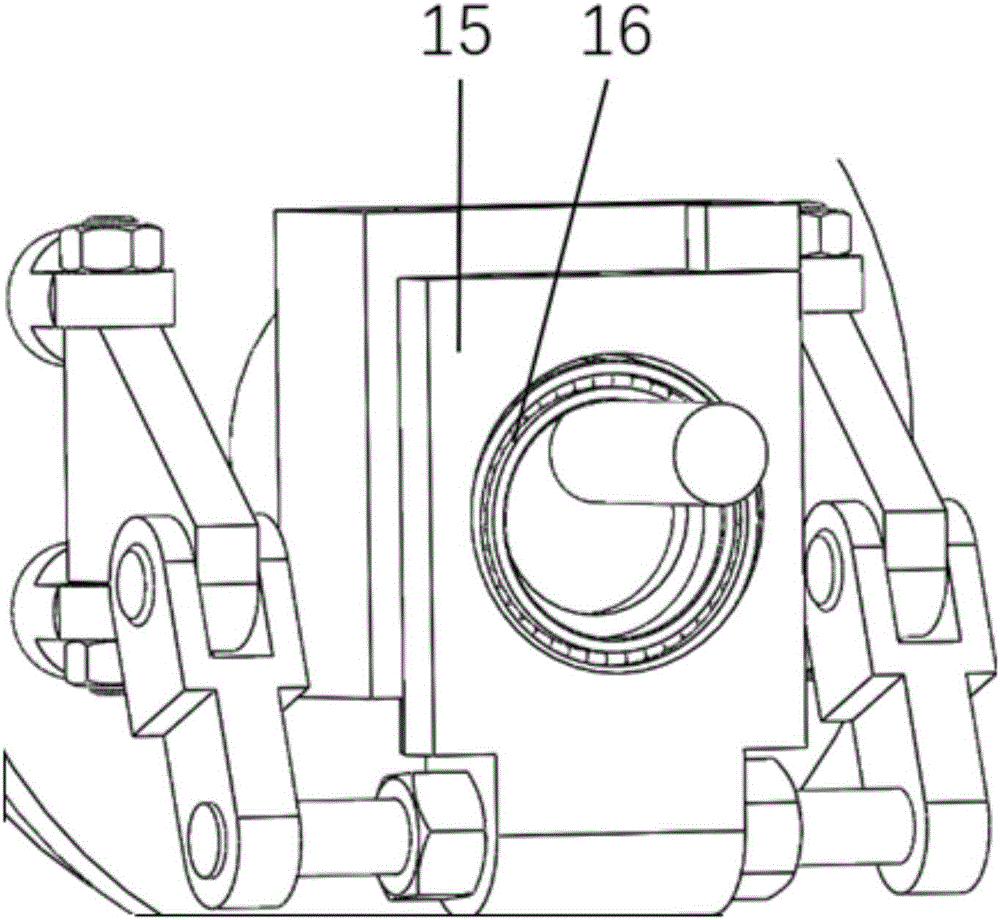

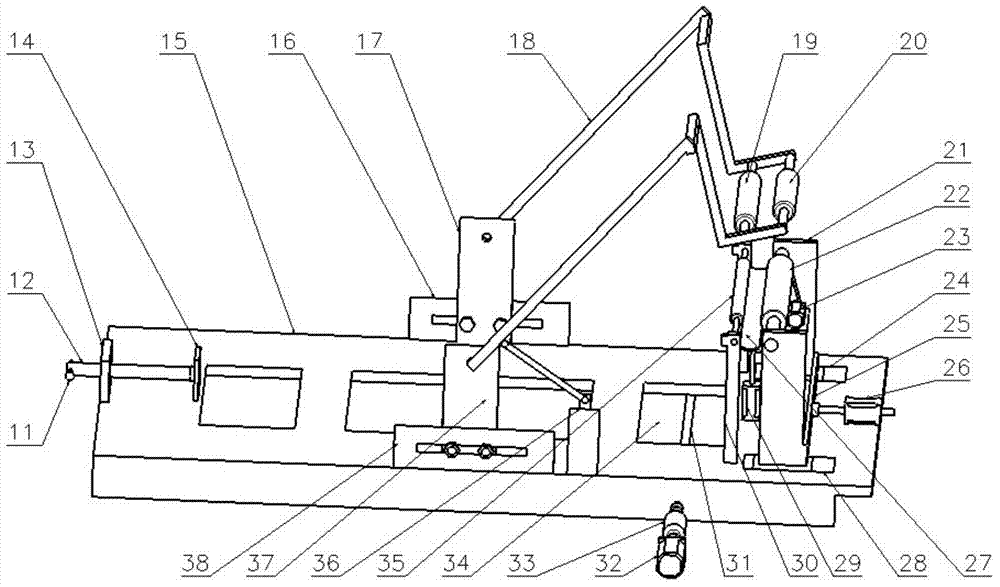

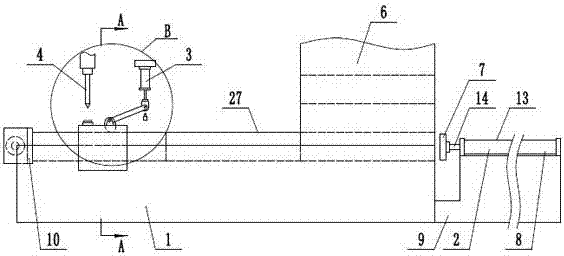

Automatic positioning and clamping device and method of drill rod and drill collar on pipe threading lathe

InactiveCN103506636ARealize automatic feeding processAchieve positioningChucksMetal working apparatusNumerical controlEngineering

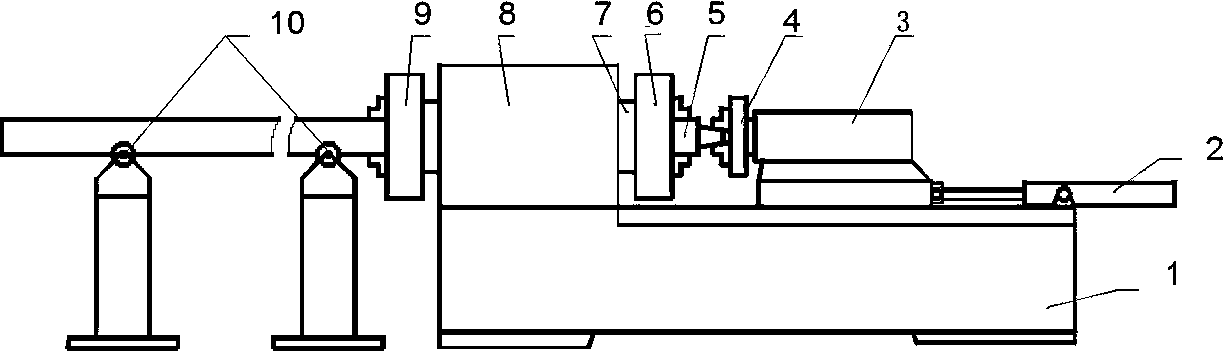

The invention provides an automatic positioning and clamping device of a drill rod and a drill collar on a pipe threading lathe. The device comprises a lathe bed, a tail platform, a headstock and a bracket multi-group carrier roller. The bracket multi-group carrier roller is arranged on one side of the lathe bed, the headstock and the tail platform are arranged on the lathe bed, and the headstock (8) is arranged on one side close to the bracket multi-group carrier roller (10). According to the device and method, automatic feeding, positioning, clamping and discharging of workpieces can be achieved. The purpose of the device and method is to achieve the full-automatic machining processes, including feeding and discharging, of the numerical control pipe threading lathe.

Owner:SHENYANG POLYTECHNIC UNIV

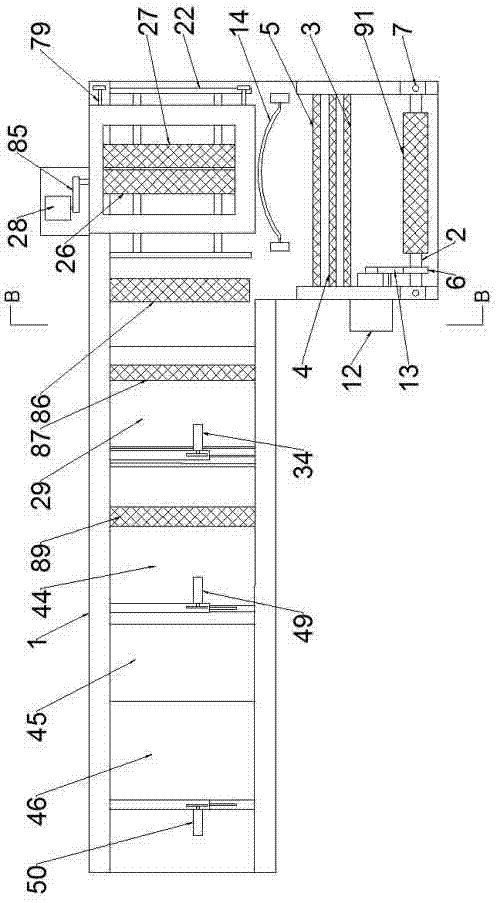

Production equipment for household furnishings

PendingCN108405900AImprove processing efficiencyReduce the amount of manual laborMaintainance and safety accessoriesBoring/drilling machinesEngineeringThreaded rod

The invention relates to the technical filed of fixture decoration processing and manufacturing, in particular to production equipment for household furnishings. The production equipment comprises a processing table with two sides symmetrically provided with fixing plates, the middle portions of the fixing plates are connected in a hinged mode to the side walls of the processing table, and a displacement limiting bar is arranged between the fixing plates. Each fixing plate is provided with a first wedge block, a wedge rod is arranged at one side of each fixing plate, each wedge rod is providedwith a clamping surface, and the first wedge blocks cooperate with the wedge rods intermittently. The wedge rods are connected in a hinged mode to the processing table, reset springs are arranged between the wedge rods and the processing table, and the wedge rods are provided with second wedge blocks. A pushing plate is coaxially and rotationally connected to each fixing plate, one end of each pushing plate is connected to the corresponding fixing plate by a telescopic rod, and an incline plane is arranged at the other end of each pushing plate to be intermittently matched with the corresponding second wedge block. Supporting columns are arranged at two sides of the processing table, the supporting columns are rotationally connected with threaded rods, the threaded rods are connected to sliding sleeves by threads, and the opposite sides of the sliding sleeves are provided with perforating knifes. The production equipment for the household furnishings solves the problem that an existing perforating machine is unable to perforate both sides of a workpiece at the same time.

Owner:重庆木头木脑文化创意有限公司

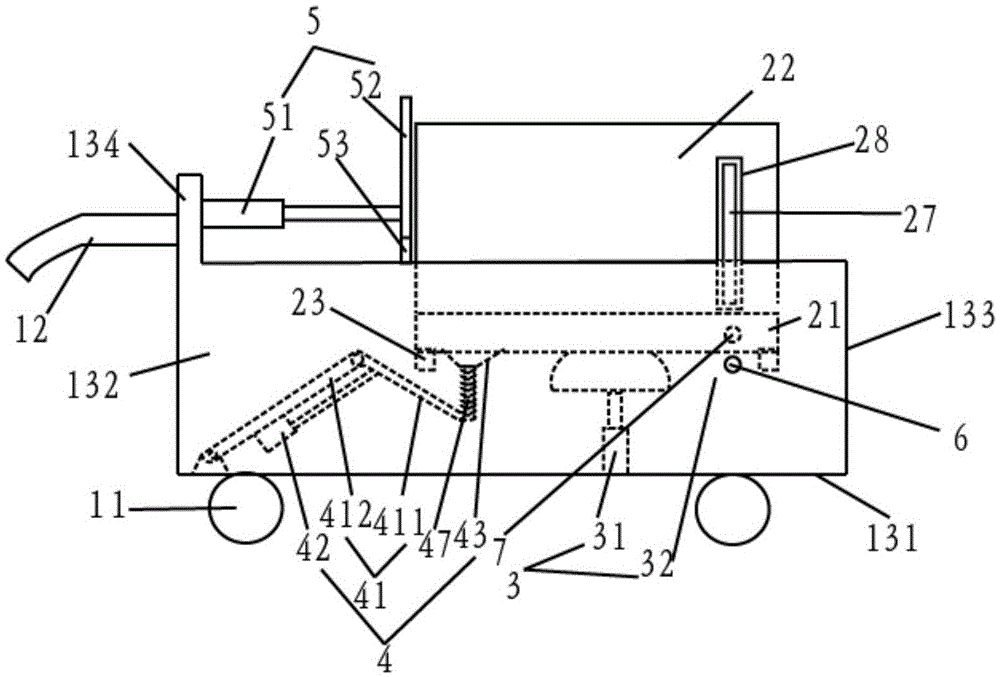

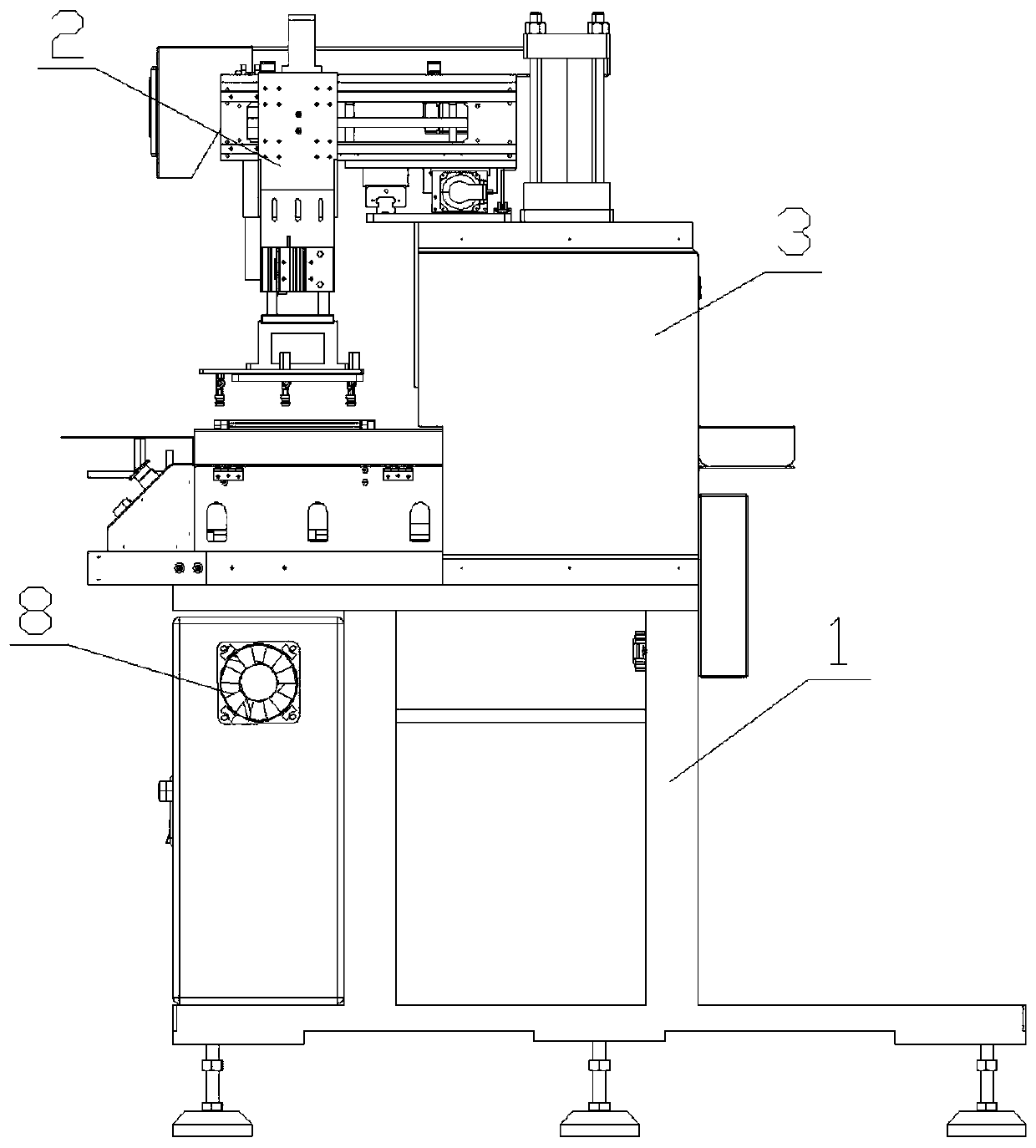

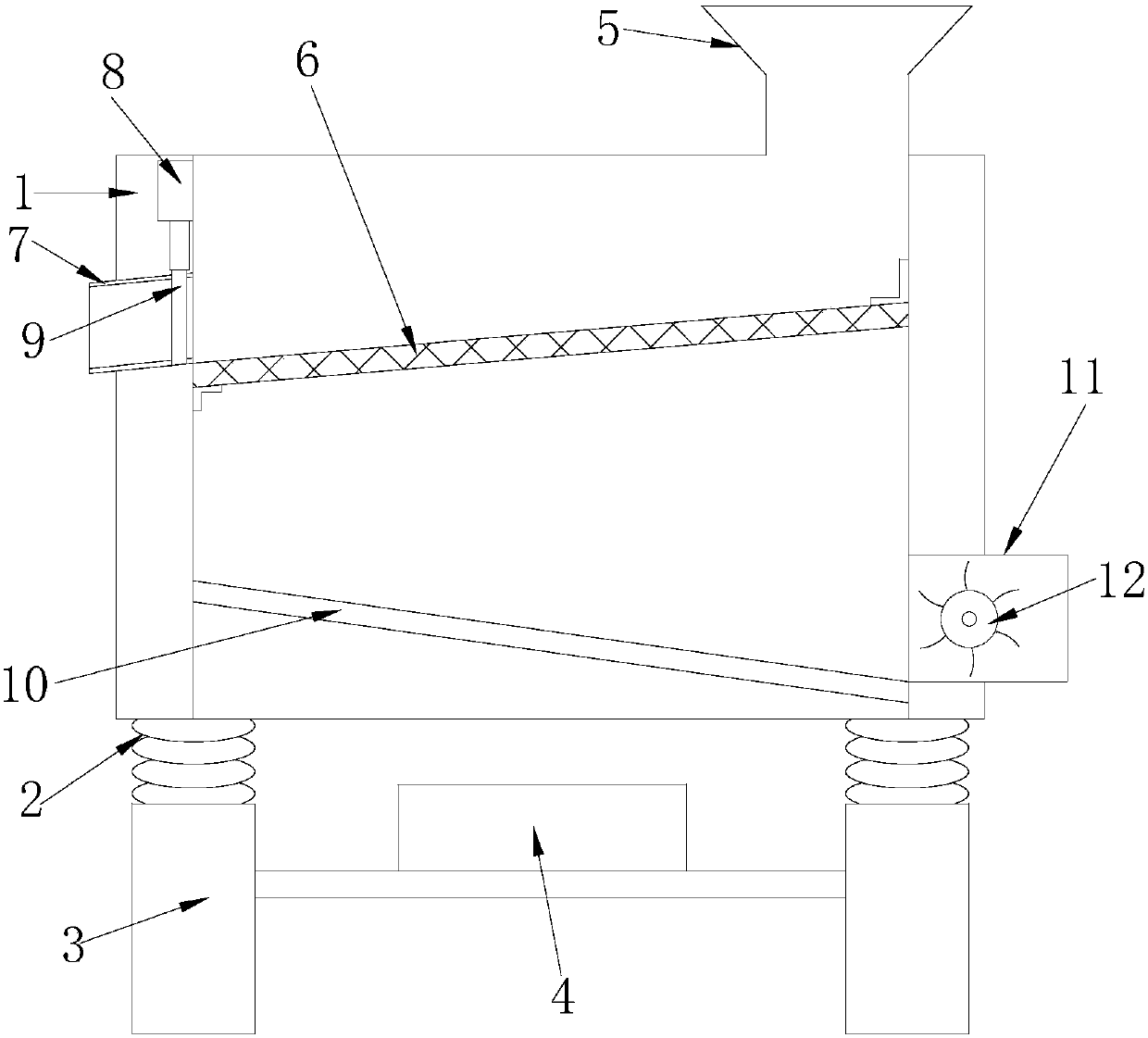

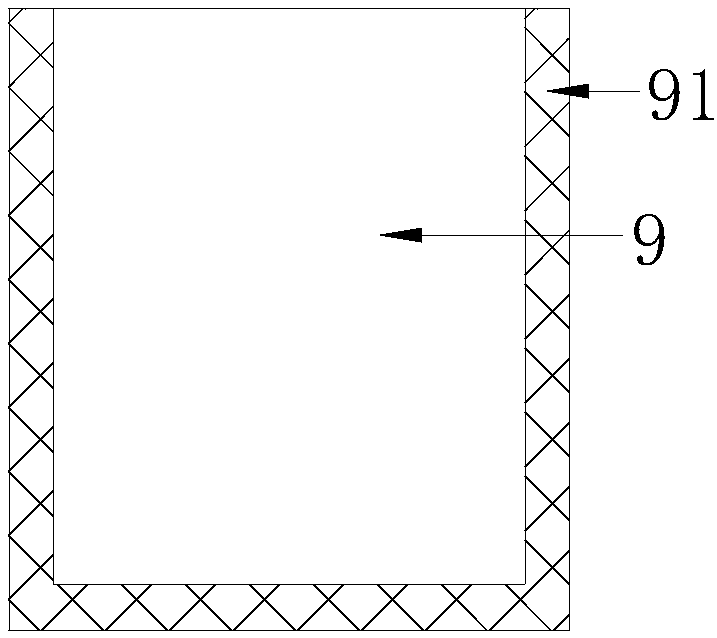

Automatic feeding and blanking punch press equipment and forming method thereof

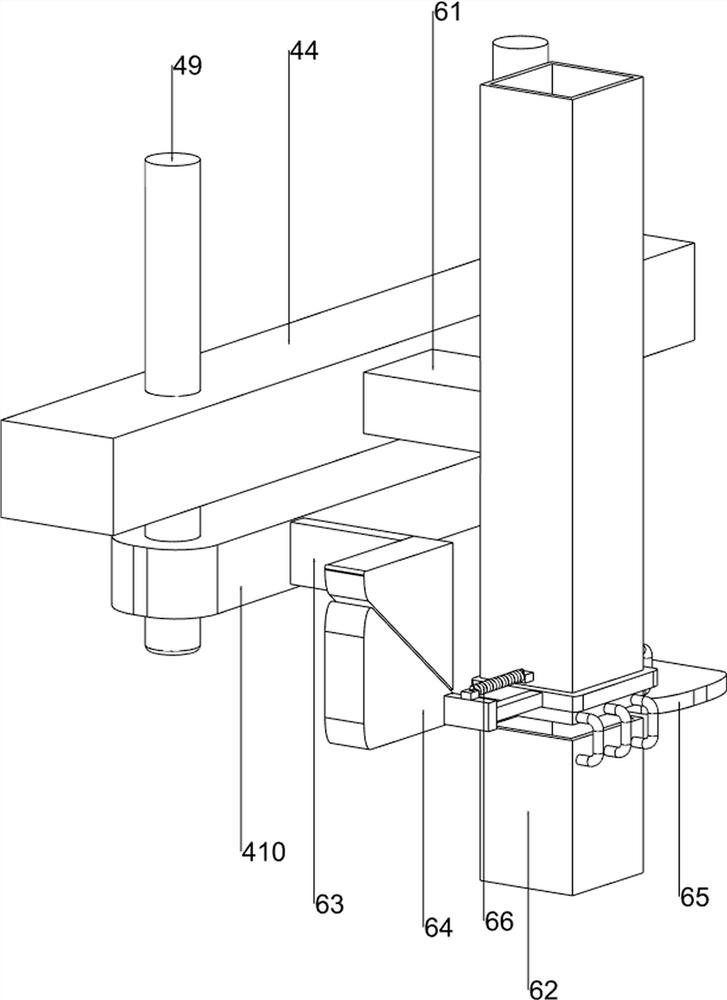

PendingCN111496118AAchieve precise deliveryImprove loading and unloading efficiencyMetal-working feeding devicesPositioning devicesCircular discPunch press

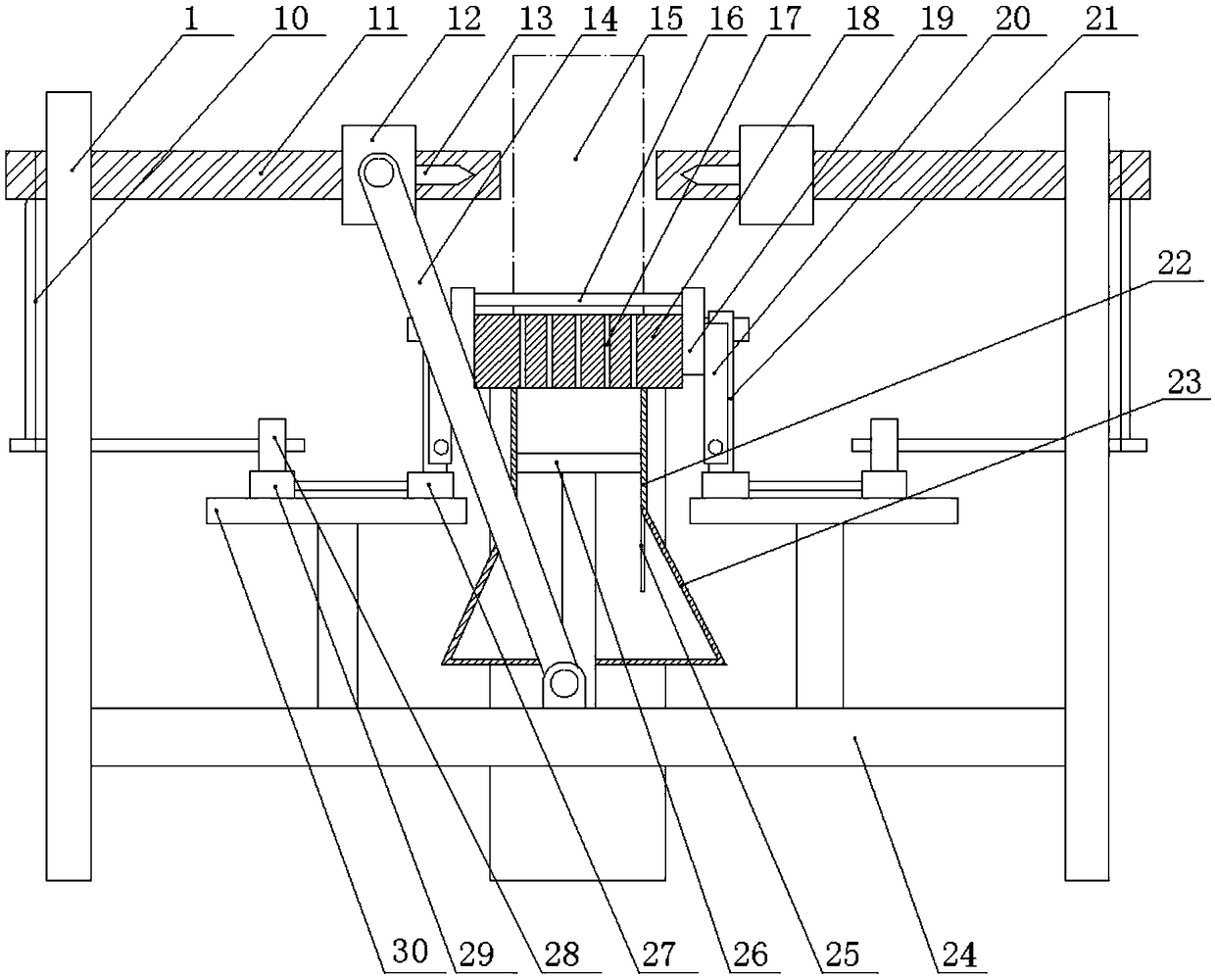

The invention relates to automatic feeding and blanking punch press equipment and a forming method thereof, and mainly solves the problems that an existing punch press needs to manually feed and blankplates one by one, the labor intensity is high, and the machining efficiency is low. The automatic feeding and blanking punch press equipment comprises a rack, a feeding and blanking mechanism, a punching mechanism and a material conveying mechanism. Disc-shaped supporting legs are fixed to the bottom of the rack, a workbench is arranged at the top of the rack, an electric cabinet used for containing electrical components is arranged on the rack, and a cooling fan is arranged on the electric cabinet; and the material conveying mechanism is arranged on the workbench, the punching mechanism isarranged on one side of the material conveying mechanism, the feeding and blanking mechanism is arranged on the punching mechanism, the feeding and blanking mechanism is located above the material conveying mechanism, a display screen support is further arranged on the punching mechanism, and a display screen is installed on the display screen support. The problems are well solved, and the automatic feeding and blanking punch press equipment can be used for punching plates.

Owner:张群

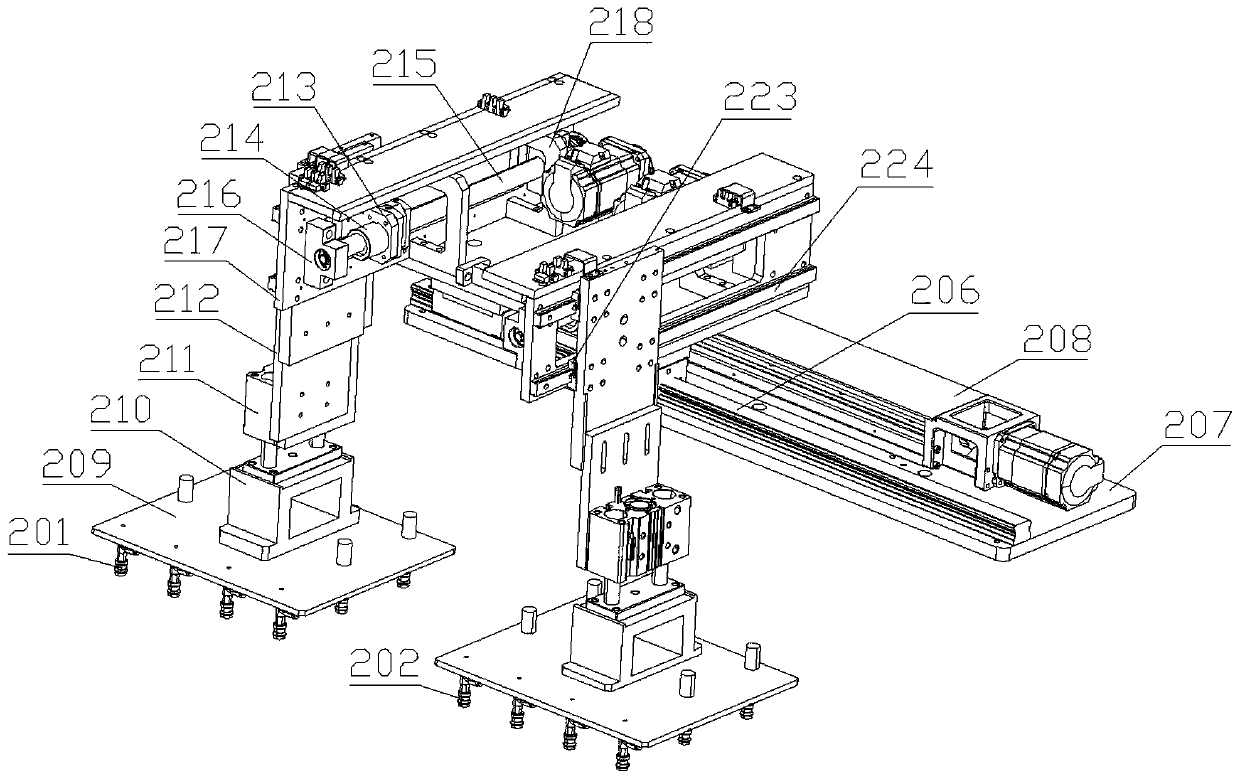

Automatic feeding equipment

InactiveCN105819179ARealize automatic feedingRealize feedingConveyor partsMechanical conveyorsAutomatic test equipmentEngineering

The invention relates to an automatic feeding device, comprising an AGV trolley, a material storage device, and a loading and unloading device. A plurality of material frames are arranged on the pallet of the material storage device. The loading and unloading device includes a Y-axis multiplying stroke mechanism, an X-axis moving module, a Z-axis moving module, a reclaiming manipulator, and an industrial control unit. The Y-axis multiplying stroke mechanism includes two first guide rails fixed on the left and right sides of the feeding direction on the frame and extending along the Y-axis, two multiplying plates that can slide along the two first guide rails, and fixed on the two multiplying plates respectively. Two second guide rails on the board and extending along the Y axis, two fixed plates that can slide along the two second guide rails, and a stroke multiplication drive unit, the stroke multiplication drive unit drives the two multiplication plates to slide along the first guide rails respectively At the same time, the two fixing plates are driven to slide along the same direction along the second guide rail to realize the stroke multiplication. The invention can meet the requirements of automatic feeding, loading and unloading, and can realize multi-point placement on the same station, and at the same time occupies a small space and operates stably.

Owner:SHENZHEN SCREEN STAR PRINTING MASCH CO LTD

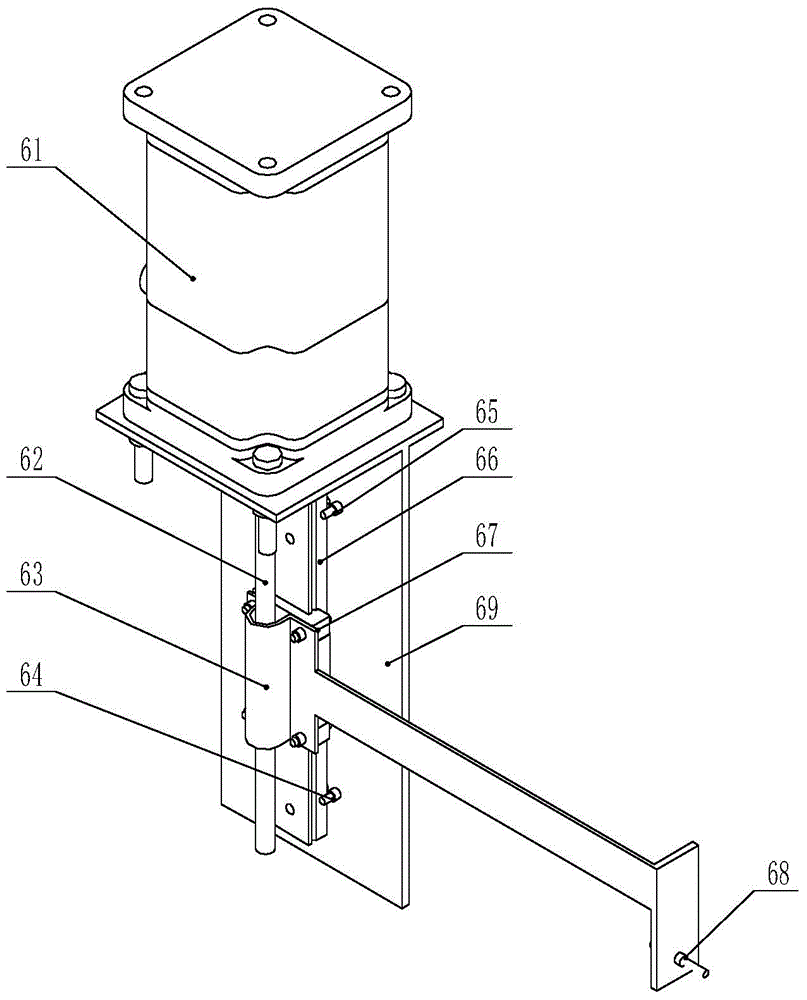

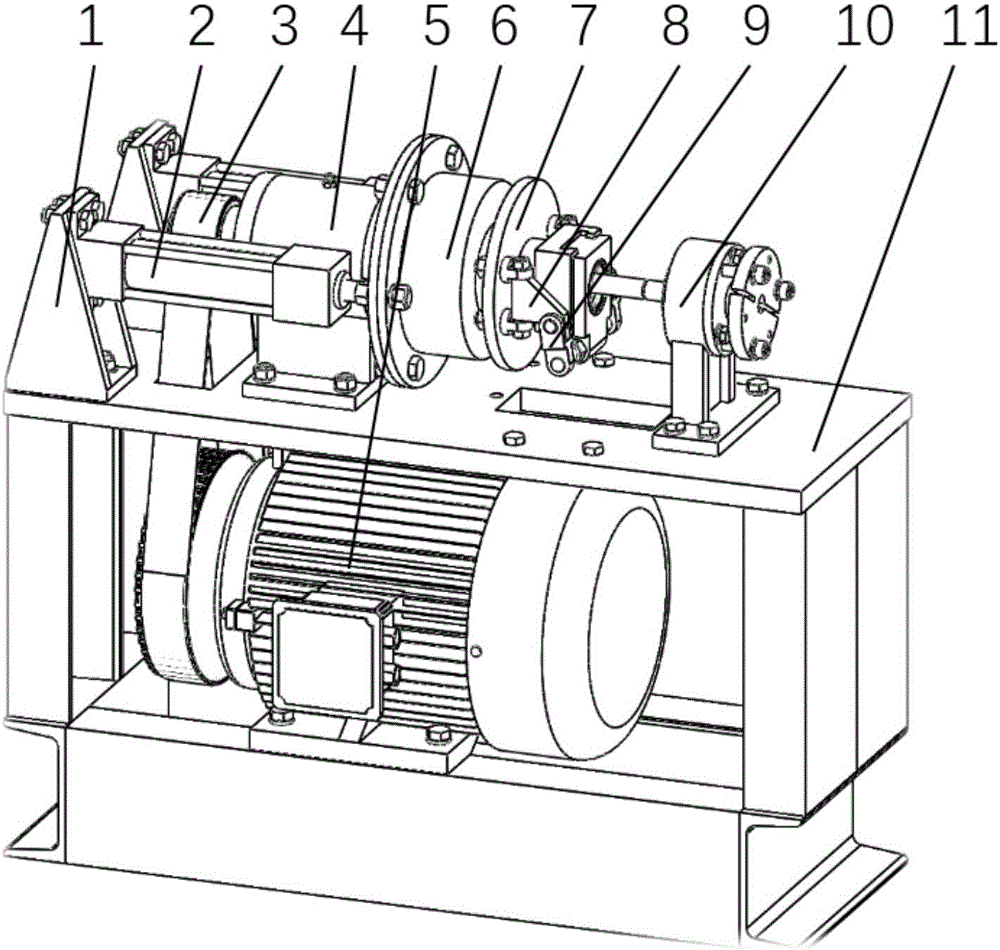

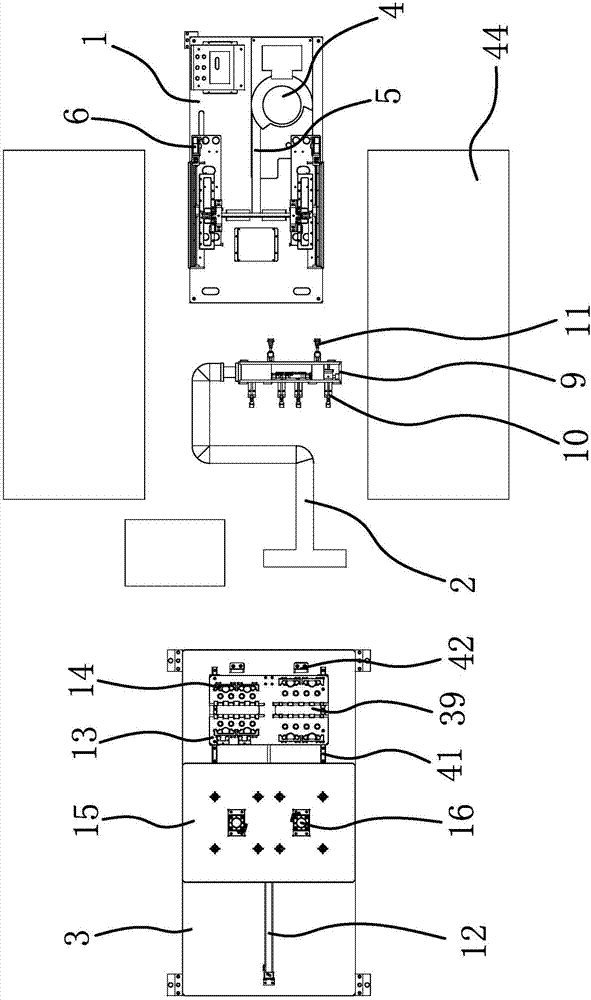

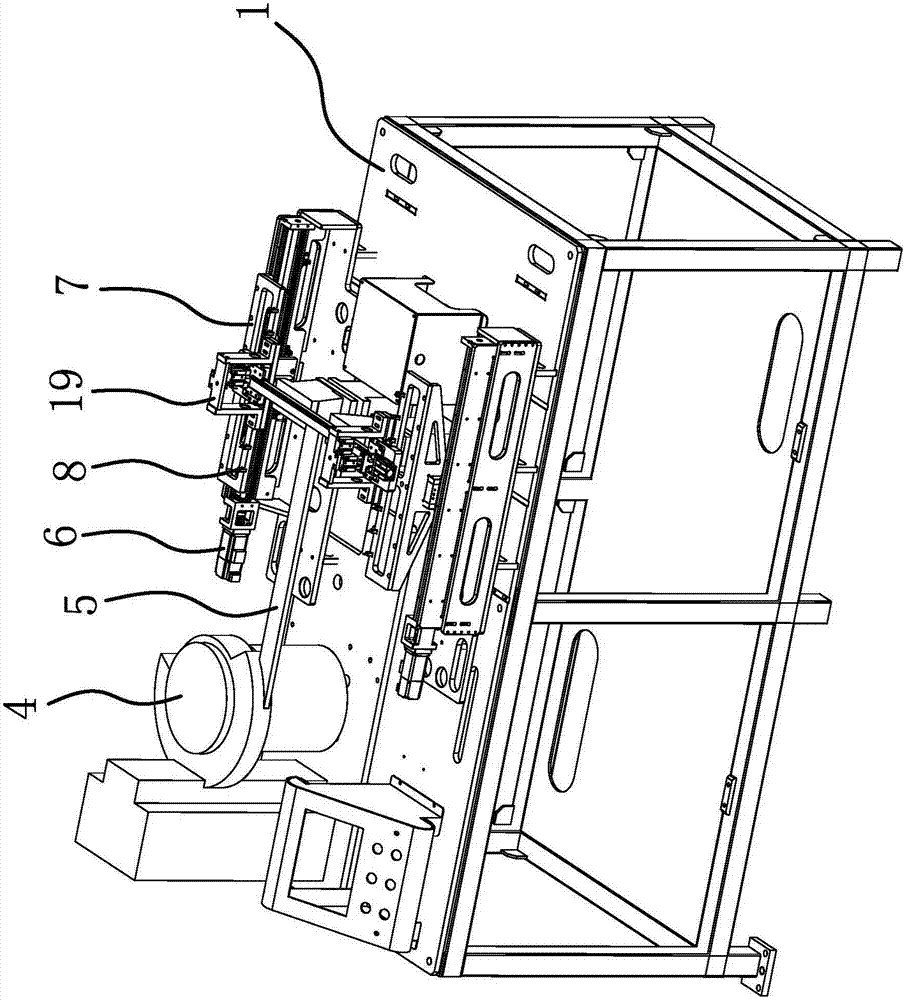

Variable-frequency centrifugal rod pipe blanking machine based on hydraulic compensation

The invention relates to a variable-frequency centrifugal rod pipe blanking machine based on hydraulic compensation. The machine comprises a hydraulic cylinder bracket, a hydraulic cylinder, a synchronous belt, a fixed bearing box, a three-phase alternating-current motor, a slide bearing box, a rotating push disc, a triangular block, a connecting block, a rod fixture, a frame, a deep groove ball bearing, a two-way thrust ball bearing, a main shaft, a slide block, a wear resistant bearing with grooves on the inner surface at equal intervals, and a material block guide groove. The machine precisely blanks rod pipes by fully using hydraulic compensation, the centrifugal effect and the stress concentration effect based on a low-stress blanking technology. During blanking, sharp annular V-shaped grooves are formed in the peripheries of the surfaces of metal rod pipes beforehand; and then, the rod pipes are peripherally extruded by using the rotating centrifugal force and the hydraulic compensation force. Under the effect of centrifugal force and hydraulic compensation force, cracks are generated in the stress concentration places of the V-shaped groove. According to traditional rupture theoretical knowledge, after the cracks at the tip ends of the V-shaped grooves are generated, the cracks can quickly expand along the radial surfaces to totally break finally, so that the blanking is realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Automatic nut burying and sprue cutting equipment

The invention belongs to the technical field of machines, and provides automatic nut burying and sprue cutting equipment which solves the problem that an existing pipe clamp is low nut burying and sprue cutting efficiency. The automatic nut burying and sprue cutting equipment is characterized in that a first driving source on a first workbench can drive a sliding rack to move; locating columns are arranged on the sliding rack in a spaced manner; the feed end of a conveying passage is connected with a vibrating material disc; the discharge end of the conveying passage is located at the locating columns; a manipulator is fixedly connected with a mounting plate; first clamping cylinders are arranged on one side of the mounting plate; clamping air nozzles are formed in the other side of the mounting plate; a second driving source and a sliding plate are arranged on a second workbench; the second driving source can drive the sliding plate to move; a locating rack is arranged on the sliding plate; a mounting rack is arranged on the second workbench; lifting air cylinders are arranged on the mounting rack; piston rods of the lifting air cylinders are fixedly connected with a first pressing plate; and the first pressing plate is fixedly connected with cutters. The automatic nut burying and sprue cutting equipment has the advantage of improving the production efficiency of a pipe clamp.

Owner:YONGGAO CO LTD

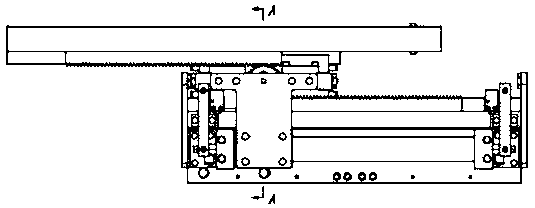

Automatic feeding system of numerical control lathe

InactiveCN107262743AGuaranteed feeding efficiencyRealize blankingAutomatic conveying/guiding stockNumerical controlEngineering

The invention discloses an automatic feeding system of a numerical control lathe, and aims to solve the problem that a traditional machine tool is low in processing and carrying efficiency. The main point of the technical scheme is that automatic feeding is carried out through a feeding mechanism, a transfer mechanism transfers and moves workpieces to a processing zone to be processed, and then, automatic discharge is carried out through a discharge mechanism. According to the automatic feeding system of the numerical control lathe, automation degree is high, and processing and transfer efficiency is high.

Owner:津上精密机床(浙江)有限公司

Automatic steel strip end cap sleeving machine

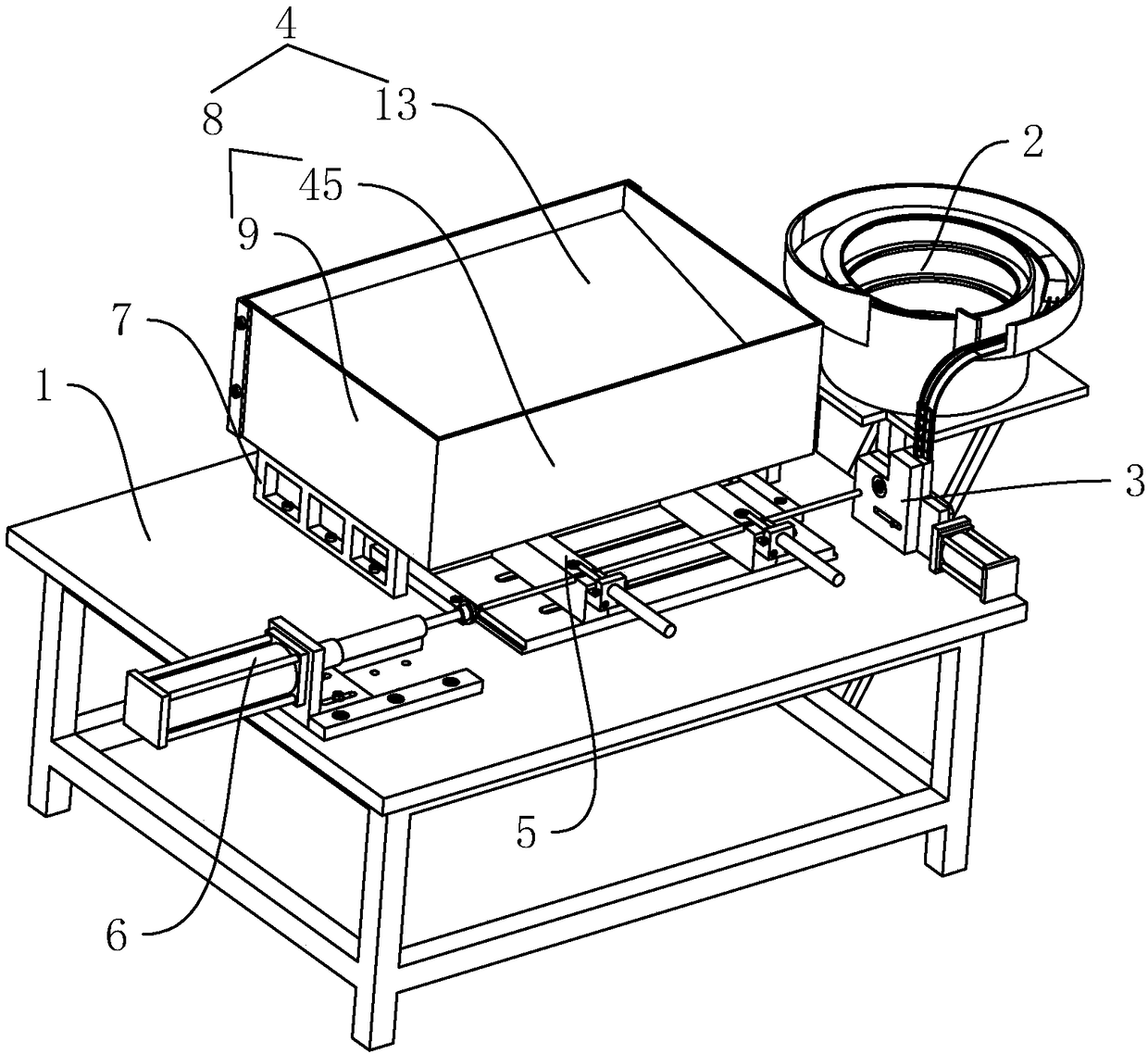

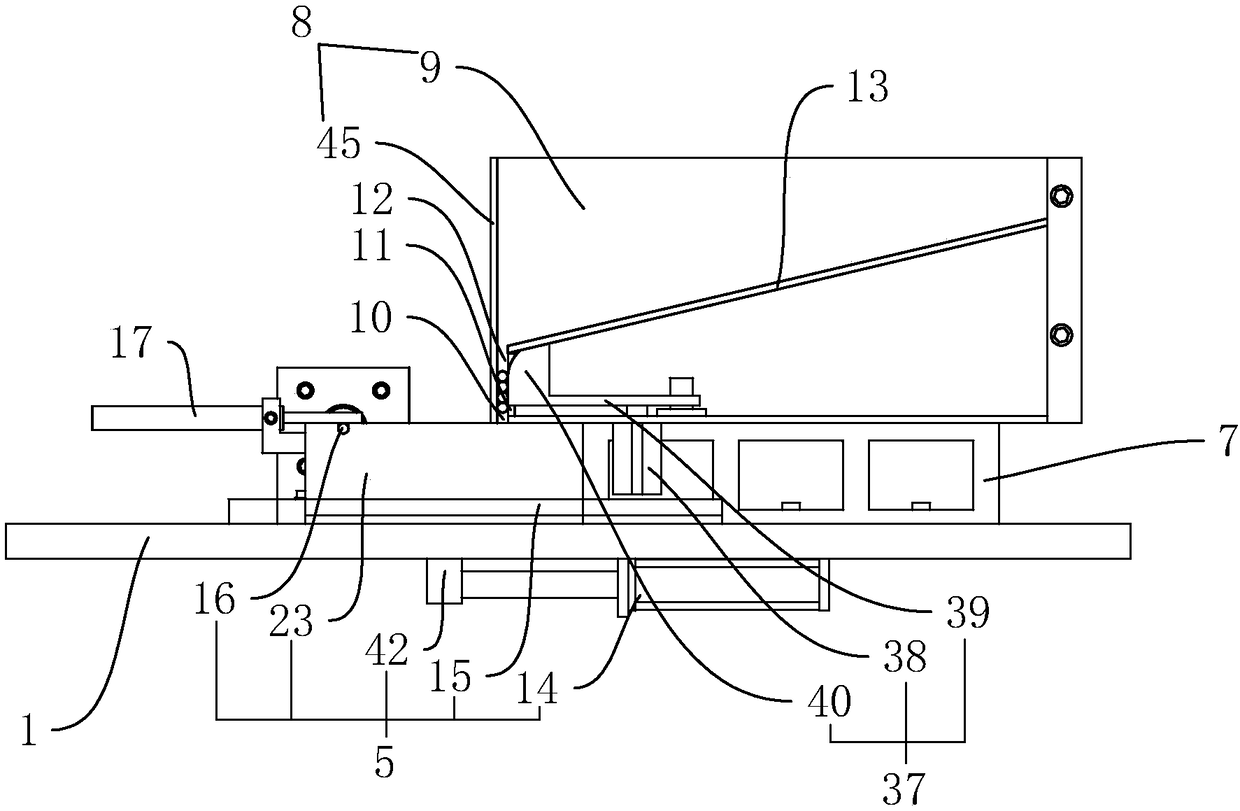

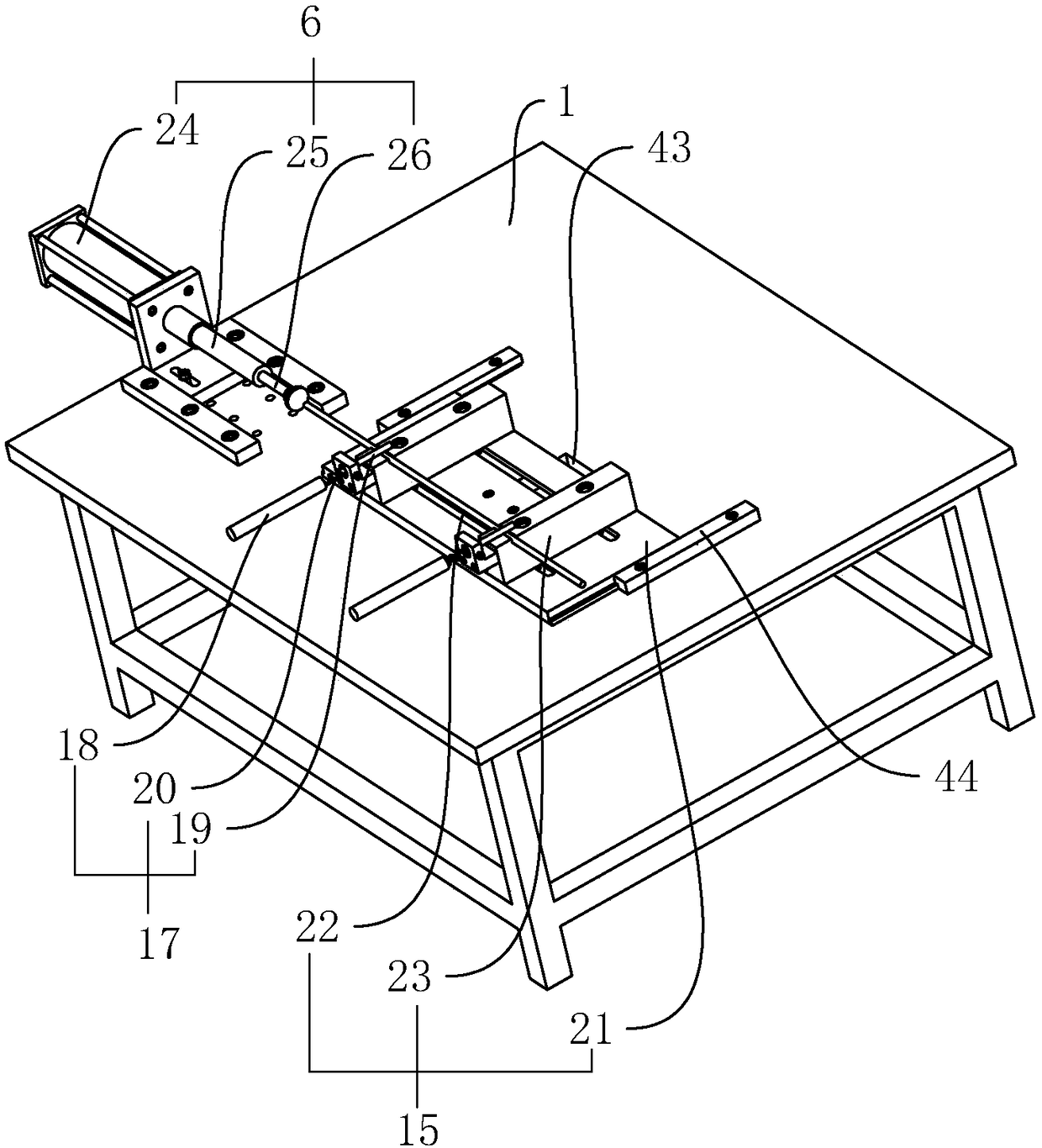

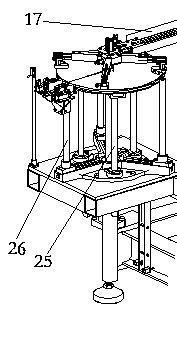

ActiveCN108213906ARealize feedingAchieve continuous feedingMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic steel strip end cap sleeving machine, and aims at solving the problems that during traditional manual steel strip and end cap installation, efficiency is low, andmanpower is wasted. According to the technical scheme, the automatic steel strip end cap sleeving machine is characterized by comprising a rack, a vibration material disc arranged on one side of the rack, a clamping assembly connected to the discharging end of the vibration material disc and used for clamping an end cap, a feeding mechanism arranged on the rack and used for arranging steel strips,a conveying assembly arranged below the feeding mechanism and used for pushing one steel strip out, and a drive mechanism which is arranged on the rack and is collinear to the discharging position ofthe conveying assembly. According to the automatic steel strip end cap sleeving machine, through automatic steel strip and end cap installation, manpower is greatly liberated, labor force consumptionis reduced, and the installing efficiency is improved.

Owner:徐锋

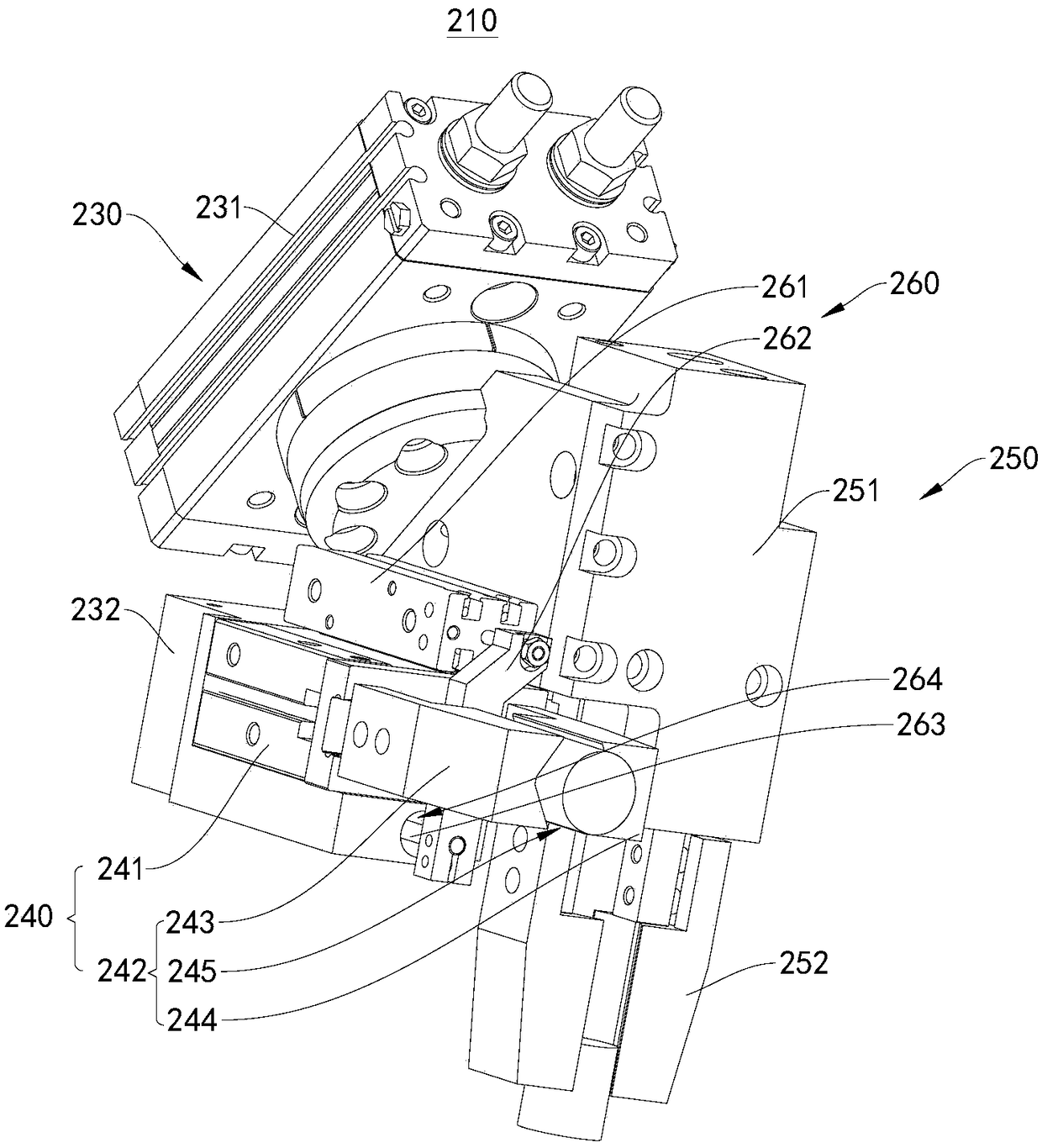

Detection device for material picking of mechanical arm

ActiveCN104002178AImprove loading and unloading efficiencyGuaranteed linear motionProgramme-controlled manipulatorMeasurement/indication equipmentsEngineeringManipulator

Owner:GUANGZHOU DAZHENG ADVANCED MATERIAL TECH CO LTD

Automatic corner polishing device for mobile phone screens

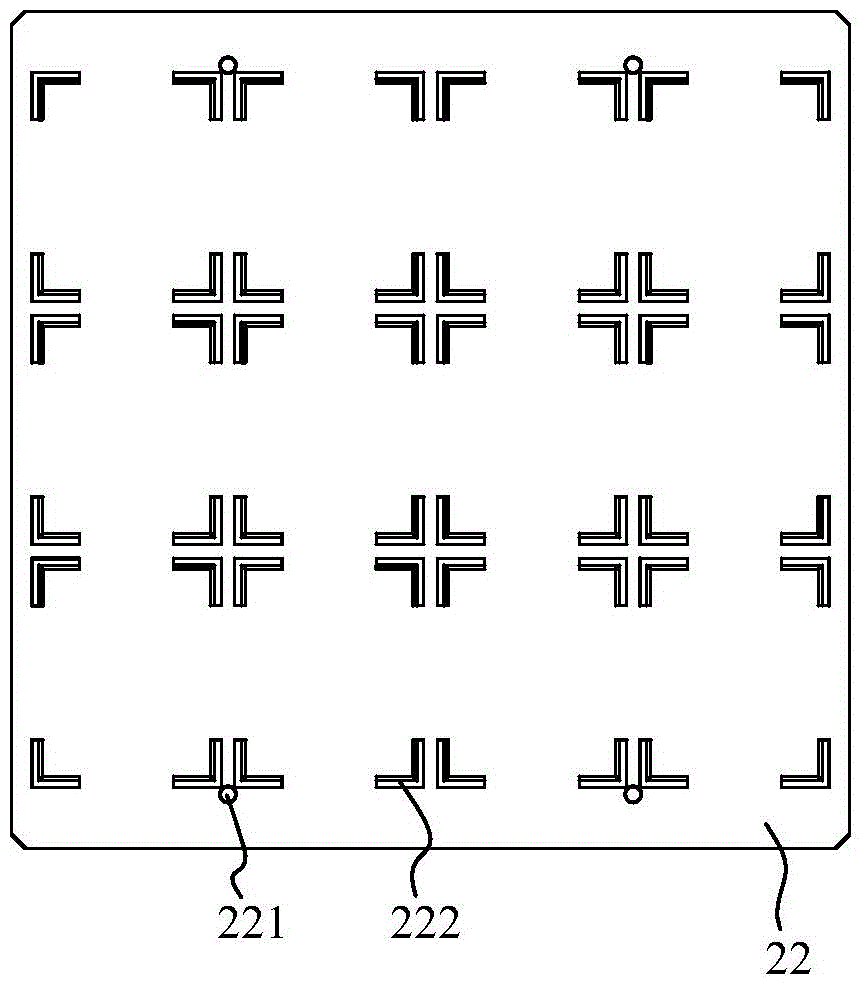

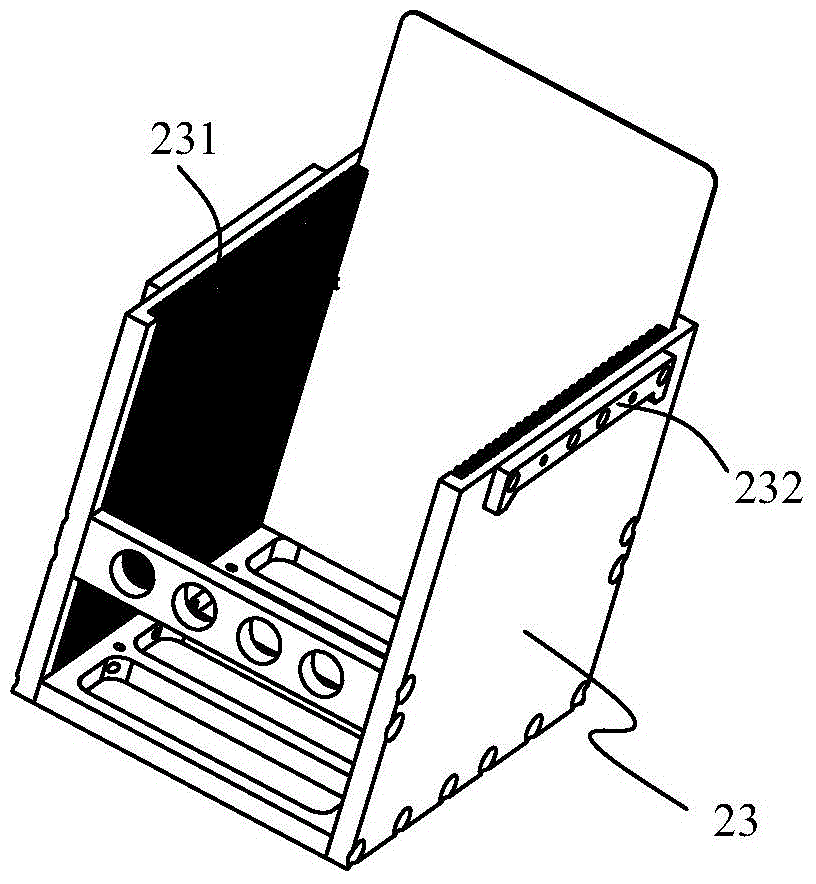

PendingCN109605165AImprove grinding efficiencyImprove delivery efficiencyEdge grinding machinesGrinding feed controlEngineeringMechanical engineering

The invention belongs to the technical field of mobile phone screen processing, and particularly relates to an automatic corner polishing device for mobile phone screens. The automatic corner polishing device comprises a feeding device, a corner polishing device for polishing the chamfered mobile phone screens, a limiting mechanism, a discharging device and a control device. The feeding device comprises an arranging assembly used for arranging the mobile phone screens and a push assembly used for pushing the mobile phone screens into the limiting mechanism from the arranging assembly, the corner polishing device comprises a plurality of corner polishing mechanisms distributed in a matrix mode, the limiting mechanism comprises a limiting assembly and a vacuum positioning assembly, the vacuum positioning assembly is arranged in the center of the corner polishing device, the discharging device comprises a sucking assembly and a moving electric cylinder used for driving the sucking assembly to move transversely, and the control device comprises a controller and a sensor assembly electrically connected with the controller. The mobile phone screen corner polishing efficiency is improved,automatic feeding and discharging are achieved, and conveying efficiency is improved.

Owner:芜湖华宇彩晶科技有限公司

Test tube labeling machine

InactiveCN103786938ARealize automatic feeding processRealize blankingLabelling short rigid containersLabelling machinesLocking mechanismSemi automatic

The invention belongs to the field of labeling and relates to a test tube labeling machine. The test tube labeling machine overcomes the problem of low efficiency of the existing semi-automatic labeling device in the prior art. The labeling machine is mainly composed of a main body mechanism, a base, a loading mechanism and an unloading mechanism, wherein the main body mechanism comprises a main roll mechanism, a supporting plate mechanism, an auxiliary roll mechanism, a rotating shaft and a compression roll mechanism, all of which are orderly fixed on a base plate; the base is composed of a substrate, a box fixedly connected with the substrate, and a loading cabin support, a motor support and an unloading cabin support, the three of which are fixed on the box; the loading mechanism is composed of a loading cabin fixed on the loading cabin support, a baffle plate mechanism fixed on the motor support, and a push plate mechanism; the unloading mechanism is composed of an unloading cabin fixed on the unloading cabin support, an XY worktable fixed on the substrate and a test tube holder placed on the XY worktable; the main body mechanism also comprises a locking mechanism and a clamping mechanism. The test tube labeling machine is capable of labeling test tubes different in diameter and is simple in structure, convenient to adjust and convenient to operate.

Owner:JILIN UNIV

Shaft body drilling device

InactiveCN107116248AWith drillingWith automatic feedingWork clamping meansMetal working apparatusEngineeringCam

The invention provides a shaft body drilling device, and belongs to the technical field of mechanical processing. The shaft body drilling device comprises an loading and unloading mechanism, a pressing mechanism and a drilling mechanism, wherein a material bin of the loading and unloading mechanism is arranged above the right end of a bearing support base; a top plate is mounted at the left end of a top plate piston rod; a positioning baffle plate can be arranged in a slide slot in the left end of the bearing support base in a front-rear sliding mode; a baffle plate piston rod is connected with the positioning baffle plate; a bearing pin roll of the pressing mechanism can be rotatably arranged on the fixed supporting lug; the lower end of a connecting rod is fixedly arranged on the bearing pin roll; a pressing cam is fixedly arranged on the bearing pin roll in the eccentric mode; the lower end of the pressing air cylinder is hinged with the upper end of the connecting rod; and a drill bit of the drilling mechanism is arranged above a guide drilling sleeve. The shaft body drilling device realizes automatic loading and unloading of the shaft body, greatly reduces labor intensity of a worker, realizes continuous and quick drilling and processing on a shaft body, is reasonable in structure, is good in reliability and is low in cost.

Owner:赵锋

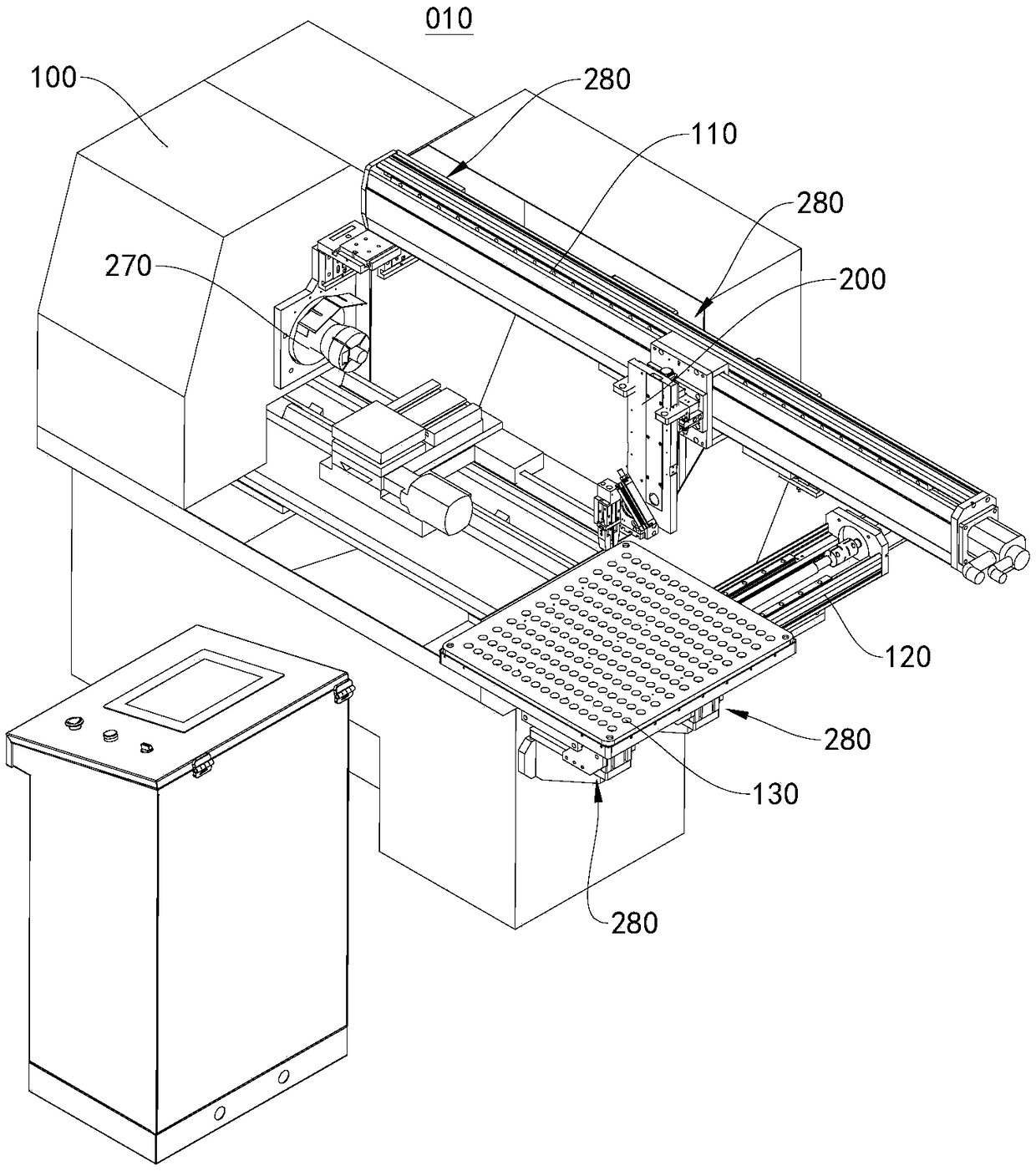

Loading and unloading device for lathe

ActiveCN109249040ARealize automatic feeding processRealize blankingMetal working apparatusEngineeringManipulator

The invention relates to the technical field of automatic equipment, in particular to a loading and unloading device for a lathe. The loading and unloading device comprises a lathe body, a first horizontal movement module, a second horizontal movement module, a manipulator mechanism and a tray. The first horizontal movement module and the second horizontal movement module are fixedly arranged on the lathe body, included angles are formed between the first horizontal movement module and the second horizontal movement module, and the second horizontal movement module is arranged below the firsthorizontal movement module at intervals along the vertical direction; the manipulator mechanism is in transmission connection with the first horizontal movement module, and the first horizontal movement module is configured in such a manner that the manipulator mechanism can be driven by the first horizontal movement module to move along first directions; the tray is in transmission connection with the second horizontal movement module, and the second horizontal movement module is configured in such a manner that the tray can be driven by the second horizontal movement module to move along second directions. The loading and unloading device has the advantages that the amounts of labor of operators can be reduced, and the workpiece feeding and discharging speeds can be increased.

Owner:HUBEI UNIV OF ARTS & SCI +2

Fully-automatic screening plant for aggregate

InactiveCN107626578ARealize blankingNot prone to cloggingSievingScreeningArchitectural engineeringElectric machinery

The invention discloses a fully-automatic screening plant for an aggregate, and relates to the technical field of building appliances. A connecting spring is installed at the bottom part of a box body; the lower end of the connecting spring is installed at the upper end of a support foot; a vibration motor is installed on a cross rod of the support foot; a feed hopper is installed at the right upper end of the box body; a screening filter screen is arranged slantly in the box body, is arranged in a way that the left part is low and the right part is high, and is fixed on the inner side wall ofthe box body through a right angle frame; a large particle discharge pipe is installed at the left end of the screening filter screen; a driver is arranged on the upper side of the large particle discharge pipe; a flashboard is installed on a driving rod of the driver and is connected in a hole groove of the large particle discharge pipe in a penetrating manner; a material guide plate is arrangedon the lower side of the screening filter screen and is arranged in a way that the left part is high and the right part is low; a small particle discharge pipe is installed at the right end of the material guide plate. The fully-automatic screening plant automatically screens and discharges the material, does not cause the phenomenon of blockage easily in use, is high in efficiency, and can workcontinuously.

Owner:JINLING INST OF TECH

Automatic iron sheet stamping equipment

InactiveCN112404214AAchieve automatic feedingRealize blankingMetal-working feeding devicesPositioning devicesElectric machineStructural engineering

The invention relates to automatic stamping equipment, in particular to automatic iron sheet stamping equipment. According to the automatic iron sheet stamping equipment, iron sheets can be automatically blanked, pushed and stamped, and people can conveniently collect the stamped iron sheets. The automatic iron sheet stamping equipment comprises a bottom plate, a table, a material pressing mechanism and a material pushing mechanism, wherein a double-shaft motor is arranged on one side of the top of the bottom plate, the table is arranged on the side, away from the double-shaft motor, of the top of the bottom plate, the material pressing mechanism is arranged on the side, close to the double-shaft motor, of the top of the bottom plate, parts of the material pressing mechanism are connectedto an output shaft of the double-shaft motor, and the material pushing mechanism is installed on the table. Under the cooperation of the double-shaft motor, the material pressing mechanism, the material pushing mechanism, the blanking mechanism, the discharging mechanism and a clamping mechanism, the effects of blanking the iron sheets, automatically pushing the iron sheets, carrying out stampingon the iron sheets and facilitating collection of the iron sheets subjected to stamping by people can be achieved.

Owner:赵勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com