Circular tube intersecting line cutting production line

A technology of intersecting wire cutting and production line, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

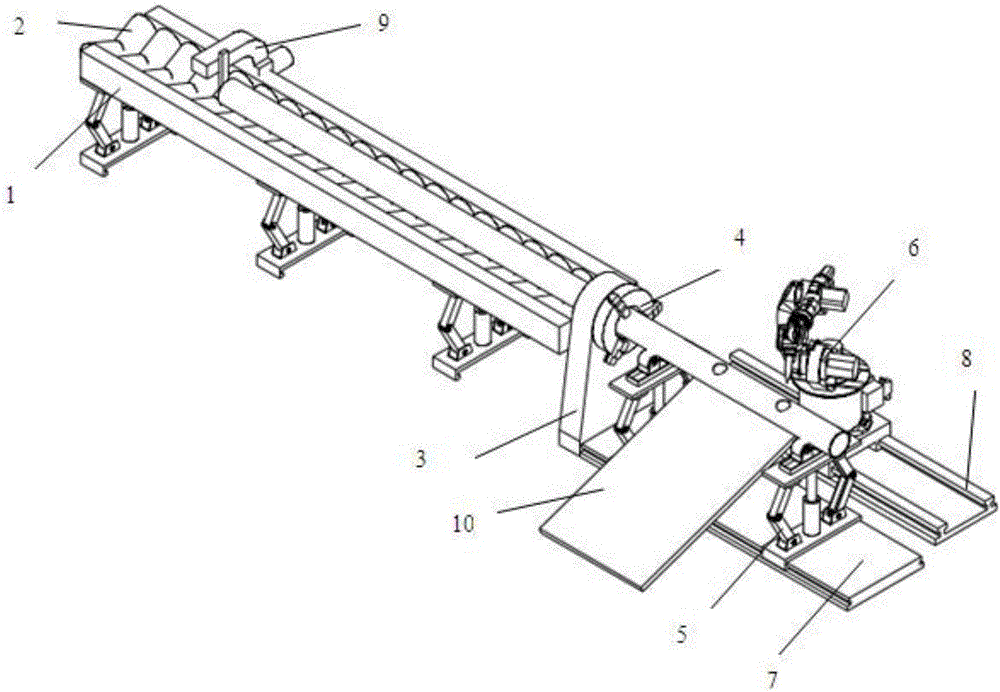

[0014] Attached below figure 1 Description, a circular tube intersecting wire cutting production line, including a feeding part for feeding round tube materials, a cutting part and a blanking part for finished product blanking, the feeding part includes a lifting platform 1 and a 1 on the round pipe transfer device; the cutting part includes a positioner 3, a hollow chuck 4, a liftable bracket 5 and a laser cutting robot 6, and the hollow chuck 4 is installed on the positioner 3, The center of the rotary unit of the positioner 3 has a round hole through which the material of the round tube can pass, and the center of rotation of the hollow chuck 4 coincides with the center of rotation of the rotary unit of the positioner 3, forming a channel for feeding the material of the round tube; There are two liftable brackets 5. When cutting the round tube material, the liftable bracket 5 rises to support the round tube material; The height is lower than the height of the rotation cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com