Automatic nut burying and sprue cutting equipment

A technology for cutting gates and nuts, applied in the field of machinery, can solve the problems of low production efficiency, reduced product quality, and high production costs, and achieve the effects of high production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

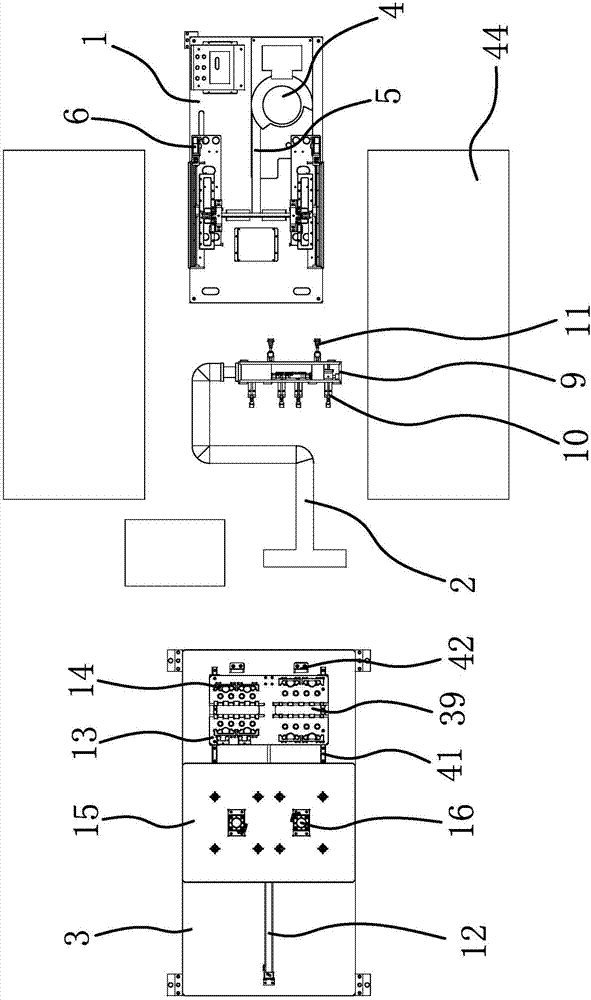

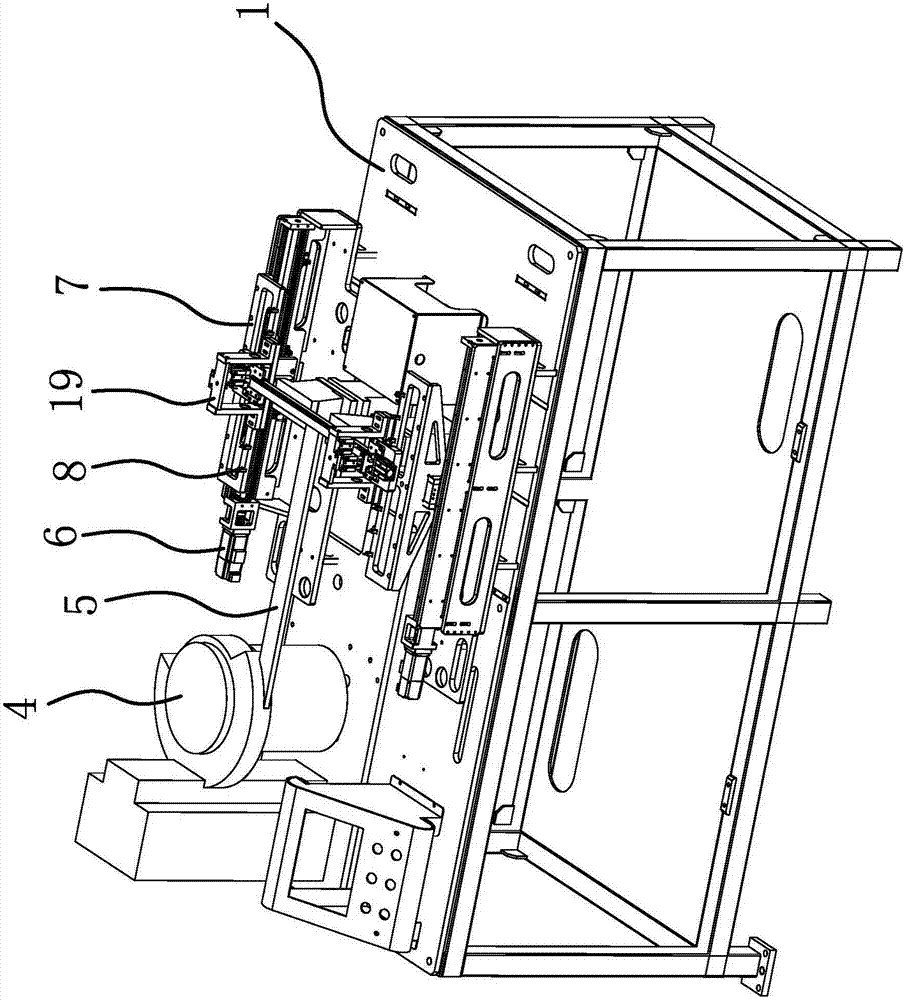

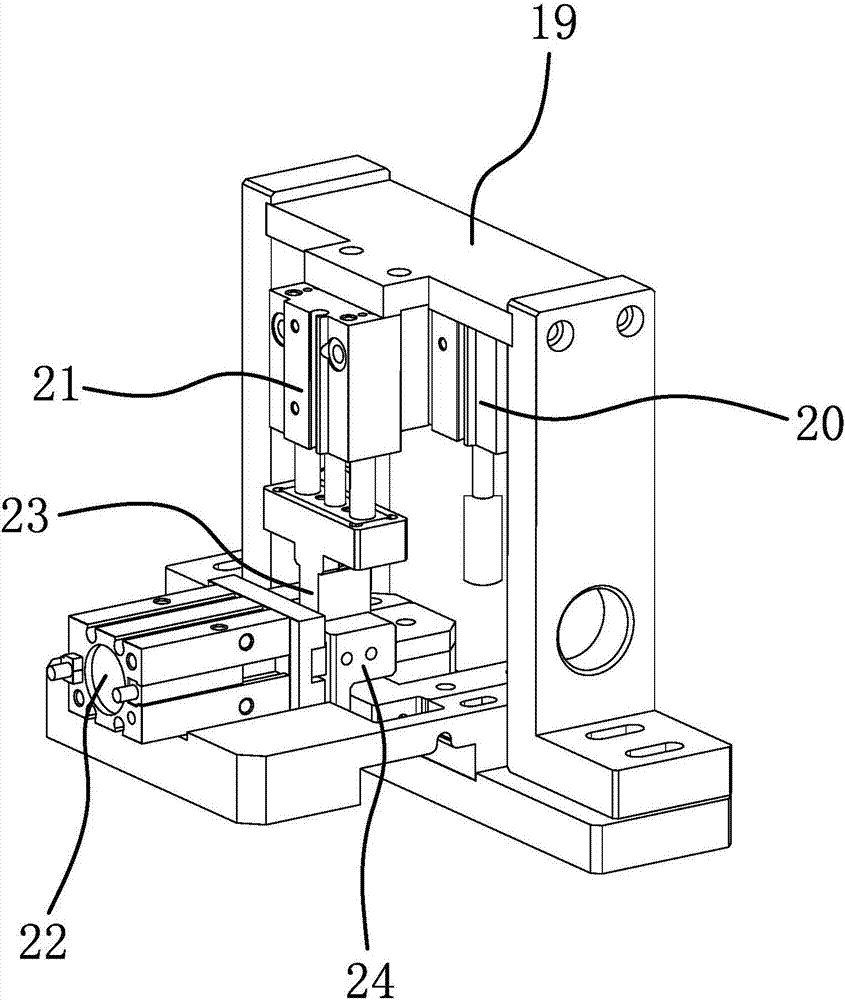

[0030] This automatic buried nut and gate cutting equipment is mainly used for buried nuts and gate cutting for pipe clamps. Such as figure 1 As shown, the automatic buried nut and gate cutting equipment includes a first workbench 1, a manipulator 2, a second workbench 3, a vibrating tray 4, a conveying channel 5, a first driving source 6, a sliding frame 7, and a positioning column 8 , mounting plate 9, first clamping cylinder 10, clamping air nozzle 11, second drive source 12, slide plate 13, positioning frame 14, mounting frame 15, lifting cylinder 16, first platen 17 and cutter 18.

[0031] Such as figure 2 As shown, the vibrating tray 4 and the conveying channel 5 are all fixedly connected on the first workbench 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com