Patents

Literature

66results about How to "With automatic feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

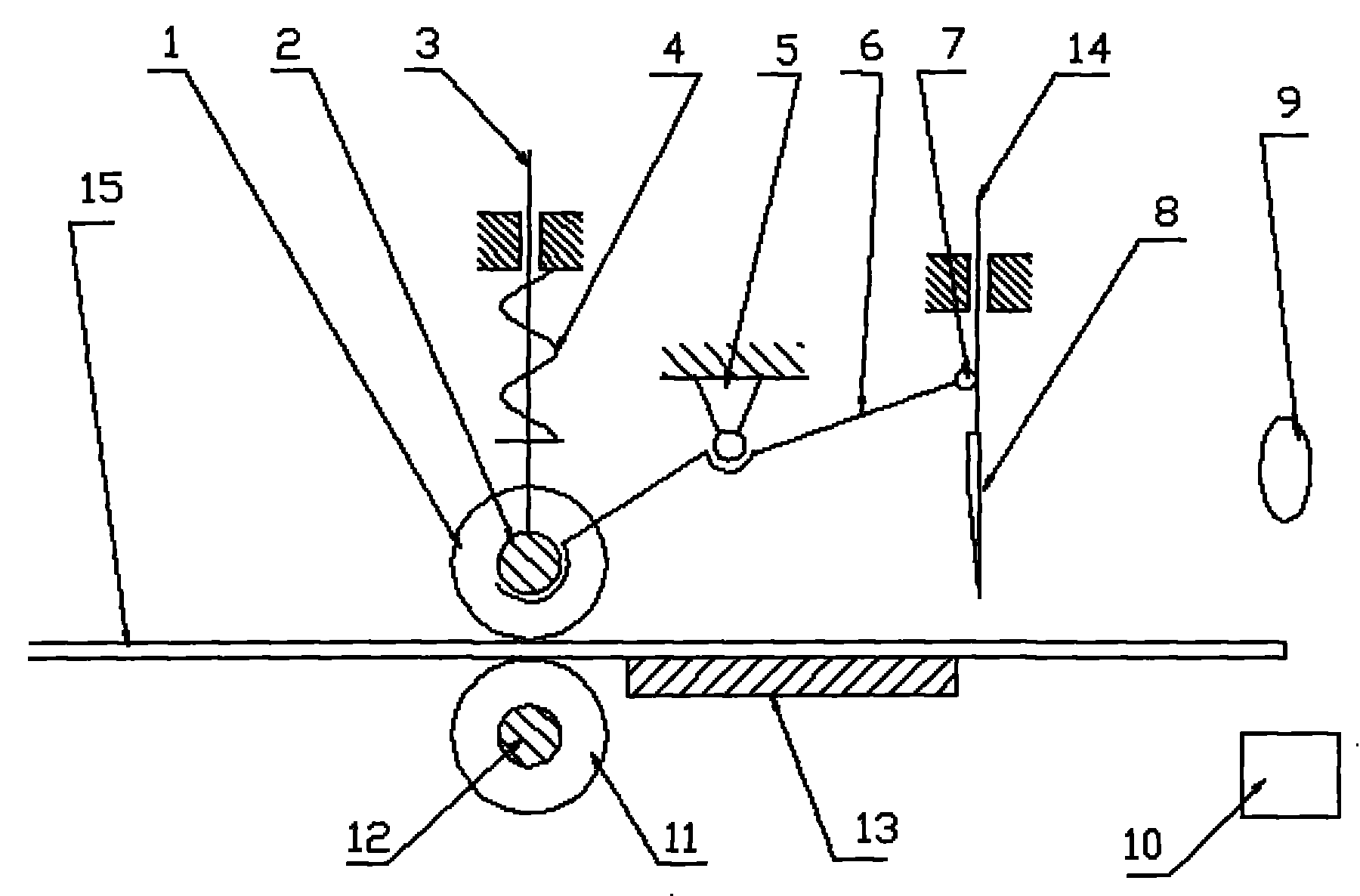

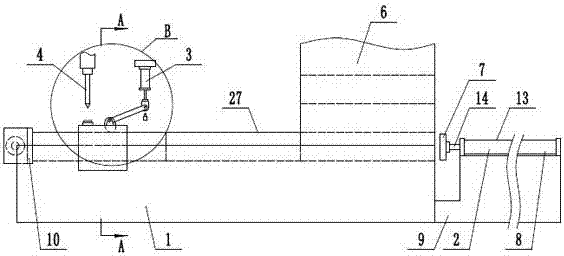

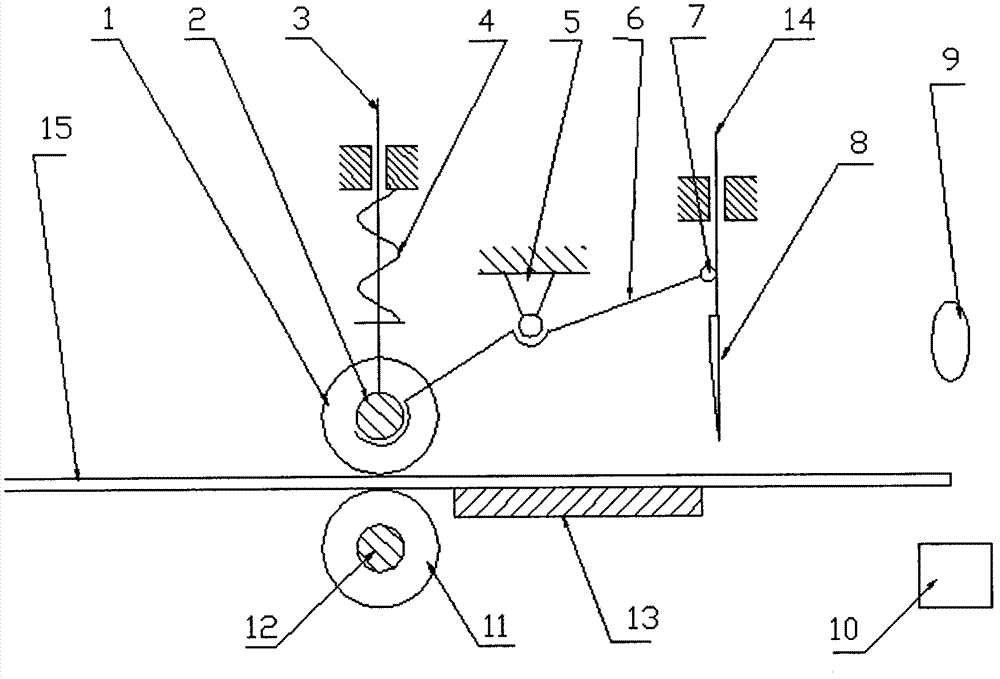

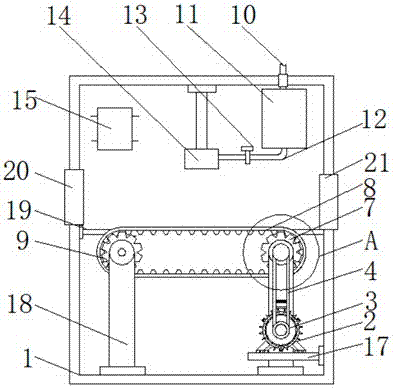

Automatically length-fixing plate shearing machine

InactiveCN102009416AWith automatic feedingHigh degree of automationMetal working apparatusArticle feedersEngineeringMechanical engineering

An automatically length-fixing shearing machine is provided. A compaction roller is installed on a pressure bar by a compression roller shaft. A compression spring is installed on the pressure bar, and the proper part in the middle of a connecting rod is installed on a bearer. One end of the connecting rod is hinged to the compression roller shaft, and the other end is hinged to a cutting knife seat through a connecting rod pin. A cutting knife is installed on the cutting knife seat. An infrared ray emitter and an infrared ray receiver are installed symmetrically in proper positions of two sides of a guide rail. Simultaneously, the positions of the infrared ray emitter and receiver can be adjusted in the guiding direction of the guide rail. The guide rail is fixedly installed on the plate shearing machine, and the guiding direction of guide rail is vertical to the cutting knife plane of the plate shearing machine. A fixed roller is fixedly installed in proper position of the plate shearing machine through a fixed roller shaft, wherein the highest position of the fixed roller is in the same plane with the upper plane of the guide rail.

Owner:杨焕敏

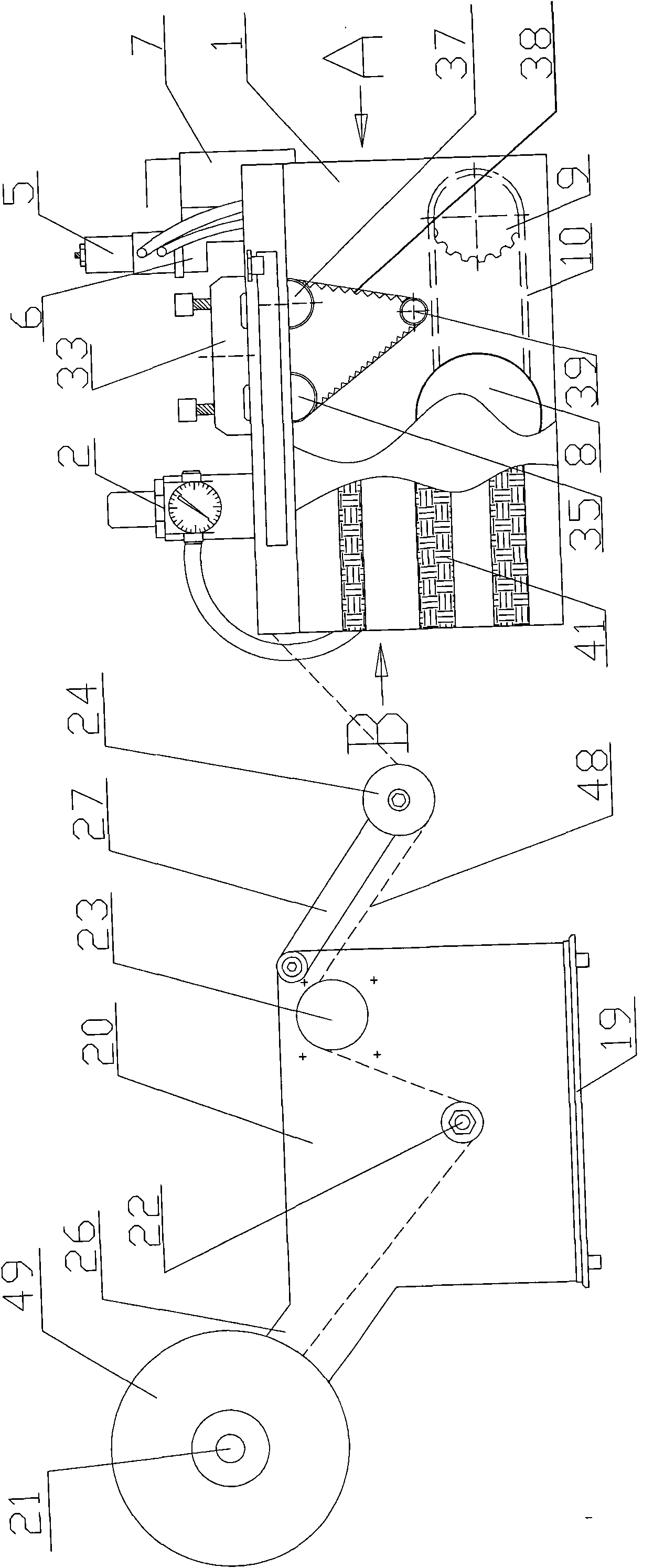

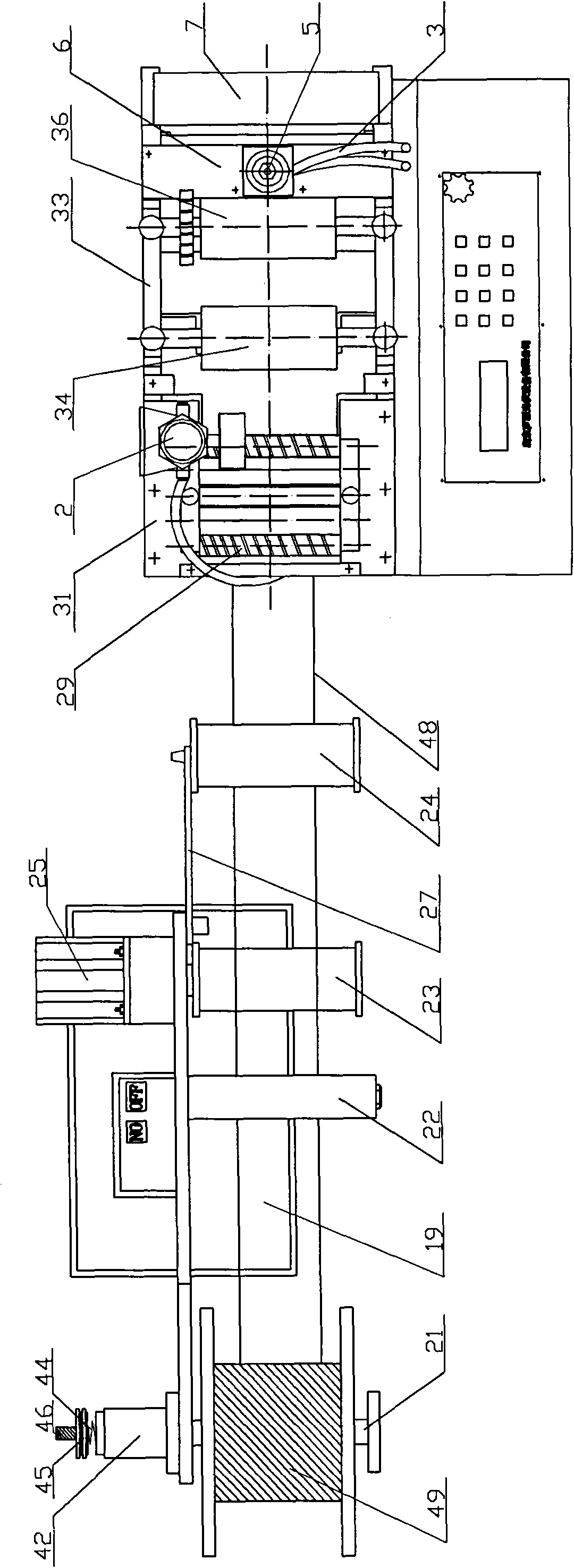

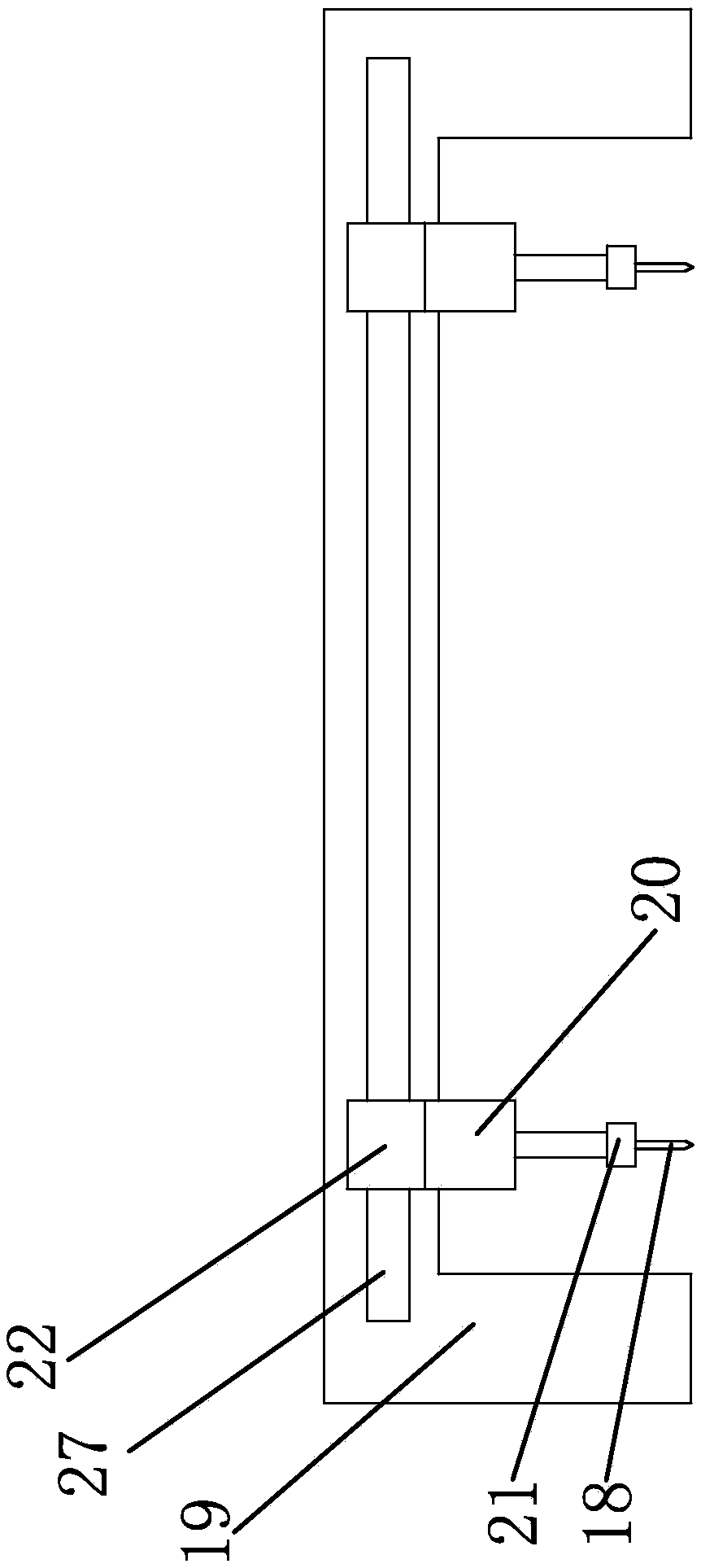

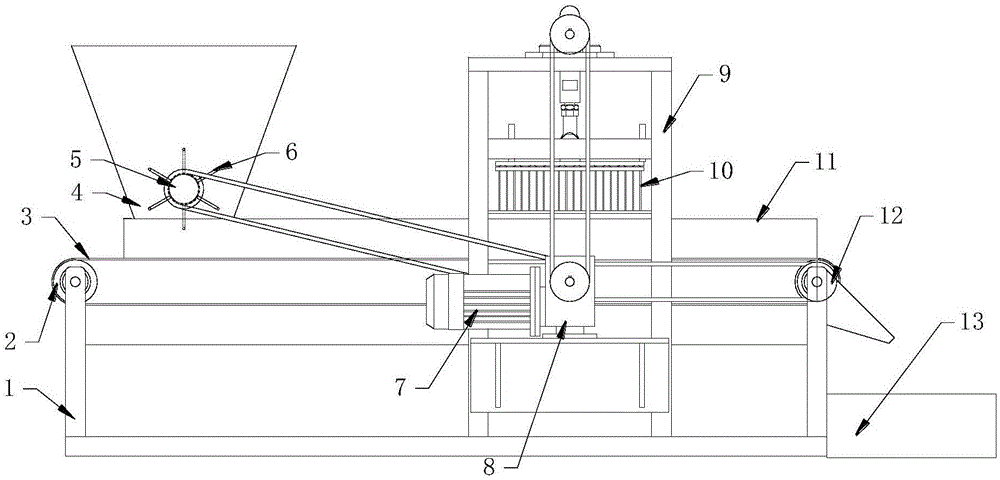

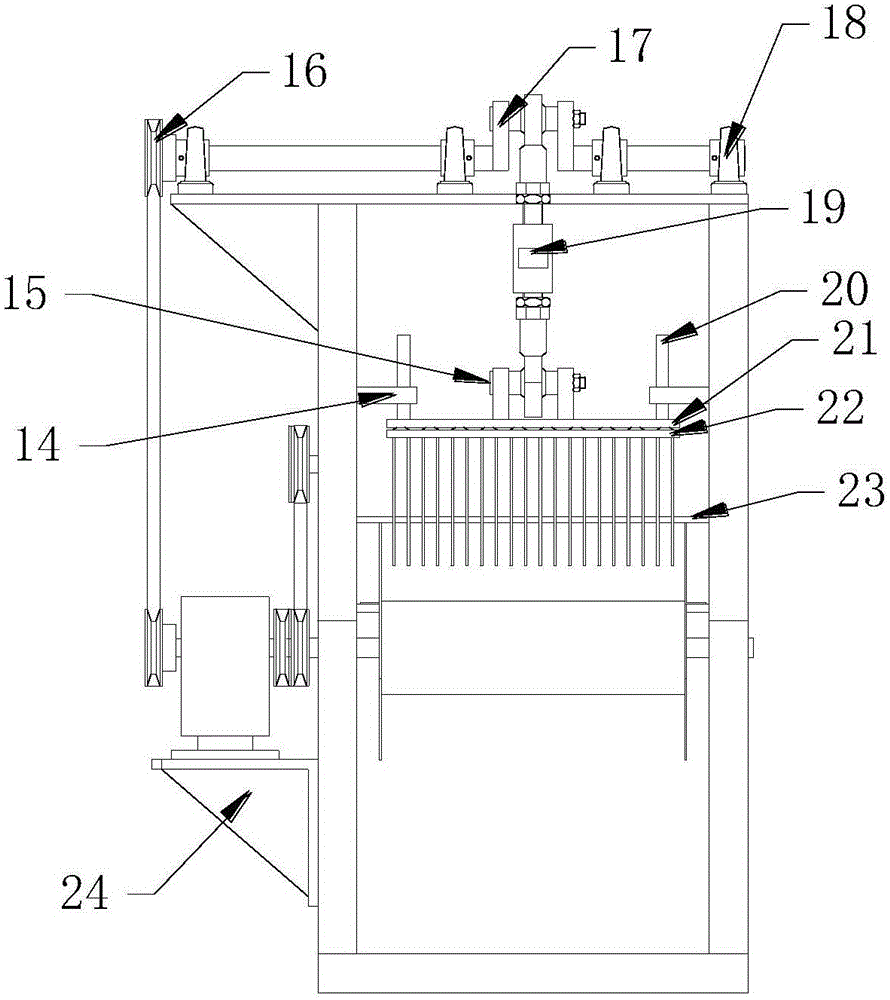

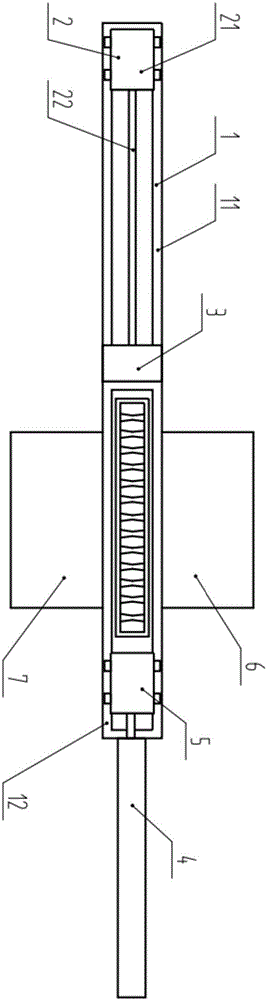

Full-automatic welding strip cutting bender

InactiveCN101837392AControl the feeding speedControl cutting speedMetal working apparatusElectric machineryPulp and paper industry

The invention relates to a full-automatic welding strip cutting bender, which is characterized by comprising an emptying mechanism, a levelling mechanism, a bending mechanism, a cutting mechanism and a box body, wherein one end of the oil-water separator of the bending mechanism is connected with a gas resource, and the other end of the oil-water separator is connected with a cylinder by a pipeline; the cylinder is fixed on a cylinder frame; the cylinder shaft of the cylinder is connected with a bending path frame; the cylinder frame is fixed on a fixed mount on the discharge end of the box body; the lower cutter of the cutting mechanism is fixed on the lower end of the fixed mount; the upper cutter is fixed on an upper cutter frame capable of moving up and down; a motor is connected with one of two eccentric sprockets with same eccentricity, and the eccentric sprockets are fixed on an eccentric shaft by a chain; two eccentric sprockets are fixedly connected with two ends on the bottom of the upper cutter frame via a link block; a small eccentric wheel with a photosenser is fixed in the middle of the eccentric shaft between two eccentric sprockets; and a photo-groove is arranged near the position below the small eccentric wheel. The invention improves production efficiency, lowers labour cost and improves product quality.

Owner:启东市罗源光伏设备有限公司

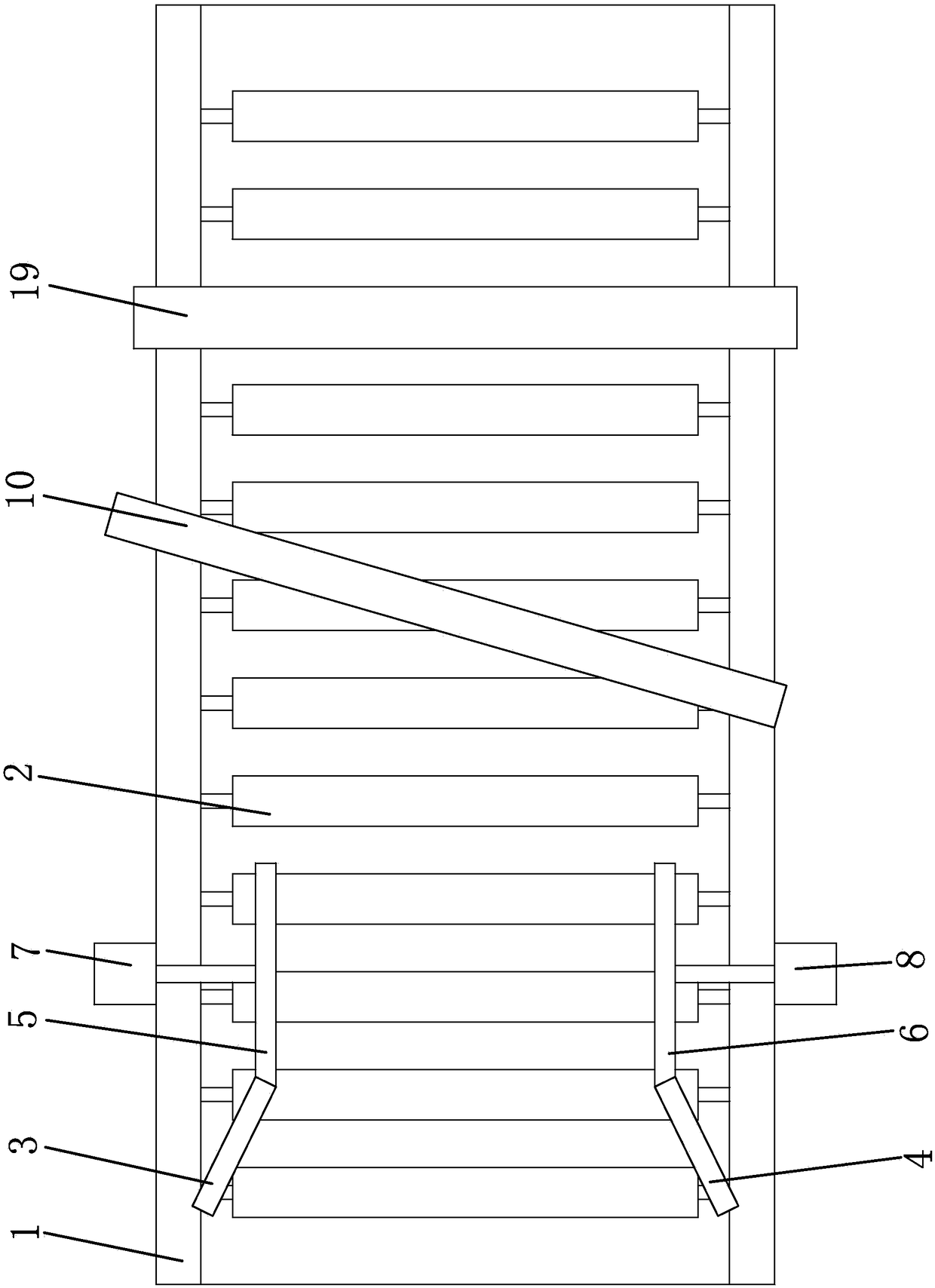

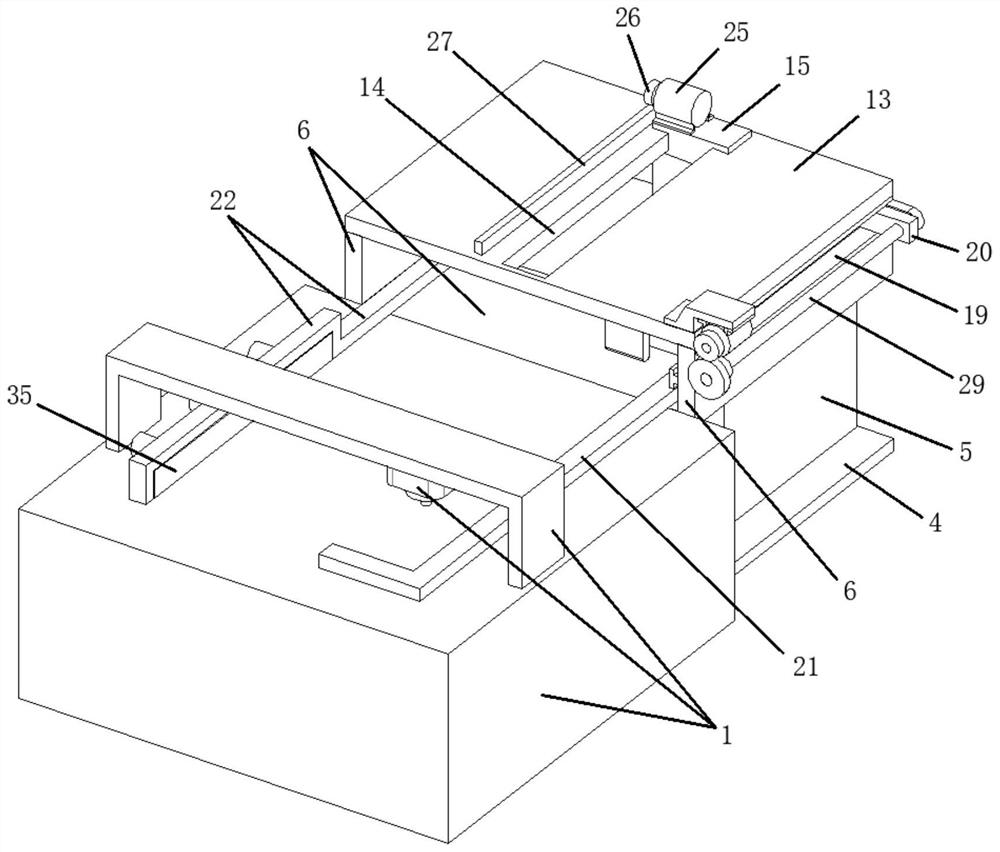

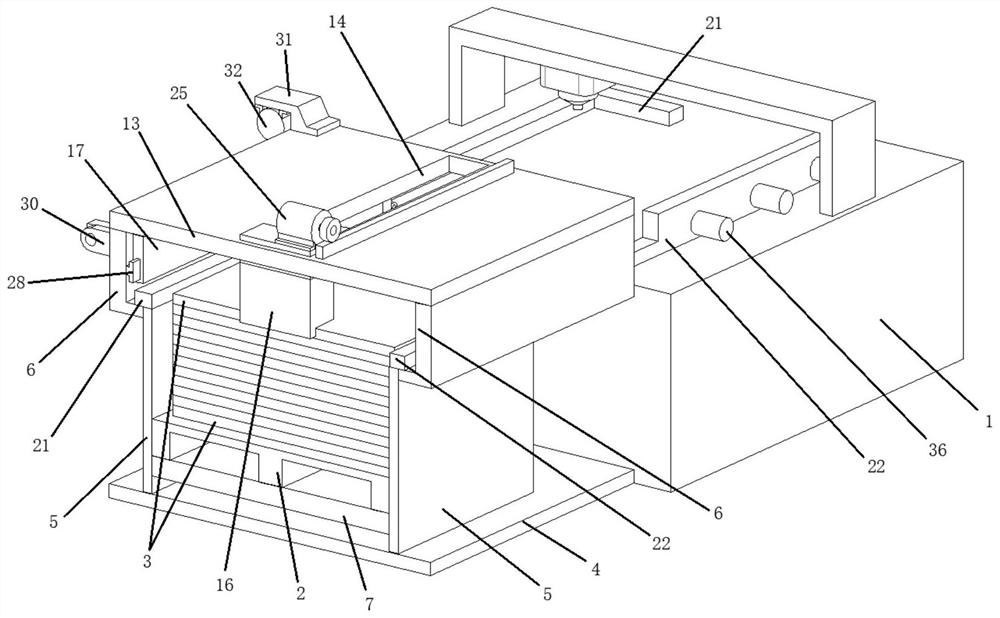

Board cutting device

InactiveCN108326615AIncrease productivityImplement aspectsLarge fixed membersPositioning apparatusEngineeringMechanical engineering

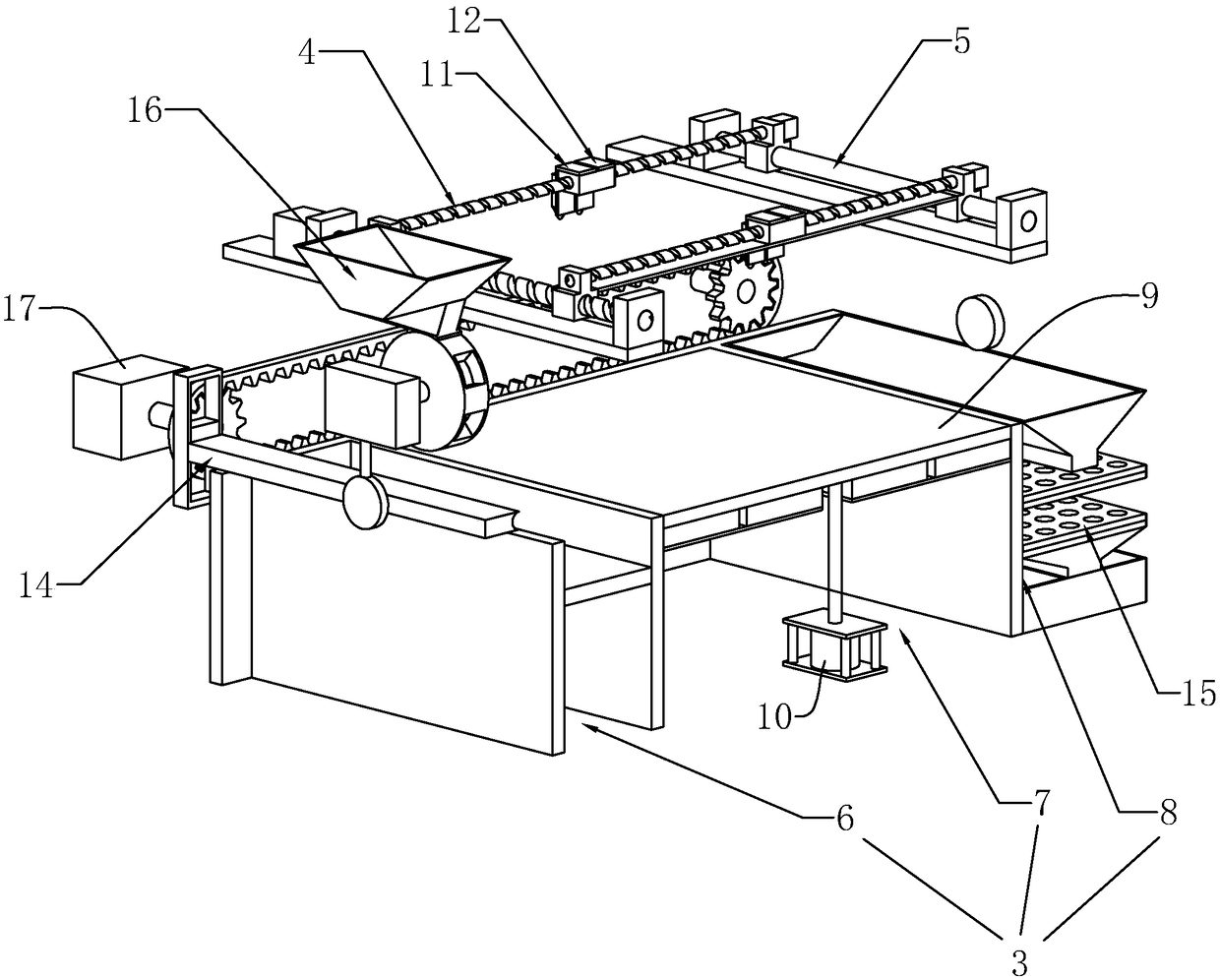

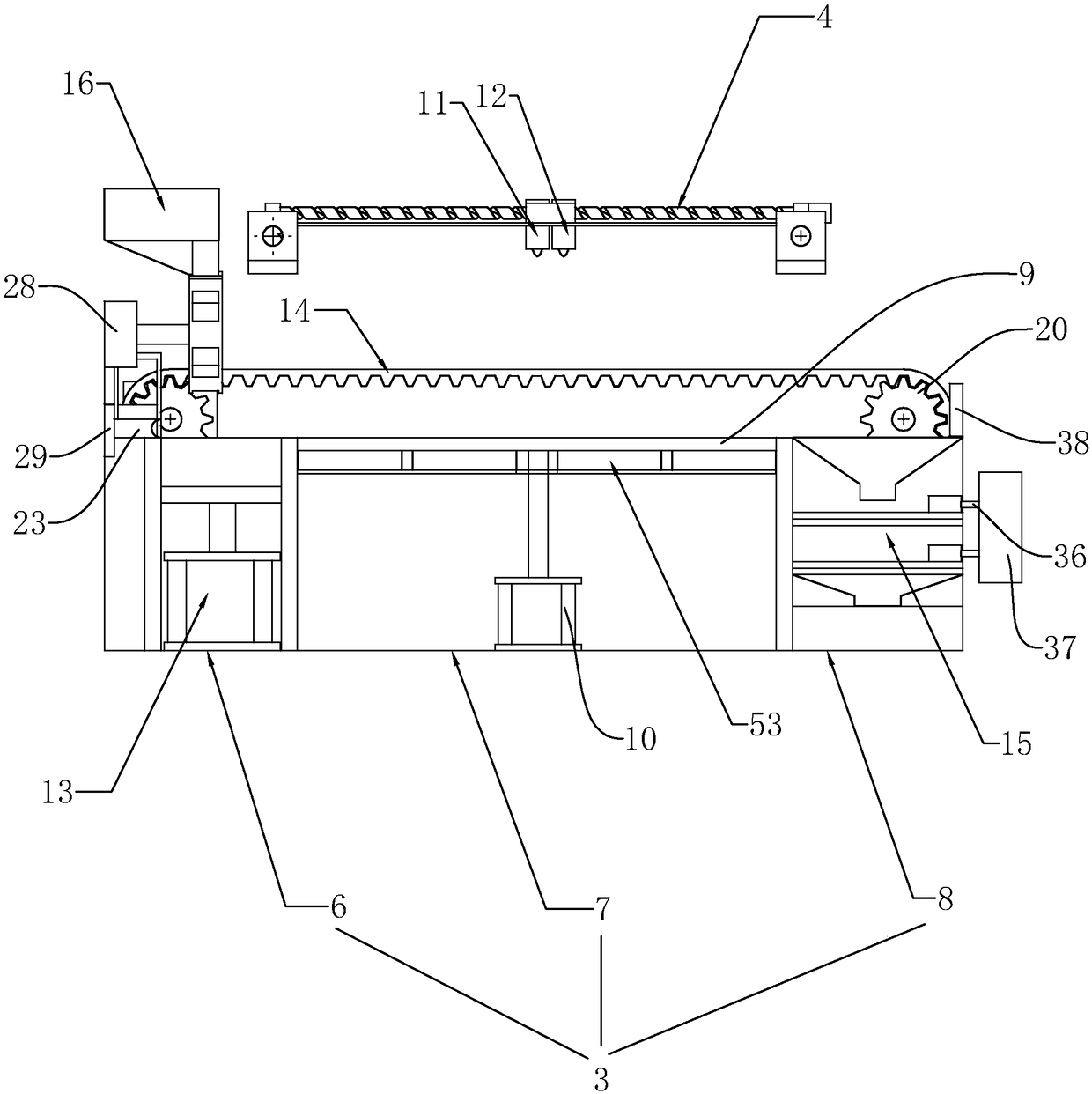

The invention provides a board cutting device, belongs to the technical field of machinery and solves the problem of low cutting efficiency in the prior art. The board cutting device comprises a long-strip-shaped workbench, wherein the workbench comprises an input end and an output end, a conveying mechanism capable of driving a board to convey forwards is arranged on the workbench, an anti-shiftmechanism for preventing the board from shifting is arranged at the input end, a horizontal cutting mechanism for cutting the board in the direction perpendicular to the board conveying direction is arranged above the rack, a longitudinal cutting mechanism for cutting the board in the board conveying direction is arranged above the workbench, and a discharging mechanism for automatically discharging the board is arranged at the output end. The board cutting device has the advantage of high cutting efficiency.

Owner:海宁市纵达新材料股份有限公司

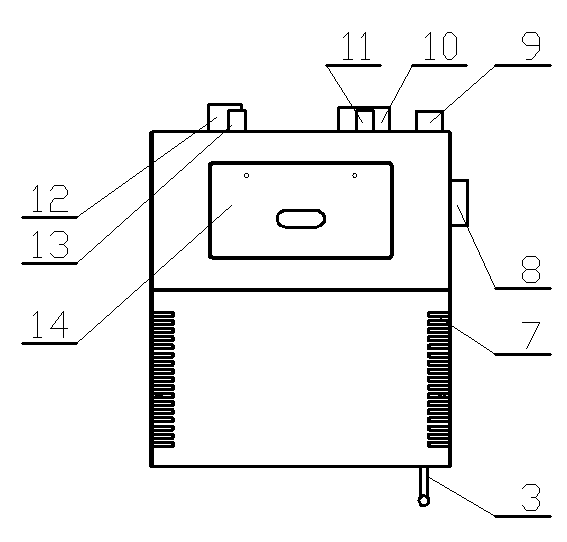

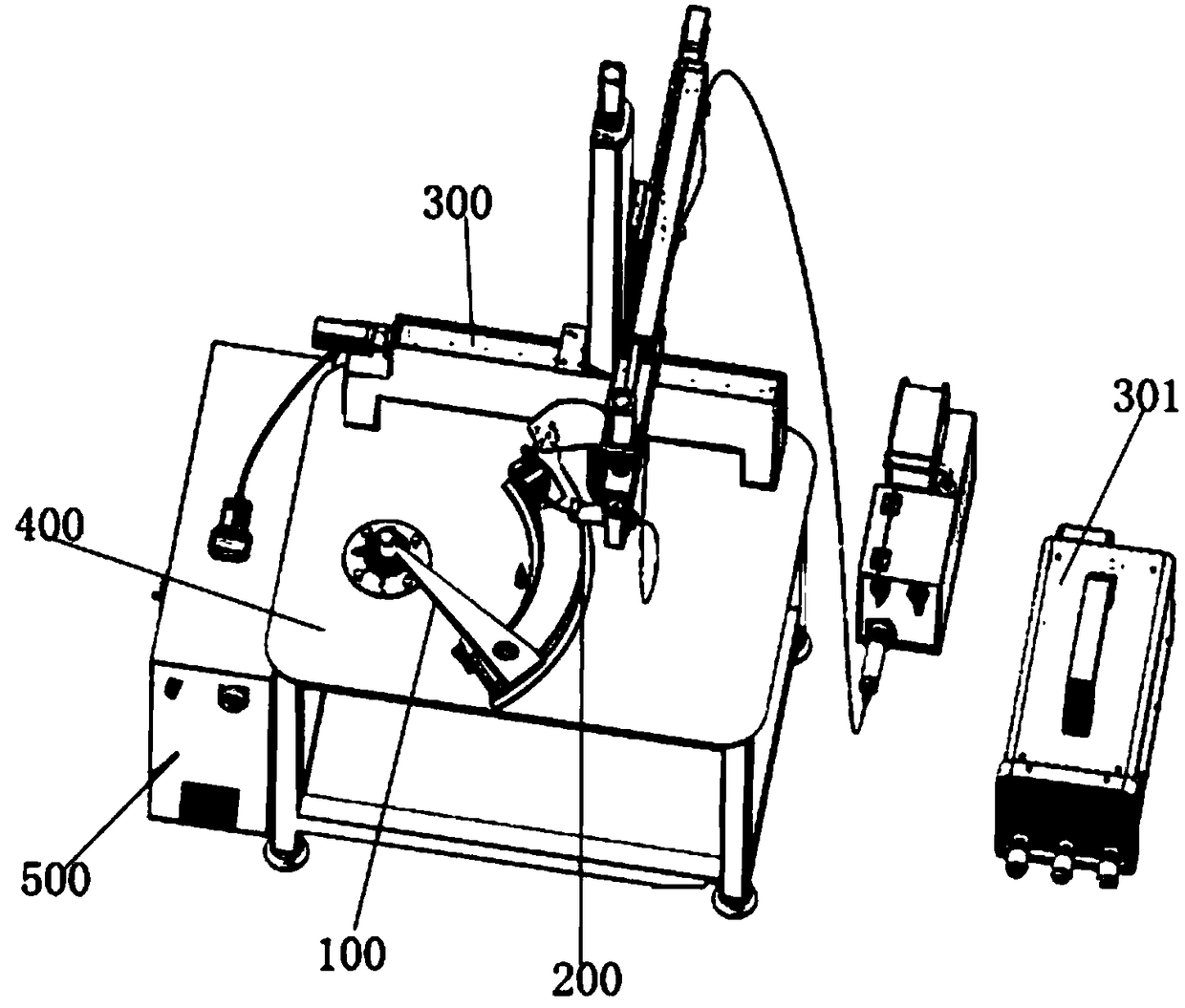

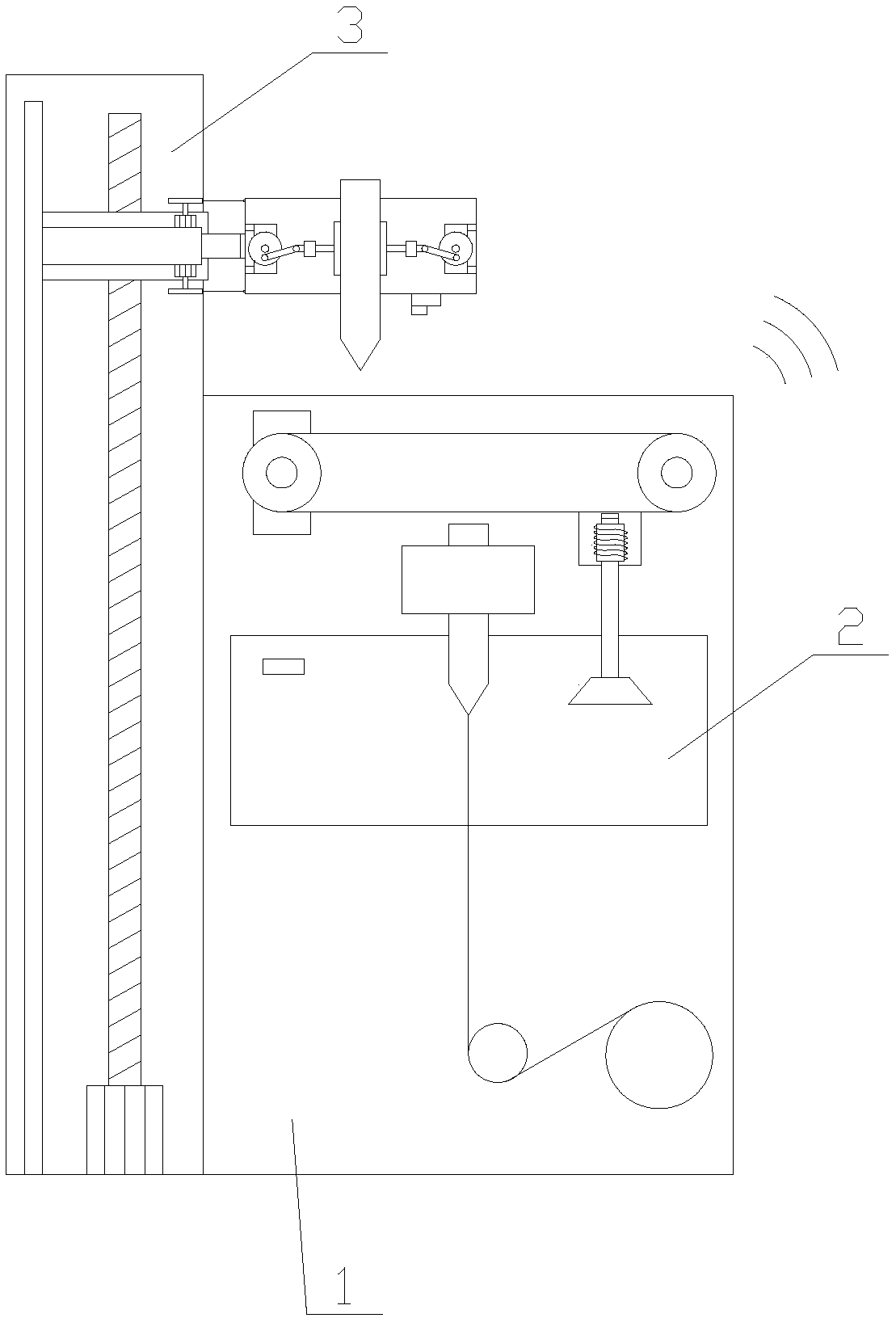

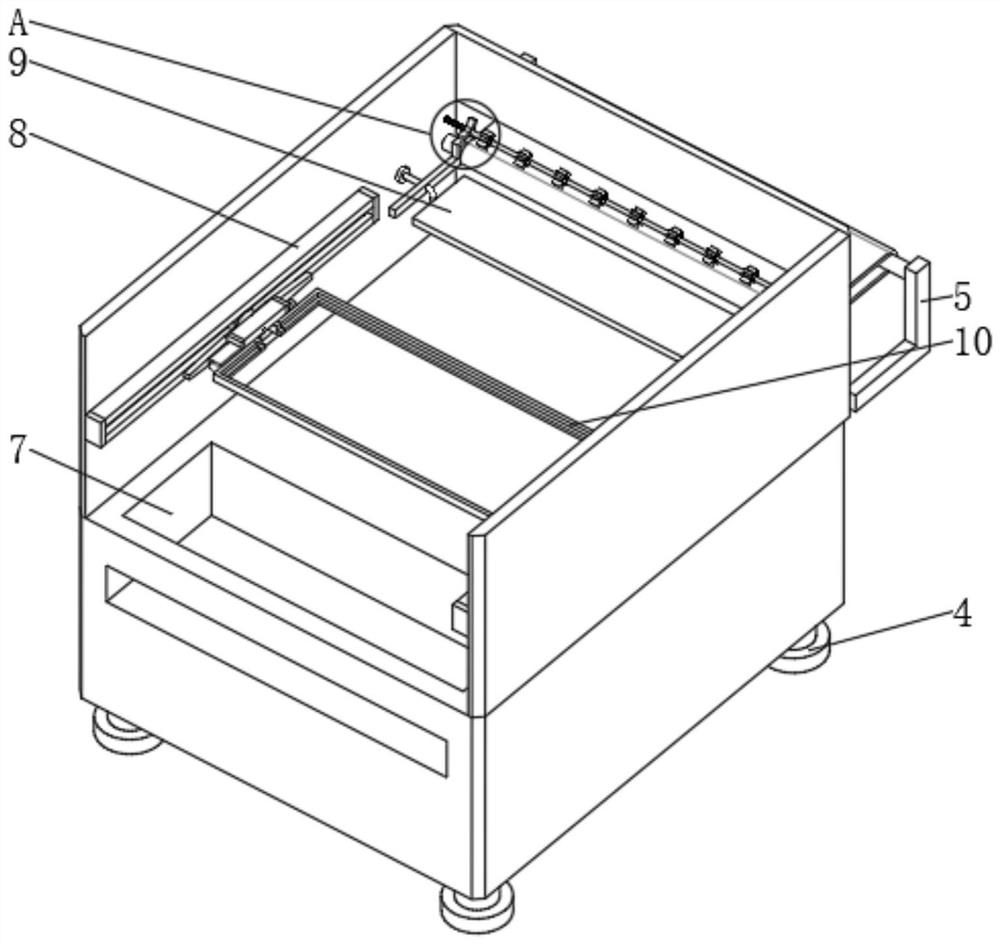

selective laser melting(SLM) 3D printer

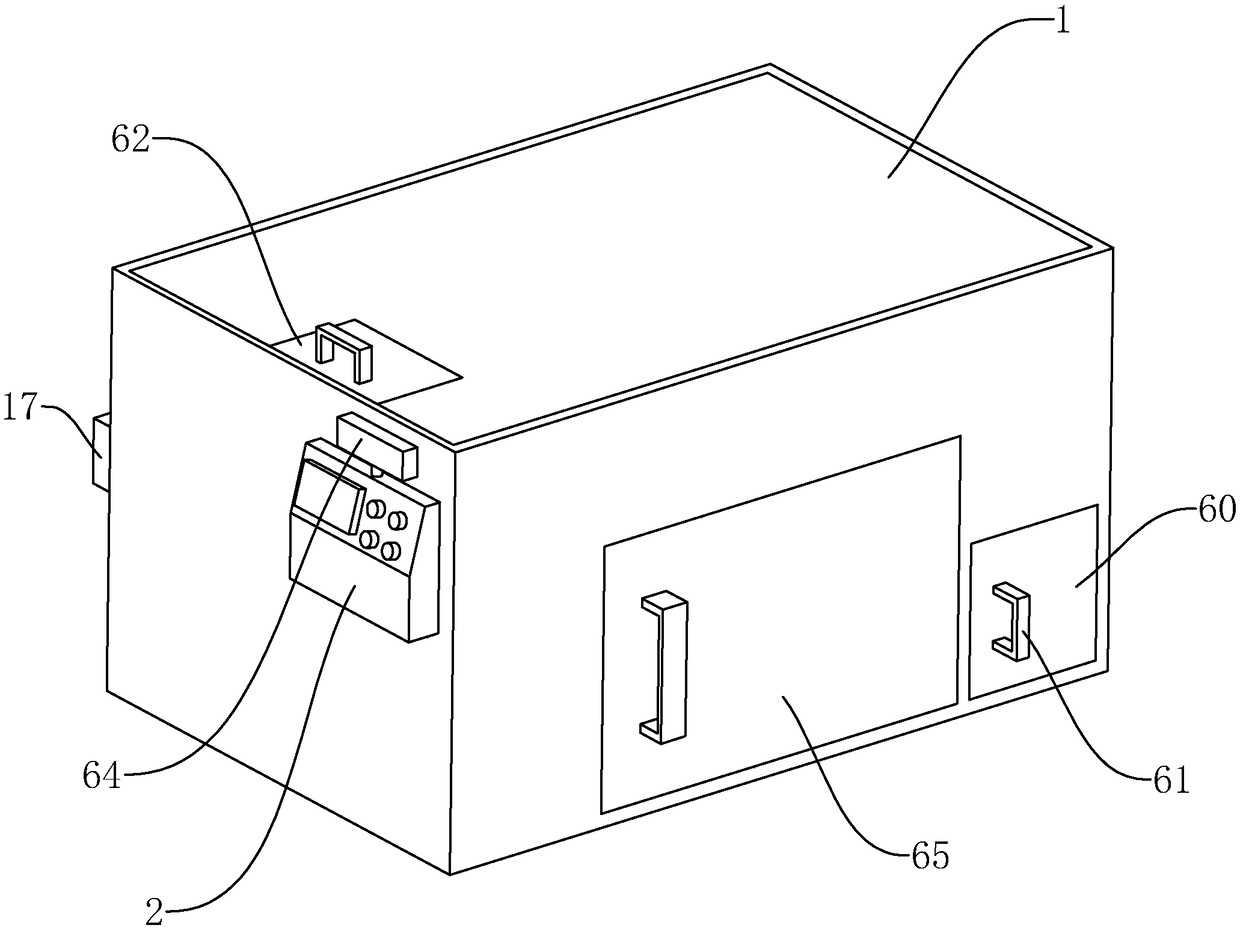

PendingCN108687347AFast scanningFast cooling and solidificationAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingEngineering

The invention discloses a selective laser melting (SLM) 3D printer. The SLM 3D printer comprises an air protection tank and a computer arranged on the outer wall of the air protection tank; the air protection tank is internally provided with a powder laying forming workbench; two groups of X-axis movement mechanisms are arranged above the powder laying forming workbench; the two groups of X-axis movement mechanisms are connected with a Y-axis movement mechanism; a powder feeding cylinder, a powder laying forming cylinder and a powder recycle cylinder are sequentially arranged on the powder laying forming workbench in an inserting mode; the powder laying forming cylinder is internally provided with a printing substrate plate; a Z-direction movement mechanism used for driving the printing substrate plate to move in the Z direction in the powder laying forming cylinder is arranged on one side of the printing substrate plate; and each group of X-axis movement mechanism is provided with a laser cladding device used for performing selective laser melting on the printing substrate plate and a laser thermal treatment device used for improving metal structure and mechanical properties. TheSLM 3D printer has the beneficial effects that cracks produced in the process of metal solidification are prevented, yield rate is further improved, and meanwhile 3D printing speed is improved to be suitable for mass production.

Owner:JILIN UNIV

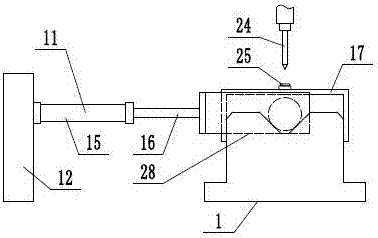

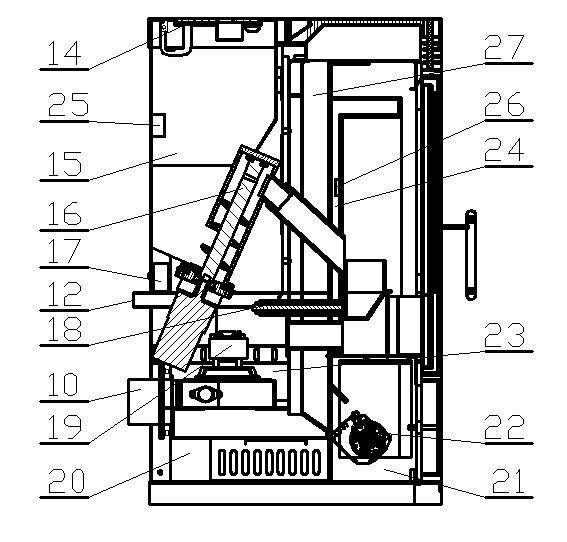

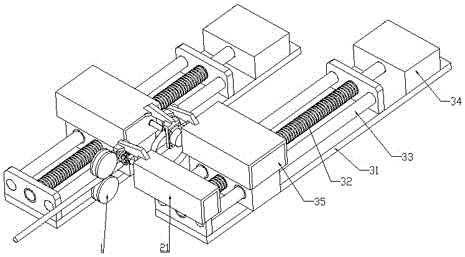

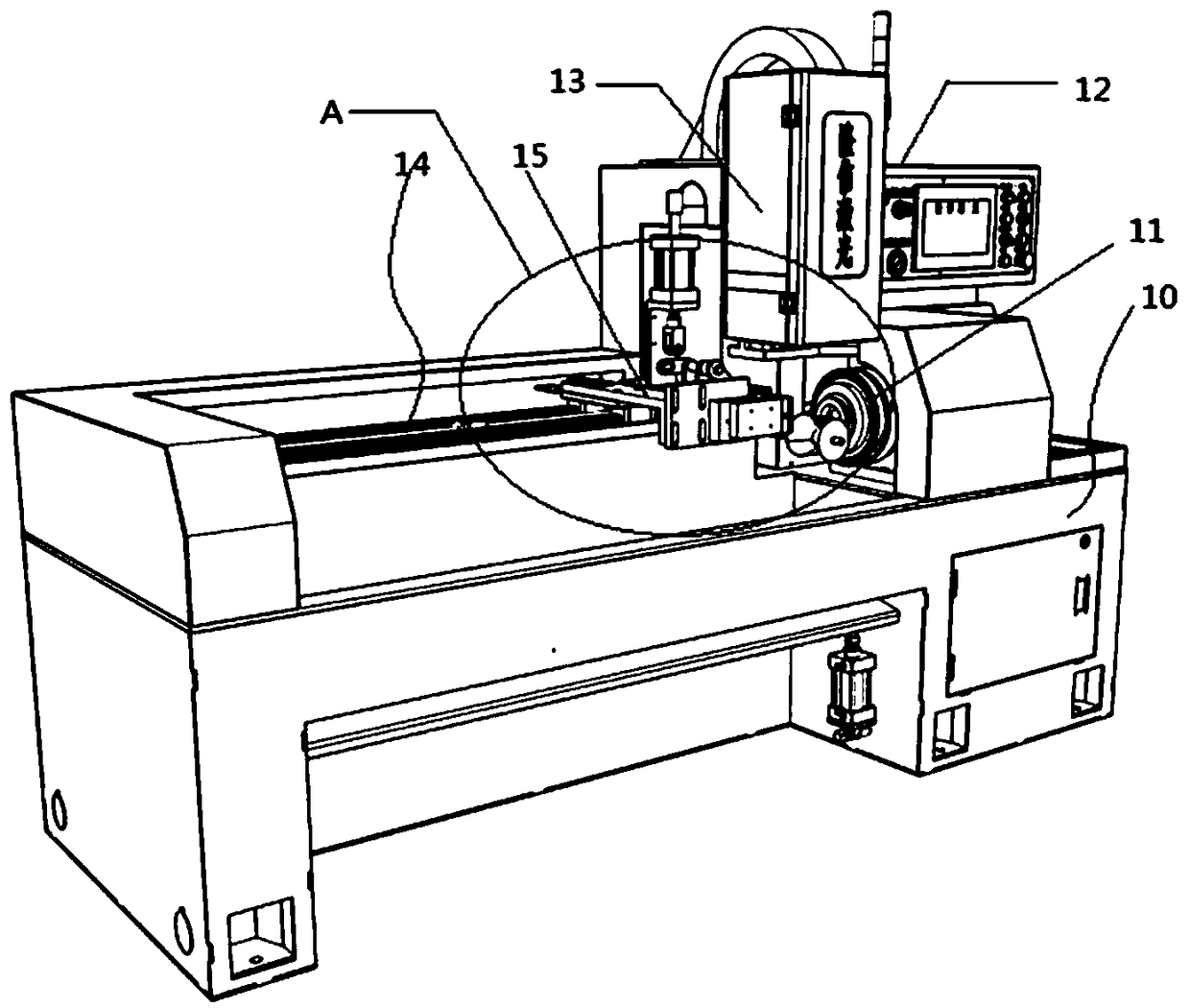

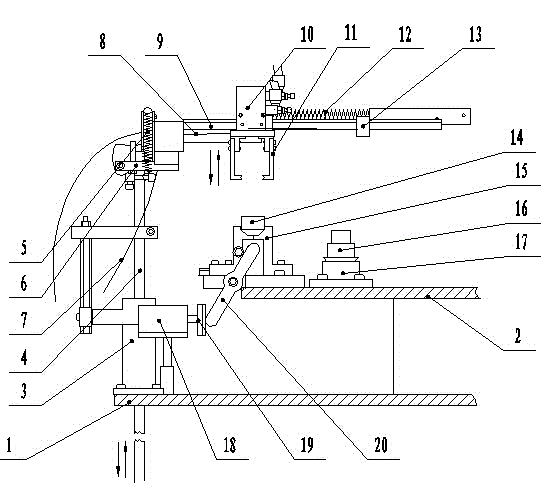

Automatic loading slitting step-shaft-type machine tool

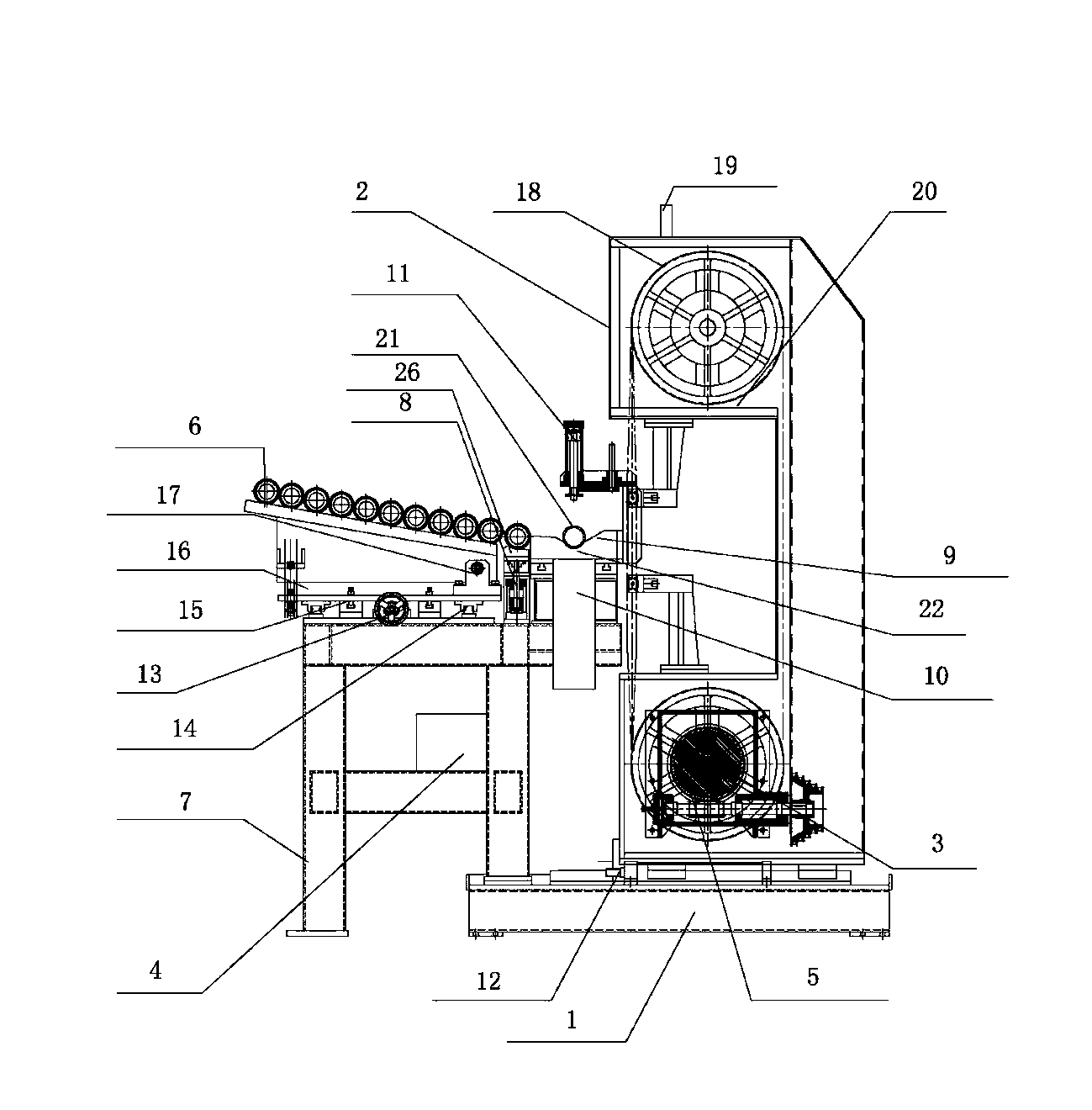

The invention discloses an automatic loading slitting step-shaft-type machine tool. The automatic loading slitting step-shaft-type machine tool comprises a base, and a saw frame, a transmission system, a guide device, a saw belt tensioning device, a cooling system, a hydraulic system, an electrical control system, an automatic loading system, a V-shaped positioning clamping mechanism and a saw frame feed oil cylinder, which are arranged on the base, wherein the transmission system comprises a worm gear speed reducer, a driving wheel and a tensioning wheel; the driving wheel, the tensioning wheel and the guide device are respectively arranged on the saw frame; a loading movement device is arranged on one side of the V-shaped positioning clamping mechanism; the automatic loading system is arranged between the loading movement device and the V-shaped positioning clamping mechanism; the loading movement device comprises an adjustable working platform and a working platform supporting frame; one end of the adjustable working platform, which is adjacent to the automatic loading system, is hinged with the working platform supporting frame; and the other end of the adjustable working platform is connected with the working platform supporting frame through a working platform adjusting bolt. The automatic loading slitting step-shaft-type machine tool has functions of automatically loading a material, overturning the material into a material frame and clamping and sawing the material, and is convenient to operate and high in production efficiency.

Owner:ZHE JIANG CHENLONG SAWING MACHINE CO LTD

Full-automatic punching machine

The invention provides a full-automatic punching machine. In the machine, a vacuum suction cup is arranged on a feed stand of a frame; a sliding bush is arranged on one side of the feed stand, and matched with a screw on a motor 1; an upper punching rack and a lower punching rack are arranged above and below the feed stand respectively; a cylinder is arranged on the upper punching rack; an upper punch is arranged on the connecting rod of the cylinder; a positioning rod 1 is arranged on the upper punch and in sliding connection with a grating scale of an upper die; the other side of a shell 1 is matched with a screw of the upper die; the lower punching rack is provided with a lifting device of a lower die; a lower punch is arranged at the upper part of the lifting device of the lower die; a positioning rod 2 is arranged on one side of the lifting device of the lower die, and connected with a grating scale of the lower die; the other side of the shell 2 is connected with the screw of the lower die; the frame is provided with an automatic feeding tank and a discharging tank; after the automatic discharging tank feeds a processing piece into the frame, the processing piece is delivered between the upper punch and the lower punch for punching along a Y direction under driving of the feed stand; and the punched processing piece is fed into a collecting tank. The full-automatic punching machine has the characteristics of small volume, automatic feeding and collecting and accurately positioned punching.

Owner:XIAN WENXIANG INTELLIGENT TECH CO LTD

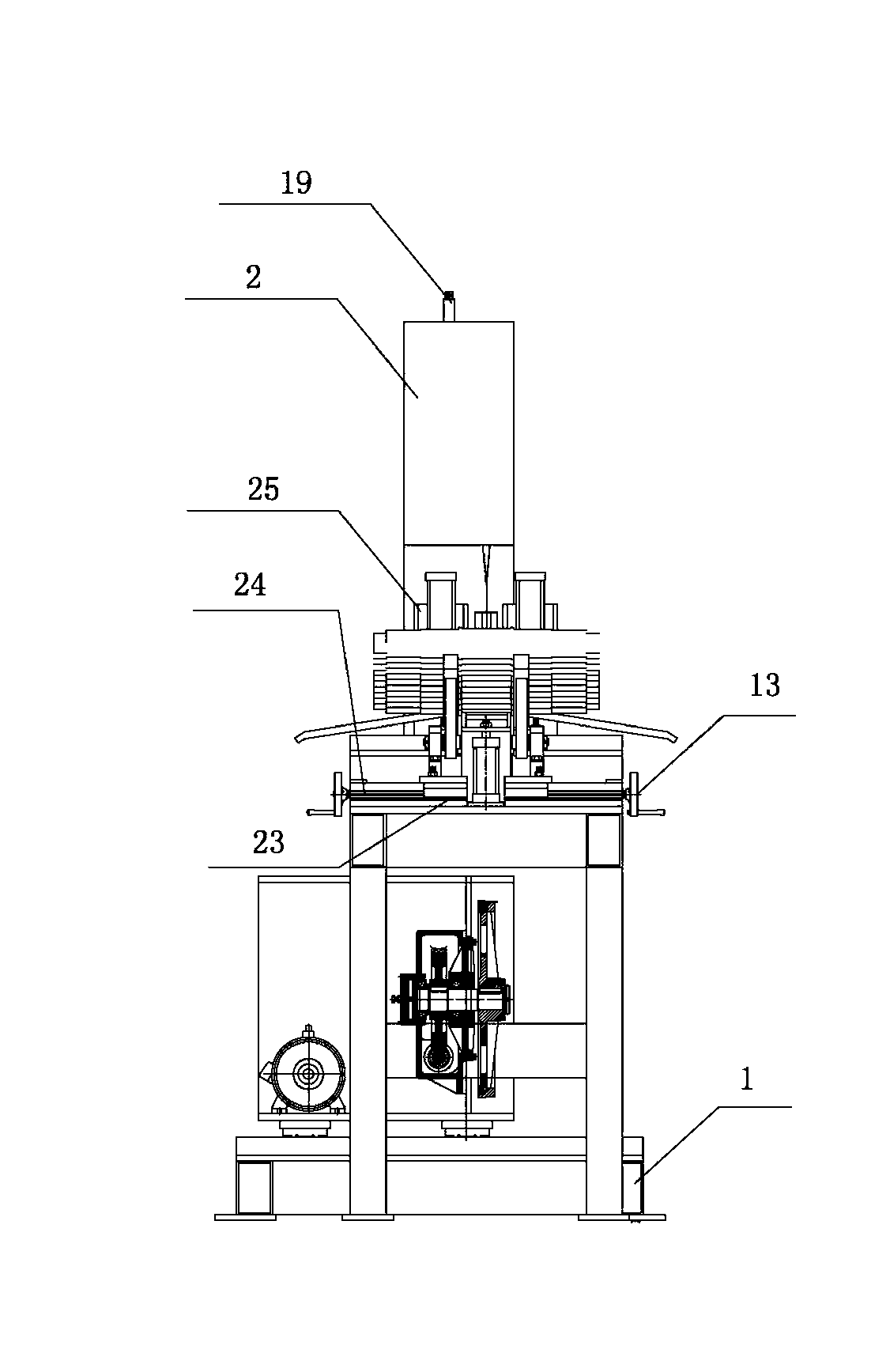

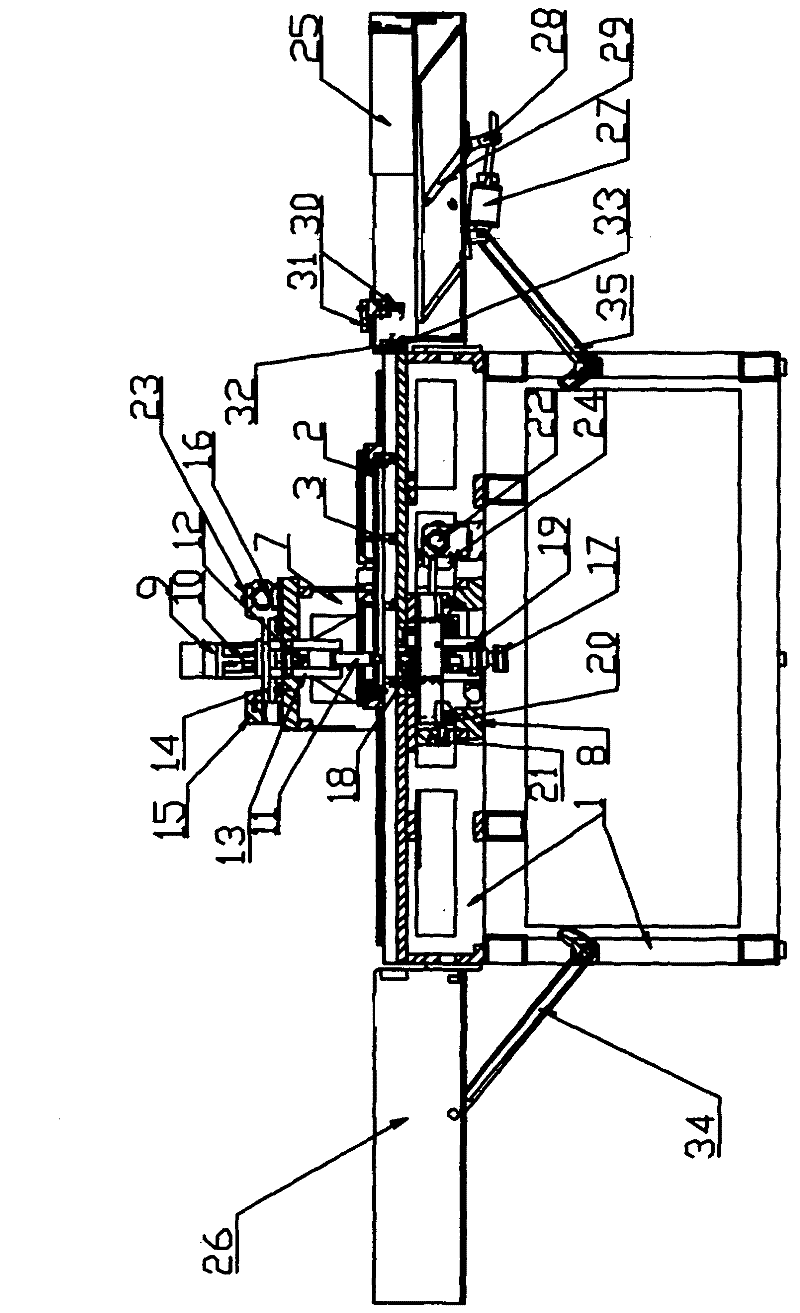

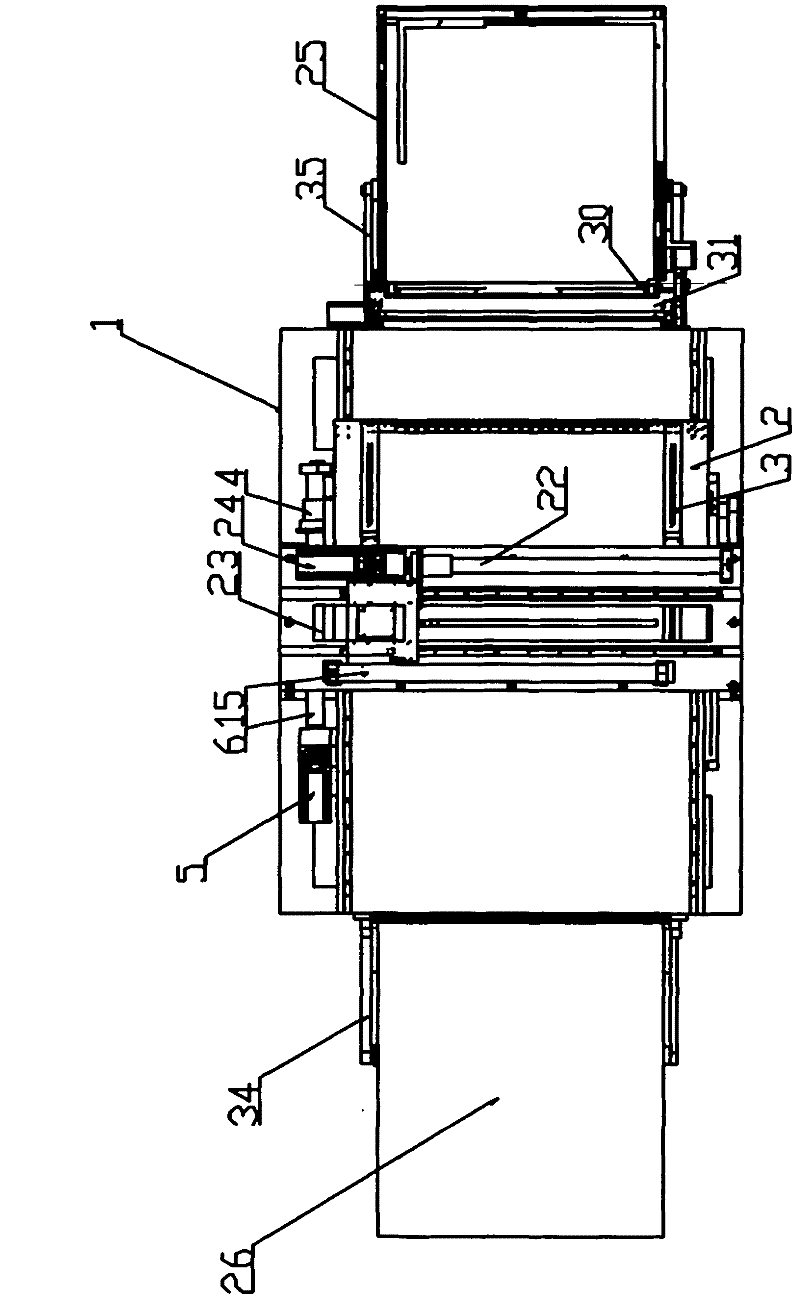

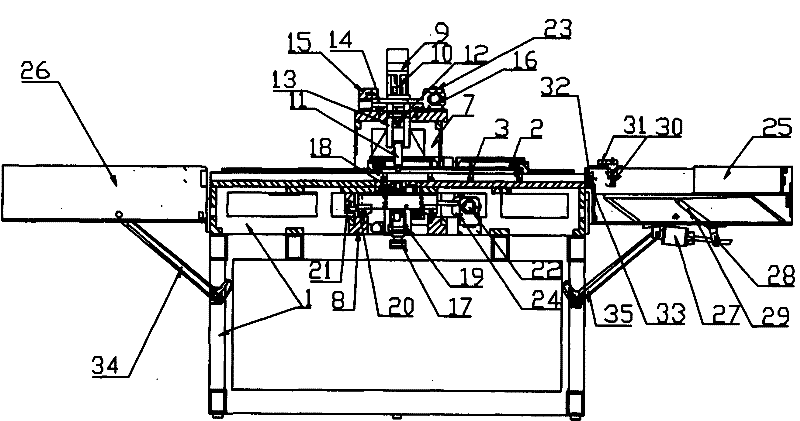

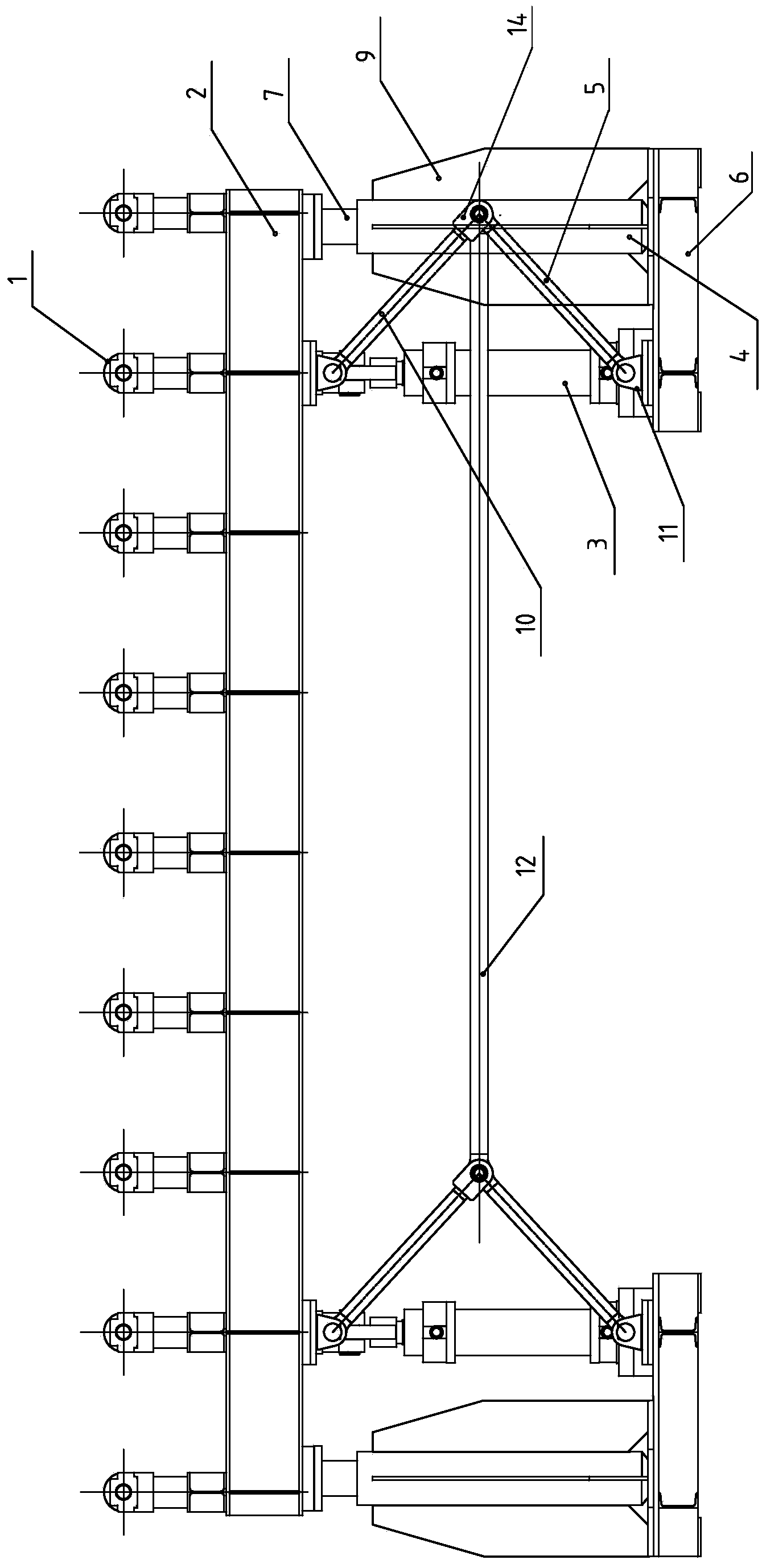

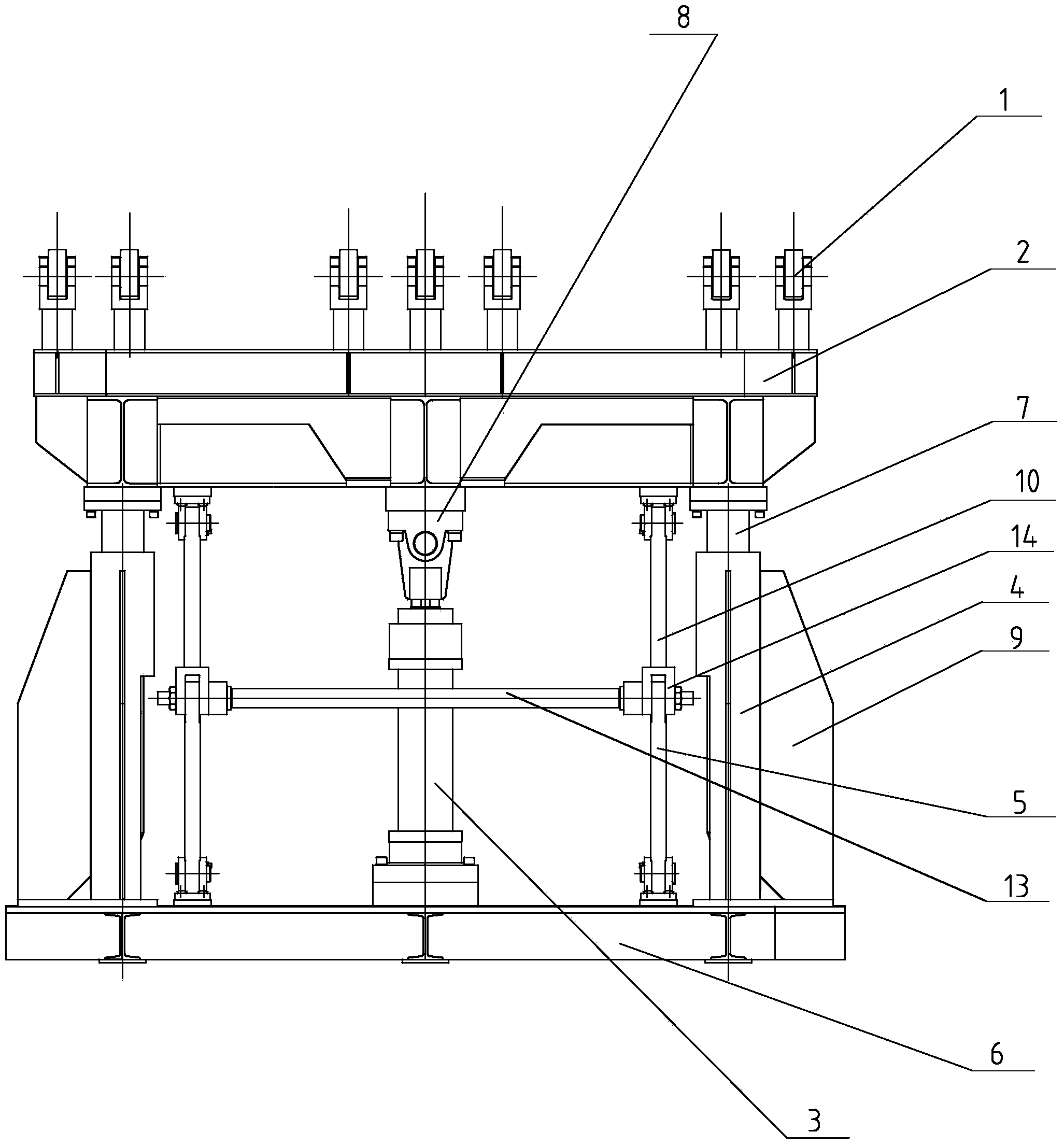

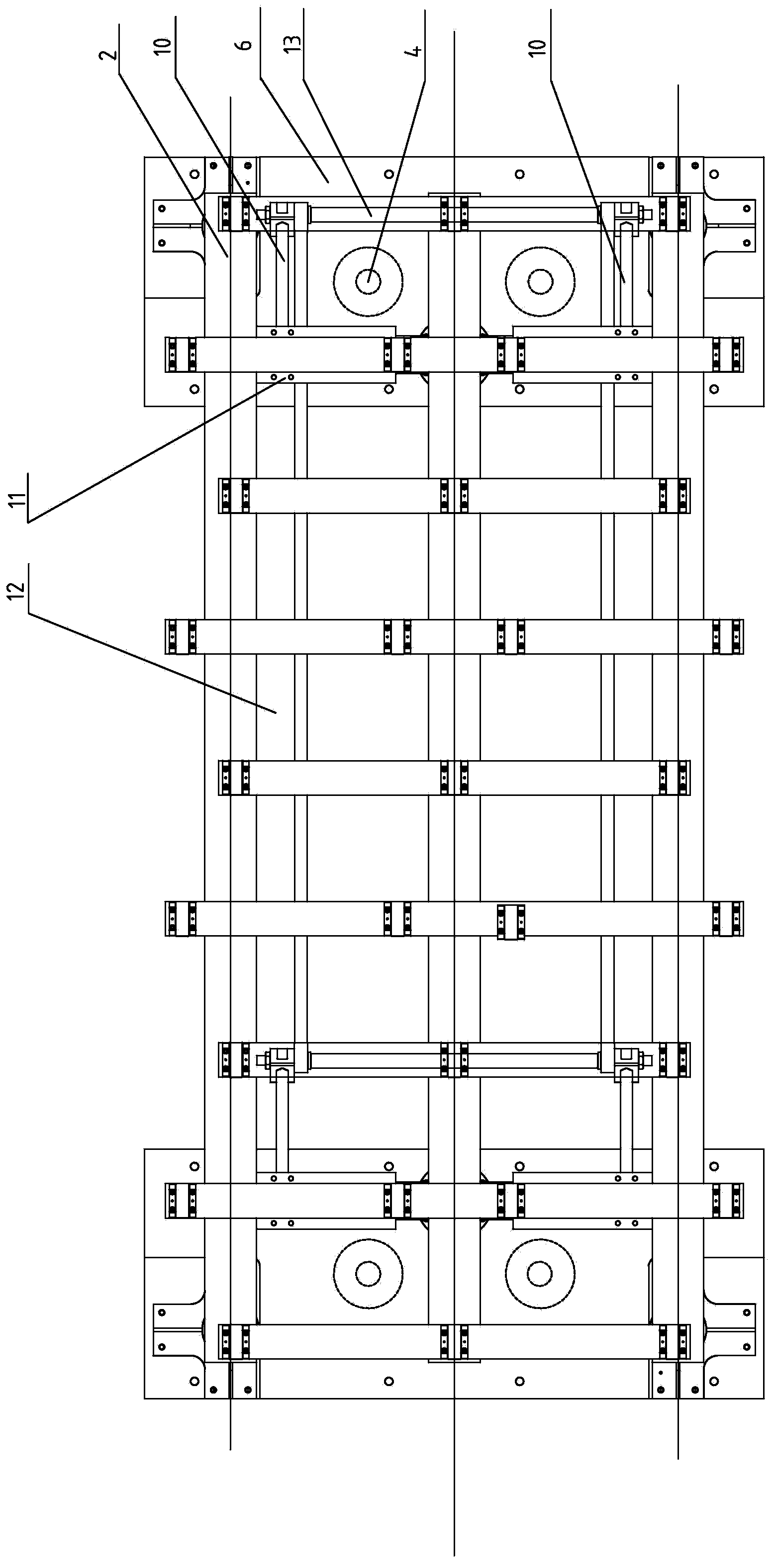

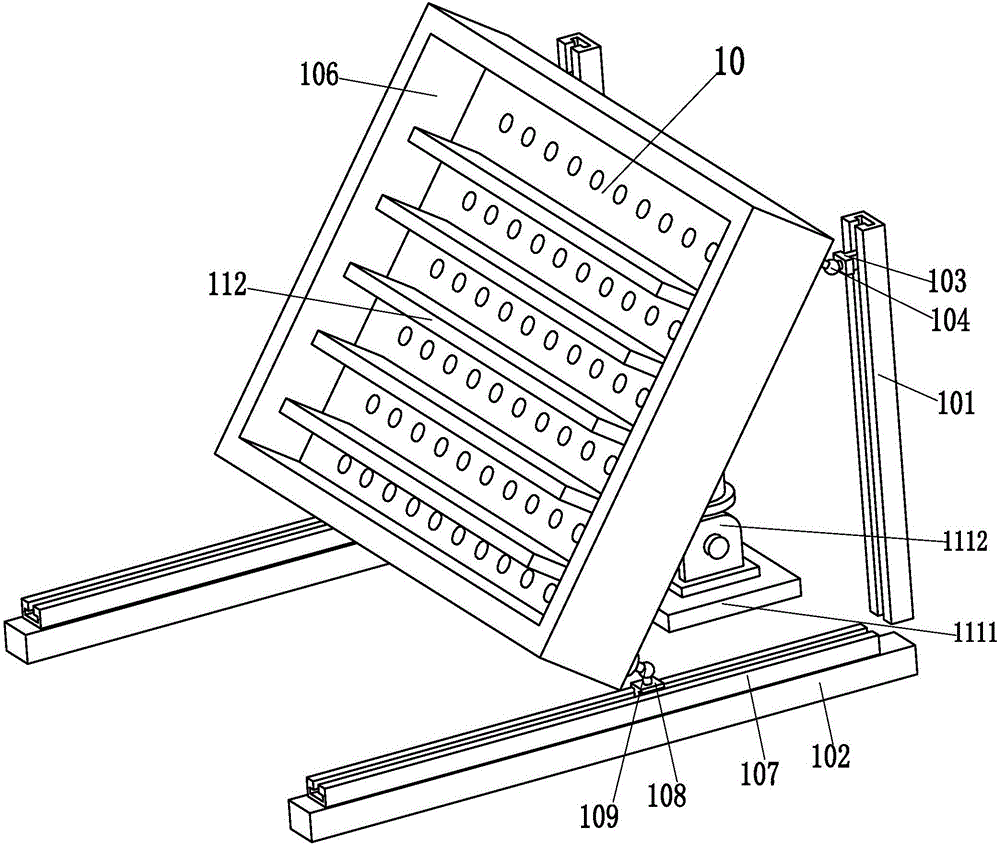

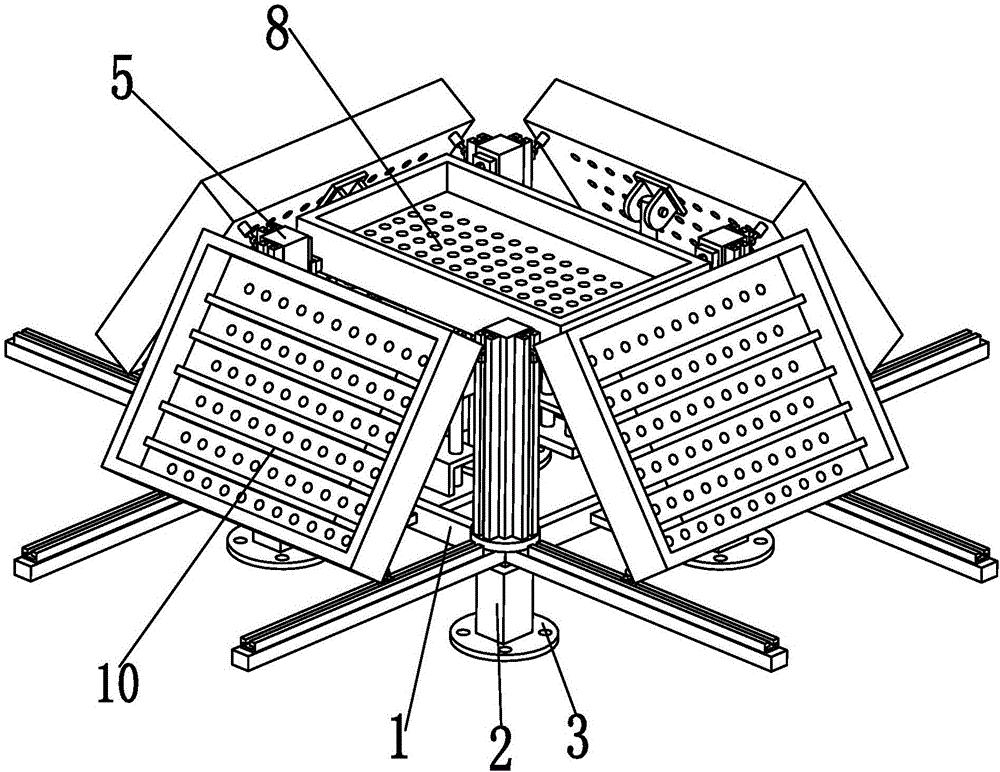

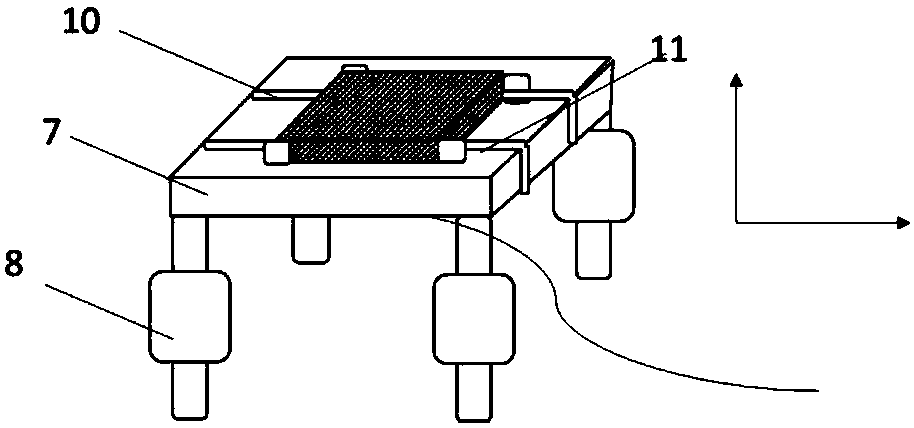

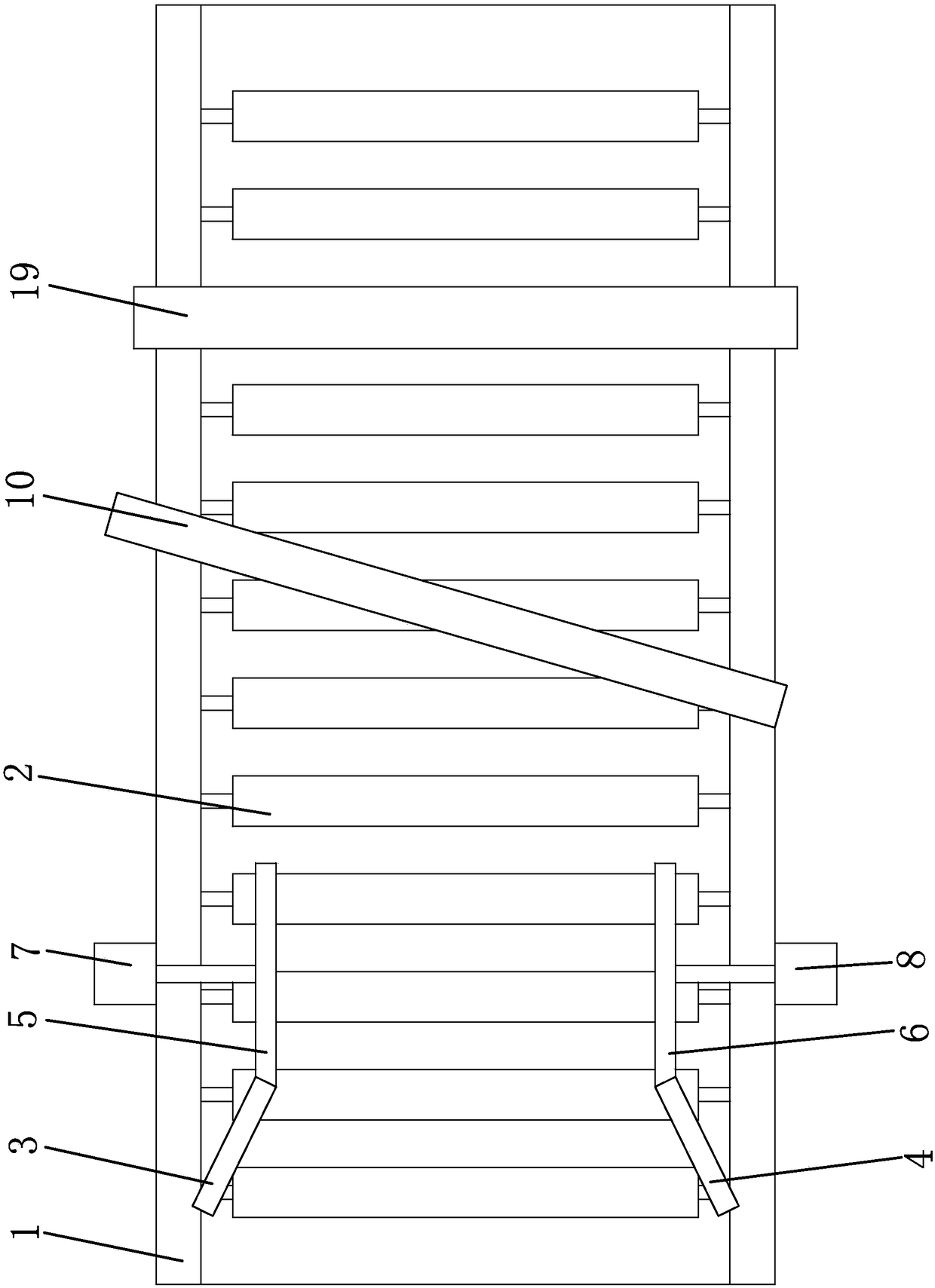

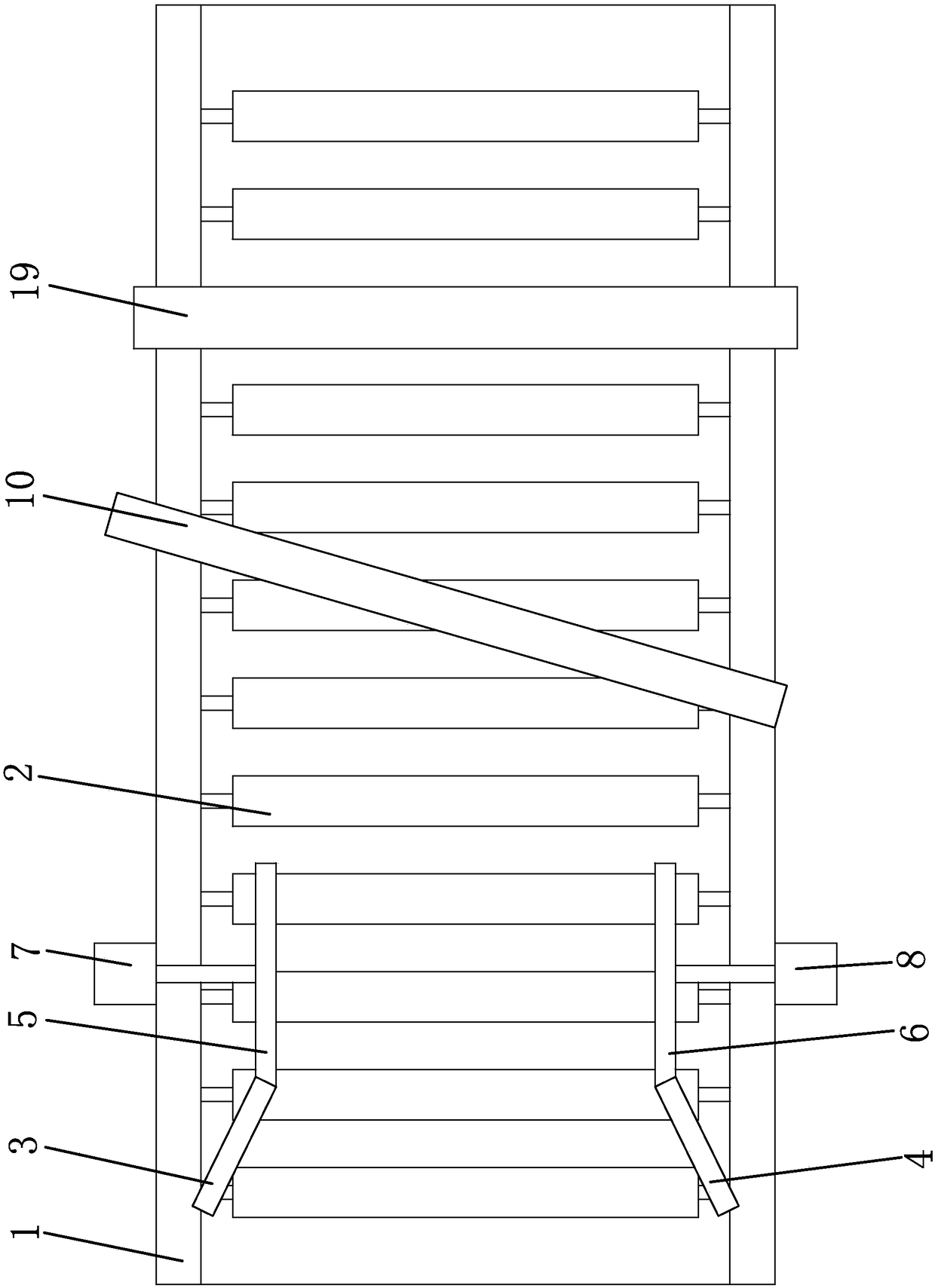

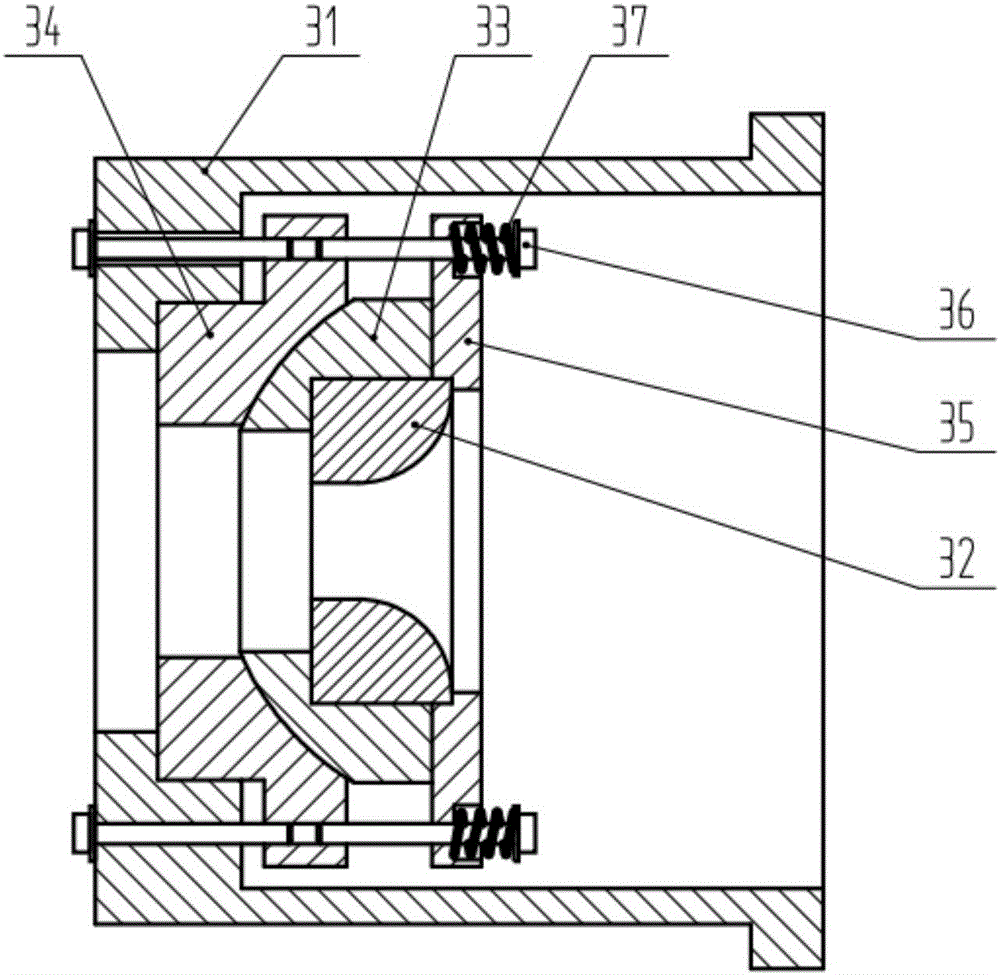

Steel plate feed roller for pressing ship body forming plates of large hydraulic machine

InactiveCN103722094AEnsure balanceReasonable designMetal-working feeding devicesPositioning devicesHydraulic cylinderEngineering

The invention belongs to a feeding device of a large hydraulic machine and particularly relates to a steel plate feed roller bed for pressing ship body forming plates of the large hydraulic machine, wherein the steel plate feed roller bed is suitable for synchronous lifting and automatic transferring at different heights. The steel plate feed roller bed for pressing the ship body forming plates of the large hydraulic machine is characterized in that a steel plate feeding roller bed is installed corresponding to the position of the hydraulic machine; the steel plate feed roller bed is composed of a base, guide devices, a support, a hydraulic cylinder and a carrier roller assembly, the base composed of two transverse base components is installed with the shape and the size consistent with those of the breadth face for pressing the forming plates, and the four guide devices and two parallel link mechanisms are installed on the top faces of the transverse base components on the two sides of the longitudinal center line of the base. The steel plate feed roller bed has the advantages of being reasonable in design, compact in structure, automatic in feeding, easy to control, very convenient to operate and use safely and the like, synchronous height lifting can be achieved, different feeding height requirements can be met, and production efficiency is improved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Multi-layer waterweed planting device special for lobster aquaculture

InactiveCN106508660APrevent the phenomenon of biting each otherIncrease productionAgriculture gas emission reductionCultivating equipmentsEconomic benefitsEngineering

The invention relates to a multi-layer waterweed planting device special for lobster aquaculture. The multi-layer waterweed planting device includes a square basic frame, four support feet are symmetrically welded onto the lower end of the square basic frame; four bases are symmetrically welded onto the upper end of the square basic frame; the four basic bases are welded onto four installation columns; an inner walls of the four installation columns are provided with four linear slide rails; four linear slide columns are arranged on the four linear slide rails; a planting box is welded among the four linear slide columns; first water holes are evenly formed in the center of the planting box; two lifting driving mechanisms are arranged on two sides of the lower end of the planting box; and four side surface planting branch chains are arranged on four end surfaces outside the square basic frame. The multi-layer waterweed planting device can achieve multi-layer waterweed supplying and high yield cultivation in lobster aquaculture, can automatically feed lobsters, is low in lobster aquaculture cost, is high in output value of the lobsters, is good in aquaculture effect, and is high in economic benefits.

Owner:黄江龙

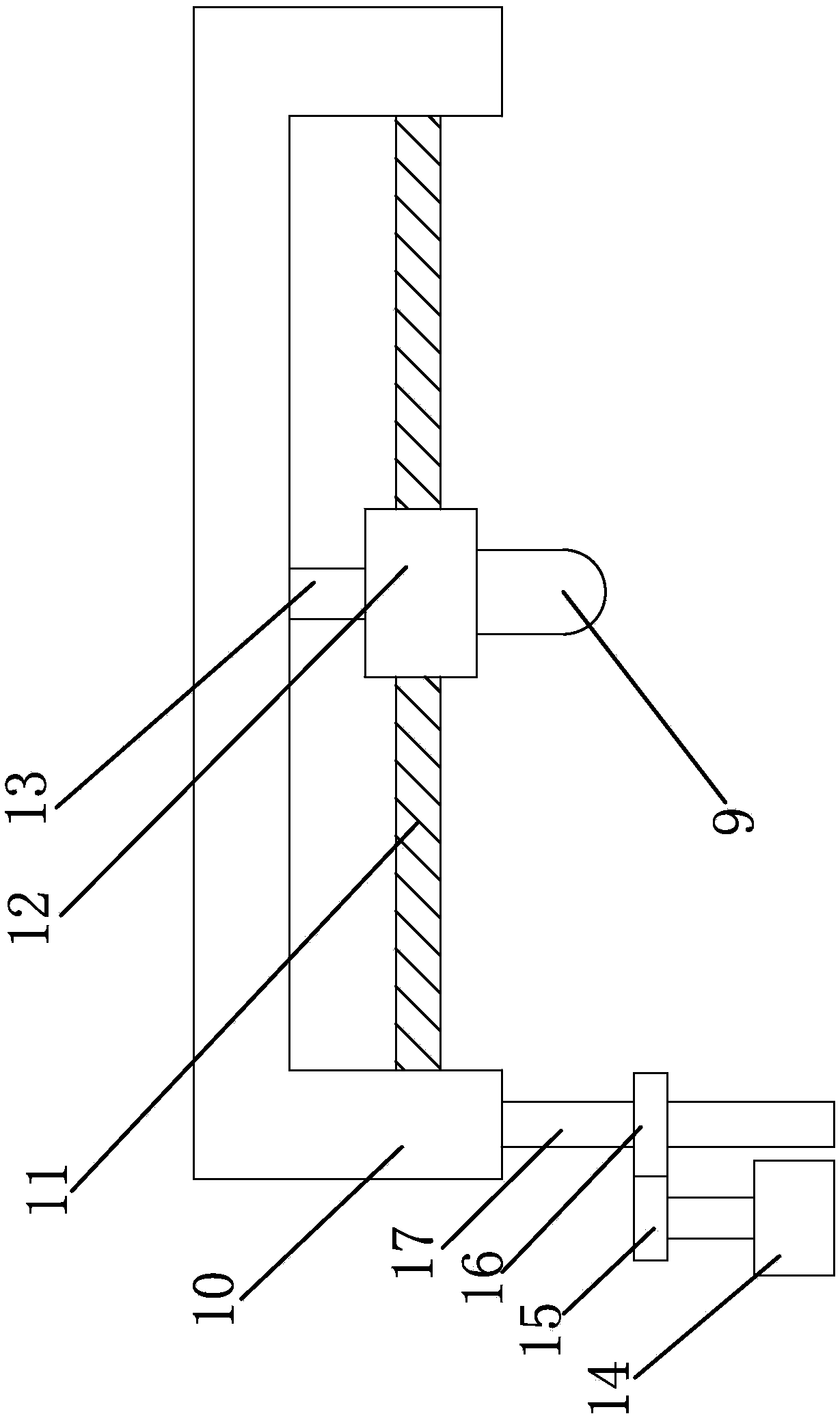

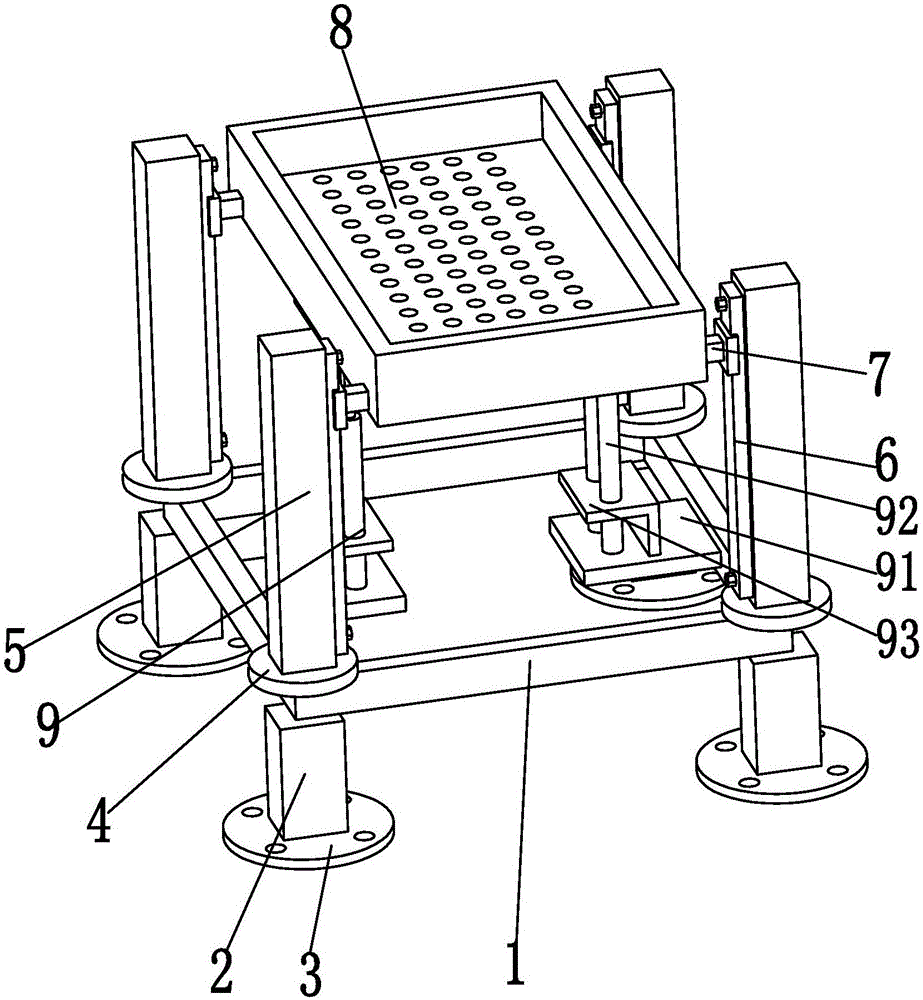

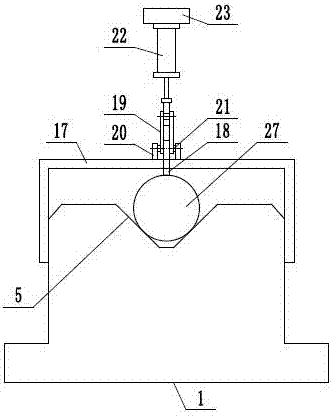

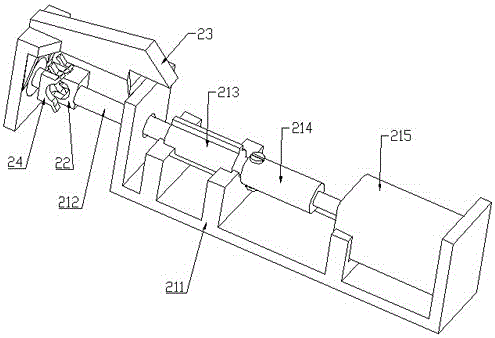

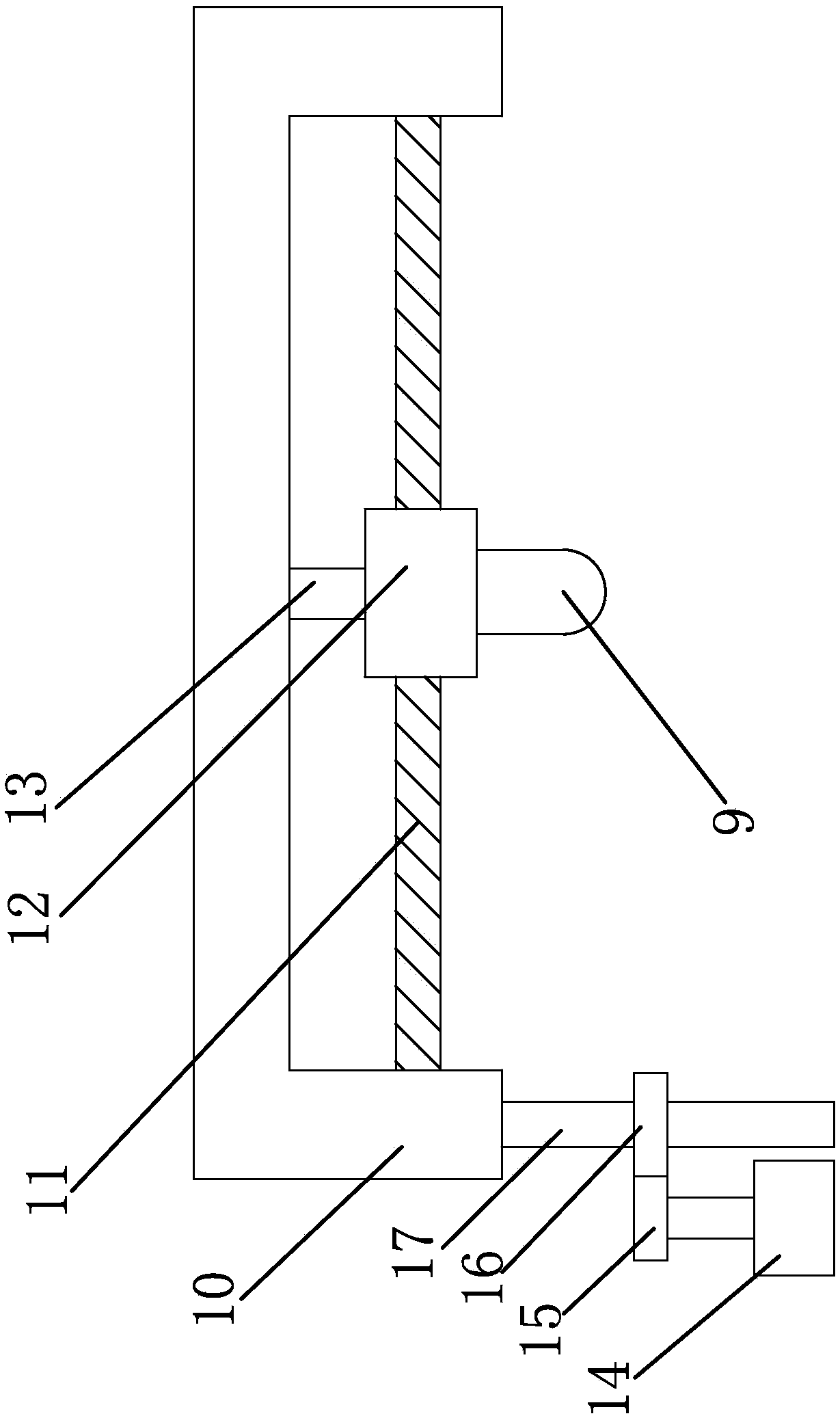

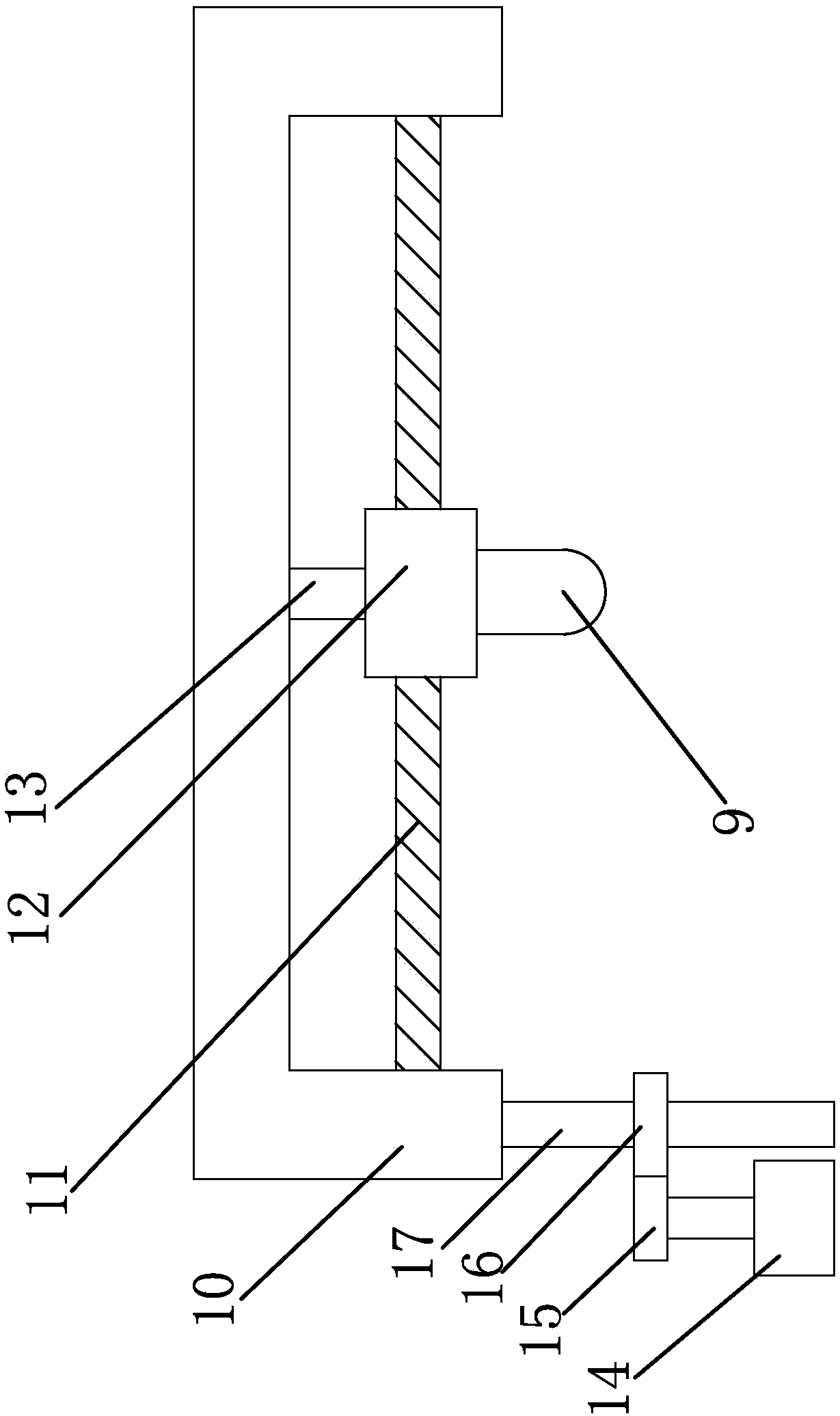

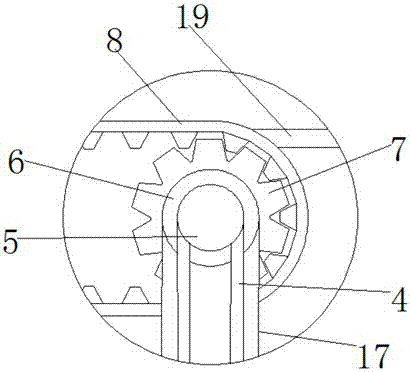

Shaft body drilling device

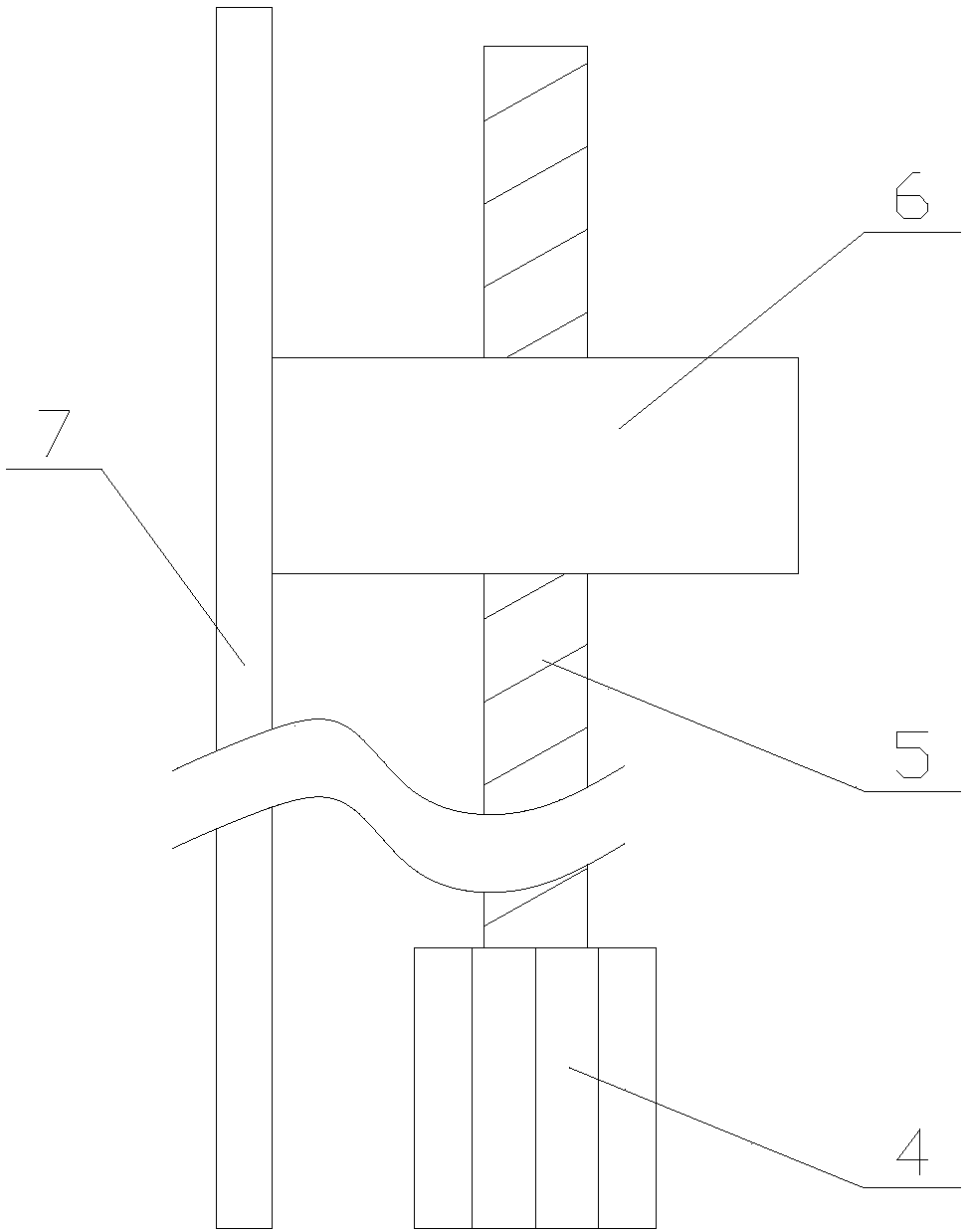

InactiveCN107116248AWith drillingWith automatic feedingWork clamping meansMetal working apparatusEngineeringCam

The invention provides a shaft body drilling device, and belongs to the technical field of mechanical processing. The shaft body drilling device comprises an loading and unloading mechanism, a pressing mechanism and a drilling mechanism, wherein a material bin of the loading and unloading mechanism is arranged above the right end of a bearing support base; a top plate is mounted at the left end of a top plate piston rod; a positioning baffle plate can be arranged in a slide slot in the left end of the bearing support base in a front-rear sliding mode; a baffle plate piston rod is connected with the positioning baffle plate; a bearing pin roll of the pressing mechanism can be rotatably arranged on the fixed supporting lug; the lower end of a connecting rod is fixedly arranged on the bearing pin roll; a pressing cam is fixedly arranged on the bearing pin roll in the eccentric mode; the lower end of the pressing air cylinder is hinged with the upper end of the connecting rod; and a drill bit of the drilling mechanism is arranged above a guide drilling sleeve. The shaft body drilling device realizes automatic loading and unloading of the shaft body, greatly reduces labor intensity of a worker, realizes continuous and quick drilling and processing on a shaft body, is reasonable in structure, is good in reliability and is low in cost.

Owner:赵锋

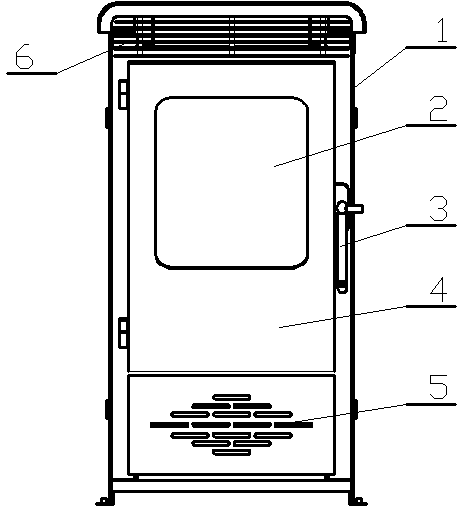

Novel particle fireplace

InactiveCN102997333AWith automatic ignitionWith automatic feedingLighting and heating apparatusSpace heating and ventilation detailsCombustion chamberLiquid-crystal display

The invention relates to a novel particle fireplace which is provided with a fireplace body. A main radiating window, a furnace door and a fan chamber air inlet hole are arranged in the front of the fireplace body; a smoke vent, a combustor air inlet, a water tank water inlet, a water outlet and a power switch are arranged at the rear of the fireplace body; auxiliary radiating holes are arranged on the top surface and the side surface of the fireplace body, a liquid crystal display is arranged on the side surface, and a feeding inlet with a top cover is arranged on the top surface; a storage chamber and a combustor are correspondingly arranged on the lower portion of the feeding inlet, and a material level meter is installed in the storage chamber; a spiral feeding inlet mechanism and an ignition rod are arranged in the combustor; an ash storage chamber is installed on the lower portion of the combustor; an air heating circulation chamber and a water tank are arranged on the front side of the combustor; a water inlet pipe and a water outlet pipe can be connected with a heating device; a temperature sensor is respectively installed on the combustor and the water tank; the air heating circulation chamber is communicated with a fan chamber, and the top end and the side surface of the air heating circulation chamber are communicated with the main radiating window and the auxiliary radiating holes; and the fireplace further comprises a circuit board, and an electric control system is installed on the circuit board.

Owner:XUZHOU CROWN IND

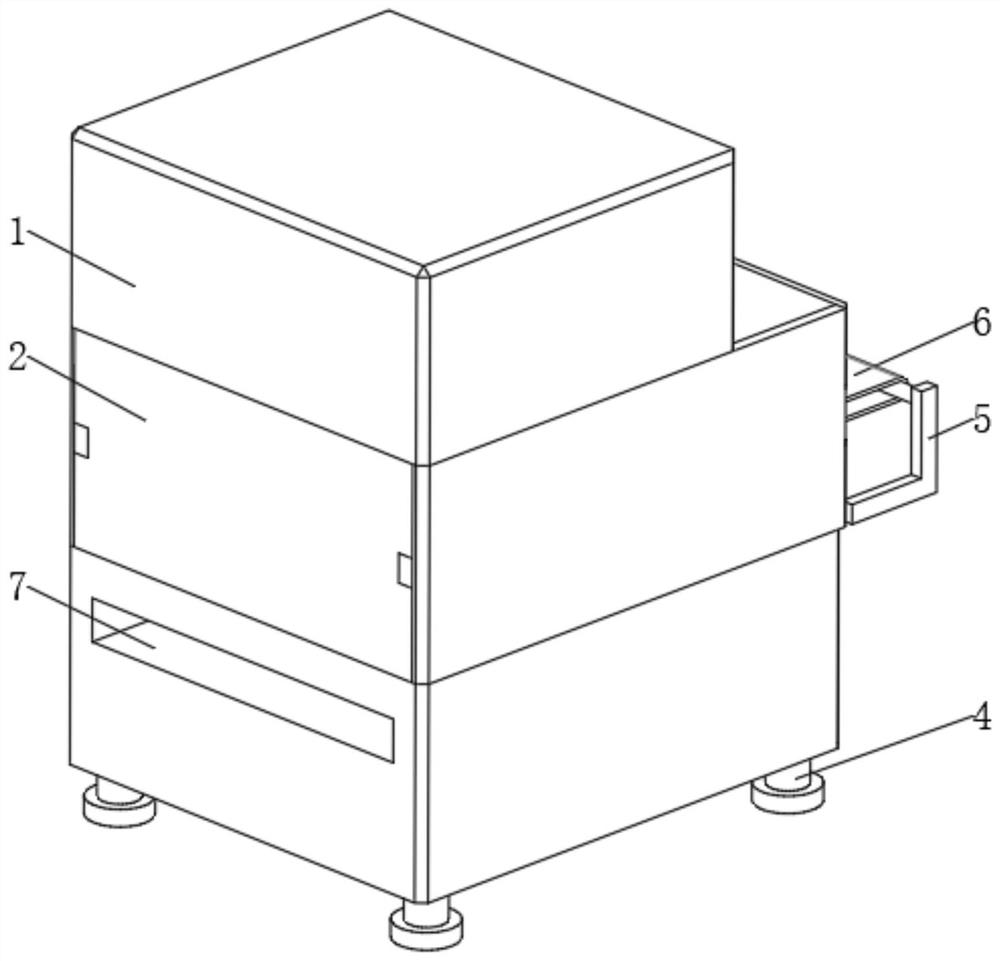

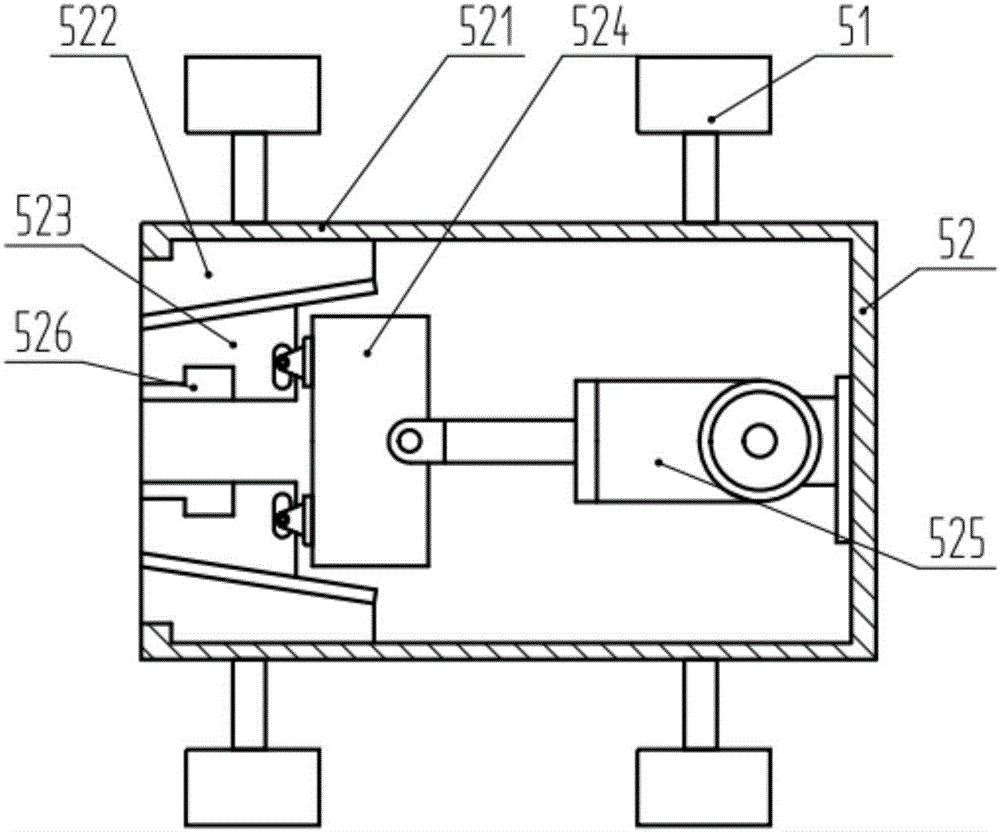

Fully automatic printer for aluminum base plate

PendingCN107757083AWith automatic feedingWith automatic positioning calibrationScreen printersScreen printingScreen printingThermal insulation

The invention provides a four-column-type fully automatic printer for an aluminum base plate, and the four-column-type fully automatic printer comprises an automatic material inlet system, an automatic printing system and an automatic material outlet system. The automatic material inlet system conveys the aluminum plate through a conveyor belt; the automatic printing system comprises a printing screen plate, screen frames, a scraper, spray mouths, a workbench and automatic lifting columns, and the automatic printing system prints heat-conducting and insulating glue on the aluminum plate evenly; the material outlet system conveys the aluminum plate with the surface being printed a dense uniform insulation layer through the conveyor belt for the output; in a silk-screen printing system, theworkbench is supported by four automatic lifting columns, the surface of the workbench is provided with horizontal sliding electric guide rails in a paved manner, and the silk-screen printing system further comprises height sensors, a scraper moving rod and a rotating head; and the rotating head connects the scraper moving rod and the scraper, the height sensors are installed under the screen frames, and the workbench, the scraper moving rod, the spray mouths, positioning sensors and the height sensors are all connected with a general control platform and are controlled. The four-column-type fully automatic printer for the aluminum base plate has the characteristics of automatic material feeding, automatic positioning calibration, automatic printing and high production capacity.

Owner:乾乐欣展新材料技术(上海)有限公司

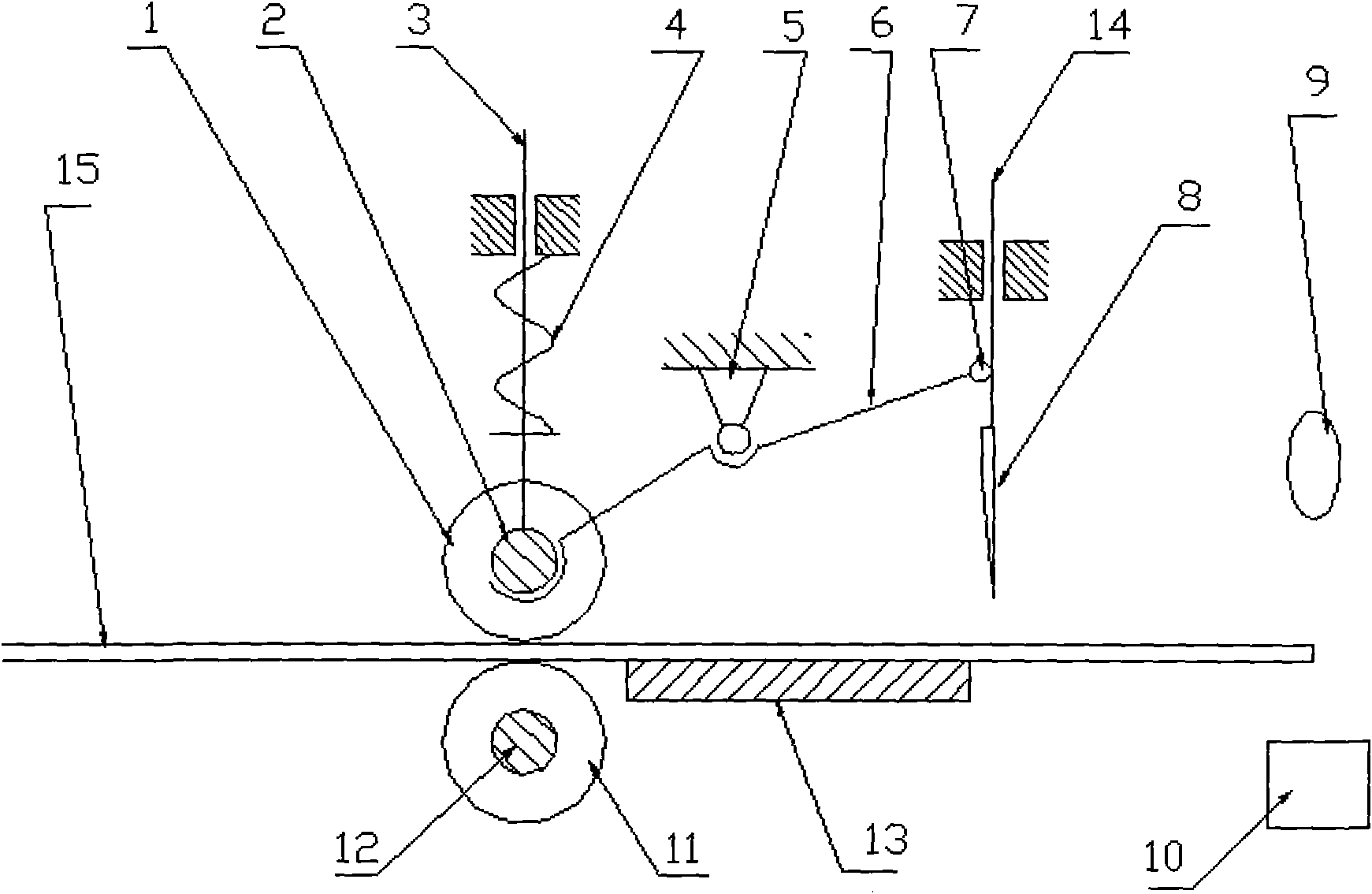

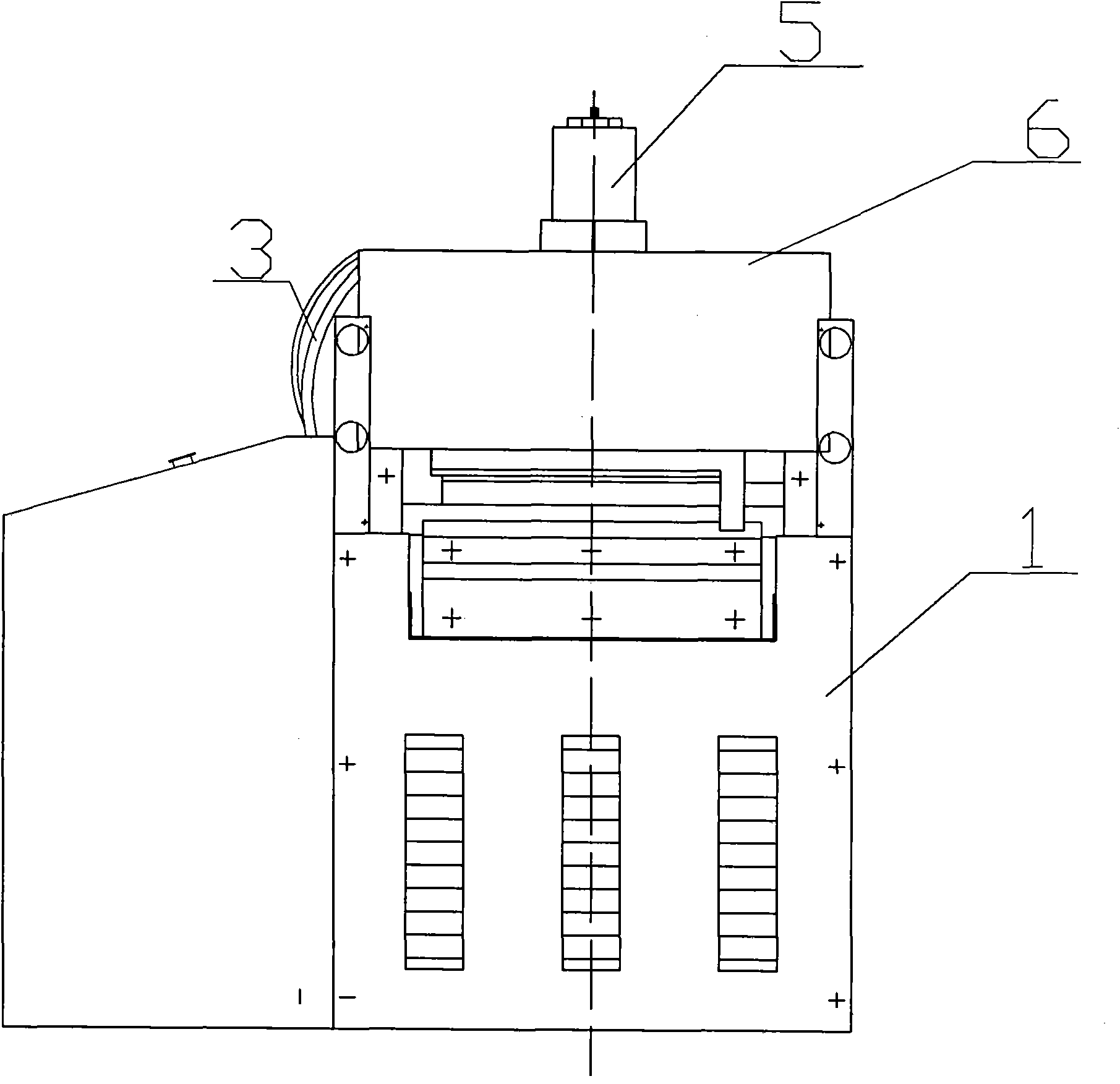

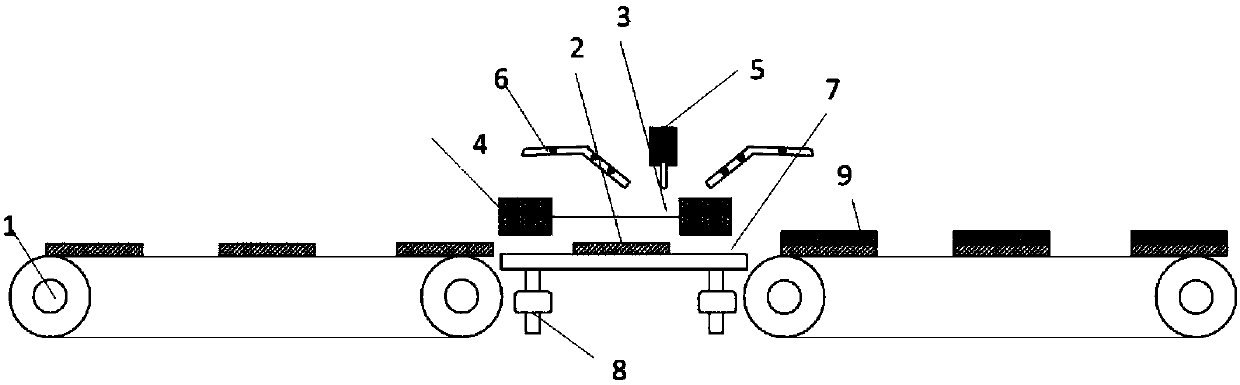

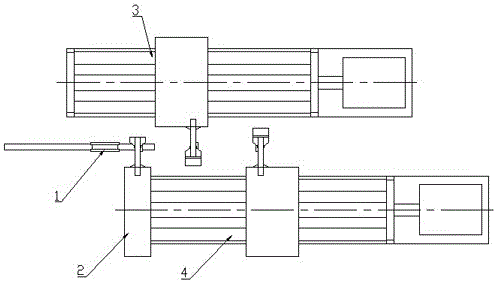

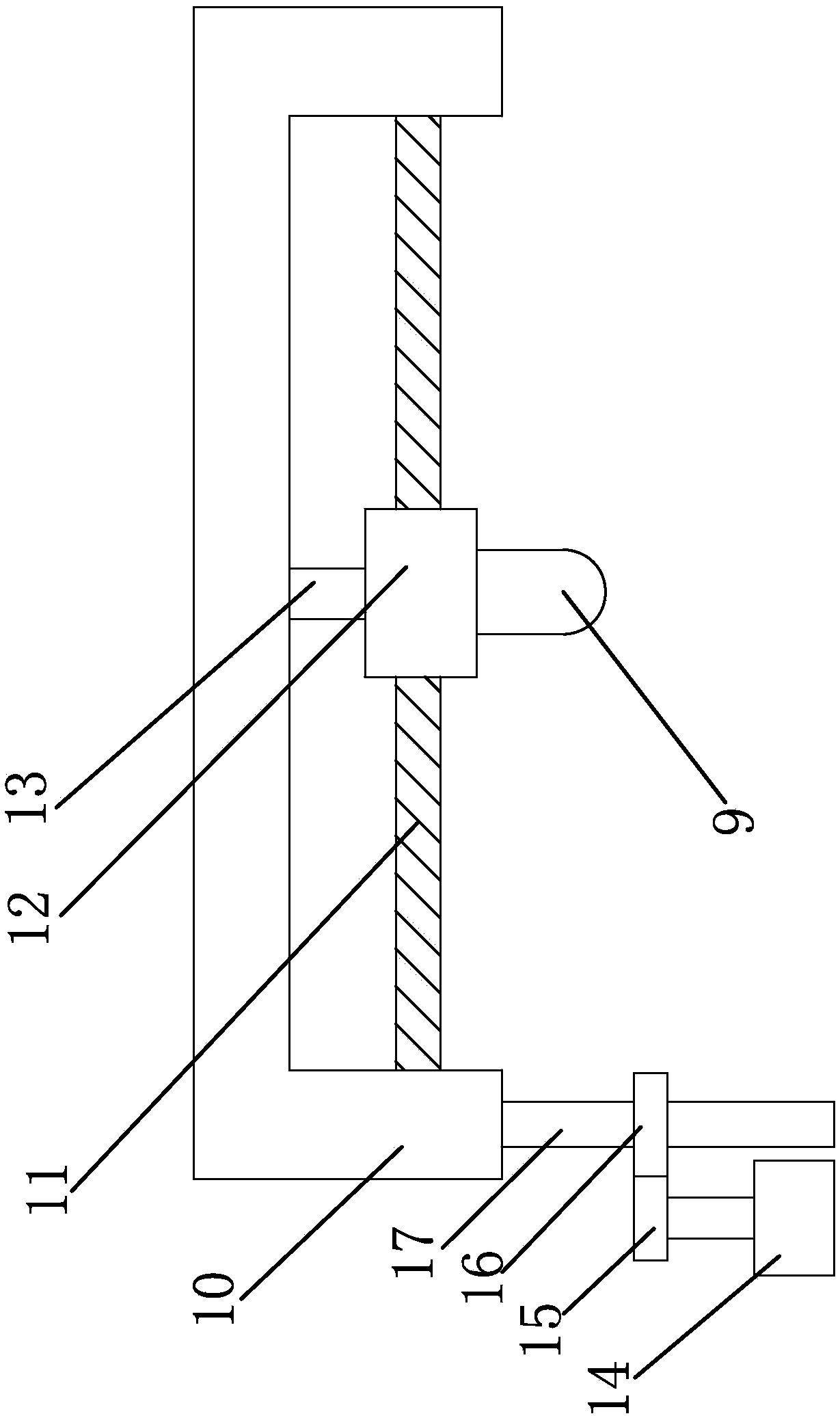

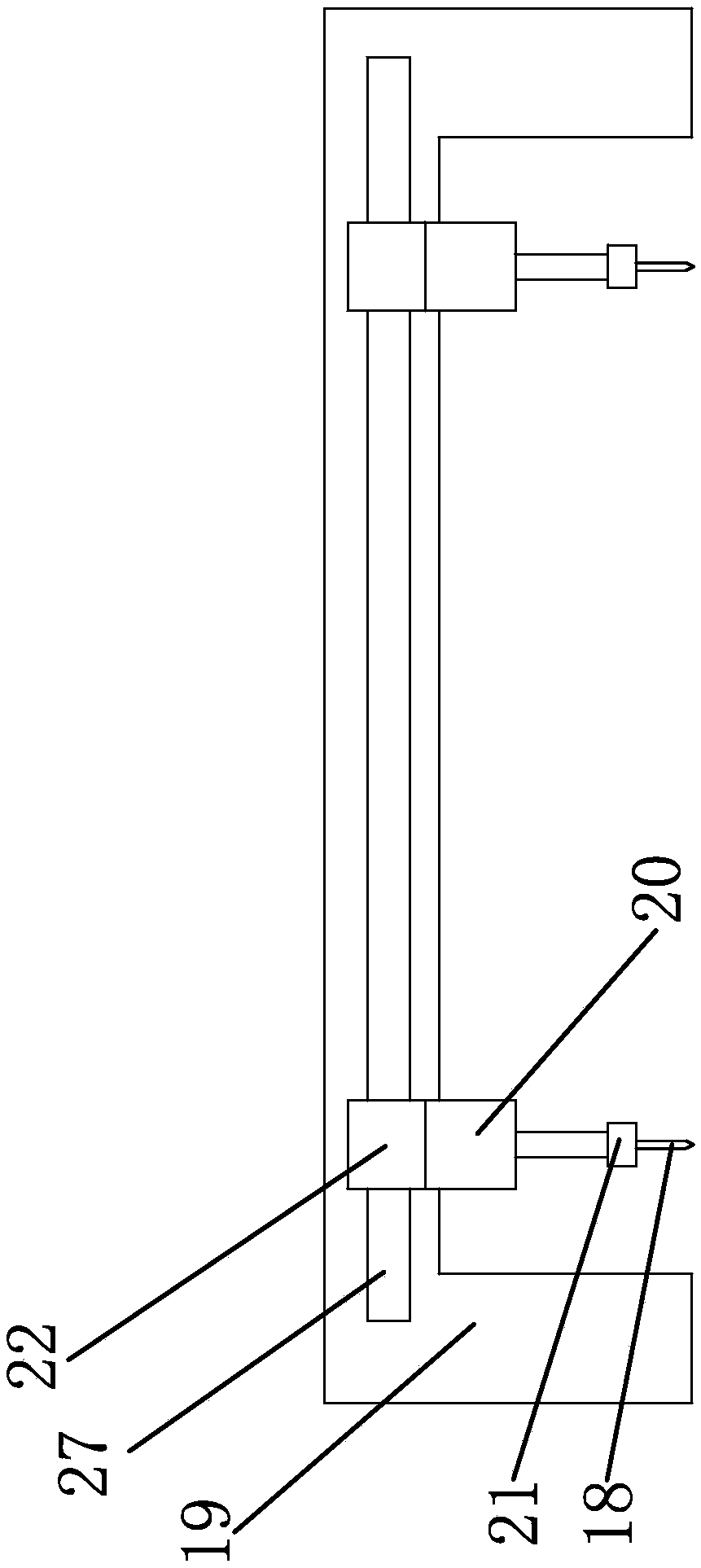

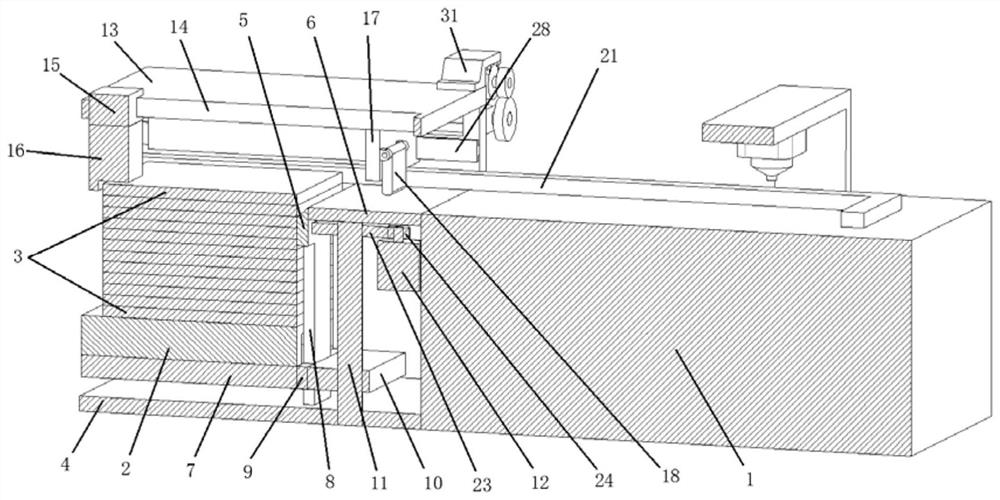

Novel cut-off plate shearing machine

InactiveCN102784957AWith automatic feedingHigh degree of automationShearing machinesShearing machine accessoriesEngineeringBar pressing

Provided is a novel cut-off plate shearing machine. A pressing roller is installed on a press rod through a pressing roller shaft, a compression spring is installed on the press rod, a support base is installed in the middle of a connection rod, one end of the connection rod is hinged to the pressing roller shaft, the other end of the connection rod is hinged to a cutter base through a connection rod pin, a cutter is installed on the cutter base, an infrared emission device and an infrared receiving device are symmetrically installed on two sides of a guiding rail, and a fixed roller is fixedly installed on the plate shearing machine through a fixed roller shaft. The novel cut-off plate shearing machine has the functions of automatic material feeding, automatic length fixing and automatic cutting off, accordingly, has the advantages of being high in automation degree and improving production efficiency, and simultaneously can effectively avoid safety accidents caused by coordination contradiction of staff during operation.

Owner:张金文

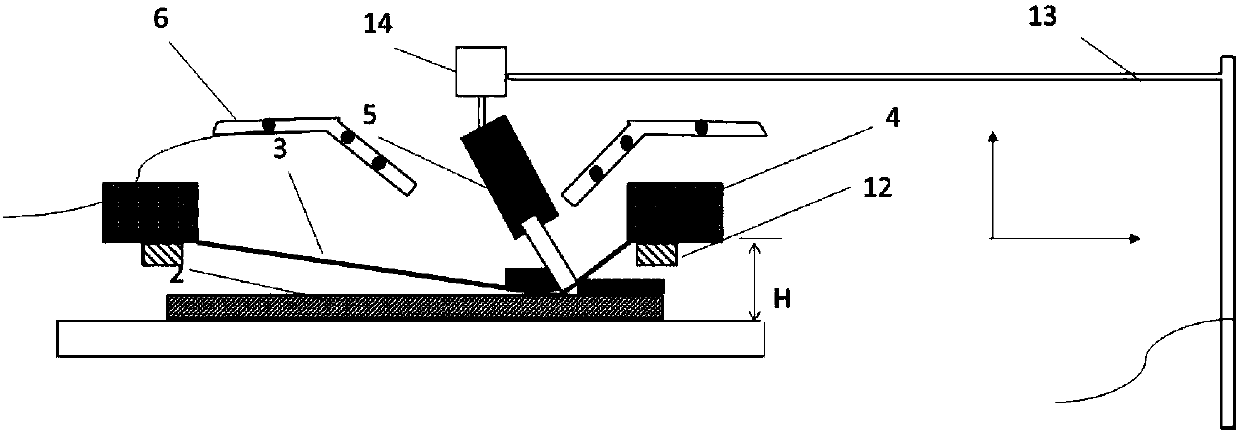

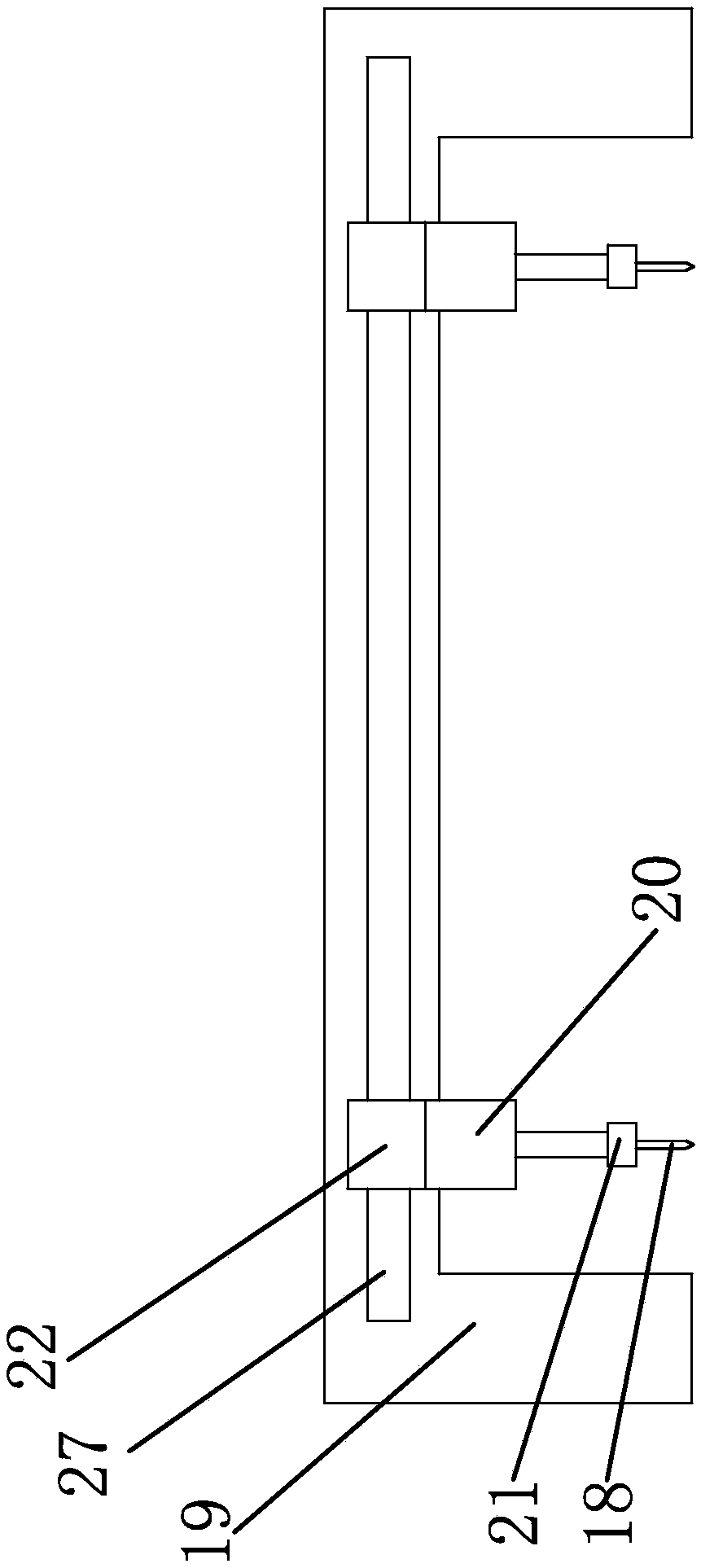

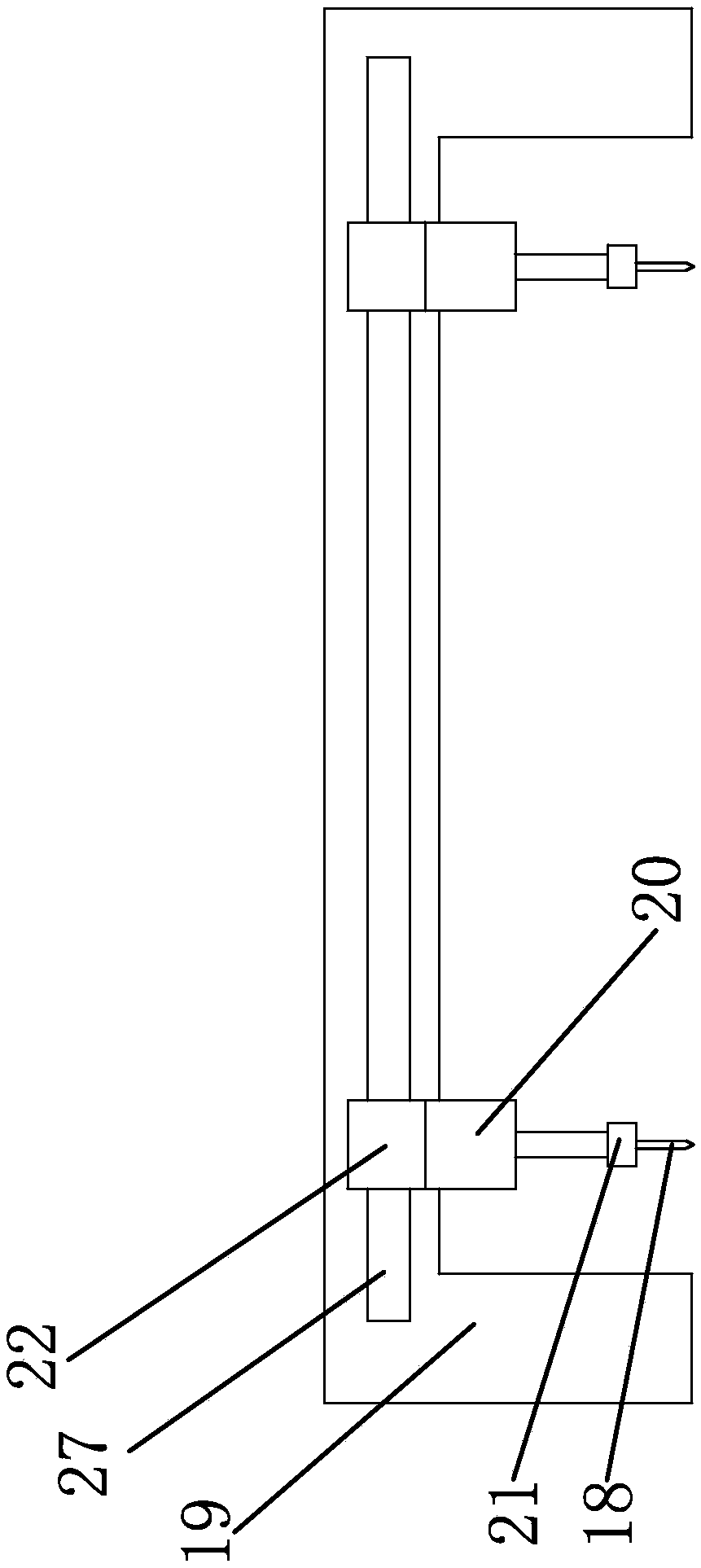

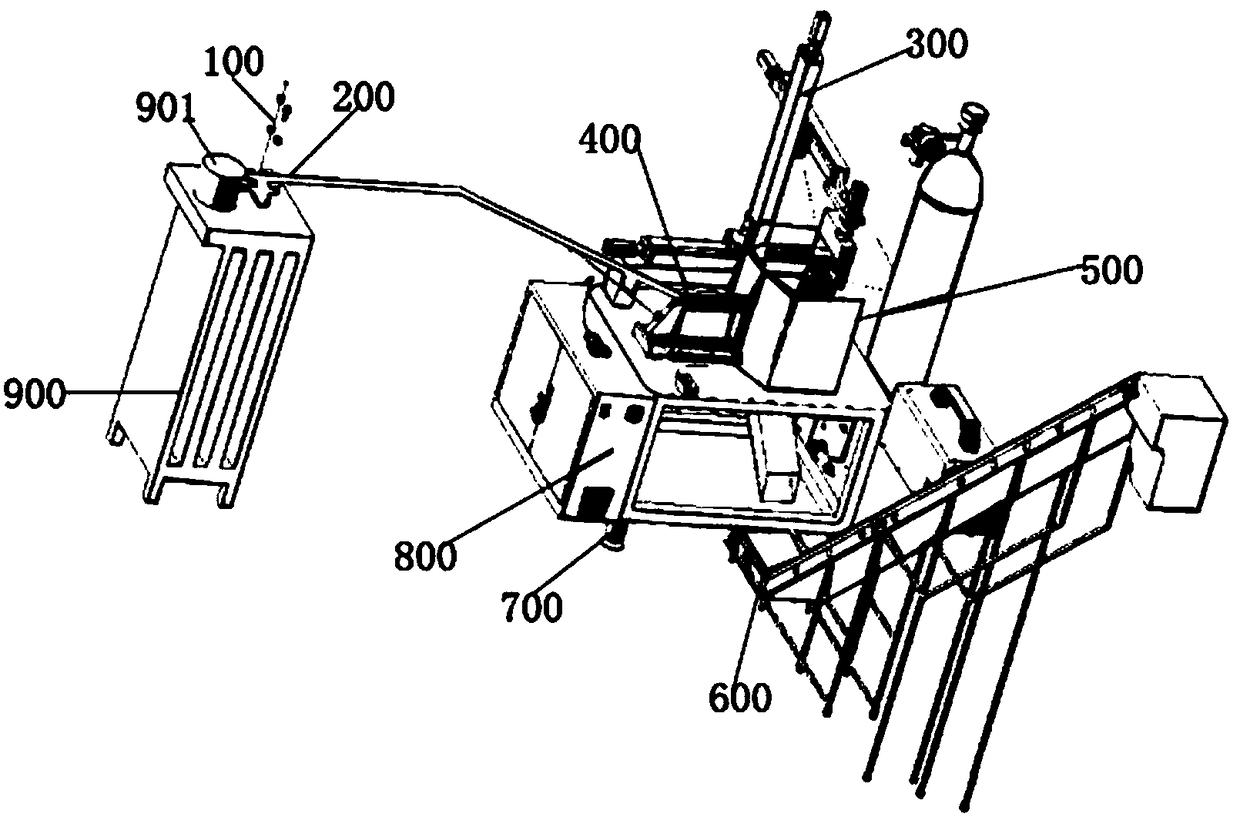

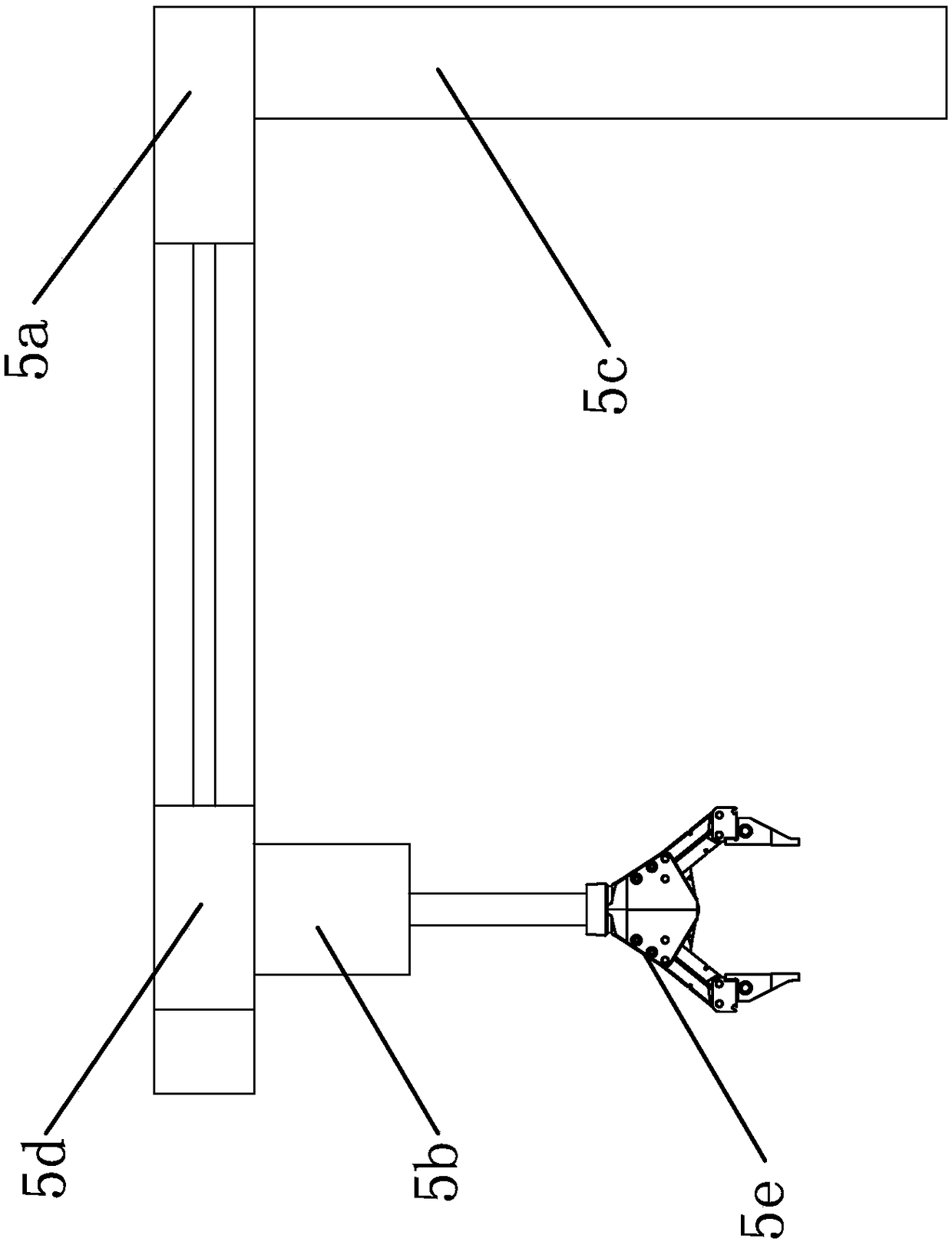

Automatic steel wire rope circular ring welding device

ActiveCN106466755AHas a guiding roleEasy to replaceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterial supply

The invention discloses an automatic steel wire rope circular ring welding device which comprises a material supply device, a steel wire rope fusing device, a first welding device and a second welding device which are arranged in sequence, wherein a fusing inner clamping claw and a fusing outer clamping claw in the steel wire rope fusing device are combined together to form a fusing opening; inner clamping claws and outer clamping claws in the first welding device and the second welding device are combined together to form welding openings; the fusing opening and the welding openings are concentrically and correspondingly arrayed; a driving wheel and a driven wheel in the material supply device supply one end of a steel wire rope into the steel wire rope fusing device, the first welding device and the second welding device in sequence; the fusing opening in the steel wire rope fusing device and the welding openings in the first welding device and the second welding device respectively clamp the steel wire rope; and after the fusing inner clamping claw and the fusing outer clamping claw fuse the other end of the steel wire rope through an electric heating device, the inner clamping claws and the outer clamping claws respectively carry out rotating, butt jointing and welding operation on two ends of the steel wire rope. The device is high in working efficiency and high in product quality.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

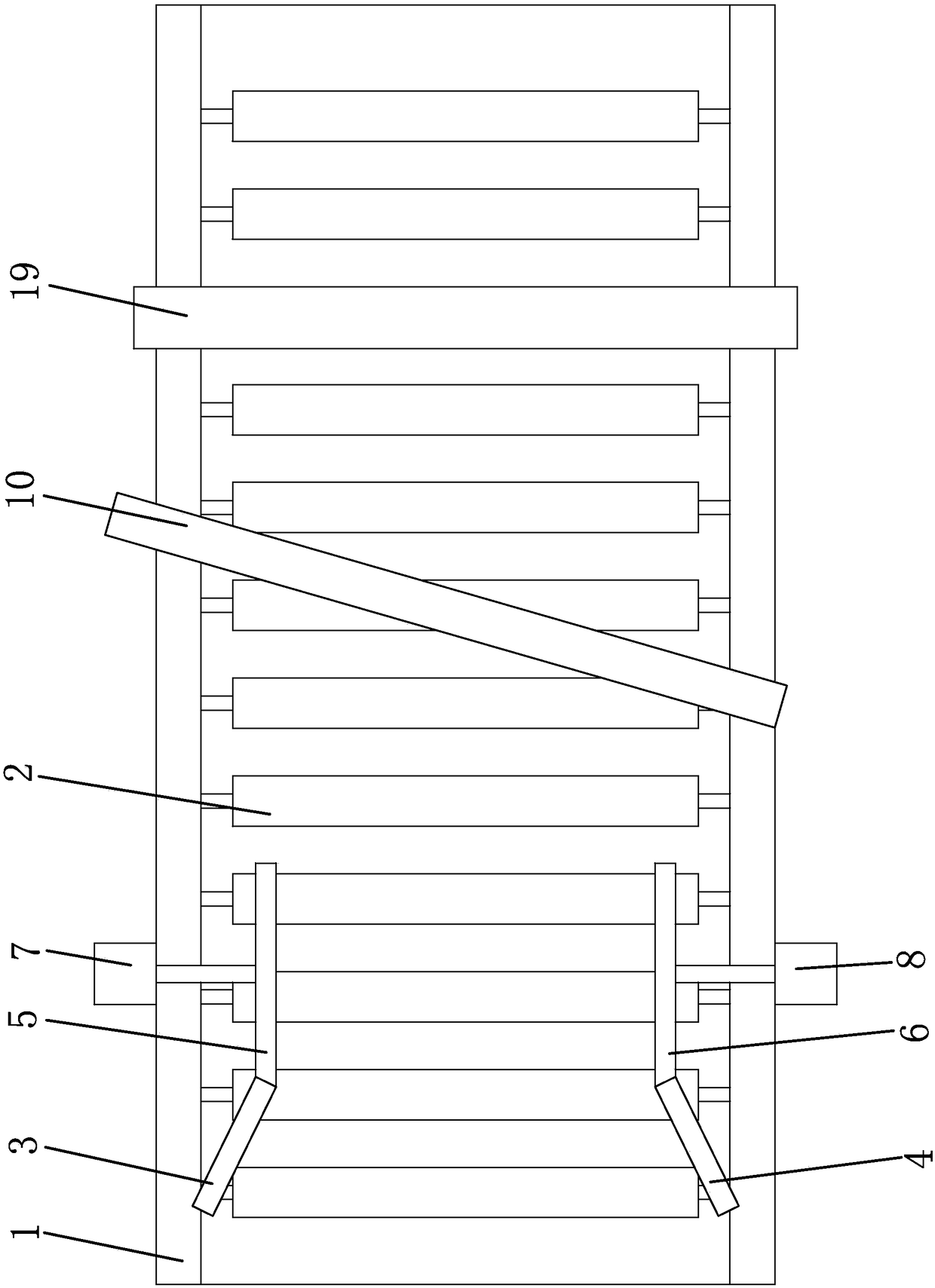

Conveying mechanism of plate cutting device

InactiveCN108326987AIncrease productivityImplement aspectsGuide fencesProfiling/shaping machinesDrive motorEngineering

The invention provides a conveying mechanism of a plate cutting device, and belongs to the technical field of machinery. The conveying mechanism solves the problem of low conveying efficiency in the prior art. The conveying mechanism of the plate cutting device is characterized in that the plate cutting device comprises a long strip-shaped work table; the work table is provided with an input end and an output end; the conveying mechanism comprises a plurality of conveying rollers; the conveying rollers are arranged on the work table in a peripheral rotation and axial fixed mode; one end of theconveying roller is fixedly provided with a first gear; the other end of the conveying roller is fixedly provided with a first bearing; a plurality of first gears are connected through a first chain;one end of the first chain is also engaged with a second gear; a driving motor is fixed onto one side of the work table; an output shaft of the driving motor is fixedly provided with the second gear.The conveying mechanism has the advantage that the conveying efficiency is high.

Owner:海宁市纵达新材料股份有限公司

Device for automatically punching chillies

The invention provides a device used for automatically punching chillies. The device comprises a rack, a conveying mechanism, a punching mechanism and a motor, wherein the motor is provided with a speed reducer; the conveying mechanism comprises a conveyor belt, a driven wheel and a driving wheel; the driving wheel and the driven wheel are arranged at the two sides of the rack; the conveyor belt is installed between the driving wheel and the driven wheel; and the punching mechanism is arranged in the middle of the rack and comprises a support frame, a crankshaft, a connecting rod, locating sleeves, directional shafts, a presser, a pin installing plate, punching pins and a punching pin guide plate. The device has a simple structure and a high degree of automation, is convenient to use and can achieve the effects of reducing the dependence of enterprises on workers and effectively reducing the production costs of the enterprises.

Owner:昆明万顺通科工贸有限公司

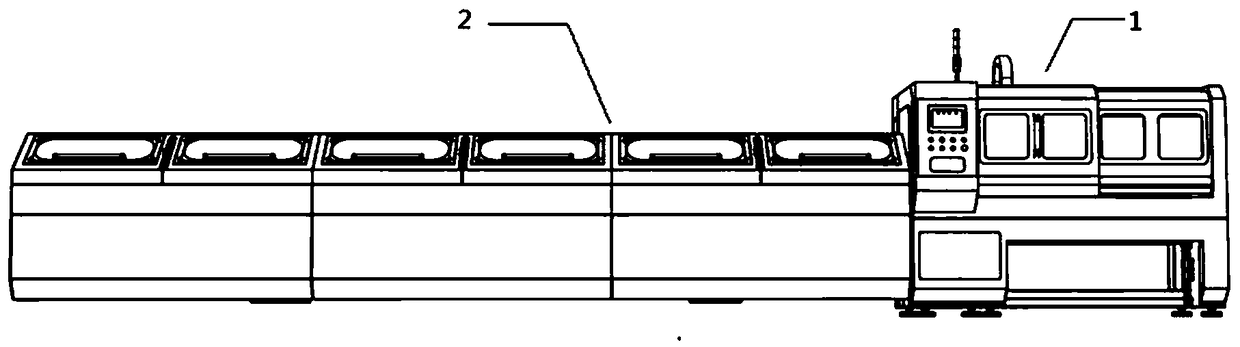

Metal tube laser cutting machine capable of automatic feeding and sorting

InactiveCN109500502ARealize automatic feeding processWith automatic feedingLaser beam welding apparatusElectrical controlEngineering

The invention provides a metal tube laser cutting machine capable of automatic feeding and sorting. The metal tube laser cutting machine capable of automatic feeding and sorting includes an automaticfeeding section and a laser cutting section, wherein the automatic feeding section includes a metal tube storage frame and a metal tube conveying frame; the metal tube conveying frame is provided witha downward sloped bevel; the top of the bevel is connected with the metal tube storage frame; the bottom of the bevel is provided with a metal tube conveyor belt; the conveyor belt is aligned with the feed opening of the laser cutting section; the laser cutting section includes a frame, a tube clamp, an electrical control system, a laser cutter, a guide rail and a positioner; the tube clamp is arranged on the frame; the laser cutter is arranged on the frame and located directly above the discharge opening of the tube clamp; the guide rail is arranged on the frame and parallel to the metal tube feeding direction; the positioner is slidably arranged on the guide rail; a finished-product storage bin and a tail product bin are separately arranged on the lower side of the frame; a baffle controlled by a turnover controller is arranged at the middle of the frame; and the baffle is located directly below falling cut metal tubes.

Owner:FOSHAN LONGXIN LASER TECH CO LTD

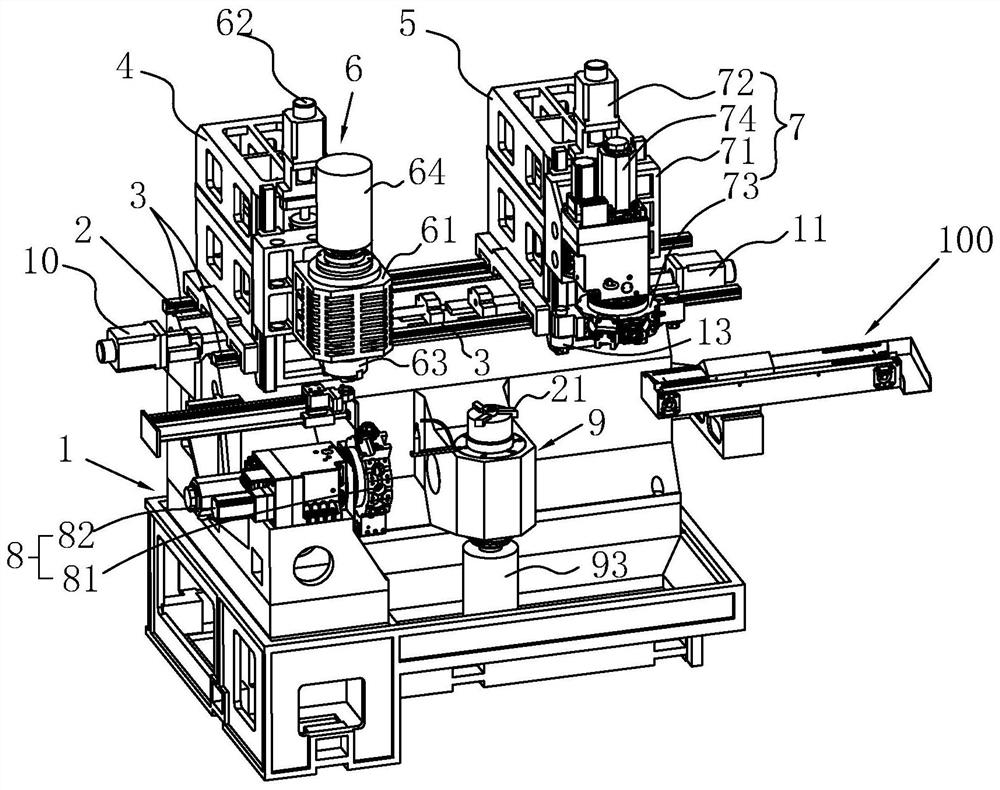

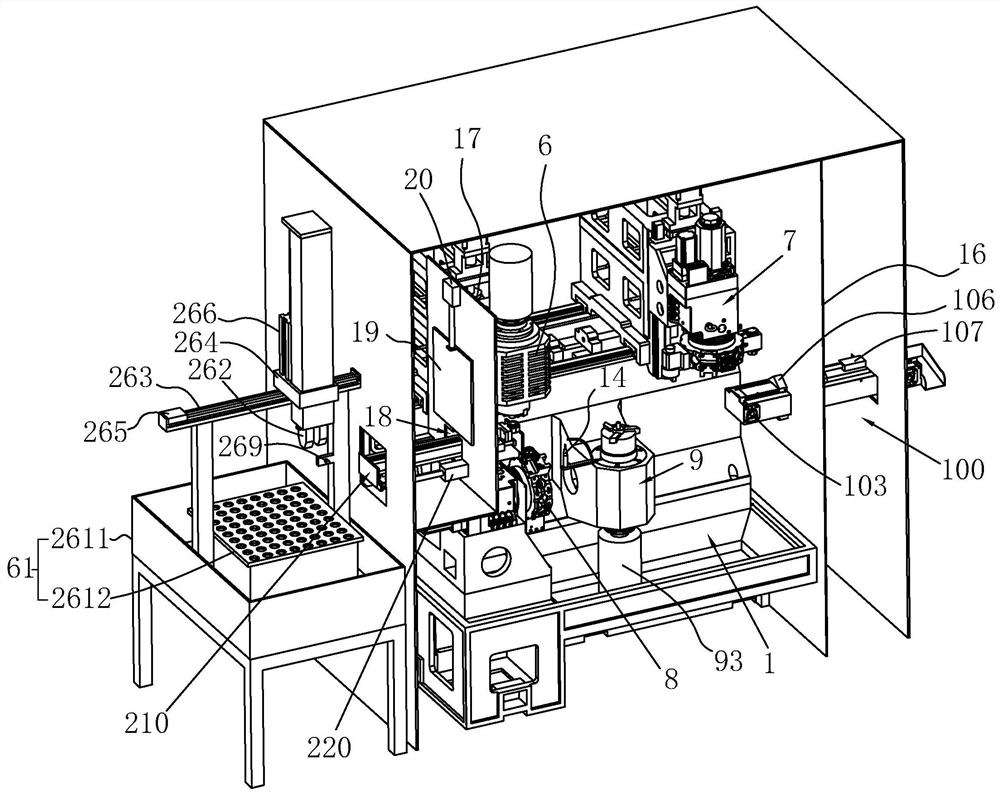

Erected-inverted machine tool with double spindles and double knife towers

PendingCN111761079AImprove machining accuracy and machining efficiencyHigh degree of automationLarge fixed membersMetal working apparatusProcessing accuracyContinuous production

The invention provides an erected-inverted machine tool with double spindles and double knife towers, and belongs to the field of numerically-controlled machine tools. The erected-inverted machine tool with the double spindles and the double knife towers comprises a machine body, wherein an installation platform is horizontally arranged on the machine body along the X axis; an X-axis guide rail ishorizontally arranged on the installation platform; a first vertical column and a second vertical column are sequentially vertically arranged above the installation platform; a first drive part driving the first vertical column to move along the X-axis guide rail, and a second drive part driving the second vertical column to move along the X-axis guide rail are further arranged on the machine body; a first spindle part is arranged on the first vertical column; a second knife tower part is arranged on the second vertical column; a first knife tower part is arranged on a part located at one side of the first spindle part, of the machine body; and a second spindle part is arranged on a part located between the first vertical column and the second vertical column, of the machine body. The erected-inverted machine tool with the double spindles and the double knife towers has the functions of automatically loading, automatically machining and automatically unloading, and is high in automation degree; the erection and the inversion of the machine tool are combined, and overturning is not needed during workpiece machining, so that continuous production can be carried out; the X-axis guiderail is horizontally arranged, so that more stable movement and high machining accuracy are achieved; and moreover; the mechanisms of the machine tool are compact in structure, and the machine tool is compact in overall layout.

Owner:湖北山铁智能装备有限公司

Deflection preventing mechanism of buckle plate cutting device

InactiveCN108326986AIncrease productivityImplement aspectsProfiling/shaping machinesWood working safety devicesEngineeringMechanical engineering

The invention provides a deflection preventing mechanism of a buckle plate cutting device, and belongs to the technical field of machinery, which solves the problem of poor deflection preventing effect in the prior art. The deflection preventing mechanism of the buckle plate cutting device is characterized in that the buckle plate cutting device comprises a strip-shaped worktable; the worktable isprovided with an input end and an output end; a conveying mechanism is arranged on the worktable and is used for driving a sheet to convey forwards; the deflection preventing mechanism comprises a guide plate I, a guide plate II, a blocking plate I and a blocking plate II; the guide plate I and the guide plate II form a guide opening which is of a structure like a character 'ba'; the input port of the guide opening is greater than the output port; the guide plate I is fixedly connected with the blocking plate I, and the guide plate II is fixedly connected with the blocking plate II; the blocking plate I and the blocking plate II are parallel with the conveying direction of a conveying roll; a movable structure is arranged on the worktable and is used for adjusting the distance between theblocking plate I and the blocking plate II. The deflection preventing mechanism has the advantage of good deflection preventing effect.

Owner:海宁市纵达新材料股份有限公司

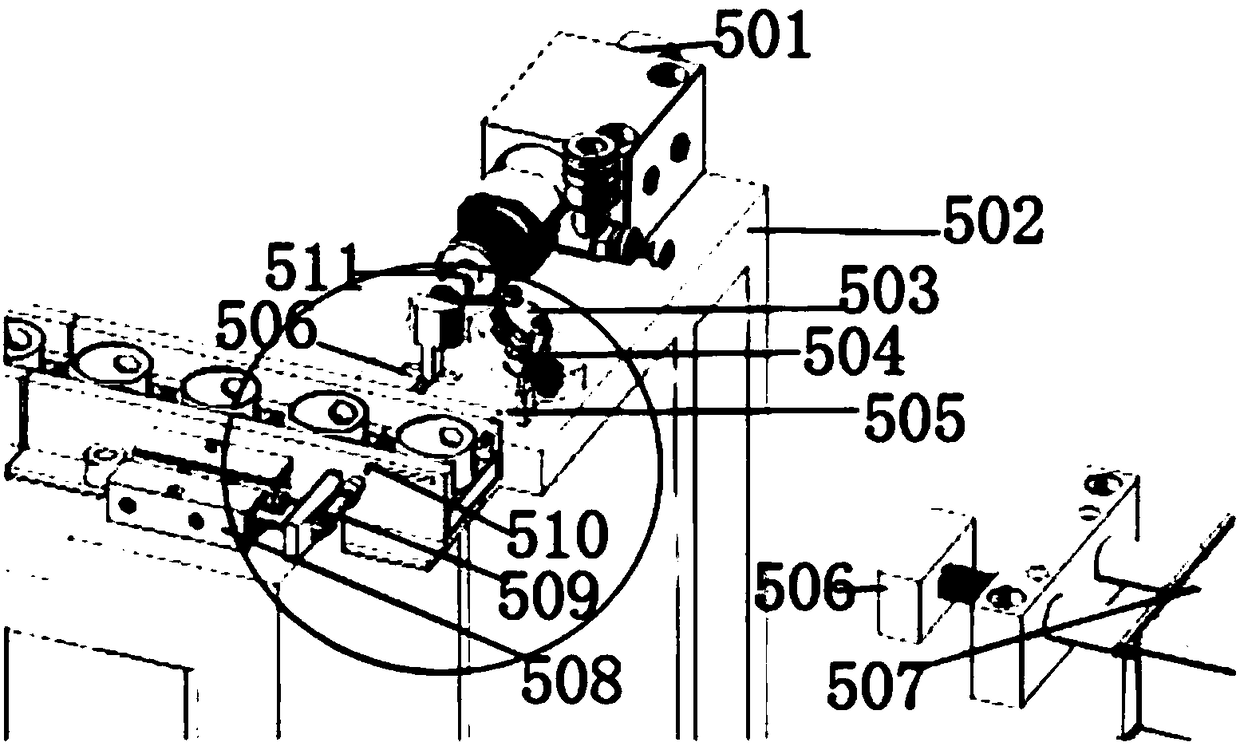

Fan-blade-shaped welding device

ActiveCN108296677AWith automatic feedingSafe and reliable workWelding/cutting auxillary devicesAuxillary welding devicesData linesFan blade

The invention discloses a fan-blade-shaped welding device comprising a workbench, an electric appliance cabinet, a feeder, a discharge device and a welding device body. The workbench is provided withthe feeder, the discharge device and the welding device body. The electric appliance cabinet is arranged on the side face of the workbench. A control panel is arranged on the electric appliance cabinet. A main power source, a control mainboard and a servo driver are arranged in the electric appliance cabinet. The main power source, the control panel and the servo driver are in electric connectionwith the control mainboard through data cables. The feeder comprises a driving device and a weldment clamping device. The driving device comprises an additional motor, a speed reducer, a motor fixingplate, a coupling, a bearing base, a sealed bearing, a rotary shaft, a fan blade plate and an end cover. The weldment clamping device comprises a cover plate and ring soft plastic fixedly arranged onthe fan blade plate. The cover plate is arranged at the top of the ring soft plastic. The fan-blade-shaped welding device has the characteristics of automatic feeding, automatic locating and safe andreliable work, to-be-welded parts of any shapes can be placed, manual welding is replaced to a great extent, the accuracy rate is high, and thus work efficiency is improved.

Owner:太仓市华盈电子材料有限公司 +1

Transverse cutting mechanism of buckle plate cutting device

InactiveCN108326985AIncrease productivityImprove cut qualityGuide fencesProfiling/shaping machinesCouplingEngineering

The invention provides a transverse cutting mechanism of a buckle plate cutting device, and belongs to the technical field of machinery, which solves the problem of poor cutting effect in the prior art. The transverse cutting mechanism of the buckle plate cutting device is characterized in that the buckle plate cutting device comprises a strip-shaped worktable; the worktable is provided with an input end and an output end; the transverse cutting mechanism comprises a transverse knife and a transverse knife base; the transverse knife base is in a strip shape; one end of the transverse knife isarranged at one side of the worktable by a swinging structure in a swinging way; a passage I is arranged between the transverse knife base and the worktable; a first screw rod is arranged under the transverse knife base, and is parallel with the transverse knife base; a bearing block II is fixedly arranged at the other end of the transverse knife base; a bearing II is arranged in the bearing blockII; one end of the first screw rod is fixedly arranged in the bearing II; a motor I is fixedly arranged on a fixed base; an output shaft of the motor I is connected with the other end of the first screw rod through a coupling; the first screw rod is connected with a screw nut I by threads. The transverse cutting device has the advantage of good cutting effect.

Owner:海宁市纵达新材料股份有限公司

Optical-fiber wire drawing device with automatic feeding and foreign matter adsorption function

InactiveCN107793023AWith automatic feedingFunctionalGlass making apparatusForeign matterOptical fiber

The invention relates to an optical-fiber wire drawing device with an automatic feeding and foreign matter adsorption function. The optical-fiber wire drawing device comprises a main body, a heating chamber and a shell, and also comprises a feeding mechanism and an absorption mechanism, the feeding mechanism comprises a lifting assembly, an adjusting assembly and a fastening assembly, and the absorption mechanism comprises a moving assembly and an absorption assembly. In the optical-fiber wire drawing device with the automatic feeding and foreign matter adsorption function, the automatic loading of an optical-fiber prefabricated rod can be realized by virtue of the feeding mechanism, compared with the manual material loading way, the time waste caused by the frequent manual operation can be avoided, more convenience and efficiency can be realized, a dust nozzle is enabled to move and swing inside the heating chamber by virtue of the absorption mechanism, compared with the fixed foreignmatter absorption apparatus, the range for absorbing foreign matters is enlarged, the effect for absorbing the foreign matters is better, the foreign matters inside the heating chamber can be prevented from adhering on an optical fiber and influencing the quality of the optical fiber, and the practicability of the optical-fiber wire drawing device is greatly improved.

Owner:南京卓茨机电科技有限公司

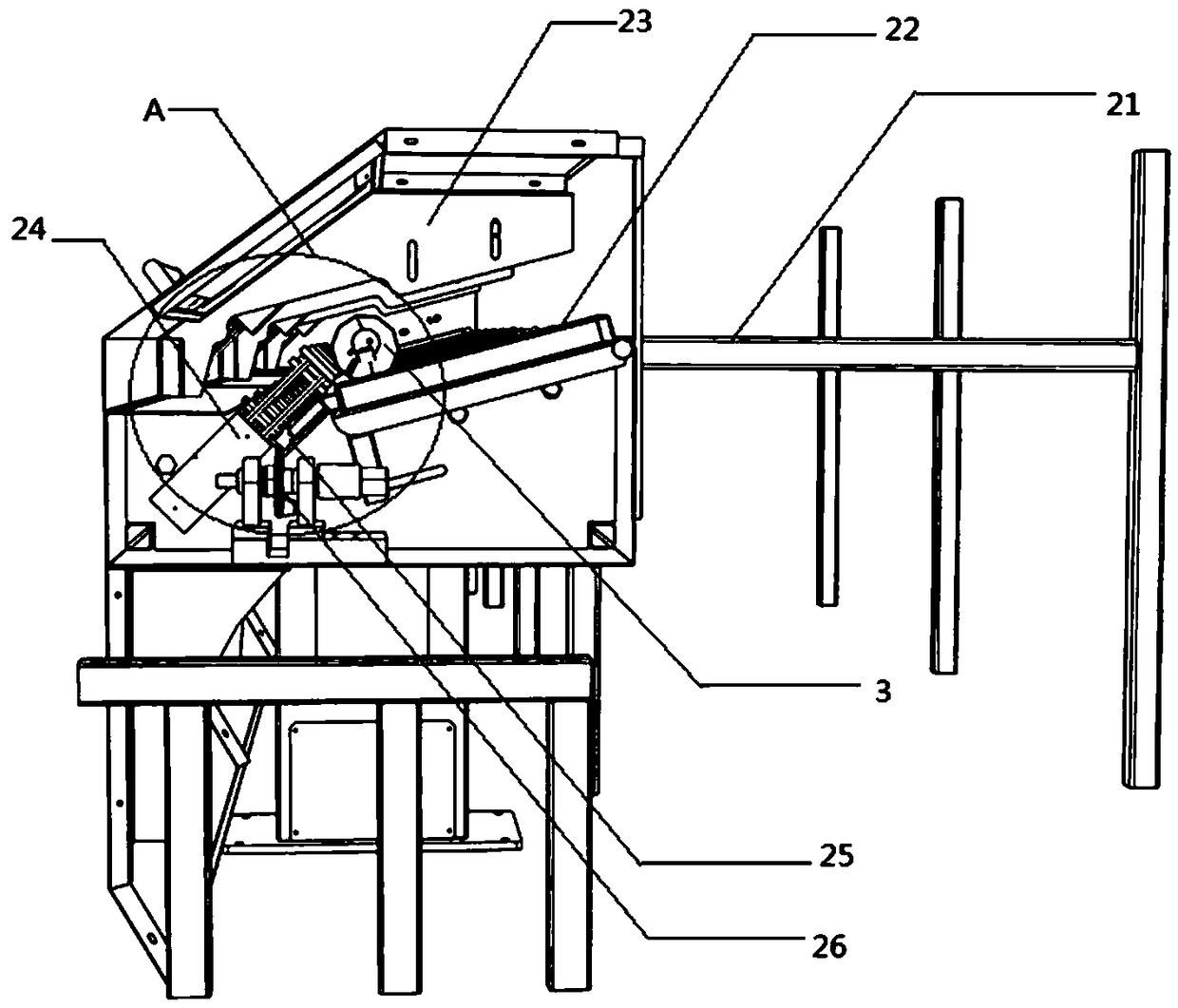

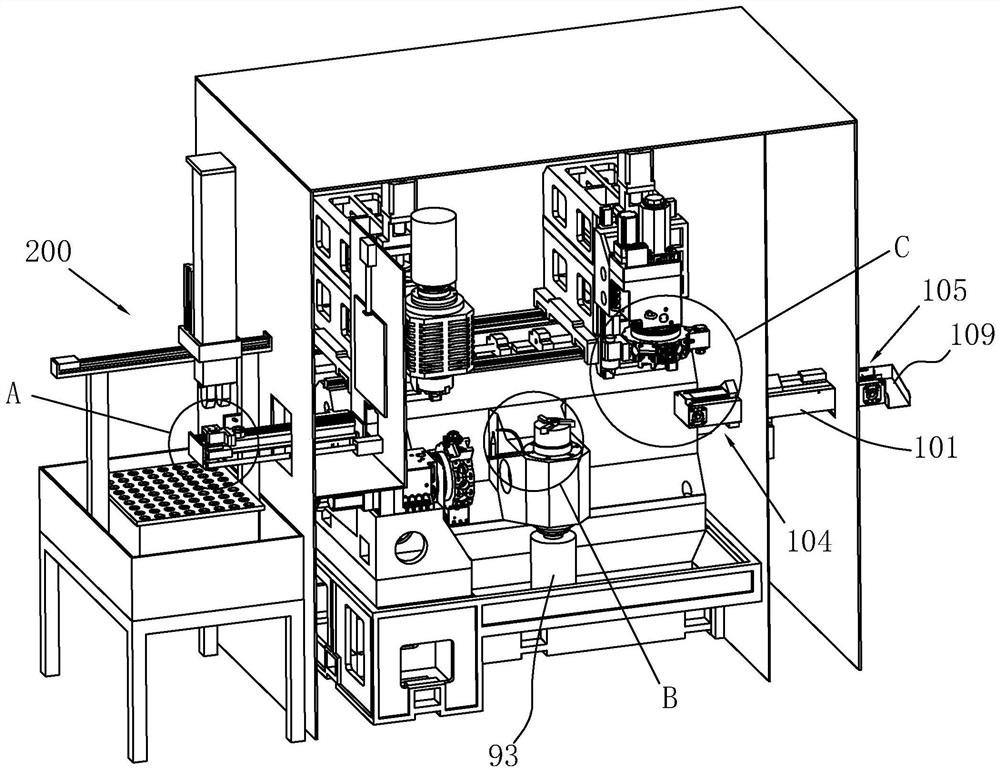

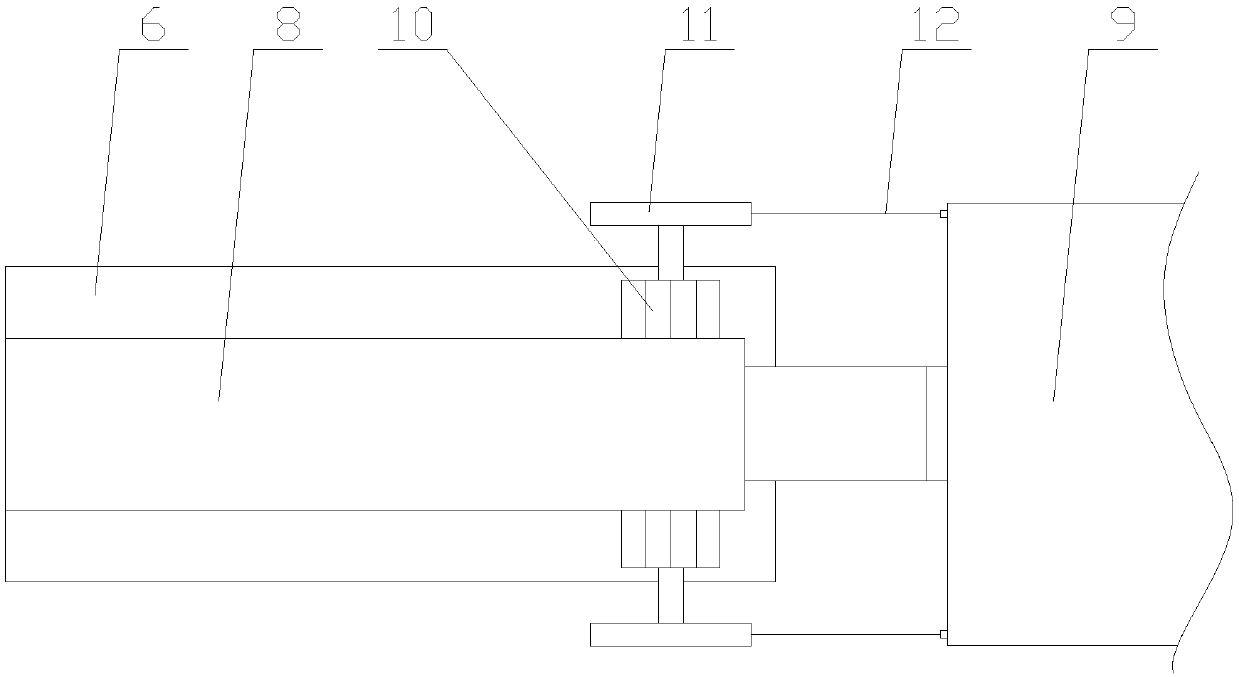

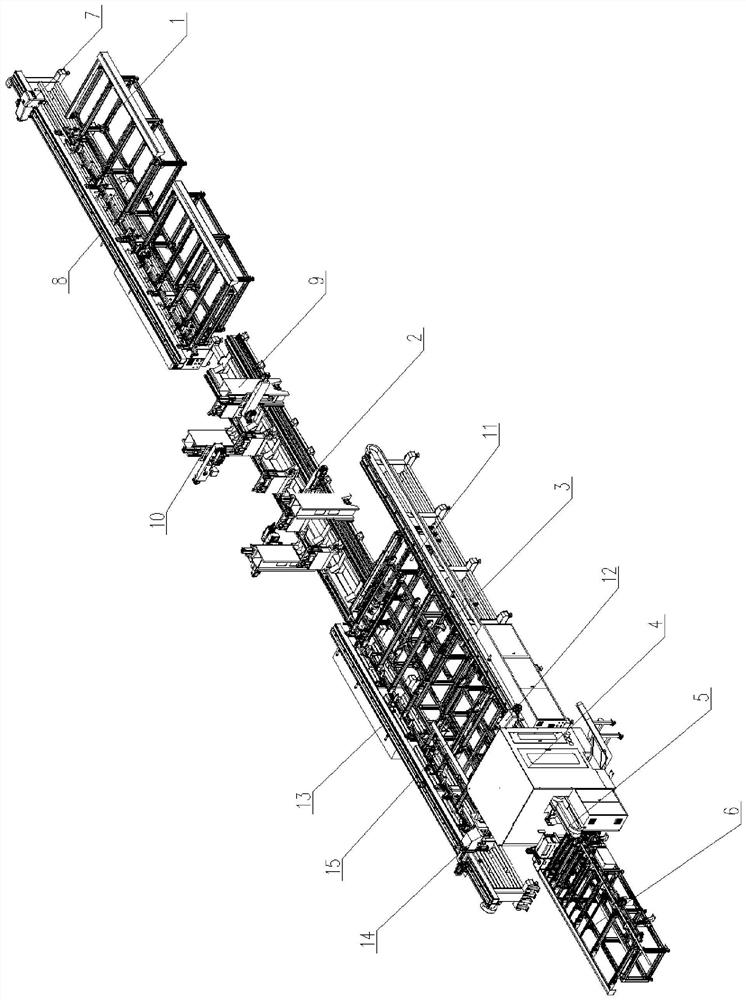

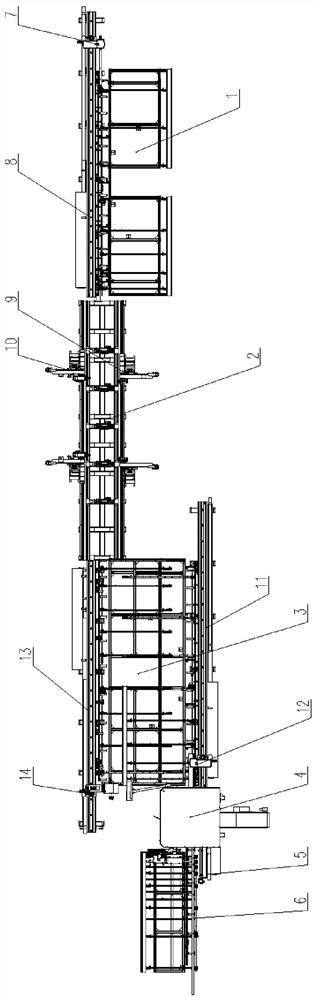

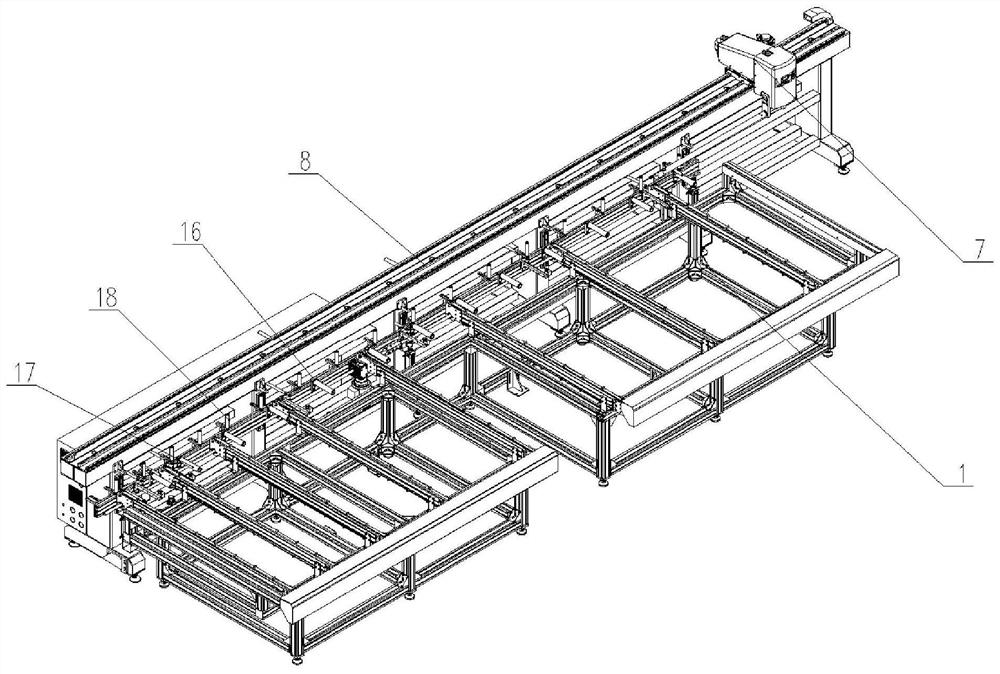

Door and window machining production line and machining technology

PendingCN113857862AWith automatic feedingWide range of processingOther manufacturing equipments/toolsPositioning apparatusProduction lineMachining process

The invention provides a door and window machining production line and a machining technology. The door and window machining production line is sequentially provided with a feeding area, a machining area, a buffer area, a cutting center area and a discharging area in the feeding direction, wherein the machining area is provided with a door and window machining center; the door and window machining center comprises a machining base; horizontal guide rails are arranged at the front end and the rear end of the machining base; at least two sets of machining machine heads are arranged on the machining base in the feeding direction; each set of machining machine heads comprises two machining machine heads; the two machining machine heads in each set of machining machine heads are oppositely arranged; and the cutting center area is provided with a saw cutting center and a milling center. The door and window machining production line and the machining technology have the beneficial effects that when a to-be-machined profile is machined, hole groove machining is conducted firstly, then cutting-off, end face milling and other machining are conducted, when the to-be-machined profile is subjected to hole groove machining, the two machining machine heads are adopted for machining the to-be-machined profile at the same time, and the machining efficiency is greatly improved.

Owner:SHANDONG LEDE CNC MACHINERY

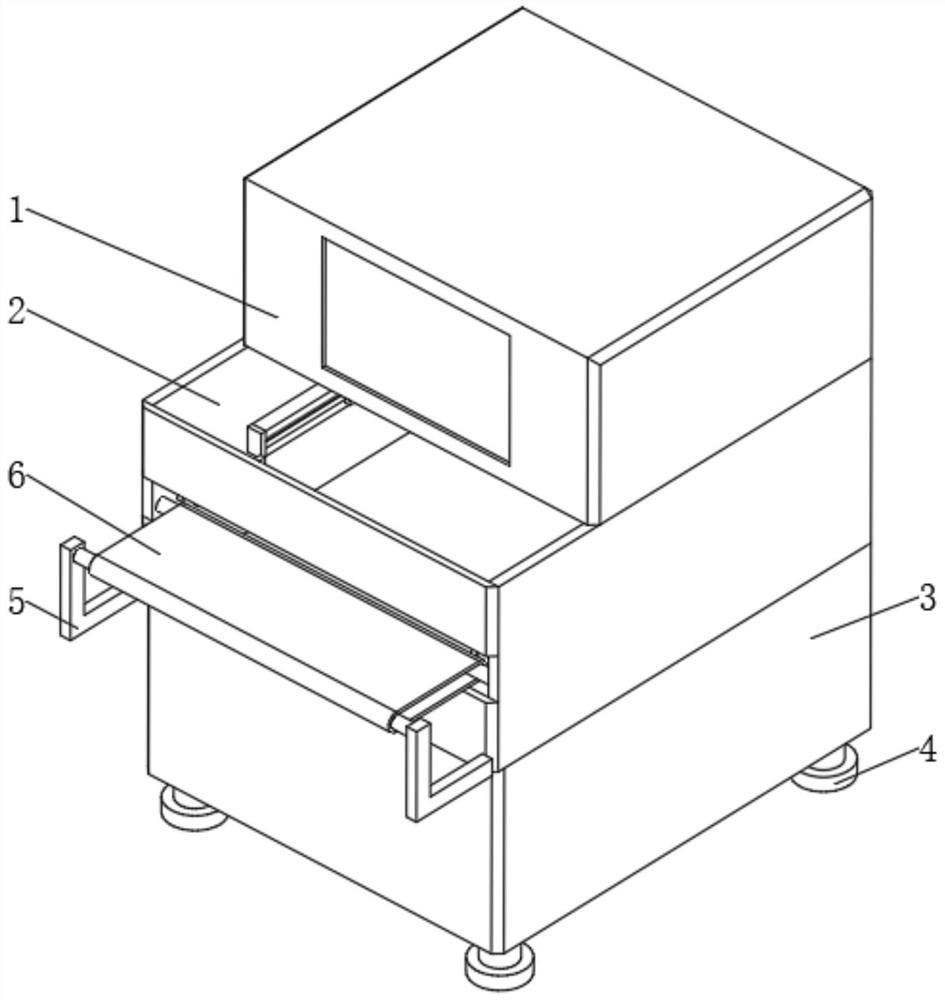

AOI automatic optical detector for appearance detection of circuit board line

InactiveCN114354640AReduce manual interventionRealize automatic unloadingOptically investigating flaws/contaminationEngineeringOptical detector

The invention belongs to the technical field of PCB detection, and discloses an AOI automatic optical detector for appearance detection of a circuit board line, the AOI automatic optical detector comprises an AOI detector body, the bottom end of the AOI detector body is fixedly provided with a detection box, the bottom end of the detection box is fixedly provided with a base, and the left and right sides of the front surface of the detection box are fixedly provided with support frames. A first servo motor is started to drive a main shaft to rotate so as to drive a movable rod to rotate, at the moment, the movable rod can apply pressure to a lever, the lever is driven by a U-shaped rod to deflect towards the inner side and drive a discharging plate to deflect towards the inner side, and a PCB slides towards the inner side along with the lever, falls into the upper portion of a containing frame and falls into a clamping groove; at the moment, the electric guide rail is reversely started to drive the sliding block and the placing frame to move towards the inner side, the movable rod does not make contact with the lever any more, the power source of the conveying belt is turned off, conveying is stopped, automatic discharging of the single PCB is completed, the manual intervention degree is reduced, and therefore the advantage of automatic discharging is achieved.

Owner:深圳易科讯科技有限公司

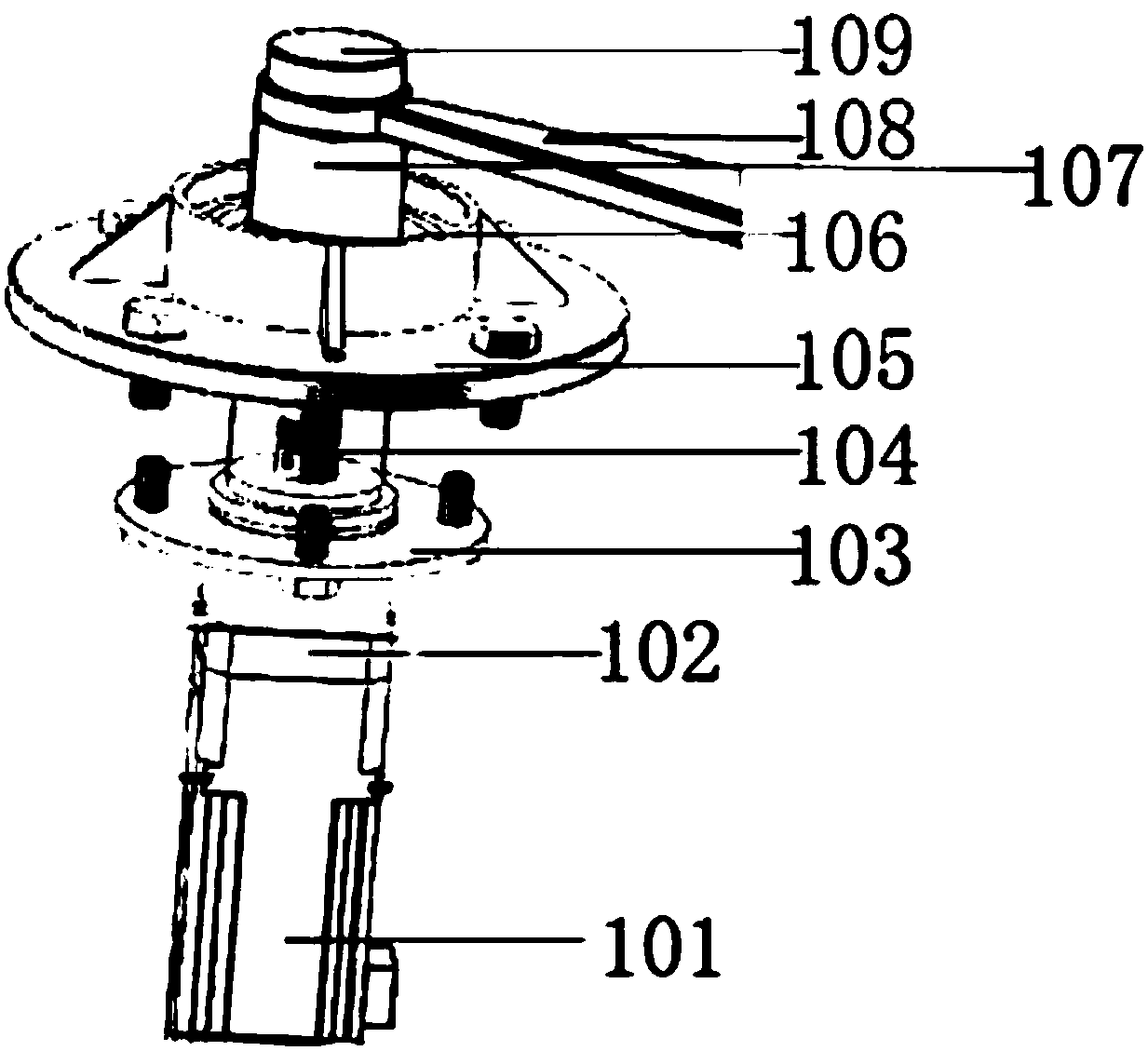

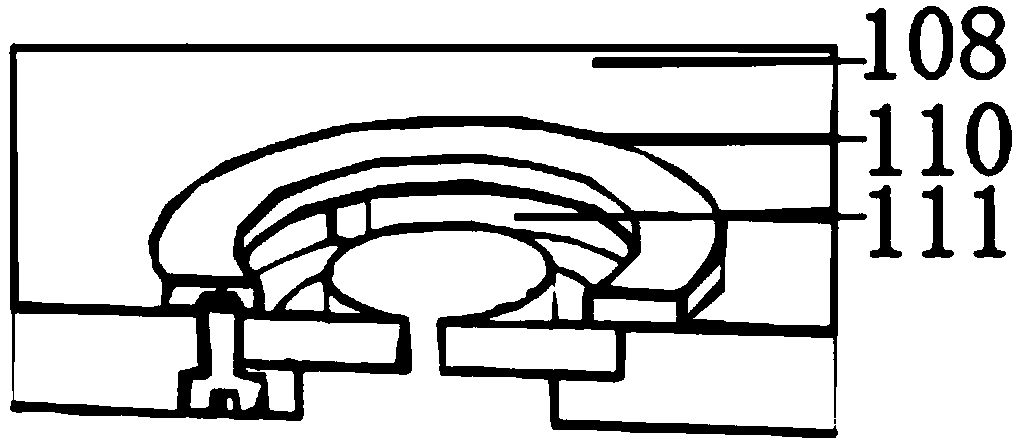

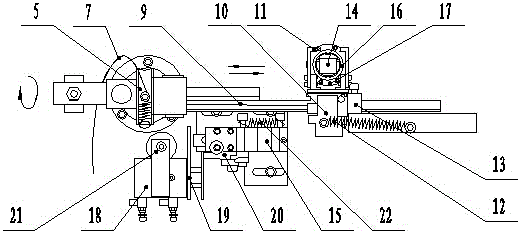

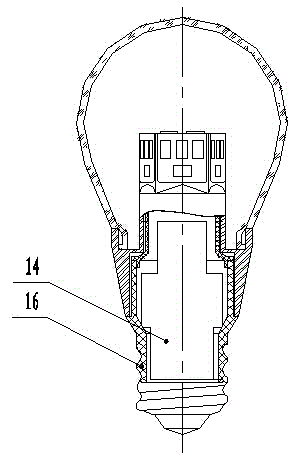

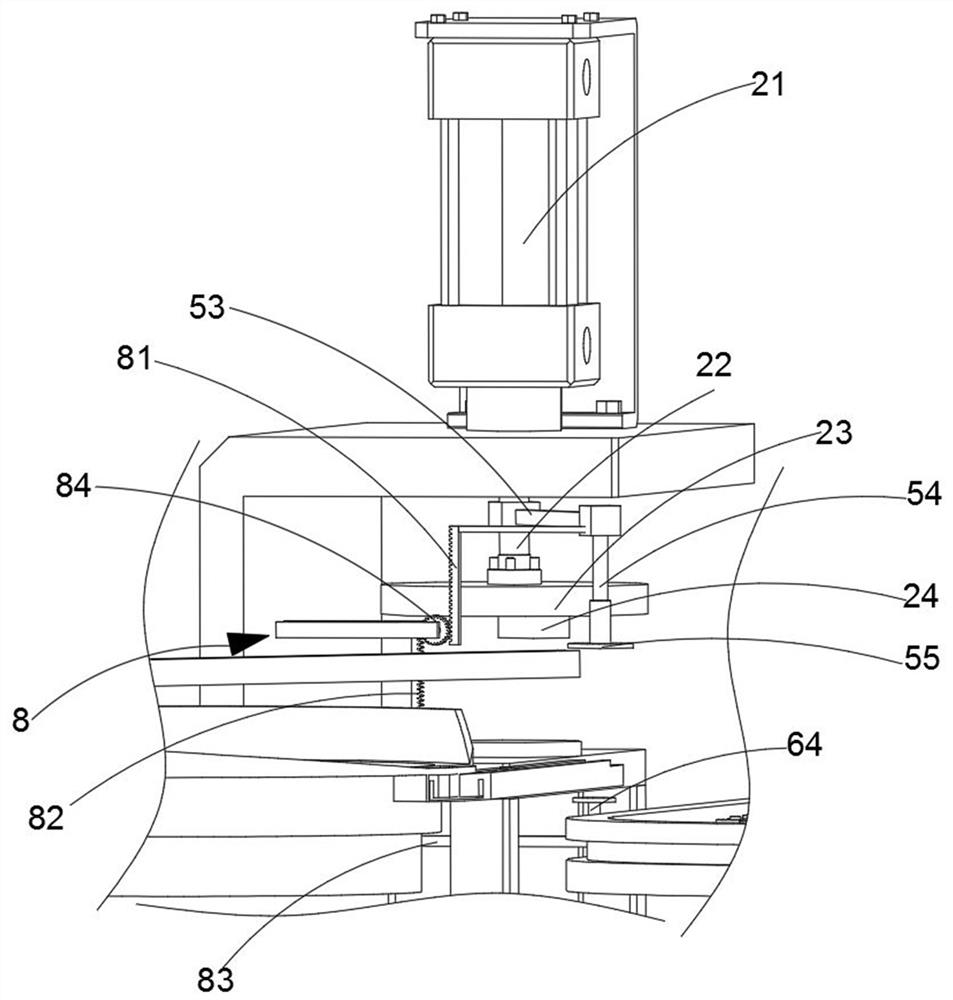

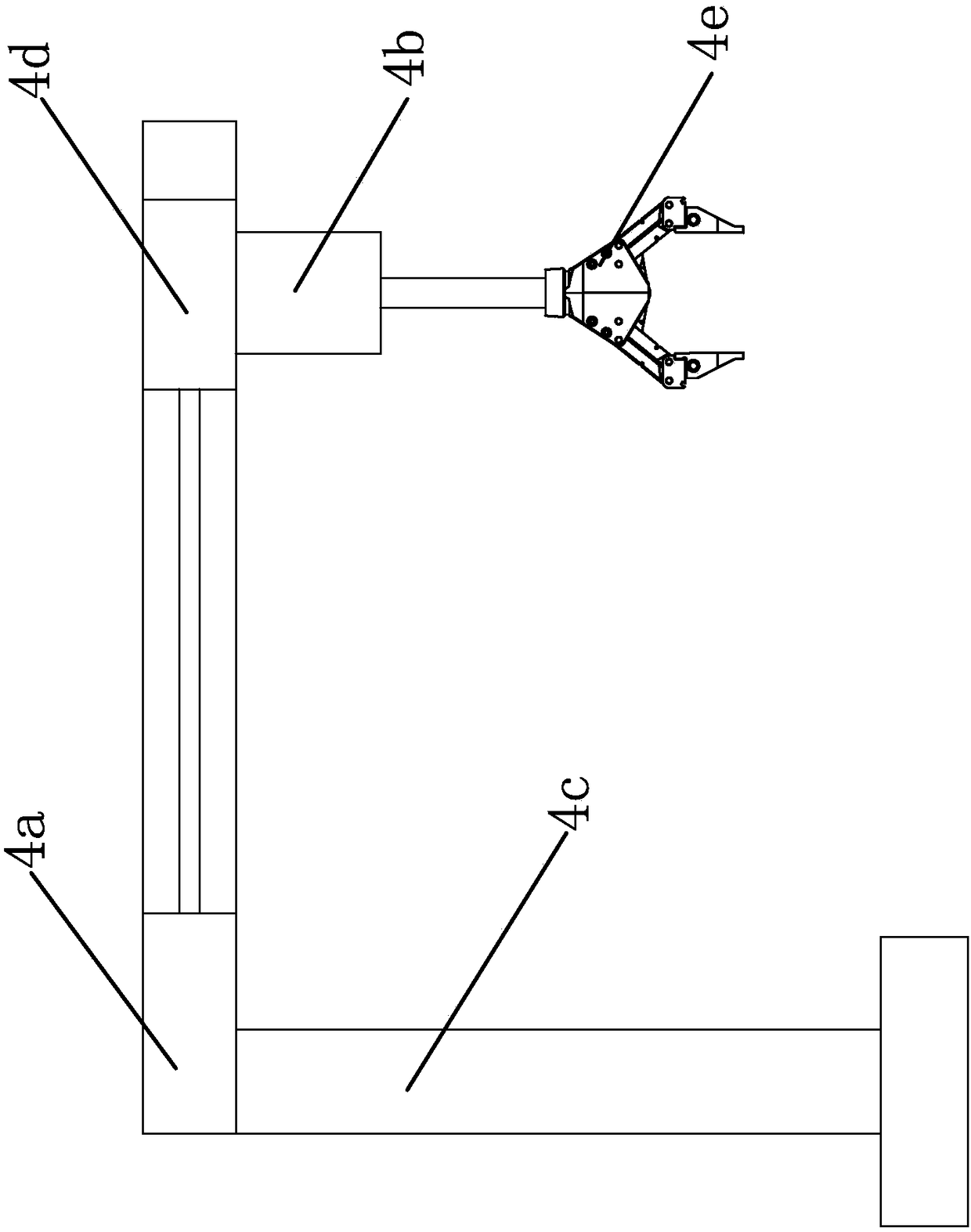

Automatic driver loading device of full-automatic LED bulb light base assembly machine

ActiveCN104353980AWith automatic feedingWith automatic welding functionMetal working apparatusManipulatorEngineering

The invention relates to an automatic driver loading device of a full-automatic LED bulb light base assembly machine. The automatic driver loading device comprises a driver clamping and opening device and a driver transfer device, wherein the driver clamping and opening device is arranged on an index plate and comprises a driver clamp for clamping a driver and a driver clamp opening device for opening the two parts of the driver clamp by overcoming the tension force of a driver clamp tension spring, and the driver clamp tension spring for enabling the two parts of the driver clamp to be in tight fit with each other to clamp the driver clamp is arranged between the two parts of the driver clamp; the driver transfer device comprises a loading mechanical hand clamp on which a longitudinal drive mechanism for enabling the loading mechanical hand clamp to move up and down, a transverse drive device for enabling the mechanical hand clamp to move back and forth and a rotary drive device for enabling the mechanical hand clamp to rotate are arranged. The automatic driver loading device has the functions of automatic driver loading, automatic inserting and automatic driver lead wire welding.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

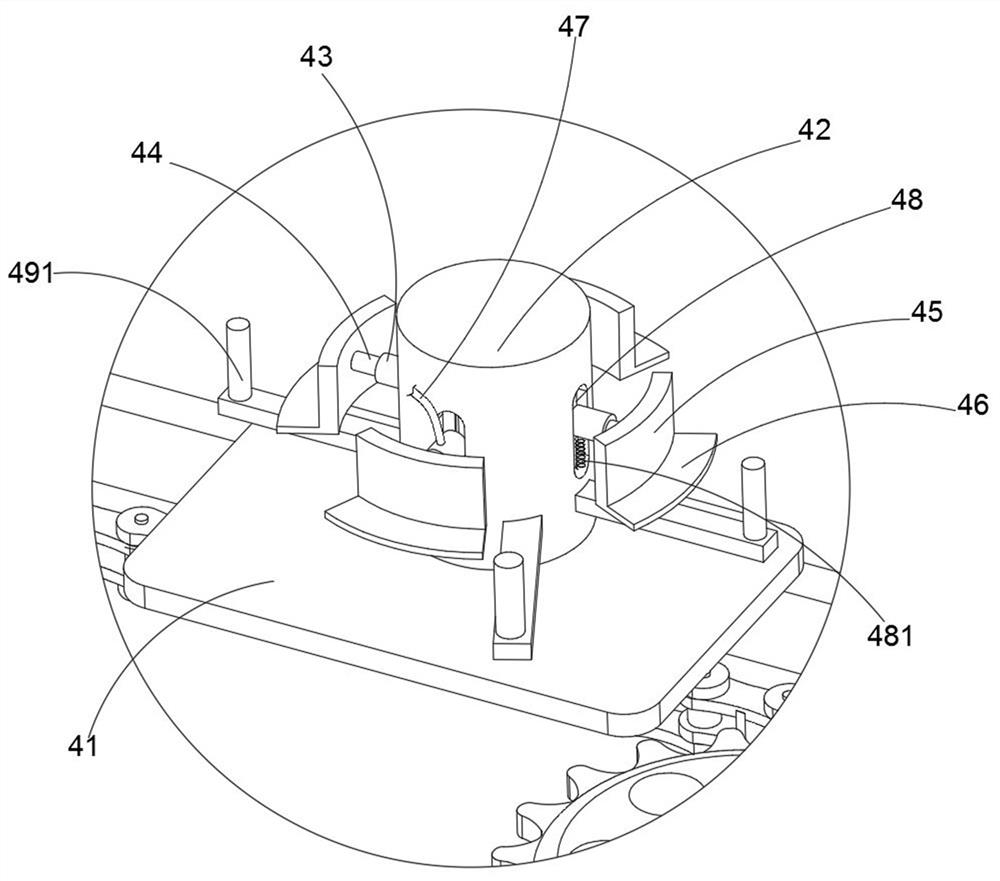

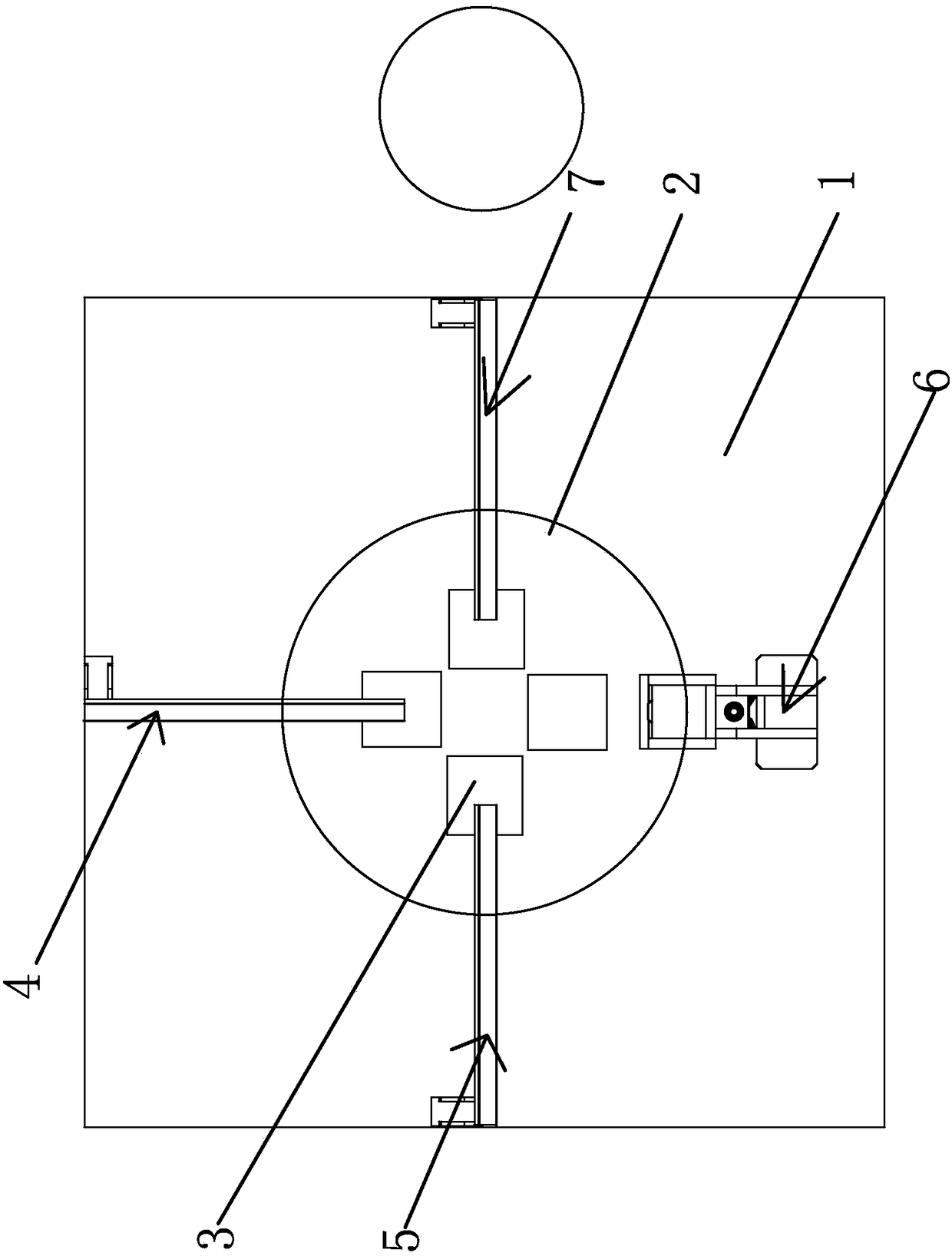

Automatic assembling device for coupler diaphragm

The invention relates to an automatic coupler diaphragm assembling device which comprises a rack, a material pressing assembly is arranged on the rack, a rotating assembly is arranged below the rack, a plurality of stabilizing assemblies are arranged on the rotating assembly in an array mode, a material supply assembly a and a material supply assembly b are further arranged behind the rotating assembly, and a rotating assembly is further arranged below the rotating assembly. A linkage assembly is further arranged between the feeding assembly a and the feeding assembly b, and the stabilizing assembly is used for being unfolded after being inflated to fix the membrane and being matched with the rotating assembly in the conveying process along the rotating assembly to be driven by the rotating assembly to switch assembly holes of the membrane. And the material pressing assembly is used for driving the material supply assembly a to move downwards in the downward pressing process to place the screw ring at the top of the assembly hole and driving the material supply assembly b to move upwards under the action of the linkage assembly to sleeve the screw into the assembly hole, so that the assembly efficiency and precision are improved.

Owner:浙江海能传动机械股份有限公司

Intelligent feeding device for steel plate cutting

InactiveCN112404757AWith automatic lifting functionWith automatic precision movement functionWelding/soldering/cutting articlesMetal working apparatusEngineeringMachine

The invention relates to the technical field of cutting, in particular to an intelligent feeding device for steel plate cutting. The intelligent feeding device comprises a metal laser automatic cutting machine, a tray is arranged at one side of the metal laser automatic cutting machine, a plurality of steel plate materials are arranged at one side of the tray, and a bottom plate is fixedly connected to one side of the metal laser automatic cutting machine; and a U-shaped guide frame is fixedly connected to one side of the bottom plate, a U-shaped supporting frame is fixedly connected to one side of the metal laser automatic cutting machine, a mounting groove is formed in one side of the U-shaped supporting frame, and the U-shaped guide frame is fixedly connected to the inner side of the mounting groove. According to the intelligent feeding device, the U-shaped guide frame, the U-shaped supporting frame, a lifting plate, a servo motor A, a first transmission device, an H-shaped slidingblock, a material pushing block, an automatic back-and-forth movement device, an L-shaped material pushing frame, a one-way passing plate, a precise driving device, an L-shaped positioning frame, a guide jacking plate and an automatic jacking device are arranged, so that the intelligent feeding device has the functions of automatic feeding, automatic continuous feeding, double material pushing, automatic positioning, automatic fixing and the like.

Owner:苏州创智汇峰信息科技有限公司

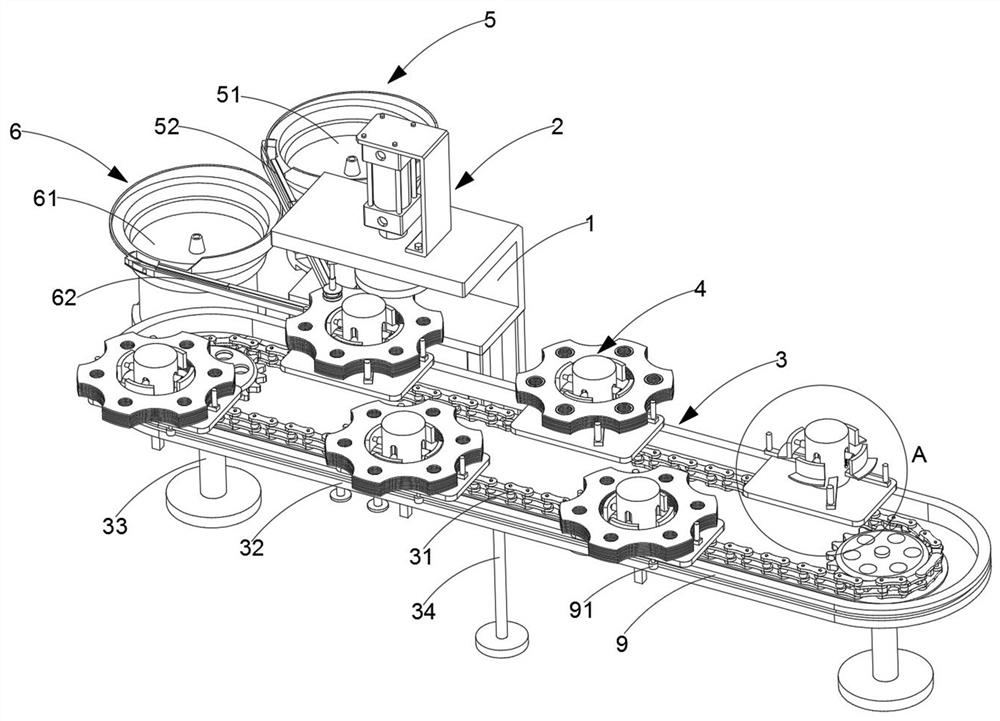

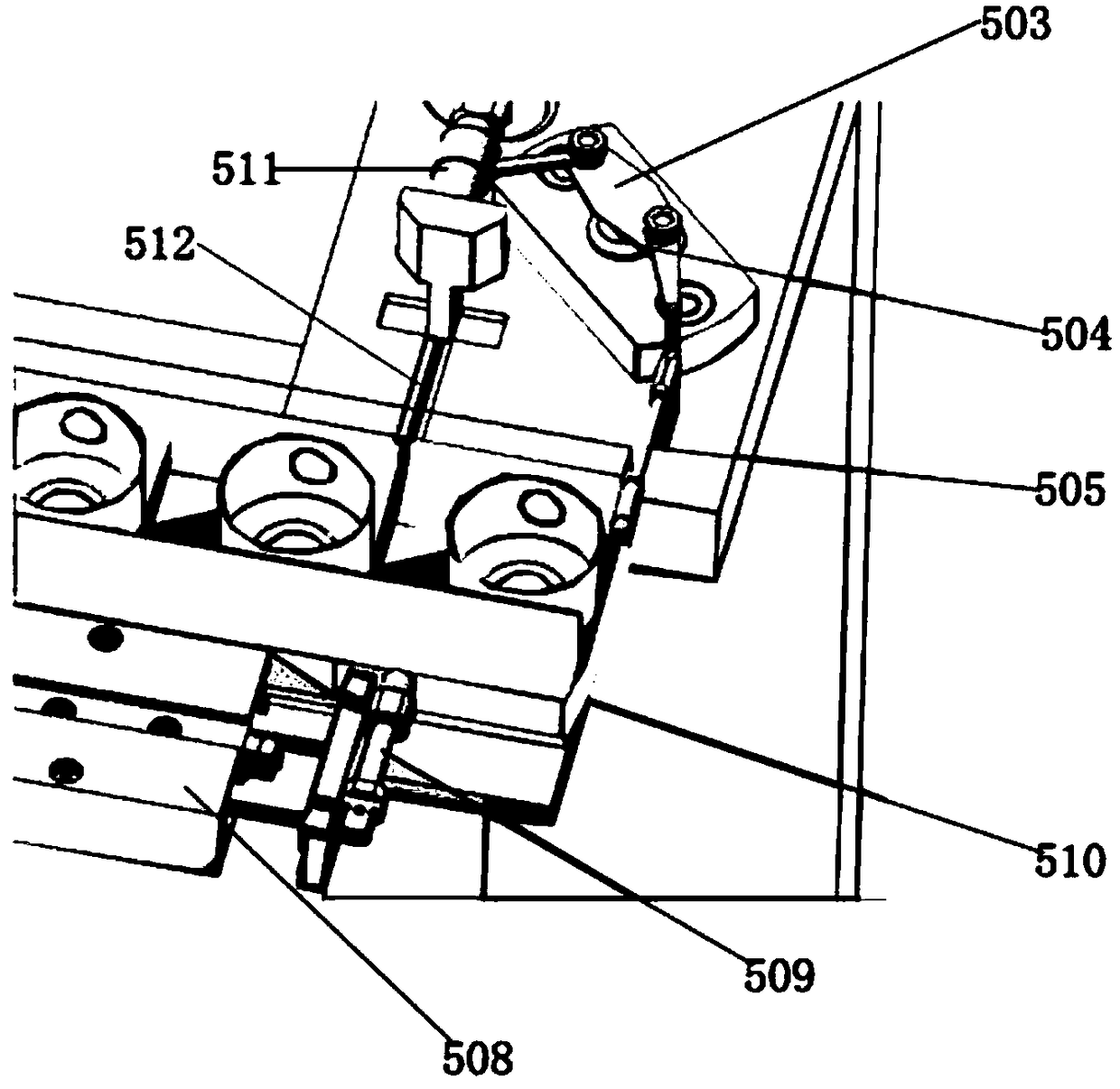

Full-automatic welding production line based on vision

ActiveCN108356451ADimensional stabilityWith automatic feedingWelding/cutting auxillary devicesAuxillary welding devicesProduction lineVision inspection

The invention discloses a full-automatic welding production line based on vision. The full-automatic welding production line based on vision comprises a vision inspection mechanism, a rotation mechanism, a vibration mechanism, a welding device, a welding positioning device, a discharging device, a workbench, an electronic control cabinet and a vibration plate. The vibration mechanism, the weldingdevice and the welding positioning device are arranged on the workbench. A control panel is arranged on an electric appliance cabinet. A main power source, a control system and a servo driver are arranged in the electric appliance cabinet. The main power source, the control system and the servo driver are electrically connected with the control system through data lines respectively. The vibrationplate is connected with the vibration mechanism. The vibration plate is arranged on a vibration rack. The vision inspection mechanism and the rotation mechanism are arranged on the vibration rack. The rotation mechanism is arranged between the vibration mechanism and the vibration rack. The welding positioning device comprises a positioning rack, a second gas cylinder, a third gas cylinder, a fourth gas cylinder, a push rod, a push block, a connecting rod, a bearing, a probe, a charging ram and a slender rod type gas cylinder. The full-automatic welding production line based on vision has theadvantages of being capable of carrying out full automatic welding in production instead of manual welding and high in accuracy, and thereby being high in production efficiency.

Owner:JIANGSU UNIV OF TECH

Welding device for machining welding connection head

PendingCN108453407AWith automatic feedingImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a welding device for machining a welding connection head and belongs to the technical field of machinery. By means of the welding device for machining the welding connection head, the problem in the prior art of being low in the machining efficiency is solved. The welding device for machining the welding connection head comprises a working box, the welding connection head comprises a first pipe and a second pipe, the first pipe and the second pipe are vertically fixed by welding, the working box is internally and rotatably provided with a working disc, the working disc is rotatably provided with four installation seats, the four installation seats are distributed in a ring shape to an axis at equal intervals, the working box is internally provided with a first driving mechanism capable of driving the working disc to rotate, the lower surface of the working disc is provided with a second driving mechanism capable of driving the installation seats to rotate, and the periphery of the working disc is provided with a first material feeding mechanism capable of performing material feeding on the first pipe, a second material feeding mechanism capable of performingmaterial feeding on the second pipe, a welding mechanism capable of welding the first pipe and the second pipe and a material unloading mechanism capable of performing material unloading on welding bend pipes in the rotating direction in sequence. The welding device for machining the welding connection head has the advantage of improving the machining efficiency.

Owner:海宁市晟达消防设备股份有限公司

Oil-pressure type steel pipe draw-bench

The invention discloses an oil-pressure type steel pipe draw-bench, comprising a rack, wherein the rack comprises an auxiliary rack and a main rack; a core rod subassembly is mounted on the auxiliary rack; the core rod subassembly includes a core rod trolley and a core rod which is mounted on the core rod trolley; the core rod trolley can move on the auxiliary rack back and forth; a drawing die subassembly is mounted on one side, close to the auxiliary rack, of the main rack; an oil hydraulic cylinder is mounted on the other side, far away from the auxiliary rack, of the main rack; a drawing trolley which can move on the main rack back and forth is mounted on the main rack; the movement of the drawing trolley relative to the main rack is driven by the oil hydraulic cylinder; and a charging device and a discharging device are respectively mounted on the two sides of the main rack. The oil-pressure type steel pipe draw-bench has the functions of automatic charging, drawing and discharging, is high in automation degree and stable in drawing, and can guarantee the drawing precision.

Owner:鹏业控股集团有限公司

Intelligent paint spraying device

InactiveCN107398377AReduce laborPaint thickness controllableSpraying apparatusEngineeringLeather belt

The invention discloses an intelligent paint spraying device, and relates to the technical field of paint spraying. The intelligent paint spraying device comprises a shell, a motor is fixedly arranged on the bottom of one side of the inner wall of the shell, the output shaft of the motor is fixedly provided with a first belt wheel, the surface of the first belt wheel is in transmission connection with a second belt wheel through a belt, a rotating shaft is fixedly connected to the axis of the second belt wheel, wherein the end, far away from the second belt wheel, of the rotating shaft is fixedly connected with a first transmission wheel, and the surface of the first transmission wheel is in transmission connection with a second transmission wheel through a conveying belt; and a control panel is installed on the surface of the shell, a controller is arranged in the shell, a control valve is fixedly arranged in a pipeline, the output end of the control panel is electrically connected with the input end of the controller, and the output end of the controller is electrically connected with the input end of the control valve and the motor. The intelligent paint spraying device has the advantages that the paint spraying thickness is controllable, and the processing effect is good.

Owner:FOSHAN YILI MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com